On-site concrete hollow floor construction method of LPM light filling embodies

A construction method and hollow-core floor technology, which is applied to the preparation of floor slabs, formwork/formwork/work frames, and building components on site, can solve problems that cannot meet the needs of green construction, achieve convenient horizontal and vertical transportation, and shorten the construction period , the effect of less concrete consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A construction method for LPM light-weight filling embodying poured concrete hollow floors. The LPM light-weight filling body is mainly filled with self-extinguishing flame-retardant lightweight porous material—polyphenylene foam, with reinforcement and isolation layers outside; The material is wrapped with an isolation layer for protection and waterproofing, and a reinforcement layer is set on the top or bottom surface to resist construction and floating loads;

[0041] The construction method includes the following steps:

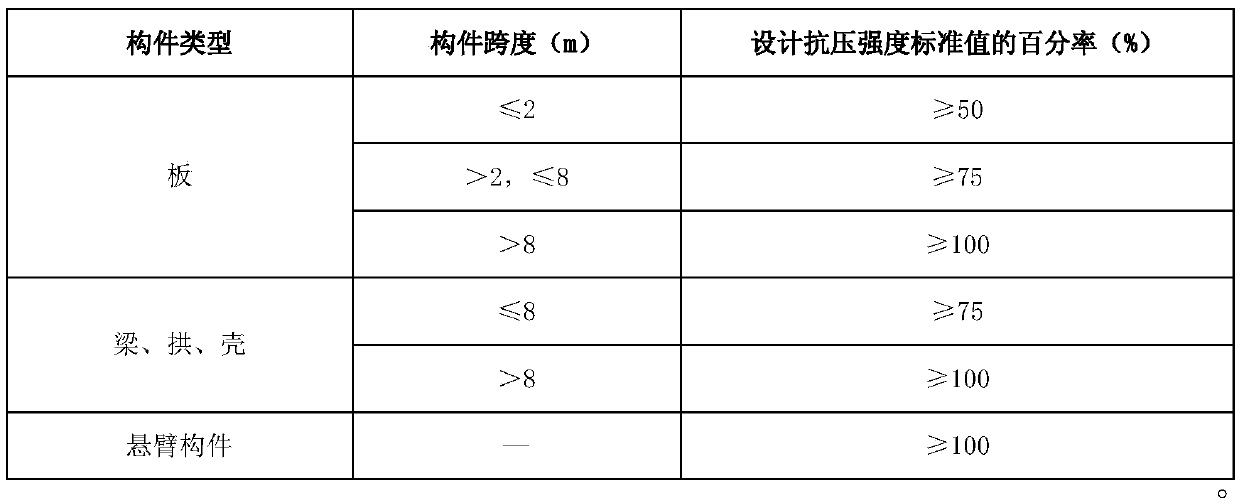

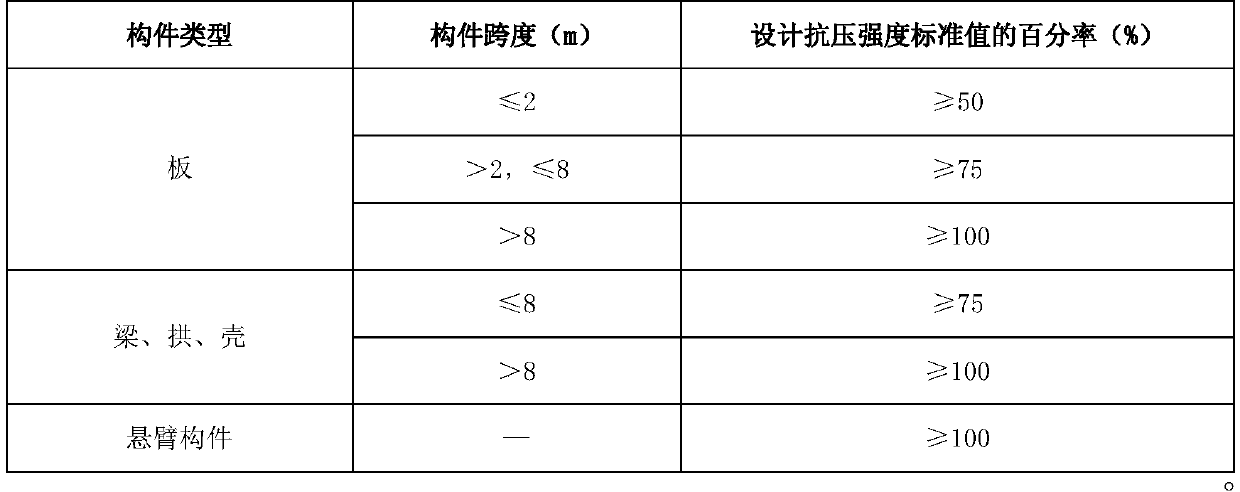

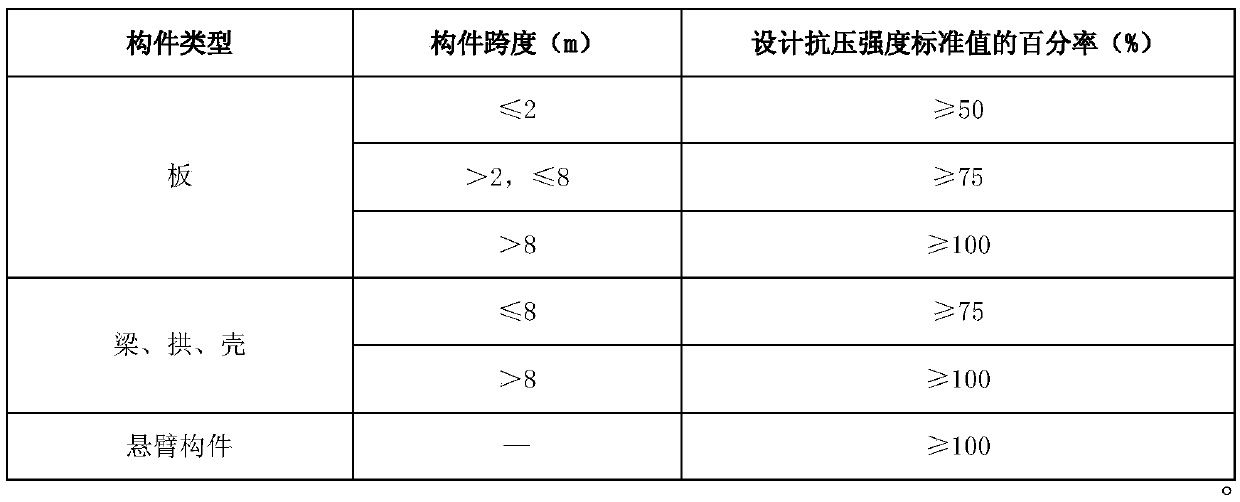

[0042] (1) Formwork for supporting the bottom of the slab

[0043] The bottom formwork of the hollow floor is made of 15mm multi-layer board, the secondary keel is made of 40mm×90mm wooden square, the main keel is made of 48mm×3.2mm double steel pipes, and the support adopts the fastener type steel pipe full house scaffold system. Adjust the top support; when the span of the slab is ≥ 4m, the top slab must be arched, and the height of the arch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com