Hollow sandwich steel pipe concrete pole for power transmission line

A technology for concrete filled steel tubes and transmission lines, which is applied in the field of towers and towers of overhead transmission lines, can solve the problems of cross-section development and large bending stiffness, and achieves the effects of flexible selection of tower positions, saving consumption and reducing foundation force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

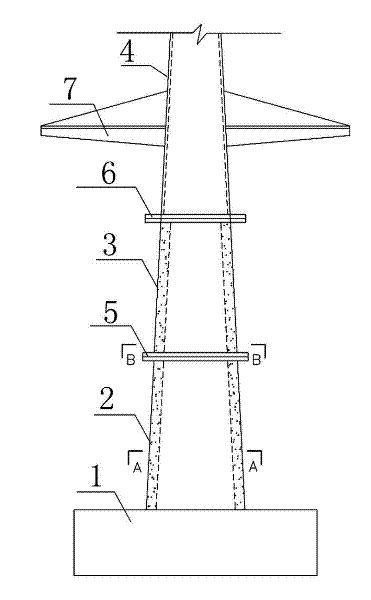

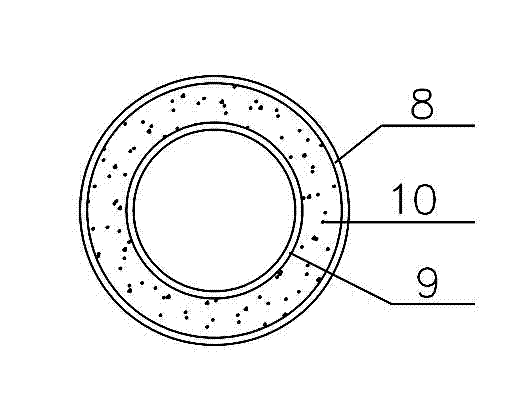

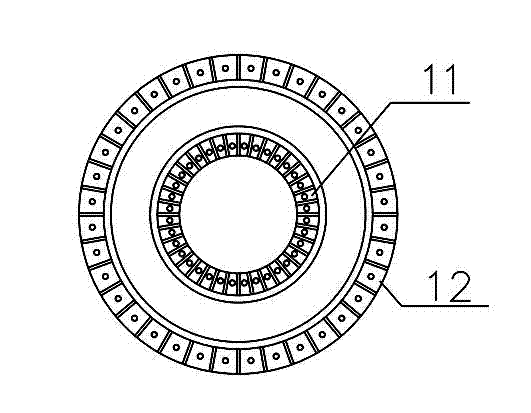

[0026] A hollow interlayer concrete-filled steel pipe rod for transmission lines provided in this specific embodiment includes foundation 1, hollow interlayer concrete-filled steel pipe rod sections 2, 3, hollow steel pipe members 4, inner and outer wall flanges 5, ordinary flanges 6, and wire crossarms 7. Among them, the hollow interlayer concrete-filled steel pipe section is composed of outer steel pipe 8 , inner steel pipe 9 and interlayer concrete 10 .

[0027] During installation, the reinforced concrete foundation 1 is first constructed, then the inner steel pipe 9 is hoisted, and the outer steel pipe 8 is hoisted in place, and the interlayer concrete 10 is poured between the two layers of steel pipes. 4 and the lower structure are connected by ordinary flange 6, and after the pole body is installed, the conductor cross arm 7 is hoisted to finally form the hollow interlayer concrete filled steel pipe pole of the overall transmission line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com