A kind of building masonry and construction masonry method

A masonry and construction technology, applied in construction, building components, building materials, etc., can solve problems such as easy construction quality problems, slow construction progress, and many construction procedures, achieve complete and reliable quality assurance, reduce management costs, and simplify The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

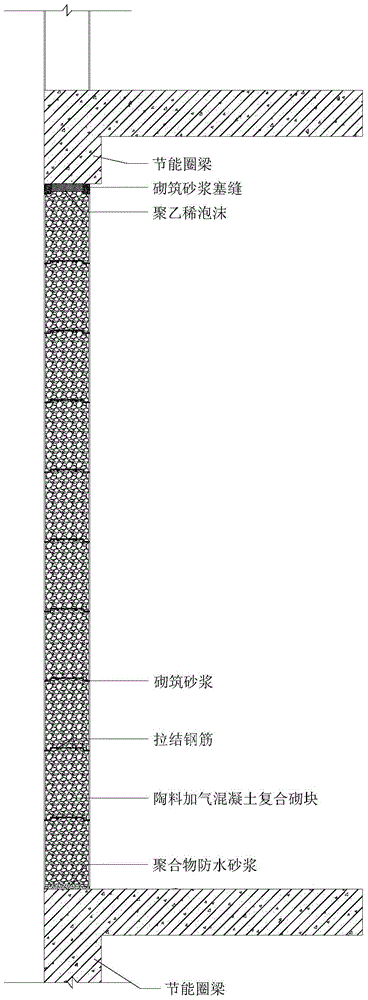

[0051] see figure 1 , the building masonry structure of the present invention, the masonry is made of lightweight aggregate concrete composite blocks with masonry mortar, and there are 1 to 3 steel bars with a diameter of 6mm along the wall at intervals of 1 to 2 mortar joints. Long pull connection.

[0052] The masonry mortar is a polymer waterproof mortar compatible with the performance of lightweight aggregate concrete composite blocks; its composition by mass ratio is cement 40-45, fly ash 8-10, fine sand 45-50, recyclable Dispersed latex powder 1.0-3, methyl cellulose ether 0.08-0.10, organic silicon 0.2-0.7, lignocellulose 0.2-0.3, water 22-24; the cement uses ordinary Portland cement with a label of not less than 42.5, and the The above fine sand can be 40-70 mesh fine sand.

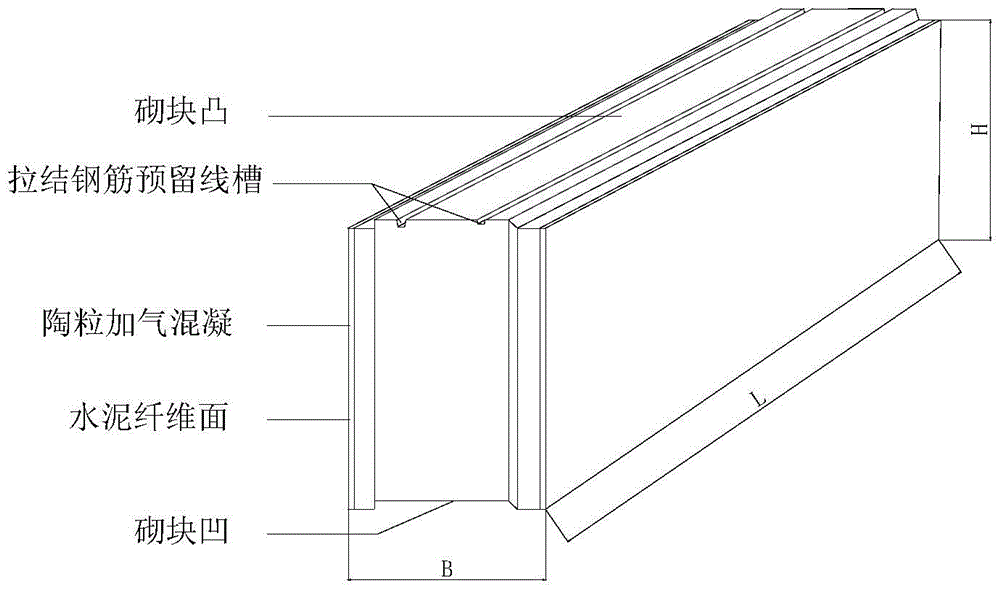

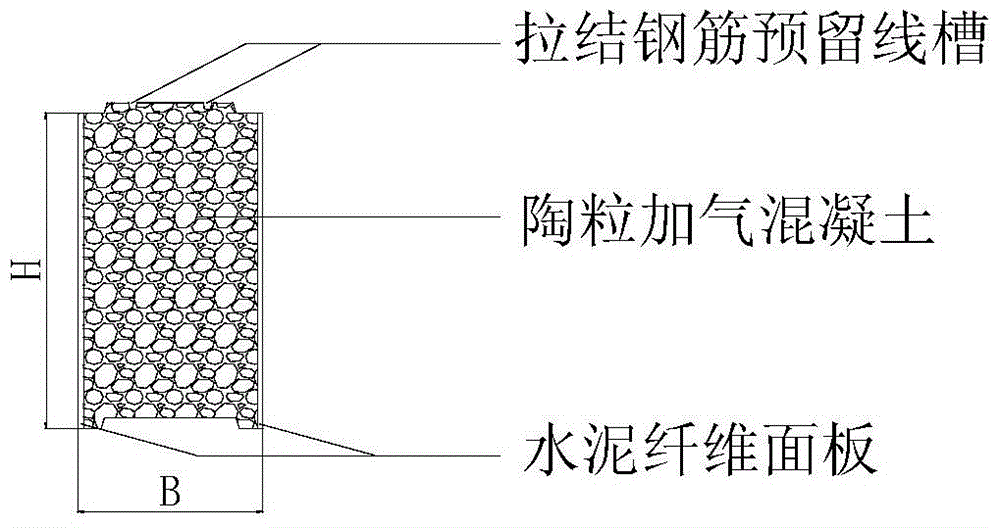

[0053] see figure 2 , the lightweight aggregate concrete compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com