Progressive die

A technology of progressive die and die base, applied in the field of progressive die, can solve the problems of inability to meet the requirements of manufacturing products, lower yield and work efficiency, inability to realize blanking work, etc., to meet product manufacturing requirements and reduce transportation. and warehouse occupancy, the effect of easy automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

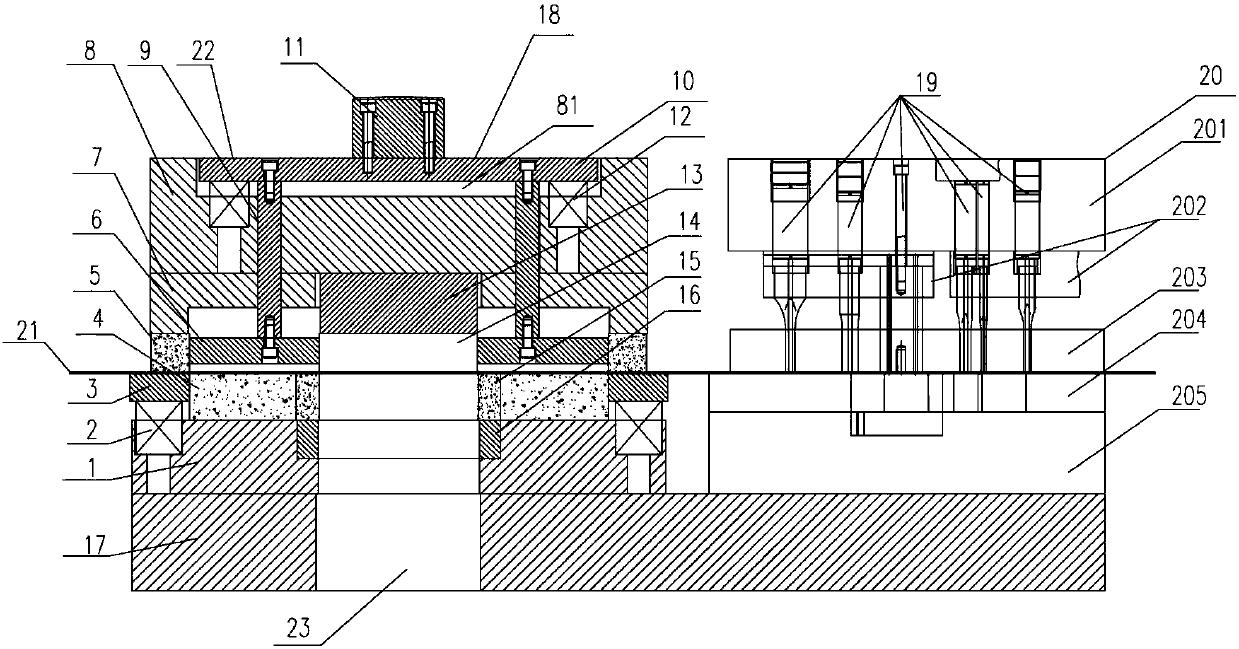

[0017] Such as figure 1 As shown, a progressive die described in this embodiment includes a lower die backing plate 17, and the lower die backing plate 17 is sequentially fixed with porous punching dies 20 for sequentially punching porous products, And the compound blanking die 22 that is used for punching, blanking, the compound blanking die 22 comprises upper mold base 8, blanking die fixed plate 7, blanking die 5, unloading plate 3 and The lower mold base 1 fixed with the lower mold base backing plate 17, the top of the upper mold base 8 is provided with a groove 81, the groove 81 has a push plate 10, and the bottom surface of the push plate 10 is fixed with a dowel 9; The concave part of the mold fixing plate 7 is matched with the through hole of the blanking die 5 to form a cavity, and the punching plate 6 is built in the cavity; After the plate 7 is fixed with the beating plate 6; the bottom surface of the upper die base 8 is fixed with an inner hole punch fixing plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com