Hollow type combination beam for quick construction and construction method

A composite beam, hollow-type technology, applied in the field of composite beams, can solve the problems of affecting the overall performance of the structure, low concrete tensile strength, waste of materials, etc., and achieve the effect of fast and convenient construction, light weight of the structure, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

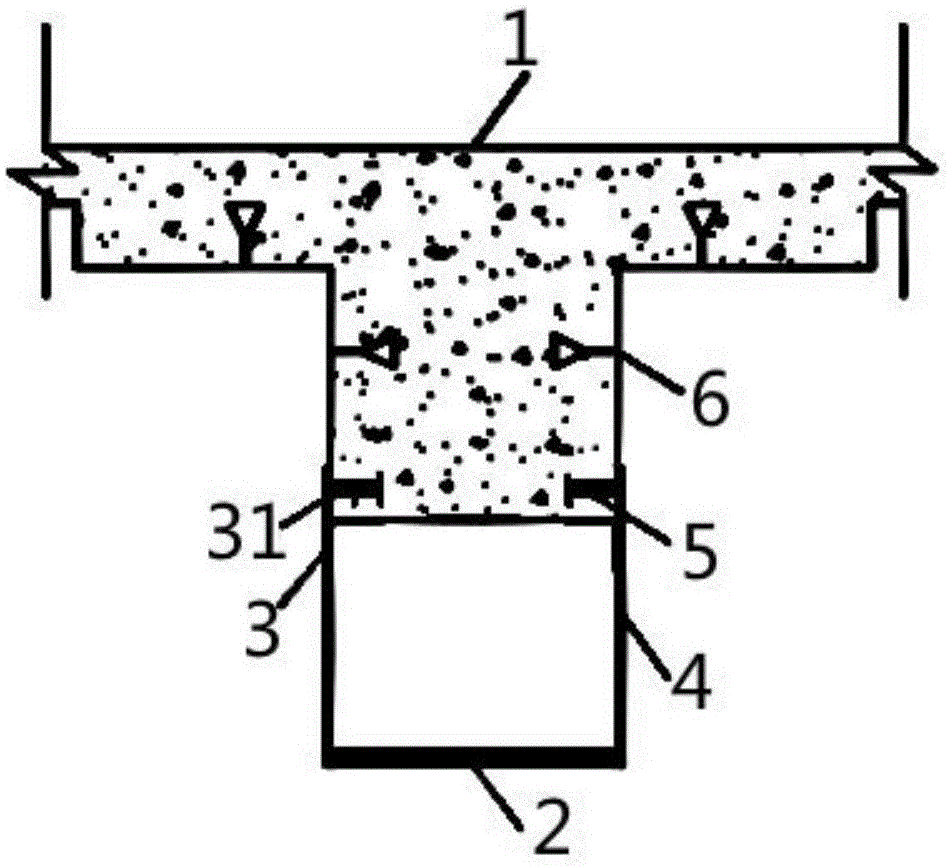

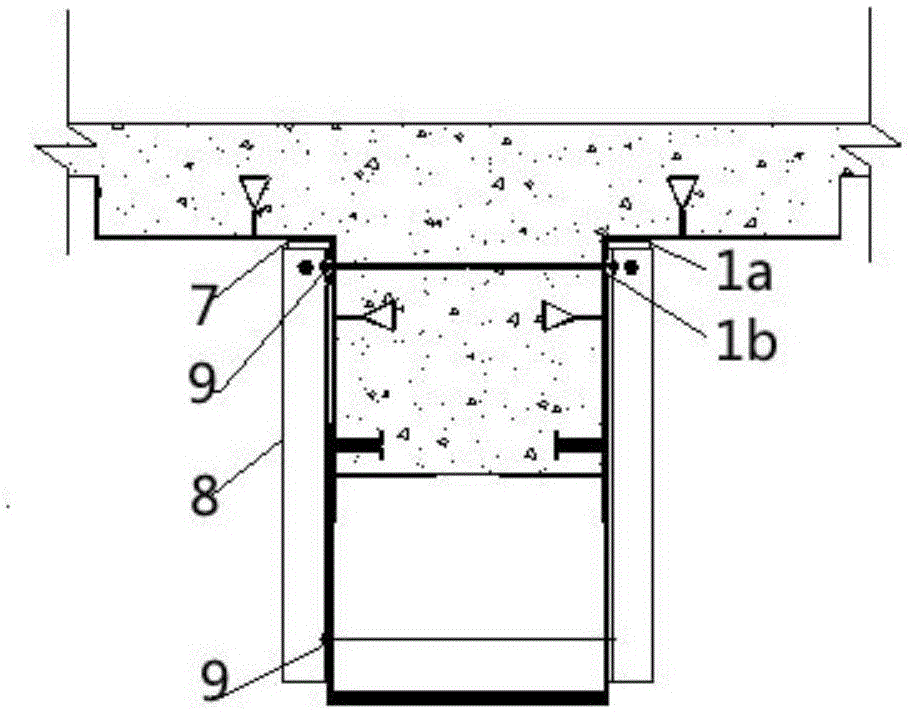

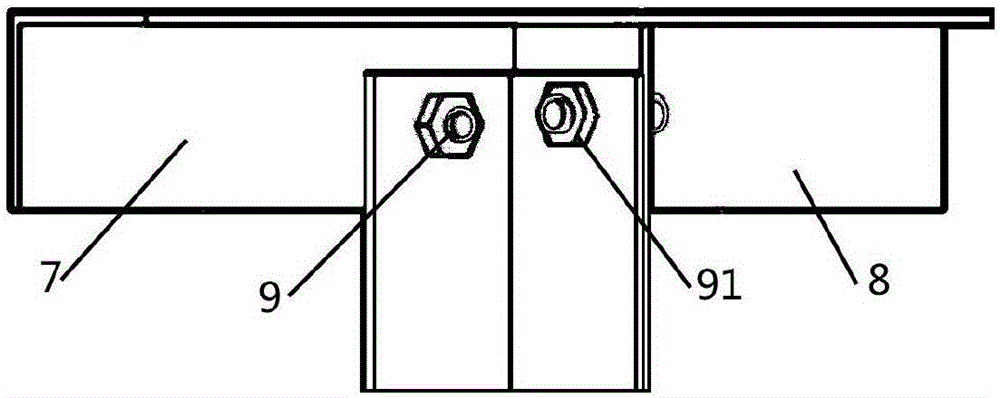

[0025] like figure 1 As shown, the hollow type rapid construction composite beam of the present invention includes a beam structural unit. Wherein, the beam structure unit includes a beam body 1 formed of concrete, and a neutral axis located on one side of the beam body. like figure 1 As shown, in this embodiment, the concrete area forms the T-beam body, with the neutral axis located in the lower part of the figure. exist figure 1 It can also be seen from the figure that the closed profiled steel plate 6 is arranged along the neutral axis and the side wall of the beam body, and the protruding part of the closed profiled steel plate faces inward and is pre-embedded in the concrete. The closed profiled steel plate is arranged along the side wall of the neutral axis and the side wall of the beam body to form a broken line structure, which is similar to a U shape. The two sides of the protruding concrete beam above the neutral axis are symmetrically embedded with welding st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com