Support device for pouring shear wall

A support device and shear wall technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of complex construction procedures, large environmental pollution, and low construction efficiency, and facilitate on-site installation and pouring Concrete, simple construction process and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

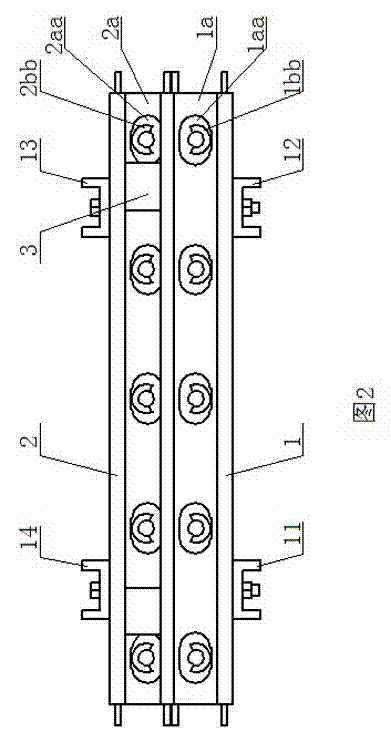

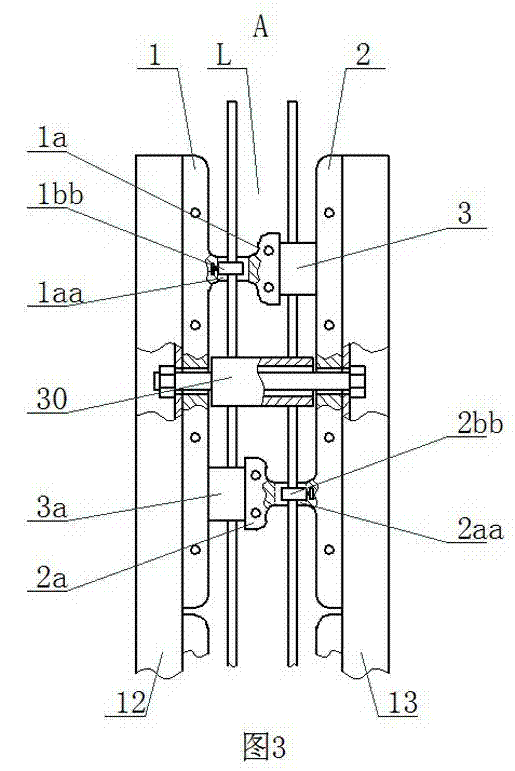

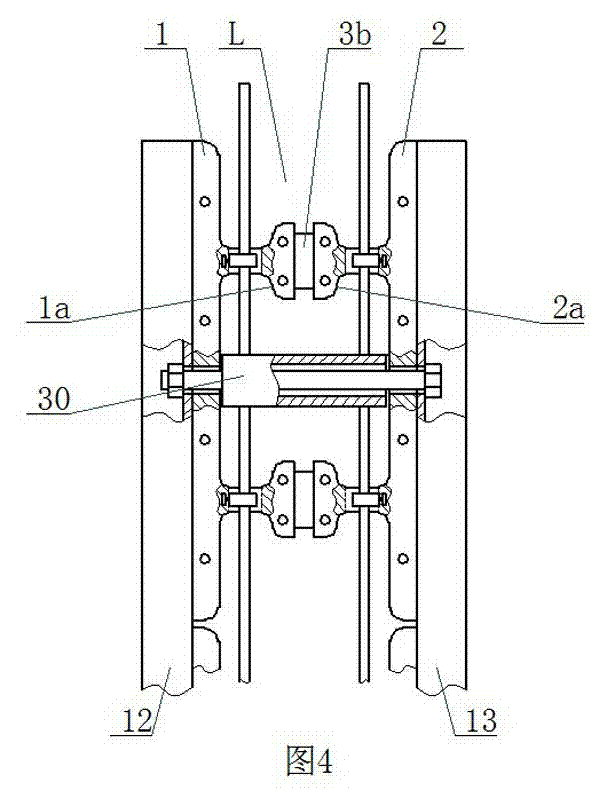

[0016] The supporting device of the pouring shear wall of the present invention comprises a plurality of ribbed plates, and the ribbed plates are connected to each other in the longitudinal direction by connectors, and every two ribbed plates are distributed in parallel in the transverse direction, and its structure is: the first ribbed plate 1 and The length direction of the second ribbed plate 2 is parallel, a space L is formed between the first ribbed plate 1 and the second ribbed plate 2, the first convex rib 1a on the first ribbed plate 1 and the second ribbed plate 2 The second ribs 2a on the top are respectively arranged in the space part L, the first ribs 1a correspond to the second ribbed plate 2, and pads 3 are installed between them, and the second ribs 2a and the first ribbed plate 1 Correspondingly, pads 3a are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com