Patents

Literature

42results about How to "Achieve turnover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

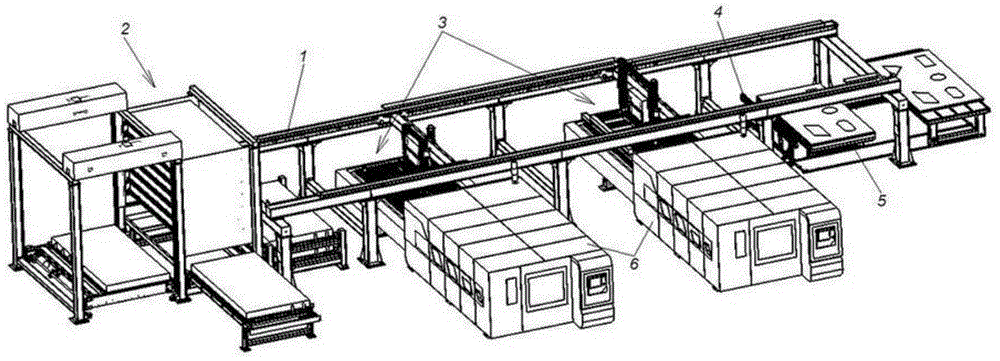

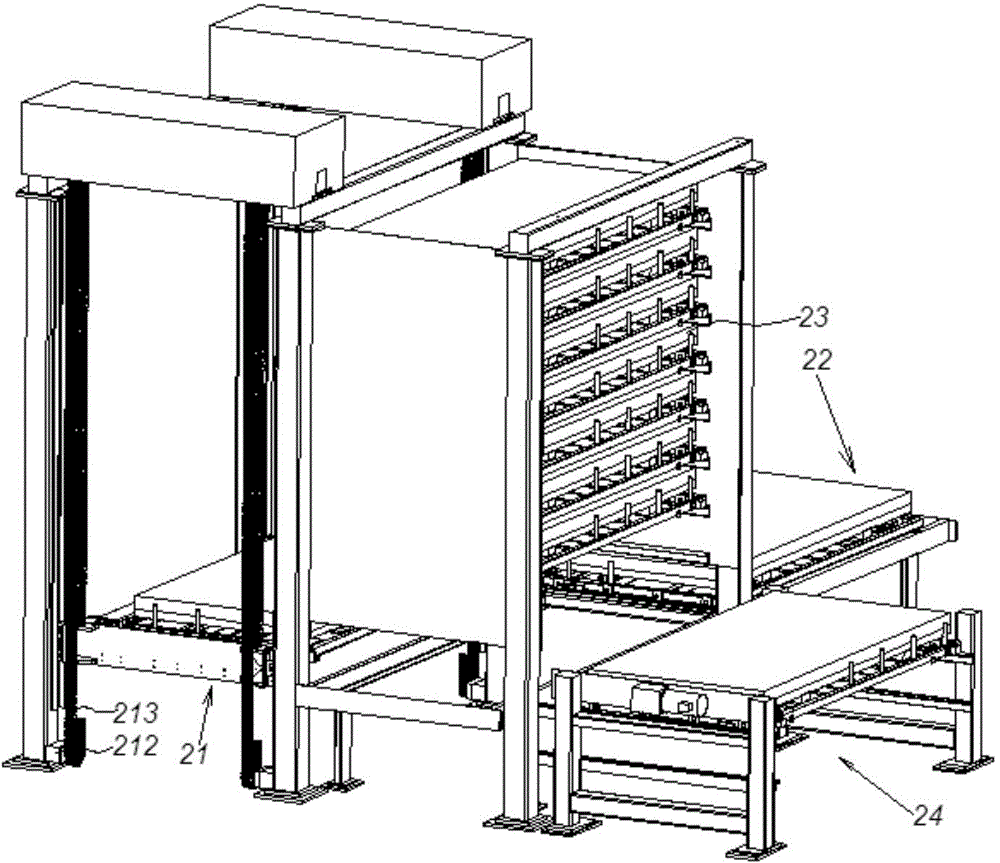

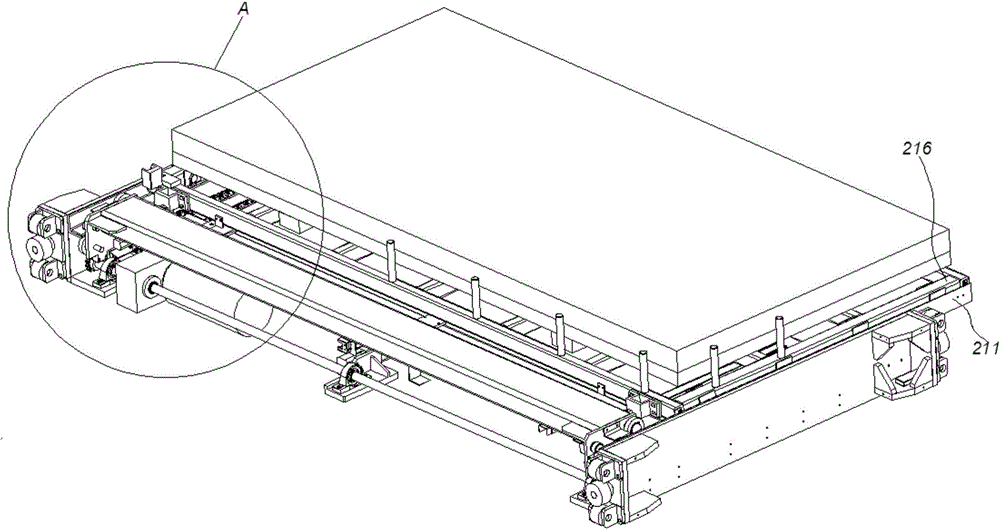

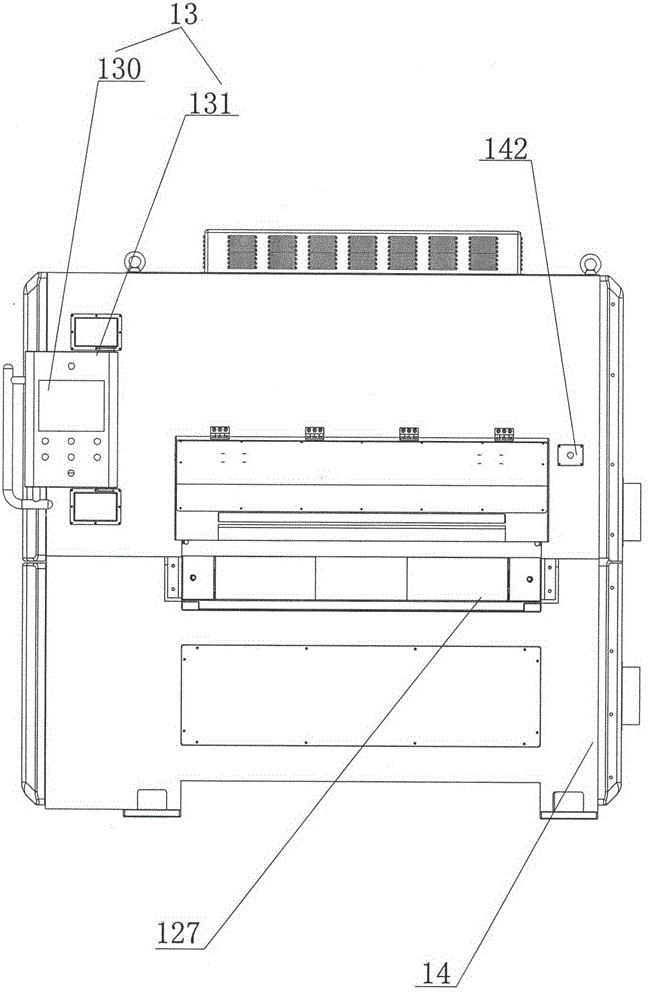

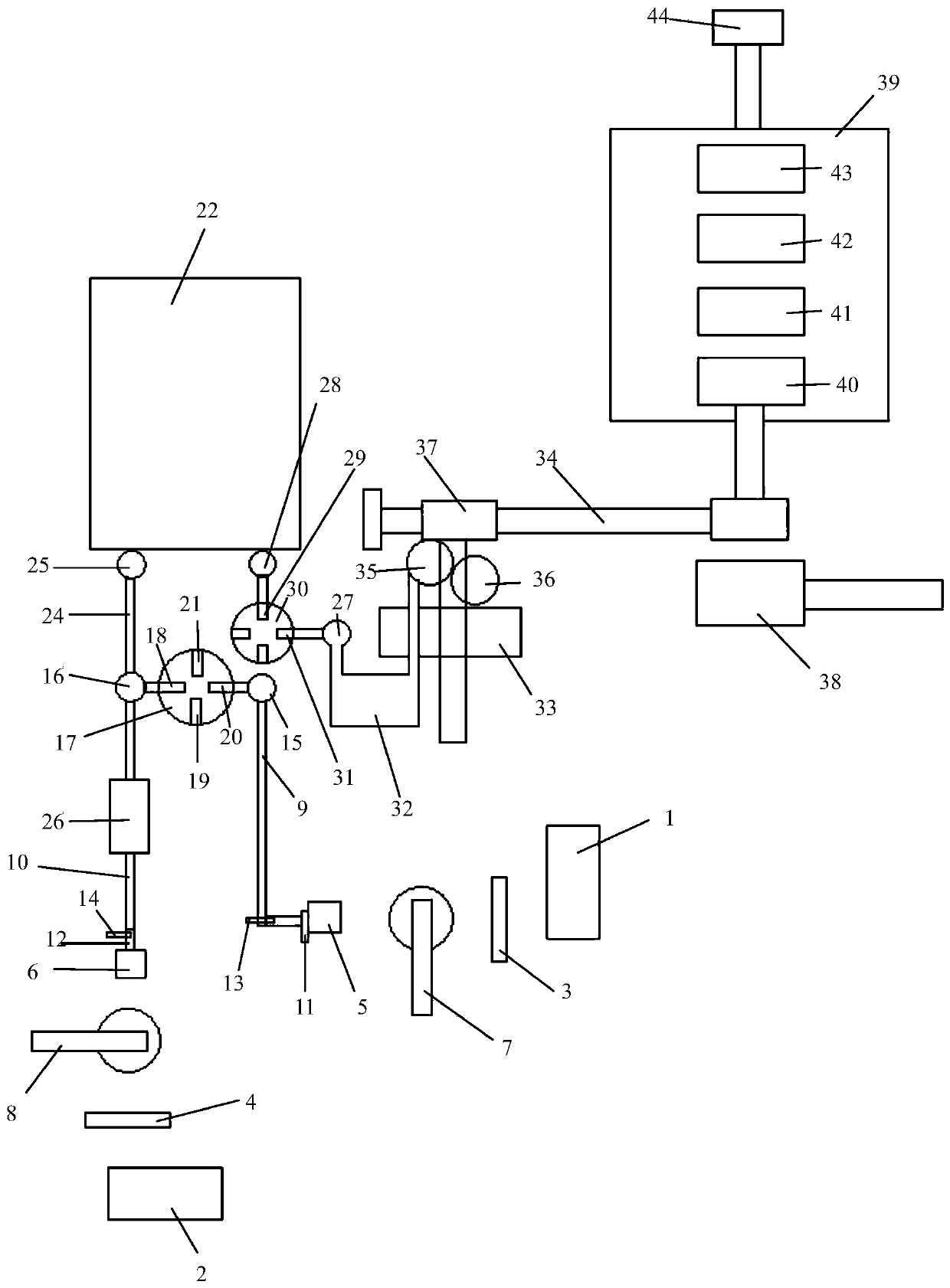

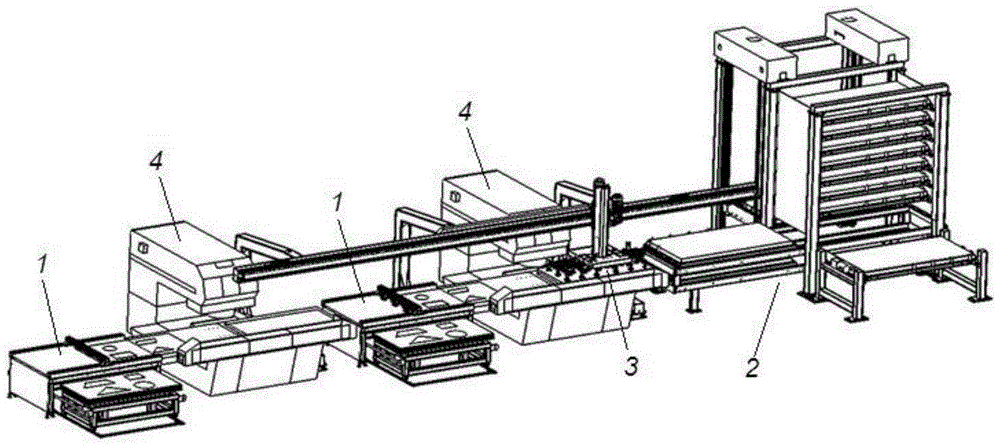

Fully-automatic laser cutting production line

ActiveCN104648931AHigh degree of automationImprove work efficiencyLaser beam welding apparatusMechanical conveyorsProduction lineEngineering

The invention discloses a fully-automatic laser cutting production line. The fully-automatic laser cutting production line comprises a line body, a material warehouse, a truss mechanical arm, a finished product trolley and a laser cutting machine; the material warehouse, the truss mechanical arm and the finished product trolley are arranged sequentially along the line body; the laser cutting machine is arranged between the material warehouse and the finished product trolley; the truss mechanical arm is used for capturing materials from the material warehouse and transferring to the laser cutting machine, then capturing finished products from the laser cutting machine and then transferring to the finished product trolley; the finished product trolley is used for transferring the finished products. The automation degree of the processing and transporting processes of the production line disclosed by the invention is high, and the working efficiency is improved.

Owner:维特罗伯特机械(苏州)有限公司

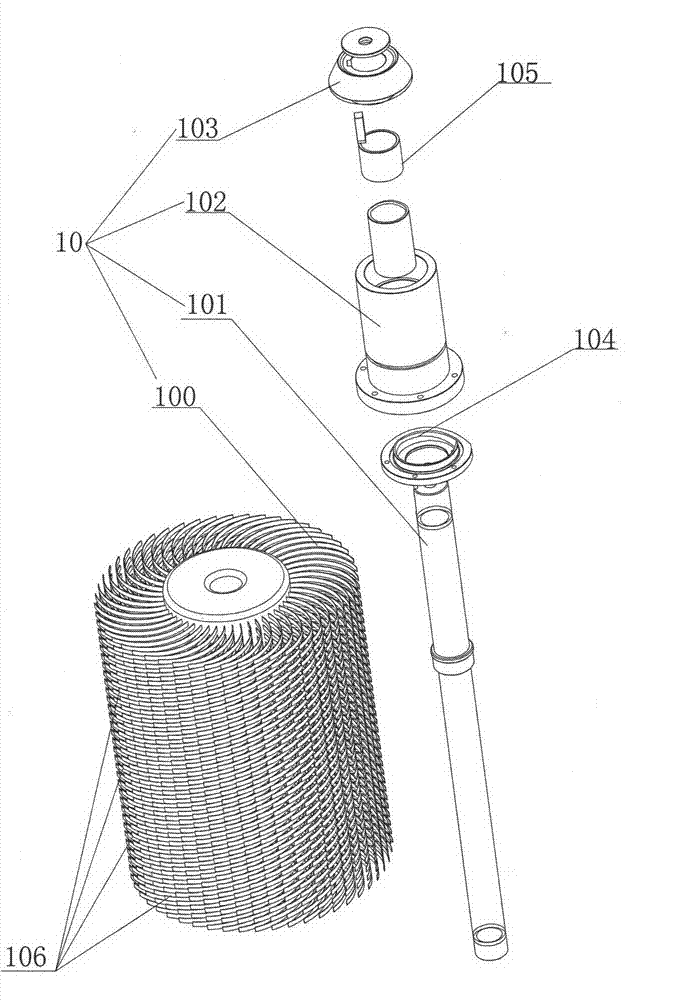

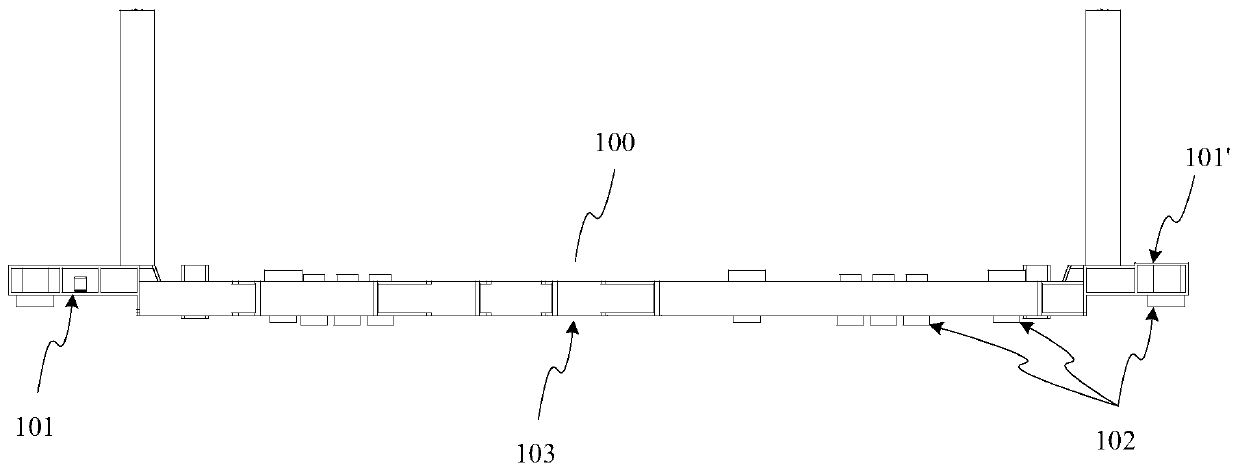

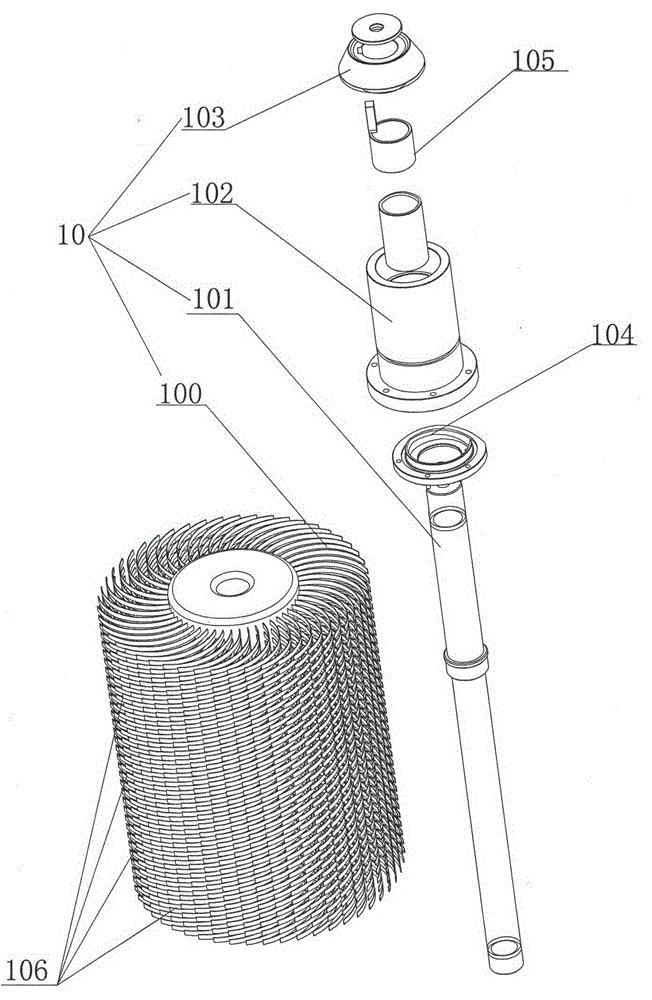

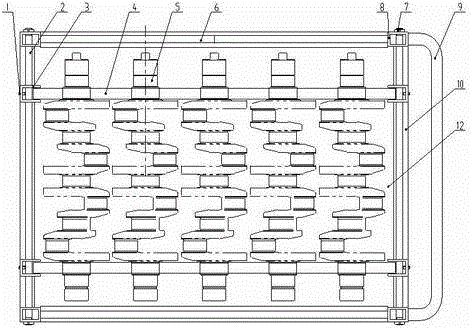

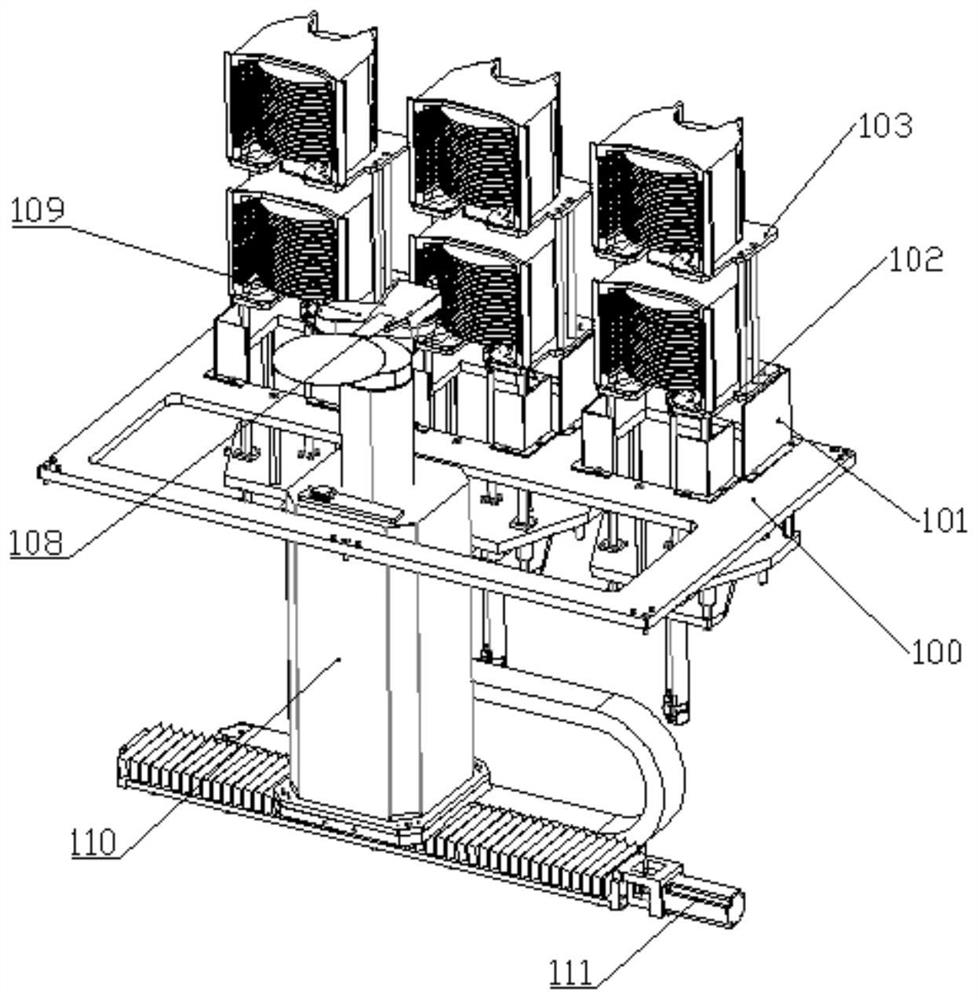

Polishing wheel device and automatic deburring machine provided with same

ActiveCN103481215AImprove work efficiencyReduce labor costsEdge grinding machinesFlexible-parts wheelsEngineeringMechanical engineering

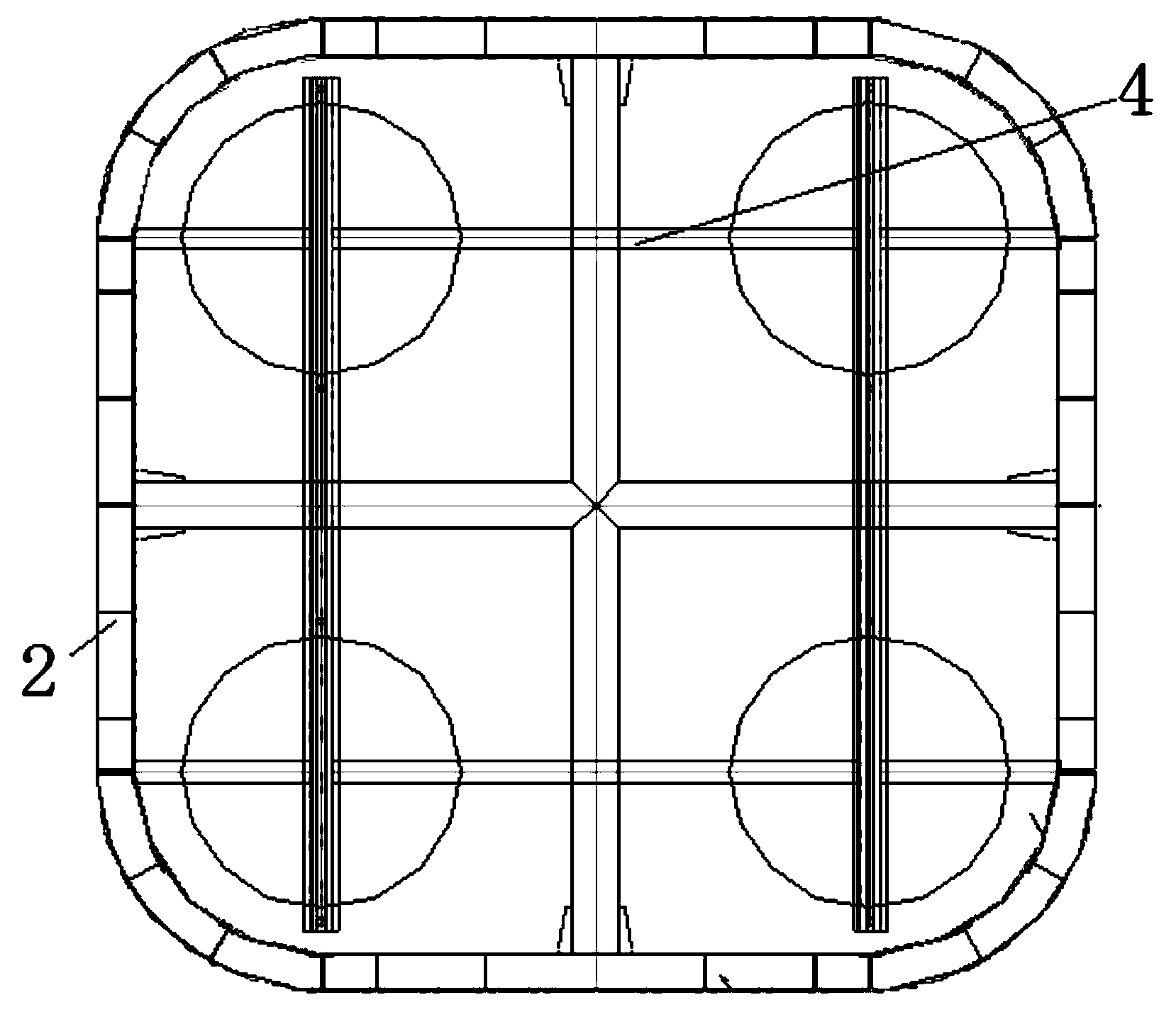

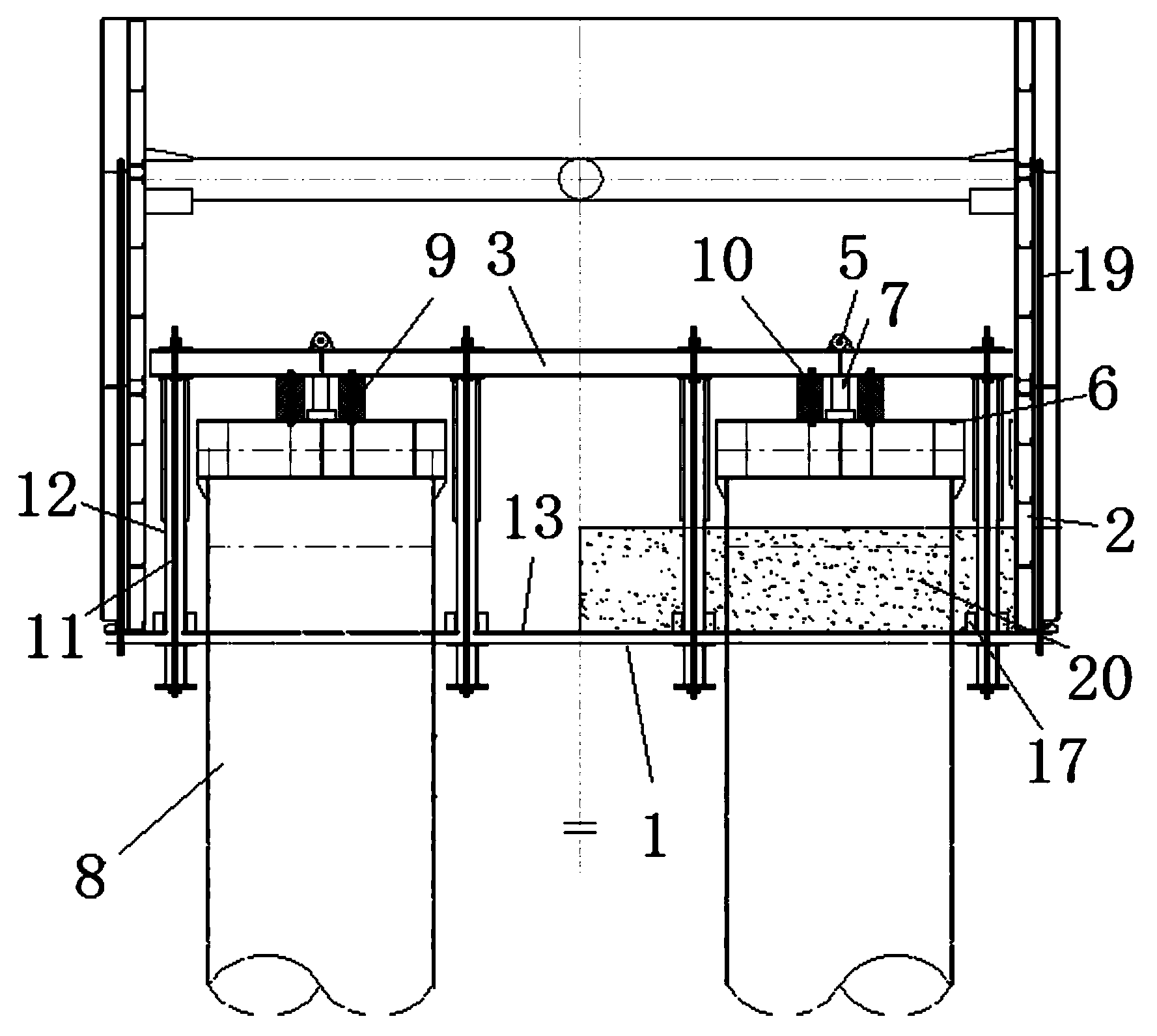

The invention discloses a polishing wheel device and an automatic deburring machine provided with the polishing wheel device. The automatic deburring machine comprises an even number of polishing wheel devices, a spindle device, a conveying device, a control device, a machine frame and a lifter used for adjusting the space between the polishing wheel devices and the conveying device; the polishing wheel devices and the spindle device are connected and fixedly arranged in the machine frame, an accommodation part is arranged on the machine frame, the conveying device is fixedly arranged in the accommodation part and positioned under the polishing wheel devices, the control device and the lifter are both fixedly arranged on the outer side of the machine frame, and the control device is electrically connected with the spindle device and the conveying device respectively; a spindle motor and a turnover motor are mounted in the two sides of the top end of the machine frame. According to the polishing wheel device and the automatic deburring machine provided with the polishing wheel device, the rotational velocity and the turnover velocity of polishing wheels, and the speed of a conveying belt of the conveying device are intelligently adjusted according to different products, so that the deburring conditions are enabled to better meet the demands of different products, the application range of the deburring machine is extended, and the automation degree and applicability of the deburring machine are further improved.

Owner:松泰精技(深圳)有限公司

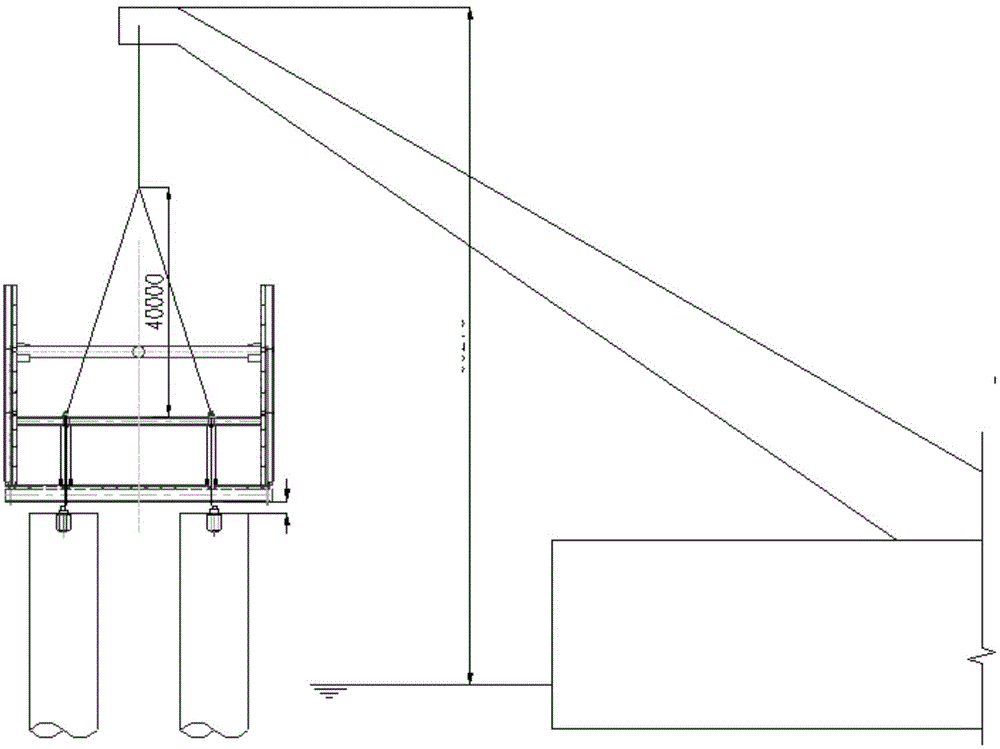

Light combined hanging box with recyclable baseplate steels and construction technology thereof

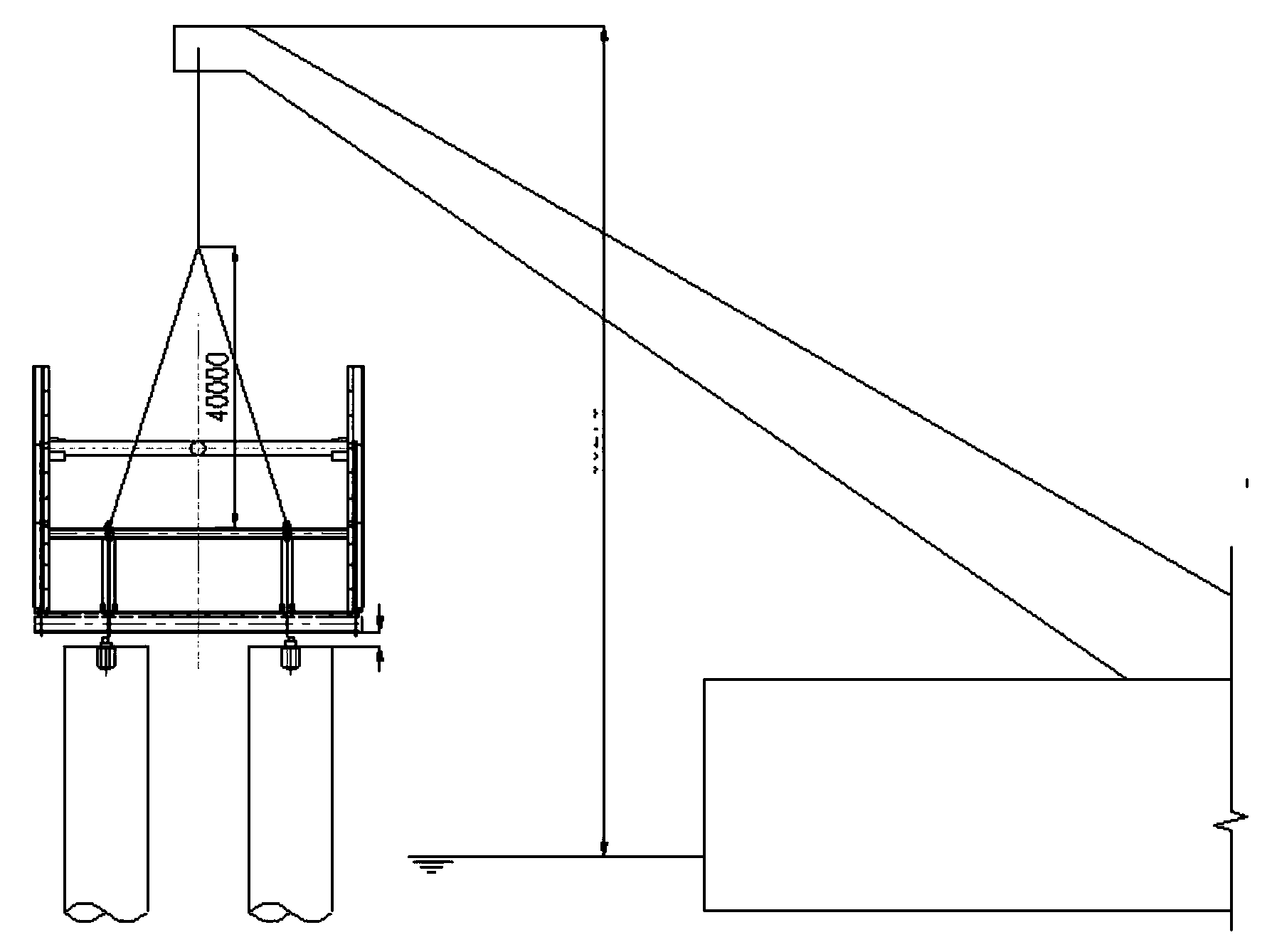

The invention discloses a light combined hanging box with recyclable baseplate steels. The light combined hanging box comprises a baseplate, four wall bodies, an outrigger, and lateral stable support beams which are connected between the outrigger and the wall bodies; wherein the four wall bodies are connected by a support frame; a lifting lug is arranged at the upper end face of outrigger; a jack placing beam is arranged under the outrigger; the outrigger is connected with the baseplate by a supporting column; a jack is arranged between the outrigger and the jack placing beam; the lower end of the jack placing beam is connected with the top end of a steel casing. The light combined hanging box has the following advantages: 1, the bearing abilities of bamboo plywood and bottom sealing concrete are fully used under a condition that a poor sea state of open seas is overcome, the turning of the baseplate steels is effectively realized, and the steel consumption is greatly reduced; 2, the structure is light; for the hanging box of the same specification, the lifting weight of the combined baseplate hanging box is similar to the self weight of a traditional steel baseplate hanging box, so that relative to the concrete prefabricated baseplate steel hanging box, the rated load weight and the lifting difficulty of a floating crane are effectively reduced.

Owner:CCCC SHEC FOURTH ENG +1

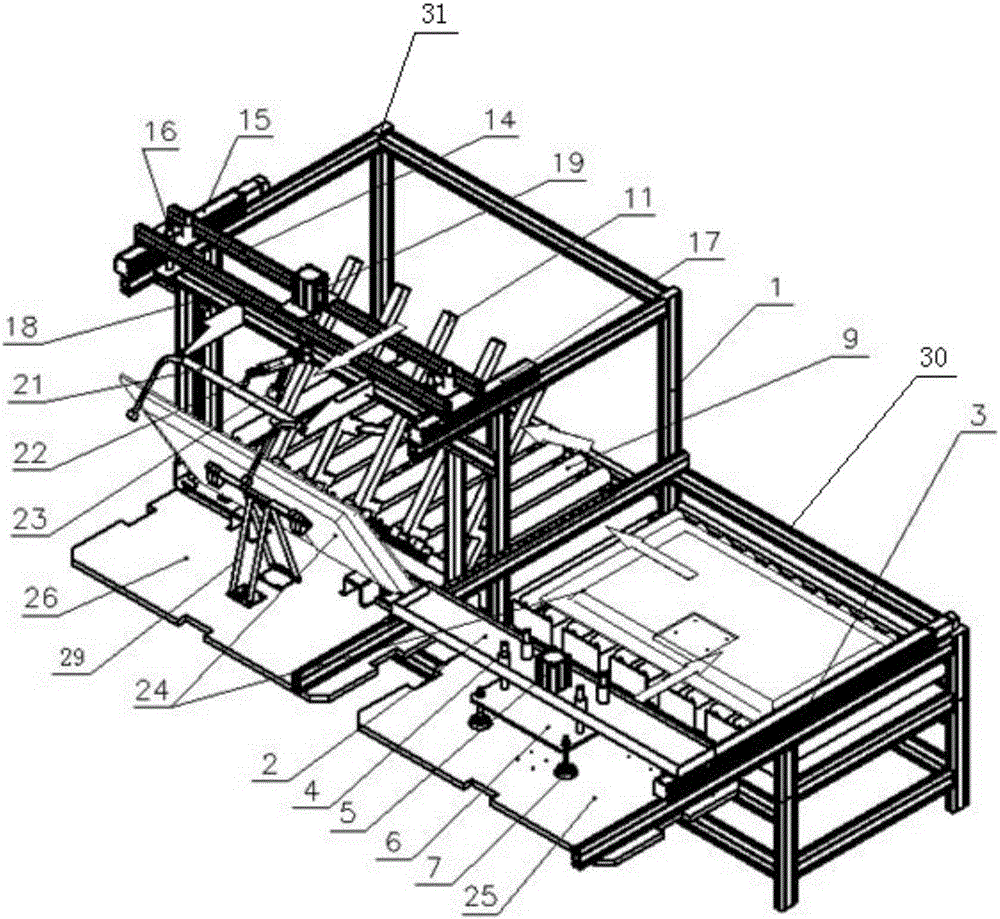

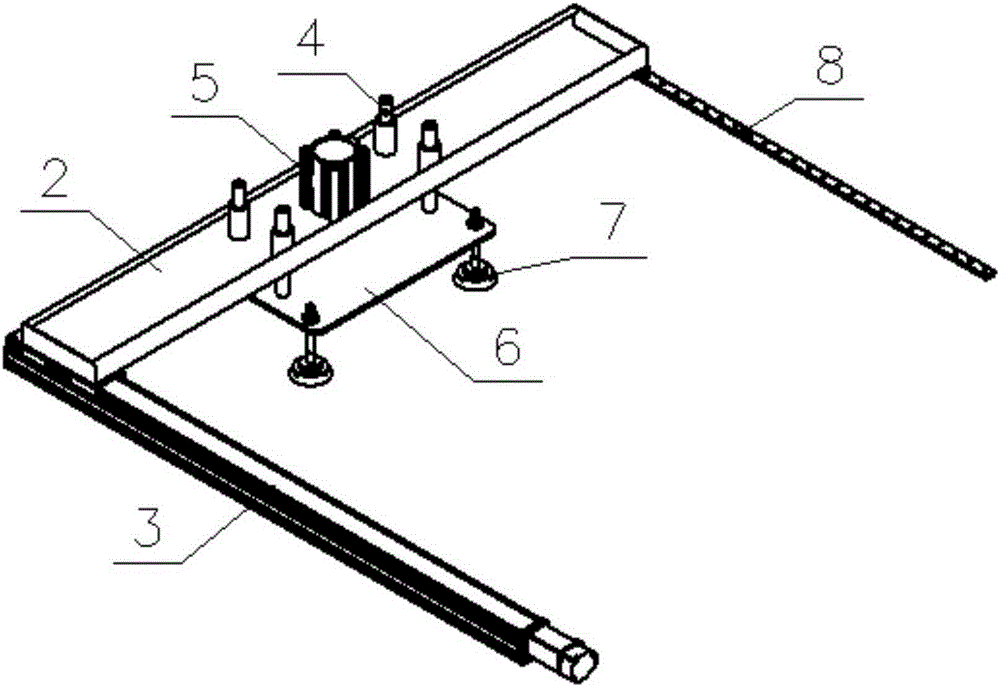

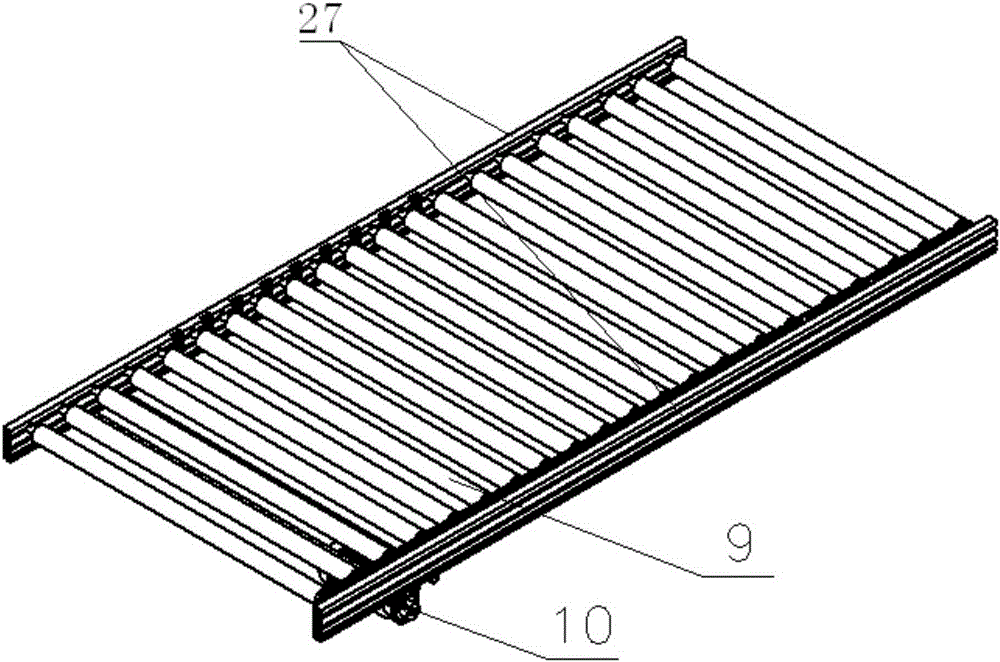

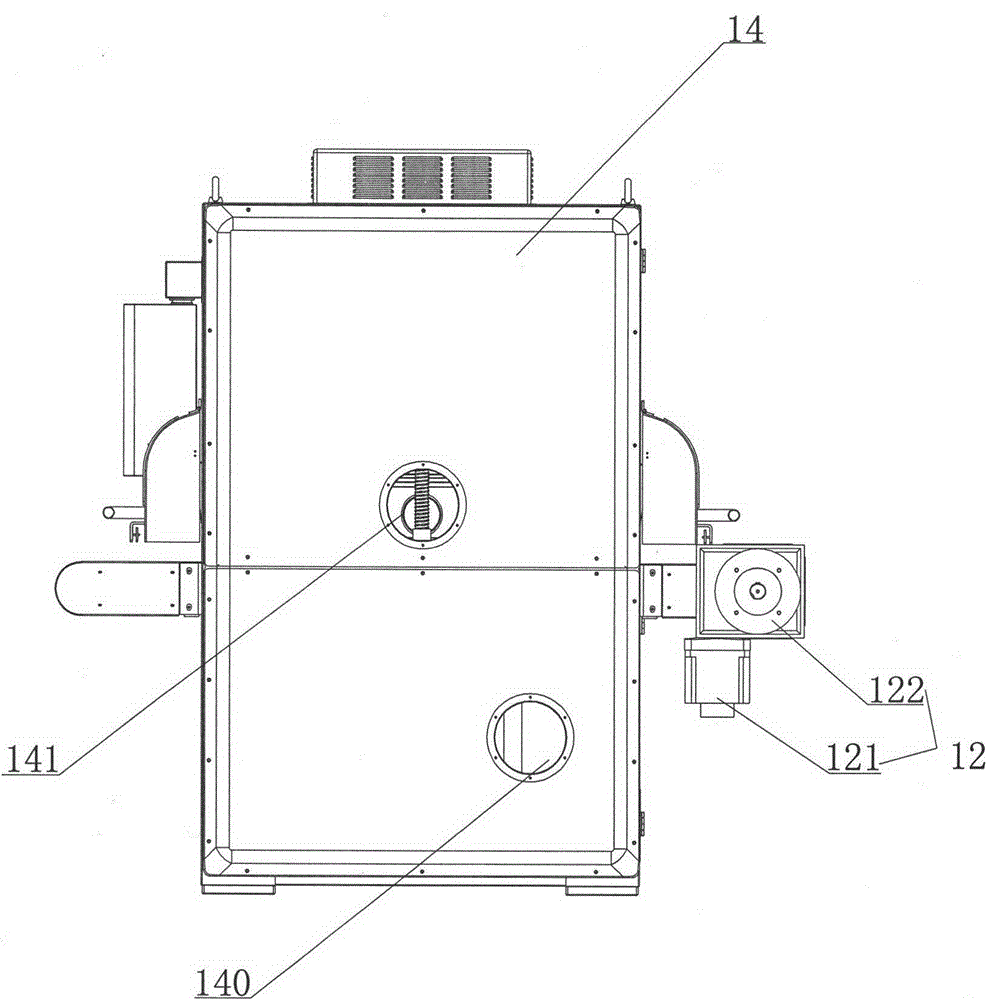

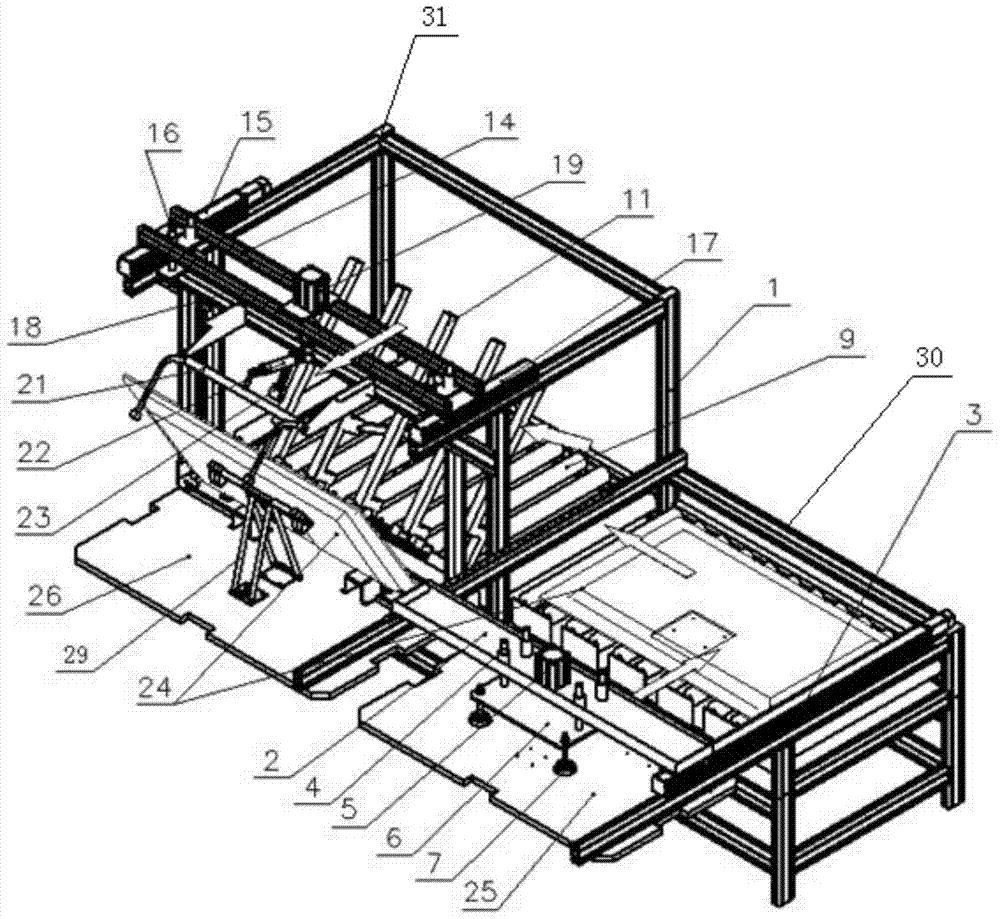

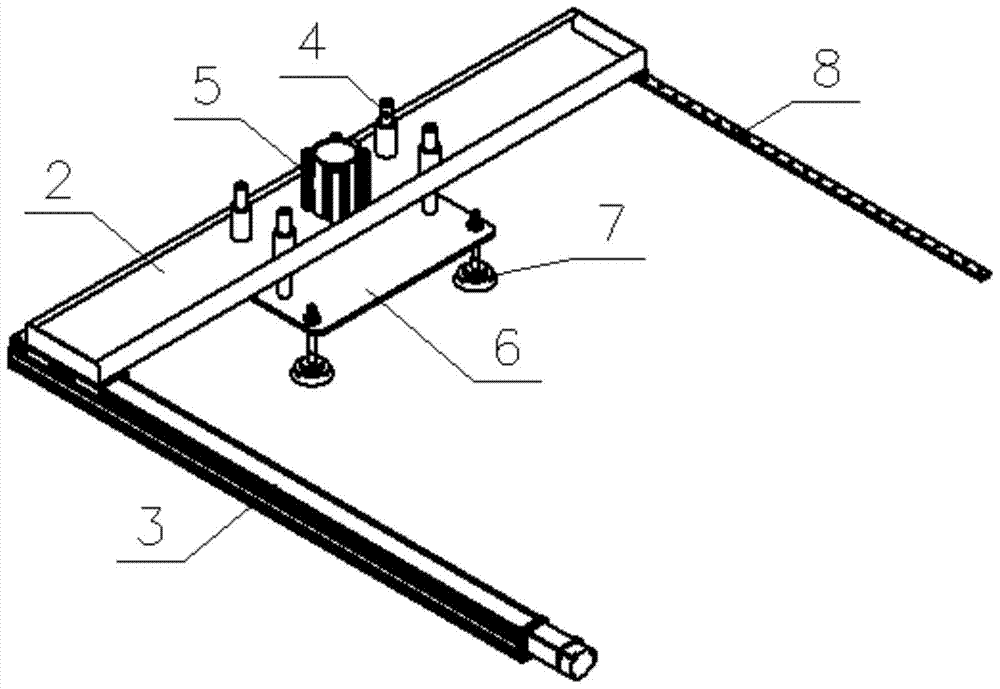

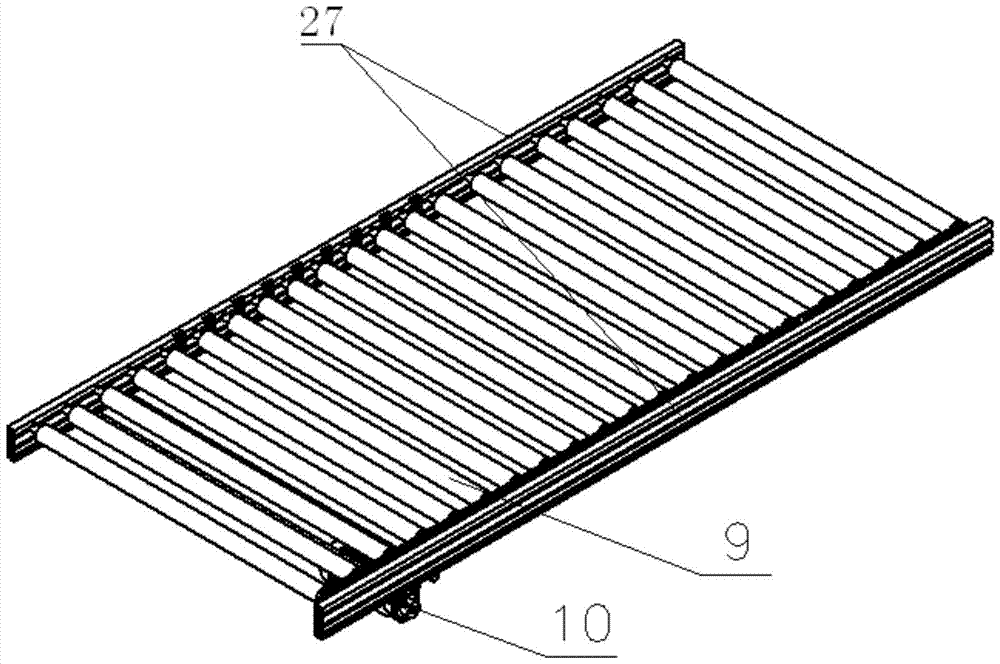

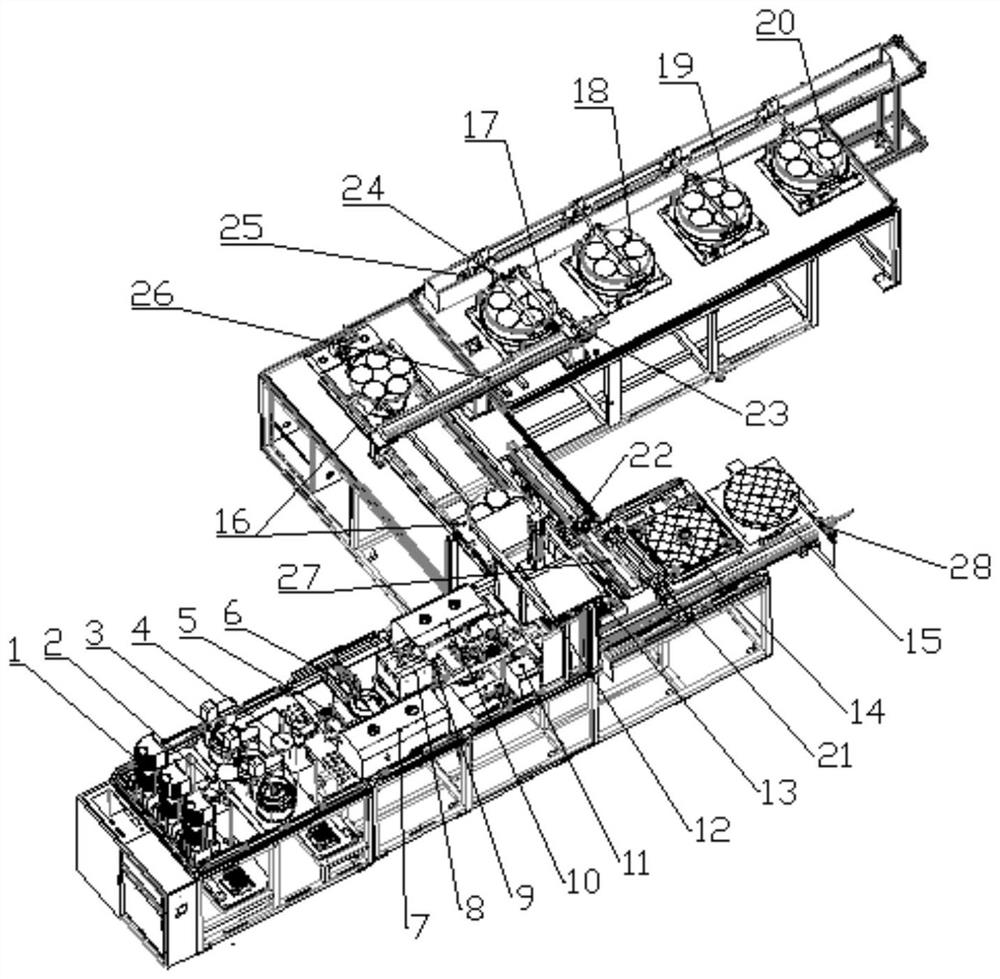

Equipment for transferring, overturning and leaning panel television set

The invention discloses equipment for transferring, overturning and leaning a panel television set. The equipment comprises a rack. The rack is composed of a first rectangular frame and a second rectangular frame. The second rectangular frame is installed on the first rectangular frame. A horizontal tool plate and a leaning tool plate are sequentially arranged on the same side of the first rectangular frame. The leaning tool plate is located below the second rectangular frame. An adsorption transferring mechanism is arranged above the horizontal tool plate. The leaning tool plate is sequentially provided with an overturning mechanism and a leaning transferring mechanism from bottom to top. The leaning transferring mechanism is connected with the upper end of the second rectangular frame. A conveying mechanism is arranged on the surface of the first rectangular frame. The equipment has the beneficial effects that it can be guaranteed that the panel television set can be smoothly transferred, overturned and leaned, manpower can be replaced, the production manner of multiple types, flexibility and easy switching is met, and meanwhile efficiency and product quality are improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

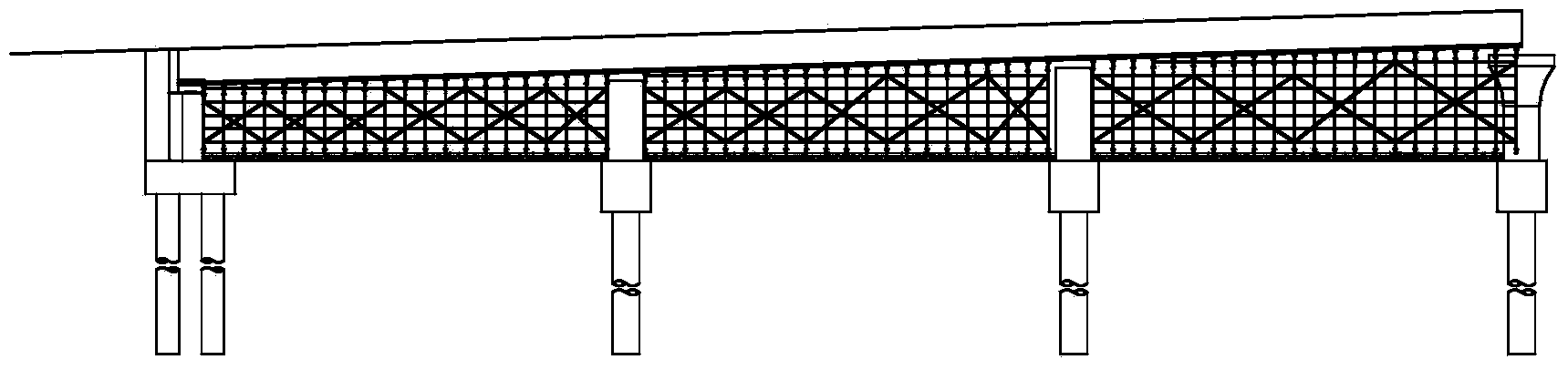

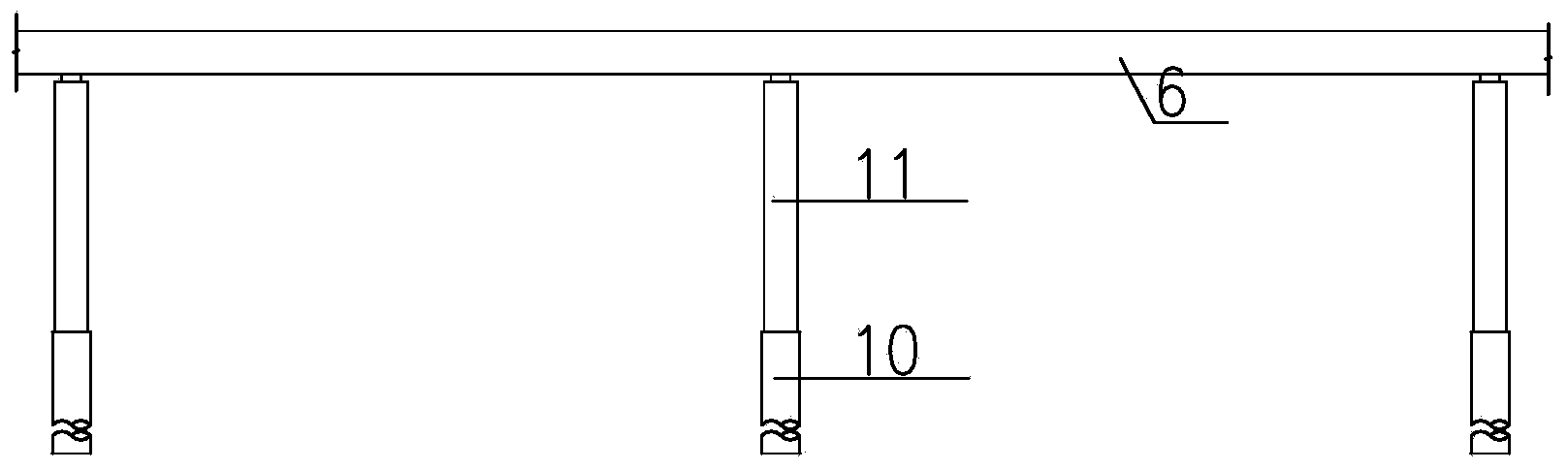

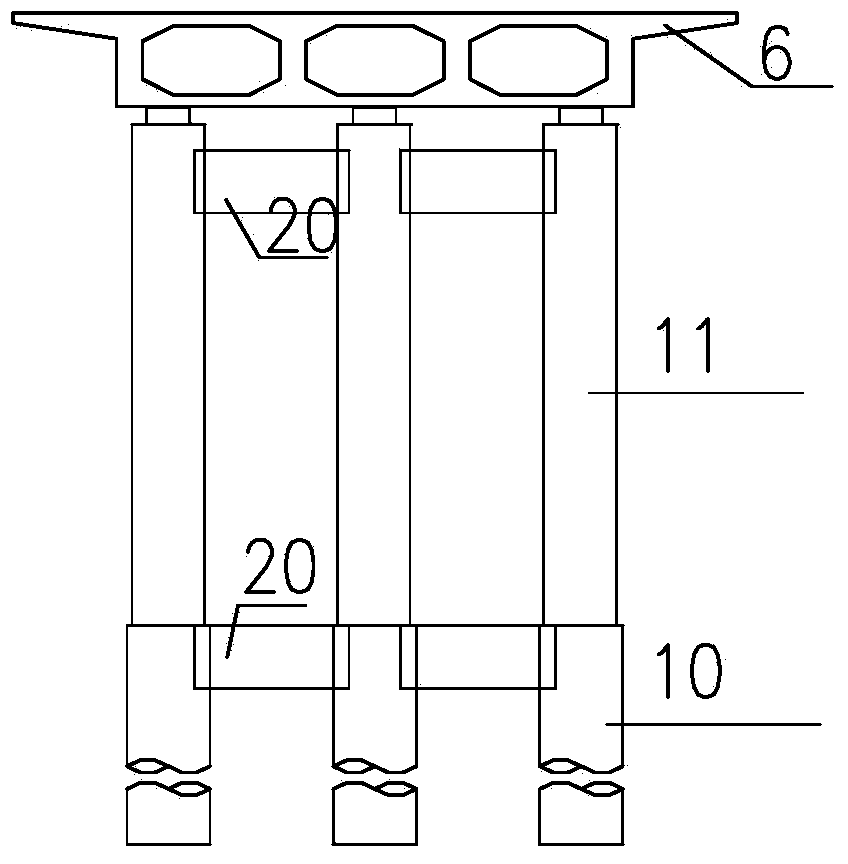

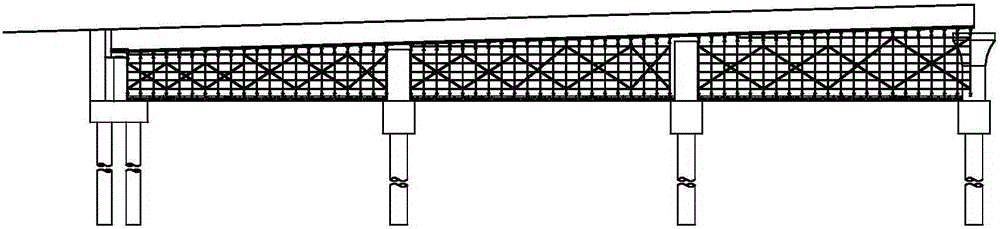

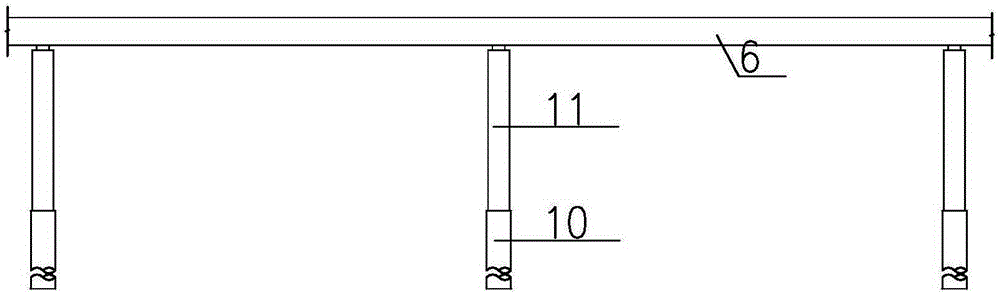

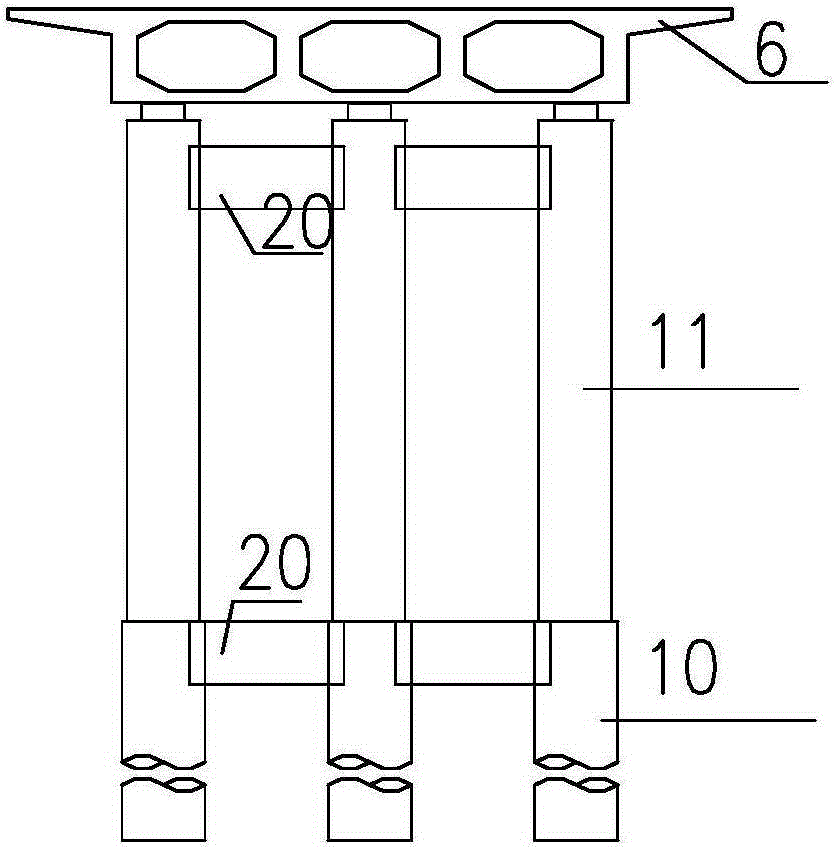

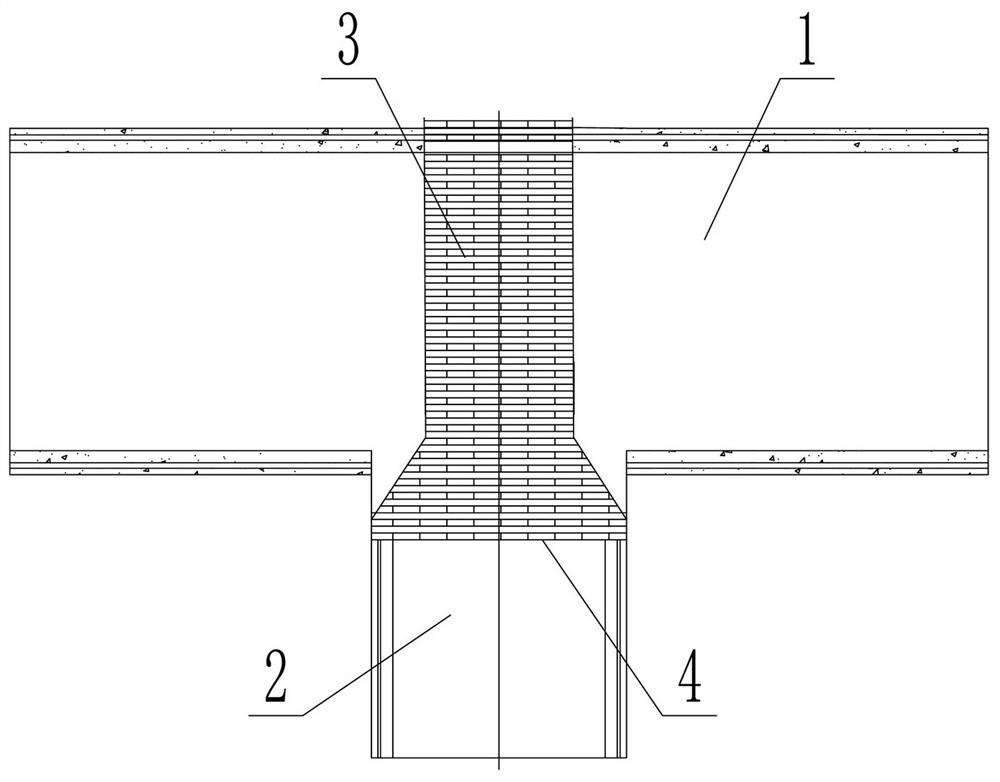

Support structure for realizing no-cushion cap approach viaduct concrete box girder less-support cast-in-place

ActiveCN103850183ASolve the "rooting" problemReduce construction difficultyBridge erection/assemblyEngineeringBox girder

The invention discloses a support structure for realizing no-cushion cap approach viaduct concrete box girder less-support cast-in-place, which belongs to the field of bridge superstructure construction, and comprises a support for box girder cast-in-place construction, wherein the box girder is supported by a cast-in-place pile and pier bodies directly supported thereon. The support structure is characterized in that the support comprises at least two rows of intermediate columns arranged in the middle of the box girder and connected in parallel, sidespan stand columns symmetrically arranged on two sides of each pier body in pairs, a truss located under the box girder and supported by the intermediate columns and the sidespan stand columns, and a connecting support thereof; each pair of sidespan stand columns is respectively supported by a hoop structure; each hoop structure is supported by the cast-in-place pile and surrounded and fixed on the pier bodies thereon; and stand columns on the same sides of the same row of pier bodies are connected through a parallel connected part in the middle, a lower cross beam on the top part and an outrigger on the bottom part. The support structure is applied to box girder cast-in-place of land approach bridge pier columns with higher clearance and without a cushion cap under the bridge, and is quick in construction progress, and low in engineering construction cost.

Owner:CCCC SHEC FOURTH ENG +1

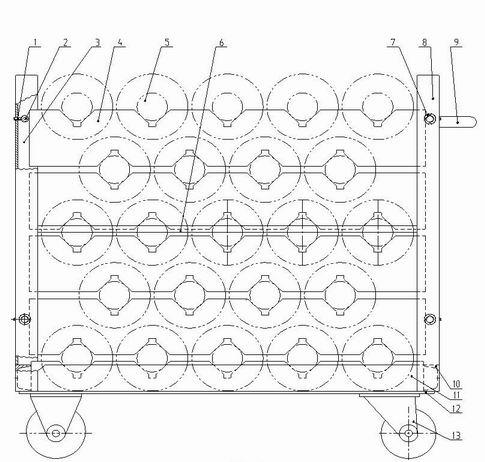

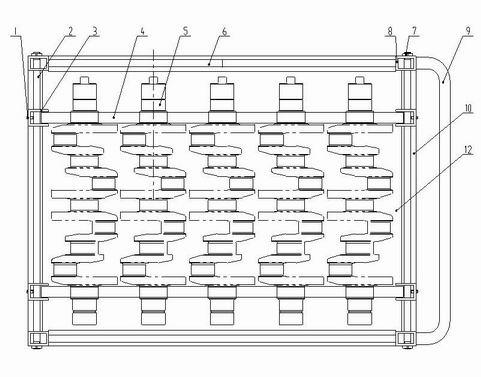

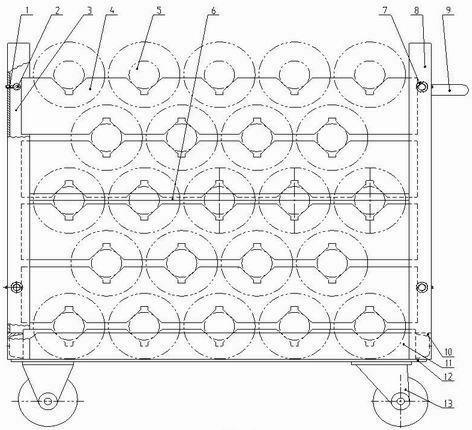

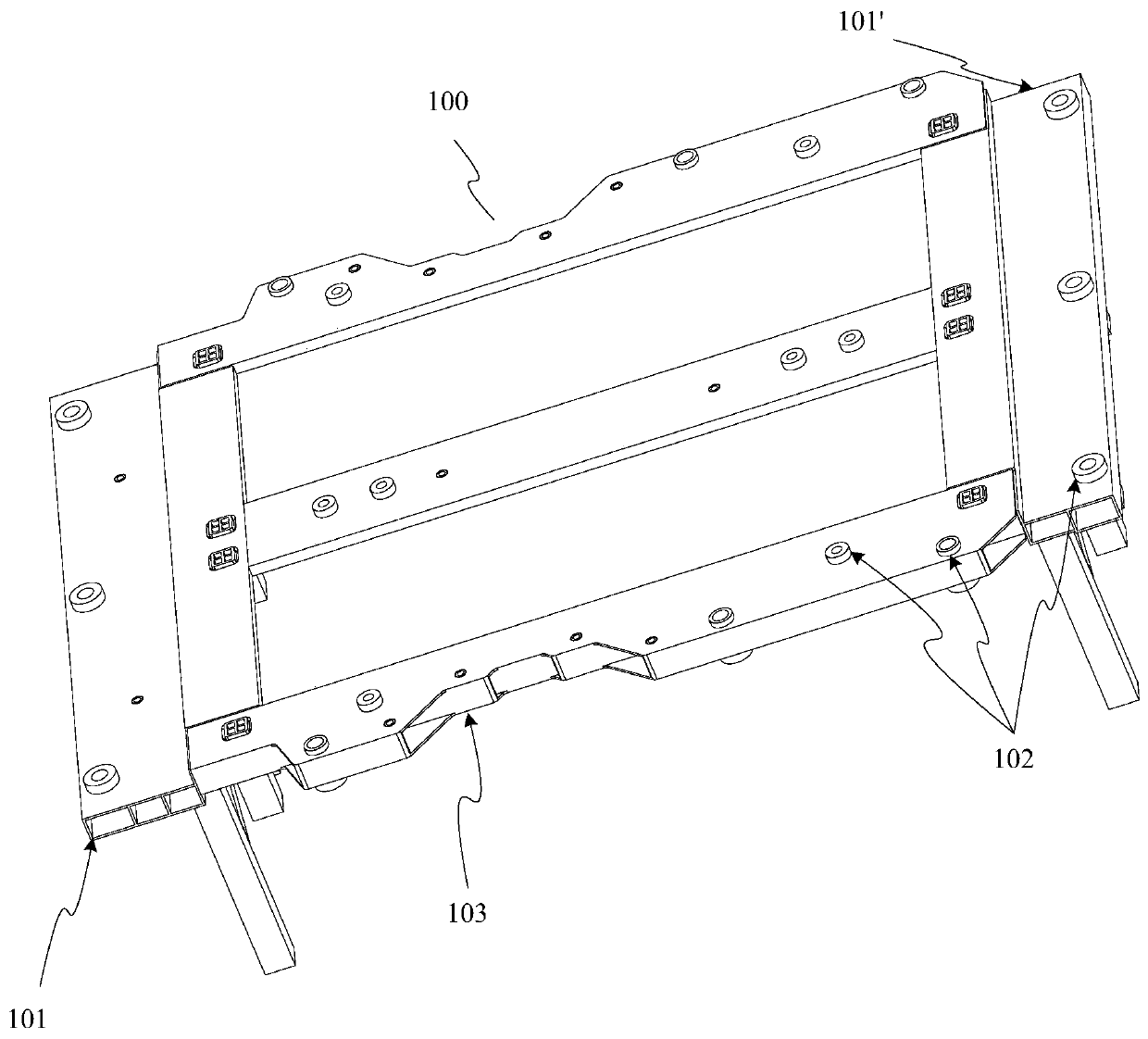

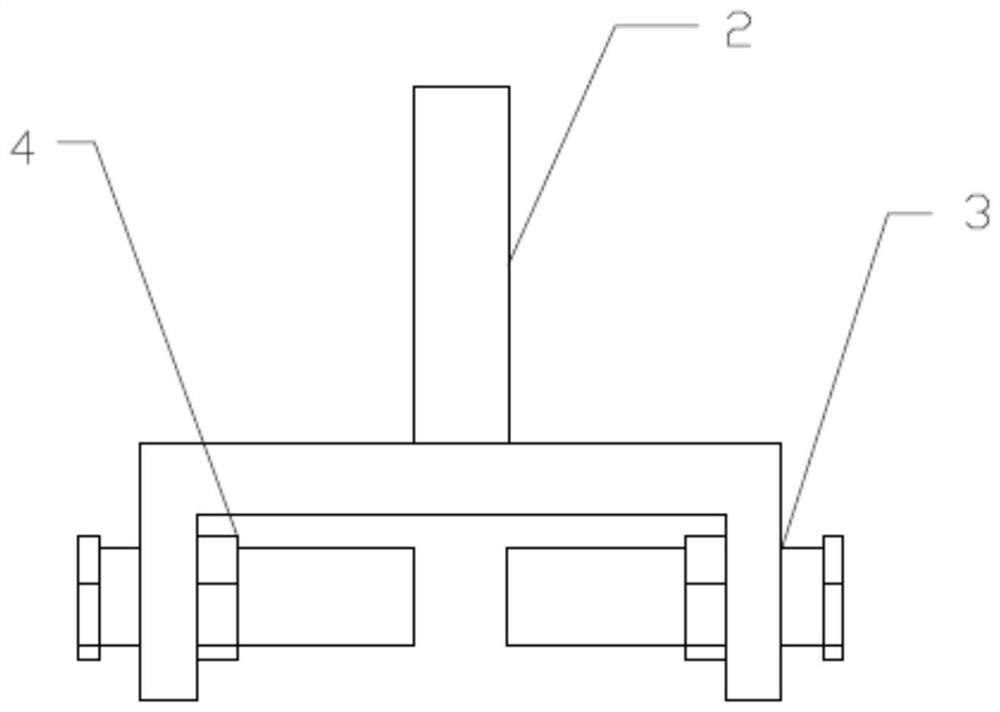

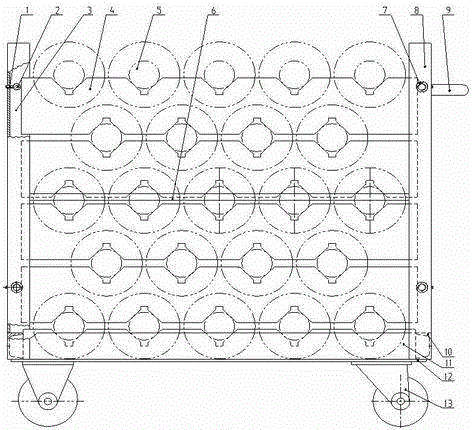

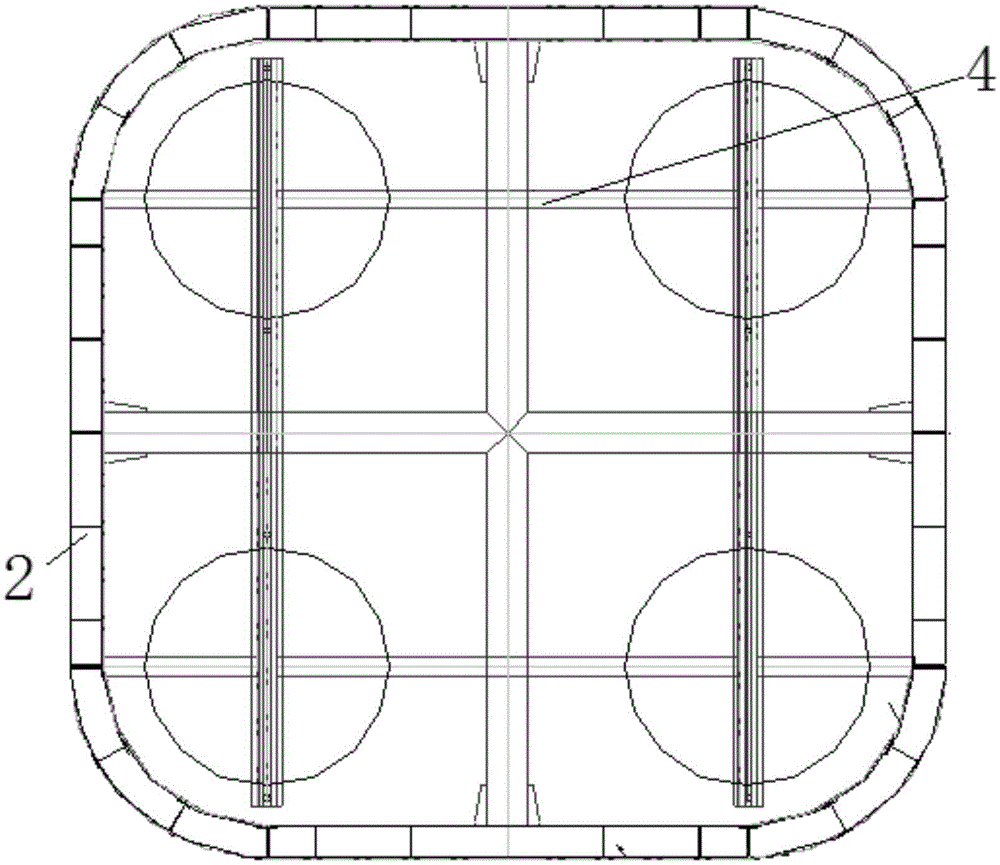

Transfer cart with crankshafts

InactiveCN102582671AAchieve turnoverReasonable structureHand carts with multiple axesArchitectural engineeringCrankshaft

The invention relates to a transfer cart with crankshafts, which is provided with a bottom plate and wheel sets. Four vertical columns and a frame are welded on the bottom plate, two guide connecting rods are respectively arranged between the two front vertical columns and between the two rear vertical columns, the two guide connecting rods on the front side and the two guide connecting rods on the rear side are perpendicularly connected with two limit groove plates respectively, and a bottom bearing plate and a plurality of middle bearing partitions are sequentially mounted between the frontlimit groove plate and the rear groove plate layer by layer. V-shaped grooves of the upper end face of the lower middle bearing partition are arranged oppositely to V-shaped grooves of the lower end face of the upper middle bearing partition, and V-shaped grooves of the lower end face and V-shaped grooves of the upper end face of the same middle bearing partition are arranged at intervals in a staggered manner. When in use, the crankshafts and the middle bearing partitions are sequentially mounted layer by layer, the crankshafts in layers are disposed in a staggered manner so that space can be utilized sufficiently and more crankshafts can be disposed. The transfer cart with the crankshafts is reasonable in structure, simple in operation, high in transferring efficiency, low in transferring cost and wide in application.

Owner:TIANRUN IND TECH CO LTD

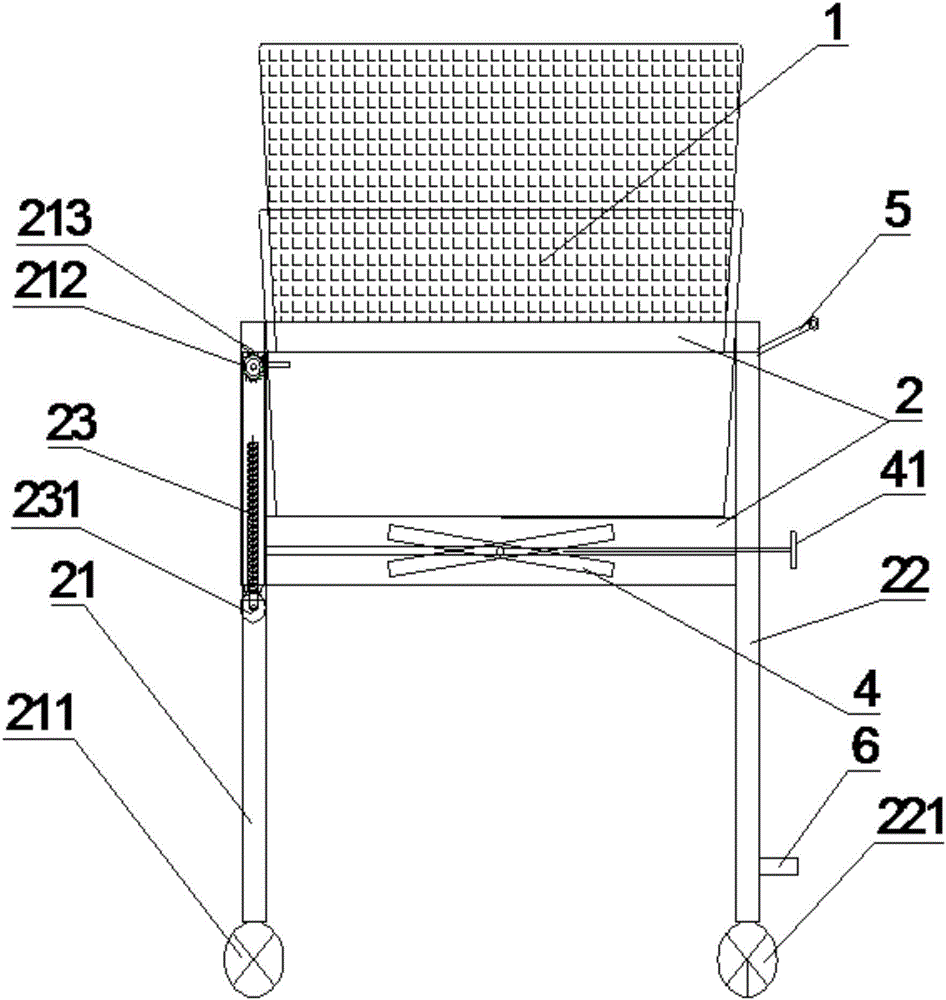

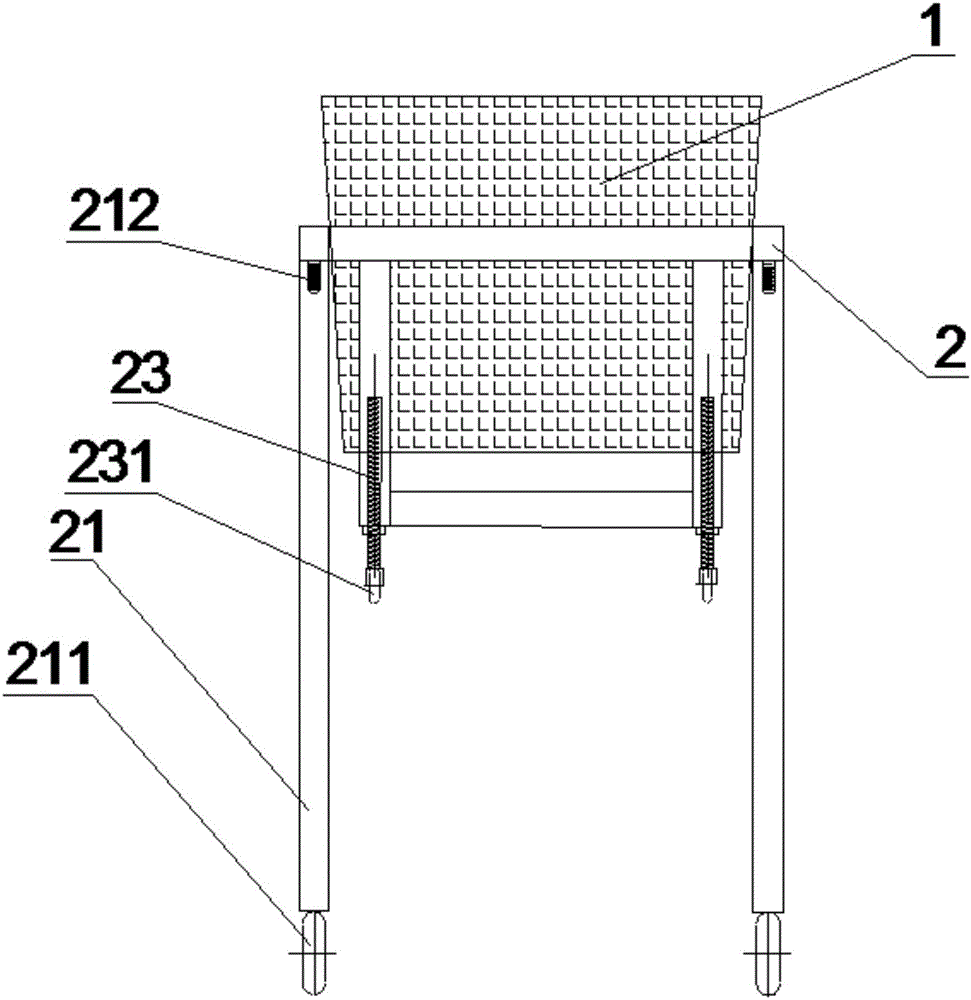

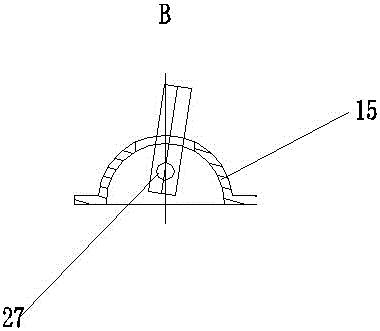

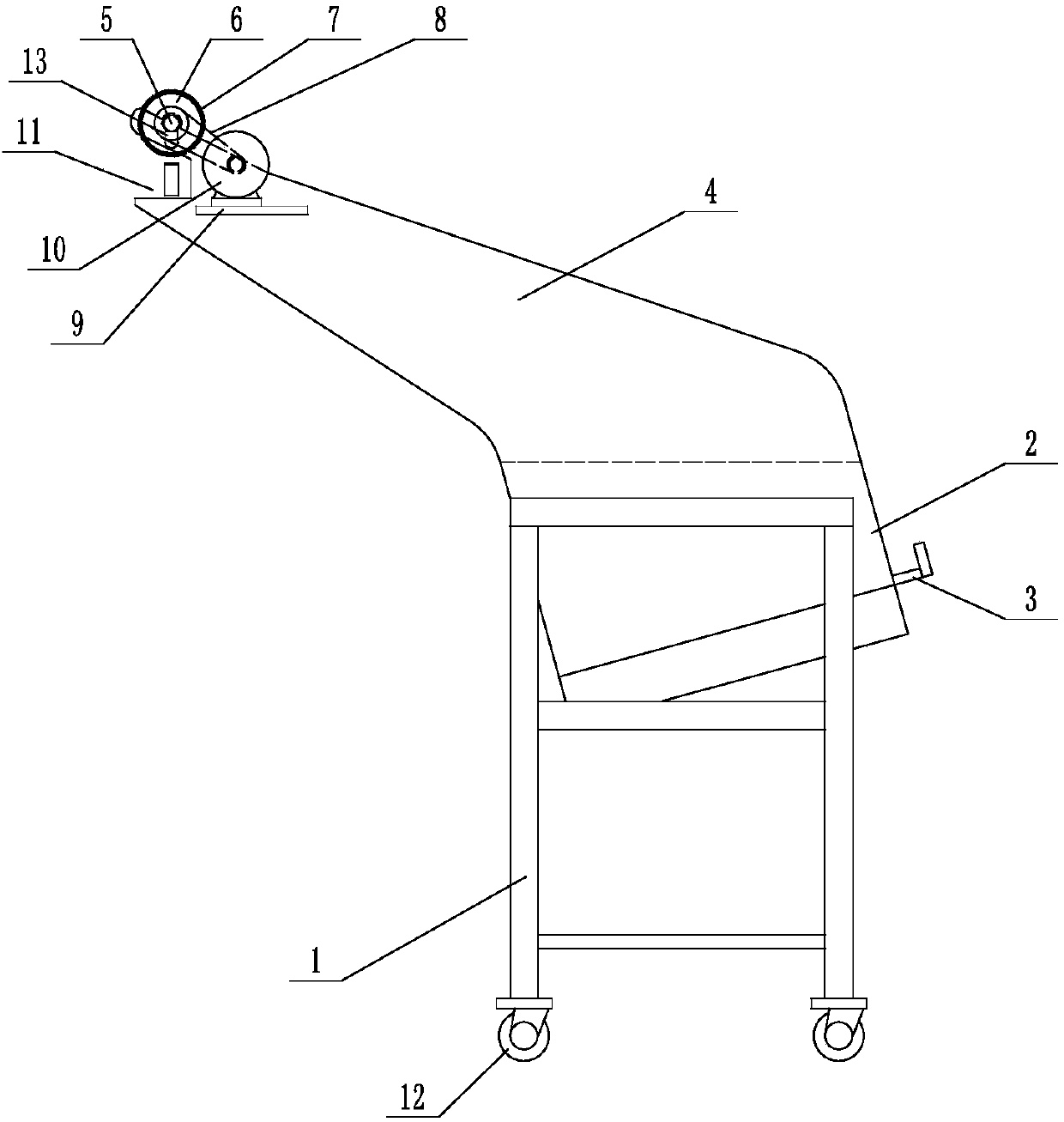

Turnover device for automatic and manual sorting equipment and application method of turnover device

PendingCN106733673AAchieve turnoverEasy to sortSupporting partsSortingLogistics managementEngineering

The invention relates to the technical field of logistics sorters, and discloses a turnover device for automatic and manual sorting equipment and an application method of the turnover device. The turnover device structurally comprises a transfer trolley; the transfer trolley comprises a bearing trolley frame; and the front end of the bearing trolley frame is provided with front supporting legs, the rear end of the bearing trolley frame is provided with rear supporting legs, the front supporting legs can rotate around the joints of the front supporting legs and the bearing trolley frame, and the bottoms of the front supporting legs and the bottoms of the rear supporting legs are all provided with casters. According to the turnover device for the automatic and manual sorting equipment and the application method of the turnover device, the wheel type trolley convenient to carry and push is adopted, the front end of the bearing trolley frame of a wheel type trolley body is provided with the front supporting legs, the front supporting legs are rotationally connected with the bearing trolley frame, and locking and rotating of the front supporting legs are controlled through a ratchet wheel structure; the front supporting legs are jacked up by the outer edge of a building wrapping rolling path; the balance of the trolley body is adjusted through balance wheels; after the turnover device is completely pushed to the position under a case port, the rear supporting legs are locked; and a rubber frame is lifted to the designated position through a shears-fork type lifting mechanism, and sorting is started.

Owner:SF EXPRESS

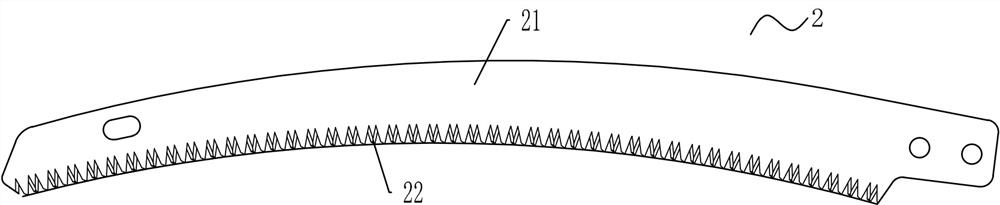

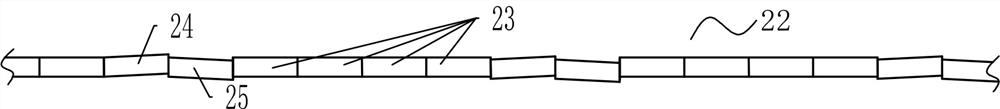

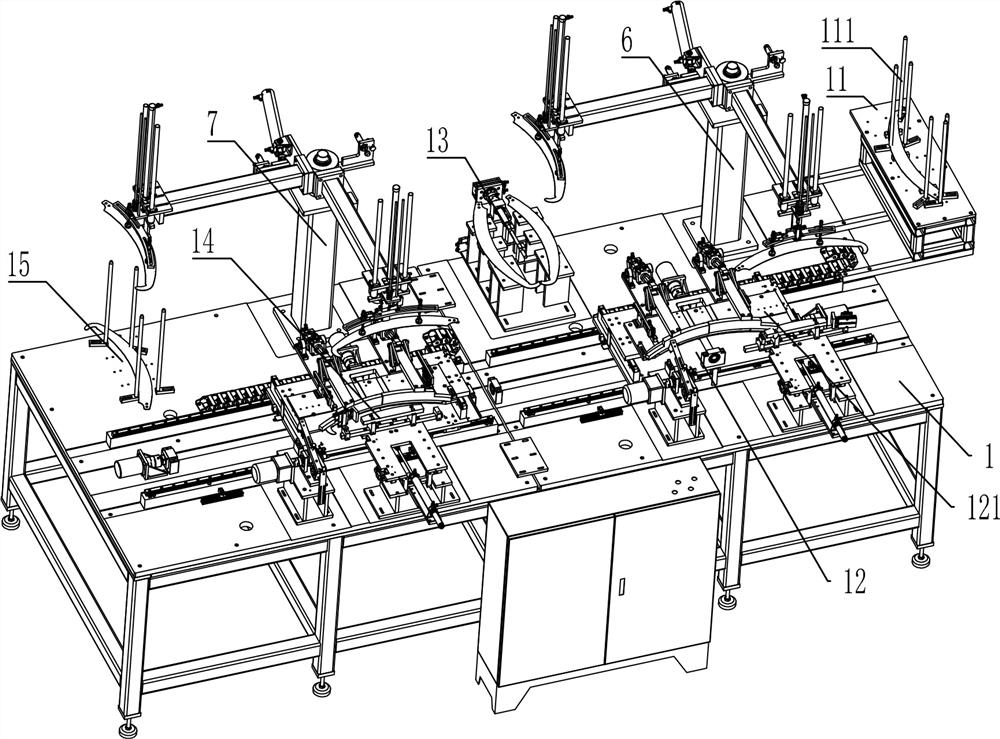

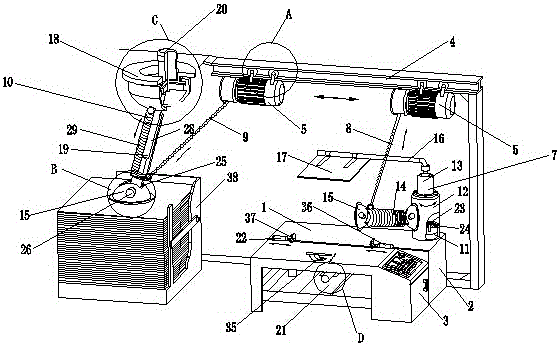

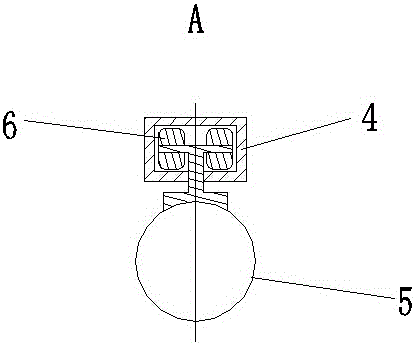

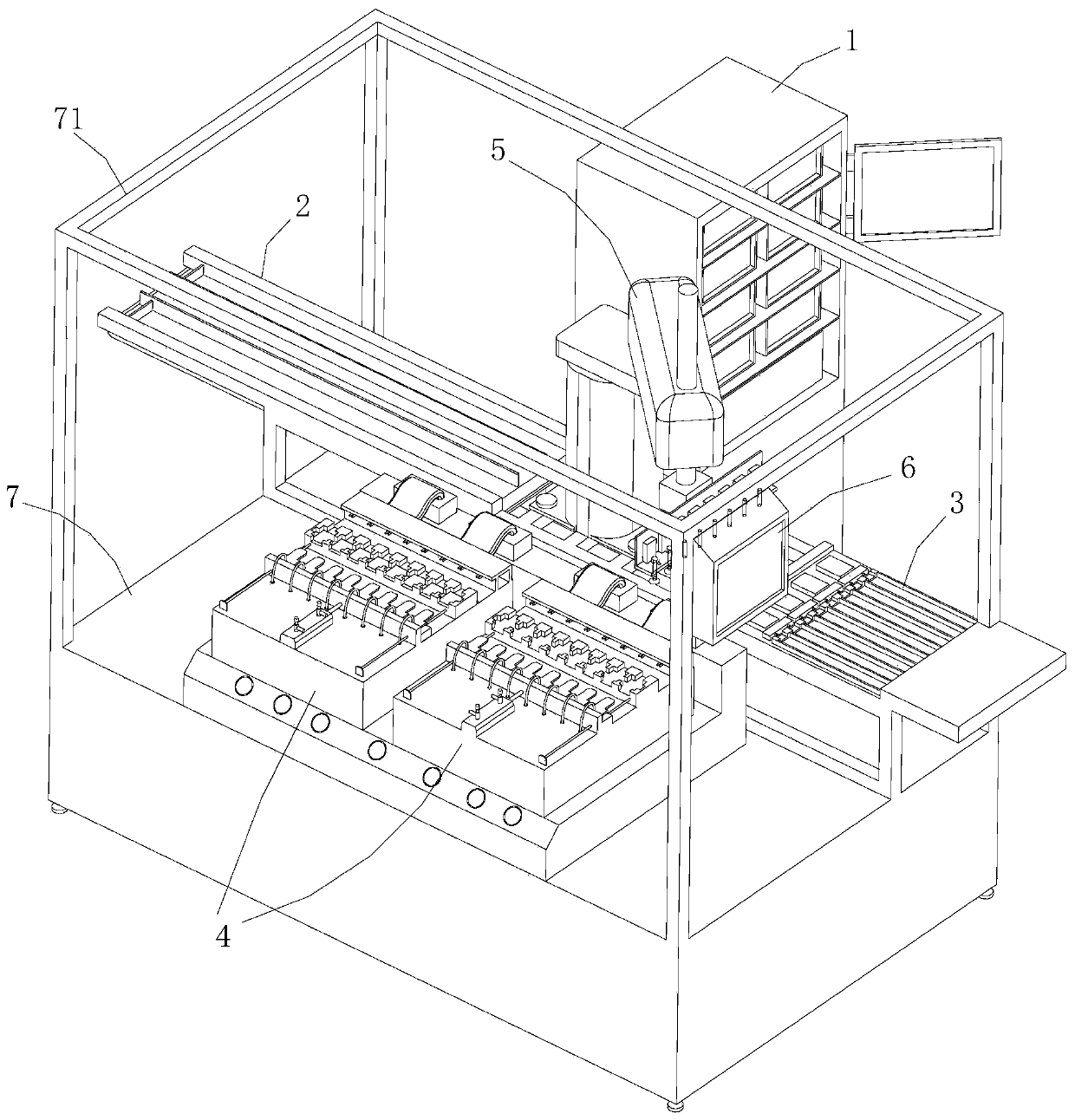

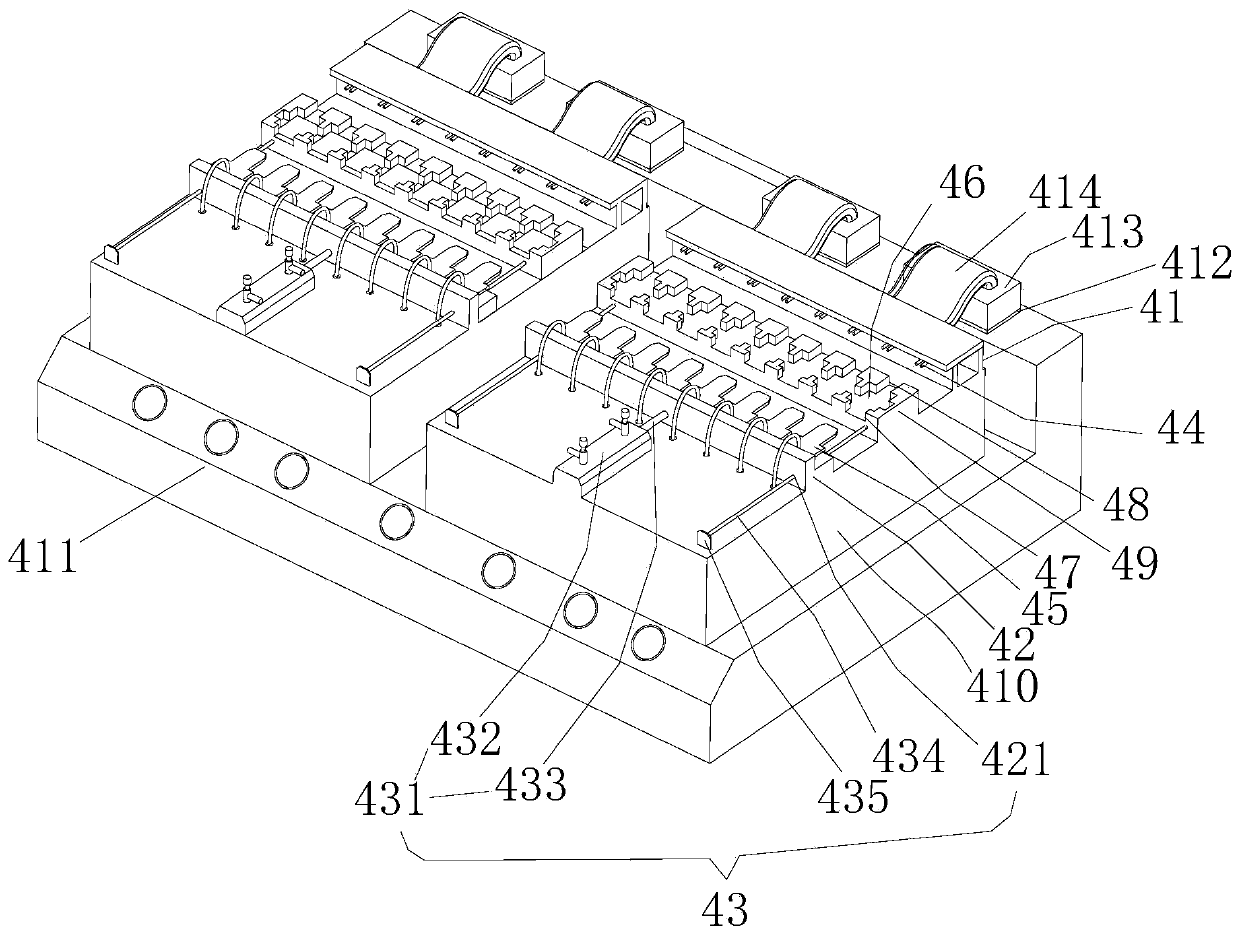

High-precision tooth dividing machine

ActiveCN113770269ACompact structureHigh degree of automationMetal-working feeding devicesMetal sawing tool makingEngineeringWorkbench

The invention discloses a high-precision tooth dividing machine which comprises a workbench, and the workbench is provided with a feeding station, a first tooth dividing station, an overturning station, a second tooth dividing station and a discharging station; the first tooth dividing station and the second tooth dividing station are each provided with a platen, a positioning mechanism, a clamping mechanism, a double-shaft sliding table and a knocking mechanism; a band saw blade is driven by the double-shaft sliding table to move to a tooth knocking position of the knocking mechanism in a sawtooth arrangement or / and interval mode; and the workbench comprises a first grabbing mechanism, a second grabbing mechanism and a turnover mechanism. A first grabbing mechanism grabs the band saw blade on the feeding station and places the band saw blade on the first tooth dividing station, the first grabbing mechanism grabs the band saw blade on the first tooth dividing station and places the band saw blade on the overturning station, the turnover mechanism turns over the band saw blade on the overturning station, and a second grabbing mechanism grabs the band saw blade on the overturning station and places the band saw blade on the platen of the second tooth dividing station, and grabs the band saw blade on the second tooth dividing station and places the band saw blade on the discharging station, so that automatic feeding, positioning, tooth dividing and discharging are achieved, and meanwhile the tooth dividing precision of the tooth dividing machine is high.

Owner:NINGBO CHEERY GARDEN TOOLS

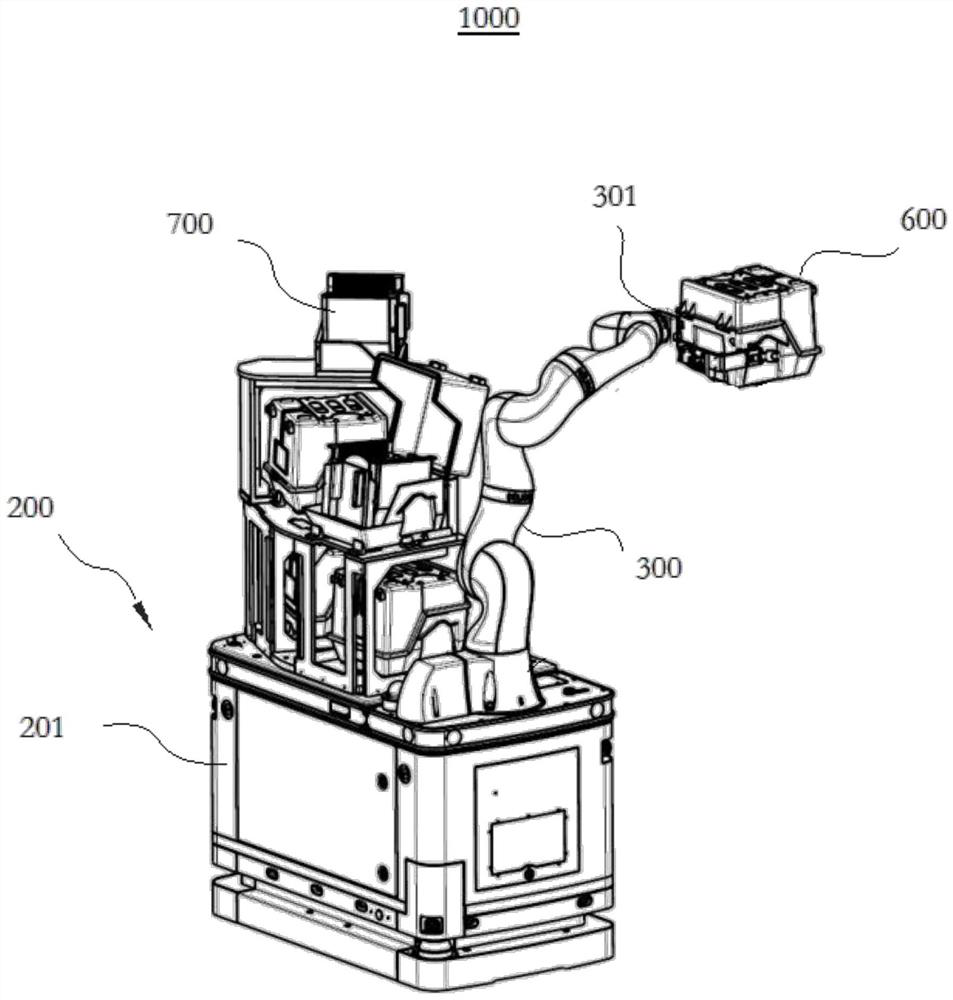

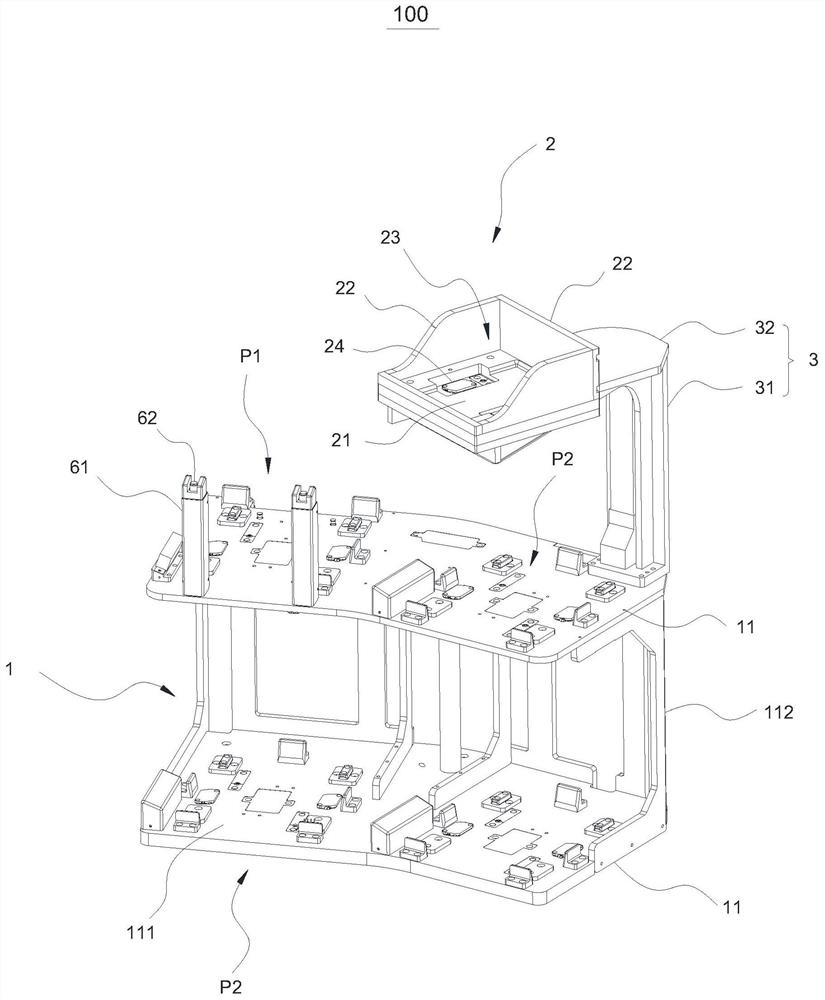

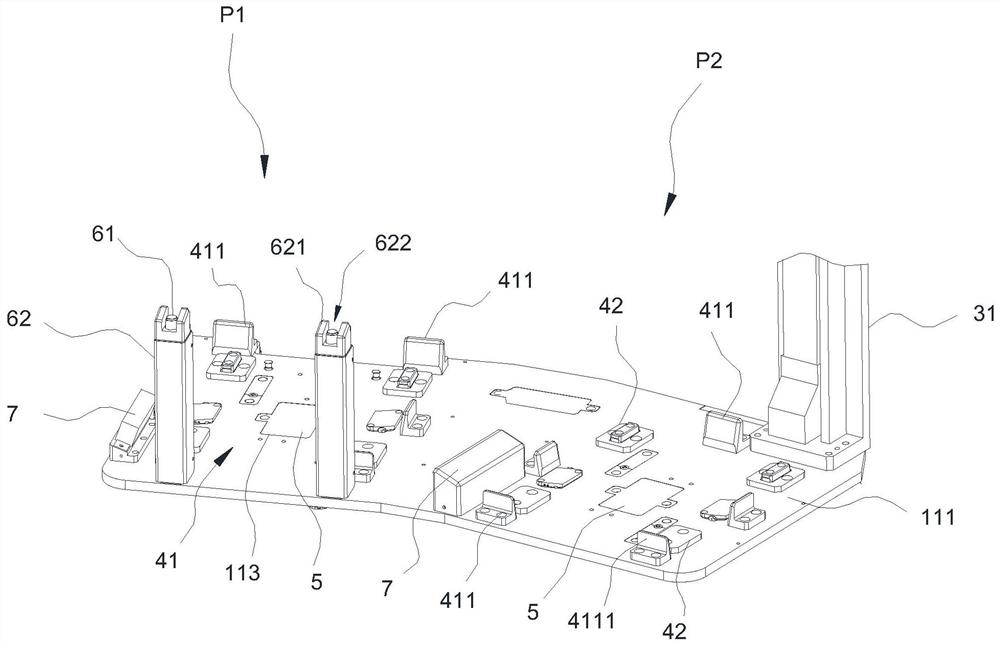

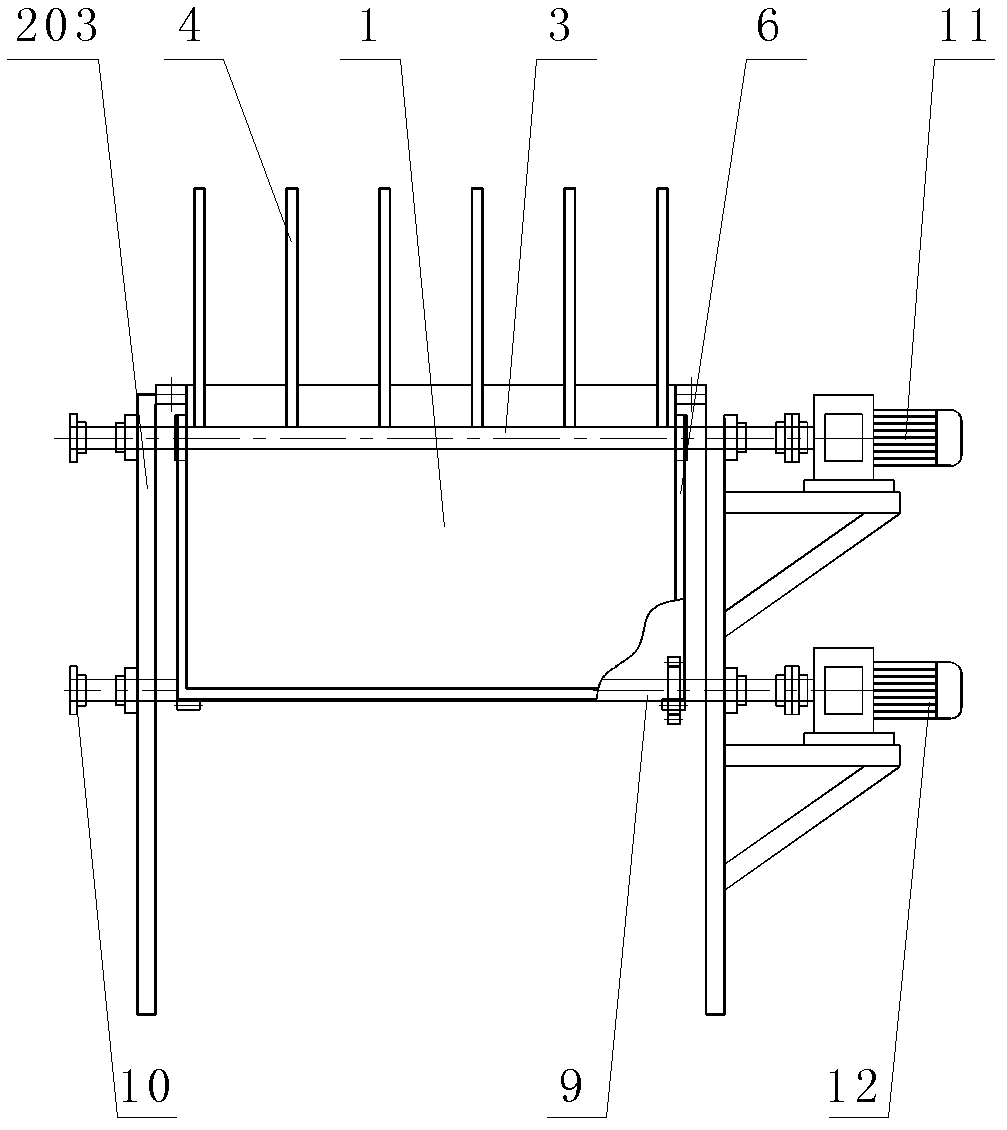

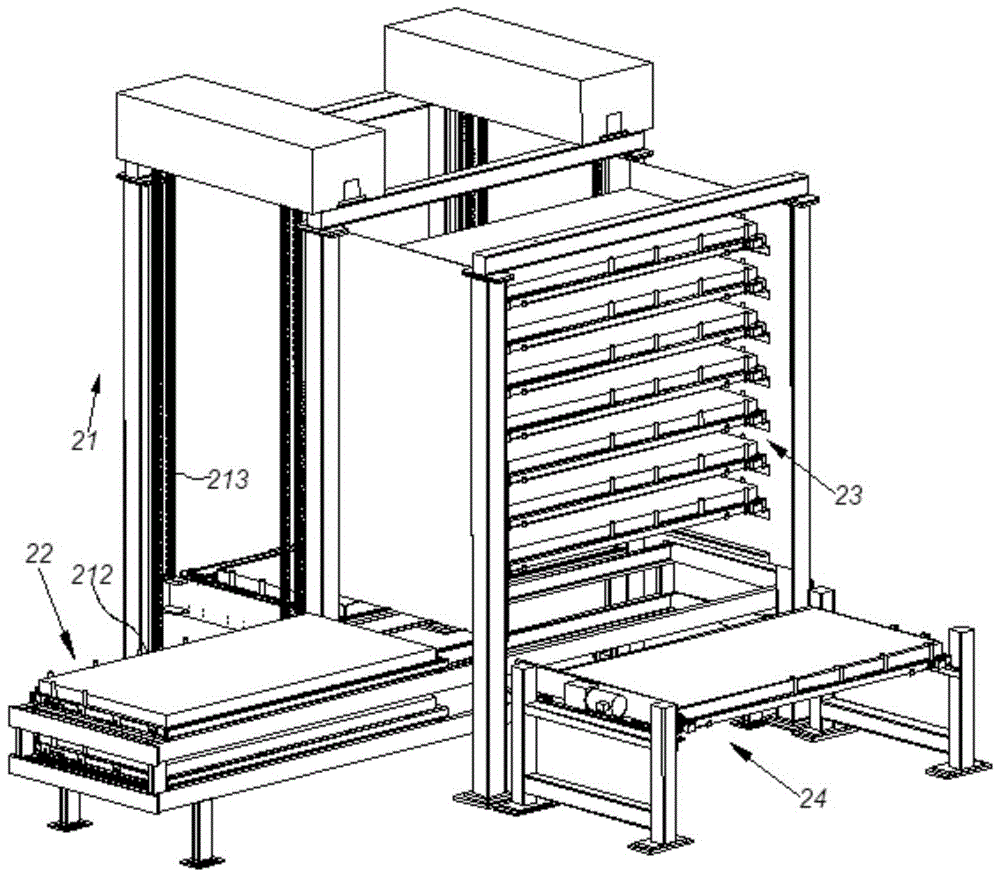

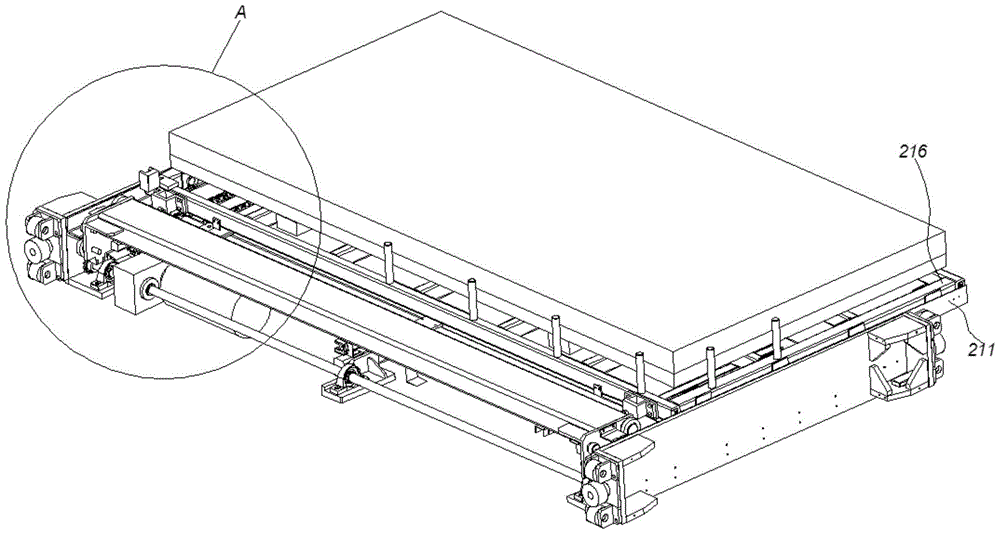

Caching platform, wafer turnover device and turnover method of device

PendingCN112447564AEasy to take outNo interferenceSemiconductor/solid-state device manufacturingConveyor partsEmbedded systemEngineering

The invention provides a caching platform, a wafer turnover device and a turnover method of the device. The caching platform comprises a loading platform for loading a wafer box and a transfer platform for temporarily placing a wafer rack. The loading platform is provided with at least one uncovering position and a plurality of loading positions, wherein the uncovering positions are used for loading wafer boxes. The space above the uncovering position is enough to enable the cover of each wafer box to be turned over to be opened and closed. The transfer platform and the uncovering position arearranged in a staggered manner, so that the wafer box and the wafer rack cannot interfere with each other in placement and carrying. A controller in the wafer turnover device automatically realizes carrying and turnover of the wafer boxes and the wafer rack by controlling a mechanical arm. The mechanical arm can replace manpower to achieve uncovering at the uncovering position, the transfer platform can provide a buffer space for the mechanical arm between the caching platform and the process equipment, the round-trip frequency of the mechanical arm is reduced, and the carrying efficiency ofwafers is improved.

Owner:库卡机器人制造(上海)有限公司

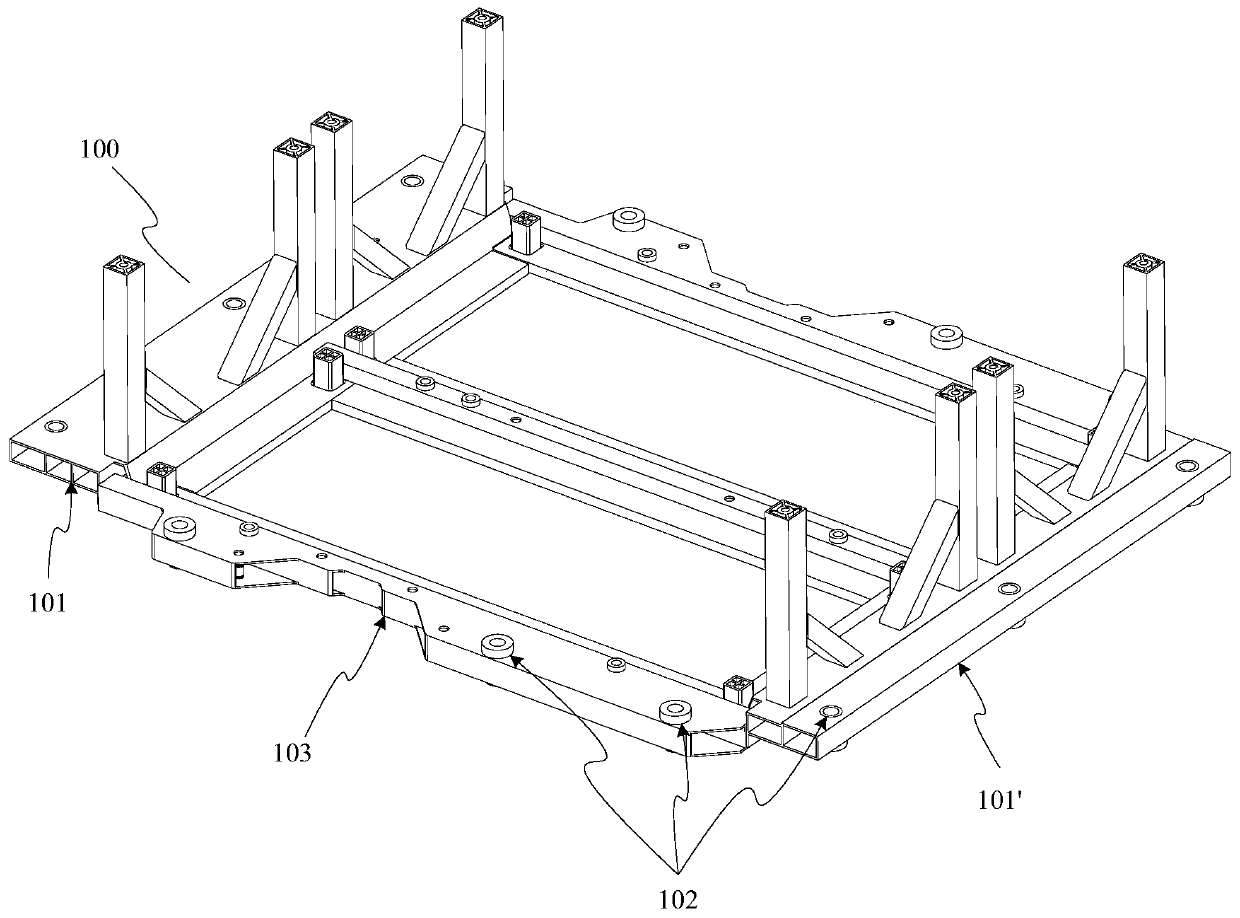

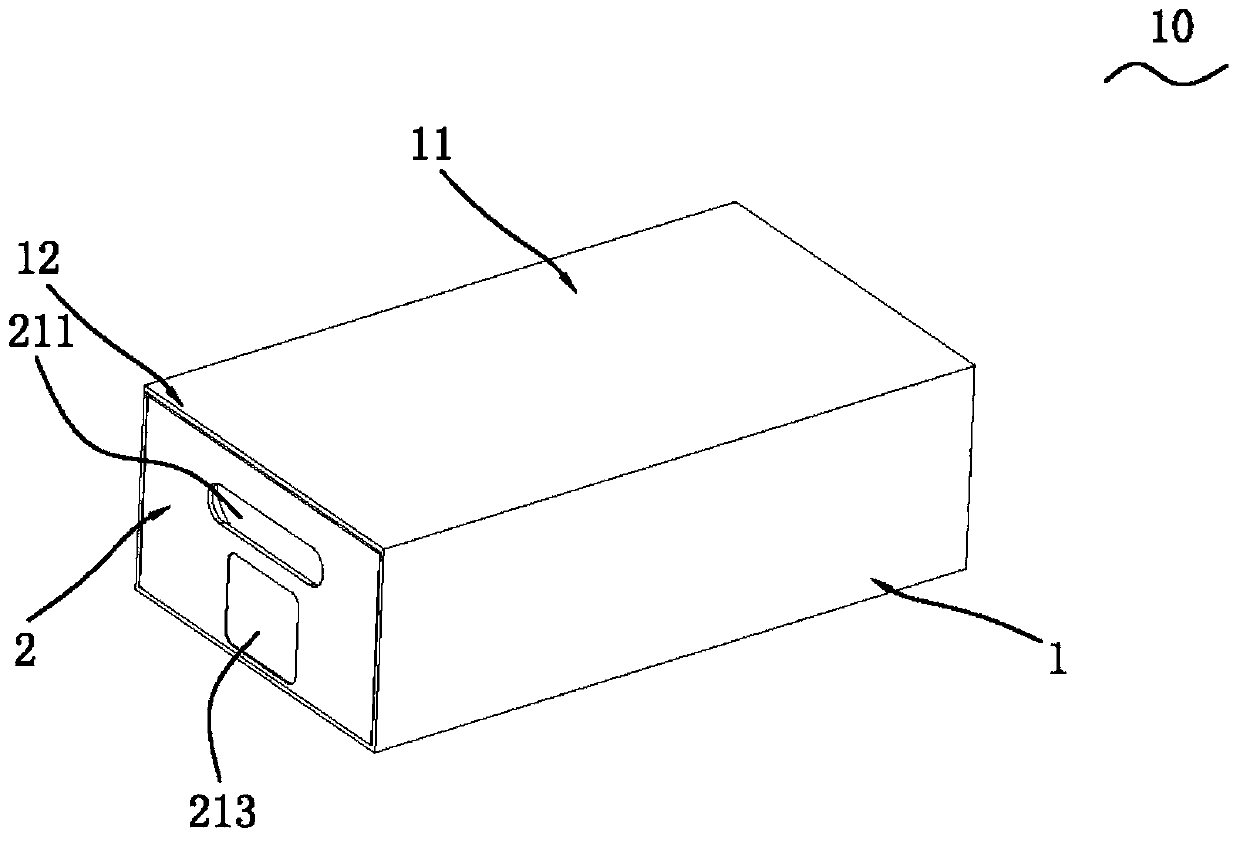

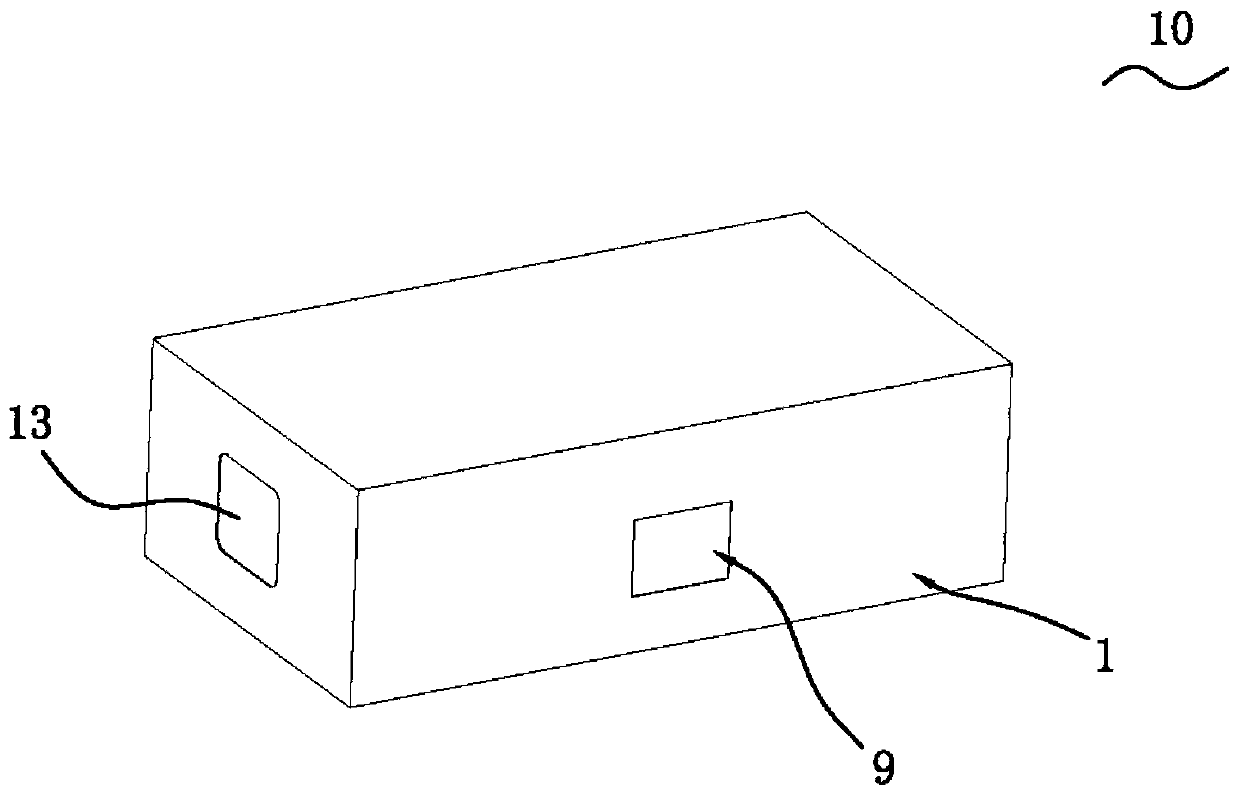

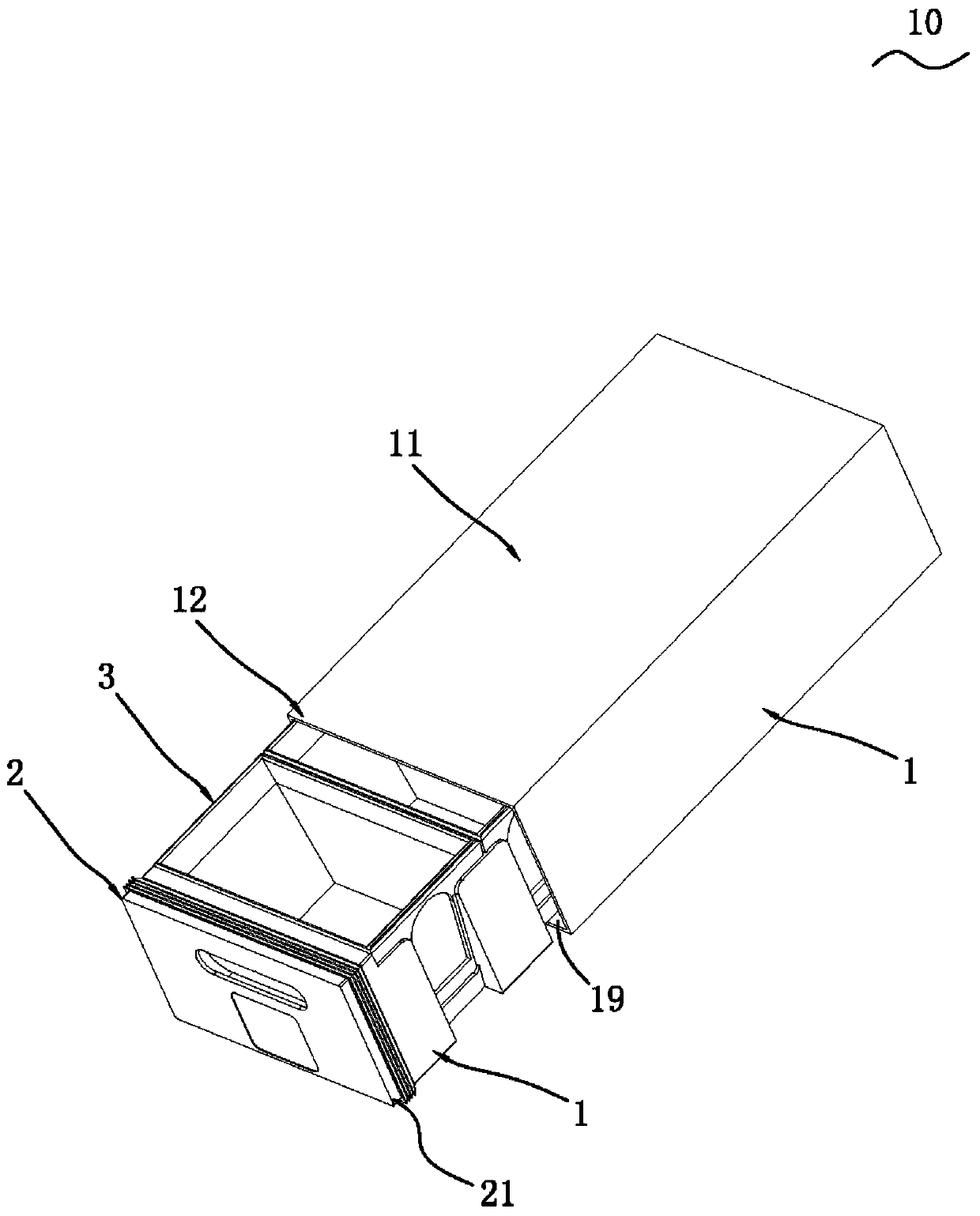

Tray for transferring power battery

The invention discloses a tray for transferring a power battery. The tray comprises a base, a first limiting unit and a second limiting unit, wherein the first limiting unit and the second limiting unit form four-corner support for a battery box frame and further form four-corner limitation for the battery box frame. The tray disclosed by the invention can realize circulation of a power battery system between a warehouse and a production line by virtue of AGV; moreover, the tray can implement limitation and restraining on the battery box frame by virtue of the first limiting unit and the second limiting unit, thereby supporting the assembly of the power battery system which takes the tray as a carrier and realizing more efficient transfer and assembly.

Owner:CH AUTO TECH CORP CO LTD

An automatic unpacking device

The embodiment of the invention discloses an automatic carton opening device. The automatic carton opening device comprises an operating table, a power distribution cabinet and a control cabinet. A sliding guide rail is arranged above the operating table, winches roll in the sliding guide rail through pulley combinations, a universal transferring device is arranged on the operating table and connected with the winch at one end of the sliding guide rail through a first flexible pull chain, and the winch at the other end of the sliding guide rail is connected with a carton taking device through a second flexible pull chain. By means of the automatic carton opening device, motions of full-automatic displacement, full-automatic folding, full-automatic bottom sealing, full-automatic delivering and the like of cartons can be achieved, the production efficiency is improved, the labor intensity is reduced, and the flexibility of the carton opening device is improved.

Owner:ZHEJIANG OUYAO MACHINERY

Polishing wheel device and automatic deburring machine with same

ActiveCN103481215BImprove work efficiencyReduce labor costsEdge grinding machinesFlexible-parts wheelsEngineeringConveyor belt

The invention discloses a polishing wheel device and an automatic deburring machine with the same. The deburring machine includes an even number of polishing wheel devices, a spindle device, a conveying device, a control device, a frame, and a device for adjusting the polishing wheel device and the conveying device. The lifter with the spacing between them; the polishing wheel device is connected with the main shaft device and is fixed in the frame, and there is a housing part on the frame, the conveying device is fixed in the housing part and is located below the polishing wheel device, the control device and the elevator They are all fixed on the outer side of the frame, and the control device is electrically connected with the main shaft device and the conveying device respectively; a main shaft motor and a revolving motor are installed on both sides of the top of the frame. The invention can intelligently adjust the rotation speed of the polishing wheel, the turnover speed of the polishing wheel, and the speed of the conveyor belt on the conveying device according to different products; make the deburring conditions more in line with the needs of different products, expand the use range of the deburring machine, and further improve the The degree of automation and applicability of the machine.

Owner:松泰精技(深圳)有限公司

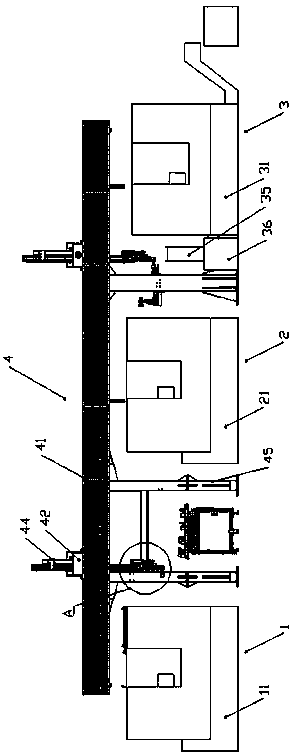

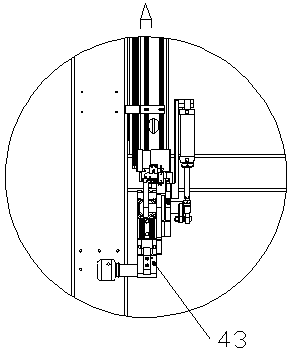

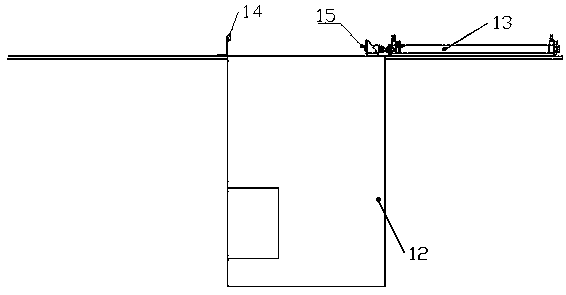

Automatic metal processing production line for ball socket casting

PendingCN110509076ARealize processingAchieve turnoverOther manufacturing equipments/toolsMetal working apparatusProduction lineMetal machining

The invention relates to an automatic metal processing production line for a ball socket casting. The automatic metal processing production line for the ball socket casting comprises a first processing station, a second processing station and a third processing station which are sequentially distributed, wherein circulation units are arranged among the three processing stations, and each circulation unit comprises a cross beam extending along the distribution direction of the three processing stations; a clamping jaw is arranged on each cross beam; and the clamping jaws are driven by two-shaftdriving mechanisms arranged on the cross beams to switch among the three processing stations back and forth and lift up and down so as to realize the taking and placing of ball socket workpieces. Theautomatic metal processing production line for the ball socket casting has the advantages that the first machining station, the second machining station, the third machining station and the circulation units are matched in the production line, so that the circulation of the ball socket in different machining machines is realized, the manual labor is reduced, the working efficiency is improved, and the automatic metal machining of the ball socket is realized.

Owner:RUGAO DASHENG LINE EQUIP

ATE (automatic test equipment) with mechanical hand and control method thereof

The invention discloses ATE (automatic test equipment) with a mechanical hand. The ATE comprises an ATE power source test system which is used for conducting a power source test. The ATE further comprises a product feeding and conveying mechanism, a product distributing and conveying mechanism, at least one test device, the mechanical hand and a controller. The test devices are used for fixing tested products. The mechanical hand comprises suction discs and can be used for putting the tested products into the test devices from the product feeding and conveying mechanism, taking out the testedproducts from the test devices and putting the tested products into the product distributing and conveying mechanism. The controller is electrically connected with the mechanical hand so as to controlthe start and stop of the mechanical hand. The invention further discloses a control method of the ATE with the mechanical hand. Compared with the prior art, the ATE with the mechanical hand has theadvantages that the purpose that the tested products are automatically put into the test devices from the product feeding and conveying mechanism, taken out from the test devices and put into the product distributing and conveying mechanism is achieved, the circulation of the products is achieved, and the manpower is saved; and the test efficiency is improved, the problem that when defective products are manually picked, workers miss the defective products and do not pick out the defective products is solved, and the quality testing capacity is improved.

Owner:DONGGUAN AOHAI TECH CO LTD

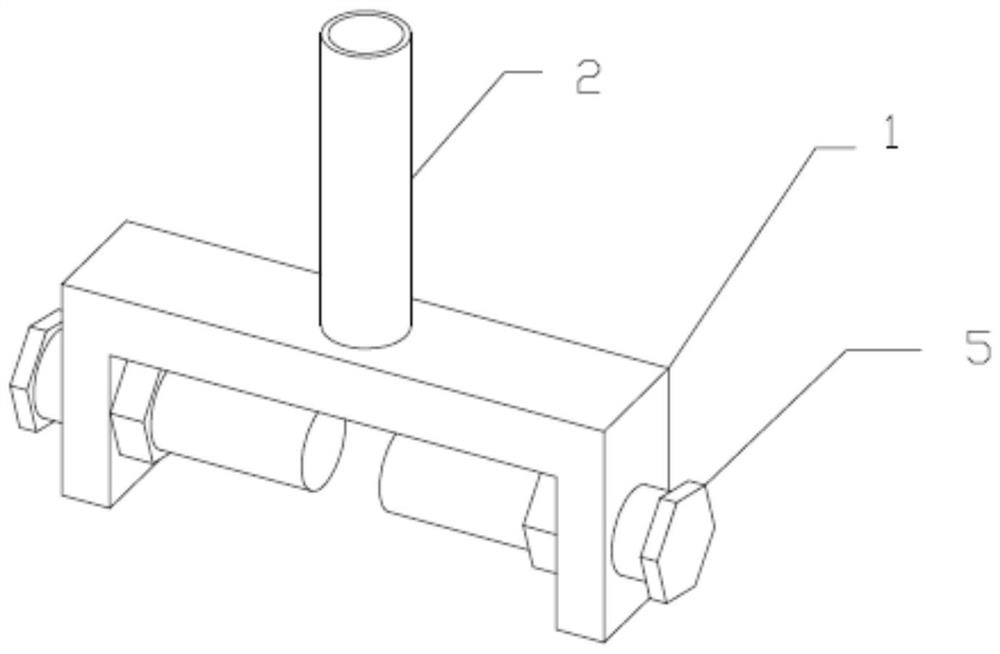

Cantilever steel beam system scaffold moving positioning pile and construction method

PendingCN112227686AImprove construction efficiency and construction accuracy requirementsEnsure construction safetyScaffold accessoriesBuilding support scaffoldsCantileverScaffolder

The invention discloses a cantilever steel beam system scaffold moving positioning pile. The scaffold moving positioning pile comprises an inverted-U-shaped base, a connecting pipe is fixedly connected to the upper portion of the base, bolt holes are formed in the two sides of the base, the central axes of the bolt holes are collinear, nuts are fixedly connected to the positions, corresponding tothe bolt holes, of the inner side faces of the base, the inner diameter of the nuts is smaller than that of the bolt holes, bolts are arranged in the bolt holes in a penetrating mode and connected with the nuts in a threaded mode, and the length of the bolts is larger than half of the width of the base. The invention further provides a construction method of the positioning pile. By adopting the positioning pile and the construction method for construction, the purpose of shortening the construction period is achieved, and the positioning pile can be widely applied to the technical field of cantilever steel beam scaffold construction.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

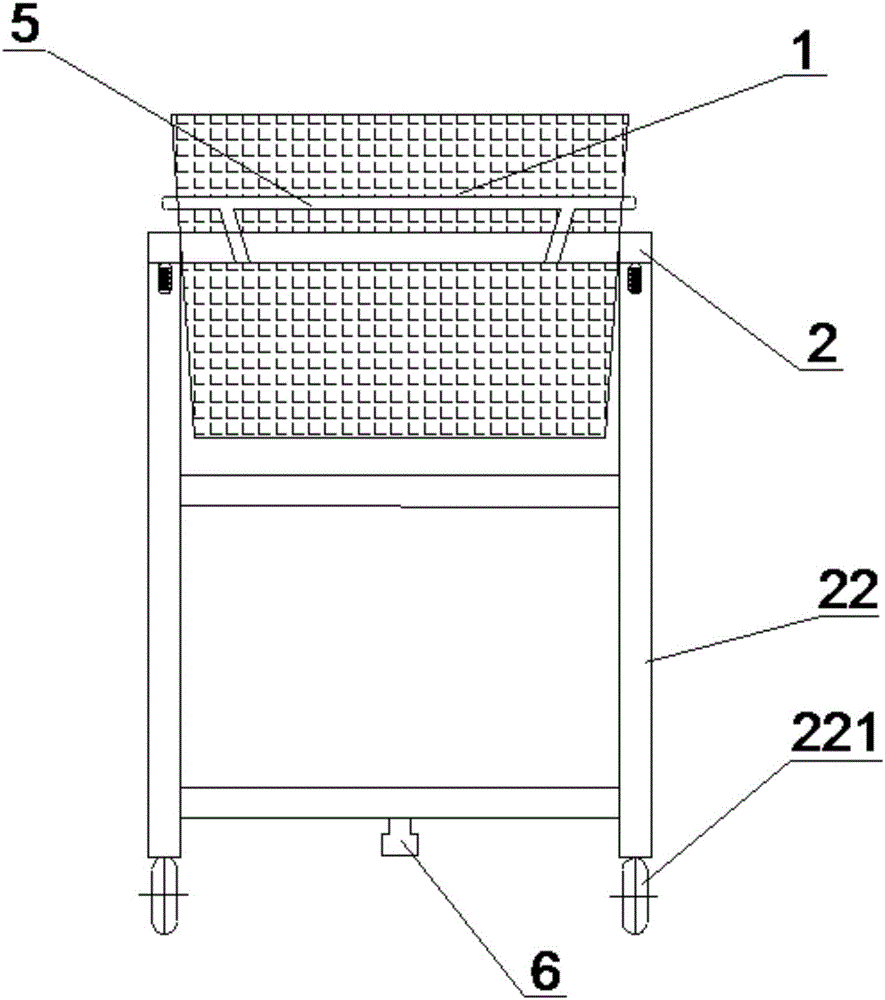

Iron scrap collecting device

InactiveCN107814130AAchieve turnoverRealize the collectionBroaching accessoriesMaintainance and safety accessoriesElectric machinerySlide plate

The invention discloses an iron scrap collecting device. The iron scrap collecting device comprises a base, and is characterized in that a collecting box is fixedly connected to the upper end of the base, a sliding bottom plate is arranged at the lower end of the collecting box, a sliding groove is formed in the upper end of the collecting box, a rotary wheel is connected to the upper end of the sliding groove through a rotary shaft, a sleeve brush is arranged at the periphery of the rotary wheel, and the rotary wheel is connected with a driving motor through a chain, wherein the driving motoris connected to the side wall of the sliding groove through a tensioning supporting frame. A notch is formed in the left portion of the upper end of the sliding groove, and the lower end of the rotary wheel extends into the notch. The iron scrap collecting device has the beneficial effects that the device is specially designed for collecting iron scraps of a horizontal broaching machine, is highin practicality, can clean thoroughly, can achieve direct collecting of the iron scraps from top to bottom, is convenient and rapid and can save labor.

Owner:诸城市润沃机械有限公司

Food material container

The invention provides a food material container. The food material container comprises a shell, an inner shell that can be inserted into / taken out of the shell, and a plurality of holding cups installed in the inner shell, wherein each holding cup is provided with a holding cavity with an upward opening, and each holding cavity is used for holding food materials to be cooked; the shell is provided with an accommodating cavity with a forward opening, and a sealing part is formed in front of the accommodating cavity; the inner shell comprises a sealing plate; and when the inner shell is well inserted into the shell, the sealing plate is matched with the sealing part, for sealing the accommodating cavity. The workload of people for preparing foods in a kitchen can be greatly reduced, and generation of garbage in the kitchen also can be reduced, so that revolutionary change of such a site, the kitchen, can be achieved.

Owner:SHENZHEN NUMBER ONE EQUIP EXPL

Transfer cart with crankshafts

InactiveCN102582671BAchieve turnoverReasonable structureHand carts with multiple axesArchitectural engineeringCrankshaft

The invention relates to a transfer cart with crankshafts, which is provided with a bottom plate and wheel sets. Four vertical columns and a frame are welded on the bottom plate, two guide connecting rods are respectively arranged between the two front vertical columns and between the two rear vertical columns, the two guide connecting rods on the front side and the two guide connecting rods on the rear side are perpendicularly connected with two limit groove plates respectively, and a bottom bearing plate and a plurality of middle bearing partitions are sequentially mounted between the frontlimit groove plate and the rear groove plate layer by layer. V-shaped grooves of the upper end face of the lower middle bearing partition are arranged oppositely to V-shaped grooves of the lower end face of the upper middle bearing partition, and V-shaped grooves of the lower end face and V-shaped grooves of the upper end face of the same middle bearing partition are arranged at intervals in a staggered manner. When in use, the crankshafts and the middle bearing partitions are sequentially mounted layer by layer, the crankshafts in layers are disposed in a staggered manner so that space can be utilized sufficiently and more crankshafts can be disposed. The transfer cart with the crankshafts is reasonable in structure, simple in operation, high in transferring efficiency, low in transferring cost and wide in application.

Owner:TIANRUN IND TECH CO LTD

Light combined hanging box with recyclable baseplate steels and construction technology thereof

The invention discloses a light combined hanging box with recyclable baseplate steels. The light combined hanging box comprises a baseplate, four wall bodies, an outrigger, and lateral stable support beams which are connected between the outrigger and the wall bodies; wherein the four wall bodies are connected by a support frame; a lifting lug is arranged at the upper end face of outrigger; a jack placing beam is arranged under the outrigger; the outrigger is connected with the baseplate by a supporting column; a jack is arranged between the outrigger and the jack placing beam; the lower end of the jack placing beam is connected with the top end of a steel casing. The light combined hanging box has the following advantages: 1, the bearing abilities of bamboo plywood and bottom sealing concrete are fully used under a condition that a poor sea state of open seas is overcome, the turning of the baseplate steels is effectively realized, and the steel consumption is greatly reduced; 2, the structure is light; for the hanging box of the same specification, the lifting weight of the combined baseplate hanging box is similar to the self weight of a traditional steel baseplate hanging box, so that relative to the concrete prefabricated baseplate steel hanging box, the rated load weight and the lifting difficulty of a floating crane are effectively reduced.

Owner:CCCC SHEC FOURTH ENG +1

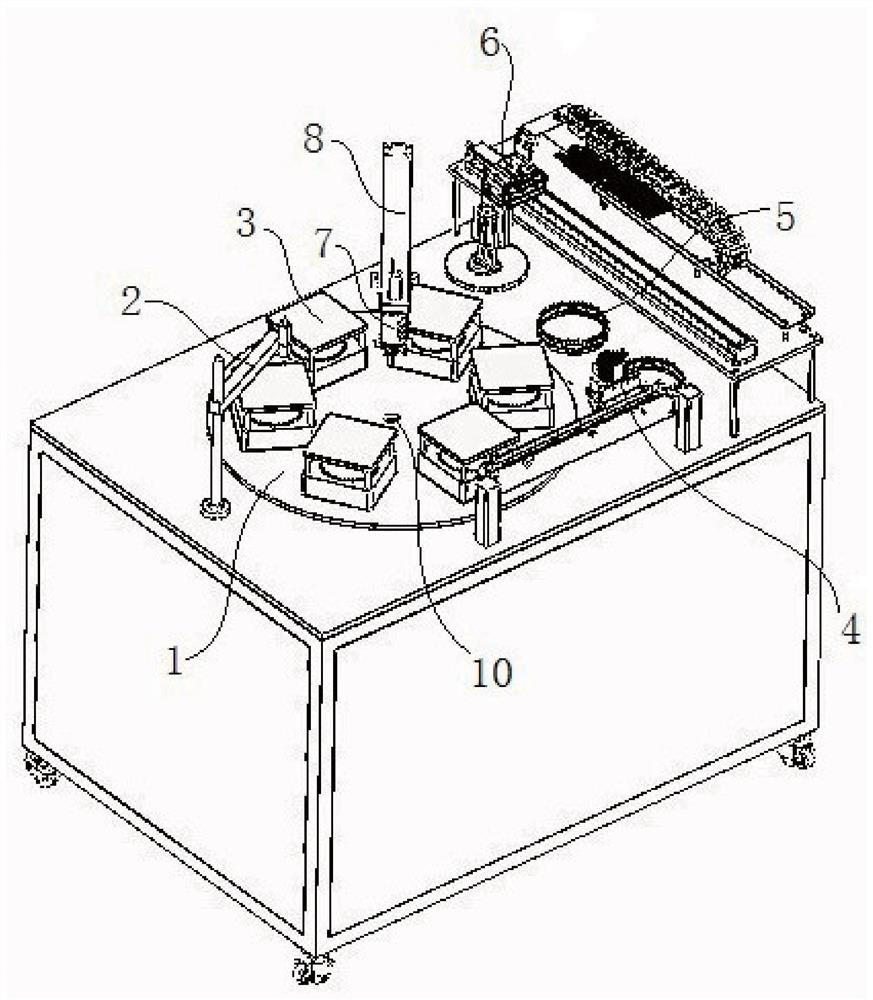

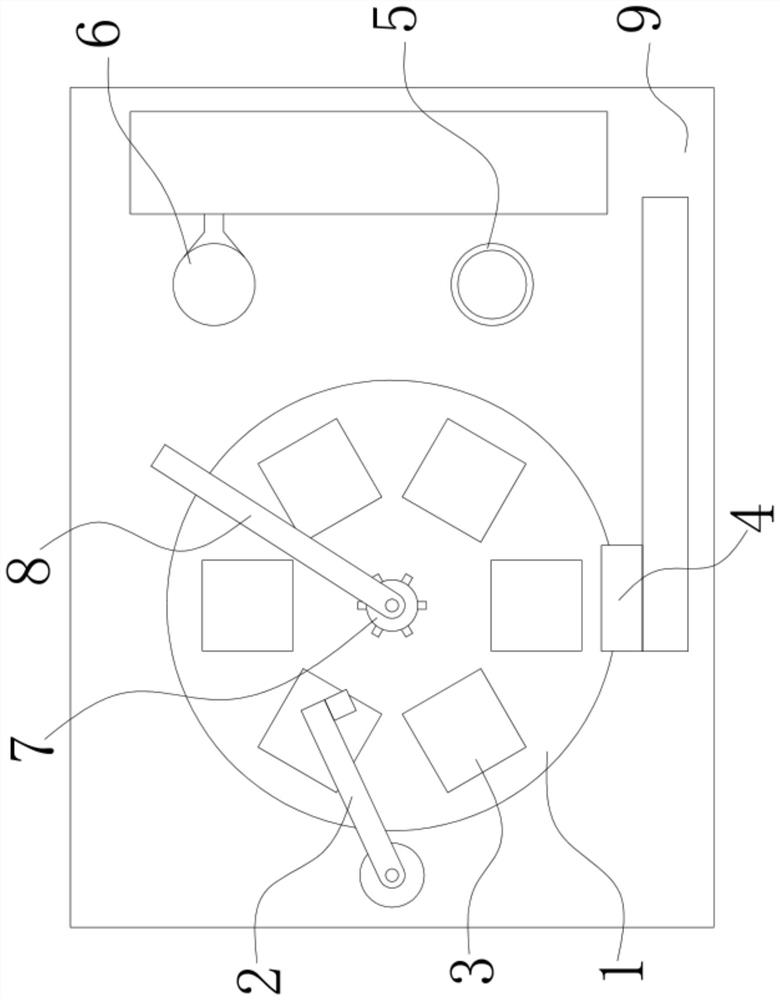

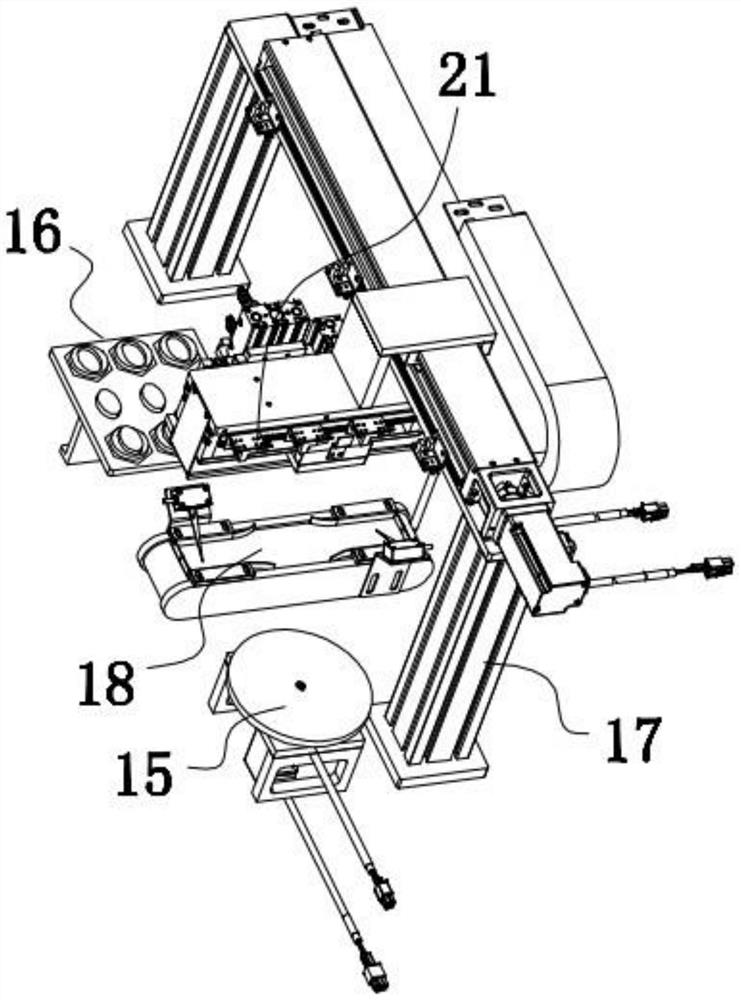

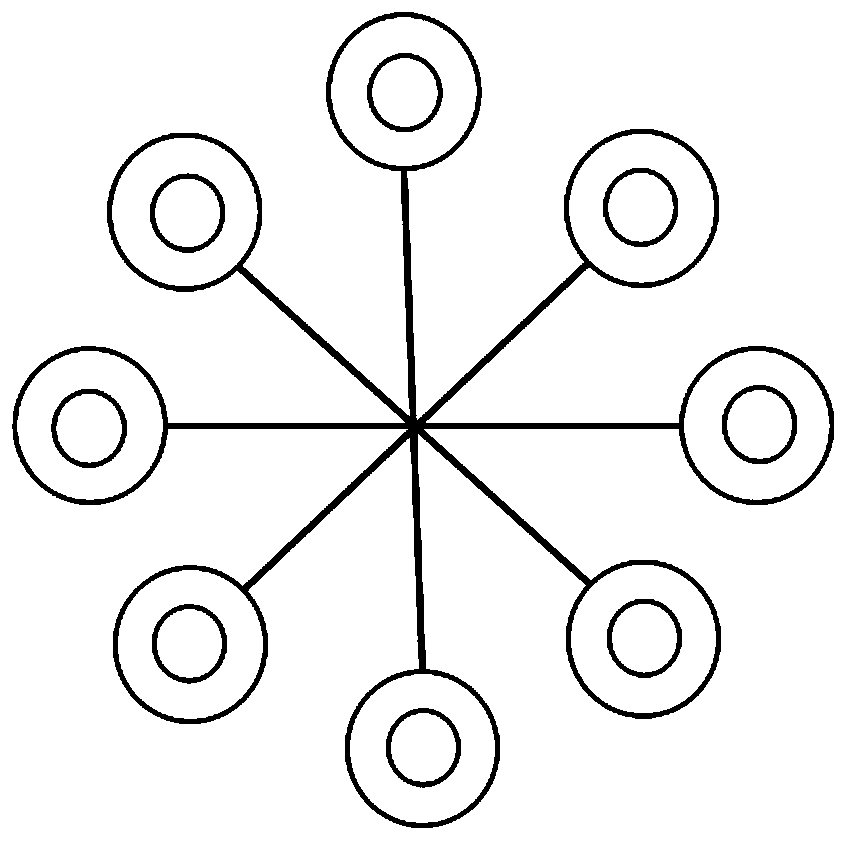

Rotating disc type mold overturning mechanism

PendingCN112239072AGuaranteed RegularityShorten exercise timeLiquid surface applicatorsCoatingsLine tubingAnnular array

The invention discloses a rotating disc type mold overturning mechanism. The mechanism comprises a rotating disc station, a mold ring taking mechanism, a mold taking mechanism and a driven pipe, wherein the rotating disc station comprises a rotating disc arranged horizontally, the upper surface of the rotating disc is provided with a plurality of station bodies in an annular array mode, the mold ring taking mechanism is horizontally arranged on one side of the rotating disc and at least has a linear reciprocating translation freedom degree in the length direction of the mold ring taking mechanism, the mold taking mechanism is horizontally arranged on one side of the rotating disc and at least has a linear reciprocating translation freedom degree in the length direction of the mold taking mechanism, the length direction of the mold taking mechanism is perpendicular to the length direction of the mold ring taking mechanism, a motion trail of the mold ring taking mechanism intersects witha motion trail of the mold taking mechanism, the driven pipe is arranged over a circle center of the rotating disc, the axis of the driven pipe is vertically arranged, the driven pipe has a rotatingfreedom degree around the axis of the driven pipe, a plurality of through pipes extending in the radial direction are arranged on the driven pipe, and the number of the through pipes is equal to the number of the station bodies. By adopting the mechanism, the cost is low, the action efficiency of each mechanism is high, and a pipeline is not easy to twist due to rotary motion.

Owner:SUZHOU GUANGYUE MICRO NANO TECH CO LTD

A support structure that can realize cast-in-place support structure with less support for concrete box girder of elevated approach bridge without platform

ActiveCN103850183BSolve the "rooting" problemReduce construction difficultyBridge erection/assemblyEngineeringBox girder

The invention discloses a support structure for realizing no-cushion cap approach viaduct concrete box girder less-support cast-in-place, which belongs to the field of bridge superstructure construction, and comprises a support for box girder cast-in-place construction, wherein the box girder is supported by a cast-in-place pile and pier bodies directly supported thereon. The support structure is characterized in that the support comprises at least two rows of intermediate columns arranged in the middle of the box girder and connected in parallel, sidespan stand columns symmetrically arranged on two sides of each pier body in pairs, a truss located under the box girder and supported by the intermediate columns and the sidespan stand columns, and a connecting support thereof; each pair of sidespan stand columns is respectively supported by a hoop structure; each hoop structure is supported by the cast-in-place pile and surrounded and fixed on the pier bodies thereon; and stand columns on the same sides of the same row of pier bodies are connected through a parallel connected part in the middle, a lower cross beam on the top part and an outrigger on the bottom part. The support structure is applied to box girder cast-in-place of land approach bridge pier columns with higher clearance and without a cushion cap under the bridge, and is quick in construction progress, and low in engineering construction cost.

Owner:CCCC SHEC FOURTH ENG +1

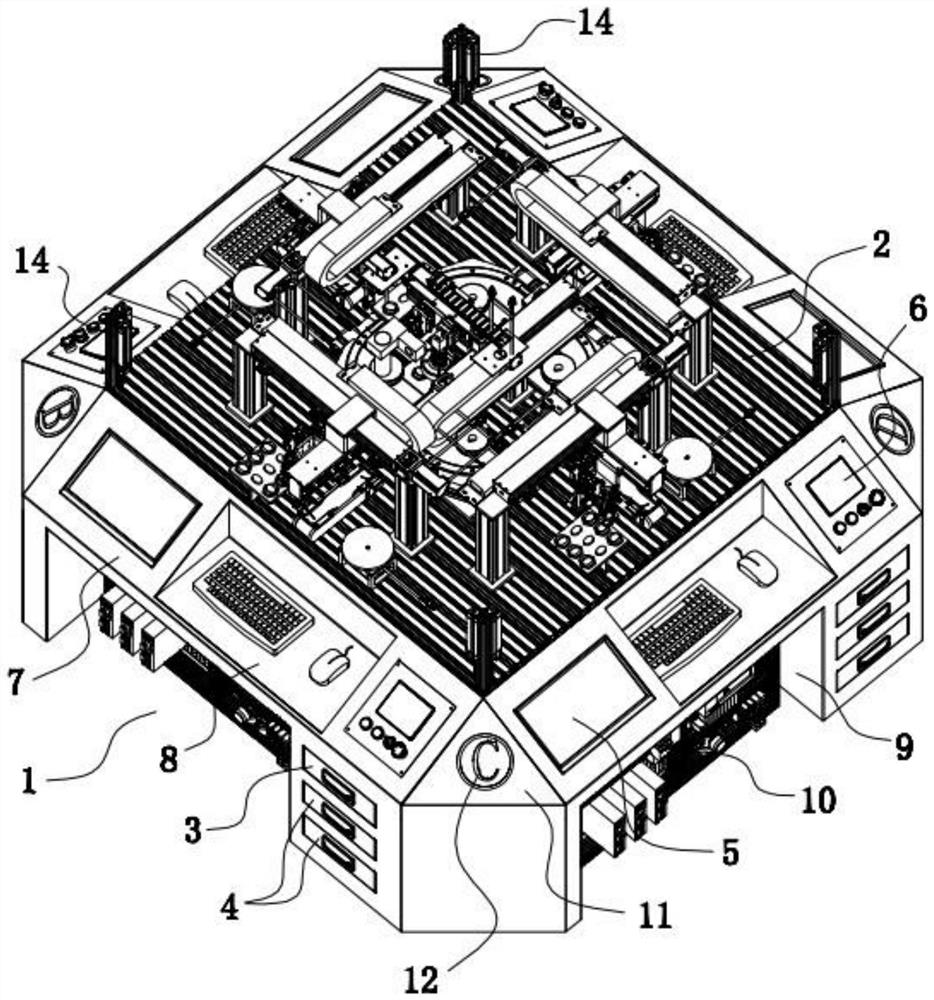

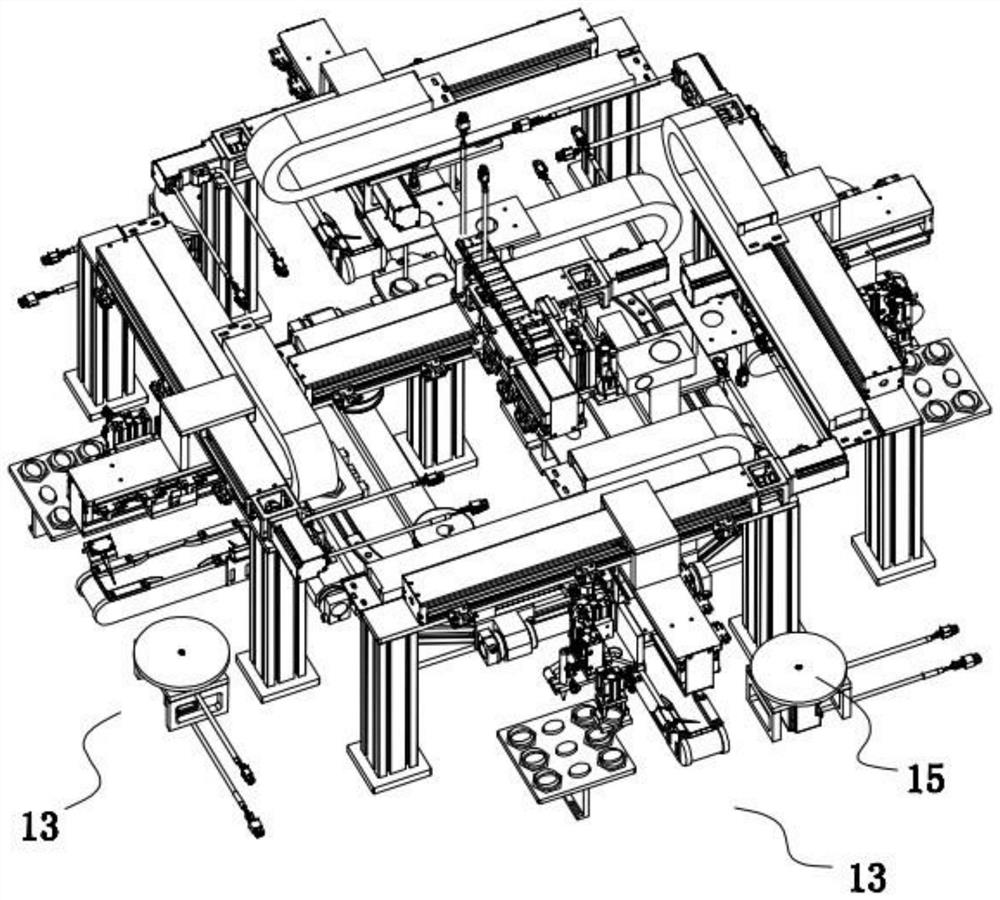

Four-station industrial scene motion control application training practice platform

PendingCN114882752AWith fixtureAchieve turnoverCosmonautic condition simulationsEducational modelsControl tableWorkbench

The invention discloses a four-station industrial scene motion control application training practice platform which comprises a table body structure and four control tables formed by edges. A working table is arranged between the tops of the four control tables, and the scene simulation mechanism is arranged on the working table; the scene simulation mechanism comprises a middle turnover mechanism group and four side turnover mechanism groups; the four side face turnover mechanism sets are arranged in an annular array mode, and the middle turnover mechanism set and the four side face turnover mechanism sets each comprise a two-axis mechanical arm. The side turnover mechanism set is further provided with a rotary tray and a linear conveying belt which are fixed to the workbench. The middle turnover mechanism set comprises a closed-loop track, the track line of the closed-loop track is in a rounded rectangle shape, four sliding tables are movably assembled on the closed-loop track, and all the sliding tables are driven by a closed-loop type transmission belt. The four-plus-one mode is adopted, all stations are coordinated, turnover is efficient, and the automatic teaching aid is high in reasonability.

Owner:苏州恒途教育科技有限公司

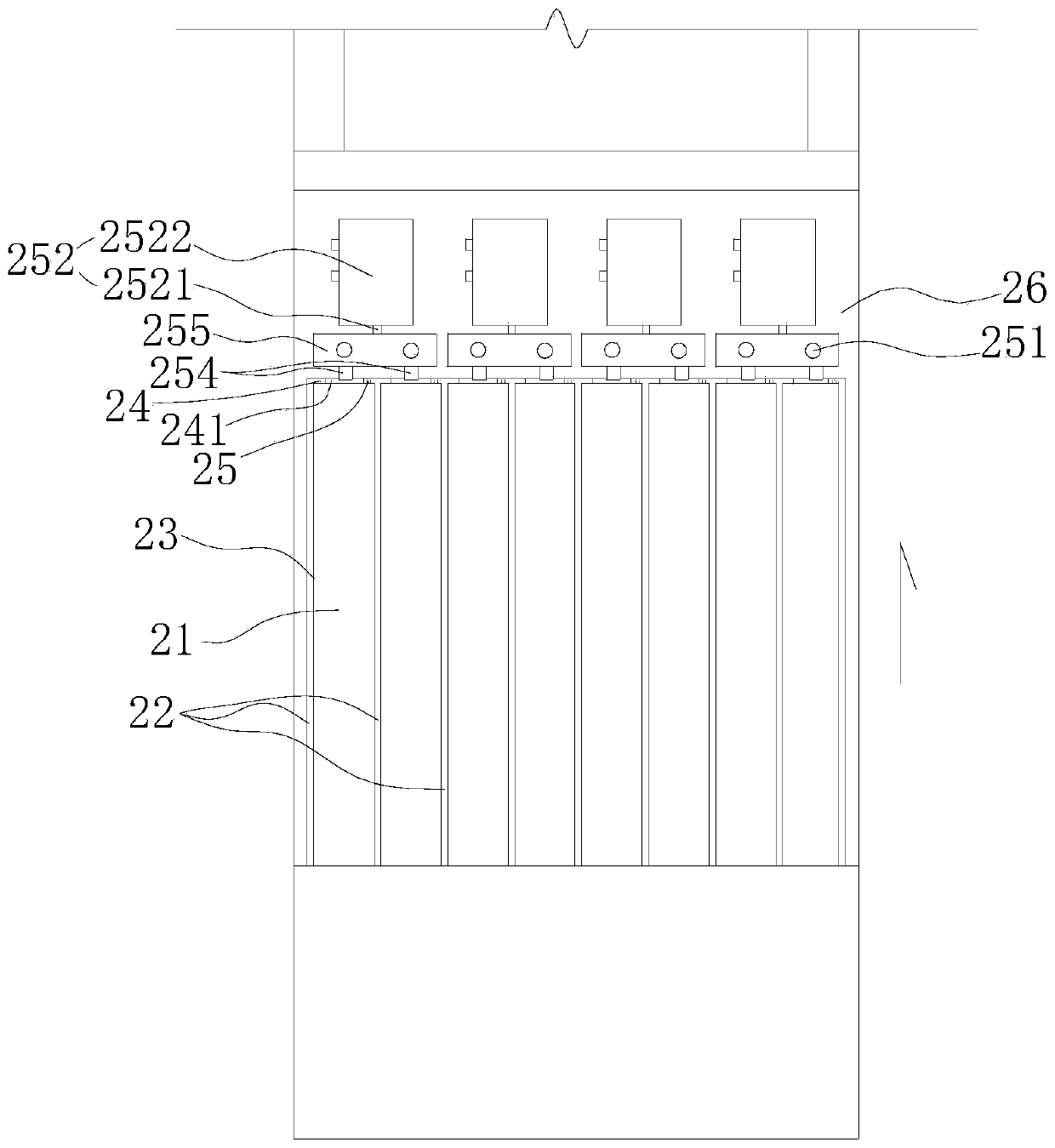

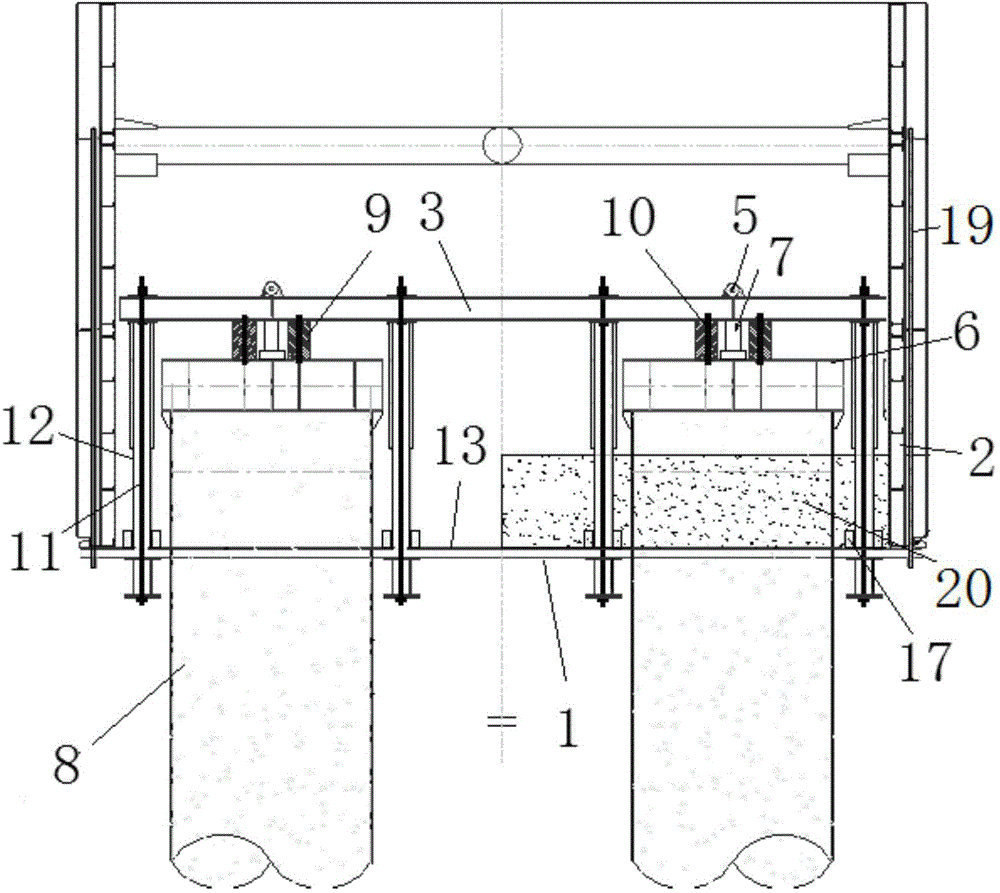

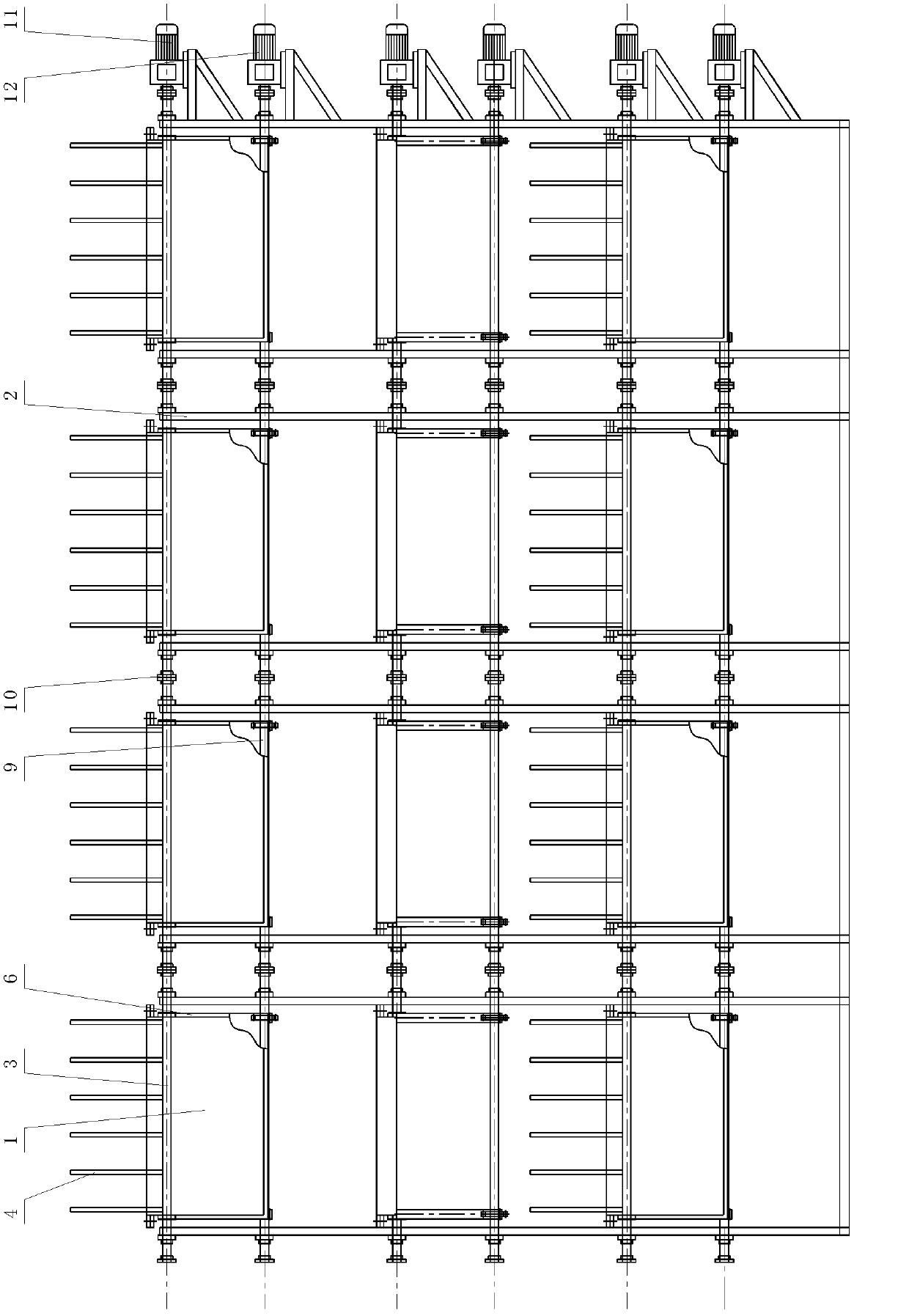

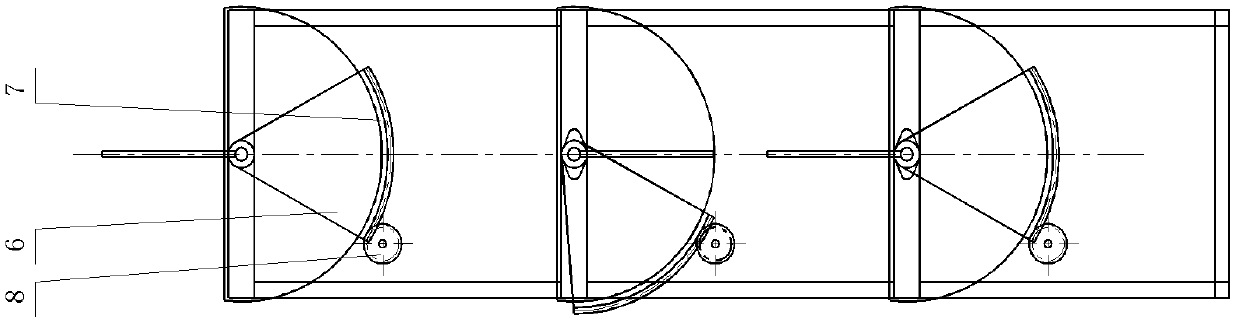

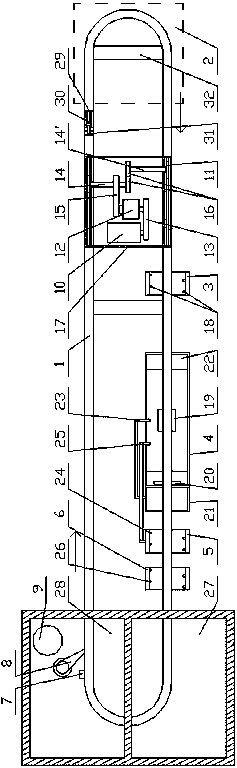

Tandem compound type solid state fermentation device

InactiveCN102488301BImplement changes quicklyAdapt to the needs of business changesFeeding-stuffAutomatic controlEngineering

Disclosed is a tandem compound type solid state fermentation device. A plurality of fermentation units are arranged in a rectangular support, which is vertically transversely arranged, in a matrix manner, semicircular fermentation containers of the fermentation units are fixed on the support, openings of the containers are upward, a stirring shaft is fittingly arranged along the axis of each container, stirring blades are fixed on each stirring shaft, when each stirring shaft rotates, outer edges of the corresponding stirring blades cling to the inner wall of the corresponding container and rotate, the bottom of each container is provided with a long discharging opening along the length direction, and an arc-shaped movable door matching with the corresponding discharging opening is arranged on the lower side of the corresponding discharging opening and clings to the outer wall of the corresponding container. Specifications of the units of equipment are unified, change of production scale can be realized fast by means of flexible combination and overlying of the fermentation units according to requirements of yield and process, and requirements of variation of operation of enterprises can be met; and the fermentation units in the same layer are driven by a unified power device, the fermentation units in the same layer are connected serially, process requirements such as fermentation, scattering, transfer and the like of materials are met, simultaneously, automatic control is realized easily, and fermentation quality of feed is guaranteed.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

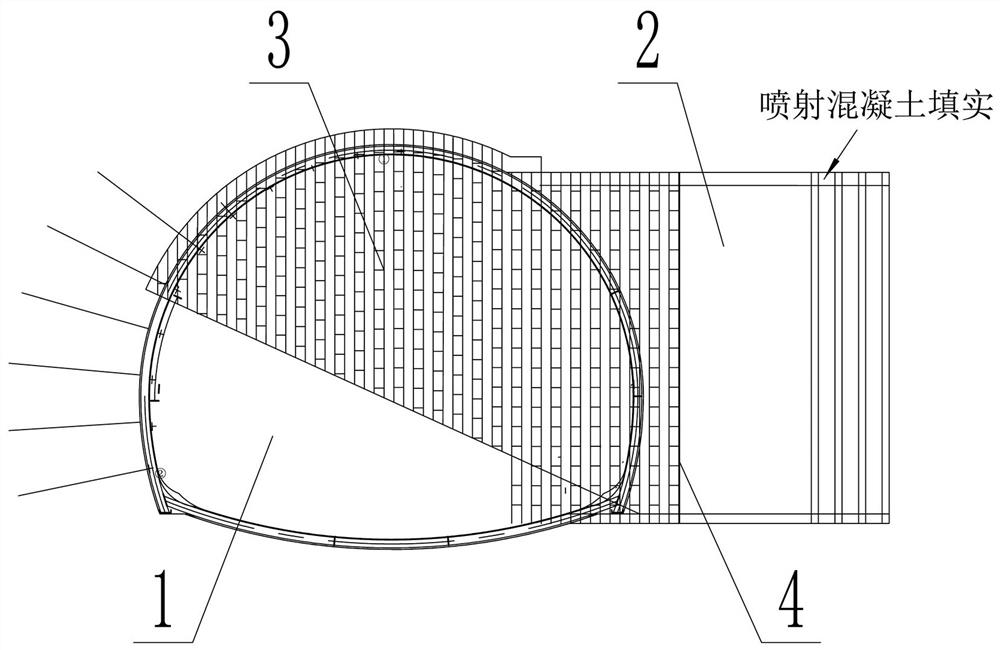

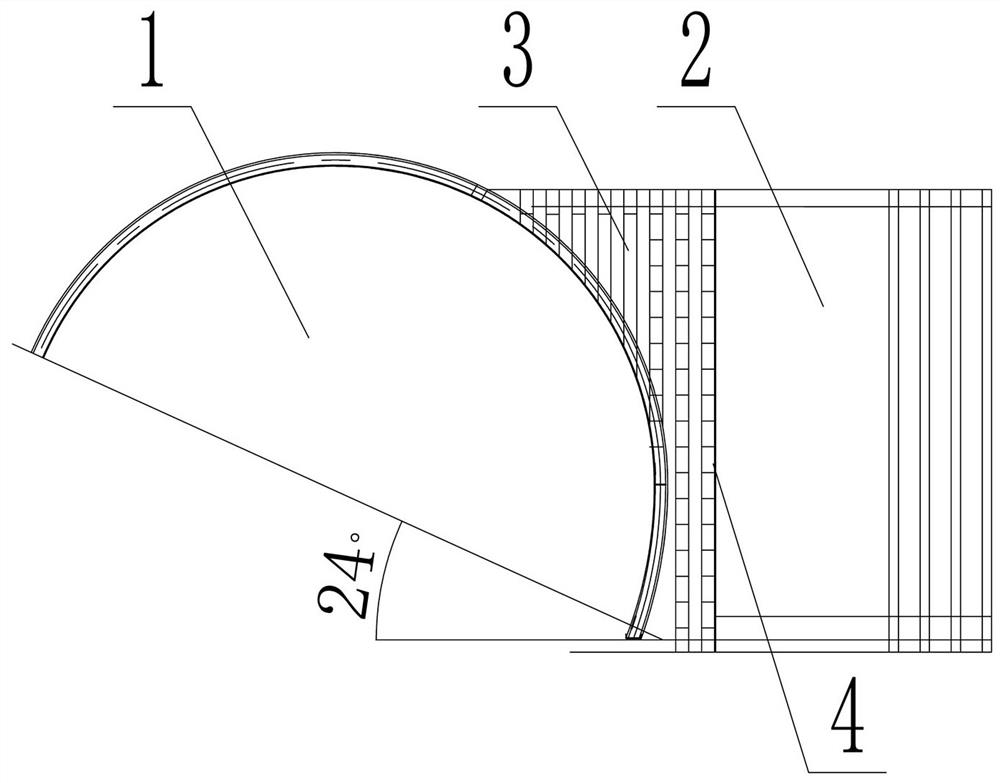

A construction method of a detachable portal frame in an expansive mudstone orthogonally inclined shaft

ActiveCN111236961BReduce the difficulty of operationAchieve turnoverUnderground chambersTunnel liningPilot holeArchitectural engineering

The invention relates to a construction method of a detachable gantry for an expansive mudstone orthogonal inclined shaft, which effectively solves the problems of narrow construction work surface, poor integrity and high construction risk in the traditional construction method; the construction method is: The steel frame construction of the pilot hole starts at the reinforcement section of the deformation joint of the well. After it is closed into a ring, the soil is backfilled from the position of the third steel frame, so that the pilot hole forms a 24° ramp, and then the construction of the pilot hole of the main hole starts. After the ring, start the main hole steel frame support in the guide hole, bind the steel mesh, spray C25 concrete, break the guide hole vertical support spray concrete, unscrew the vertical support bolts, take out the vertical support, support the main hole steel frame, start three The construction method of the temporary inverted arch of the steps is to cyclically excavate in the direction of the entrance and the exit, and finally start the construction of the main hole to complete the process conversion; this construction method speeds up the excavation, reduces the difficulty of the workers' operation, reduces the safety risk, and realizes the turnover of materials at the same time. , saving materials and reducing construction costs.

Owner:中建七局交通建设有限公司 +1

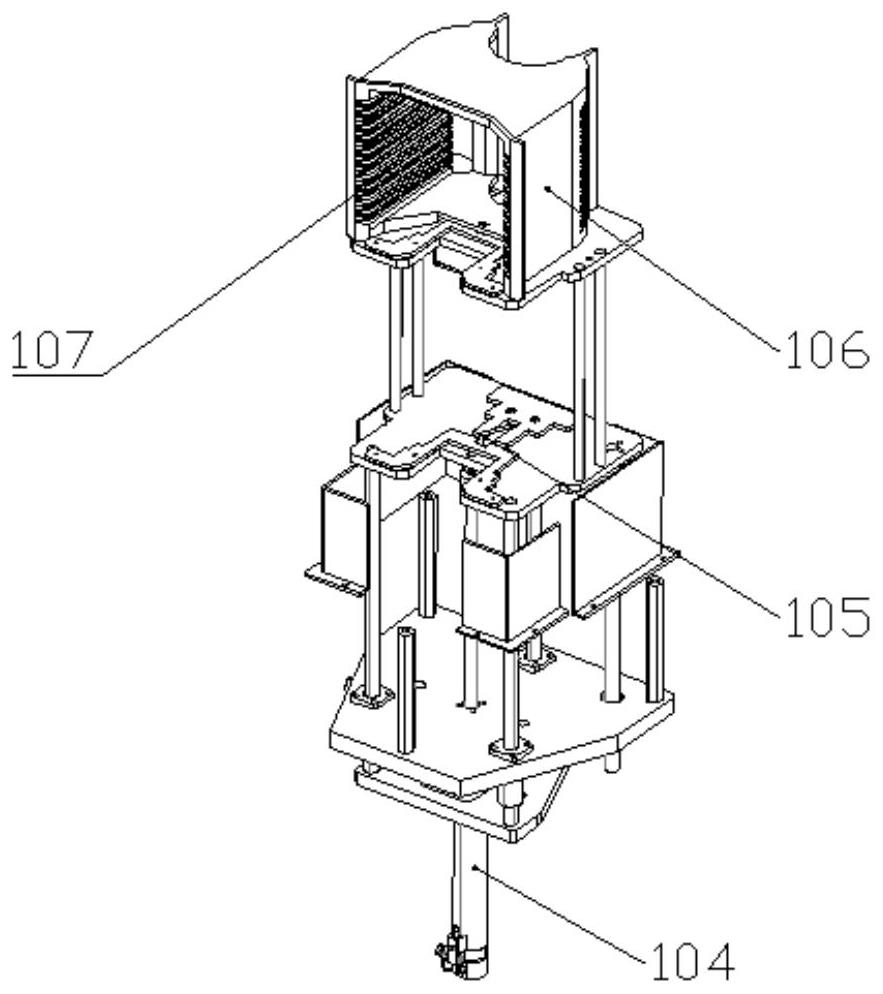

Automatic production line of colored contact lenses and method thereof

PendingCN110815880AReasonable layoutRealize automated productionOptical articlesCoatingsColor printingMold removal

The invention relates to an automatic production line of colored contact lenses and a method thereof. The production method comprises the following working procedures of upper mold injection molding,lower mold injection molding, upper mold cutting, lower mold cutting, upper mold arrangement, lower mold arrangement, lower mold color printing, lower mold injection liquid, upper and lower mold pressing, molding, upper and lower mold separation, lens demolding, hydration plate loading, hydration, extraction, cleaning, soaking, and rough inspection. According to the production line, layout is reasonable, structure is compact, and site area can be effectively saved; each equipment in the production line is connected smoothly, unnecessary turnover is reduced, and full-automatic production of colored contact lenses can be effectively realized; and production with large yield can be realized, and production efficiency can be improved.

Owner:甘肃天后光学科技有限公司

Turret CNC Stamping Flexible Line

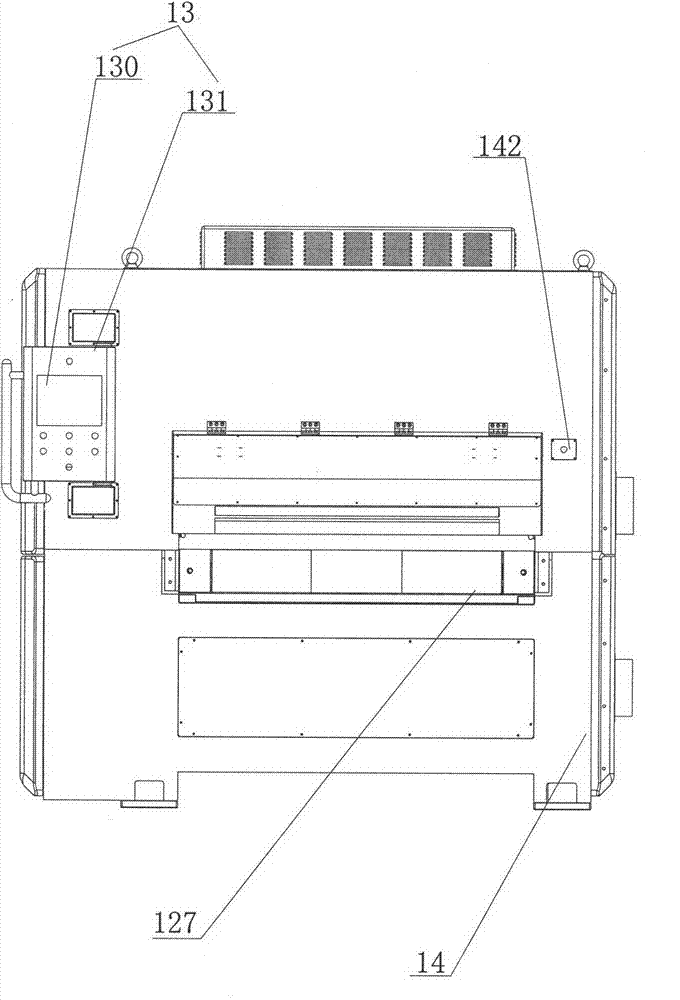

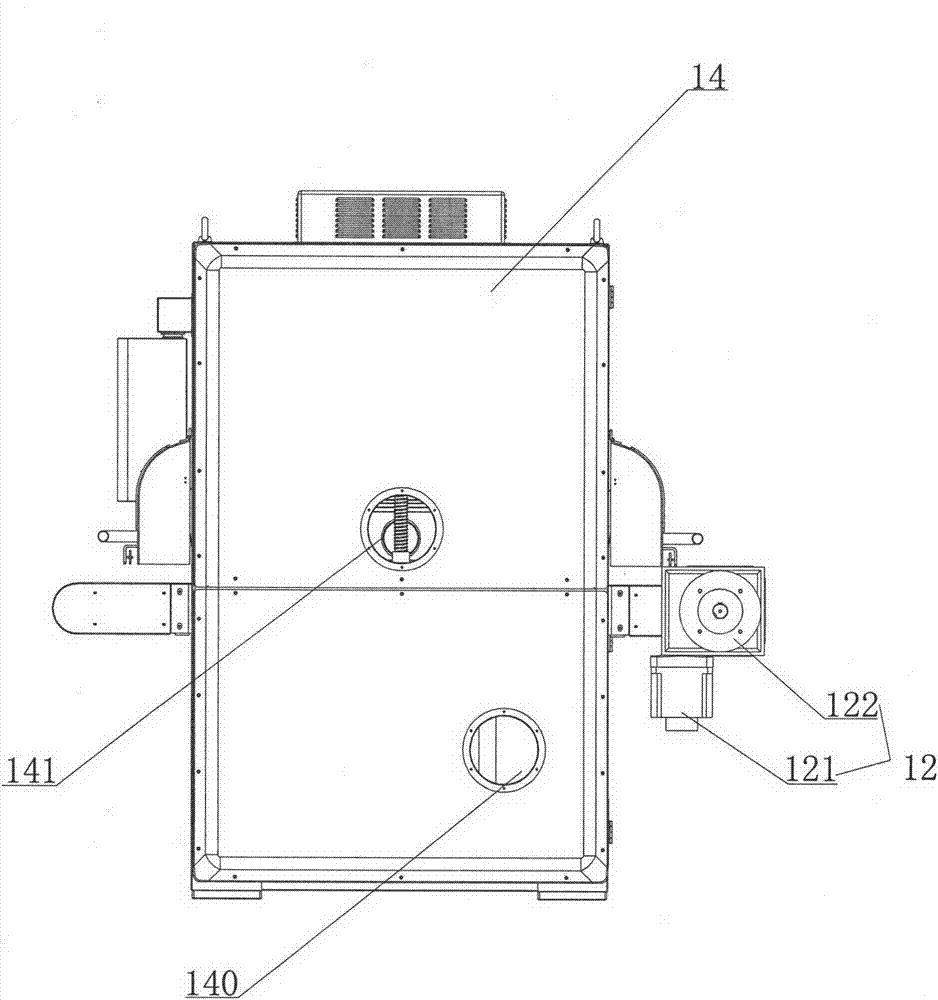

ActiveCN104624839BHigh degree of automationImprove work efficiencyMetal-working feeding devicesStripping-off devicesPunchingManipulator

The invention discloses a numerically-controlled flexible turret punching line comprising a material bin, a gantry robot, a numerically-controlled turret punch press and a finished product dragging stacker crane arranged along the same straight line. The gantry robot is used for grabbing materials from the material bin and transferring the materials to the numerically-controlled turret punch press, and the finished product dragging stacker crane is used for dragging finished products from the numerically-controlled turret punch press prior to stacking. The automation level in machining and transporting process of a production line is high, and working efficiency is increased.

Owner:维特罗伯特机械(苏州)有限公司

A device for moving, flipping, and leaning flat-panel TVs

ActiveCN105217285BQuality assuranceSimple structureConveyor partsAgricultural engineeringTransfer mechanism

The invention discloses a device for realizing the shifting, turning, and reclining of a flat-panel TV, which includes a frame, the frame is composed of a first rectangular frame and a second rectangular frame, and the second rectangular frame is installed on the first rectangular frame On the same side of the first rectangular frame, a horizontal tooling plate and a leaning tooling plate are sequentially arranged, the leaning tooling plate is located below the second rectangular frame, and an adsorption transfer mechanism is arranged above the horizontal tooling plate. The leaning tooling plate is provided with a turning mechanism and a leaning transfer mechanism sequentially from bottom to top, the leaning transfer mechanism is connected to the upper end of the second rectangular frame, and the surface of the first rectangular frame is provided with a transmission mechanism. Mechanism, the beneficial effects of the present invention are: the present invention can not only ensure the successful completion of the process of transferring, turning and leaning on the flat-panel TV, but also can replace manual work, satisfy multi-variety, flexible and easy-to-switch production methods, and at the same time improve efficiency, Improve product quality.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Wax mold automatic cleaning production line

The invention discloses an automatic washing production line of a wax mold. The automatic washing production line comprises an annular track. A conveying chain is arranged in the annular track and moves along the annular track. On the bottom of the conveying chain, a plurality of hooks are evenly distributed along the conveying chain. A drive device provides power for the conveying chain and is arranged on an upper region of the middle part of the annular track, one end of the annular track is a feeding region, and the other end of the annular track is a sizing region. A pre-blowing device, a washing device, a spray washing device and a blowing device are sequentially arranged on the side, from the feeding region to the sizing region, of the annular track. From the structure, the automatic washing production line of the wax mold can achieve automatic washing and turnover of a fired mold pouring gate before sizing, the labor intensity of an operator is lowered, and the production efficiency is improved.

Owner:连云港冠钰精密工业有限公司

Full-automatic wafer wax pasting machine

ActiveCN114361081AAutomateKeep cleanFinal product manufactureSemiconductor/solid-state device manufacturingCooling UnitsManufacturing engineering

The invention discloses a full-automatic wafer wax pasting machine which comprises a wafer supply unit, a mechanical arm, a wafer cleaning unit, a centering unit, a wax dripping unit, a double-arm wafer transplanting unit, a wafer overturning unit, a wafer pressing unit, a ceramic plate heating unit, a turnover unit, a cooling unit and a carrier. A wafer passes through the wafer supply unit, the manipulator, the wafer cleaning unit, the centering unit, the double-arm wafer transplanting unit, the wax dripping unit, the wafer overturning unit, the ceramic plate heating unit, the wafer pressing unit, the turnover unit and the cooling unit to be assembled with a ceramic plate. According to the automatic wax dripping device, the functions of automatic feeding, automatic cleaning, automatic wax dripping, automatic baking, automatic overturning, automatic pressing, automatic heating, automatic turnover and automatic cooling are integrated, the production efficiency of products is greatly improved, and automatic production is achieved.

Owner:CHENGYANG AUTOMATION TECH CO LTD HANGZHOU

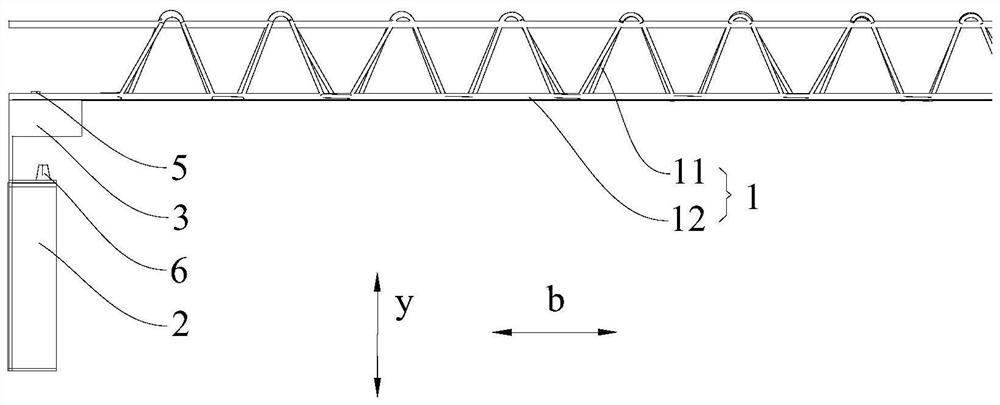

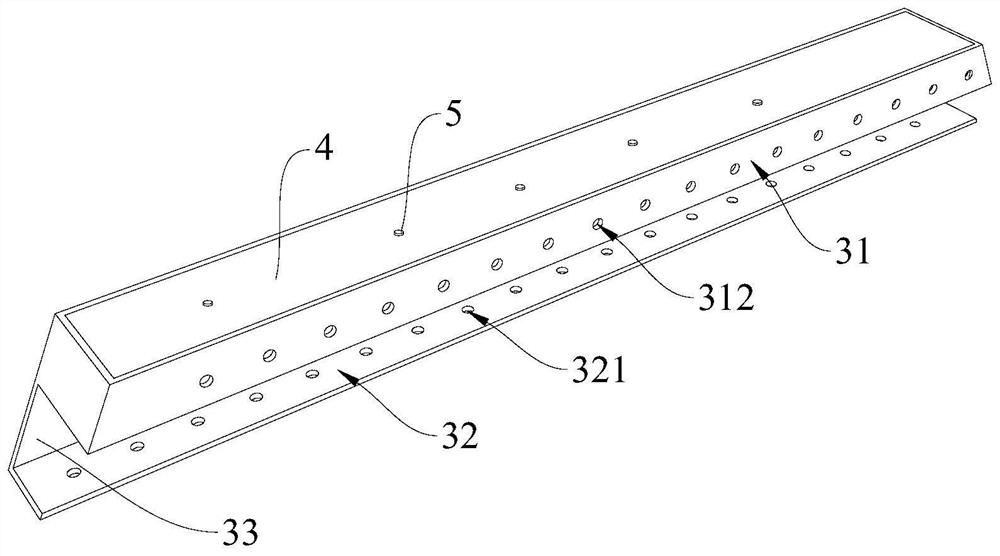

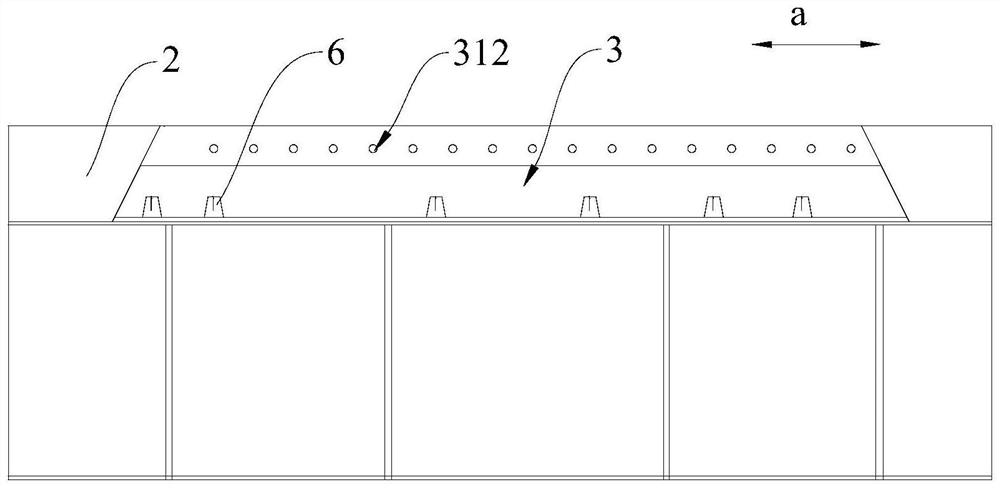

Construction system for steel bar truss floor support plate

PendingCN113202221AAchieve turnoverIt is convenient for subsequent construction and useFloorsArchitectural engineeringRebar

The invention is suitable for the technical field of fabricated buildings, and provides a construction system for a steel bar truss floor support plate. The construction system involves the steel bar truss floor support plate, an aluminum formwork, a connecting piece and a circulation material piece, wherein the aluminum formwork is arranged below the steel bar truss floor support plate, the connecting piece is detachably connected to the aluminum formwork, the circulation material piece is detachably connected to the connecting piece, and the circulation material piece is fixed to the bottom of the steel bar truss floor support plate through a first fastening piece and can be detached from the first fastening piece. Through the connecting piece and the circulation material piece, combined use of the steel bar truss floor support plate and the aluminum formwork is achieved, the working efficiency of concrete pouring is improved, and after concrete pouring work is completed, the circulation material piece can be detached from the first fastening piece so as to achieve detachment of the aluminum formwork and the steel bar truss floor support plate, circulation of the aluminum formwork is achieved, the construction cost is reduced, and through cooperation of the connecting piece and the circulation material piece, disassembly and assembly between the aluminum formwork and the steel bar truss floor support plate are simplified, and the pouring work efficiency is improved.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com