Method for rotary burning of thin coal layer

A combustion method and thin coal seam technology are applied in the field of burning coal particles in a rotating combustion chamber with a high temperature fire bed, which can solve the problem of difficult computer control and management, inability to meet scientific coal combustion requirements, and insufficient detection and adjustment means. and other problems, to achieve the effect of compact structure, reduced coal consumption and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

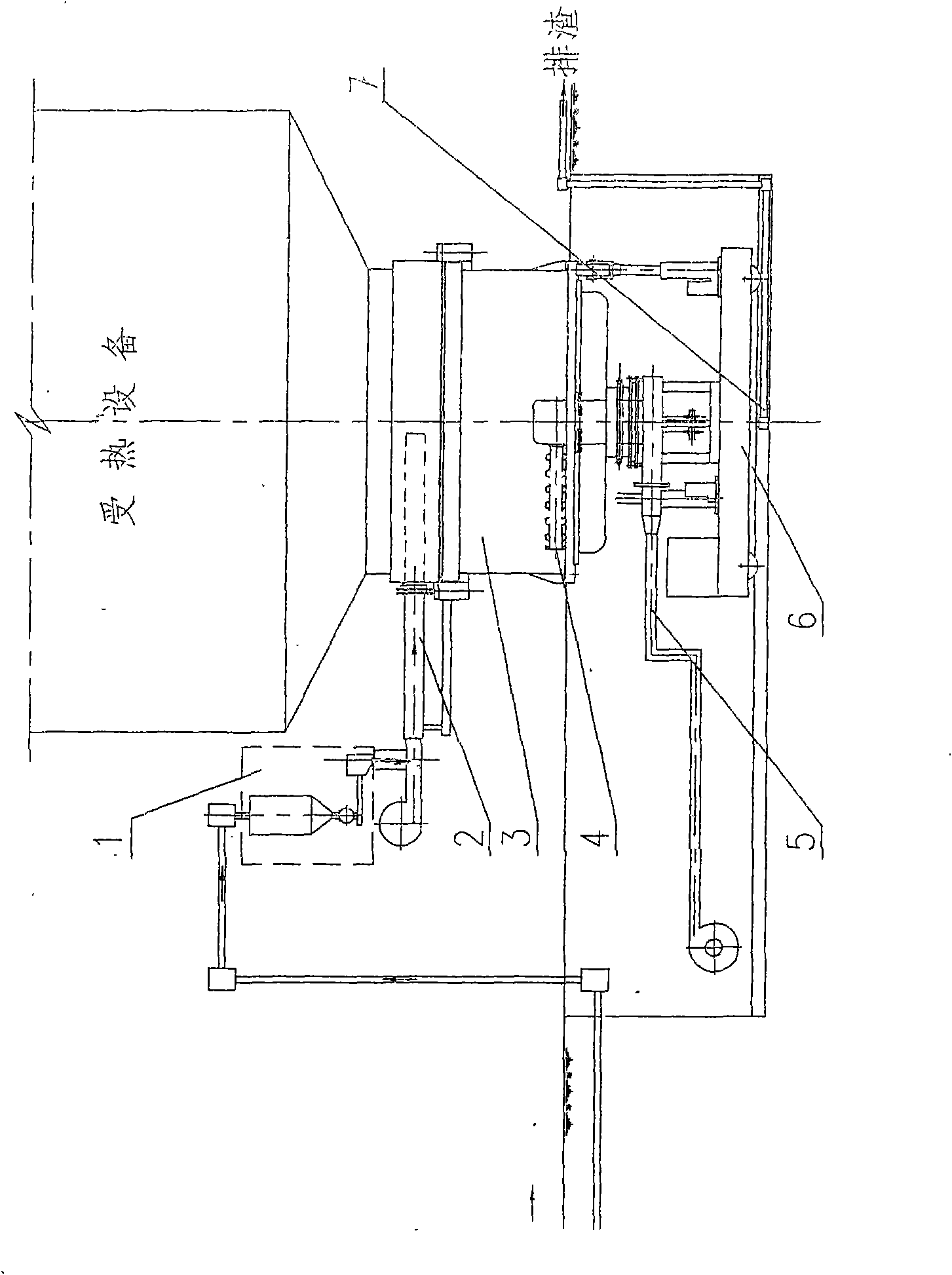

[0022] Depend on figure 1 It can be seen that the device for the thin coal seam rotary combustion method includes a metering coal feeder 1 connected to the coal inlet end of the coal charging rod 2, and the coal outlet end of the coal charging rod 2 is placed above the rotary furnace 3, driven by the driving device, and the wind force coal feeding pipe It is placed in the coal charging rod 2 and connected with the high-pressure blower; the rotary furnace 3 is connected with the heating equipment, and the center of the rotary furnace 3 is provided with a fixed shaft, and the cylindrical slag roller and slag discharge screw of the slag discharger 4 are respectively fixed on the On the fixed shaft; the center of the rotary furnace 3 is also equipped with a slag drop pipe 7; the rotary shaft 3 is provided with a rotating shaft, which is connected with the transmission device, and the furnace 3 is driven to rotate by it;

[0023] Depend on figure 1 It can also be seen that the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com