Lightweight-steel-structure grain storing granary

A light steel structure and granary technology, applied in climate change adaptation, building types, buildings, etc., can solve the problems of unreasonable use of space, energy consumption, slow construction speed, etc., to achieve significant ventilation effect, reduce adverse effects, construction fast cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

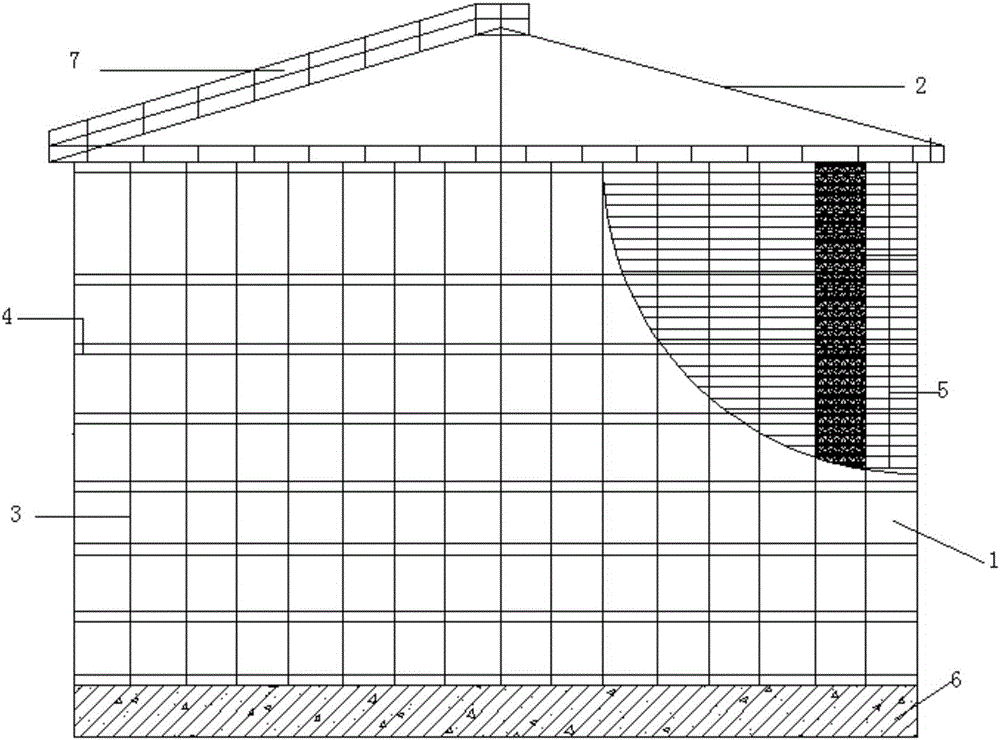

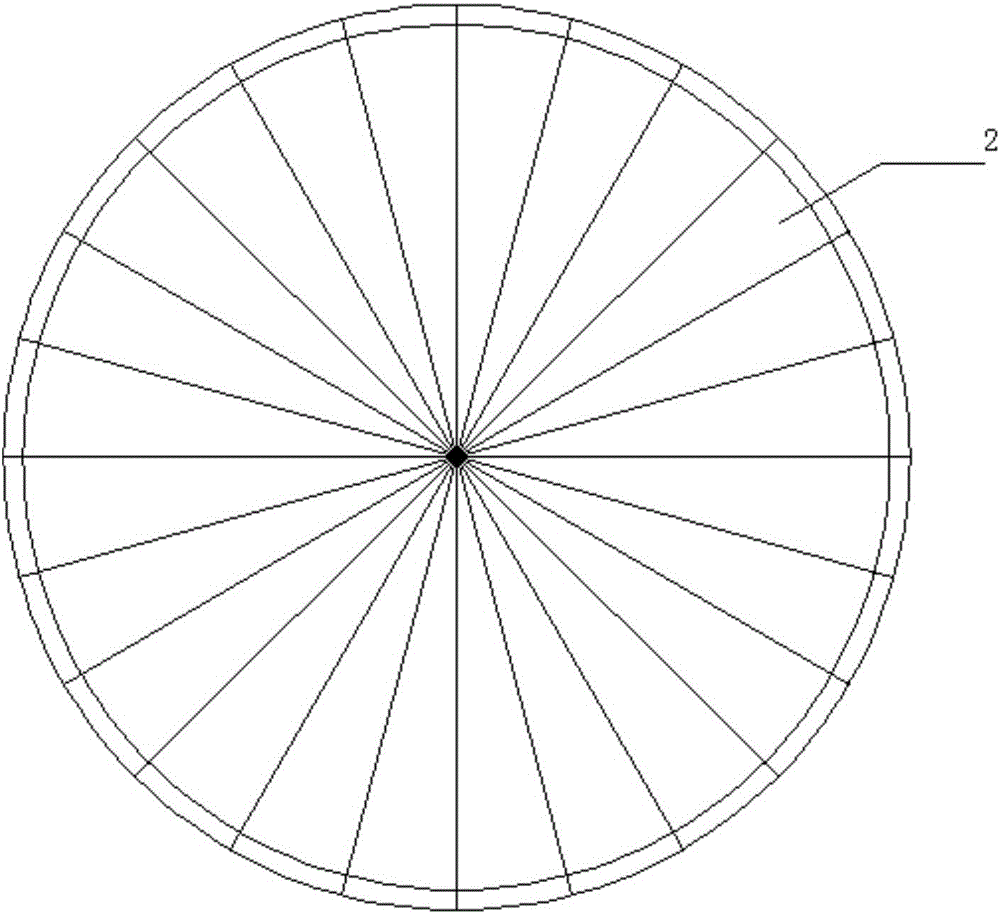

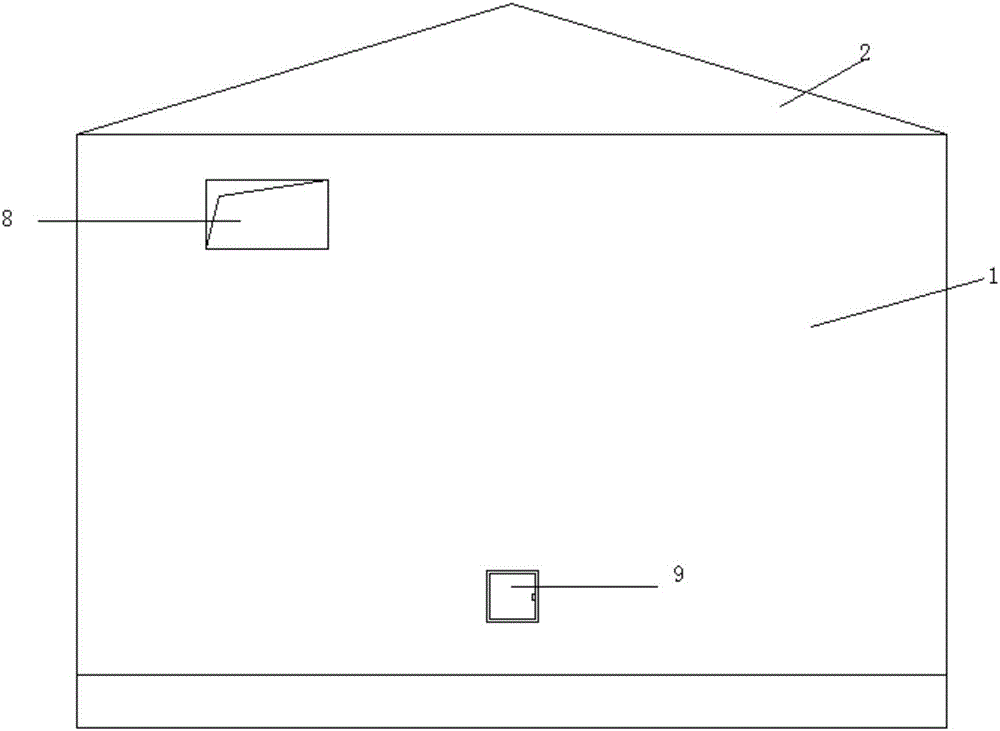

[0031] The structure of the light steel structure grain storage silo is as follows: figure 1 and figure 2 As shown, the structure of the light steel structure grain storage silo is 8-10m high, the diameter of the storage body is 14 meters long, and the height of grain storage is 7.2m.

[0032] When building, the foundation 6 shall be rammed and pressed first, and a 20cm reinforced concrete foundation shall be made, and a waterproof layer and troweling shall be done. The column 3 of the warehouse body 1 and the conical roof truss of the roof 2 are all made of light round steel pipes, and the steel pipes are treated with double-sided lap welds. The bottom of each column 3 and the foundation 6 are welded with steel bars. The size of the welds meets Relevant national norms and requirements.

[0033] The warehouse body 1 is welded with a circle of steel bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com