Broaching and adjusting measurement tool for turbine disk of combustion gas turbine

A technology of gas turbines and turbine discs, applied in the field of measuring tools, can solve the problems of lack of special tools, etc., and achieve the effects of easy operation, improved work efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

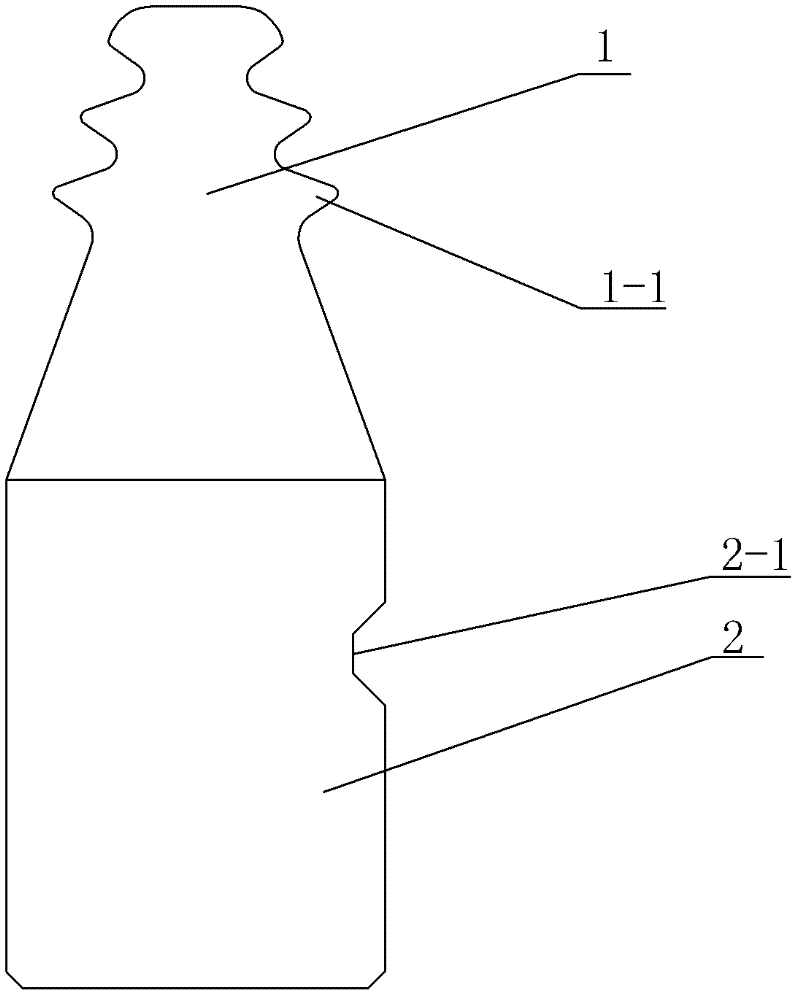

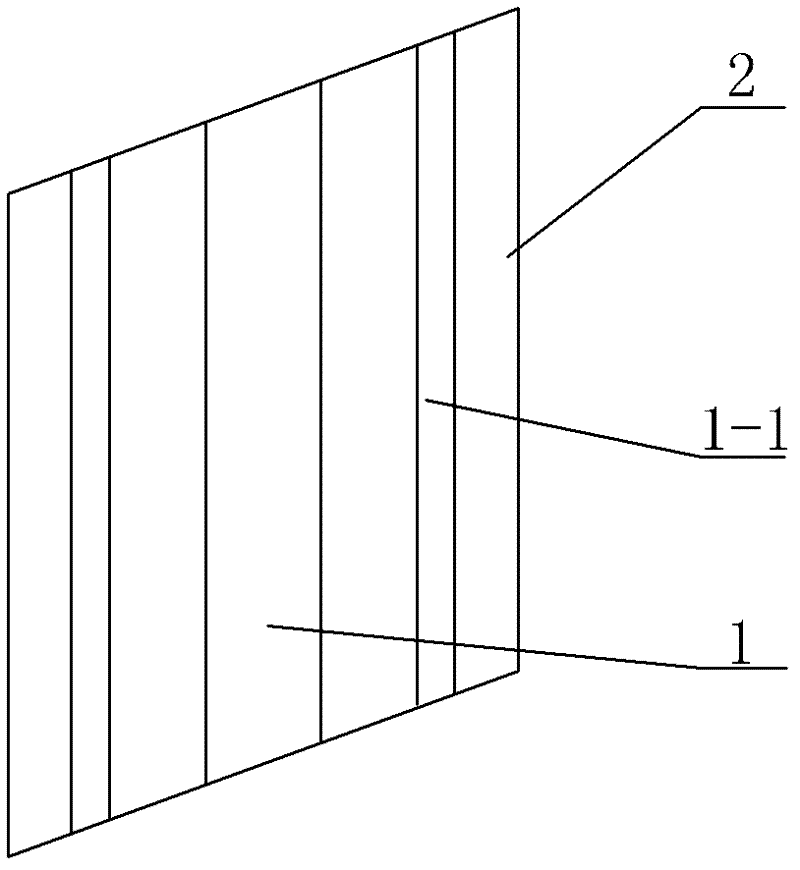

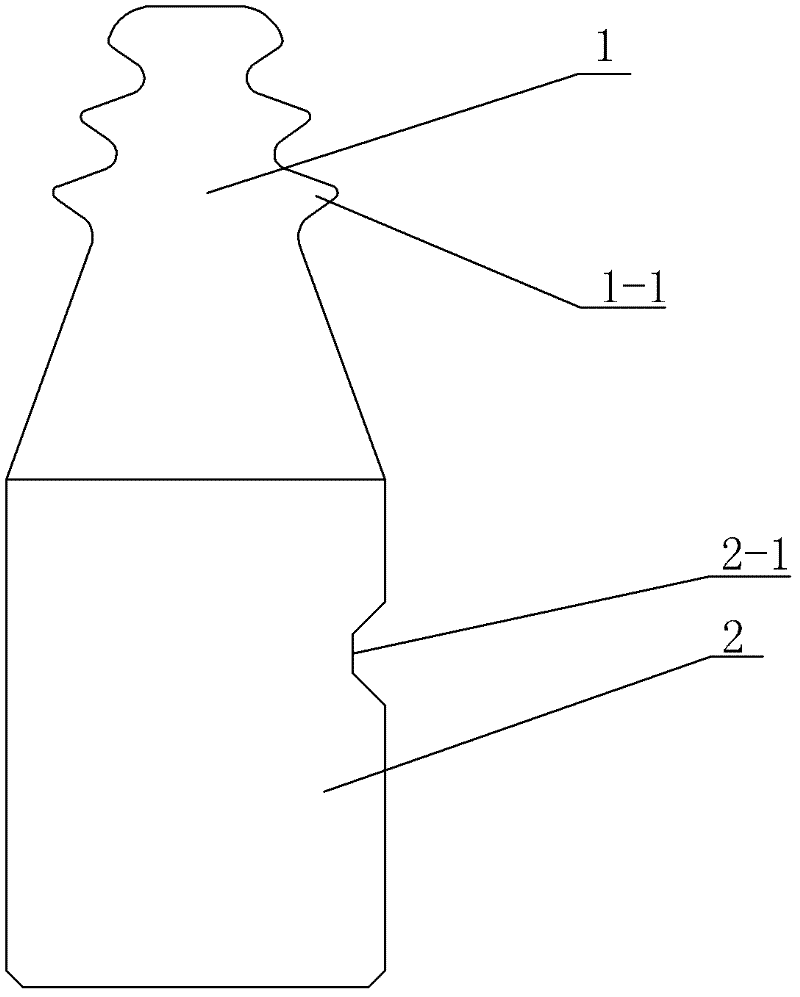

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the gas turbine turbine disc broaching tool setting measuring tool described in this embodiment includes a measuring part 1 and a broaching machine assembly part 2, the measuring part 1 and the broaching machine fitting part 2 are integrated, the measuring Part 1 is composed of two symmetrical wavy curved surfaces 1-1 that taper from bottom to top and two symmetrical planes 1-2 that taper from bottom to top. The cross-section of the measurement part 1 It is quadrilateral, and the broaching machine assembly part 2 is a quadrilateral prism in cross section, and the projection of the two wavy curved surfaces 1-1 on the horizontal plane is the tongue-and-groove profile of the turbine disc. In this embodiment, the dimensions of the two wavy curved surfaces 1-1 in the measuring part 1 are obtained according to the equivalent scaling principle of the wheel groove profile, which is 0.2mm...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a mounting bay 2-1 is provided on the outer wall of the broaching part 2 of a gas turbine disk broaching tool setting tool described in this embodiment. This embodiment ensures that the mating part 2 of the broaching machine is firmly connected with the broaching machine and will not become loose. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, the measurement part 1 of a gas turbine turbine disk broaching tool setting tool described in this embodiment is a measurement part 1 made of 40Cr, and the broaching part 2 is a broaching part 2 made of 40Cr . Other components and connections are the same as those in the first embodiment.

[0010] working principle

[0011] Working steps of the present invention are as follows:

[0012] Step 1. Determine the maximum and minimum physical dimensions of the wheel groove according to the tolerance zone of the wheel groove profile (that is, the shape of the broaching wheel groove in the turbine disk);

[0013] Step 2. Determine the shape of the wheel groove after broaching by the rough broach according to the rough broach. Under the condition that there is no interference with the broaching wheel groove and there is sufficient measurement space, determine the size of the profile part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com