Outer wall structure and construction and installation method

An installation method and exterior wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of many construction procedures, long period, slow construction progress, etc., to simplify construction procedures, reduce management costs, and speed up construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

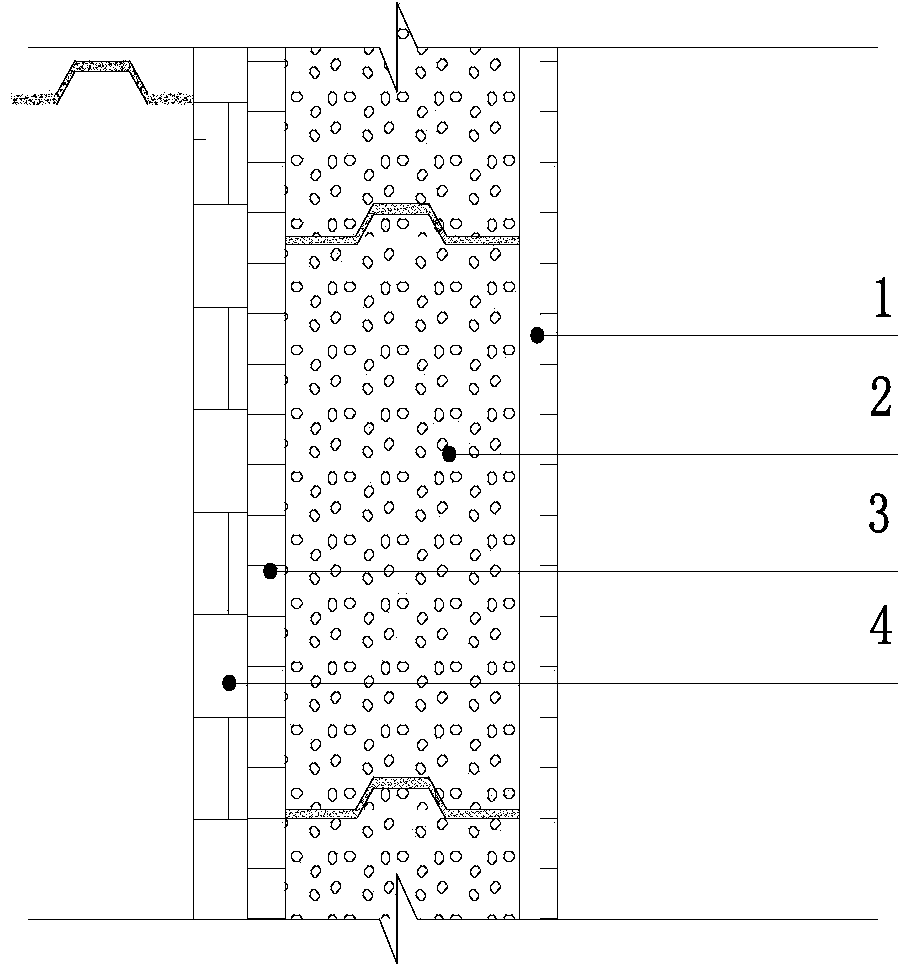

[0069] see figure 1 , the exterior wall structure of the present invention is sequentially provided with an interior decoration layer 1, a strip wall structure layer 2, a polymer anti-cracking waterproof mortar alkali-resistant mesh cloth or a galvanized steel wire mesh reinforcement layer 3 and an exterior surface from the inside to the outside. decorative layer4.

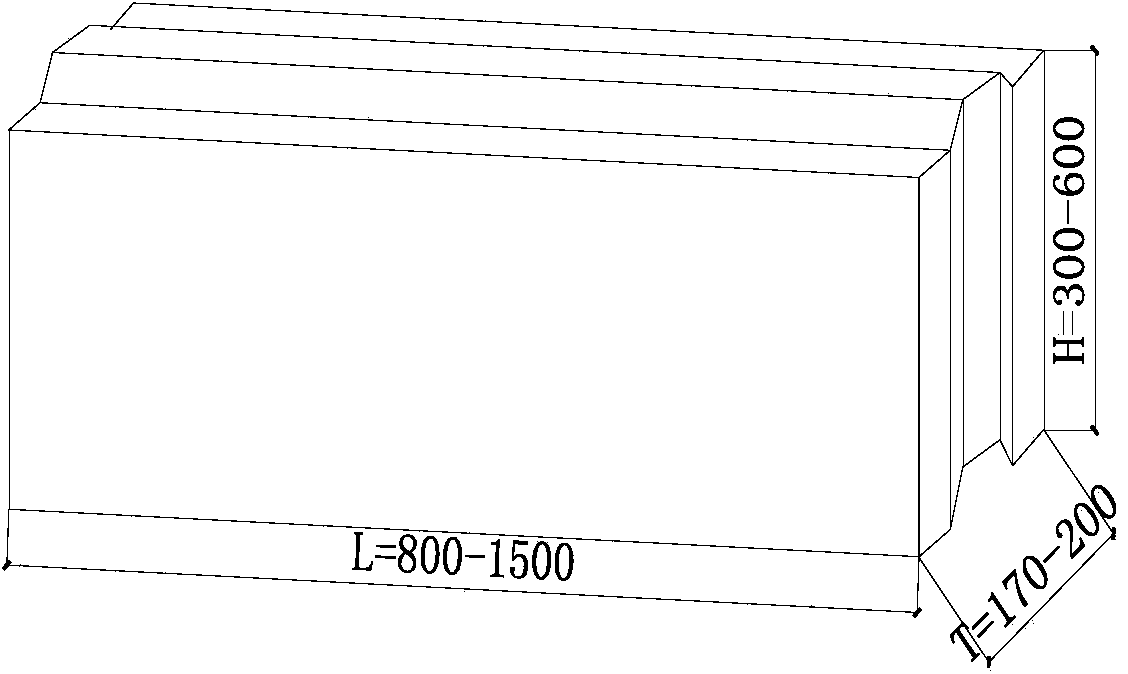

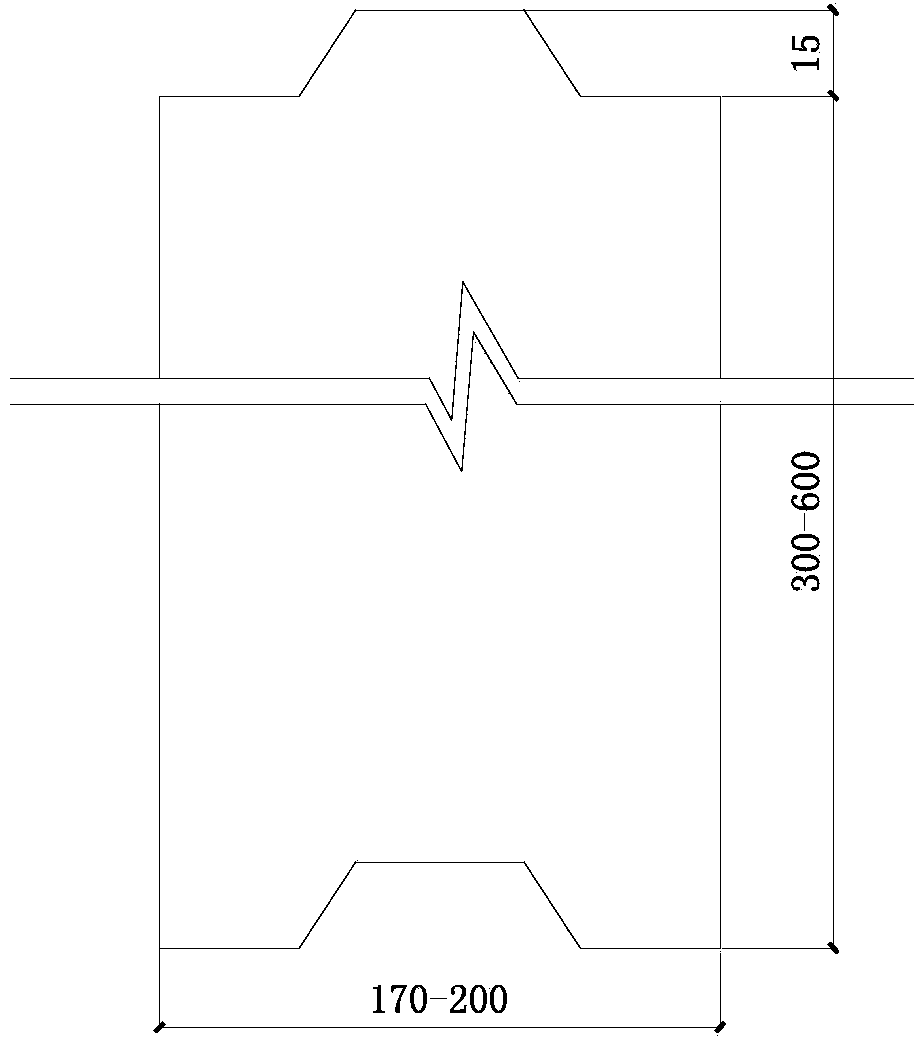

[0070] see figure 2 , the structural layer of the present invention is a composite wall strip, with concave-convex male and female joints around the composite wall strip, which is formed by factory prefabrication on-site installation; its length L is 800-1500mm, its height H is 300-600mm, and its thickness T is 170-200mm; when installing on site, the groove faces downward, the convex groove faces upward, and the gaps are filled with caulking mortar.

[0071] see image 3 , the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com