Stacking and transporting device for integral type side wall of car

An integral, side-walled technology, applied to lifting devices and other directions, can solve the problems of poor safety and inability to transfer in batches, and low efficiency of side-wall stacking and transfer tooling, so as to facilitate forklift operator operation, warehouse management and control, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

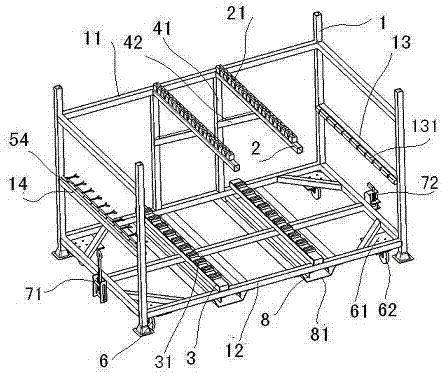

[0036] Example: such as figure 1 , 4As shown in , 6, a stacking transfer device for the integral side wall of a car, including a rectangular parallelepiped frame 1, the upper member 11 on the rear side of the frame 1 is connected with a front and rear side wall upper support rod 2, and the frame 1 The lower member 12 below is connected with the side wall lower support rod 3 moving forward and backward, and the upper support rod 2 of the side wall is fixed with trapezoidal groove rubber strips 21. There are 10 trapezoidal grooves, and the trapezoidal groove shape is suitable for the upper edge of the side wall door frame. Fitting; side wall lower support bar 3 is fixed with a Y-shaped groove rubber strip 31, the Y-shaped groove has 10 grooves, and 10 grooves can place 10 pieces of side wall A, and the shape of the Y-shaped groove is adapted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com