Preparation method for negative electrode active material of lithium ion battery

A negative electrode active material, lithium ion battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem that the electrochemical performance of silicon negative electrode materials cannot be effectively improved, silicon nanoparticles are easy to agglomerate, and the coating is uneven, etc. problems, to achieve the effect of improving cycle stability, avoiding adhesion, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

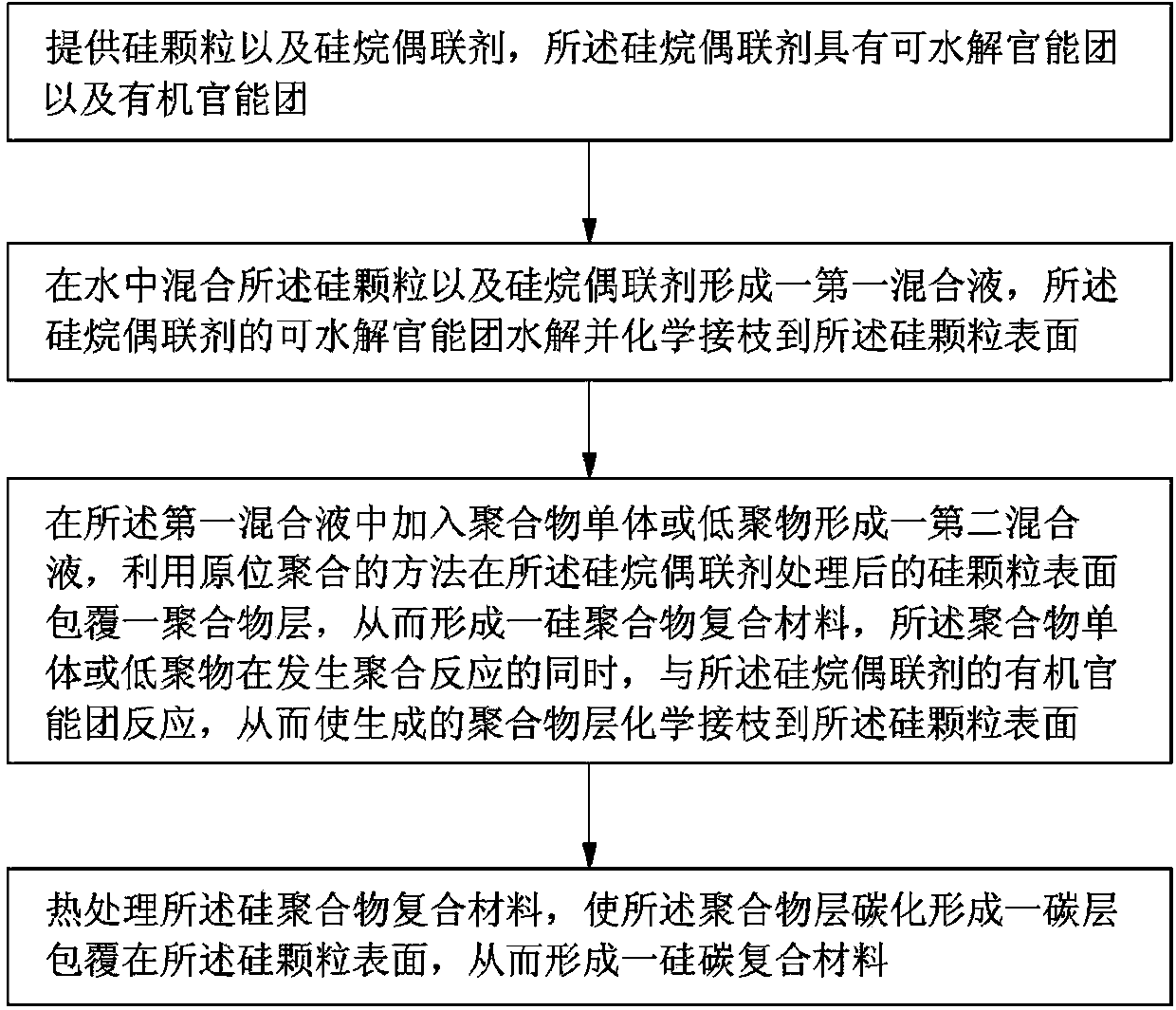

[0017] see figure 1 , the embodiment of the present invention provides a kind of preparation method of negative electrode active material of lithium ion battery, comprises the following steps:

[0018] S1, providing silicon particles and a silane coupling agent, the silane coupling agent has a hydrolyzable functional group and an organic functional group;

[0019] S2, mixing the silicon particles and a silane coupling agent in water to form a first mixed solution, wherein the hydrolyzable functional groups of the silane coupling agent are hydrolyzed and chemically grafted onto the surface of the silicon particles;

[0020] S3, adding polymer monomers or oligomers to the first mixed solution to form a second mixed solution, and coating a polymer layer on the surface of the silicon particles by in-situ polymerization to form a silicon polymer In a composite material, the polymer monomer or oligomer reacts with the organic functional group of the silane coupling agent while unde...

Embodiment

[0050] 1.2 g of nano-silicon powder was dispersed in 100 ml of ethanol solution, and then 1.5 ml of hydrofluoric acid was added to etch the silicon powder for 2 hours. Then, 50 ml of deionized water and 50 ml of ethanol were added to the ethanol solution dispersed with silicon powder, and the dispersion liquid was formed by ultrasonication in an ultrasonic magnetic crusher for 3 hours. Add 1 ml of vinyltriethoxysilane coupling agent dropwise to the dispersion liquid and continue ultrasonic stirring to form the first mixed liquid. Then this first mixed solution is poured in a three-necked flask, and 1ml nitric acid is added in this first mixed solution to keep this first mixed solution under acidic environment. 5 ml of acrylonitrile monomer and 0.05 g of benzoyl peroxide as an initiator were added to the first mixed liquid to form a second mixed liquid. The second mixed solution was heated under a constant temperature oil bath at 80°C to cause free radical in-situ polymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com