Patents

Literature

133results about How to "Light weight structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

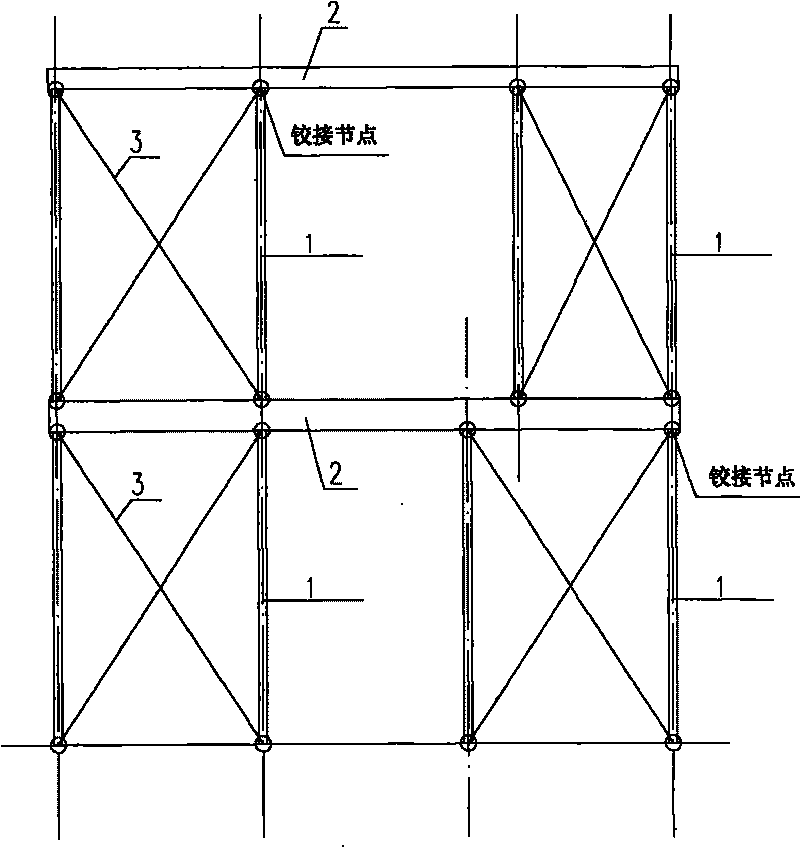

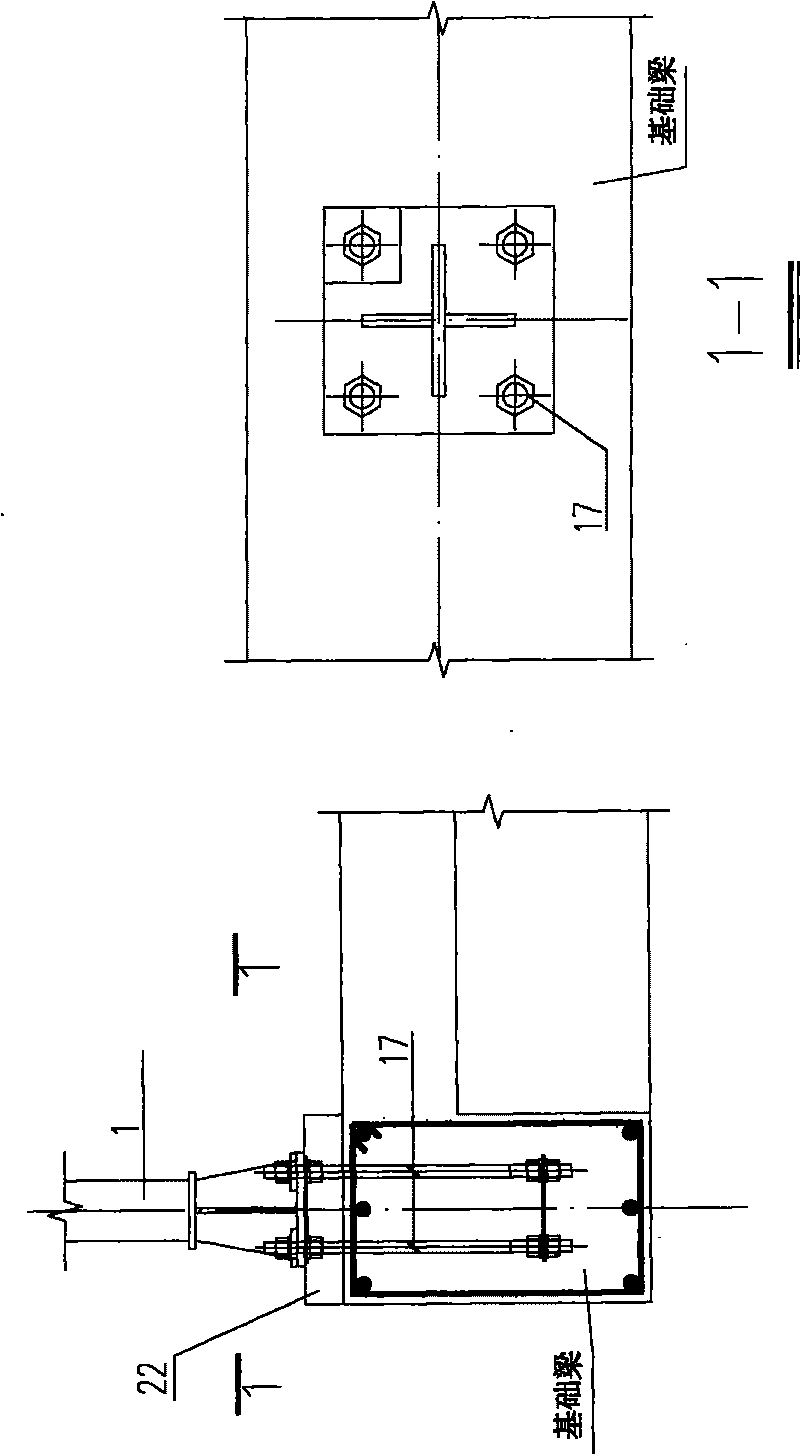

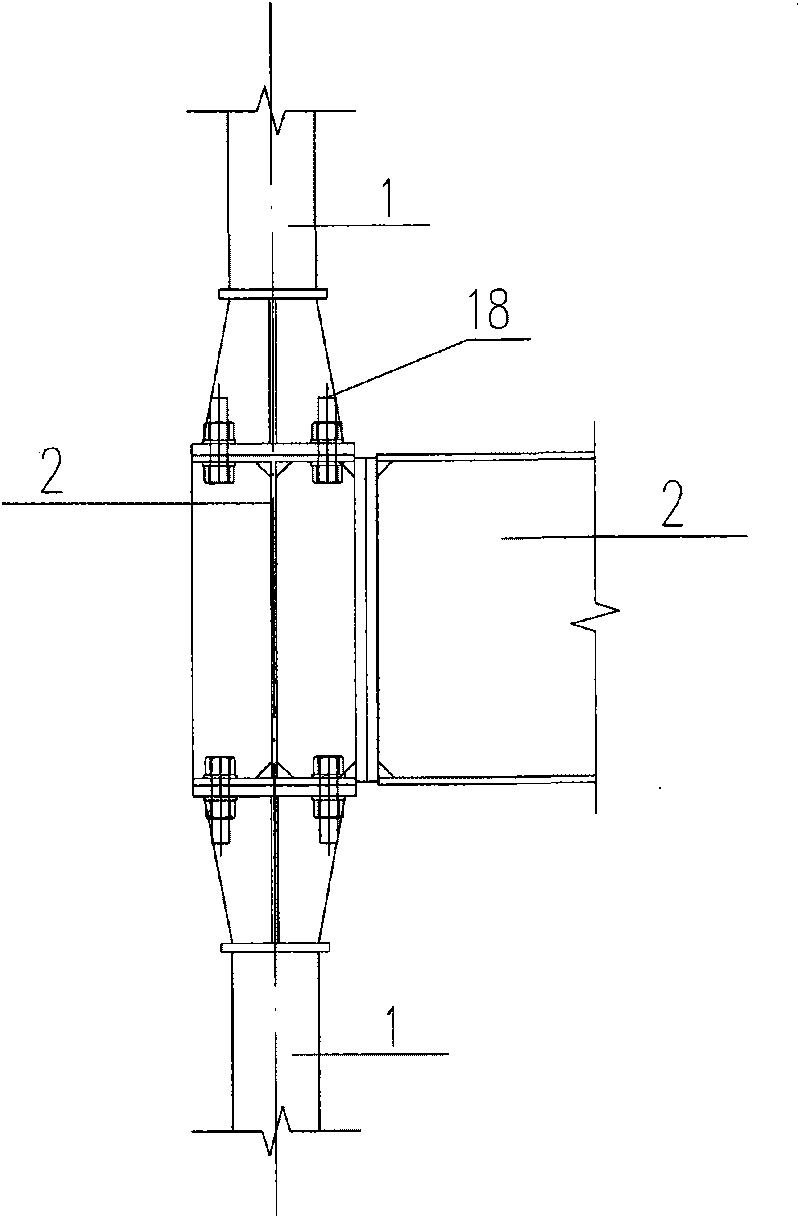

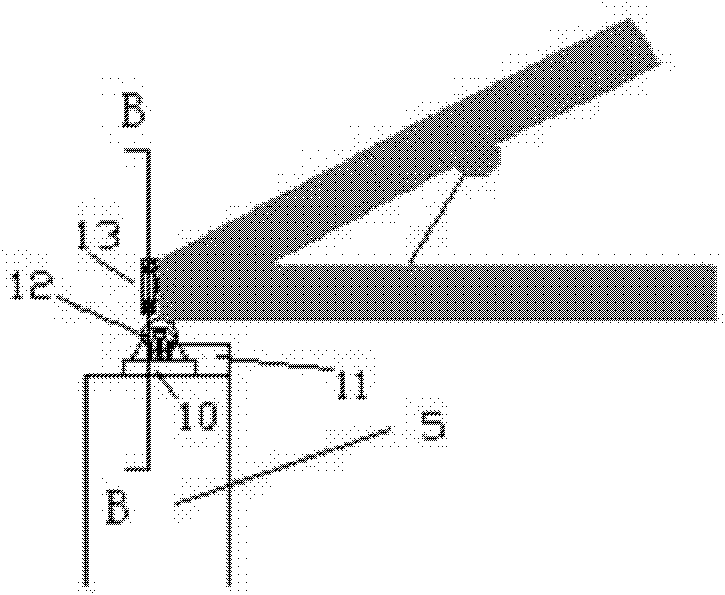

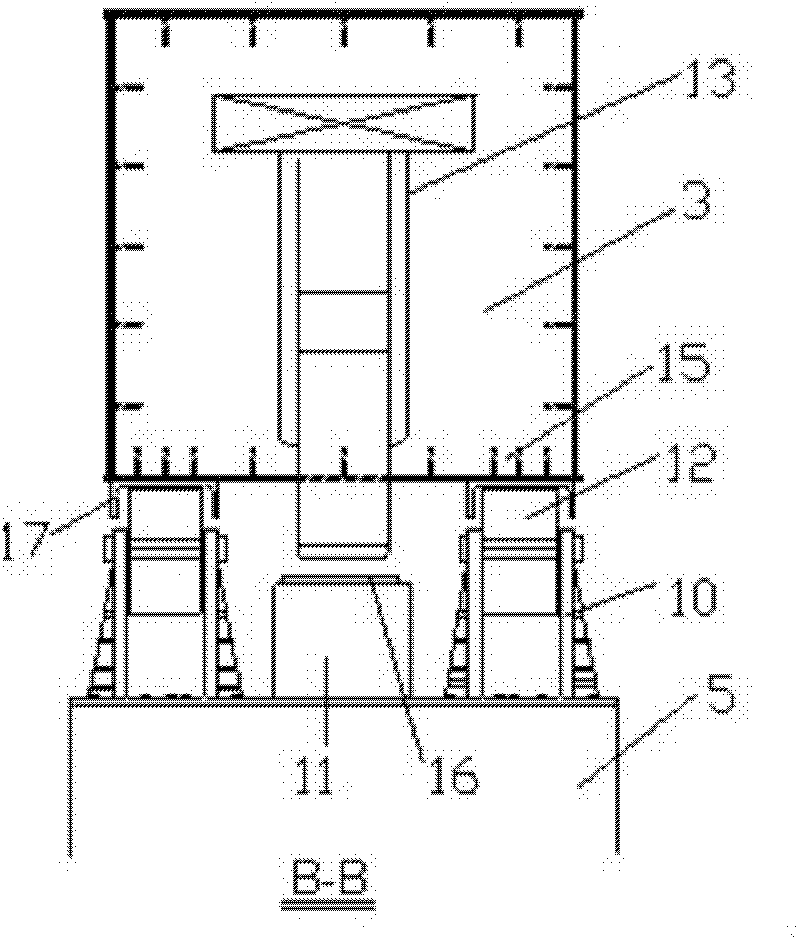

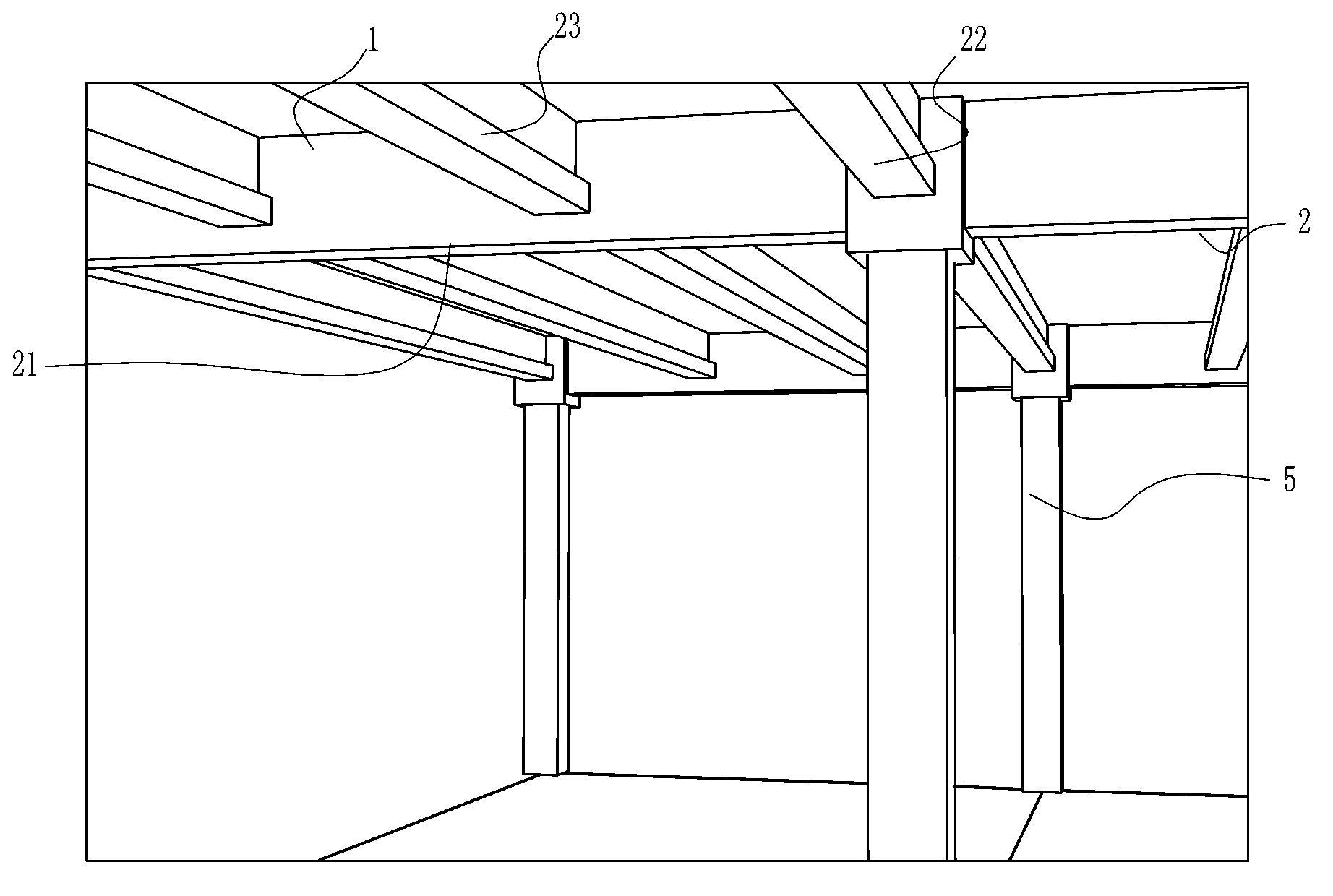

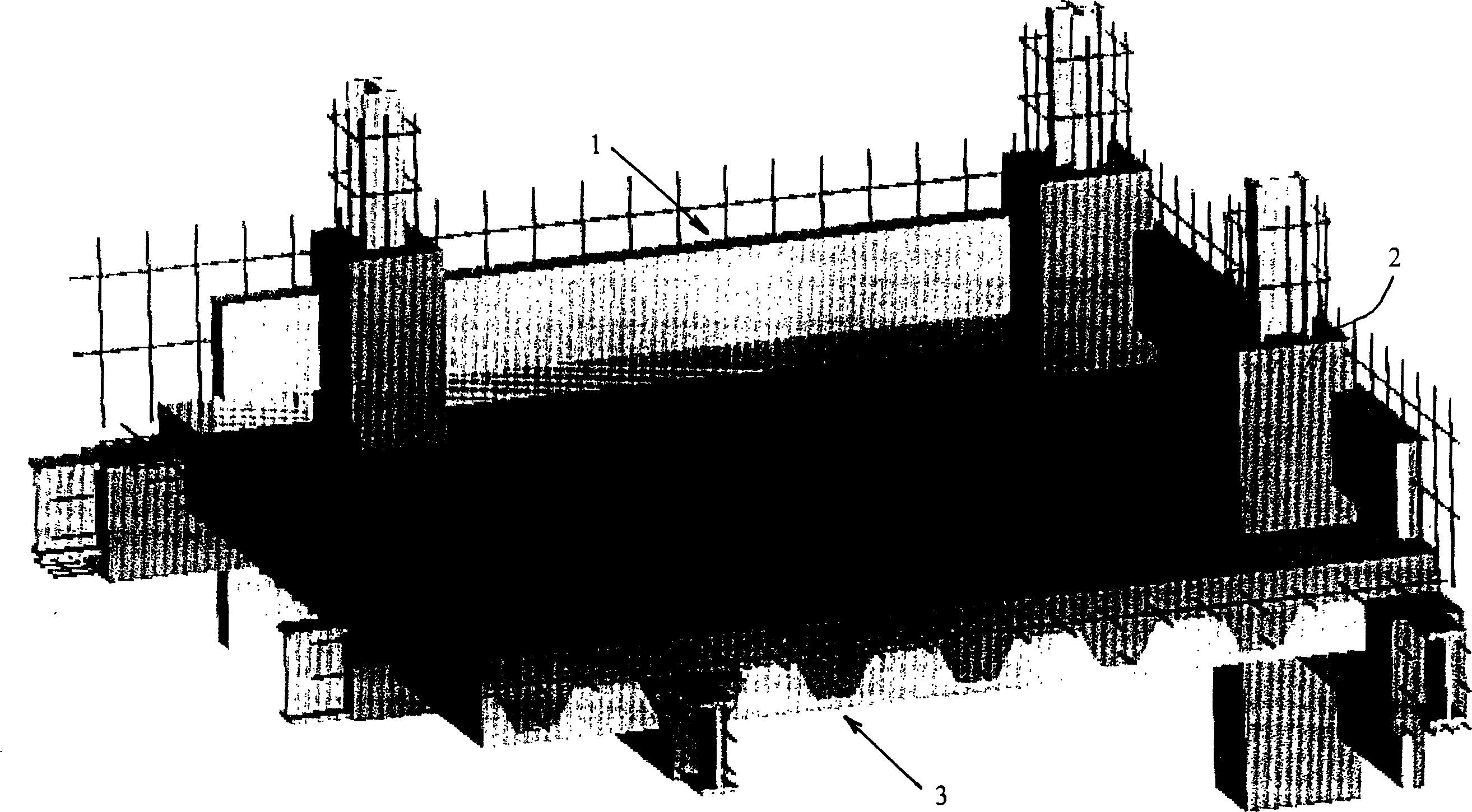

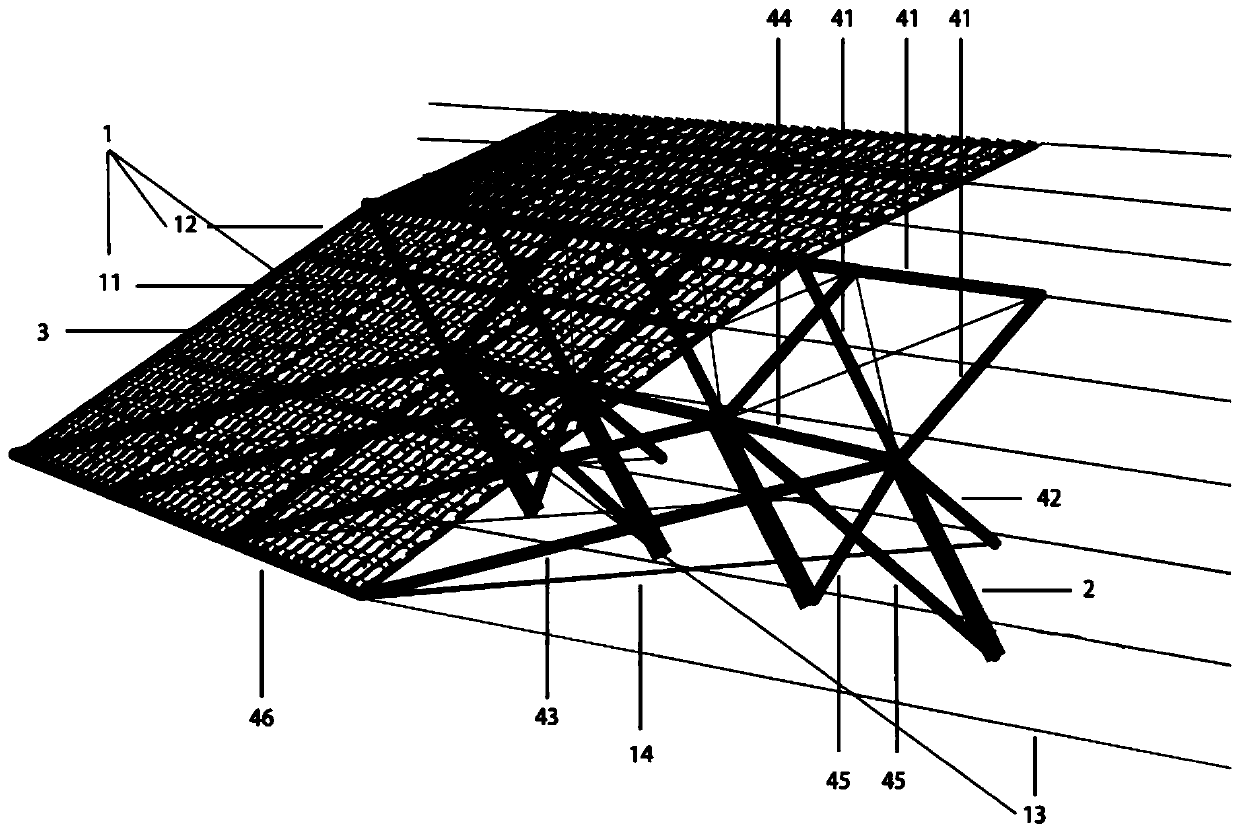

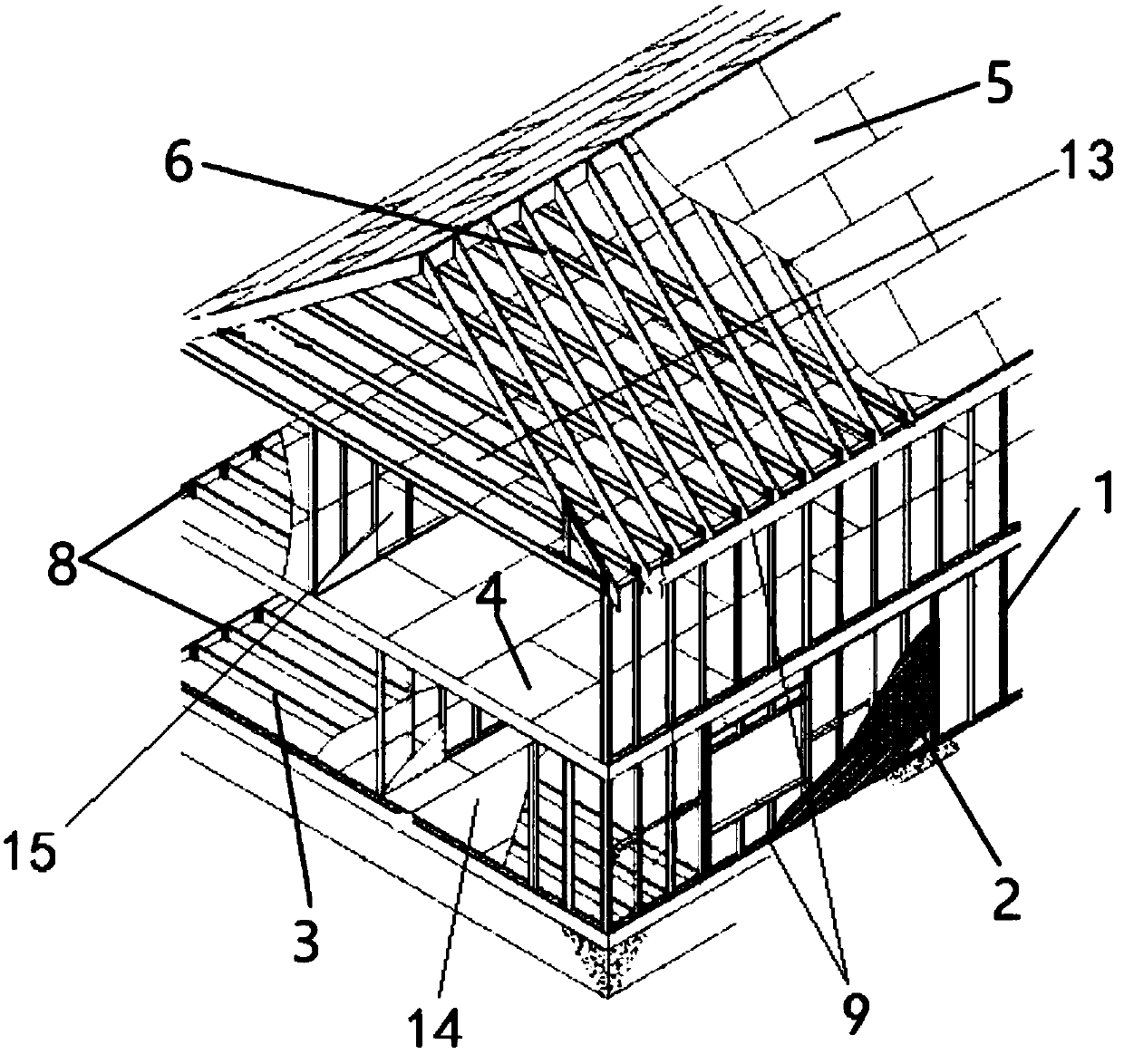

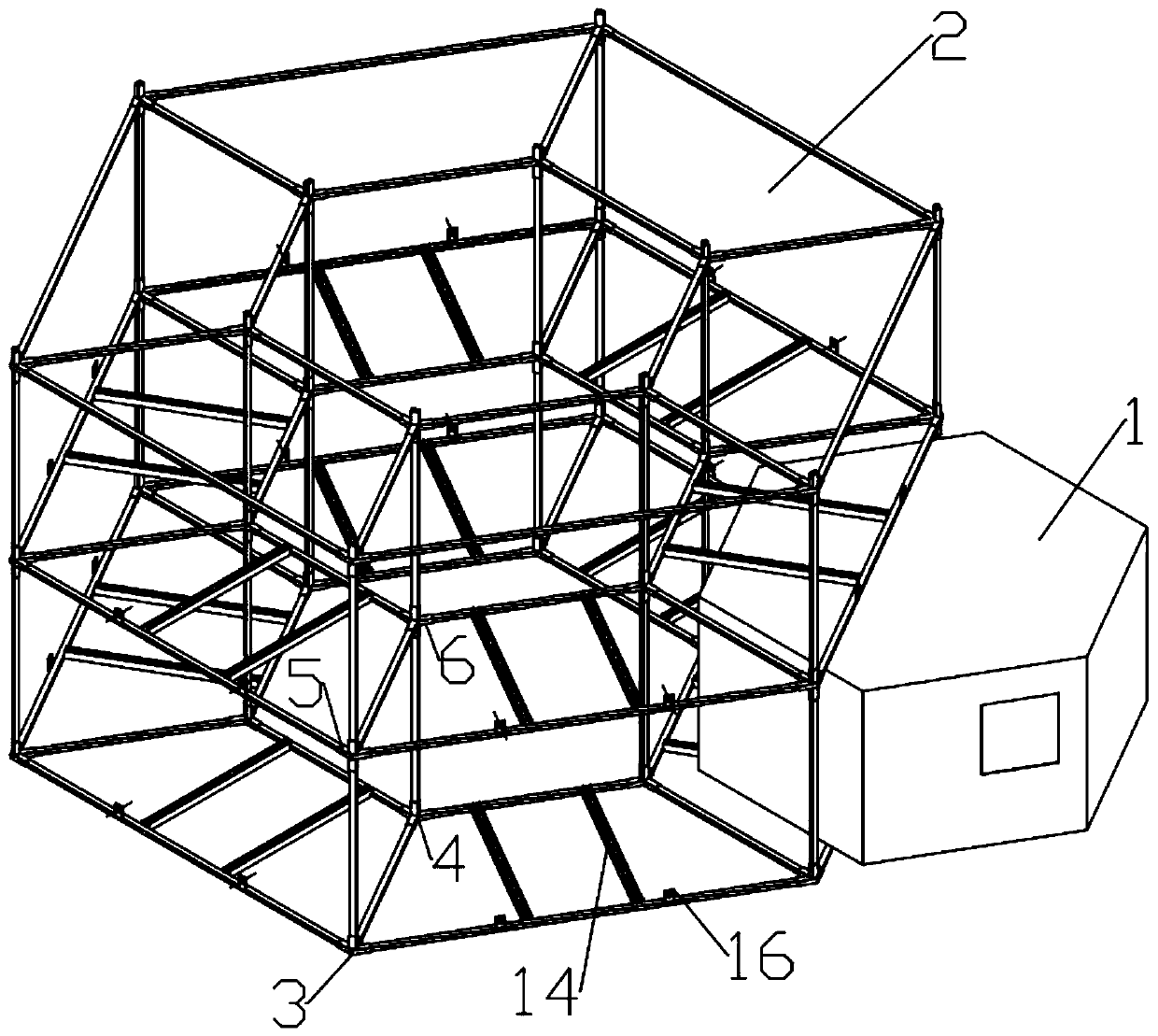

Structural system of industrial low storied dwelling

ActiveCN101748903AReasonable forceAvoid wastingBuilding constructionsDwelling buildingFloor slabSimple component

The invention belongs to the field of building structures, and in particular relates to a structural system of an industrial low storied dwelling adopting modularized design, factory production and field mounting. The structural system of the industrial low storied dwelling comprises steel columns, steel girders, inter-column supports, steel girder horizontal supports, floor slabs, connecting nodes between the steel columns and a foundation, the connecting nodes between the steel columns and the steel girders, the connecting nodes between the steel columns and the inter-column supports, the connecting nodes between the steel girders and the steel girder horizontal supports, rigid connection nodes between the steel girders, the connecting nodes between the steel girders and the floor slabs, roofing surrounding systems and wall surface surrounding systems, wherein the steel columns are connected with the foundation through pre-embedded bolts; the steel columns are connected with the steel girders through bearing type high-strength bolts; the steel columns are connected with the inter-column supports through ordinary bolts; the steel girders are connected with the steel girder horizontal supports through the ordinary bolts; the steel girders are in fully rigid connection through continuous girders; the slabs are connected with the steel girders through male pins or special fasteners; and each of the roofing surrounding systems and the wall surface surrounding systems is of a block type. The structural system of the invention has the characteristics of clear stress of the structure, simple component connection, convenient and quick mounting, attractive appearance, good rationality and economical efficiency of unit steel amount, and is favorable for industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

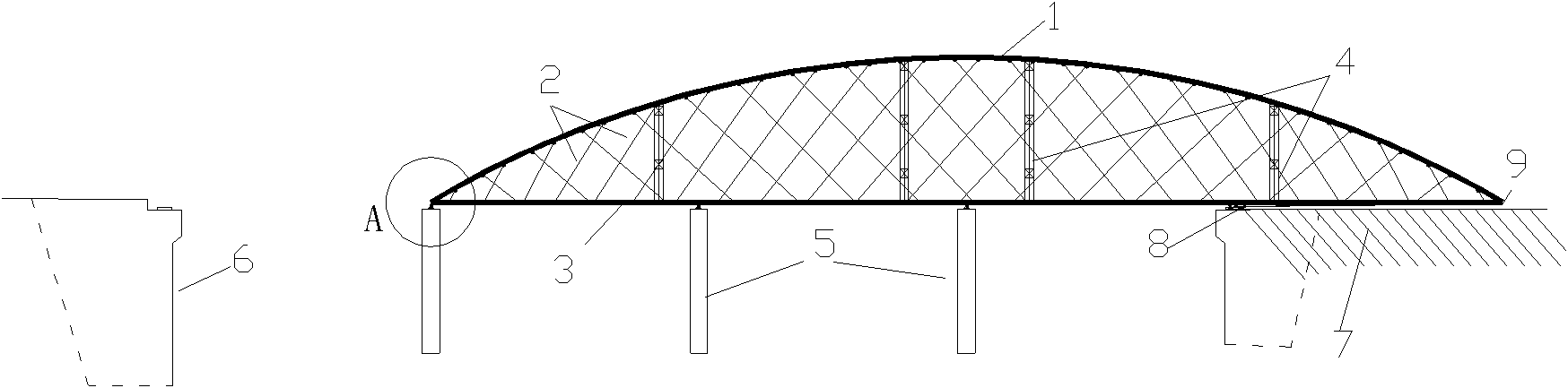

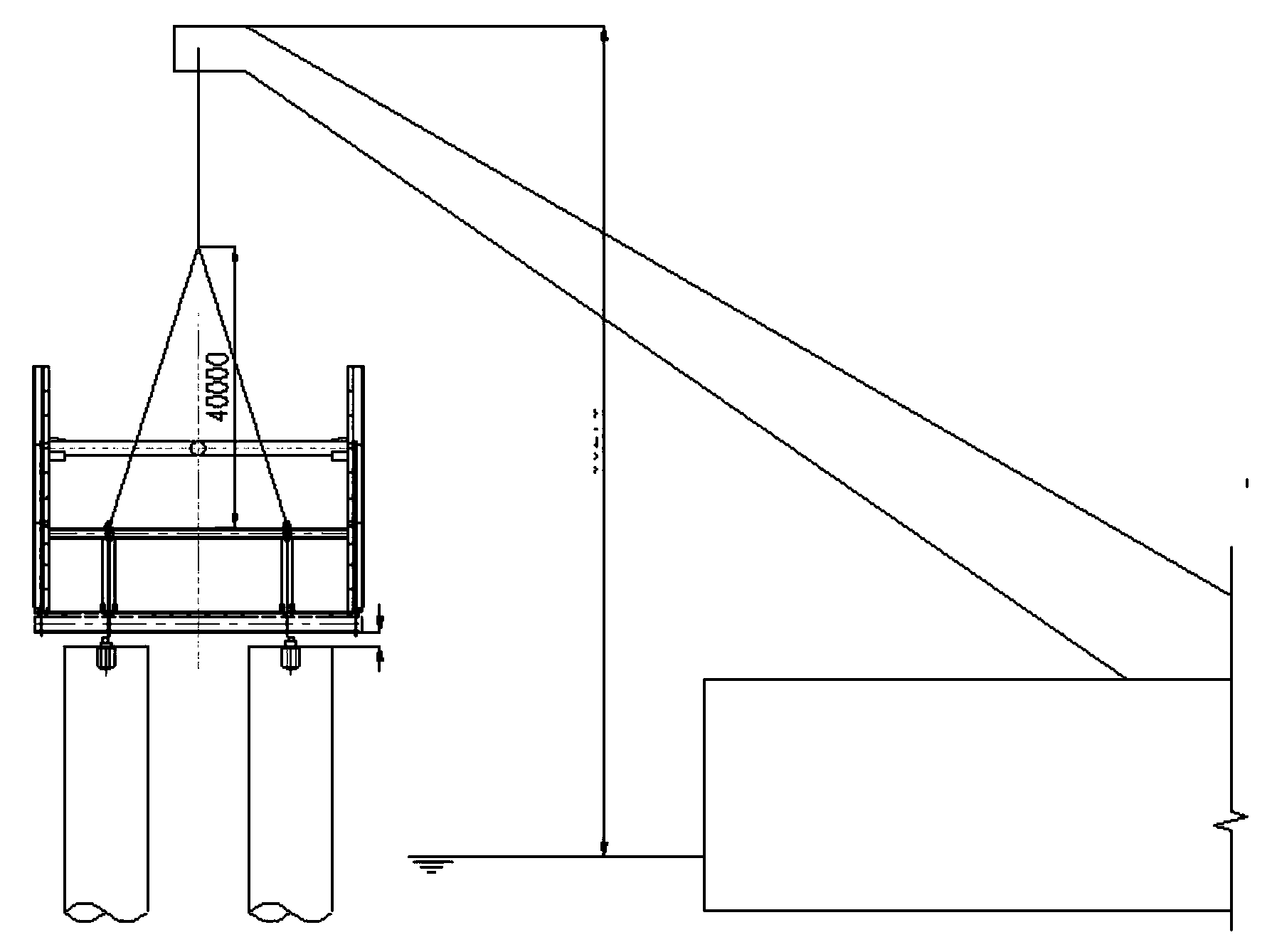

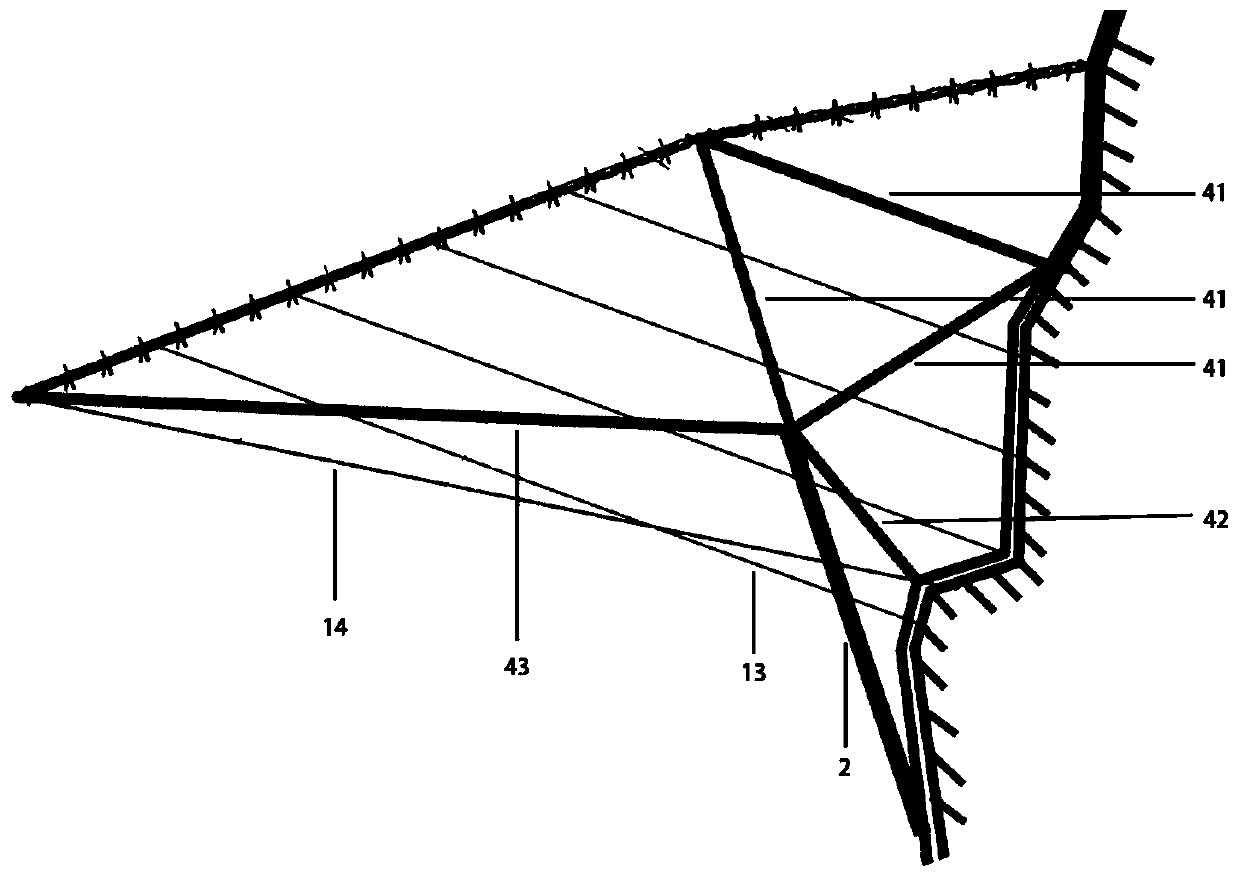

Integral Pushing Construction Method of Network Tied Arch Bridge

InactiveCN102261039AFast constructionReduce coefficient of frictionBridge erection/assemblyArch-type bridgeEngineeringPiston

The invention relates to a guiding-beam-free integral thrusting construction method of a network tied arch bridge. The method is characterized in that the following structure and method are adopted for thrusting the network tied arch bridge: a vertical jack is arranged at the front end in the thrusting direction of a steel box tie beam; a sliding mechanism which can ensure a piston of the jack toslide on the top surfaces of temporary piers is arranged on the top surfaces of the temporary piers; during thrusting, when the front end of the arch bridge is close to the temporary piers, the piston of the jack moves downwards to push against the sliding mechanism and the height of the front end of the arch bridge relative to the top surfaces of the temporary piers is adjusted by controlling the extension elongation of the piston to ensure chutes at the bottom of the steel box tie beam to fall on pulleys; and the chutes are supported by the pulleys and slide relative to the pulleys along with thrusting movement of the arch bridge. The method has the following beneficial effects: in the thrusting process, a main arch ring, inclined hangers, the steel box tie beam, the temporary supports and the like are integrally thrust, thus giving play to the function of partial inclined hangers to enhance the structural rigidity in the thrusting process, simultaneously avoiding installation inconvenience and construction difficulty after the members are thrust in place and improving the thrusting construction efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reinforced concrete superposed mixed girder bridge construction method

ActiveCN108547223ALight weight structureAvoid investmentBridge erection/assemblyConcrete beamsBridge deck

The invention discloses a reinforced concrete superposed mixed girder bridge construction method. The method includes the following steps that S1, concrete beam sections are constructed on adjacent piers at the same time, opposite front cantilever sections and opposite rear cantilever sections of the beam sections are formed, start number zero blocks are poured in place through a support, and other number blocks of the concrete beam sections are poured in a suspended mode through a hanging basket; S2, steel beams of reinforced concrete combination sections are hung and connected to the front cantilever sections of the beam sections and the rear cantilever sections of the beam sections; S3, the multiple small-section steel beams are hung section by section to the surfaces of the constructedconcrete beam sections and assembled into a large-section steel beam; S4, a front guide beam and a rear guide beam are installed at the two ends of the large-section steel beam to form a combined steel beam; S5, the large-section steel beam of the combined steel beam is hung; and S6, a bridge floor is paved. The method has the beneficial effects that the method is suitable for the construction conditions with the poor water transport environment and large stormy waves, construction is safe, construction efficiency is high, and the method can be widely applied to the technical field of bridgeconstruction methods.

Owner:CCCC SECOND HARBOR ENG +2

Construction method of waste tyre earth roadbed

The invention relates to highway construction, in particular to a roadbed construction method. A construction method of waste tyre earth roadbed comprises the following steps: a. selecting basement processing area; b. preparing materials and construction equipments (waste tyres and stainless steel bolt connecting pieces); c. adding auxiliary reinforcing layers at edges of each layer of the basement and non high filling square tyre earth, which mainly comprises geogrid and geotextile pavement; d. installing bottom layer waste tyre to connected into an integral; e. transporting to location and filling filler materials; f. continuing to construct the waste tyre earth structure of the second layer and the third layer according to steps d and e until reaching the designed height; and g. paving geogrids and reinforcing on the top of the uppermost layer of waste tyre earth.

Owner:CHINA MCC20 GRP CORP

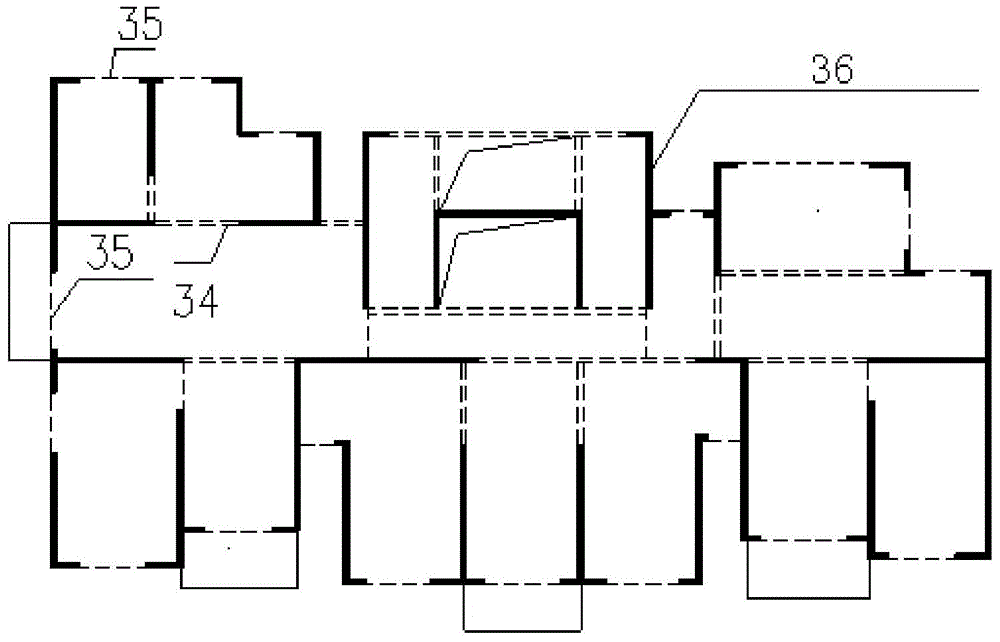

Large span prefabricated monolithic casting structure and construction method

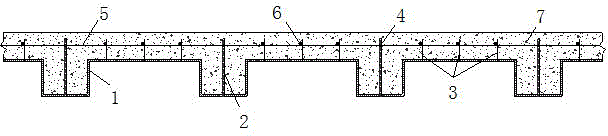

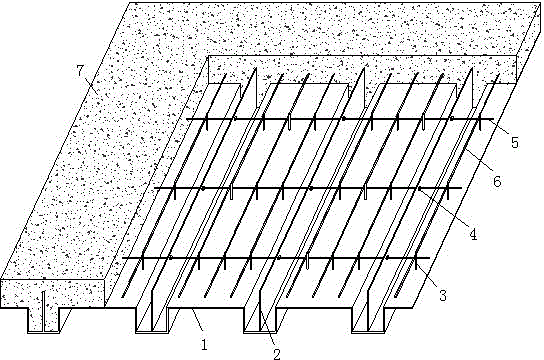

ActiveCN103046645AImprove shear resistanceSmall floor spanBuilding material handlingShaped beamFloor slab

Disclosed is a large span prefabricated monolithic casting structure. The large span prefabricated monolithic casting structure comprises a floorslab, a superposed beam and a column, the superposed beam and the column are used for supporting the floorslab, the superposed beam is divided into a short frame main beam, a long frame beam and an auxiliary beam, the auxiliary beam is connected with the main beam, the superposed beam comprises a prestress prefabricated beam and a cast-in-situ portion, the prestress prefabricated beam comprises a beam body and a pre-stressed steel strand which is buried in the beam body and serves as a main rib, two ends of the short frame main beam and the long frame beam are connected with the column, cross sections of prefabricated beam portions of the long frame beam and the auxiliary beam are invertedly T-shaped, the superposed beam after monolithic casting is an I-shaped beam connected with the floorslab, and the auxiliary beam and the long frame beam utilize the inverted T-shaped prestress prefabricated beams with small intervals. The large span prefabricated monolithic casting structure has the advantages that the span, the thickness and the self weight of the floorslab are small, heights of the beams are reduced, reinforcing bars are reduced, and the short main beam which uses a superposed rectangular beam is good in shear resistance and convenient to connect with the auxiliary beam.

Owner:宁波优造建筑科技有限公司

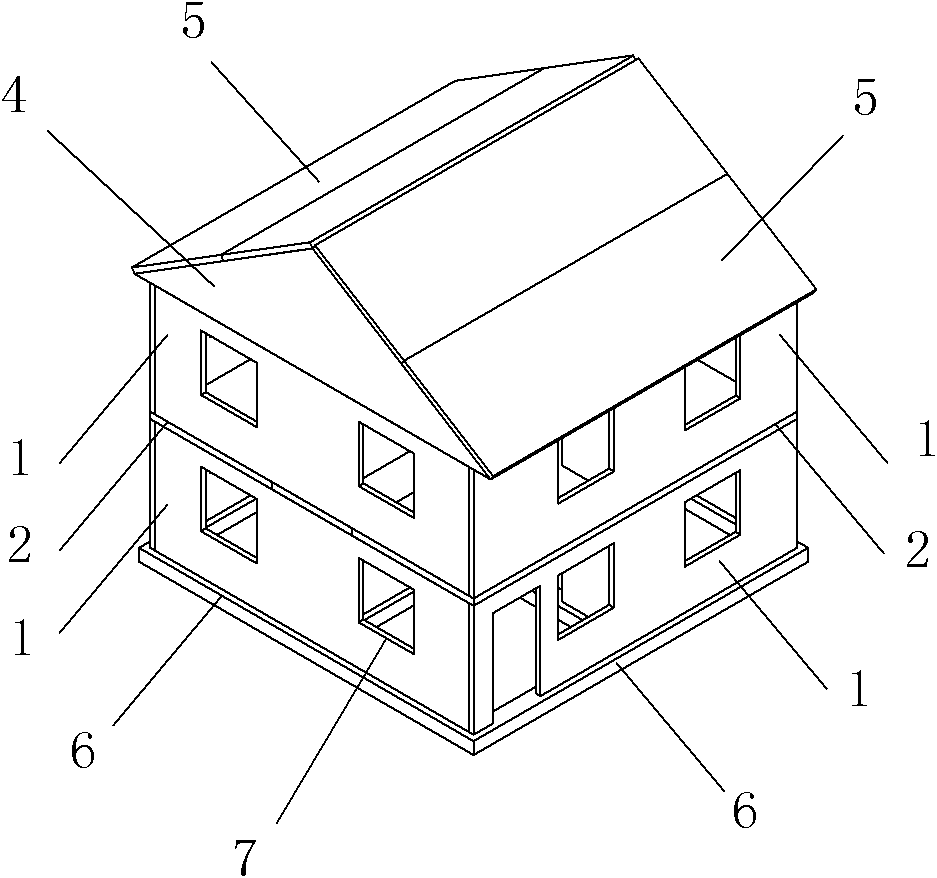

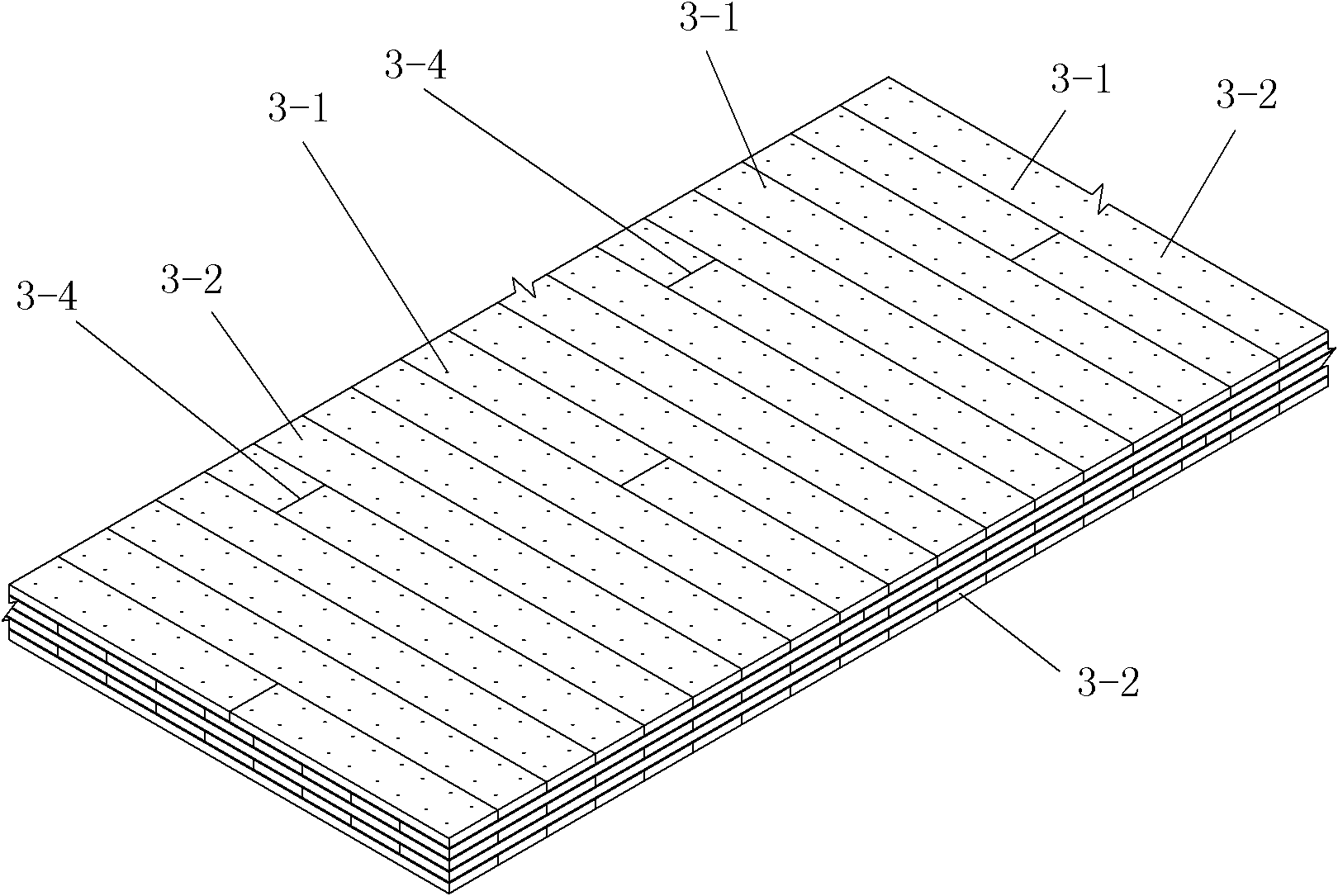

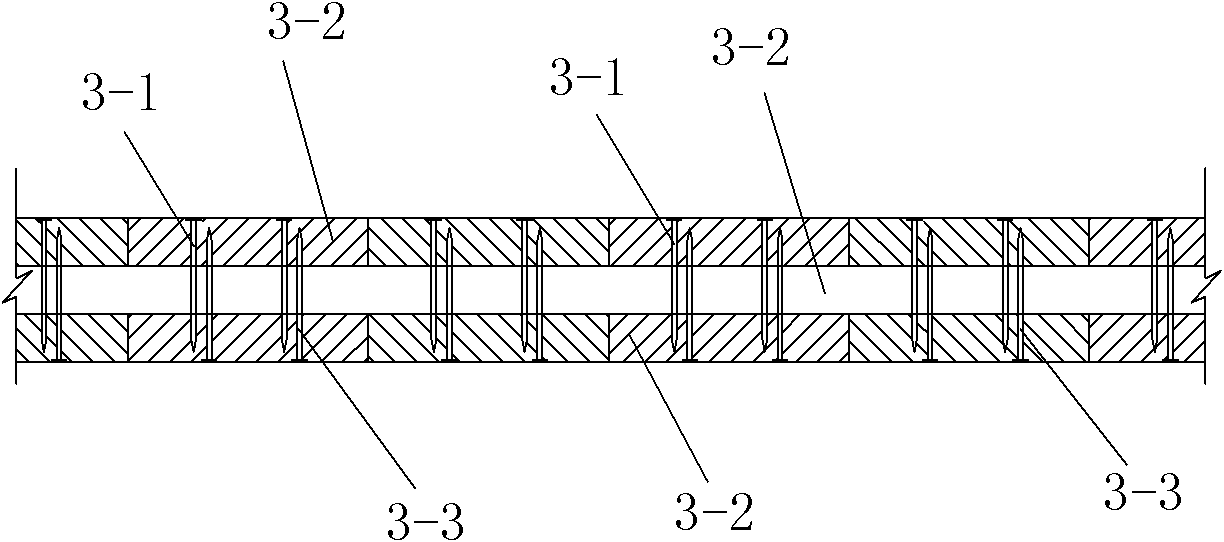

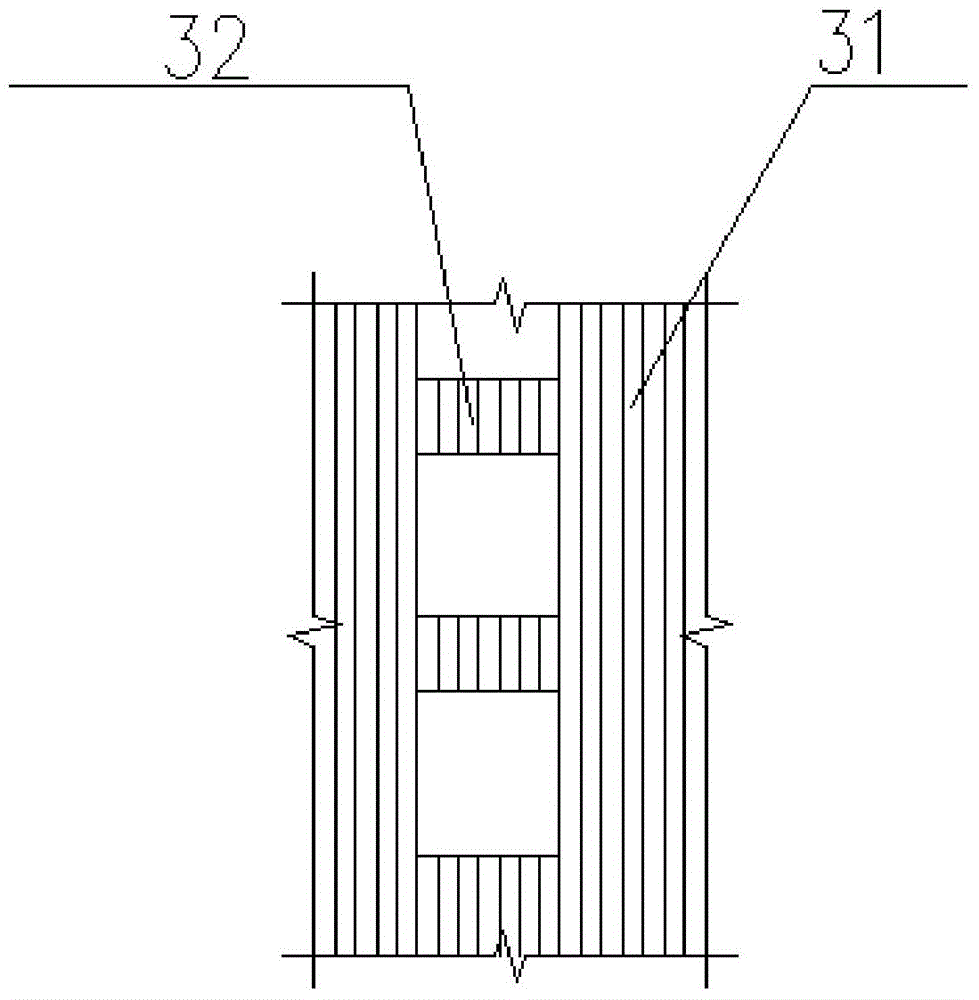

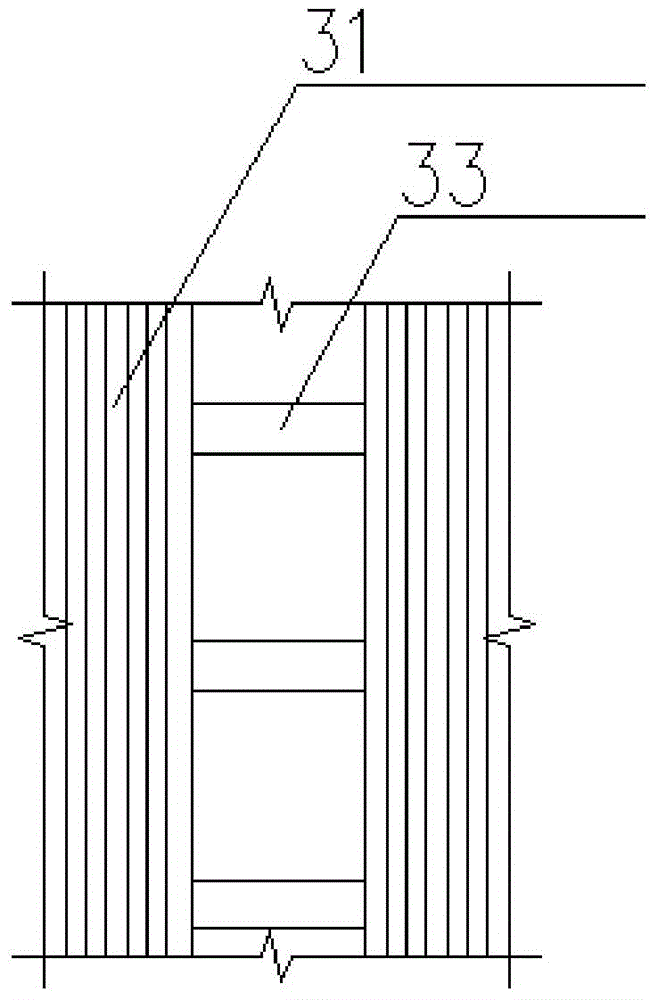

Wooden structure house and building process thereof

InactiveCN102174859ASimple structureClear mechanical propertiesRoof covering using slabs/sheetsBuilding roofsBasementOn board

The invention discloses a wooden structure house and a building process thereof. The wooden structure house comprises a house main body structure and a roof structure, wherein every floor of the house main body structure comprises a plurality of wall bodies 1; the adjacent floors are separated by a floor plate; the wall bodies 1 and the floor plate are an integrated composite board or are formed by splicing a plurality of composite boards arranged on the same plane; the integrated composite board is formed by piling a plurality of layers of wooden boards with same shapes and sizes; and the wooden board is formed by splicing a plurality of wooden plate strips which are arranged on the same plane. The building process comprises the following steps of: 1, on-site constructing foundation and basement, factory-prefabricating and transporting the integrated composite boards; and 2, using the prefabricated composite boards to assemble the wooden structure house on the spot. The wooden structure house in the invention is simple in construction process, controllable in construction quality, low in input investment, rational in structural stress of the built house, beautiful in shape, wide in application range and convenient for prefabricating the integrated boards and suspending on the spot.

Owner:杨岳华

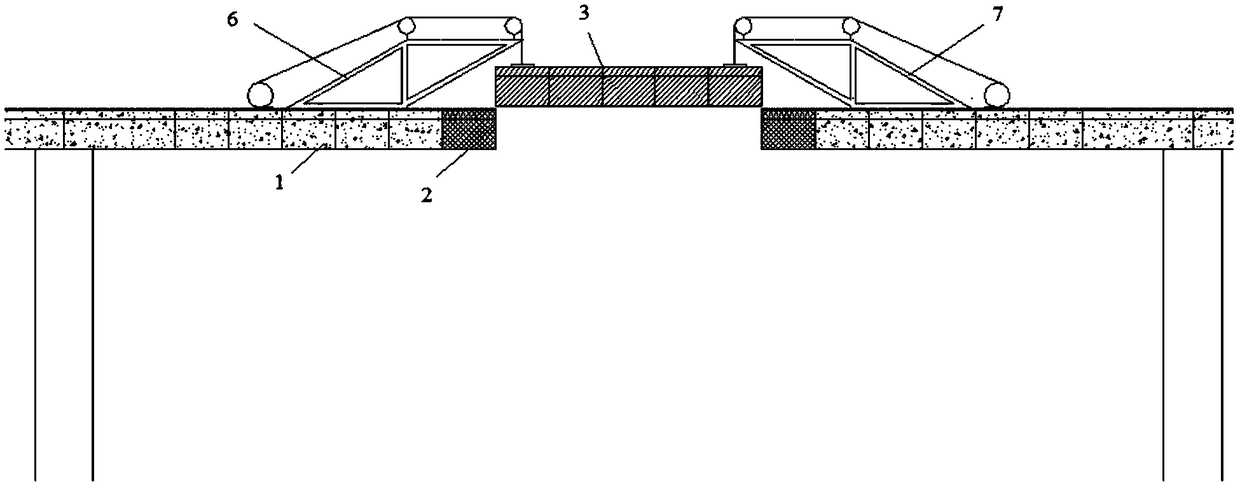

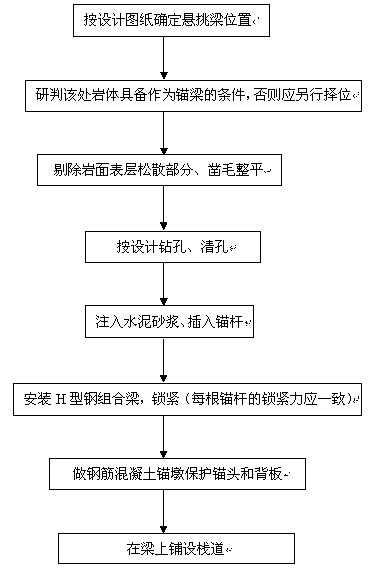

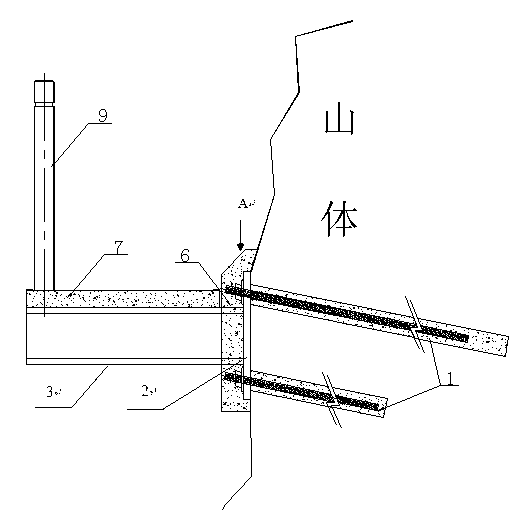

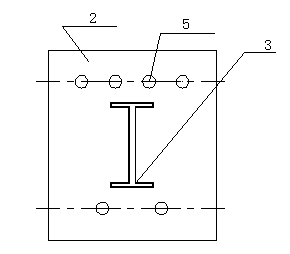

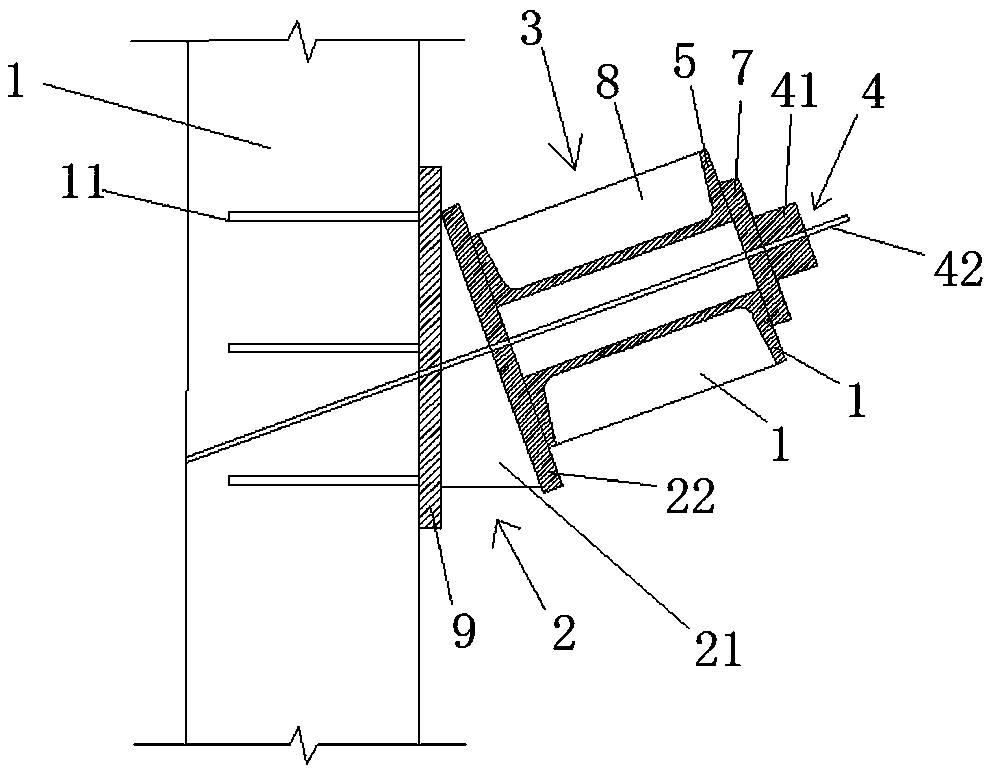

Cantilever beam structure of antique plank road along cliff and construction technology thereof

The invention discloses a cantilever beam structure of an antique plank road along a cliff and a construction technology thereof. The cantilever beam structure is formed by an H-type steel assembly, and a rock bolt assembly fixedly anchored on the rock wall of a mountain in a combining way, wherein the H-type steel assembly is formed by the combination of a steel backing plate (2) and H-type steel (3); the H-type steel (3) is welded on the steel backing plate (2) vertically and serves as the supporting beam of a road panel (7) of the antique plank road along the cliff; the rock bolt assembly is formed by the connection of rock bolts (1), bolts and nuts; and the rock bolts (1) are welded with the bolts in a surfacing manner. The construction technology of the cantilever beam structure is as follows: ensuring the position of the cantilever beam according to the design graph paper; eliminating the weathering surface and fractured rock mass of the locating-point rock surface, and scabbling and leveling; ensuring the length of the rock bolts (1) and drilling holes in the rock bolts; filling cement mortar into the rock bolt holes and inserting the rock bolts (1) welded with anchor heads; mounting the H-type steel assembly on the rock bolts after the cement mortar is solidified to a degree of the designed strength; and fastening with bolts. The cantilever beam structure is safe and reliable in structure, simple and convenient in construction technology, quick in speed, low in engineering cost, and good in simulating of the style of the antique, and is suitable for application along the cliff.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

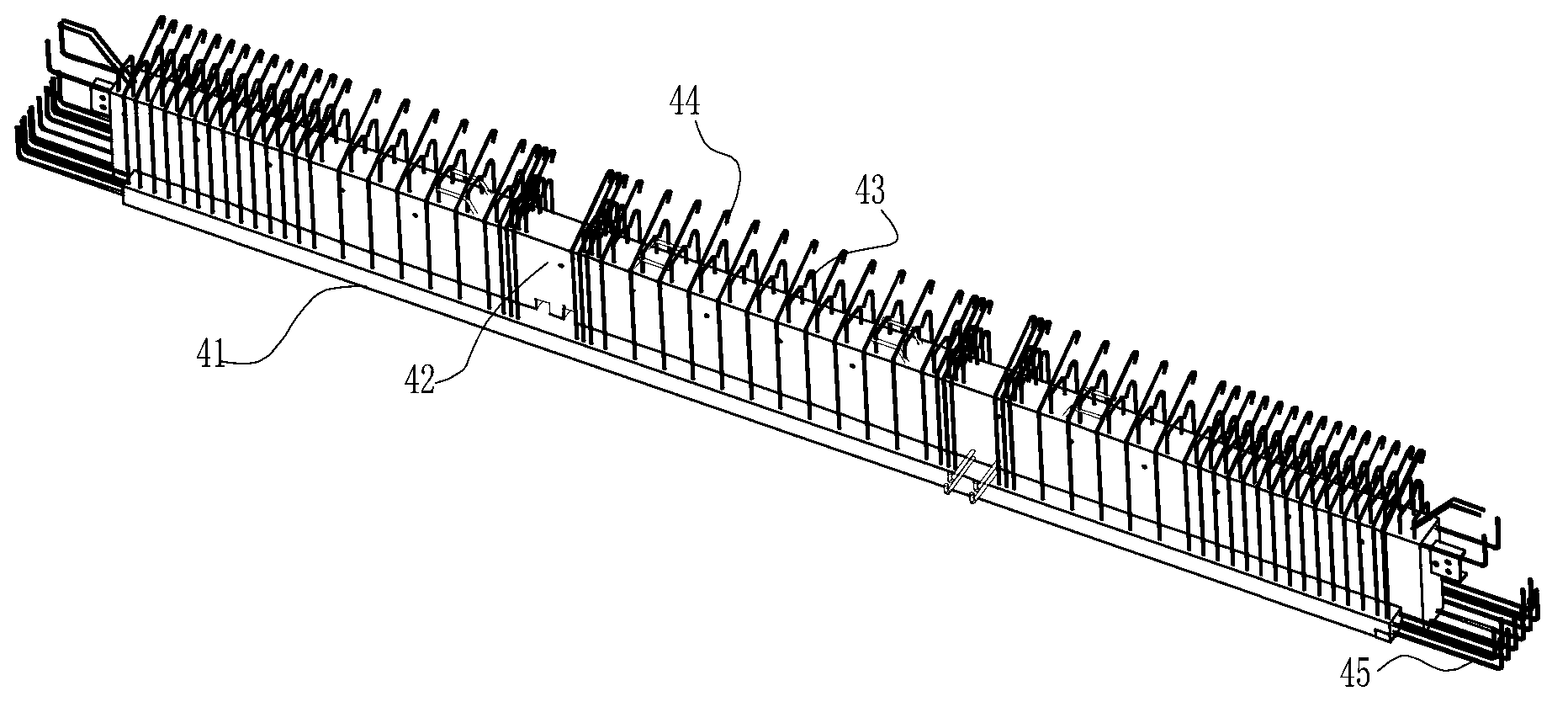

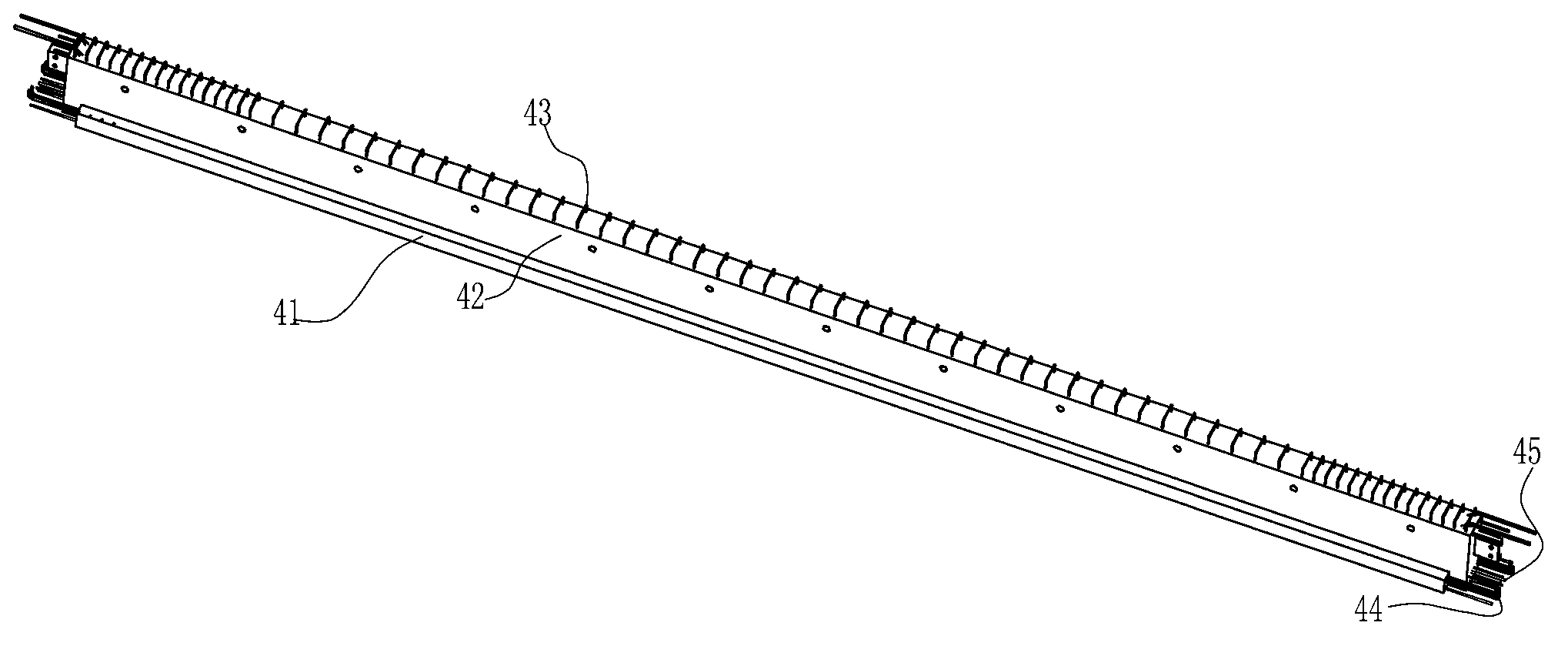

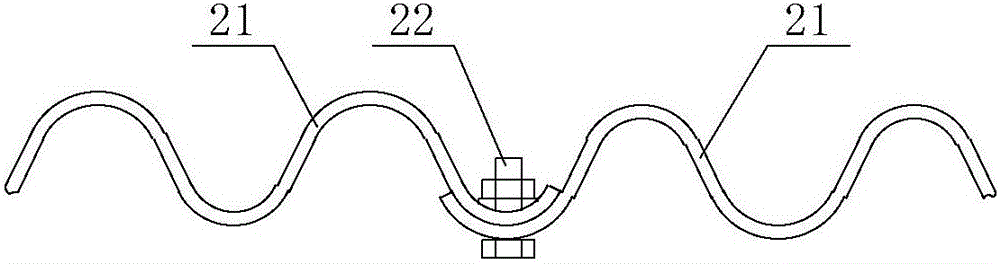

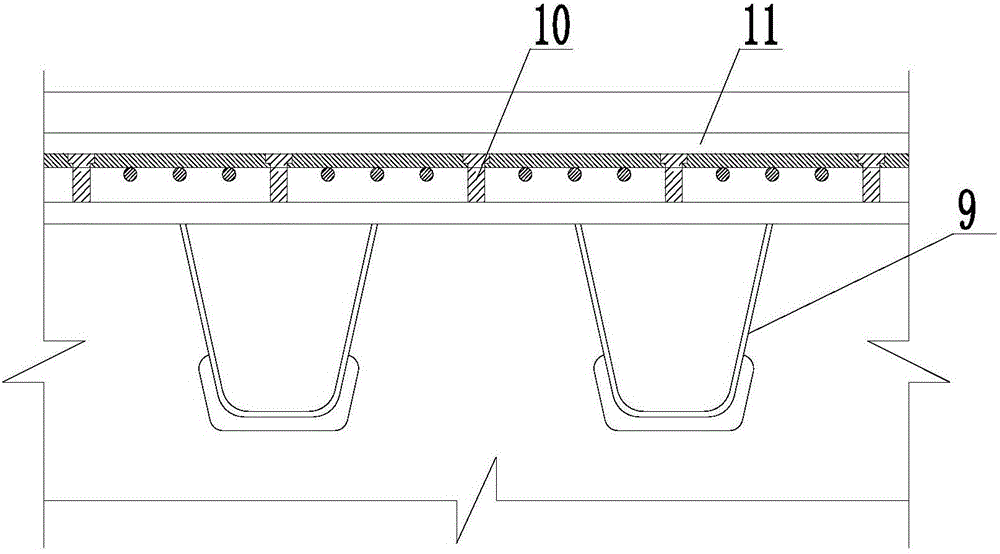

Profiled steel sheet-UHP (ultra high performance) fiber reinforced concrete composite bridge deck

InactiveCN104674657ATake advantage of the tensile strengthReduce in quantityBridge structural detailsBridge materialsBridge deckRebar

A profiled steel sheet-UHP (ultra high performance) fiber reinforced concrete composite bridge deck comprises U-shaped profiled steel sheets, perforated steel sheets, vertical studs, horizontal reinforcements, longitudinal reinforcements and UHP fiber reinforced concrete. The vertical perforated steel sheets are longitudinally fixed in the centers of the grooves of the U-shaped profiled steel sheets. A plurality of fixed vertical stud rows are arranged on raised portions of the U-shaped profiled steel sheets. The horizontal reinforcements penetrate connecting holes in the perforated steel sheets and are welded with the upper ends of the vertical studs. The longitudinal reinforcements are perpendicular to the horizontal reinforcements and fixedly connected with joints of the horizontal reinforcements and the vertical studs. The UHP fiber reinforced concrete is poured in the U-shaped profiled steel sheets to cover the perforated steel sheets, the vertical studs and the horizontal and the longitudinal reinforcements. According to the arrangement, the adhesion performance of the interfaces of the profiled steel sheets and the UHP fiber reinforced concrete is improved, and mechanical advantages of the profiled steel sheets and the UHP fiber reinforced concrete are fully played. The profiled steel sheet-UHP fiber reinforced concrete composite bridge deck dead is low in weight, high in bearing capacity, excellent in anti-fatigue performance, available in industrialized production and on-field assemble, higher in bridge deck building and changing speed and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY

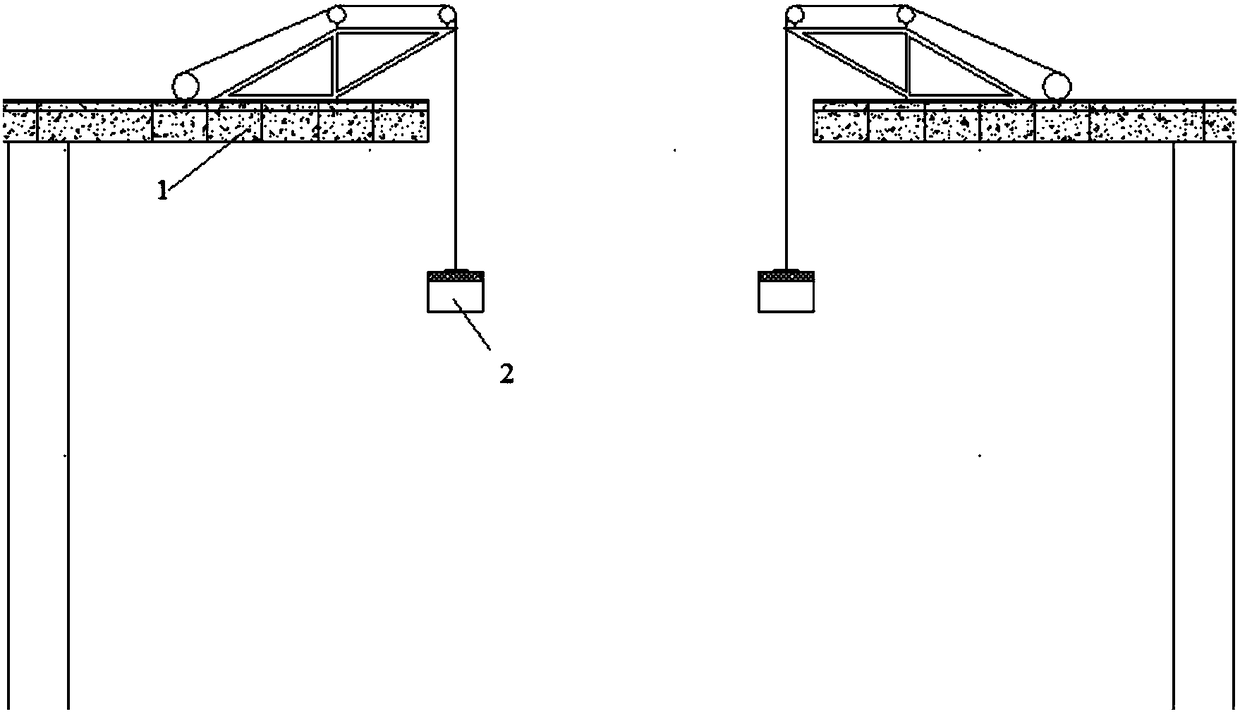

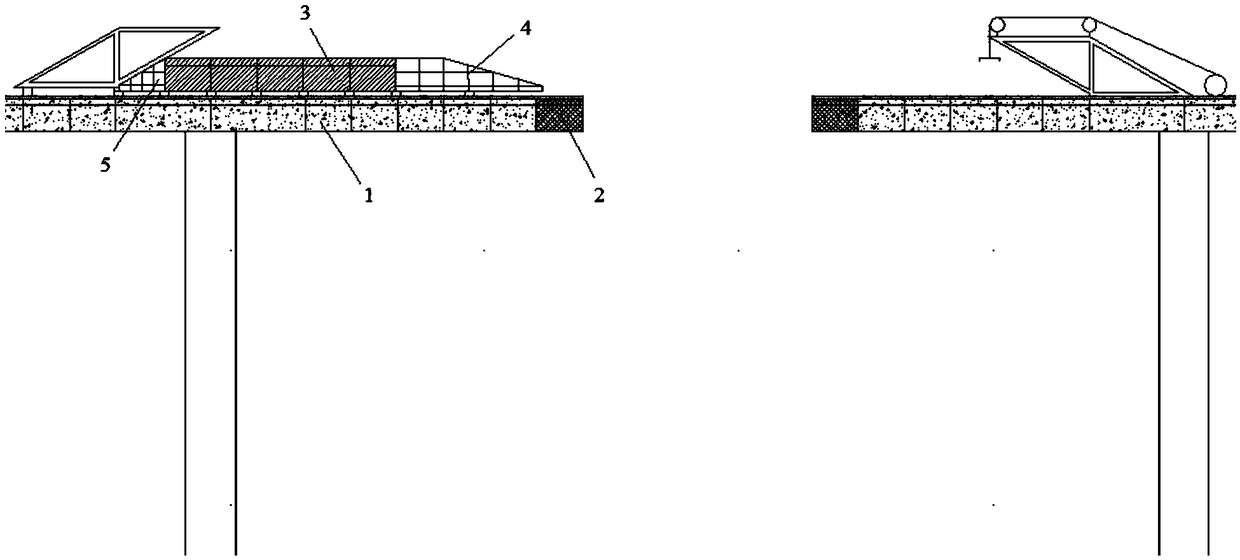

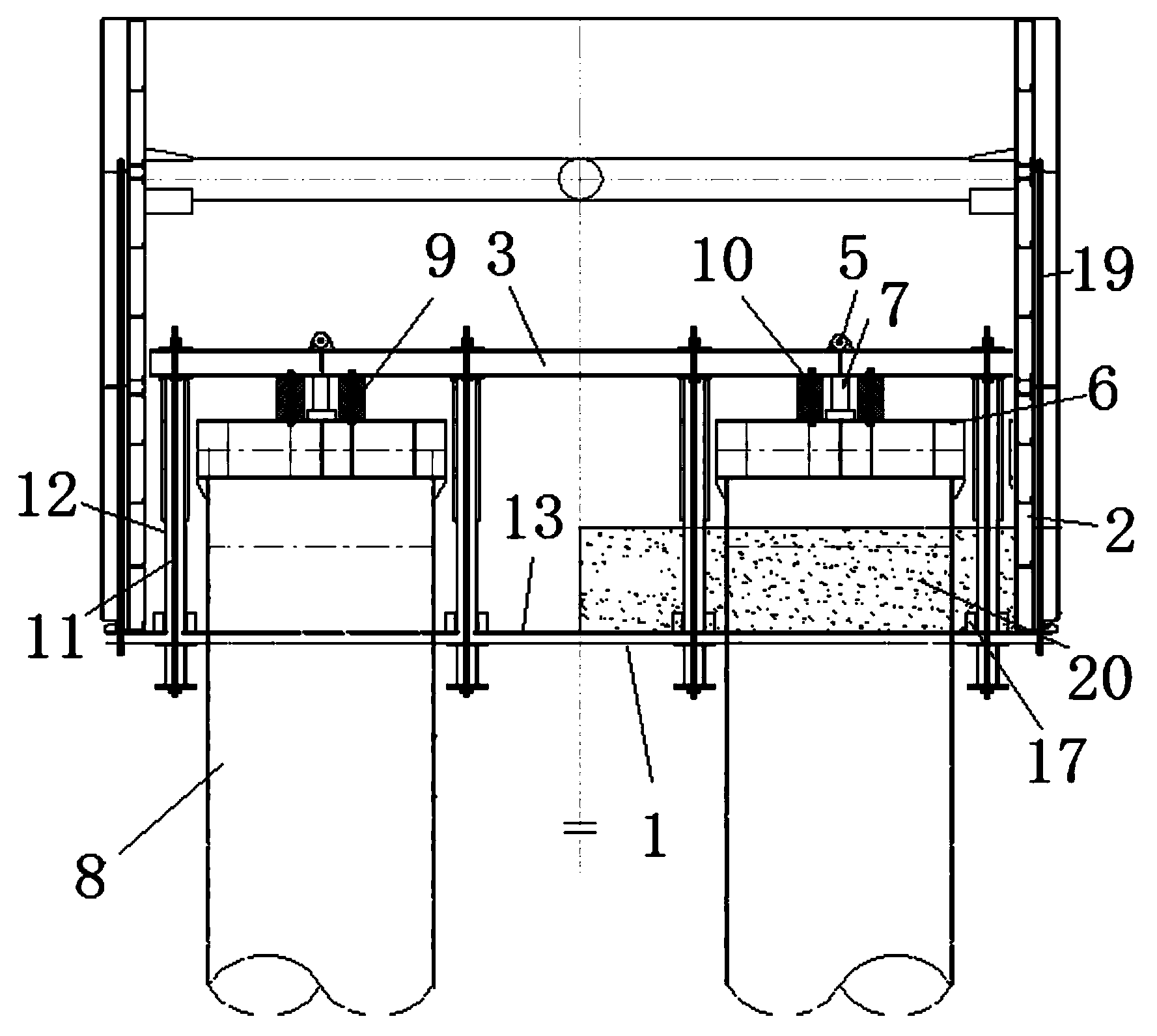

Light combined hanging box with recyclable baseplate steels and construction technology thereof

The invention discloses a light combined hanging box with recyclable baseplate steels. The light combined hanging box comprises a baseplate, four wall bodies, an outrigger, and lateral stable support beams which are connected between the outrigger and the wall bodies; wherein the four wall bodies are connected by a support frame; a lifting lug is arranged at the upper end face of outrigger; a jack placing beam is arranged under the outrigger; the outrigger is connected with the baseplate by a supporting column; a jack is arranged between the outrigger and the jack placing beam; the lower end of the jack placing beam is connected with the top end of a steel casing. The light combined hanging box has the following advantages: 1, the bearing abilities of bamboo plywood and bottom sealing concrete are fully used under a condition that a poor sea state of open seas is overcome, the turning of the baseplate steels is effectively realized, and the steel consumption is greatly reduced; 2, the structure is light; for the hanging box of the same specification, the lifting weight of the combined baseplate hanging box is similar to the self weight of a traditional steel baseplate hanging box, so that relative to the concrete prefabricated baseplate steel hanging box, the rated load weight and the lifting difficulty of a floating crane are effectively reduced.

Owner:CCCC SHEC FOURTH ENG +1

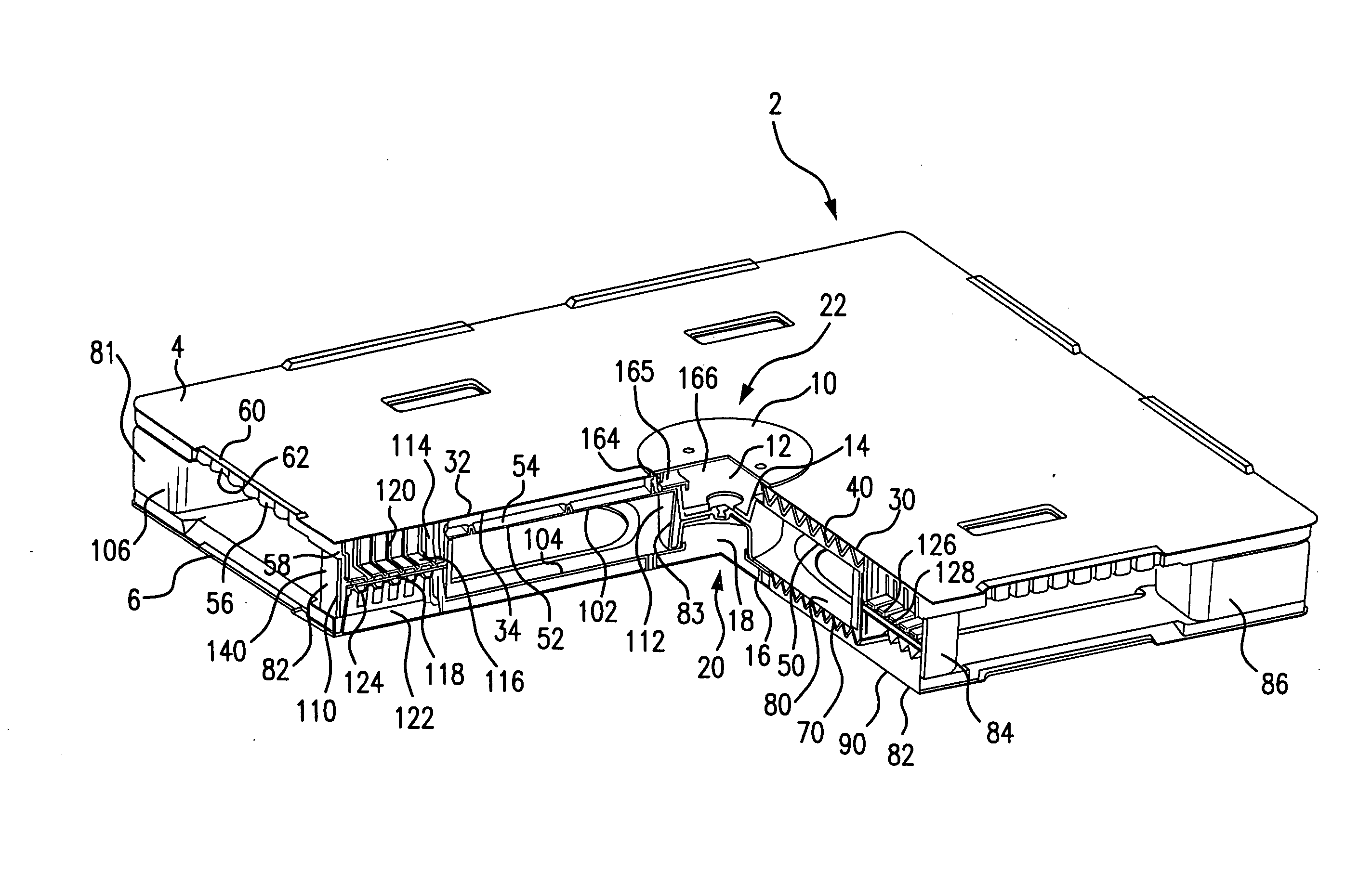

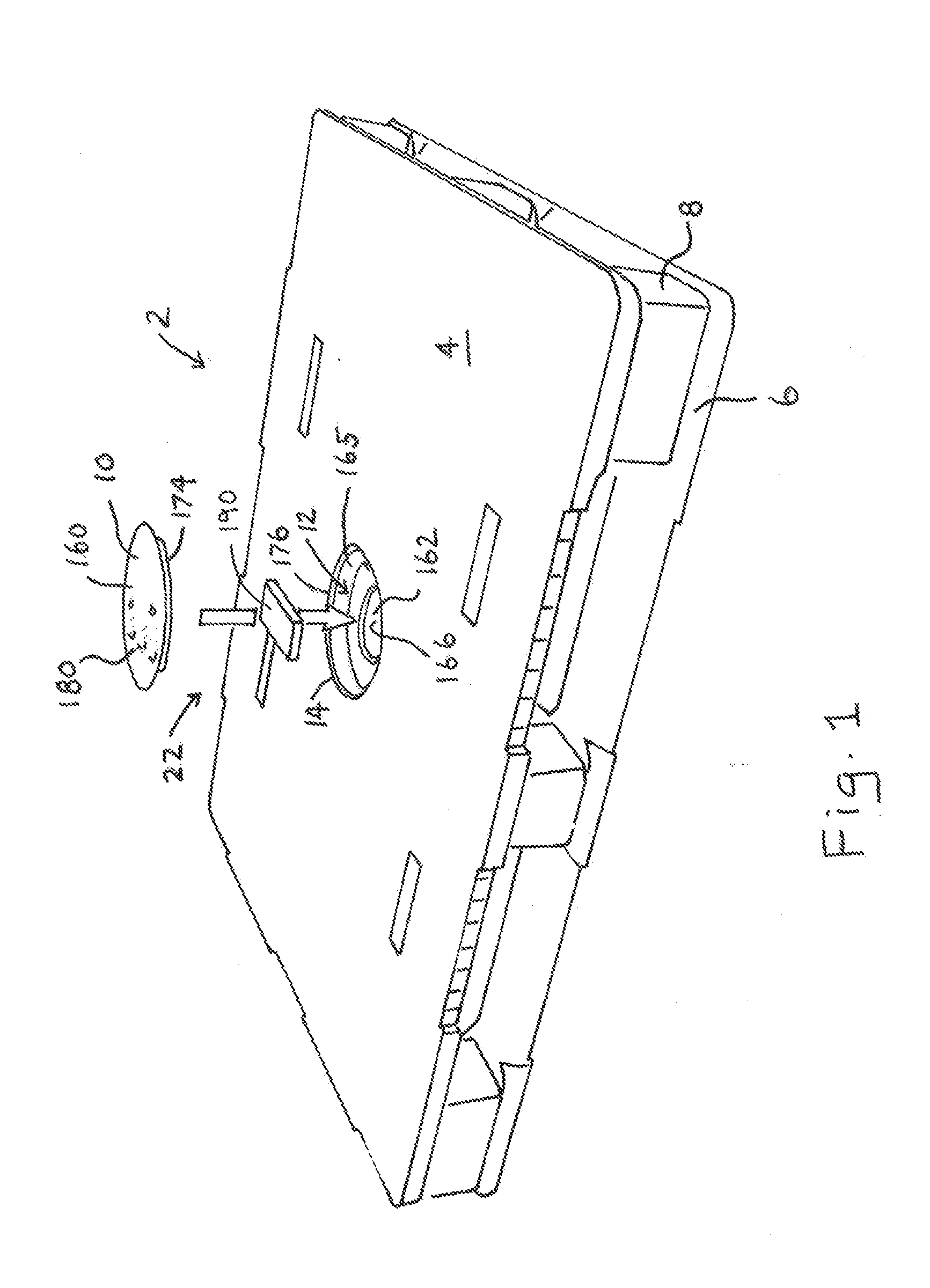

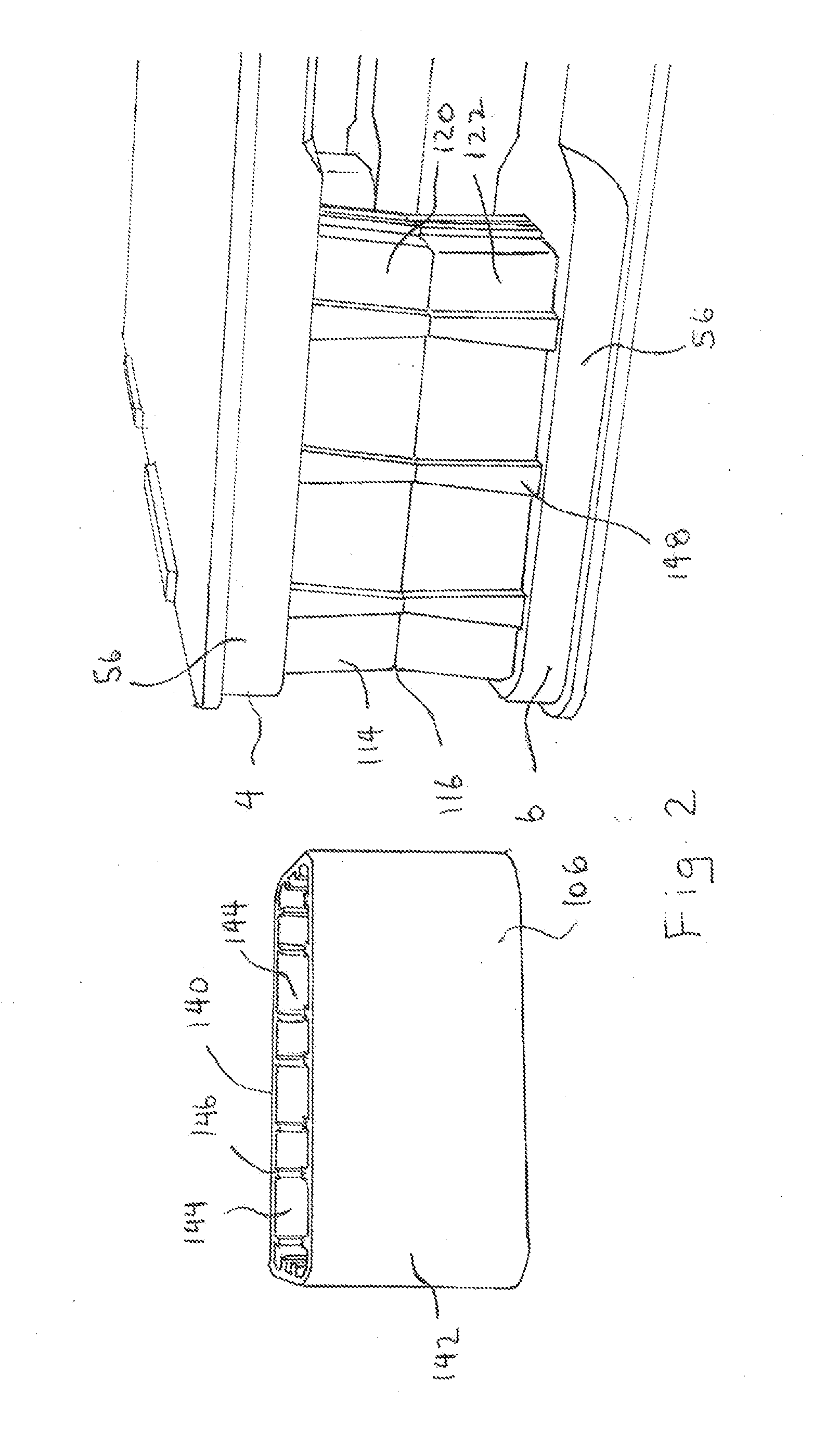

Pallet with impact guards

InactiveUS20160114936A1Low costLight weight structureContainer decorationsLevel indicationsPallet jackInterior space

A pallet structure that resists damage sustained by prior art pallets in pooled pallet distribution is disclosed. The pallet comprises a deck and a base separated by opposed block structures spaced to accommodate fork tines, pallet jacks and other pallet moving equipment. The block structures are inset from the boundary established by the outer dimensions of the pallet. Impact guards are provided to protect the block structures against impacts that could pierce the walls of the block structures allowing foreign materials to enter an interior space of the deck, base or block structure. The impact guards surround the block structures preventing impacts from all sides. The exterior surfaces of the impact guards, at the four pallet corners, form a continuous vertical wall which extends from the top of the deck to bottom of the base. Other new and useful improvements and advancements are described.

Owner:NEXTREME

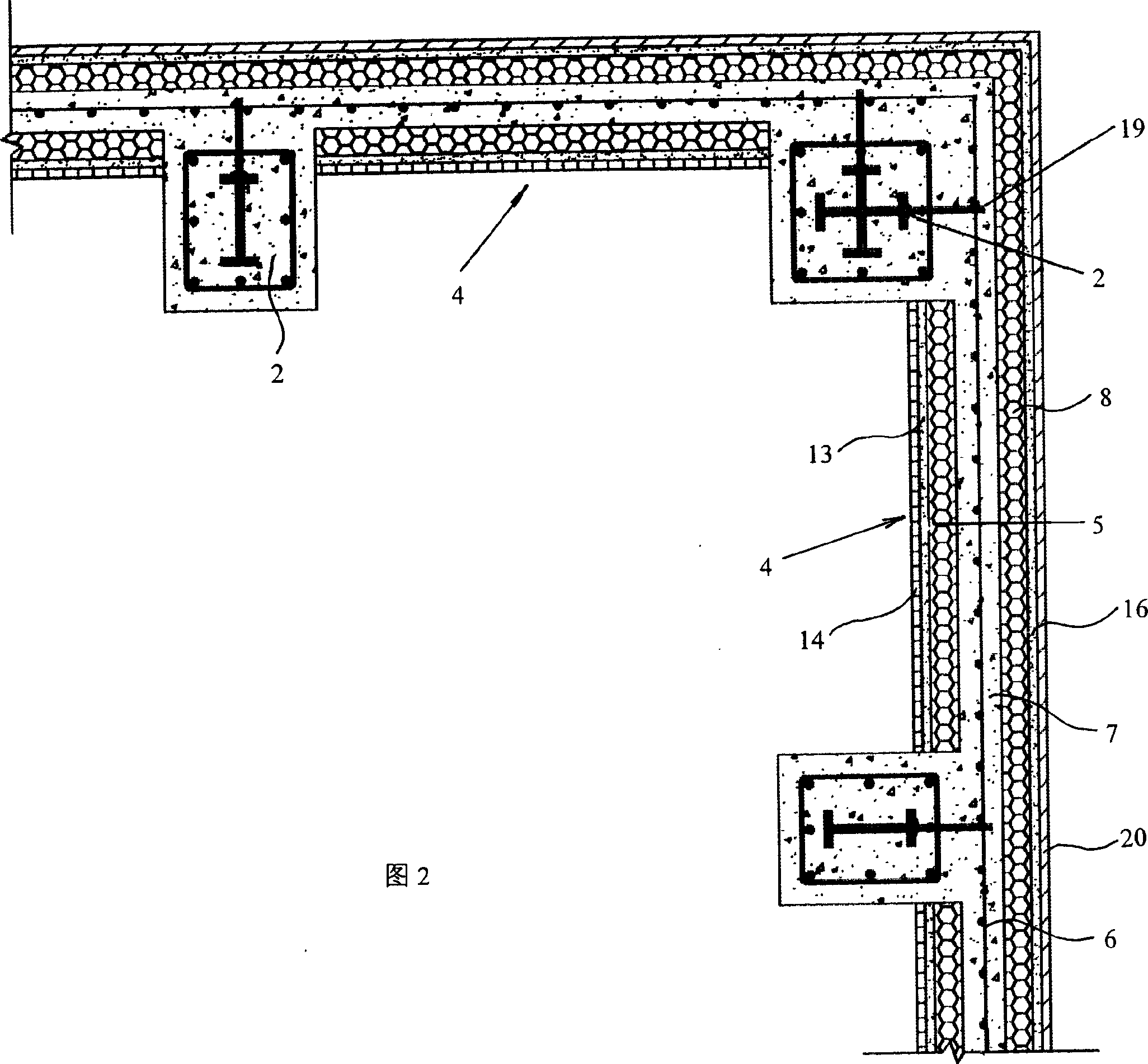

Steel-concrete combined building structure and its construction method

InactiveCN1460756AReduce the weight of the structureLighten the loadWallsFloorsRebarBuilding material

The present invention relates to a steel-concrete composite building structure and its construction method. The structure includes the bearing member and building exterior-protected construction, the bearing member includes several bearing vertical columns which are spaced and arranged and several layers of floor members which are spaced and arranged, and the building exterior-protected construction includes non-bearing wall panel and several hanging components fixed on the floor member, and the non-bearing wall panel includes the rebar welding net fixed on the hanging component, it also includes internal heat-insulating plate and external heat-insulating plate and internal surface crack-resisting protecting layer and external surface crack-resisting protecting layer.

Owner:张英保

Ultra-high performance concrete and ordinary reinforcement concrete combined beam

PendingCN108118610AReduce the height of the structureLight weight structureBridge structural detailsBridge materialsReinforced concreteRebar

The invention relates to the technical field of structure design, and particularly relates to an ultra-high performance concrete and ordinary reinforcement concrete combined beam. The ultra-high performance concrete and ordinary reinforcement concrete combined beam comprises a UHPC prefabricated main beam and a post-cast ordinary reinforced concrete bridge panel; the ultra-high performance concrete and ordinary reinforcement concrete combined beam is characterized in that the UHPC main beam is prefabricated in early period, and the top part of the UHPC main beam is provided with a hear force connector in advance; the UHPC main beam is erected in place and then used as a construction platform; the top edge of the UHPC main beam is provided with a reinforcement mesh piece post-cast ordinaryconcrete; through combination of the shear force connector at the top of the UHPC prefabricated beam, the combined beam is formed. The combined beam is light in member, simple in transportation and hoisting, convenient to construct, good in economic efficiency, and able to fully display the material stress performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

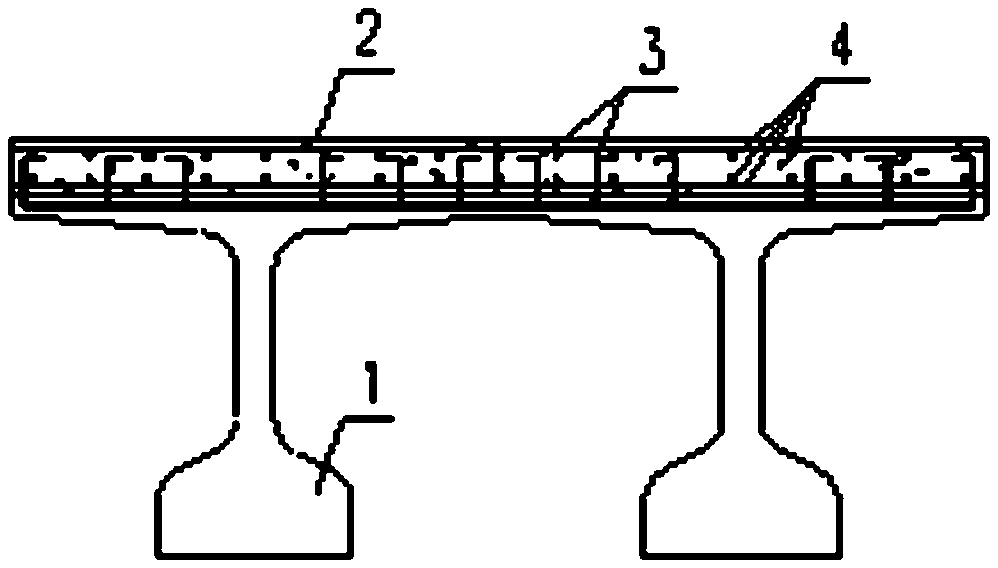

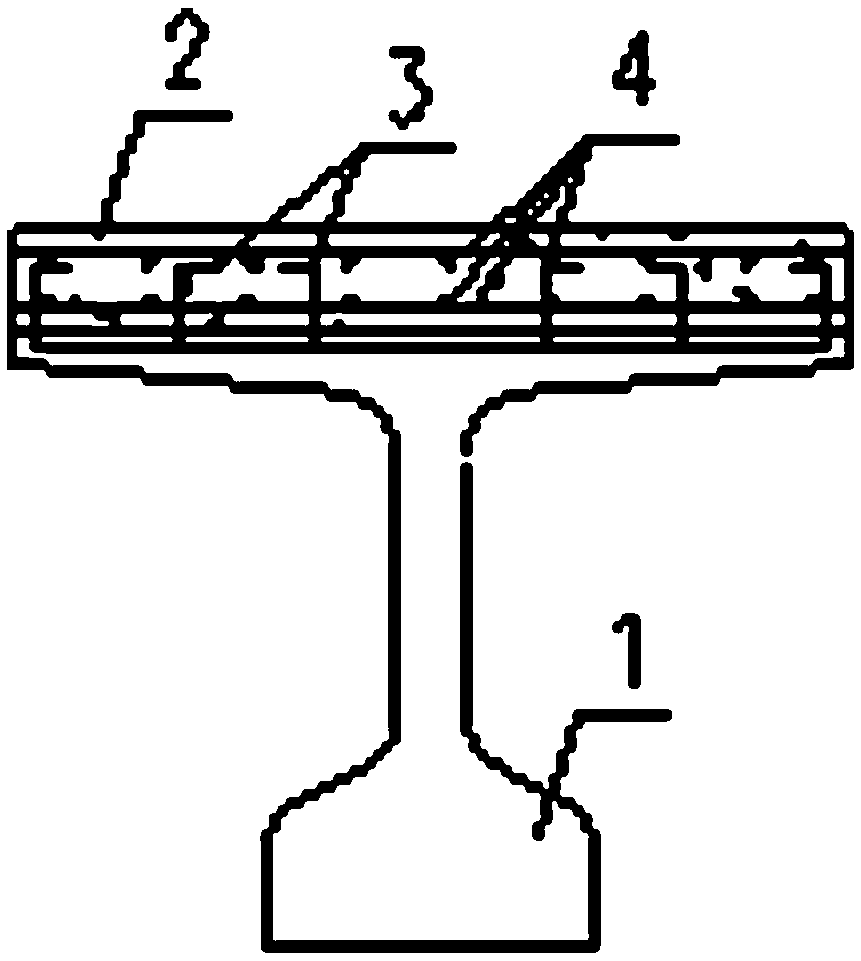

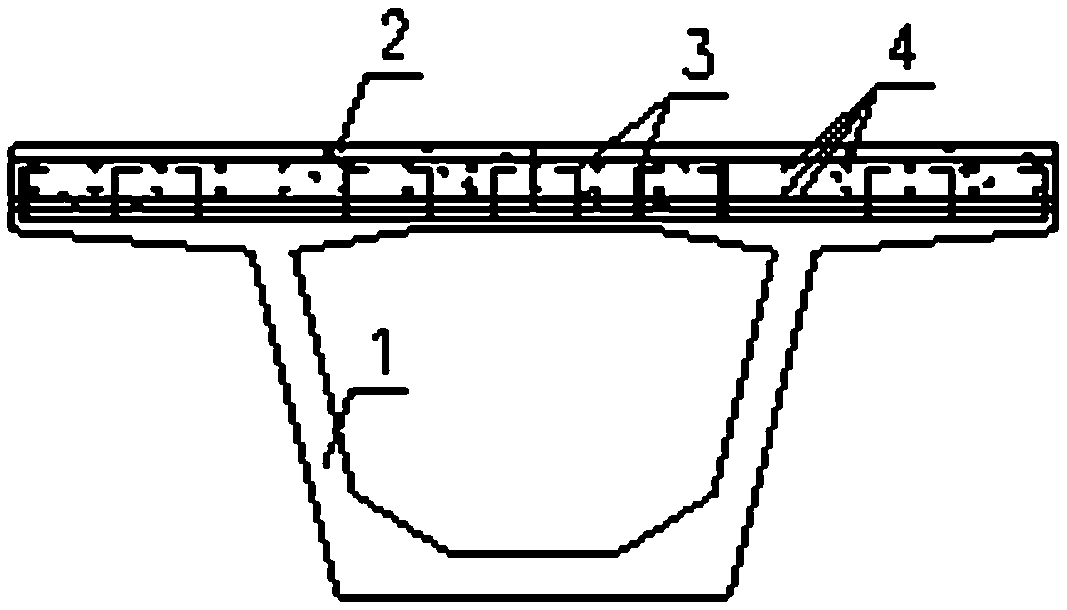

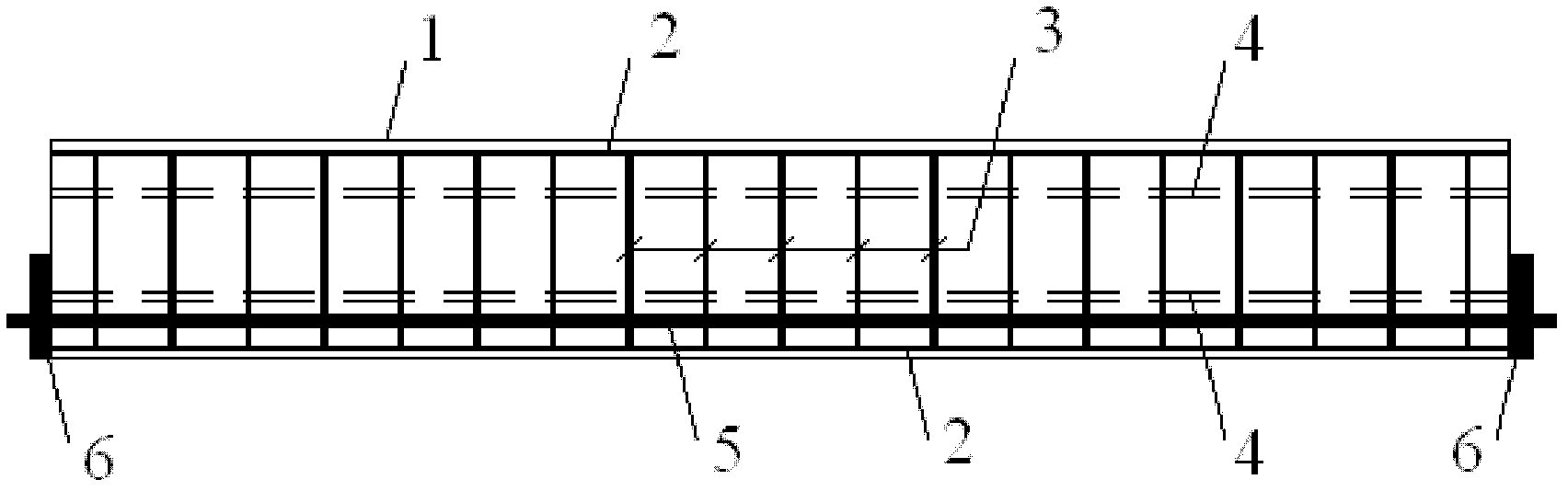

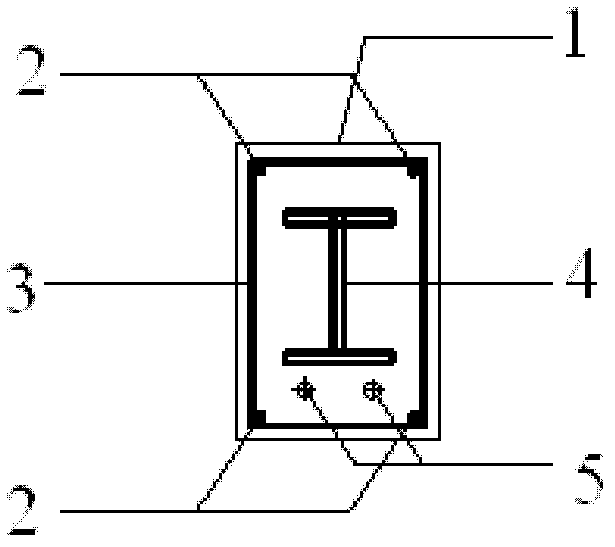

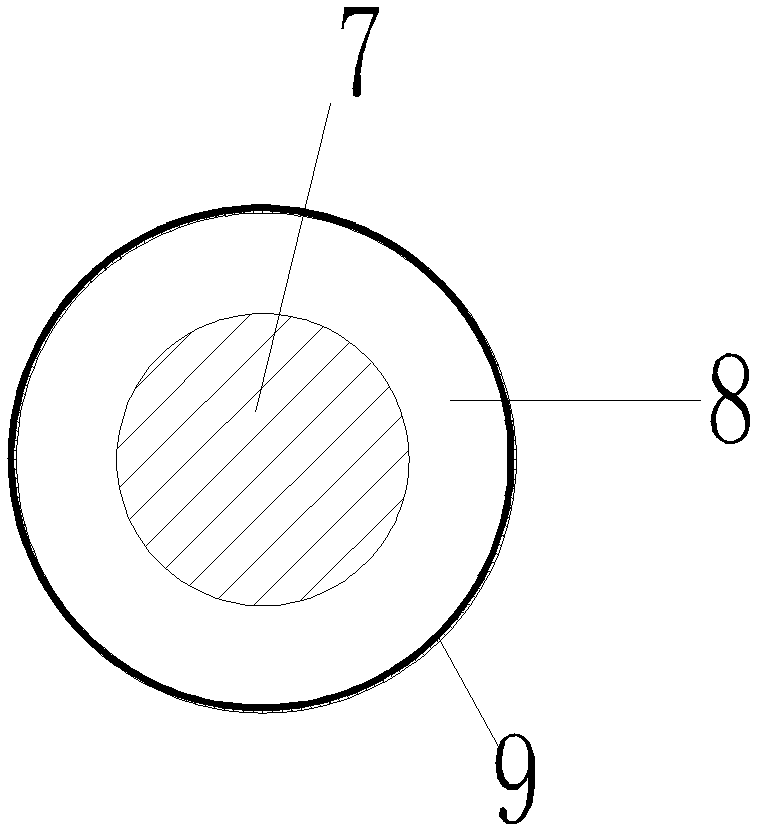

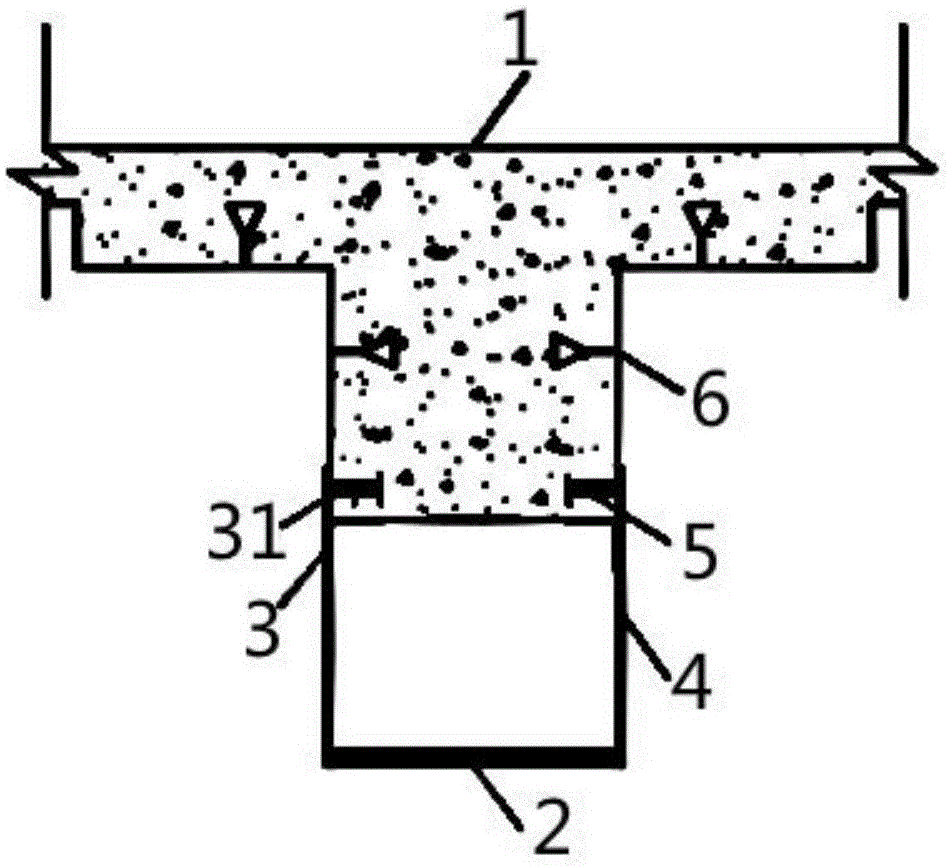

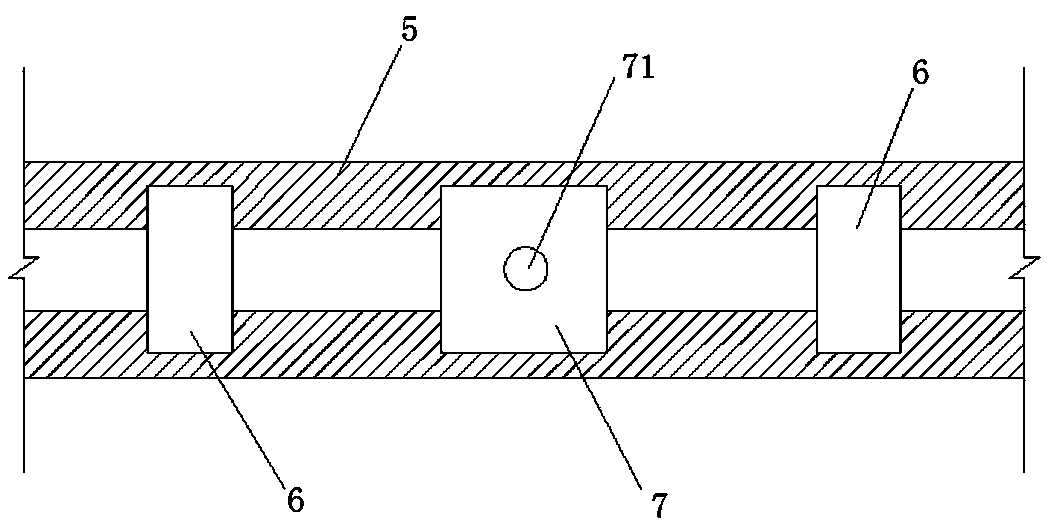

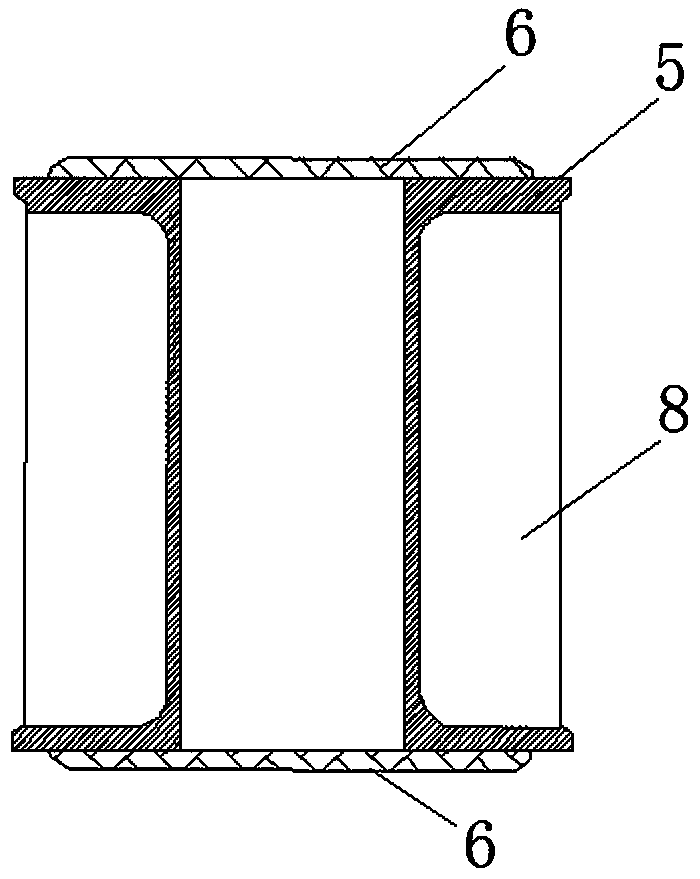

Retarded adhesive prestressed steel reinforced concrete beam

InactiveCN102561591ALight weight structureEasy constructionLoad-supporting elementsConcrete beamsAdhesive

The invention relates to a steel reinforced concrete beam which belongs to the field of civil engineering. A retarded adhesive prestressed steel reinforced concrete beam comprises a concrete beam (1), wherein non-prestressed reinforcing steels (2) are arranged in the concrete beam (1), and stirrups (3) are bound and installed outside the non-prestressed reinforcing steels (2). The retarded adhesive prestressed steel reinforced concrete beam is characterized in that: an H-shaped steel (4) is arranged in the non-prestressed reinforcing steels (2) of the concrete beam (1); retarded adhesive prestressed reinforcing steels (5) penetrate through the concrete beam (1) to be arranged at the lower side of the H-shaped steel (4); and retarded coagulation mortar (8) is coated outside prestressed reinforcing steels (7) and is then coated by a waterproof plastic cloth (9) into a round bar shape, so as to form the retarded adhesive prestressed reinforcing steels (5). The retarded adhesive prestressed steel reinforced concrete beam has the characteristics of light structure self-weight, convenience in construction, high speed, high bending-resistant ultimate bearing capacity, good use performance and good economy and applicability.

Owner:TONGJI UNIV +1

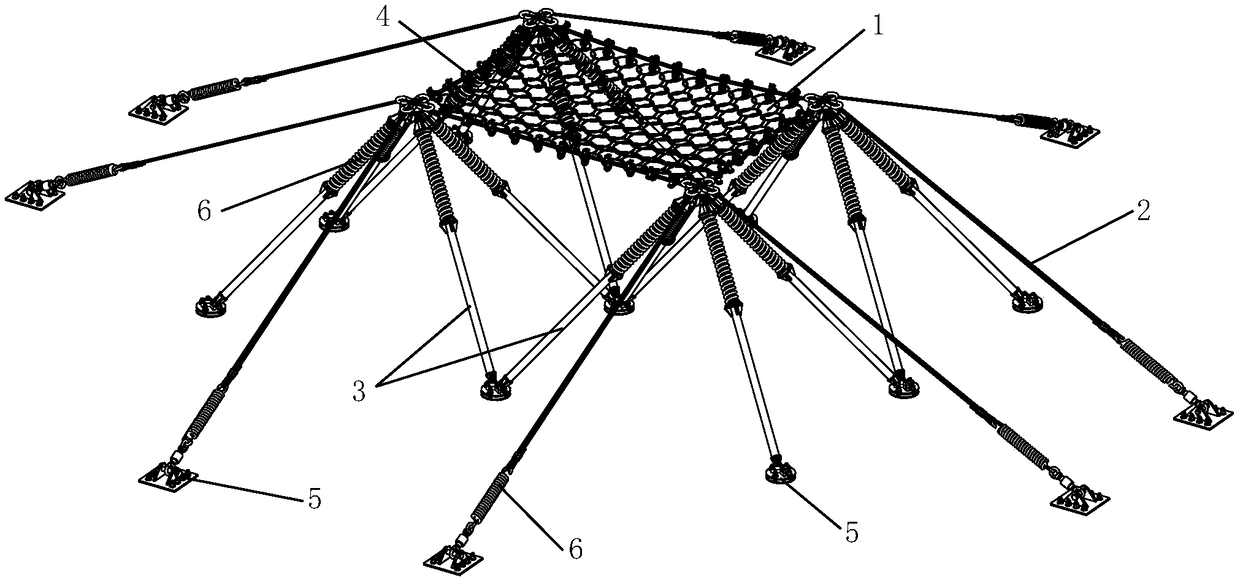

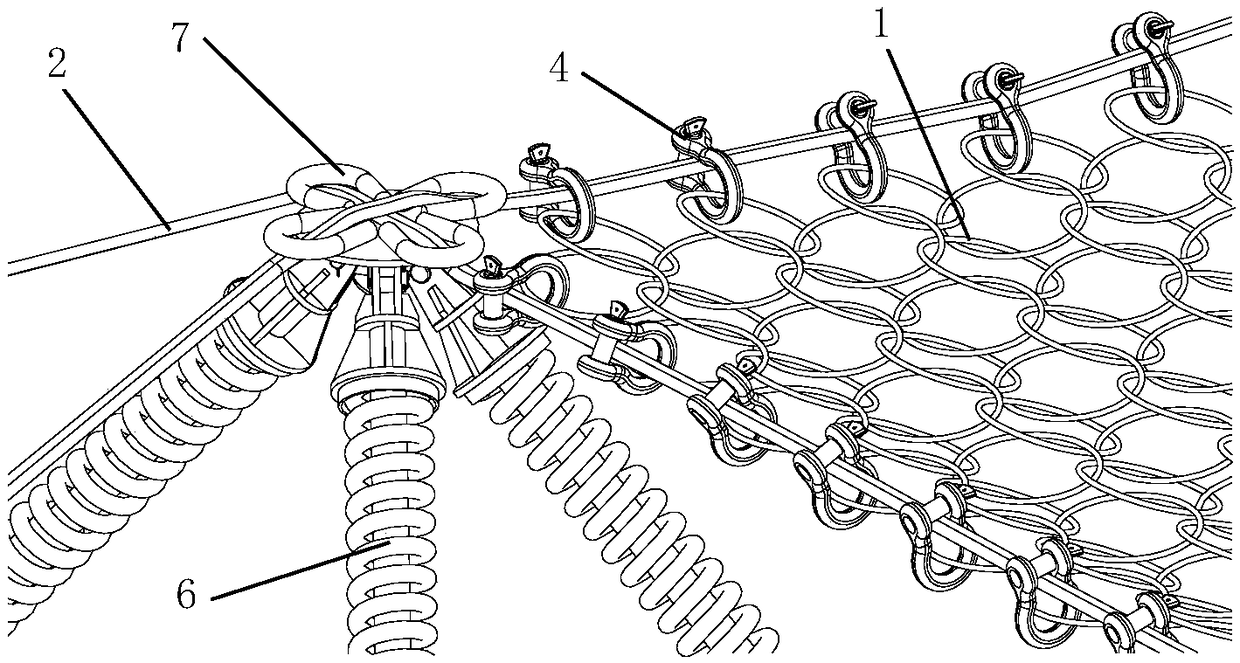

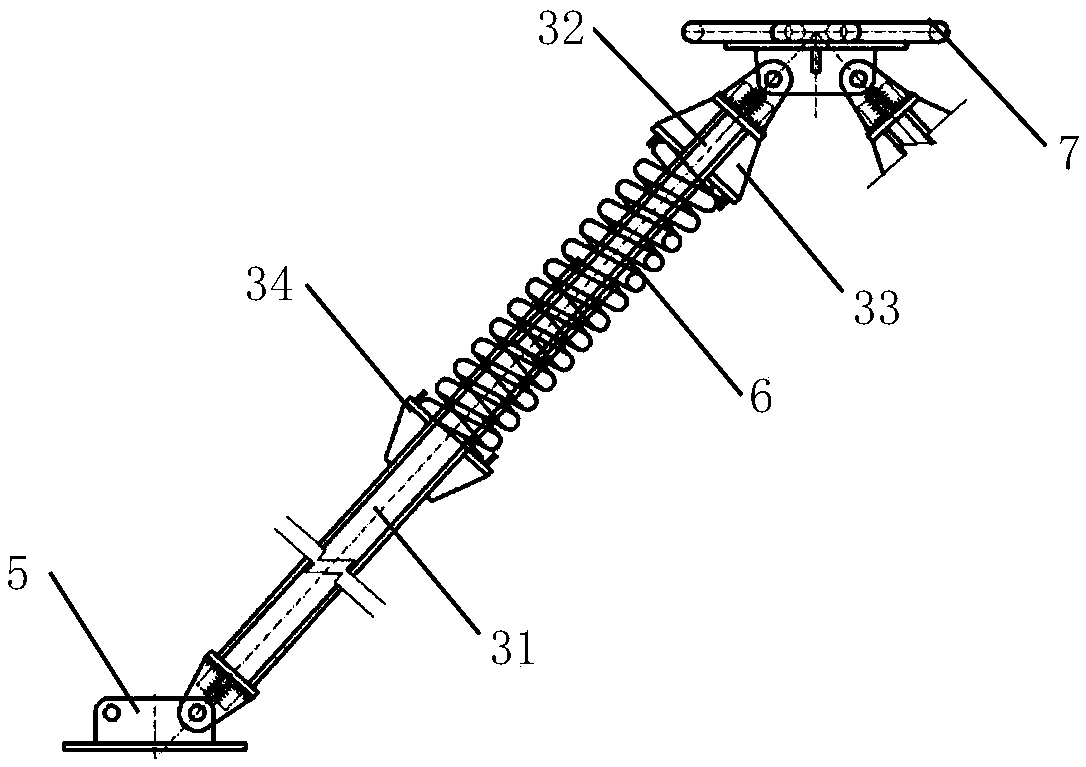

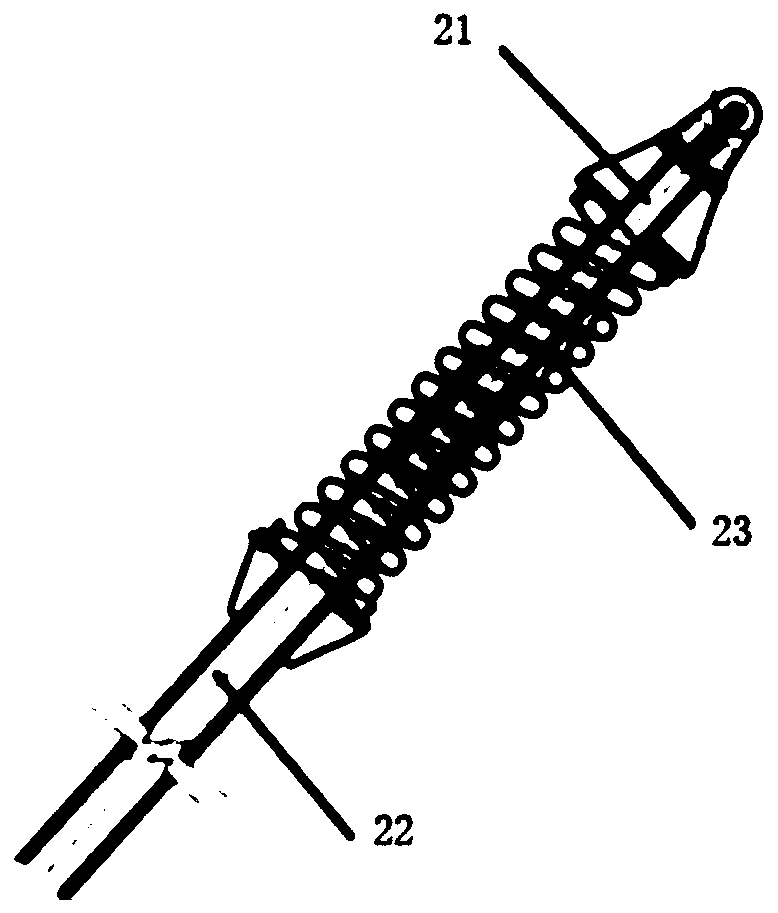

Point-supporting self-recovering flexible buffering structure adopting piston rods for hangar tunnel project

ActiveCN109487712AIncrease buffer deformation capacityIncrease buffer isolation spaceProtective constructionReinforced concreteCoil spring

The invention provides a point-supporting self-recovering flexible buffering structure adopting piston rods for a hangar tunnel project. The structure comprises an intercepting screen used for intercepting falling stones, supporting ropes used for supporting the intercepting screen, the piston rods, spiral springs connected to the supporting ropes and the piston rods and connecting pieces tying the intercepting screen to the supporting ropes. Compared with existing buffering cushion layers of gravels, rubber tyres and the like, the flexible buffering structure is wider in application range andmore flexible in structure arrangement and can be used by respectively combining rebar concrete hangar tunnels of different types with steel-structure hanger tunnels of different types. The flexiblebuffering structure has self-recovering performance, after impacting of the falling stones, the falling stones can be thrown outward, and accumulating of the falling stones is avoided; self-cleaning for the falling stones is achieved, and later maintenance cost is reduced. The flexible buffering structure is spliced by several prefabricated steel structure members on site, is light in weight and convenient to install and dismantle, can greatly reduce the born weight of hangar tunnels, sizes of members of the hangar tunnels and the embedded depth of the foundation, and is better in economical efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

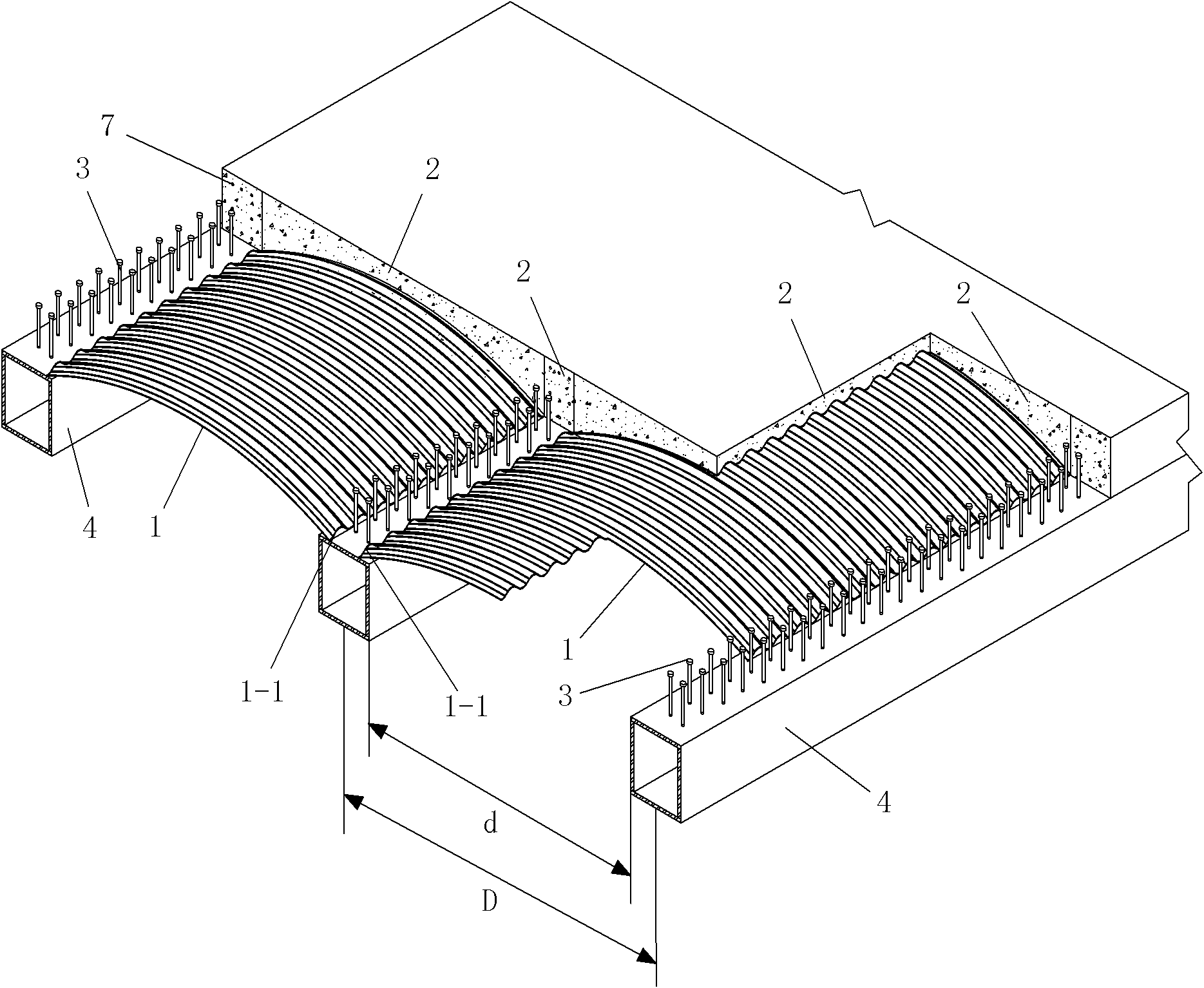

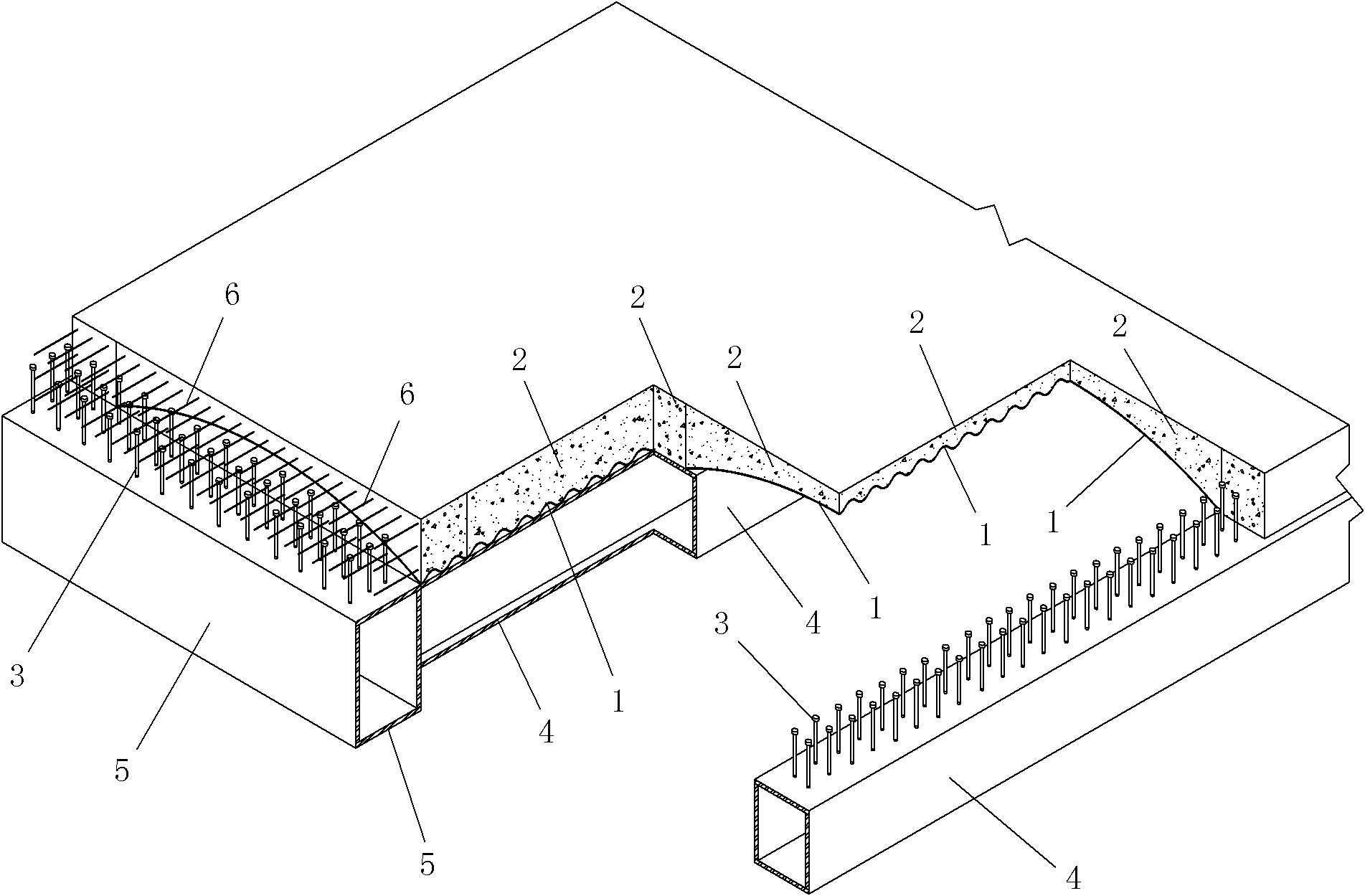

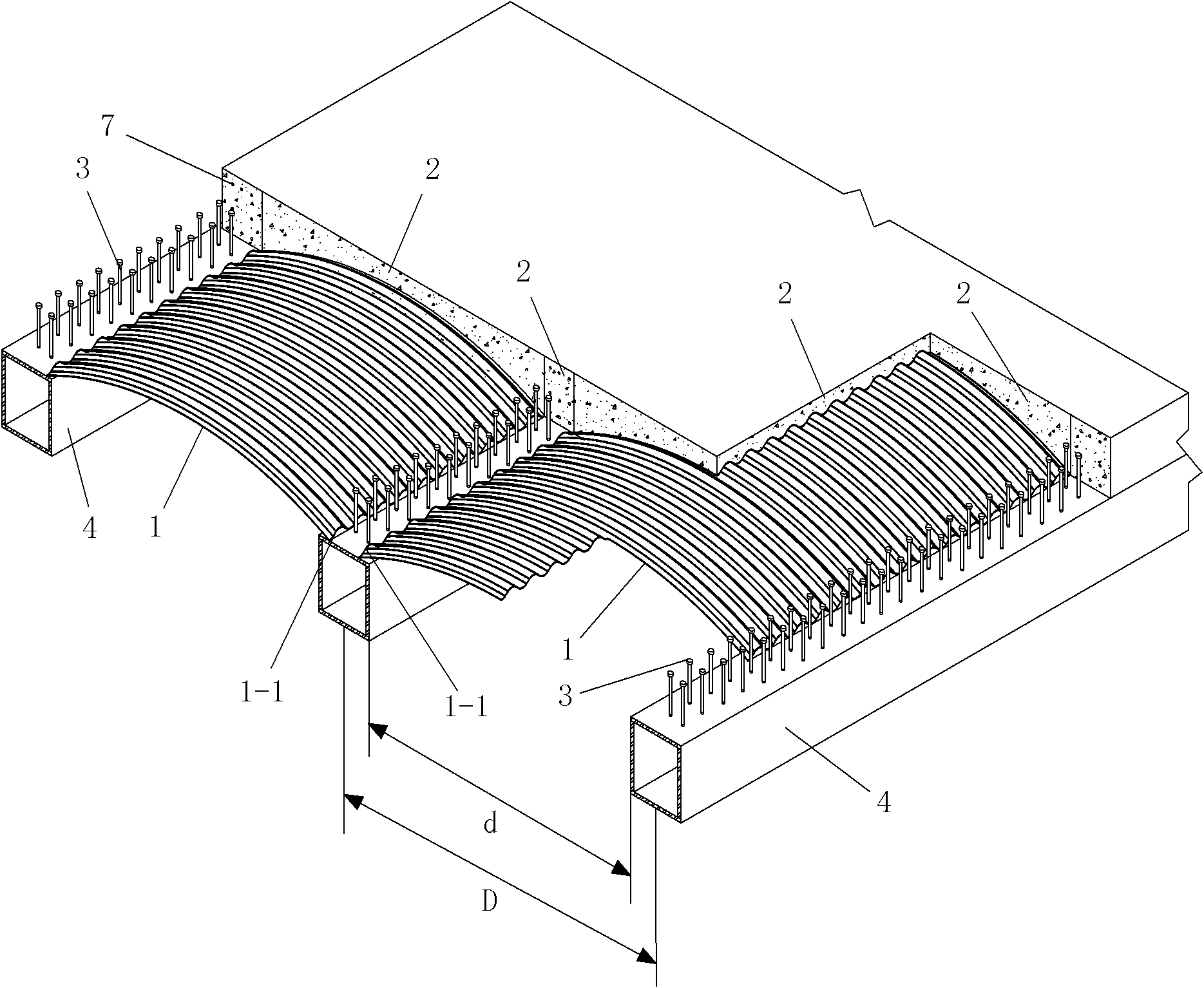

Combined bridge deck of arched corrugated steel plates and concrete

InactiveCN102121227AIncreased bending stiffnessImprove adhesionBridge structural detailsBridge materialsBridge deckStructural engineering

The invention discloses a combined bridge deck of arched corrugated steel plates and concrete, and the combined bridge deck comprises a bridge deck substrate consisting of a plurality of rows of arched corrugated steel plates arranged in parallel, a bridge deck bottom supporting structure for supporting and fixing the bridge deck substrate, and a concrete top layer formed on the bridge deck substrate in a pouring manner; the bridge deck bottom supporting structure is formed by assembling a plurality of beams which comprise a plurality of rows of lower vertical beams arranged in parallel and a plurality of lines of lower beams arranged in parallel; each row of arched corrugated steel plates are all fastened between two rows of lower vertical beams; arch springings on the left and right of the corrugated steel plates are fixedly arranged on the two adjacent rows of lower vertical beams respectively; the corrugation of each corrugated steel plate is in the transverse direction; and the rows of lower vertical beams and the rows of corrugated steel plates form a formed bottom template for pouring the formed concrete top layer. The combined bridge deck of arched corrugated steel plates and concrete is simple in structure, convenient to manufacture and construct and good in structural mechanical property, and can be used for effectively solving the problems existing in the existing bridge deck structure.

Owner:CHANGAN UNIV +1

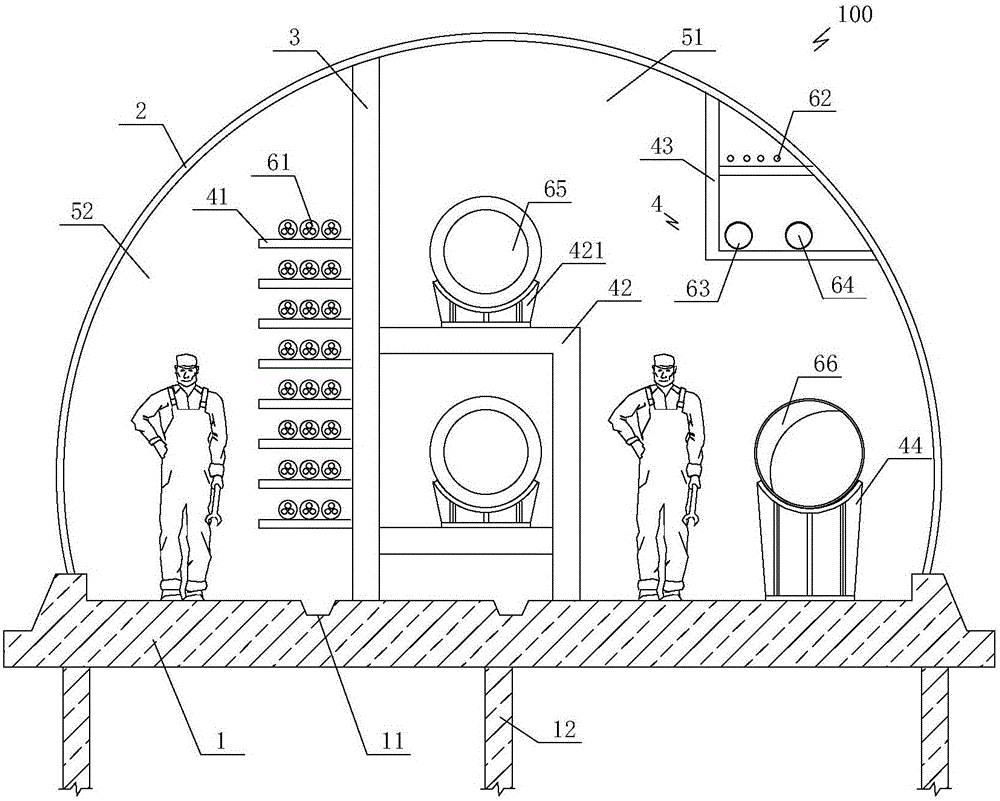

Corrugated steel plate city underground comprehensive pipe gallery with arch-shaped cross section

InactiveCN106013235AReduce the weight of the structureReduce shipping costsArtificial islandsUnderwater structuresSteel platesUnderground pipeline

The invention provides a corrugated steel plate city underground comprehensive pipe gallery with an arch-shaped cross section. The corrugated steel plate city underground comprehensive pipe gallery with the arch-shaped cross section comprises a pipe gallery base structure which is arranged at the bottom. A pipe gallery main body which is composed by corrugated steel plates in an enclosed way is fixed above the pipe gallery base structure. The cross section of the pipe gallery main body is in an arch shape. An internal separating wall structure is arranged in the pipe gallery main body along the longitudinal direction of the pipe gallery main body. The interior of the pipe gallery main body is separated into a plurality of chambers which are separated from each other in a sealed way by the internal separating wall structure and a supporting frame structure used for erecting underground pipelines is arranged in each chamber. According to the city underground comprehensive pipe gallery, the problems that the prior art is heavy in weight, slow in construction speed, high in cost and the like can be overcome and the objective of light weight, fast construction speed and low cost can be realized; moreover, the inner space of the pipe gallery is separated into a plurality of chambers which are separated from each other in a sealed way by the internal separating wall structure which arranged in the pipe gallery main body and pipelines of water, heat and electric are laid in a partition way, so that laying and management of the pipelines are convenient and the safety can be improved at the same time.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Overhanging type self-recovery flexible protection shed hole

ActiveCN110241747ALow operating and maintenance costsImprove economyProtective constructionSelf recoveryEngineering

The invention provides an overhanging type self-recovery flexible protection shed hole suitable for high and steep side slope rockfall protection engineering. The overhanging type self-recovery flexible protection shed hole includes an annular net for intercepting rockfalls, a rigid supporting rod used for supporting the annular net, a piston rod, and a supporting rope, and further includes shackles for connecting the annular net and the supporting rope and springs connected to the supporting rope, and the supporting rope and the supporting rod are connected to a nearby steep mountain through an anchorage supporting seat. Compared with an existing traditional shed hole, the overhanging type self-recovery flexible protection shed hole is an overhanging structure which only needs to arrange the supporting seat on the road side mountain, suitable for the condition of steep mountain on one side, and is especially suitable for the condition of steep mountain on one side and not easy to arrange the reliable supporting seat on the other side; the overhanging type self-recovery flexible protection shed hole has the abilities of recovering and rockfall self-cleaning, and the operation and maintenance cost after putting into use is greatly reduced; and at the same time, the self-recovery flexible protection shed hole has the characteristics of being convenient to on-site assemble, light in dead weight, and good in economy.

Owner:SOUTHWEST JIAOTONG UNIV

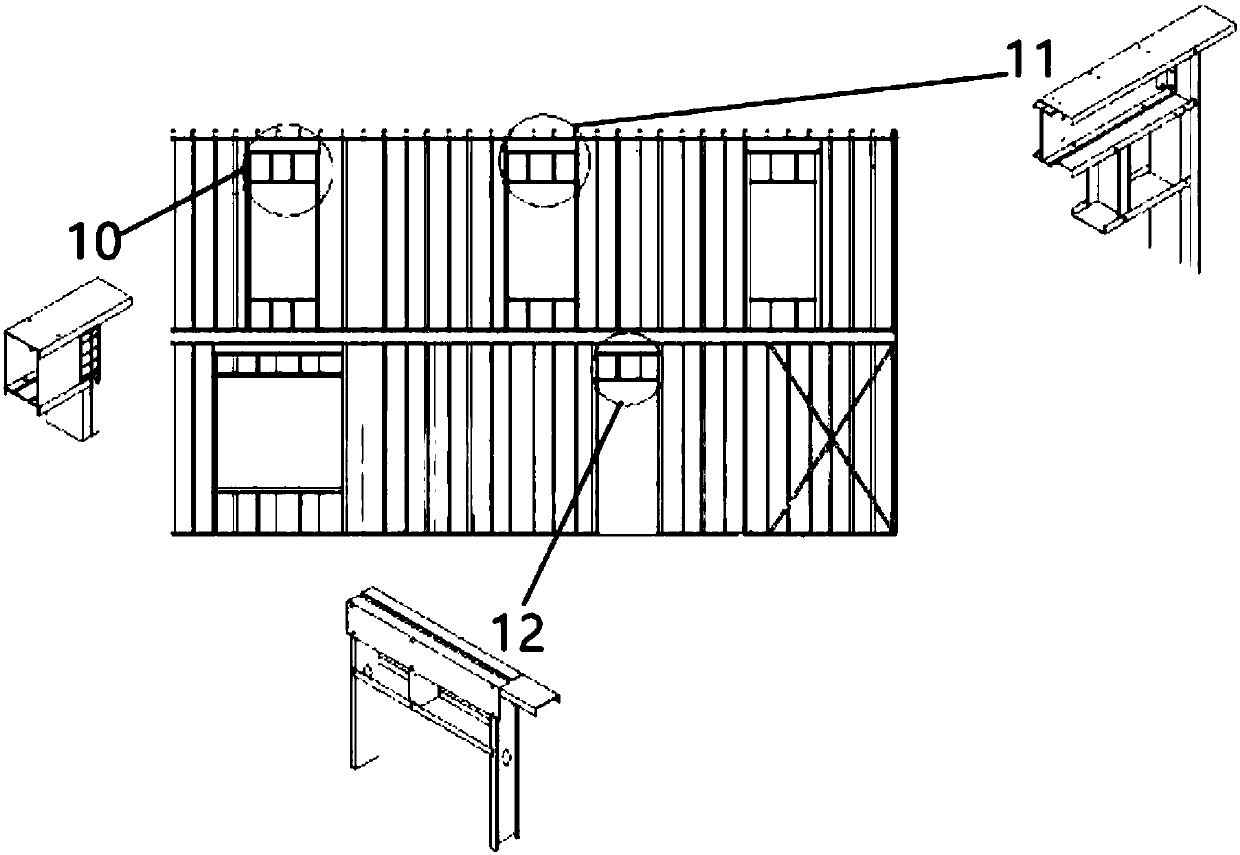

Steel pipe bundle and steel plate concrete combined shear wall structure system

The invention discloses a steel pipe bundle and steel plate concrete combined shear wall structure system formed by connecting steel plate concrete combined shear walls, steel pipe bundle combined structures, and H-shaped steel beams or box-shaped beams or short steel pipe bundle combined structures. The steel plate concrete combined shear walls can be formed by connecting steel plates and middle connecting rods or connecting L-shaped steel and connecting reinforcements. The steel pipe bundle combined structures and the short steel pipe bundle combined structures are composed of steel pipe bundle assemblies which are in one of the shapes of C shape, I shape, Z shape, T shape, crossed shape or L shape and which are formed by sequentially connecting a plurality of steel pipe units. The steel pipe units are provided with cavities and are filled with concrete. All components and elements of the steel pipe bundle and steel plate concrete combined shear wall structure system are designed in a standardized manner, produced industrially, constructed in a configured manner and managed in an informationized manner.

Owner:HANGXIAO STEEL STRUCTURE

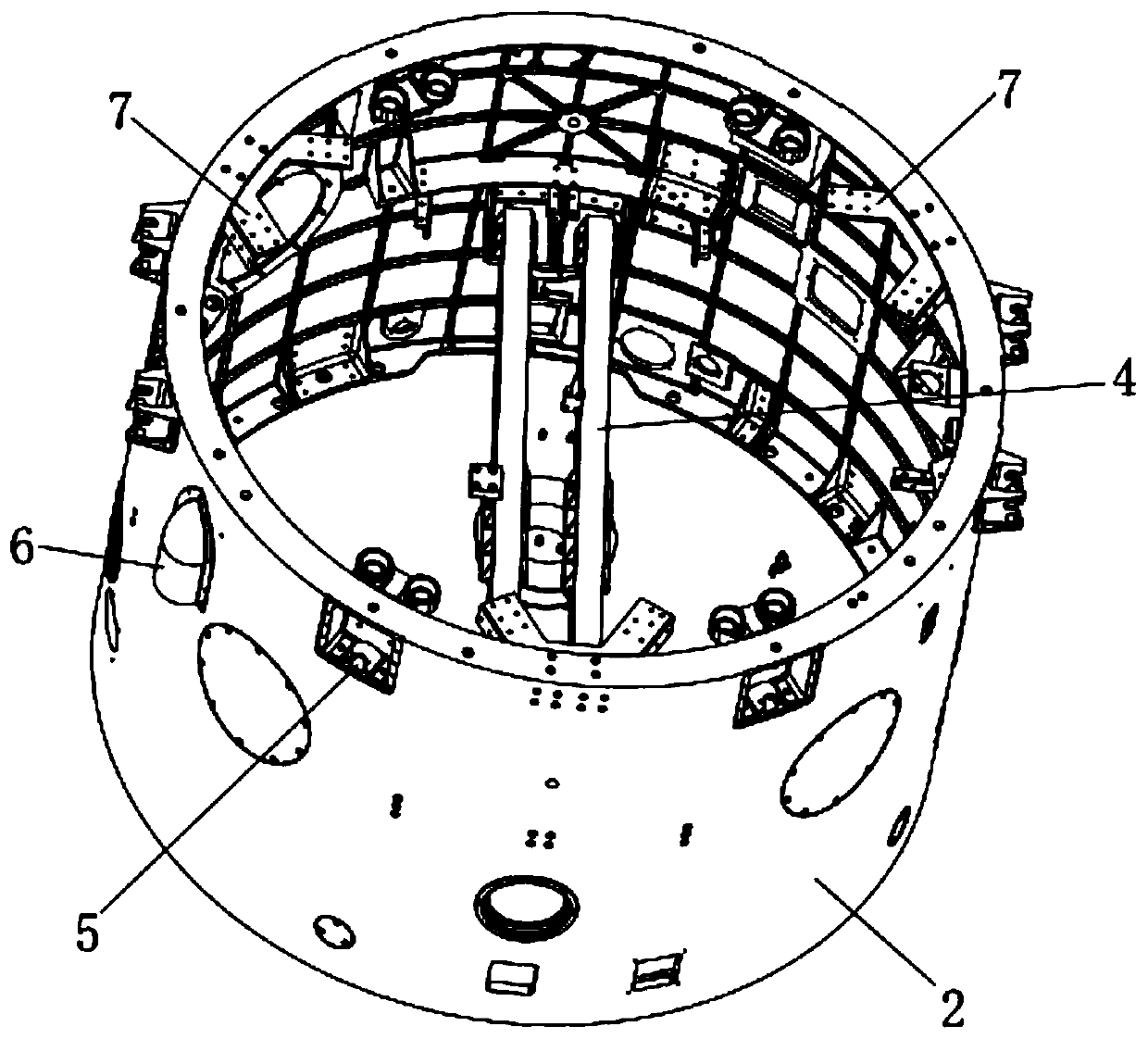

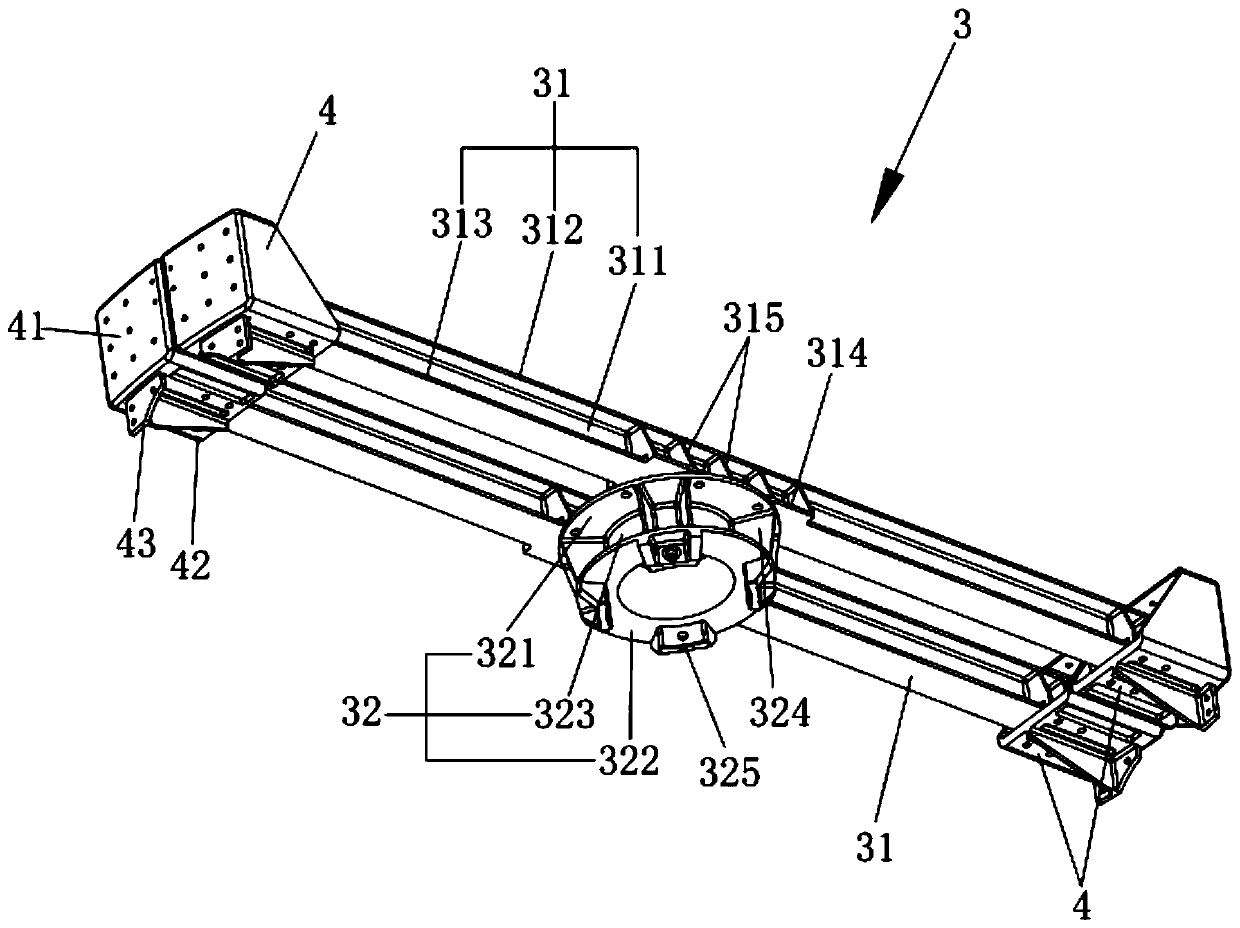

Carrier rocket tail sub-stage structure

PendingCN111023913AImprove delivery efficiencySimple structureSelf-propelled projectilesRocketMechanical engineering

The invention discloses a carrier rocket tail sub-stage structure, which comprises a power cabin, an instrument cabin and a stiffening beam structure, wherein the power cabin provides mounting space for a tail sub-stage power system; the instrument cabin is connected to the upper end of the power cabin, and a plurality of mounting interfaces for mounting instruments are formed in the inner wall ofthe instrument cabin; the stiffening beam structure comprises at least two stiffening beams which are arranged in parallel, and two ends of each stiffening beam are respectively connected with the inner wall of the instrument cabin; and the middle parts of the at least two stiffening beams are connected with a connecting disc for providing a connecting interface for the tail sub-stage power system. The stiffening beam structure of a double-beam parallel structure is adopted in the instrument cabin, the self weight of the stiffening beam structure can be reduced on the premise that the stability of a connecting disc installation structure is guaranteed, the power cabin and the instrument cabin are respectively made of an integrated structure, and the effect of reducing the self-weight of the whole carrier rocket tail sub-stage structure can also be achieved. Meanwhile, the inner wall of the instrument cabin can provide mounting interfaces for a large quantity of equipment, and the carrying efficiency of the rocket is improved while the starting resistance during rocket launching is reduced.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

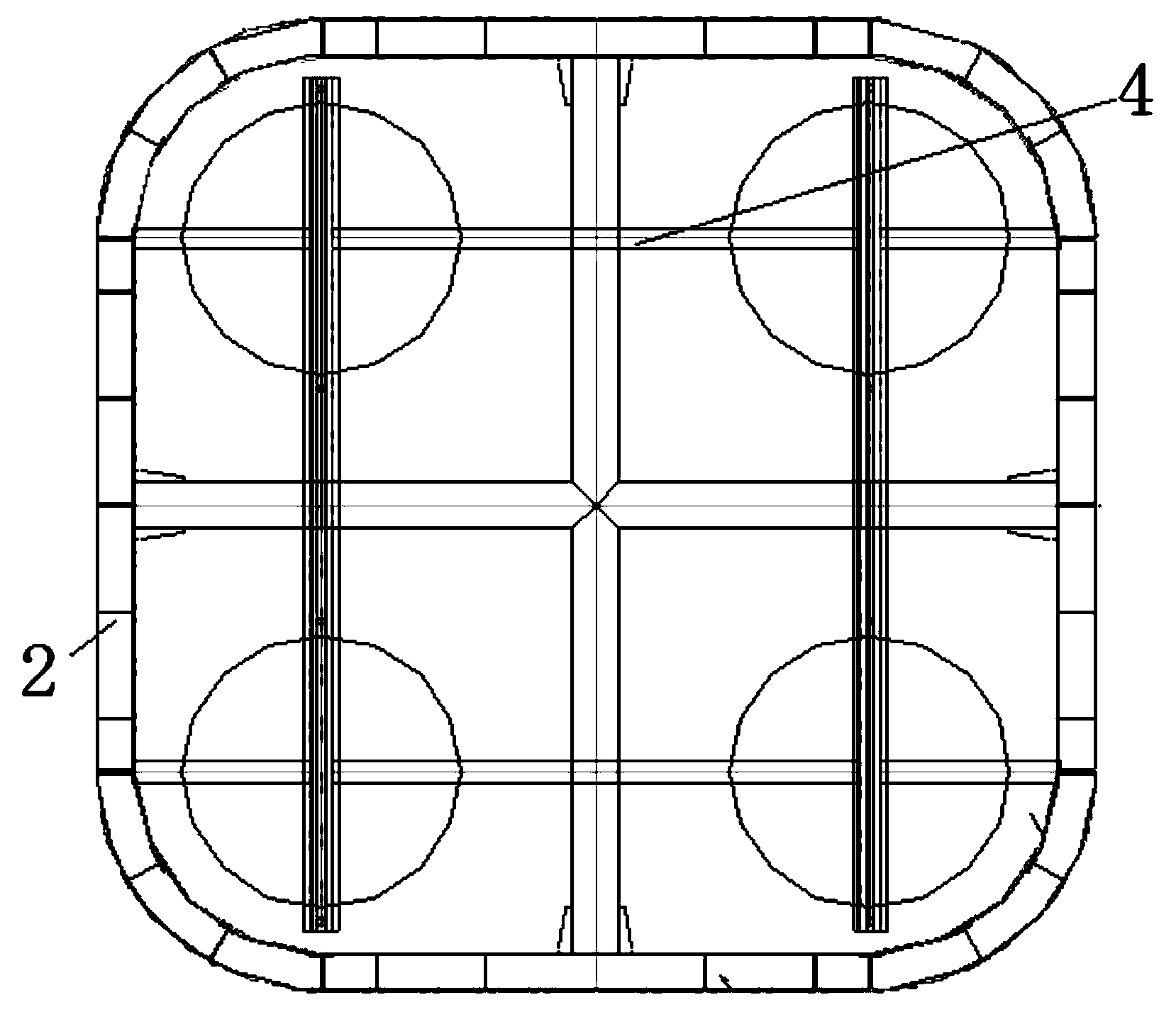

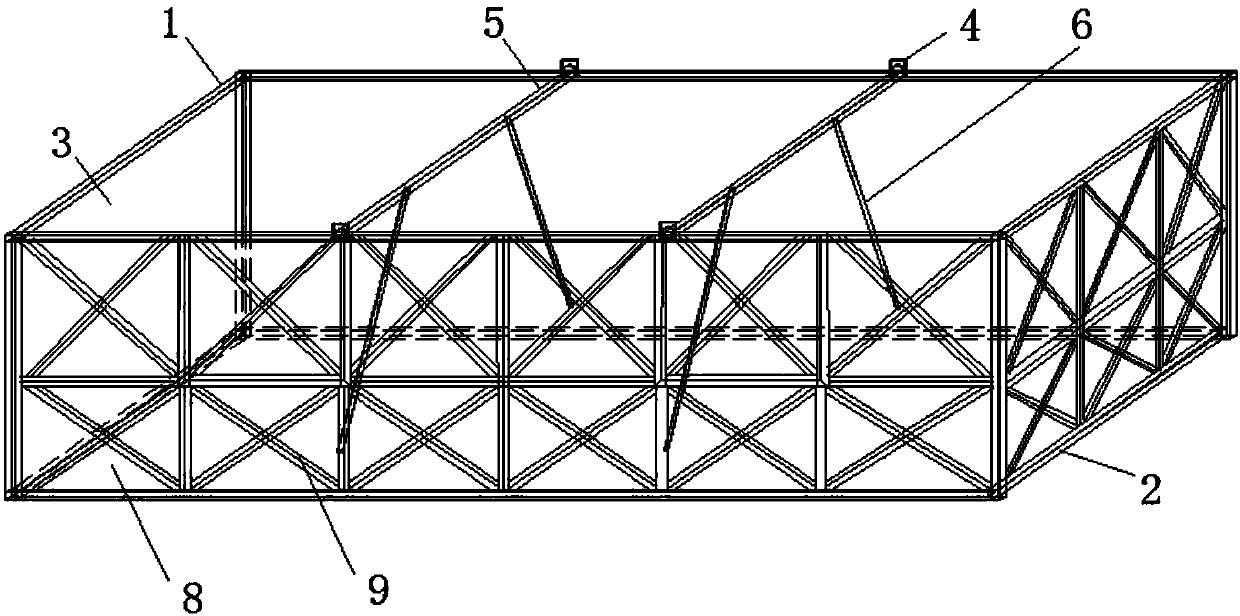

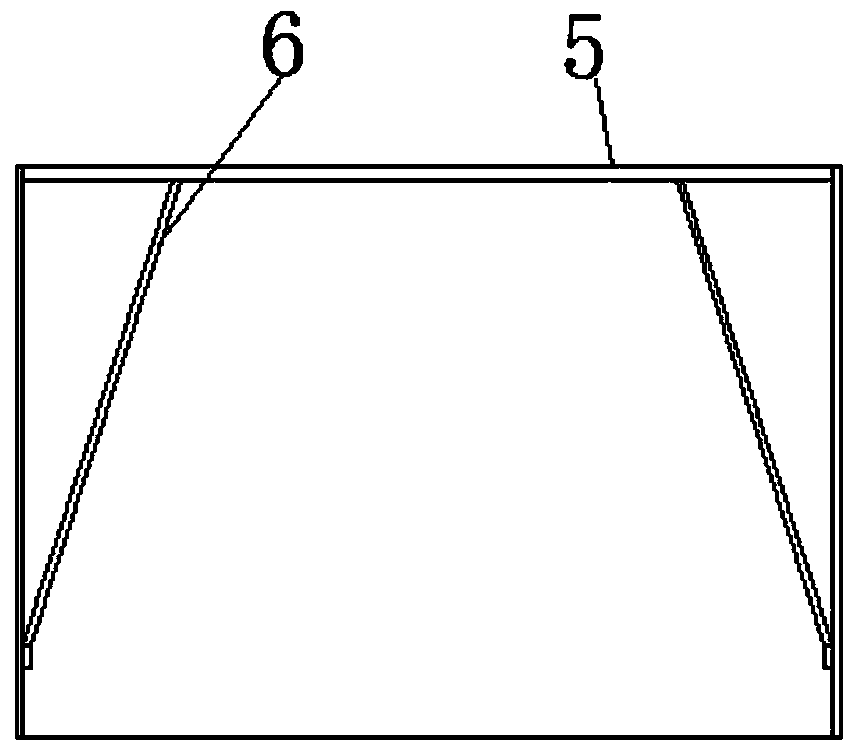

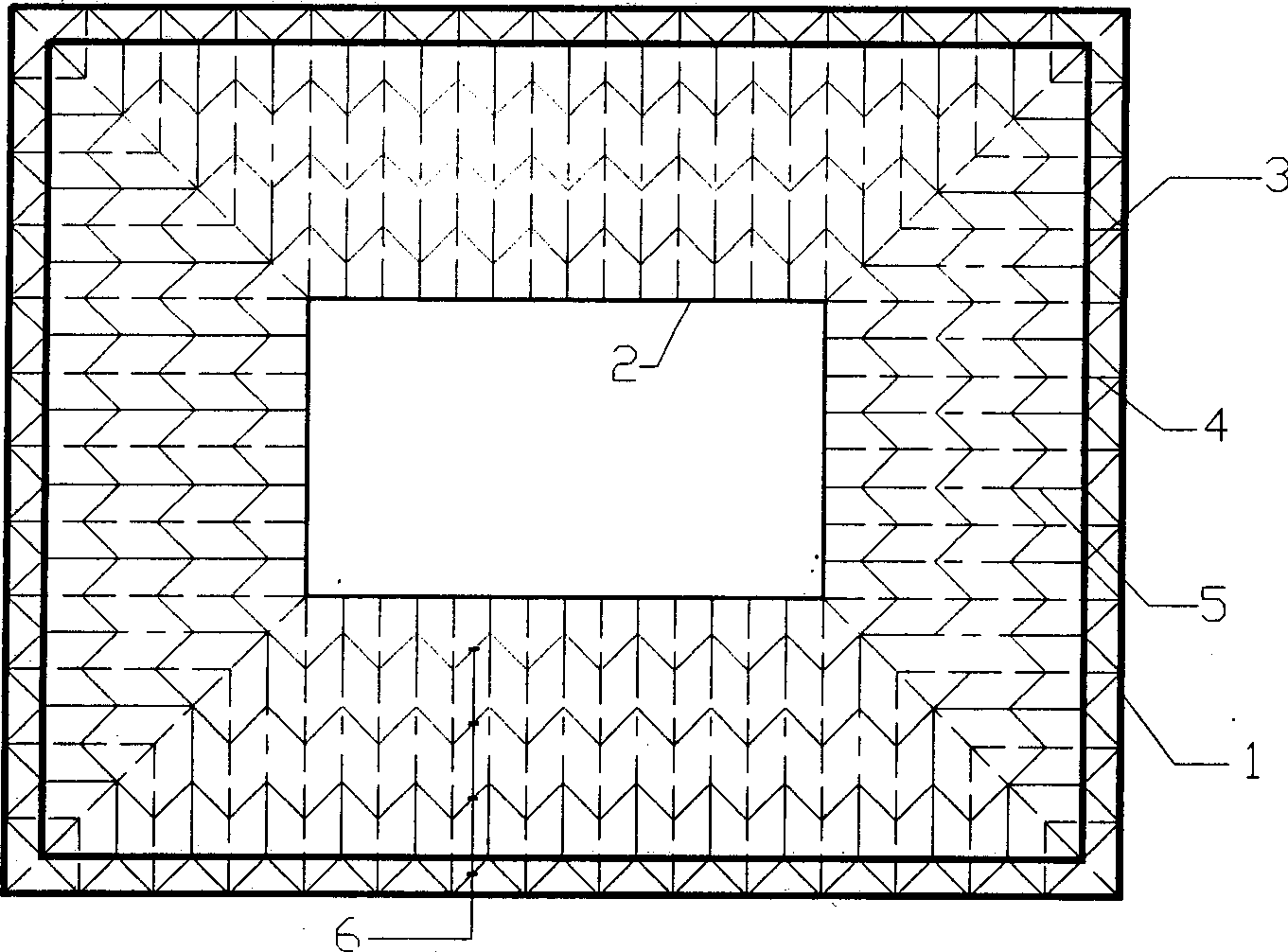

Model box used for large scale dimension shaking table test, model experiment device used for large scale dimension shaking table test and usage method of model experiment device

PendingCN107907285ALight weight structureSuitable for a wide range ofEarth material testingVibration testingModel dynamicsClassical mechanics

The present invention discloses a model box used for a large scale dimension shaking table test. The model box comprises a box body, the box body is a cuboid structure of which the top surface is open, the bottom surface of the box body comprises a flexible steel plate, and the side surface comprises a box iron frame, a rigid steel plate and an angle iron frame. The box iron frame, the rigid steelplate and the angle iron frame are welded orderly from inside to outside, and the flexible steel plate is welded at the bottom of the rigid steel plate. The model box is light in dead-weight, high intest result accuracy and wide in application range, combines the flexibility and the rigidity, and adopts the inner and outer frames to combine into a model box body structure, thereby saving the rawmaterials and improving the overall rigidity of the model box. By applying a model box test device of the present invention, the model dynamic response characteristics under the action of different earthquake loads can be obtained, the influence of a model box body boundary effect is reduced, the propagation process of an earthquake wave in the model box can be reproduced really, and the model box, the model experiment device and the usage method of the model experiment device can be widely used for researching the rock-soil slope and tunnel mechanisms of deformation and failure.

Owner:CENT SOUTH UNIV +1

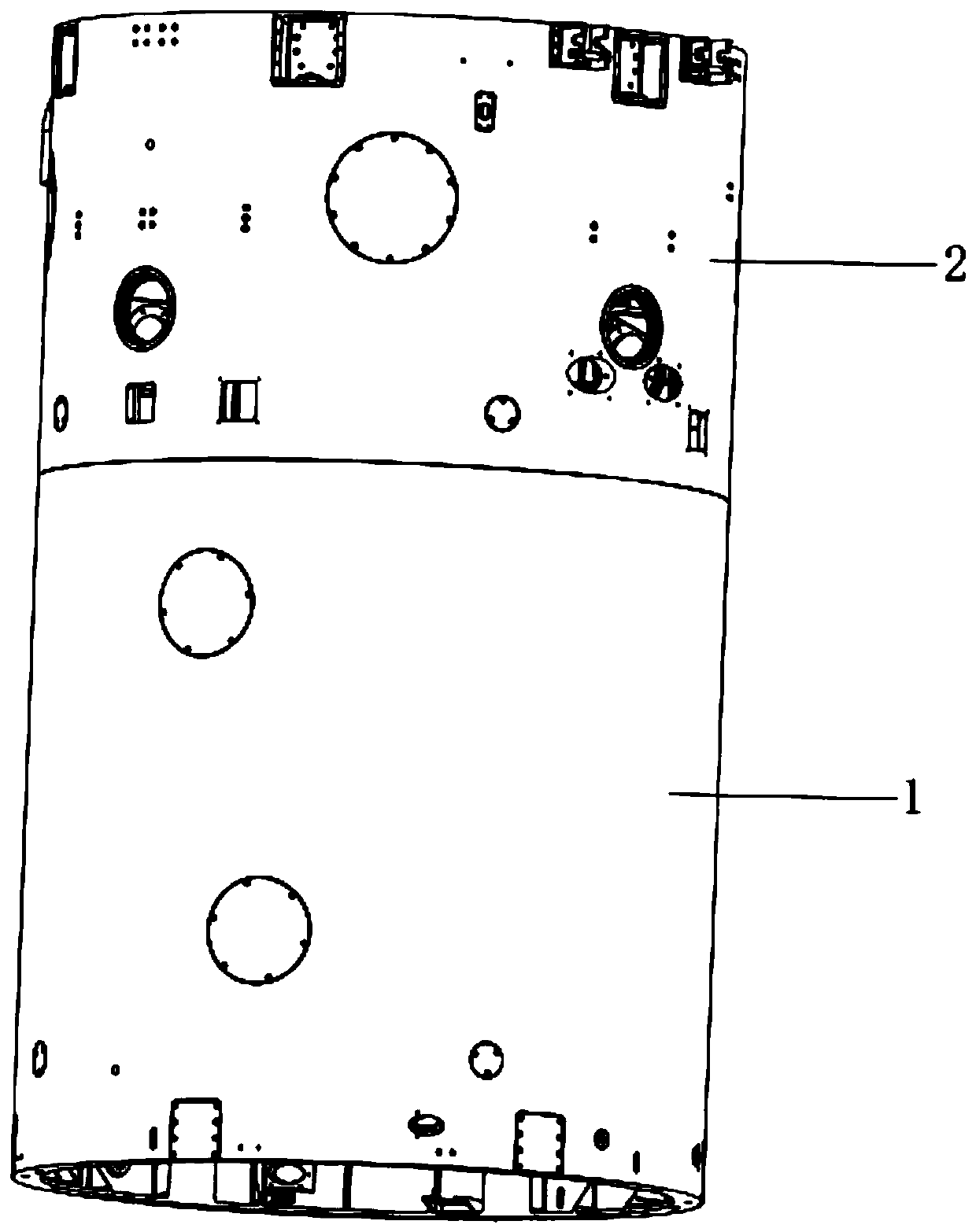

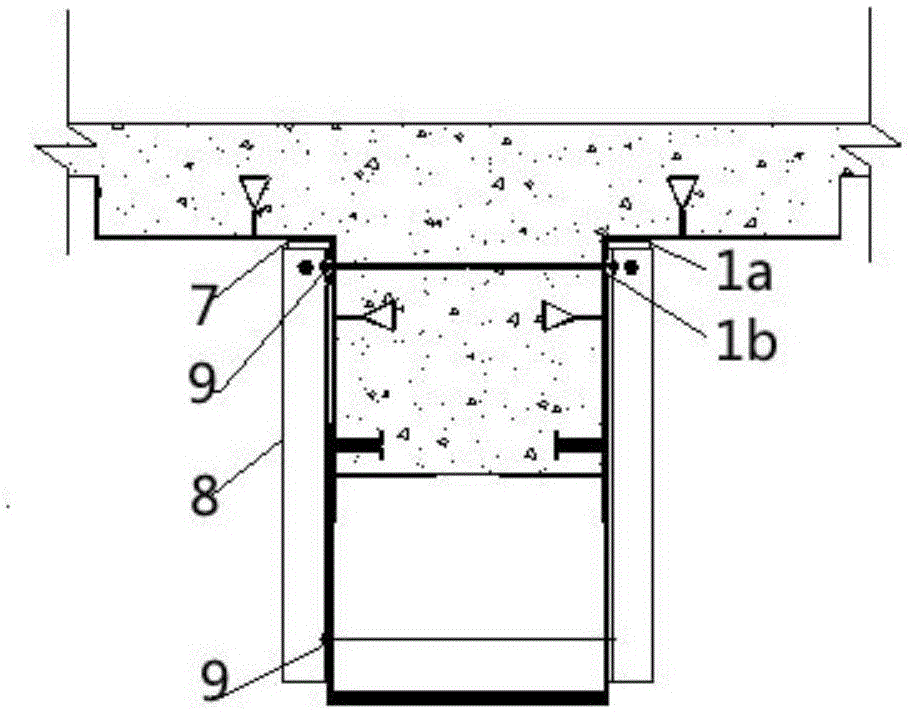

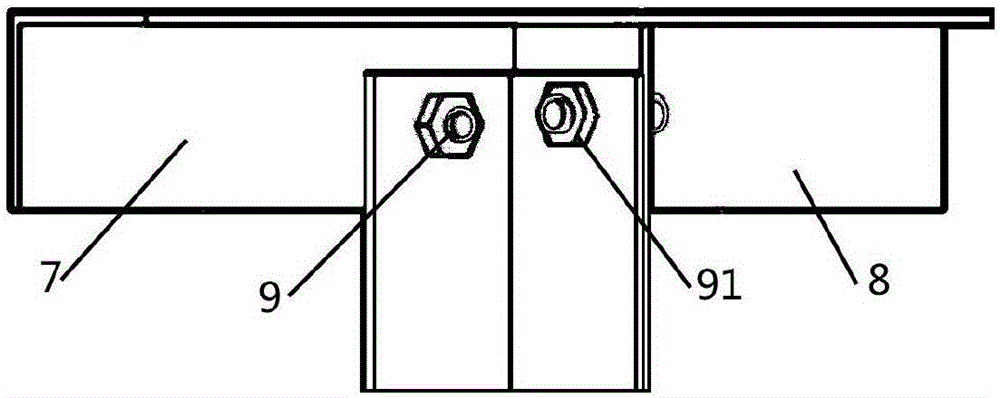

Lowe layer light steel structure fabricated residence

PendingCN107893475ALight weight structureImprove seismic performanceBuilding roofsWallsEarthquake resistanceEngineering

The invention relates to the technical field of housing construction structures, in particular to a low layer light steel structure fabricated residence. The lower layer light steel structure fabricated residence comprises a wall body, flat bed bodies, a roof, first bearing components and second bearing components. A plurality of dense columns of the wall body are connected through the first bearing components. Each flat bed body comprises dense beams and layer face plates. The two ends of the dense beams are aligned, the multiple dense beams of the top flat bed body and the bottom flat bed body are connected through the first bearing components, and the multiple dense beams of the middle flat bed body are connected through the second bearing components. The roof comprises roof inclined beams and roof plates. The two ends of the dense beams of the top flat bed body are connected with the roof inclined beams, the roof inclined beams arranged at the two ends of the dense beams of the topflat bed body are connected to form a triangle above the top flat bed body, and the roof plates are laid on the surfaces of the multiple roof inclined beams. The lower layer light steel structure fabricated residence is low in structural dead weight, has good heat insulation performance, fire resistance and durability, and is good in anti-seismic performance, and the construction period is short.

Owner:GUANGDONG XIANGBO ECOLOGICAL TECH CO LTD

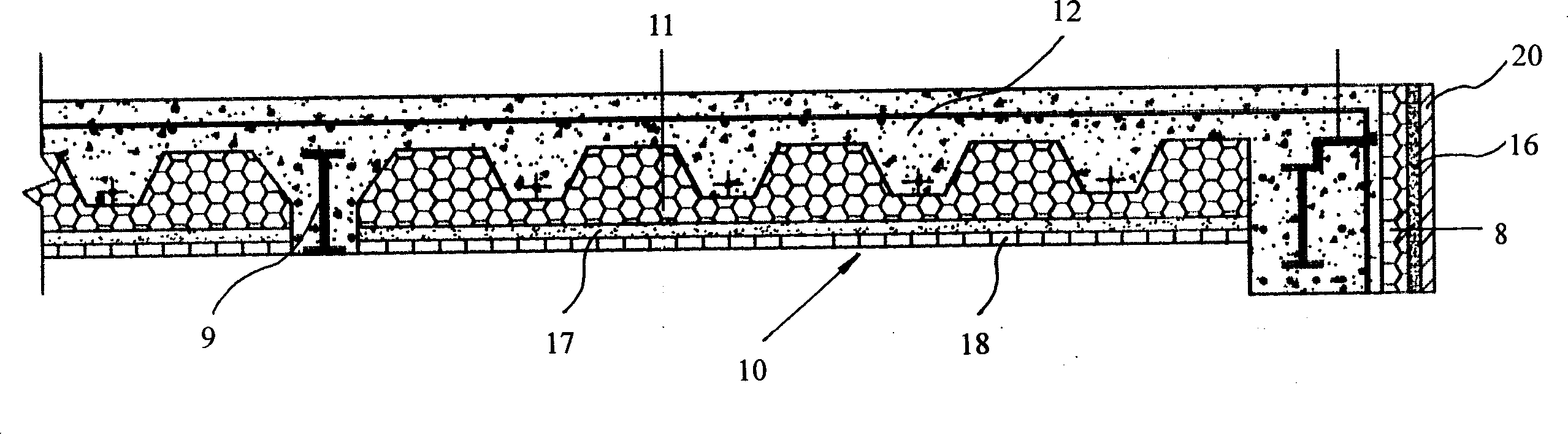

Hollow type combination beam for quick construction and construction method

The invention discloses a hollow type combination beam for quick construction, and a construction method. The hollow type combination beam for quick construction comprises a beam structure unit including a concrete made beam body, a neutral shaft positioned at side of the beam body, a closed profiling steel plate prefabricated along the neutral shaft and sidewall of the beam body, welding nails pre-embedded at two sides of the beam body on upper part of the neutral shaft, a steel web welded and fixed to the closed profiling steel plate via welding nails and angle irons, and a steel plate welded and fixed with the steel web and forming a cavity. The combination beam for quick construction has an inside hollow cavity and has advantages of materials conservation, low cost, and light self-weight. In a further embodiment, the combination beam can be casted with a combined board, a concrete column as a whole and the combination beam has advantages of good integration, free of template, quick and convenient construction, and reliable connection with steel beams and concrete columns.

Owner:HOHAI UNIV

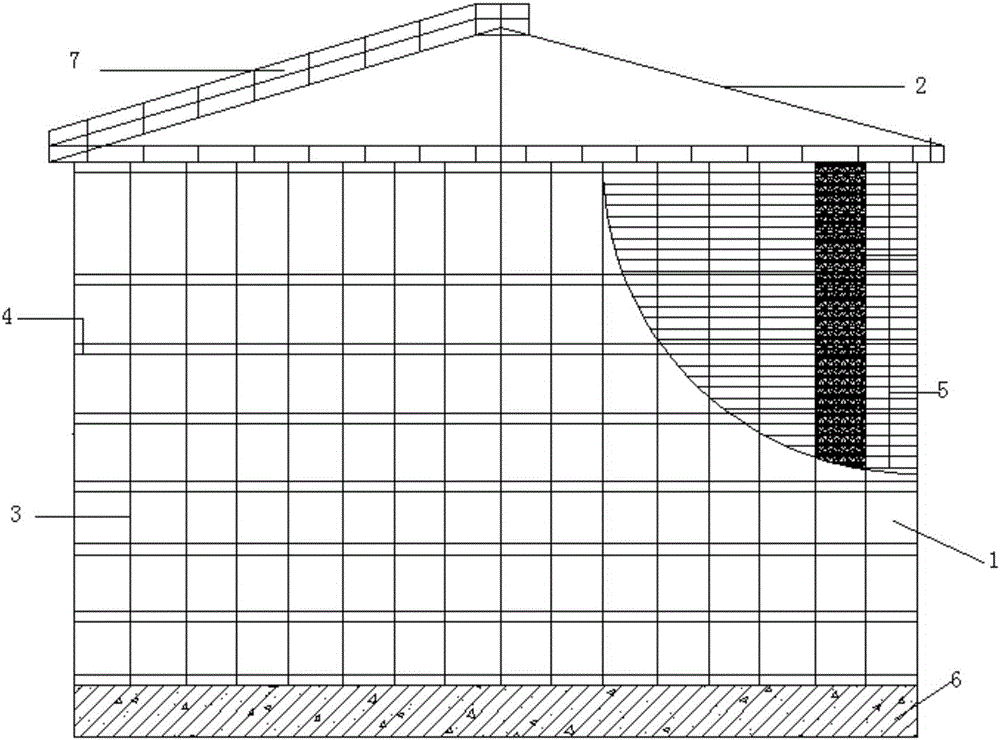

Lightweight-steel-structure grain storing granary

InactiveCN106639452ASolve mildewSolve the problem of food pestsClimate change adaptationBulk storage containerEarthquake resistanceLand policy

The invention relates to the field of grain storing, in particular to a lightweight-steel-structure grain storing granary. A granary body is of a cylinder structure, and a roof is conical; a foundation is arranged at the bottom of the granary body; stand columns of the granary body and supports of the roof are made of lightweight steel pipes in a welded mode; reinforcing steel bars and square steel pipes are welded onto the stand columns of the granary body, and a fireproof net, a rock wool fireproof insulating layer and a rainproof color steel plate are sequentially installed on the outer side wall of the granary body; inlets and outlets are formed in the side wall; the roof is made of rainproof color steel plates. The lightweight-steel-structure grain storing granary has the advantages of being small in structure dead weight and good in earthquake resistance; the basic manufacturing cost can be greatly reduced, and the lightweight-steel-structure grain storing granary is particularly suitable for regions with poor location conditions. Due to factory standardized production, quality is stable and free of environment and season influence, the construction period is short, the construction way is simple and efficient, and a large amount of manpower and a large quantity of financial resources are avoided. The lightweight steel structure is also convenient to disassemble and reuse, the wall is efficient and saves energy, and the lightweight steel structure conforms to the national land policy, the environment protection policy and the sustainable development strategy, and is a novel environment-friendly structure.

Owner:XIHUA UNIV

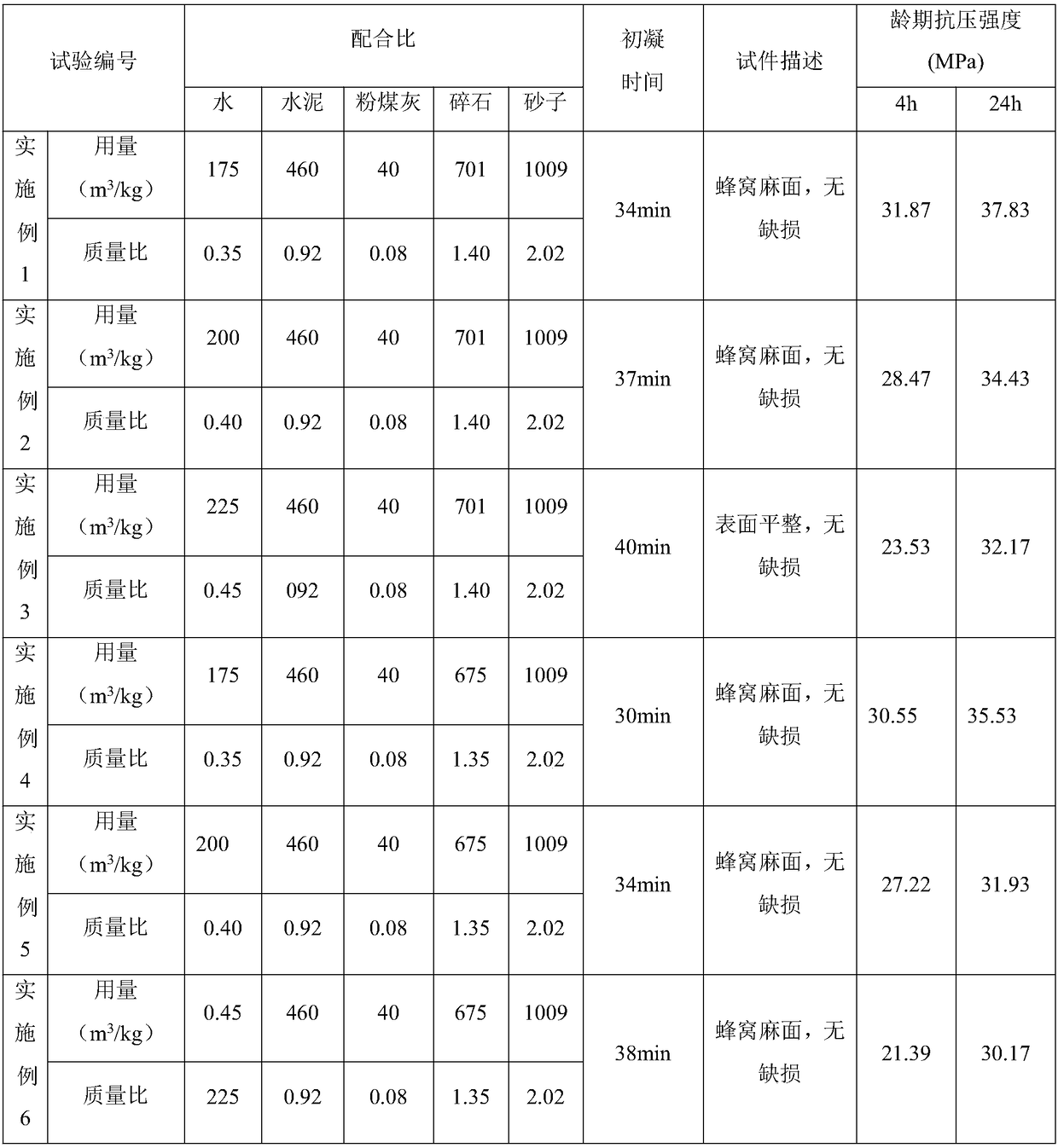

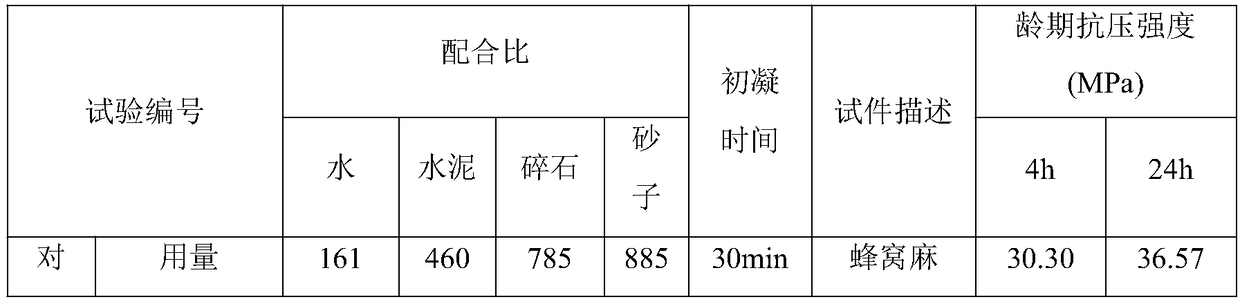

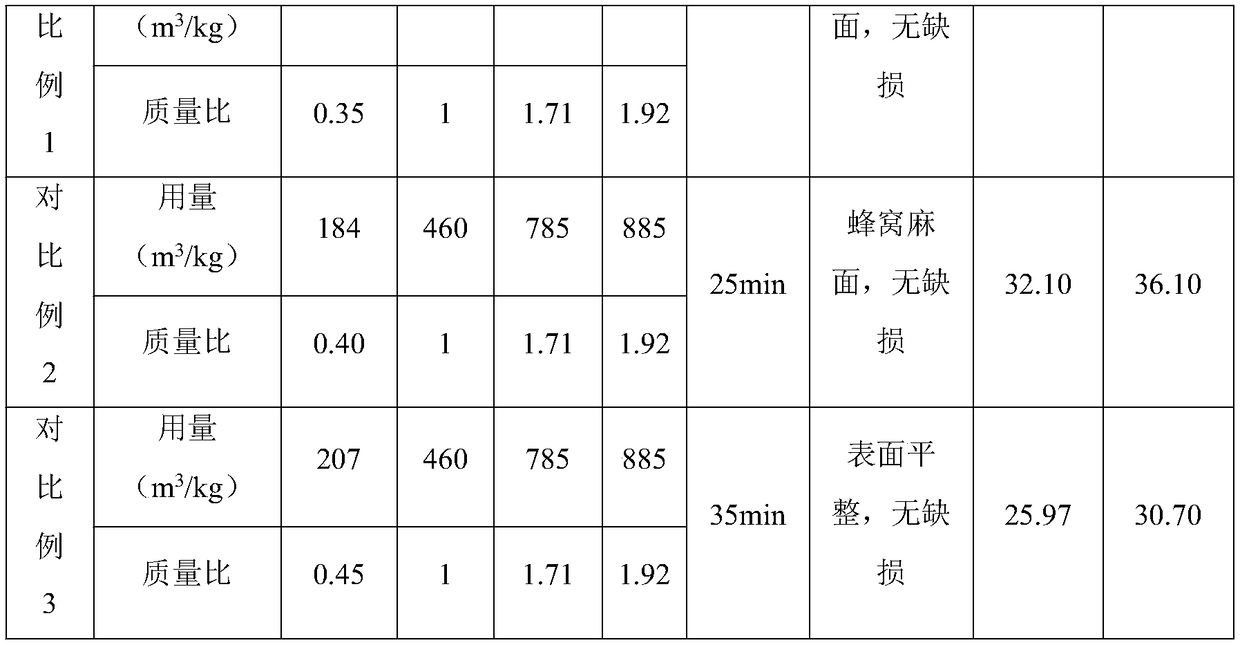

High-strength and quick-hardening shotcrete and soft-rock tunnel surrounding rock closing and strengthening method

The invention discloses high-strength and quick-hardening shotcrete and a soft-rock tunnel surrounding rock closing and strengthening method. The high-strength and quick-hardening shotcrete compriseswater, cement, fly ash, gravel and sand, wherein the weight ratio of the fly ash to the cement is 0.92:0.08, the ratio of the weight of water to the total weight of the cement and the fly ash is (0.35-0.45):1, the ratio of the weight of the gravel and the total weight of the cement and the fly ash is (1.35-1.4):1, and the ratio of the weight of the sand and the total weight of the cement and the fly ash is 2.02:1. The high-strength and quick-hardening shotcrete is high in setting speed, can achieve initial setting within 35min plus or minus 5min, has the cubic average compressive strength being higher than or equal to 20MPa at 4h, has the cubic average compressive strength being higher than or equal to 30MPa at 24h, can timely and quickly close and strengthen an excavated surface, and hashigh early strength. In tunnel construction, the high-strength and quick-hardening shotcrete is sprayed first and then ordinary shotcrete is sprayed, so that effective connection of the low-age strength and the high-age strength of the shotcrete is achieved, and optimization of the functionality and the economy of the shotcrete is achieved.

Owner:CHANGAN UNIV

Press-stressed anchor cable assembly type steel waist rail and construction method thereof

PendingCN111395356AReduce pollutionLight weight structureExcavationsBulkheads/pilesPre stressArchitectural engineering

The invention discloses a pre-stressed anchor cable assembly type steel waist rail. The pre-stressed anchor cable assembly type steel waist rail comprises a plurality of triangular steel inclined cushions which are fixedly arranged on a support pile, a steel waist rail body which is welded on inclined surfaces of the triangular steel inclined cushions and an anchor cable for keeping stability of the support pile, wherein the steel waist rail body comprises two pieces of channel steel which are the same, are symmetrical back to back and are arranged in a spaced mode, a plurality of connecting batten plates for connecting the two pieces of channel steel and a plurality of pressure-bearing plates which are symmetrically welded on left and right side surfaces of the two pieces of the channel steel; the connecting batten plates are arranged in the spaced mode; the two ends of each connecting batten plate are separately welded on the side surfaces of two pieces of channel steel; through holes are formed in positions, different from a welding area, on middle regions of the pressure-bearing plates; the anchor cable comprises an anchorage device, an anchor cable body and an anchor root, wherein the anchorage device is blocked outside the pressure-bearing plates; the anchor cable body sequentially passes through the through holes, the triangular steel inclined cushions and the support pile; and the anchor root at the tail end is fixedly arranged on a nearby rock body.

Owner:FUJIAN YONGTAI CONSTR ENG CO +1

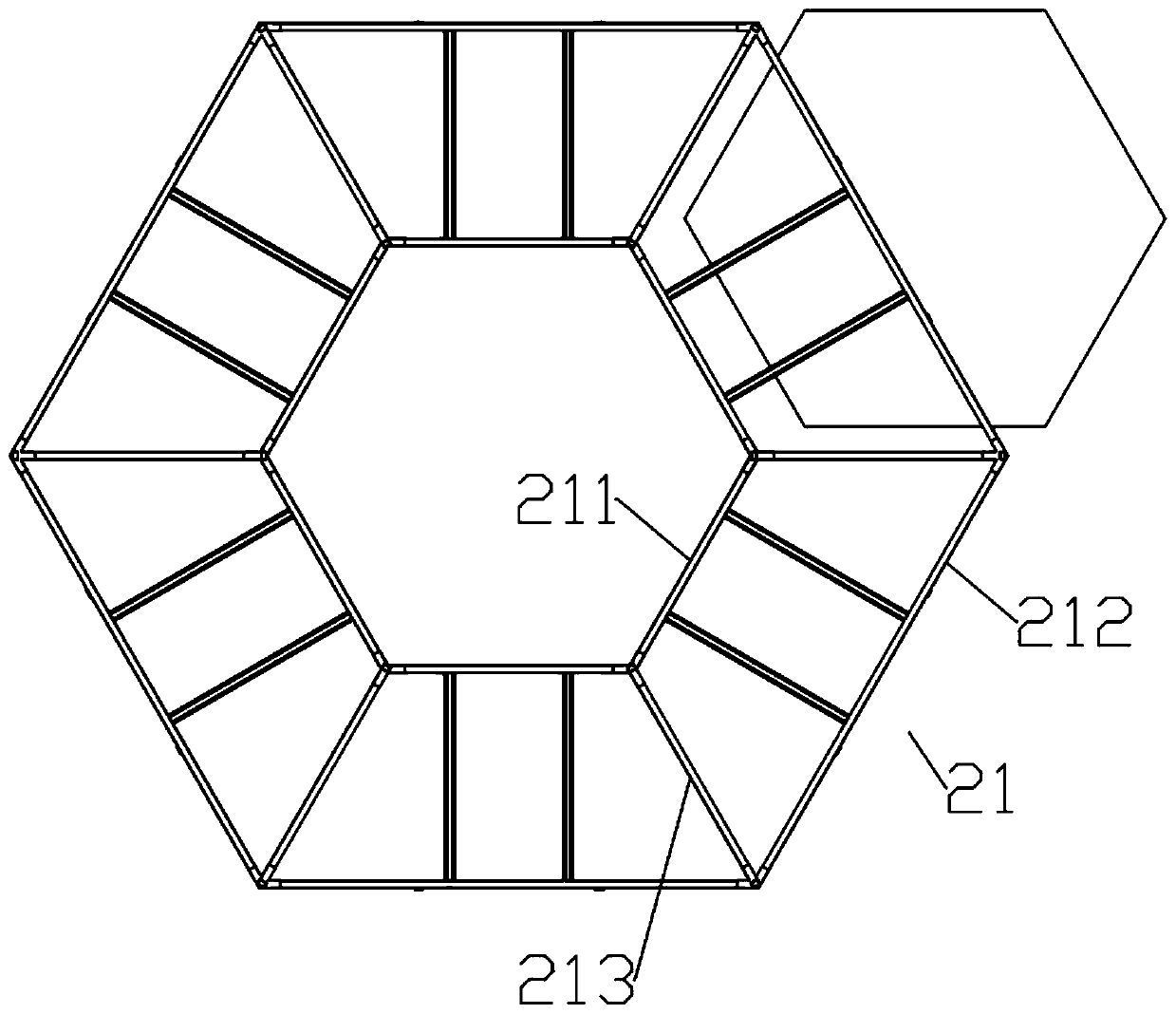

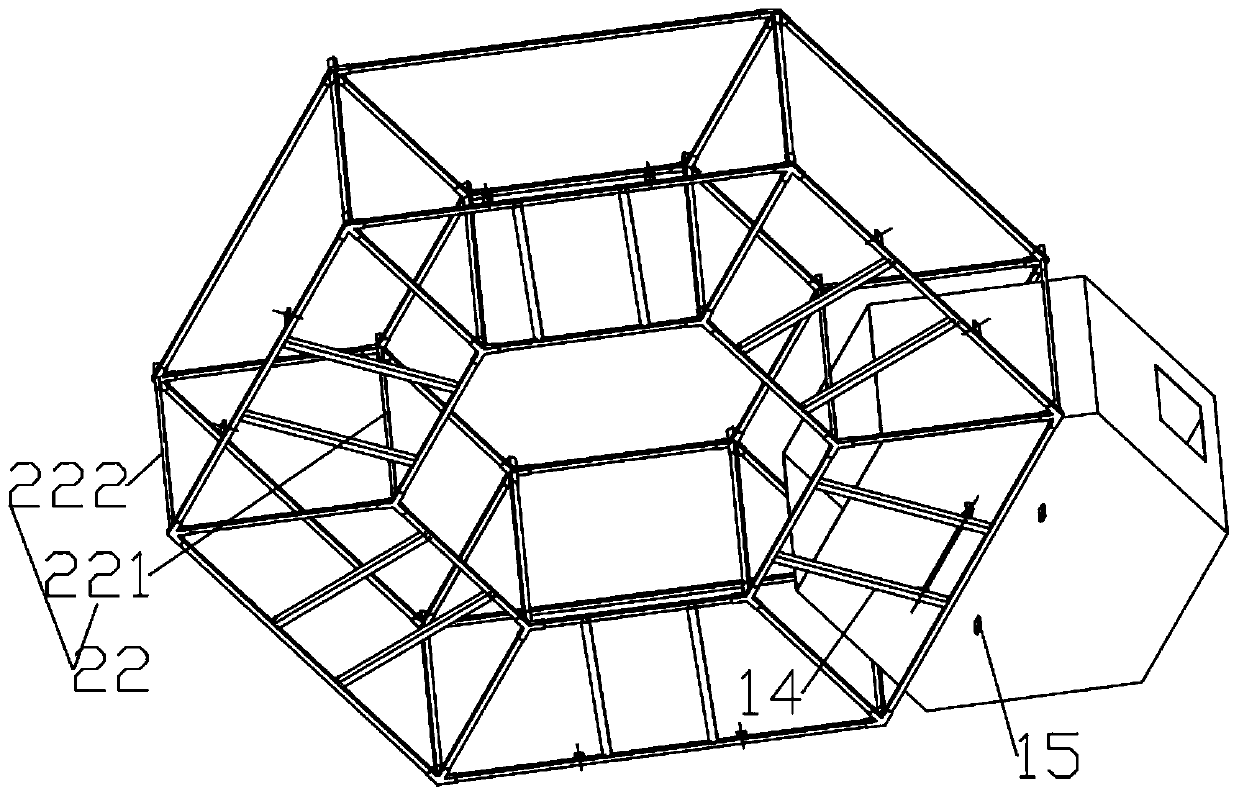

Combined type honeycomb building capable of being quickly constructed

ActiveCN111236437ABuild fastCompact structureBuilding constructionsBraced frameArchitectural engineering

The invention discloses a combined type honeycomb building capable of being quickly constructed, and belongs to the field of fabricated buildings. The building comprises a plurality of honeycomb structure units and a honeycomb structure supporting frame used for supporting the honeycomb structure units; the honeycomb structure units are of hexahedron structures; the honeycomb structure supportingframe comprises a plurality of layers of horizontal frames arranged in parallel, the adjacent horizontal frames are connected through vertical steel stand columns, the inner steel stand columns are used for connecting inner hexagonal frames of the adjacent horizontal frames so that a hexagonal cylinder frame used for containing stairs can be formed in the center of the honeycomb building, and theouter steel stand columns are used for connecting outer hexagonal frames of the adjacent horizontal frames so that six trapezoidal frames used for being spliced with the honeycomb structure units canbe formed on the outer side of the honeycomb building; and the honeycomb structure units are inserted into the trapezoidal frames in the radial direction of the honeycomb building. The building structure has the advantages of being light in structure self-weight, high in construction speed, capable of being recycled, modularized, energy-saving and environment-protecting, convenient to transport, convenient to store and the like.

Owner:CHONGQING UNIV

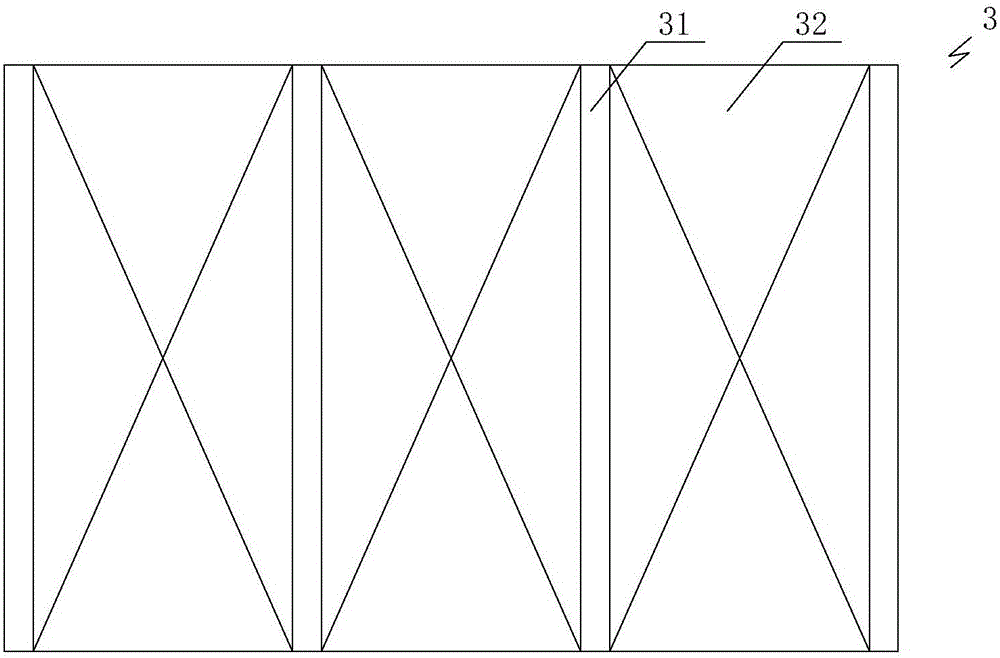

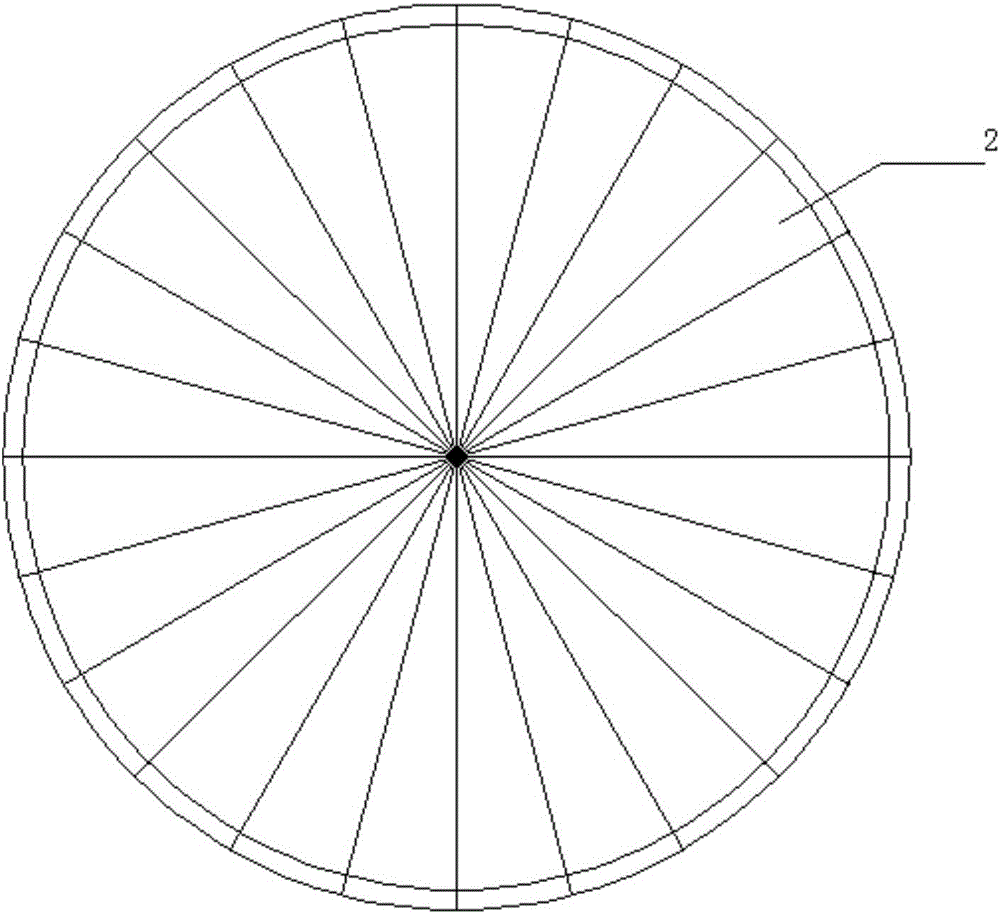

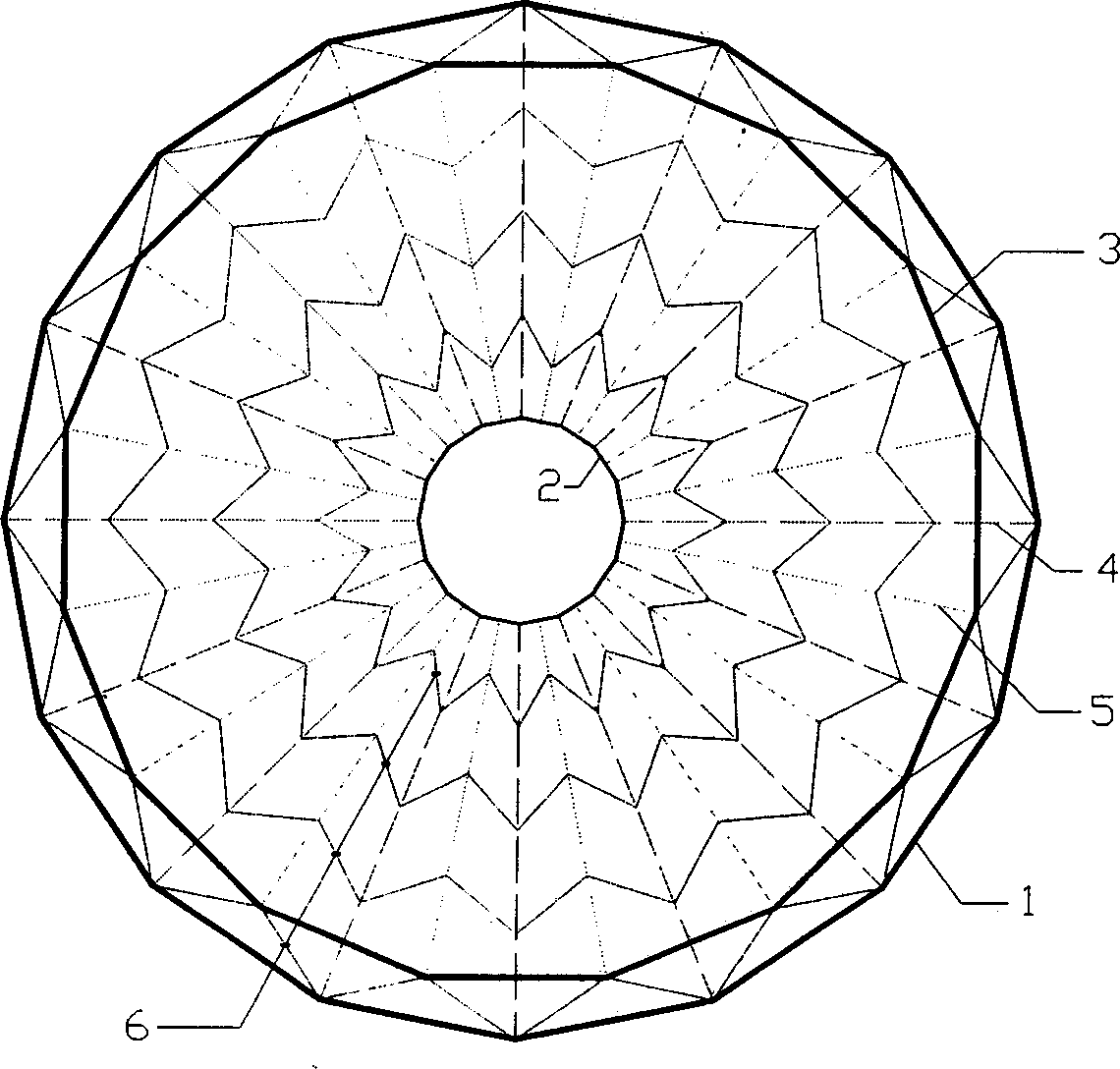

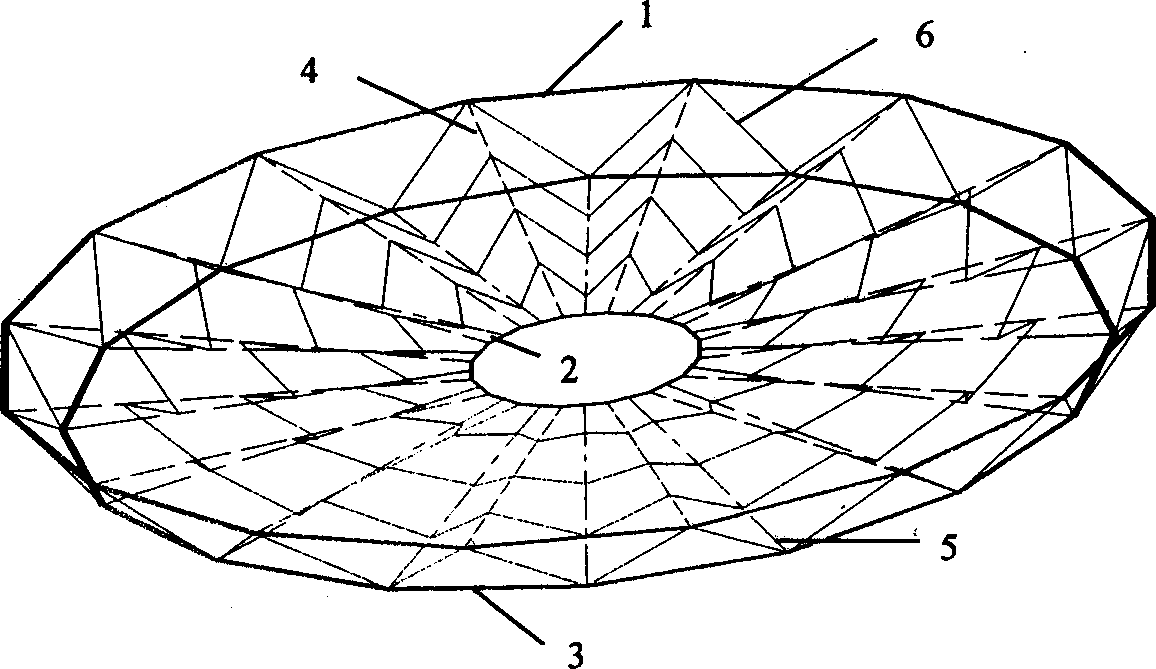

Folding plate type rope disc structure

InactiveCN1861948ALight weightLight weight structureBuilding roofsPull forceUltimate tensile strength

The present invention discloses a kind of folded plate type cable sheet structure. It possesses upper ring beam, inner ring beam, bottom ring beam, ridge cable, valley cable and ring cable. The ridge cable, valley cable and ring cable are prestress slay cables, the upper ring beam and bottom ring beam are pressure-bearing ring beams and the inner ring beam is the ring beam capable of bearing tension, between adjacent ridge cable and valley cable a sheet-shaped folded surface is formed. Said structure is simple, and possesses strong stress behaviour.

Owner:ZHEJIANG UNIV

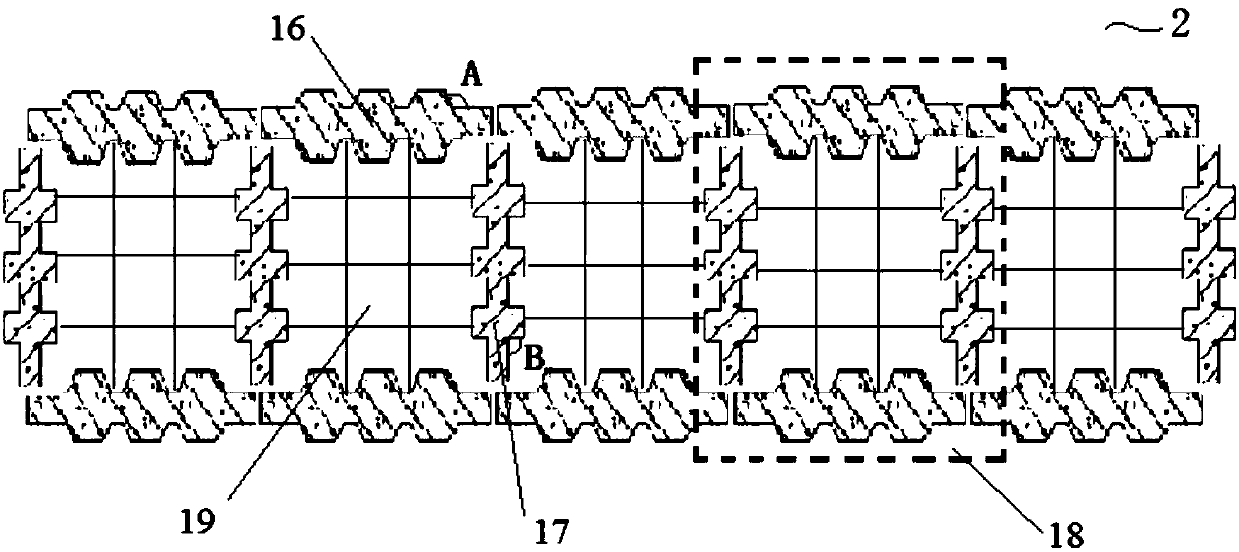

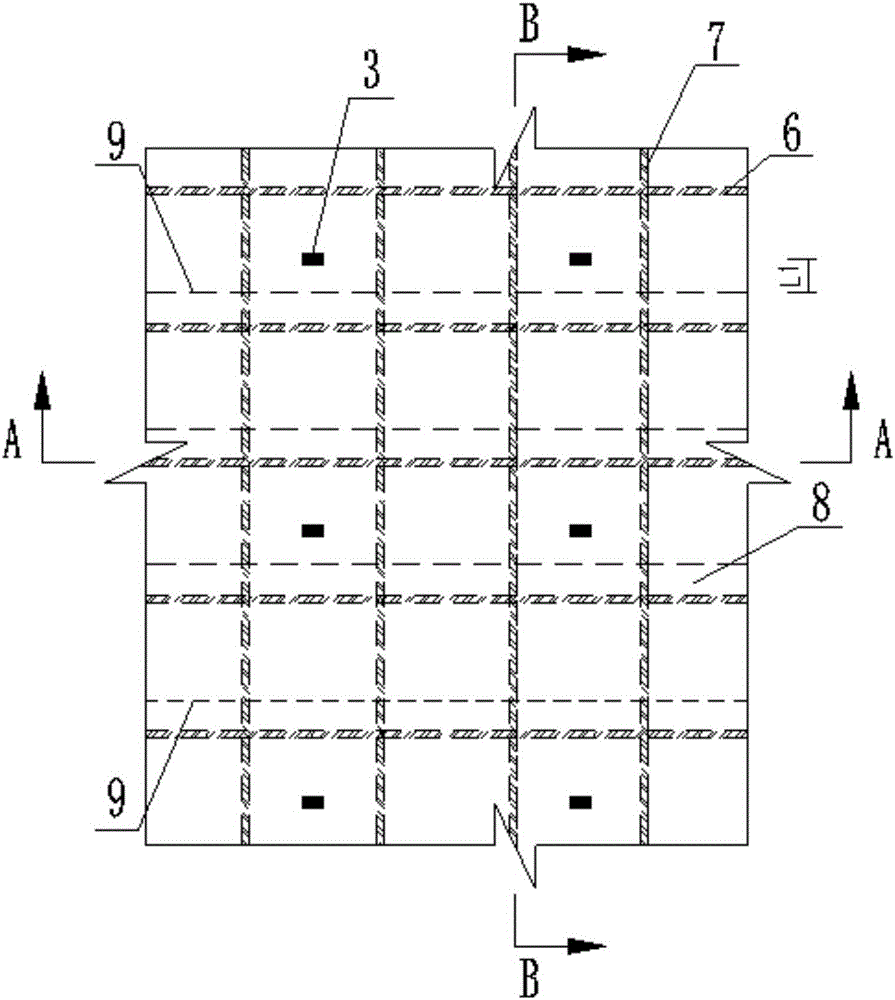

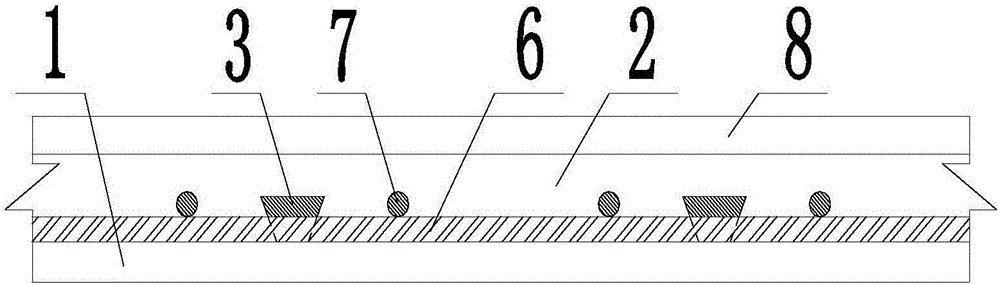

Steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and construction method thereof

ActiveCN106638306ALow construction heightIncreased shear strengthBridge structural detailsBridge materialsRebarHigh performance concrete

The invention discloses a steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and a construction method thereof. The combined bridge deck structure comprises a steel bridge deck layer (1) and an ultrahigh performance concrete layer (2) poured on the steel bridge deck layer (1). The steel bridge deck layer (1) is fixedly connected with the short-steel-bar anti-shear structures, each short-steel-bar anti-shear structure comprises a plurality of short steel bars (3) fixedly connected to the upper surface of the steel bridge deck layer (1), wherein the short steel bars (3) are horizontally arranged in the longitudinal bridge direction. The short-steel-bar anti-shear structures are wrapped in the ultrahigh performance concrete layer (2). According to the steel-ultrahigh performance concrete combined bridge deck structure with the short-steel-bar anti-shear structures, the thickness of the ultrahigh performance concrete layer can be reduced, the weight of a bridge deck can be lowered, the shear key structure is small in size and simple in construction process, and the steel-ultrahigh performance concrete combined bridge deck structure is especially suitable for large-span flexible bridges which are sensitive in bridge weight.

Owner:HUNAN UNIV

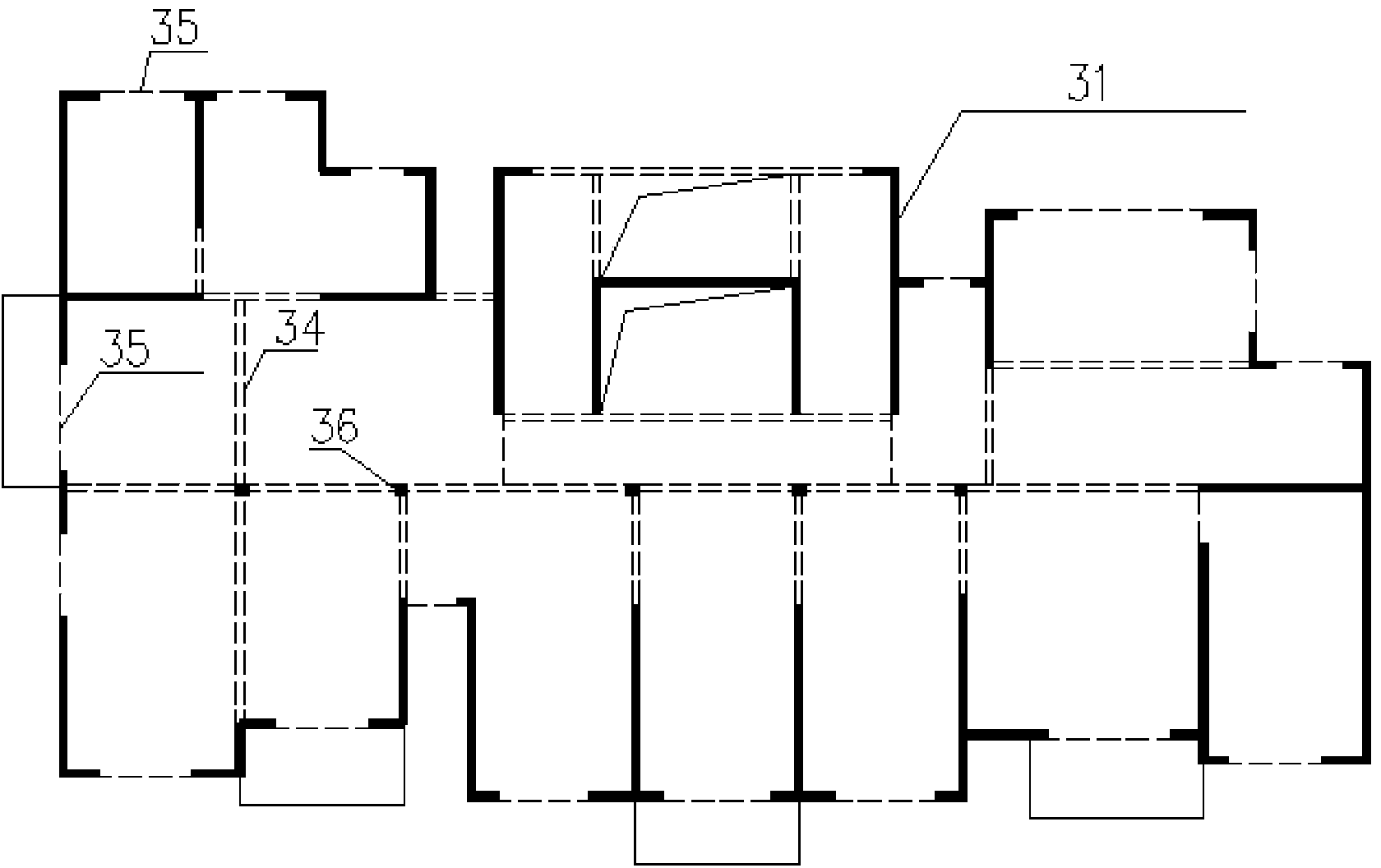

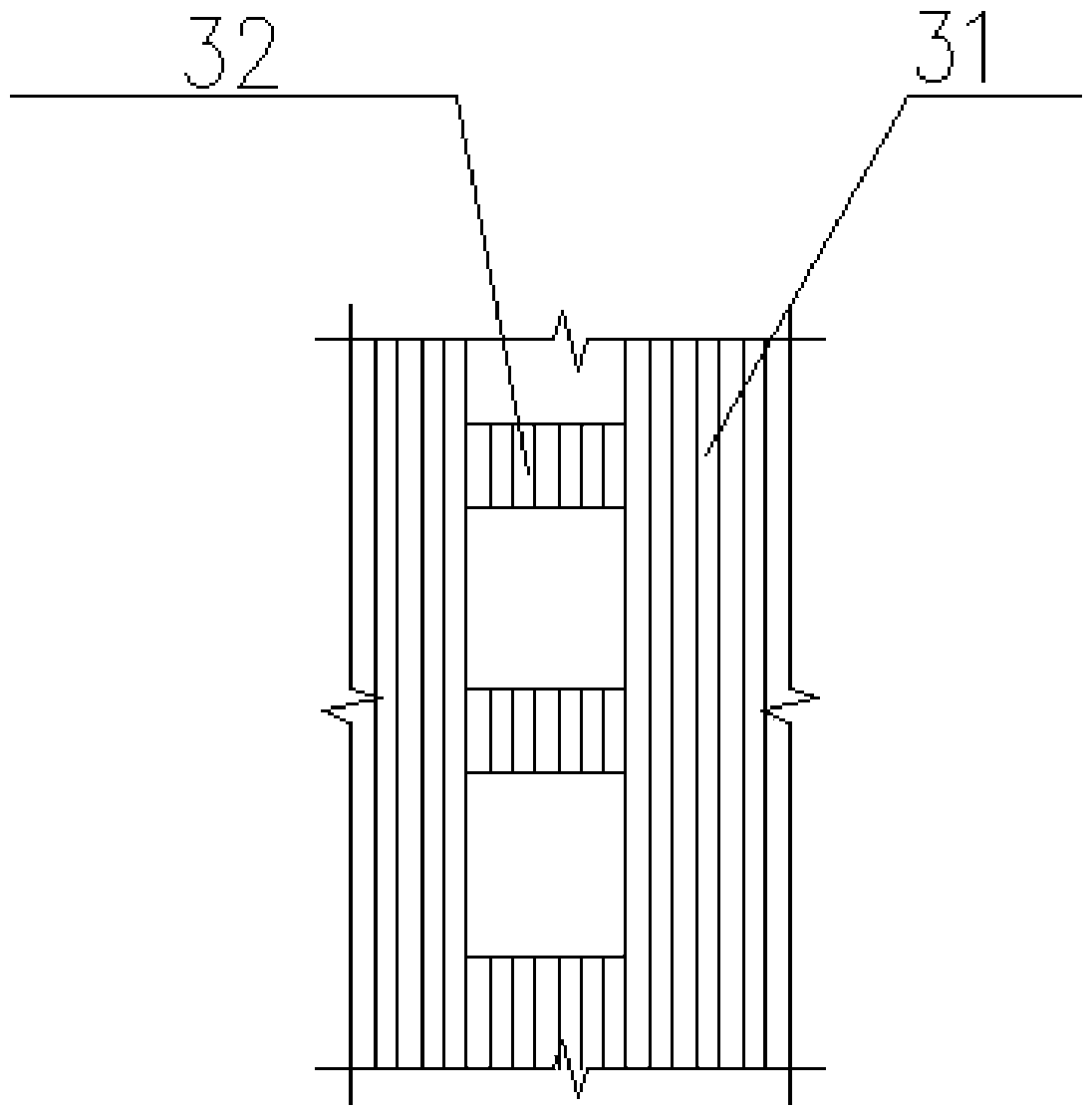

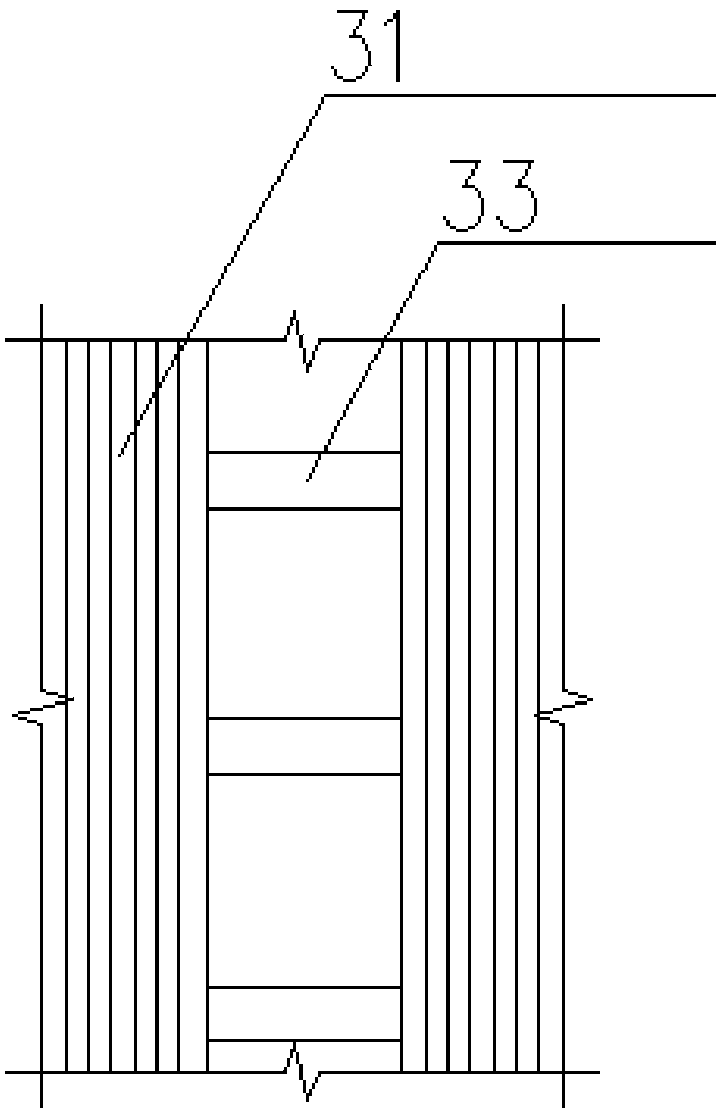

Frame-steel pipe bundle combined structure system for industrial residential building

InactiveCN103850349ALabor savingReduce labor intensityStrutsConstruction materialStructural elementStructure system

The invention discloses a frame-steel pipe bundle combined structure system for an industrial residential building. The frame-steel pipe bundle combined structure system is formed by connecting a post and steel pipe bundle combined structure component and an H-type steel beam or box beam or short steel pipe bundle combined structure component, wherein a post and the H-type steel beam or the box beam are combined to form a frame; the steel pipe bundle combined structure component and the short steel pipe bundle combined structure component consist of steel pipe bundle assemblies; each steel pipe bundle assembly is C-shaped, transverse I-shaped, Z-shaped, T-shaped, cross-shaped or L-shaped; each steel pipe bundle assembly is formed by sequentially connecting a plurality of steel pipe units; each steel pipe unit is provided with a cavity; concrete is cast in each cavity. All the components and parts of the steel pipe bundle combined structure system are designed in a standardizing way, industrially produced, constructed in an assembling way, and managed in an informationization way; the traditional building site farmer workers are transformed into industrial workers, so that a large amount of labor is saved, the labor intensity is reduced, the production efficiency is improved, the construction speed is increased, and the service life of the building is prolonged.

Owner:HANGXIAO STEEL STRUCTURE

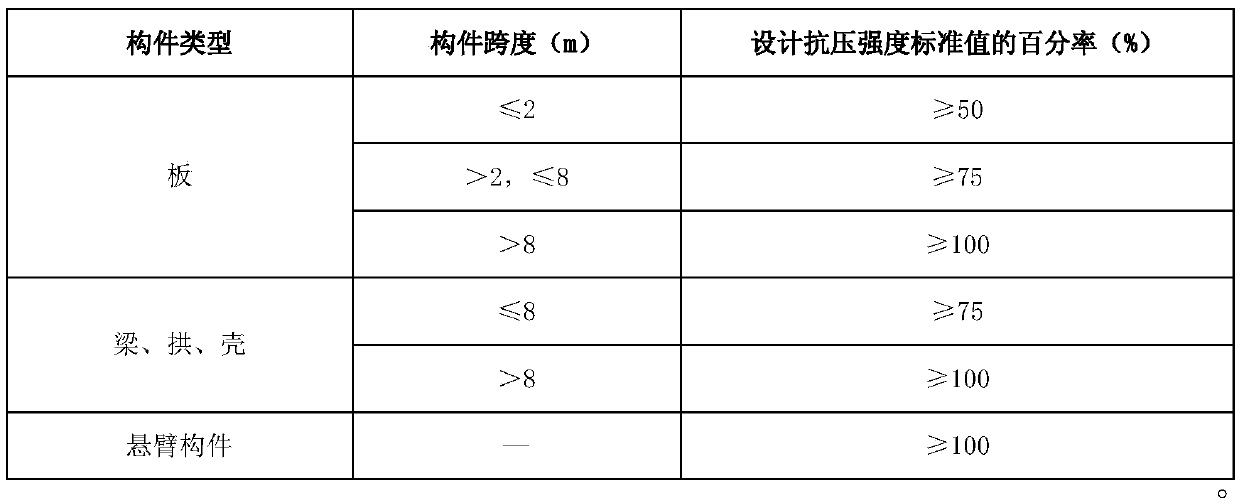

On-site concrete hollow floor construction method of LPM light filling embodies

InactiveCN110080454AReduce dosageSimple processConstruction materialFloorsStructure of the EarthEngineering

The invention discloses an on-site concrete hollow floor construction method of LPM light filling embodies. The construction method comprises the steps that a plate bottom formwork is erected, plate bottoms and hidden rib beam steel bar binding cushion blocks are installed, anti-floating drilling is conducted; and plate bottoms and hidden rib beam steel bars are bound, and a specially-assigned person is dispatched to punch holes in the bottom plate template according to the anti-floating distribution diagram, install water and electric pipelines, hoist LPM light filling pieces, place the filling pieces, bind plate surface reinforcing steel bars, reinforce anti-floating iron wires of the filling pieces, pour concrete, maintain, demold and the like. The method is simple in process, convenient to construct and easy to operate; by the adoption of the technology in a proper structure, the engineering quality is guaranteed, and meanwhile the beneficial effects of being small in concrete consumption, large in space, low in structural self-weight, small in earthquake acting force, good in structural heat insulation and sound insulation performance, capable of shortening the construction period and the like are achieved.

Owner:中联世纪建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com