Bamboo wood with mildew-proof performance and modification method thereof

A bamboo material and high-performance technology, which is applied in the direction of impregnating wood, wood impregnation, and manufacturing tools, can solve the problems of losing the color and texture of bamboo, dark color of modified bamboo, and large amount of modified reagents. The preparation method is easy to operate and low cost. Low, good anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

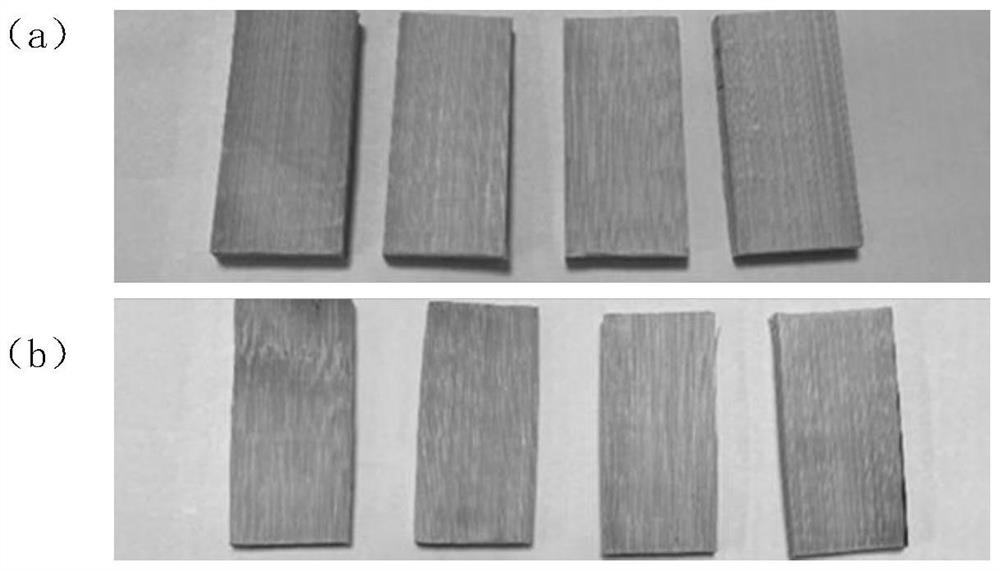

[0030] 1. Preparation: (1) Bake the Moso bamboo sample (50mm*20mm*5mm) to an absolutely dry state (that is, the free water and bound water in the bamboo are completely removed) to obtain an absolutely dry Moso bamboo sample, which is sealed for use;

[0031] (2) prepare 500 mL of N-methylol acrylamide aqueous solution with a mass concentration of 2%, add ammonium persulfate as a catalyst (the mass of ammonium persulfate is 1% of the added mass of N-methylol acrylamide) and stir A clear and transparent modified solution was obtained.

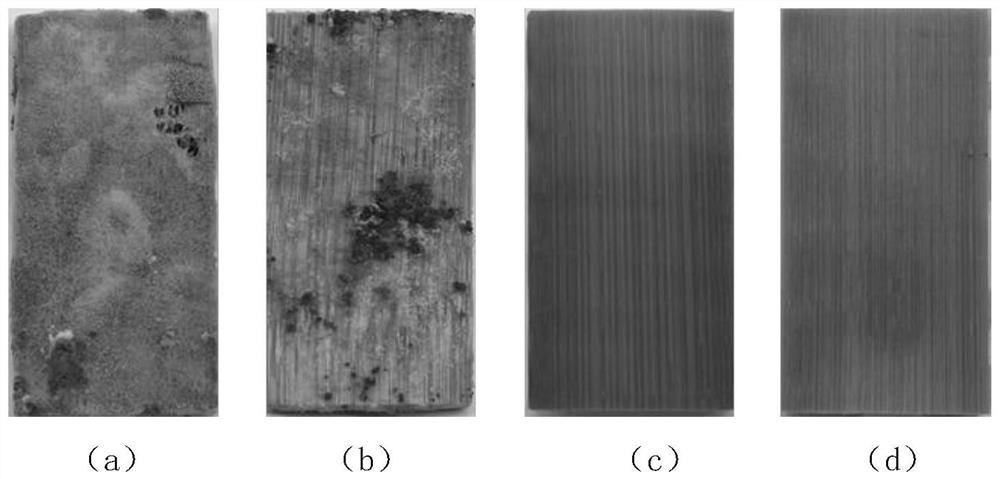

[0032] (3) Completely immerse the dry bamboo sample in the modified solution, vacuum for 1 hour, then pressurize to 0.8MPa, and maintain the pressure for 3 hours. Continue to soak at atmospheric pressure for 8h after depressurization. After taking it out, it was placed in an oven, and polymerized at 80° C. for 12 hours; after polymerization, it was dried to absolutely dry at 105° C. to obtain a modified bamboo material, which was a bamboo materi...

Embodiment 2

[0035] 1. Preparation: (1) Bake the Moso bamboo sample (50mm*20mm*5mm) to an absolutely dry state (that is, the free water and bound water in the bamboo are completely removed) to obtain an absolutely dry Moso bamboo sample, which is sealed for use;

[0036] (2) prepare 500mL of N-methylol acrylamide aqueous solution with a mass concentration of 4%, add ammonium persulfate as a catalyst (the quality of ammonium persulfate is 1% of the added N-methylol acrylamide mass), stir A clear and transparent modified solution was obtained.

[0037] (3) Completely immerse the dry bamboo sample in the modified solution, vacuum for 1 hour, then pressurize to 0.8MPa, and maintain the pressure for 3 hours. After depressurization, it was soaked at normal pressure for 8 hours, placed in an oven, and polymerized at 80 °C for 8 hours; after polymerization, it was dried at 105 °C to dryness to obtain modified bamboo, which is bamboo with anti-mildew properties.

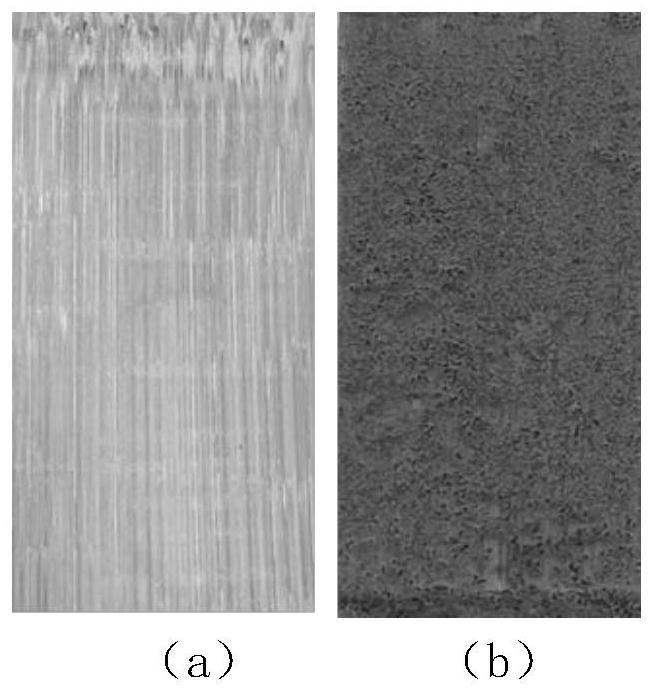

[0038] 2. Anti-mildew test: The a...

Embodiment 3

[0040] 1. Preparation: (1) Bake the Moso bamboo sample (50mm*20mm*5mm) to an absolutely dry state (that is, the free water and bound water in the bamboo are completely removed) to obtain an absolutely dry Moso bamboo sample, which is sealed for use;

[0041] (2) prepare 500mL N-methylol acrylamide aqueous solution whose mass concentration is 6%, add ammonium persulfate (the quality of ammonium persulfate is 1% of the added N-methylol acrylamide mass) as a catalyst, stir A clear and transparent modified solution was obtained.

[0042] (3) Completely immerse the dry bamboo sample in the modified solution for 2 days under normal pressure. The sample was taken out and placed in an oven, and polymerized at 65°C for 12 hours; after polymerization, it was dried at 105°C to dryness to obtain modified bamboo, which is bamboo with anti-mold properties.

[0043] 2. Anti-mildew test: The anti-mildew effect of the bamboo with anti-mildew properties obtained in this example is 0 (the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com