Rice cooling device

A technology of cooling device and refrigeration device, which is applied in applications, grain processing, agriculture, etc. It can solve the problems of easy dehydration of rice, inability to dissipate heat, and reduce shipments, so as to improve processing quality and pass rate, and reduce enterprise site area, the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

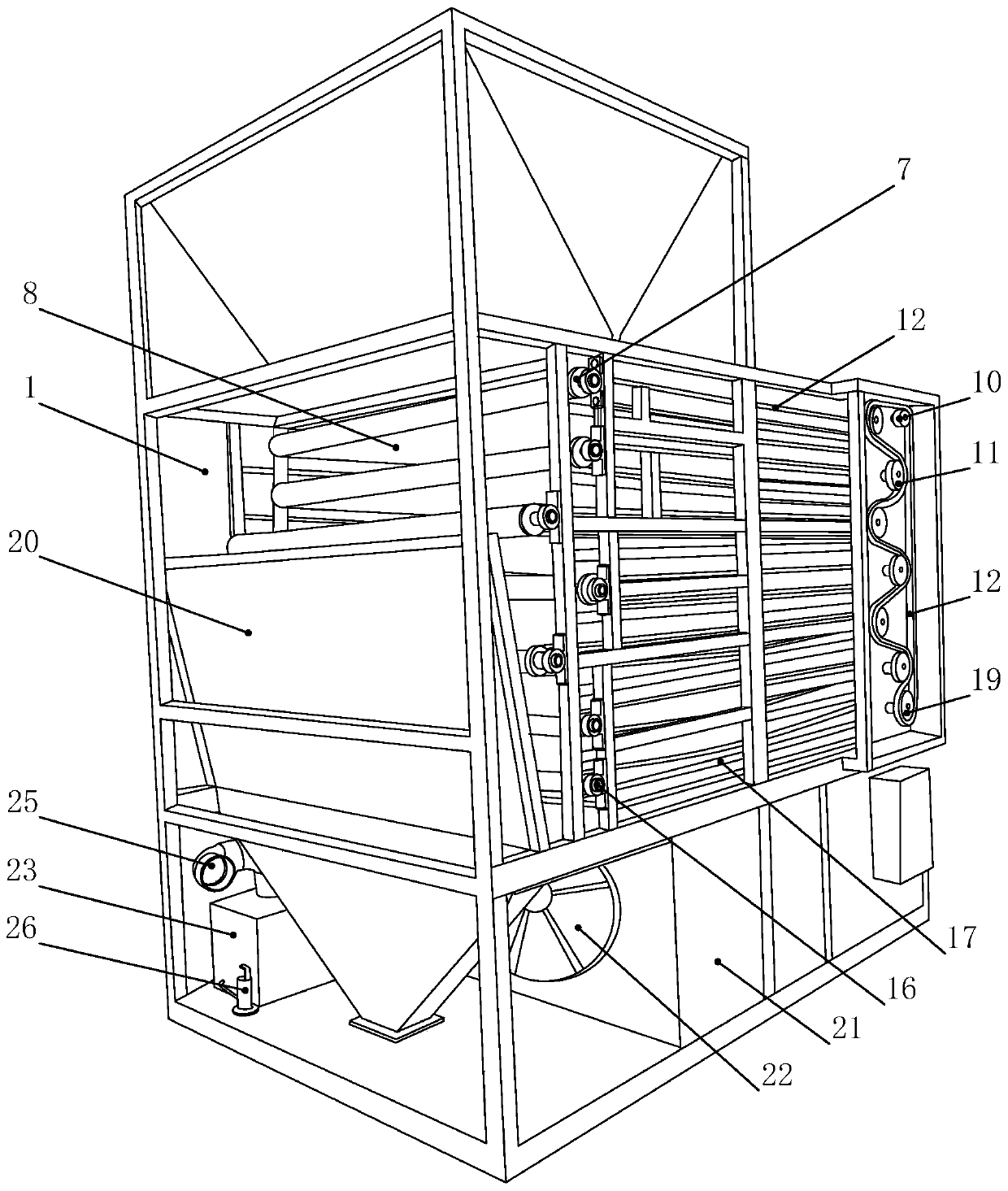

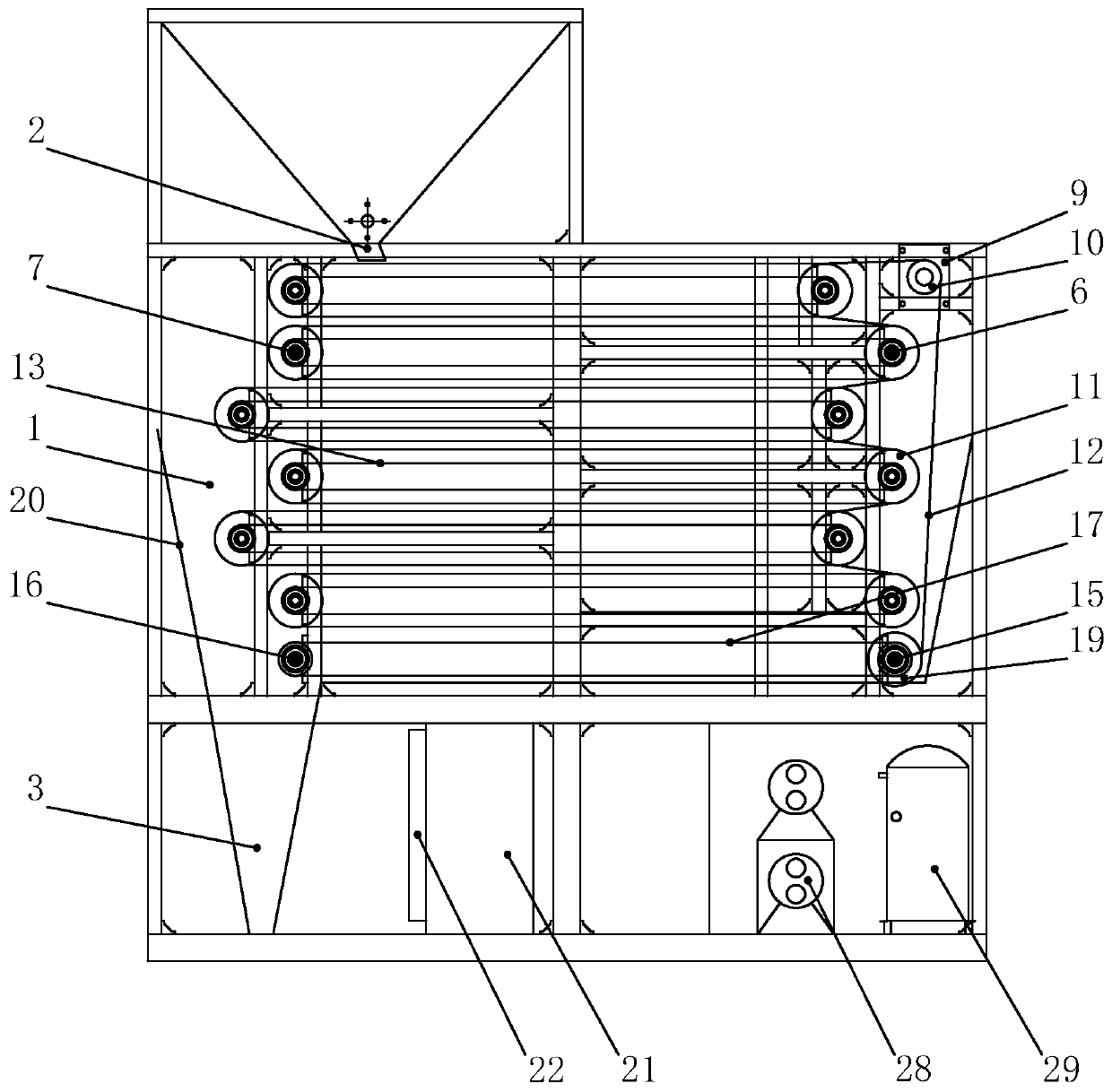

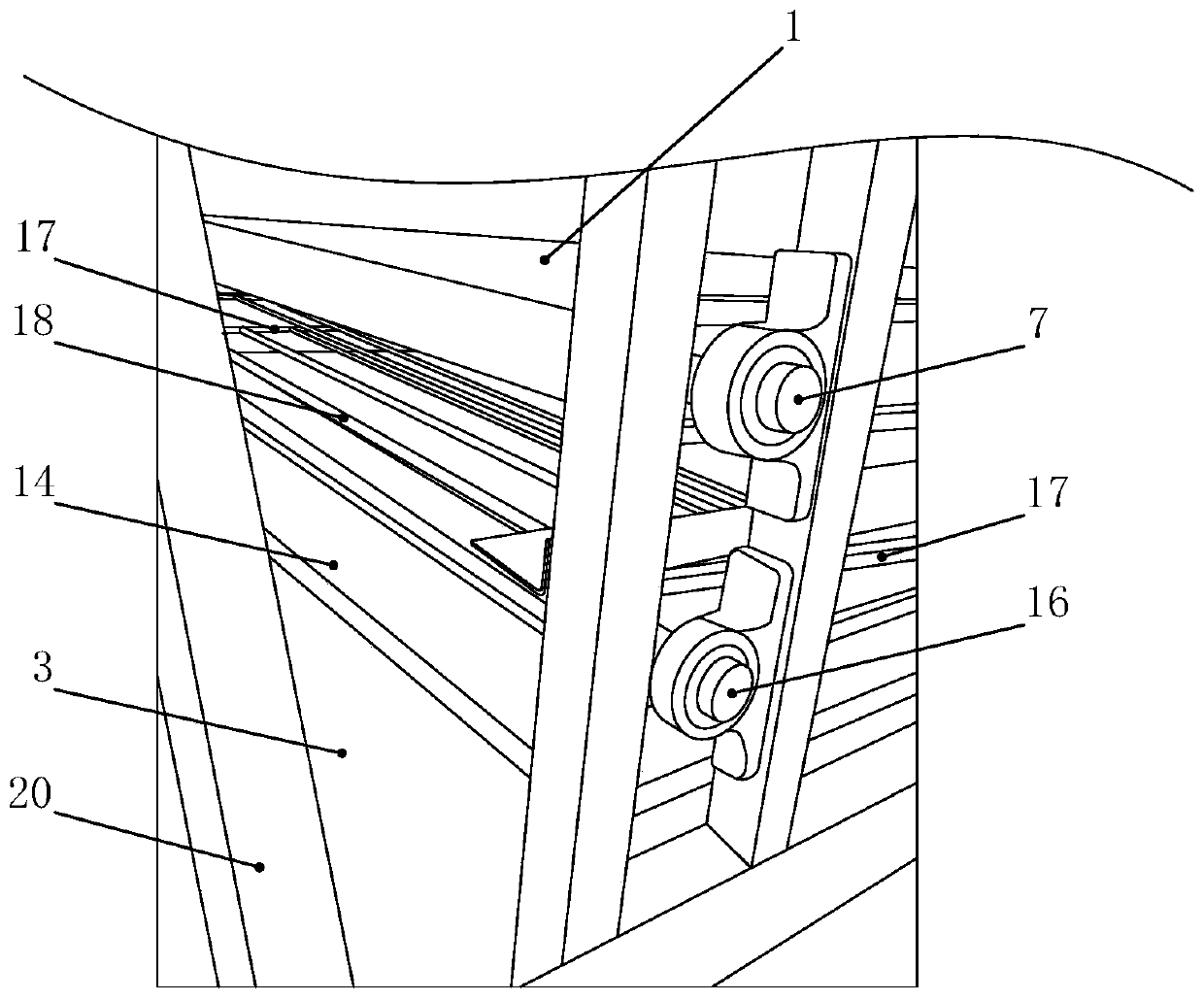

[0023] The present invention will be further described below with specific embodiment, see figure 1 -5:

[0024] A rice cooling device, comprising a cooling chamber 1, on the cooling chamber 1, several rice conveying assemblies are arranged vertically at intervals, two adjacent rice conveying assemblies up and down are alternately arranged left and right, and the last rice conveying assembly The conveying end is opposite to the conveying head of the next rice conveying assembly, a feed inlet 2 is arranged above the conveying head of the rice conveying assembly at the top, and a discharge port is arranged below the conveying end of the rice conveying assembly at the bottom 3. The cooling chamber 1 is provided with a refrigerating device, a humidifying device, a temperature sensor 4 for detecting the temperature in the cooling chamber 1, and a humidity sensor 5 for detecting the humidity in the cooling chamber 1, the refrigerating device, the humidifying device, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com