Patents

Literature

447results about How to "Avoid mess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laundry sheet

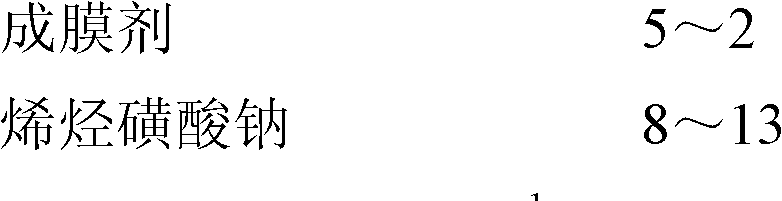

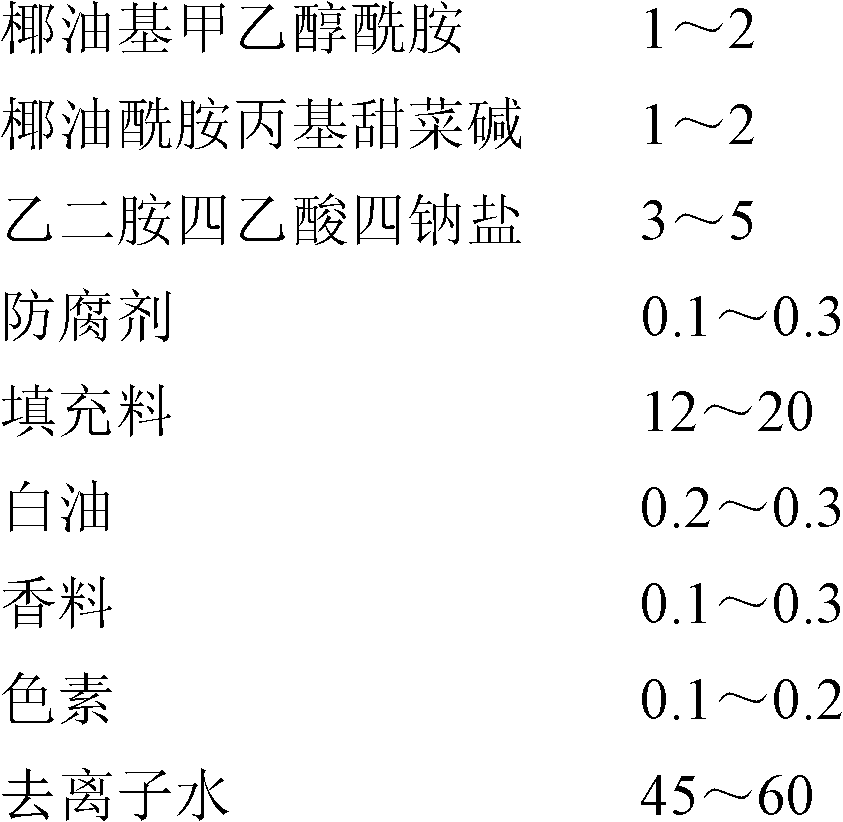

ActiveCN102492573APrevent overflowAvoid messOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsPhysical shapeCocamidopropyl betaine

The invention relates to a laundry sheet which comprises film former, sodium olefinsulfonate, coconut oil base methyl glycollic amide, coconut oil amide propyl lycine, ethylene diamine tetraacetic acid tetrasodium salt, preservative, filling material, white oil, essence, pigment and deionized water. The laundry sheet is prepared by the following steps: evenly mixing the raw materials according tomass parts, carrying out film formation by drying to a obtain paper type laundry sheet, cutting, punching, packaging and the like. The invention implements paper type laundry detergent in the aspect of physical shape, maintains the washing effect of the traditional laundry detergent, has the characteristics of less foam and high efficiency, and can be completely dissolved in water; the laundry sheet is convenient to store and use, and avoids the overflow problem in the common laundry detergent, thereby avoiding mess and difficulty in cleaning due to overflow of the laundry detergent; and the laundry sheet is convenient to, overcomes the defect that the traditional laundry detergent has heavy volume and can not be conveniently carried and stored after being opened, thereby providing convenience for clothes cleaning for people on a journey. The laundry sheet is free of any environment-polluting component, and can be completely degraded naturally, thereby making a contribution to environmental protection.

Owner:广州市黄埔南方供水环保工程有限公司

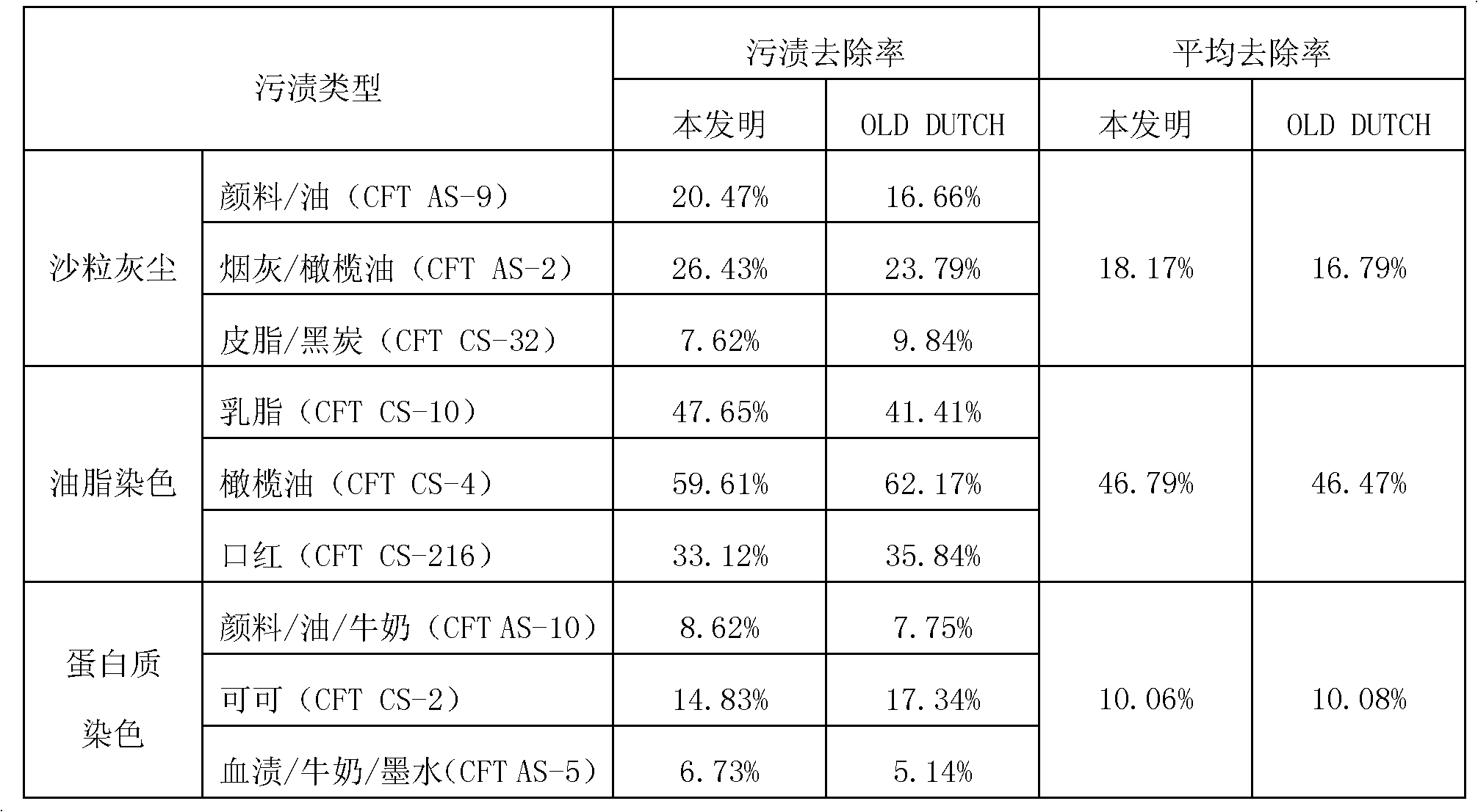

A method and device for marking electronic documents

InactiveCN102722476AConvenient labelingImprove usabilitySpecial data processing applicationsElectronic documentEngineering

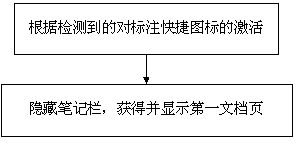

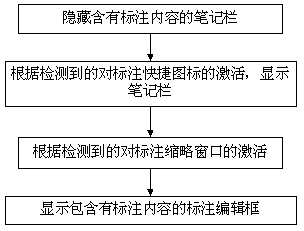

The invention discloses a method and device for marking electronic documents, and relates to the field of electronic document processing in the computer application technology. The method of the invention comprises: presetting an electronic document, an marking shortcut icon, a note bar and an marking edit box, displaying a first document page on a screen and loading the marking shortcut icon, detecting the activation of the marking shortcut icon, displaying the note bar, editing the electronic document page by invoking a document-editing engine, and acquiring a second document page, detecting an operation action executed in the note bar and displaying the marking edit box, and completing the marking of the document content and saving the marked content in a preset directory. The device of the invention arranges the marking, remarks and note by setting the note bar and displays and hides the note bar by zooming the electronic document page, preventing reading trouble caused by directly marking on the reading interface of the electronic document, facilitating the marking and the recording of the reading note and improving user experience.

Owner:HANVON CORP

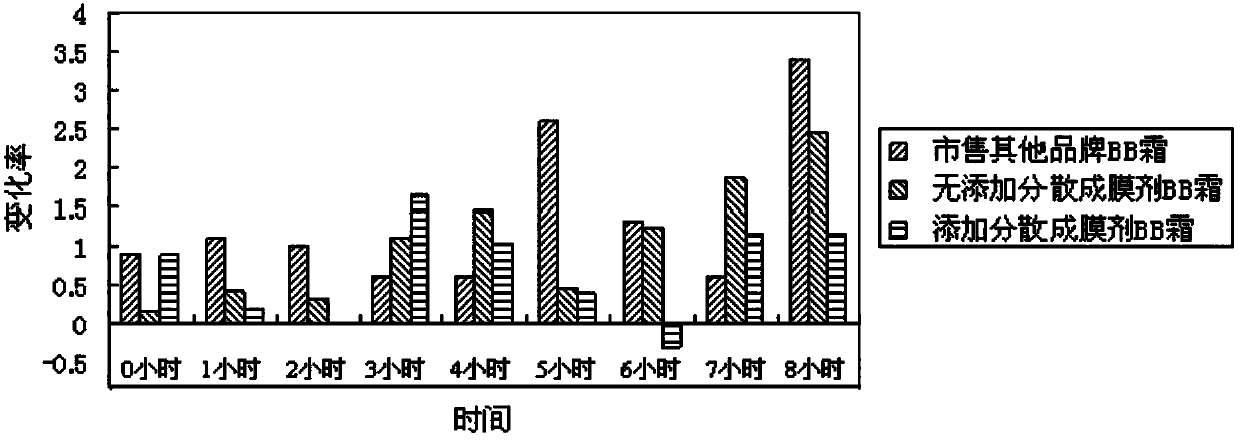

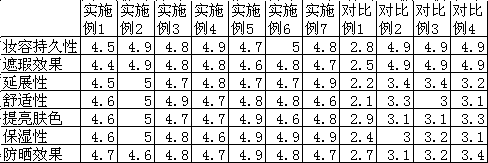

Blemish balm (BB) cream capable of preventing makeup meltdown for seven hours and preparation method thereof

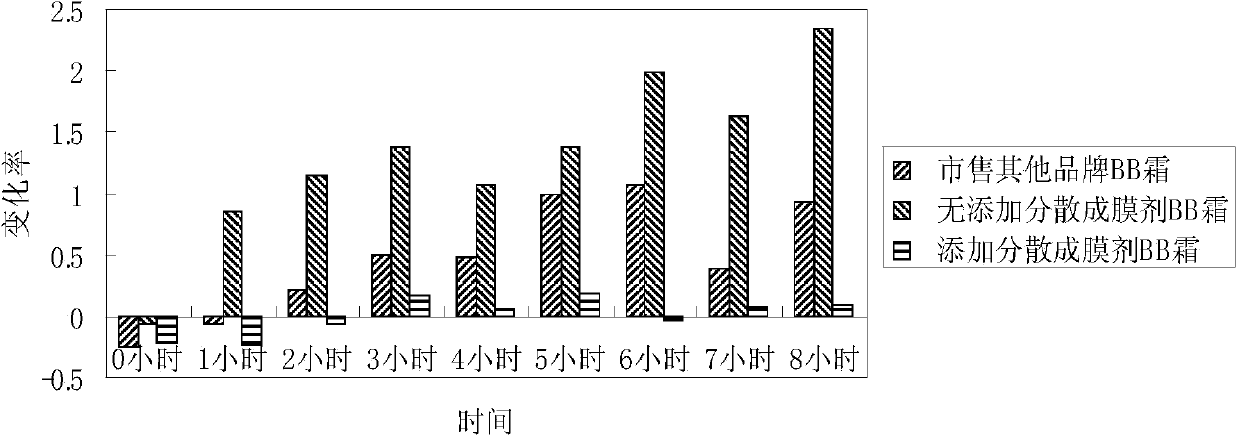

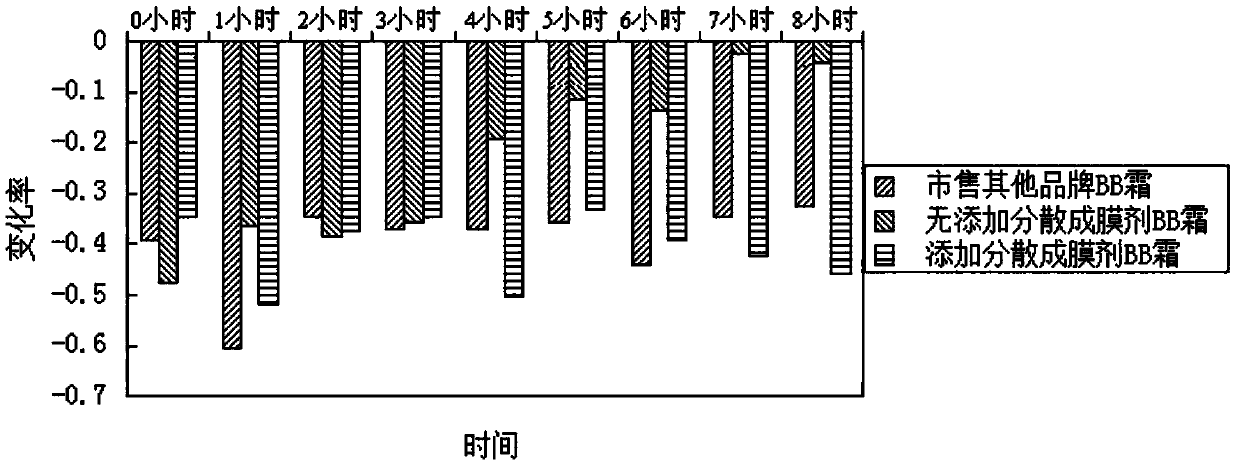

ActiveCN103735461AAvoid messInhibit aggregationCosmetic preparationsToilet preparationsChemistryBrown iron oxide

The invention provides a blemish balm (BB) cream. The blemish balm cream is prepared from the following components in percentage by weight: 8-12% of cyclopentasiloxane, 4-6% of isononyl isononanoate, 1.5-3% of PEG (polyethylene glycol)-10 polydimethylsiloxane, 1-1.5% of PEG / PPG (polypropylene glycol)-10 / 1 polydimethylsiloxane, 2-3% of superfine silicone treated titanium dioxide powder, 2-3% of nanometer silicon treated titanium dioxide powder, 0.1-0.2% of red iron oxide, 0.05-0.1% of yellow iron oxide, 0.2-0.5% of black iron oxide, 2-5% of glycerol, 3-6% of 1,3-butanediol, 0.5-1% of sodium chloride, 0.3-0.8% of polyacrylic acid / dimethyl siloxane / cyclopentyl dimethyl siloxane, 0.5-1% of phenoxyethanol / methyl paraben / butyl paraben / ethyl paraben / propyl paraben, 0.02-0.05% of essence, 1-4% of bletilla extract and the balance of deionized water. The BB cream disclosed by the invention can be used for effectively preventing makeup meltdown for seven hours and has good isolating, moisturizing and skin-caring functions.

Owner:H&B COSMETICS

Air cushion BB cream for look beautifying and skin caring

InactiveCN108186405AImprove stabilityGood nutrition and moisturizing effectCosmetic preparationsBody powdersCross-linkSkin color

The invention discloses an air cushion BB cream for look beautifying and skin caring. The BB cream comprises diphenylsiloxyphenyl polytrimethylsiloxane, butanediol dioctanoic acid / dicaprate, polydimethylene siloxane, cyclopentasiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, sorbitan stearin, acrylic acid / stearyl alcohol acrylic acid ester / polydimethylsiloxane methacrylate copolymer, polydimethylsiloxane crosspolymer, trimethylsiloxyphenyl dimethicone, HDI / trimethylol hexyl lactone cross-linked polymer, disteardimonium hectorite, titanium dioxide, tin oxide, synthetic fluorophlogopite, ironoxide, mica, polyhydric alcohols, magnesium sulfate, silica and water balance. According to the BB cream, emulsifier, emollient, stabilizer and film-forming agent are selected, the stability, efficacyand feeling of use of products are fully considered, the best formula component thereof is obtained, and the BB cream has the effects of correcting skin color, isolating ultraviolet rays and nourishing and moisturizing the skin.

Owner:FOSHAN WENSENTE INTPROP SERVICE CO LTD

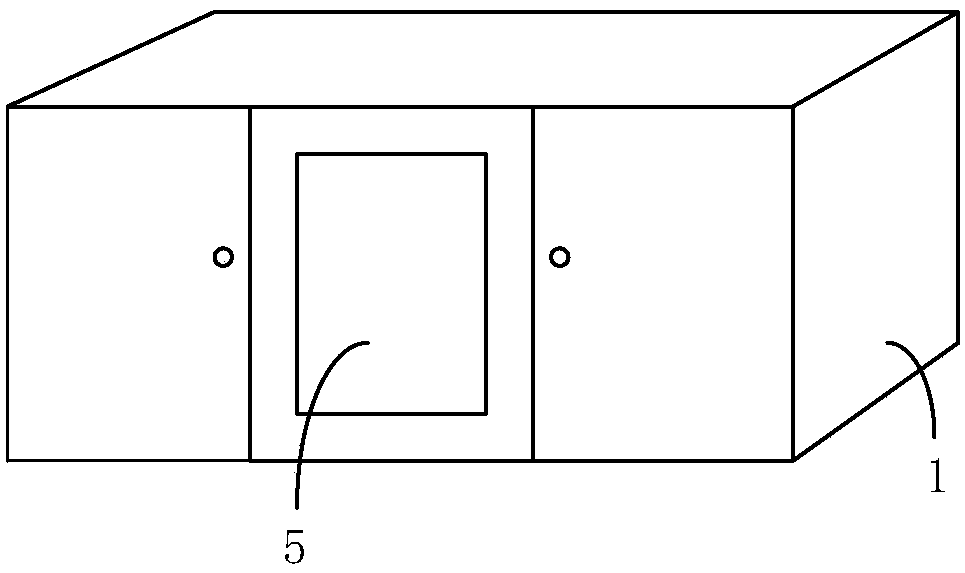

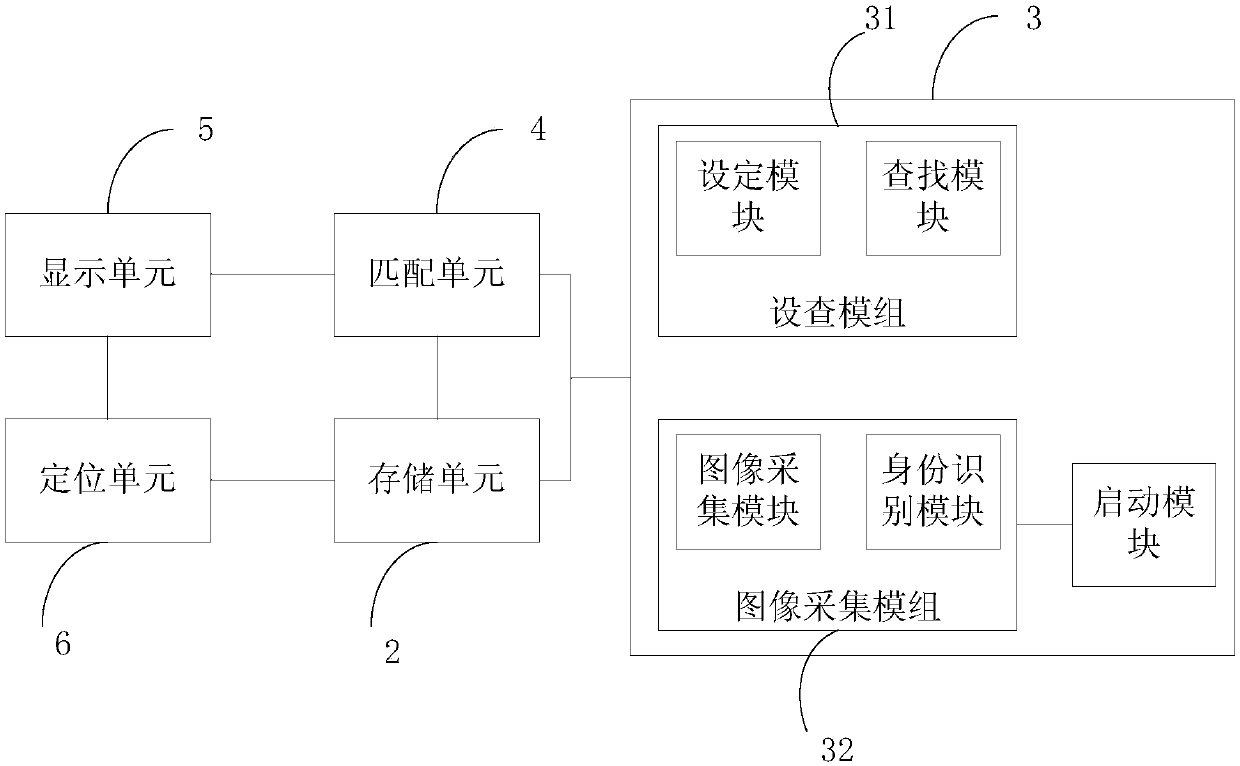

Wardrobe

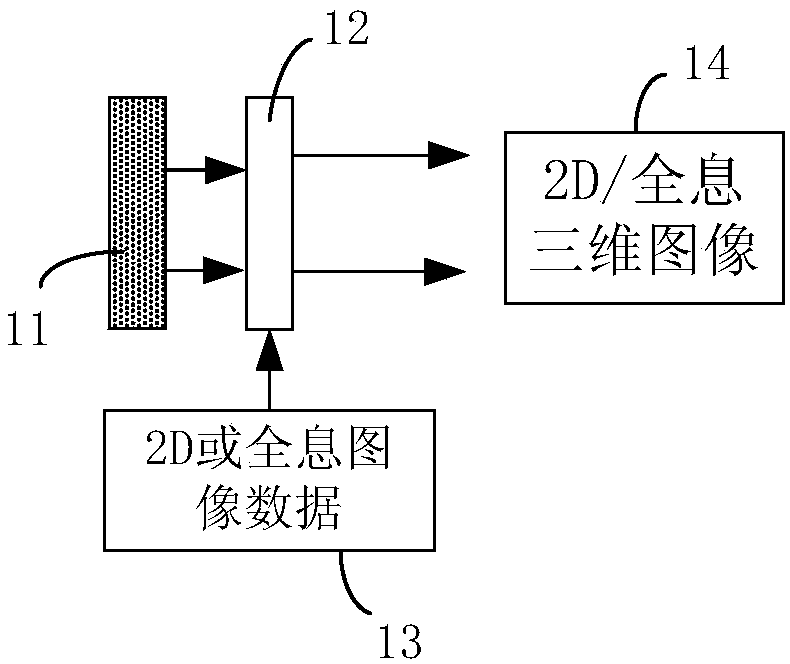

InactiveCN108022121ADesign intelligenceConvenient lifeWardrobesDigital data information retrievalInteraction interfaceComputer science

The invention belongs to the technical field of smart home, and specifically relates to a wardrobe. The wardrobe comprises a body, and is characterized by further comprising a storage unit, an acquisition unit, a matching unit, a display unit and a positioning unit, wherein the storage unit is used for storing parameters and placement positions of clothes placed inside the body and pre-stored figure data of a wearer; the acquisition unit is connected with the storage unit and used for acquiring the clothes parameters or the figure data of the wearer; the matching unit is connected with the storage unit and the acquisition unit and used for matching clothes fitting the figure of the wearer in the body according to the figure data of the wearer; the positioning unit is connected with the storage unit and used for positioning the position of the clothes selected by the wearer; and the display unit is connected with the matching unit and the positioning unit and used for providing a human-computer interaction interface and displaying a try-on dressing effect of the clothes recommended to the wearer and the position of the selected clothes. The wardrobe can at least partially solve a problem that it is difficult for the wearer to find and match the clothes.

Owner:BOE TECH GRP CO LTD

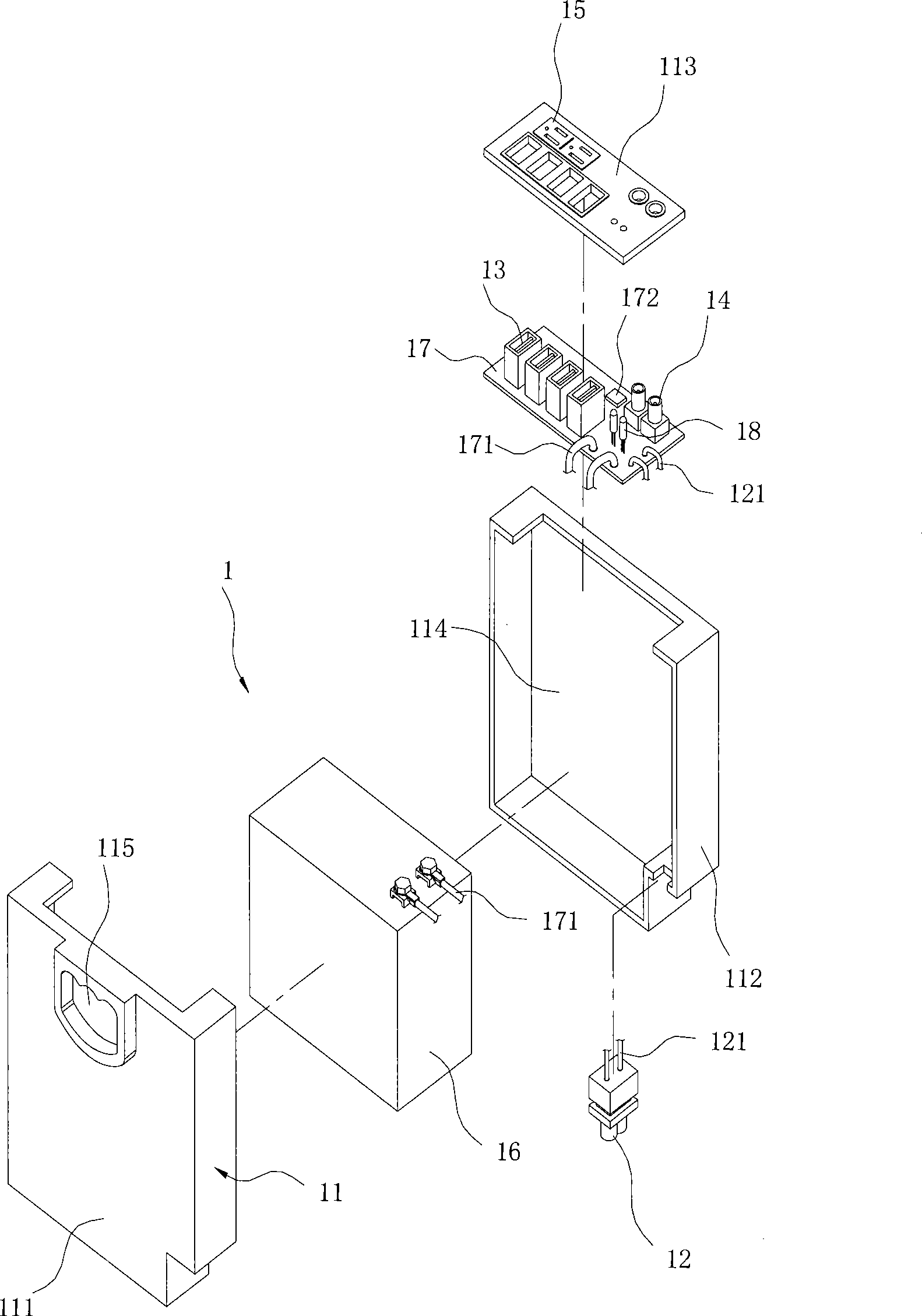

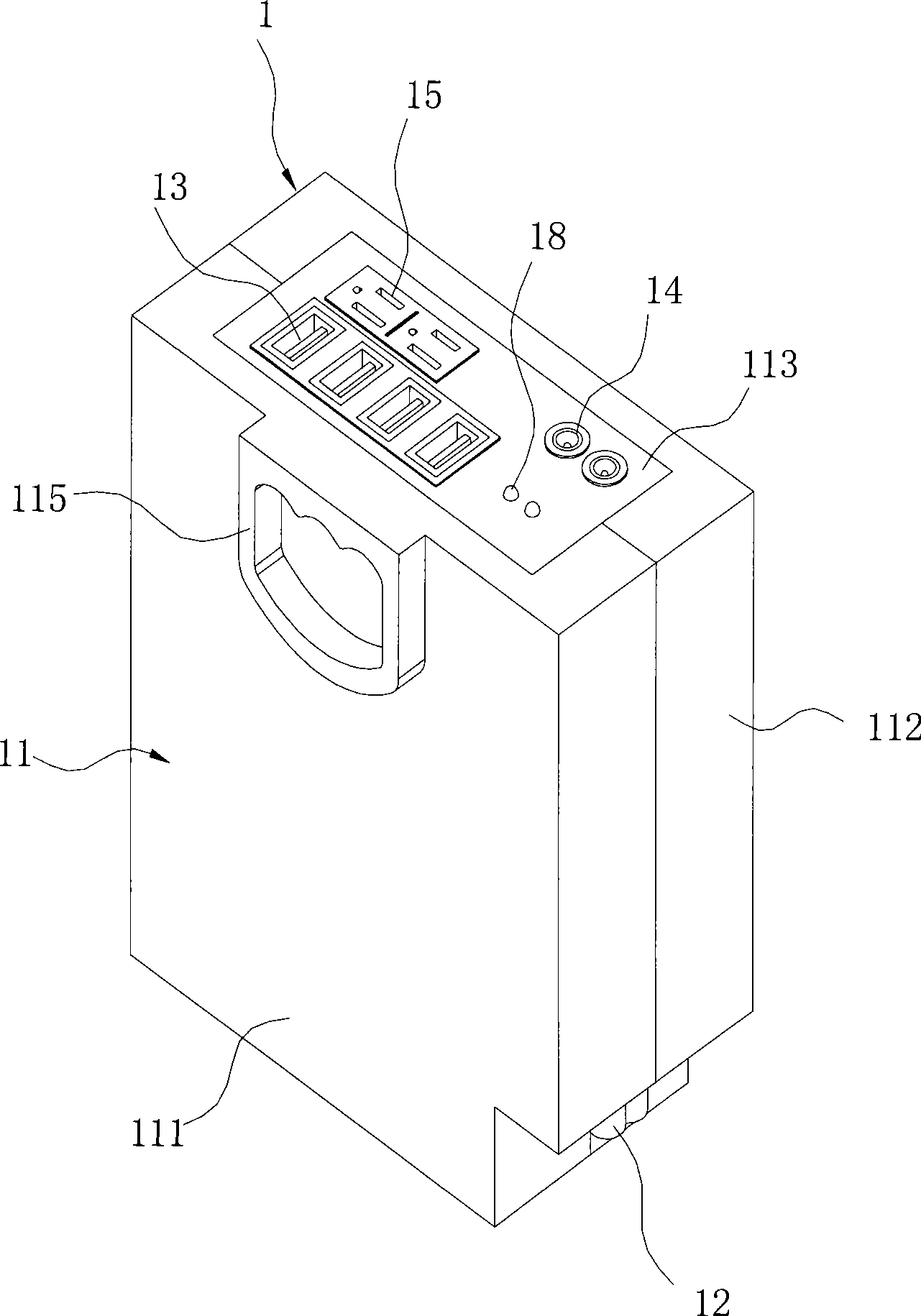

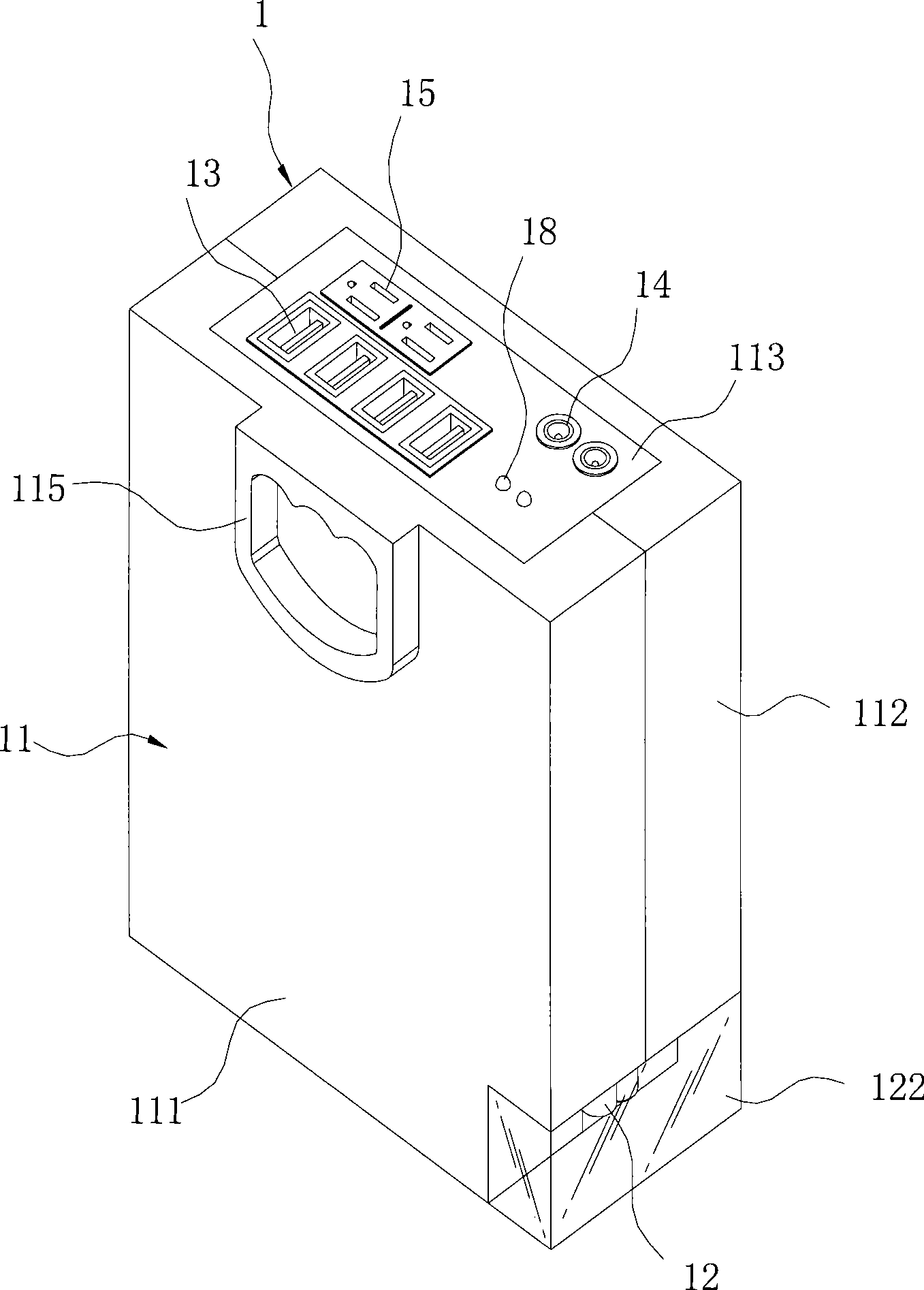

Convenient electric power supply system of mobile equipment

InactiveCN101394099ASimplify the power supply systemFast power supply systemCoupling device connectionsBatteries circuit arrangementsCharging stationPower output

A convenient power supply system for mobile equipment comprises a plurality of power supplies and at least a charging station. Each power supply comprises a casing, a power input part, a plurality of power output parts, a battery jar and a first circuit board, the battery jar and the first circuit board are electrically connected and are arranged inside the casing, and the power input part and the power output parts are electrically connected with the first circuit board; and the charging station comprises a base, a plurality of charging connecting heads and a second circuit board, the base has a plurality of charging interfaces, which can be used for the insertion of the plurality of power supplies, the second circuit board is arranged inside the base, the plurality of charging connecting heads are electrically connected with the second circuit board, and the plurality of charging connecting heads respectively correspond to the plurality of charging interfaces, so as to charge the power supplies which are inserted into the charging interfaces. By adopting the invention, the problem that customers have to take a charging wire because a plurality of mobile sockets cannot be provided is effectively solved.

Owner:POWERTECH INDAL

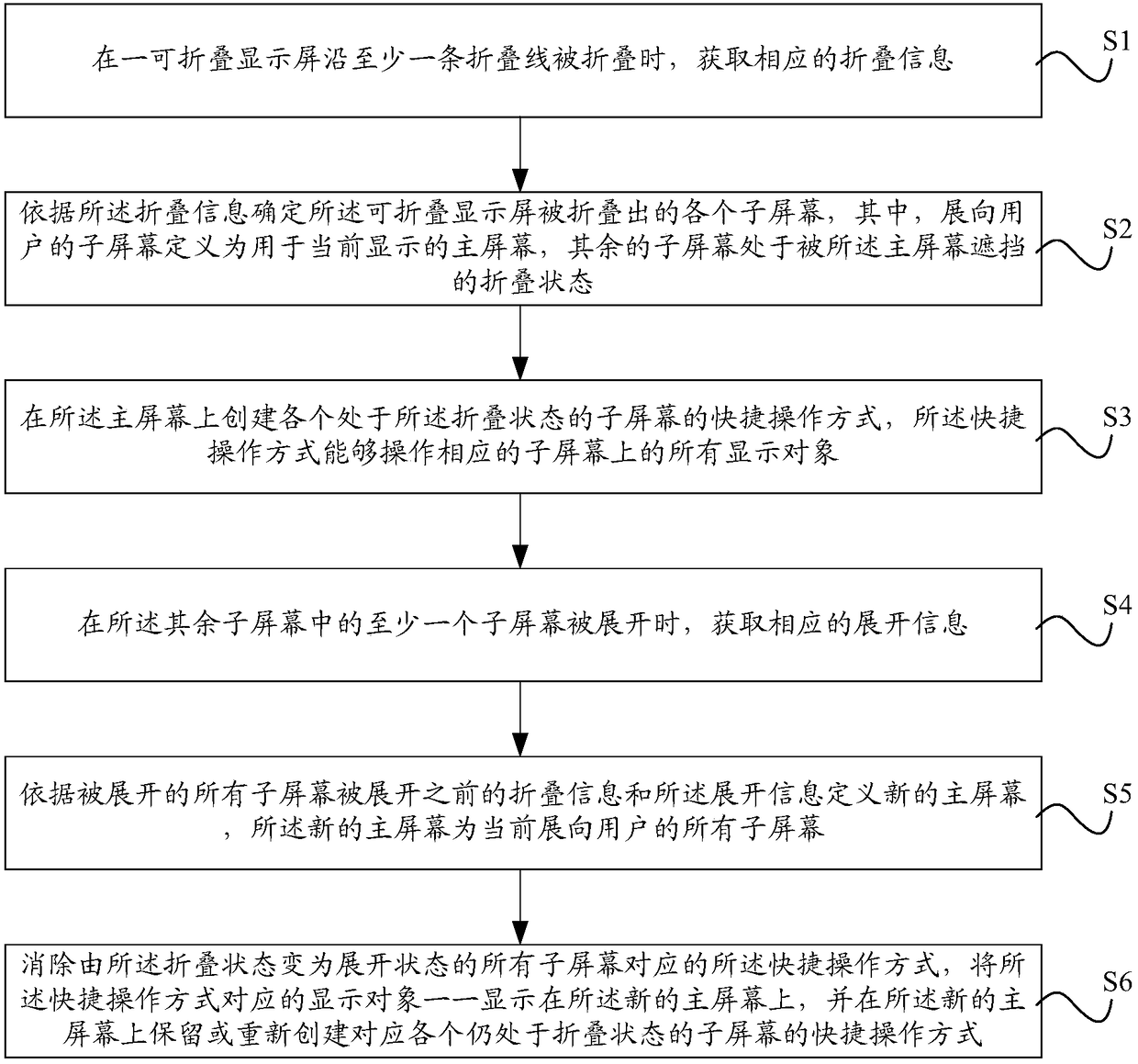

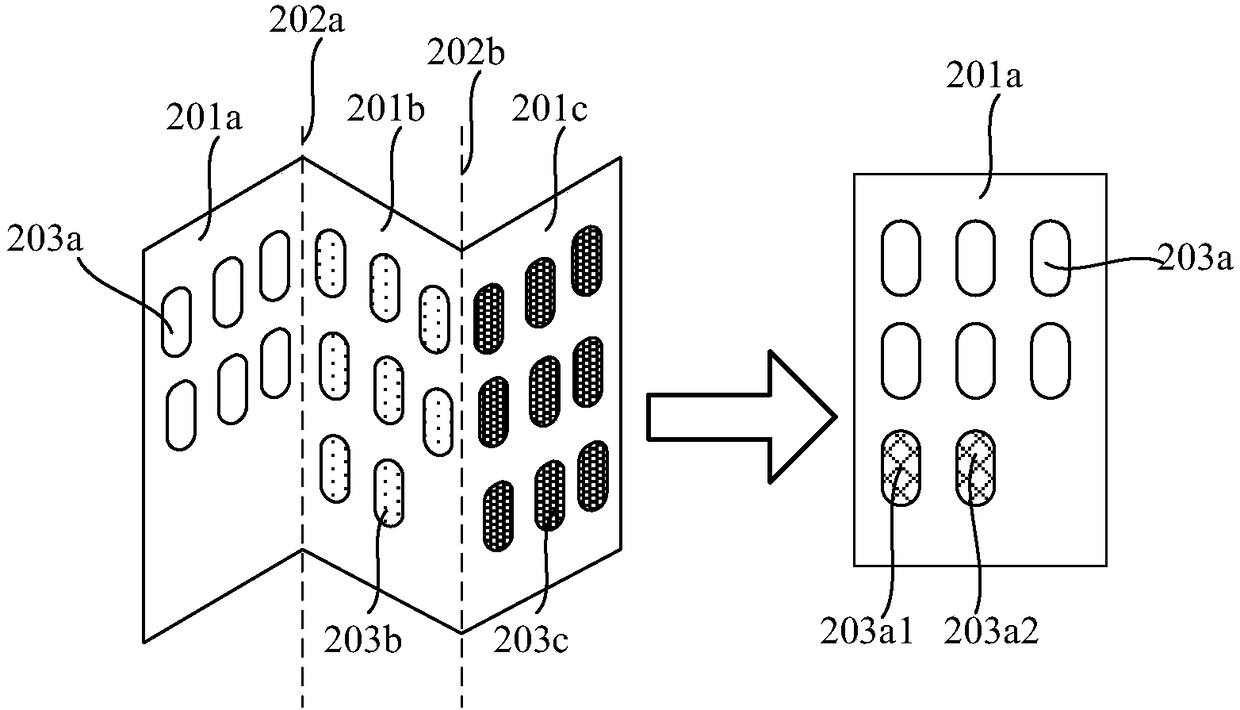

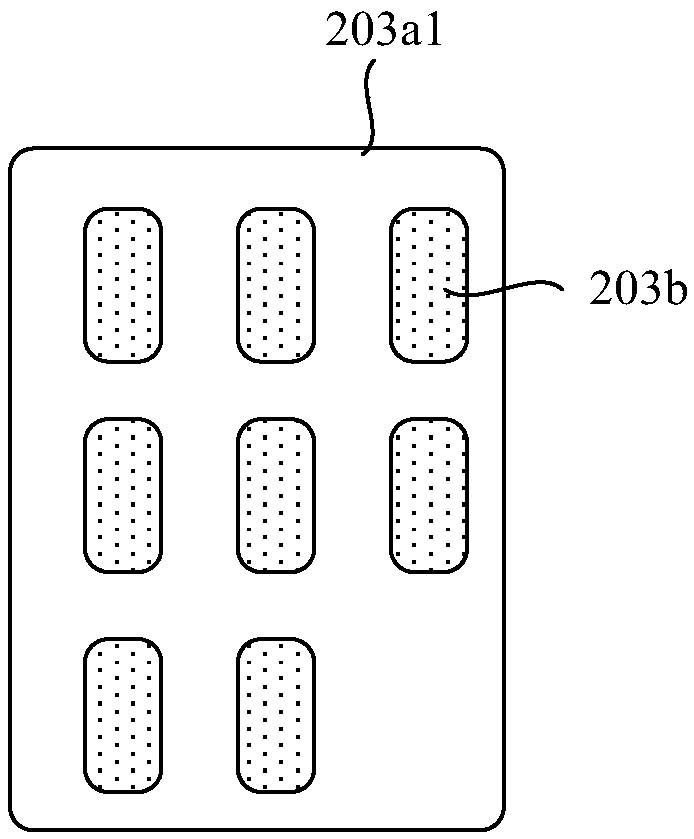

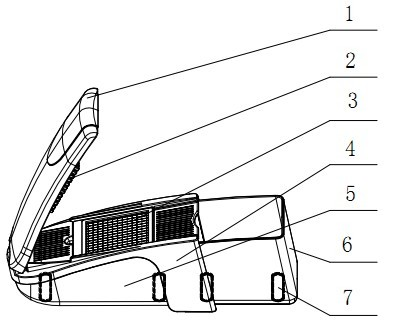

Display adjusting method of foldable display screen and display device

ActiveCN108196807AAvoid messImprove cleanlinessDigital output to display deviceDisplay deviceHome screen

The invention provides a display adjusting method of a foldable display screen and a display device. When the foldable display screen is folded, a shortcut operation mode capable of operating remaining sub-screen bodies shielded by a main screen body can be created on the main screen body so that a user can conveniently use the display screen; meanwhile, the problem that all display objects on theremaining shielded sub-screen bodies are directly moved to the main screen body during folding and accordingly the main screen body is messy is avoided, and the display tidiness degree of the main screen body is improved; in addition, when the folded foldable display screen is unfolded, the main screen body can be redefined according to current unfolding and folding conditions, the display objects on the unfolded sub-screen bodies are displayed in order, and meanwhile, the shortcut operation mode capable of operating the remaining sub-screen bodies which are still shielded by a new main screen body is reserved or re-created on the new main screen body so that display images on the main screen body can be sorted when the folded foldable display screen is unfolded.

Owner:YUNGU GUAN TECH CO LTD

Polyurethane elastic fiber finishing agent

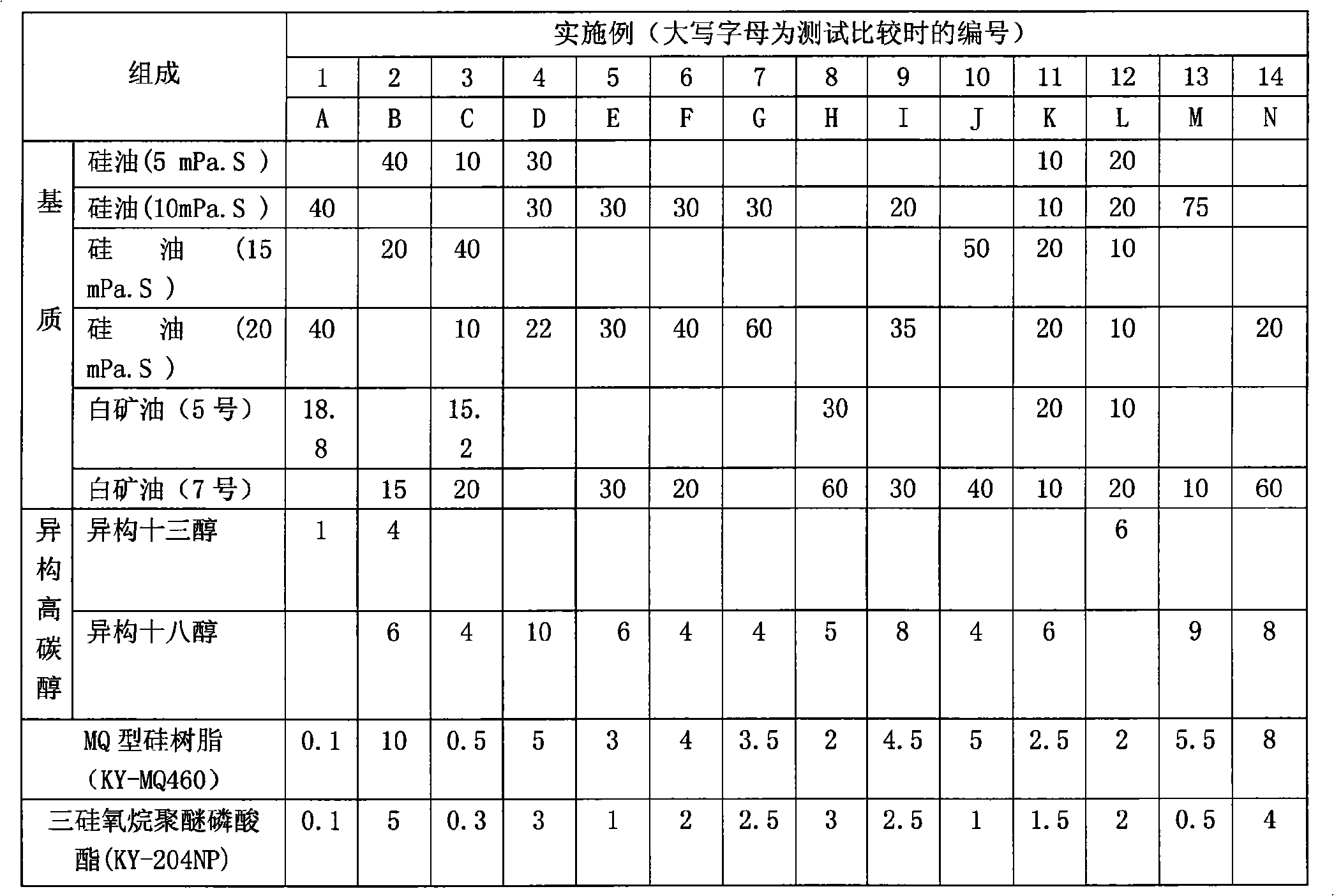

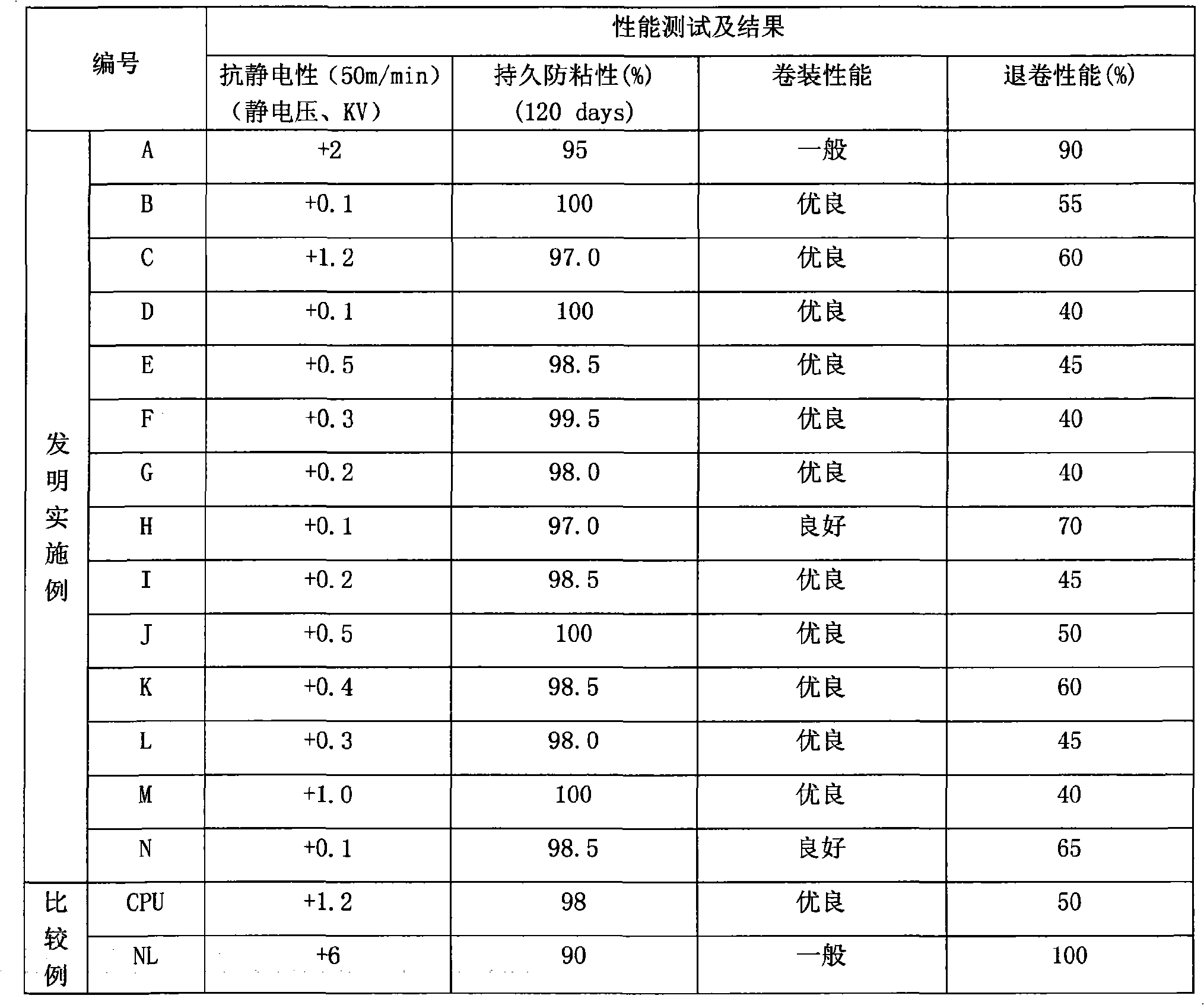

InactiveCN101666040AGood sealing and anti-sticking effectUniform sealing and anti-stick effectFibre typesAlcoholPhosphate

The invention discloses a polyurethane elastic fiber finishing agent, comprising the following components in parts by weight: 75.0-98.8 parts of at least one substrate selected from silicon oil and white mineral oil, 1.0-10.0 parts of isomerous high-carbon alcohol, 0.1-10.0 parts of MQ silicon resin of which the pour point is smaller than or equal to 100 DEG C and 0.1-5.0 parts of trisiloxane polyether organic phosphate. The finishing agent enables the polyurethane elastic fiber to have favorable antistatic property, lubricating property and grating balancing property in the filament reeling process, so that the polyurethane elastic fibers reeling at high speed have stable tension and do not skid or cause the filament roller to mess up, thereby endowing the polyurethane elastic fibers withfavorable reeling property. The finishing agent also enables the polyurethane elastic fibers rolled on the roller to have enduring anti-adhesion insulation property, so that the polyurethane elasticfibers have favorable cocoon reelability and thorough root unreeling property in the downstream unreeling process, thereby endowing the polyurethane elastic fibers with favorable unreeling property.

Owner:HUAIAN KAIYUE TECH DEV

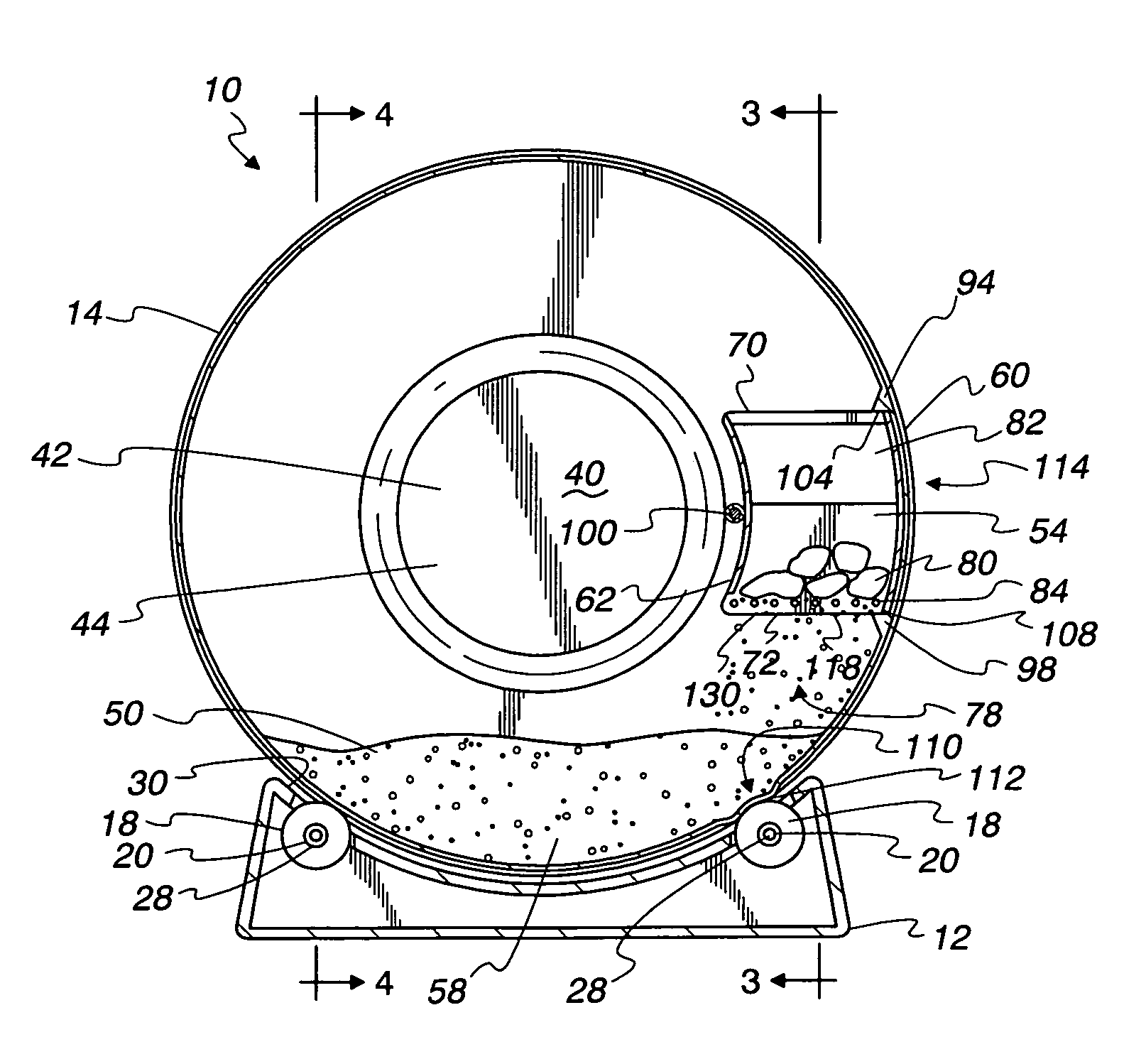

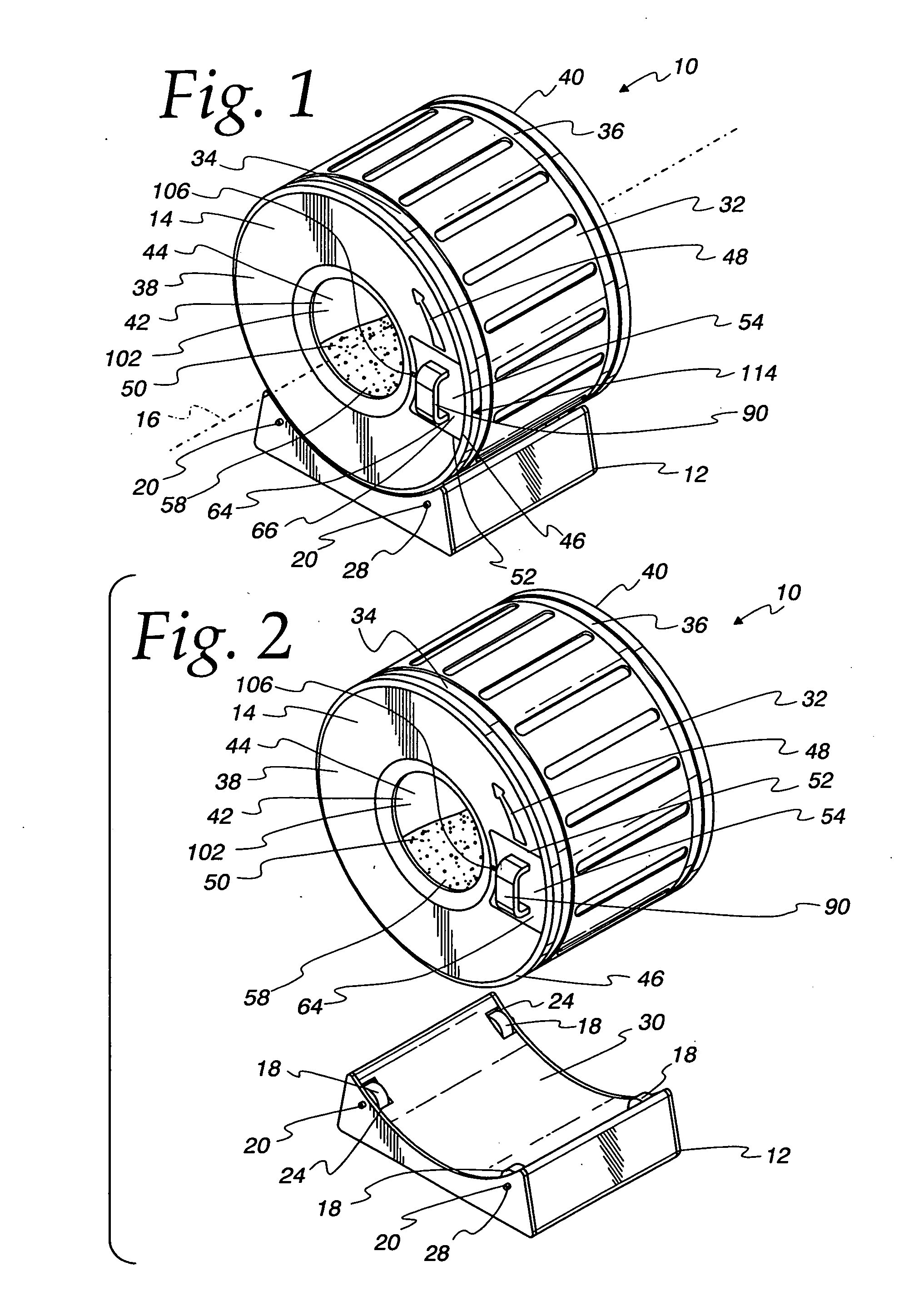

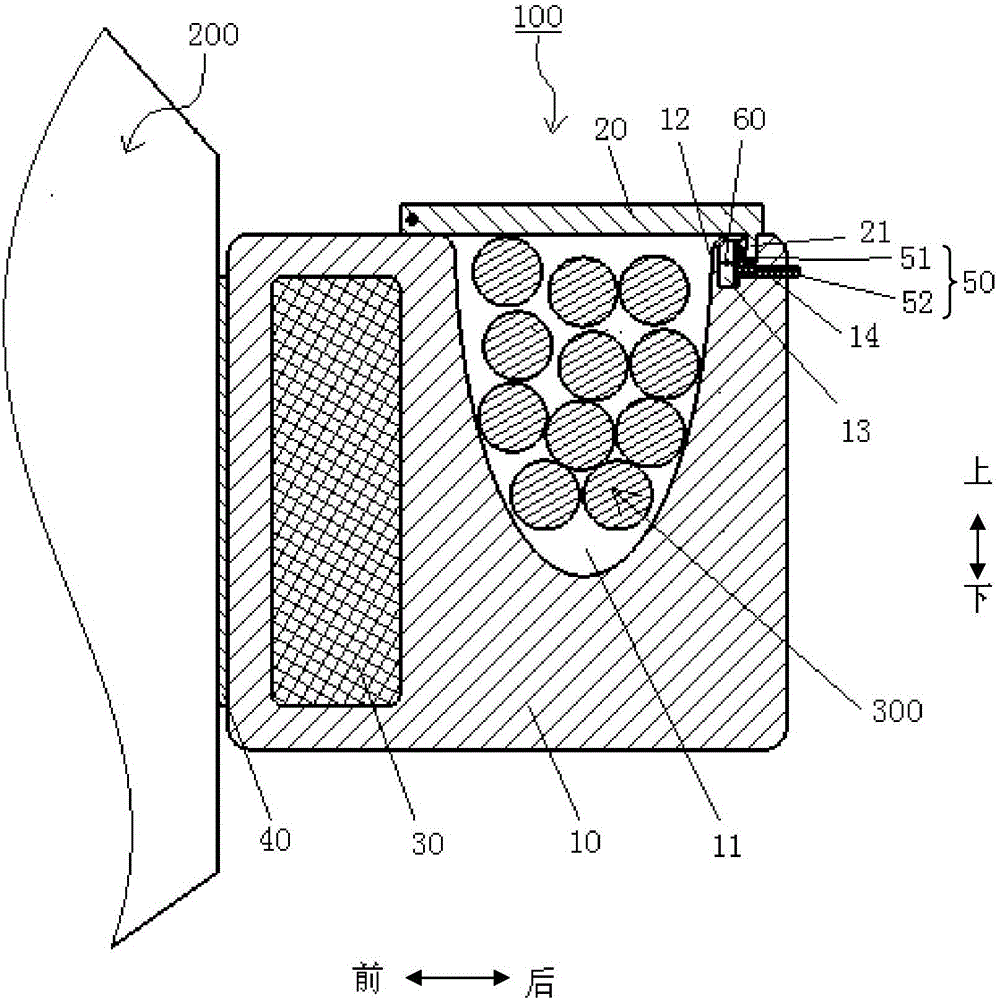

Apparatus and method for handling animal waste

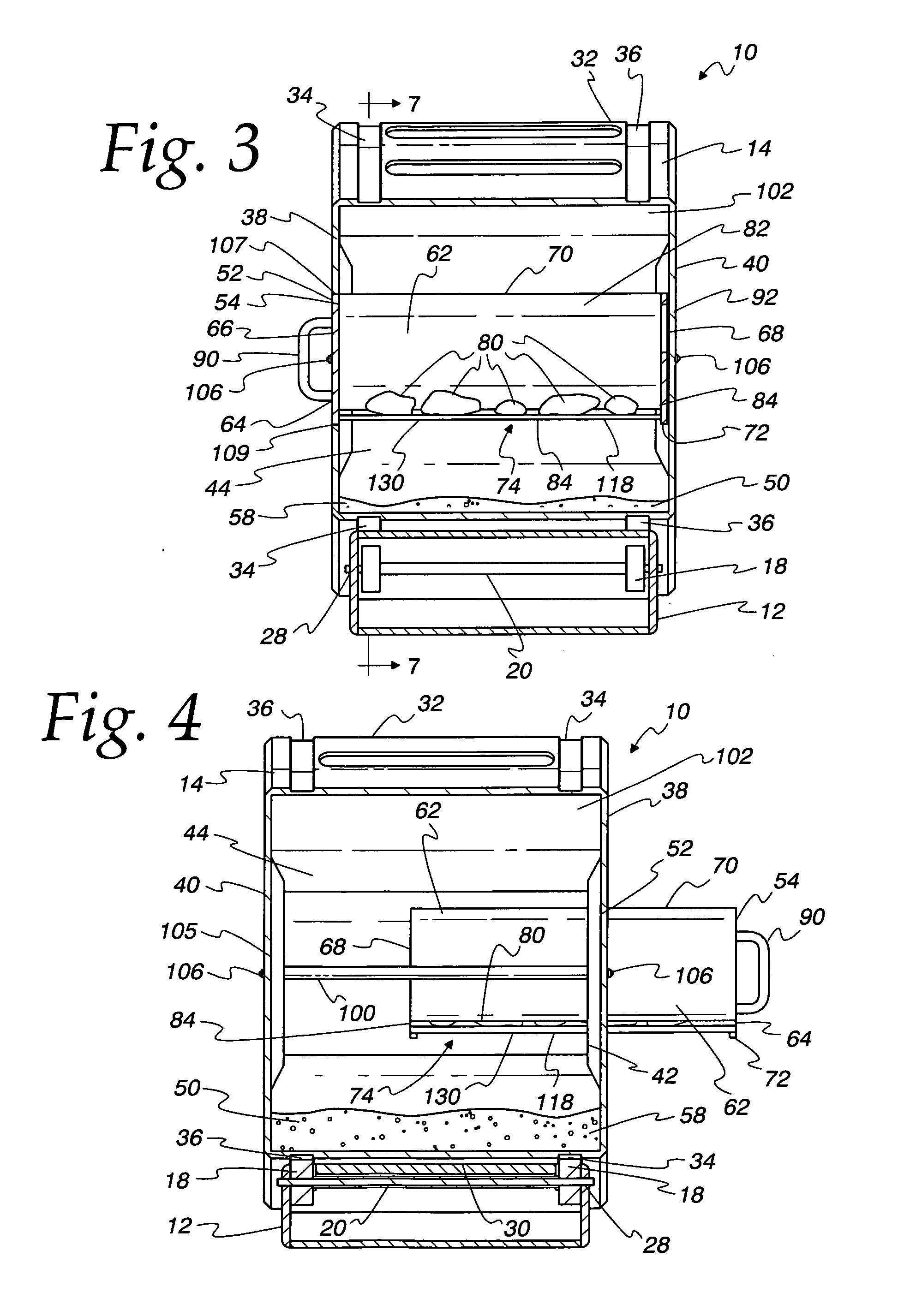

ActiveUS20110214614A1Reduced footprintLimit its operationAnimal housingOther apparatusLitterEngineering

An animal waste handling apparatus having a cylindrical housing with an opening to allow an animal to enter to relieve itself in litter held in the interior volume of the housing. The apparatus has a sifting drawer that is removably mounted in the interior volume of the housing and is carried for rotational movement when the housing is rotated about its axis. The sifting drawer includes an open top, an unobstructed interior volume and a filter member spaced from the open top. During a rotational sifting cycle, the sifting drawer enters the litter to capture the litter for filtering to separate animal waste from the litter. The filtered litter remains in the interior volume of the housing and filtered out waste is retained in the sifting drawer. The sifting drawer is removed along a direction that is parallel to the axis of the housing about which the housing is rotated.

Owner:SHARP RANDALL +1

Multifunctional food processor

InactiveCN102599830AReasonable designSimple structureMetal working apparatusStrainersEngineeringMultiple function

Owner:SHUANGMA PLASTIC MFG INC

Device facilitating painting for decoration

InactiveCN108355892AEasy to paint and colorGood colorCleaning using toolsCleaning using gasesEngineeringWorkload

The invention relates to the technical field of decoration equipment, and discloses a device facilitating painting for decoration. The device comprises a work table, a work box is fixedly installed onthe top of the work table, two partition plates arranged at equal intervals are fixedly connected to the interior of the work box, a box door is fixedly installed on the left side of the work box, the front face and the back face of the work box are each fixedly connected with two symmetrical springs, the close sides of the springs are fixedly connected with connection plates, and the close sidesof the connection plates are fixedly connected with brush plates. According to the device facilitating painting for decoration, decoration workers are helped to clean materials or tools, effective painting is ensured, air drying time is greatly saved, manual labor is greatly saved, harm caused to the human body and mess caused by manual painting are avoided, the workload of workers is relieved, the whole decoration process is carried out more rapidly and efficiently, and painting work of workers is greatly facilitated.

Owner:庄楠键

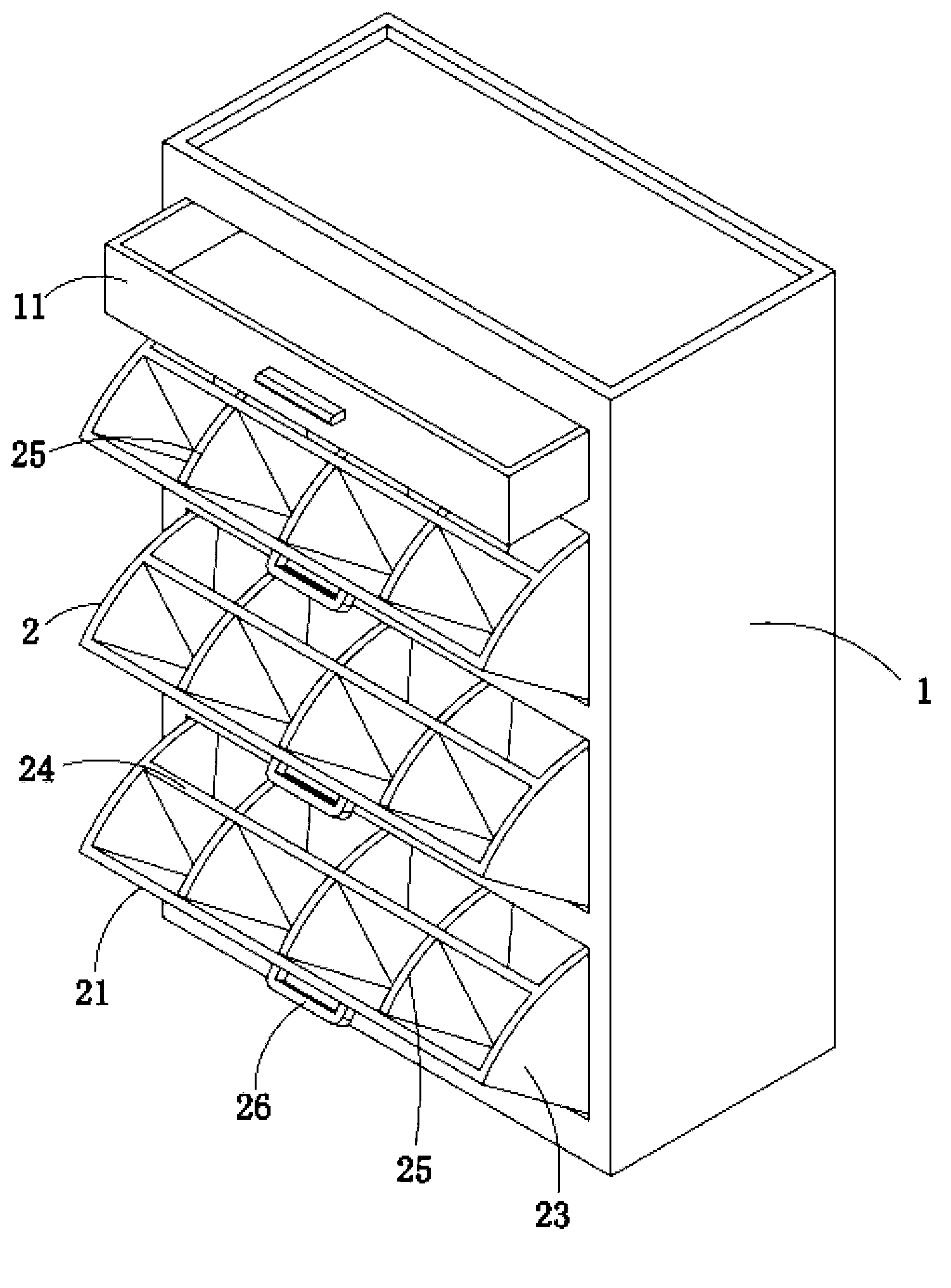

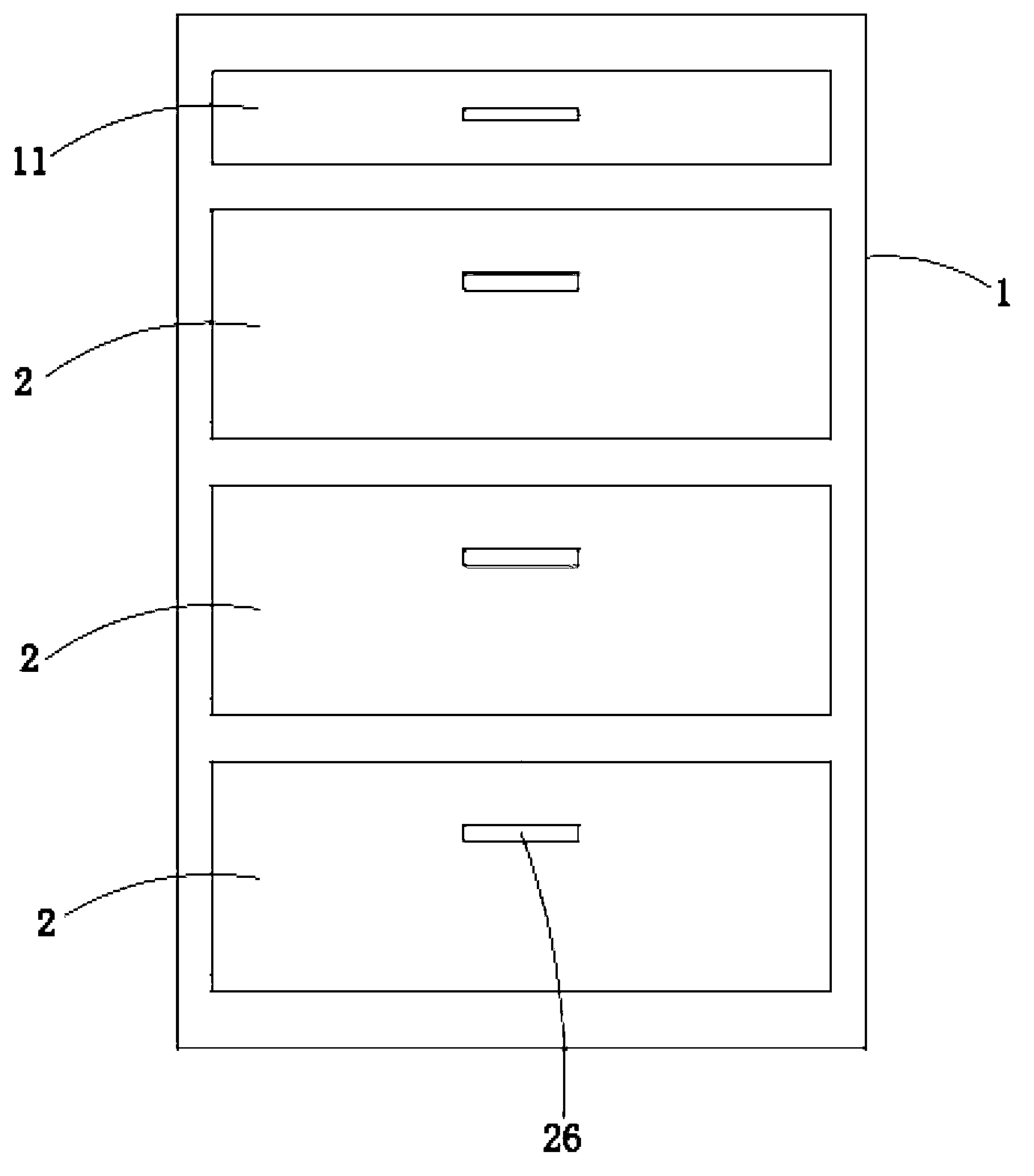

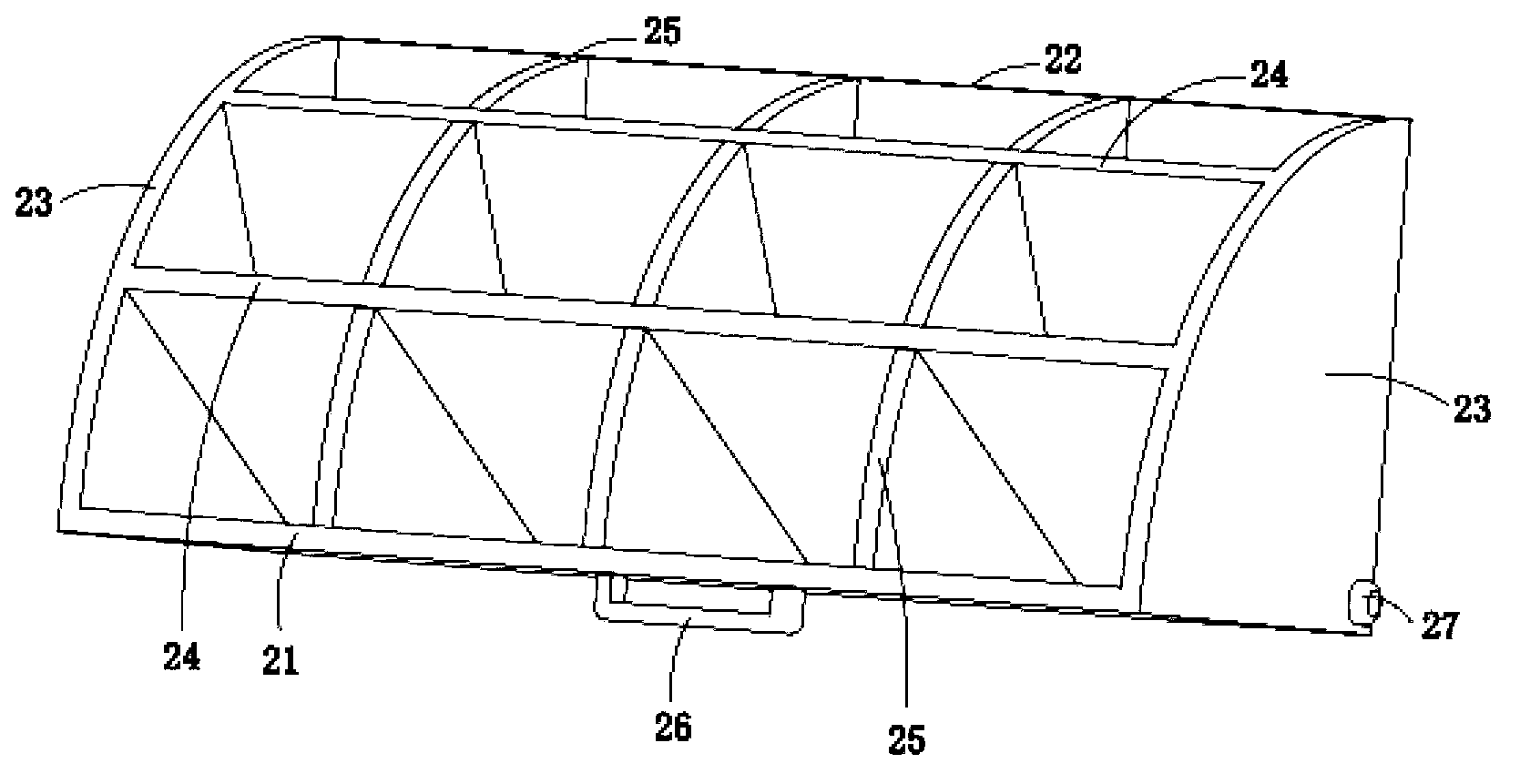

High-capacity turnover shoe cabinet

The invention relates to a high-capacity turnover shoe cabinet which comprises a cabinet body and a plurality of layers of shoe boxes mounted in the cabinet body, wherein each layer of shoe box comprises a front baffle, a rear baffle and fan-shaped side baffles; the two ends of each front baffle and each rear baffle are fixed with the fan-shaped side baffles; a plurality of transverse plates can be arranged between the front baffles and the rear baffles; each layer of shoe box is divided into multiple layers by the transverse plates; a rotating shaft is arranged in the fan-shaped centers of the fan-shaped side baffles of each layer of shoe box; a plurality of grids are arranged in the shoe boxes; a fan-shaped partition plate is mounted between every two adjacent grids; a drawer is mounted at the top end of the cabinet body; the shoe boxes are arranged at the front of the cabinet body from the top down; and handles are arranged on the front baffles of the shoe boxes. According to the high-capacity turnover shoe cabinet, the grids are arranged in each shoe box to prevent shoes from falling and turning when the shoe boxes are turned over upward, and the high-capacity turnover shoe cabinet is convenient to use, small in floor area, high in capacity and high in practicability.

Owner:苏州丝路旅游发展有限公司

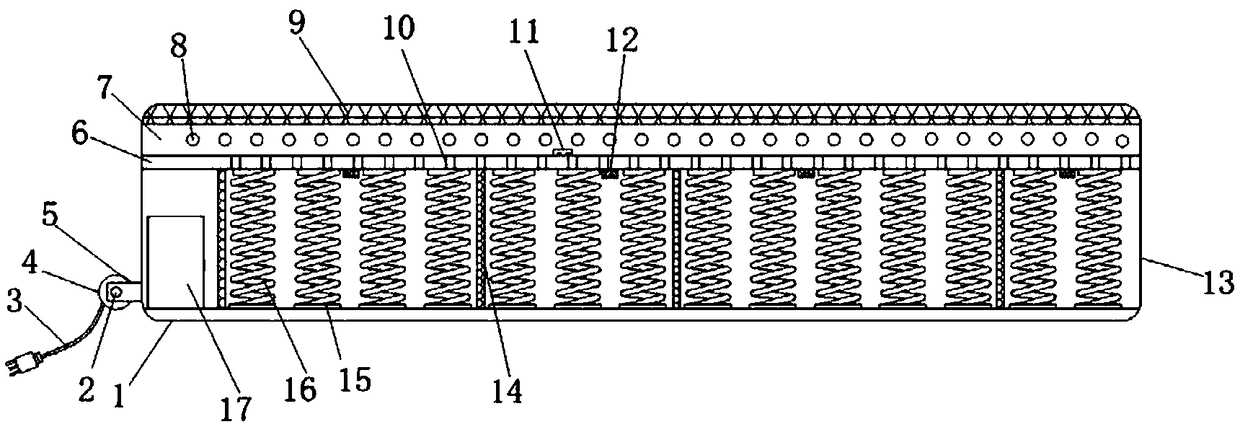

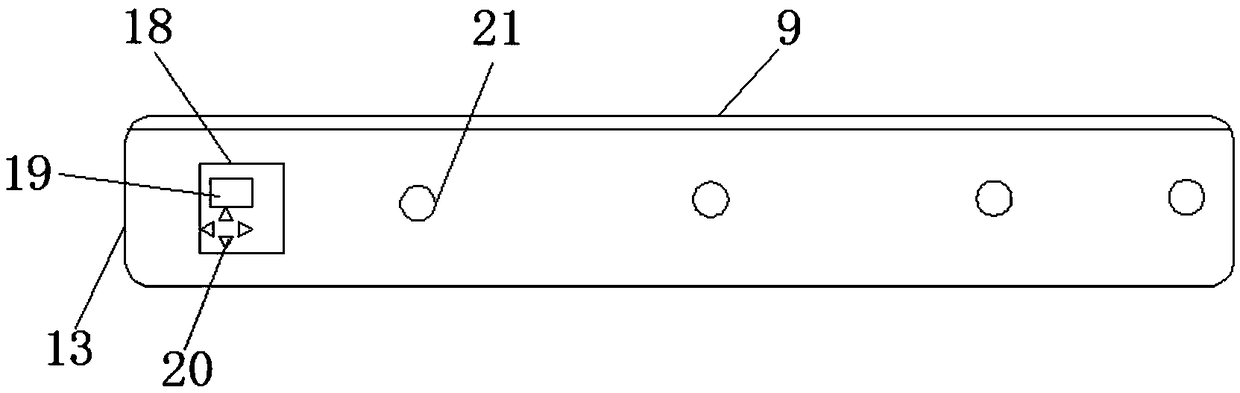

Spring mattress with specified region local heating function

PendingCN108784122AMonitor temperature in real timeSave energyStuffed mattressesSpring mattressesElectricityEngineering

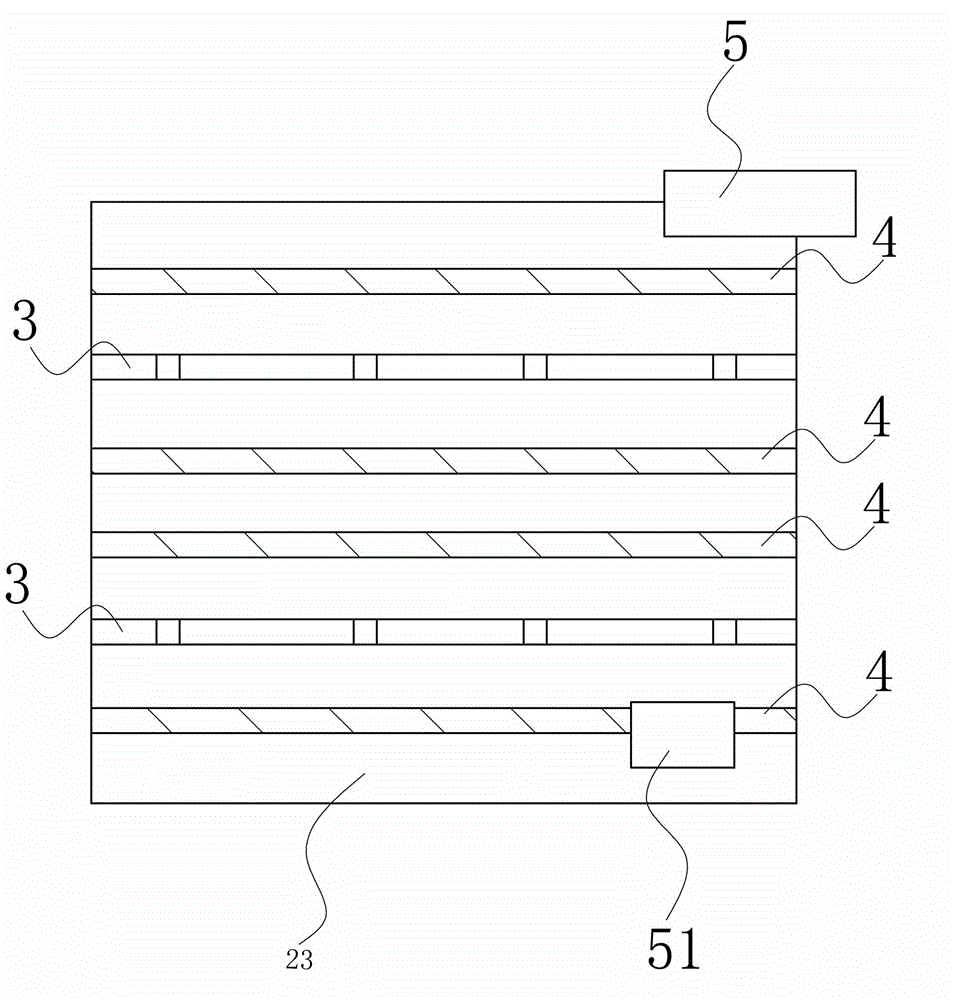

The invention discloses a spring mattress with a specified region local heating function. The spring mattress comprises a base, wherein a mattress outer cover is connected to the outer wall of the base in a sleeving manner; four first through holes distributed in equal distance are formed in one side of the mattress outer cover; air pressure valves are connected inside the first through holes by virtue of cutting sleeves; a hot-air blower is connected to one side of the top of the base by virtue of bolts; spring bases distributed in equal distance are connected to the top of the base by virtueof screws; buffer springs are welded on the tops of the spring bases. According to the arrangement of a heating wire, a temperature sensor, the hot-air blower and a hot air duct, the spring mattresscan be wholly heated by the heating wire, the temperature in the mattress outer cover is monitored in real time by the temperature sensor and transferred to the controller by a signal line, the controller controls the hot-air blower to heat the air to be delivered via the hot air duct, the electromagnetic valve is controlled to open by an adjustment button so as to heat the specified region, the energy is greatly saved, and the applicability is high.

Owner:ZHEJIANG ANJI MEI JIAQI HOME CO LTD

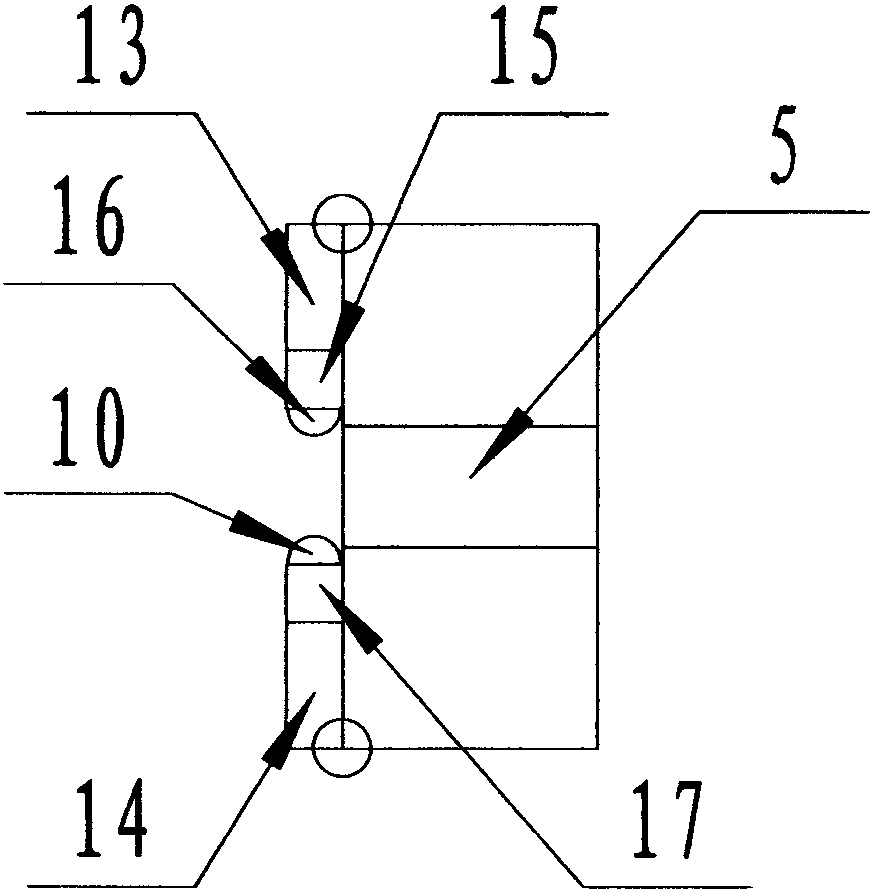

Support device for pouring shear wall

ActiveCN103243906ASimplify the construction processOperation saves time and effortForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallArchitectural engineering

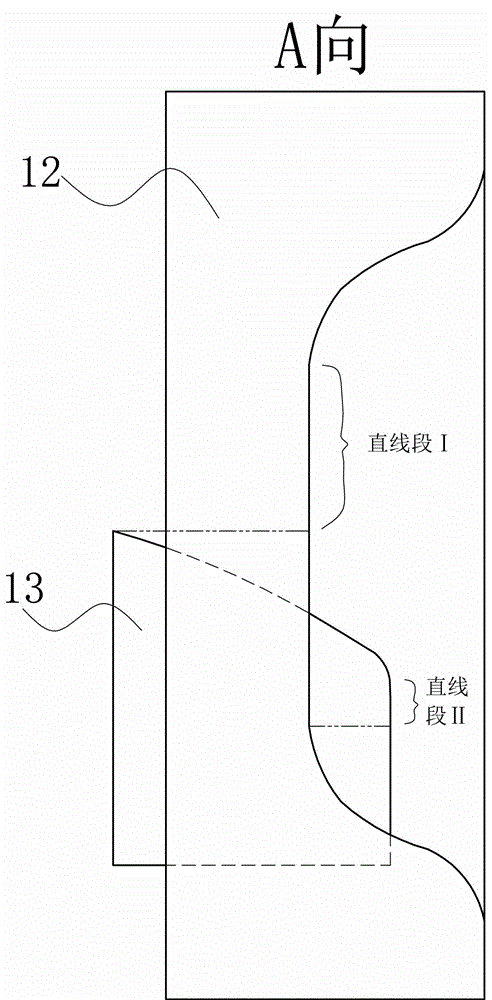

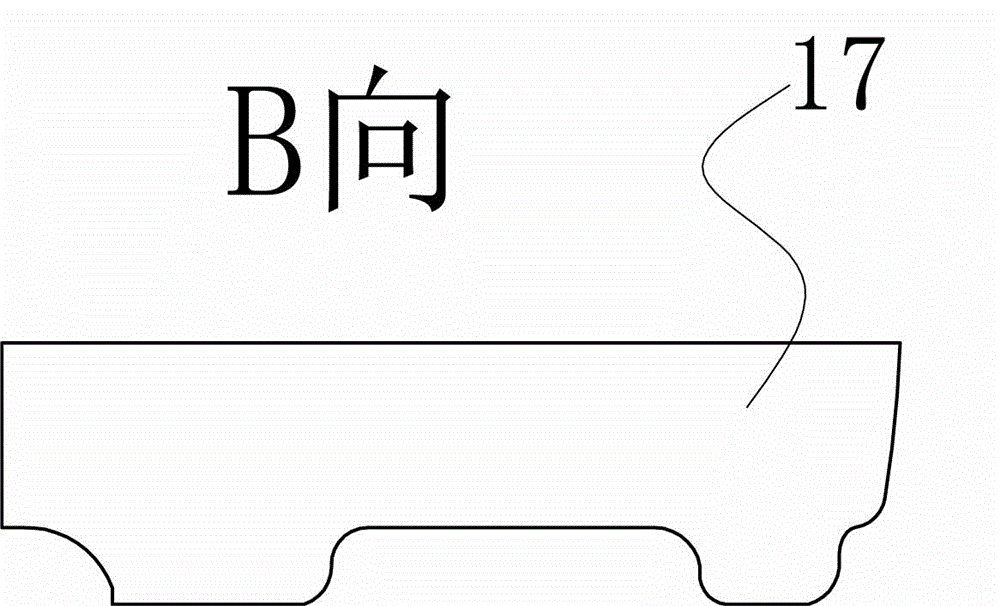

The invention provides a support device for pouring a shear wall. The support device comprise a plurality of ribbed plates which are longitudinally mutually connected through connectors. Each two ribbed plates are horizontally parallelly distributed. The support device is structurally characterized in that a first ribbed plate is parallel with a second ribbed plate in the length direction, a spatial part is formed between the first ribbed plate and the second ribbed plate, a first protruding rib on the first ribbed plate and a second protruding rib on the second ribbed plate are disposed in the spatial part, the first protruding rib corresponds to the second ribbed plate, a cushion block is mounted between the first protruding rib and the second ribbed plate, the second protruding rib corresponds to the first ribbed plate, a cushion block is mounted between the second protruding rib and the first ribbed plate, the connectors are disposed on the outer sides of the first ribbed plate and the second ribbed plate and respectively connected to the first ribbed plate and the second ribbed plate. The support device uses concrete pouring after industrialized production and field assembling and removes the connectors after the shear wall is manufactured, and the problems of complex construction procedures, low construction efficiency and high construction cost in the prior art can be solved.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

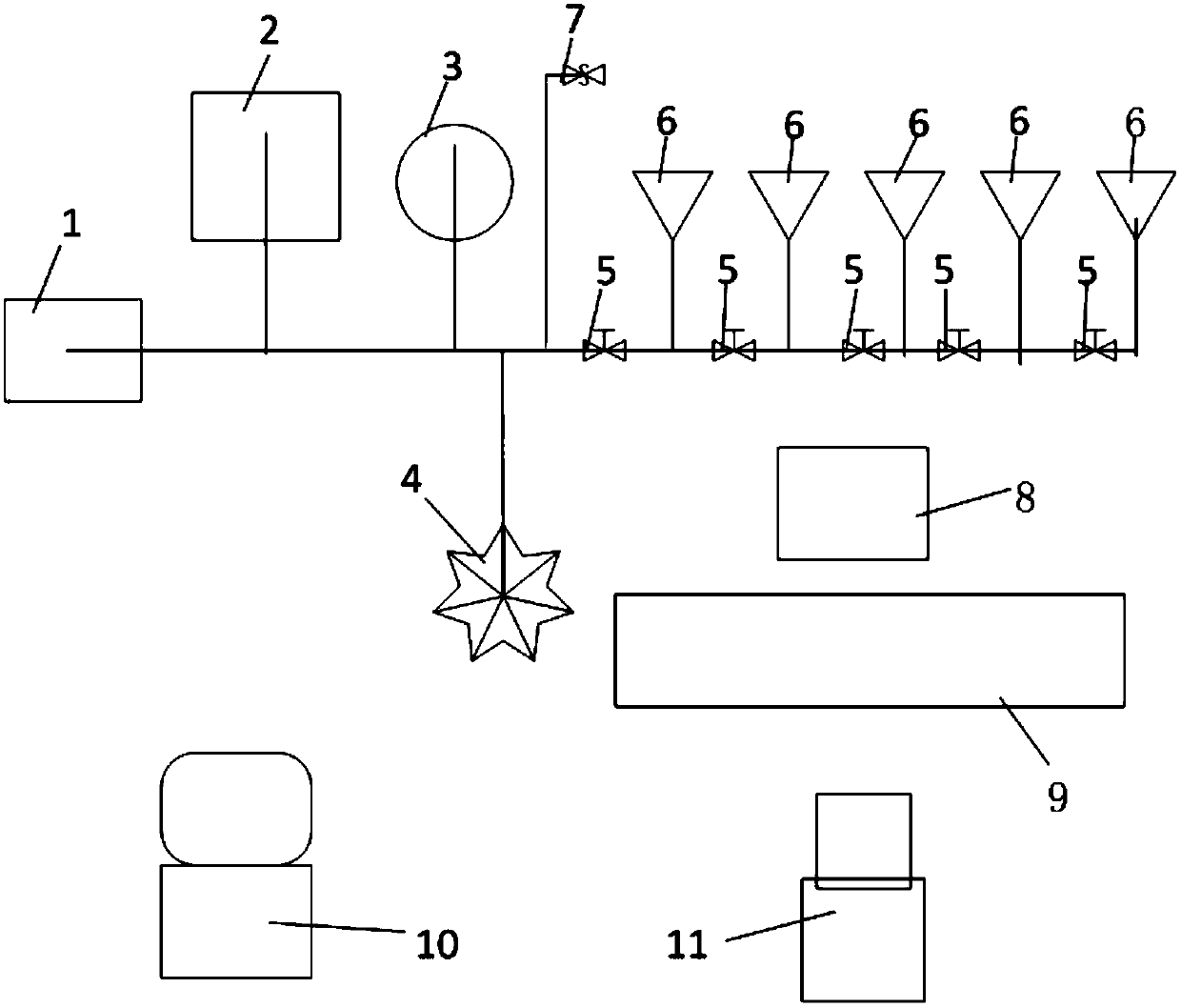

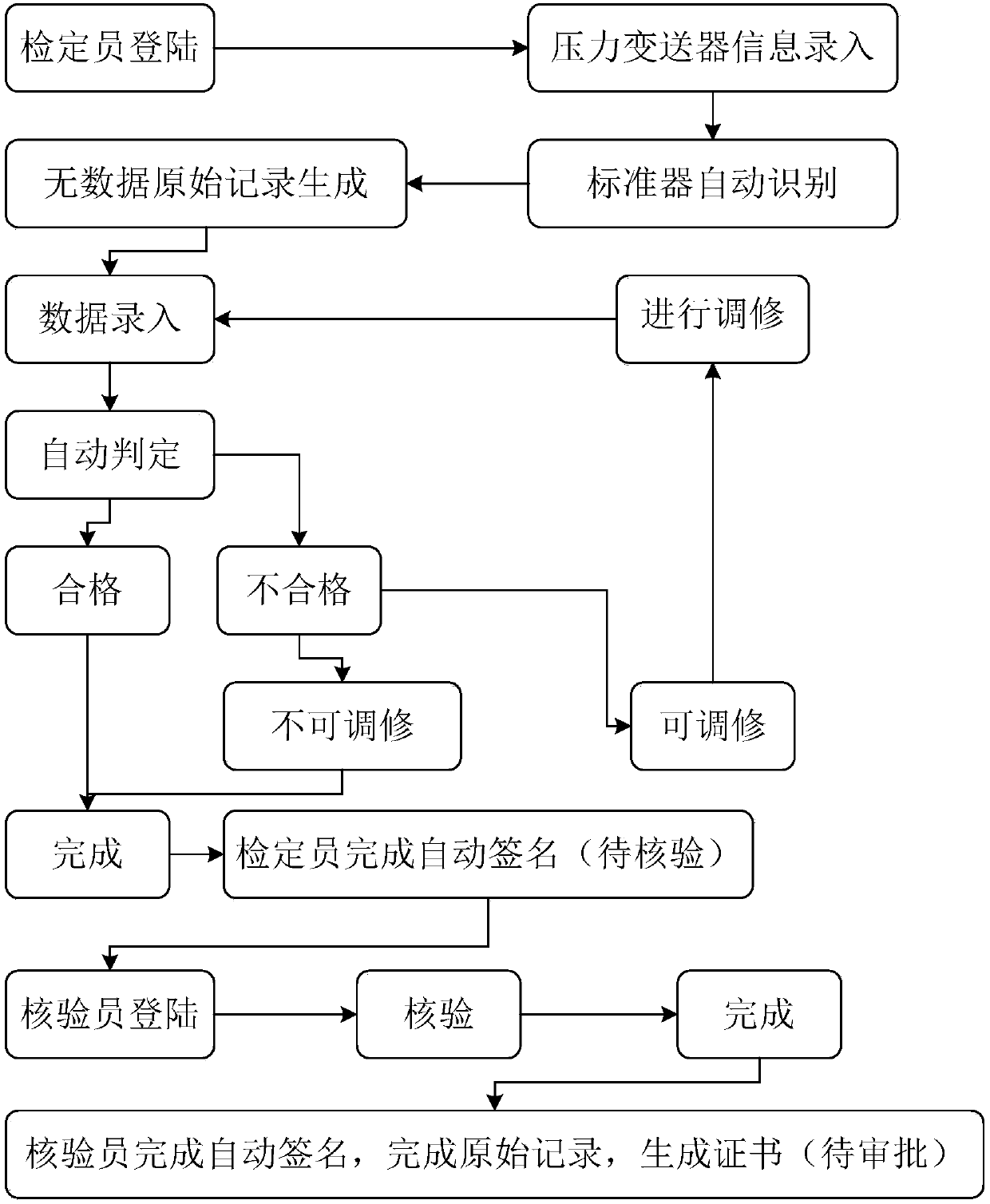

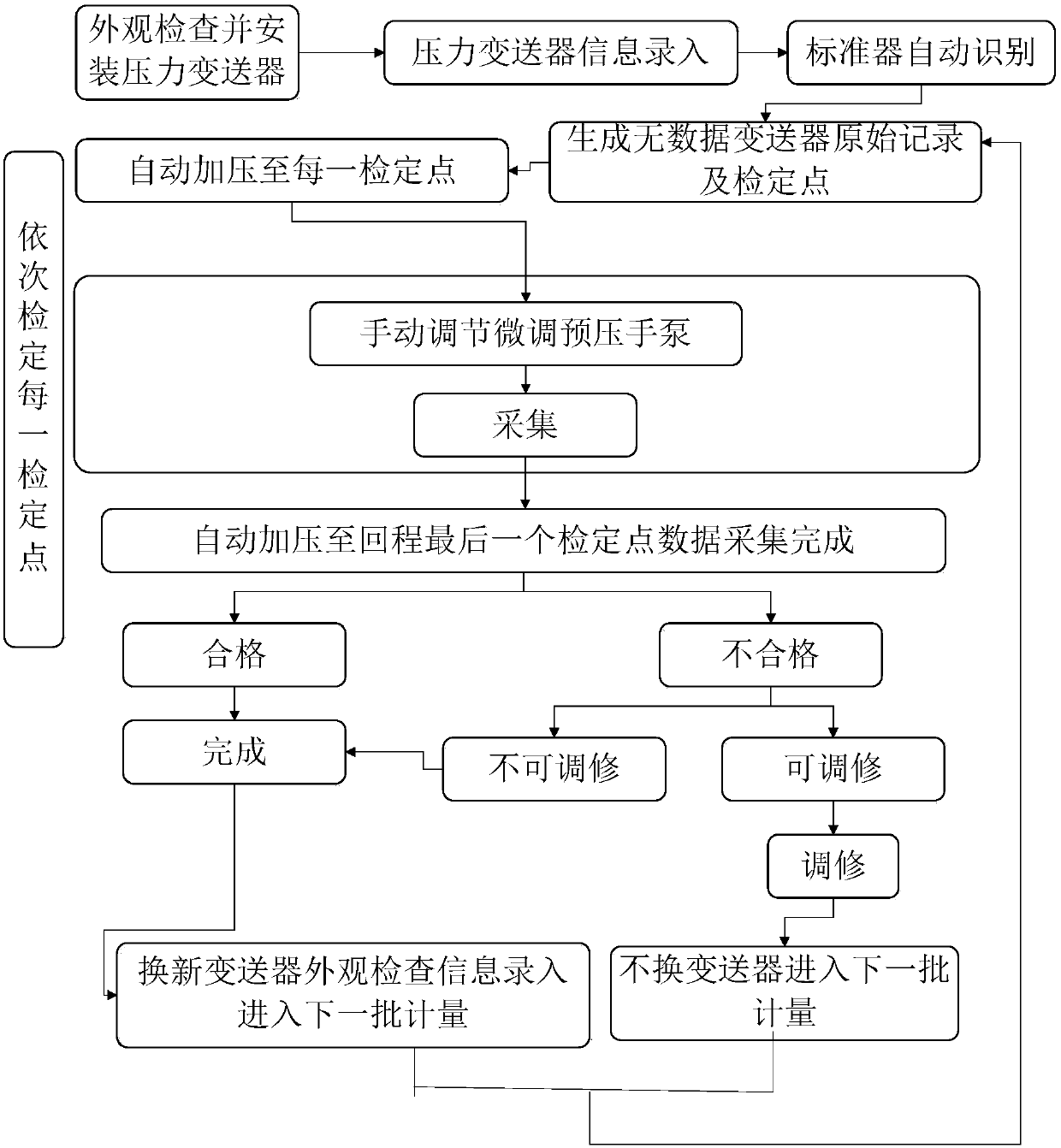

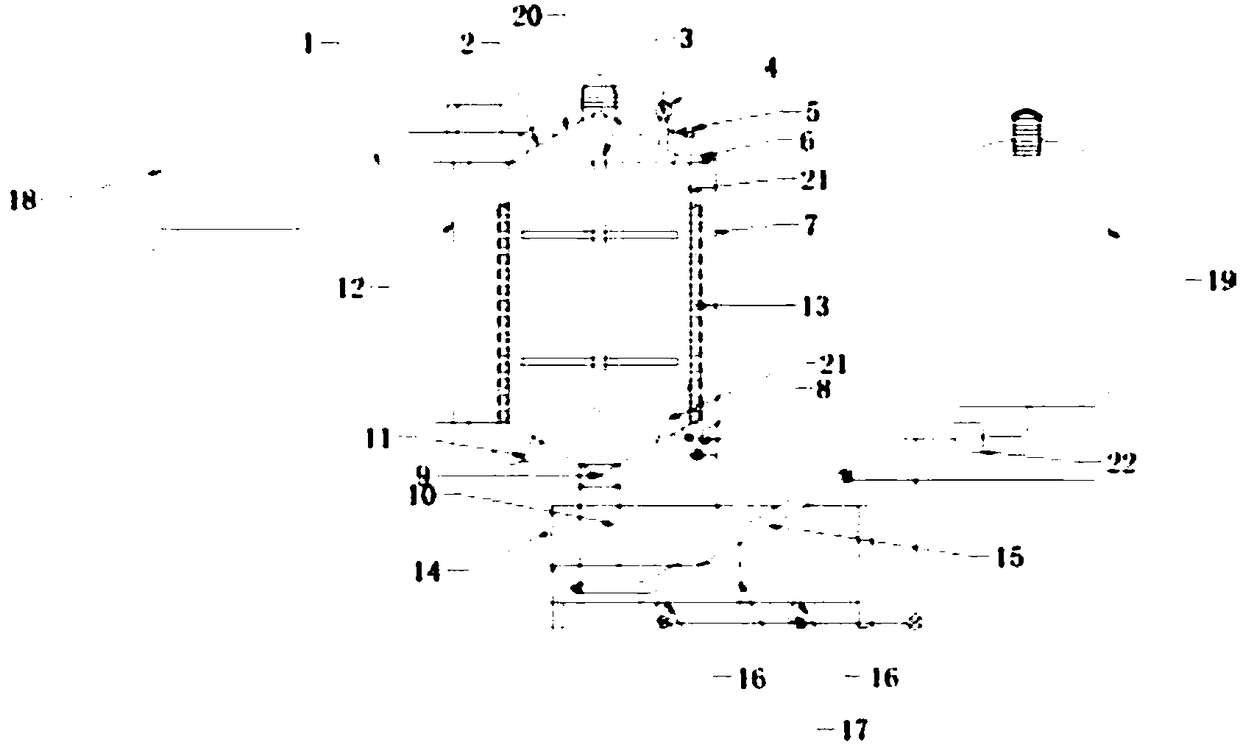

Automatic pressure transmitter batch measurement and verification system and method

InactiveCN107727313ARealize metering automationGo digitalFluid pressure measurementBatch processingControl system

The invention relates to an automatic pressure transmitter batch measurement and verification system and method. The system comprises a pre-pressure device, a medium container, a digital precision pressure gauge, a manual fine-adjustment pre-pressure hand pump, a plurality of stop valves, and a plurality of inspected pressure transmitter connectors, a DC standard power supply, a multi-channel digital meter and a control system. The inspected pressure transmitter connectors are used for connecting inspected pressure transmitters, and each of the inspected pressure transmitter connectors is corresponding to a group of stop valves. The DC standard power supply supplies power to the inspected pressure transmitters. The multi-channel digital meter is used for measuring output signals of the inspected pressure transmitters. The control system comprises a control unit, an information input unit, a data acquisition unit and a data processing unit. According to the automatic pressure transmitter batch measurement and verification system and method, problems of low efficiency, no realization of digitization, intelligentization and batch processing and a large error introduction probability of existing automatic pressure transmitter batch measurement and verification are solved, and a problem of artificial active intervention of an existing verification method is eliminated.

Owner:郑显锋 +1

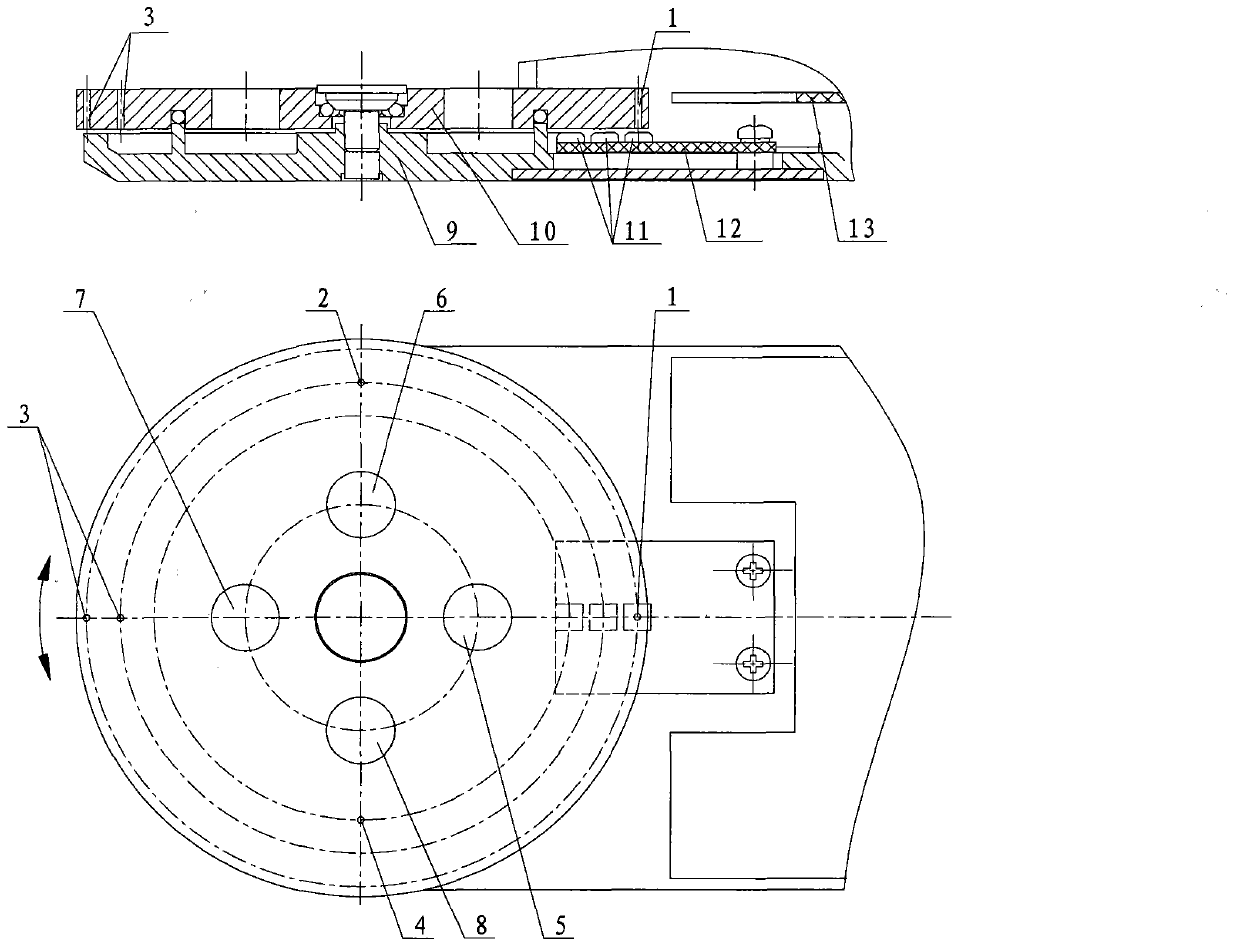

Position identification device of telescope

InactiveCN104216102AAvoid wear and tearAvoid noise and other problemsMicroscopesIdentification deviceControl circuit

The invention discloses a position identification device of a telescope. The position identification device is composed of a work position switching device, a plurality of differently arranged magnet sets, a fixing board, a Hall sensor set and a control circuit, wherein the work position switching device is provided with a plurality of work positions linearly or circumferentially, and each work position is provided with an exclusive binary code indicated by one magnet set; the magnet sets are mounted on the work position switching position, and the Hall sensor set is provided with a plurality of Hall sensors. During working, the work position switching device moves to a certain work position, the magnet sets of the codes of the work positions moves or rotates to the positions corresponding to the Hall sensor set, and the control circuit senses level signals through the Hall sensors to acquire the codes of the magnet sets to be compared with the codes of the preset work positions, thus, the current work positions can be identified. The position identification device adopts a non-contact identification way, so wear and sound caused by contact identification are avoided, and wiring is simple and high in reliability.

Owner:MOTIC CHINA GRP CO LTD

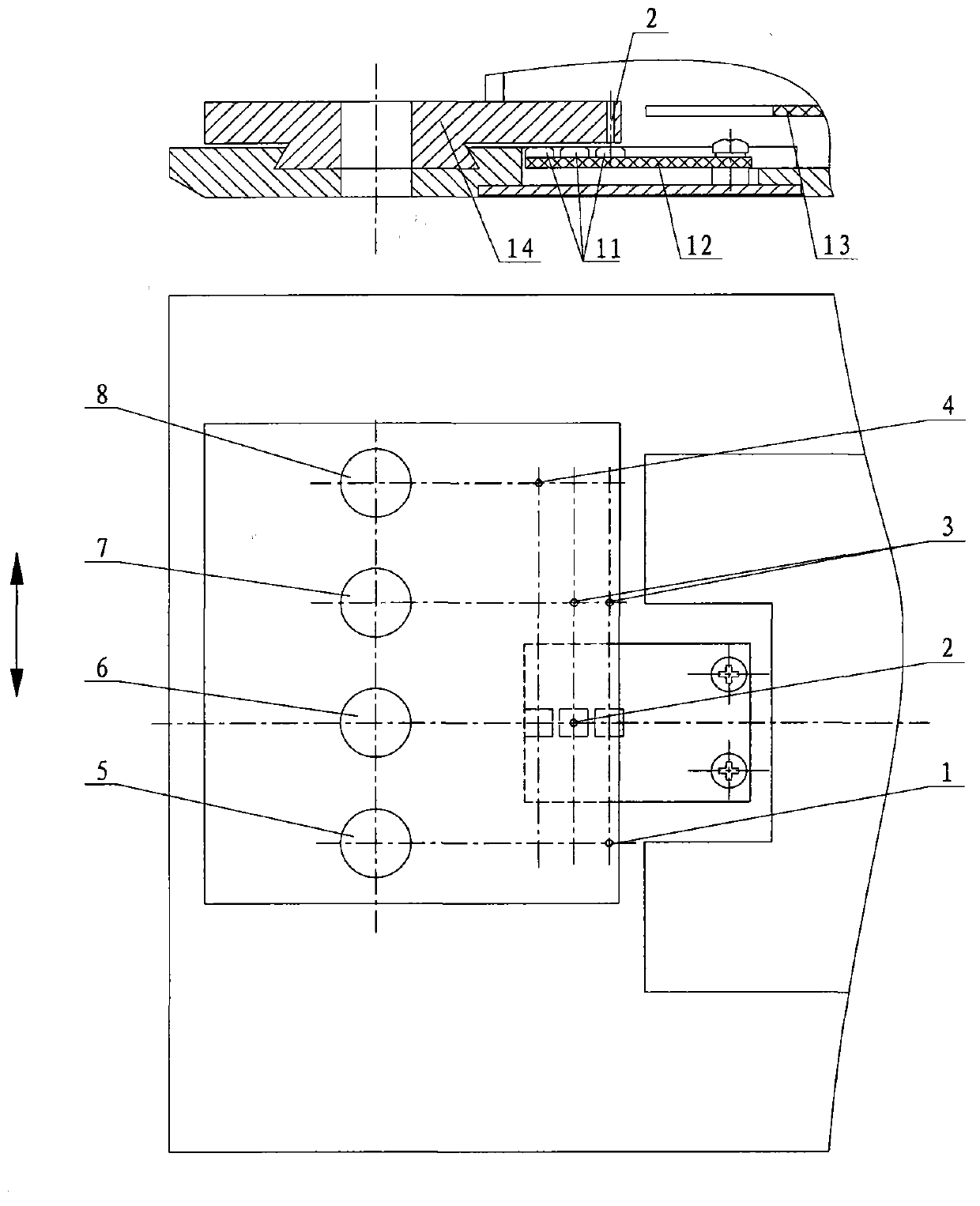

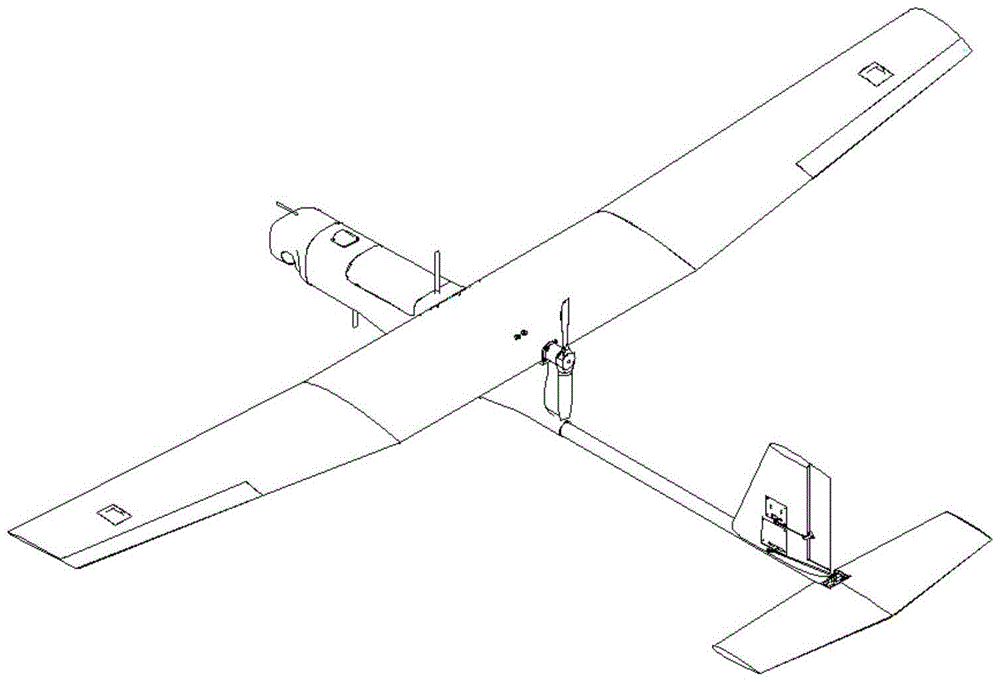

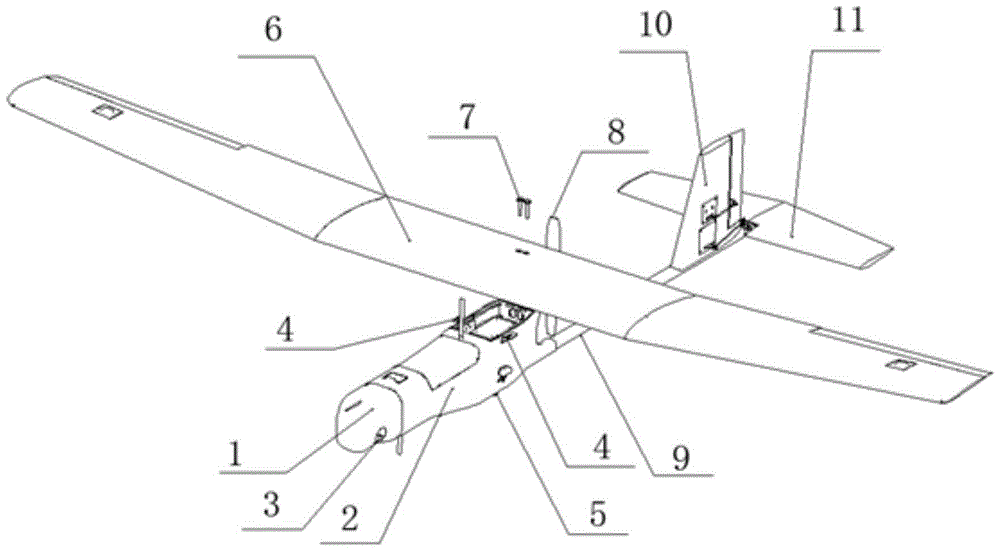

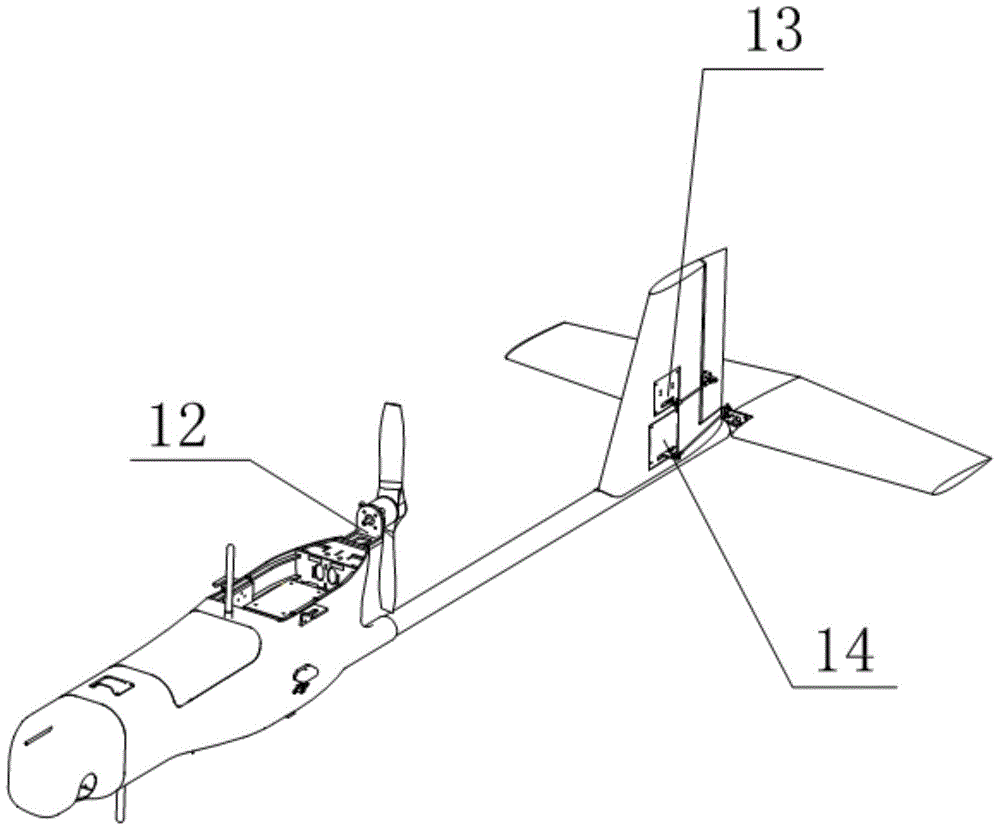

General layout of unmanned aerial vehicle capable of taking off with catapult assisted and being recovered by bumping net

InactiveCN105667790AConducive to collision net recoveryAvoid damageAircraftsUncrewed vehiclePropeller

The invention discloses the general layout of an unmanned aerial vehicle capable of taking off with catapult assisted and being recovered by bumping a net. The unmanned aerial vehicle comprises a vehicle head, a vehicle body, a wing, a propeller, a tail pipe, a horizontal tail and a vertical tail. The abdomen of the vehicle body is a plane, the wing is mounted on the upper portion of the vehicle body, and the tail pipe and the propeller are mounted at the tail of the vehicle body. The propeller is mounted at the upper end of the tail of the vehicle body, the tail pipe is mounted at the lower end of the tail of the vehicle body, and the bottom of the tail pipe is flush with the abdomen plane of the vehicle body. A paddle closest to the tail pipe is kept a distance from the tail pipe when the paddles of the propeller are located in the vertical direction. A catapult hanging point for catapult-assisted taking off of the unmanned aerial vehicle is arranged on the abdomen of the vehicle body. The vehicle body and the wing are directly connected in a detachable mode, the vehicle body and the tail pipe are directly connected in a detachable mode, and the tail pipe and the horizontal tail are directly connected in a detachable mode. The unmanned aerial vehicle has the characteristics of being capable of being conveniently recovered by bumping the net, convenient to assemble and disassemble, high in pneumatic efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

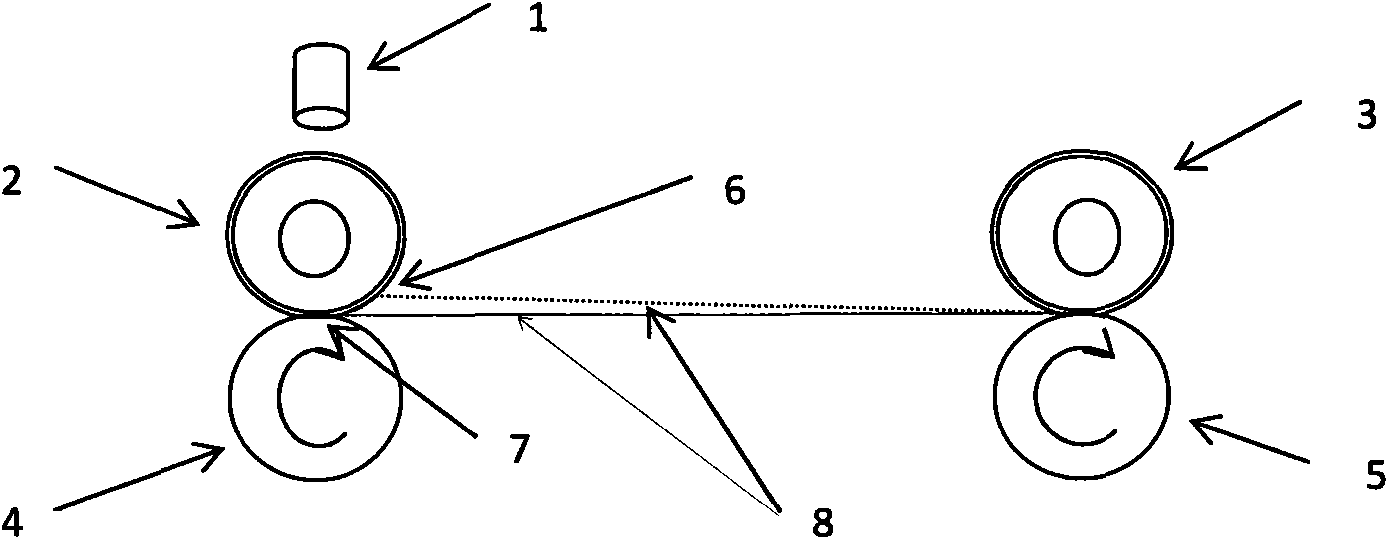

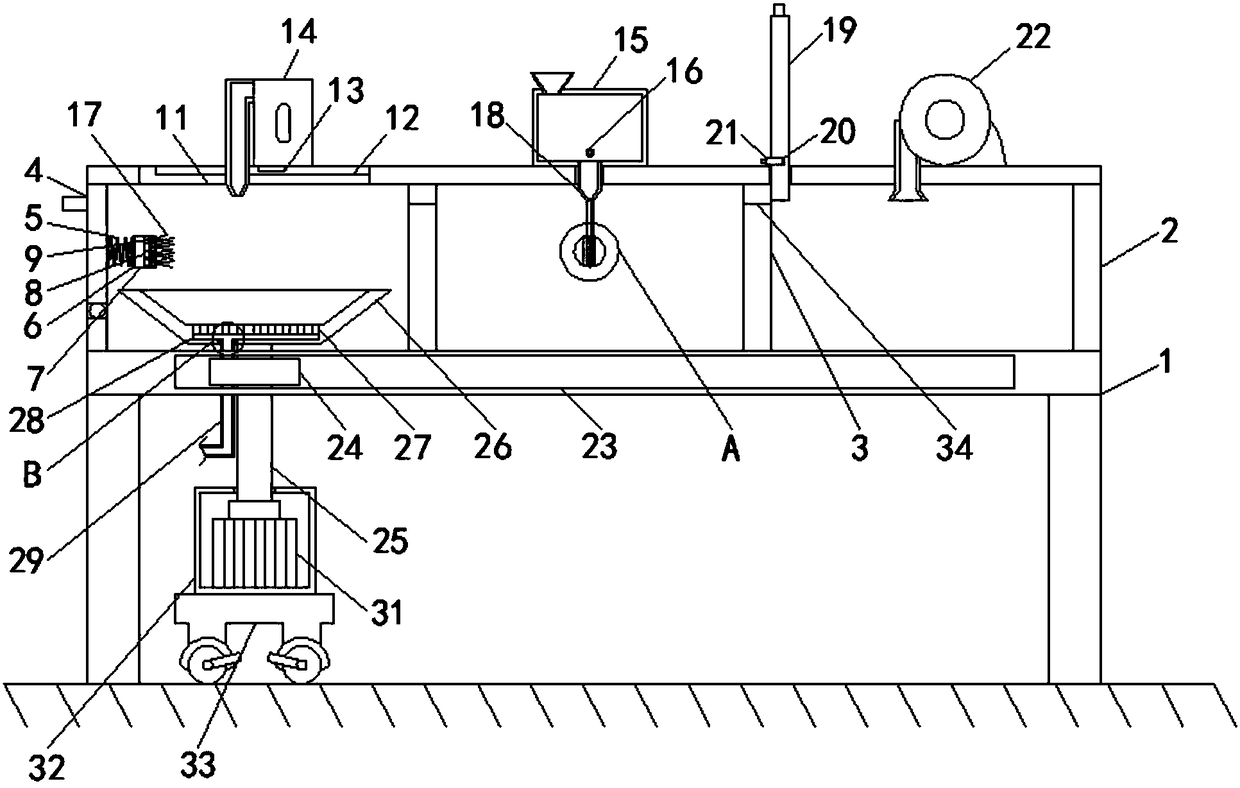

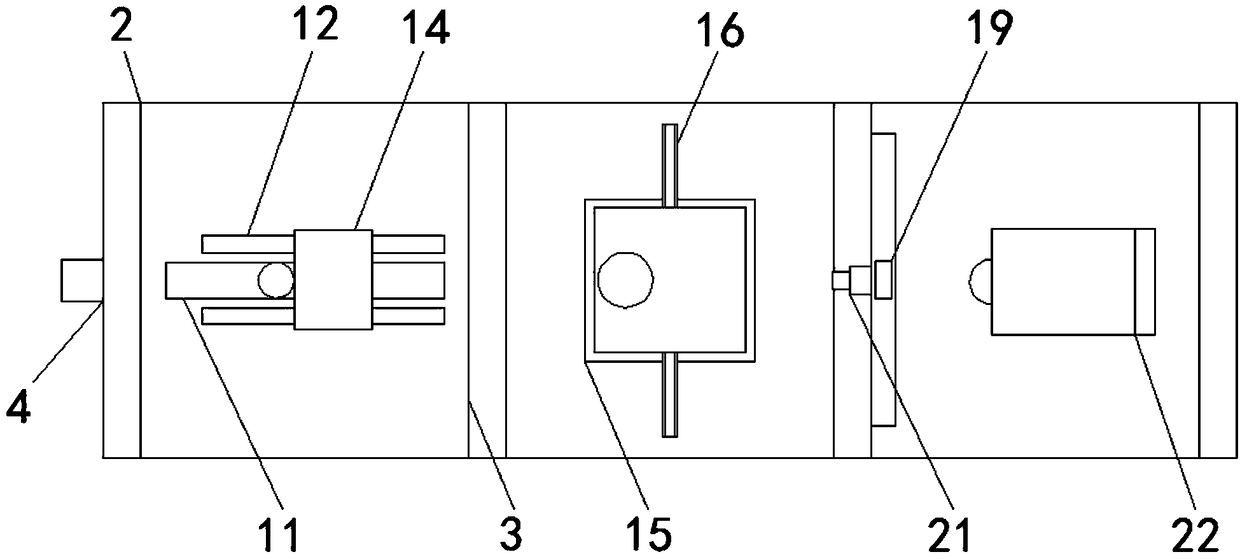

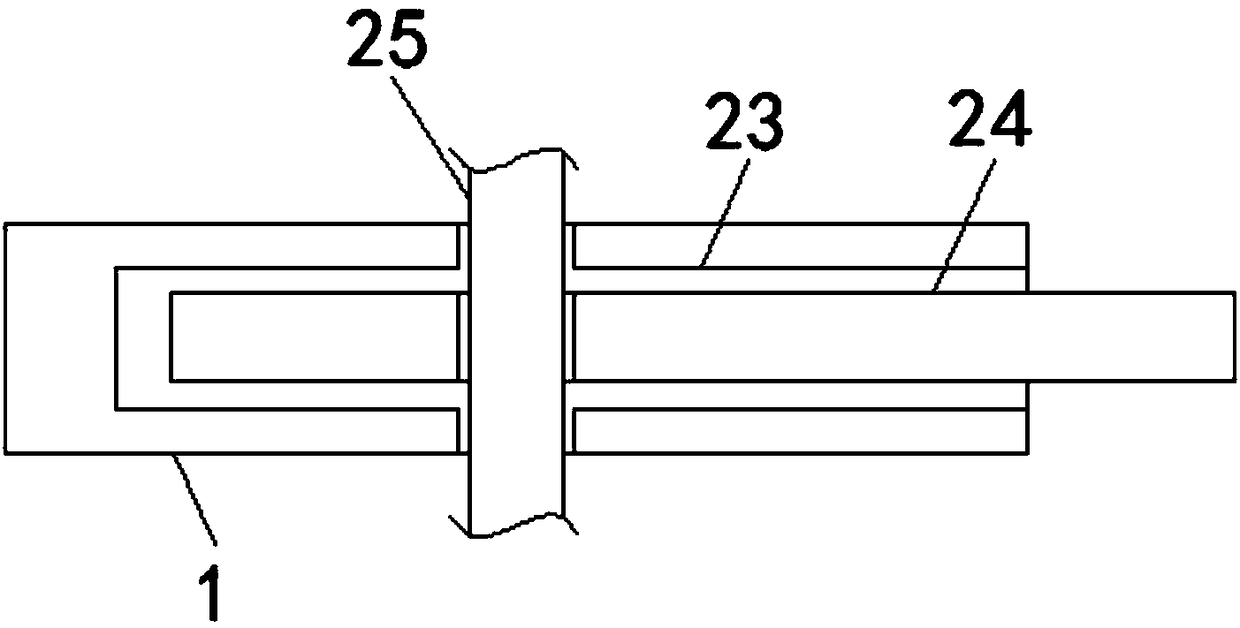

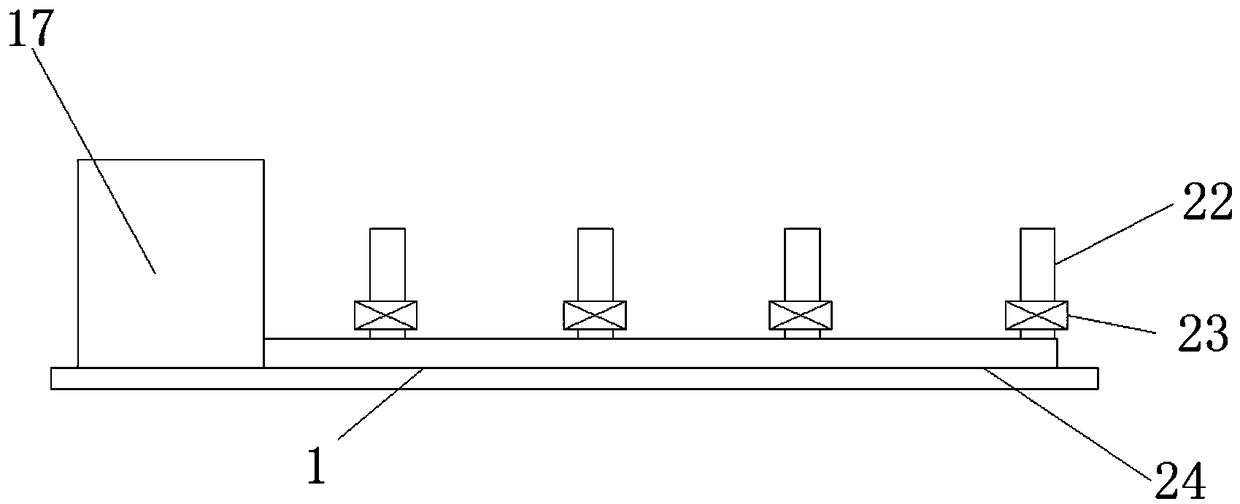

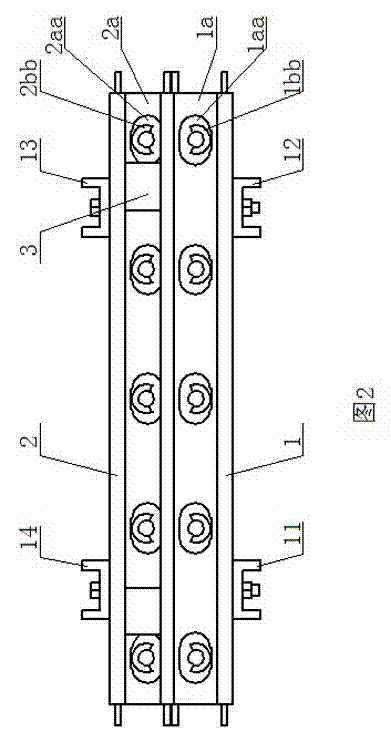

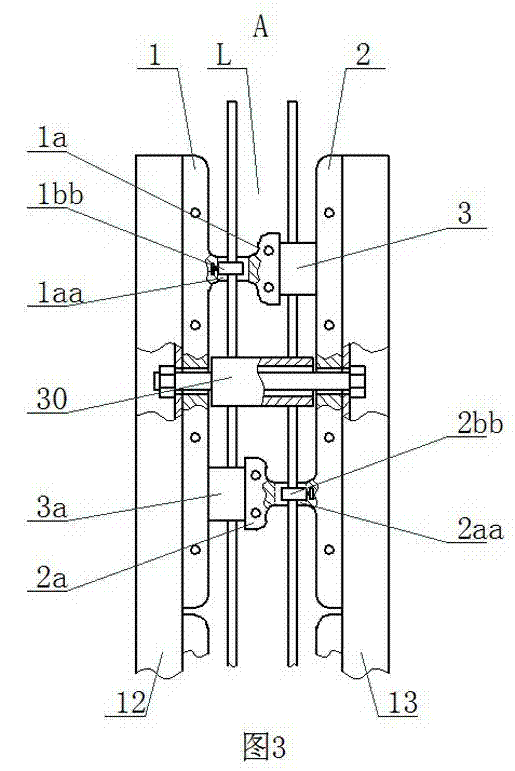

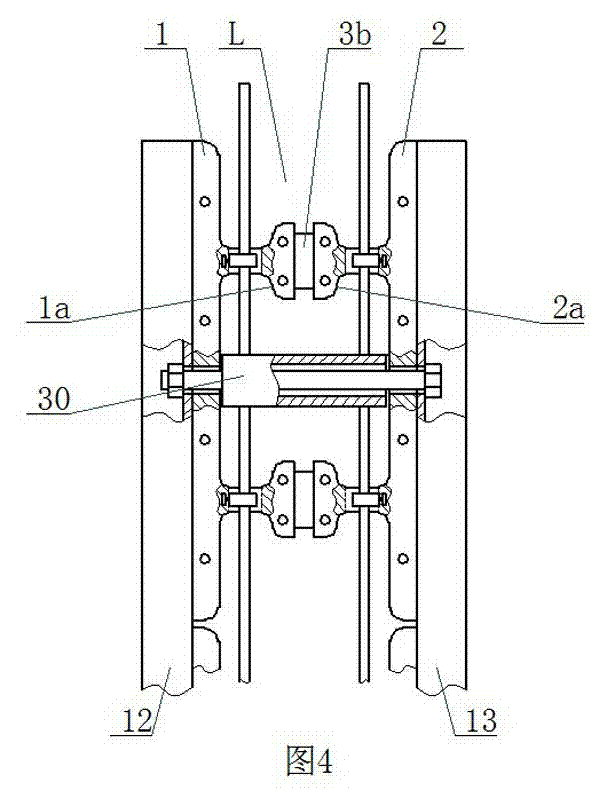

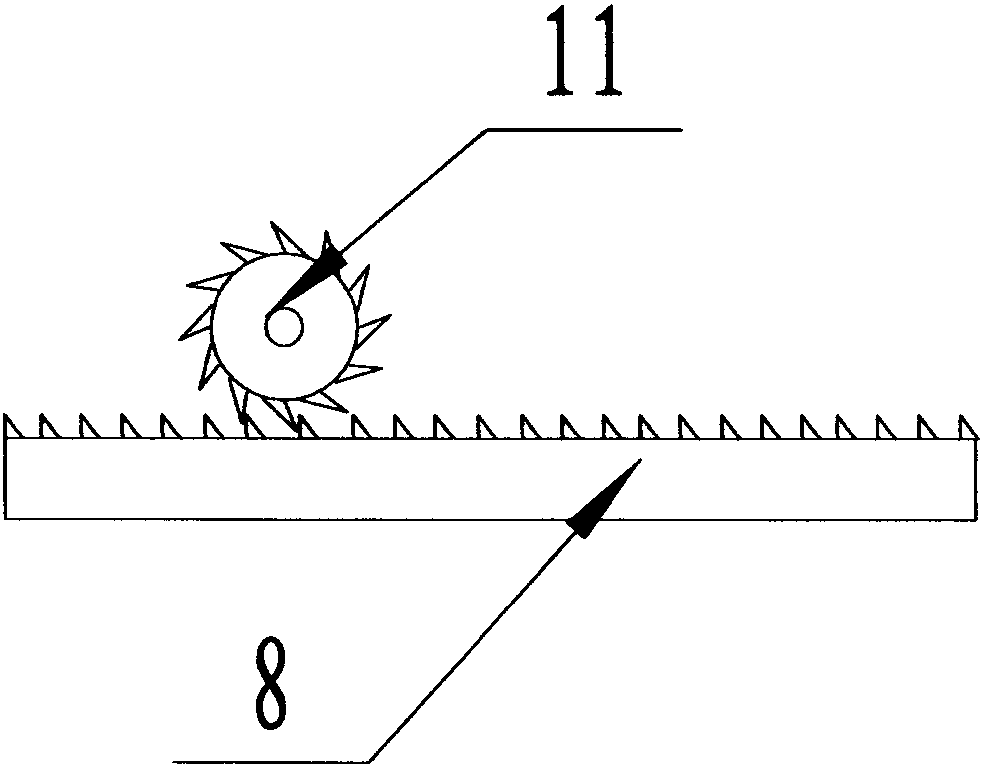

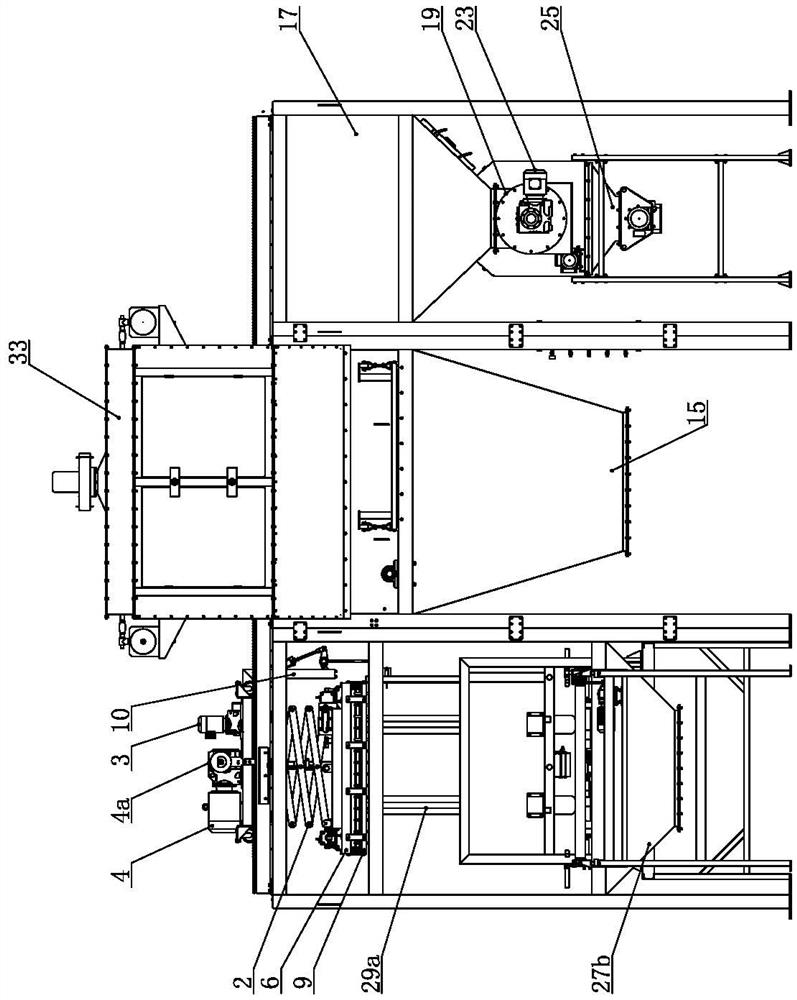

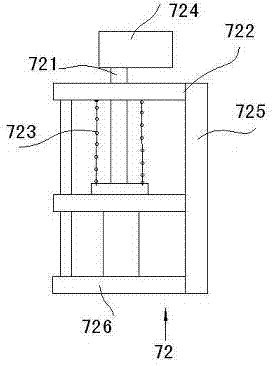

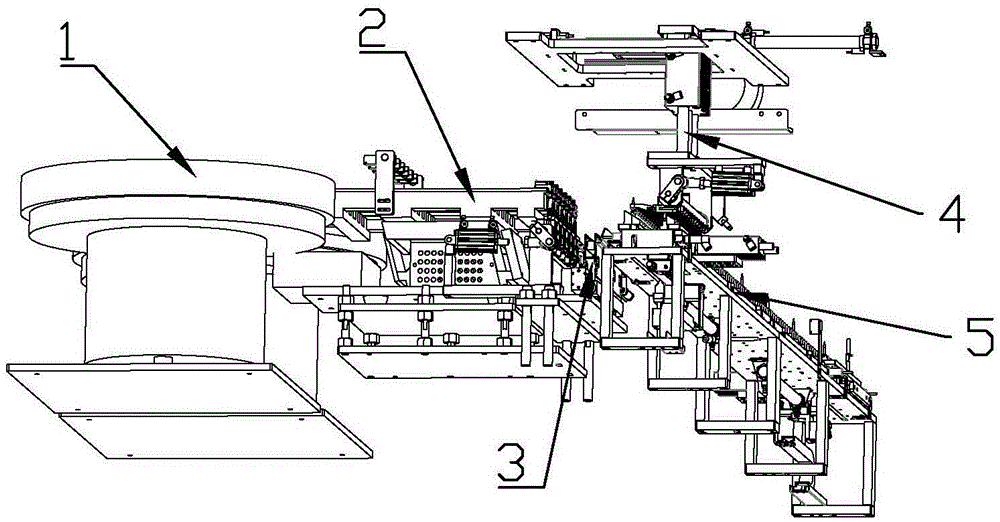

Mobile printing, positioning and conveying device

ActiveCN104692157AHigh speedShorten blowing timeArticle feedersPrinting press partsPaperboardEngineering

The invention relates to a printing device, in particular to a mobile printing, positioning and conveying device, and aims to provide a printing, positioning and conveying device which is long in positioning time, high in printing speed, high in overprinting accuracy and high in paper feeding speed. In order to solve the technical problem, the invention provides a mobile printing, positioning and conveying device which comprises a paper feeding device, a mobile front gauge positioning device, a circulation side gauge positioning device, an articulation tooth moving device, an electro-optical distance measurement device and a paper conveying roller. By virtue of the mobile printing, positioning and conveying device, the paper feeding efficiency can be improved; the paper moving distance can be accurately controlled by adjusting the distance between a movable cam and an annular fixed cam; the device is stable in structure, low in damage possibility and accurate to position; due to the cooperation of the circulation side gauge positioning device and a paper conveying plate, the paper positioning time can be prolonged; the printing speed is increased; the overprinting accuracy is ensured.

Owner:郭石生

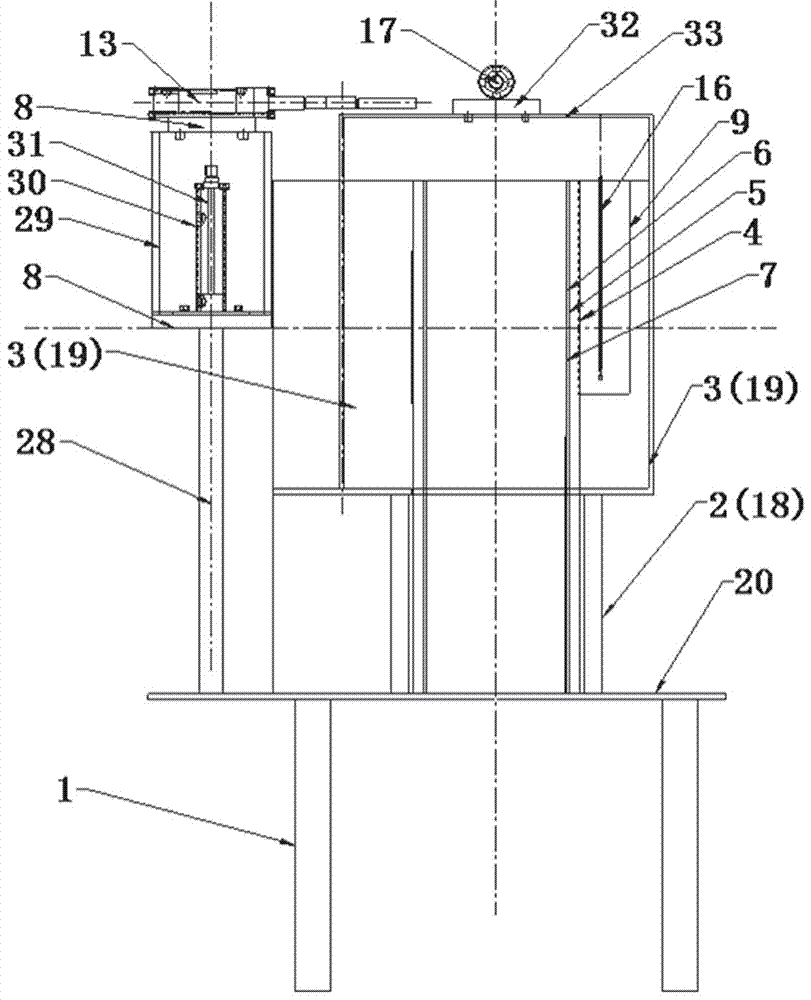

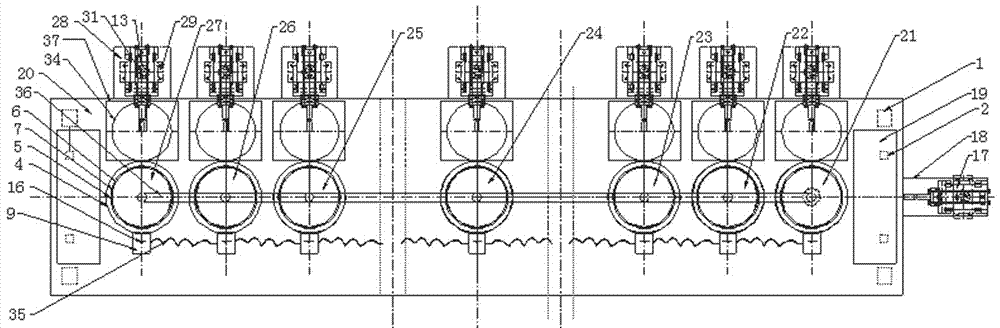

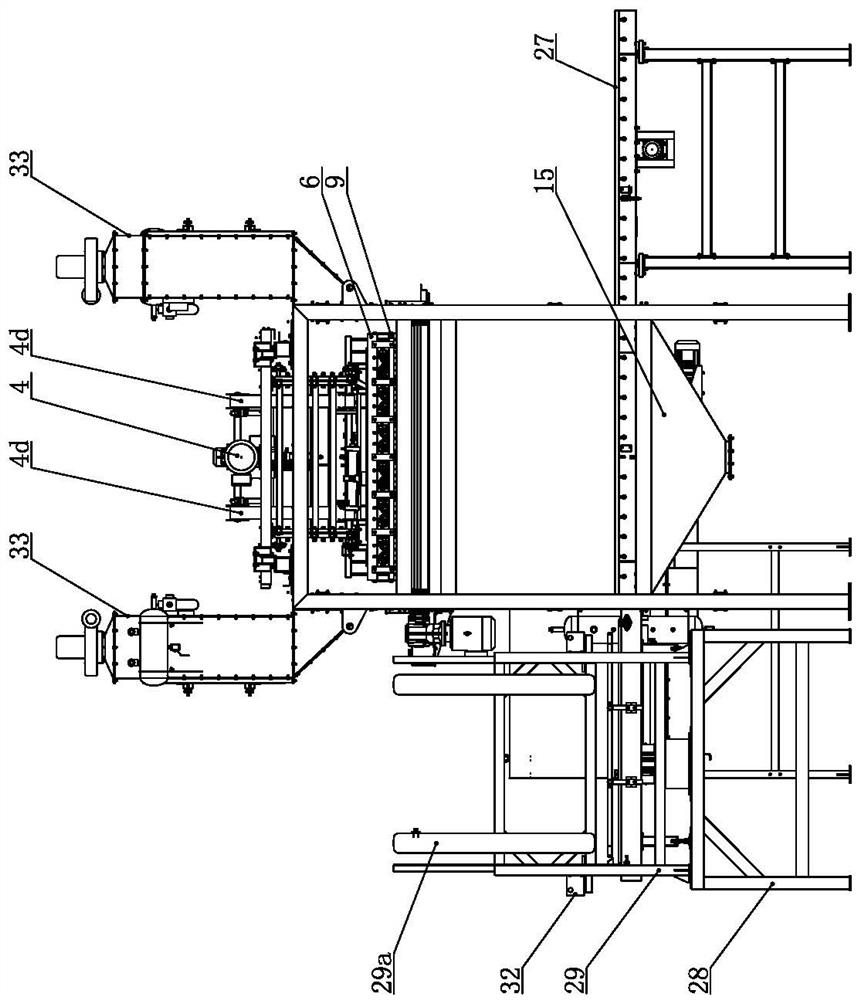

Automatic float-and-sink test apparatus with linear structure

ActiveCN107167404ASimple structureEasy to operateSpecific gravity measurementWet separationHydraulic cylinderWater baths

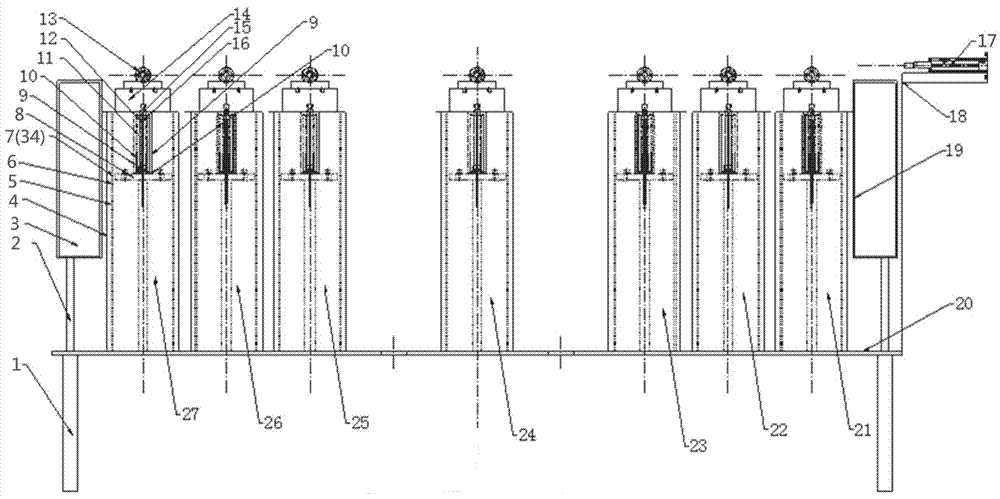

The invention discloses an automatic float-and-sink test apparatus with a linear structure. The automatic float-and-sink test apparatus comprises a plurality of density-level devices which are successively arranged between a pretreatment collecting tank and a gangue collecting tank from left to right in a sequence from low density level to high density level; each density-level device comprises an external water-bath heating tank and a float-and-sink heavy liquid barrel arranged in the water-bath heating tank, the water-bath heating tank is composed of an outer wall of the water-bath heating tank and an inner wall of the water-bath heating tank, and the float-and-sink heavy liquid barrel is composed of an outer wall of the float-and-sink heavy liquid barrel and an inner wall of the float-and-sink heavy liquid barrel; the front side of each water-bath heating tank is provided with a floating-substance collection tank; the rear side of each floating-substance collection tank is provided with a group of a vertically-moving hydraulic cylinder and a short-distance horizontally-moving hydraulic cylinder; the outer side of each water-bath heating tank is provided with a density and pressure determination sensor; and a long-distance horizontally-moving hydraulic cylinder is arranged on the outer side of the gangue collecting tank and perpendicular to the moving direction of the short-distance horizontally-moving hydraulic cylinders. The automatic float-and-sink test apparatus with the linear structure in the invention can carry out layering according to density and separate out corresponding products of each density level.

Owner:河北地质大学

Marinating device and method for marinated products

InactiveCN108936378AHalogenization device is simpleEasy to operateCheese manufactureFood scienceEngineeringSieve

The present invention discloses a marinating device for marinated products. The marinating device comprises a marinating tank, a material discharge chute and a control system. The marinating tank comprises a tank body, a material feeding port, a compressed air connection port, an overflow port, a material discharge port, a marinating soup inlet port and a stirring device; the overflow port is externally connected to an overflow pipe; the marinating soup inlet port is connected with a marinating soup blending tank; the material discharge chute is placed under the material discharge port; duringa material discharge process, marinating soup in the material discharge chute submerge the material discharge port; and the control system controls the feeding amount of compressed air in the marinating tank and the stirring of the stirring device. By controlling the amount of the compressed air in the marinating tank during the material discharge process, the device controls the material discharge speed of the marinated products after the marinating, does not use a marinating sieve during a marinating process, reduces the use amount of the marinating soup, reduces the breakage rate of the marinated products, and is highly efficient and environmentally friendly in the marinating process.

Owner:WUQIONG FOOD

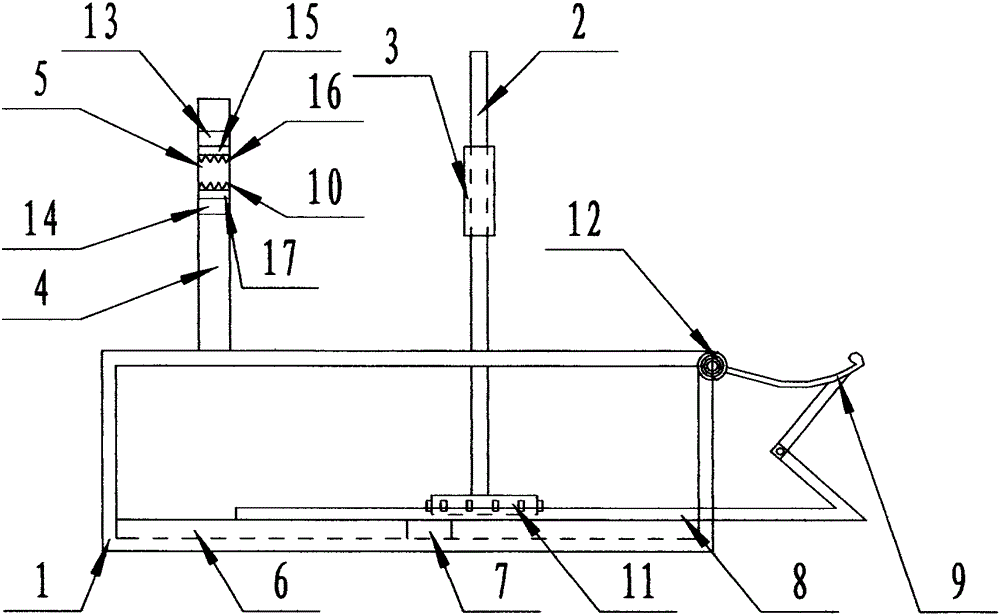

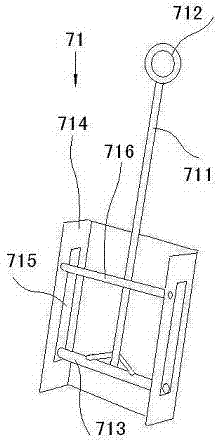

Pedal type electric wire and cable winding/unwinding machine

ActiveCN105016133AAvoid messImprove assembly efficiencyFilament handlingConductor CoilElectric cables

The invention discloses a pedal type electric wire and cable winding / unwinding machine. The machine comprises a base, wherein the internal of the base is a cavity structure; a winding unit is arranged on the base, and consists of a driving mechanism arranged in the cavity structure, a rotating rod and a fixed clamp; the lower end of the rotating rod is fixedly connected with the driving mechanism, and the upper end extends outside the upper surface of the base; the fixed clamp is arranged on the rotating rod; a longitudinal plate is arranged on the upper surface outside the base; a through groove for passing through electric wires and cables is formed in the upper part of the longitudinal plate; and a pair of resistance mechanisms is arranged on the longitudinal plate. The machine has the beneficial effects of simple structure and strong practicability.

Owner:HEBEI GAOJING ELECTRICAL EQUIP

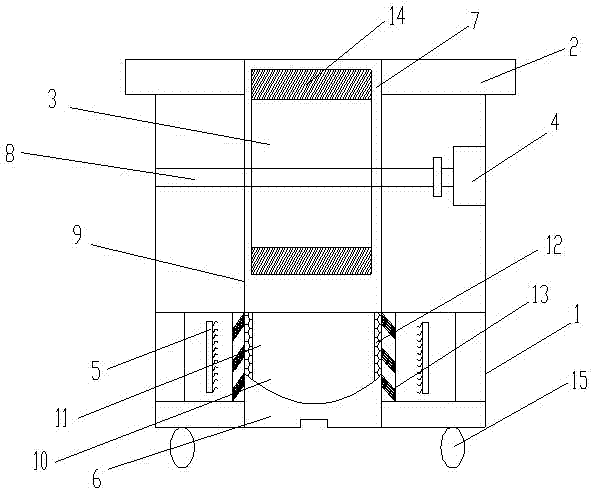

Air suction and collection hair brushing machine

InactiveCN104120601ABrush thoroughlyBristles fullMechanical cleaningPressure cleaningWorking environmentPulp and paper industry

The invention discloses an air suction and collection hair brushing machine. The air suction and collection hair brushing machine comprises a machine frame body, a hair brushing table, a hair brushing roller, a motor, exhaust sucking fans and a collecting tank. The hair brushing table is arranged at the upper end of the machine frame body, the center of the hair brushing table is provided with a hair brushing roller slot, the upper end of the hair brushing roller is protruded out of the hair brushing roller slot, and the lower end of the hair brushing roller is arranged inside the machine frame body; the hair brushing roller sleeves a shaft rod which is coaxially connected with the output end of the motor; the motor is fixed onto the side wall of one end of the machine frame body; the inside of the machine frame body at the lower end of the hair brushing roller is provided with an exhaust guide barrel; the collecting tank is mounted at the bottom of the exhaust guide barrel, the bottom of the collecting tank is provided with a discharging hopper, both sides of the collecting tank are provided with the exhaust sucking fans, and the two side walls of the collecting tank are provided with deflecting openings wherein the exhaust sucking fans are arranged at the rear ends of the deflecting openings, and the deflecting openings are provided with stopping grates. Therefore, according to the air suction and collection hair brushing machine, clothes can be well sucked onto the hair brushing roller to perform hair brushing treatment through the exhaust sucking fans, thereby being hair-brushed thoroughly and completely; the collecting tank can collect hairy scraps generated during hair brushing treatment and accordingly avoid disarrangement of working environment due to flying of the hairy scraps of the clothes.

Owner:WUXI CAIYUN MACHINERY & EQUIP

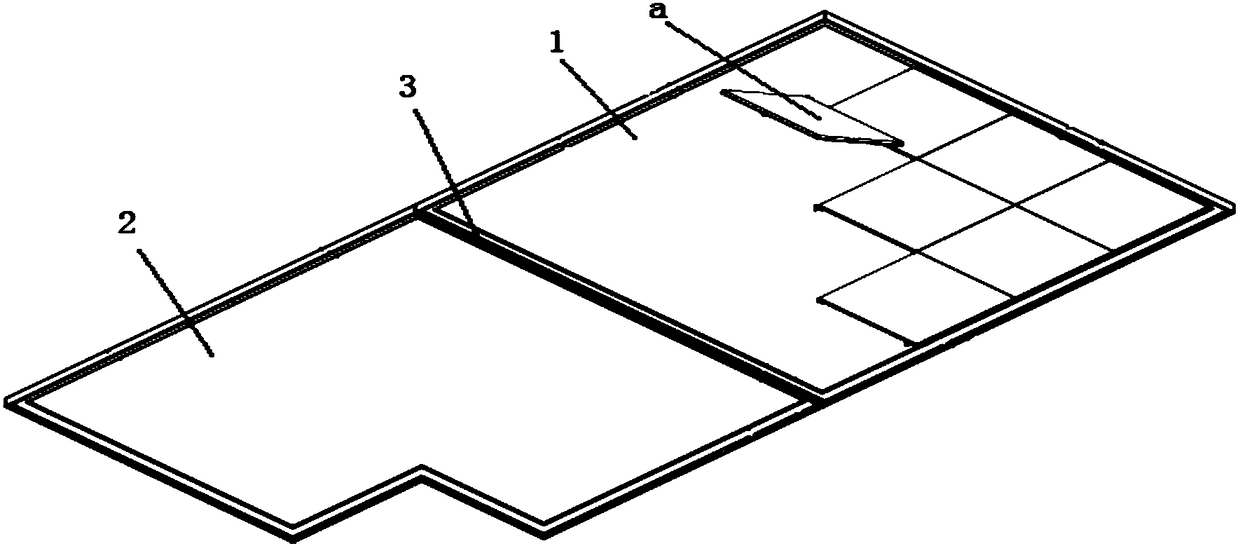

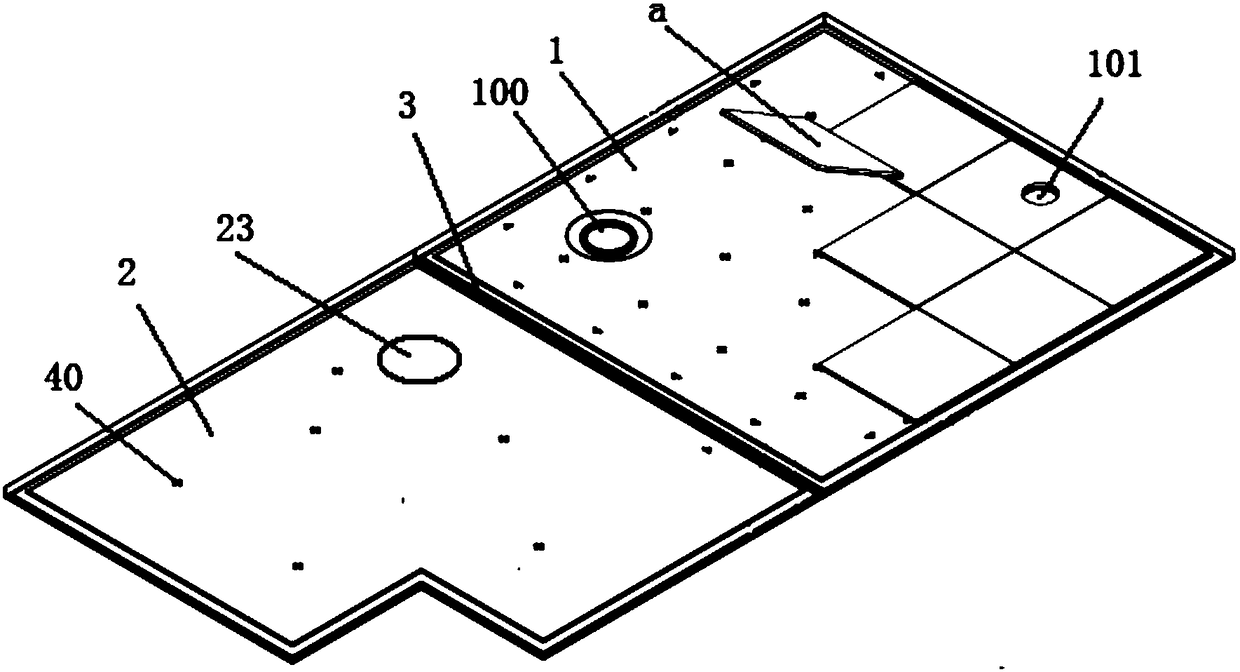

Toilet ground and laying method

The invention provides a toilet ground and a method for laying the toilet ground. The toilet ground comprises a waterproof bottom box and floor tiles; the shape and area of the waterproof bottom box are the same as those of an original building ground of a toilet to be decorated; the waterproof bottom box comprises a water retaining strip, a dry area part and a wet area part, wherein the dry areapart and the wet area part are located on the two sides of the water retaining strip; and the floor tiles are laid in the waterproof bottom box, bonding layers are composited on the back faces of thefloor tiles, and the back faces of the floor tiles are the faces making contact with the waterproof bottom box. According to the toilet ground and the laying method, simple mounting only needs to be conducted on a decoration site, rapid construction is achieved, and the mess of a traditional decoration operation site is avoided.

Owner:ZHEJIANG YASHA DECORATION

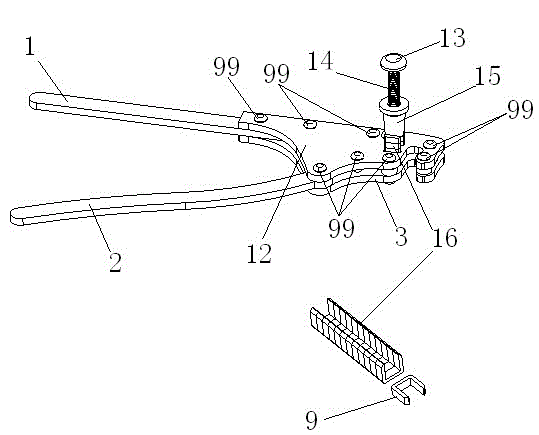

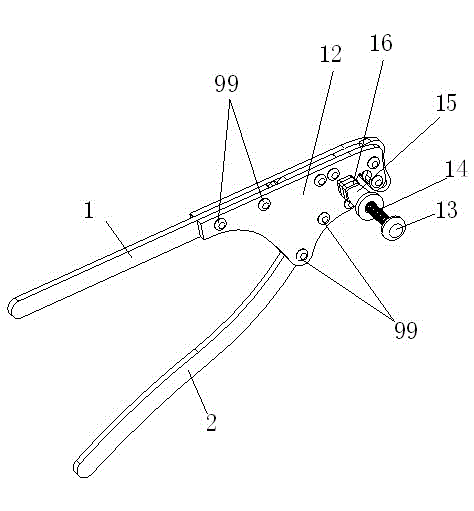

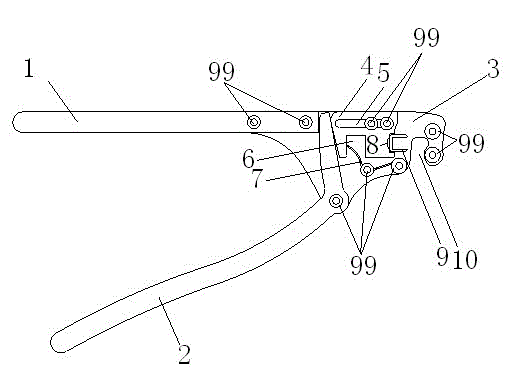

Self-feeding line buckle clamp

InactiveCN102862698AEasy and convenient strapping handlingAvoid messBundling machine detailsEngineeringMechanical engineering

The invention discloses a self-feeding line buckle clamp which comprises a fixed handle and a movable handle, wherein the fixed handle is shaped like a Chinese character yi, and a main bracket is fixed at one end of the fixed handle; the movable handle is in a '7' shape and is arranged on the main bracket by a pressure riveting pin or a screw; a sliding block is also arranged on the main bracket and is provided with a big groove; one end of a sliding block reset spring acts on the big groove arranged on the sliding block, and the other end of the sliding block reset spring acts on the pressure riveting pin or the screw; and the sliding block is also provided with a small groove which is provided with a C-shaped ring. The self-feeding line buckle clamp can be used for conveniently bundling or clamping lines or wire harness, thus avoiding that the wire harness is in disorder or pulled off from limit; and the self-feeding line buckle clamp is simple to operate, greatly improves the working efficiency, and is worth of being popularized.

Owner:袁野

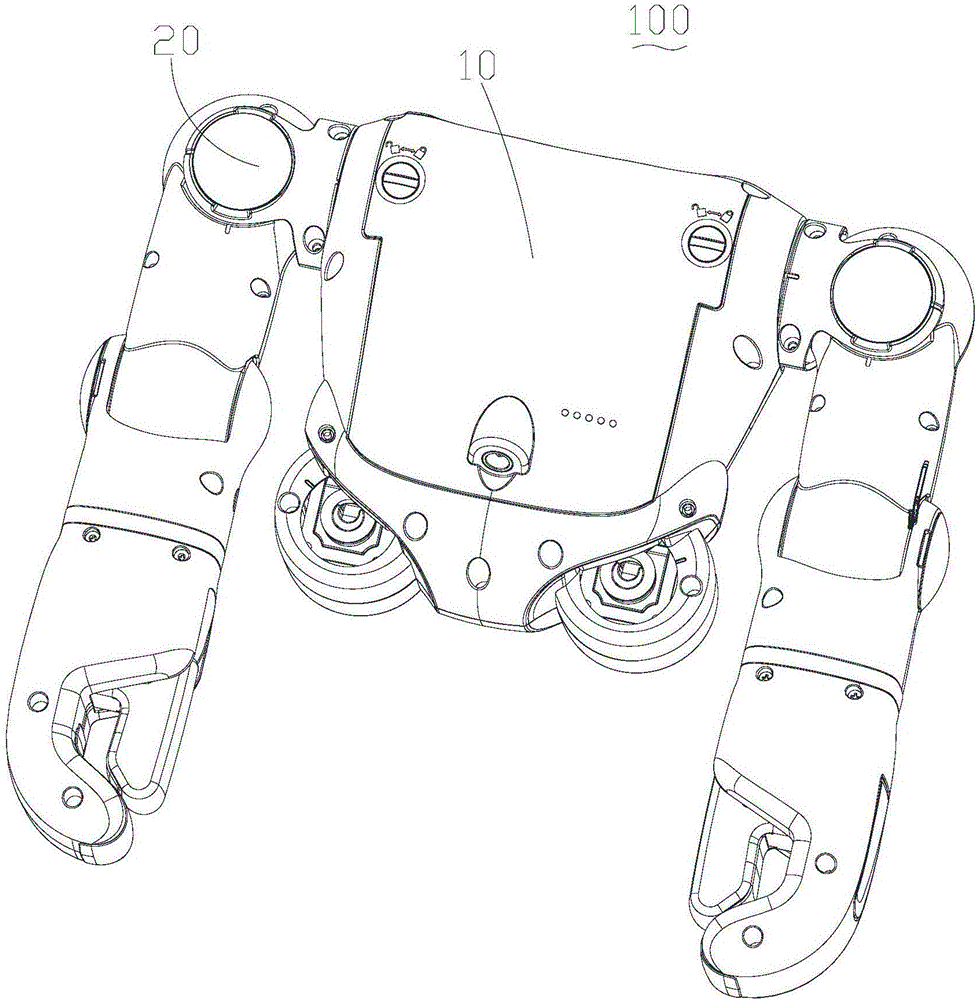

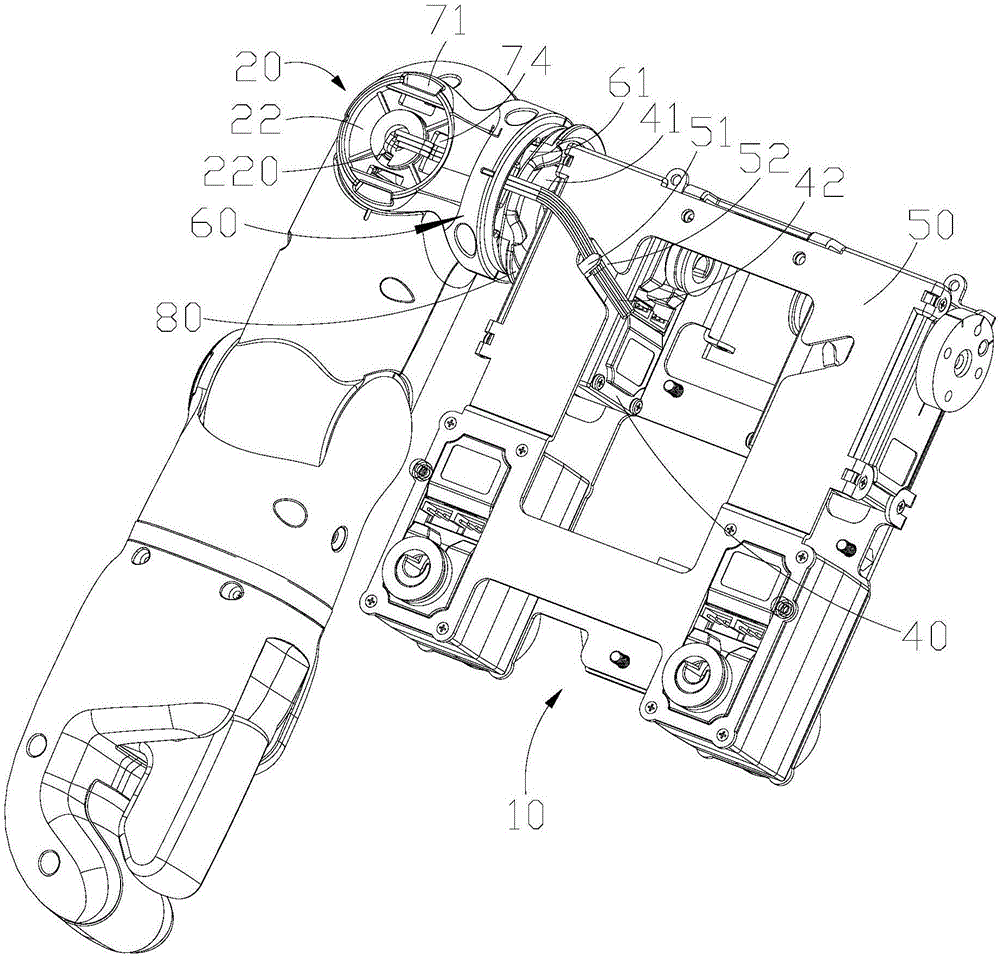

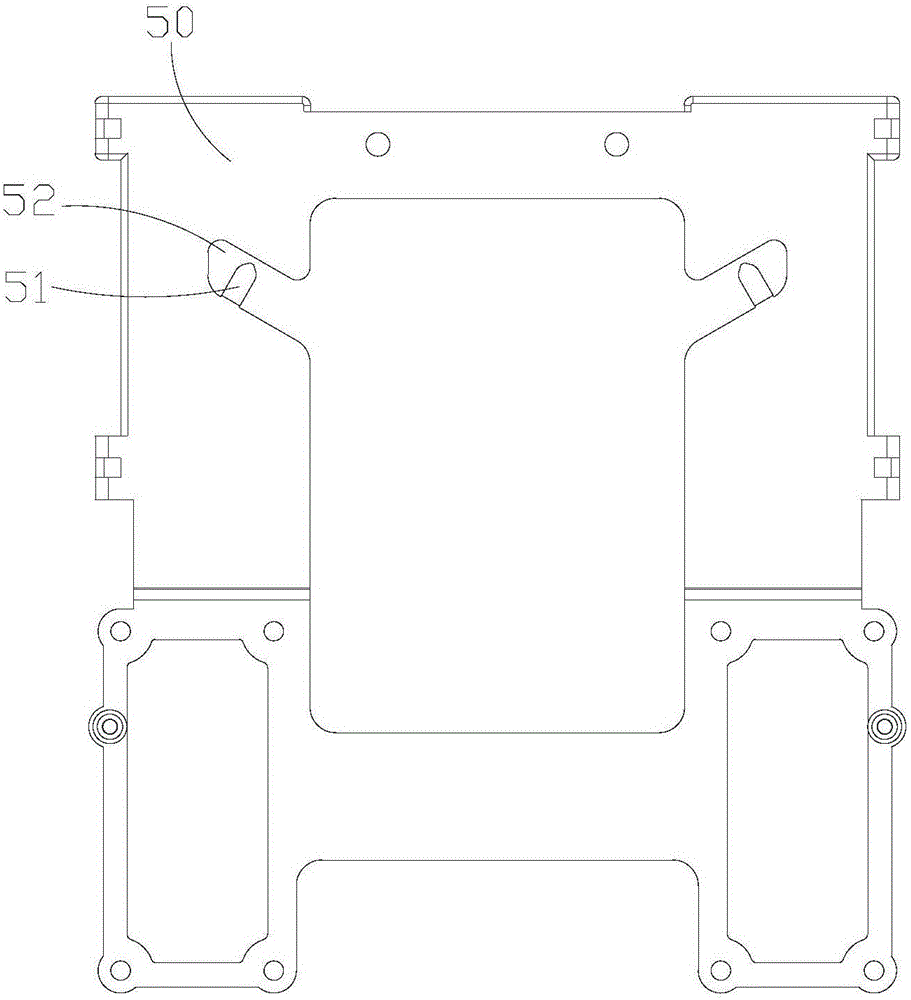

Robot

ActiveCN106112992AAvoid messAvoid deformationProgramme-controlled manipulatorEngineeringMechanical engineering

The invention provides a robot. The robot comprises a main body portion, a rotation portion and a terminal line, wherein the rotation portion is provided with a first steering engine, the first steering engine is provided with a first terminal interface, the main body portion is provided with a second steering engine, the second steering engine comprises a tiller and a second terminal interface, the first terminal interface of the first steering engine is connected with the second terminal interface of the second steering engine through the terminal line, the main body portion is provided with a fixing plate used for fixing the first steering engine, a line pressing tongue is arranged on the edge of the fixing plate, the terminal line penetrates out of the main body portion and is pressed under the line pressing tongue, a connecting shell is connected between the rotation portion and the main body portion, an arc groove is formed in the connecting shell, and the terminal line is led out of the second terminal interface of the second steering engine, and penetrates through the arc groove after passing the line pressing tongue so as to be connected with the first terminal interface of the first steering engine. The terminal line slides in the arc groove when the rotation portion rotates relative to the main body portion, it is avoided that the terminal line is pressed or bent to deform, and therefore, the service life of the terminal line is prolonged.

Owner:UBTECH ROBOTICS CORP LTD

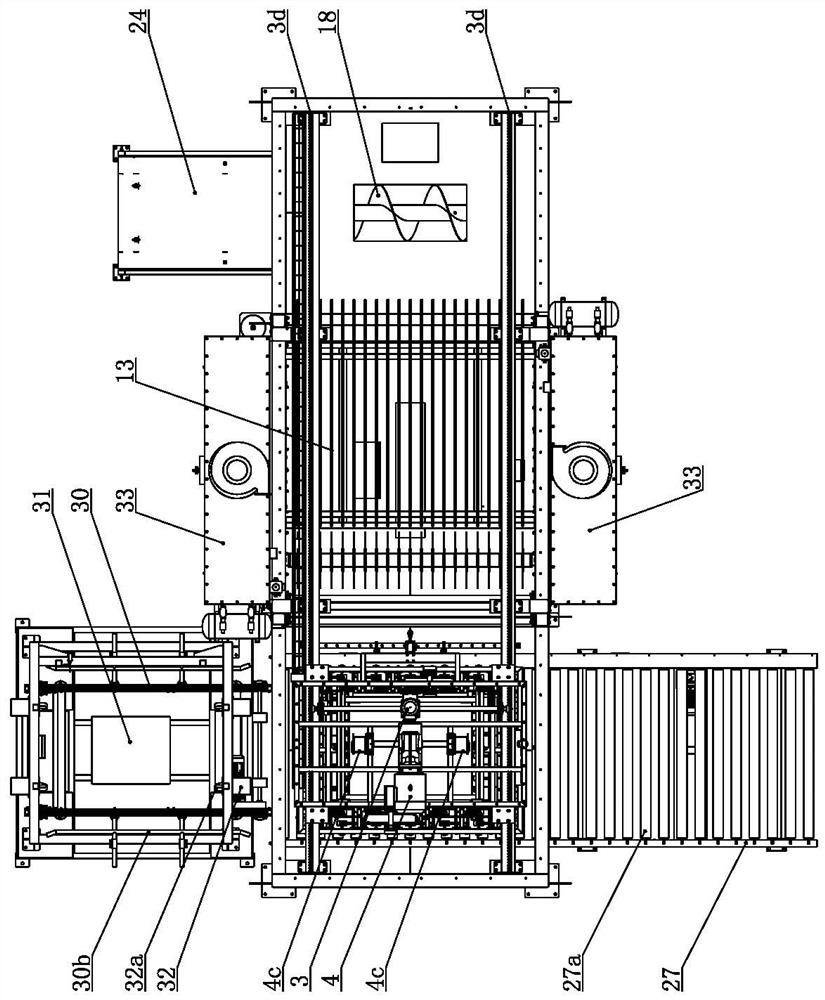

Automatic packaging bag feeding system and automatic feeding method

ActiveCN111924241ADoes not affect broken bagDoes not affect unloadingConveyor partsUnpacking by cuttingElectric machineryChain link

The invention relates to an automatic packaging bag feeding system and an automatic feeding method. The system comprises a bag grabbing mechanism, a bag cutting and discharging device and a bag peel collecting device. A lifting frame is connected to the lower portion of a moving frame of the bag grabbing mechanism through a scissor arm, C-shaped hooks are arranged on the lower portion of the lifting frame, a limiting plate is arranged below the C-shaped hooks, and a plurality of limiting plate hook holes are uniformly formed in the limiting plate. The moving frame is provided with a walking speed reducing motor, the output end of the walking speed reducing motor is provided with a walking driving shaft, and the two ends of the walking driving shaft are each provided with an X-direction walking chain wheel meshing with an X-direction chain. The method sequentially comprises the following steps that a belt winding drum releases lifting belts downwards, and the lifting frame and the limiting plate descend; when the limiting plate falls on packaging bags, the belt winding drum stops; the C-shaped hooks extend out and are inserted into the packaging bags; the lifting belts are wound tolift the grabbed packaging bags; the belt winding drum is stopped after deceleration; and the moving frame moves the packaging bags to a bag cutting station. According to the system, the packaging bags can be grabbed, cut and automatically discharged.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

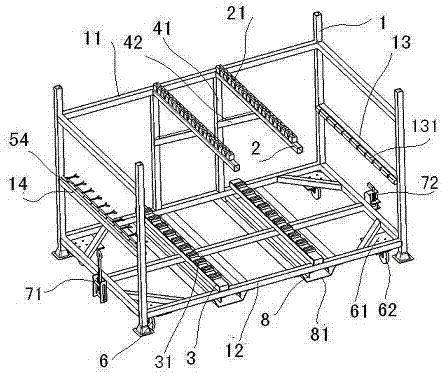

Stacking and transporting device for integral type side wall of car

The invention discloses a stacking and transporting device for an integral type side wall of a car. The stacking and transporting device comprises a frame. An upper component of the rear side of the frame is connected with an upper side wall supporting rod horizontally arranged. The upper side wall supporting rod is connected with a trapezoid-shaped groove rubber strip matched with the upper edge of the frame of the side wall. A lower component of the frame is connected with a lower side wall supporting rod horizontally arranged. The lower side wall supporting rod is connected with a Y-shaped groove rubber strip matched with the lower edge of the frame of the side wall. The middle of the right side of the frame is provided with a right cross rod. The inner side of the right cross rod is connected with a concave rubber strip matched with the right edge of the side wall. The middle of the left side of the frame is provided with a left cross rod connected with a left locating rod. The end portion of the left locating rod is provided with a Y-shaped branch and provided with a rubber sleeve. The upper portion of the front side of the frame is of an open structure. The two sides of the frame are provided with hauling mechanisms. Each hauling mechanism is composed of a hauling frame connected to one end of the frame and a hauling base connected to the other end of the frame. The upper ends of stand columns of the four corners of the frame are provided with guiding and locating sleeves. The lower sections of the guiding and locating sleeves are provided with guide sleeves in a horn-mouth shape, and the upper sections of the guiding and locating sleeves are provided with locating sleeves in a square straight cylinder shape. The stacking and transporting device can be applied to the processes of manufacturing, storing and transporting parts of the integral type side wall of the car, and has the advantages of being convenient in location and easy to manage, and preventing impact.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

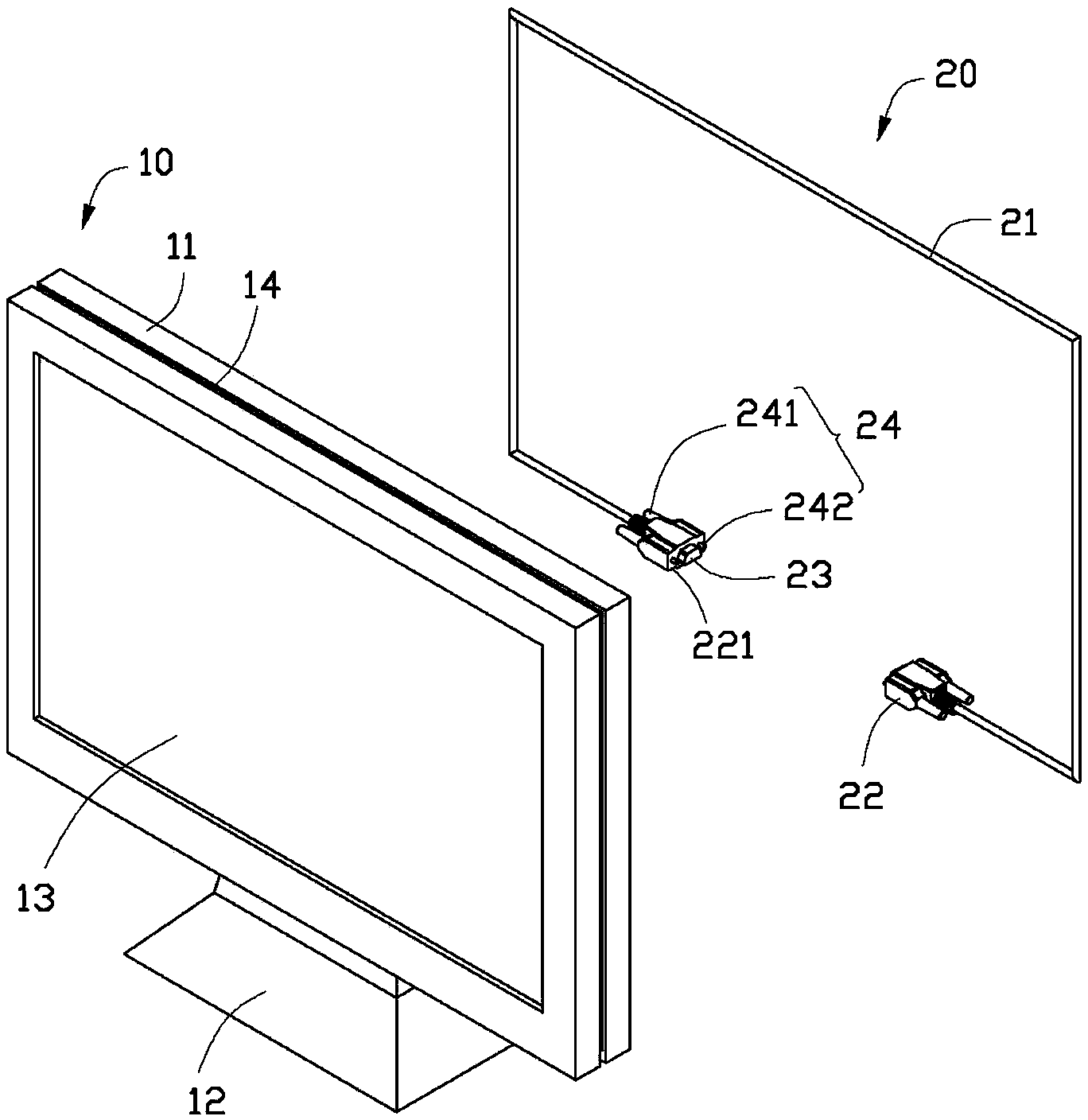

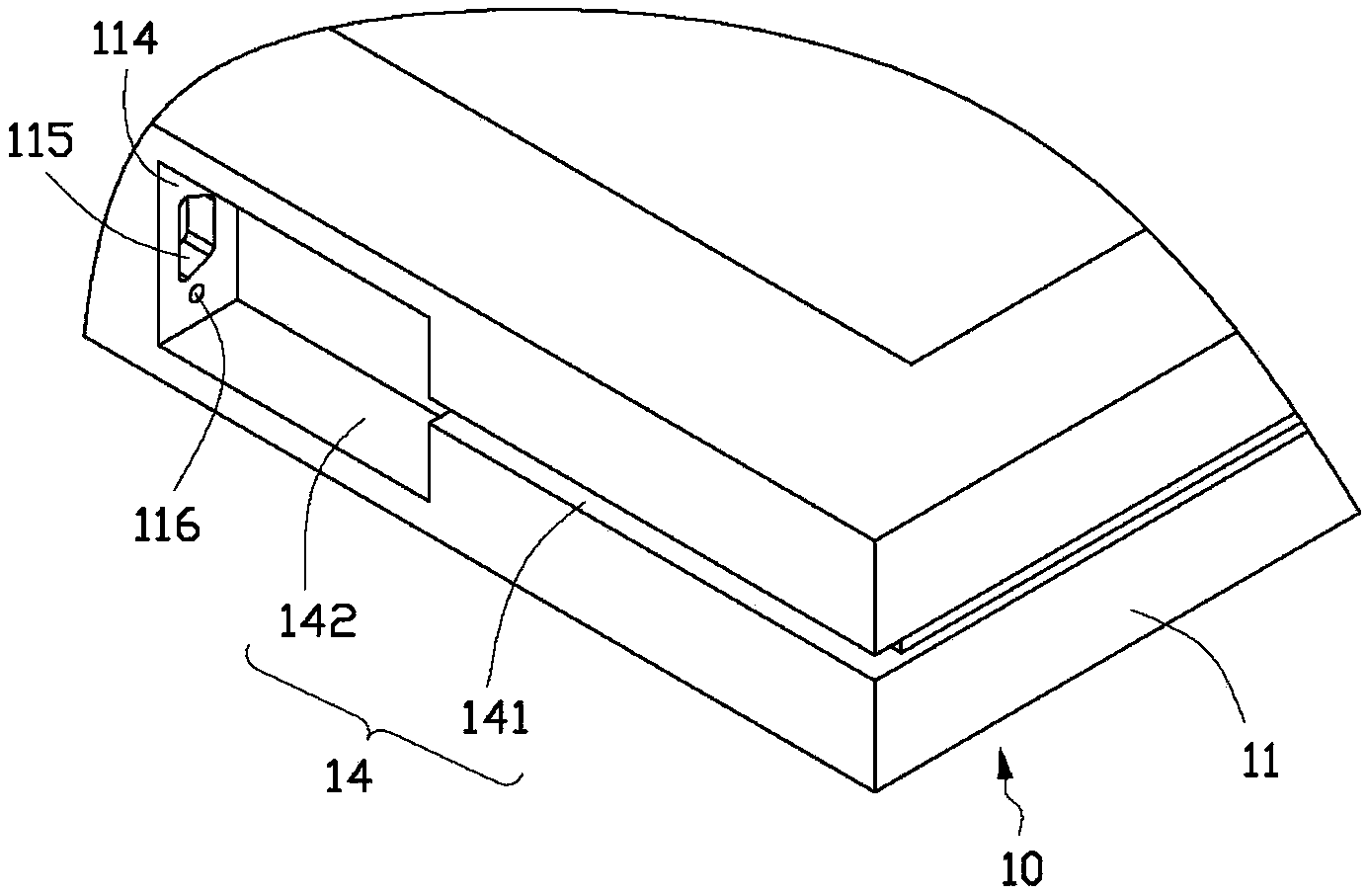

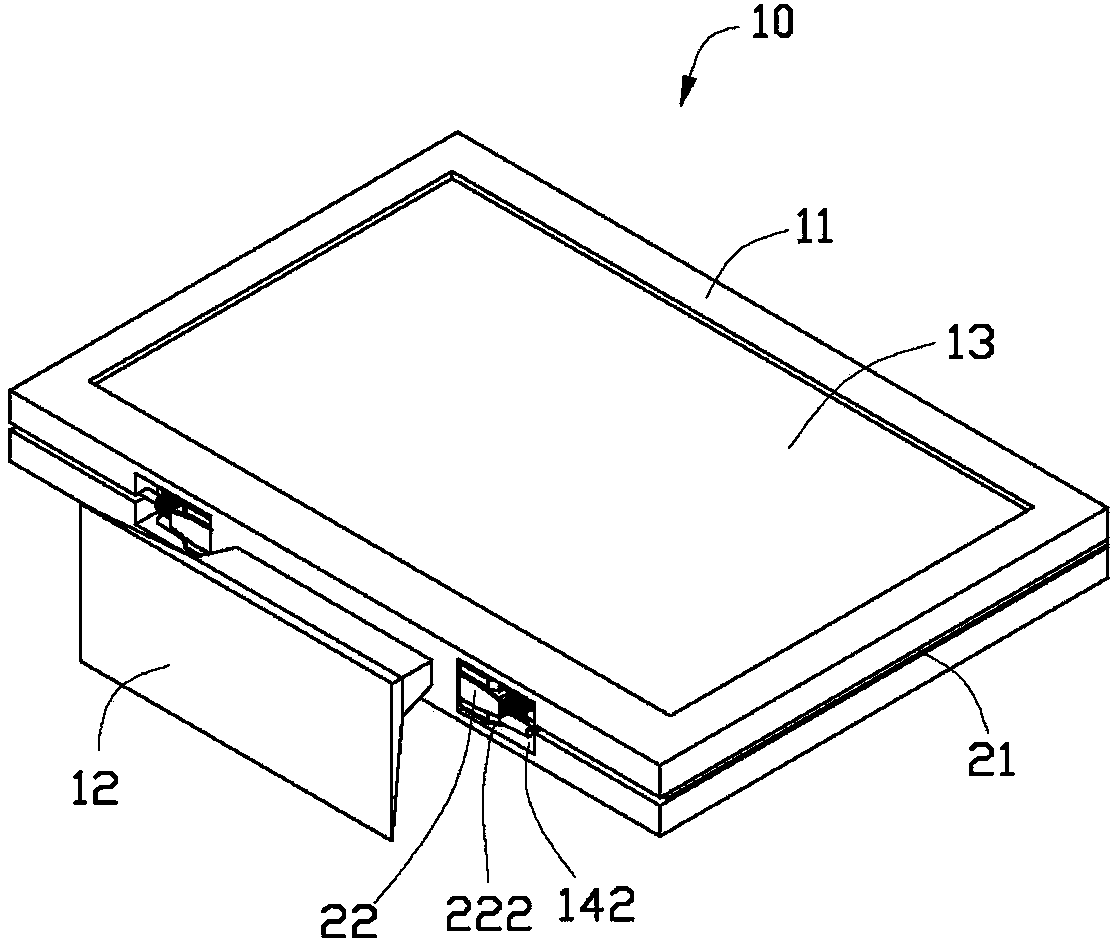

Display

InactiveCN104112395AAvoid messEasy to storeCasings/cabinets/drawers detailsIdentification meansDisplay deviceComputer engineering

A display comprises a main case, a display screen, a base and a data line. The display screen is installed in the main case, the base is installed under the main case, the data line is used for connecting the display with other electronic equipment, and an accommodating groove matched with the data line in shape and used for accommodating the data line is formed in the side wall around the main case. The display has the advantages that the data line can be accommodated in the main case of the display when the data line is not connected to the other electronic equipment, and integral storage and transportation of the data line and the display can be realized.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Charging line storage device

InactiveCN105947808AOrderly storageAvoid messArrangements using take-up reel/drumElectrical and Electronics engineering

The invention discloses a charging line storage device. The charging line storage device comprises a shell body, a cover body and a magnetic adsorption piece, wherein a storage chamber is defined in the shell body and provided with an opening, the cover body is connected to the shell body and can open and close the opening, and the magnetic adsorption piece is connected to the shell body. According to the charging line storage device of the embodiment of the invention, in the using process of a charging line, the contact between the charging line and the ground is avoided, and when the charging line is stored, the effect that the charging line is orderly stored in a trunk is ensured, so that the messy and disorderly phenomena of the charging line are avoided.

Owner:BEIJING ELECTRIC VEHICLE

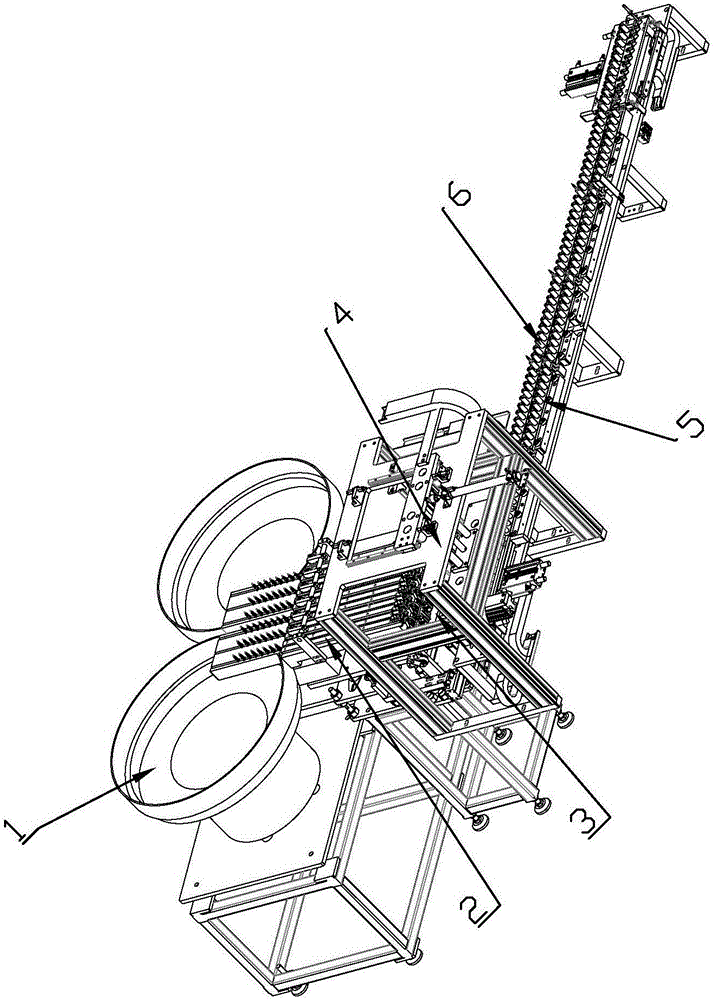

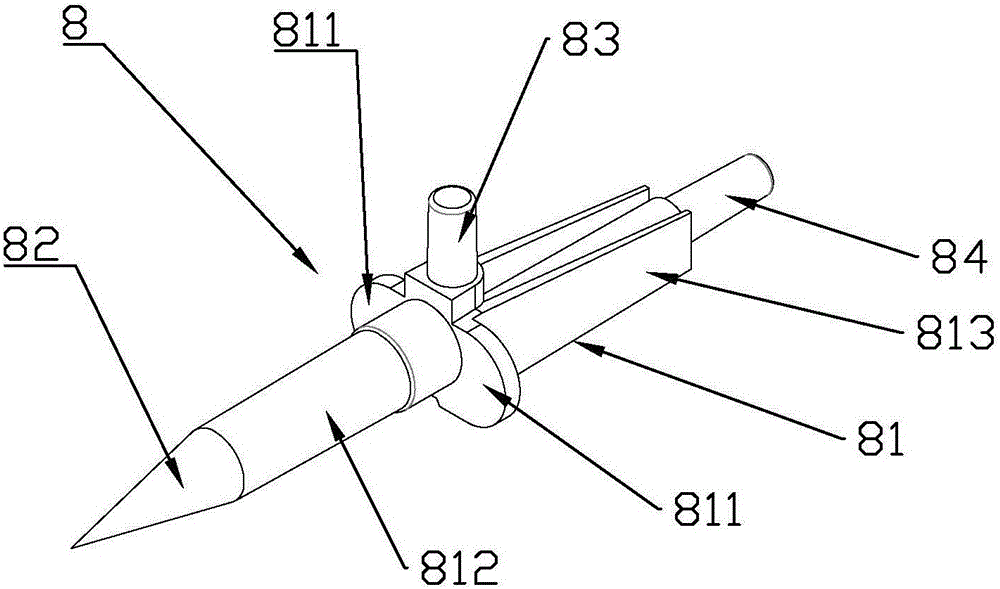

Bottle-pricking needle feeding mechanism

ActiveCN106044132AEnsure consistent directionIncrease success rateConveyorsInfusion devicesMedical equipmentEngineering

The invention provides a bottle-pricking needle feeding mechanism and belongs to the technical field of medical equipment. The bottle-pricking needle feeding mechanism comprises vibrating discs, a straight vibrating plate and a staggered material receiving device. One end of the straight vibrating plate is connected with the vibrating discs and the other end of the straight vibrating plate is connected with the staggered material receiving device. Bottle-pricking needle material ways for bottle-pricking needles to arrange and move forward are arranged on the straight vibrating plate. A carrier circulating device is arranged on the other side of the staggered material receiving device and the carrier circulating device comprises bottle-pricking needle carriers used for receiving and transferring the bottle-pricking needles. A bottle-pricking needle placing device, which is capable of clamping the bottle-pricking needle from the staggered material receiving device and conveying the bottle-pricking needles onto the bottle-pricking needle carriers, is arranged on the carrier circulating device. The bottle-pricking needle feeding mechanism further comprises a bottle-pricking needle overturning and shaping device which is arranged in the staggered material receiving device. A material taking device, used for taking the bottle-pricking needles out of the straight vibrating plate and placing the bottle-pricking needles onto the staggered material receiving device, is arranged between the straight vibrating plate and the staggered material receiving device. The feeding mechanism is simple and ingenious in design, high in automation degree, capable of guaranteeing the orientation consistency of air inlet pipe ports of the bottle-pricking needles and convenient for assembly of bottle-pricking needles.

Owner:梁启明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com