Steel-concrete combined building structure and its construction method

A technology of building structure and building envelope structure, applied in the field of steel-concrete composite building structure and its construction, can solve the problems of lack of matching and serialization of building materials, immature and perfect application of complete sets of technology, complex construction technology, etc., to achieve Significant energy saving effect, light structure weight and high level of building industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

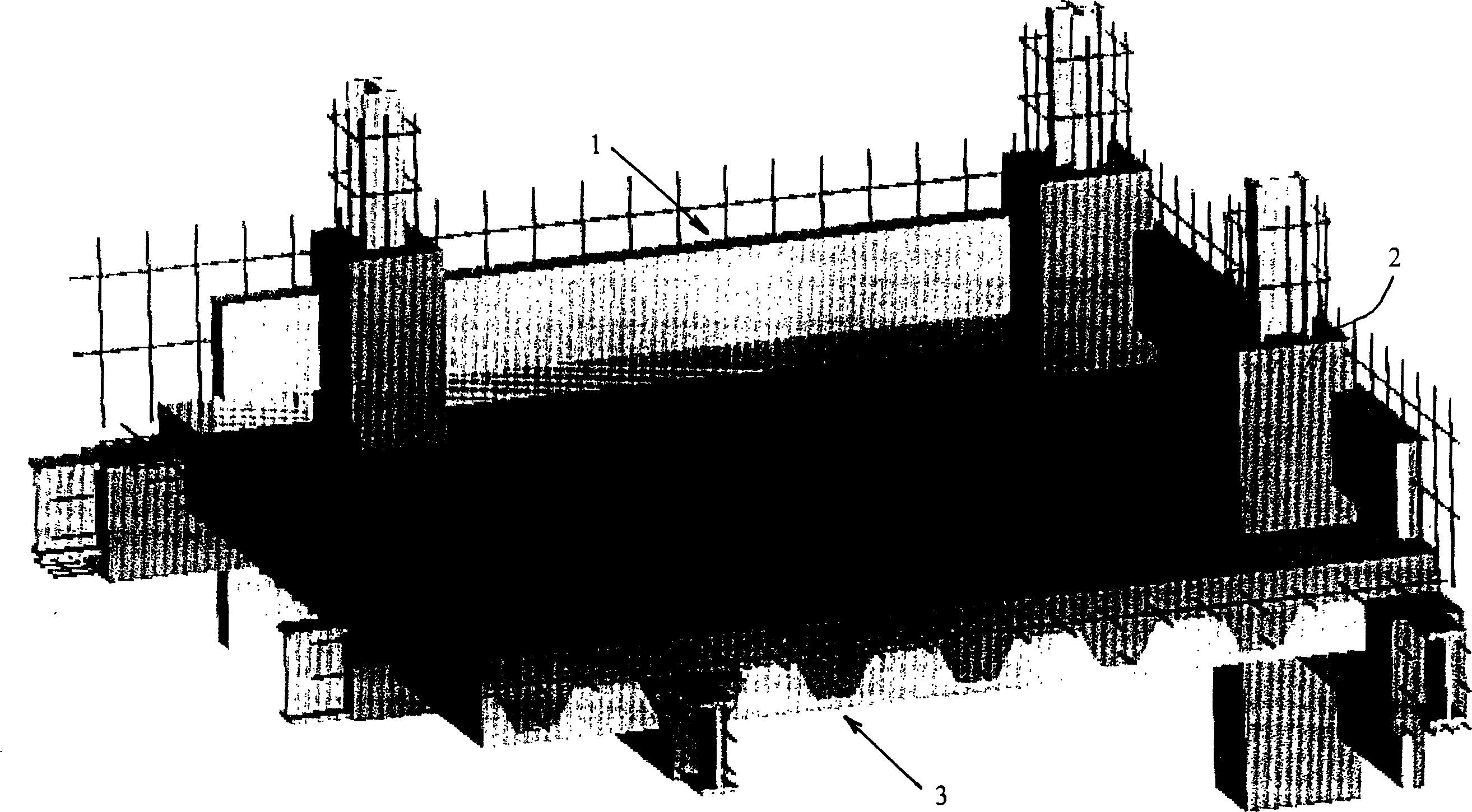

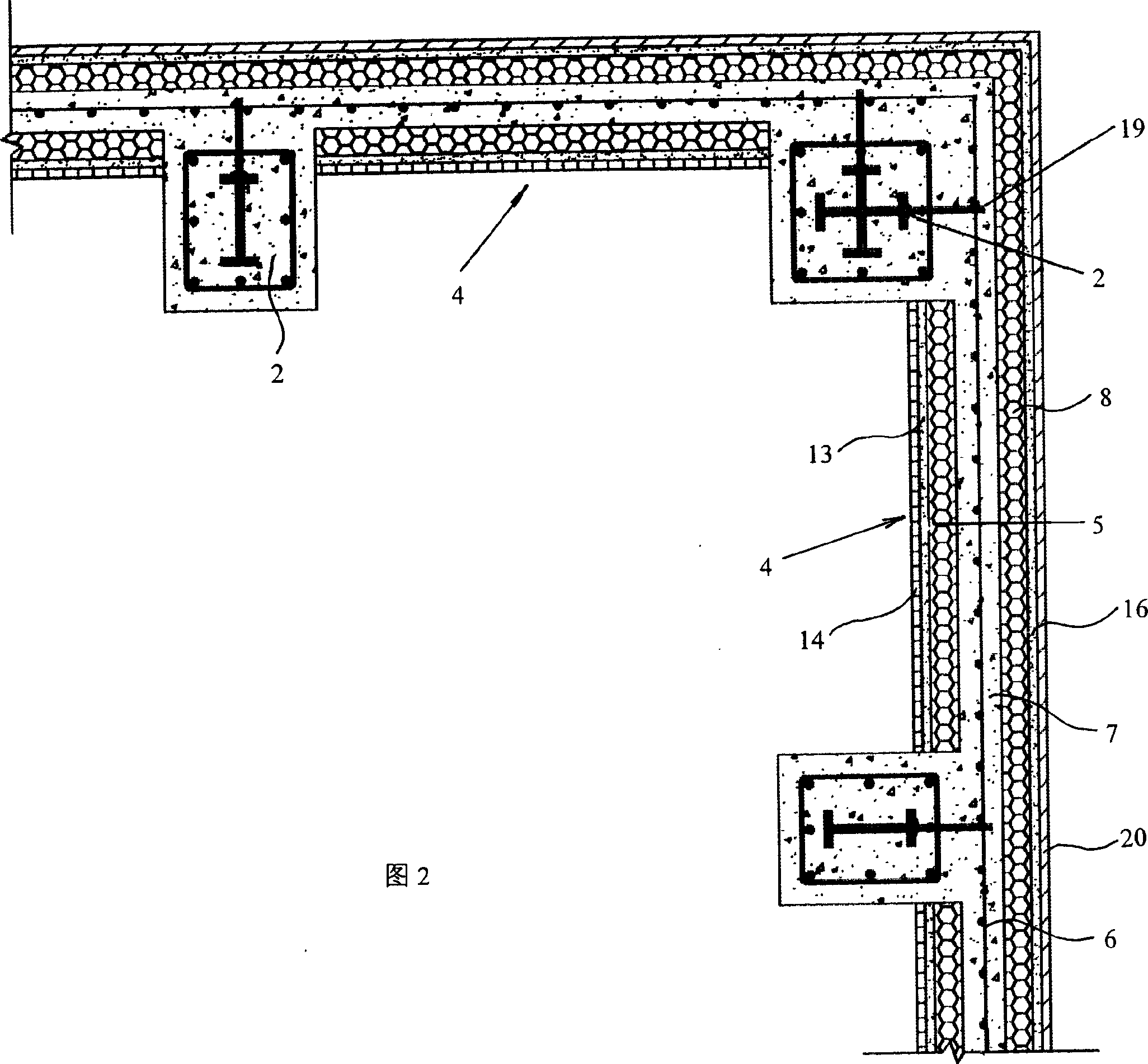

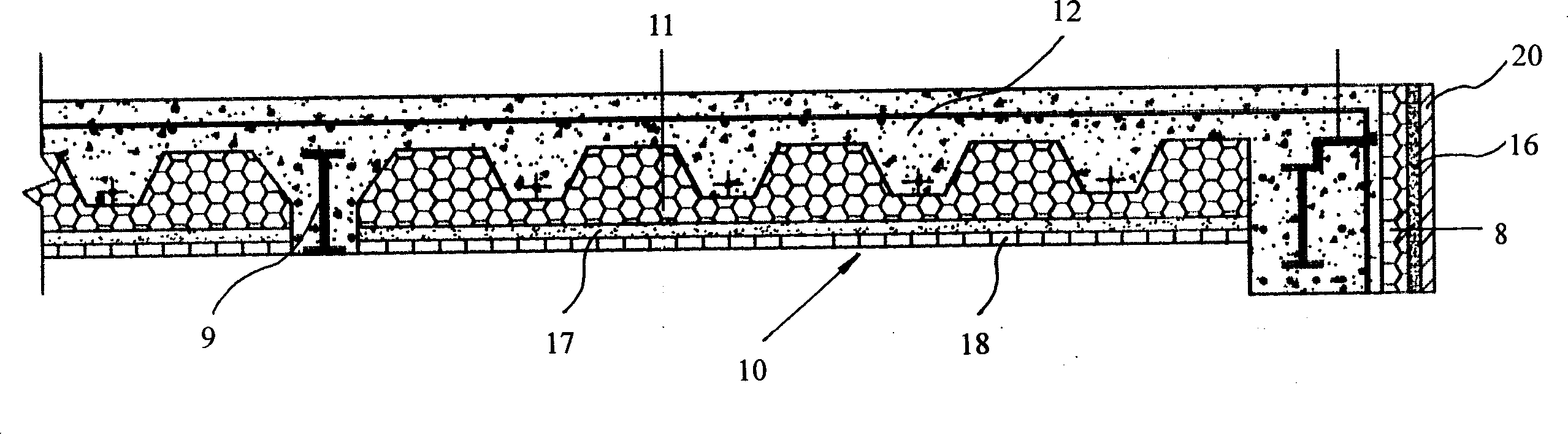

[0036] figure 1 The three-dimensional schematic diagram of the steel-concrete composite building structure shown in the figure shows only a part. The whole building structure is composed of several load-bearing columns, building envelope 1 and several layers of steel-concrete composite floors 3. The load-bearing columns are The steel-reinforced concrete columns 2 in the vertical direction are set at intervals required by the design. The steel-reinforced concrete columns are reinforced concrete surrounded by steel members, also called stiff concrete. The steel-concrete composite floor 3 is arranged horizontally at intervals according to the design requirements to form each floor of the building. The steel-concrete composite floor 3 can also use other floor components, and the building envelope 1 is arranged on Between the steel-reinforced concrete col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com