Broaching machine

A technology of pull rod and bed, which is applied to broaching machines. In this field, it can solve the problems of cutting teeth with iron filings and impurities are not easy to remove, so as to prevent the broach from rusting, save manpower and material resources, and improve production efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

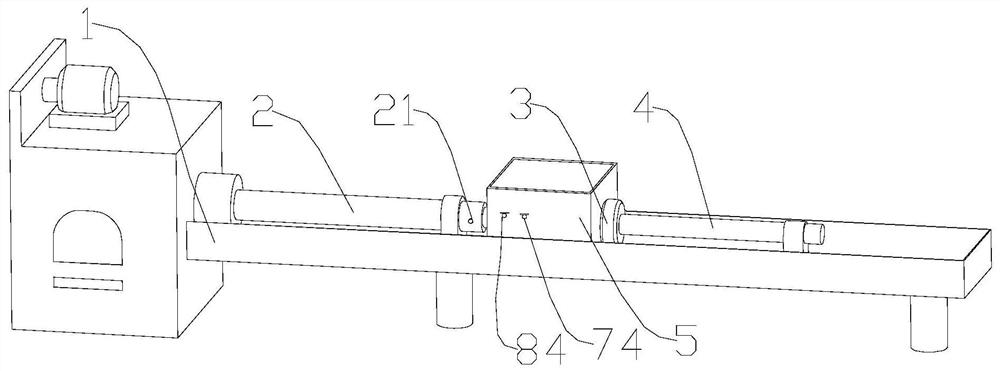

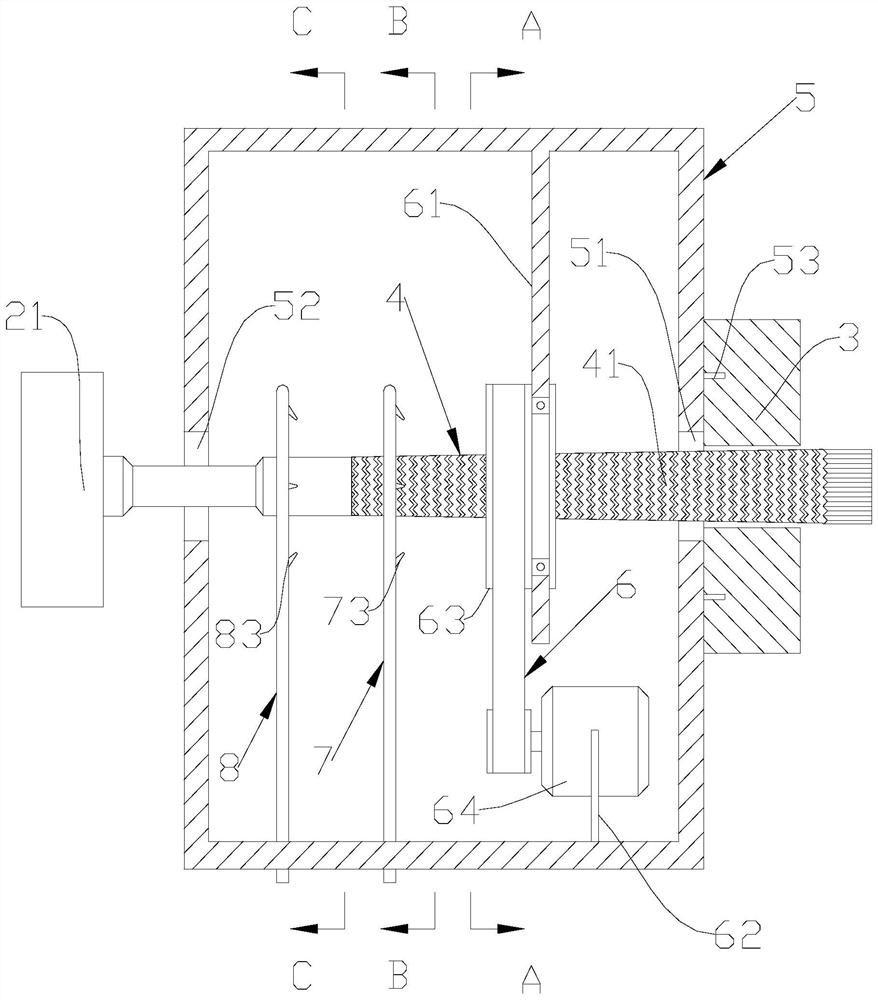

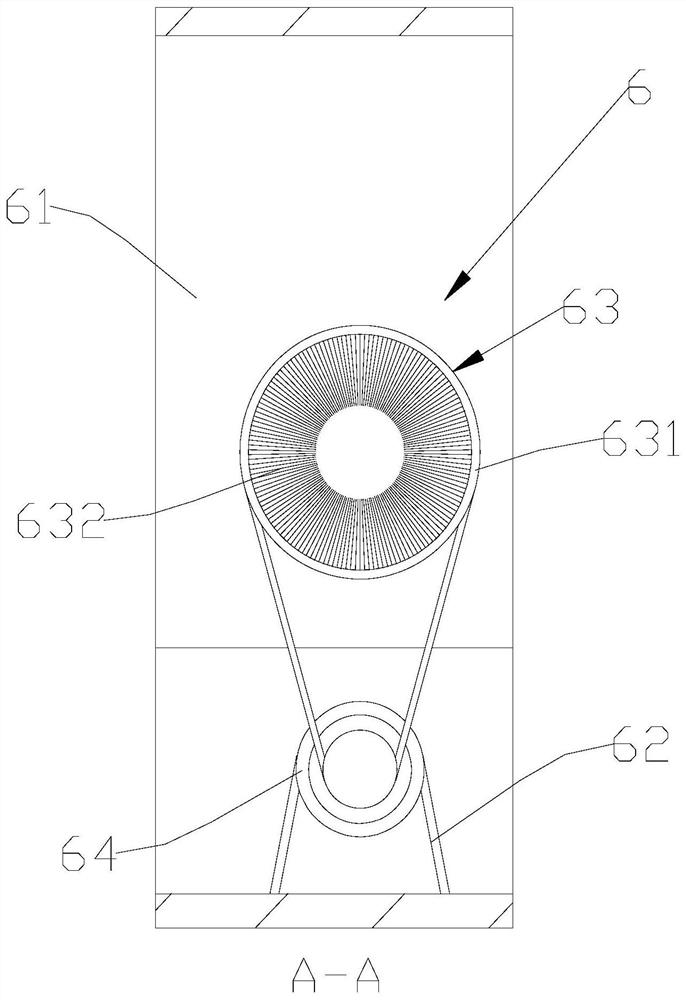

[0014] like figure 1 As shown, the embodiment of the present invention proposes a broaching machine, which includes a machine bed 1 and a piston rod 2 arranged on the machine bed 1. The piston rod 2 is fixedly connected with a follower tool rest 21 that clamps the broach 4, The front end of the follow-up tool rest 21 is also provided with a cleaning chamber 5, the upper and lower ends of the cleaning chamber 5 are opened up, the top opening is to facilitate the maintenance of the cleaning chamber 5 and the installation of other devices, and the bottom opening is to facilitate the outflow of cleaned impurities and iron filings; Both ends of the cleaning chamber 5 are provided with a knife inlet hole 51 and a knife outlet hole 52 for the broach 4 to pass through. The diameter of the knife inlet hole 51 and the knife hole 52 are bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com