Retarded adhesive prestressed steel reinforced concrete beam

A technology for slow-bonding prestressed concrete beams, applied in the field of shaped steel concrete beams, can solve the problems of slow speed, complicated construction of bonded prestressed bars, etc., achieves fast speed, is conducive to popularization and application, and is resistant to bending limit load. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with specific embodiments.

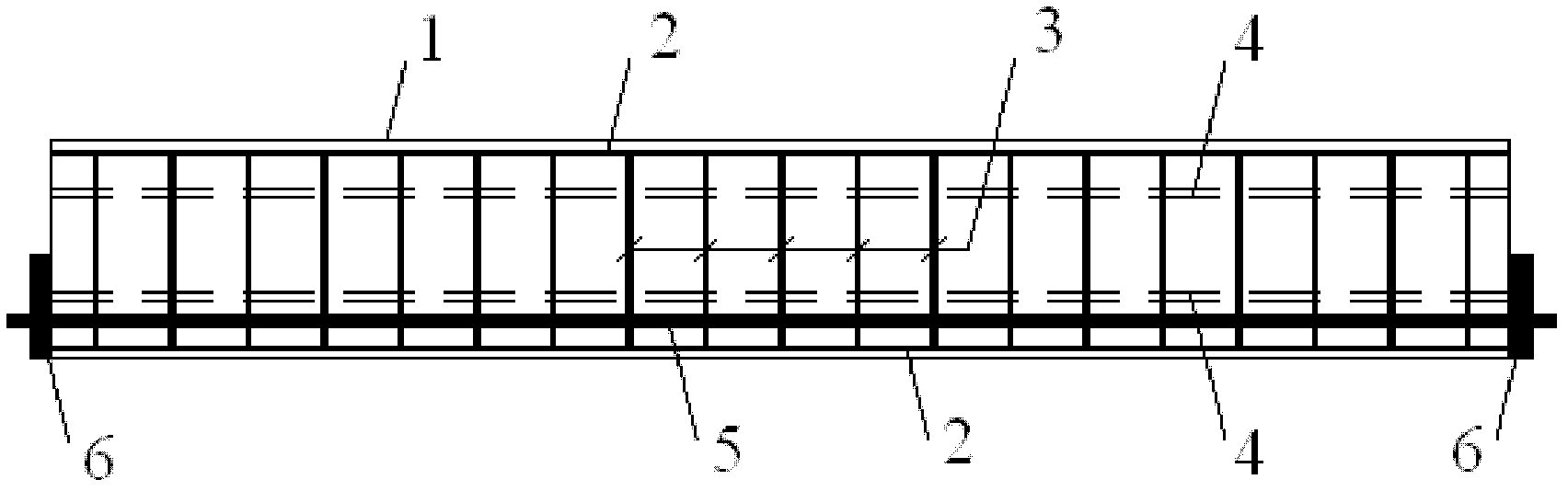

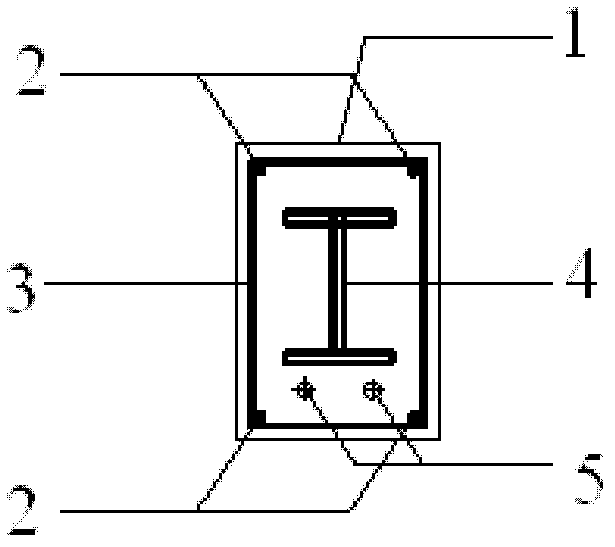

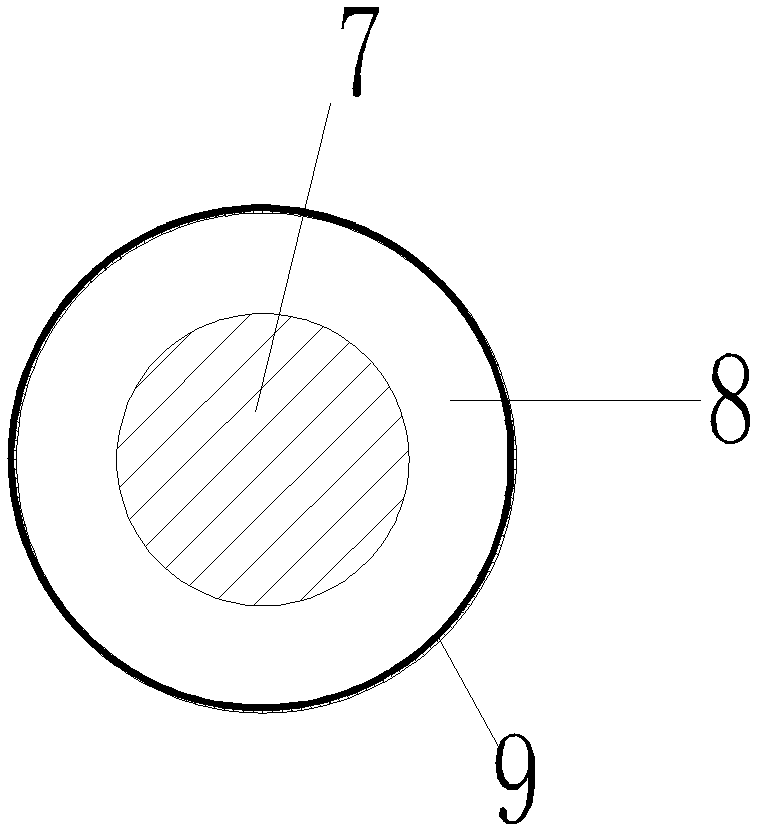

[0017] A slow-bonding prestressed steel concrete beam, comprising a concrete beam 1, in which a non-prestressed tendon 2 is arranged, and a stirrup 3 is bound and installed outside the non-prestressed tendon 2. The inside of the concrete beam 1 The non-prestressed tendon 2 is provided with an I-beam 4, and a slow-bonding prestressed tendon 5 is provided on the underside of the I-beam 4 through the concrete beam 1. The slow-bonded prestressed tendon 5 is used in the prestressing The stress tendons 7 are wrapped with a retarded mortar 8 and then wrapped with an impermeable plastic sheet 9 outside the retarded mortar 8.

[0018] The slow-bonding prestressed tendons 5 pass through the concrete beam 1 and are fixed on the concrete beam 1 with anchoring devices 6.

[0019] The I-shaped steel 4 is symmetrically arranged in the middle of the section of the concrete beam 1.

[0020] There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com