Patents

Literature

135results about "Broaching accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

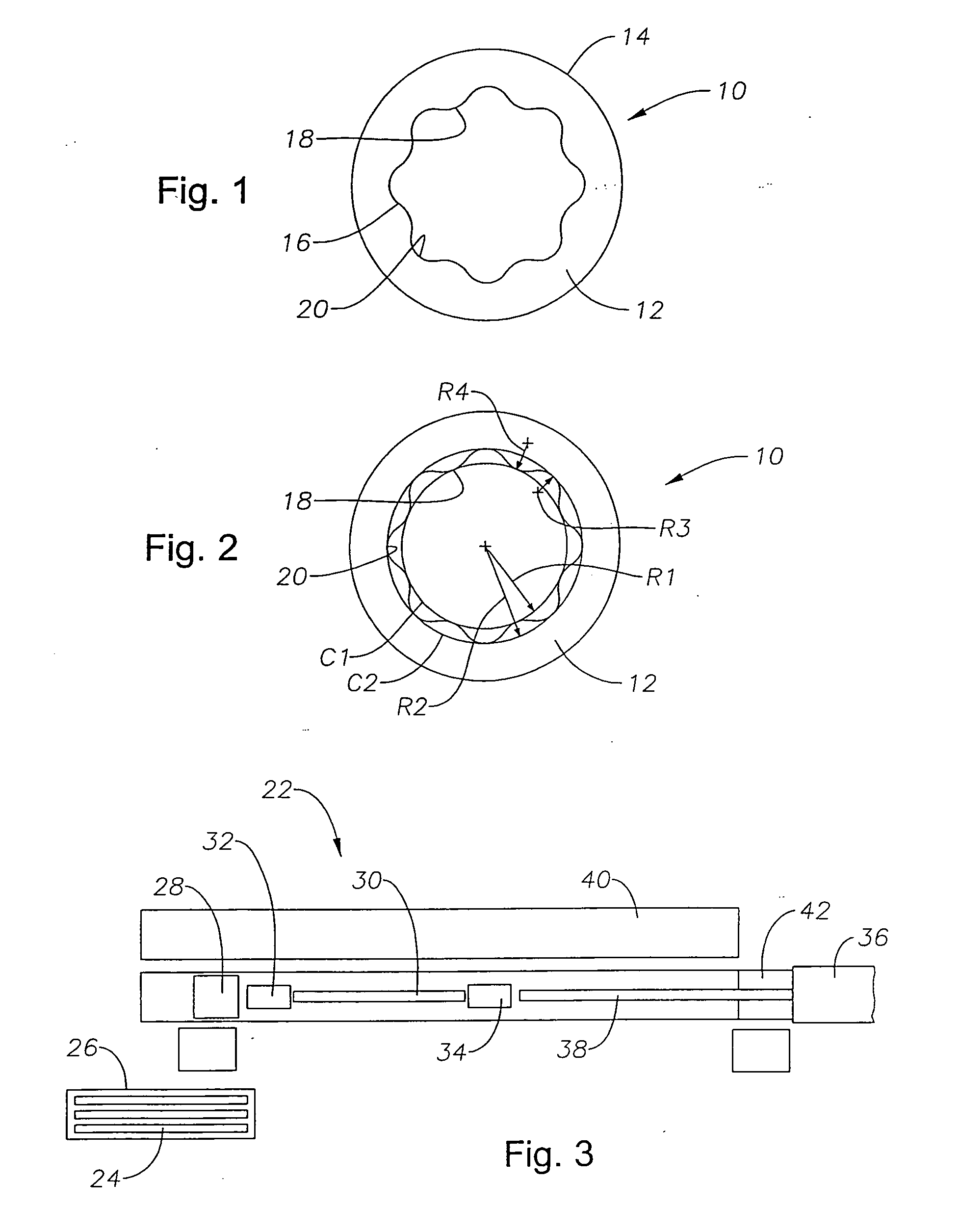

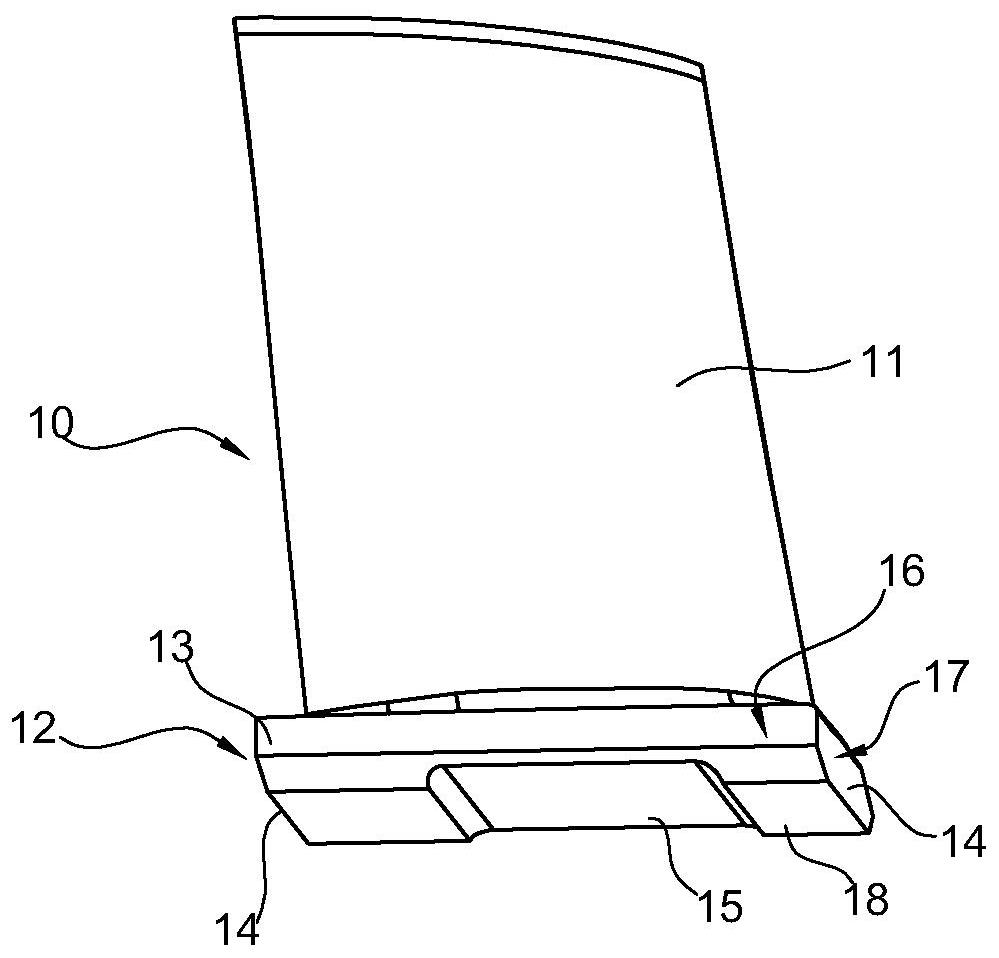

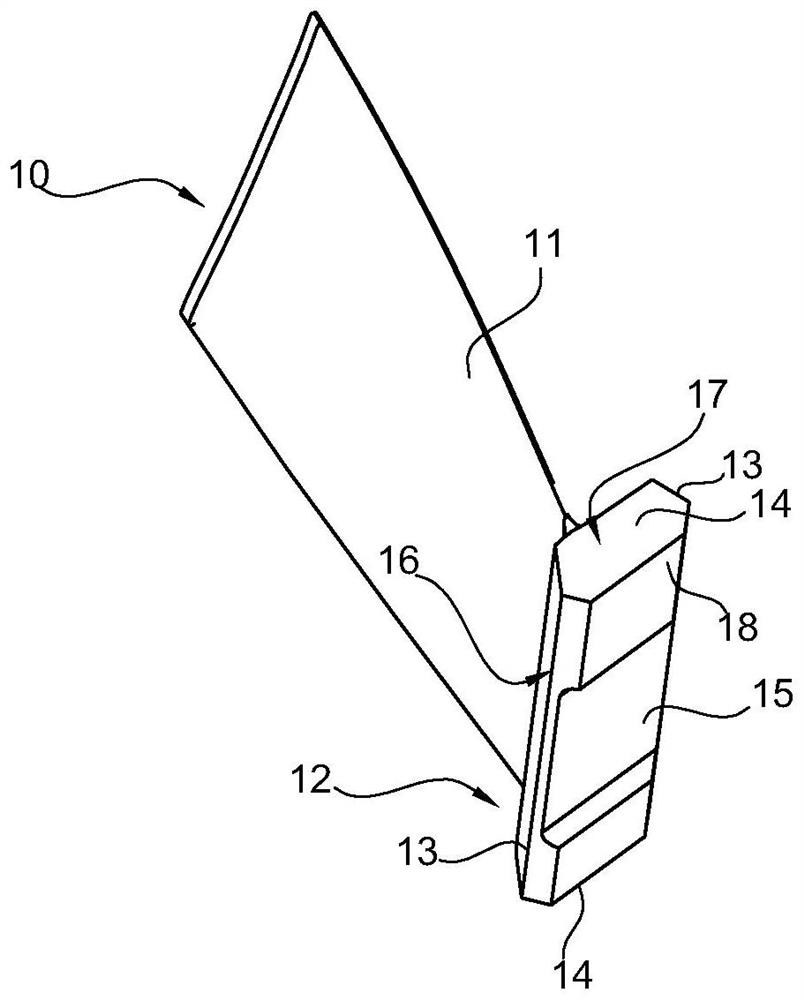

Hole cutting tool

InactiveUS6851900B2Drilling/boring measurement devicesThread cutting feeding devicesDust particlesGasket

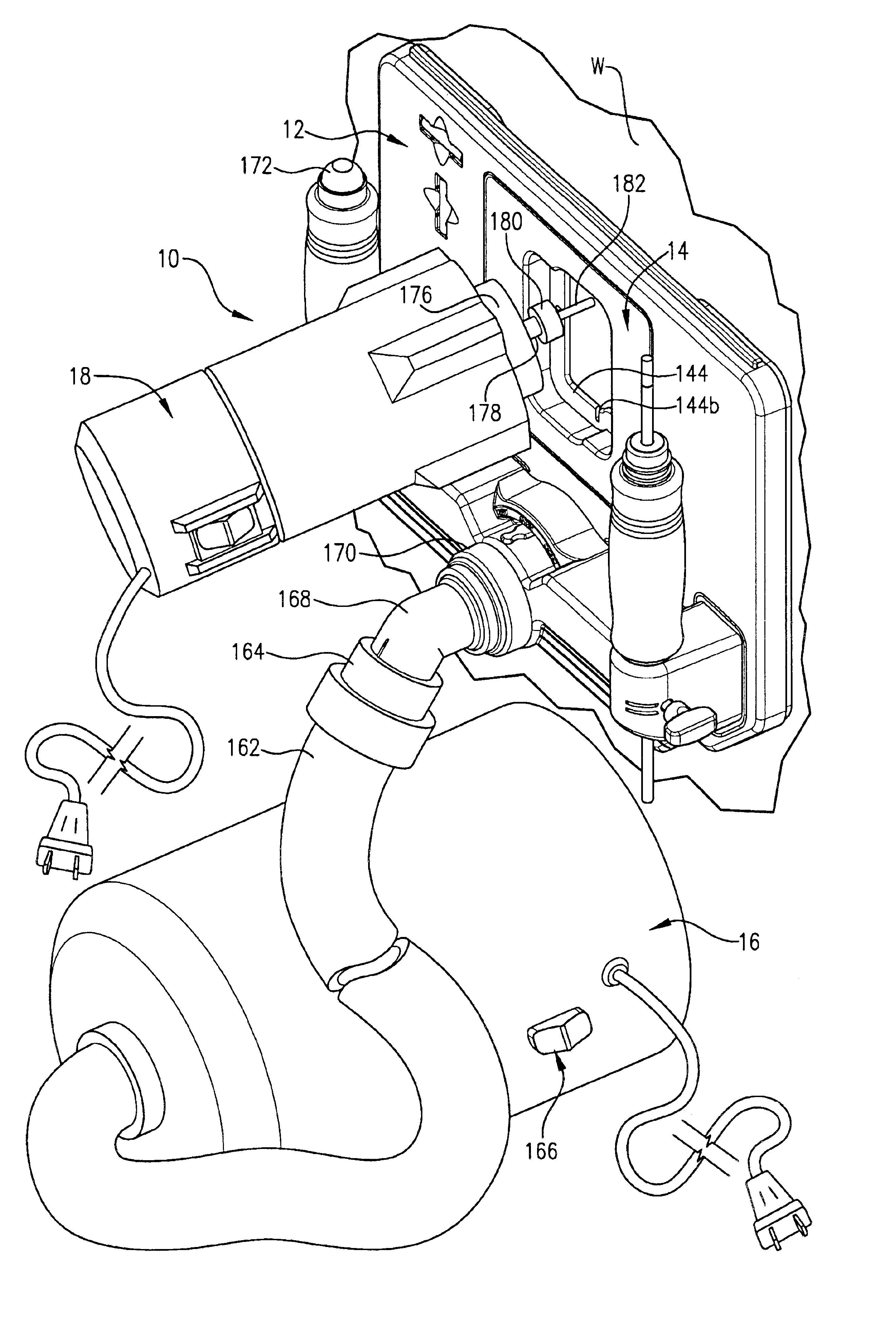

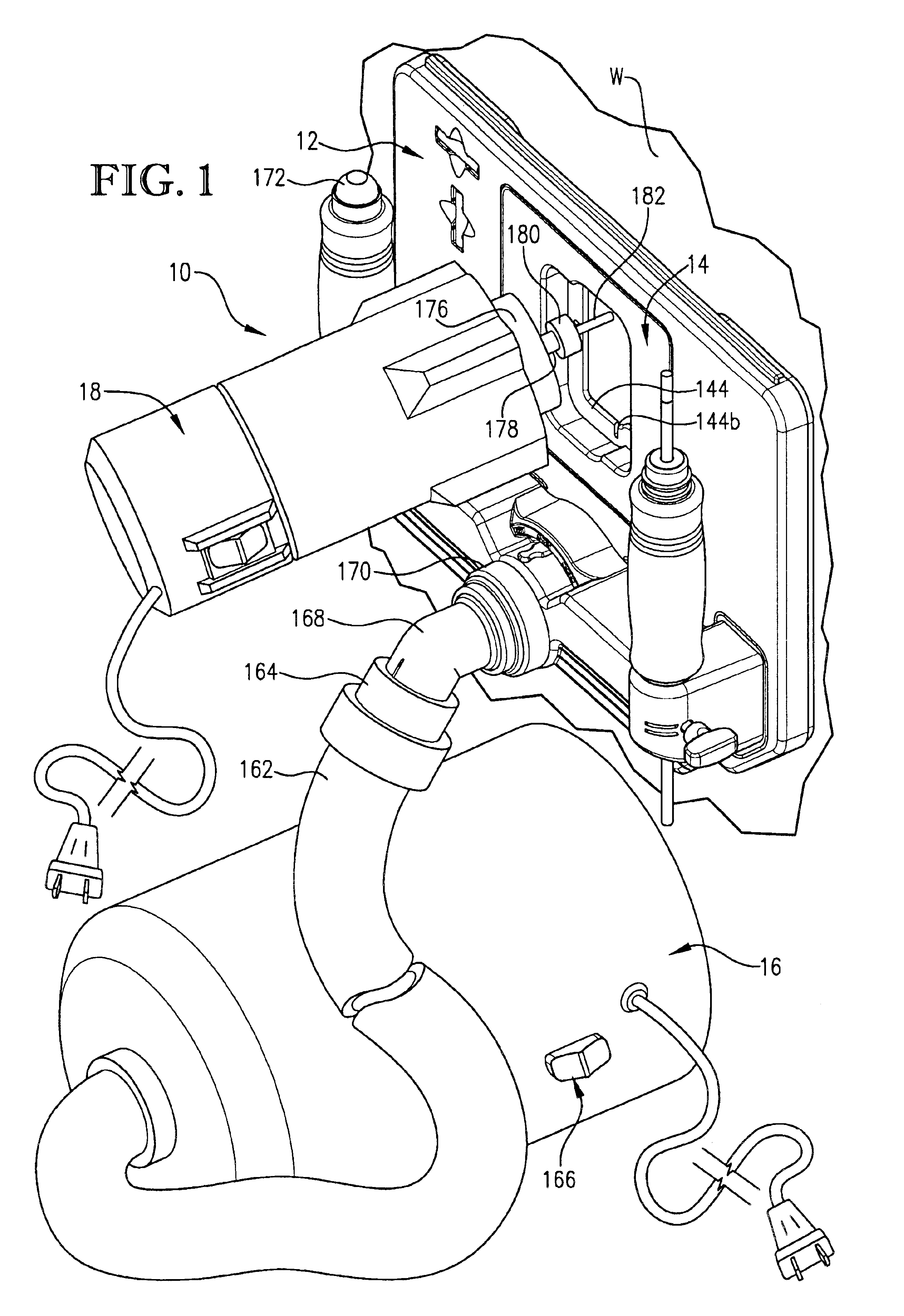

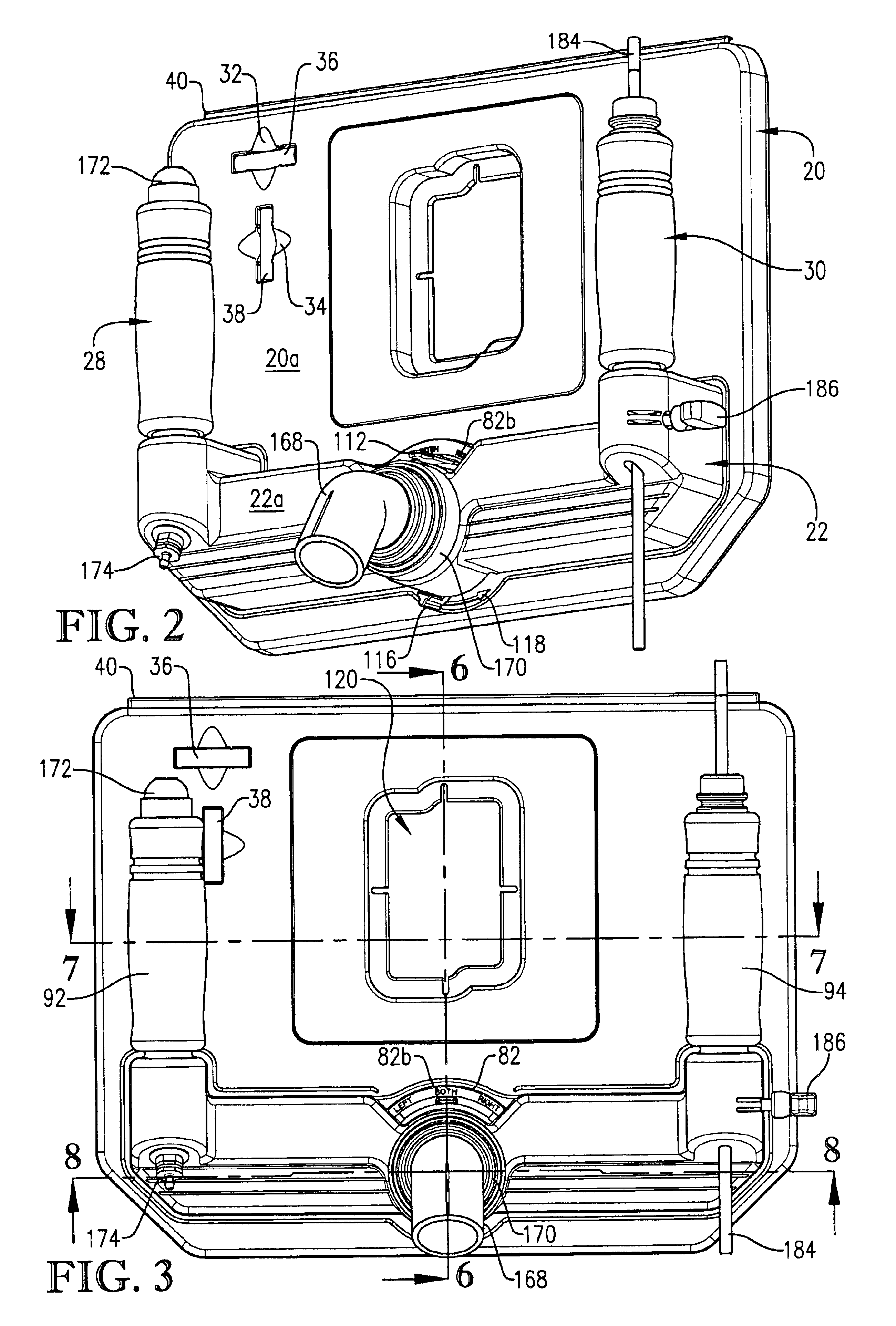

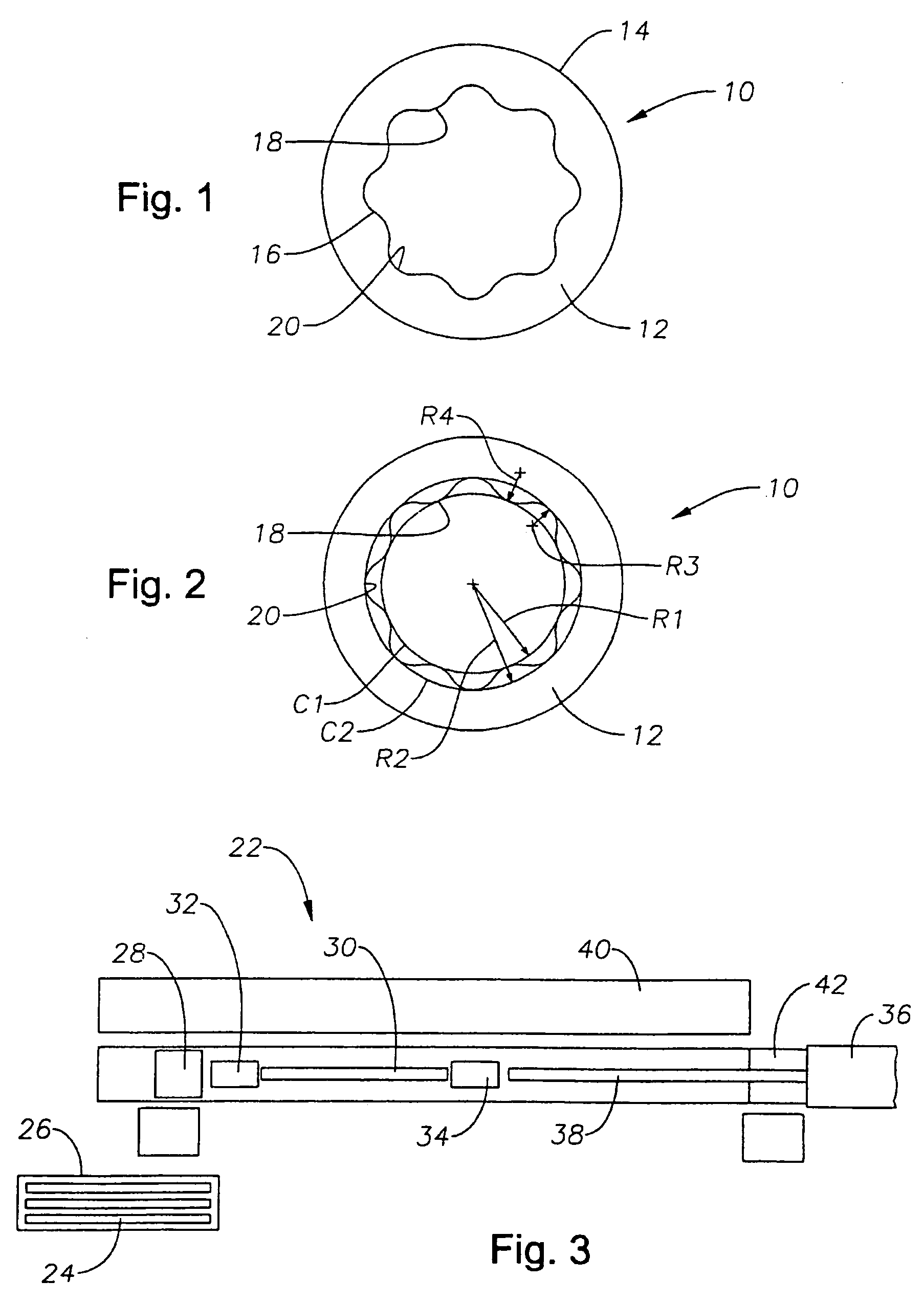

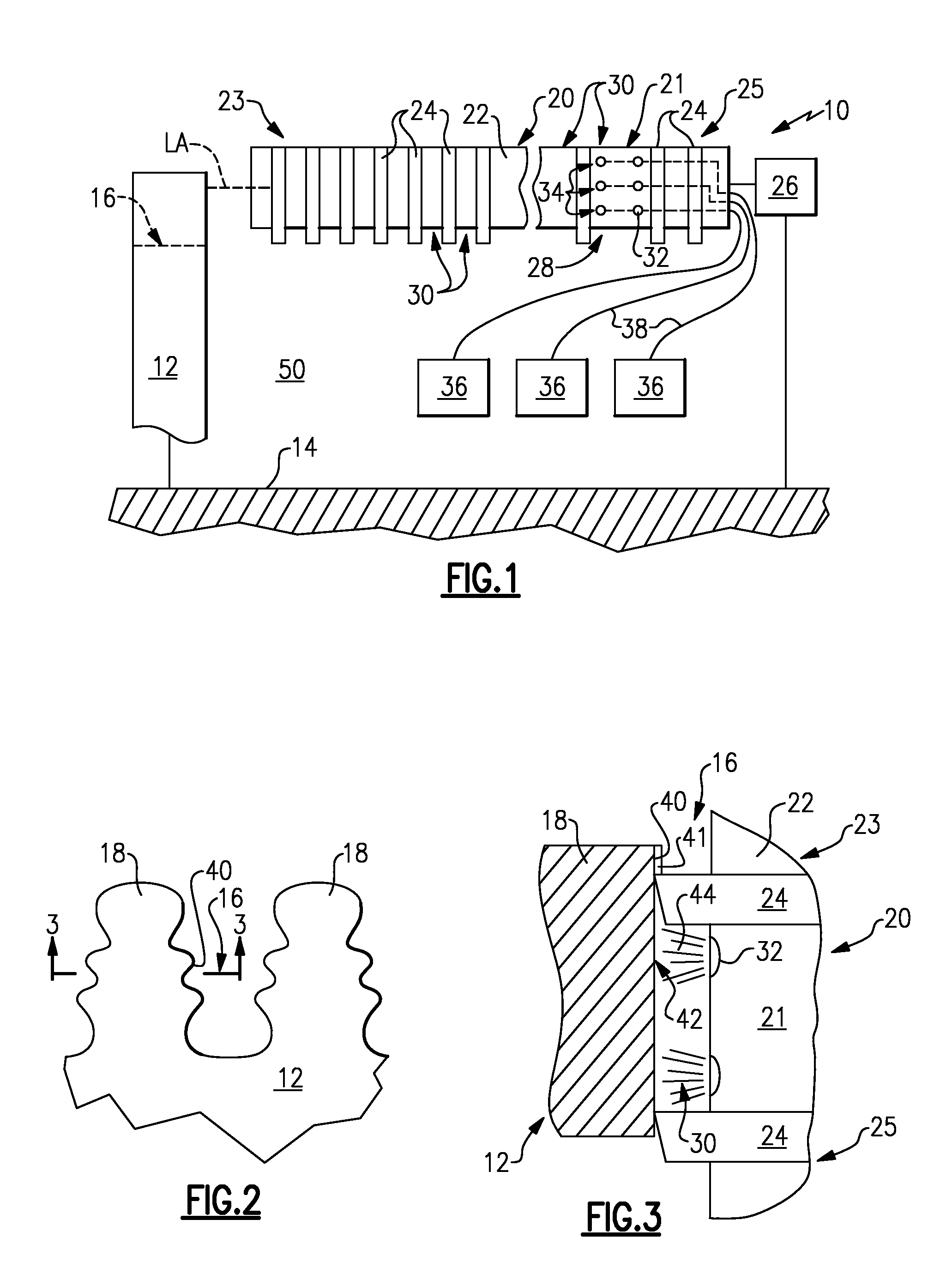

A hole cutting tool (10) configured for cutting an accurately located and precisely shaped hole in a surface, such as a wall (W) of a finished residential or commercial building is disclosed. The tool (10) provides a frame assembly (12) which is self-adhering to the surface (W) and carries removable templates (14, 146-152) for handsfree use in cutting an accurately located and precisely shaped hole. The unique frame assembly (12) provides multiple selectable, pneumatically isolated suction chambers (50,52) that enable the self-adhesion function even when the frame assembly (12) is placed over existing holes in the surface (W). The suction chambers (50,52) are formed in part by a unique corrugated gasket (56) that enables the frame assembly (12) to self-adhere to porous surfaces. The removable template (14) enables dust particles created during the cutting process to be simultaneously vacuumed away regardless of the orientation of the template (14) relative to the frame assembly (12).

Owner:PYTHON PERFECT CUTTER

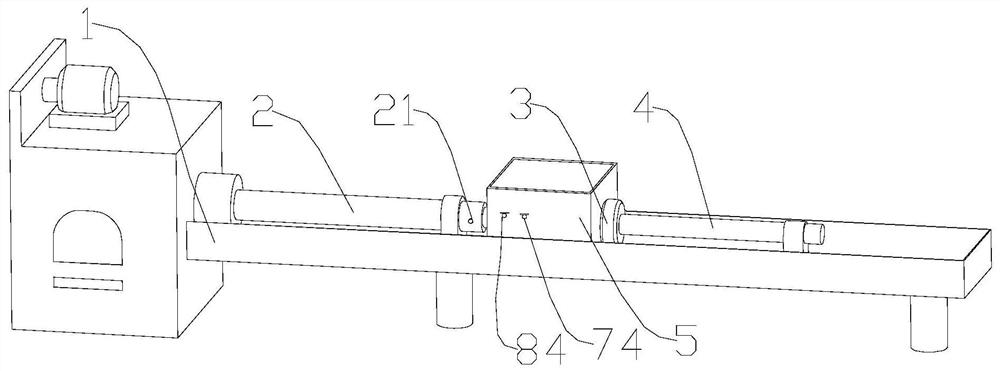

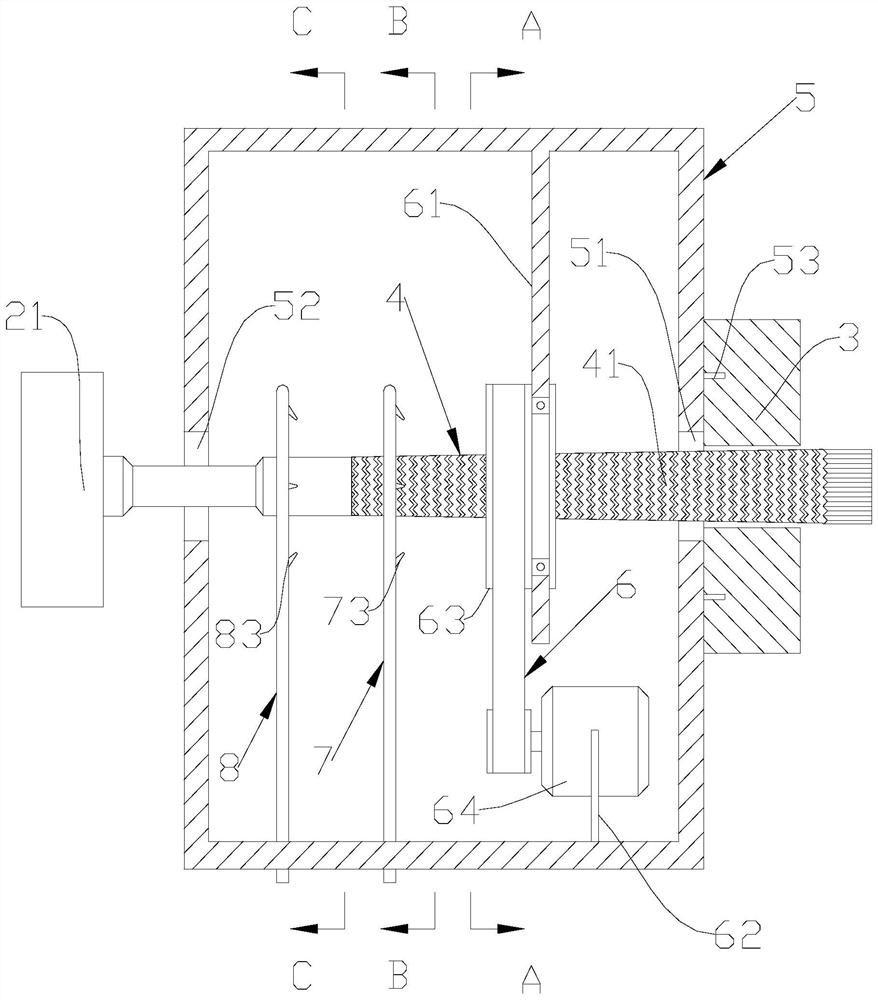

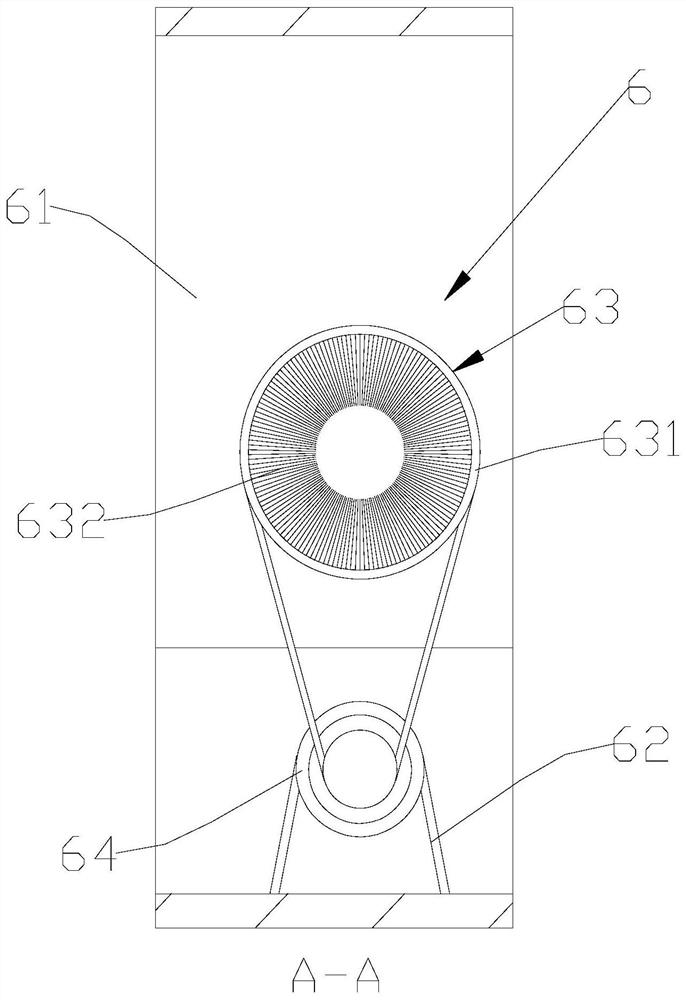

Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

ActiveCN109967789AExtended service lifeImprove broaching efficiencyBroaching accessoriesBroaching toolsGratingUltrasonic sensor

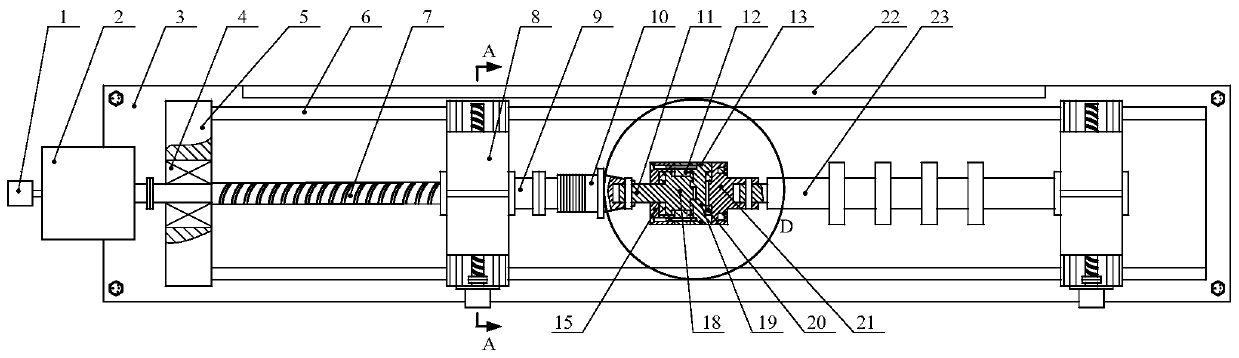

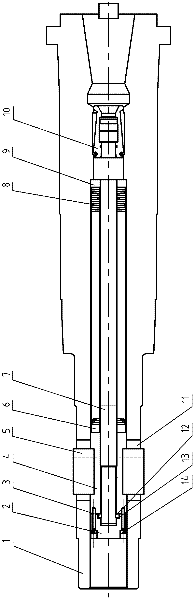

The invention discloses an ultrasonic broaching tool, a high-efficiency precise ultrasonic broaching device and a broaching process thereof. An existing broaching tool and an existing broaching machine are not provided with integrated information acquisition devices and are short in service life. The ultrasonic broaching tool comprises an ultrasonic transducer, a detection assembly and a broachingtool body. The detection assembly comprises a detection substrate, a laser transceiving belt, an image sensor, an axial pressure sensor, a first radial pressure sensor and a second radial pressure sensor. The high-efficiency precise ultrasonic broaching device comprises a broaching machine body, an optical grating and the ultrasonic broaching tool. The broaching machine body comprises a broachingmachine drive assembly, a broaching machine body, a broaching machine guide rail and a fast positioning and clamping device. A broaching tool three-directional vibration value, a broaching tool axialtensile force, a broaching tool displacement value, and a workpiece dimension based on an image are measured. Real-time detection data is provided for a working condition feedback loop and a stop control loop of a control system. The service life of the broaching tool can be effectively prolonged.

Owner:HANGZHOU DIANZI UNIV

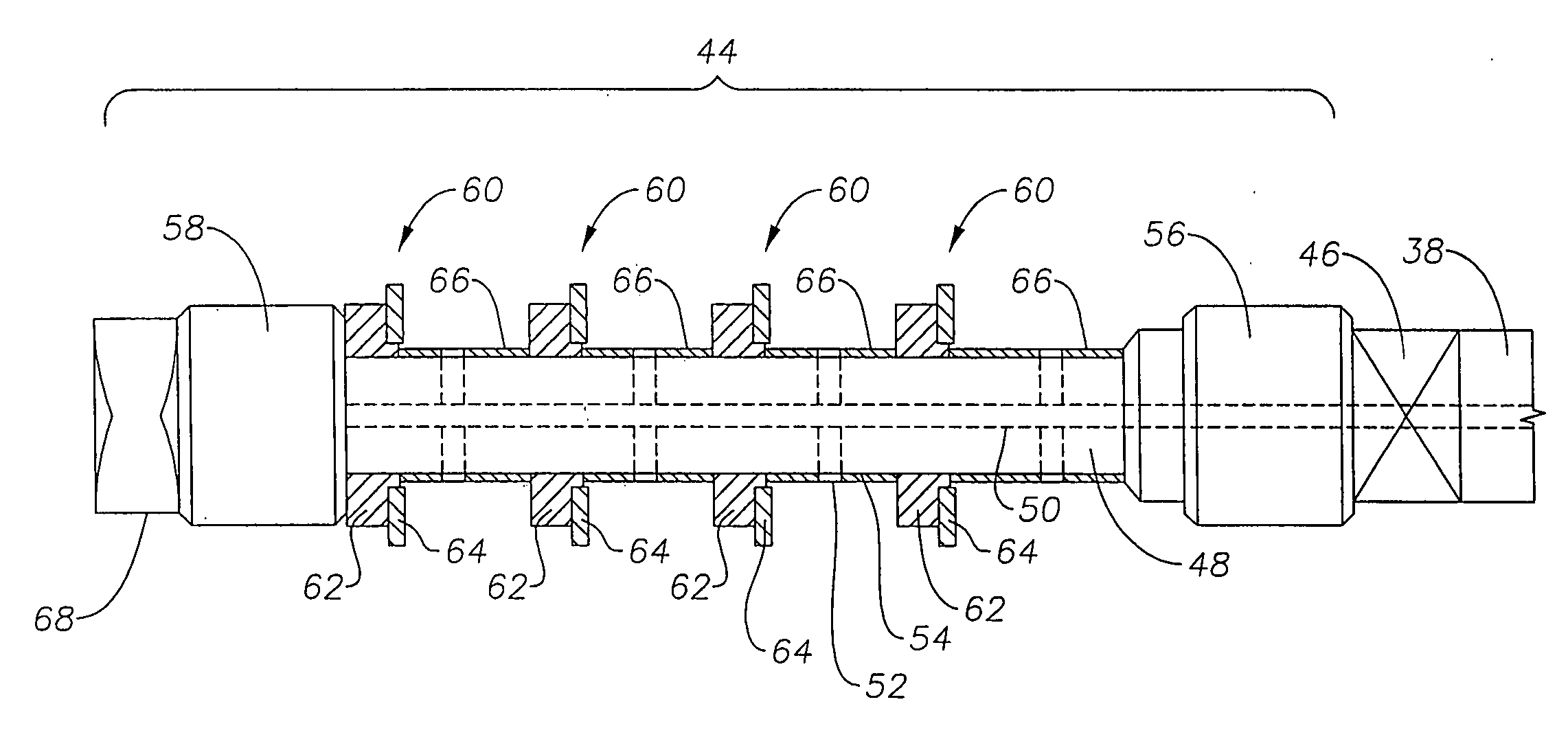

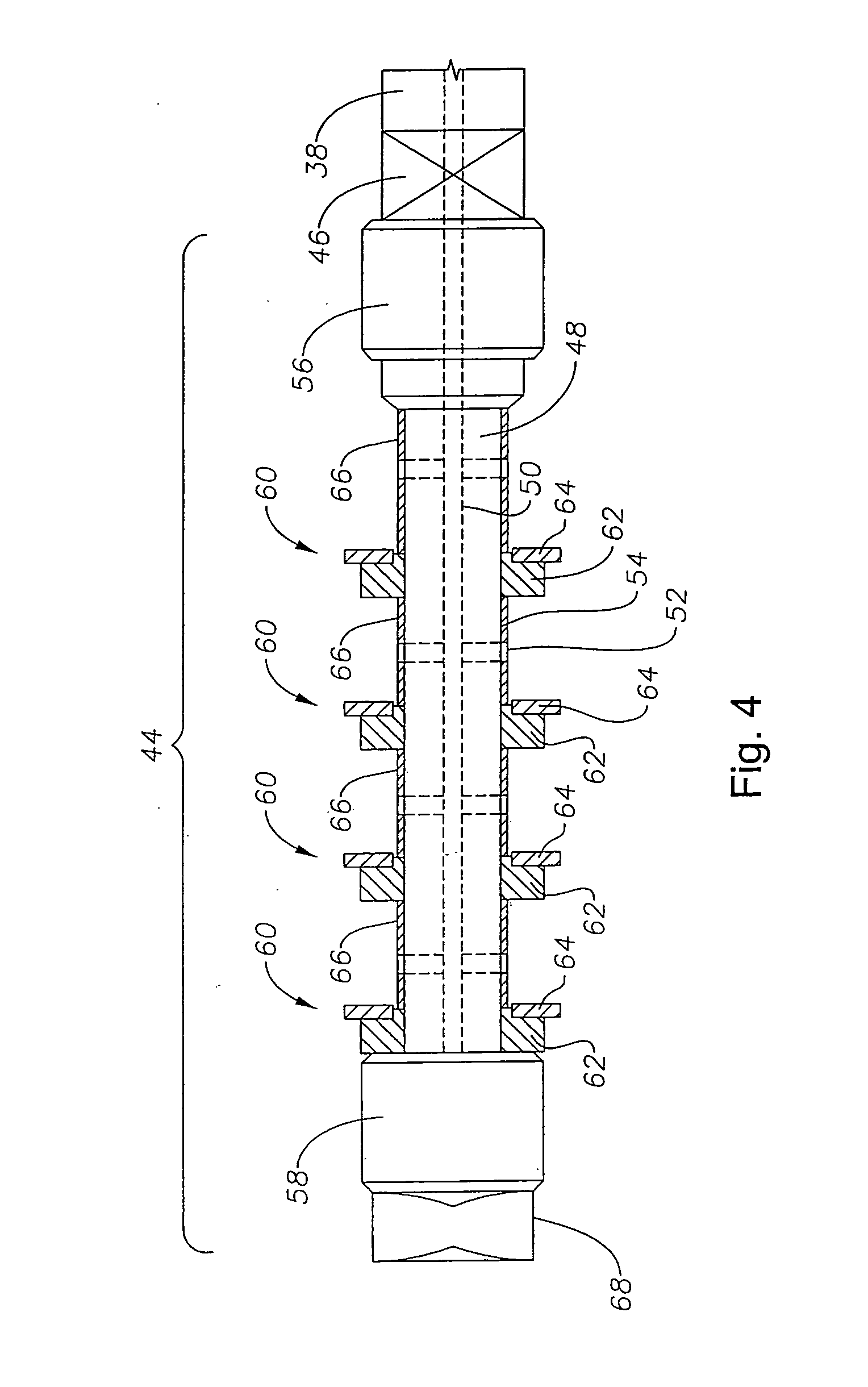

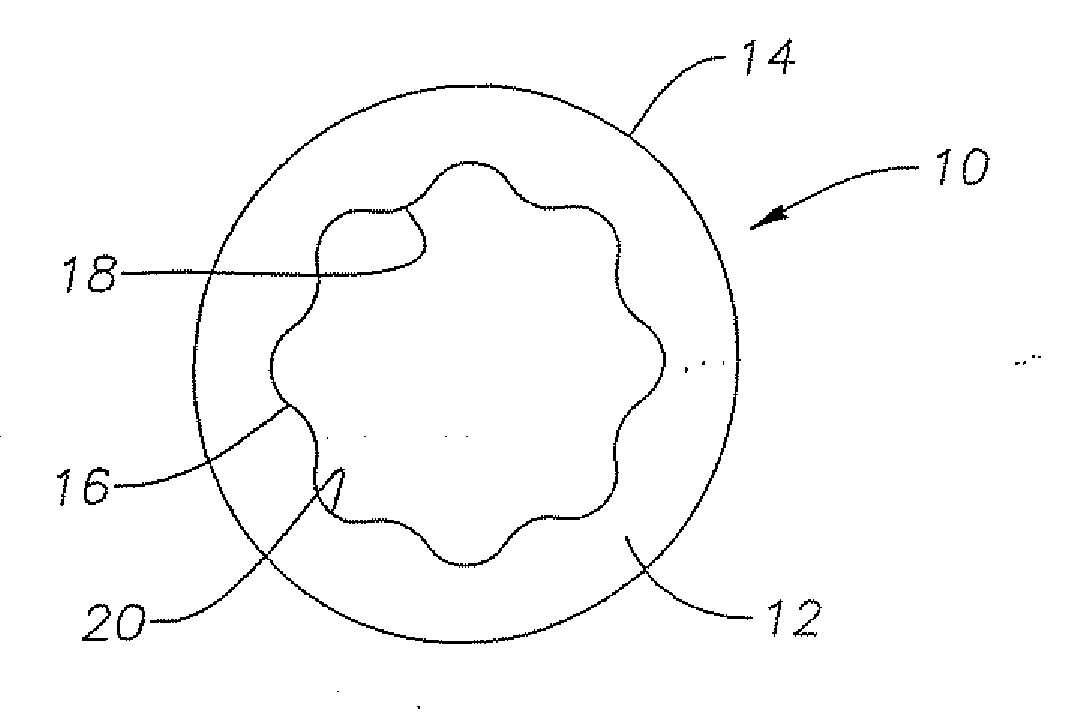

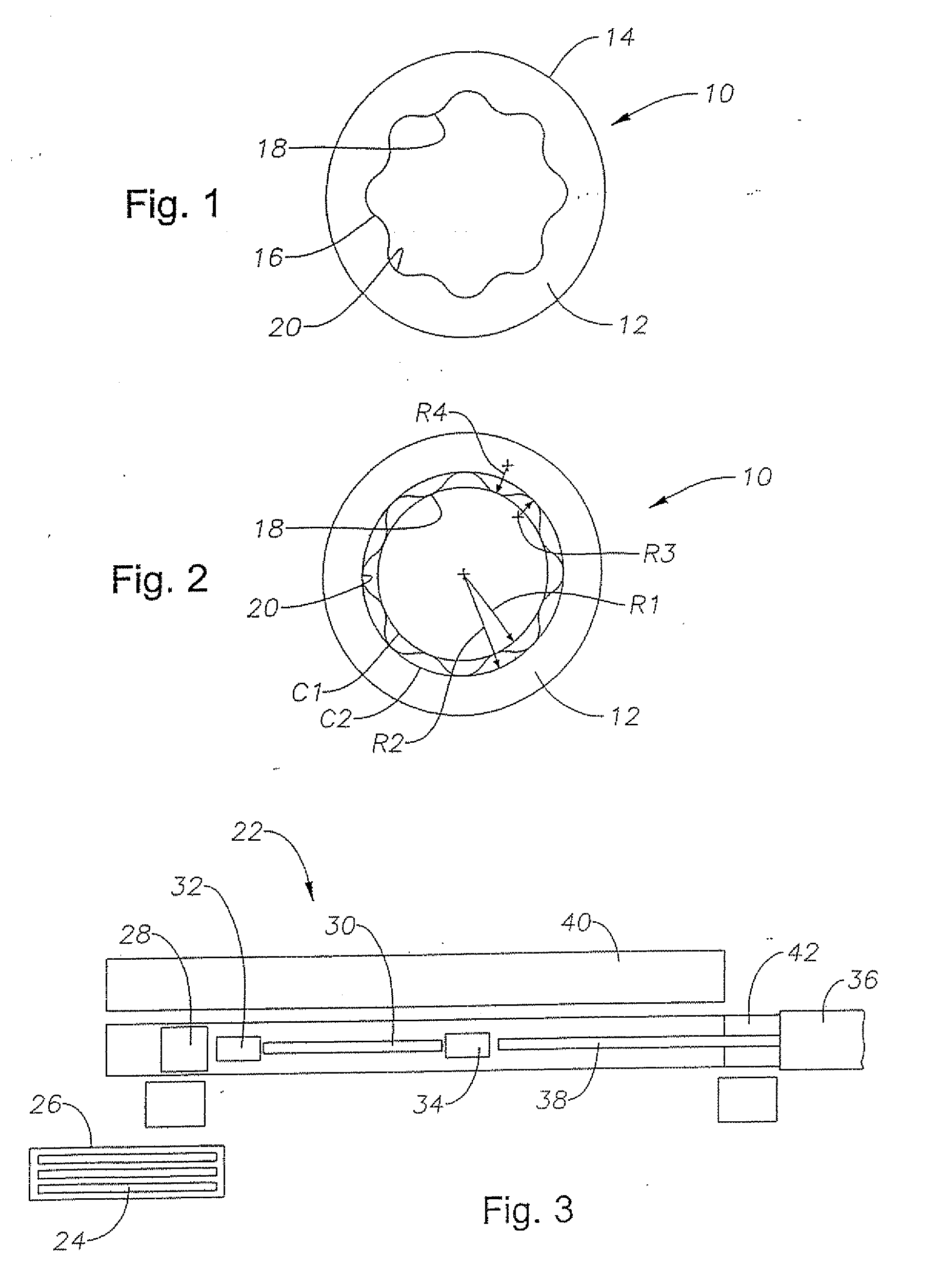

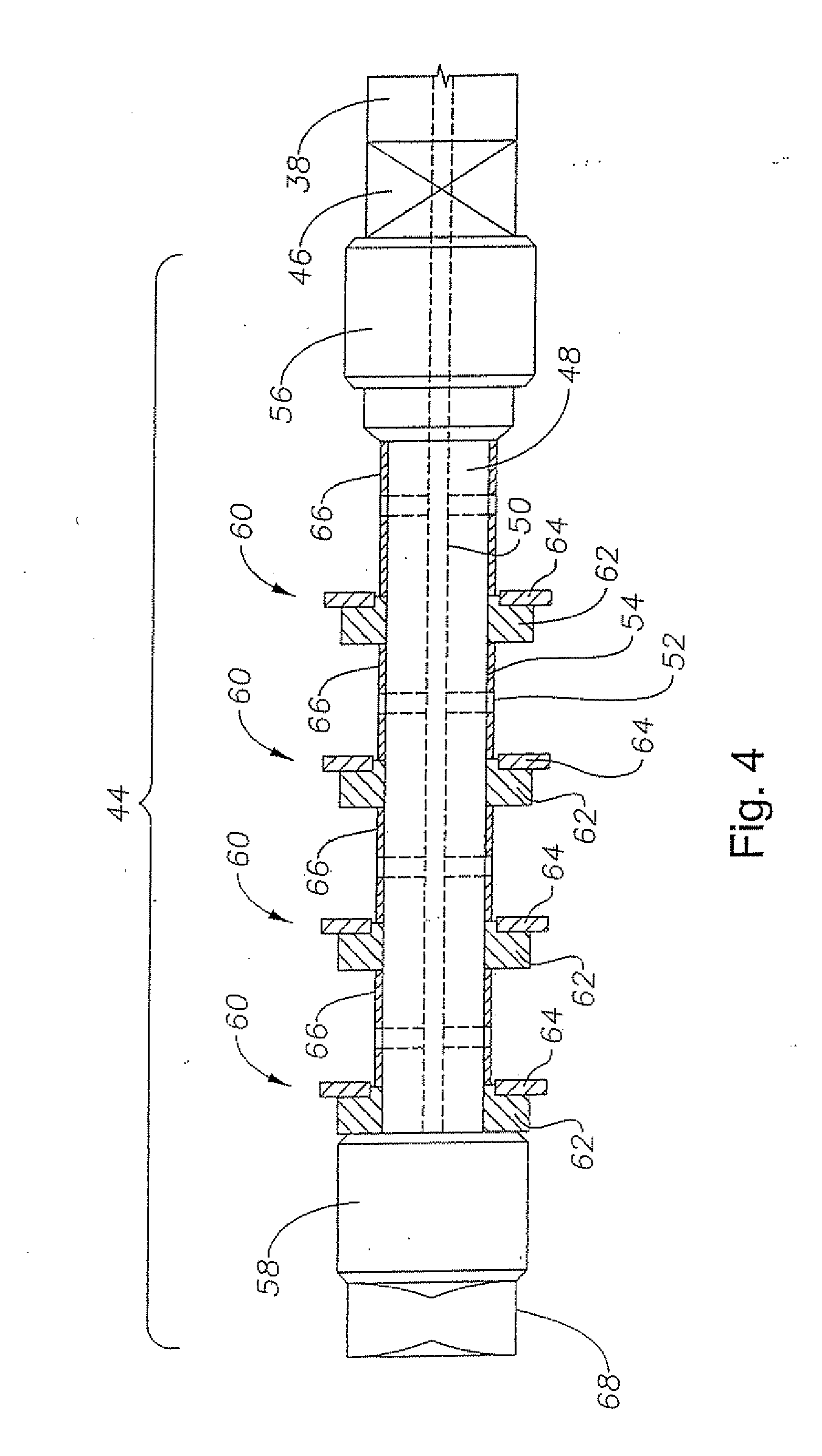

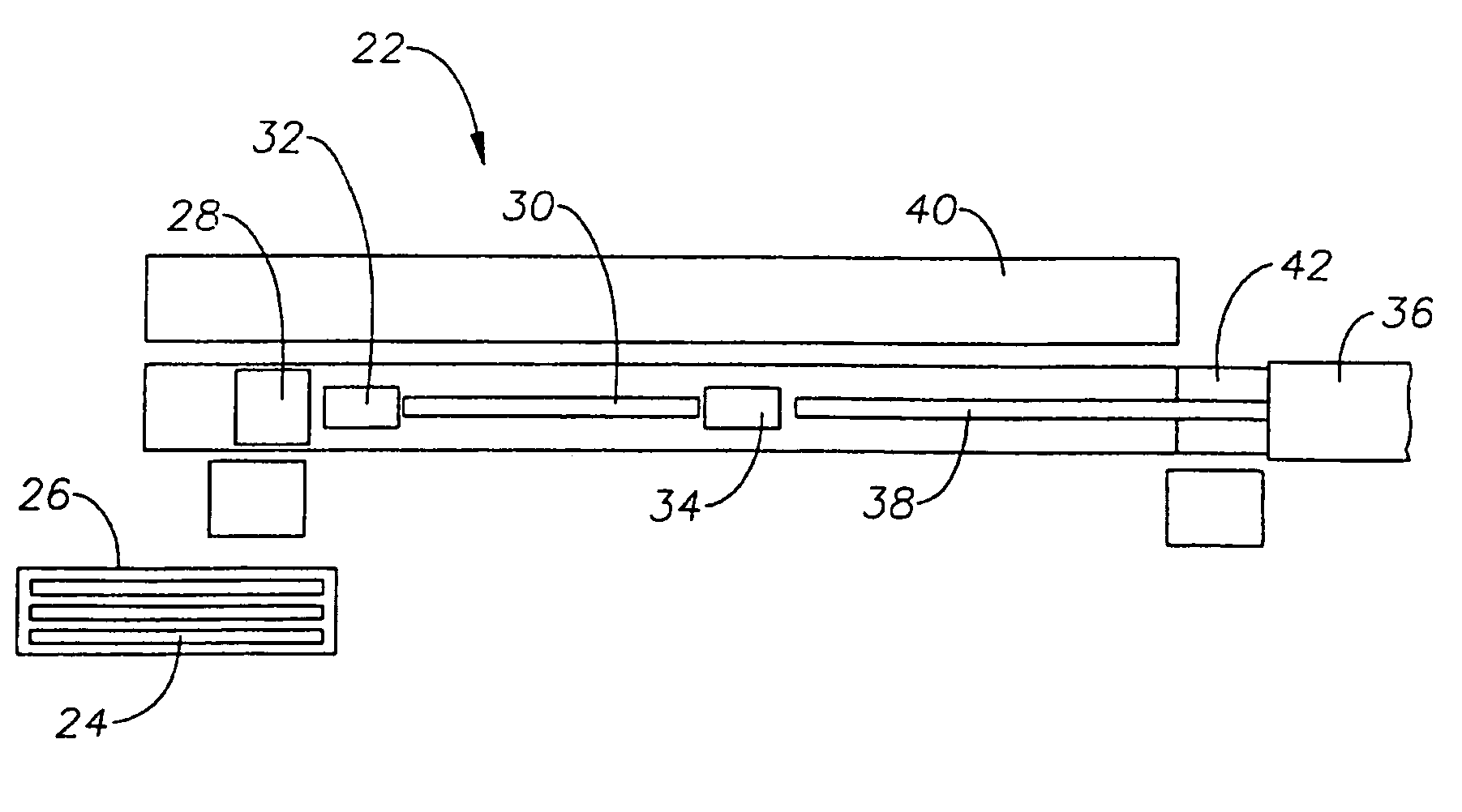

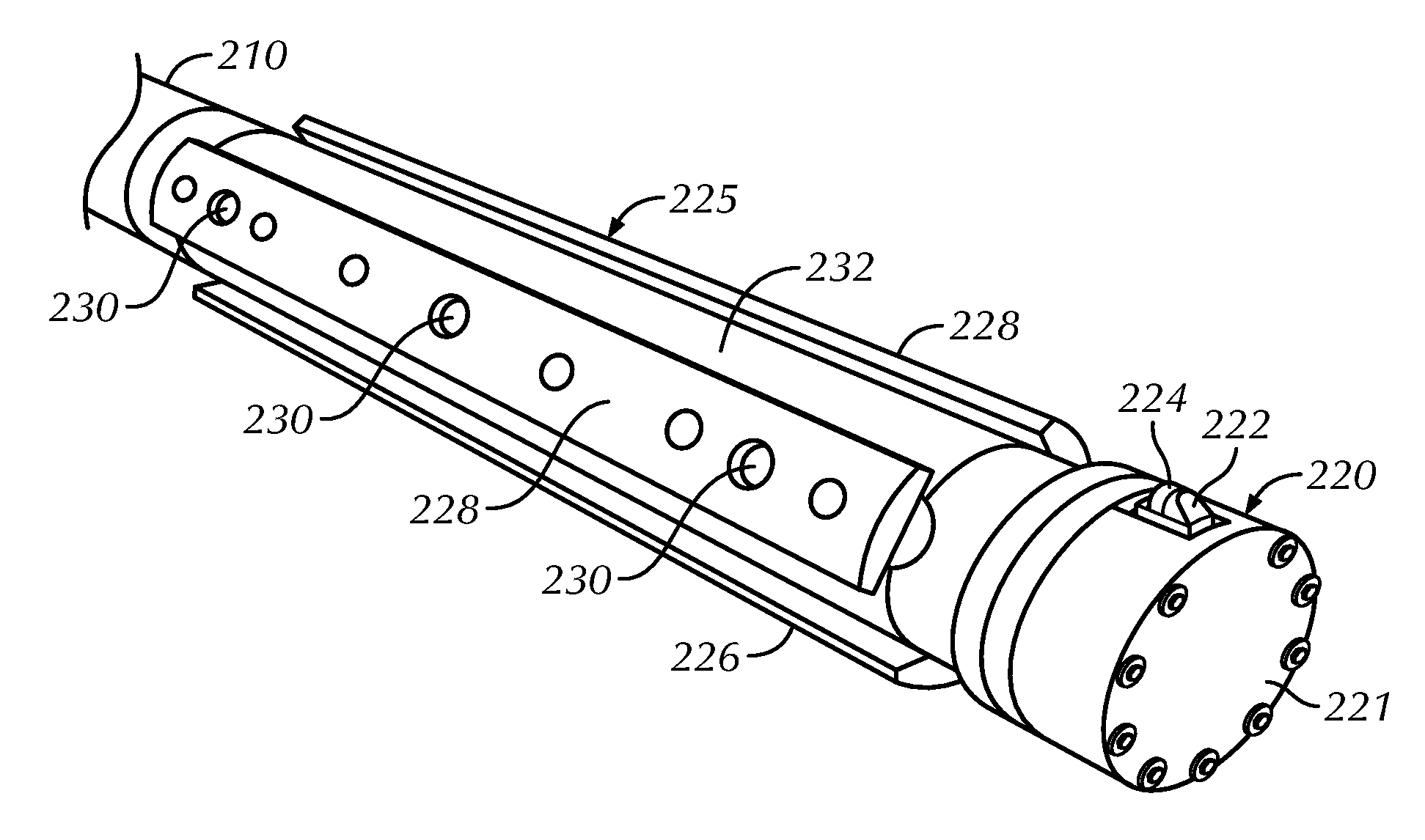

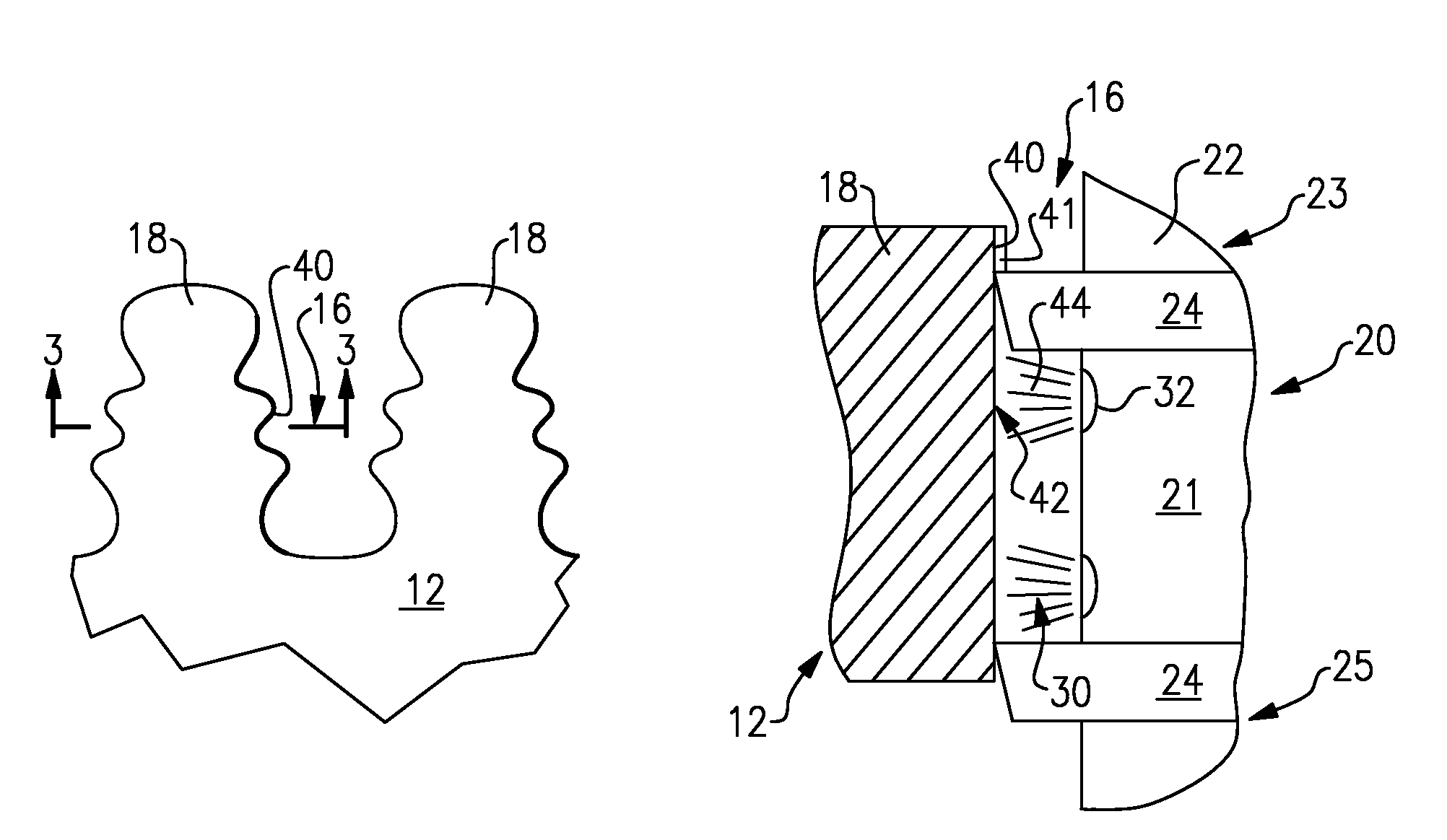

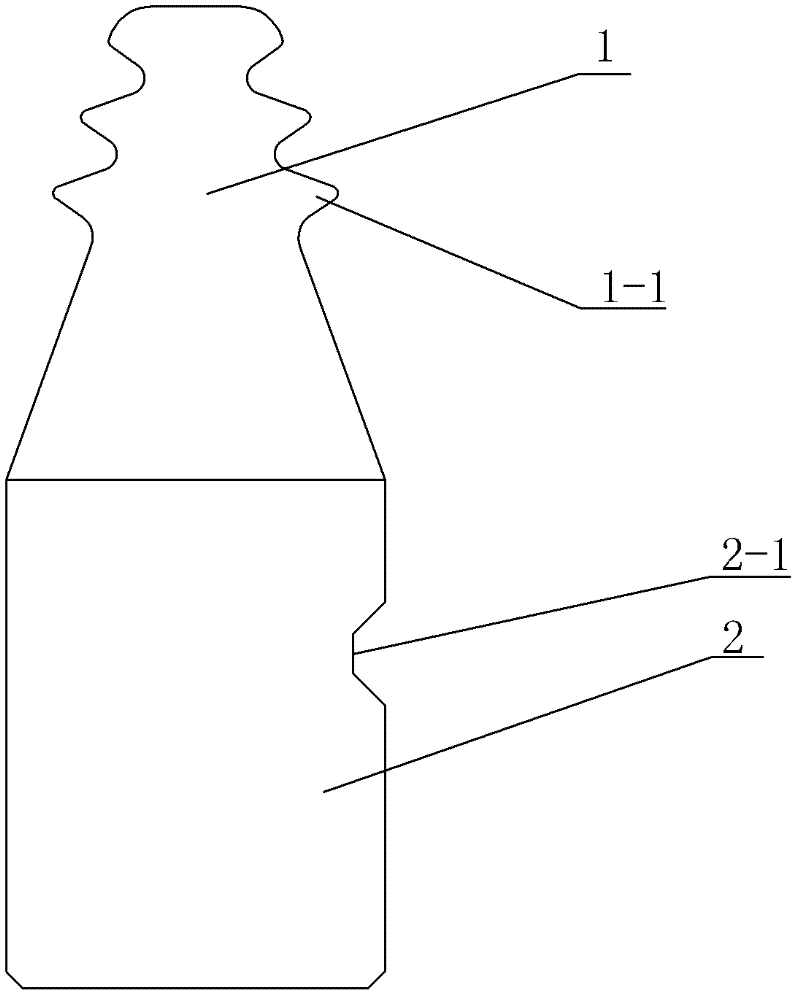

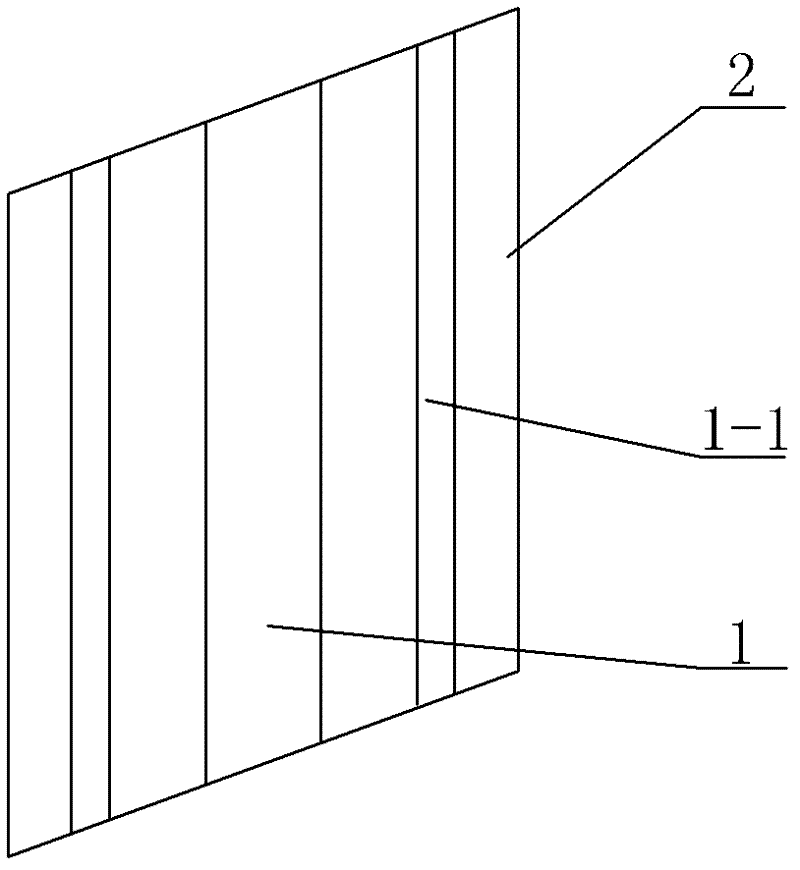

Centrifugally-cast tube and related method and apparatus for making same

InactiveUS20060056934A1High dimensional accuracyImprove roughness accuracyBroaching accessoriesRectilinear broachMetal dustingEnhanced heat transfer

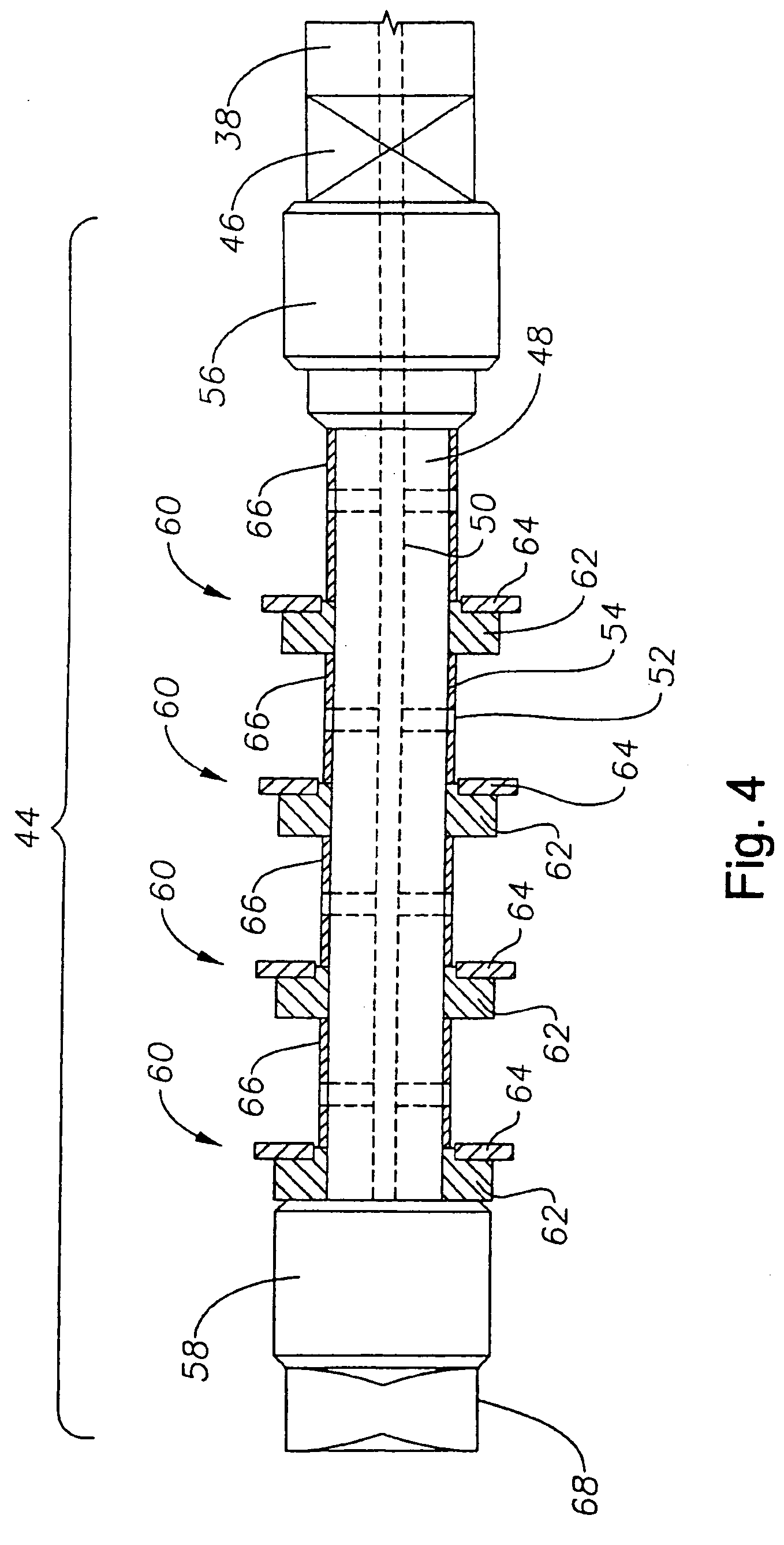

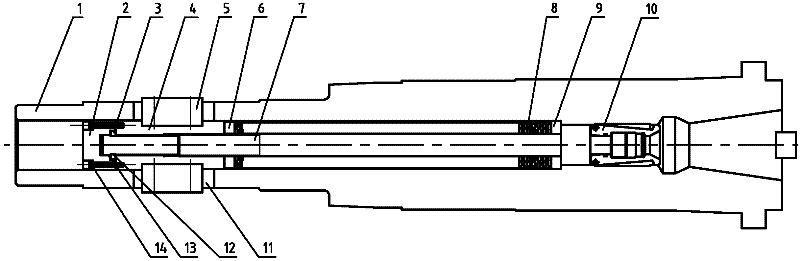

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:DEMAREST JOEL +1

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The table also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

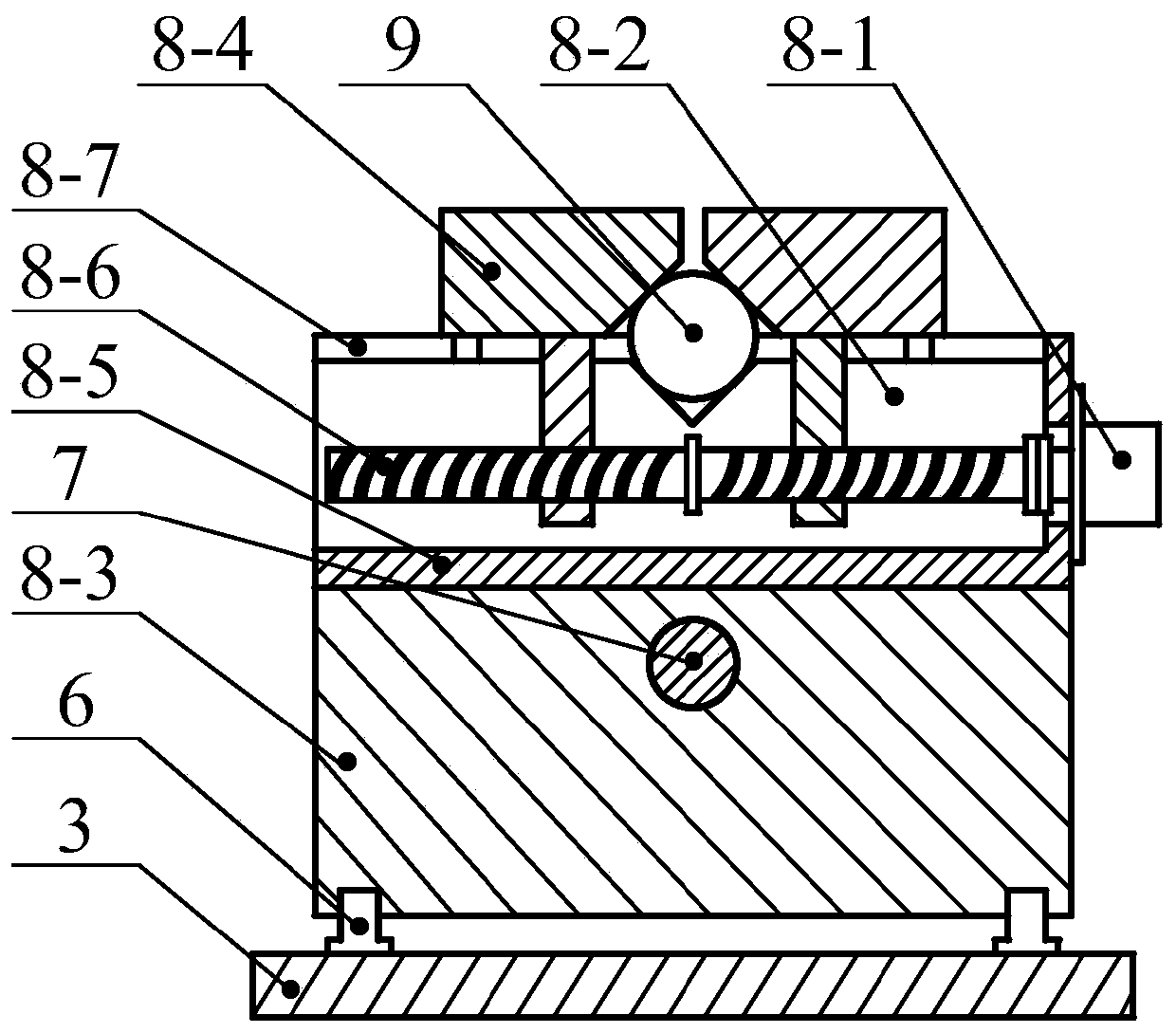

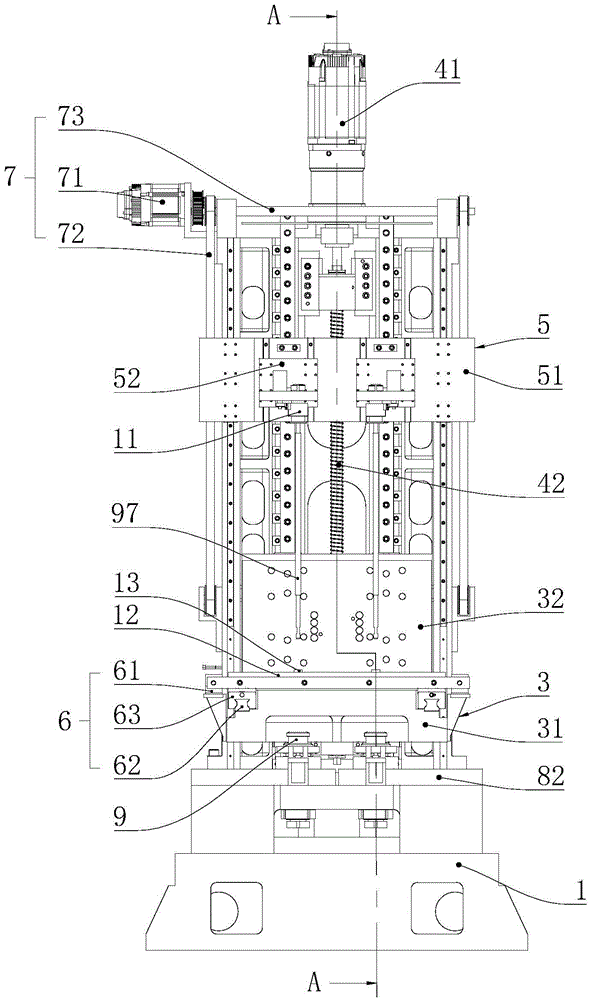

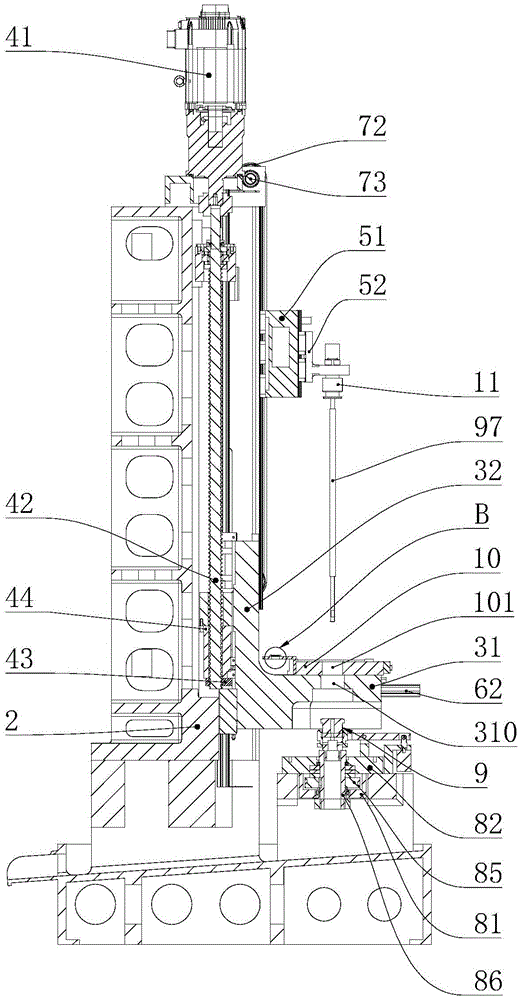

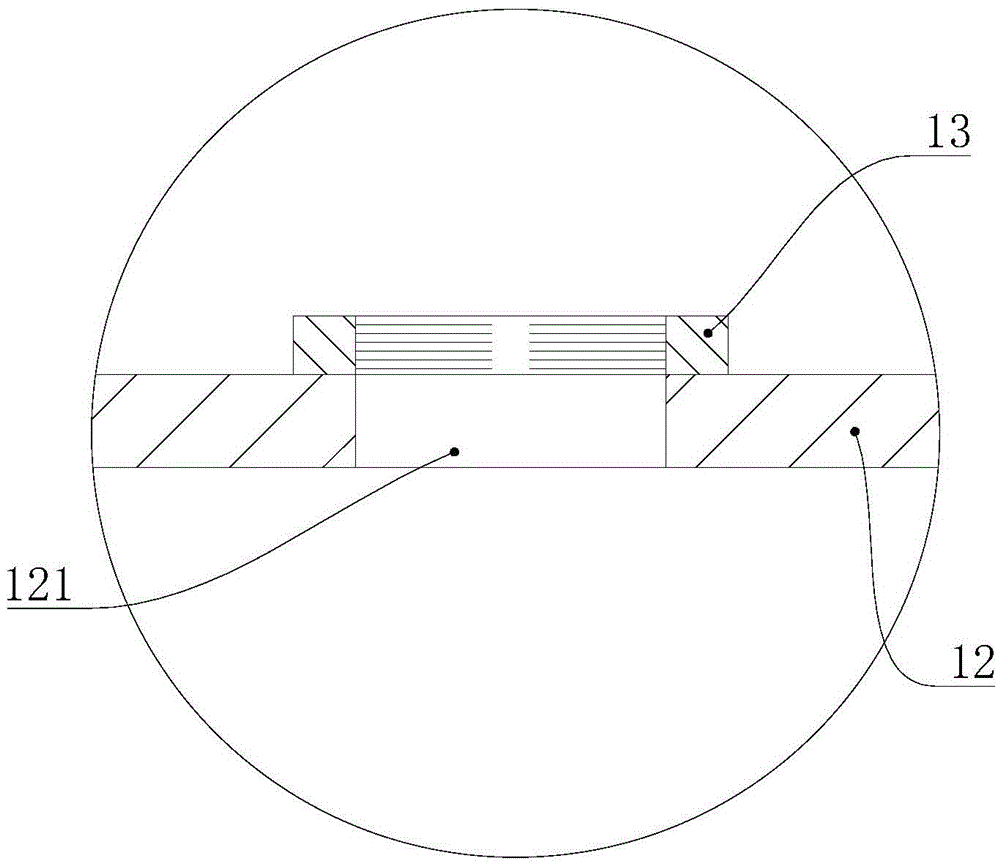

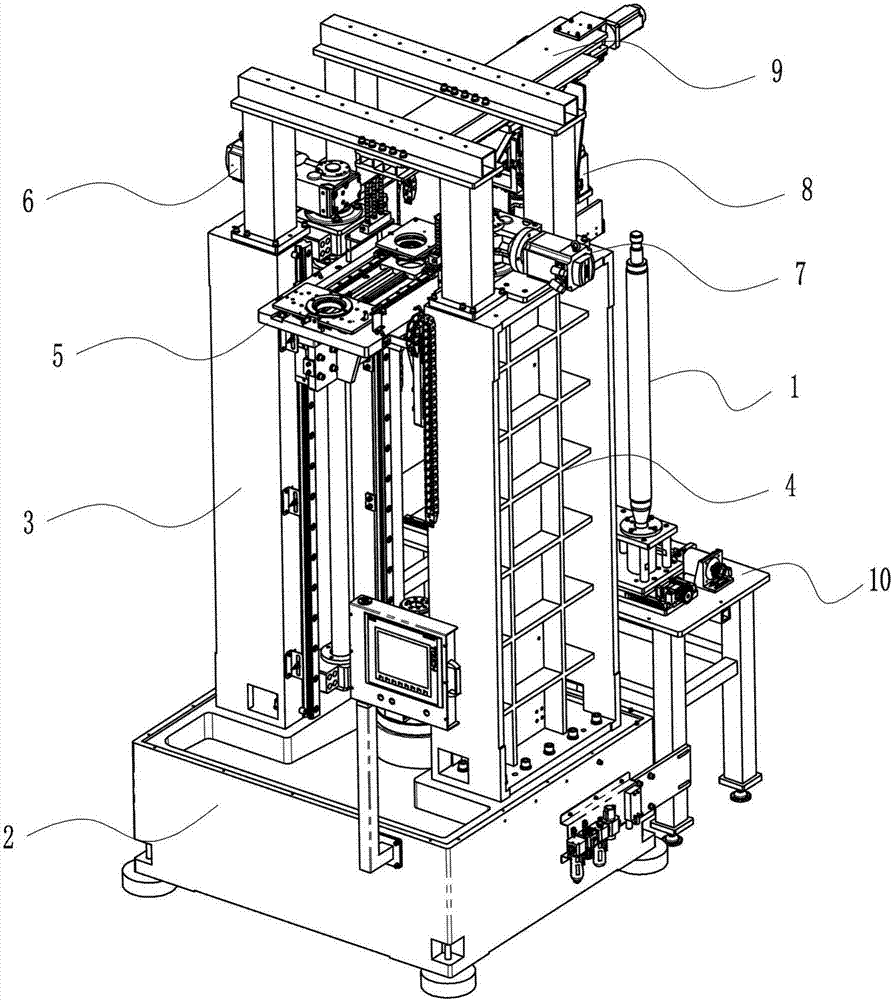

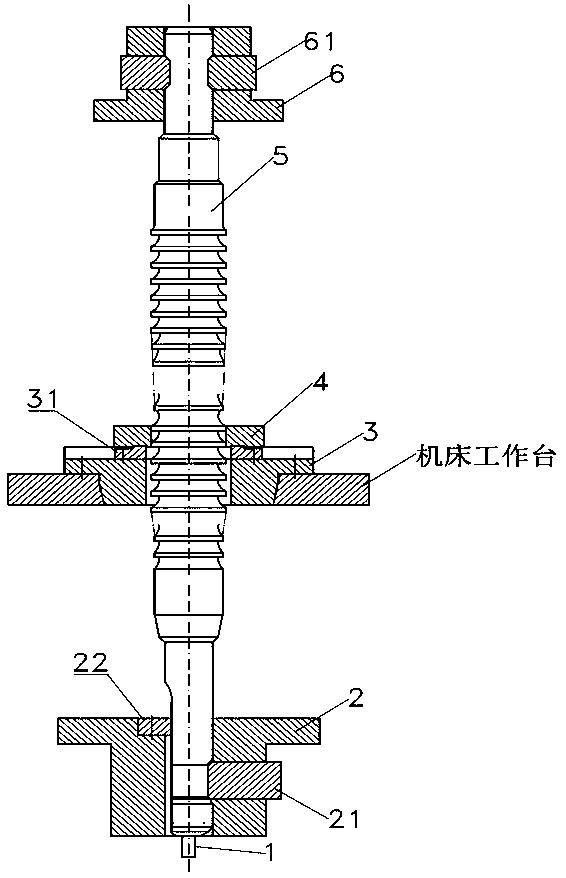

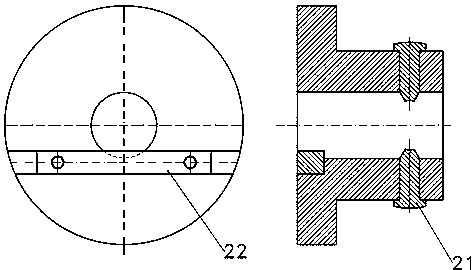

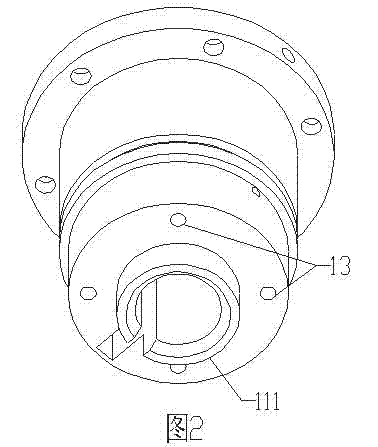

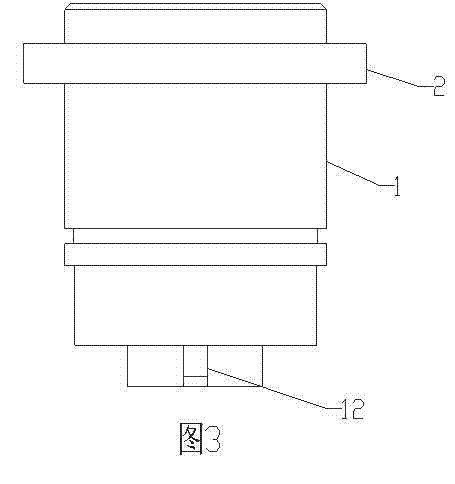

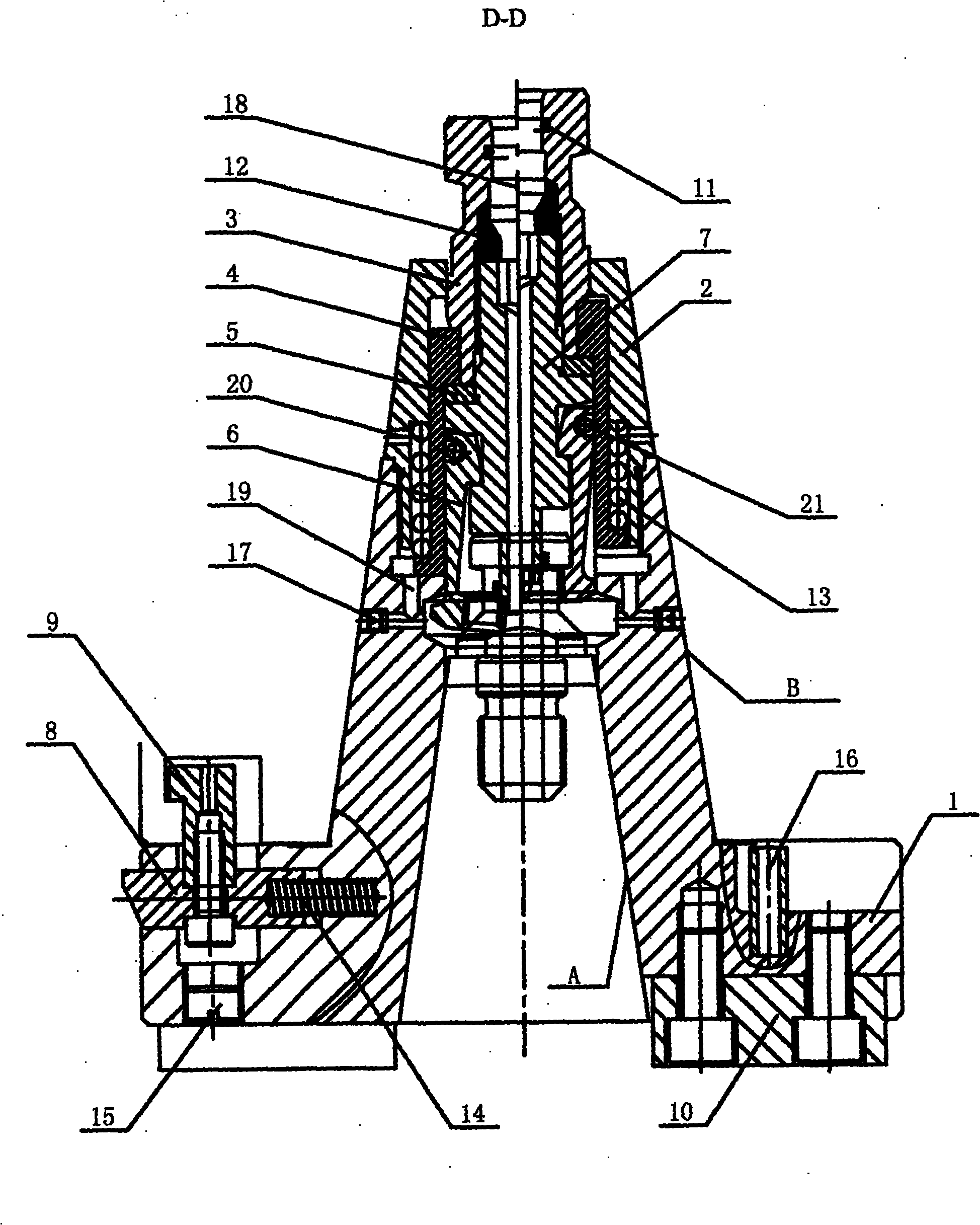

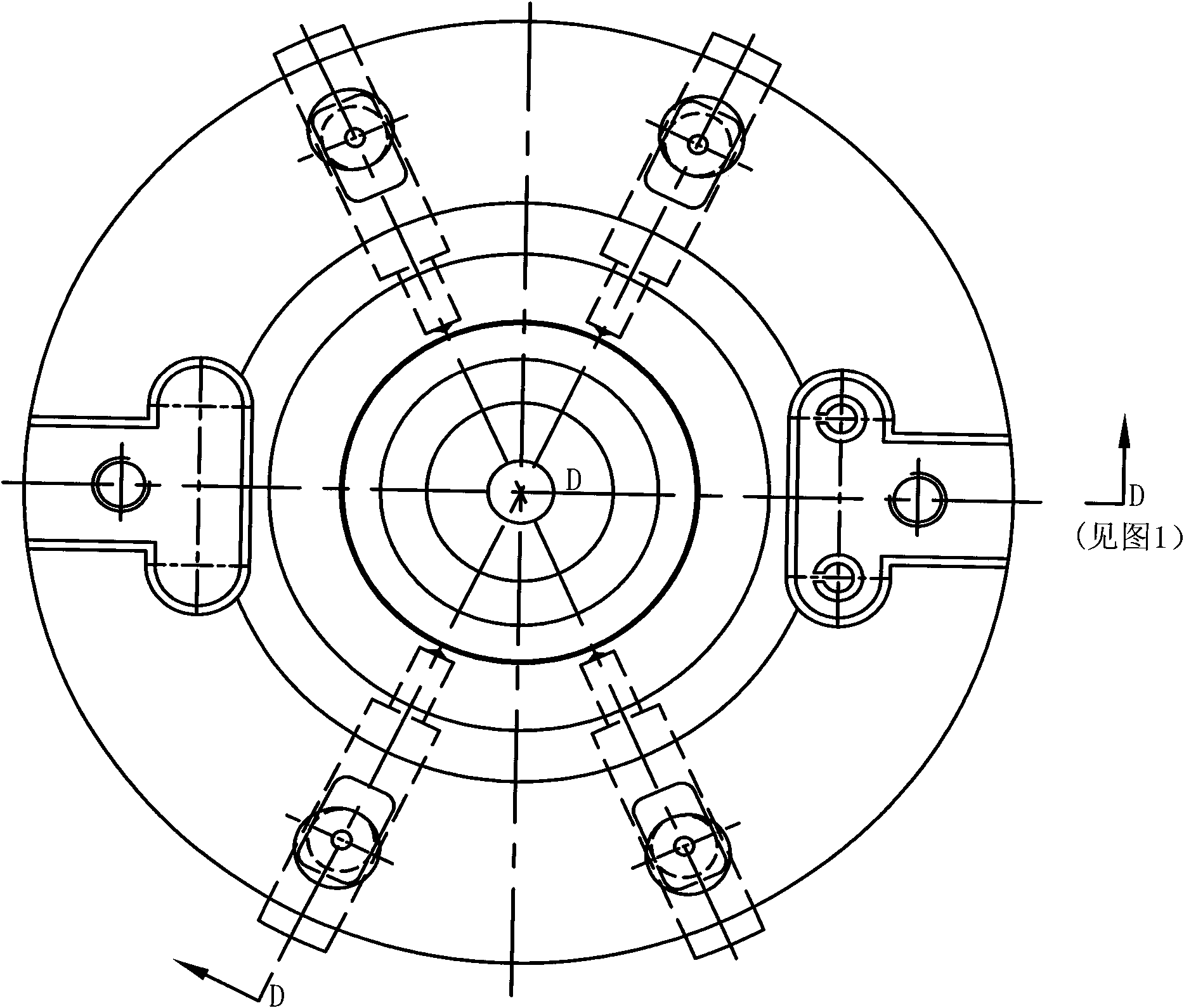

Spiral pull-up type broaching machine

ActiveCN105522437AGuaranteed cleanlinessGuaranteed broaching accuracyBroaching accessoriesBroaching machinesReciprocating motionEngineering

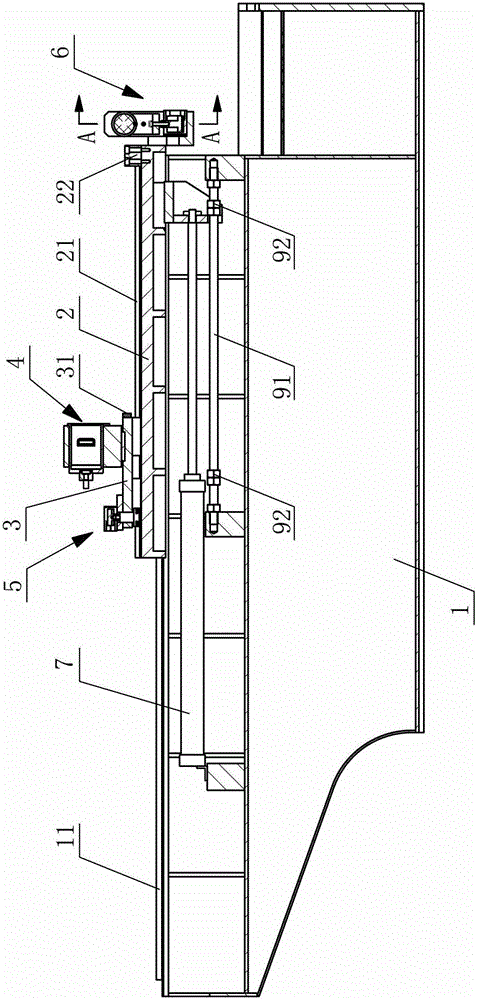

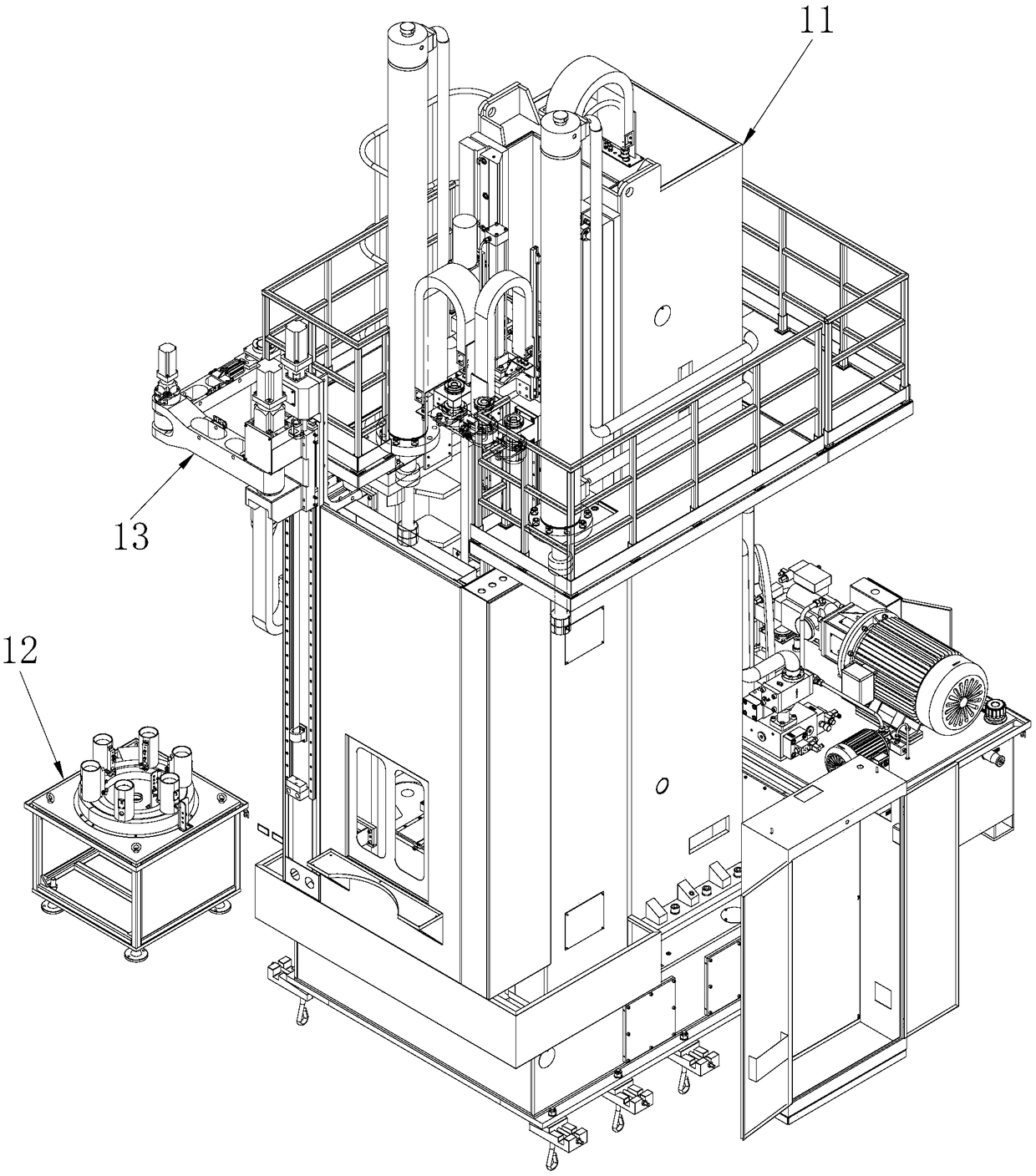

The invention belongs to the technical field of machinery, and relates to a metal cutting machine tool, in particular to a spiral pull-up type broaching machine. The spiral pull-up type broaching machine comprises a base, a machine body, a slide carriage, a first driving mechanism, a working table, a knife lifting and feeding mechanism and a broach, wherein the machine body is vertically fixed on the base; the slide carriage is fixed on the machine body and moves in the up-down direction along the machine body; the first driving mechanism drives the slide carriage to move in the up-down direction; the working table is arranged on the slide carriage and moves in the up-down direction along with the slide carriage; the knife lifting and feeding mechanism and the broach are positioned above the working table; a lower chuck body for fixing the bottom of the broach and a power mechanism for driving the lower chuck body to rotate are arranged on the base and positioned below the working table; a driving assembly which drives the working table to move in the front-back direction in a reciprocating manner along the machine body is arranged on the slide carriage; a brush mounting plate is arranged on the inner wall of the working table; and a brush which is used for cleaning the broach is arranged on the brush mounting plate. The invention aims to provide the spiral pull-up type broaching machine which is good in structure optimization, high in work efficiency and low in manufacturing cost, and can improve quality of products.

Owner:浙江成春自动化设备有限公司

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

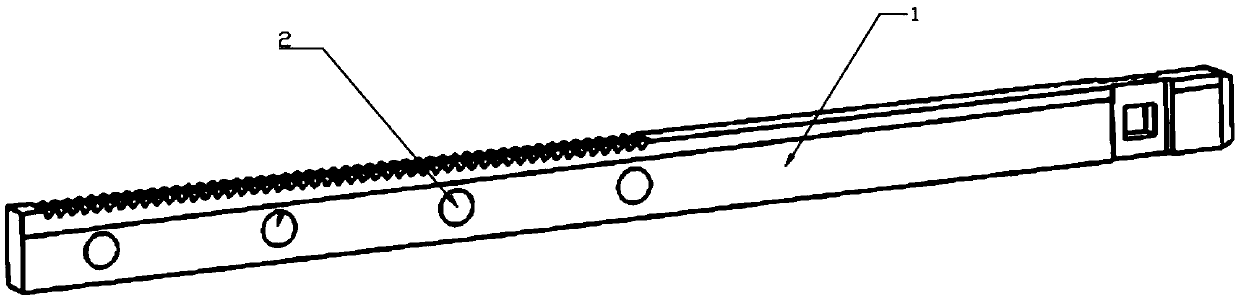

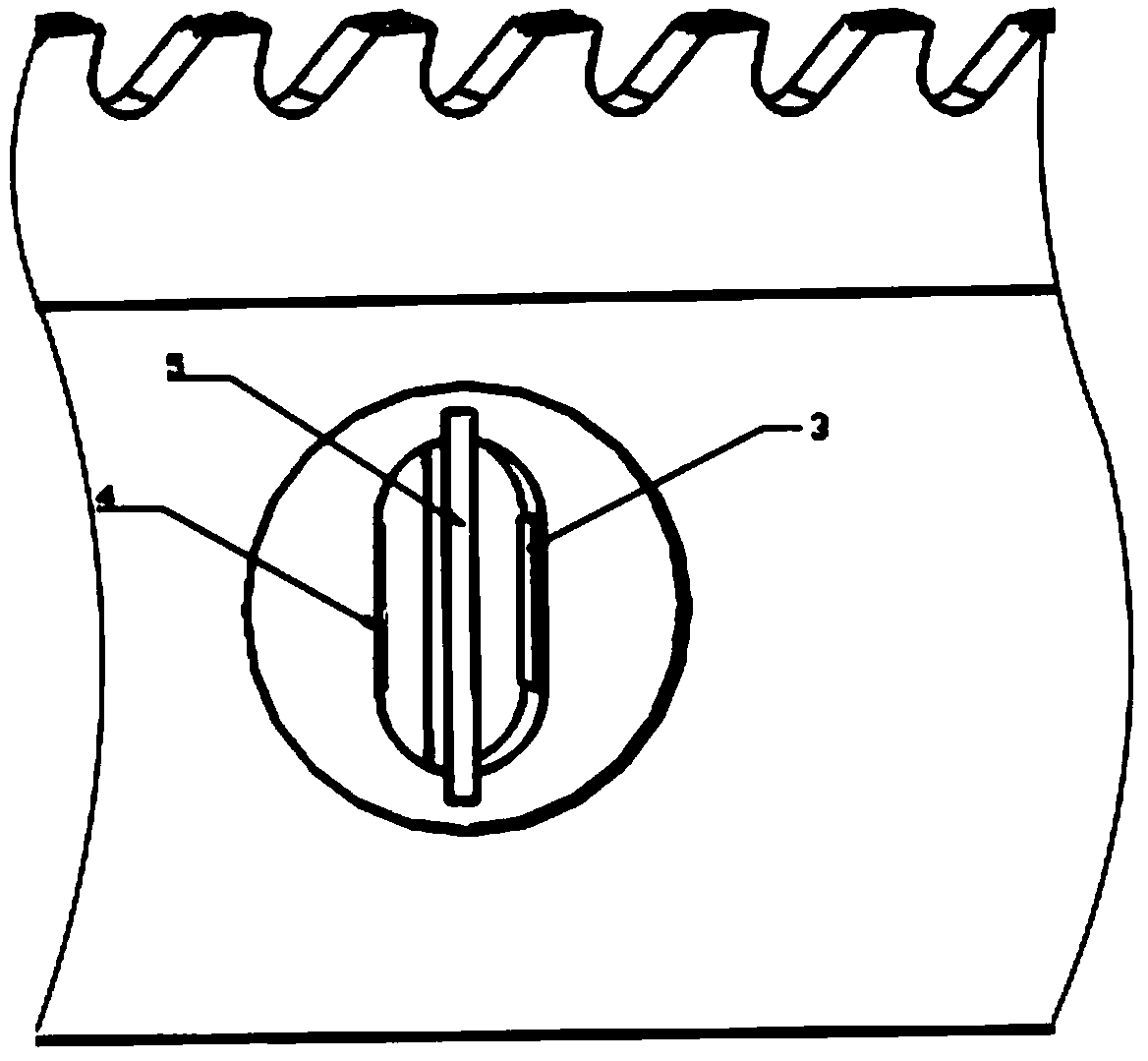

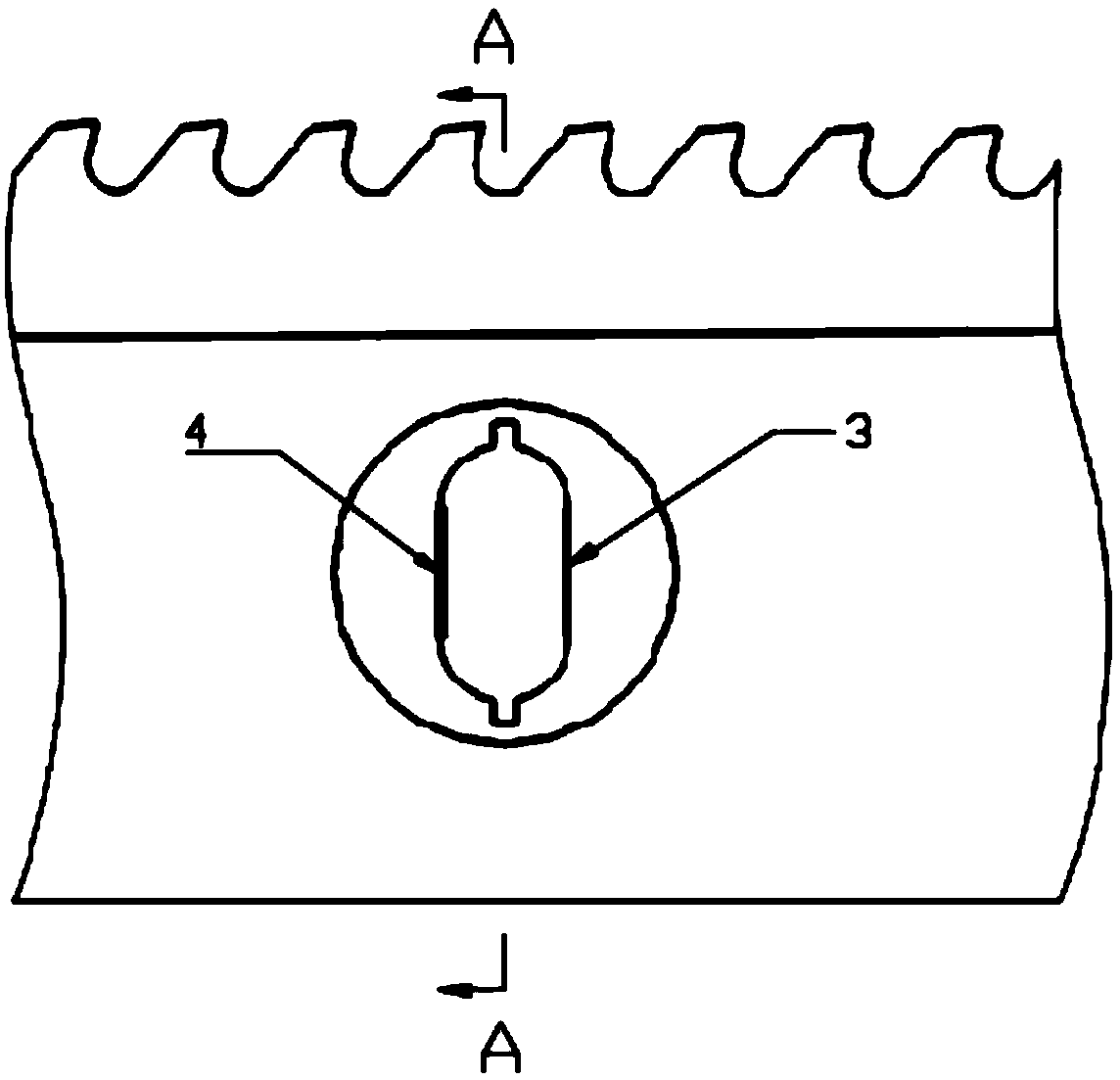

Automatic cutter conveying device of horizontal type broaching machine

ActiveCN102873399AAchieve broachingImprove machining accuracyBroaching accessoriesPositioning apparatusLinear motionSlide plate

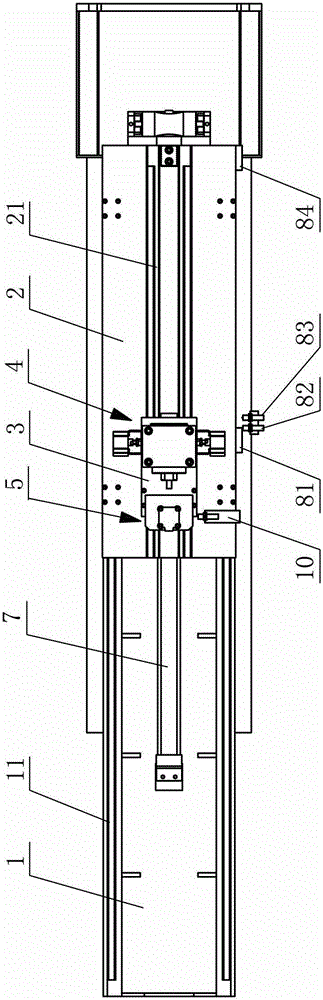

The invention discloses an automatic cutter conveying device of a horizontal type broaching machine. The automatic cutter conveying device comprises a base and a main sliding plate, wherein a first linear guide rail is horizontally arranged on the base; the main sliding plate is driven by a power device and can do reciprocating linear motion along the first linear guide rail; a second linear guide rail which is in the same direction as that of the first linear guide rail is arranged on the main sliding plate; a lifting cutter supporting device is arranged at the end of the main sliding plate; a cutter conveying sliding plate is arranged on the second linear guide rail in a sliding manner; and a broaching cutter automatic clamping device and a brake device are fixedly arranged on the cutter conveying sliding plate. The automatic cutter conveying device is arranged at one end of the horizontal type broaching machine, a series of operations such as clamping, cutter conveying, broaching and returning are automatically executed; compared with the manual operation method, the automatic cutter conveying device is high in clamping precision, and formed workpieces are high in machining precision; the labor intensity of operators is greatly reduced; the production efficiency is improved; and labor is saved.

Owner:CHAGYI LIHUI BROACHING MACHINE MAFACTURE

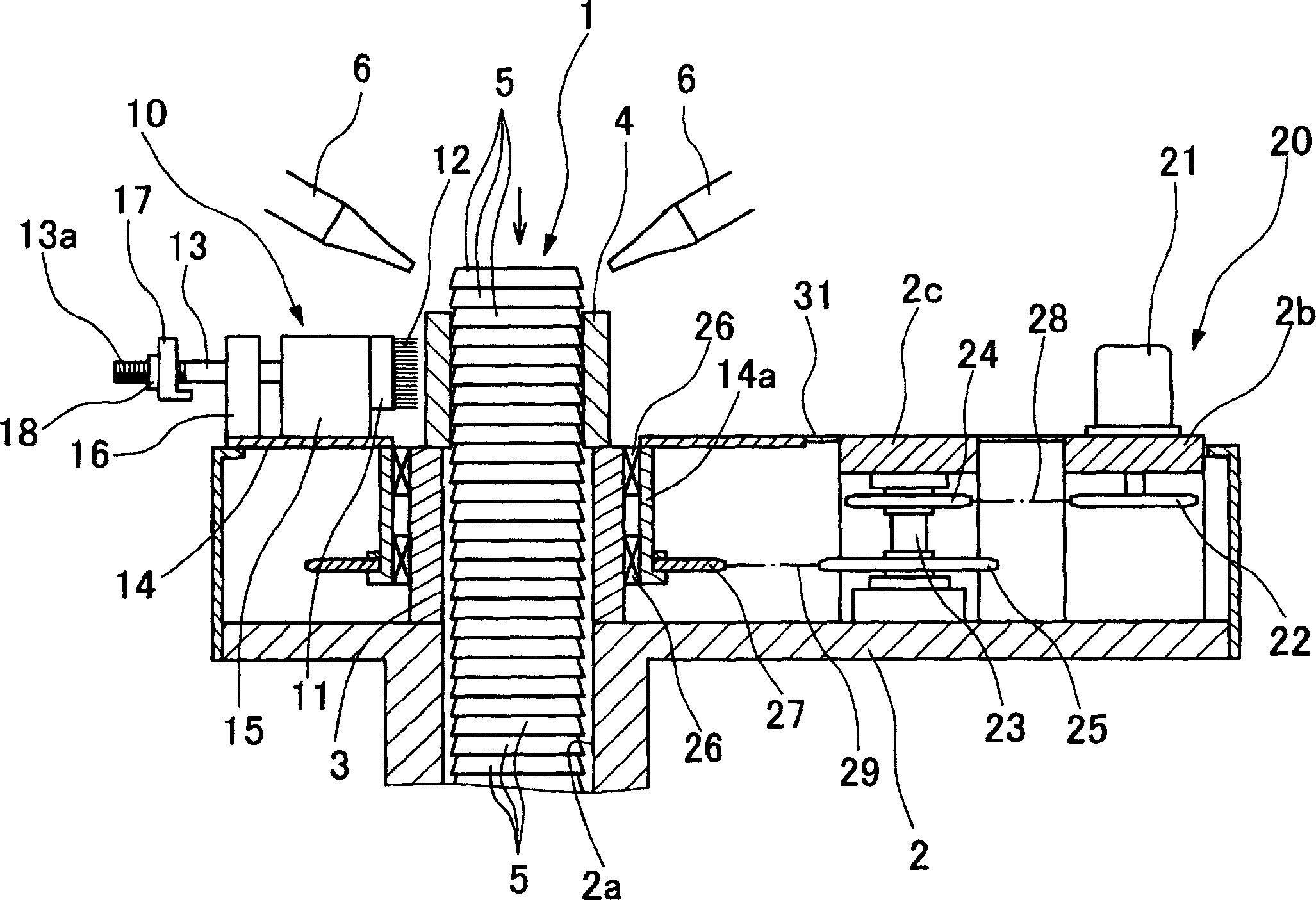

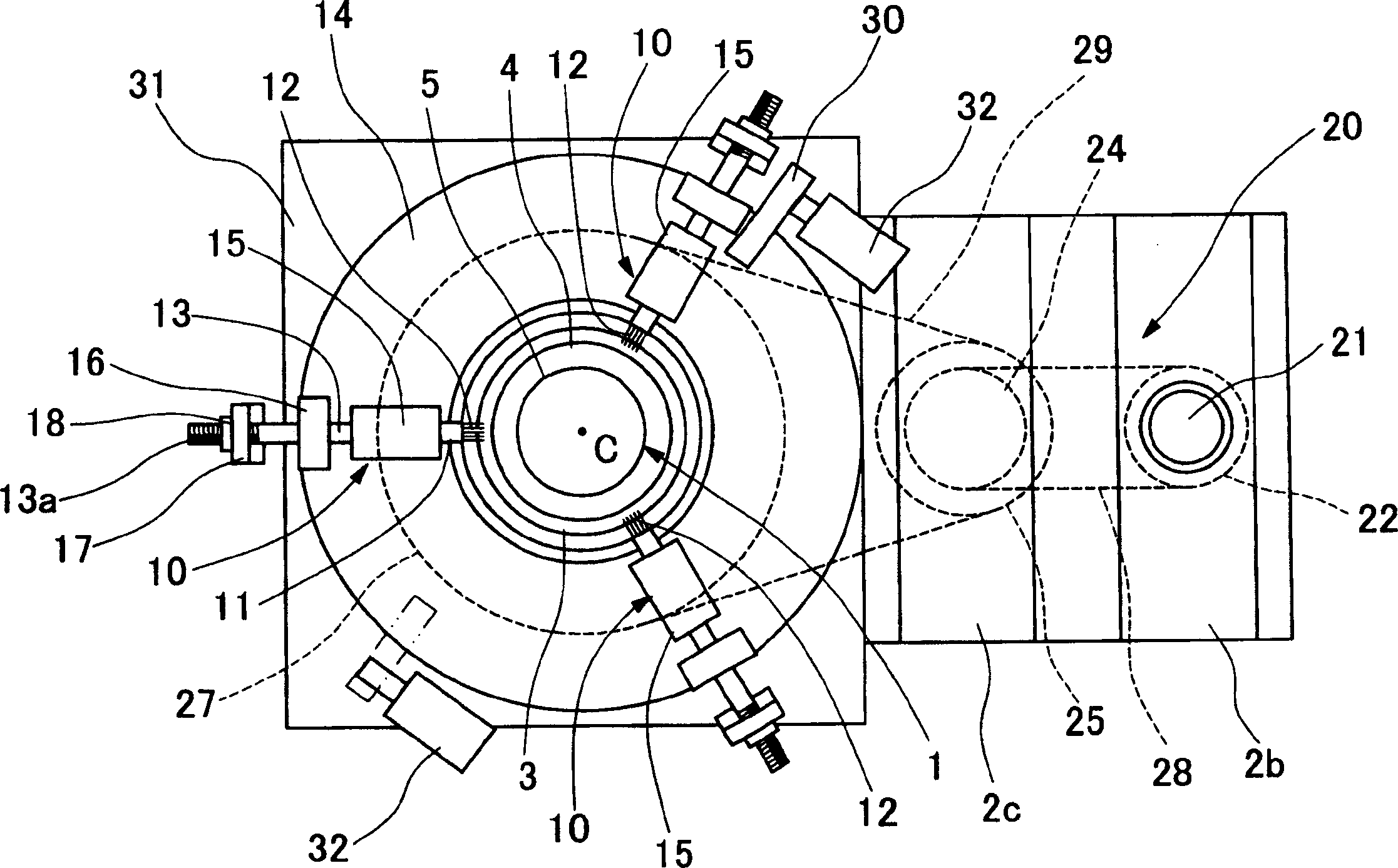

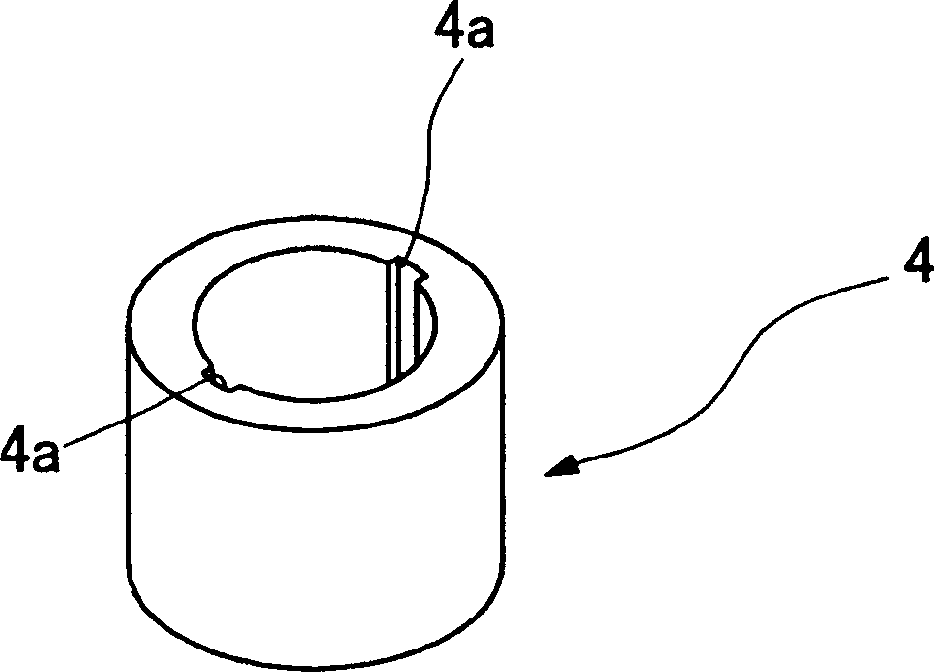

Broach cleaning device

InactiveCN1647892AGain longevityEfficient removalBroaching accessoriesBroaching toolsEngineeringSwarf

To lengthen the service life, by improving the cleaning function of chips, by strongly rubbing a broach by a brush. This device is arranged in three places so that a brush unit 10 forms a concentric circle to the center C of the broach 1, and is constituted so as to be reciprocatably supported in the direction for approaching / separating to the center C of the broach 1 by a driving cylinder 15. This device is rubbed in the circumferential direction along a cutting edge part 5 of the broach 1 by reciprocatably rotating a turntable 14 in the horizontal direction by 180[deg.] in a state of putting the brush in an operation position, and brushes off and removes the chips sticking to a part over an inner surface part 5c from an edge part 5b of a cutting edge 5a for constituting the cutting edge part 5 in the broach 1.

Owner:FUJINON SANO

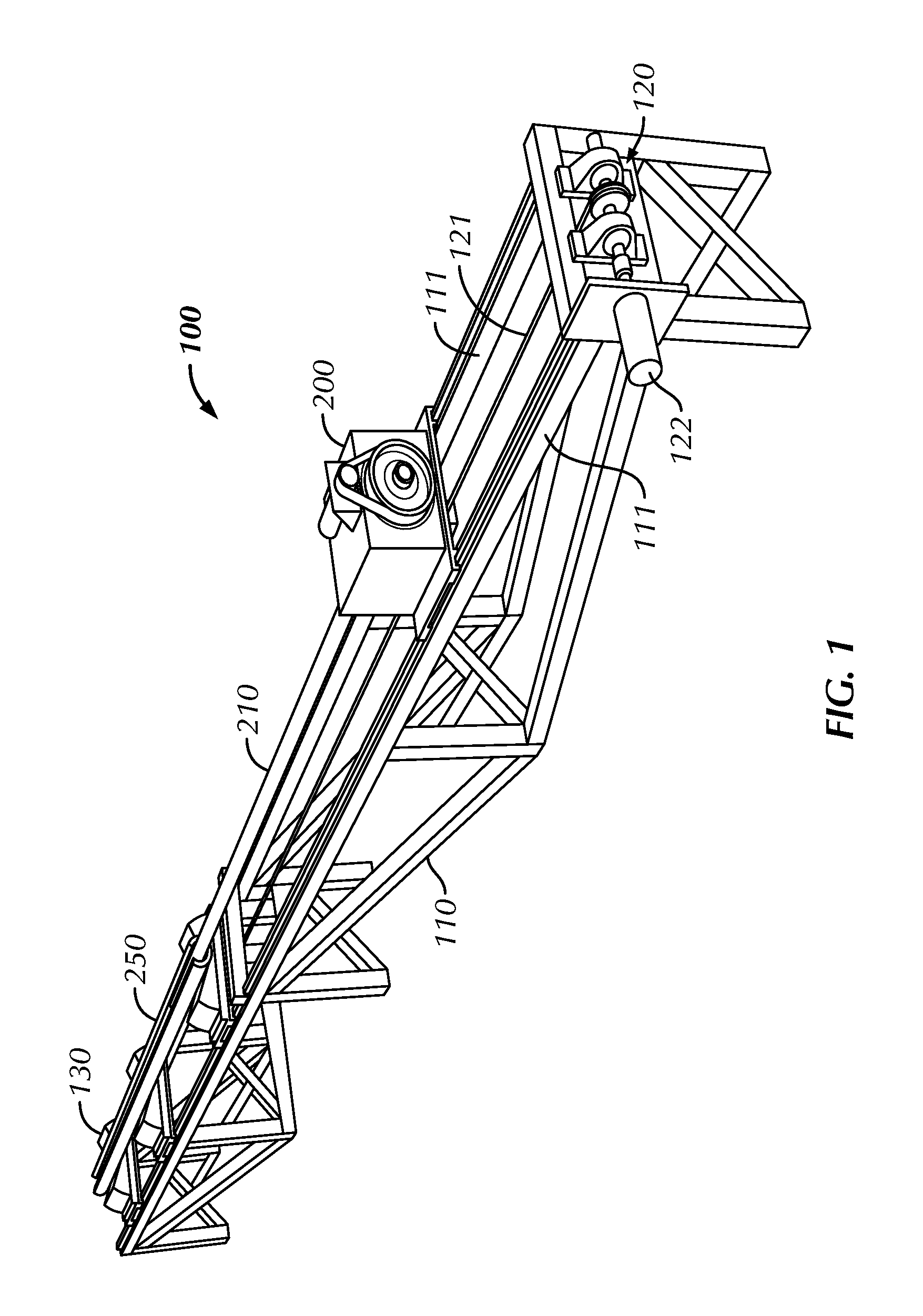

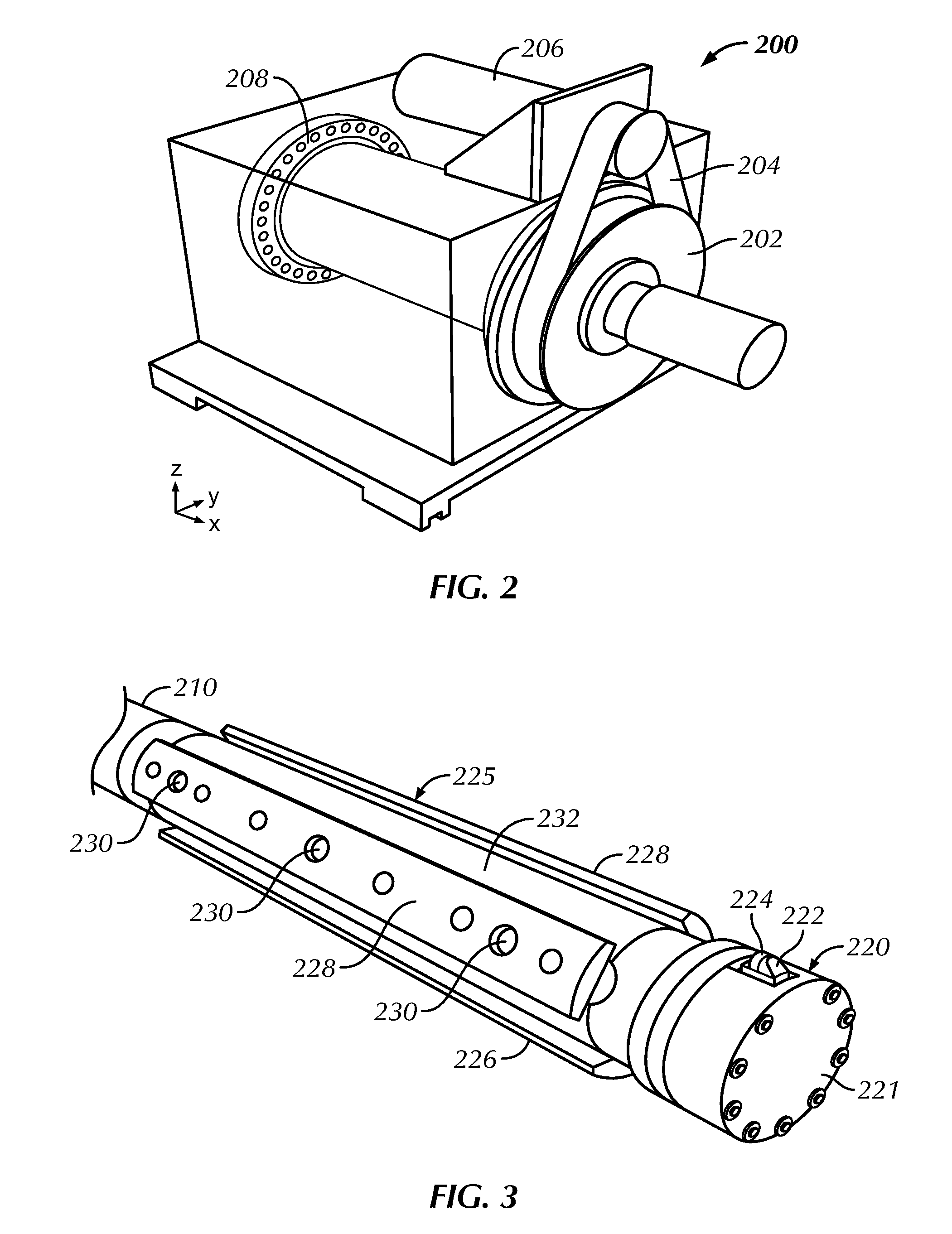

Machining apparatus for long tube lengths and related methods

An apparatus for machining a profile in an inner wall of a tubular includes a frame on which a drive system is disposed, a carriage head disposed on at least one track of the frame, wherein the drive system is configured to operate the carriage head along the at least one track, a torque tube coupled to the carriage head and extending therefrom, the torque tube having a cutting tool coupled thereto, and a plurality of stabilizer pads disposed proximate the cutting tool and along a circumference of the torque tube, wherein the plurality of stabilizer pads are configured to engage the inner wall of the tubular and centralize the cutting tool within the tubular.

Owner:SMITH INT INC

Control of white-etched layer during machining

A machining system includes a support configured to retain an article, such as a rotor disk, having an area, such as a surface of a slot in the disk. A cutting tool, for example, a broach, is movable relative to the support to cut the area. A heating member, such as a laser, is configured to locally heat the area of the article. In one example, the cutting tool includes a body having a cutting edge. The heating member is supported by the body and is configured to provide heat adjacent to the cutting edge. The cutting edge cuts the locally heated area while the area is still heated.

Owner:RAYTHEON TECH CORP

Loose-preventing structure of automatic cutter releasing pulling mechanism

InactiveCN102240819AThe connection length does not changeBroaching force decreasedBroaching accessoriesScrew threadControl equipment

The invention relates to a loos-preventing structure used for numeric control equipment automatic cutter releasing pulling mechanism, and the loos-preventing structure comprises a transition shaft arranged in a hollow spindle and a pull rod which is in threaded connection with the transition shaft, wherein the spindle is provided with a key slot, the transition shaft is provided with a key which penetrates through the key slot and can axially move in the key slot, and a spring assembly is arranged between the inner end of the transition shaft and the inner step of the spindle; and the pull rod is in threaded connection with the interior of the transition shaft and penetrates through the transition shaft, the pull rod arranged at one side of the outer end of the transition shaft is provided with a semi-ring mounting slot, the semi-ring mounting slot is internally provided with a semi ring, and the outer end of the transition shaft is provided with a gland used for fixing the semi ring at a mounting position. In the invention, the semi ring is arranged on the pull rod, the locations of the pull rod and the transition shaft are fixed, the length of threaded connection of the pull rodand the transition shaft is maintained constant, and the phenomenon that the cutter pulling force of the spindle is reduced as the threaded connection of the pull rod and the transition shaft is loosened can be prevented.

Owner:无锡桥联数控机床有限公司

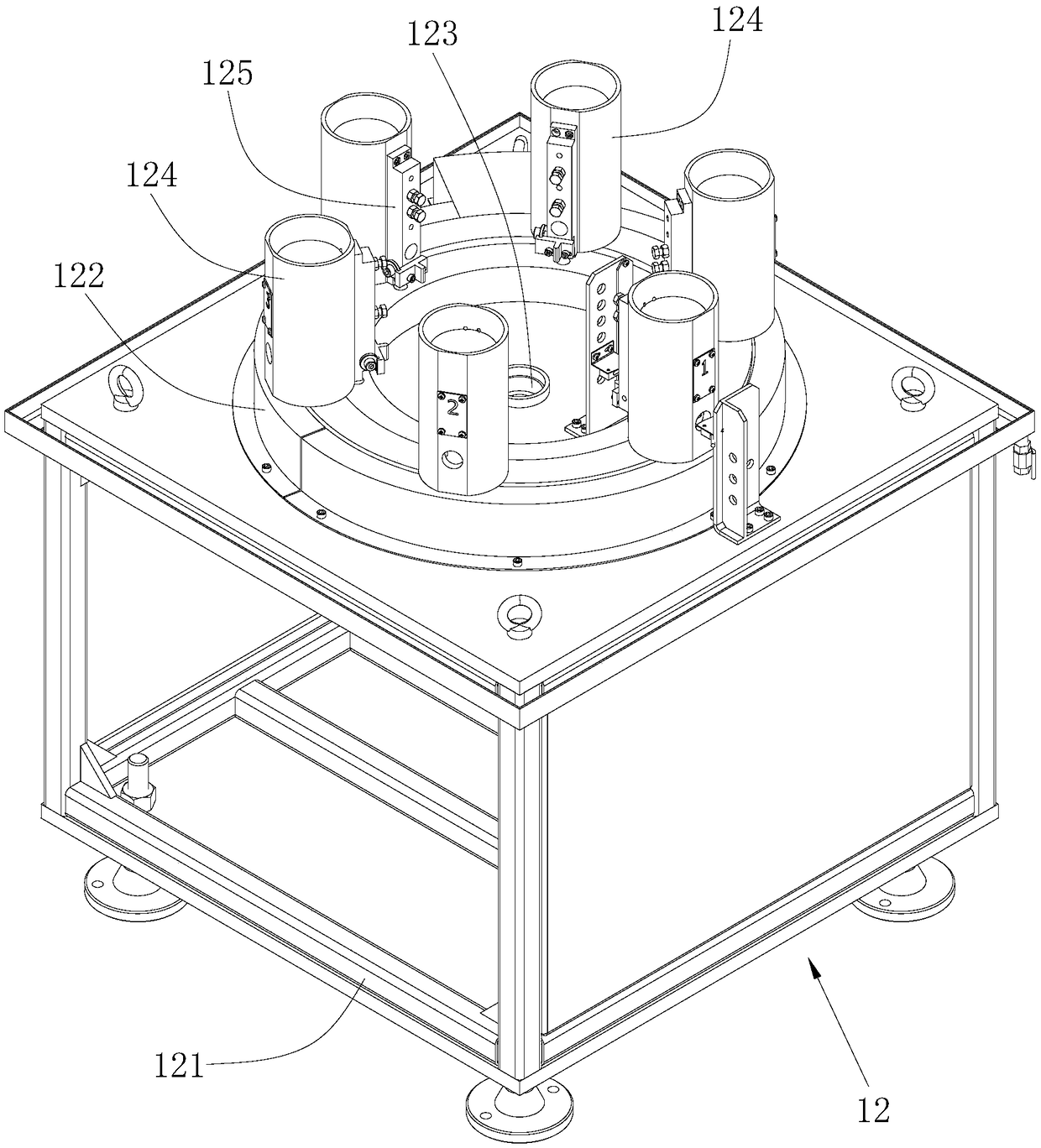

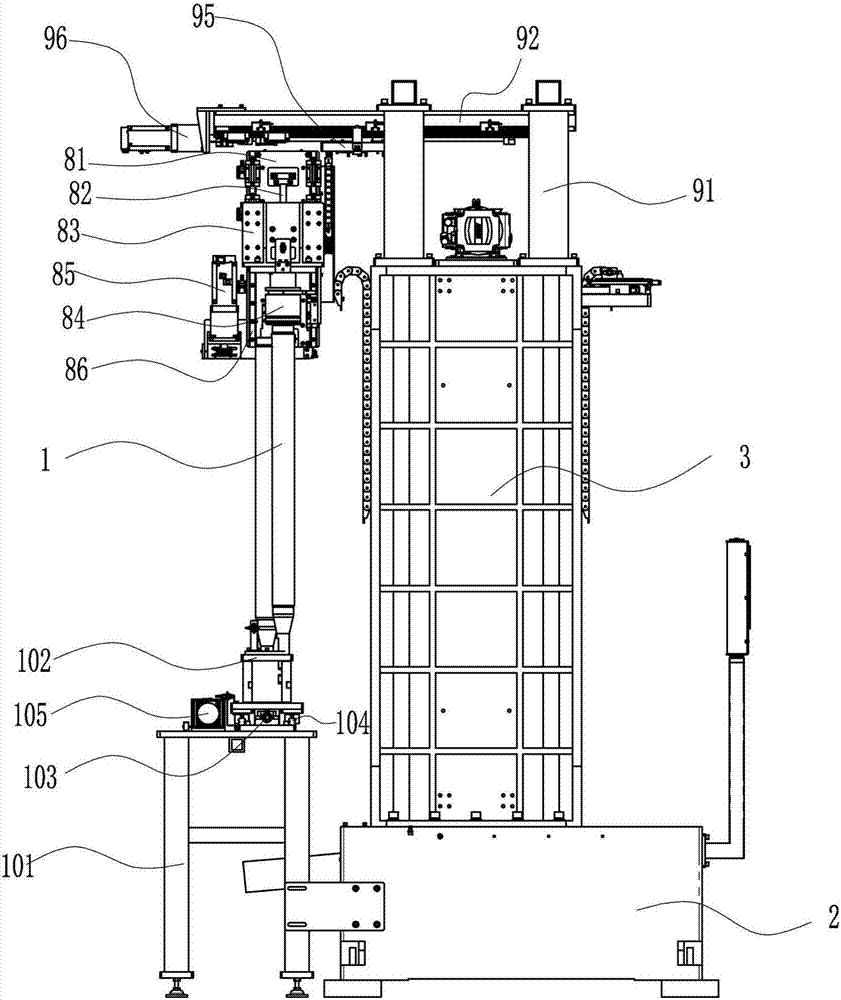

Automatic tool changing system for broaching machine

InactiveCN109202167ARealize automatic disassemblyAchieve installationBroaching accessoriesControl systemAutomotive engineering

The invention is applicable to the technical field of broaching machines, and provides an automatic tool changing system for a broaching machine. The automatic tool changing system comprises a broaching machine for broaching a workpiece, a tool magazine for storing the broach and an automatic tool changing device for replacing a broach between the tool magazine and the broaching machine as needed.The automatic tool changing system further comprises a control system for controlling the tool magazine and the automatic tool changing device to operate according to a preset program. The automatictool changing device is fixedly coupled to the broaching machine, the tool magazine is disposed below the automatic tool changing device, and the control system is in signal communication with the tool magazine and the automatic tool changing device, respectively. The automatic tool changing system of the broaching machine provided by the invention realizes automatic and accurate replacement of abroach. The replacement operation is convenient, time-saving and labor-saving. Also, the safety of an operator is ensured, and the use reliability is high.

Owner:CHANGSHA SISHENG INTELLIGENT EQUIP

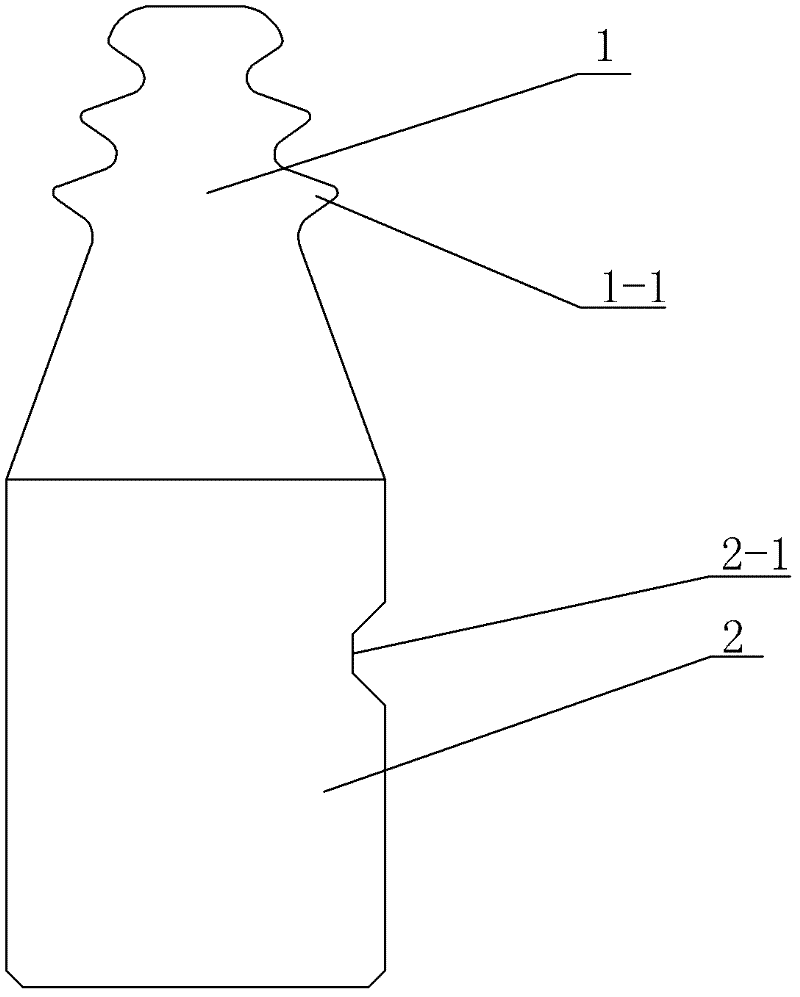

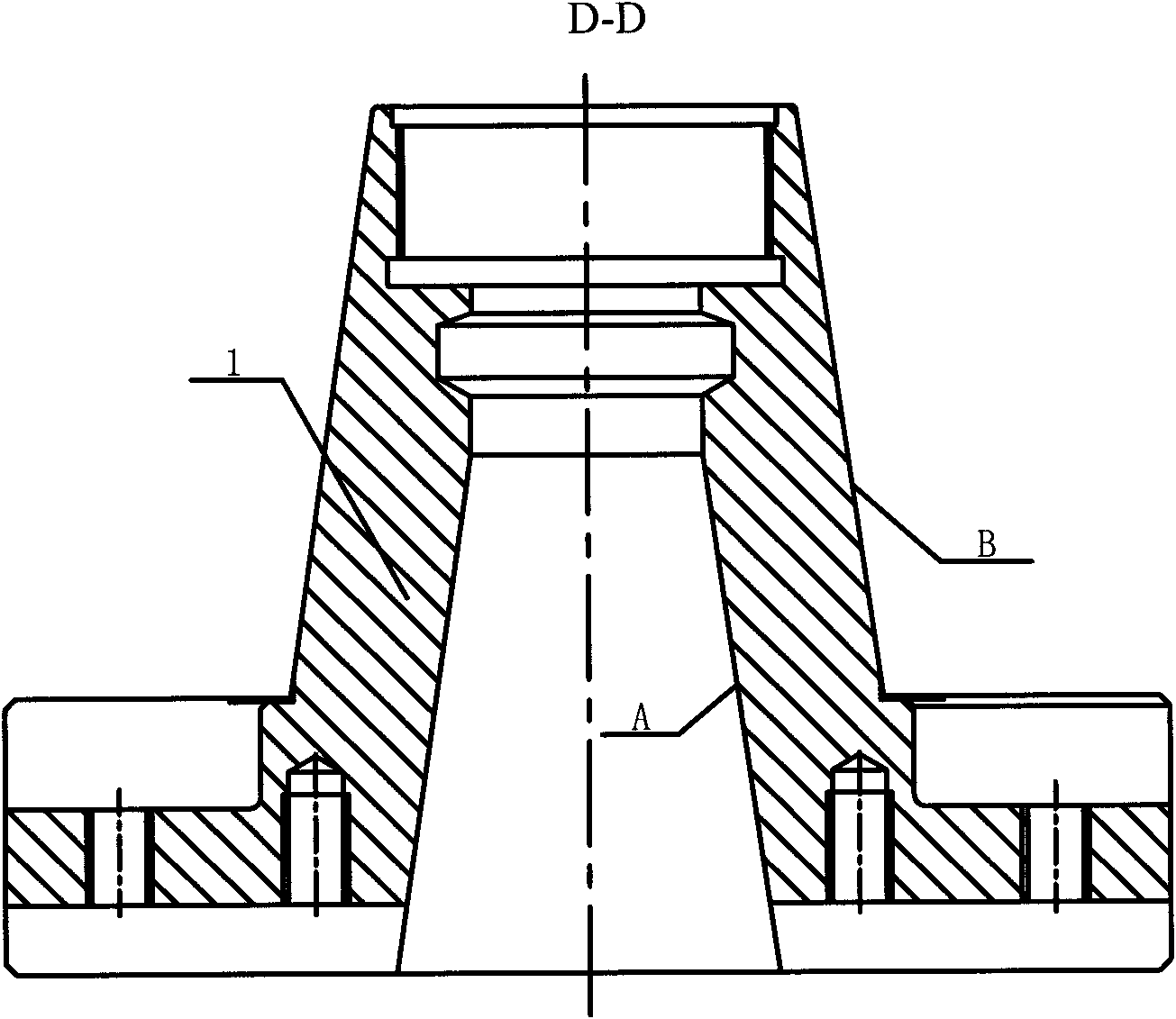

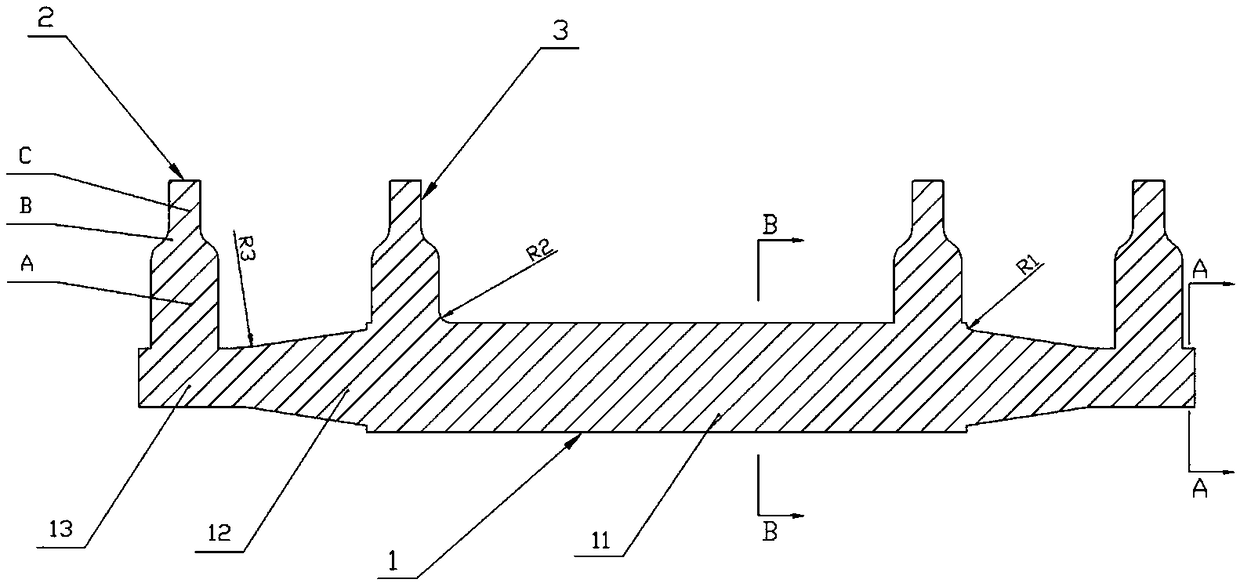

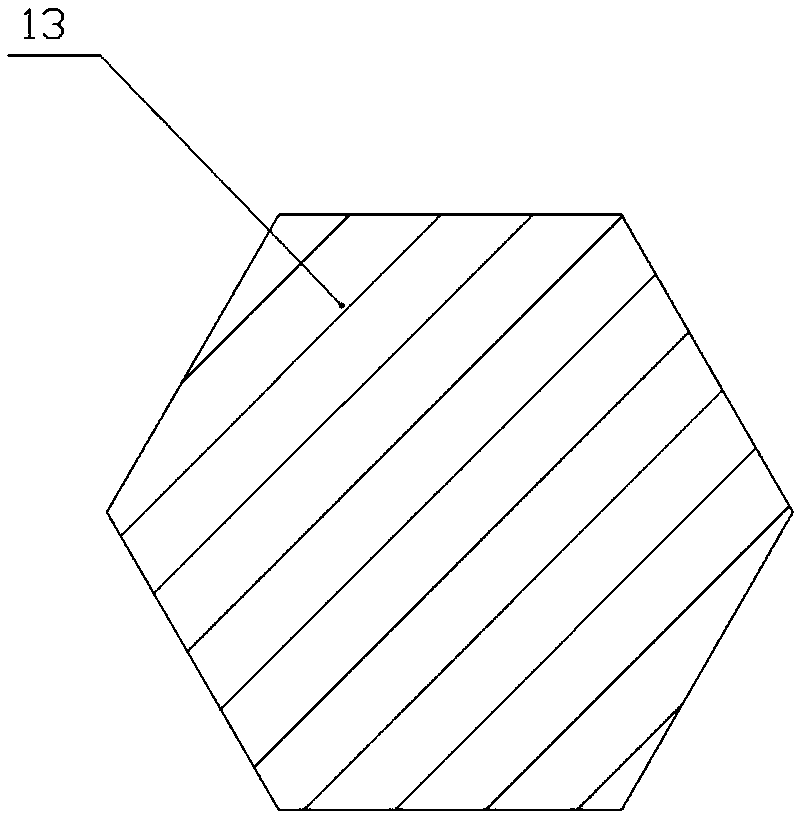

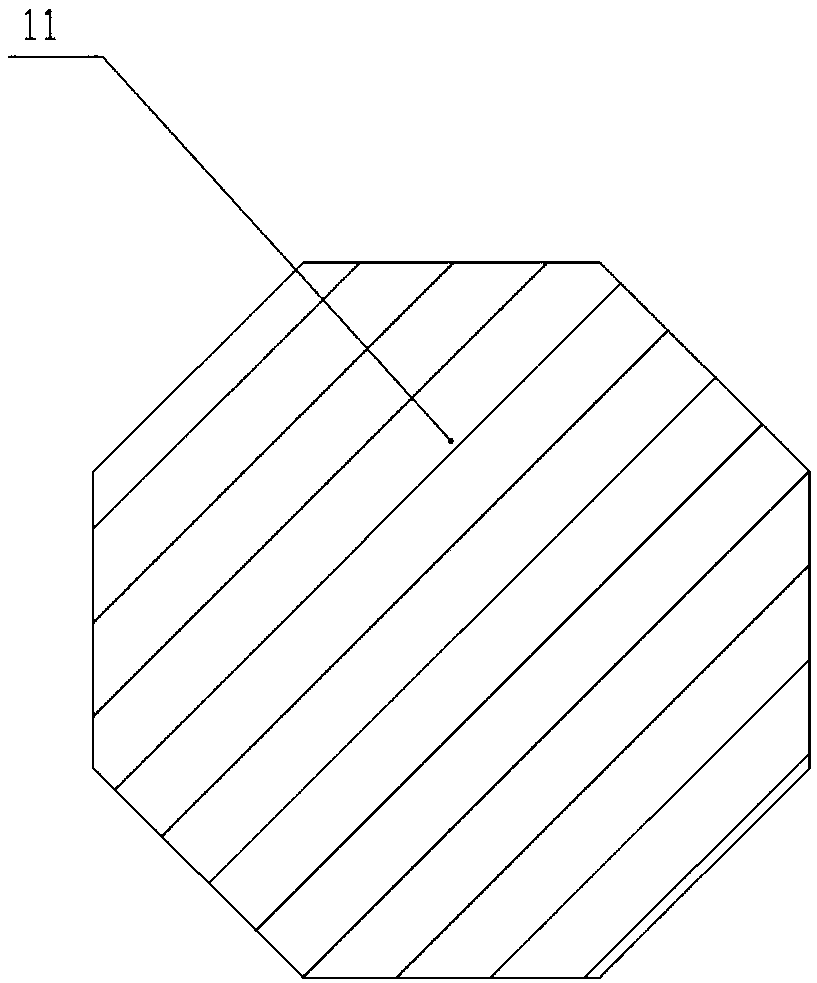

Broaching and adjusting measurement tool for turbine disk of combustion gas turbine

InactiveCN102501142AImprove work efficiencyEasy to useBroaching accessoriesMeasurement/indication equipmentsEarly warning systemCombustion

The invention relates to a measurement tool, in particular to a broaching and adjusting measurement tool for a turbine disk of a combustion gas turbine, solving the problems that the detection can be performed only after the conventional race broaching process is finished, no warning control measurement tool is arranged during the process, problems happening in the broaching process only can be judged according to experience, and no special tool can be used for measuring. The broaching and adjusting measurement tool disclosed by the invention comprises a measurement part and a broaching machine assembling part, which are integrated into a whole. The measurement part is a prismatic table consists of two symmetrical wave-shaped curved surfaces which are shrunk progressively from bottom to top and two symmetrical planes which are shrunk progressively from bottom to top. The cross section of the measurement part is a quadrangle, and the broaching machine assembling part is a prism of which the cross section is a quadrangle. The projections of the two wave-shaped curved surfaces on a horizontal plane are turbine disk tongue-and-groove shaped lines. The broaching and adjusting measurement tool disclosed by the invention is used for measuring the size of race broaching shaped lines.

Owner:HARBIN TURBINE

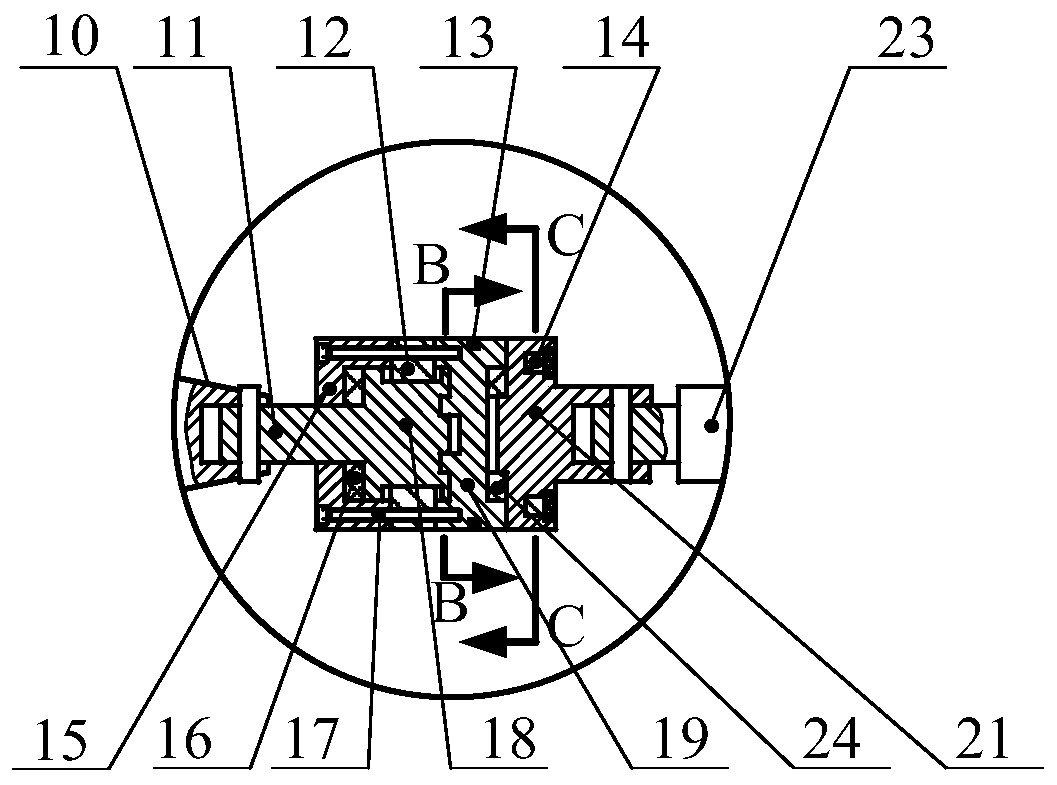

Automatic tooth alignment device and tooth alignment method thereof

InactiveCN109365901AHigh gear alignment efficiencyImprove securityBroaching accessoriesBroaching machinesEngineering

The invention relates to a tooth alignment device, in particular to an automatic tooth alignment device and a tooth alignment method thereof. In order to solve the technical problems that when parts need to be broached and formed for multiple times is broached for the second time or the third time, the manual tooth alignment efficiency is low, and the potential safety hazard exists, the inventionprovides the technical solution that the automatic tooth alignment device comprises a positioning fixture, a tooth alignment body, a positioning block and a broach, wherein the positioning fixture isfixed onto a table board of a broaching machine; the broach is arranged in the table board of the broaching machine in a sleeving way; the tooth alignment body is arranged in an annular cavity betweenthe positioning fixture and the broach in a sleeving way and is fixedly connected with a lower chuck of the broaching machine; a positioning tooth is arranged at one end of the tooth alignment body;a first positioning surface is arranged at the other end of the tooth alignment body; a second positioning surface is arranged on the excircle of the small end of the broach; a positioning block is arranged on a first positioning surface of the tooth alignment body; the small end of the positioning block penetrates through a positioning hole formed in the side wall of the tooth alignment body so as to contact a second positioning surface; and the positioning tooth and any one cutter tooth of the broach are arranged on the same straight line. The invention further provides the tooth alignment method of the automatic tooth alignment device at the same time.

Owner:SHAANXI FAST GEAR CO

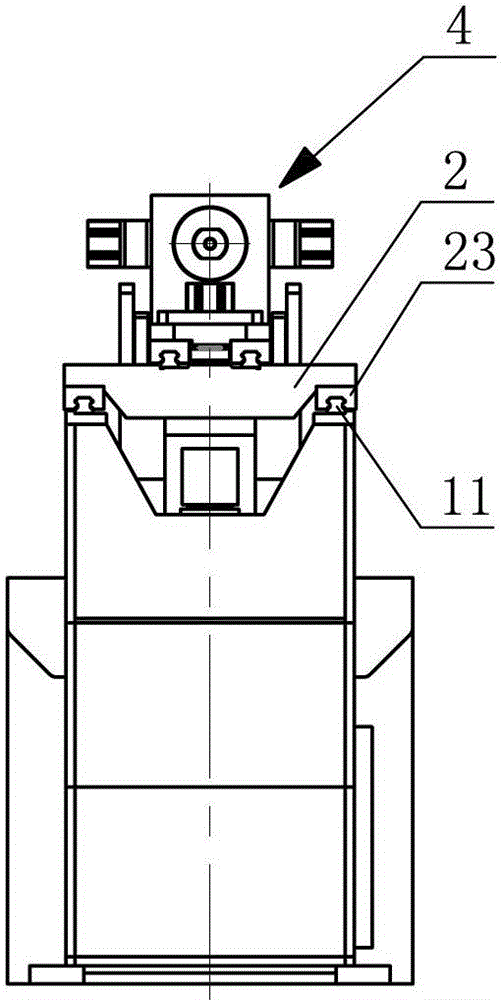

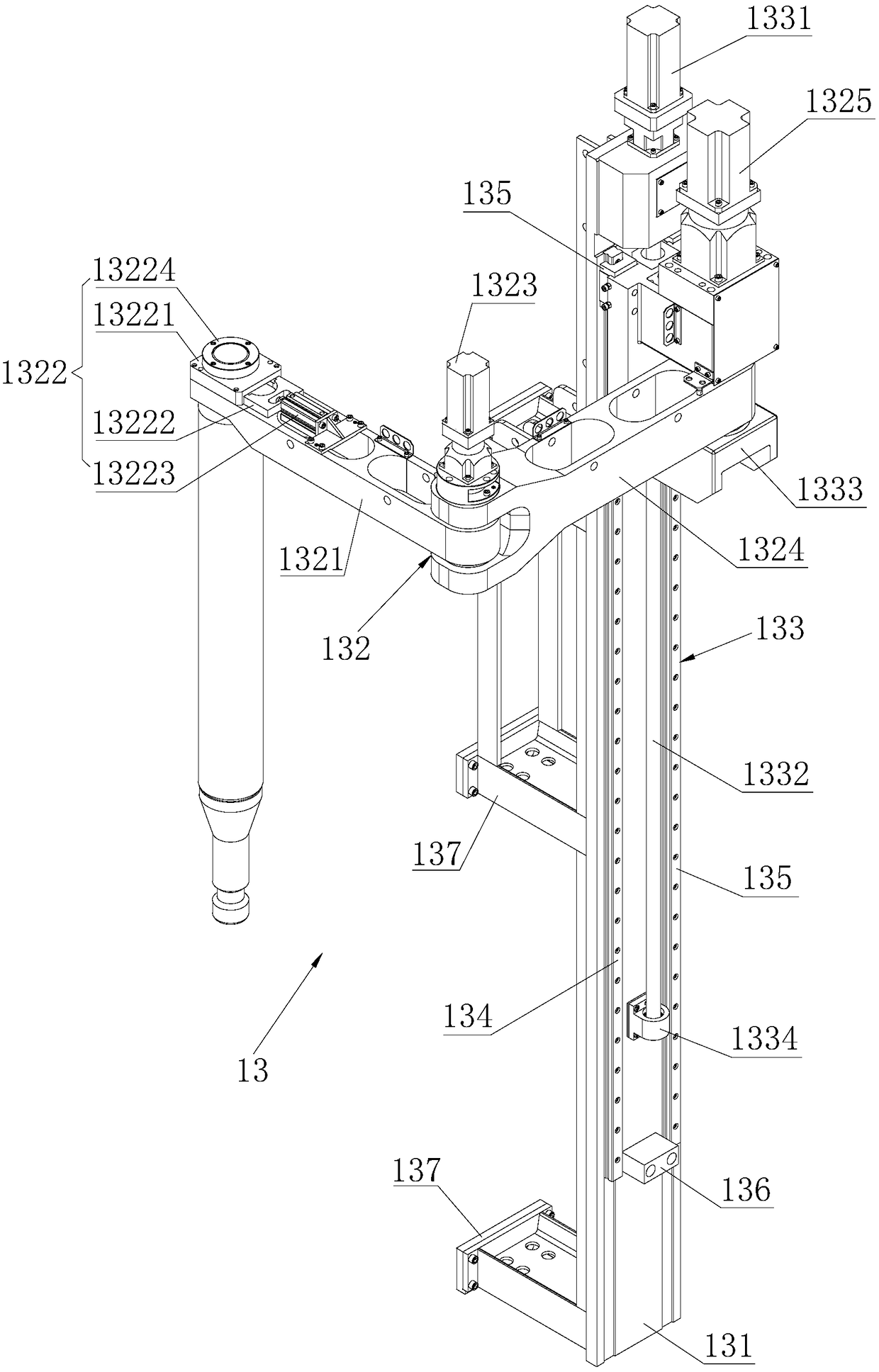

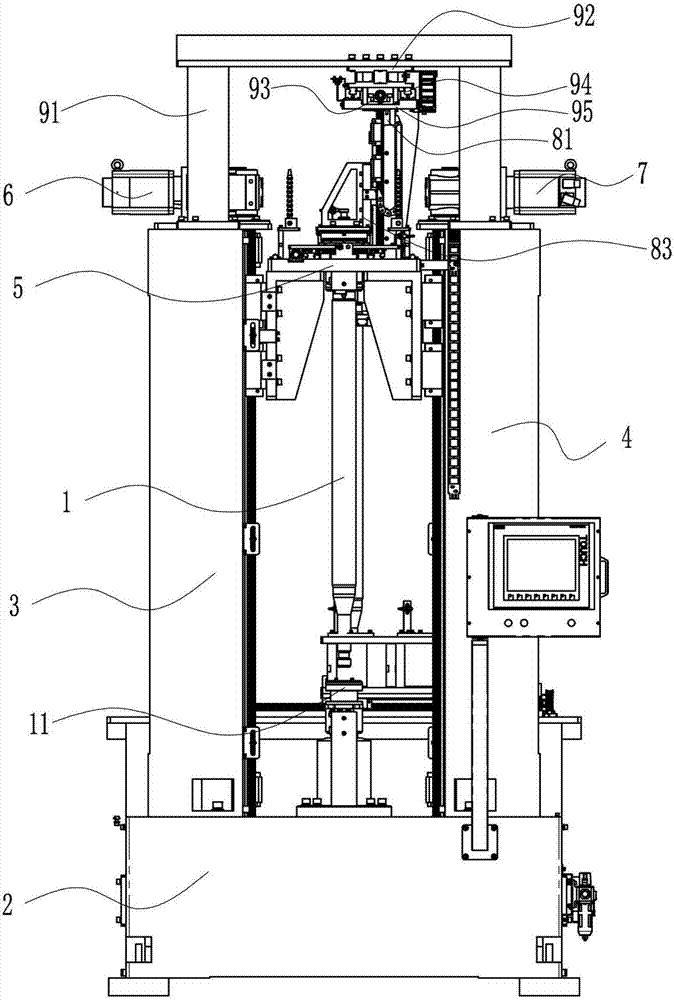

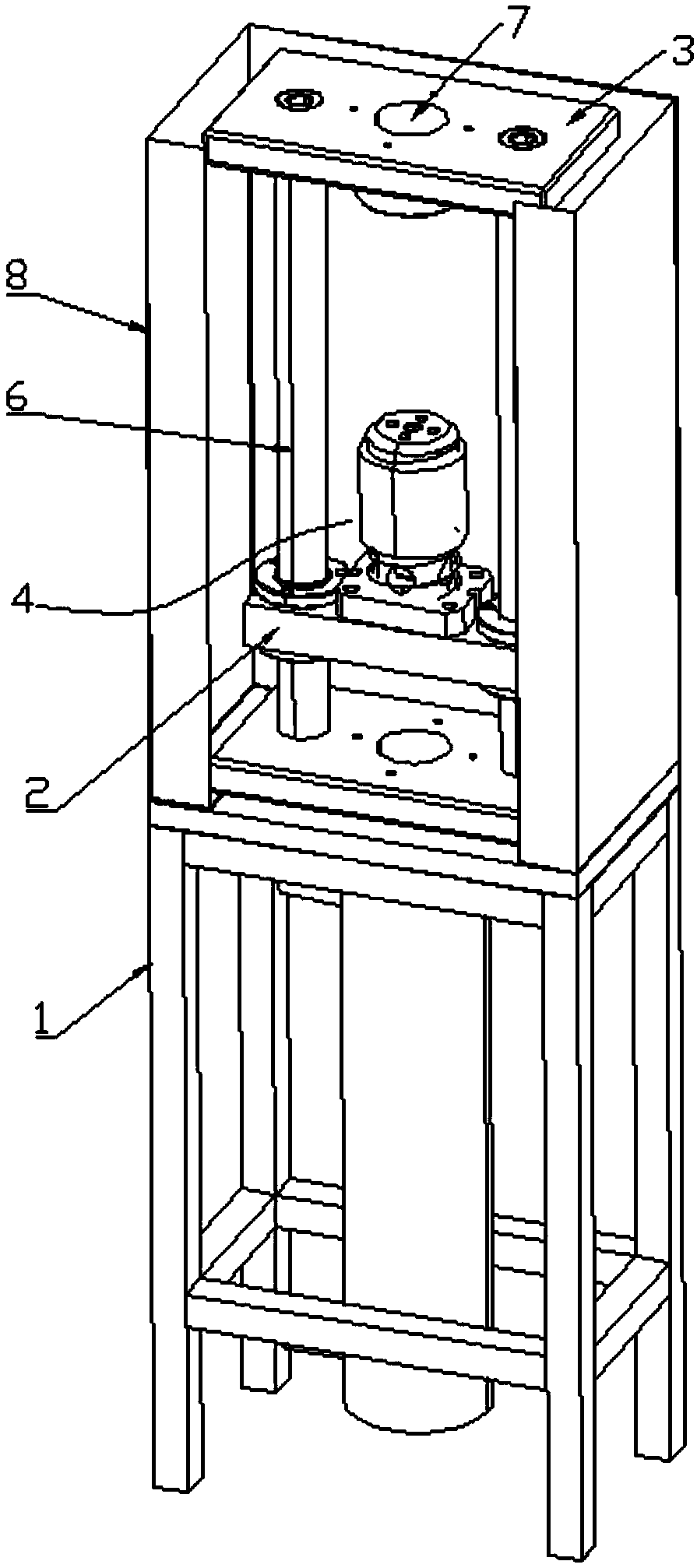

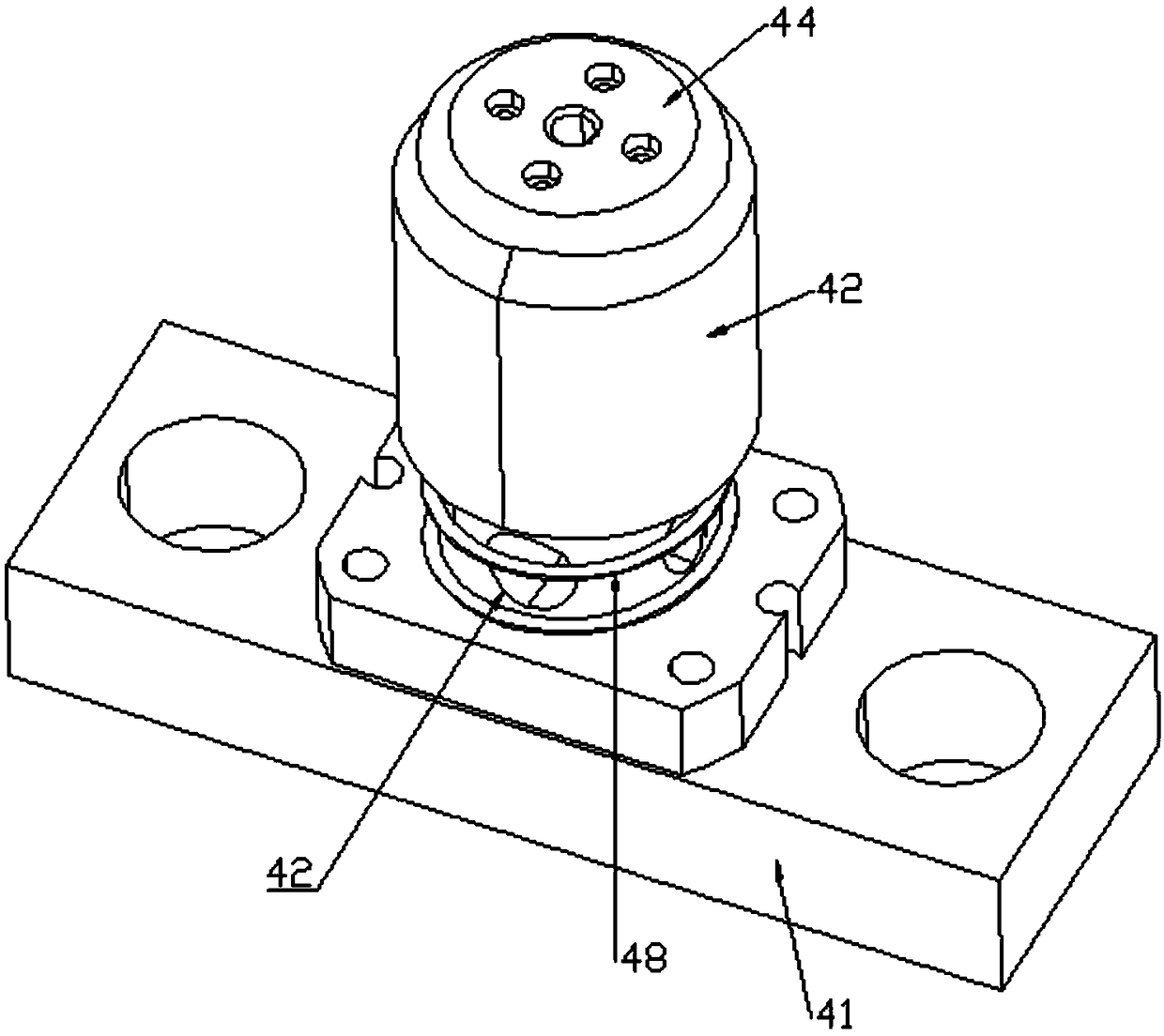

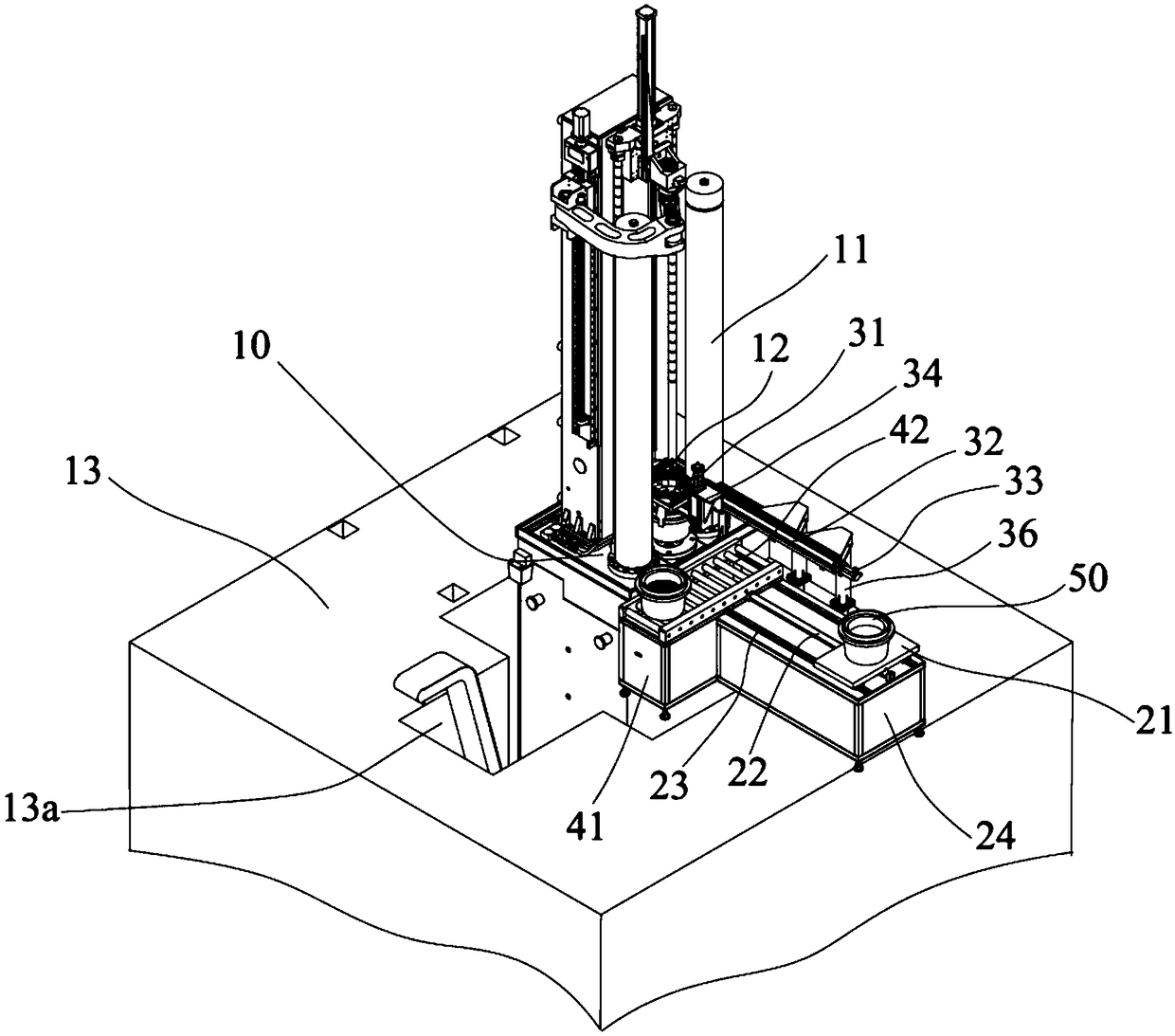

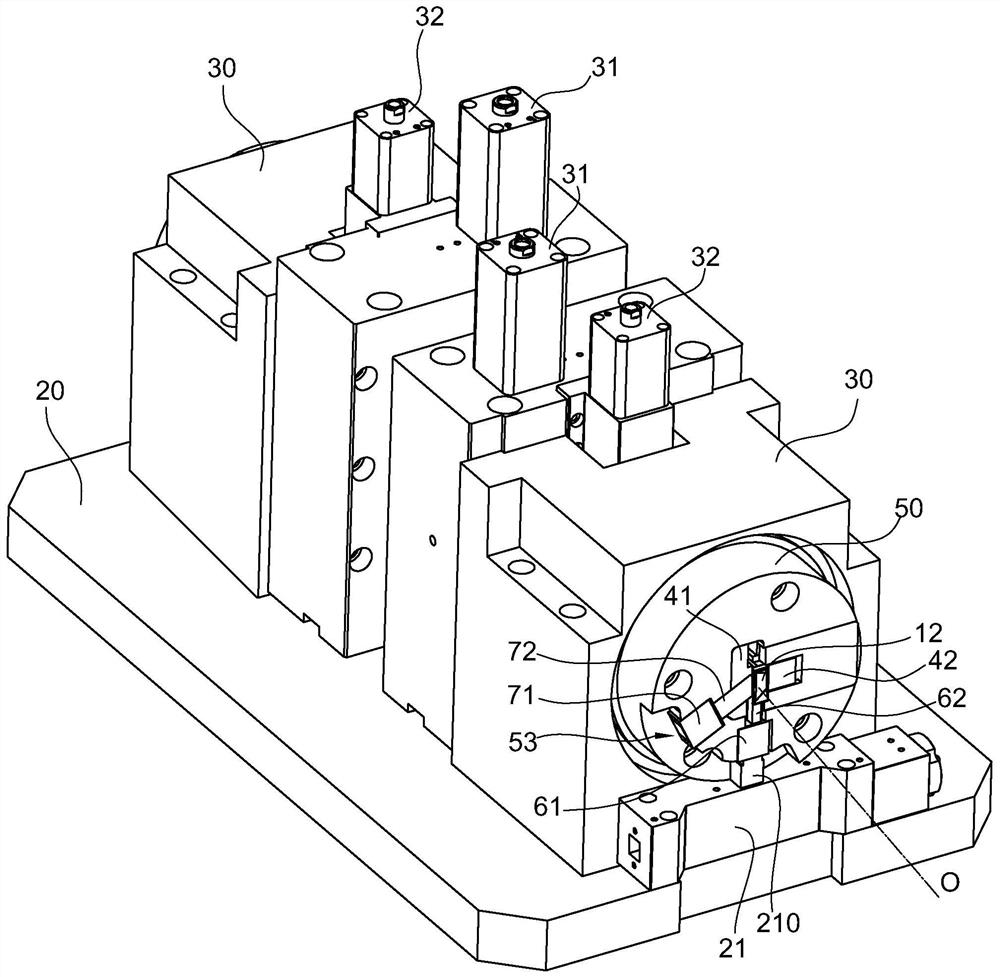

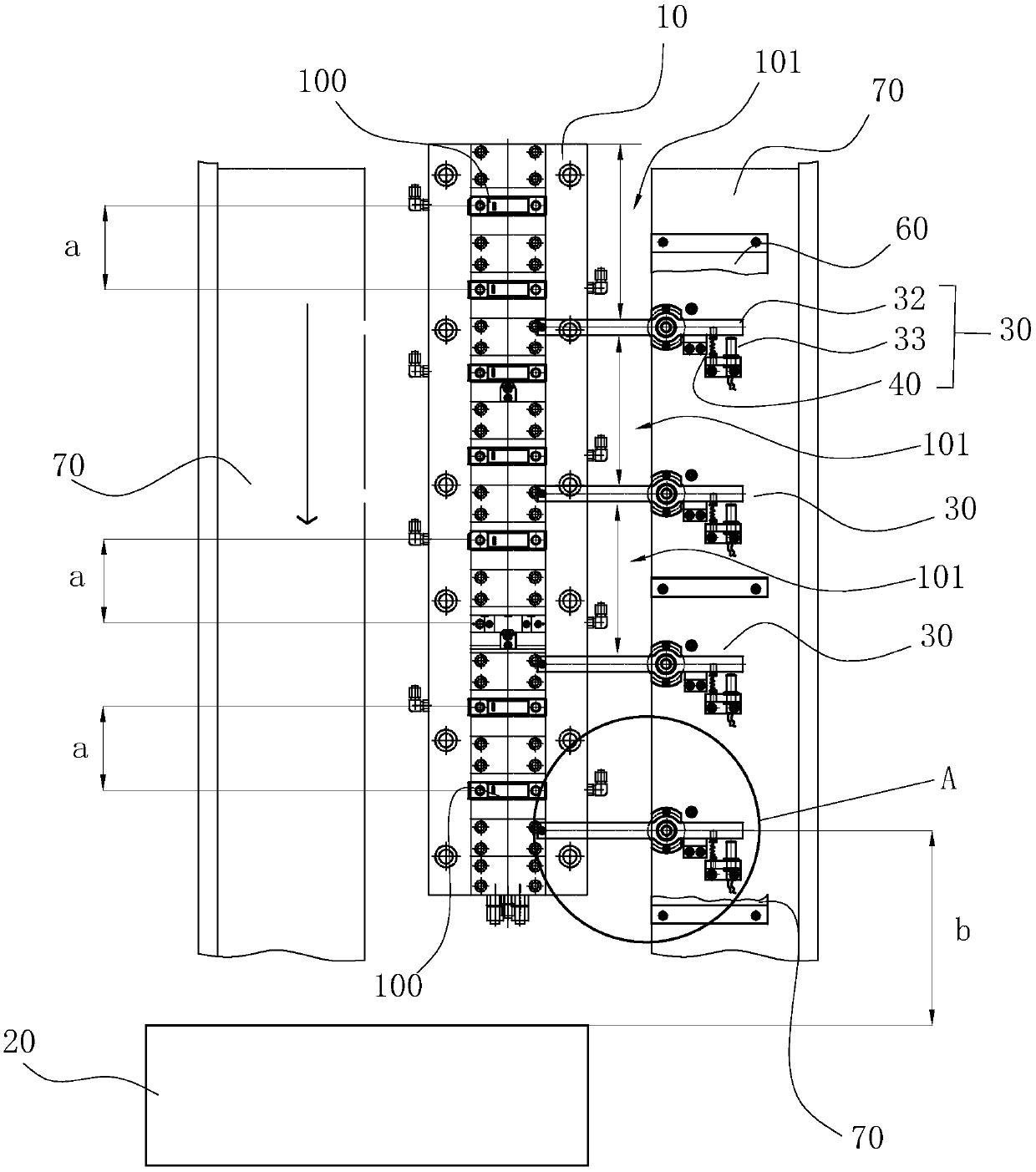

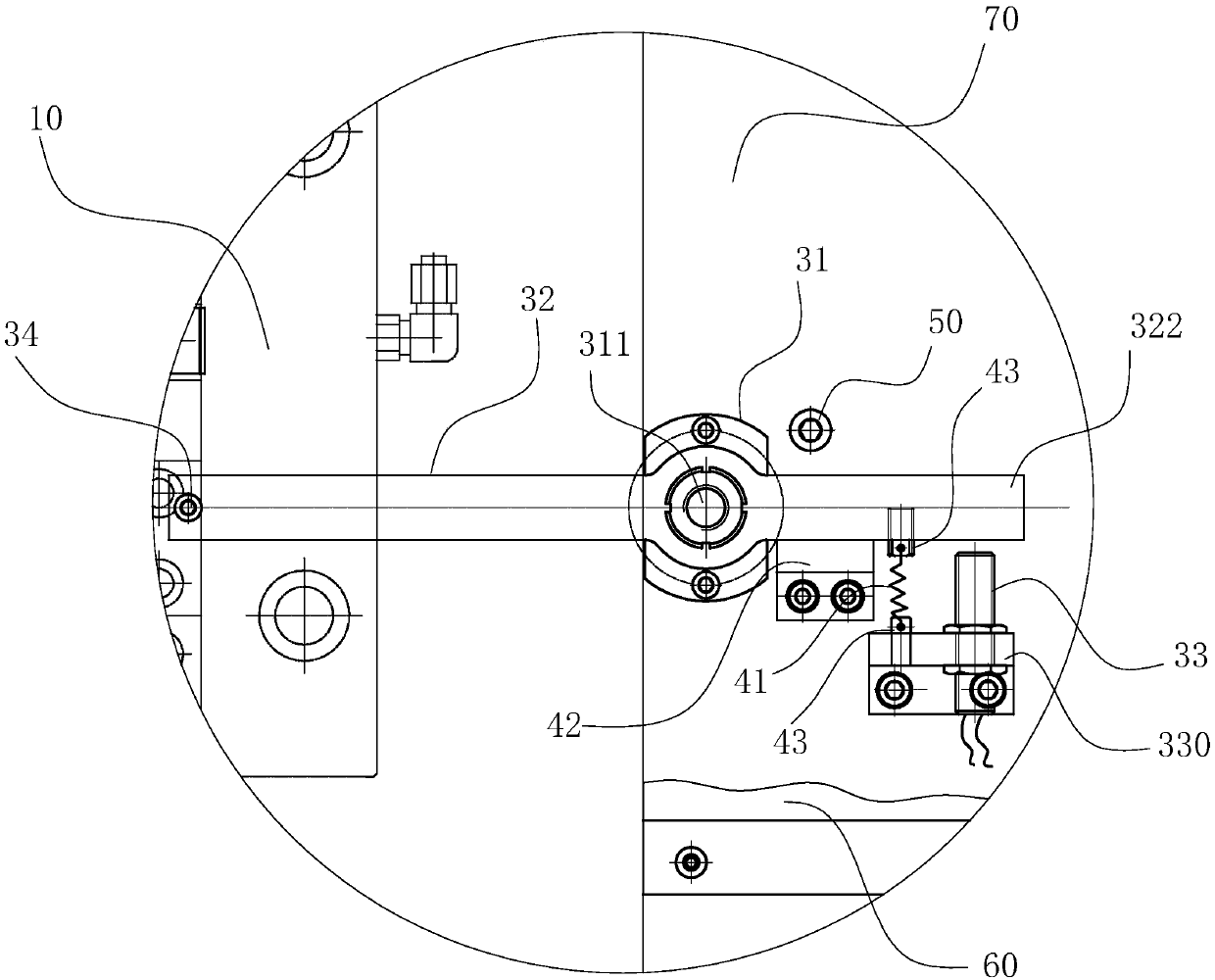

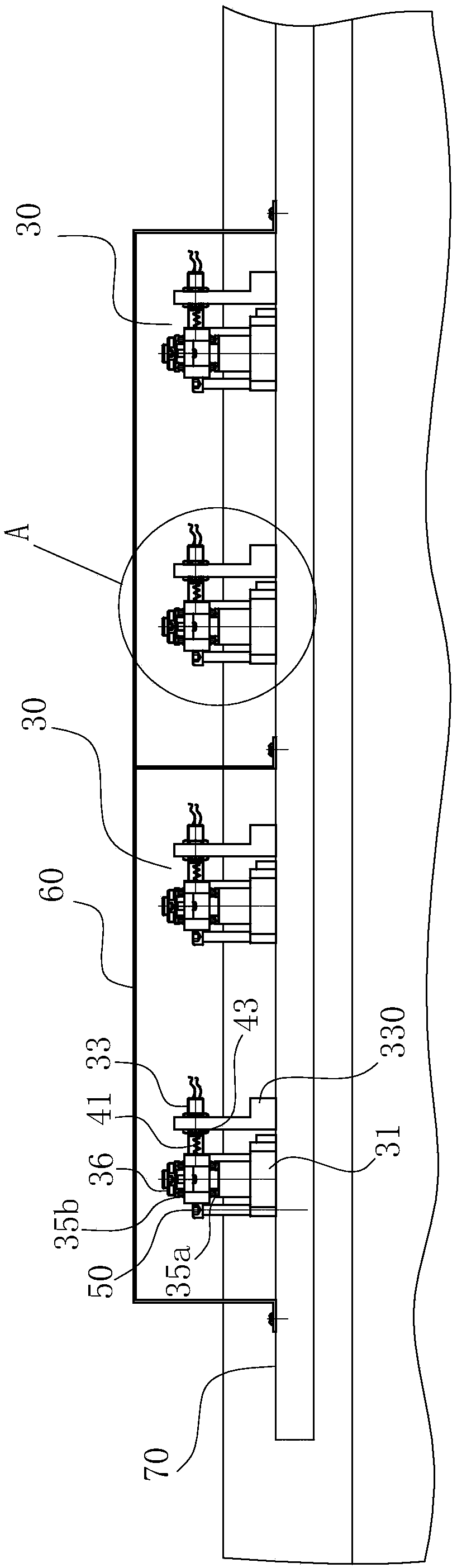

Upward-pulling type broaching machine toolchanger

InactiveCN106903368AReduce labor intensityFully automatedBroaching accessoriesPositioning apparatusEngineeringMachining process

The invention belongs to the technical field of broaching machines and provides an upward-pulling type broaching machine toolchanger. The toolchanger comprises a base, a broaching machine body, a tool lifting and sending assembly, a tool changing assembly and a tool library assembly arranged beside the base, wherein the broaching machine body, the tool lifting and sending assembly and the tool changing assembly are vertically fixed to the base; the tool changing assembly is arranged on the broaching machine body, and the tool lifting and sending assembly and the tool changing assembly are in hung connection. The upward-pulling type broaching machine toolchanger has the advantages that in the upward-pulling type broaching machine toolchanger, the tool lifting and sending assembly is matched with the tool changing assembly and the tool library assembly to move in the X direction, the Y direction and the Z direction, under the control of a numerical control system, automatic broach changing of a broaching machine is achieved, labor intensity of operation staff is lowered, production efficiency is improved, and safety risks existing in the tool changing process is further lowered; automatic tool changing of the broaching machine is achieved, the tool changing speed is high, and accuracy is high; and in an automated production line, a broaching machine process can be embedded into the automated production line, manufacturing automation and intelligence are achieved, and the upward-pulling type broaching machine toolchanger has wide development prospect.

Owner:GANZHOU QUNXING MACHINERY +1

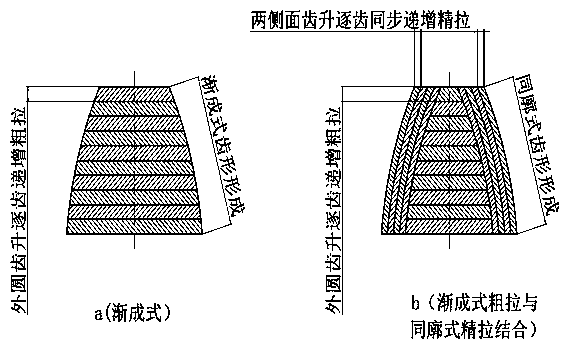

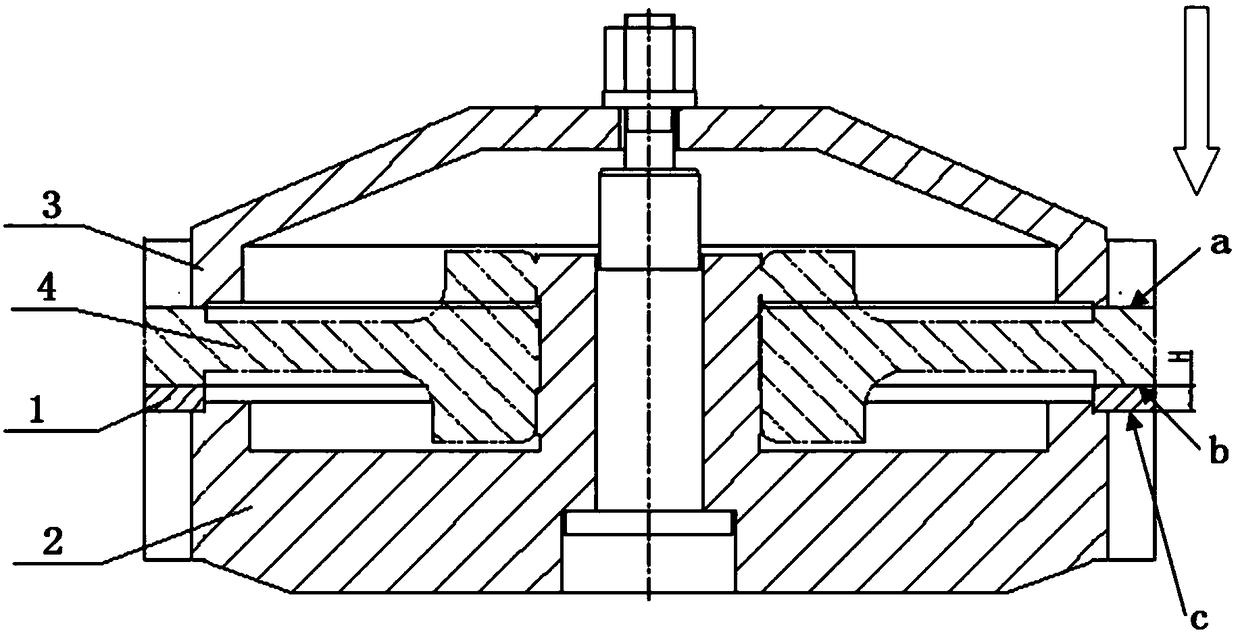

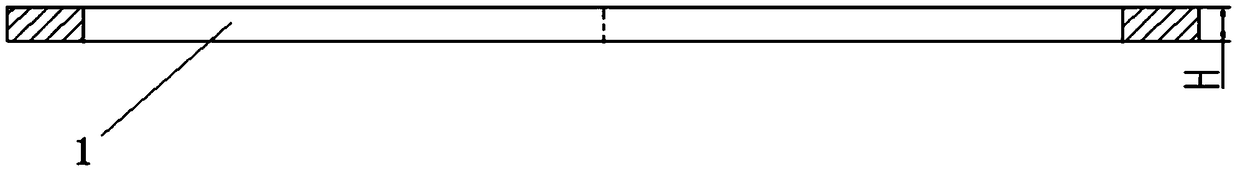

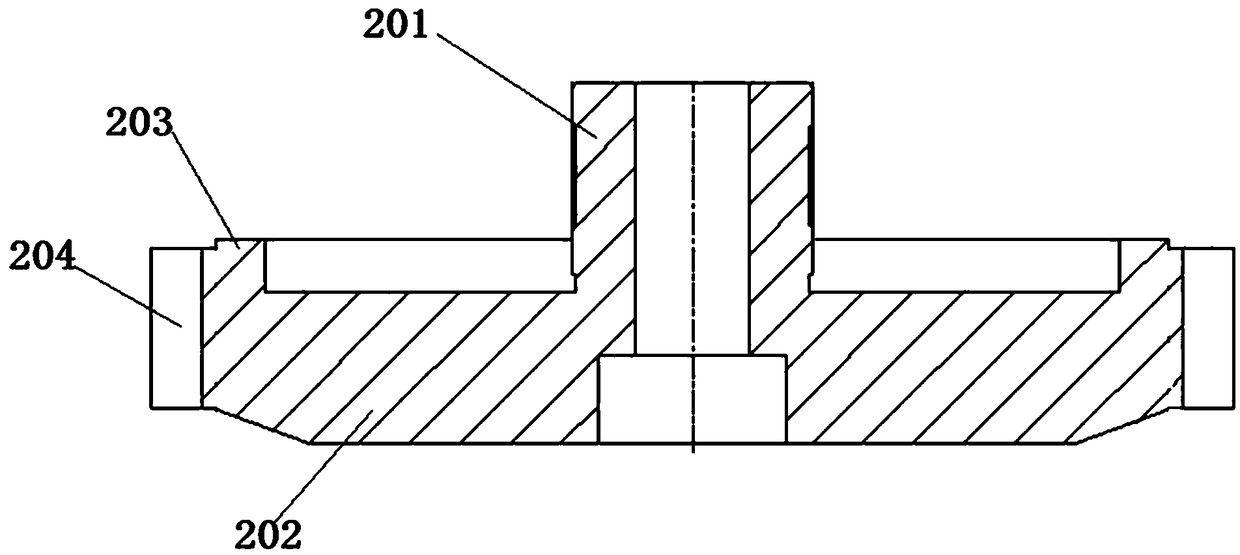

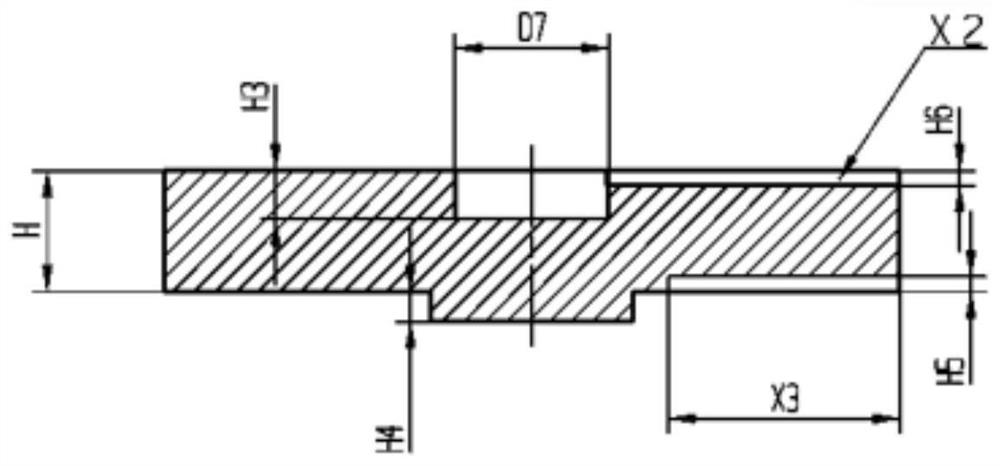

Broaching process method for small-modulus internal gear

The invention provides a broaching process method for a small-modulus internal gear. The broaching process method comprises an ejector rod, a lower chuck, a flange plate, a workpiece, a broach and anupper chuck. The broaching process method is characterized in that the lower chuck is provided with a lower clamping jaw and a limiting key, wherein the flange plate is provided with an anti-skid jaw;the broach is provided with a rough broaching part and a fine broaching part; and the upper chuck is provided with an upper clamping jaw. The broaching process method comprises the steps that firstly, the workpiece is mounted on the anti-skid jaw of the flange plate; secondly, the broach penetrates through the workpiece and the flange plate and then is inserted into the lower chuck; thirdly, thelower clamping jaw is automatically inserted into a clamping groove in the handle part of the broach, and the ejector rod abuts against the end face of a front handle of the broach and clamps the broach together with the limiting key; fourthly, the upper chuck moves downwards and clamps a rear handle of the broach together with the upper clamping jaw; and finally, the workpiece is adjusted to be placed at the front guide position of the broach, and a machine tool workbench is started to move upwards to drive the workpiece to enter the broach for cutting the part.

Owner:EST TOOLS

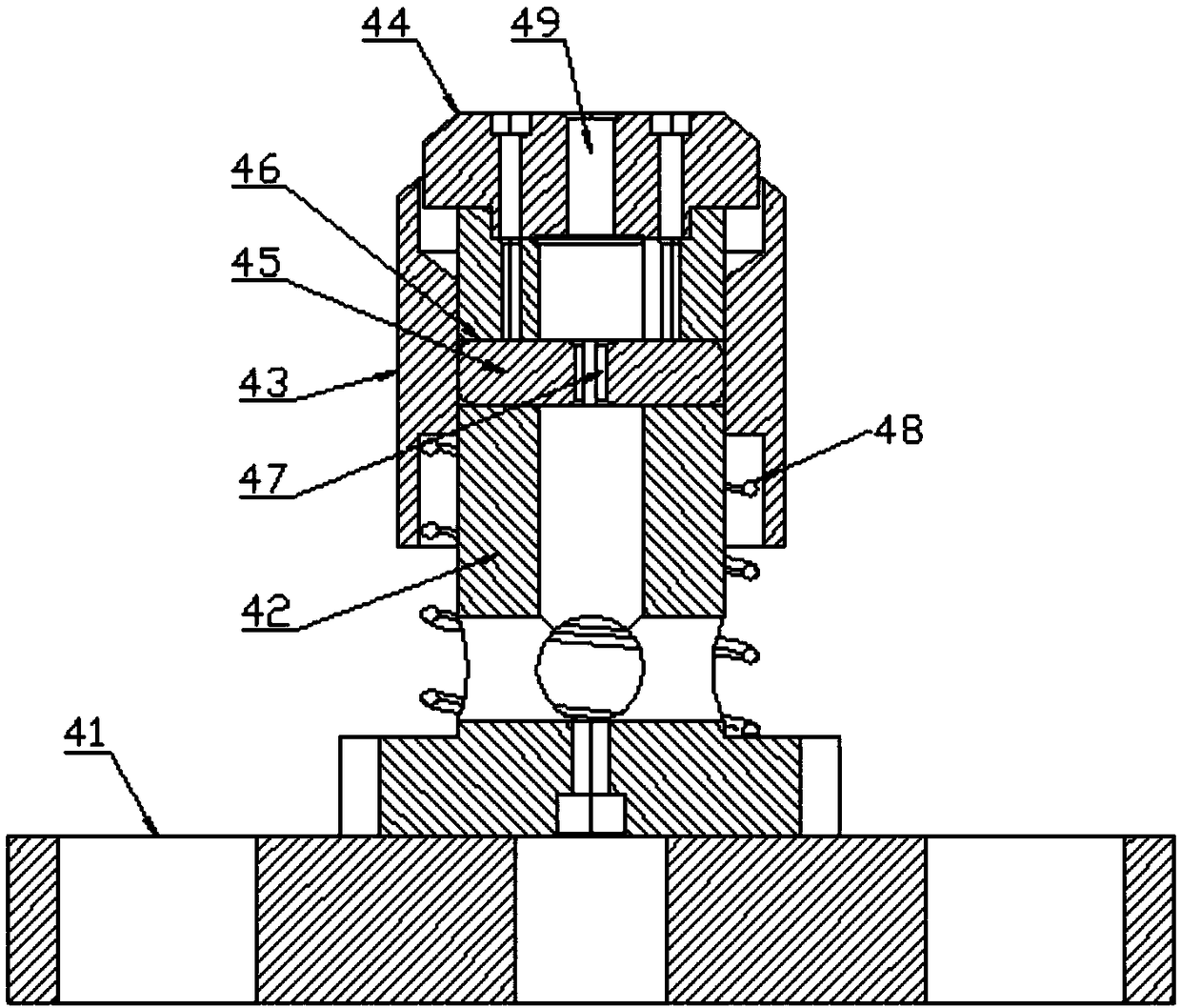

Broach positioning clamping device

PendingCN109352071ASimple structureEasy to operateBroaching accessoriesBroaching machinesEngineeringMechanical engineering

The invention discloses a broach positioning clamping device and relates to the field of machinery. The broach positioning clamping device comprises a worktable, support platforms, guide seats and a clamping assembly. The top of the worktable is provided with two guide pillars. The support platforms are installed on the guide pillars and are separated from the top surface of the worktable by a distance. The guide seats are arranged on the top of the guide pillars and guide holes are arranged on the guide seats. The clamping assembly includes a base, a column, a movable sleeve, a cover and a movable block. The Broach positioning clamping device has simple structure and convenient operation; by moving a movable sleeve up and down, the movable block can be loosened and clamped, and then the broach can be disassembled and assembled; the whole clamping assembly adopts integrated design to simplify the structure; with the help of an elastic assembly, the movable block can slide back and forth in a guide groove by means of the moving up and down of the movable sleeve; and the guide seats can assist workers in putting a broach into the clamping assembly.

Owner:WUHU JINYI MACHINERY

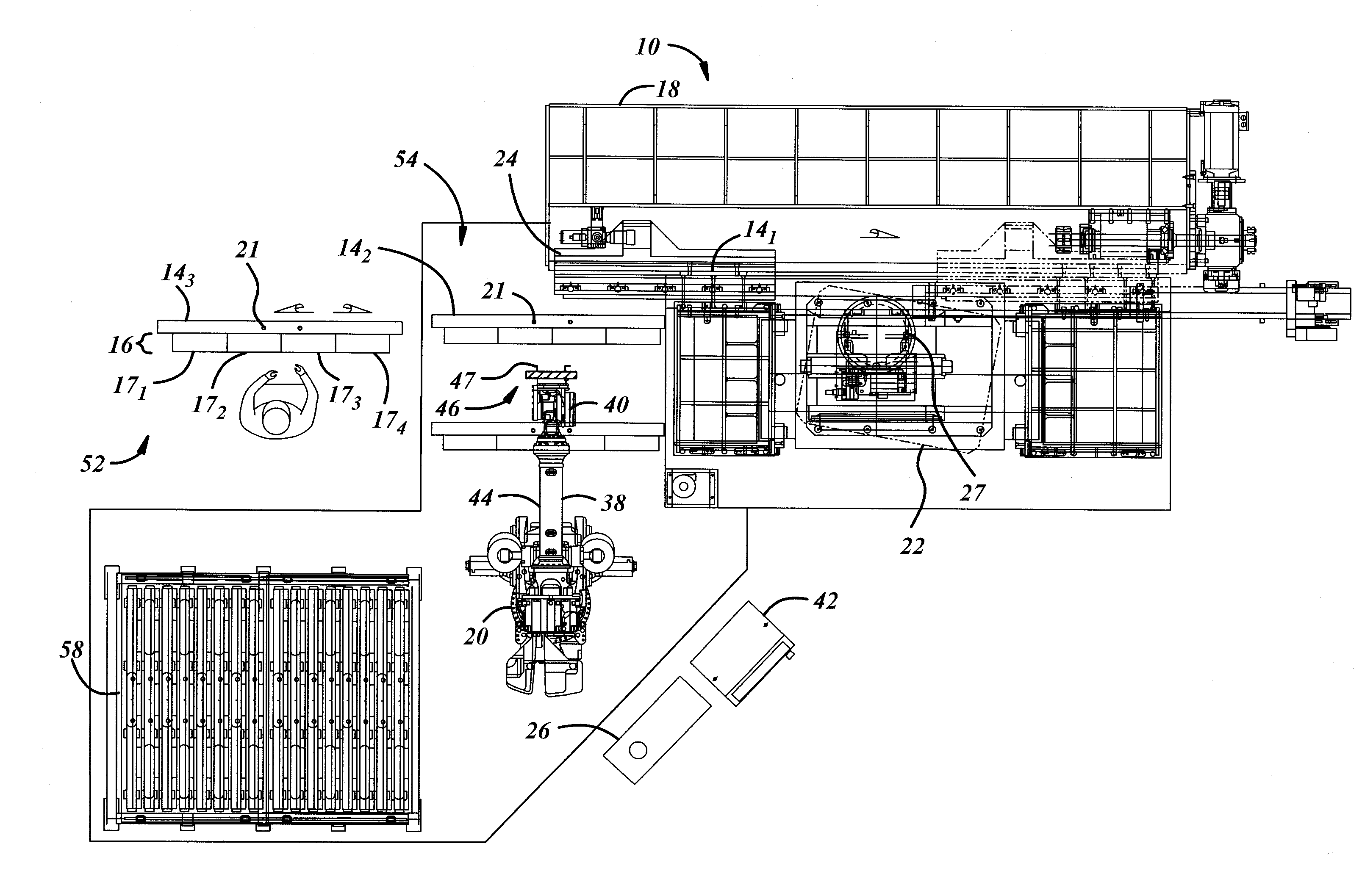

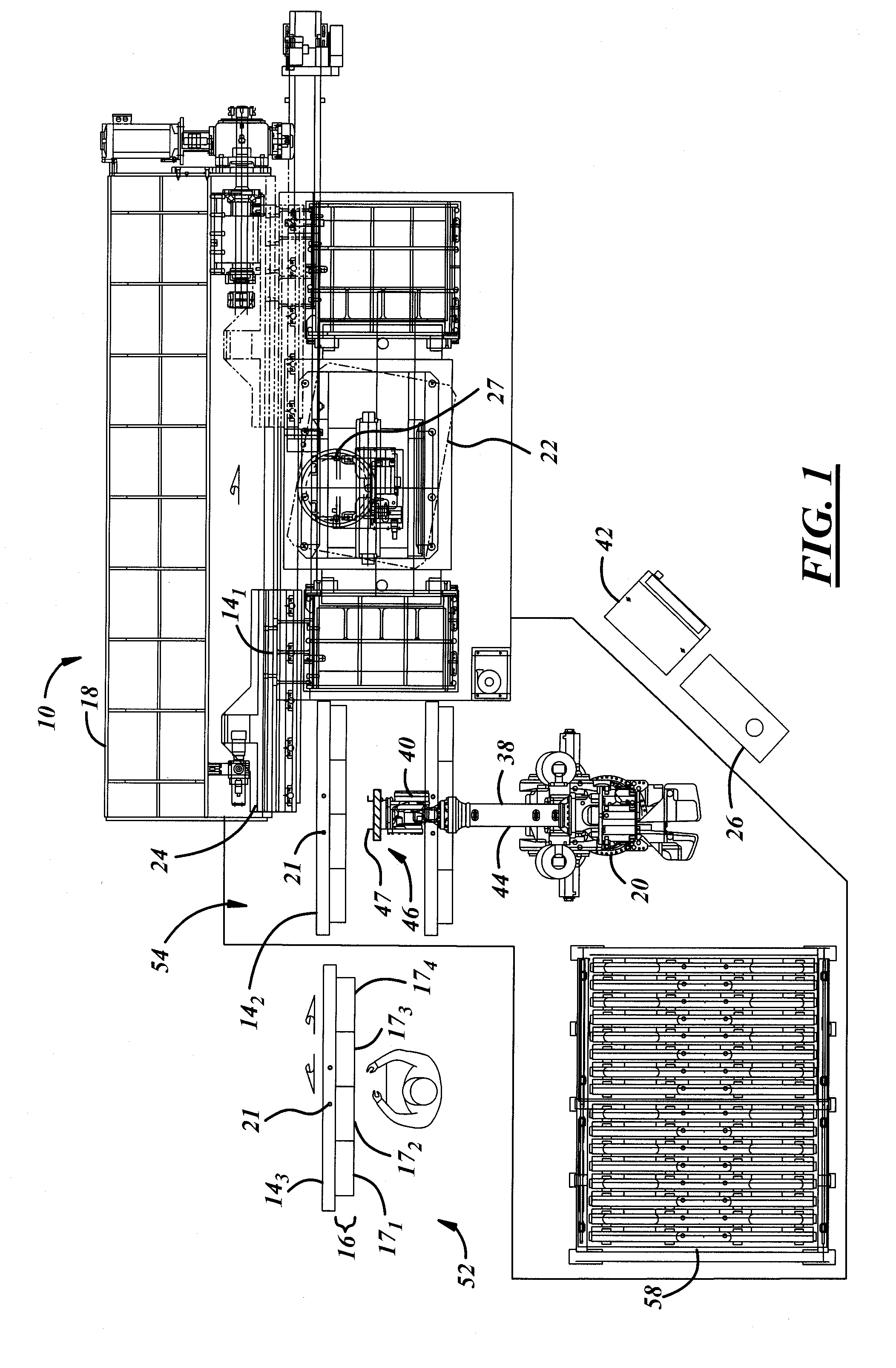

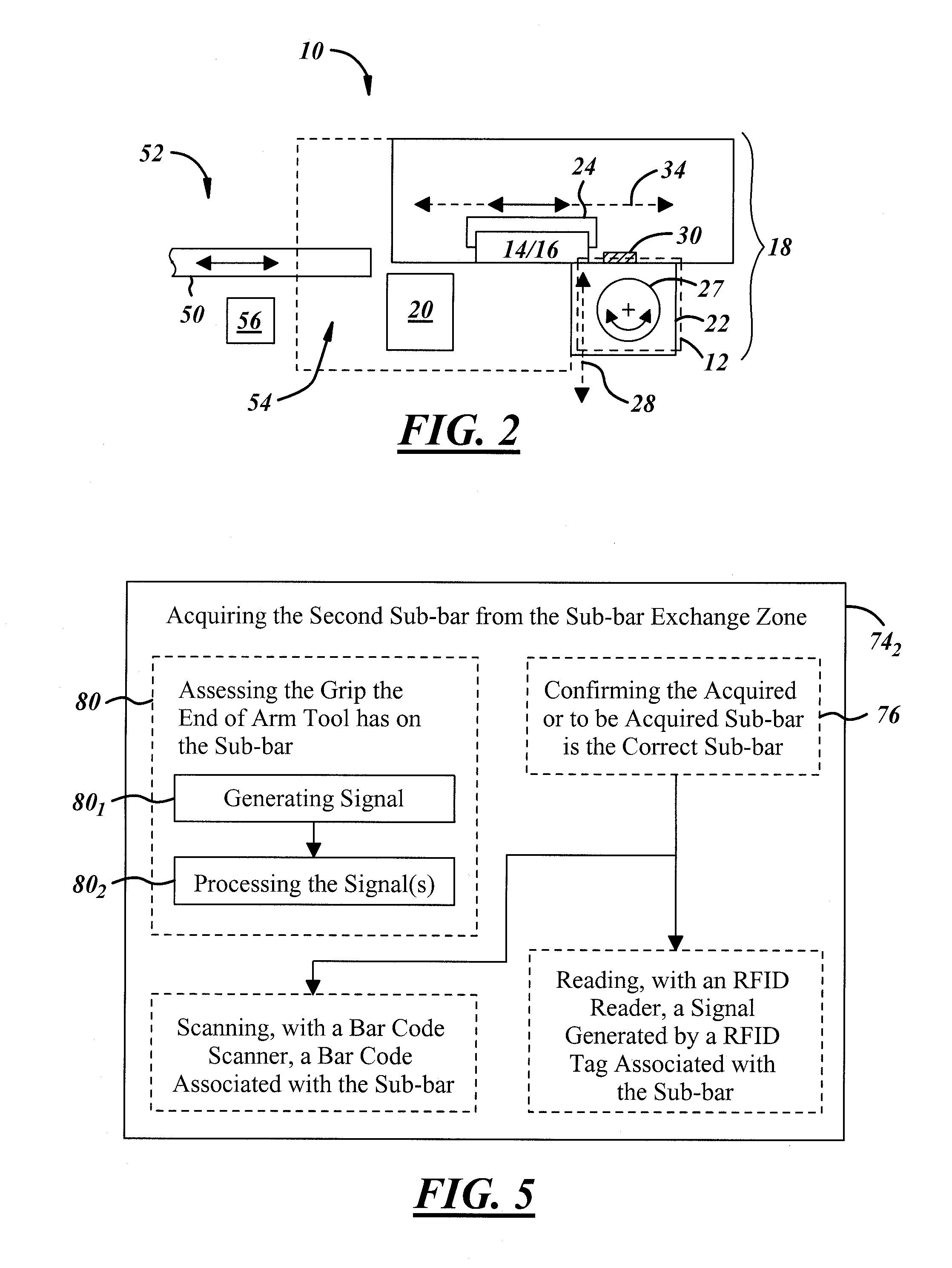

System and method for broaching a workpiece

A broaching system comprises a plurality of sub-bars configured to receive broaching tools. The system further comprises a broaching machine and a robot, the robot being configured to mount and remove sub-bars from the broaching machine. The robot includes an arm operable in three or more axes, and an end of arm tool. A method of broaching comprises providing a plurality of sub-bars, a broaching machine, and a robot having an arm operable in three or more axes and an end of arm tool. The method further includes mounting, by the robot, a sub-bar onto the broaching machine; and performing a broaching operation using the sub-bar. Simultaneous to the performance of the broaching operation, the method includes affixing another tool to another sub-bar, and / or moving, by the robot, another sub-bar to a storage location.

Owner:FEDERAL BROACH HLDG

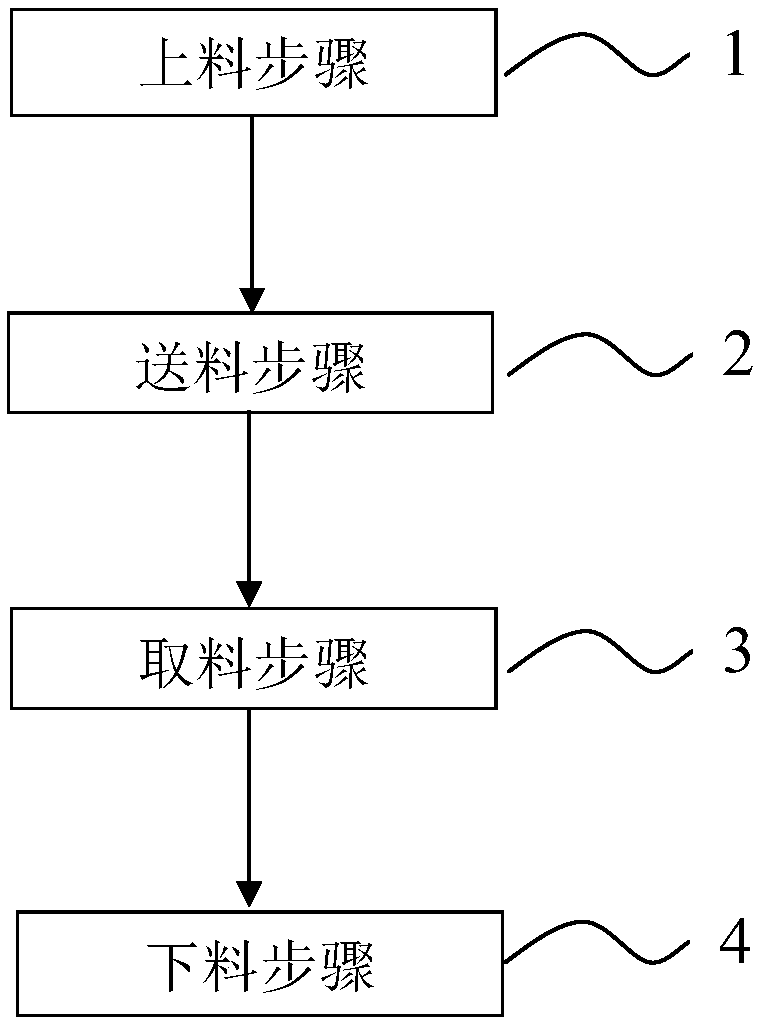

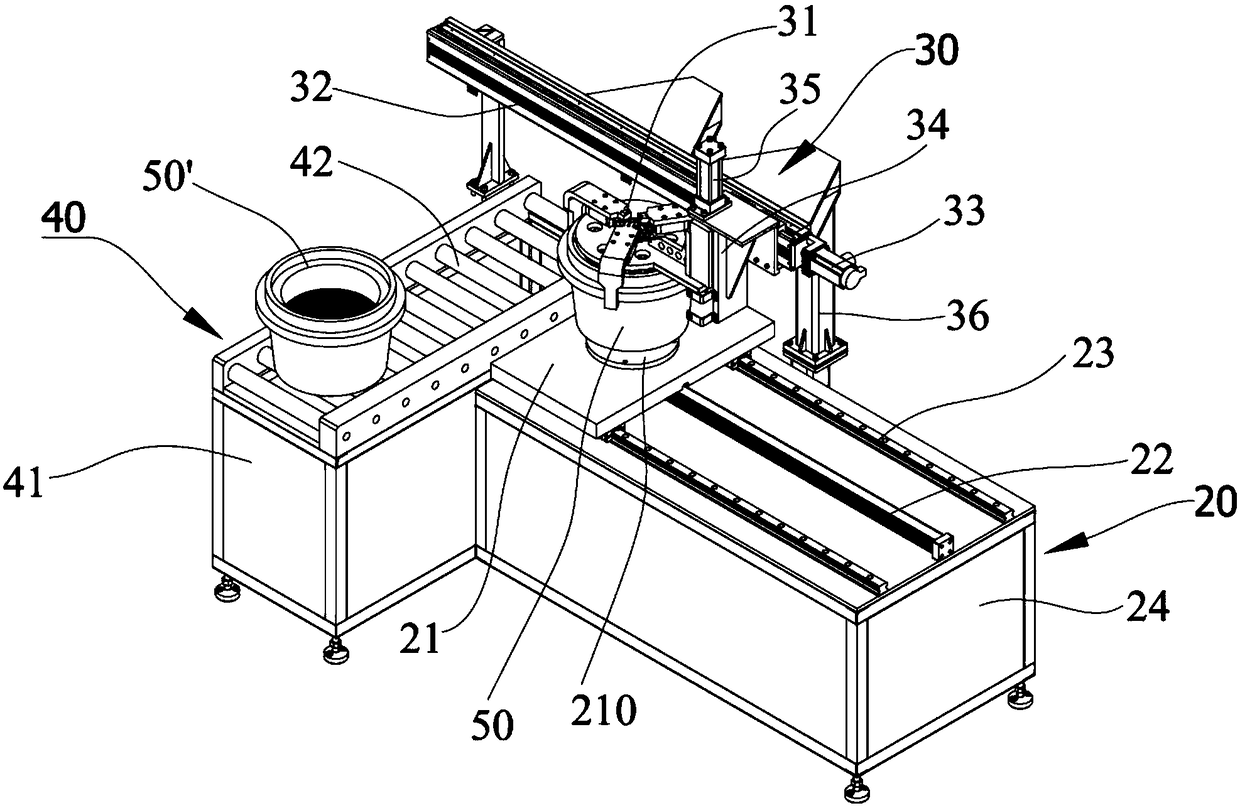

Loading and unloading control method for broaching machine

InactiveCN109202168AEasy to useReduce labor intensityBroaching accessoriesEngineeringUltimate tensile strength

An embodiment of the present invention provides a loading and unloading control method for a broaching machine. The control method comprises a loading step, in which a loading mechanism slidingly transports a workpiece to be processed from a loading position to a delivery position; conveying step, in which a claw mechanism grabs and slides the workpiece to be processed from the delivery position to a processing position; a picking step, in which the claw mechanism grabs and slides the processed workpiece from the processing position to one end of a unloading mechanism away from an unloading position; and an unloading step, in which an unloading mechanism transports the processed workpiece to the unloading position. According to the loading and unloading control method of the broaching machine, the loading and unloading mechanisms of the broaching machine are controlled to transport a workpiece to be processed from the loading position to the processing position, and then to the unloading position after the workpiece is processed, thereby greatly reducing labor intensity and improving production safety.

Owner:CHANGSHA SISHENG INTELLIGENT EQUIP

Automatic backlash-eliminating scale-dividing device used for numeral control helical deep hole broacher

InactiveCN101716736ALow costImprove securityPrecision positioning equipmentBroaching accessoriesDrive wheelGrating

The invention belongs to the technical field of broacher devices, in particular to an automatic backlash-eliminating dividing device used for a numeral control helical deep hole broacher. The device comprises a box body, an alternating current servo motor, an input-output mechanism, and a circular grating detection mechanism. In the device, scale division is controlled directly through the alternating current servo motor; and through pushing a driving axle to glide axially by an adjusting washer and a disc spring, the driving axle and a double-tooth backlash-eliminating mechanism consisting of driven wheels can automatically compensate to eliminate backlashes after a gear is worn. The driving device of the invention has the advantages of low cost and maintenance cost, high safety, and good reliability.

Owner:MIANYANG WEIBO ELECTRONICS

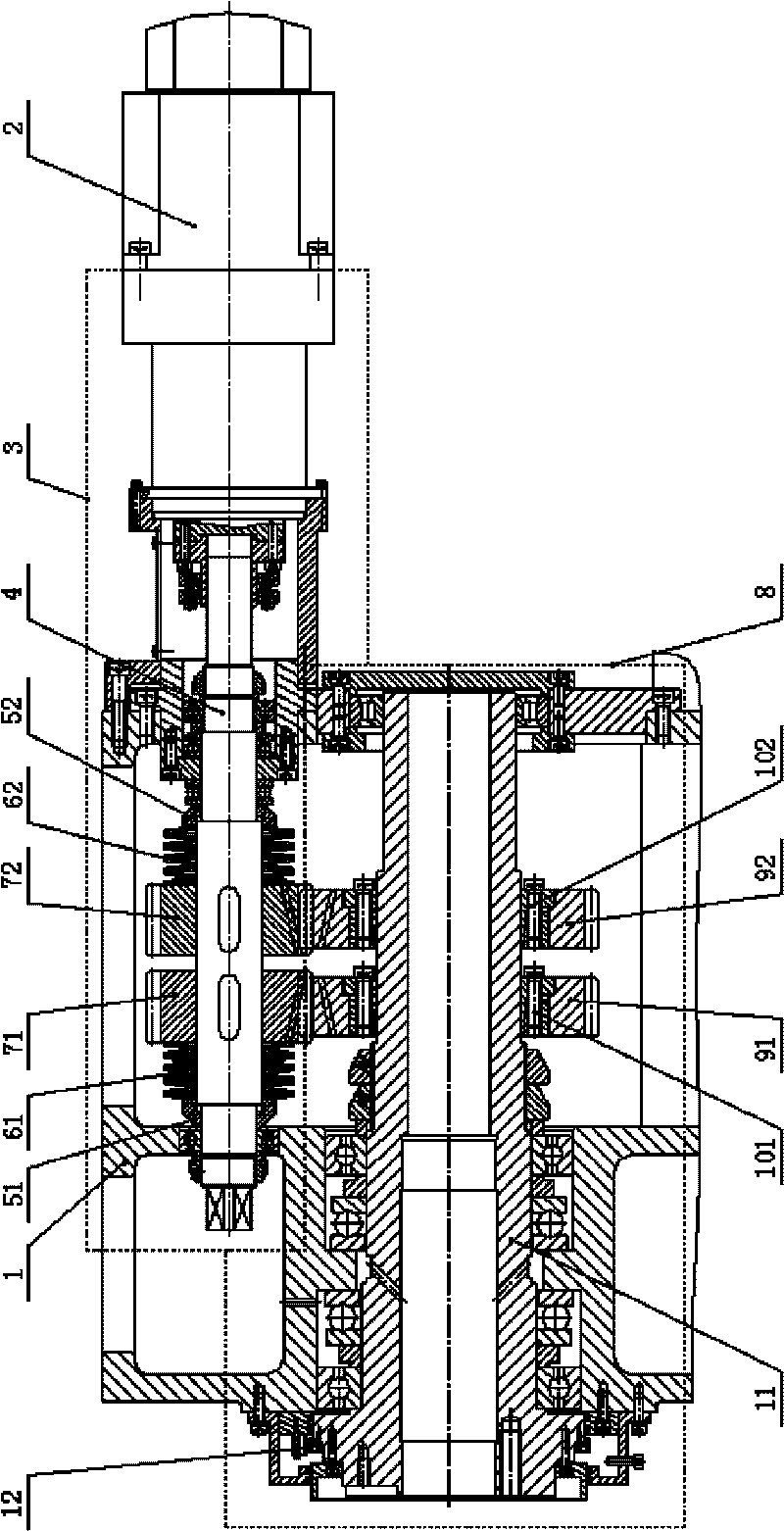

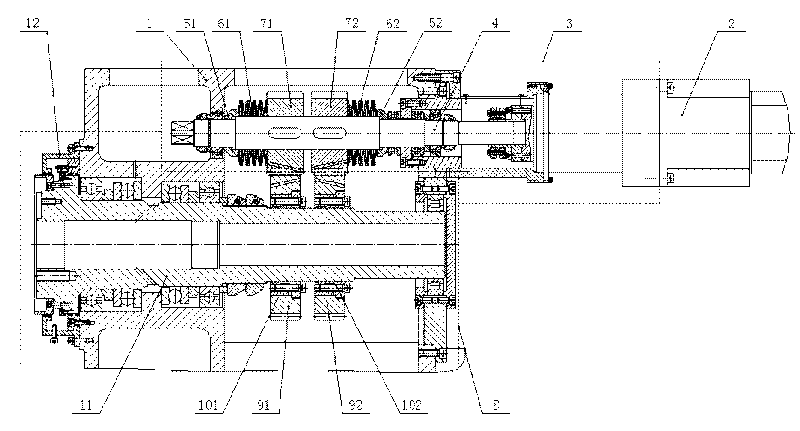

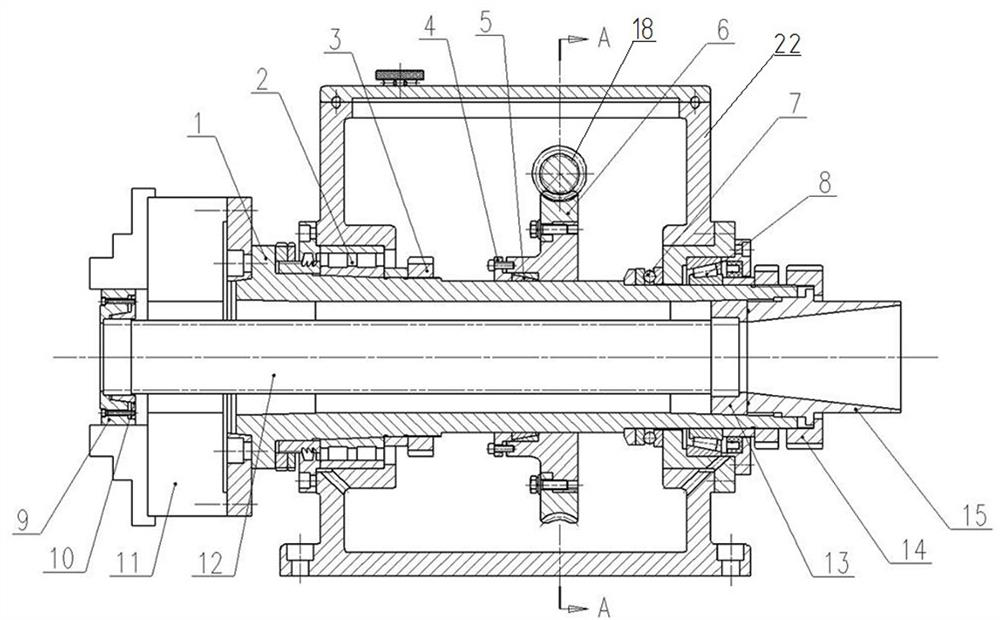

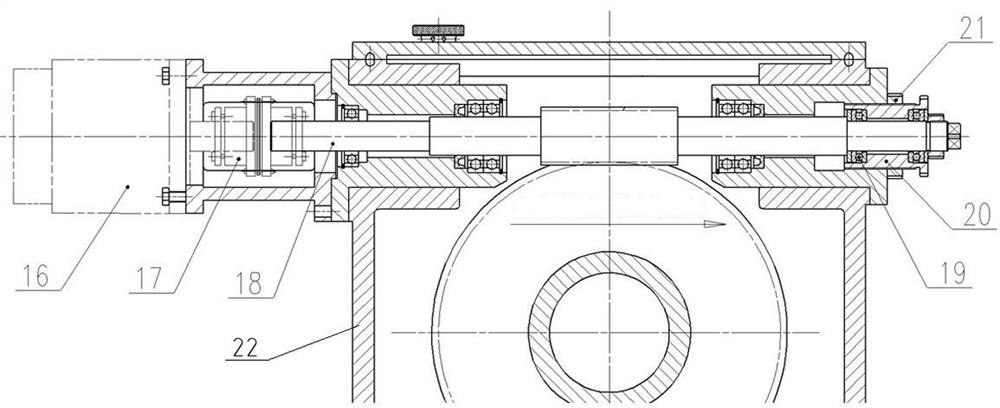

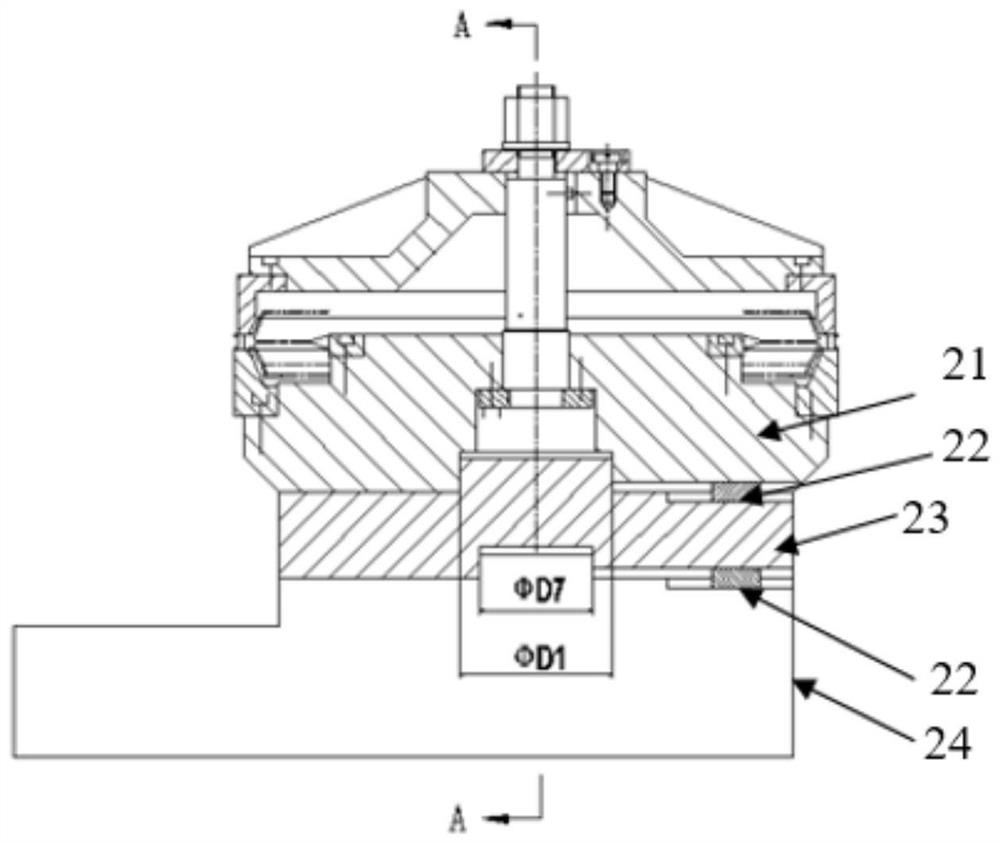

Clamping and rotating device for thin-wall workpiece

ActiveCN112024979AAvoid deformationHigh positioning accuracyBroaching accessoriesBroaching machinesNumerical controlRotation - action

The invention relates to machining equipment, in particular to a clamping and rotating device for a thin-wall workpiece. The clamping and rotating device comprises a main shaft with an axial central through hole, a transmission case, a double-lead worm mechanism and a chuck, wherein the main shaft is transversely arranged on the transmission case in a penetrating mode, the main shaft is clamped and driven to rotate by the double-lead worm mechanism, the double-lead worm mechanism is arranged inside the transmission case, and the chuck is arranged on the front end surface of the main shaft; andthe workpiece is arranged inside the main shaft in a penetrating mode, the front end of the workpiece is clamped by the chuck, and the rear end of the workpiece is clamped in the central through holeof the main shaft. The gun barrel workpiece is arranged inside the main shaft hole, and the axis of a gun barrel and the main shaft of the device rotate strictly, coaxially and synchronously throughreliable clamping of the front end and the rear end; and control over high-precision rotating motion of the main shaft is achieved through the double-lead worm and worm gear mechanism, so that numerical control rotating motion according to the rifling winding angle and indexing motion for machining another group of rifling in the wire drawing process are achieved.

Owner:德州普利森机床有限公司

Broaching machine

The invention provides a broaching machine, and particularly relates to the field of broaching machine equipment. The broaching machine comprises a machine bed and a piston pull rod arranged on the machine bed, wherein the piston pull rod is fixedly connected with a follow-up broach rest for clamping a broach, and the front end of the follow-up broach rest is further provided with a cleaning cabin; and the two ends of the cleaning cabin are provided with a broach inlet and a broach outlet for allowing the broach to penetrate through, a clamp fixing pin is arranged on one end face of the broachinlet of the cleaning cabin, and a ring brush device, a water spraying device and an air spraying device are sequentially arranged inside the cleaning cabin. The cleaning cabin deeply cleans the broach which finishes working, so that impurities and scrap iron on the broach are thoroughly removed, manpower and material resources for manual removal are saved, and the production efficiency and the product quality are also improved.

Owner:重庆秋虎机械制造有限公司

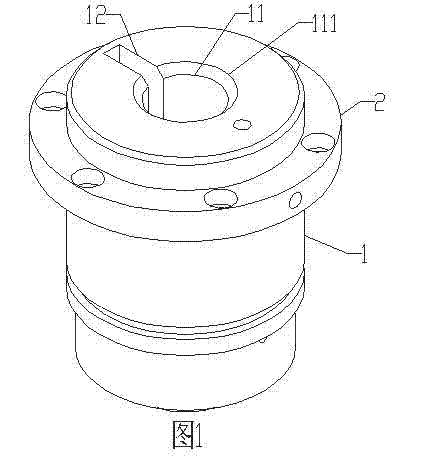

Guide jacket of broacher

The invention discloses a guide jacket of a broacher. The guide jacket of the broacher comprises a sleeve and a fixed flange which are integrated. The sleeve is provided with a guide hole, a broacher tooth through groove and one or more guide slots, threaded holes are reserved at the lower end of the sleeve, and two ends of the guide hole are provided with chamfers. The guide jacket of the broacher has the advantages of simple structure, low production cost, capabilities of effectively positioning and protecting the broacher, and the like.

Owner:JIANGSU CHUNLAN MACHINERY MFG

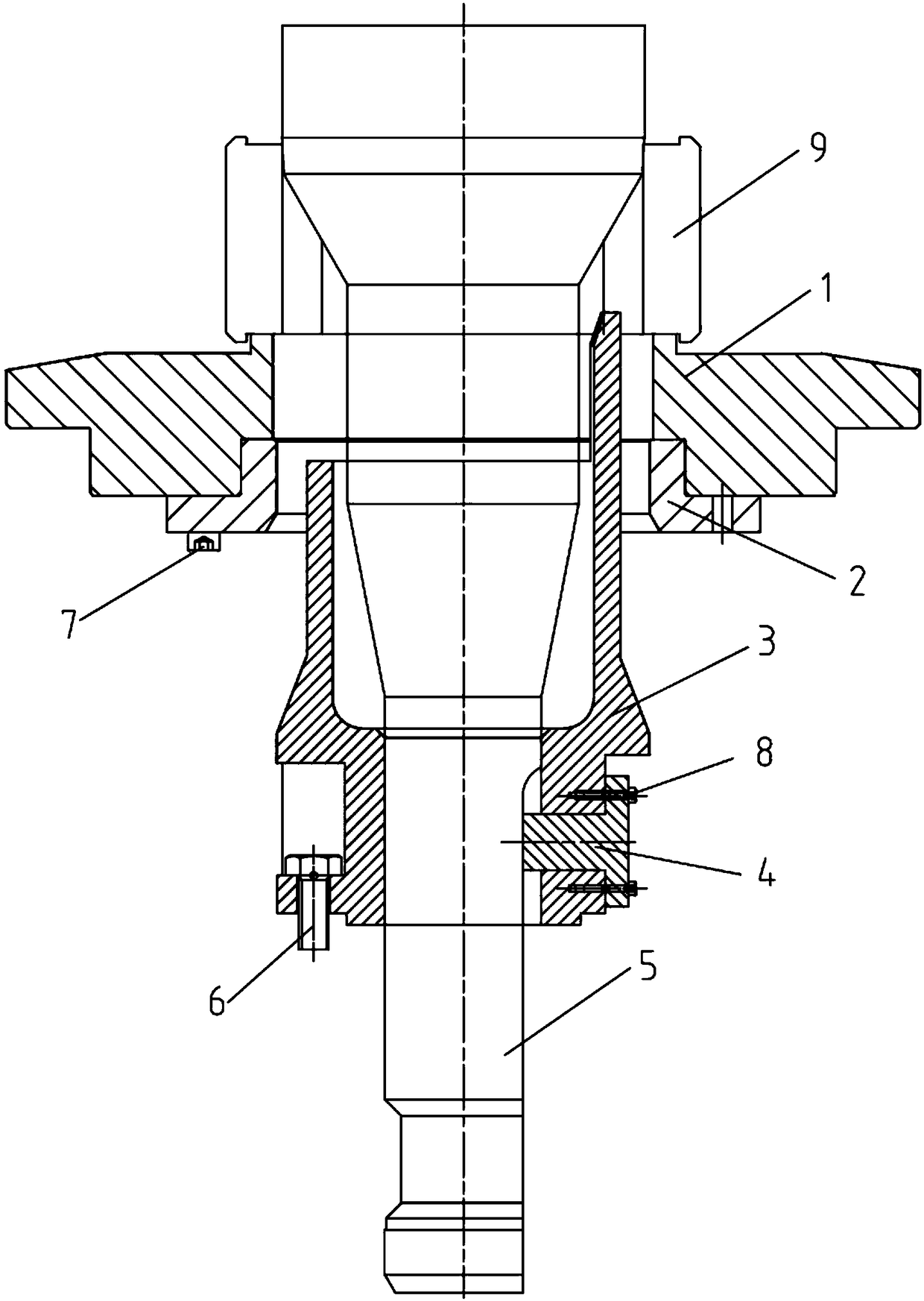

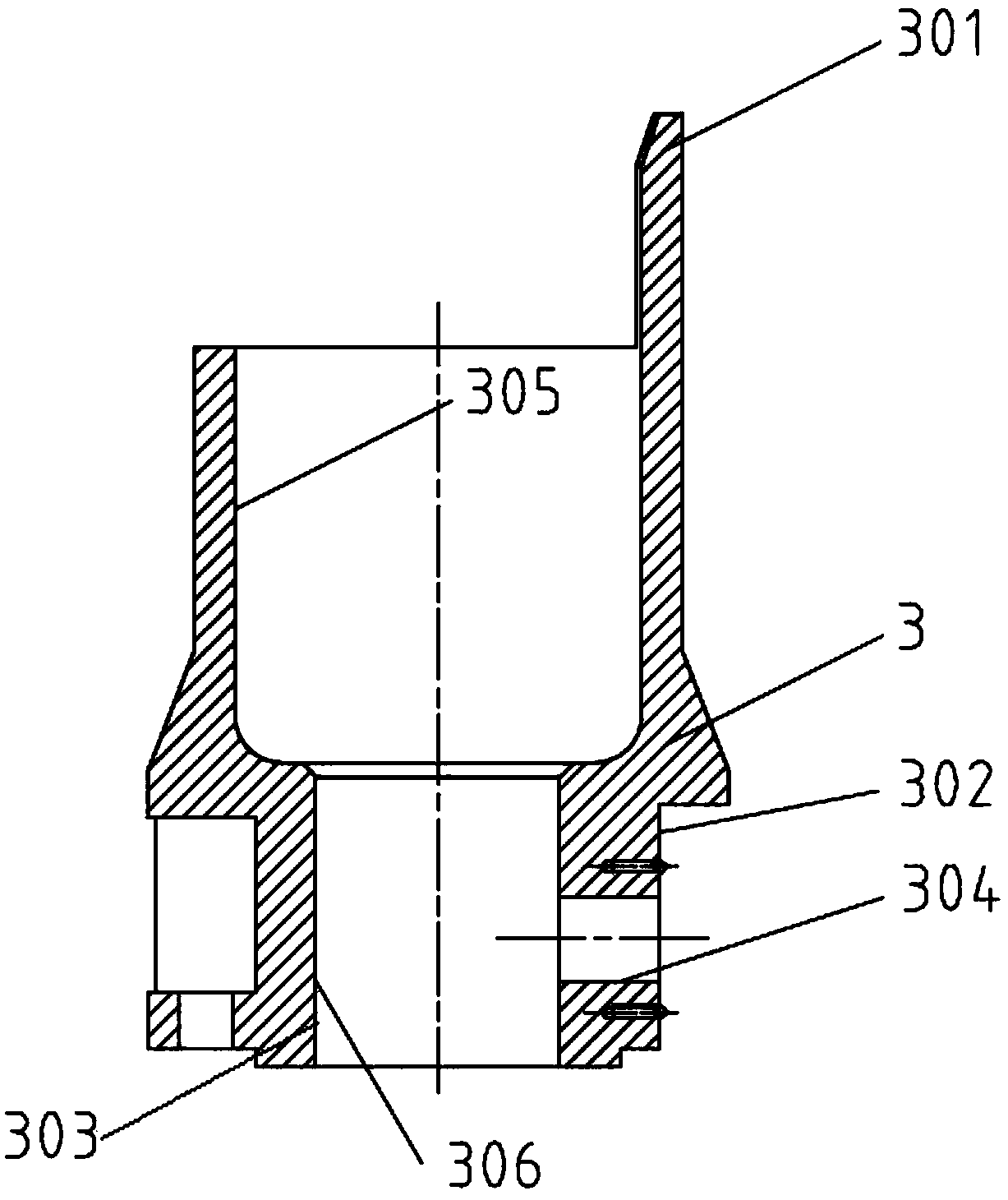

Device for converting two types of spindle tapered bores of machine tool

InactiveCN101786239AMeet needsRealize automatic clampingBroaching accessoriesPositioning apparatusEngineeringMachine tool

A device for converting two types of spindle tapered bores of a machine tool, as a milling head, is arranged in the head part of the machine tool with a spindle tapered bore in the type of ISO60 and is further embedded with a guidance key of the primary spindle tapered bore. The device for converting two types of spindle tapered bores of a machine tool is characterized by a broach mechanism of an ISO50 tapered bore: a tapered handle is combined with an upper tapered handle up and down to form a conical shell; a pop-rivet is arranged on the dome of the first large outer diameter of a claw spindle which is arranged around the circle, the small inner diameter of a slide sleeve is arranged outside the small outer diameter of the pop-rivet, the small inner diameter at the upper section of a claw is blocked at the dome of the second large outer diameter of the claw spindle, a spring is arranged in an arc groove located on the outer wall of the claw, and a spring set is arranged along the outer edge and the lower part of the slide sleeve; a slide rod and a hook are arranged on the later side of the large-diameter platform of the tapered handle, and an elastically cylindrical pin is arranged inside a key which is combined with the transmission key of the spindle; the pop-rivet of an ISO50 cutter is clamped inside the tapered handle by the claw spindle to form a pop-rivet claw. The device enables one machine tool to use two types of cutters, realizes automatic dismounting and clamping and automatic cutter switching, and has an inner-cooling interface, high automation and high efficiency, thereby reducing the cost and better meeting the requirement of customers.

Owner:ZHONGJIE MACHINE TOOL

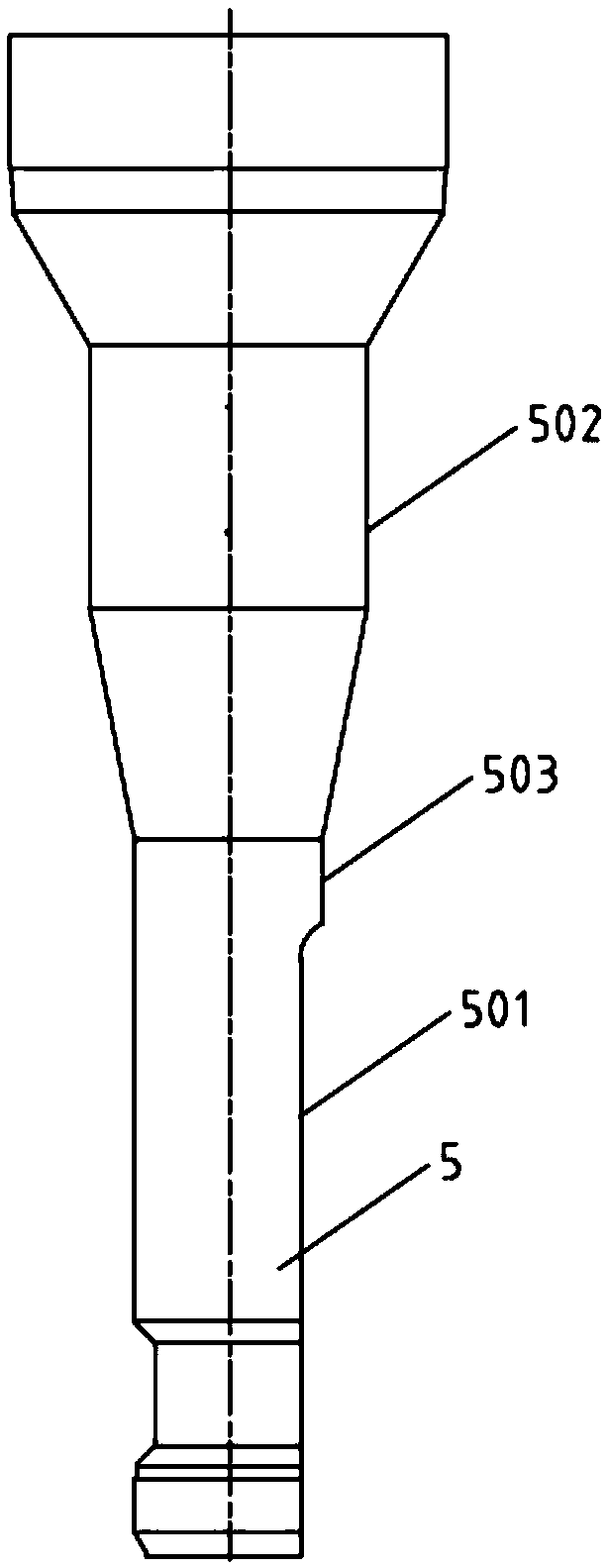

High-amplitude vibration amplitude variable rod for ultrasonic high-speed vibration auxiliary processing

ActiveCN109013259AAvoid damageGuaranteed disengagementBroaching accessoriesMechanical vibrations separationPhysicsHigh amplitude

The invention discloses a high-amplitude vibration amplitude variable rod for ultrasonic high-speed vibration auxiliary processing. The high-amplitude vibration amplitude variable rod is a whole pieceand includes a main body rod and a plurality of amplitude variable rod bodies, the main body rod is a diameter variable rod arranged in the length direction of a tool workbench, the amplitude variable rod bodies are the amplitude variable rod bodies with the rod diameter reducing from the tool workbench to a cutter pulling cutter box, and the bottom end of each amplitude variable rod body is connected to the variable diameter position of the main body rod. When used, the energy can be concentrated on a smaller area because the rod diameter of each amplitude variable rod body reduces from thevibration penetrating-in end to the transferring-out end, the vibration is amplified and transmitted to the cutter pulling cutter box and a pulling cutter, the high vibration speed is achieved, high vibration speed requirements when a turbine disk tenon groove is processed are met, and the surface quality is improved; and the amplitude is enlarged, the fact that cutter teeth are completely separated from a workpiece within a vibration frequency cycle, the possibility of a tool hitting the workpiece when the tool is returned from a non-cut-off material is avoided, the machining efficiency can be improved, the damage caused by the interference to the tool can be reduced, and the service life of the tool is prolonged.

Owner:CENT SOUTH UNIV

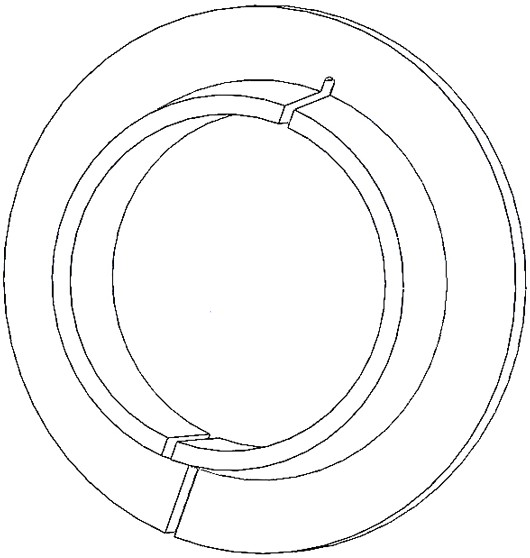

Burr removal device for mortise outlet

ActiveCN109454290AExtended service lifeReduce depthBroaching accessoriesEngineeringLattice deformation

The invention provides a burr removal device for a mortise outlet. The burr removal device comprises a chip breaking ring which is of a circular ring structure, and the chip breaking ring is fixed tothe part below a cleaned plate-part; through arrangement of the chip breaking ring below the plate-part, the outlet end, during broaching of a mortise, extends to the position of the chip breaking ring, so that hard burrs are not liable to generate at the outlet end of the plate-part and the depth of a lattice deformation layer is reduced effectively; and thus the service life of the plate-part isprolonged.

Owner:AECC AVIATION POWER CO LTD

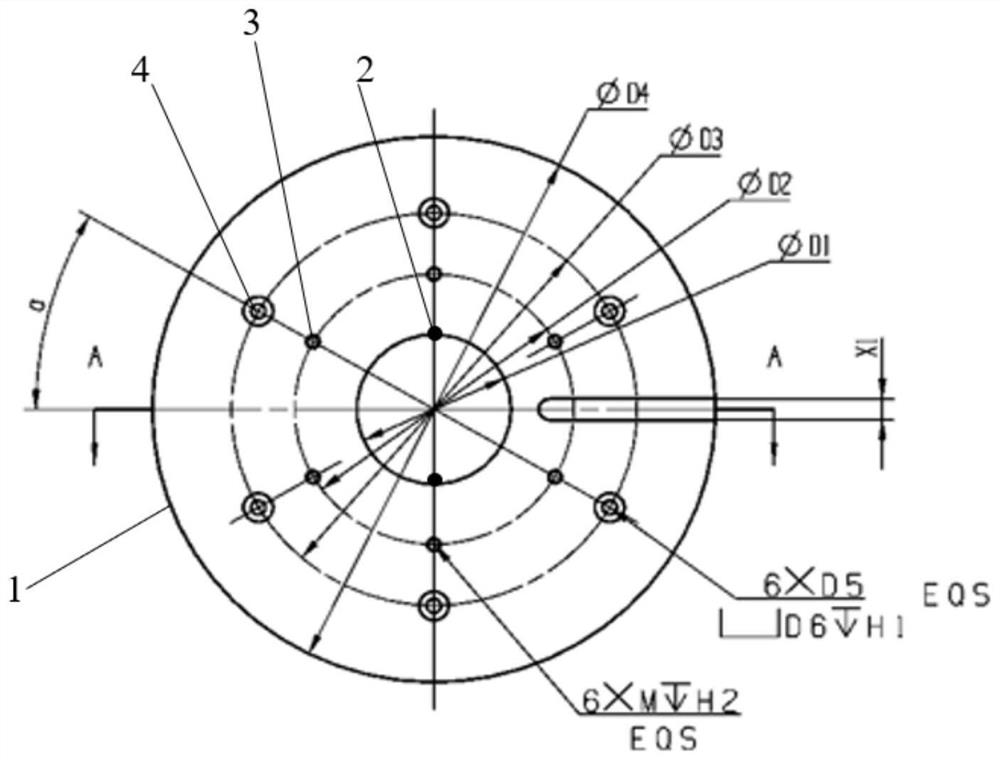

Adapter plate for mortise broaching of disc parts and disc part machining device

ActiveCN113664286AThe solution cannot be sharedImprove interchangeabilityBroaching accessoriesBroaching machinesEngineeringMachine

The invention discloses an adapter plate for mortise broaching of disc parts and a disc part machining device, and belongs to the technical field of machining process equipment. A first through hole, a second through hole and a third through hole are sequentially formed in the diameter of an adapter plate body from the circle center to the outer circumference; the first through hole is used for being connected with a bottom hole of an external broaching machine clamp in a matched mode; the second through hole is used for fixing the broaching machine clamp; and the third through hole is used for being connected with an external index plate. By using the adapter plate, the problem that the broaching machine clamp cannot be shared due to the fact that the connecting pitch circles on different index plates are different is solved, the interchangeability of the broaching machine clamp is improved, the number of clamps is reduced, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

Broaching tool for blade tenon

PendingCN113857563AMake sure the clamp is in placeEasy to processBroaching accessoriesPositioning apparatusStructural engineeringMachining

The invention relates to a broaching tool for a blade tenon. The broaching tool comprises a workbench, a tool clamp and an auxiliary supporting device; the tool clamp is arranged on the workbench and comprises a fixed seat, a profiling clamp and a rotary seat with a central axis, and the rotary seat is arranged on the fixed seat in the mode that the rotary seat can rotate around the central axis of the rotary seat; the auxiliary supporting device comprises a first supporting block and a second supporting block, the first supporting block and the second supporting block are both movably arranged on the rotary seat and can be close to or away from the blade tenon, and therefore the auxiliary supporting device at least has a first state and a second state, in the first state, the first supporting block moves towards the blade tenon and abuts against the end face of the blade tenon, and the second supporting block is far away from the side face area of the blade tenon; and in the second state, the second supporting block moves towards the blade tenon and abuts against the side face of the blade tenon, and the second supporting block is far away from the end face area of the blade tenon. According to the broaching tool, the blade can be firmly clamped, the blade tenon machining procedure is simplified, and the production efficiency is effectively improved.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

Detecting device for multi-workpiece broaching production line

PendingCN109530791AImprove detection efficiencyIncrease productivityBroaching accessoriesMeasurement/indication equipmentsProduction lineControl system

The invention relates to a detecting device for a multi-workpiece broaching production line. The detecting device comprises at least two detecting mechanisms arranged in an advancing direction of a mobile worktable at intervals; the detecting mechanisms are used for identifying clamping states of workpieces, and are in signal communication with a control system of a machine tool; detecting units are formed between any two adjacent detecting mechanisms; an overall area of the mobile worktable is correspondingly divided into multiple detecting sections by the detecting units; detecting gaps areformed between the workpieces at the front ends in the detecting sections of the mobile worktable and the workpieces at the tail ends; a reserved gap is formed in the advancing direction of the mobileworktable between the detecting mechanism at the most front end and a machining position of a machining unit; and the reserved gap is larger than and equal to the detecting gaps. The detecting deviceadopts a segmented detecting mode to quickly detect the workpieces, prevents the cutter damage of a broaching machine tool, and effectively improves the production efficiency.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

Broaching force detection device and detection method thereof

ActiveCN109623027AEnable self-powered detectionSolve the difficulty of external power supplyBroaching accessoriesMeasurement/indication equipmentsWireless transmissionEngineering

The invention discloses a broaching force detection device and a detection method thereof. Due to the particularity of a broaching machining technology, a general cutting force detection device cannoteffectively detect the size of broaching load. The device and the method thereof involve a self-detection broach with a vibration energy collecting function and comprises a broach body and detectors.N placement through grooves are formed in the side portion of a broach body of the broach body. The detectors are arranged in the n placement through grooves. Each detector comprises a strain sensor,a piezoelectric plate and a circuit base board, wherein the strain sensor and the piezoelectric plate are arranged on the two sides of the corresponding placement through groove correspondingly, thecircuit base board is fixed in the corresponding placement through groove, the circuit base board is provided with a detection-energy collection circuit, and the detection-energy collection circuit comprises an energy collection module, a broaching load detection module and a wireless transmission module. According to the device and the method thereof, the sensors and a cutting part are combined to realize integration measurement of cutting force, so that the measurement of the cutting force is not limited by the size of a machining space any more.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com