Nano silicasol / acrylic ester composite emulsion and preparation thereof

A nano-silica sol, acrylate technology, applied in coatings and other directions, can solve the problems of reducing emulsion stability, time-consuming, cumbersome process, etc., and achieve the effect of eliminating modification steps, reducing usage, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

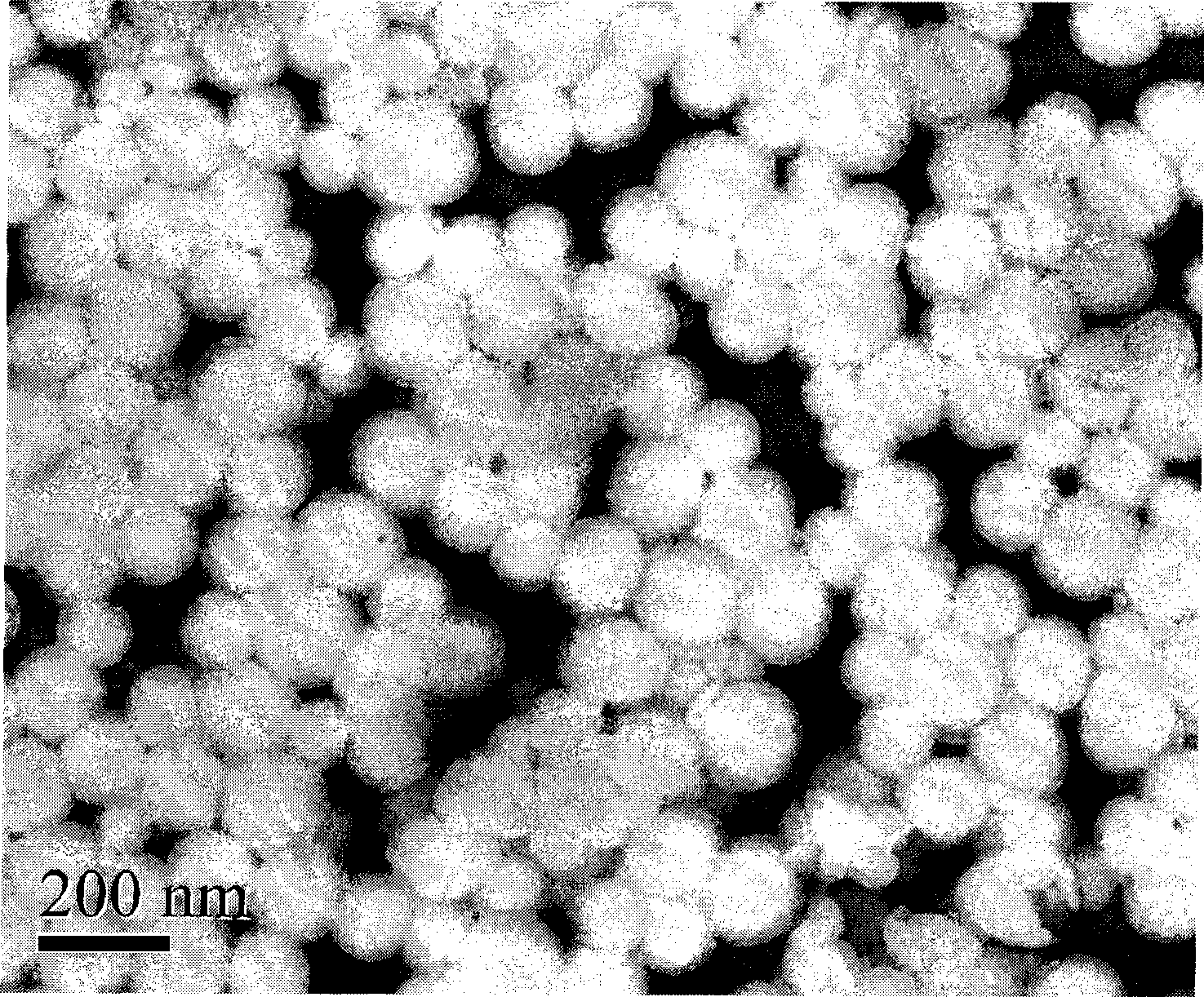

[0030] Take the commercially available acidic nano silica sol (SiO 2 The content is 3 grams, the primary particle size is 20nm, pH=3), 4.5 grams of ethanol are mechanically dispersed in 50 grams of water for 20 minutes at high speed, the dispersed mixed solution is added to the flask and heated to 80°C, and (NH 4 ) 2 S 2 O 8 0.2 g, NaHCO 3 0.2 g, and pre-mix 80 g of butyl acrylate, 60 g of methyl methacrylate, 5 g of methacrylic acid, 2.5 g of sodium lauryl sulfate, and 2.5 g of nonyl phenol polyoxyethylene ether OP-10 emulsifier And 50g of water are mixed and pre-emulsified for 15 minutes to form a monomer pre-emulsified liquid; take 10% of the monomer pre-emulsified liquid dropwise into the flask, control the reaction temperature at 80 ℃, after the reaction proceeds for 30 minutes, drop the remaining monomer pre-emulsified Liquid and initiator ((NH 4 ) 2 S 2 O 8 And buffer NaHCO 3 A solution of 0.8 g and 50 g of water is heated to 85°C for 2 hours after the dripping is completed...

Embodiment 2

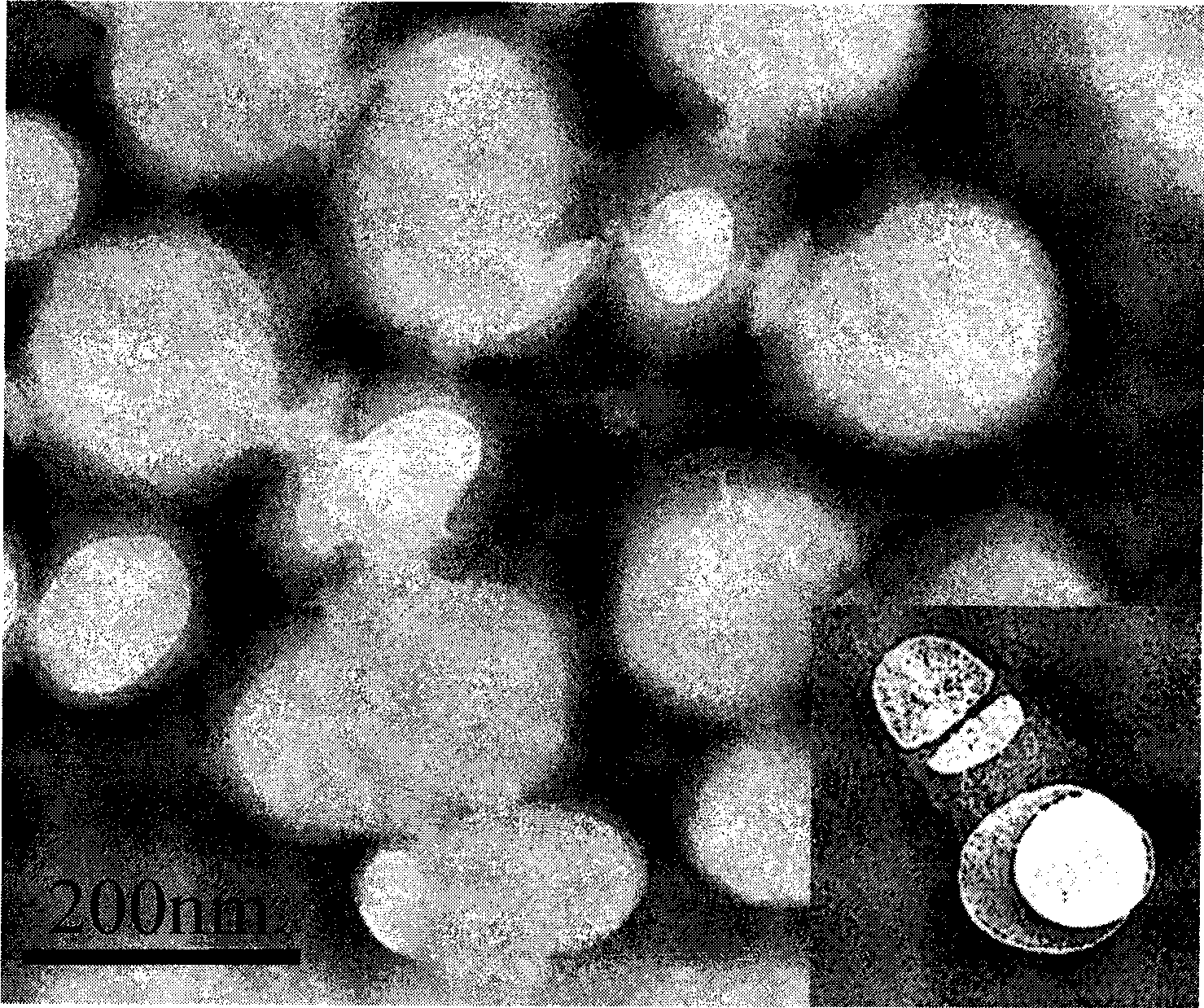

[0032]Take commercially available alkaline nano silica sol (SiO 2 The content is 4.5 grams, the primary particle size is 10nm, pH=10.5), 6 grams of propylene glycol, 80 grams of water, 3 grams of sodium lauryl sulfate, nonyl phenol polyoxyethylene ether OP-101.8 grams, and butyl acrylate 60 grams , 80 grams of butyl methacrylate, 4 grams of acrylic acid and 4 grams of hydroxyethyl methacrylate mixed, pre-emulsified for 15 minutes into a pre-emulsified liquid; (NH 4 ) 2 S 2 O 8 1.5 grams, NaHCO 3 1.5 grams and 50 grams of water are used to prepare the initiator and buffer solution; first take 10% of the pre-emulsion solution and add 5% of the initiator and buffer solution dropwise at the same time. After reacting at 80°C for 30 minutes, add the remaining pre-emulsion solution dropwise. Emulsion and initiator and buffer solution are heated to 85°C for 2 hours after dripping. After cooling, ammonia water is added to adjust the pH value to 9, and the material is discharged.

Embodiment 3

[0034] Take commercially available alkaline nano silica sol (SiO 2 The content is 1.2 grams, the primary particle size is 7nm, pH=8), 3 grams of isooctyl alcohol, 50 grams of water, 1.8 grams of sodium lauryl sulfate, nonyl phenol polyoxyethylene ether OP-101.2 grams, ethyl acrylate 30 grams, 30 grams of hexyl acrylate, 25 grams of methyl methacrylate, 10 grams of butyl methacrylate, 3 grams of acrylic acid and 2 grams of methacrylic acid were mixed, pre-emulsified for 15 minutes into a pre-emulsion; K 2 S 2 O 8 0.5 g, NaHCO 3 0.5 g and 30 g of water are used to prepare the initiator and buffer solution; first take 15% of the pre-emulsion solution and add 10% of the initiator and buffer solution dropwise, react at 82°C for 30 minutes, and then add the remaining pre-emulsion solution dropwise The emulsified liquid and the aqueous solution of initiator and buffer are heated to 85°C for 2 hours after the dripping is completed. After cooling, ammonia water is added to adjust the pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com