Patents

Literature

63results about "Portable planing/slotting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

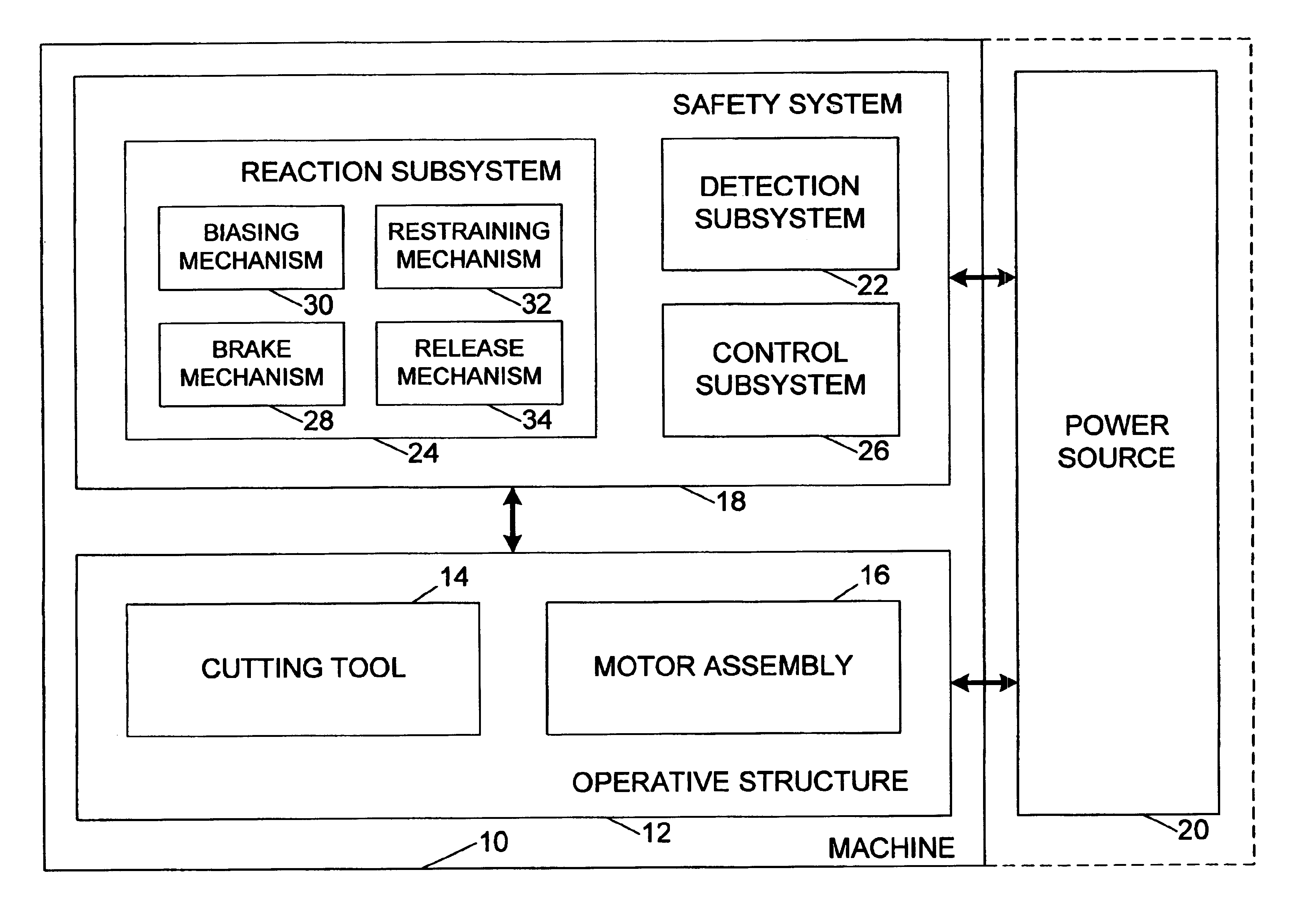

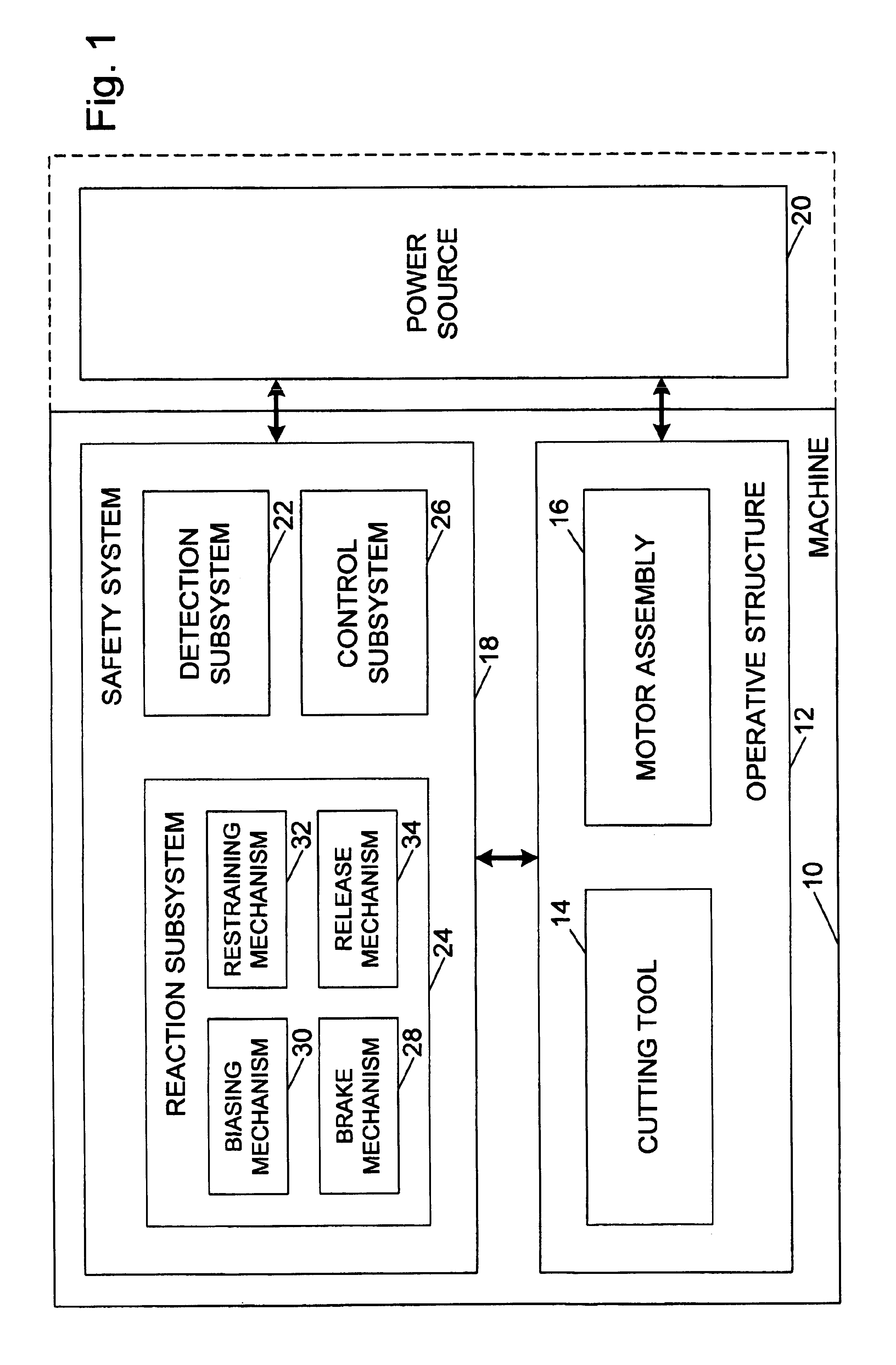

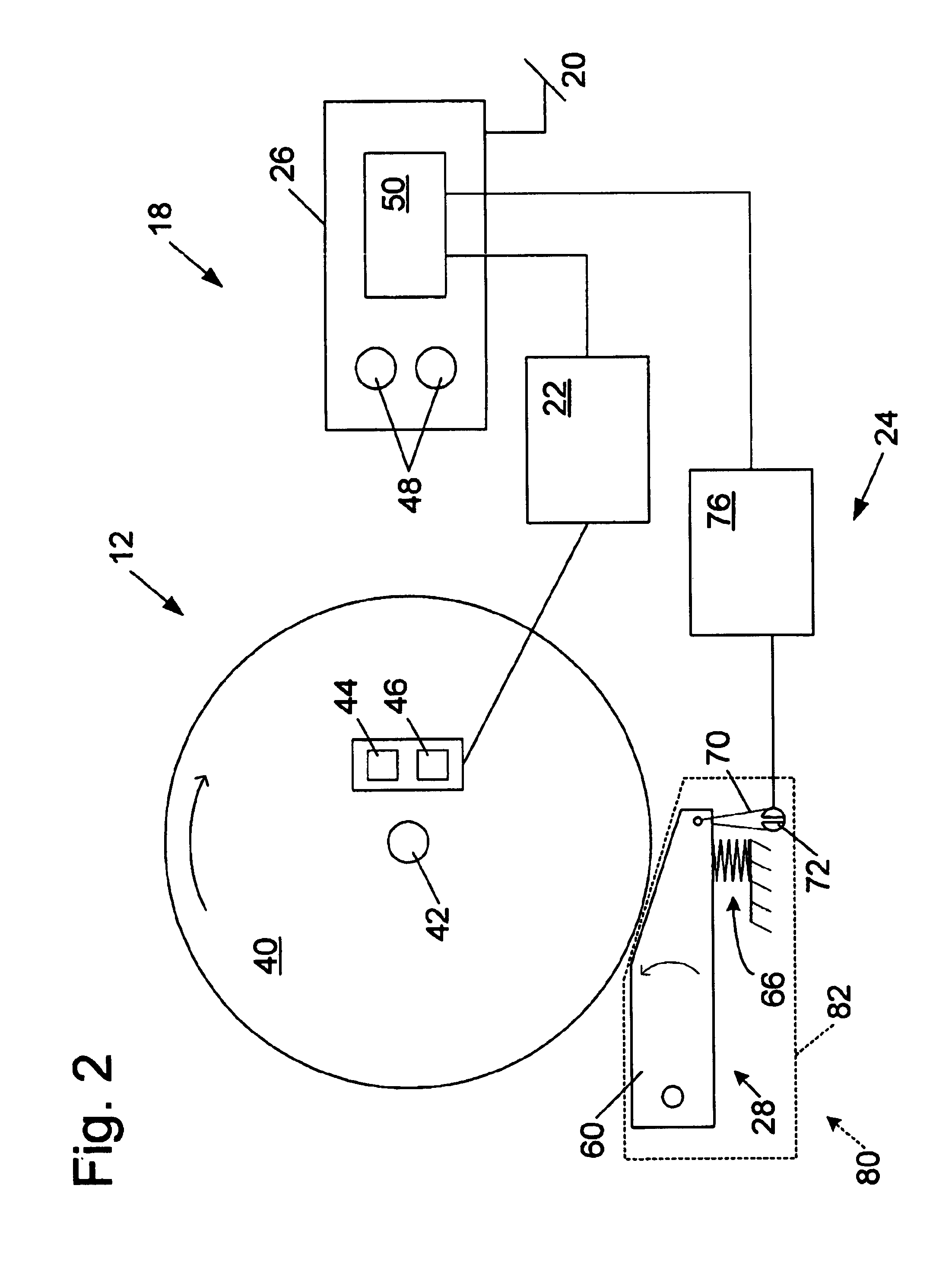

Actuators for use in fast-acting safety systems

Cutting machines with high-speed safety systems, and actuators used in high-speed safety systems, are disclosed. The cutting machines may include a detection system adapted to detect a dangerous condition between a cutting tool and a person. A reaction system performs a specified action, such as stopping the cutting tool, upon detection of the dangerous condition. An actuator may be used to trigger the reaction system to perform the specified action.

Owner:SAWSTOP HLDG LLC

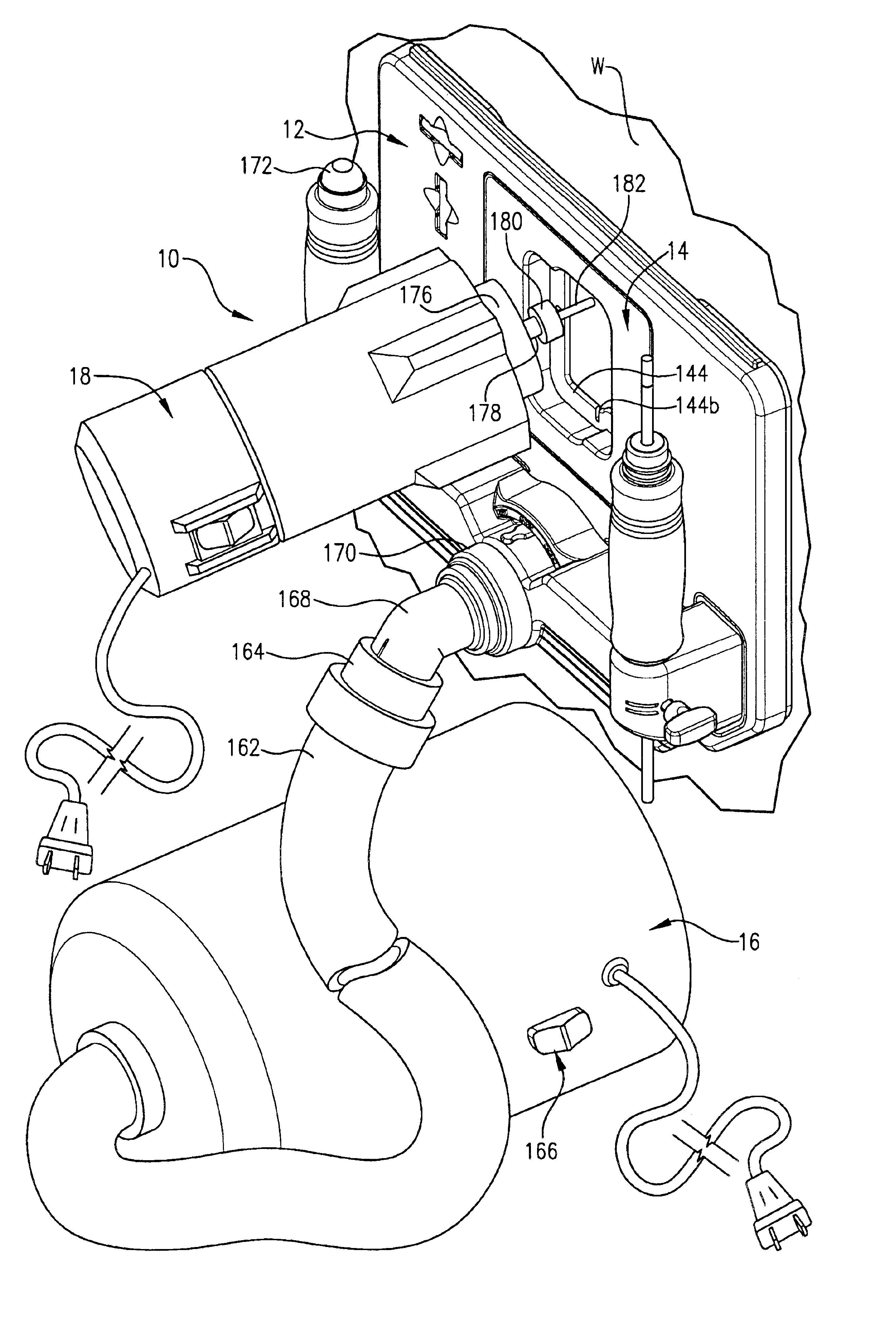

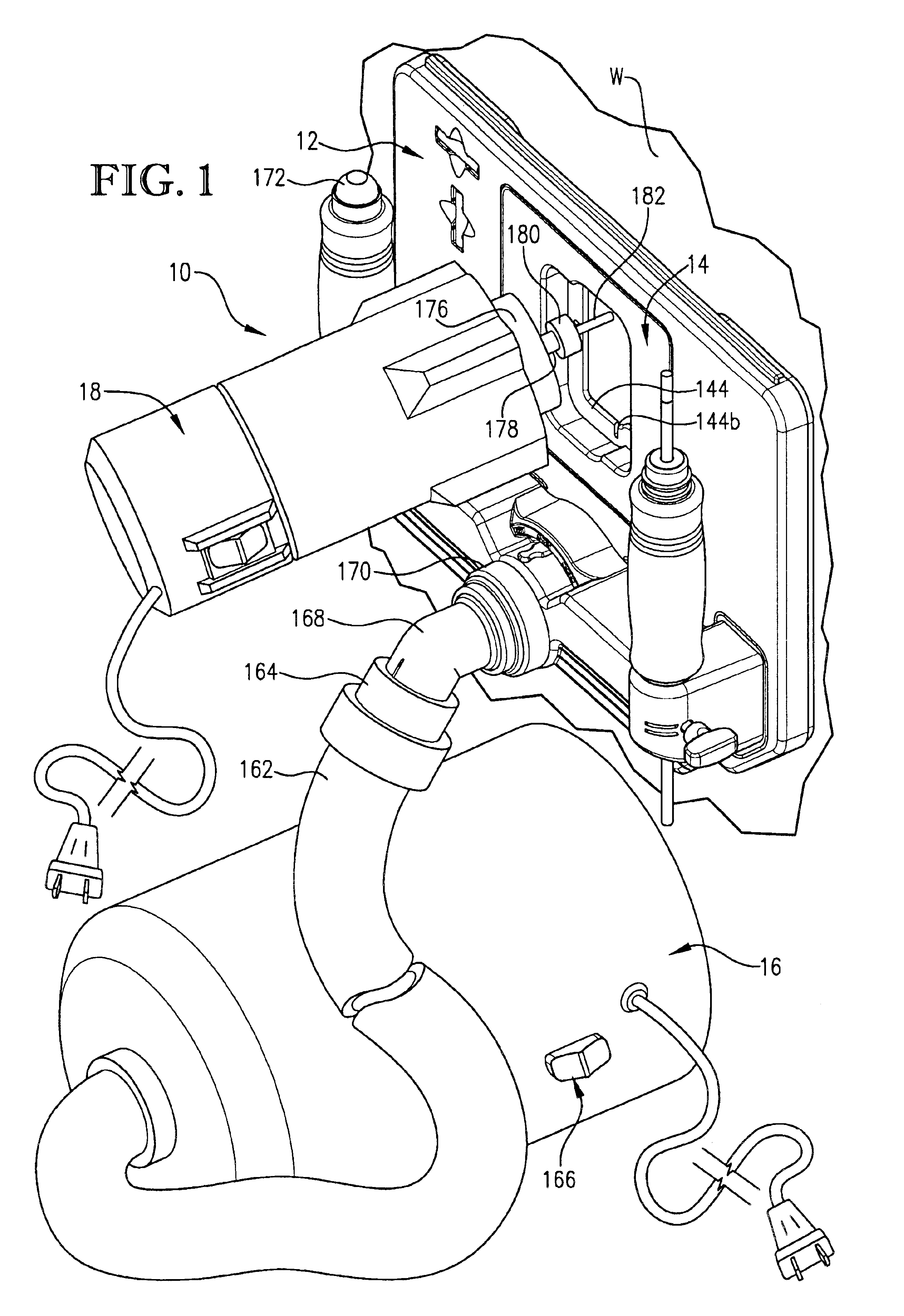

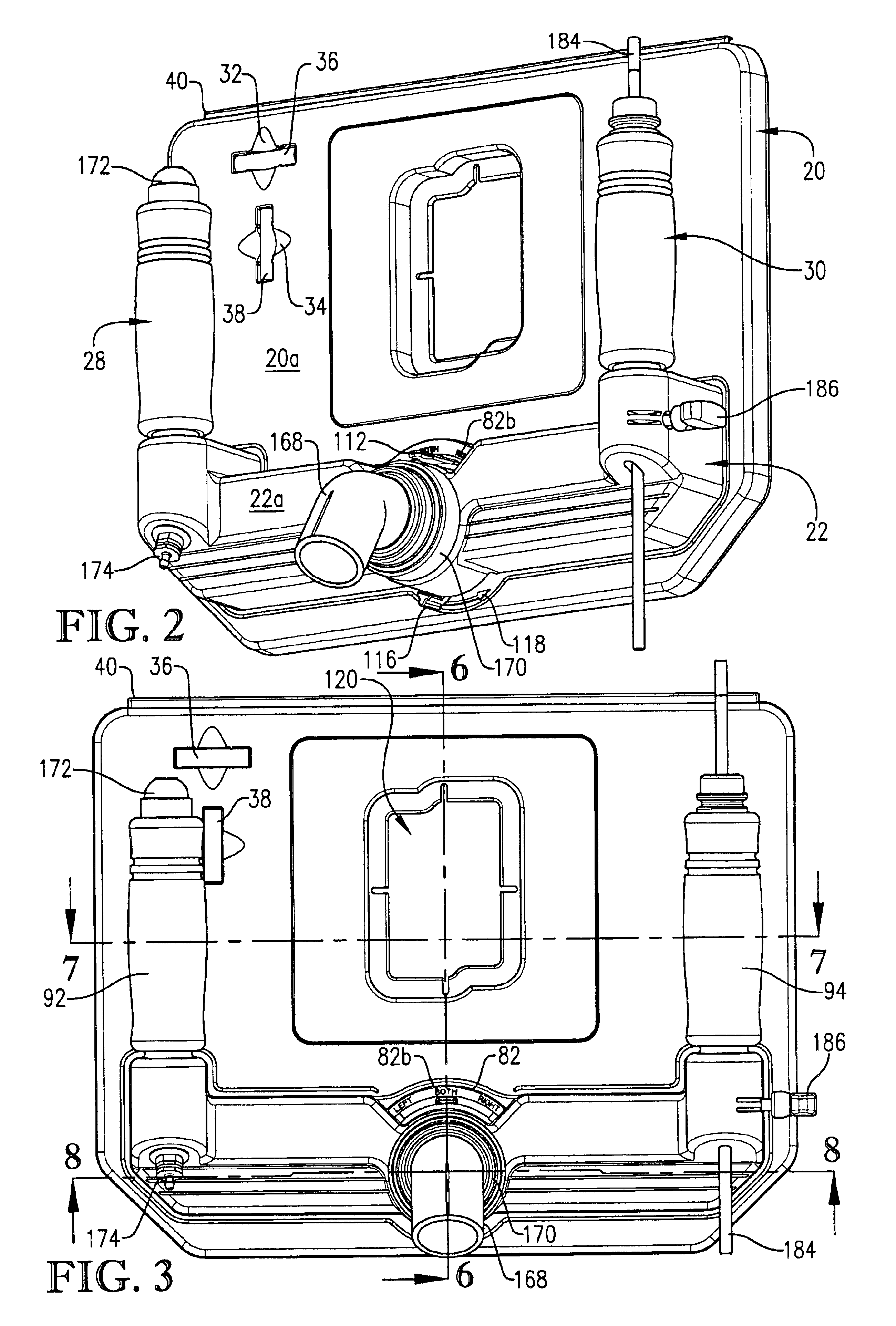

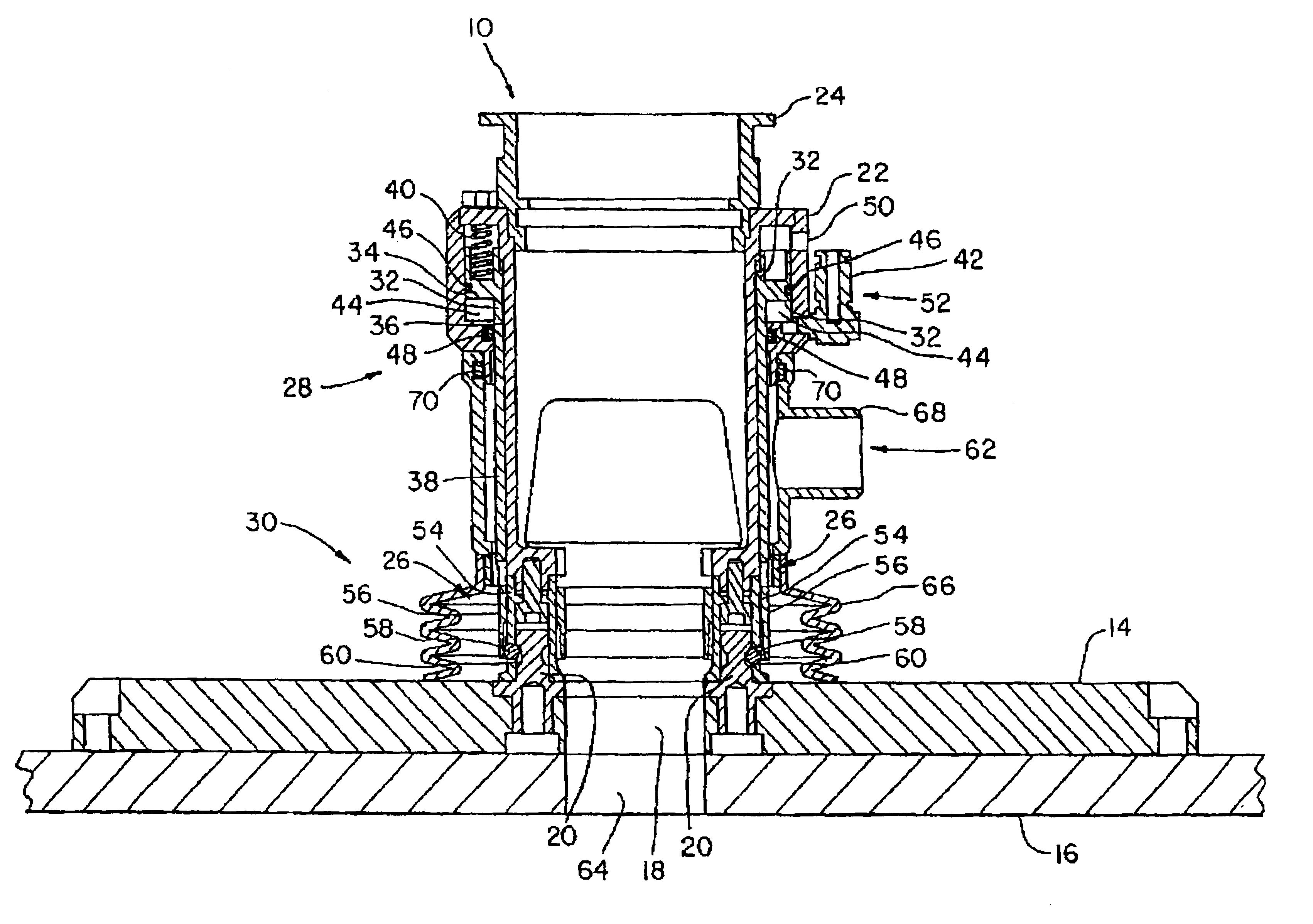

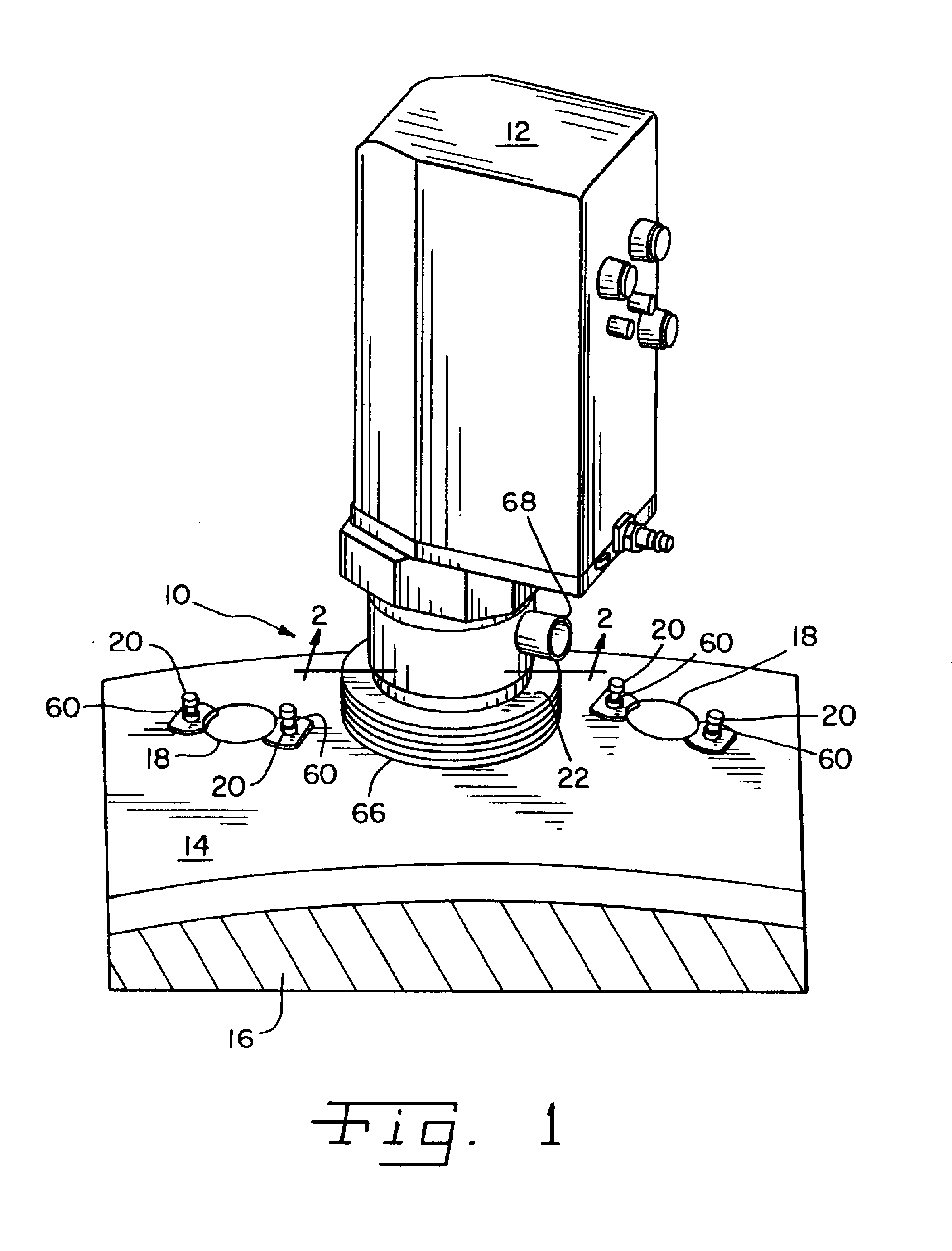

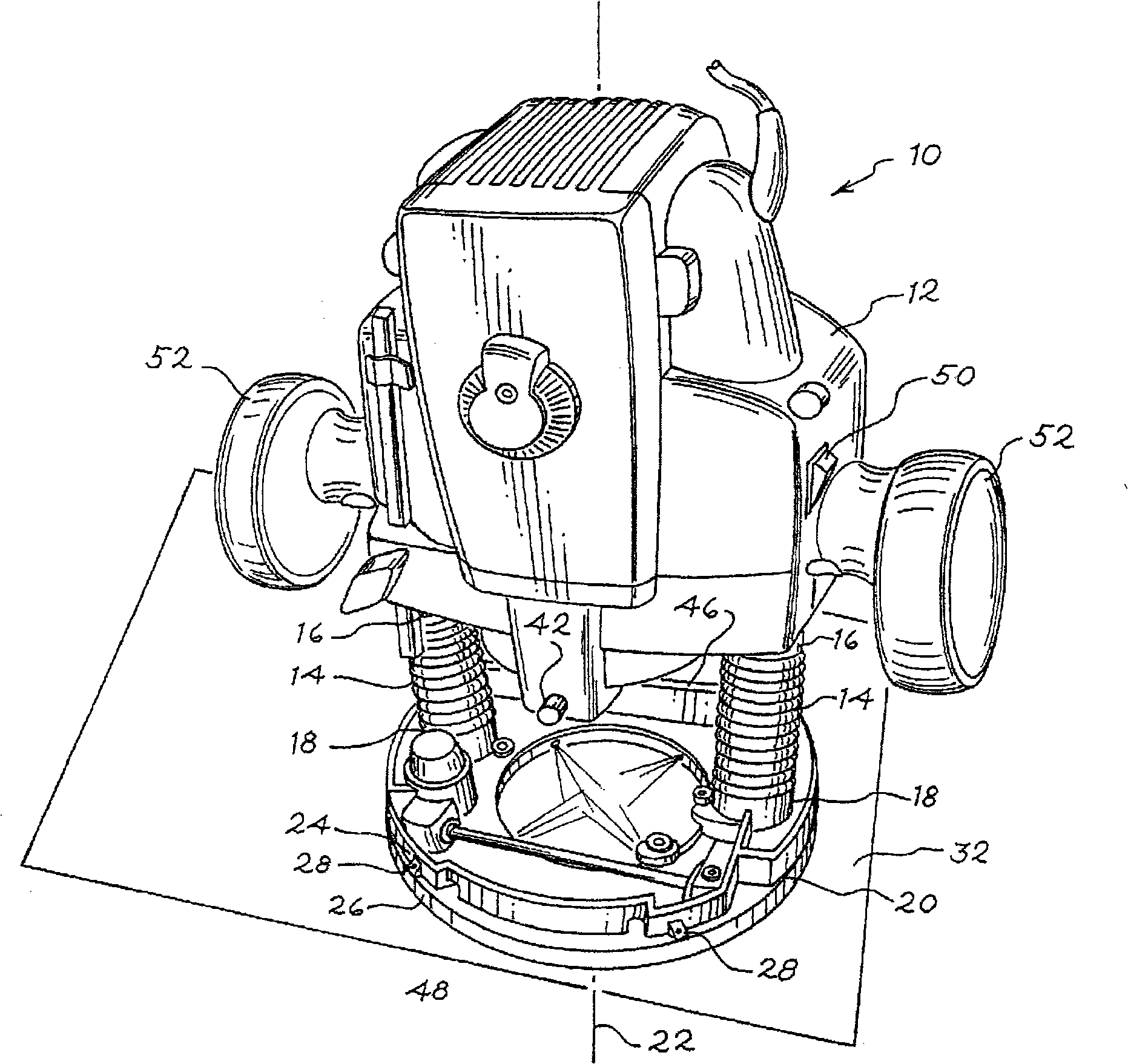

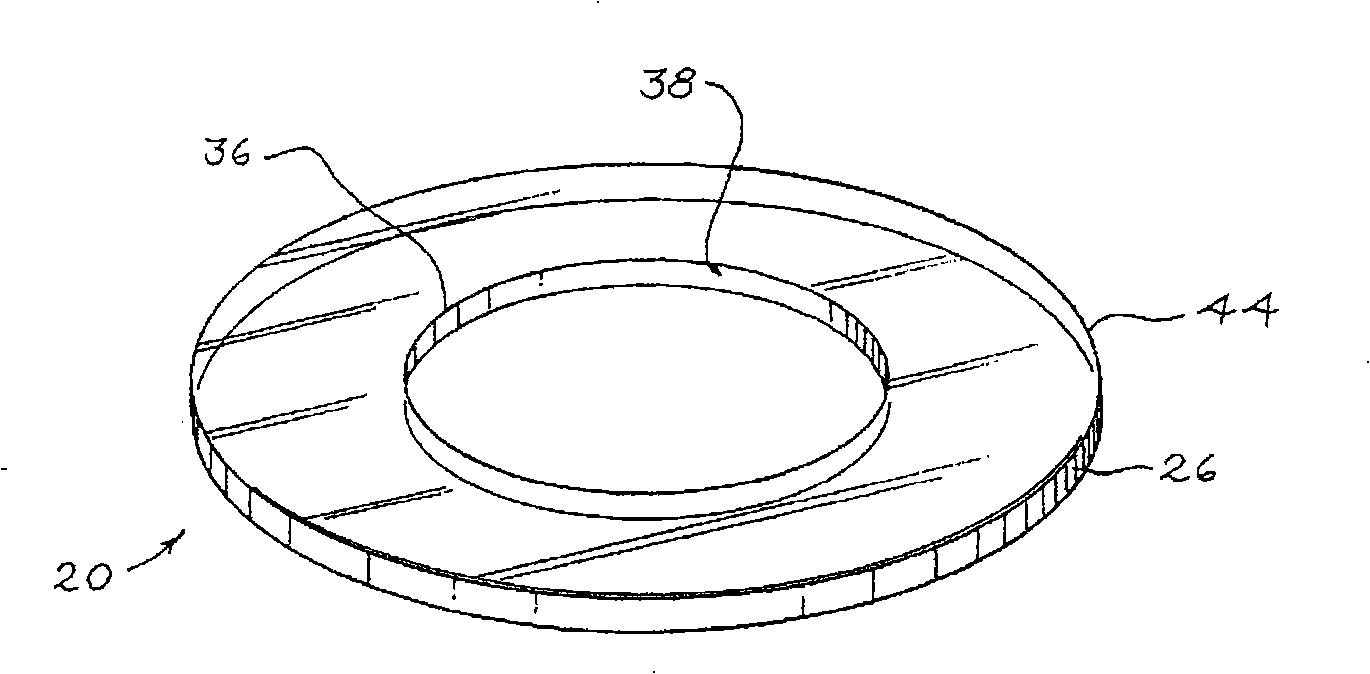

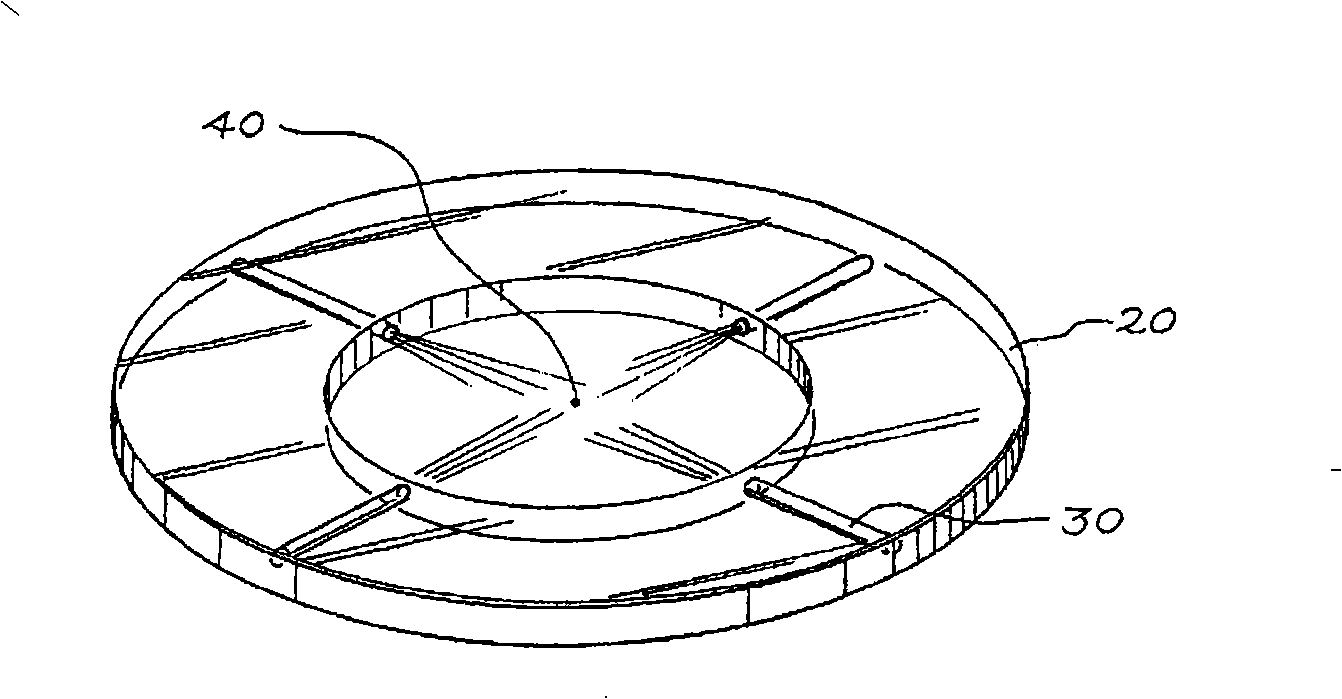

Hole cutting tool

InactiveUS6851900B2Drilling/boring measurement devicesThread cutting feeding devicesDust particlesGasket

A hole cutting tool (10) configured for cutting an accurately located and precisely shaped hole in a surface, such as a wall (W) of a finished residential or commercial building is disclosed. The tool (10) provides a frame assembly (12) which is self-adhering to the surface (W) and carries removable templates (14, 146-152) for handsfree use in cutting an accurately located and precisely shaped hole. The unique frame assembly (12) provides multiple selectable, pneumatically isolated suction chambers (50,52) that enable the self-adhesion function even when the frame assembly (12) is placed over existing holes in the surface (W). The suction chambers (50,52) are formed in part by a unique corrugated gasket (56) that enables the frame assembly (12) to self-adhere to porous surfaces. The removable template (14) enables dust particles created during the cutting process to be simultaneously vacuumed away regardless of the orientation of the template (14) relative to the frame assembly (12).

Owner:PYTHON PERFECT CUTTER

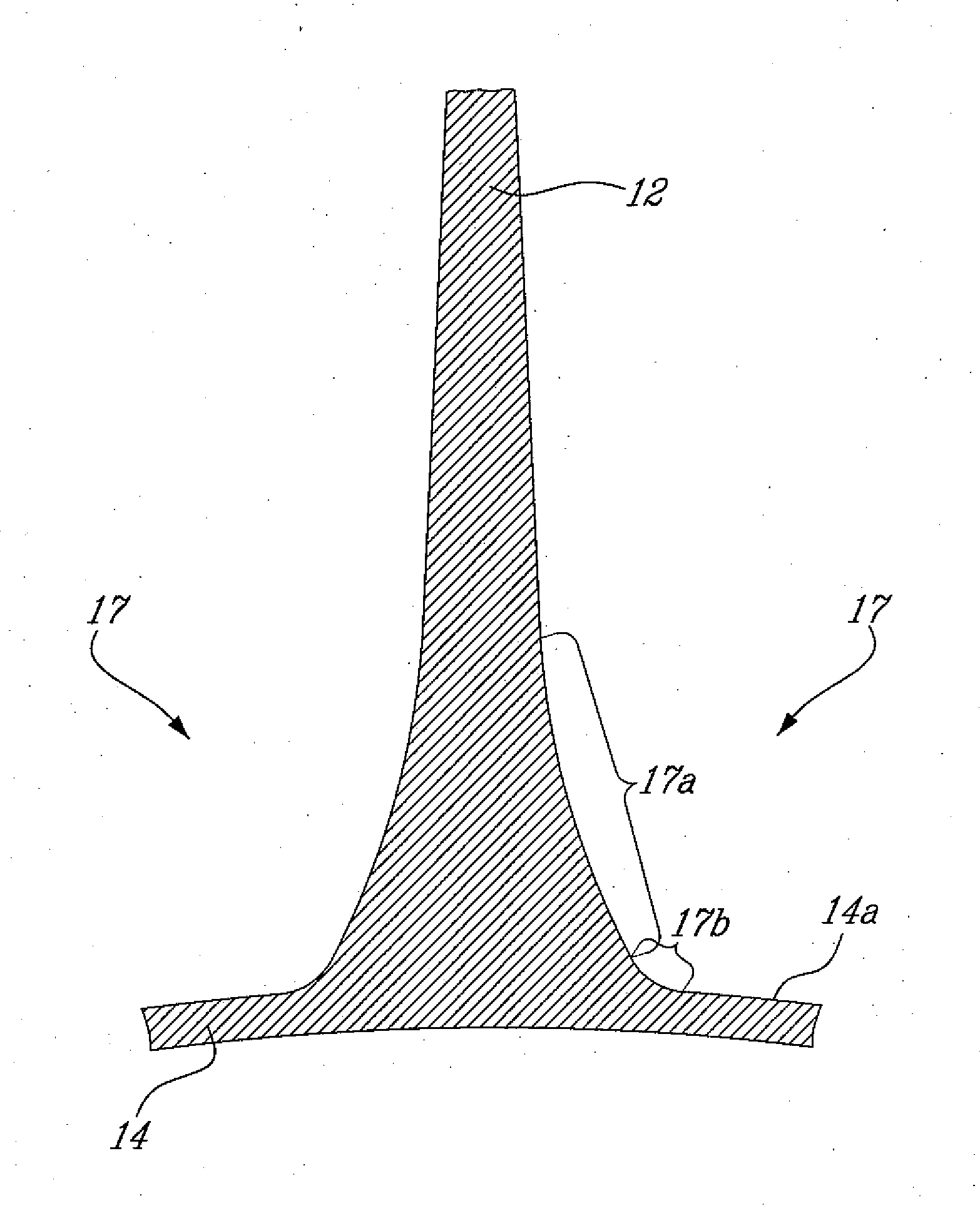

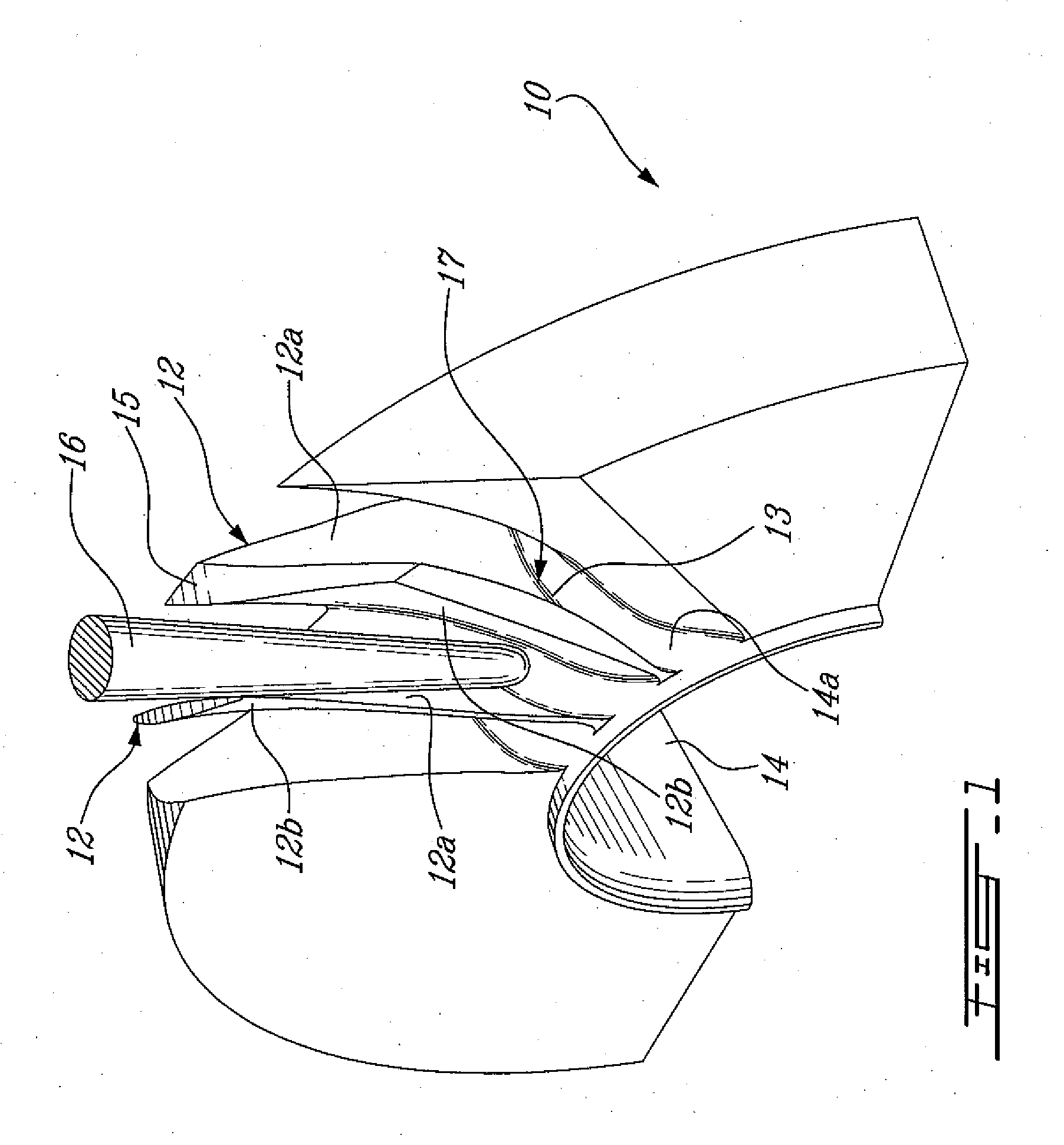

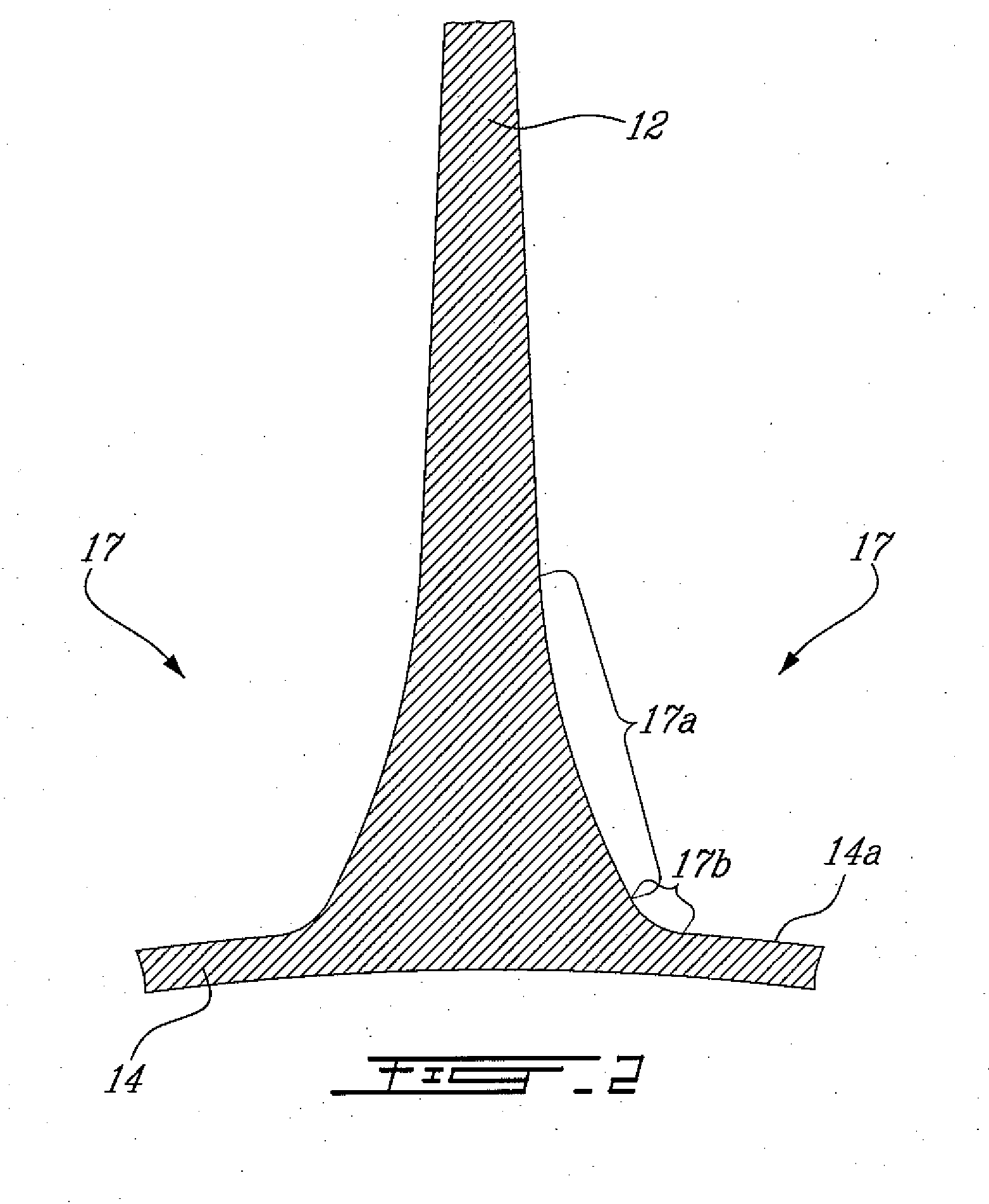

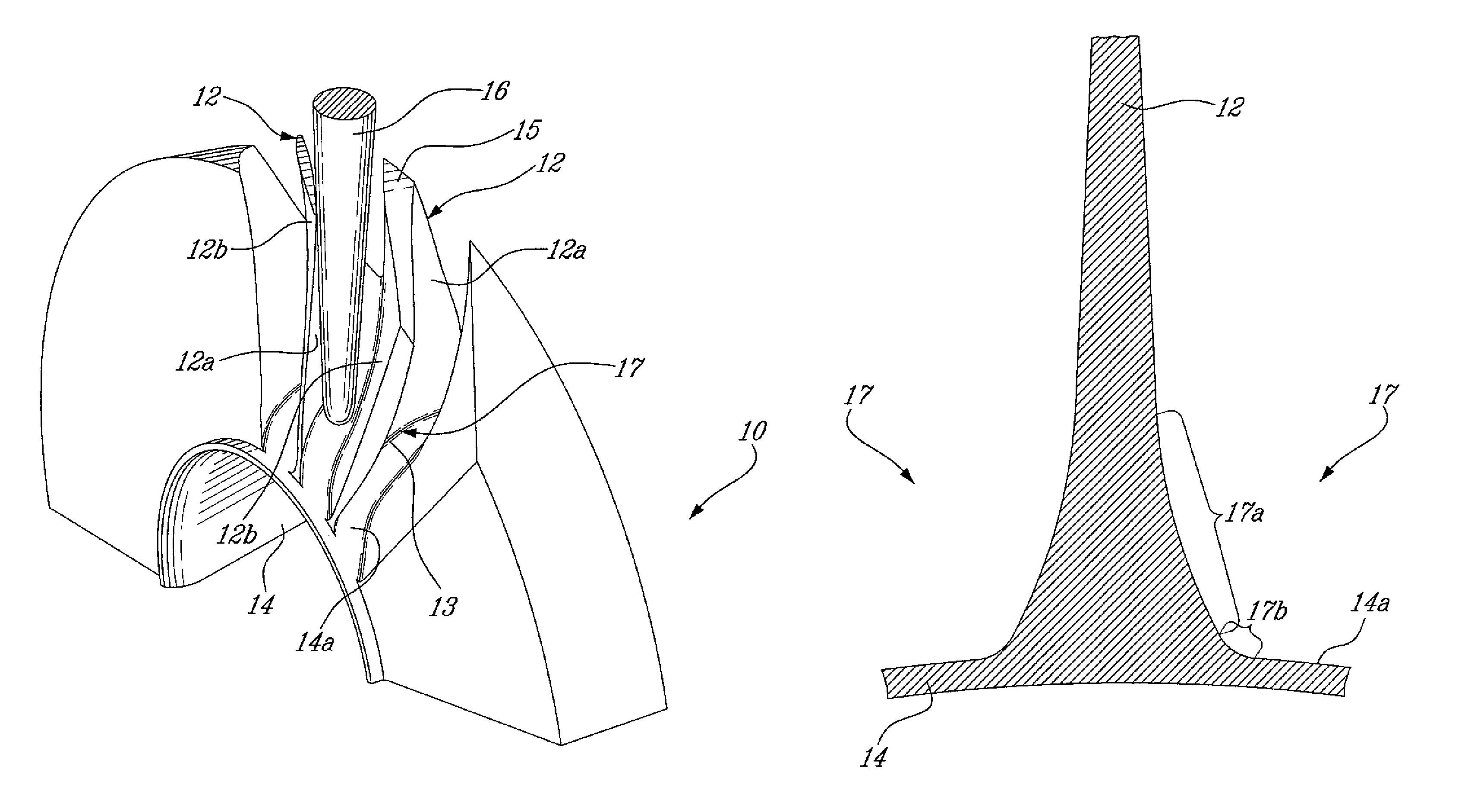

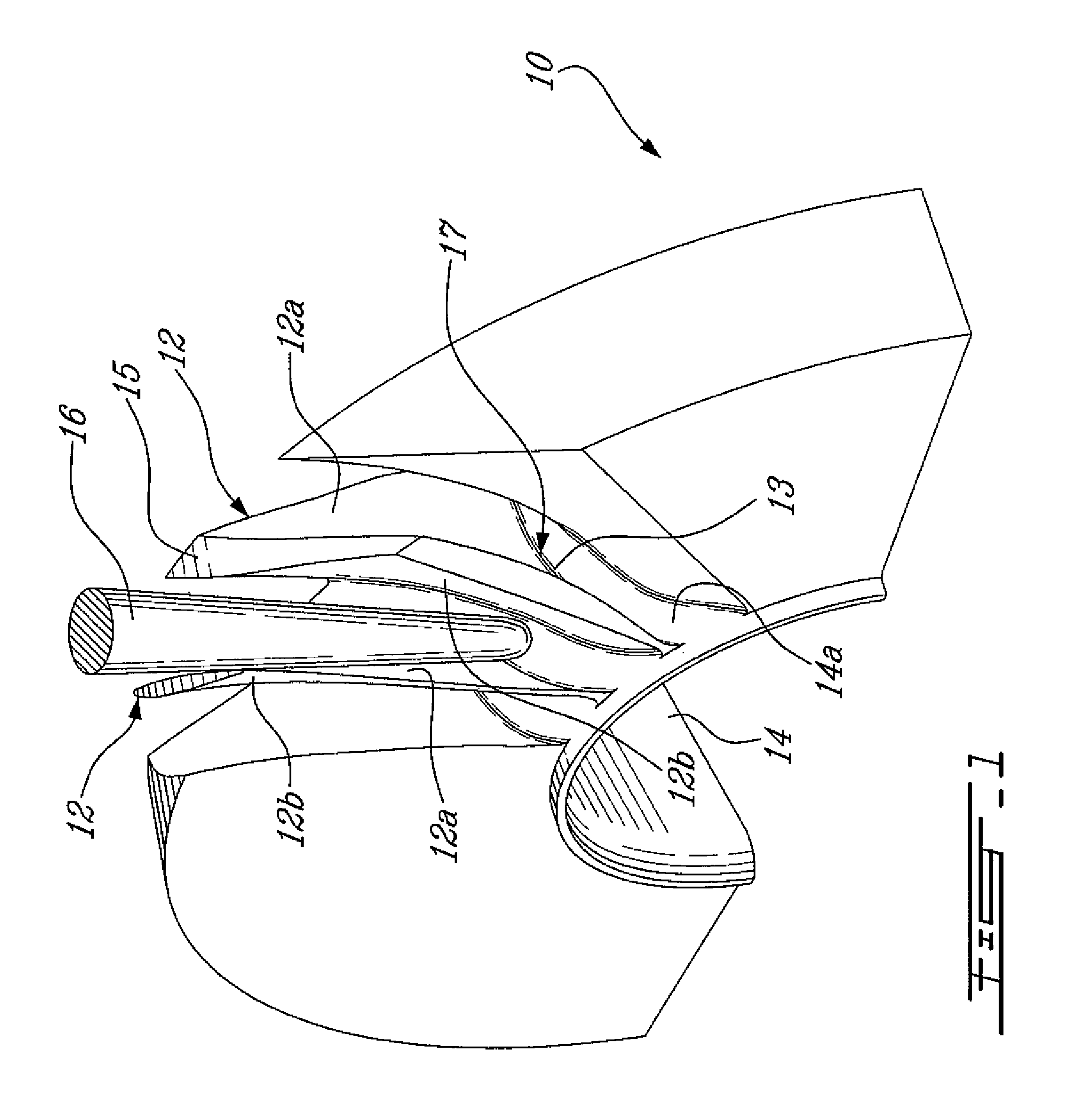

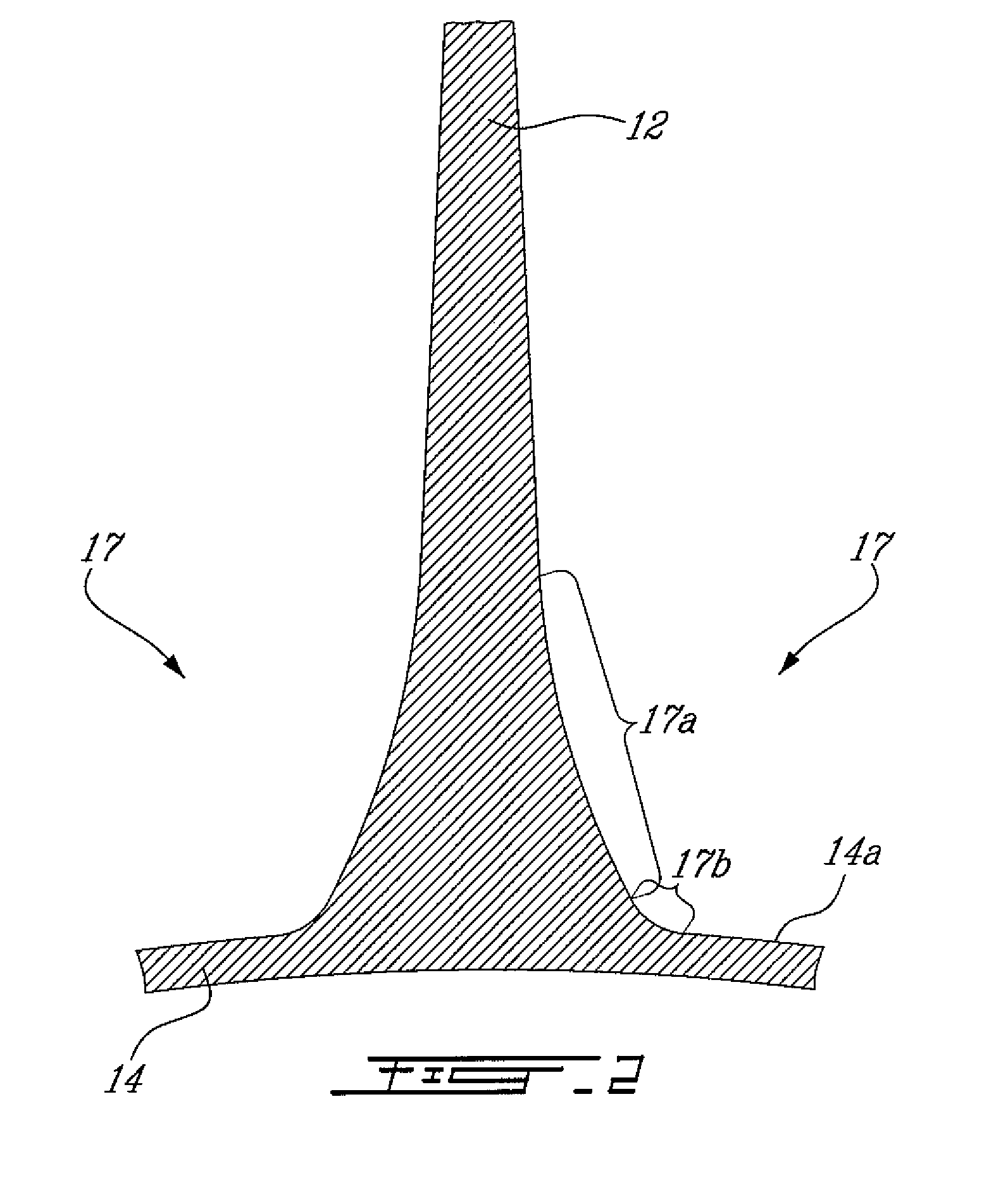

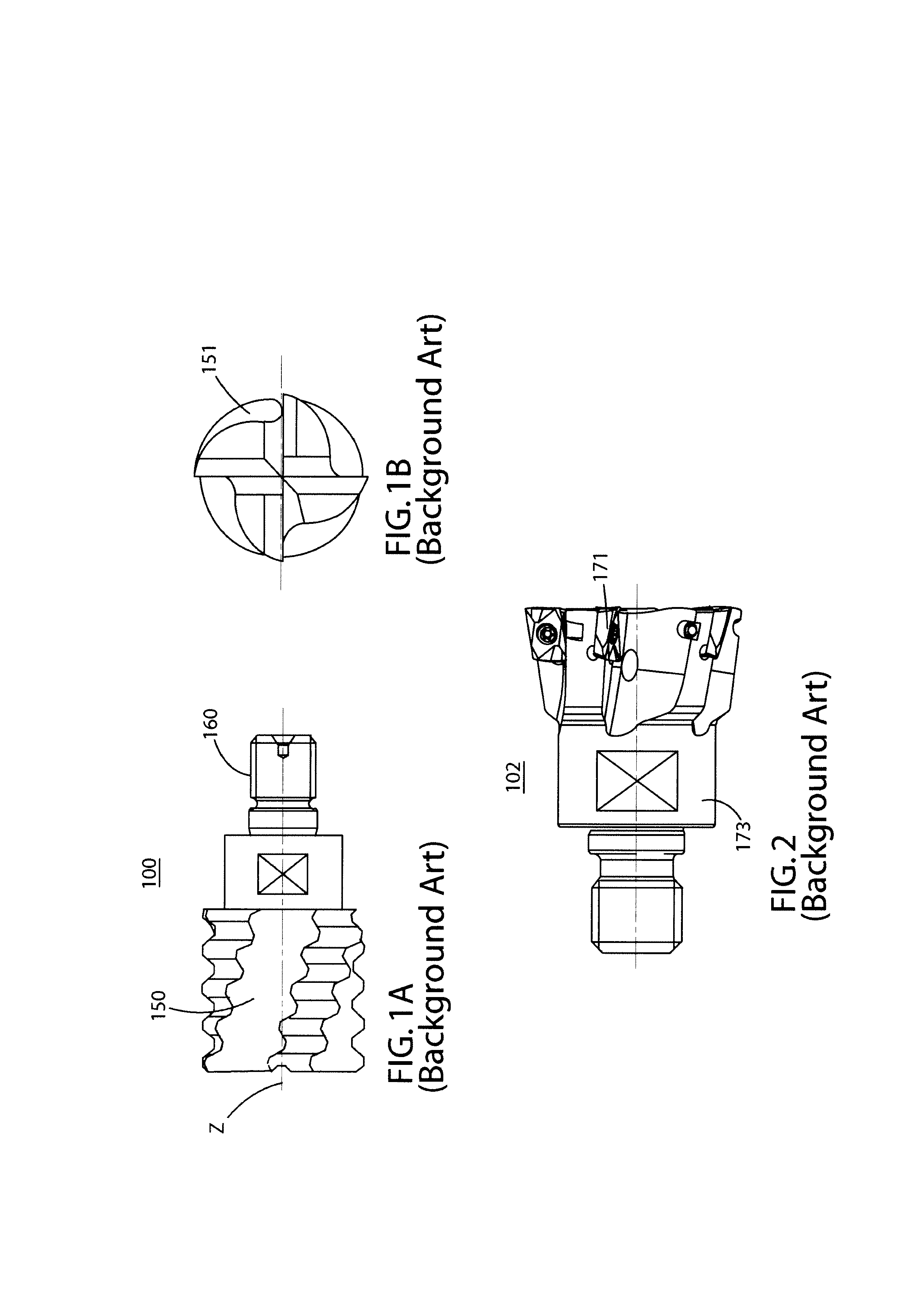

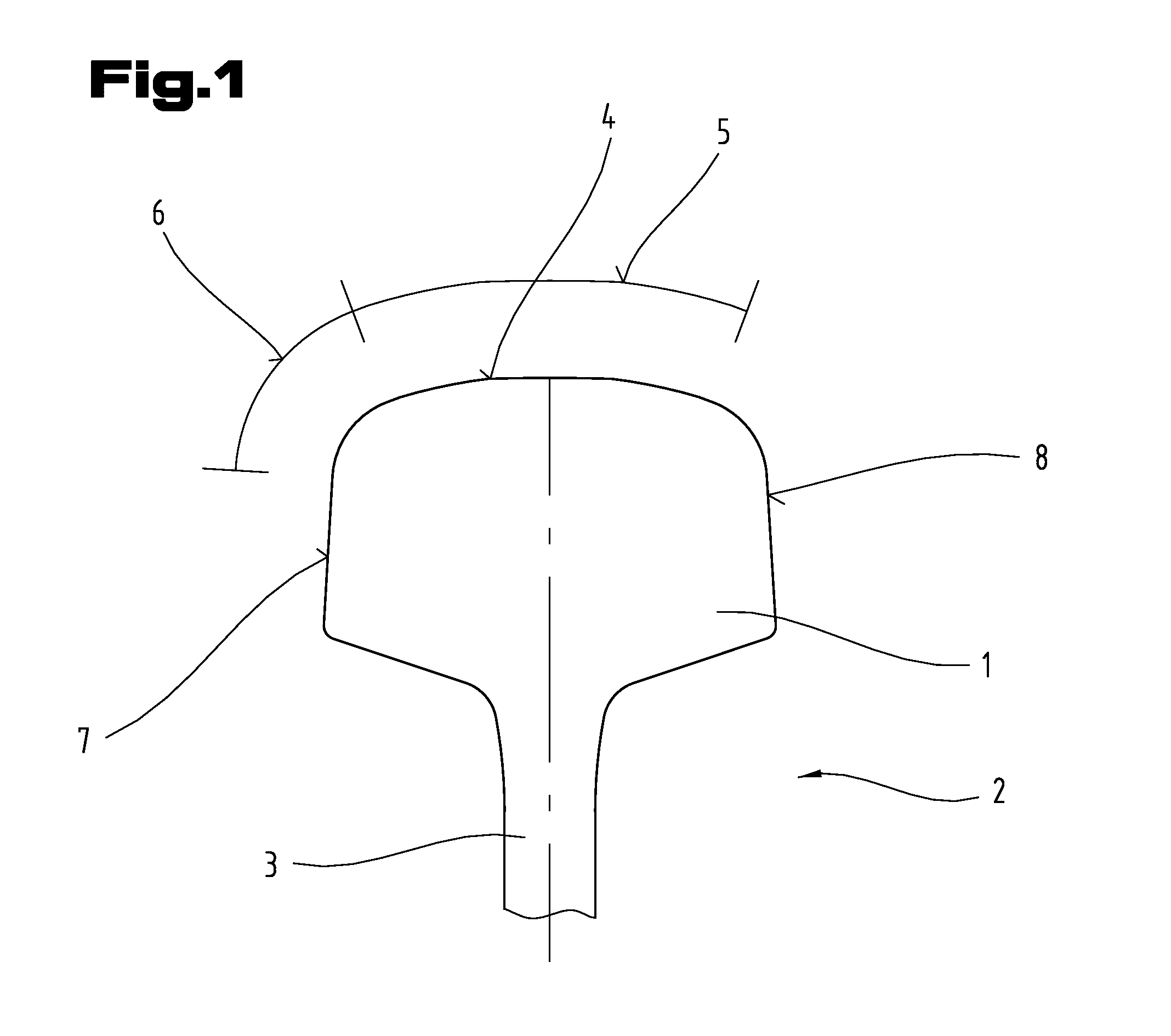

Method of machining airfoil root fillets

An airfoil root fillet having a predetermined compound curve profile can be flank milled with a single flank milling cutter having a generally conical flank milling portion and a rounded tip portion defining a compound curve.

Owner:PRATT & WHITNEY CANADA CORP

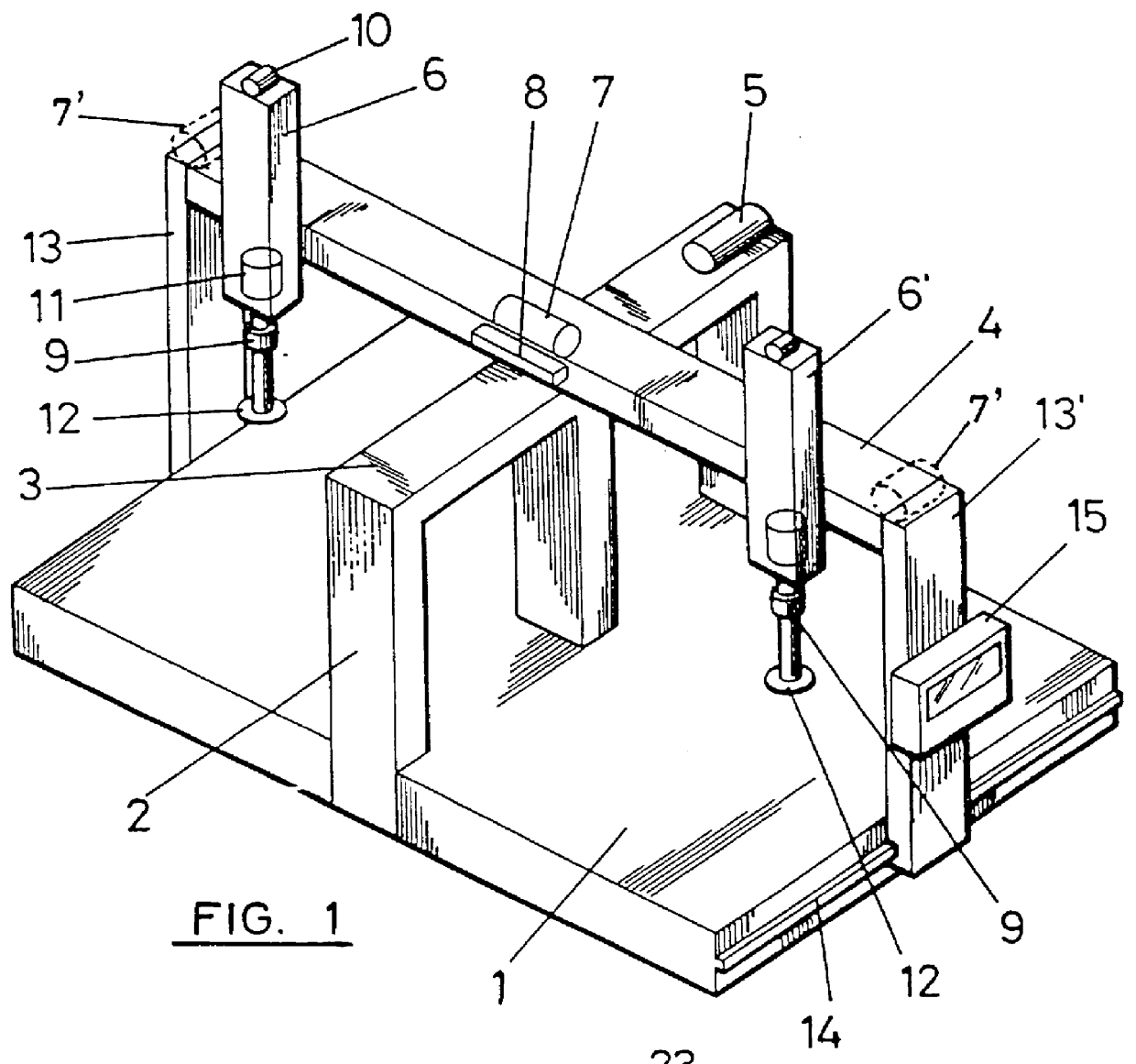

Double arm vertical miller

Owner:NORAN

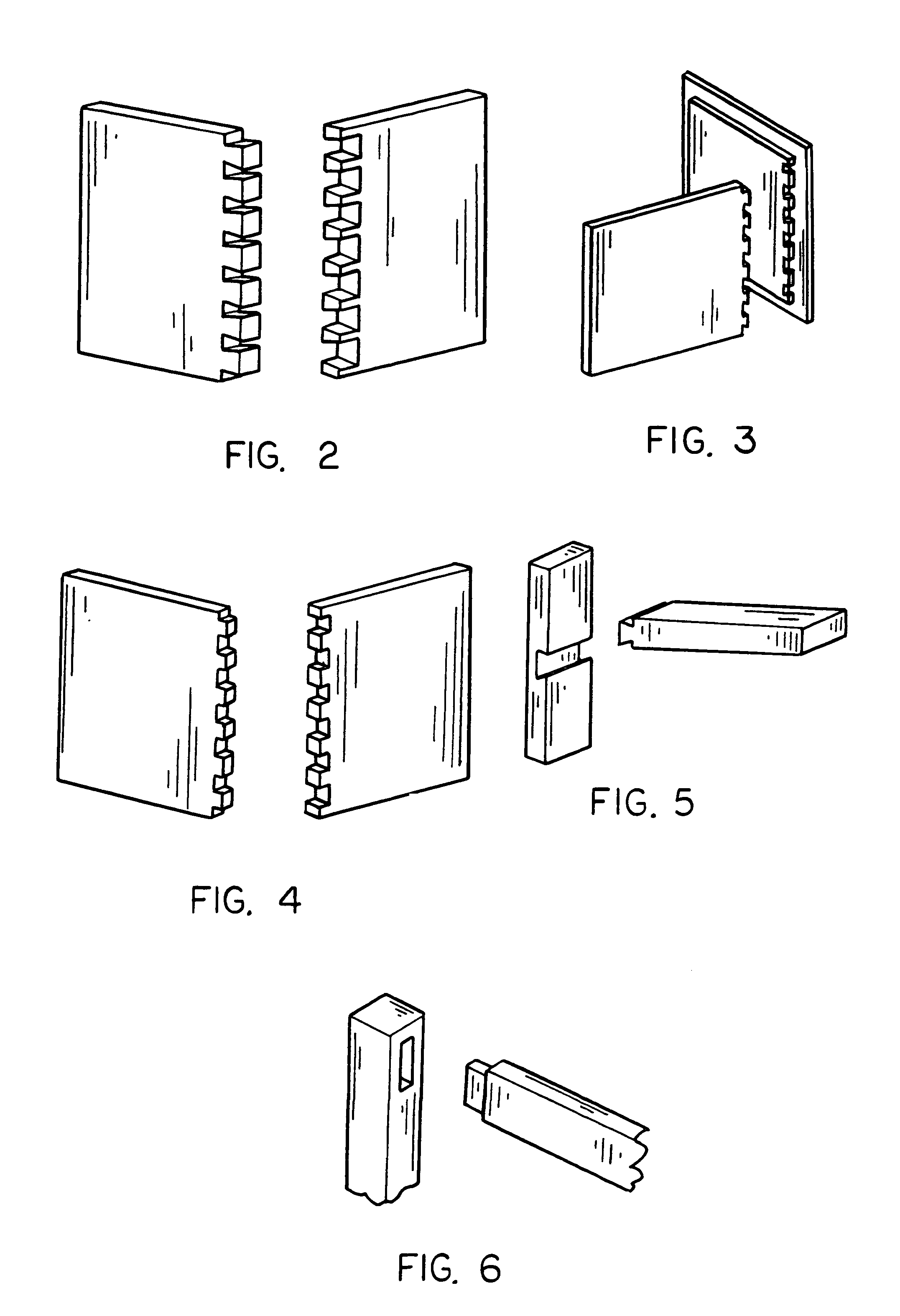

Jig apparatus

InactiveUS7455089B2Improve versatilityEffective positioningTongue/grooves making apparatusMulti-purpose machinesHand heldEngineering

A jig apparatus for aiding in the formation of a variety of mechanically interconnecting structures in workpieces. The jig apparatus may include a base and a template mounting system for adjustably positioning a template with respect to the base. A securing system for securing a workpiece in a desired position may be included. An adjustable workpiece mounting fence may also be included for varying the angular orientation of a workpiece to be shaped with respect to a template. Additionally, a collar guide system for a router for utilization with a template may be implemented with a hand held router being implemented for removing material from a workpiece. A router bit positioning system for aiding in establishing a pre-determined bit depth may be included.

Owner:BLACK & DECKER INC

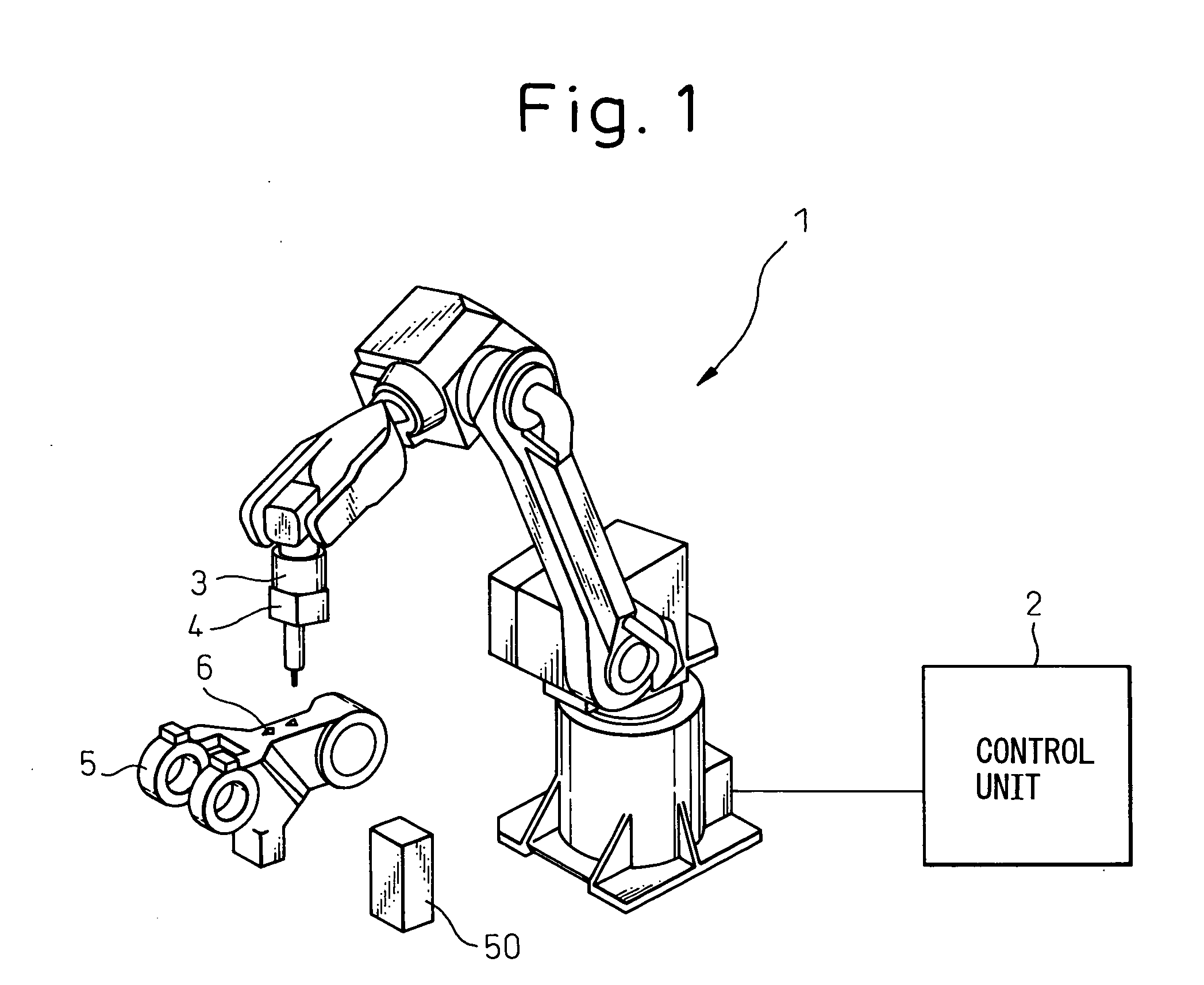

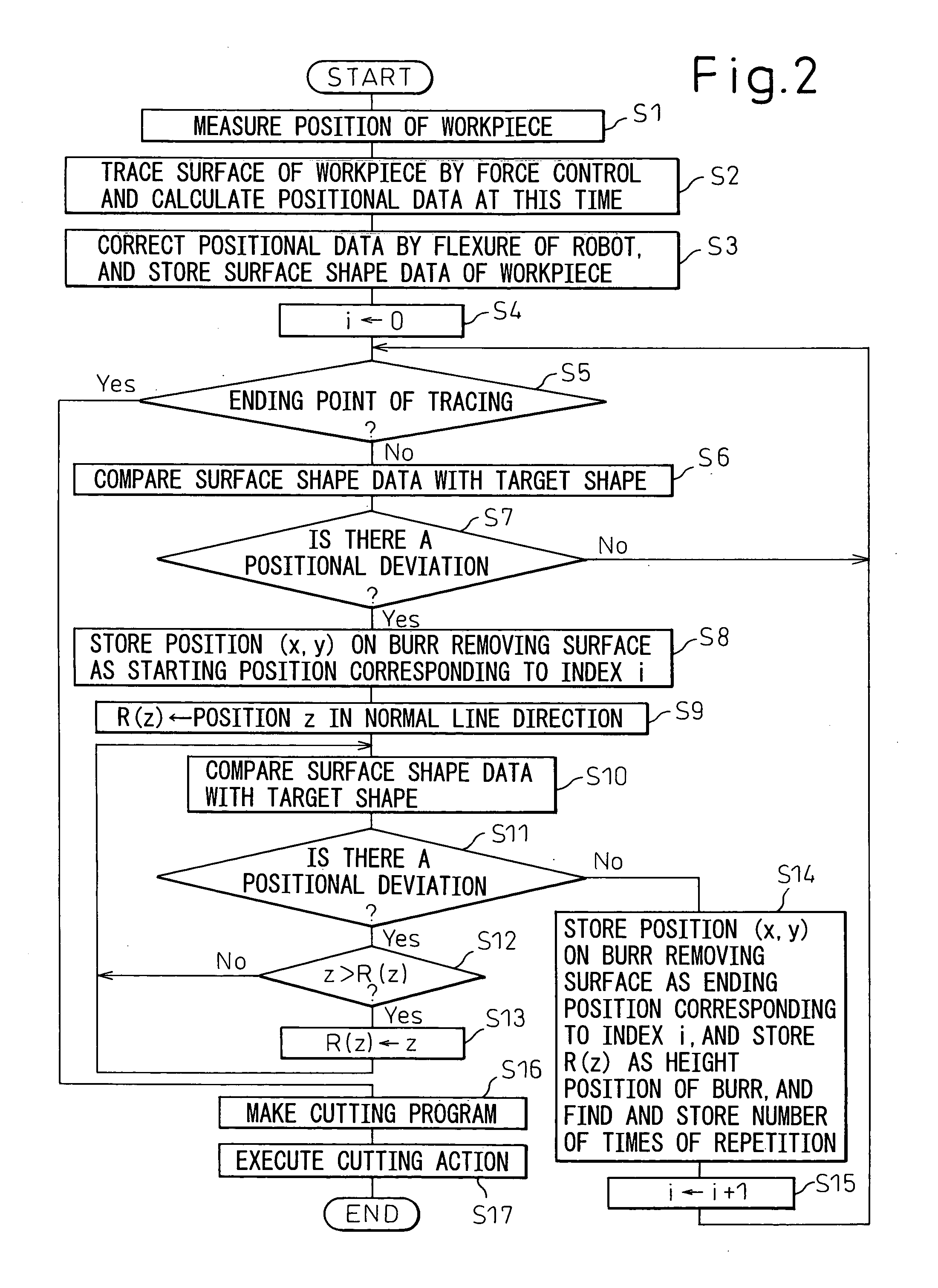

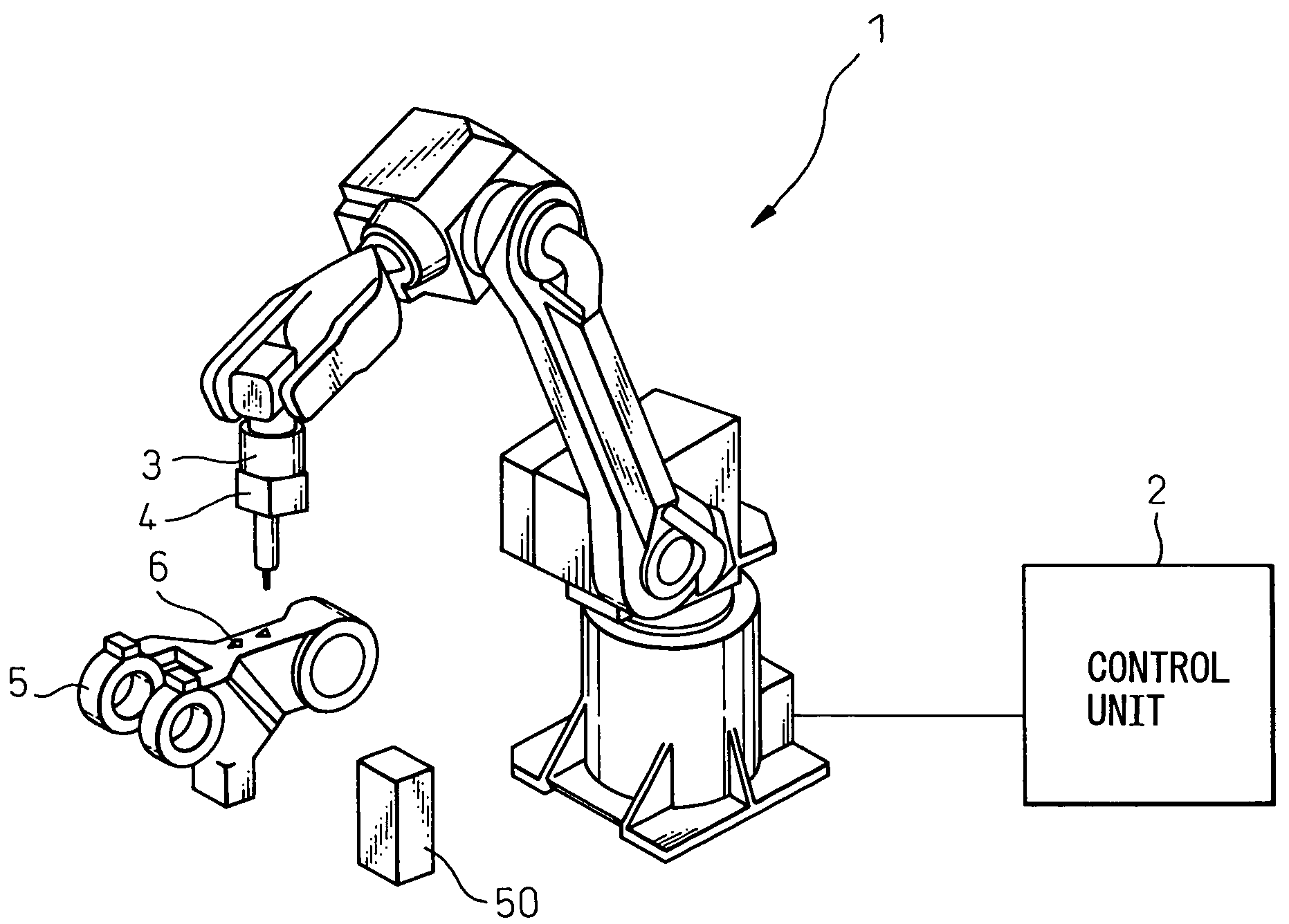

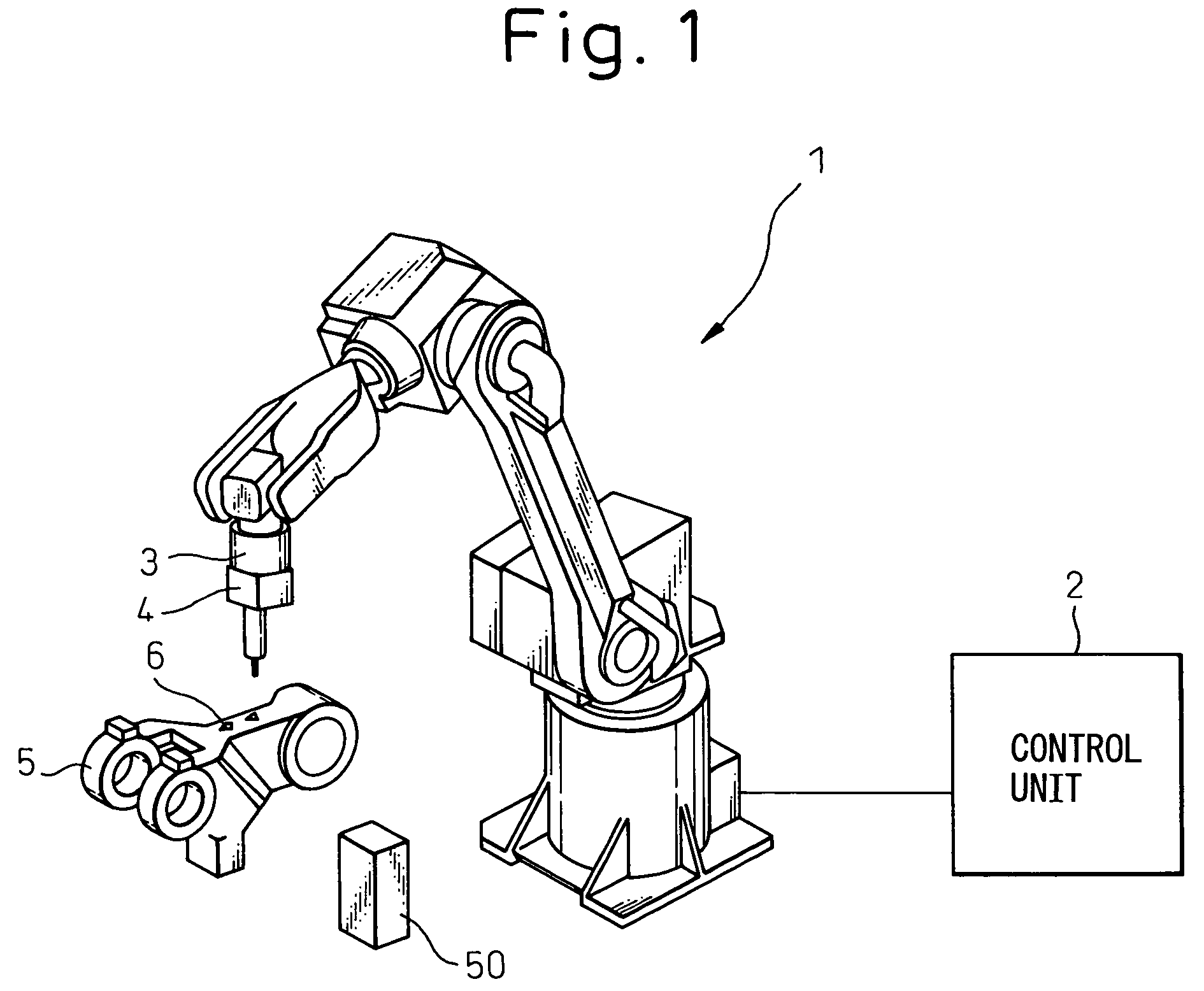

Finishing machine

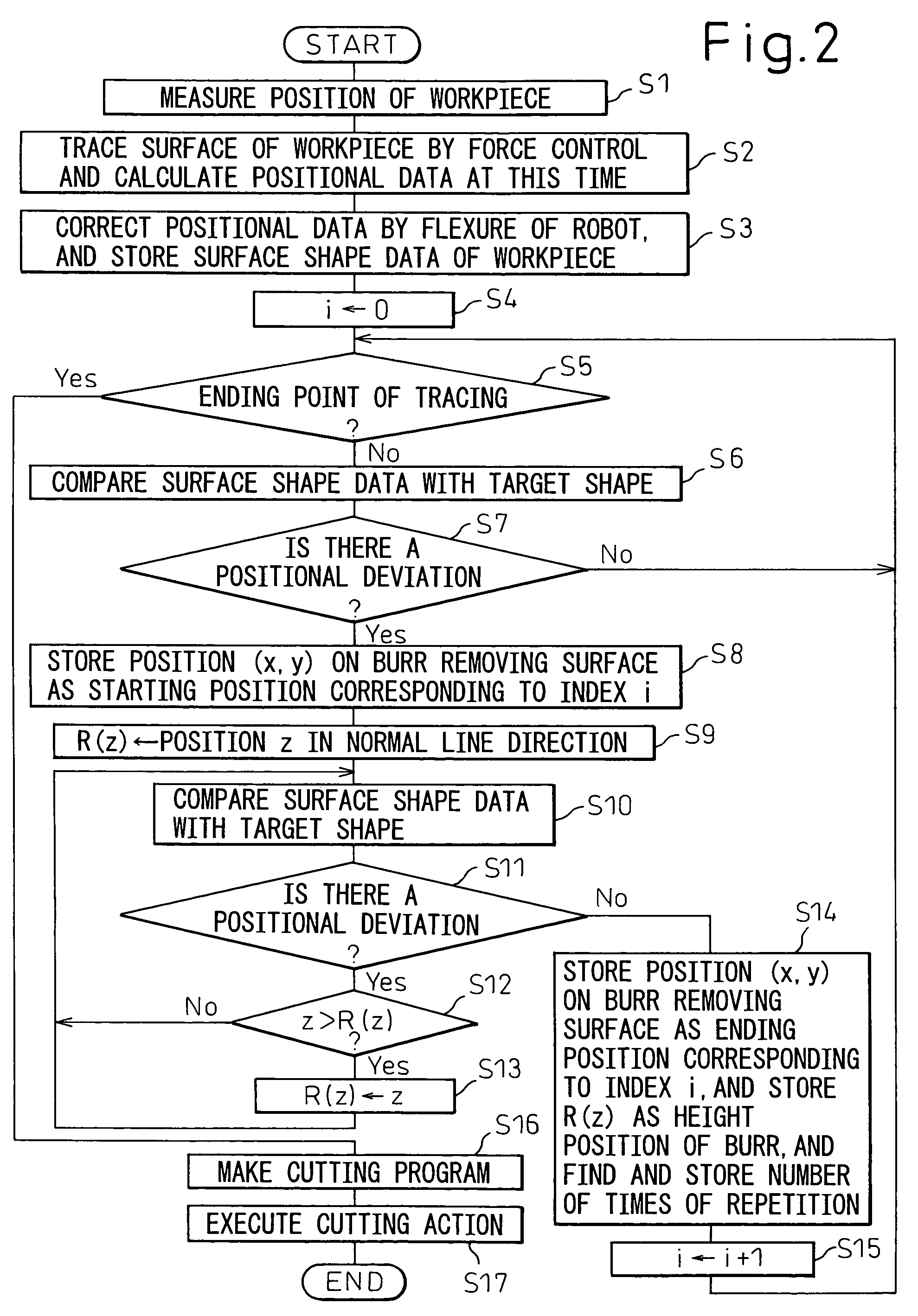

ActiveUS20060039768A1Guaranteed to workEfficient conductionProgramme controlComputer controlMachine toolSurface shape

A surface of a workpiece, from which the burr is removed, is traced when a machining tool is pressed onto the surface of the workpiece under force control so as to find the positional data of the surface shape (S1). This positional data is corrected by an error caused by a bend of a robot (S2). The thus obtained positional data is compared with the target shape of the surface, from which the burr is removed, obtained from CAD data (S6, S10). A shift of the surface shape in the normal line direction is found (S7, S11). The burr generation start position, the burr generation end position and the height of the burr are found by the shift start position (S8), the shift end position and the shift size (S14). A machining program is made which is composed of a pass connecting the burr end position with the burr start position and also composed of a cutting pass for removing the burr, and the thus made machining program is executed (S16, S17). As the burr position is found and the burr is removed when the machining tool is moved to the burr position, the burr can be effectively removed. Due to the foregoing, it is possible to provide a finishing machine characterized in that useless burr removing actions can be reduced and, further, that the overcutting of a workpiece can be prevented.

Owner:FANUC LTD

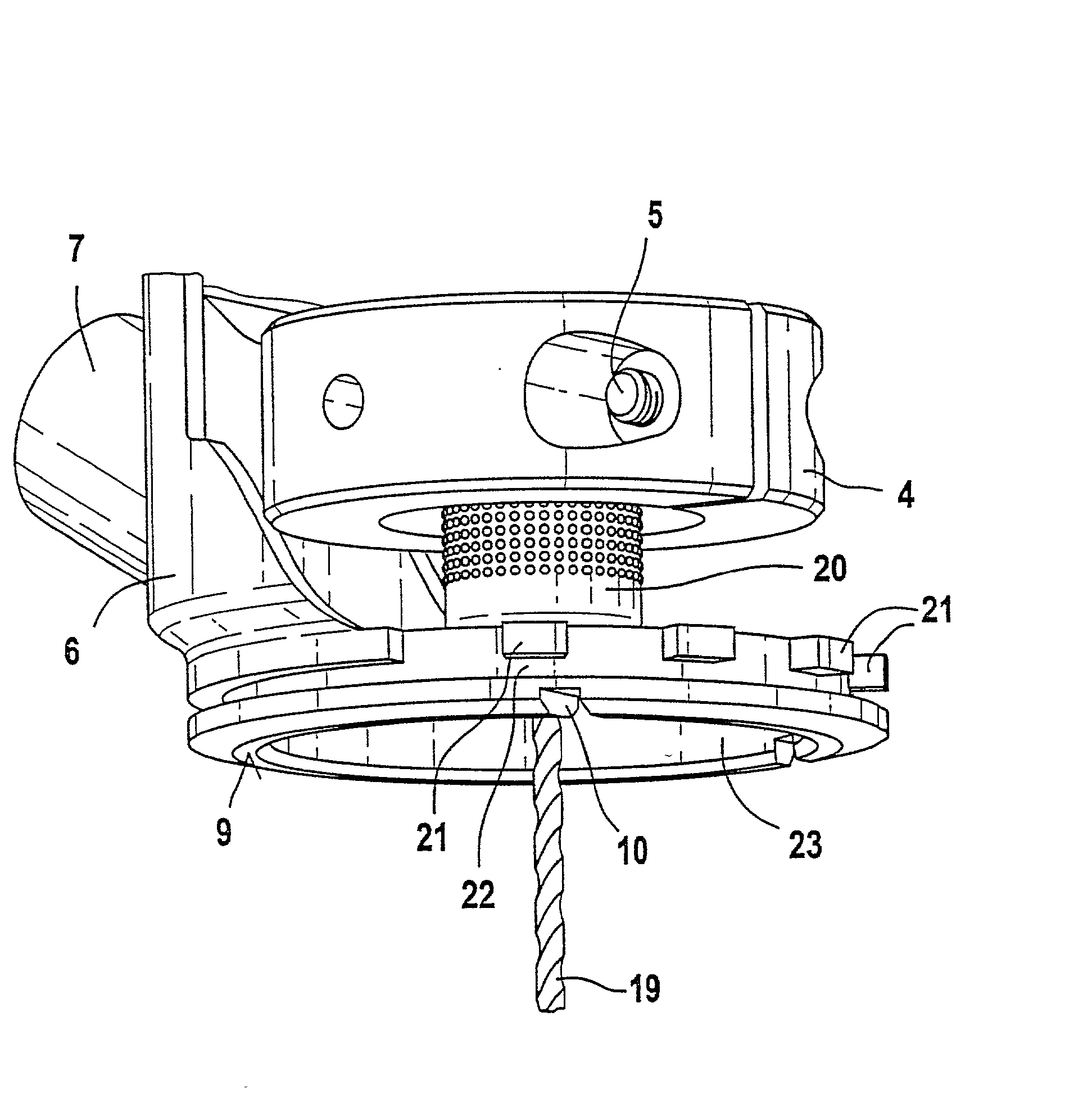

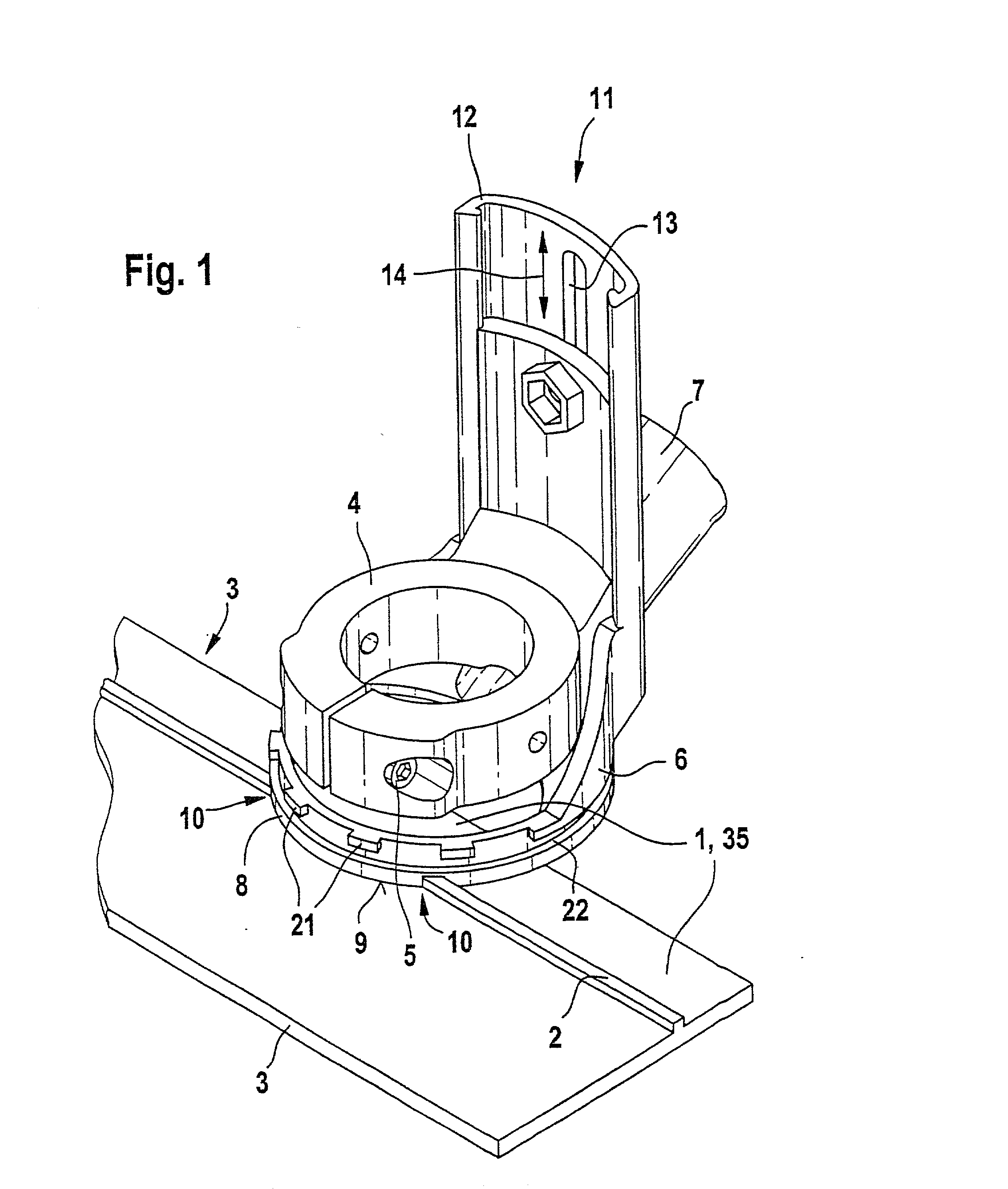

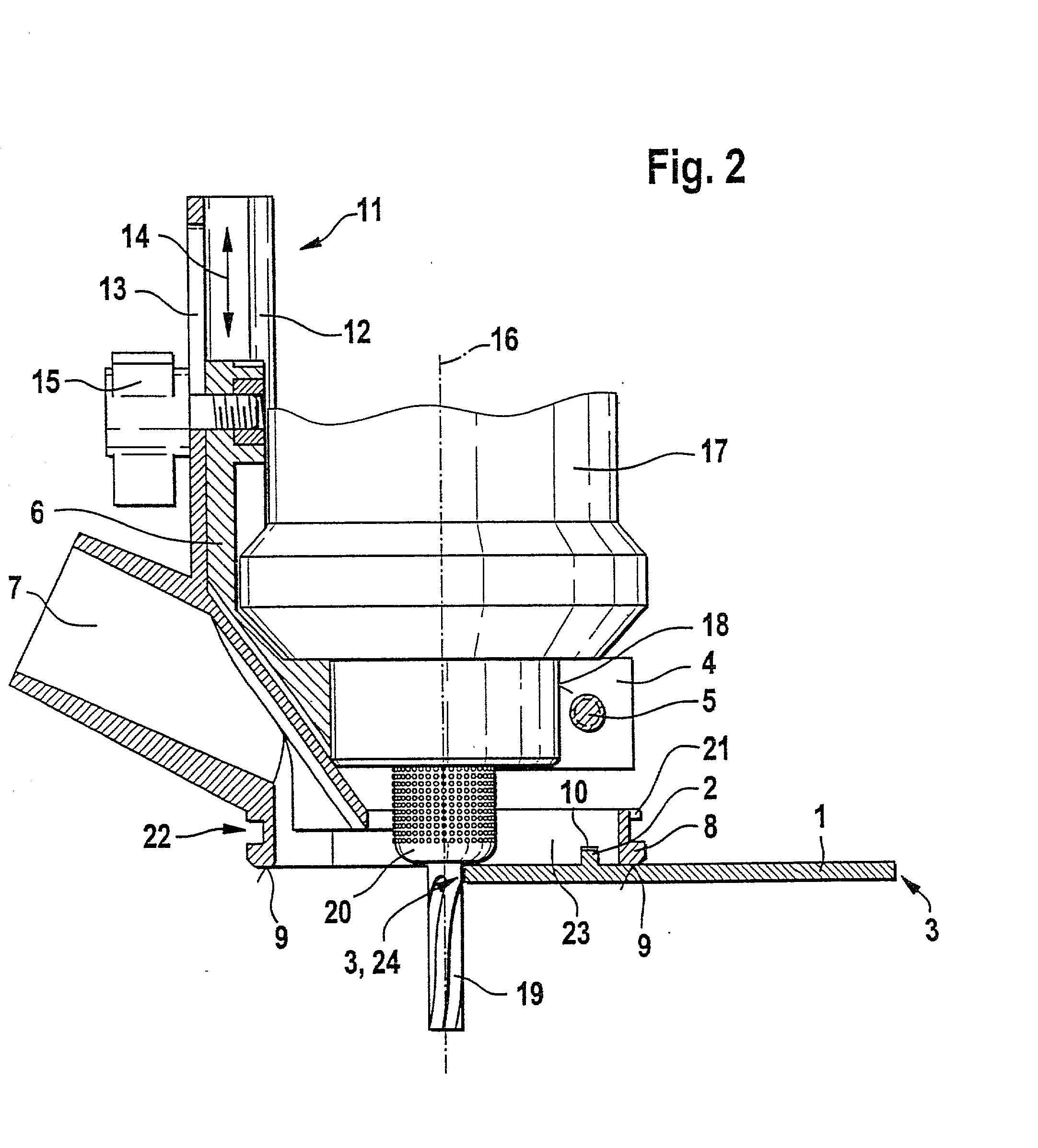

Electric tool comprising a universal mounting for tool attachments

InactiveUS20020187014A1Increase flexibilityMilling cuttersMulti-purpose machinesEngineeringPower tool

The invention relates to an electric power tool with a housing, in which a drive mechanism is received; the electric power tool includes a shaft, with a chuck (20) received in it, for receiving a tool insert (19). The chuck (20) is surrounded by an annular bearing face (9). The bearing face (8, 9) includes receiving elements that enable the guidance of the electric power tool on a guide rail (1, 35), such as receptacles (21, 22; 31, 32) and (33) for slip-on tools (25), such as templates, that can be received on the support (8, 9).

Owner:ROBERT BOSCH GMBH

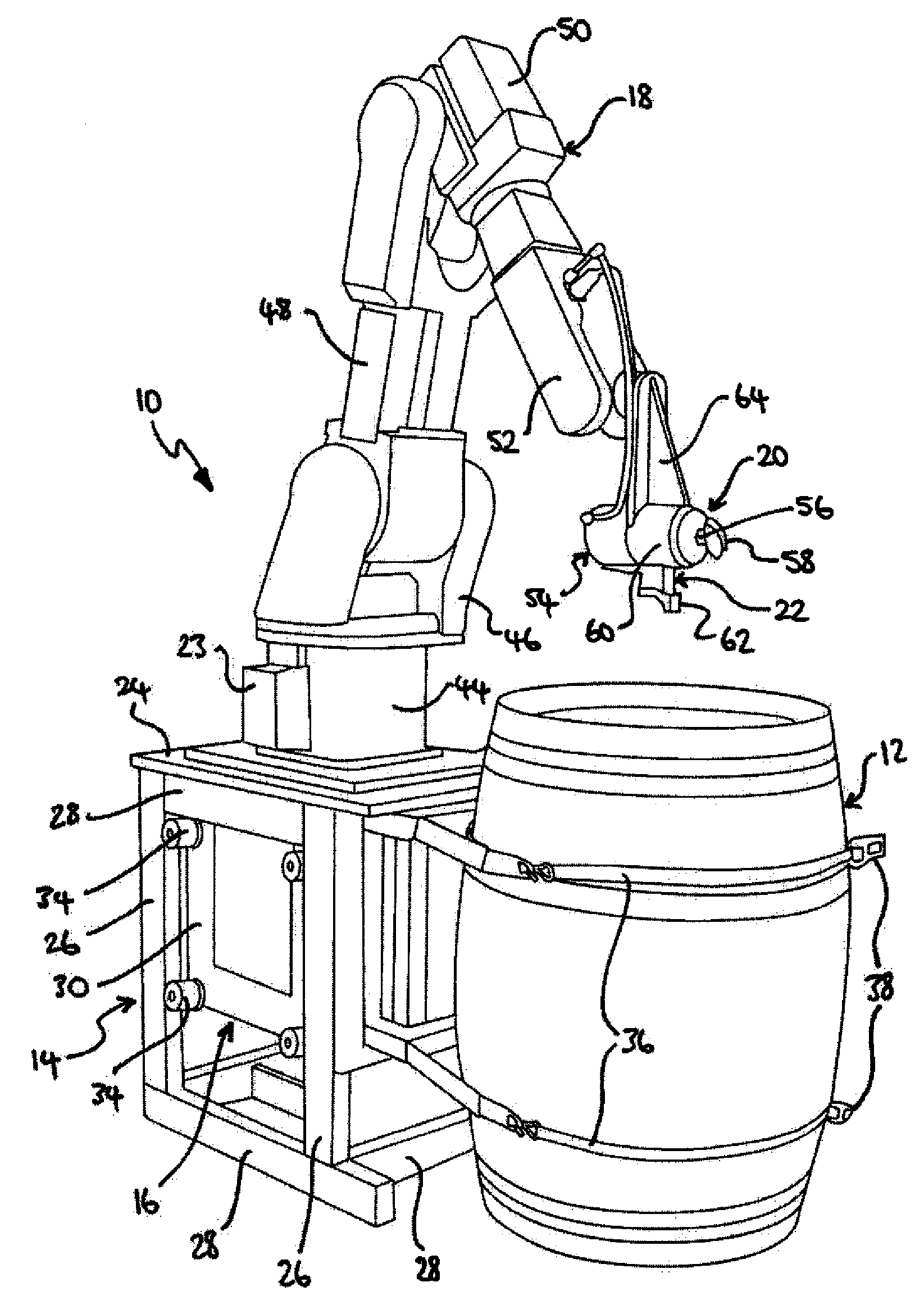

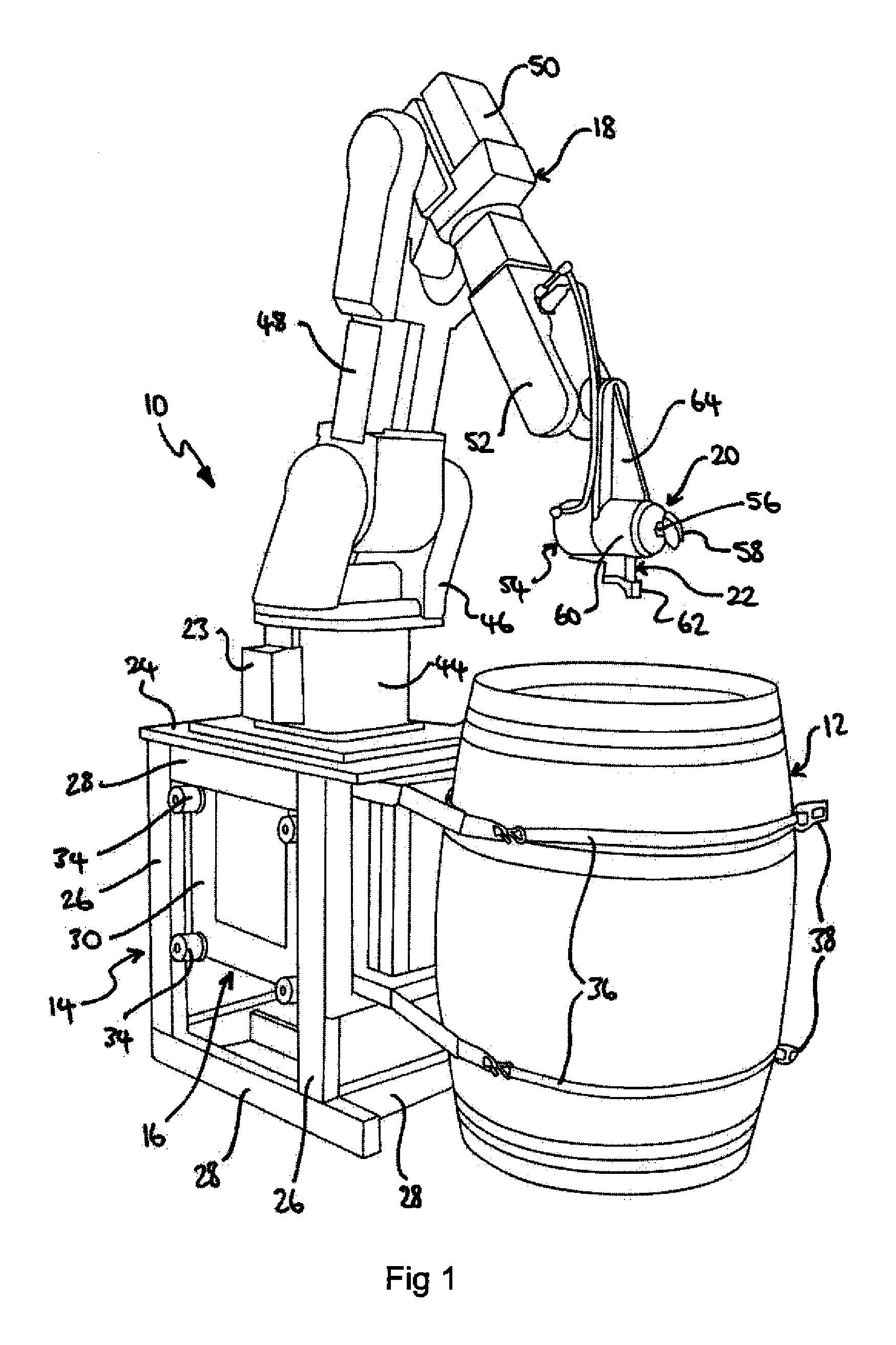

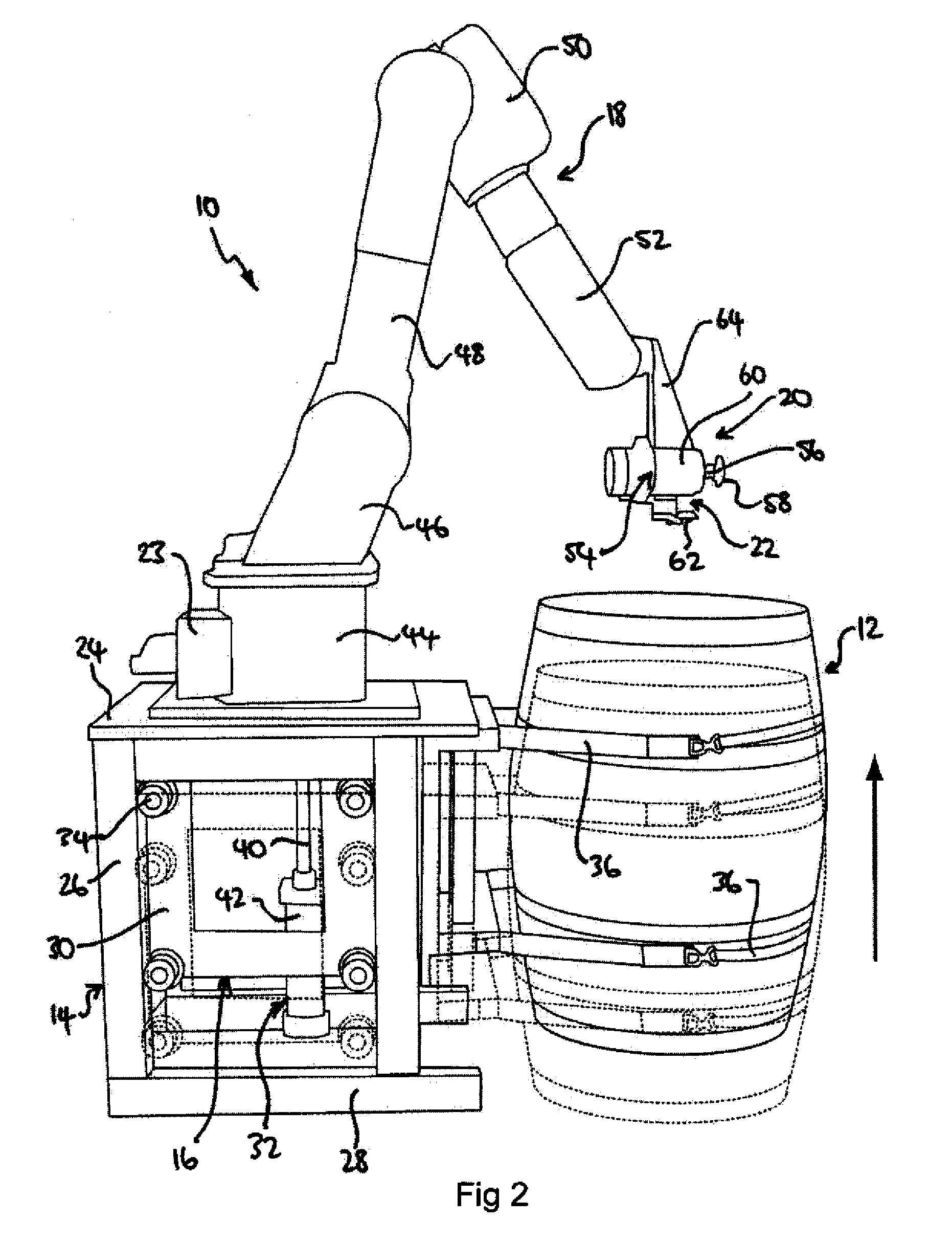

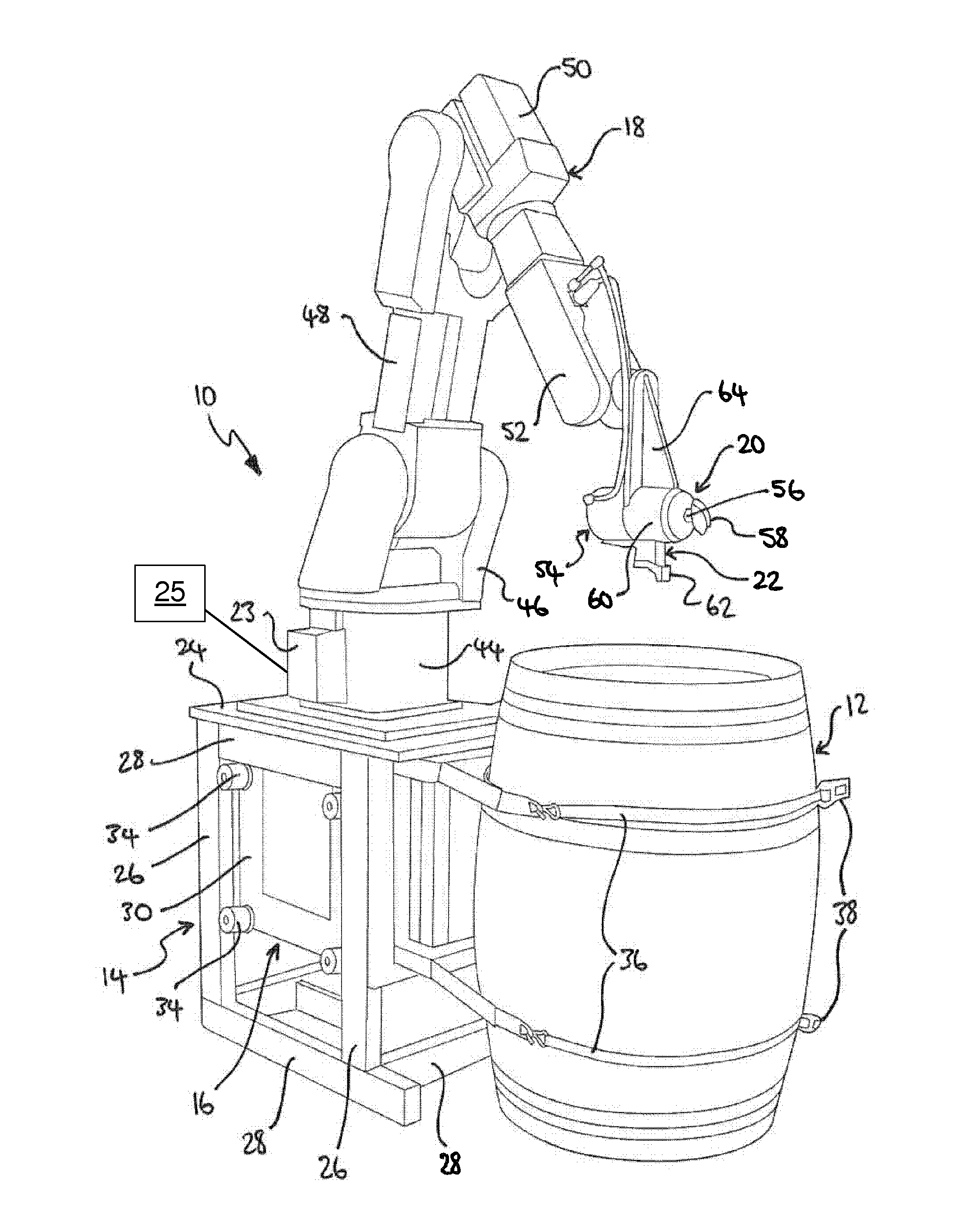

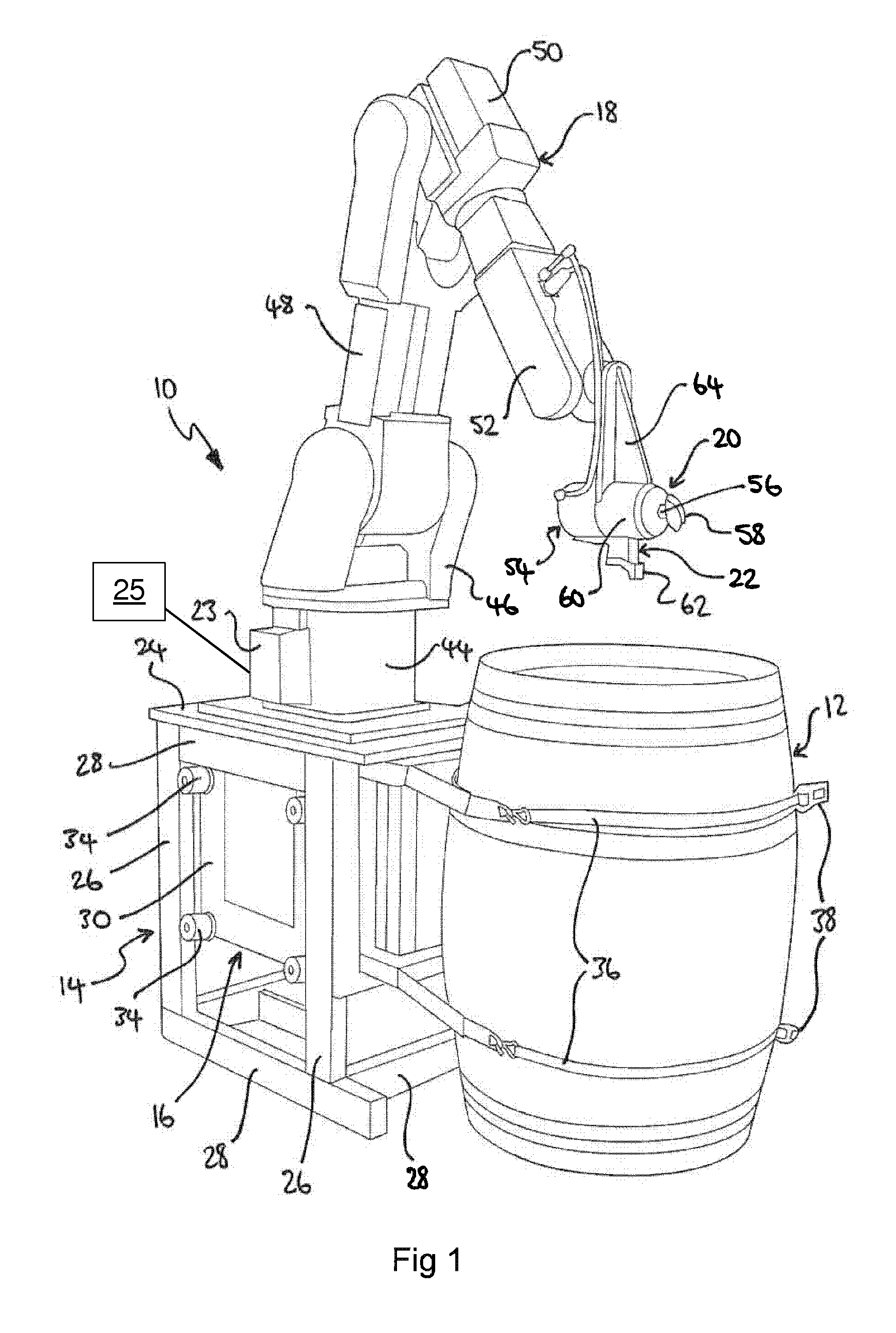

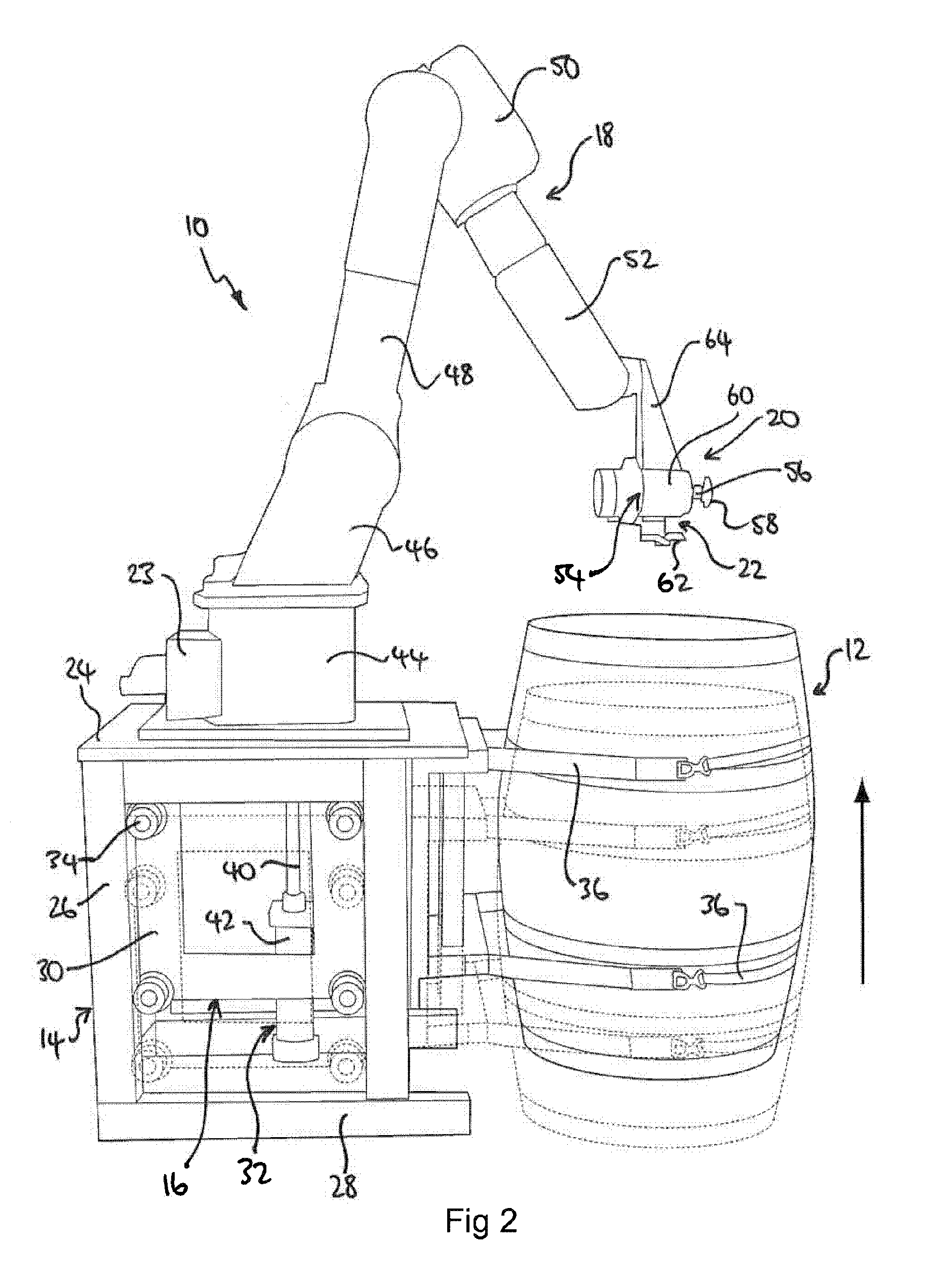

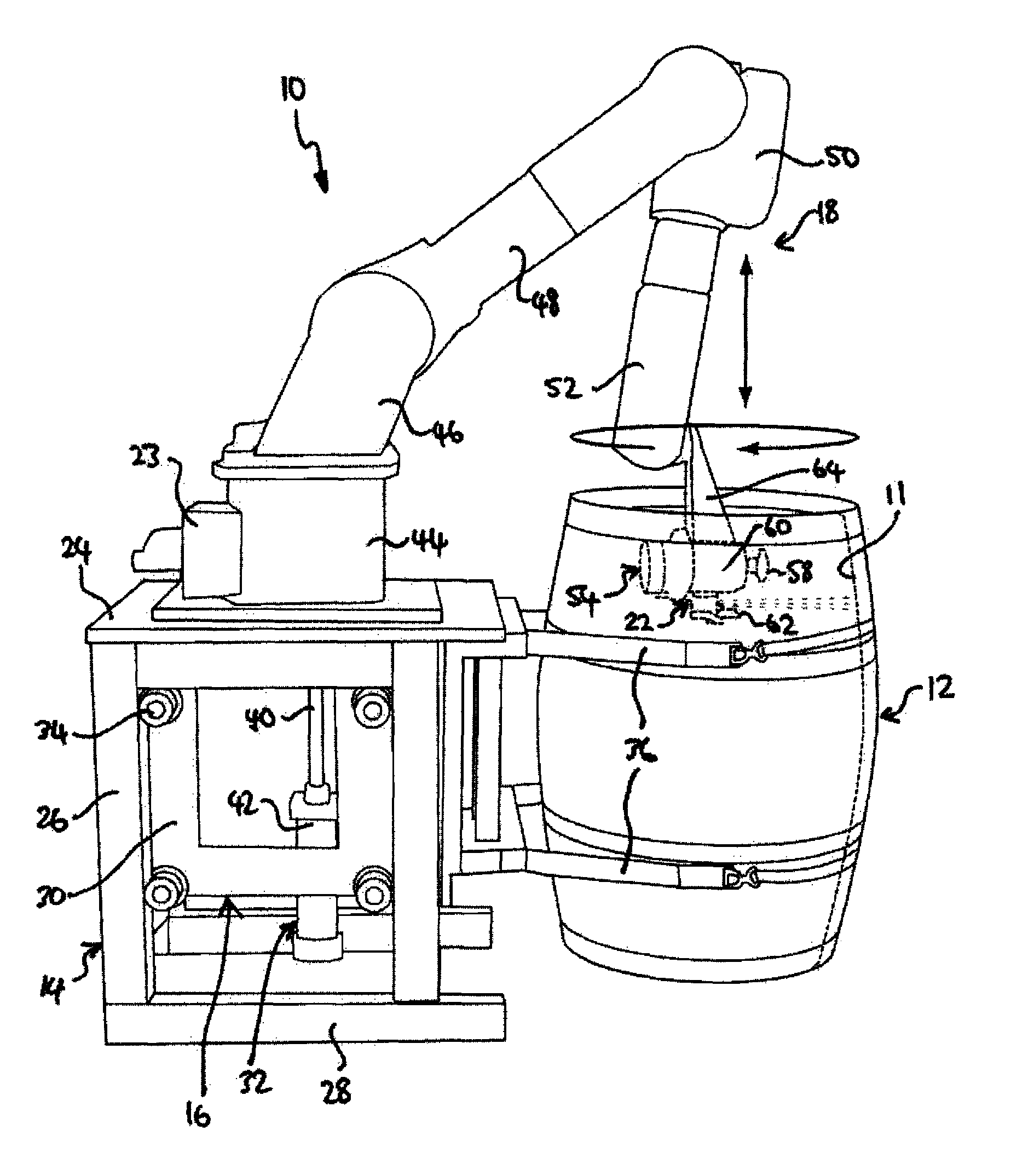

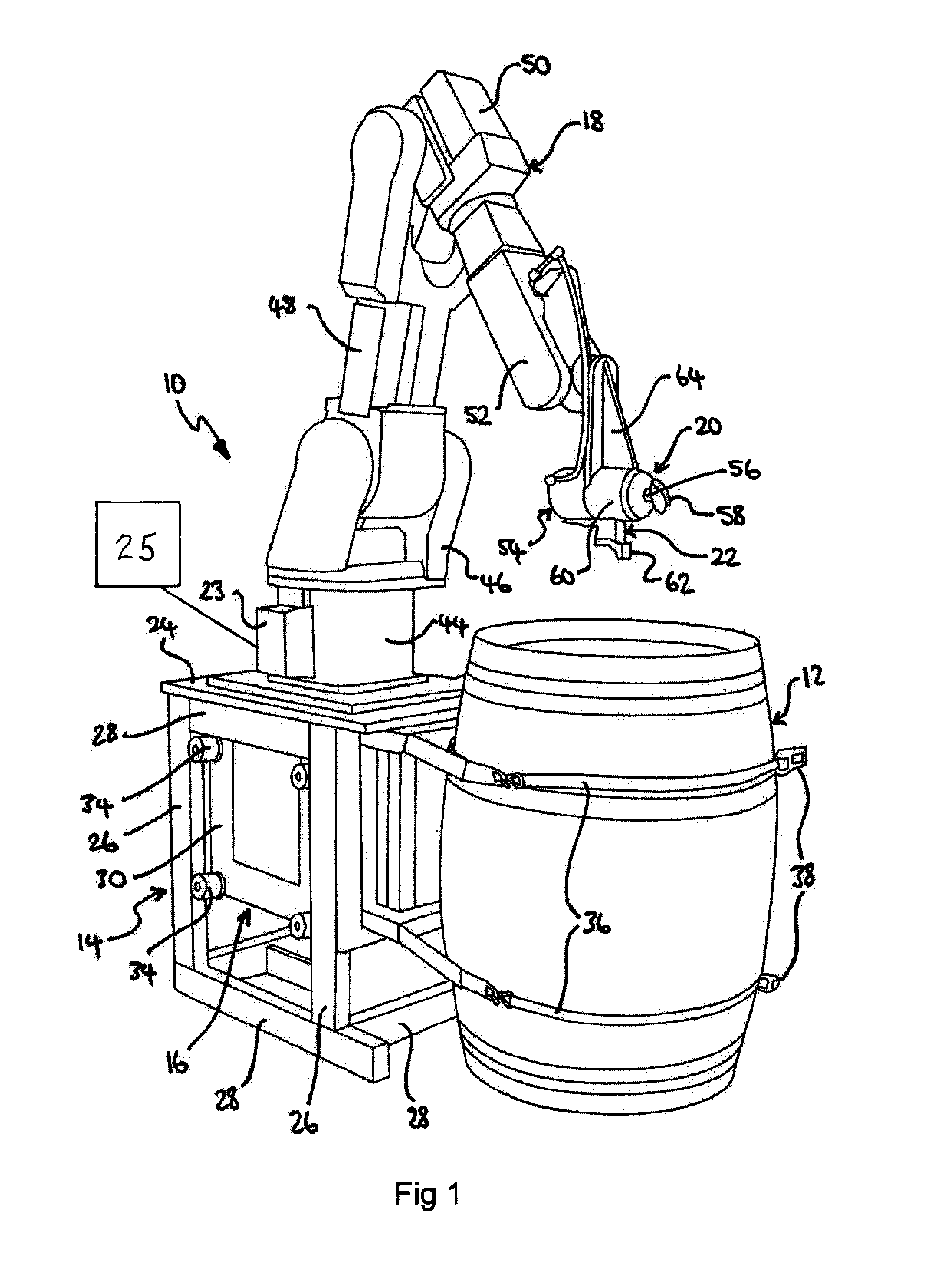

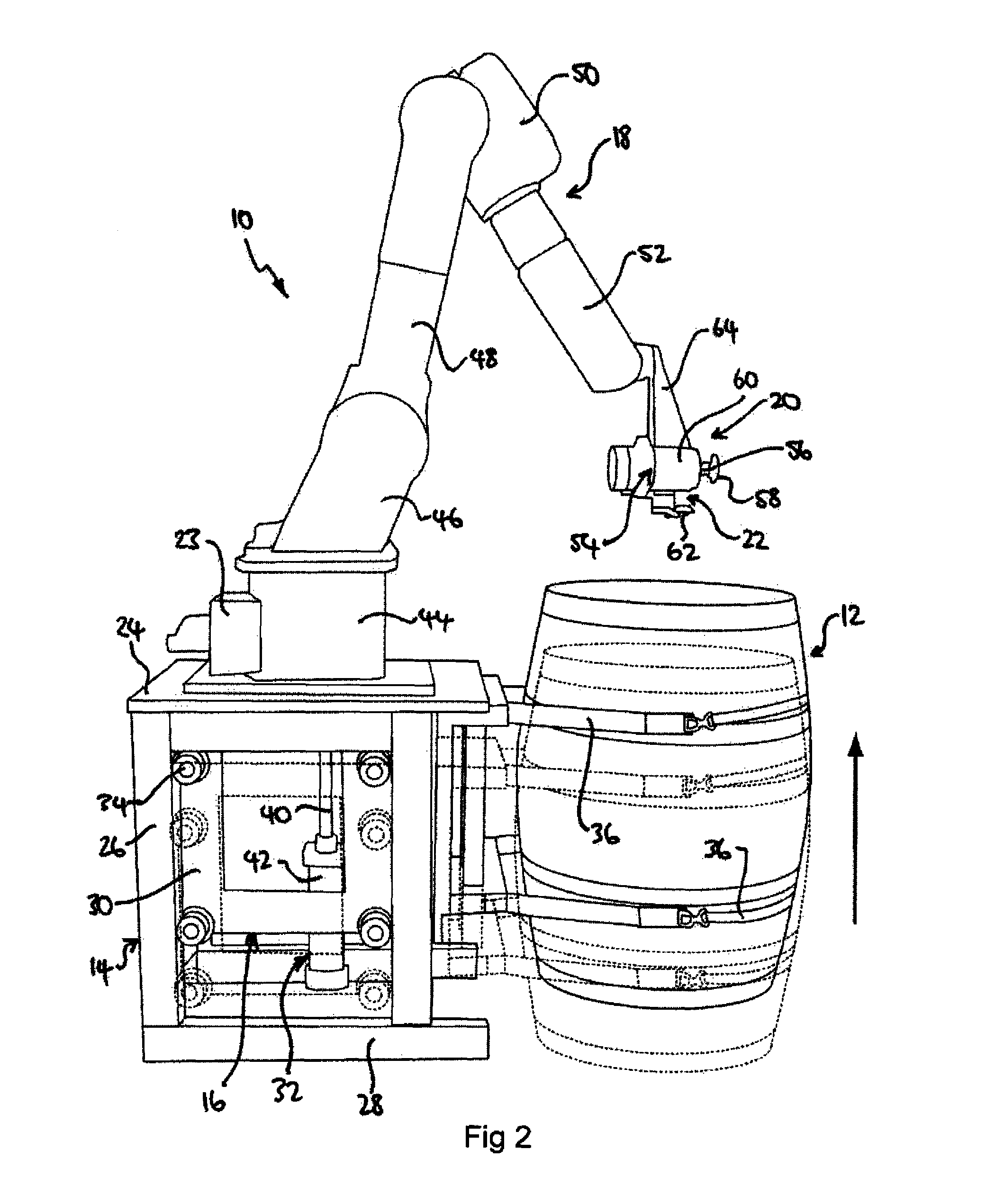

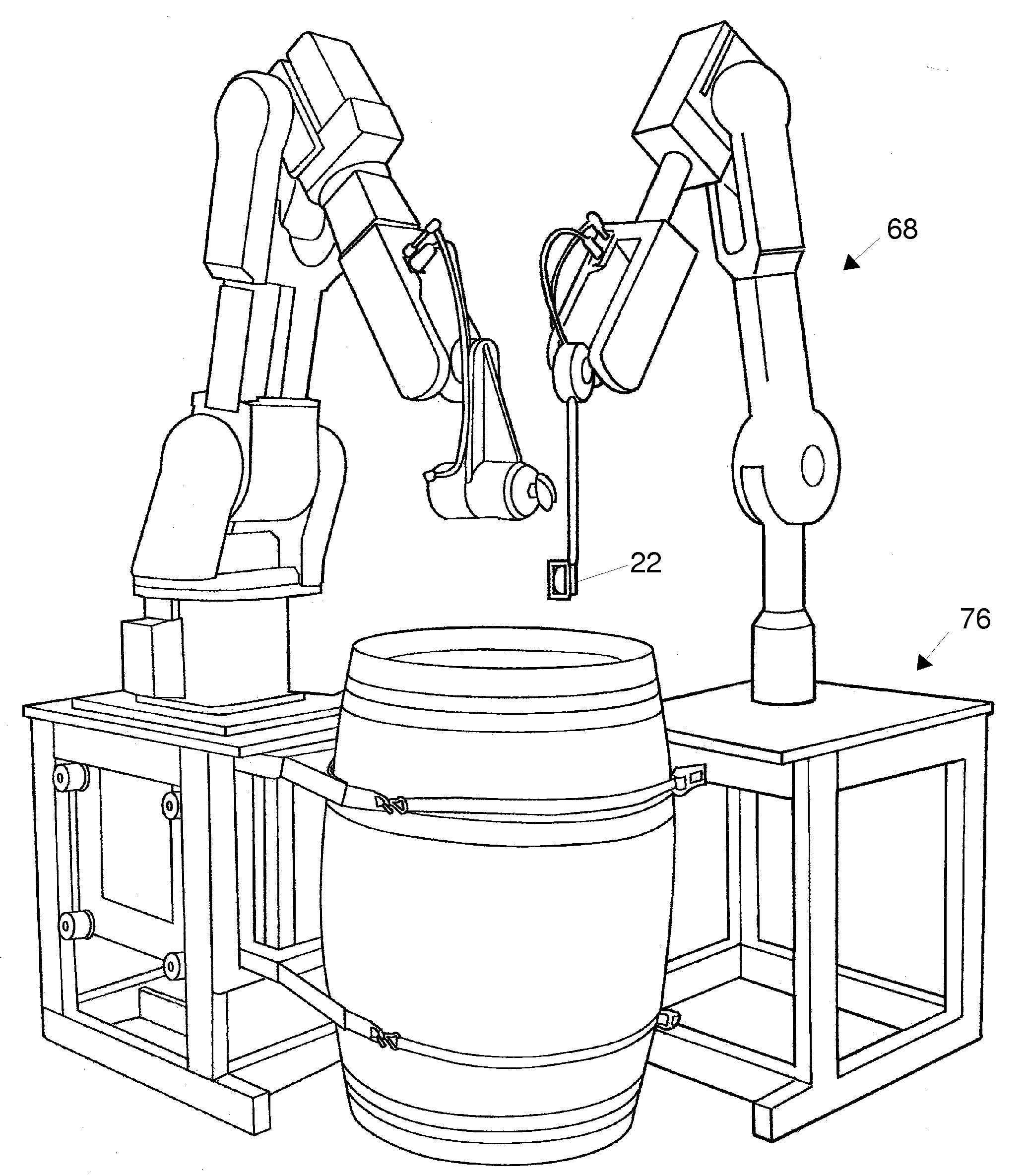

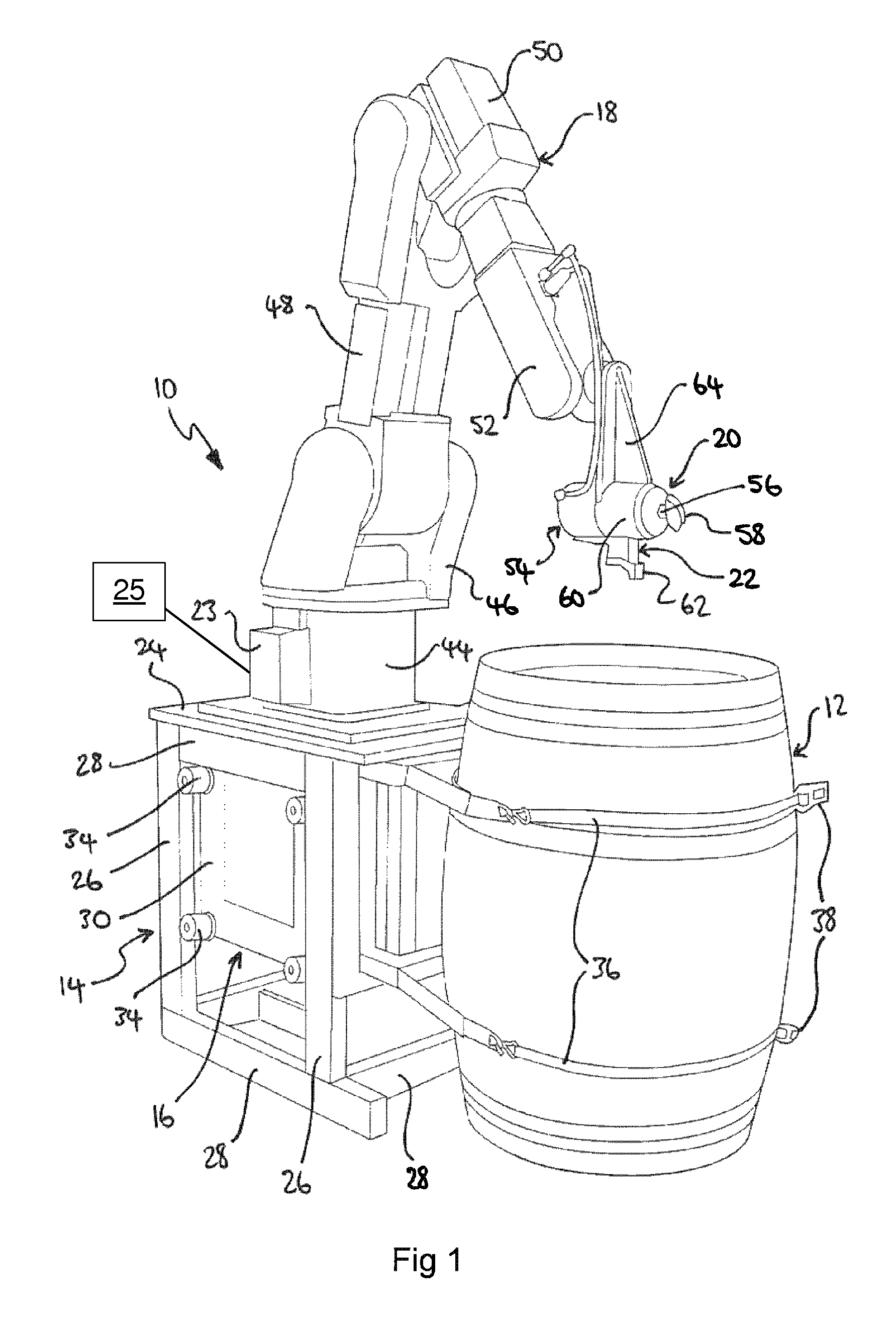

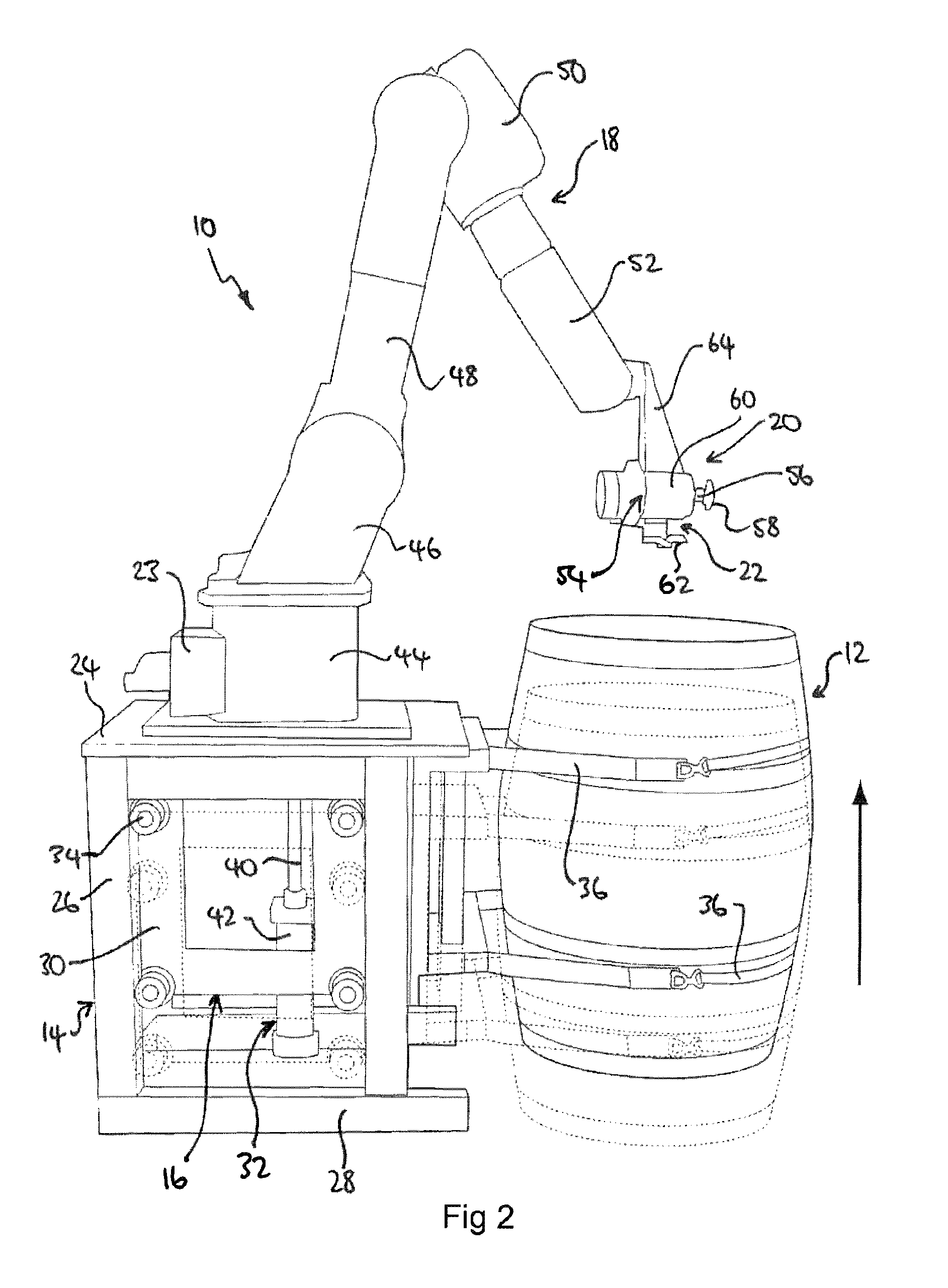

Apparatus and method for shaving the inside of barrels

The present invention relates to an apparatus and method for shaving the inside of barrels. In particular, the present invention relates to reconditioning used wine barrels by shaving the inside surface to a predetermined depth, ready for re-crozering, toasting, and re-use. Conventional shaving methods typically involve routing the internal surface by hand, but this technique is problematic in that it is a very slow process, the quality of the wood is often adversely affected, and there is no way of ensuring that the surface will be shaved to the same depth across the entire surface. Therefore, the resultant internal dimensions of the barrel are not reflective, relatively, of the original barrel surface. The apparatus of the present invention includes a scanning means adapted to scan the internal dimensions of the barrel, and a cutting means adapted to shave the internal surface to a predetermined depth relative to the scanned internal dimensions.

Owner:SOUTHERN CROSS COOPERAGE

Method of machining airfoil root fillets

An airfoil root fillet having a predetermined compound curve profile can be flank milled with a single flank milling cutter having a generally conical flank milling portion and a rounded tip portion defining a compound curve.

Owner:PRATT & WHITNEY CANADA CORP

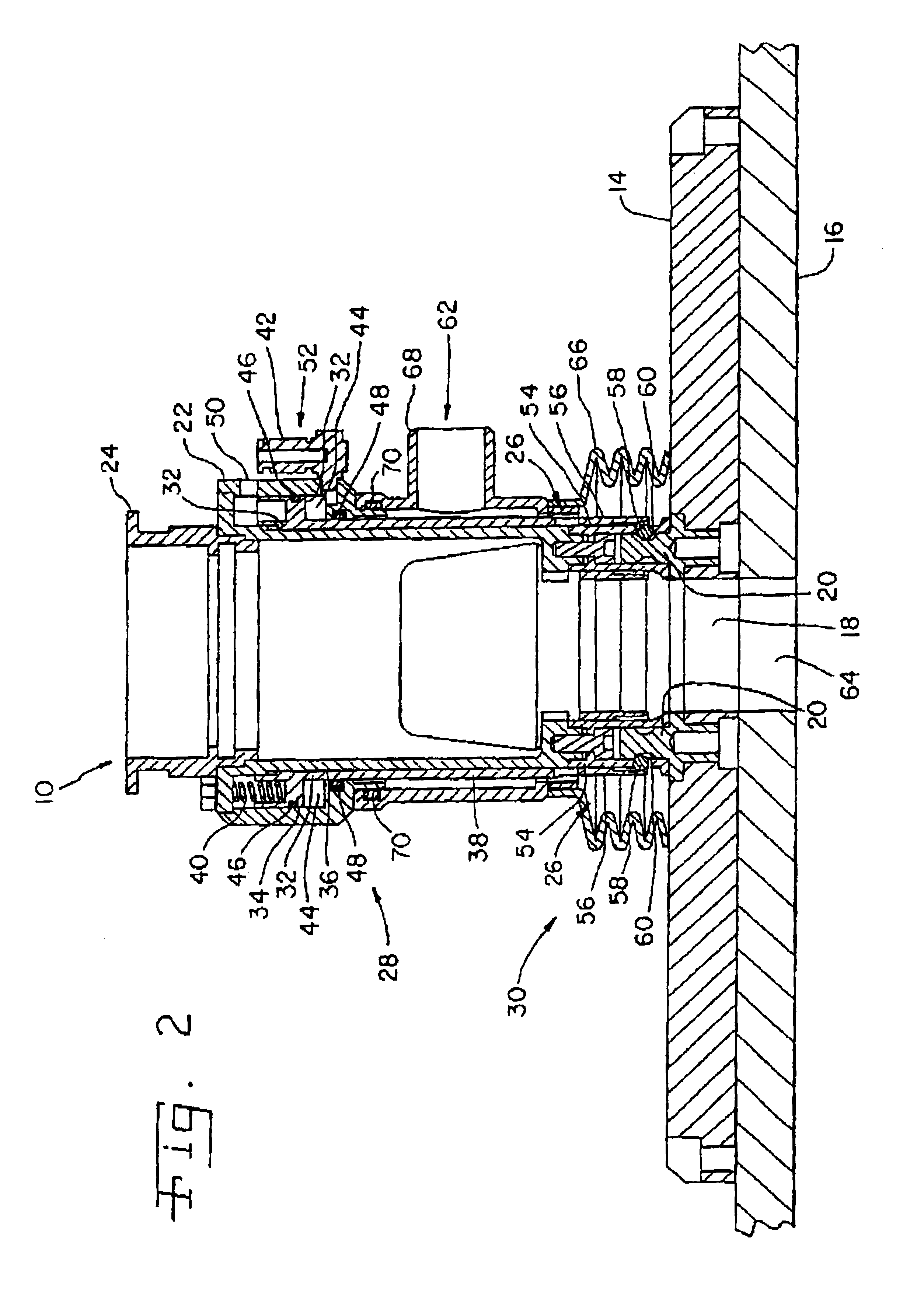

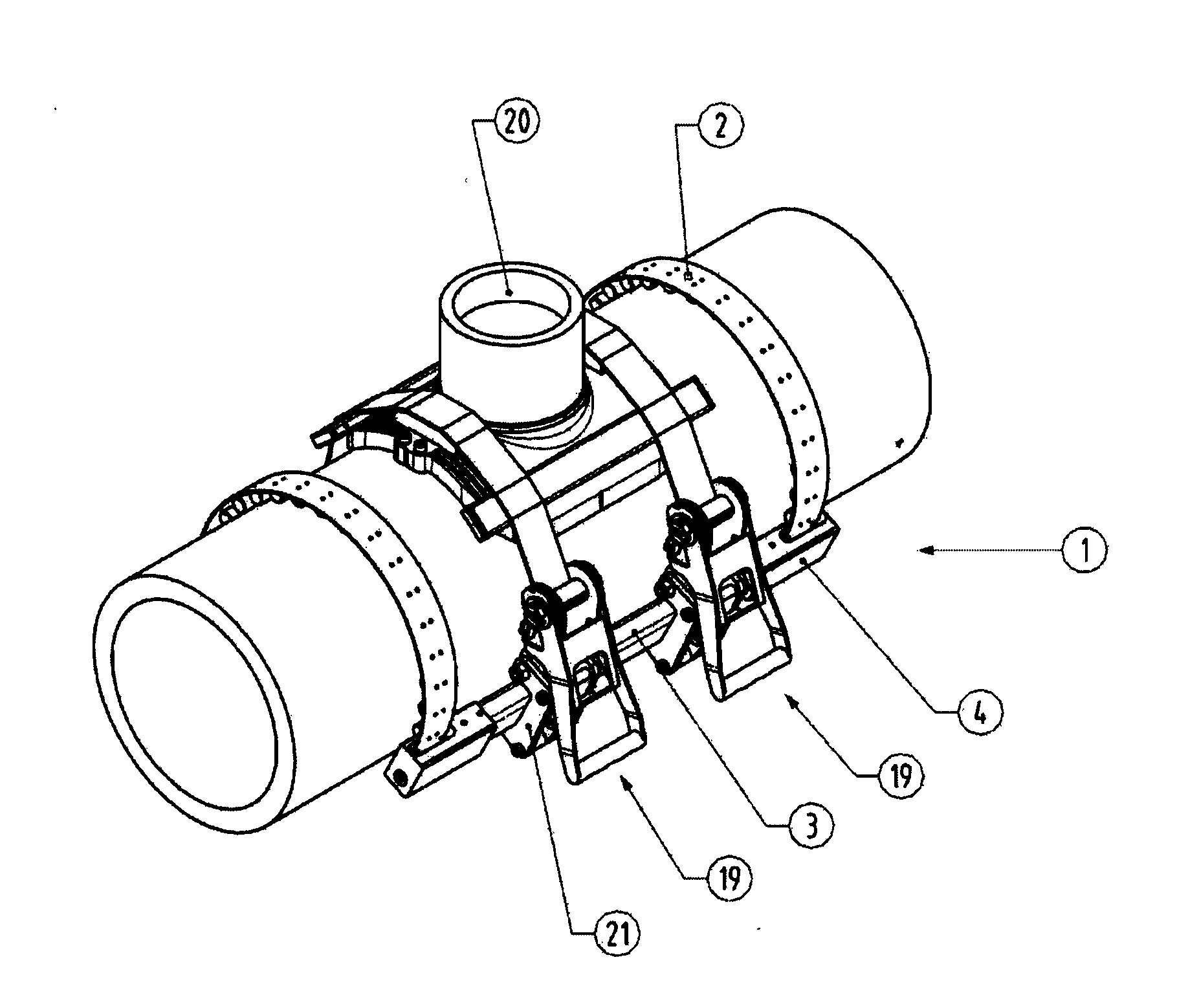

Fixation device for a portable orbital drilling unit

InactiveUS6902361B2Facilitated releaseDrilling/boring measurement devicesTurning machine accessoriesMachine tool

A fixation device for positioning a rotating machine tool onto a template, the template having at least one hole and at least one locating pin. The fixation device includes a housing with a housing tool end and a housing template end, a seat located on the housing tool end for coupling with the rotating machine tool, and a clamping mechanism disposed at least partially at the housing template end for coupling with at least one locating pin.

Owner:NOVATOR

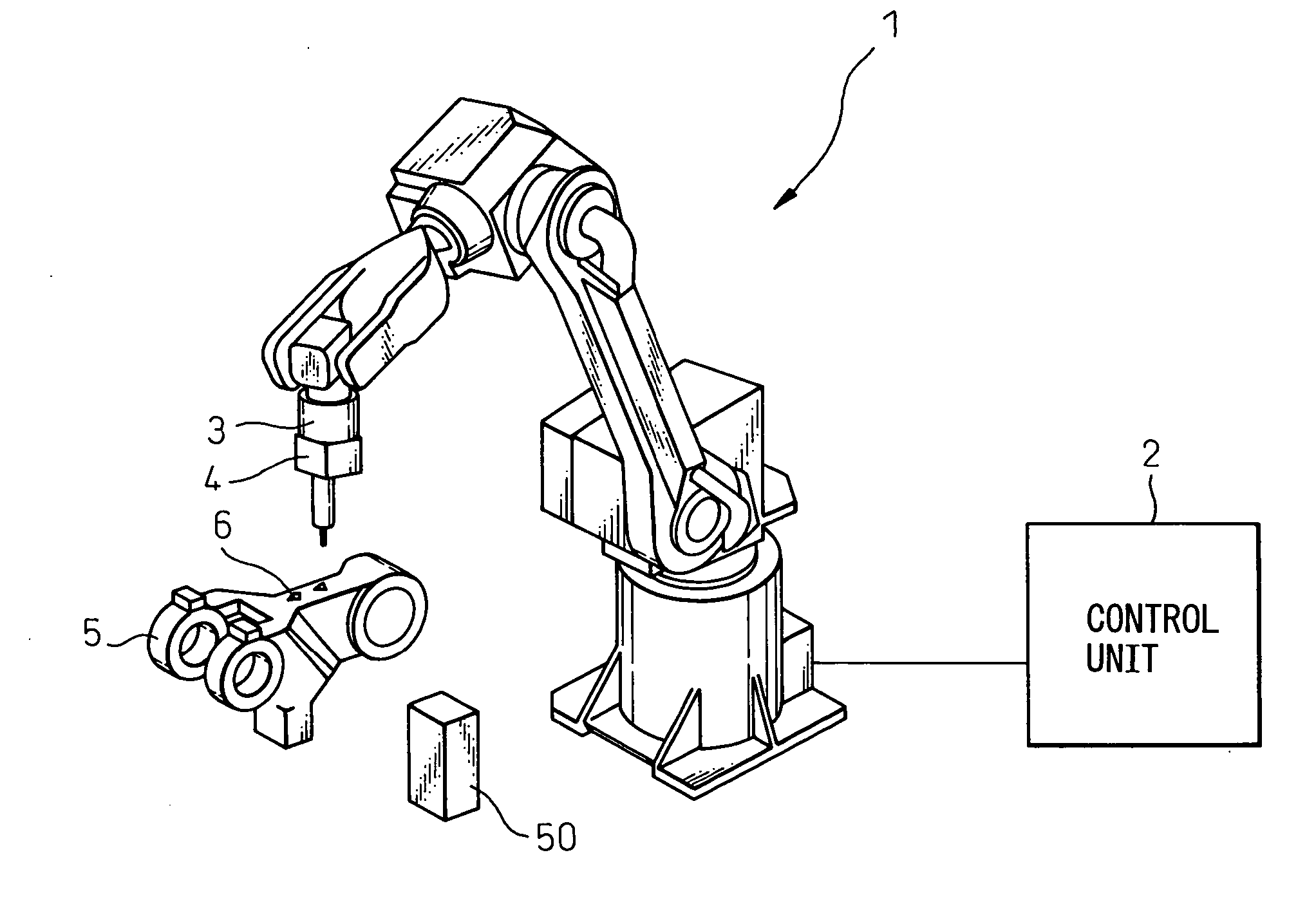

Finishing machine

A surface of a workpiece is traced when a machining tool is pressed onto the surface of the workpiece under force control so as to find the positional data of the surface shape. This positional data is corrected by an error caused by a bend of a robot. The positional data is compared with the target shape of the surface, from which the burr is removed. A shift of the surface shape in the normal line direction is found. The burr generation start position, the burr generation end position and the height of the burr are found by the shift start position, the shift end position and the shift size. A machining program is made which is composed of a pass connecting the burr end position with the burr start position and also composed of a cutting pass for removing the burr, and the thus made machining program is executed. As the burr position is found and the burr is removed when the machining tool is moved to the burr position, the burr can be effectively removed.

Owner:FANUC LTD

Apparatus and method for shaving the inside of barrels

An apparatus and method for shaving the inside of barrels. The invention relates to reconditioning used wine barrels by shaving the inside surface to a predetermined depth, ready for re-crozering, toasting, and re-use. Conventional shaving methods typically involve routing the internal surface by hand, but this technique is problematic in that it is a very slow process, the quality of the wood is often adversely affected, and there is no way of ensuring that the surface will be shaved to the same depth across the entire surface. The resultant internal dimensions of the barrel are not reflective, relatively, of the original barrel surface. The invention includes a scanning device to scan the internal dimensions of the barrel, and a cutting device to shave the internal surface to a predetermined depth relative to the scanned internal dimensions and where the scanning device and the cutting device may be supported by different robotic arms.

Owner:SOUTHERN CROSS COOPERAGE

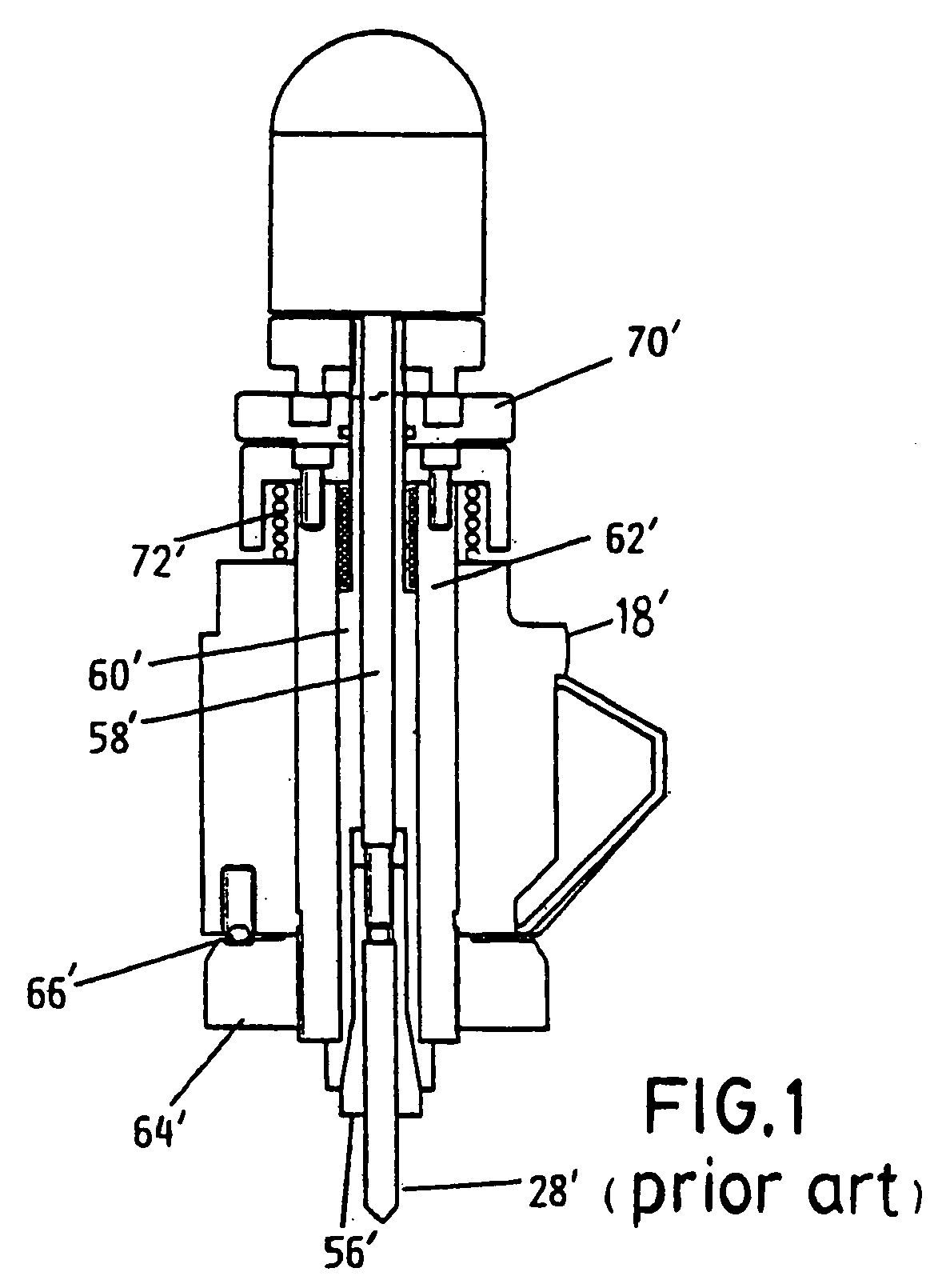

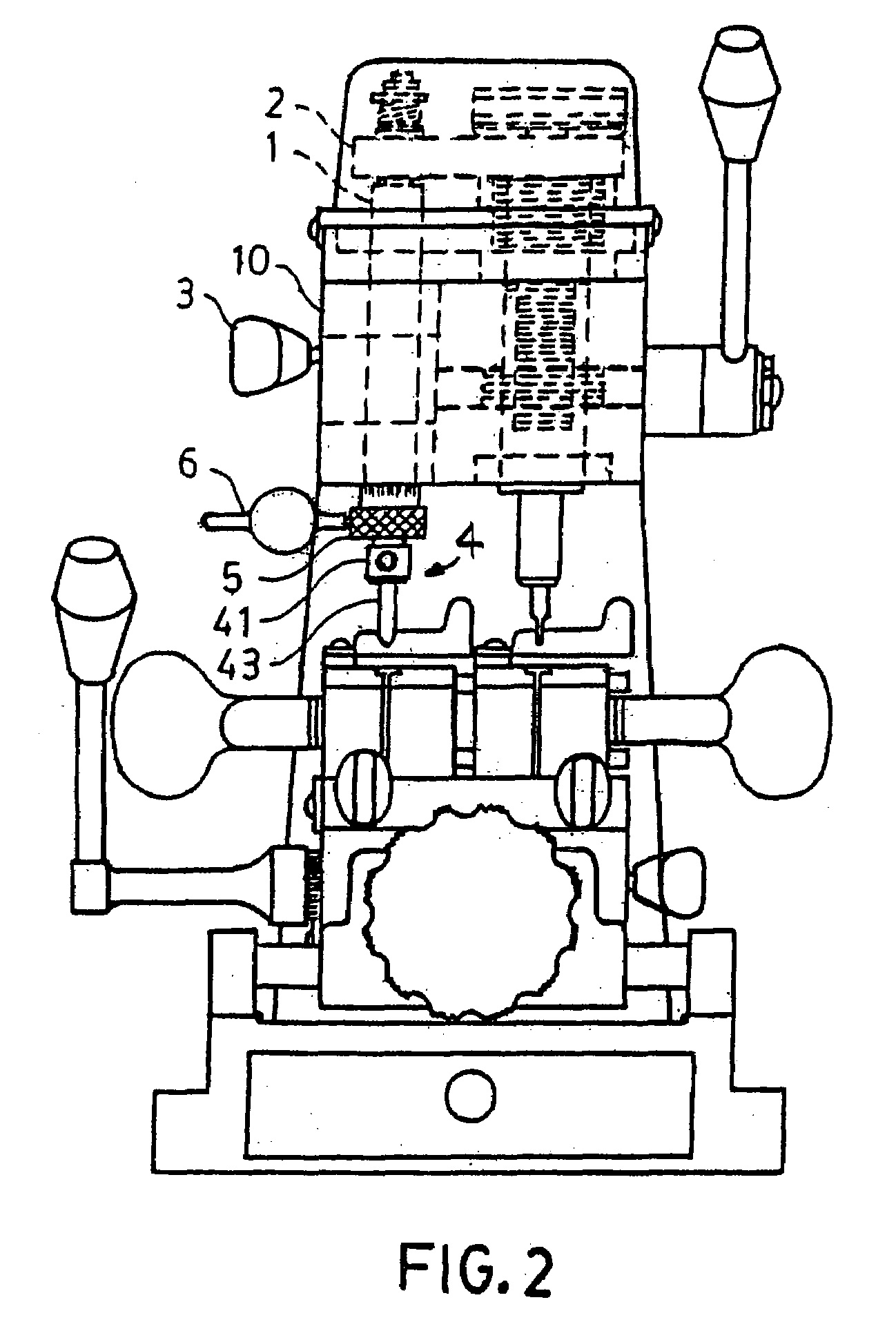

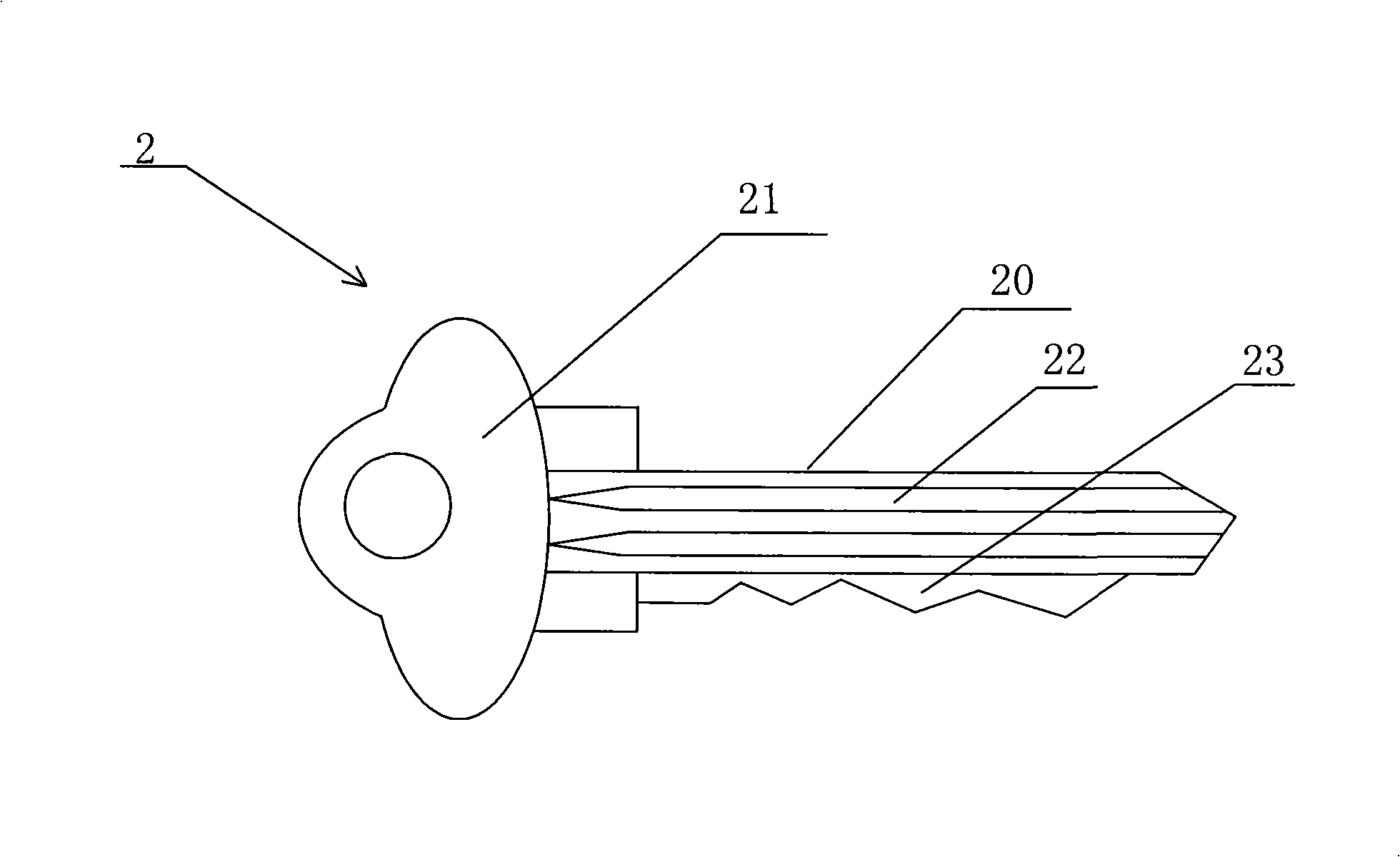

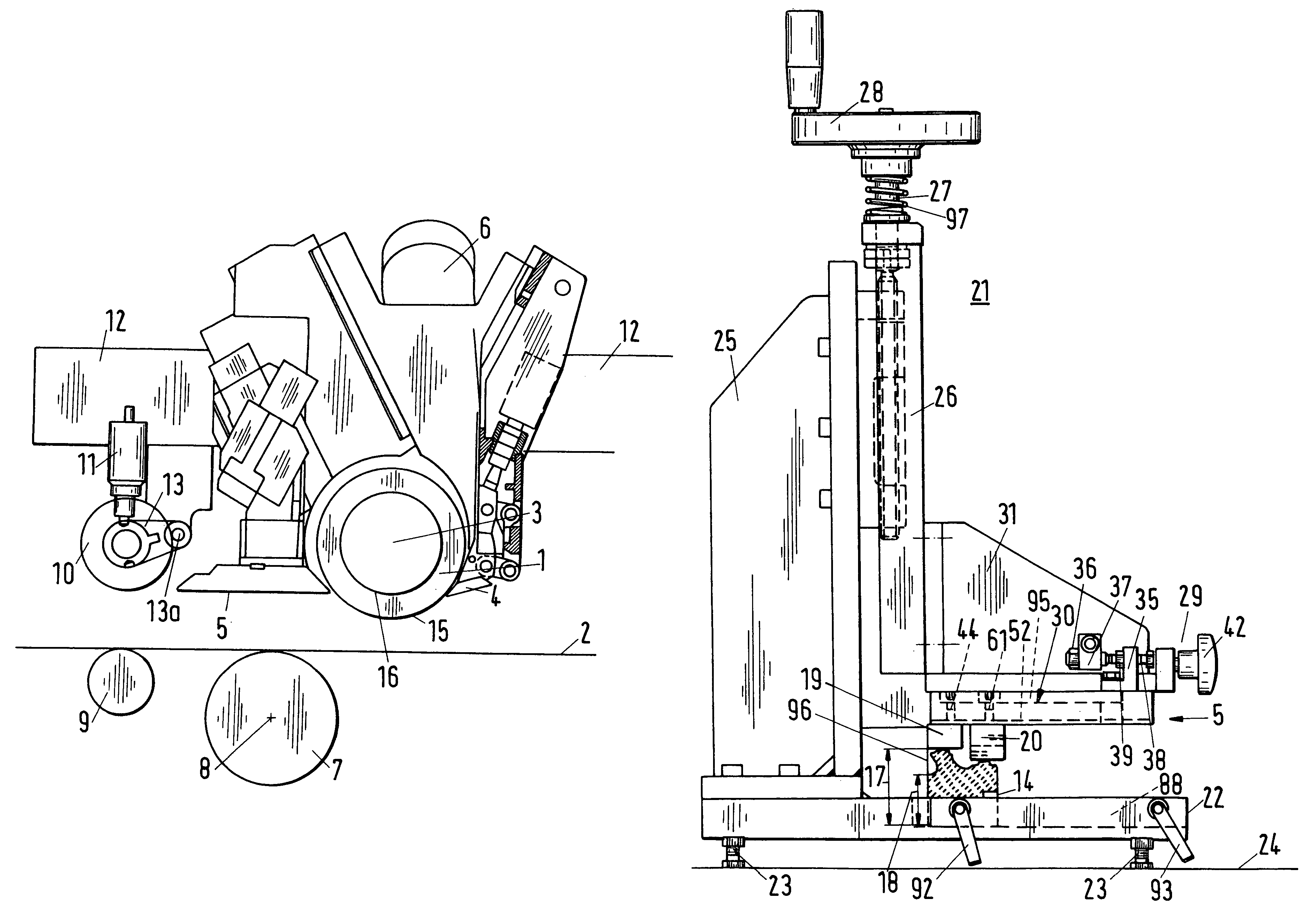

Spring tracer for duplicating machine for punched and laser keys

An improved spring tracer for duplicating machine for punched and laser keys comprising a longitudinal spindle suspended from an end of a synchronous lateral lever having the other end laterally connected to a longitudinal shaft for a duplicating tool in parallel with the longitudinal spindle, which can be longitudinally slidably secured on a body portion in accordance with a common longitudinal axis of the longitudinal spindle; a spring-loaded tracer engaged in the inner lower end of the longitudinal spindle for biasing a tracer stylus against an original punched or laser key by means of the spring force for tracing the depths of the key teeth of the original punched key in accordance with the said common longitudinal axis; and a regulating sleeve rotatably secured at the outer lower end of the longitudinal spindle for regulating the elevation of the spring-loaded tracer in accordance with the said common longitudinal axis, in order that a regulating action, a securing action and a biasing action can be effected in a common longitudinal axis, so as to increase the duplicating precision and simplify the construction of the duplicating machine for punched and laser keys.

Owner:EAST OF WU

Apparatus and method for shaving the inside of barrels

The present invention relates to an apparatus and method for shaving the inside of barrels. In particular, the present invention relates to reconditioning used wine barrels by shaving the inside surface to a predetermined depth, ready for re-crozering, toasting, and re-use. Conventional shaving methods typically involve routing the internal surface by hand, but this technique is problematic in that it is a very slow process, the quality of the wood is often adversely affected, and there is no way of ensuring that the surface will be shaved to the same depth across the entire surface. Therefore, the resultant internal dimensions of the barrel are not reflective, relatively, of the original barrel surface. The apparatus of the present invention includes a scanning device adapted to scan the internal dimensions of the barrel, and a cutting device adapted to shave the internal surface to a predetermined depth relative to the scanned internal dimensions.

Owner:SOUTHERN CROSS COOPERAGE

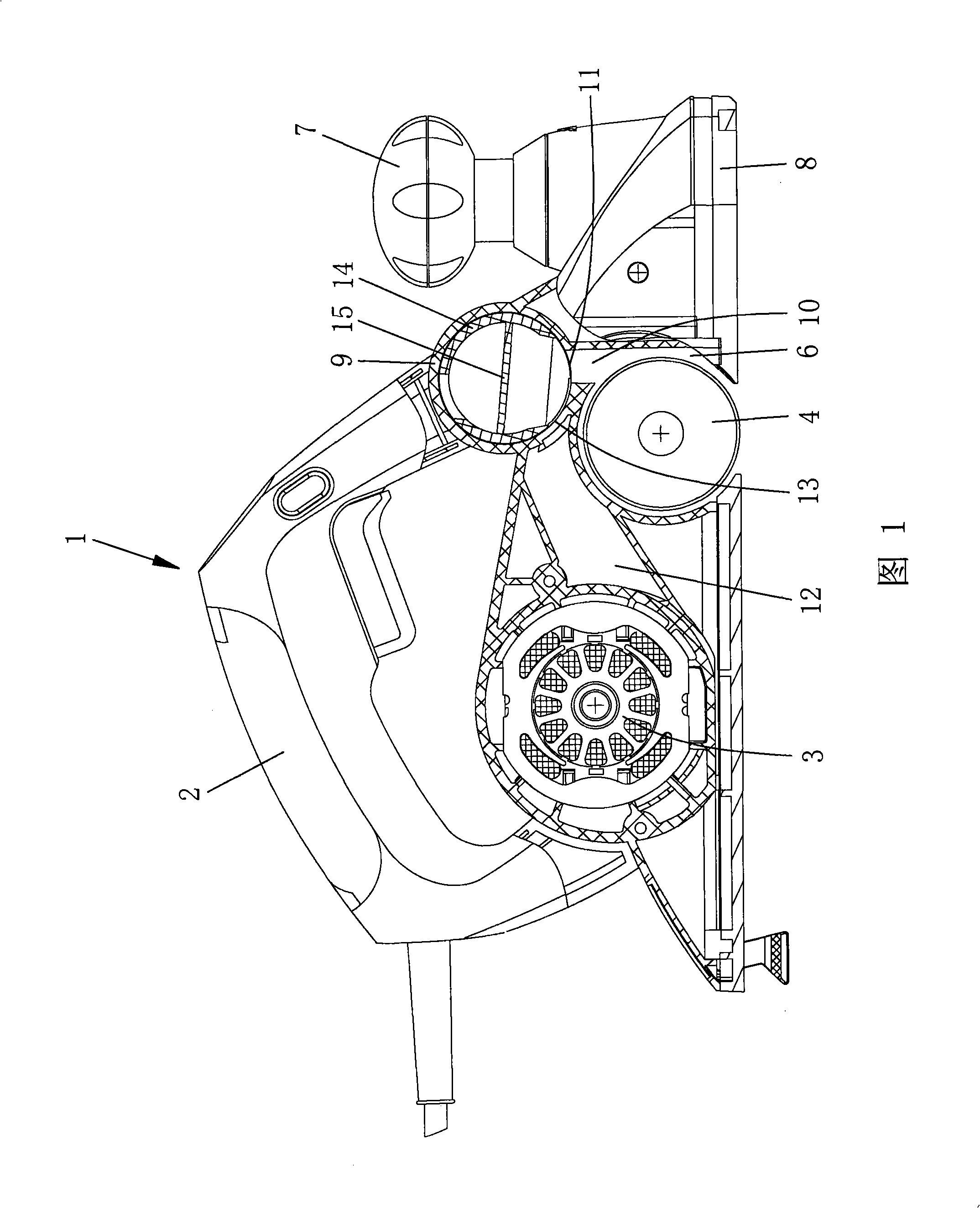

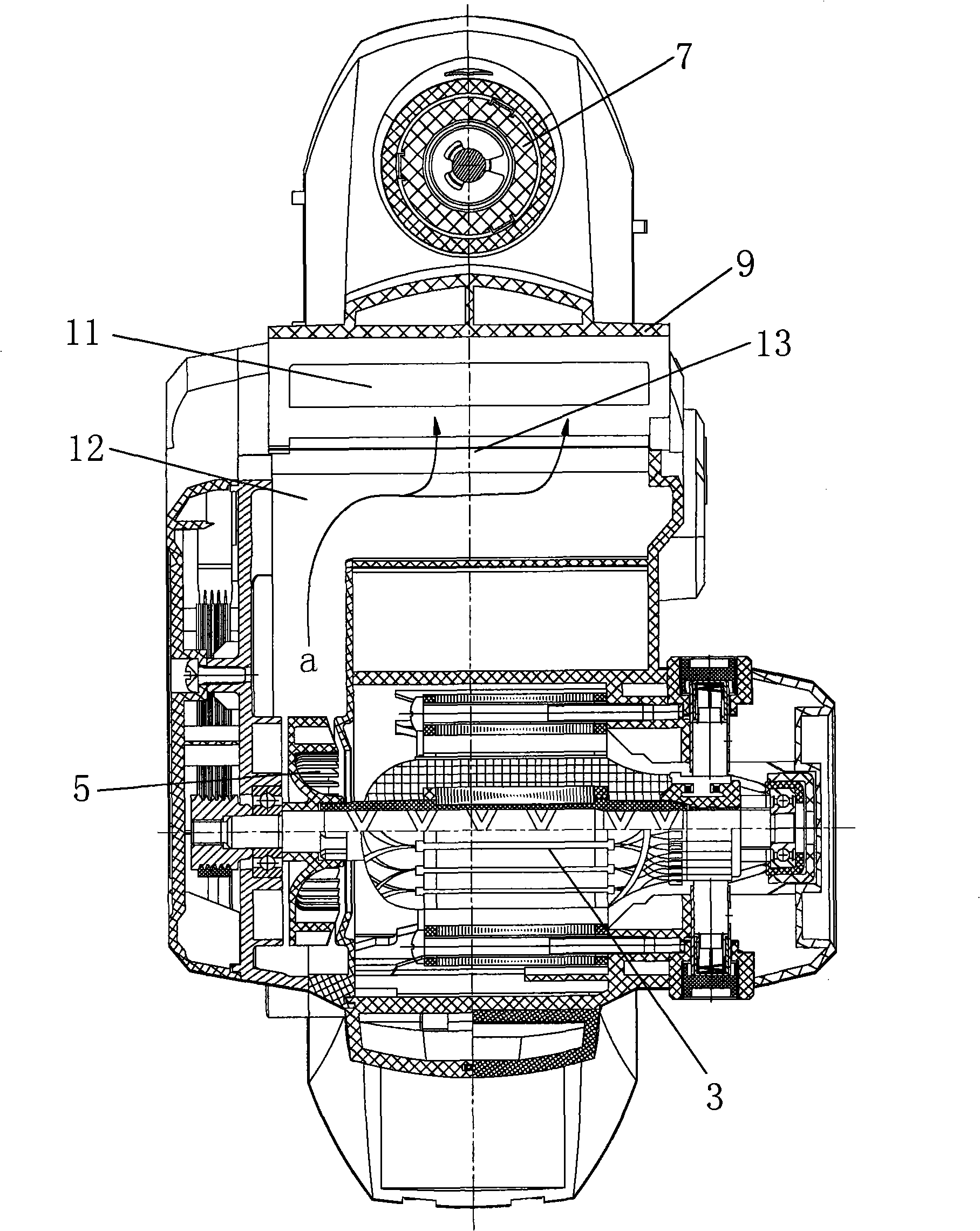

Power tool

InactiveCN101332599ANot easy to block chipsWon't accumulateHand planesPortable planing/slotting machinesPower toolMotive power

The invention discloses a power tool which comprises a shell, a power source arranged in the shell, a fan connected with the power source and a tubular chip removal valve arranged on the shell; a reversing plate is arranged in the chip removal valve, air inlets are arranged on the tube walls of the chip removal valve at the two sides of the reversing plate, the airflow generated by rotation of the fan enters the chip removal valve from the air inlets, a splitter plate is arranged on the reversing plate near the air inlets, the splitter plate divides the airflow entering the chip removal valve into at least two parts, one part of the airflow is used for reversing the chip entering the chip removal valve, and another part of the airflow is used for blowing chip, therefore, the chip does not accumulate in the chip removal valve, chip removal is thorough and chip removal efficiency is high, and the power tool is not easy to be blocked by the chip in the process of operation.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

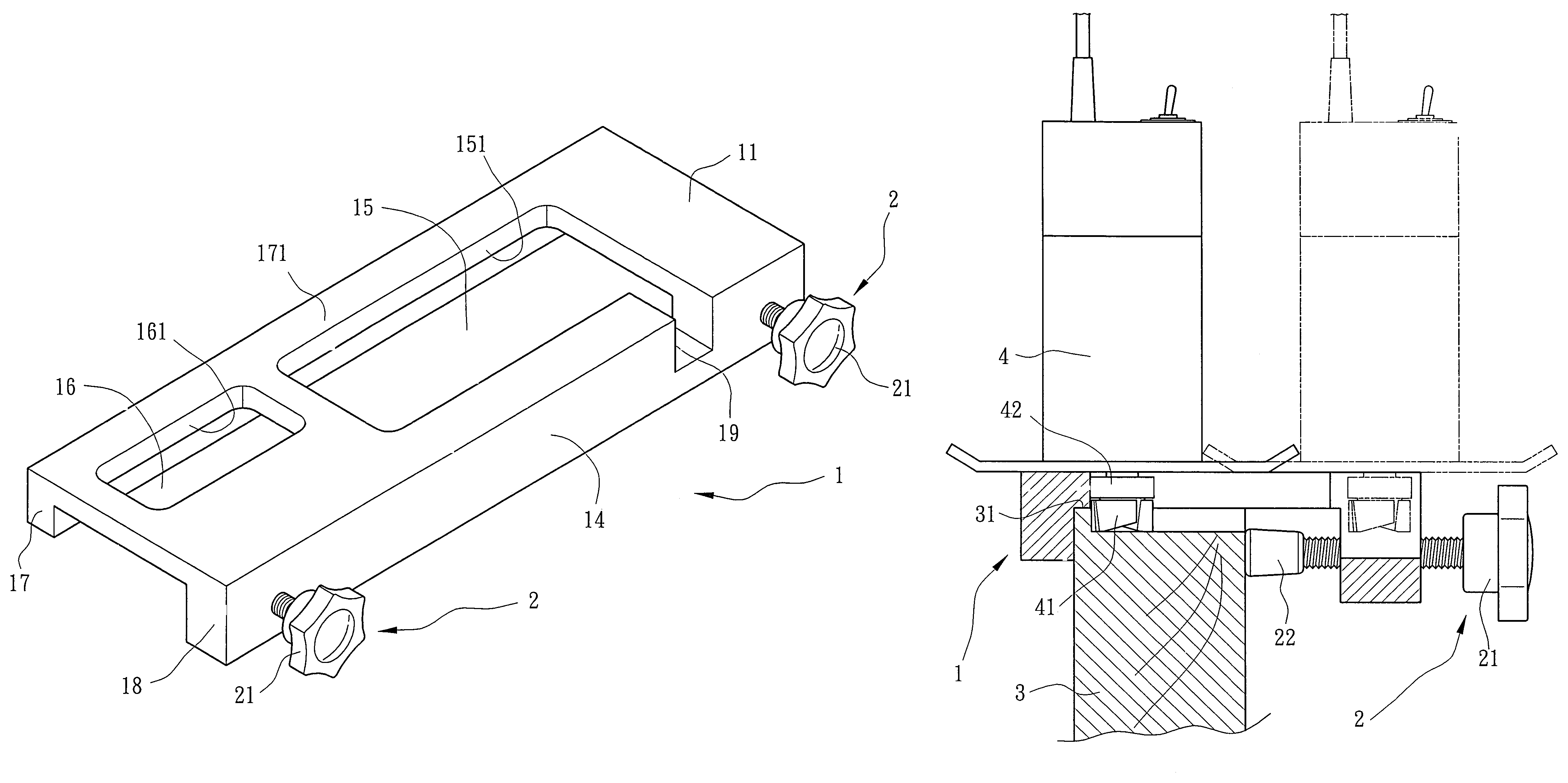

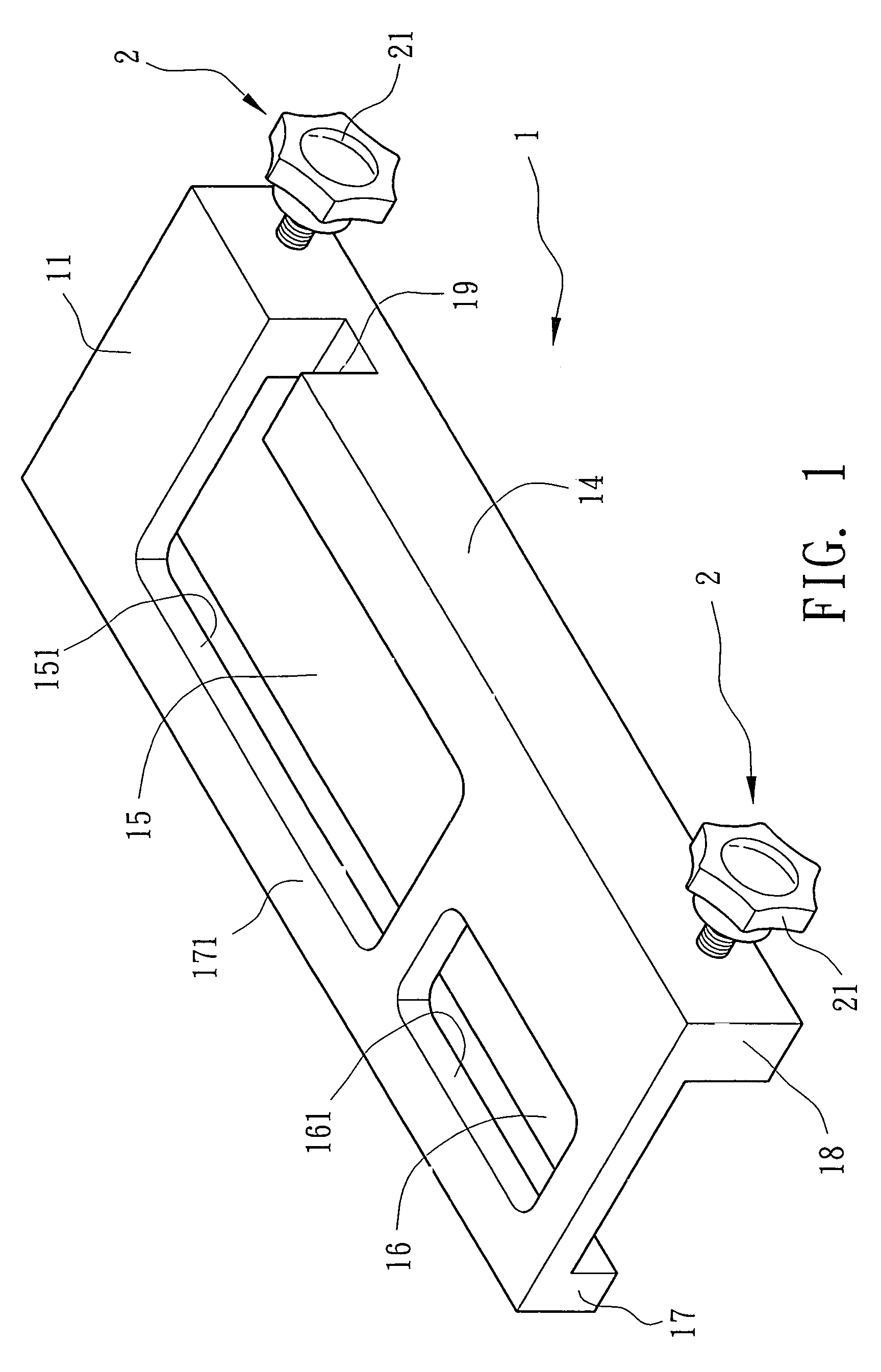

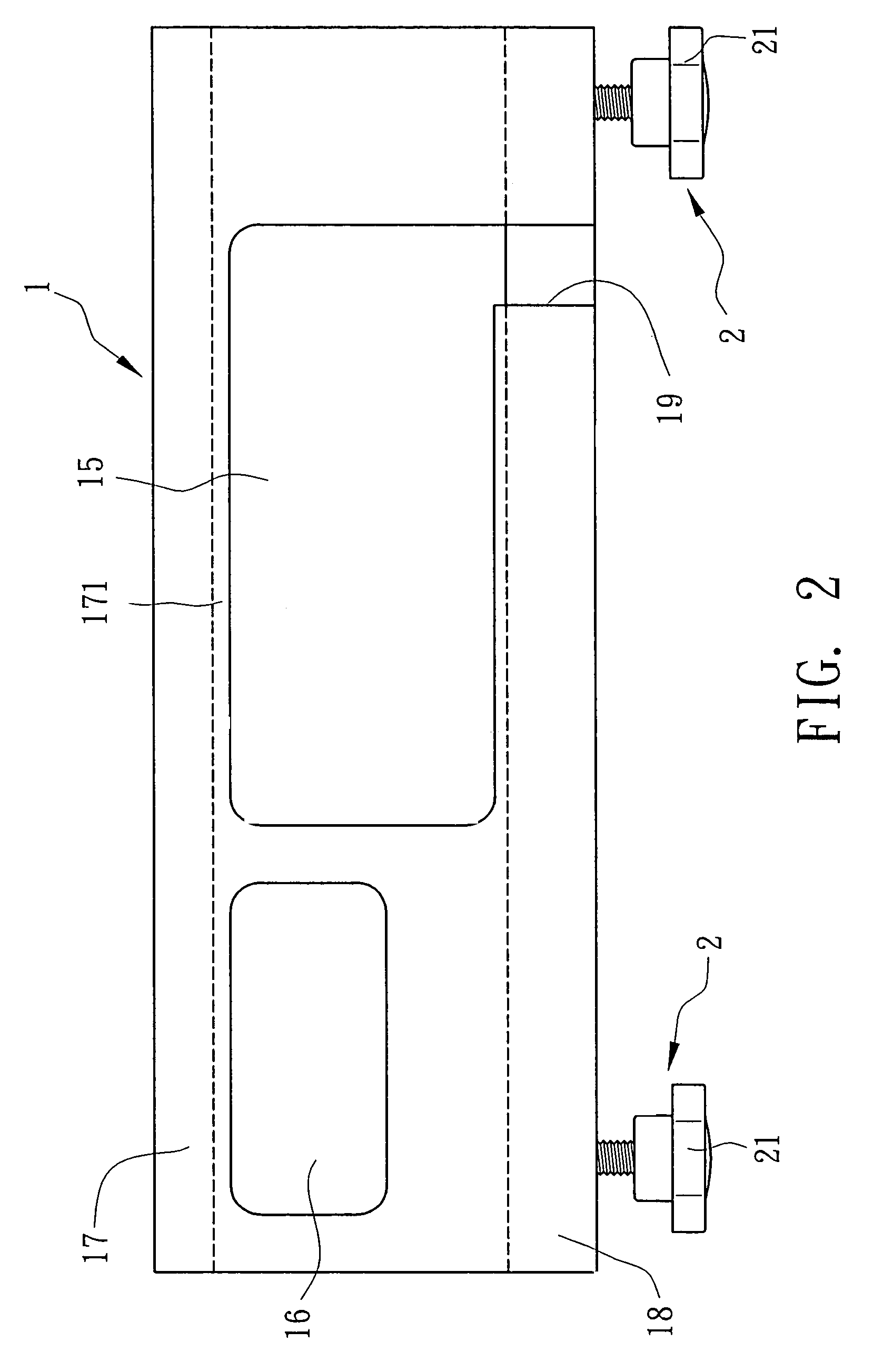

Decoration-used mold unit

InactiveUS7241091B1Facilitate cutting and millingQuality improvementDrilling/boring measurement devicesThread cutting machinesKnife bladesMachining process

A decoration-used mold unit for defining a border on a work piece to facilitate cutting or milling. The mold unit includes an elongated rectangular main body formed with a first window for processing a first sink and a second window for processing a second sink. A first chucking section protrudes from a first side of the main body. A second chucking section protrudes from a second side of the main body. At least one abutting member is adjustably arranged at the second chucking section. The first chucking section and the abutting member respectively abut against two opposite sides of the work piece to clamp the work piece. In the processing procedure, the blade is restricted within the first and second windows so that the work piece will not be over-milled and the borders of the sinks keep straight.

Owner:YANG KUN YING

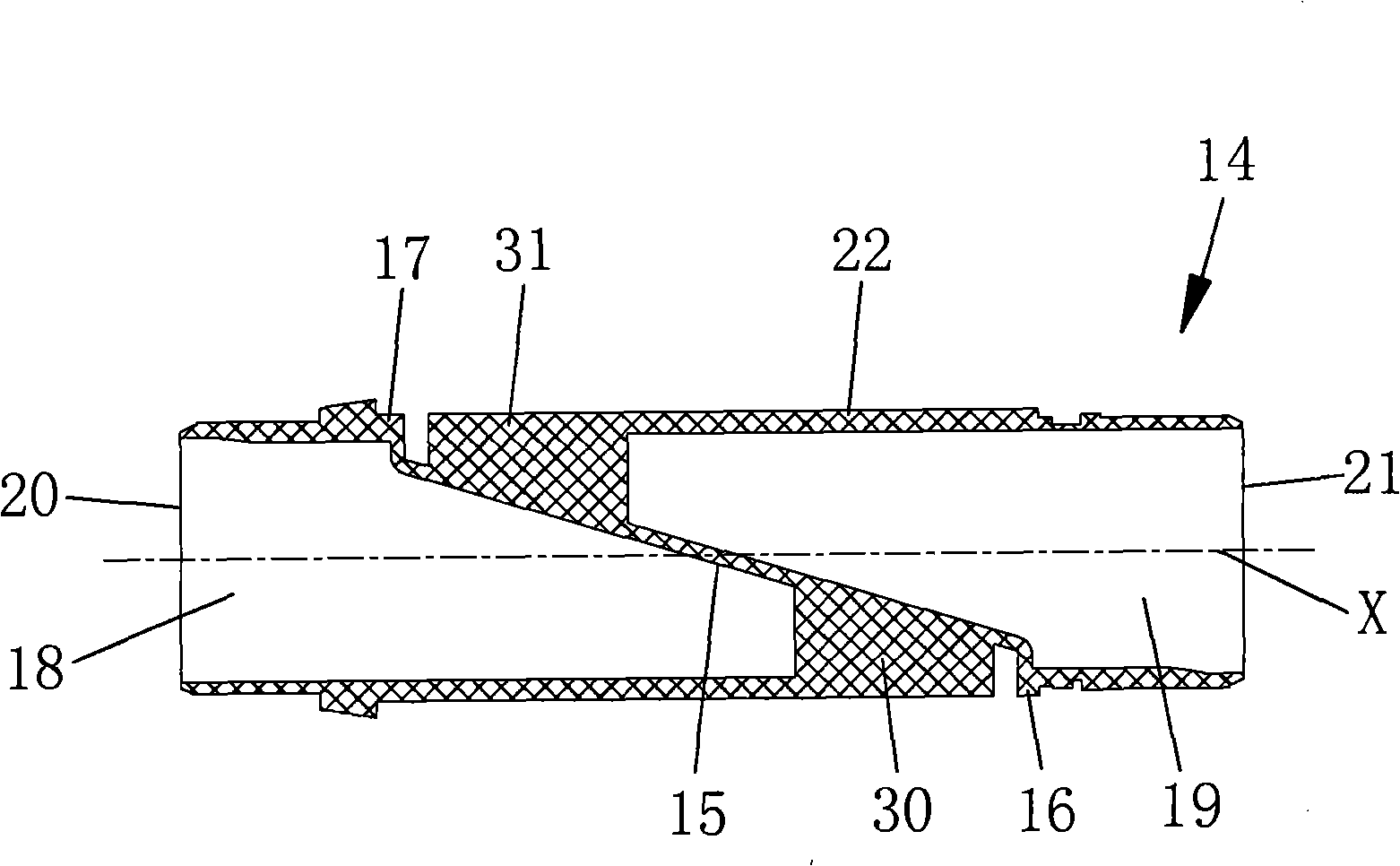

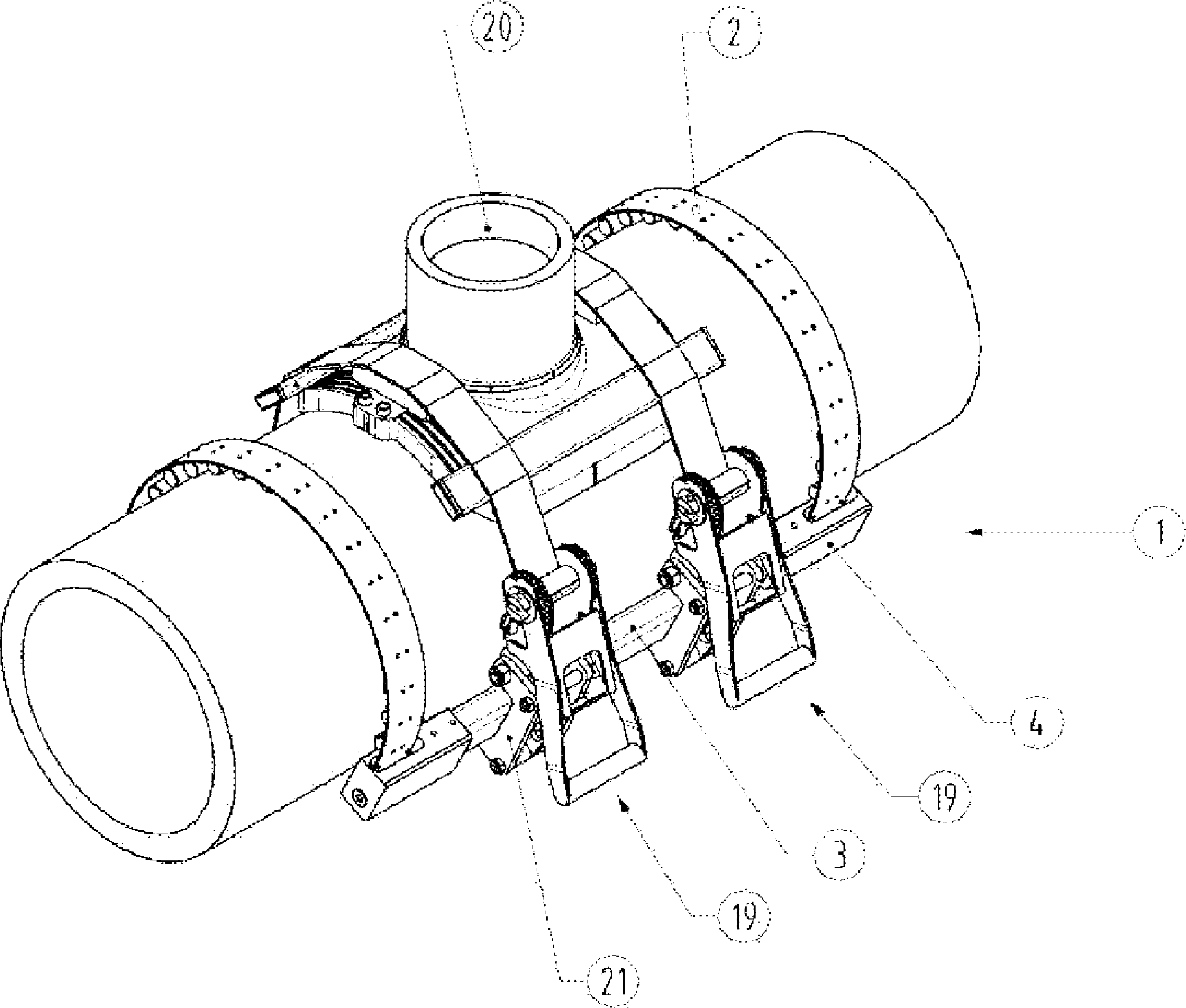

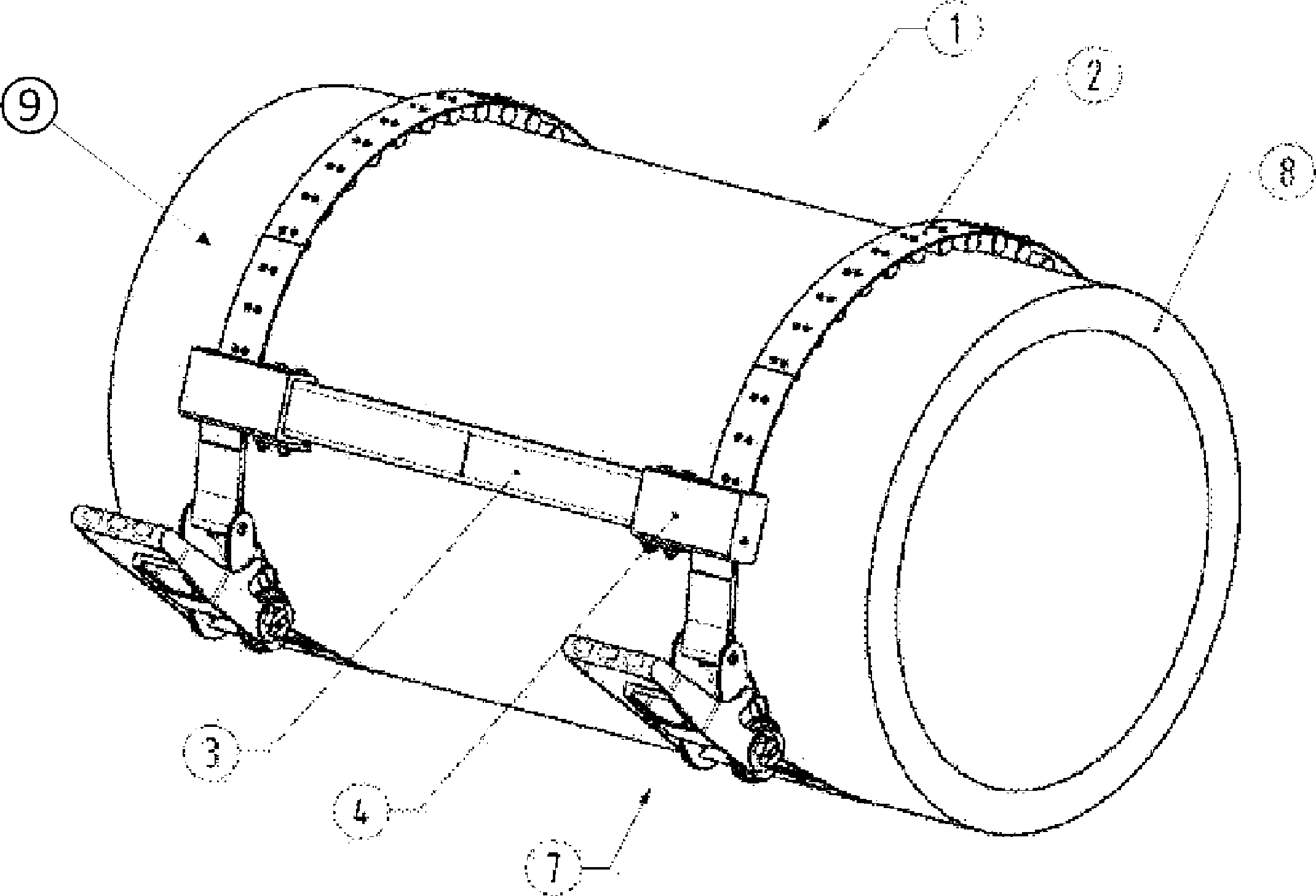

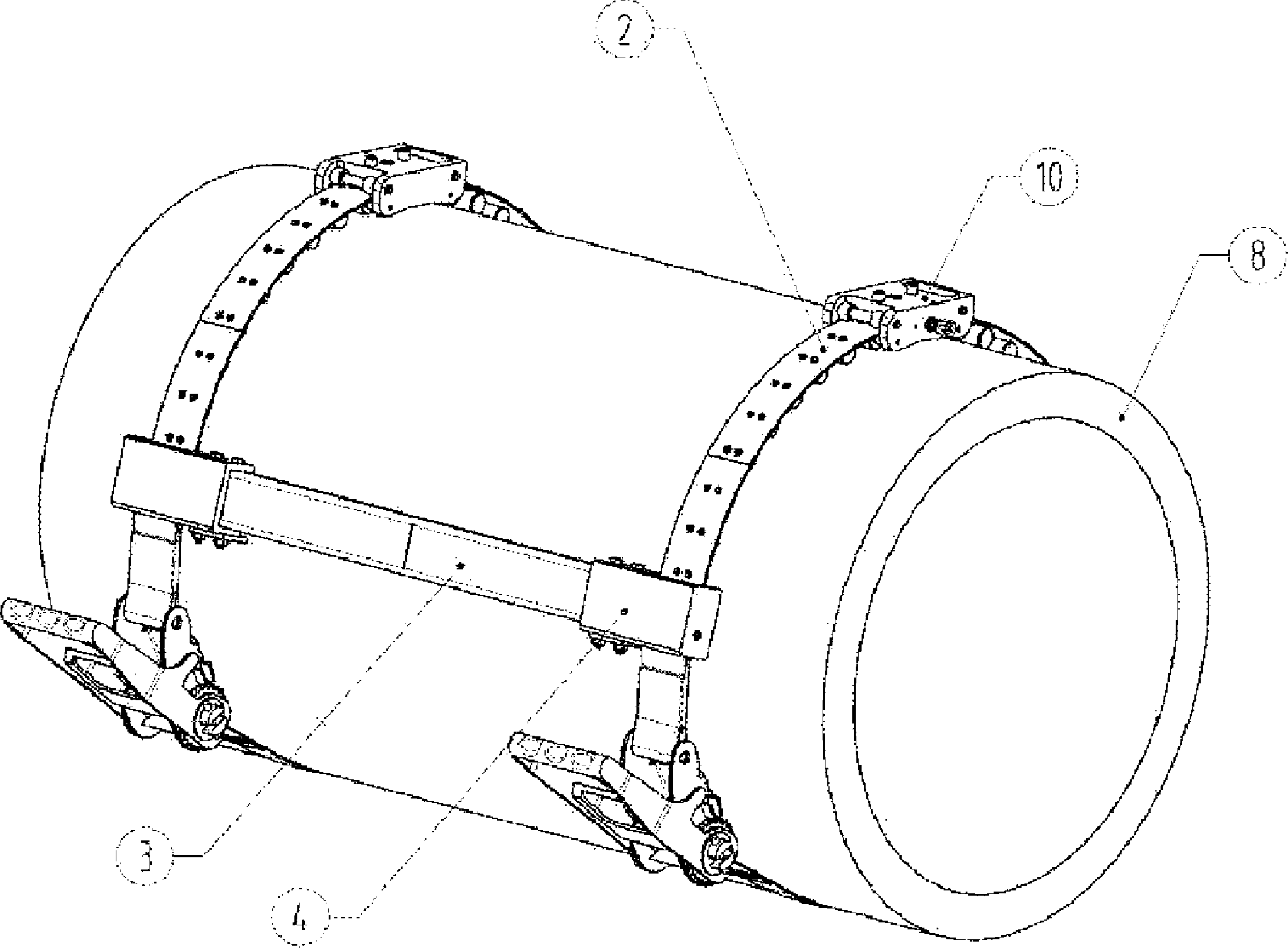

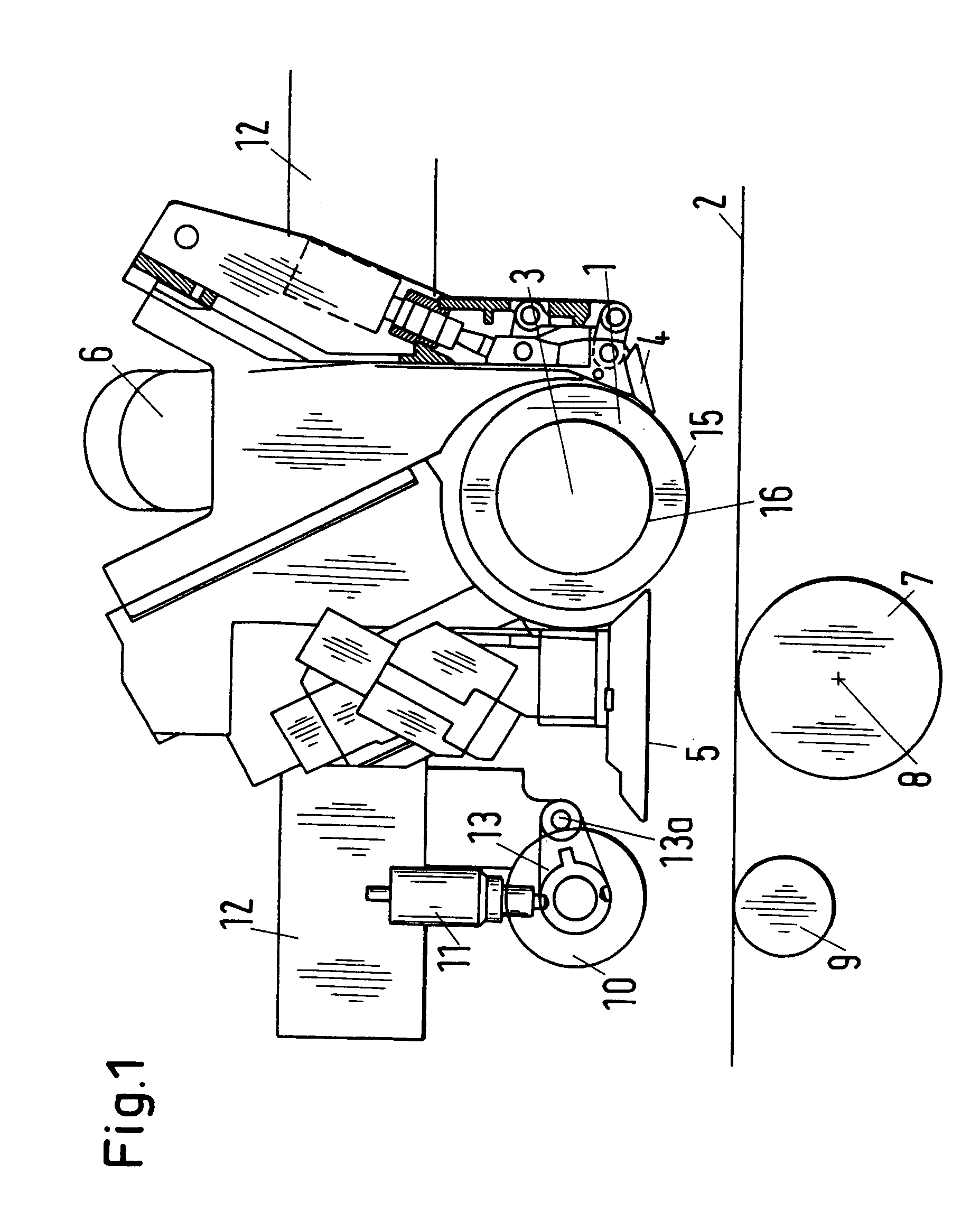

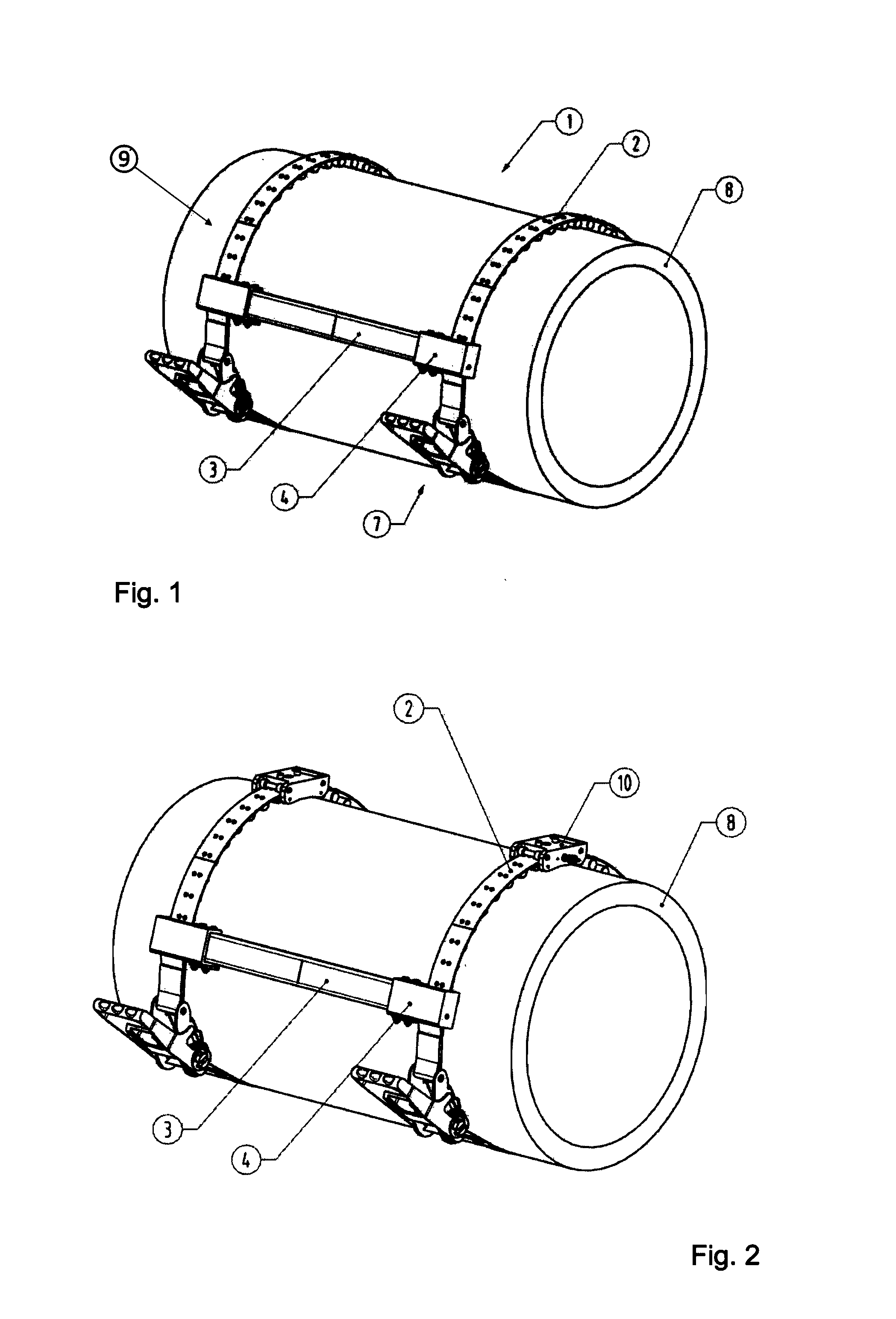

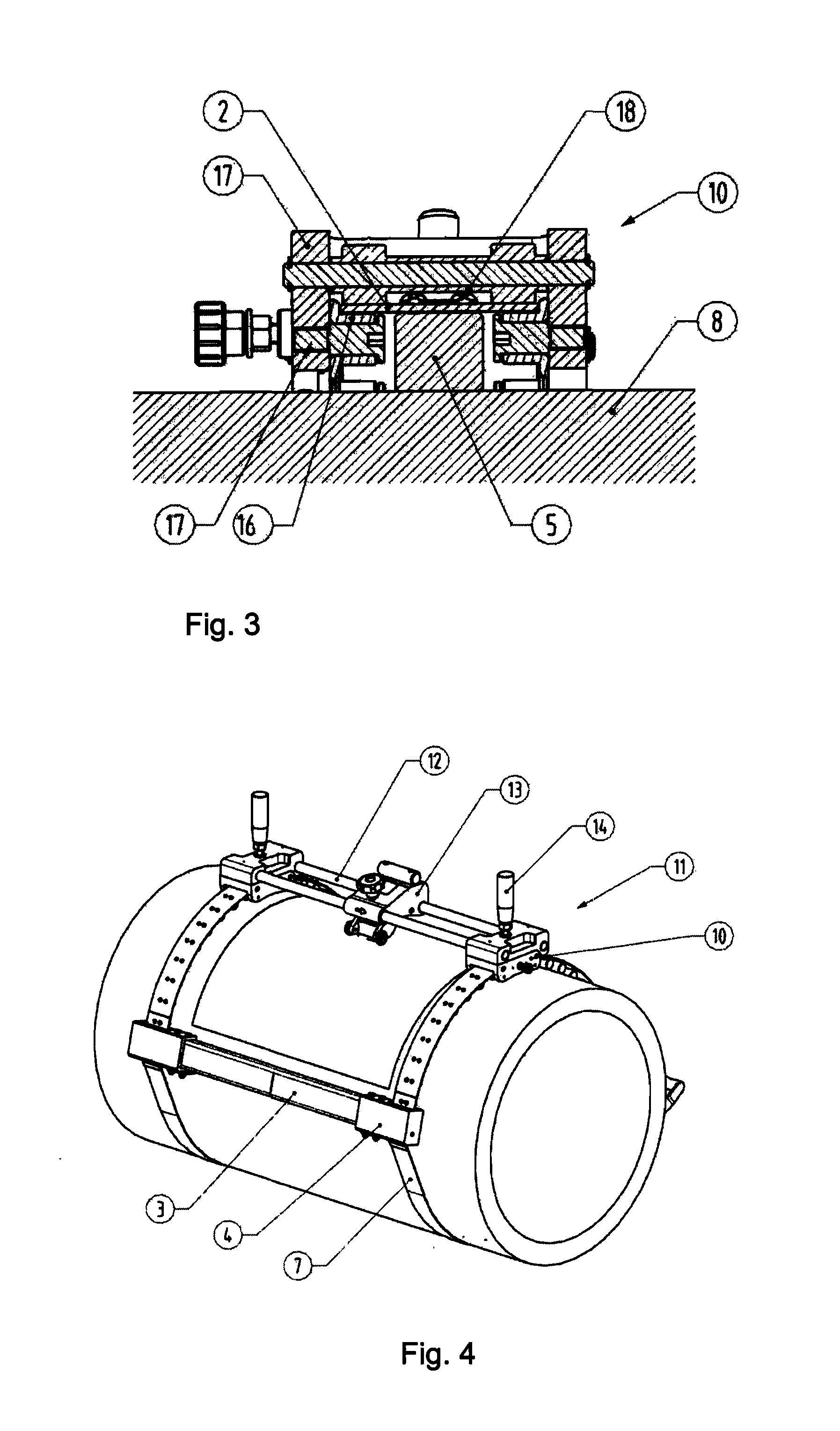

Apparatus for guiding tube processing devices

ActiveCN103506681AMake sure to removeUniform planingTurning machine accessoriesWelding/cutting auxillary devicesTwo bandGuide tube

An apparatus for guiding tube processing devices, in particular planing devices, wherein the apparatus is arranged on an outer circumference of the tube to be processed, wherein the apparatus has at least two bands which extend in parallel.

Owner:GEORG FISCHER WAVIN AG

Apparatus and method for shaving the inside of barrels

An apparatus and method for shaving the inside of barrels. The invention relates to reconditioning used wine barrels by shaving the inside surface to a predetermined depth, ready for re-crozering, toasting, and re-use. Conventional shaving methods typically involve routing the internal surface by hand, but this technique is problematic in that it is a very slow process, the quality of the wood is often adversely affected, and there is no way of ensuring that the surface will be shaved to the same depth across the entire surface. The resultant internal dimensions of the barrel are not reflective, relatively, of the original barrel surface. The invention includes a scanning device to scan the internal dimensions of the barrel, and a cutting device to shave the internal surface to a predetermined depth relative to the scanned internal dimensions and where the scanning device and the cutting device may be supported by different robotic arms.

Owner:SOUTHERN CROSS COOPERAGE

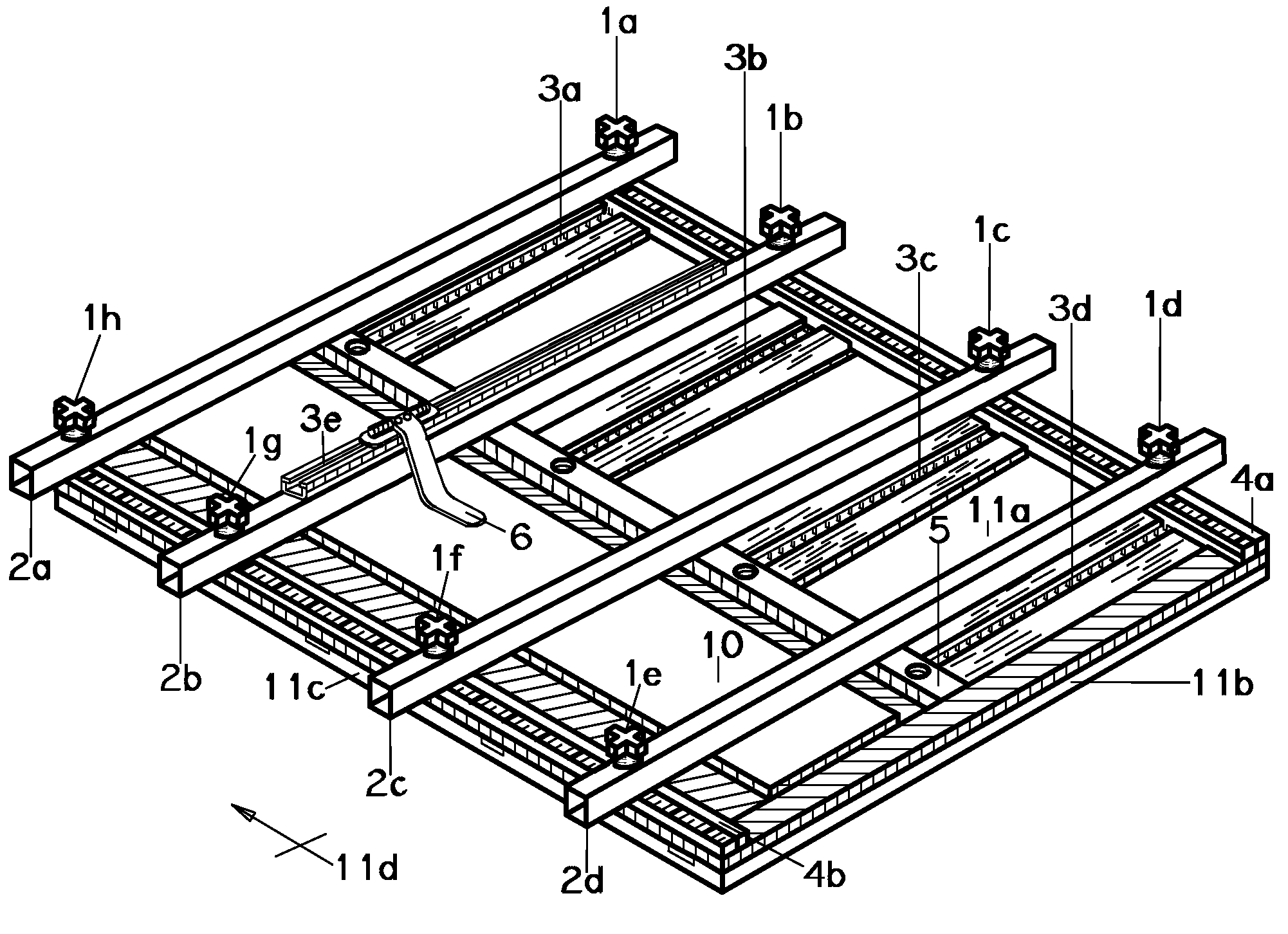

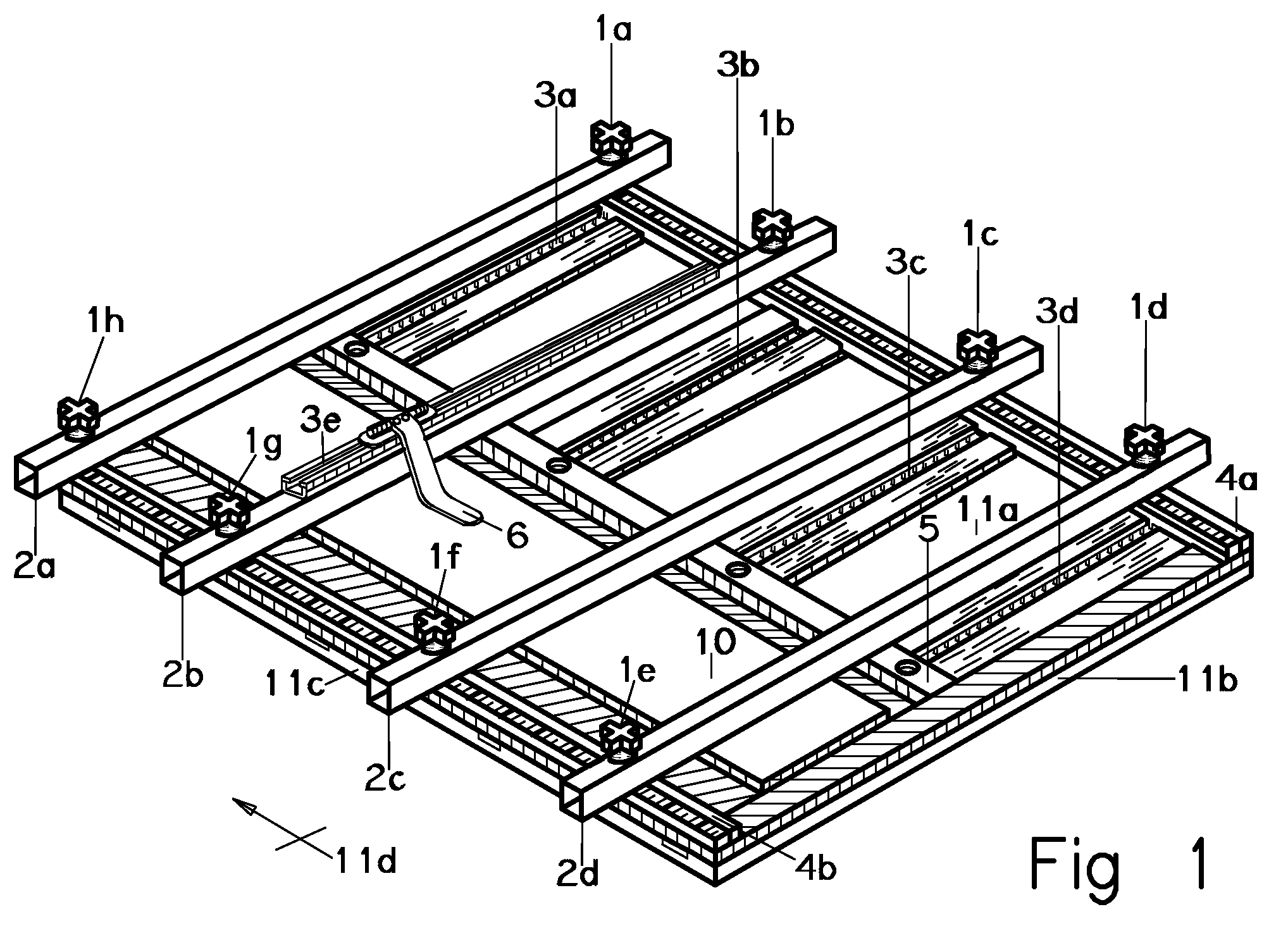

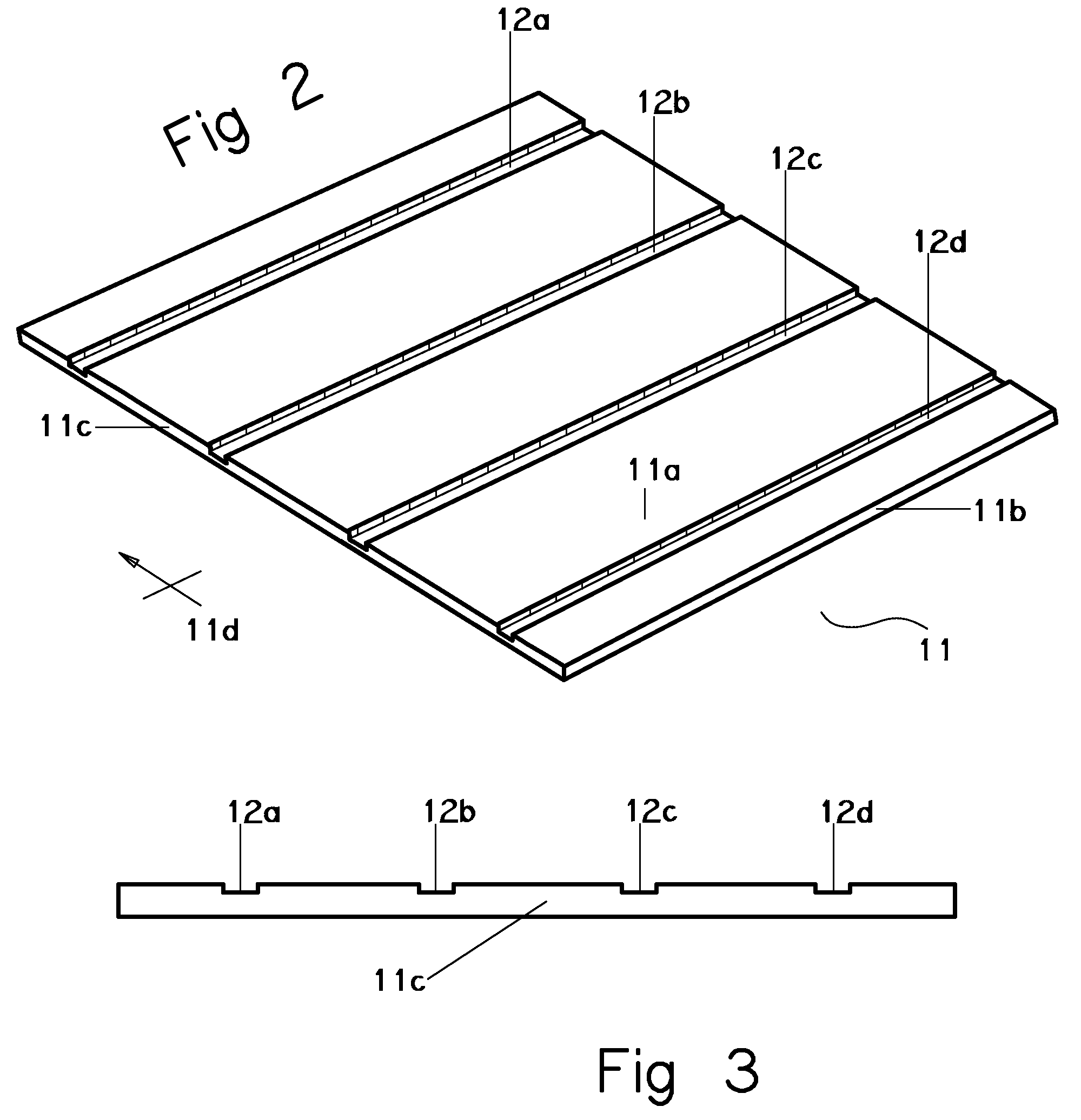

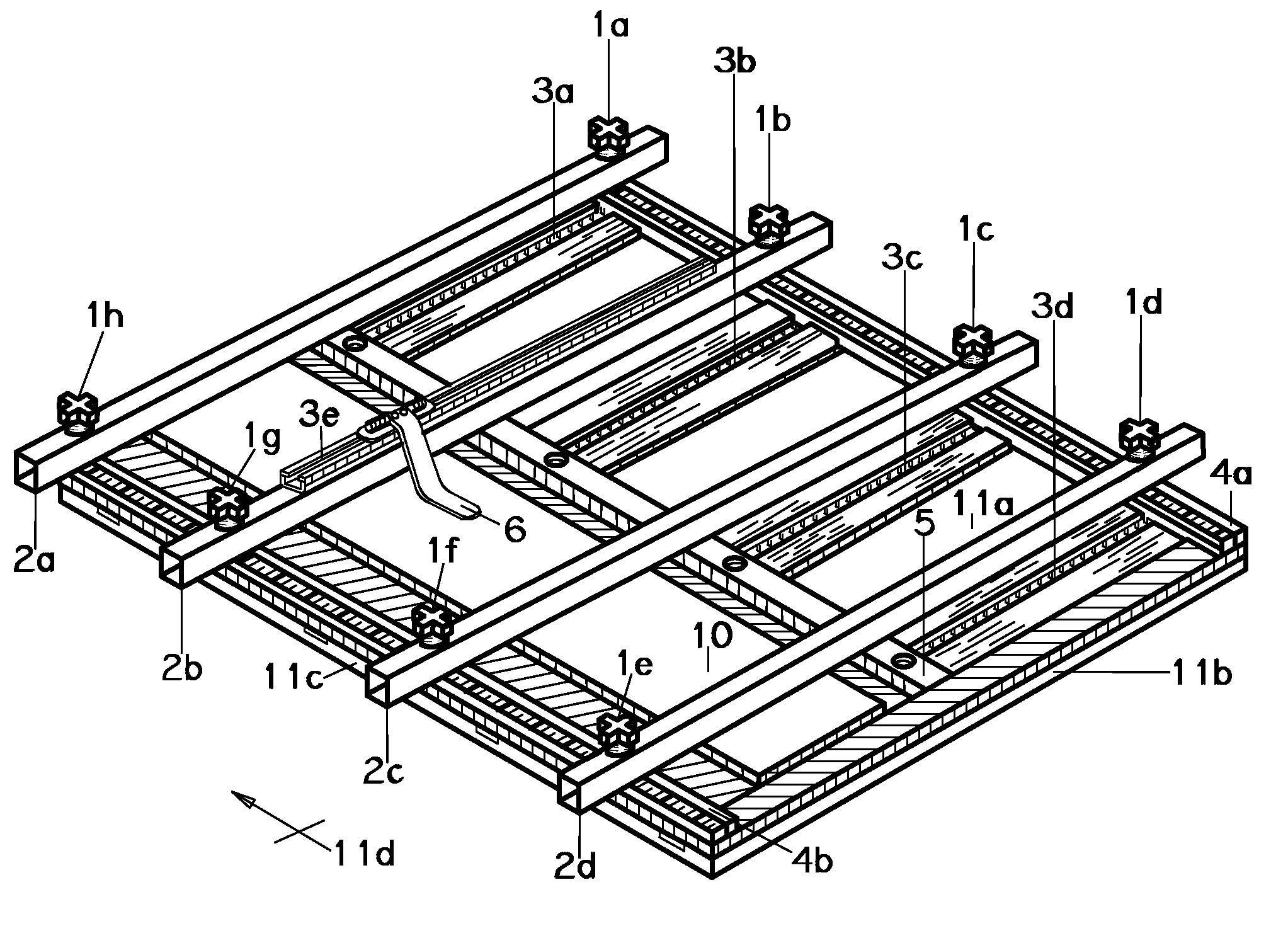

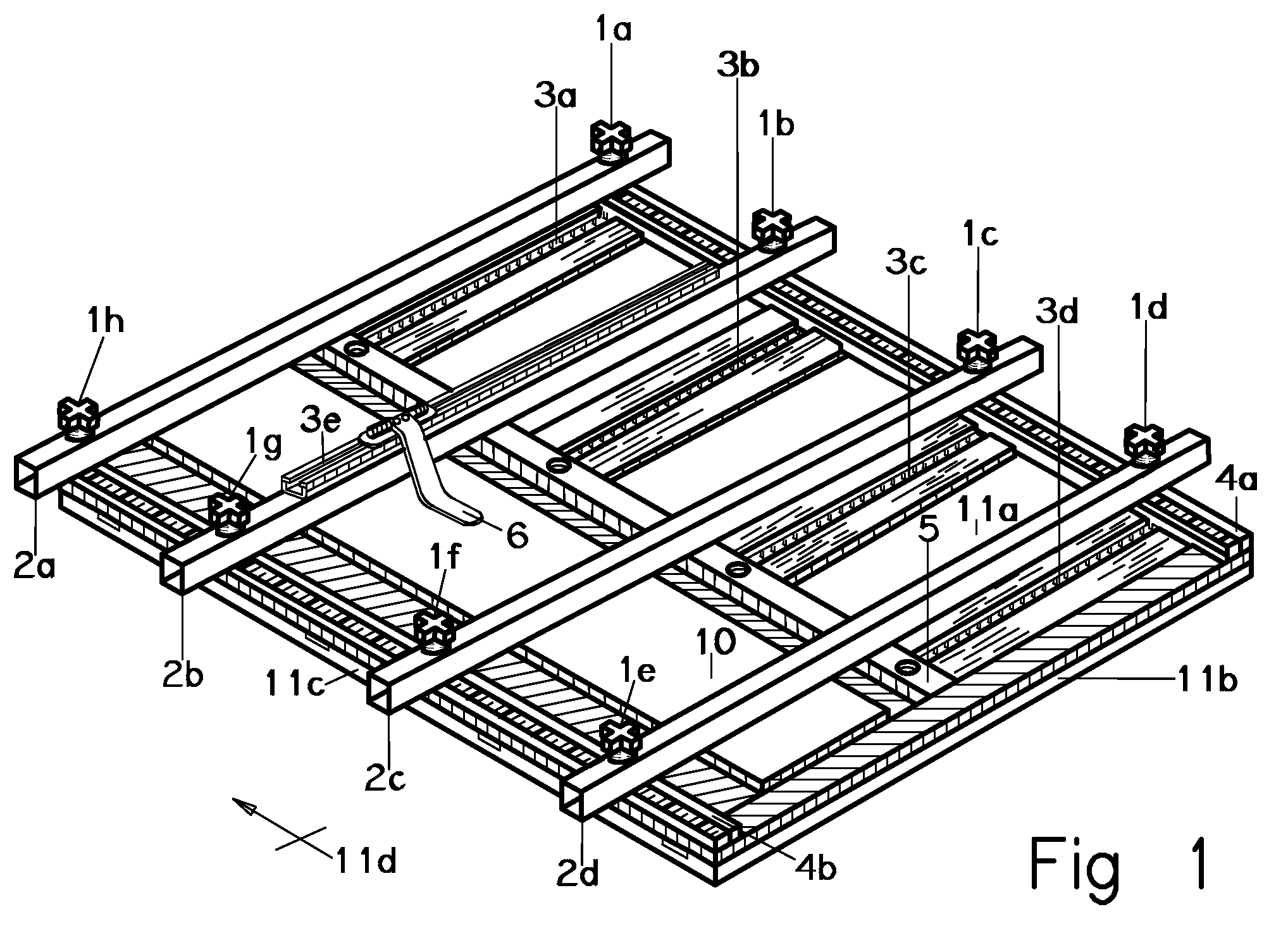

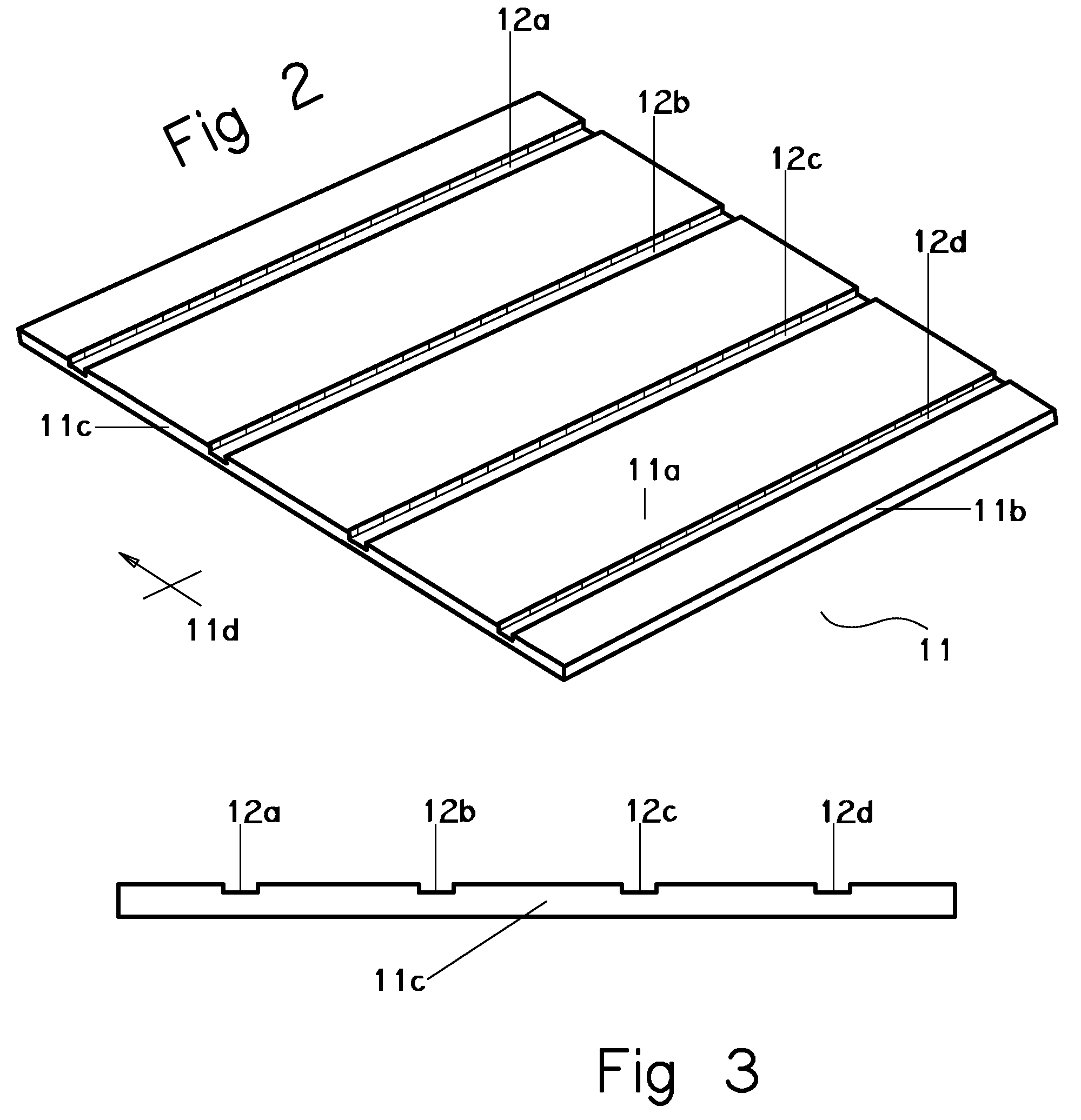

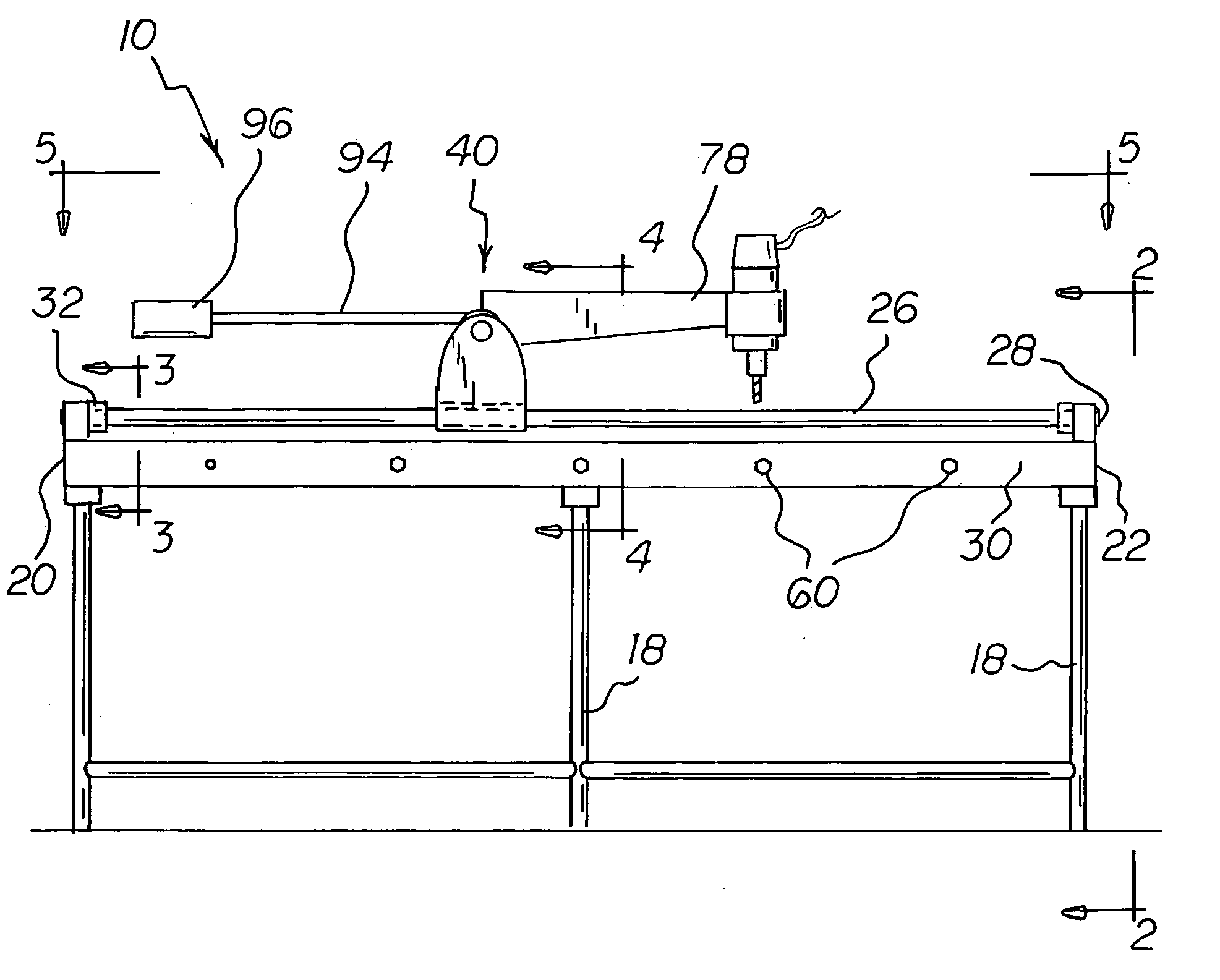

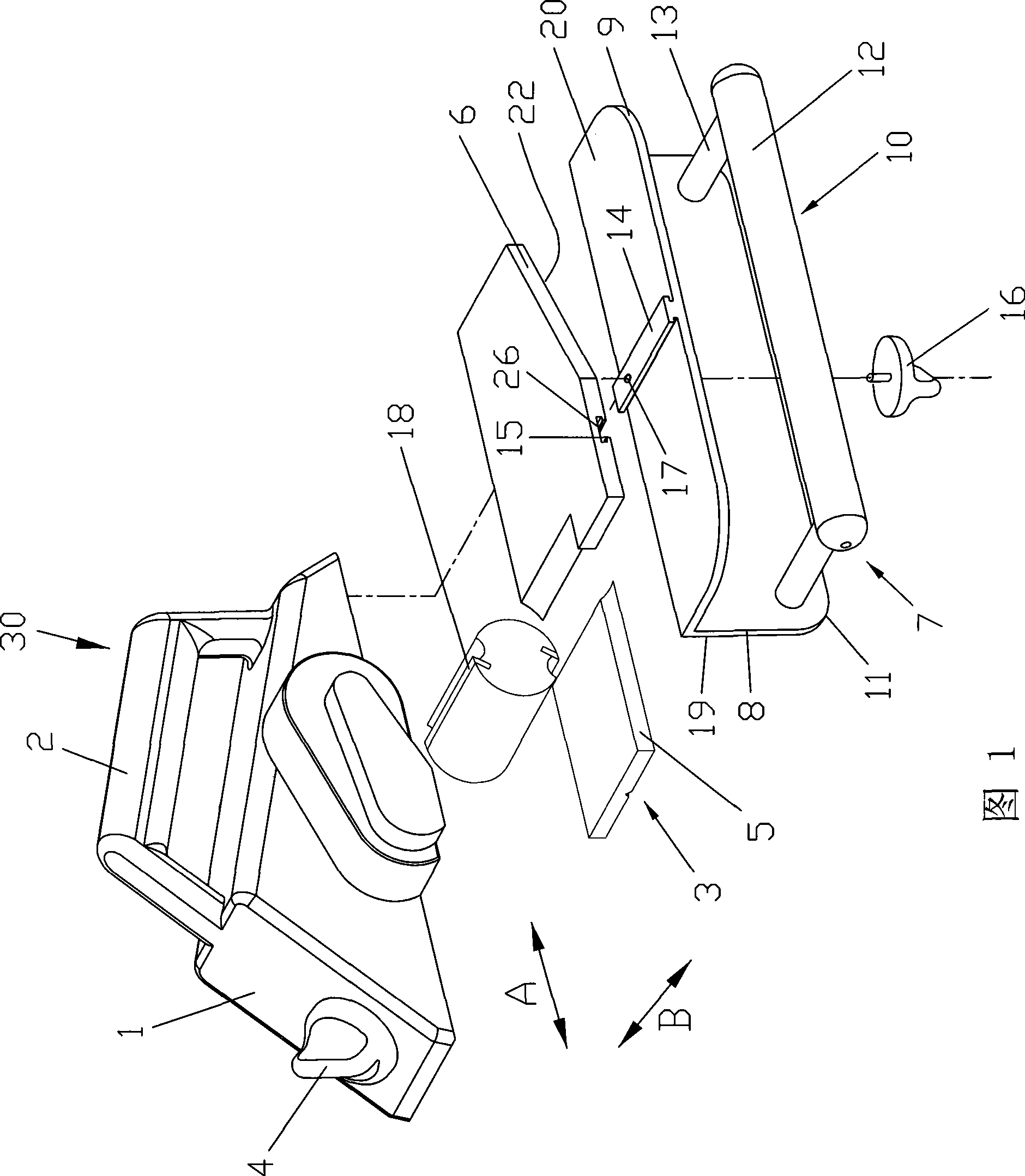

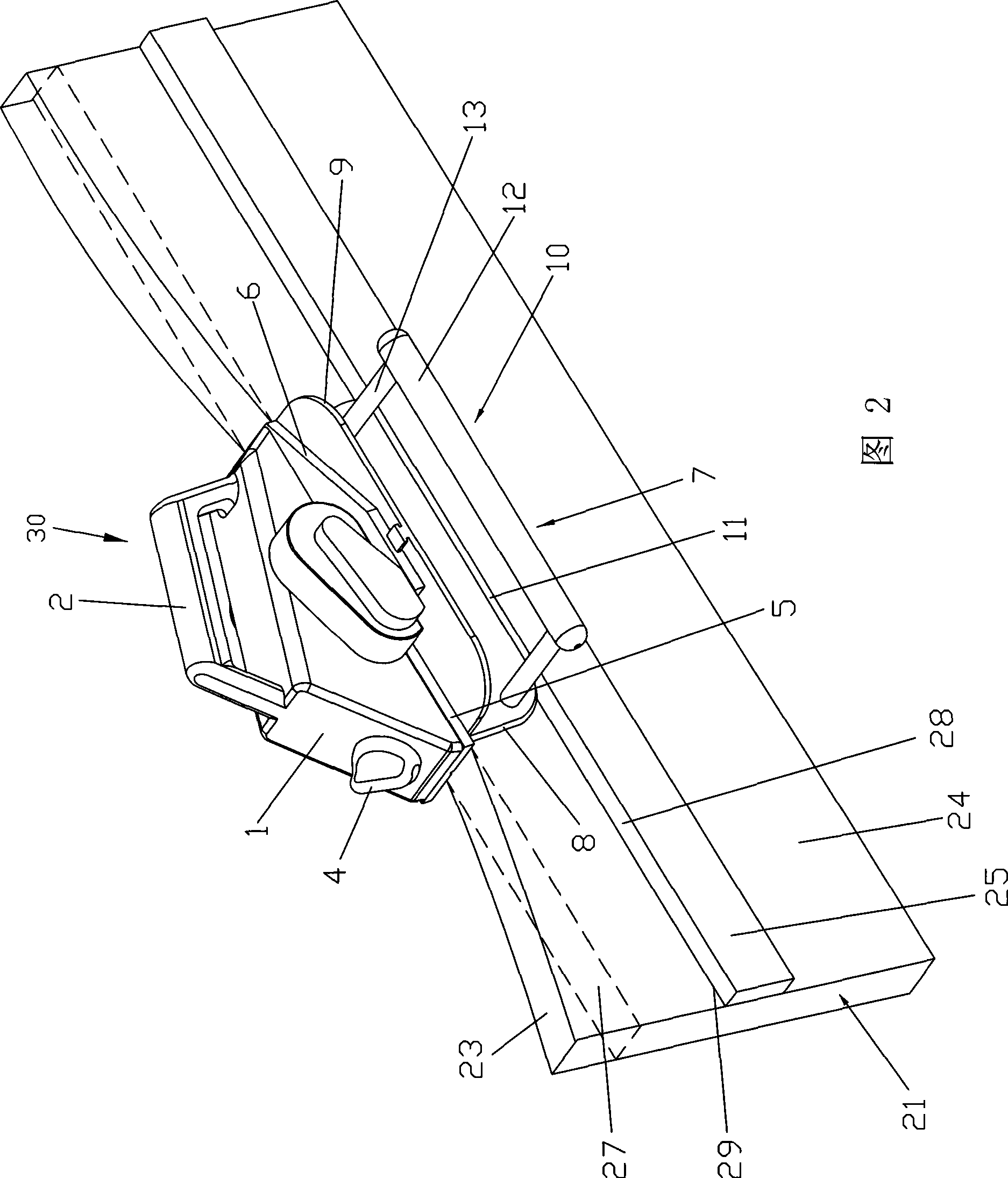

Dadoing System

InactiveUS20080121311A1Easy to set upEasy to useMulti-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

A dadoing system that can be set up to cut multiple dados in a workpiece. The dadoing system uses a sliding channel clamp to keep the workpiece from moving in a transverse direction, while the dados are being cut into the workpiece. The sliding guide rails are used to put downward pressure on a workpiece while guiding a router across the workpiece during the dadoing process. Once the system is set up to cut the dados in the desired locations on the workpiece, the sliding guide rail stops can be secured into place. The stops will insure that the sliding guide rails are set up in the same place thus allowing multiple workpieces to have matching dados that line up properly during assembly.

Owner:YOUNG STEVEN PALMER

Hand-held machine tool

A hand-held machine tool comprises a housing 10 with a guide duct for conducting shavings and / or abrasive particles away from an operating region. A collecting container for the shavings and / or abrasive particles is connected to the guide duct, having at least one opening for conducting away air from the collecting container. The opening in the collecting container is at least partially covered by a retaining element made of metal. Preferably the retaining element has a net, gauze, mesh, knit or lattice structure. The tool may be a planing machine.

Owner:ROBERT BOSCH GMBH

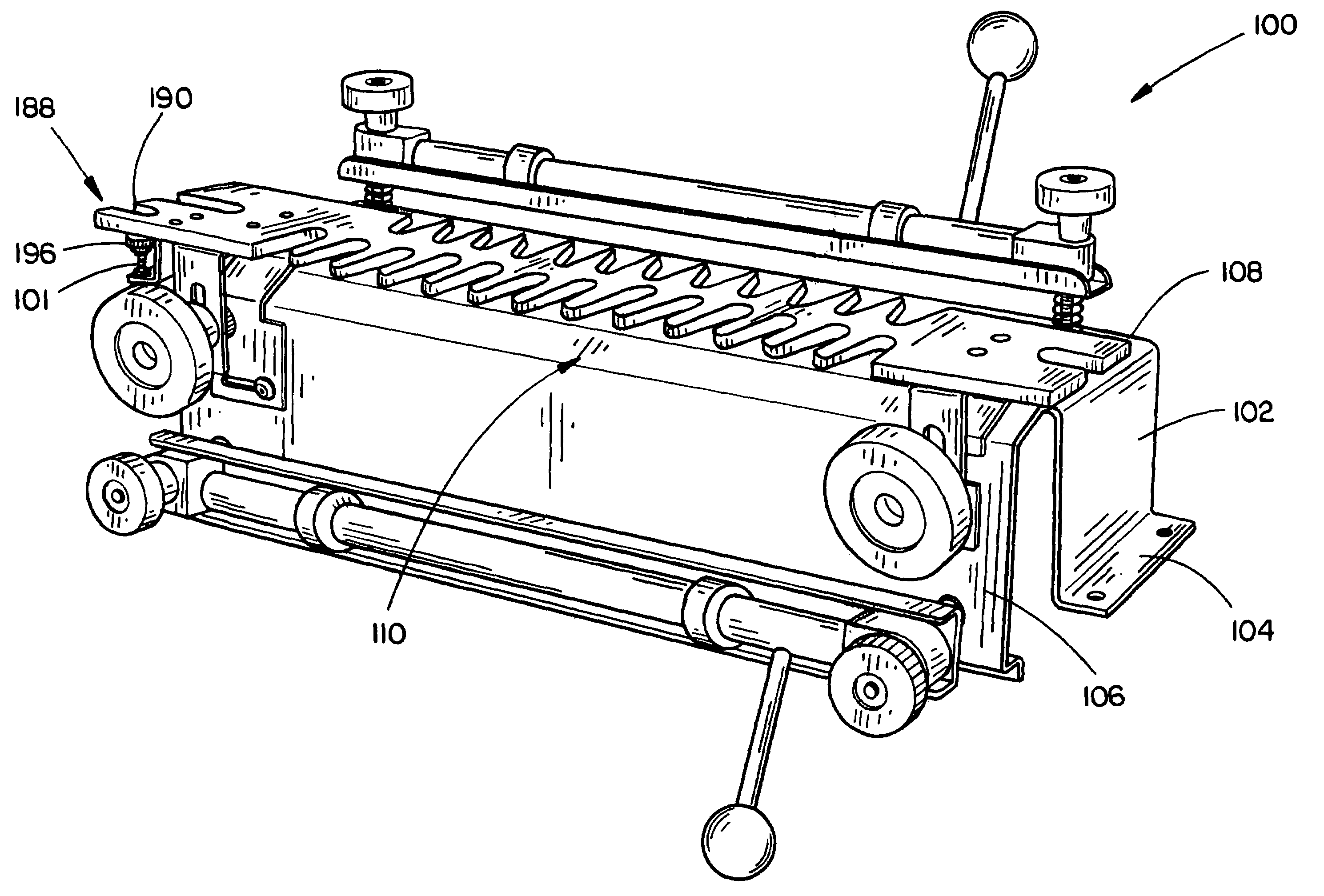

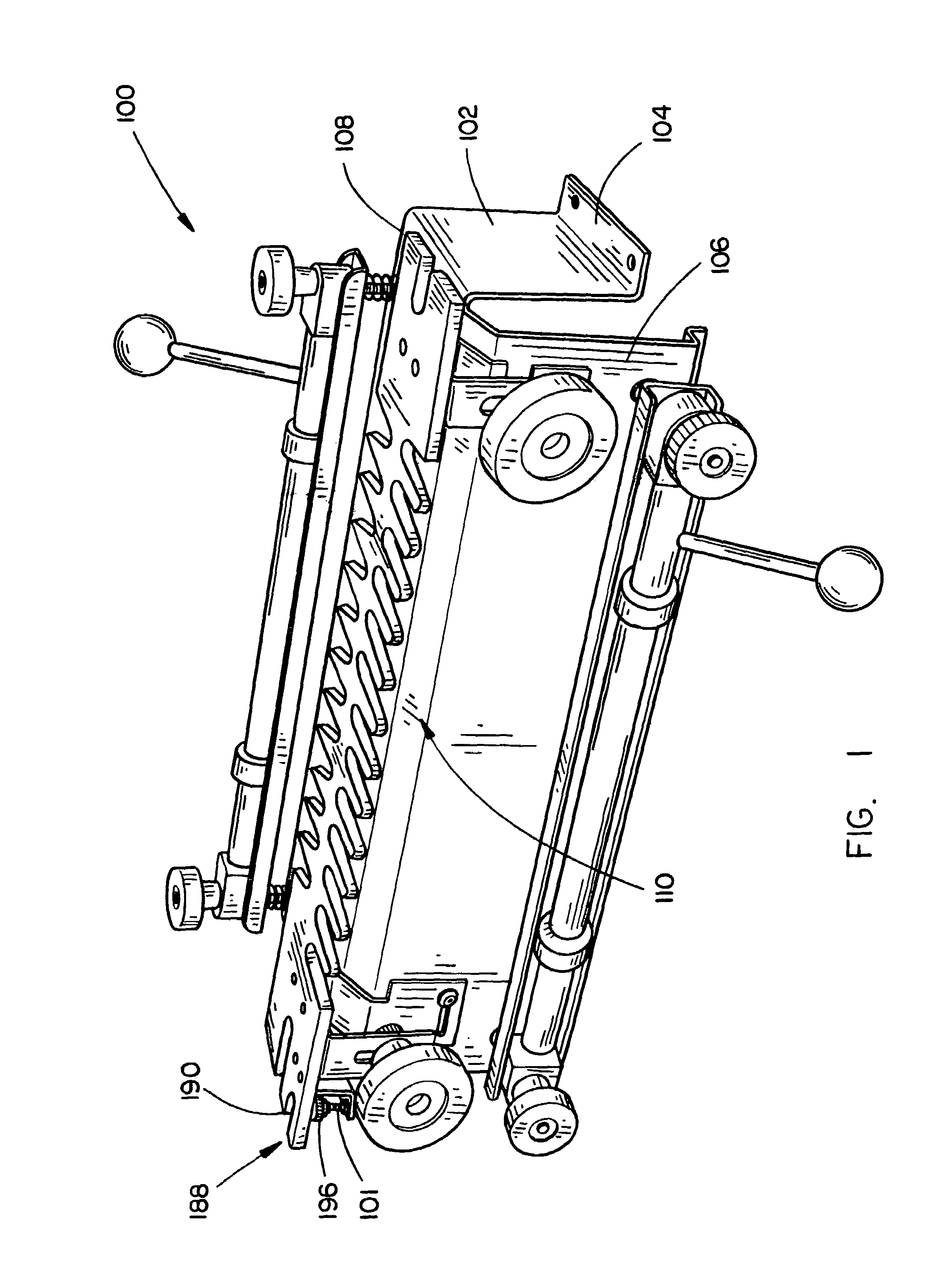

Dadoing system

InactiveUS7748420B2Easy to set upEasy to useMulti-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

A dadoing system that can be set up to cut multiple dados in a workpiece. The dadoing system uses a sliding channel clamp to keep the workpiece from moving in a transverse direction, while the dados are being cut into the workpiece. The sliding guide rails are used to put downward pressure on a workpiece while guiding a router across the workpiece during the dadoing process. Once the system is set up to cut the dados in the desired locations on the workpiece, the sliding guide rail stops can be secured into place. The stops will insure that the sliding guide rails are set up in the same place thus allowing multiple workpieces to have matching dados that line up properly during assembly.

Owner:YOUNG STEVEN PALMER

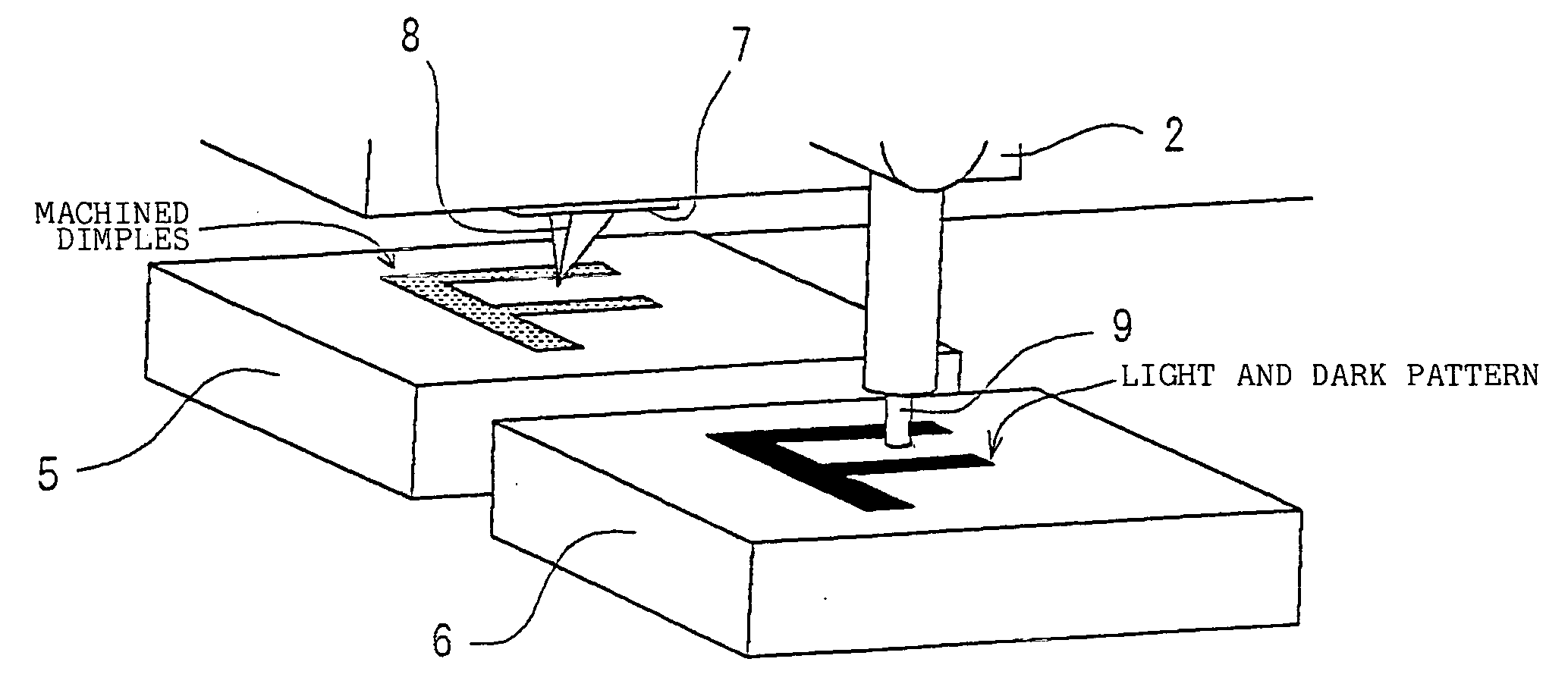

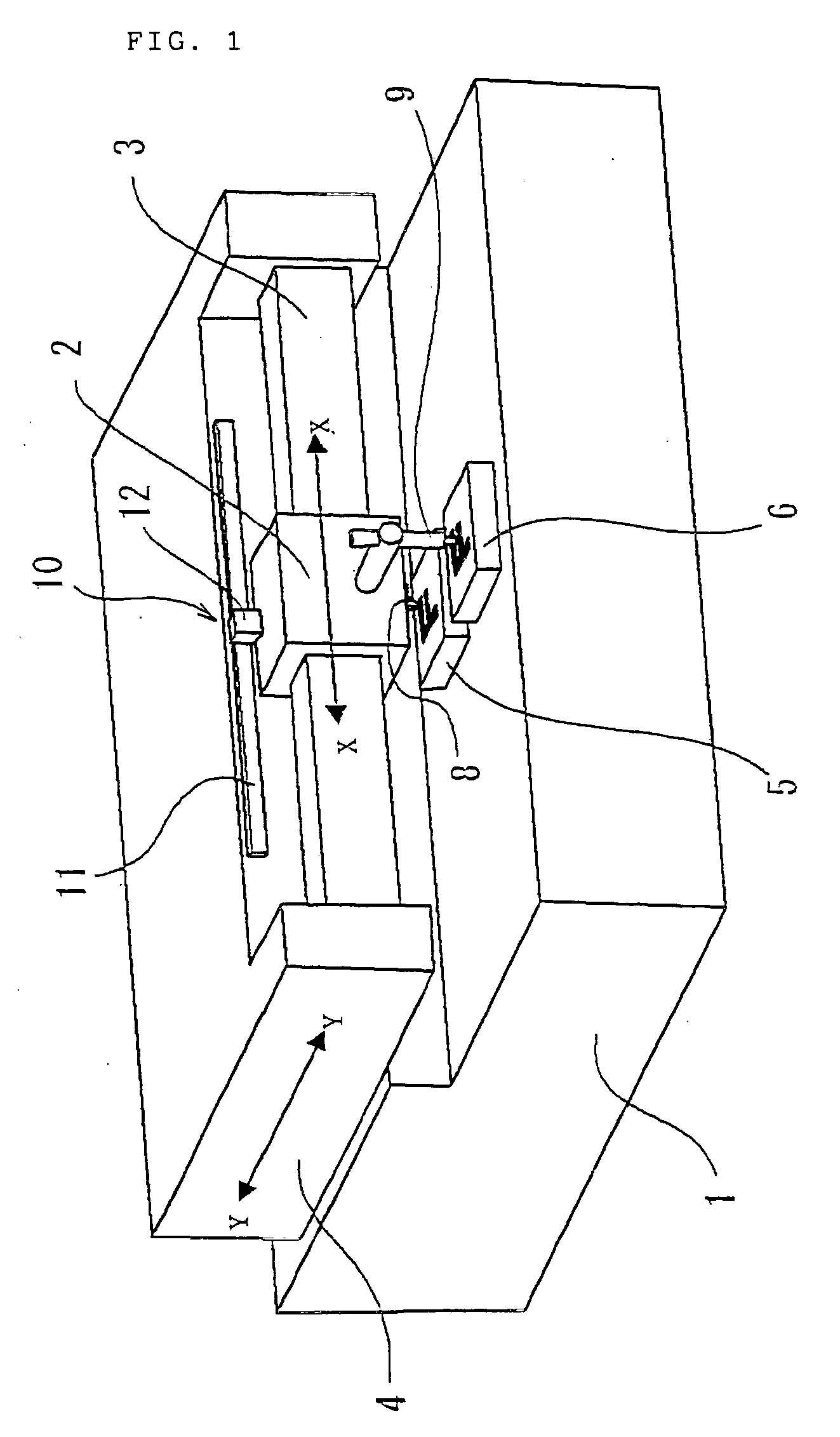

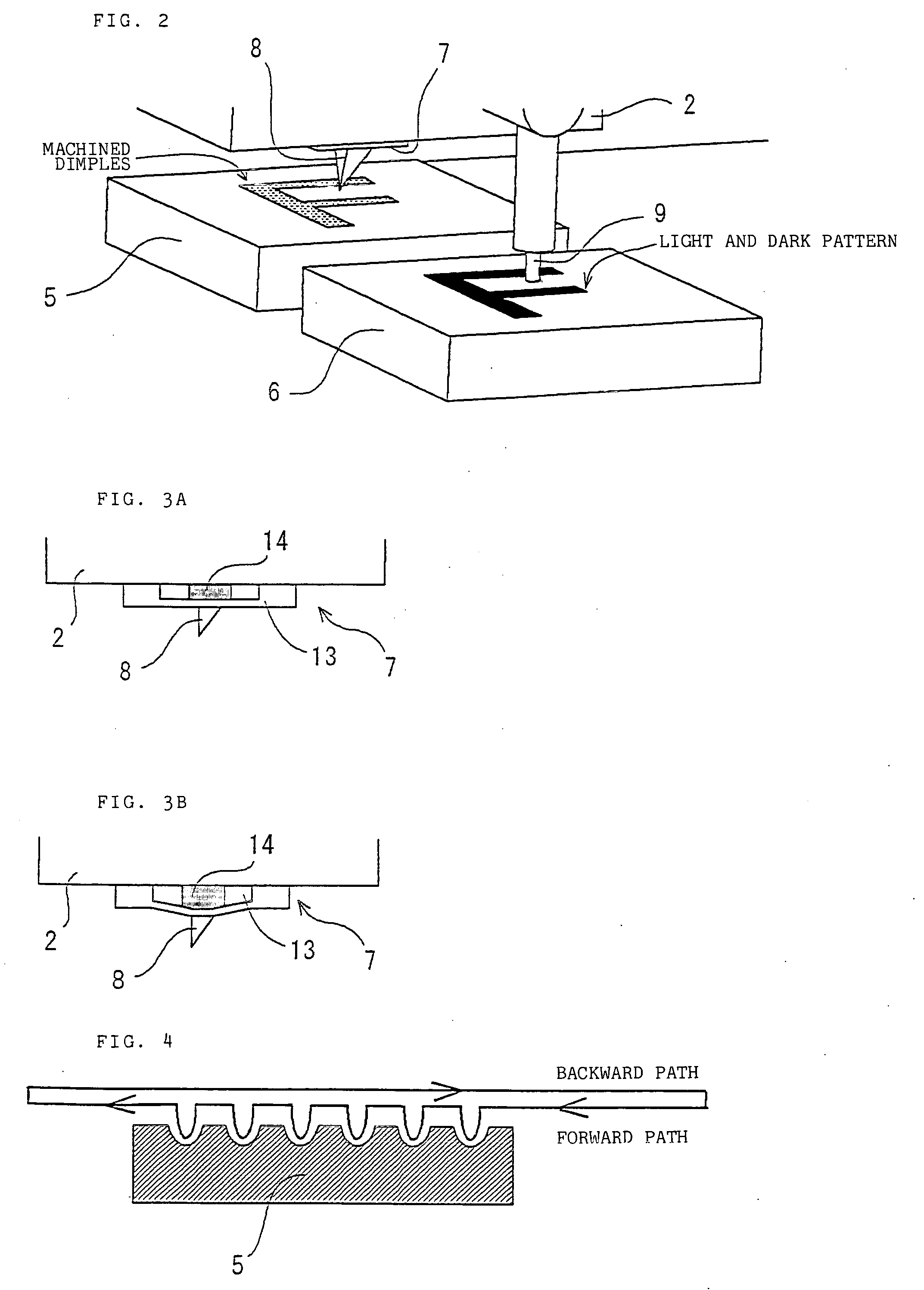

Machining apparatus

InactiveUS20070086869A1Rapid and precise micromachiningPlaning/slotting machinesPortable planing/slotting machinesLinear motionEngineering

A pulse generation means that generates a pulse each time an XY movable member moves linearly by a certain amount relative to a base is provided. A workpiece and a light and dark pattern member are provided on the base. A tool, a light and dark pattern scanning sensor that scans the light and dark pattern and outputs a scanning signal, and a cutting means that moves the tool with respect to the workpiece in a cutting depth direction, orthogonal to the linear motion direction, are provided on the XY movable member. While the XY movable member moves relative to the base, the tool is moved by the cutting means in accordance with a logical AND operation performed on the scanning signal from the light and dark pattern scanning sensor and the pulse from the pulse generation means to perform machining.

Owner:FANUC LTD

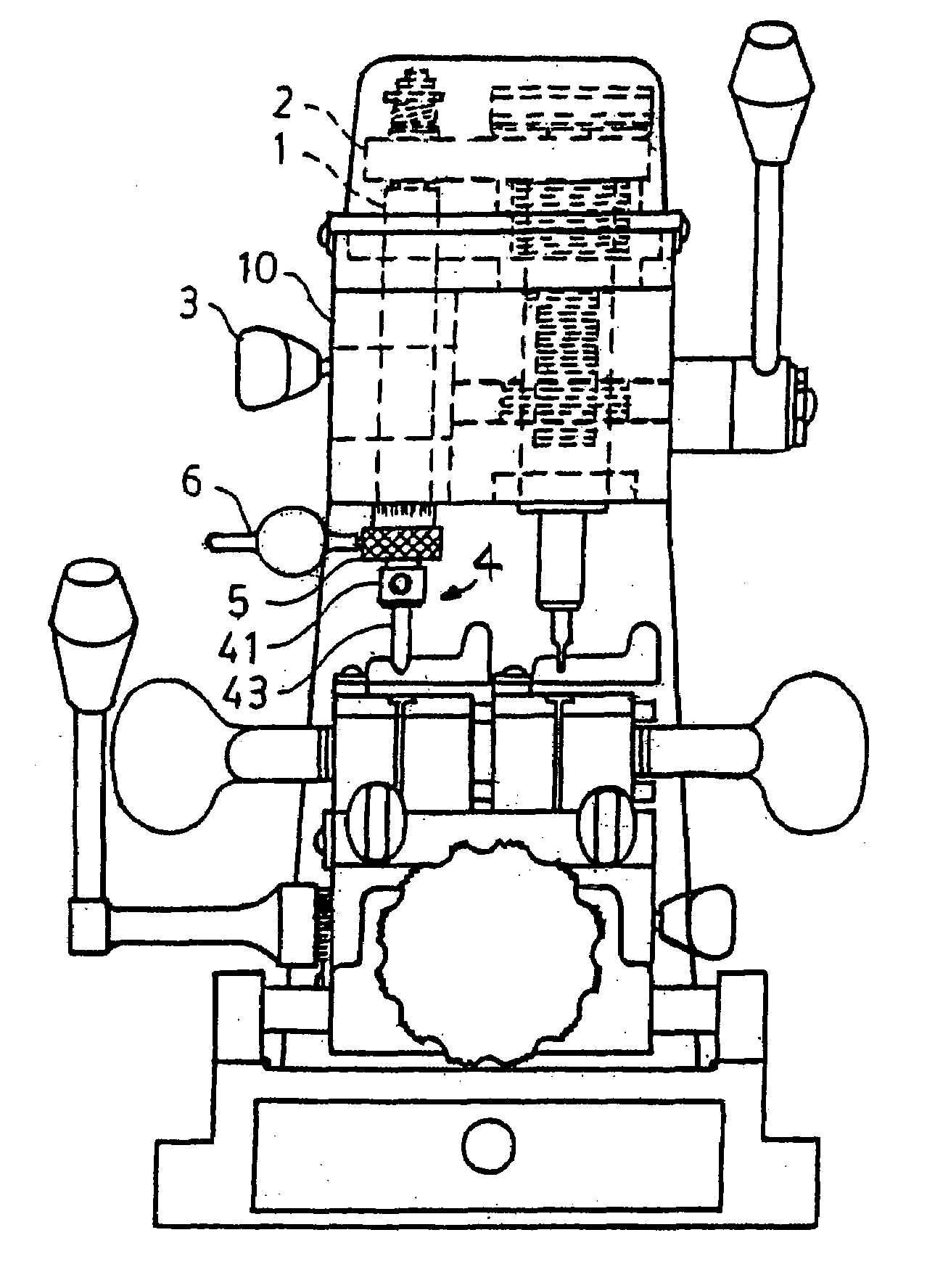

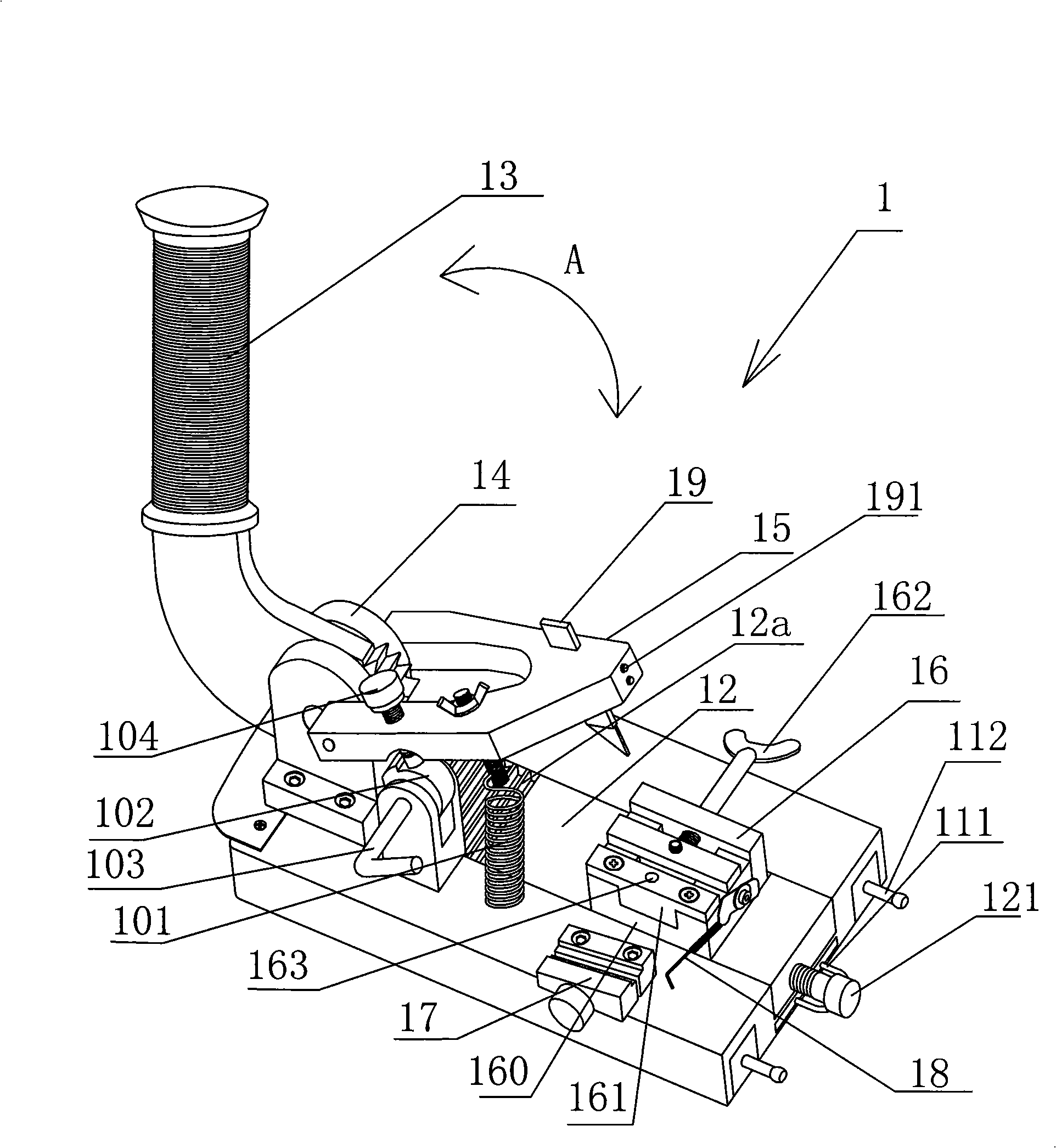

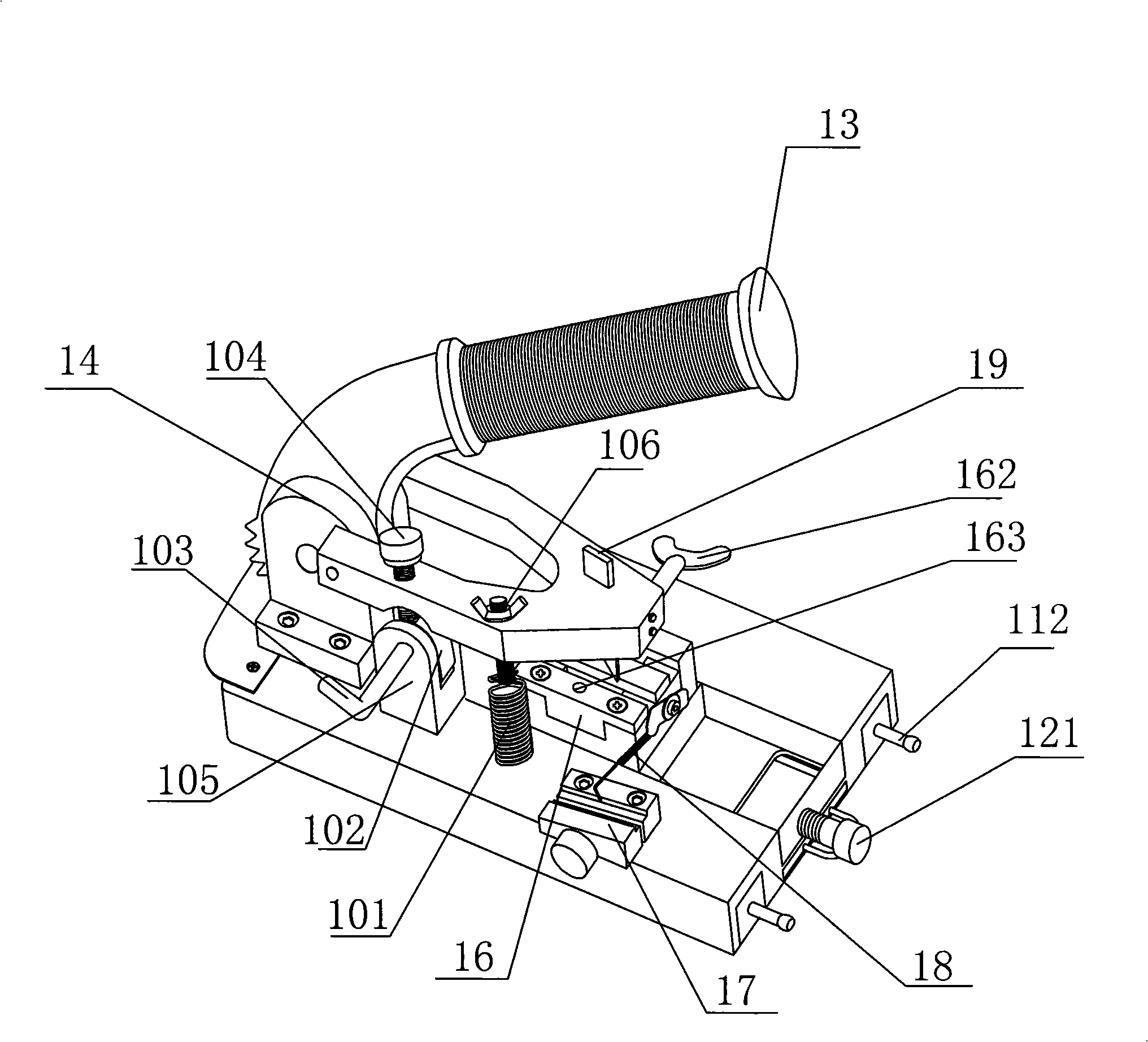

Manual key miller

InactiveCN101332520AEasy to useDid not fly outPlaning/slotting machinesPortable planing/slotting machinesPull forceGear wheel

The invention relates to a manual key dent planer which comprises: a base; a handle which is pivotally connected to a connecting support and the lower end of which is provided with a gear part, the rotation center of which coincides with that of the handle; a toothed plate which can move under the drive of the handle via the mesh between the toothed plate and the gear part; a movable clamp which is used for clamping a key billet; a fixing clamp which is used for clamping an original key; a tool head, which is arranged above the movable clamp and one end of which is rotatablely connected to the other end of the connecting support and provided with a planer tool; a tool head positioning mechanism which comprises a draught spring and a lifting device, with one end of the draught spring connected with the base and the other end connected to the tool head, and the lift system positioned between the base and the tool head and causing the tool head to rotate upward; and a dent position indicator probe, one end of which is connected to the movable clamp and the other end of which extends to the fixing clamp so as to determine the position of the dent in the key billet according to the position of the dent in the original key. The manual key dent planer of the invention has the advantages of simple structure, safe use and convenient operation.

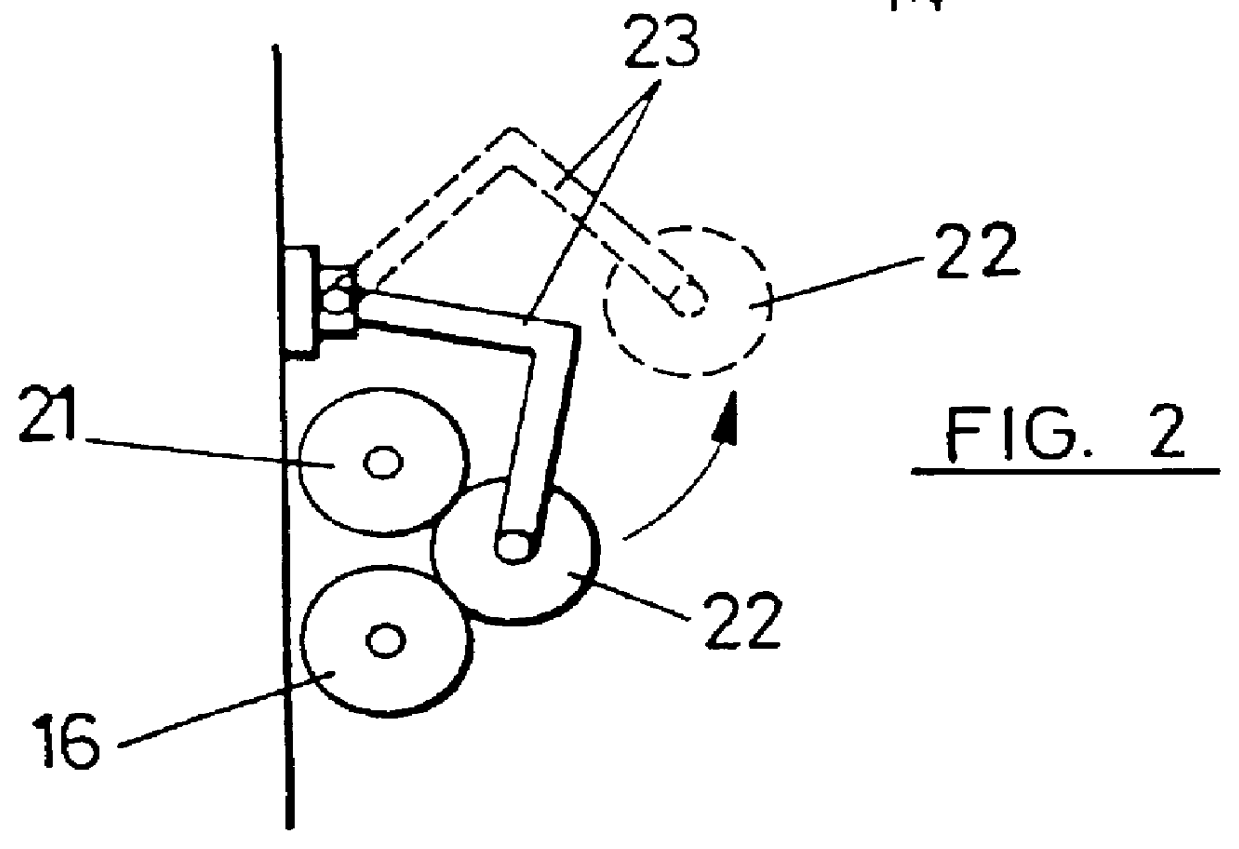

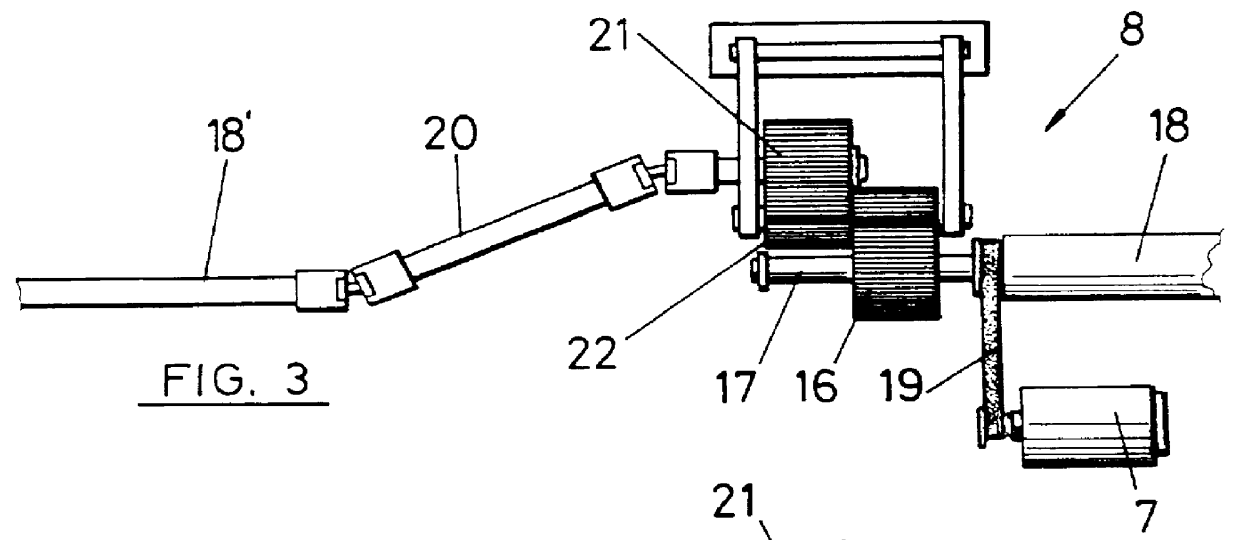

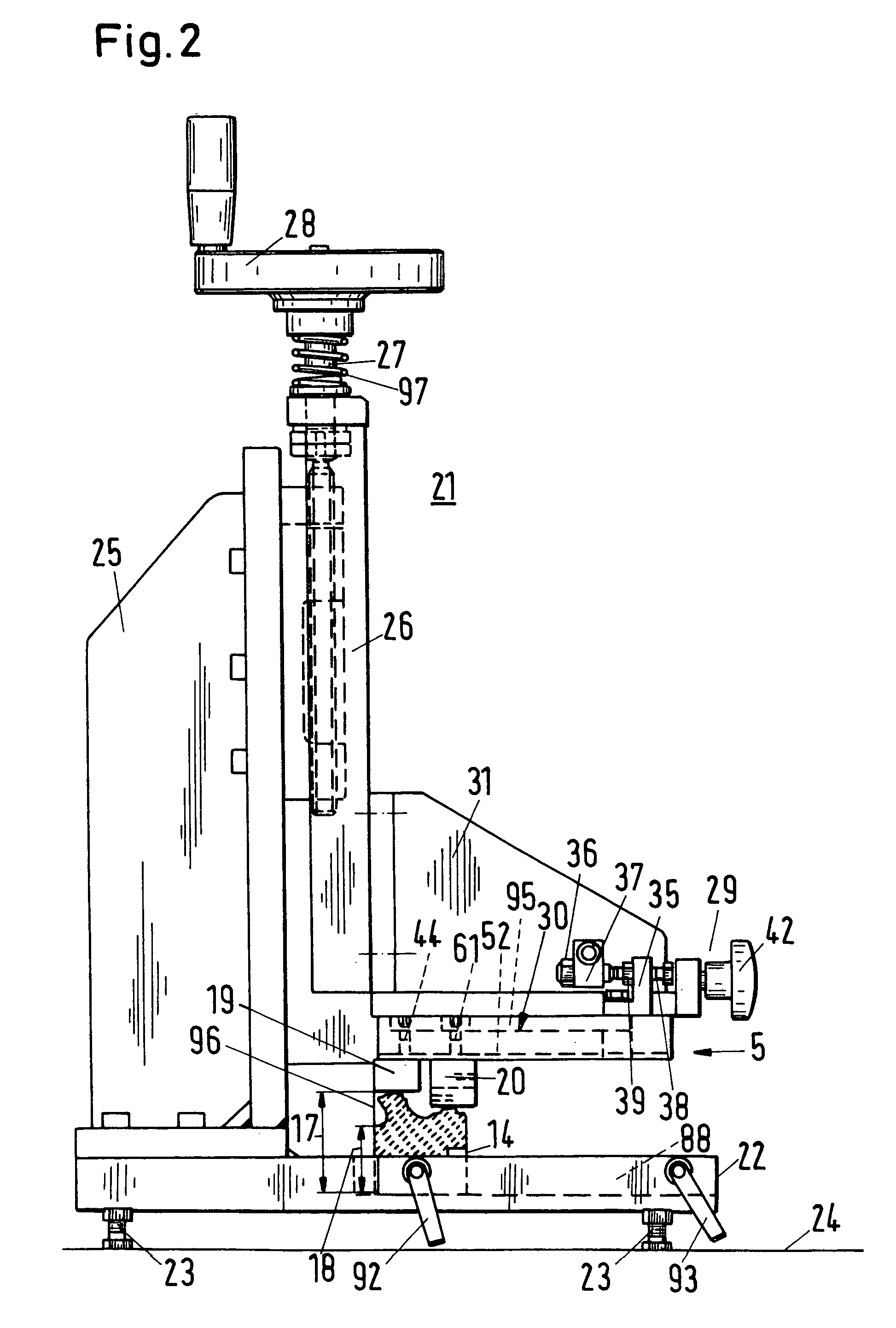

Pressing element of a machine for machining wood or plastic workpieces and method and device for adjusting such pressing element

InactiveUS6976514B2Automatic/semiautomatic turning machinesMulti-purpose machinesMolding machinePlastic materials

In a method for adjusting at least one pressing element of a molding machine for machining workpieces of wood or plastic material relative to a workpiece, transported through the machine and to be machined by the machine, the pressing element is adjusted outside of the molding machine in an adjusting device with the aid of a template of the workpiece and the adjusted pressing element is then inserted into the molding machine.

Owner:MICHAEL WEINIG AG

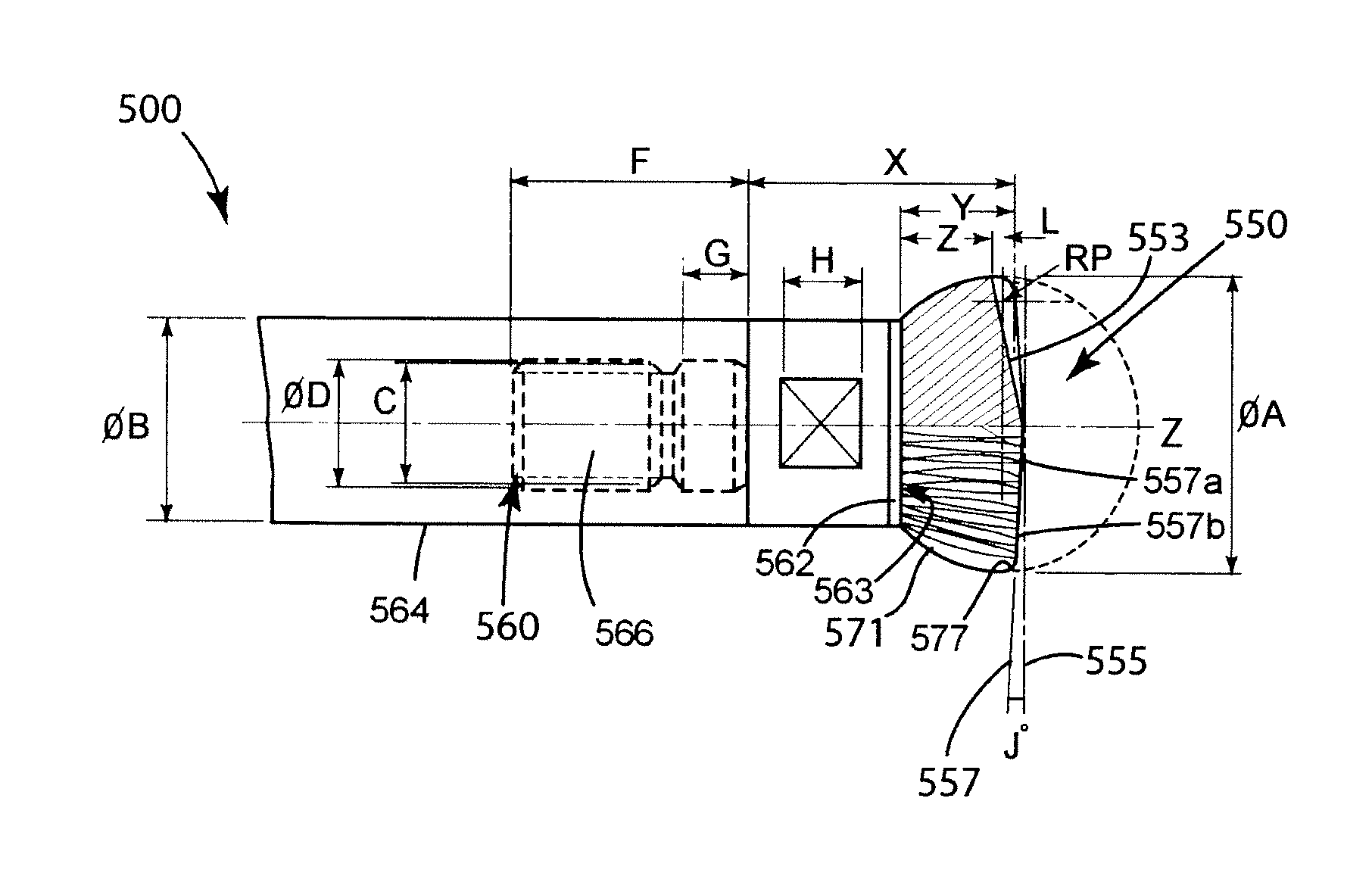

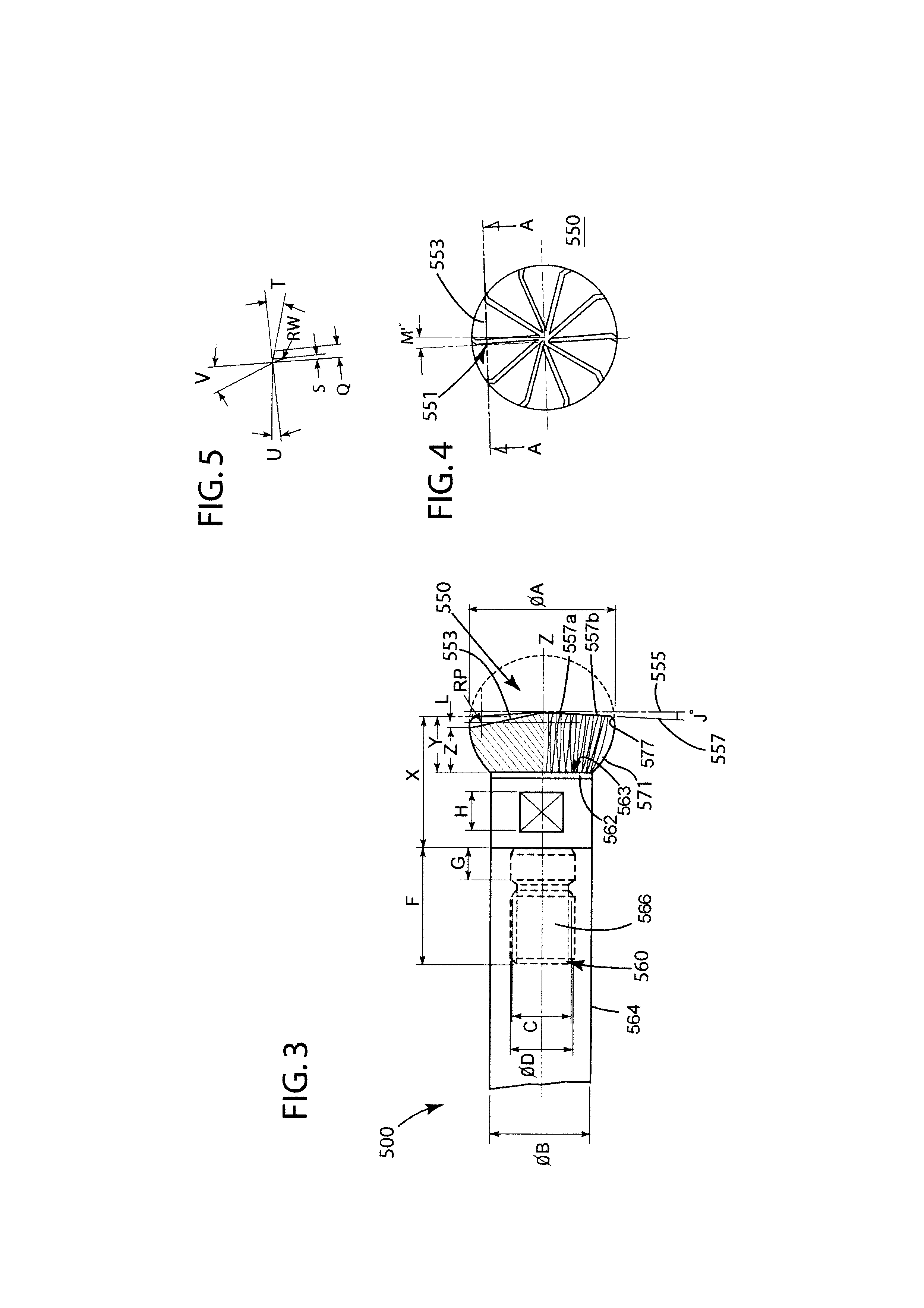

Mill and method of use

A method for plunge milling a workpiece. The method includes rotating a cutting head while advancing the cutting head along a direction towards the workpiece; removing material from the workpiece with frontal teeth disposed on a frontal face of the cutting head; bending a tool holder configured to lead the cutting head inside the workpiece; stopping the advancing of the cutting head along the direction towards the workpiece when the cutting head has reached a predetermined depth inside the workpiece; and retrieving while rotating the cutting head from the inside of the workpiece such that side teeth of the cutting head remove material from the inside of the workpiece due to the bending of the tool holder.

Owner:NUOVO PIGNONE TECH SRL

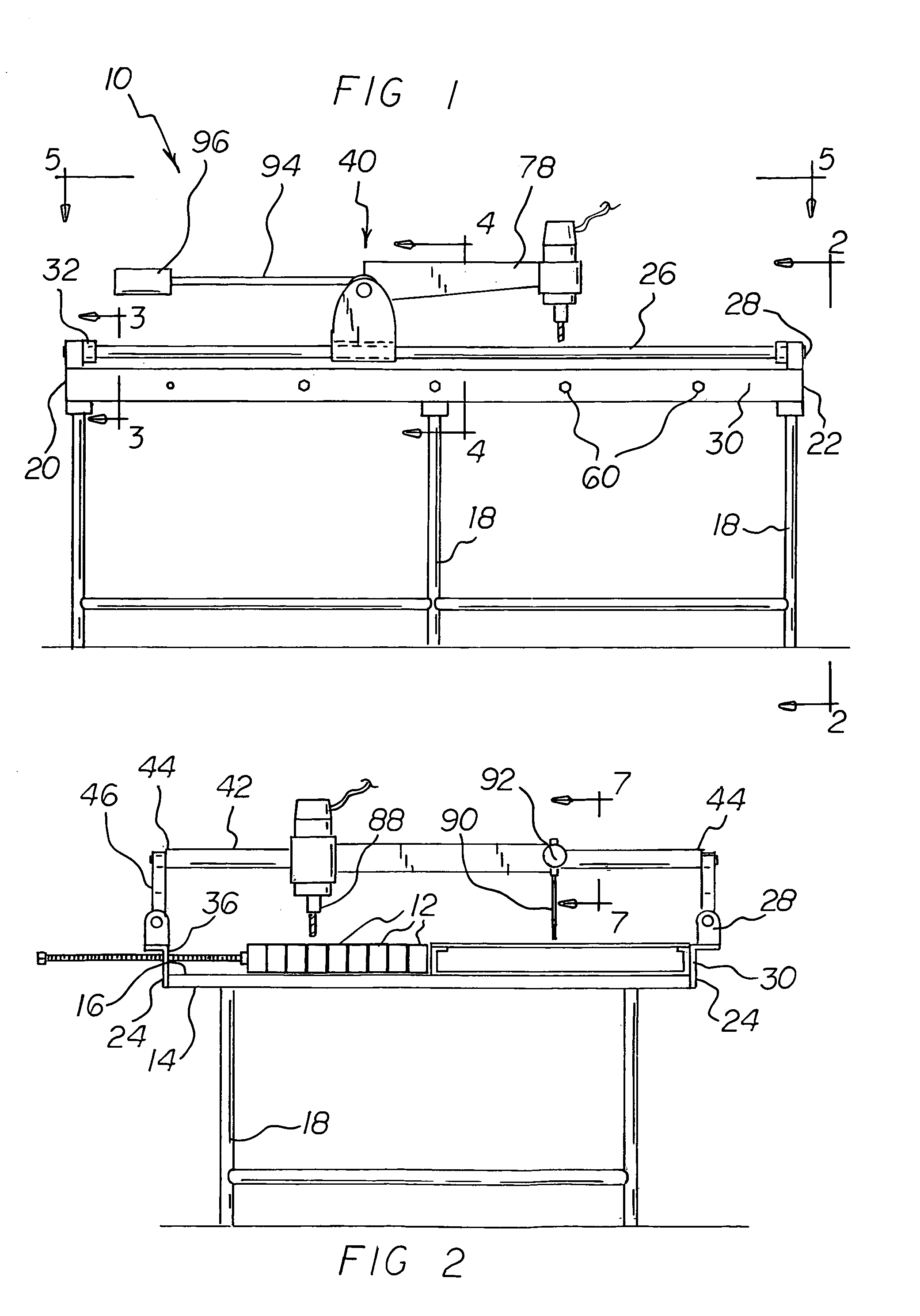

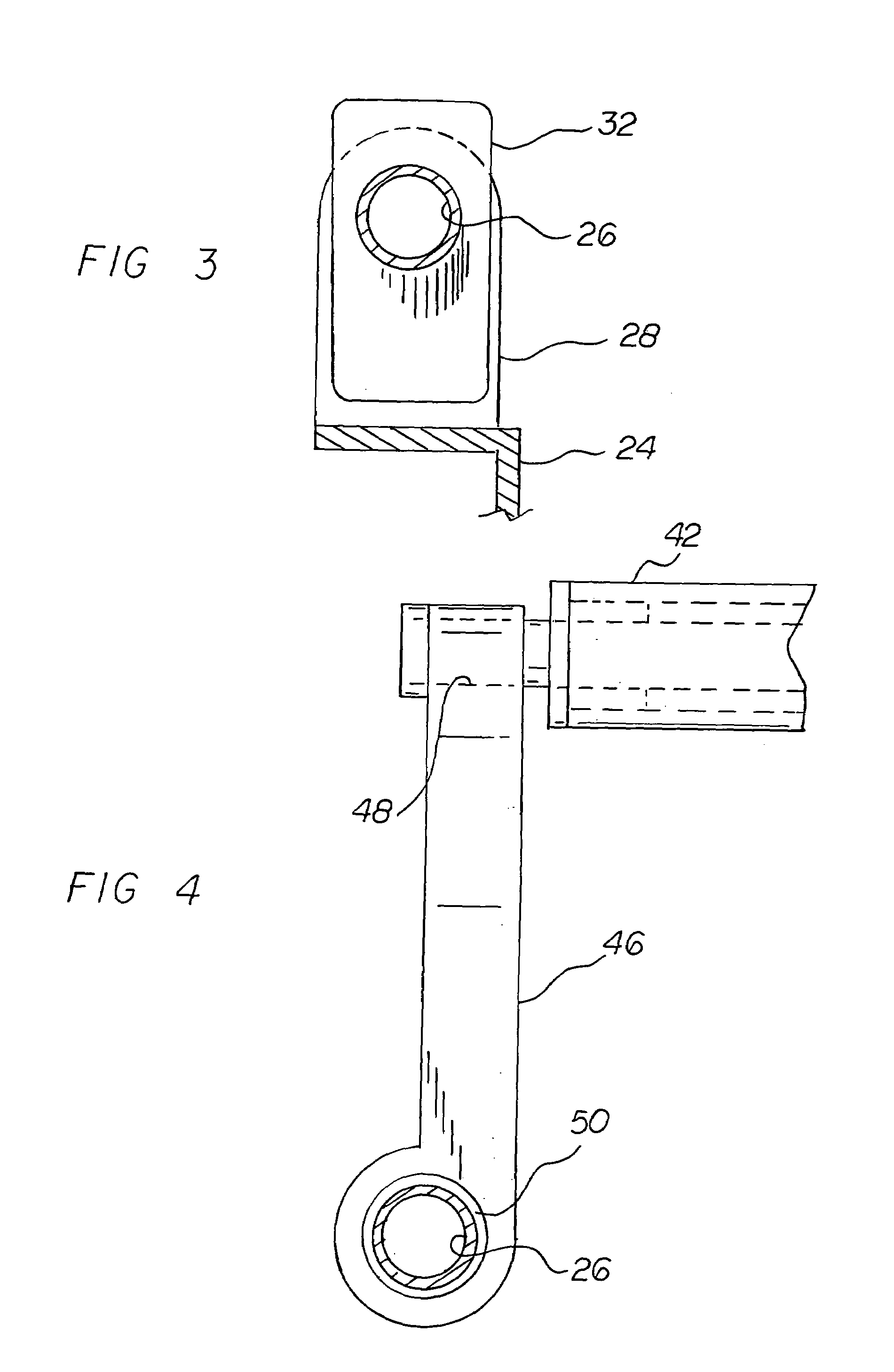

Fence router table system

InactiveUS7131470B1Easy and efficient to manufactureDurable and reliable constructionWriting aidsMulti-purpose machinesEngineeringMechanical engineering

A table with a working surface has a parallel rail on each side of the working surface. A slide assembly includes a shaft with ends and a pair of brackets. Each bracket has a hole. The holes receive the ends of the shaft. The slide assembly includes cylindrical tunnels. The tunnels slidably receive the rails. An operating assembly has primary and secondary arms. Each arm has a free exterior end and an interior portion. The interior portion is coupled to the shaft. A router is secured to, and depends from, the free end of the secondary arm. Control mechanisms include a scribe. The scribe is secured to, and depends from, the free end of the primary arm. Movement of the primary arm and scribe with respect to a template will cause corresponding movement of the secondary arm and router with respect to work pieces to be routed.

Owner:SOMMERS JAMES

Router with lighted base

InactiveCN101318235AProfiling/shaping machinesMeasurement/indication equipmentsOptoelectronicsLight source

A hand operated router having a base, with a portion that is transparent. Disposed within the base is at least one light emitting source, where the light emitting source is designed to partially emit light towards a workpiece. The light emitting source may be battery operated or may receive power from the same source as the router.

Owner:TECHTRONIC IND CO LTD

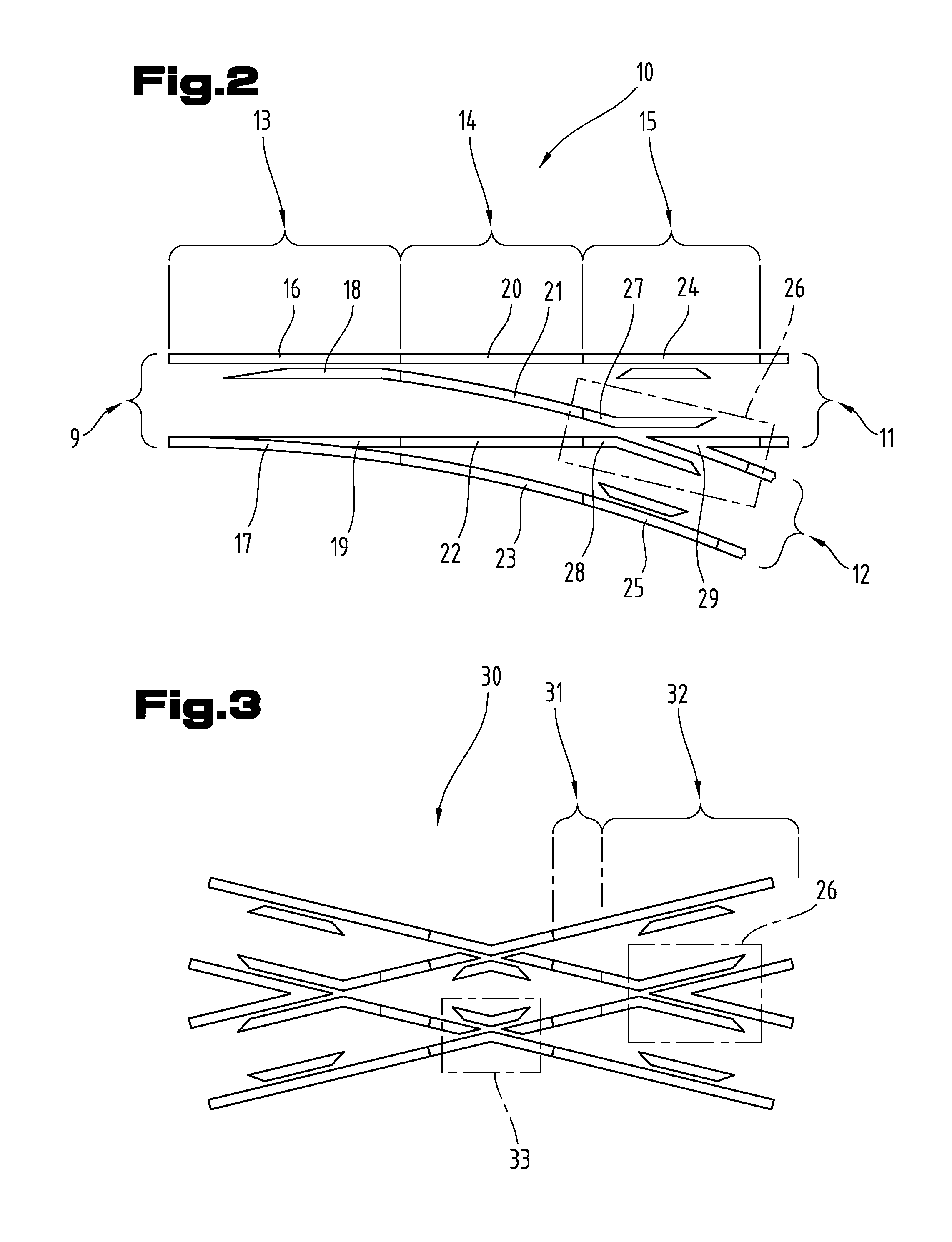

Method For Profiling A Laid Rail And Processing Vehicle

ActiveUS20130318762A1Easy to getKeep for a long timeWorkpiecesGrinding feed controlEngineeringMechanical engineering

The invention relates to a method of profiling a running surface of a laid rail by means of a processing vehicle, in particular in the region of a switch, comprising placing a first copying probe element displaceable transversely to the rail in contact with the running edge or the inner side edge and machining the rail.

Owner:LINSINGER MASCHENBAU GES

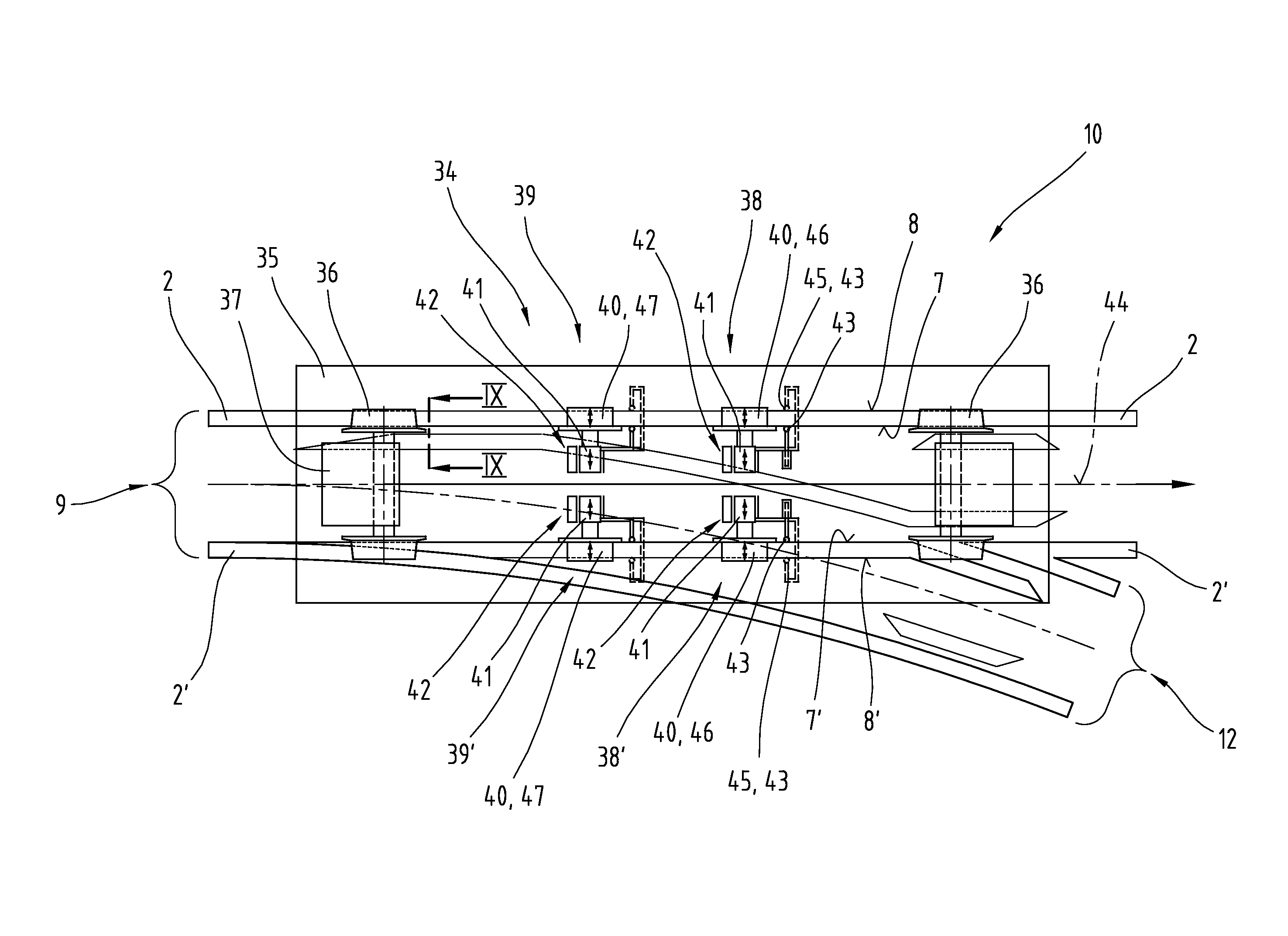

Apparatus for guiding tube processing devices

ActiveUS20130334751A1Increase flexibilityHigh degreeWelding/cutting auxillary devicesPortable planing/slotting machinesTwo bandEngineering

An apparatus for guiding tube processing devices, in particular planing devices, wherein the apparatus is arranged on an outer circumference of the tube to be processed, wherein the apparatus has at least two bands which extend in parallel.

Owner:GEORG FISCHER WAVIN AG

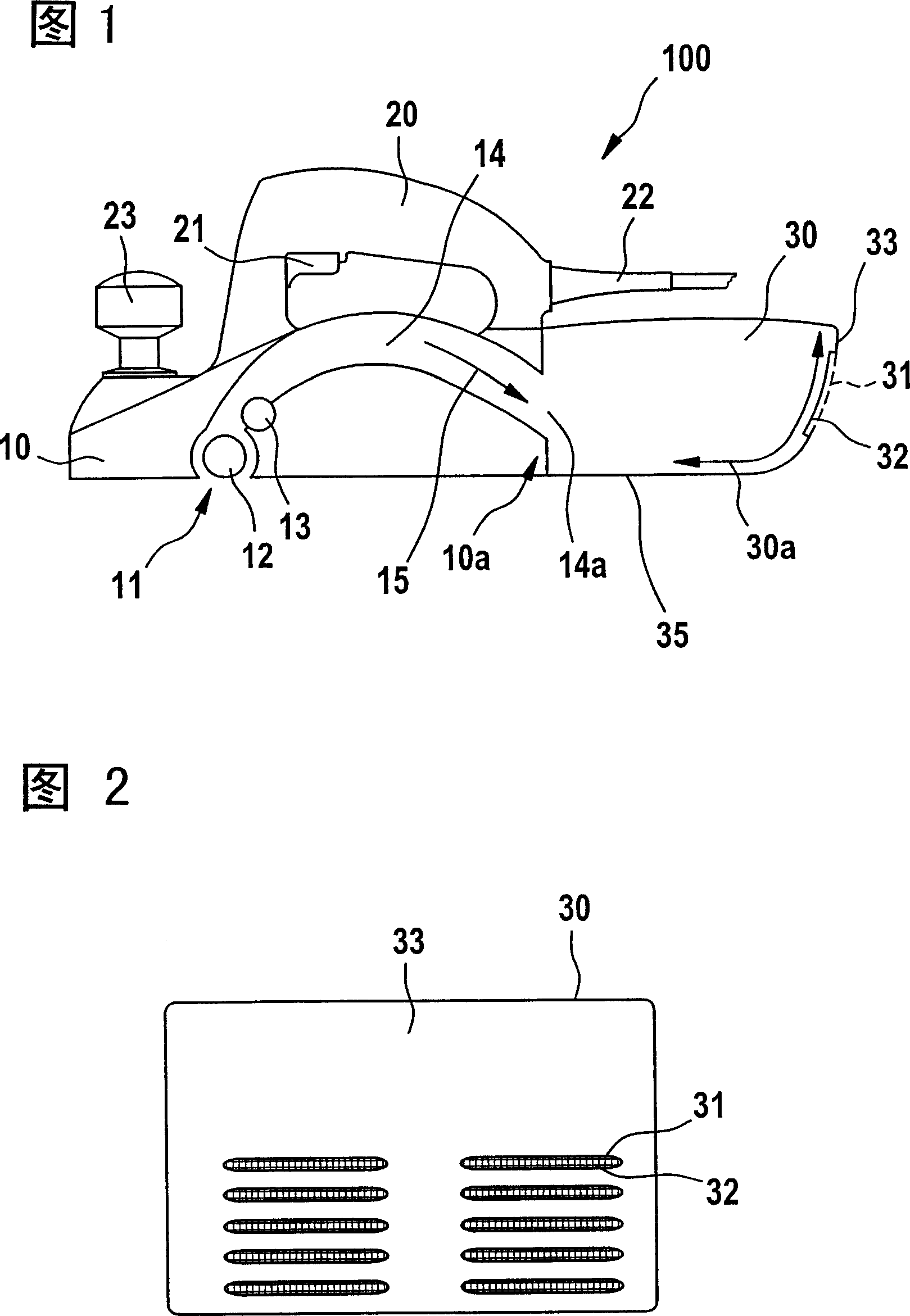

Guiding device

InactiveCN101391317AImprove flatnessSimple and fast operationHand planesPortable planing/slotting machinesEngineeringMechanical engineering

Disclosed is a guiding device used on an electric planer, wherein, the electric planer has a shell and a bottom plate arranged on the shell, the guiding device can be detachably mounted on the bottom plate, the guiding device includes a guiding piece vertical to the bottom plate and a handle disposed on the guiding piece, the guiding piece is provided with a guiding part parallel to the bottom plate, and the guiding part is matched with a reference piece arranged on a workpiece. The surface of the workpiece can be parallel to a datum plane by only moving the electric planer to make the guiding part of the guiding device slide on the datum plane of the reference piece when processing a curved plane into a flat plane by adopting the guiding device, the operation is simple and convenient, and the processed workpiece surface has very high flatness.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com