Patents

Literature

380 results about "Side Tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

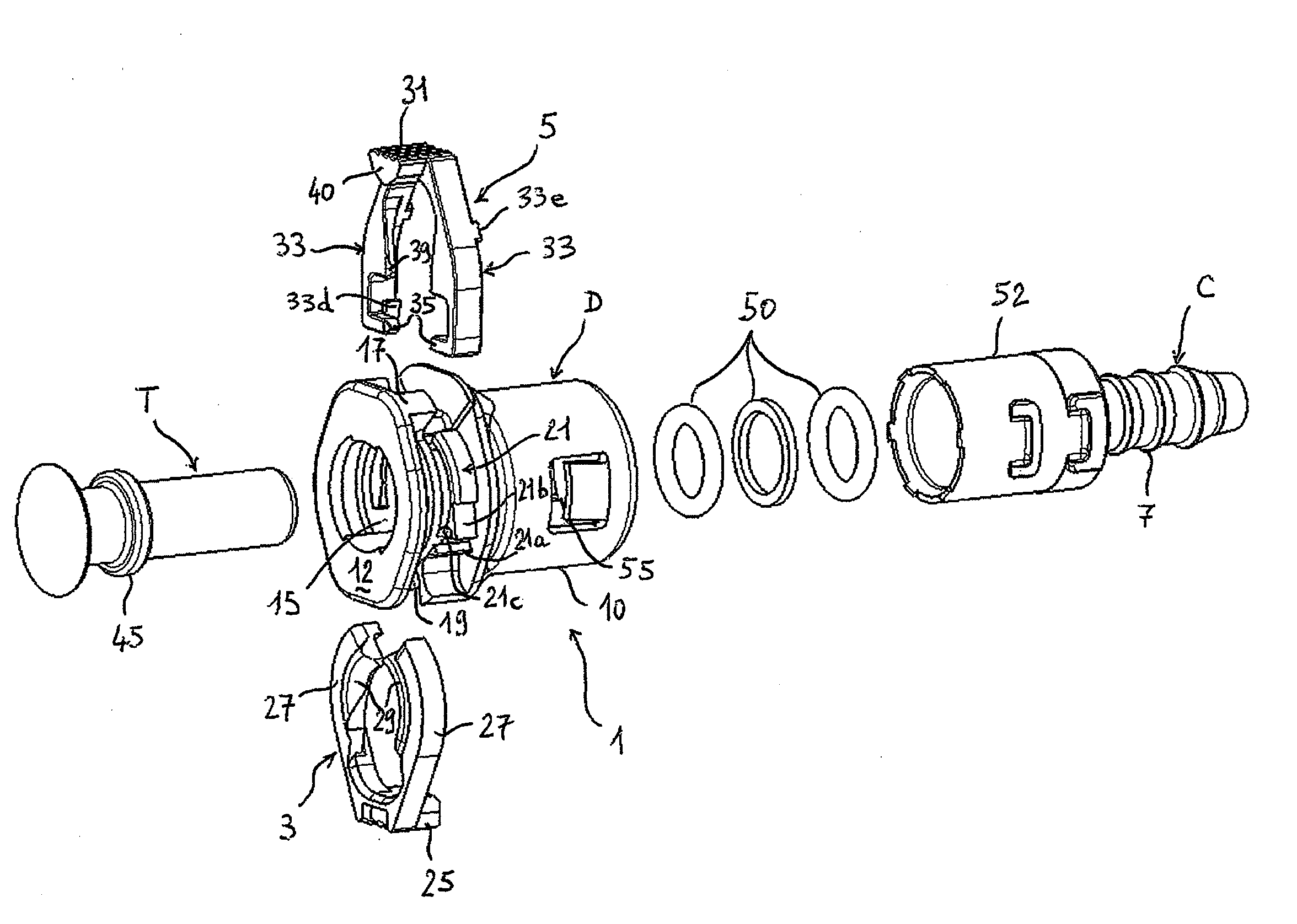

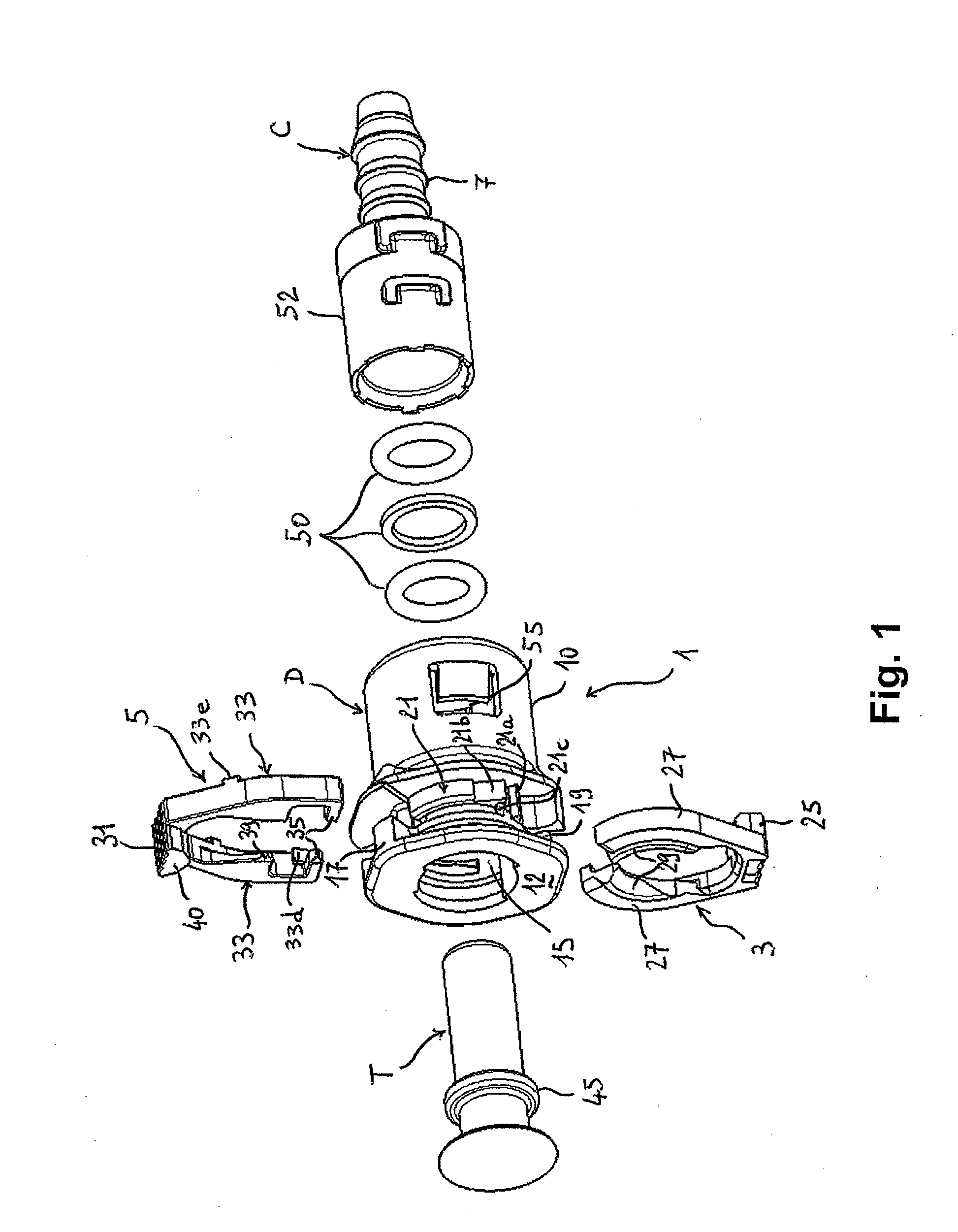

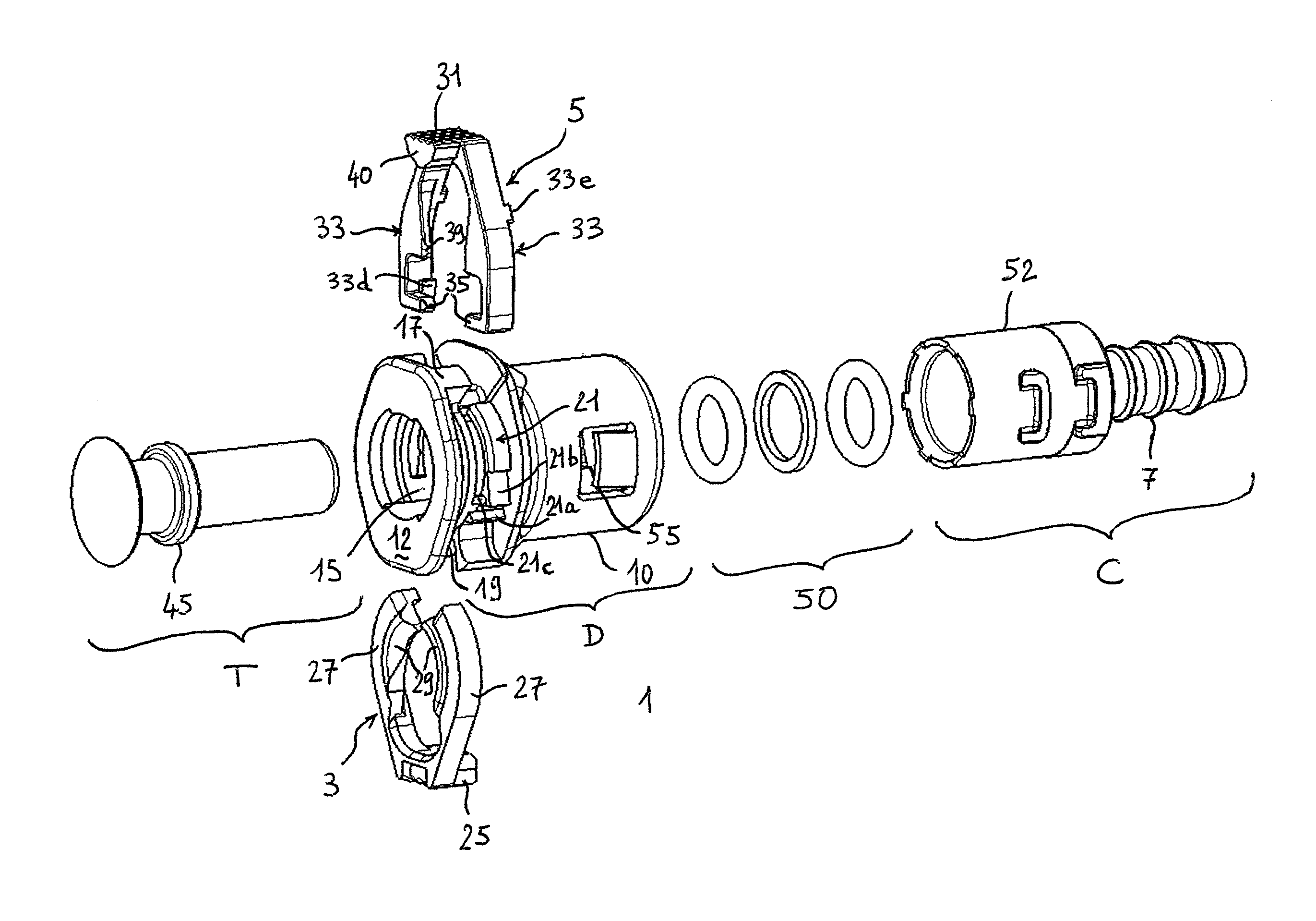

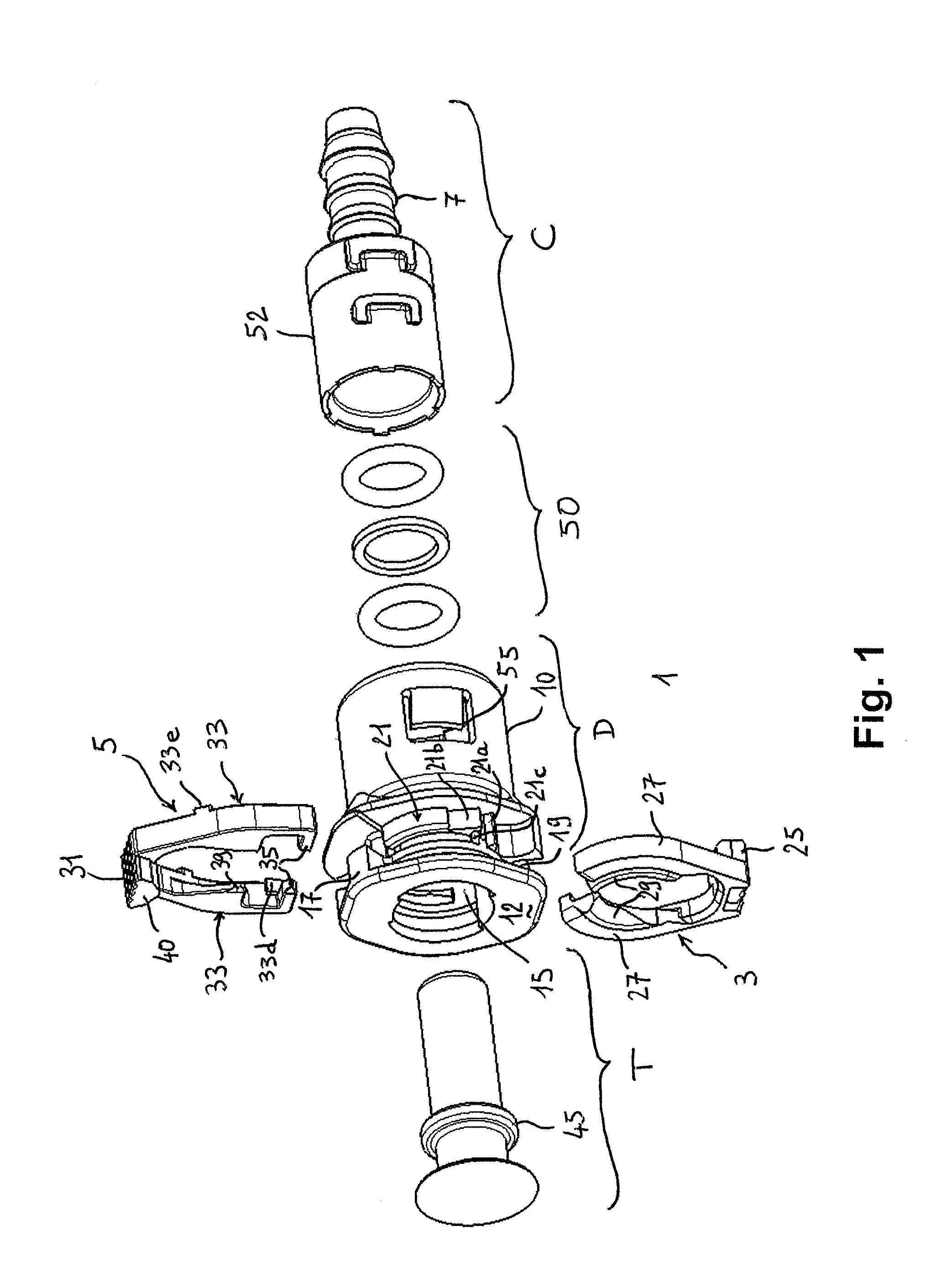

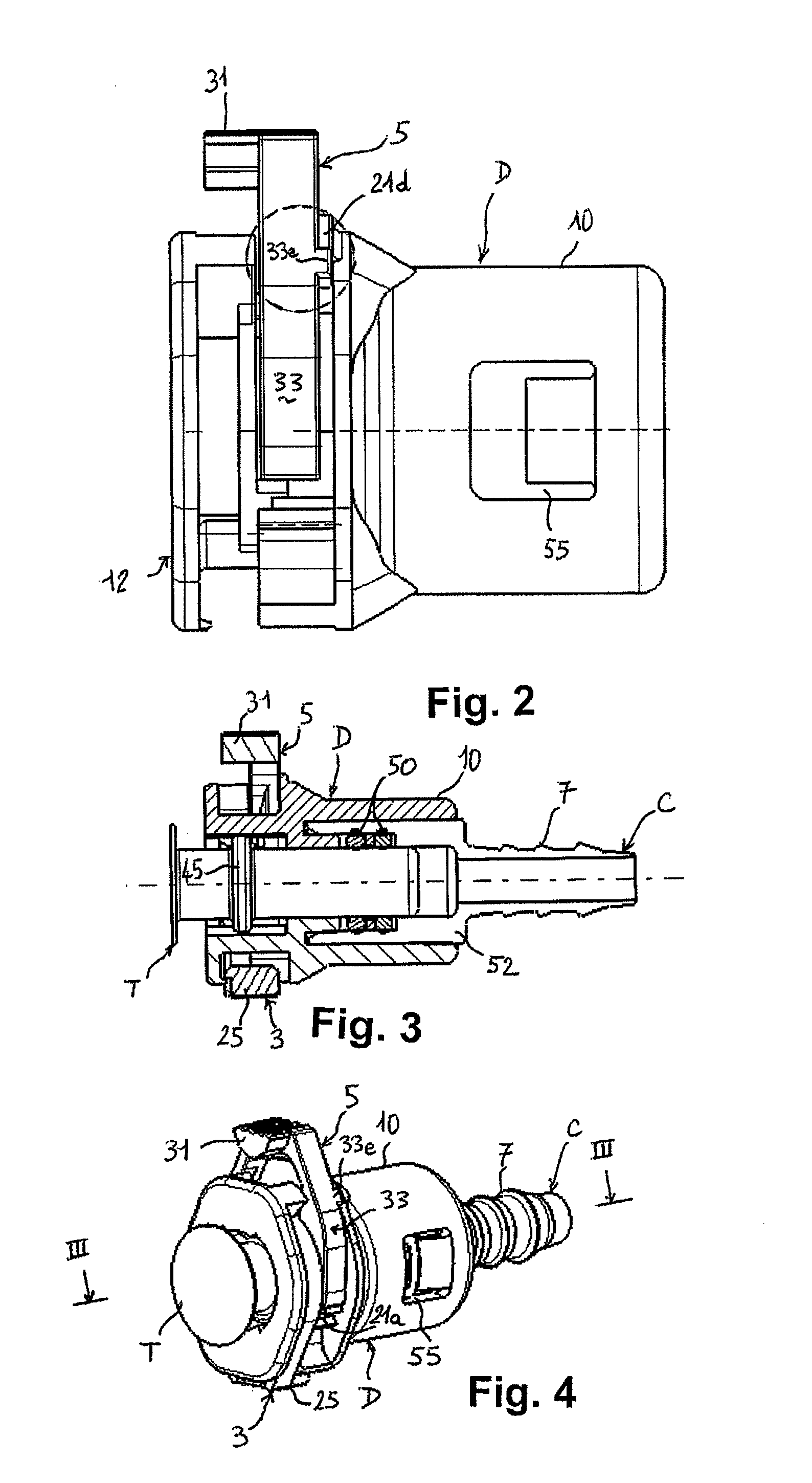

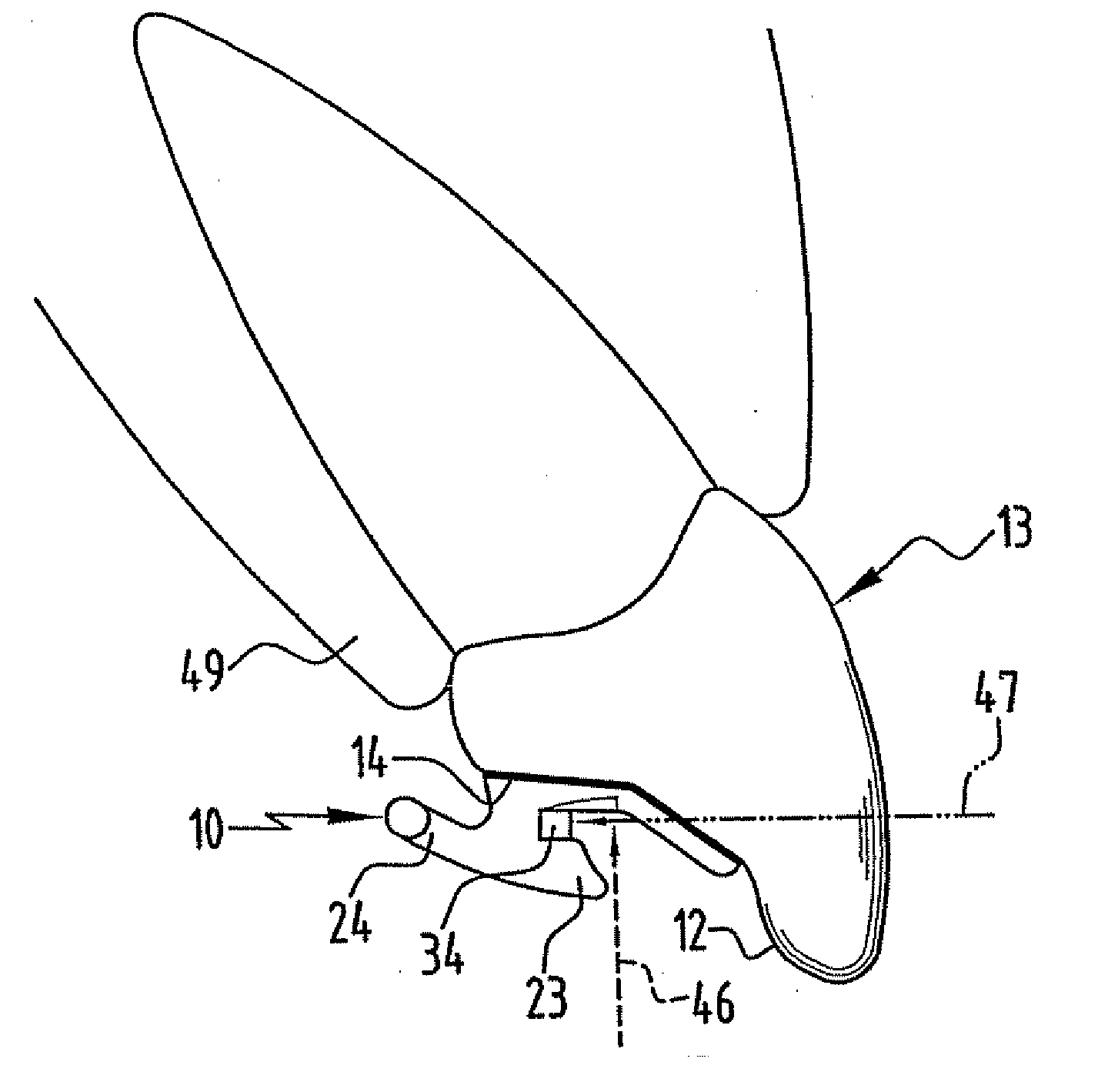

Snap-on coupling for connecting a fluid pipe to a rigid end fitting with a connection indicator and method of inspecting this connection

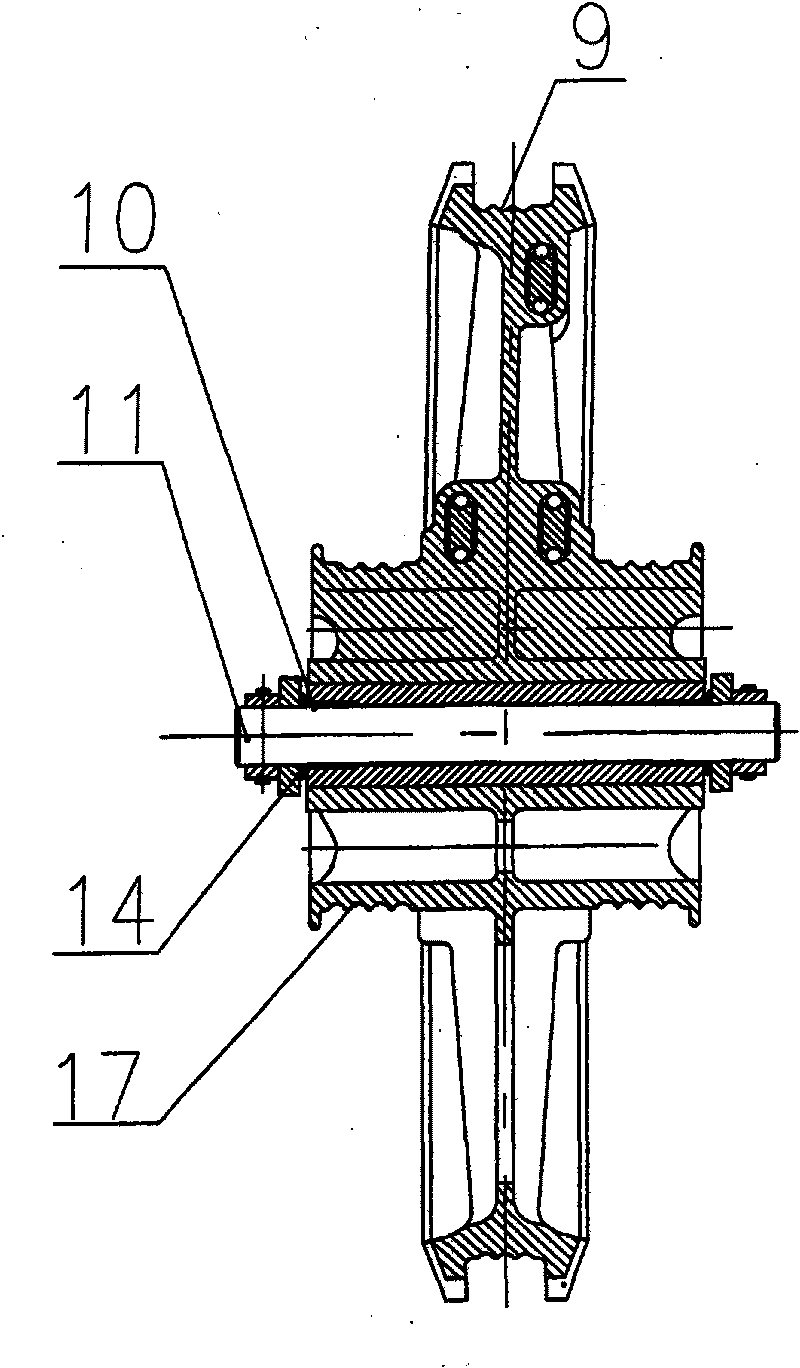

The present invention relates to a snap-on coupling between a fluid pipe and a rigid tubular end fitting, this coupling comprising:a sleeve mounted on a pipe to be coupled to an end fitting that has a peripheral connecting projection,a locking member engaging with this projection to retain the end fitting in the sleeve, anda visual indicator which engages with the projection behind the locking member and occupying an extended position and a depressed position in the sleeve, the member and the indicator each having a head and two elastically deformable side legs, each leg of the indicator having a retention arm engaging with a lower side tooth and with a bottom stop, both formed on the corresponding side of the sleeve, when the indicator occupies the depressed and extended positions, respectively.According to the invention, this indicator is such as to: be retained in the extended position by these arms and by locking means formed on each leg bearing against the sleeve; be released by the connection; then be moved to the depressed position by pressure on its head; and then be held by the locking of the arms underneath these lower teeth, in such a way as to serve as an indicator and to double-lock the connection.

Owner:HUTCHINSON SA

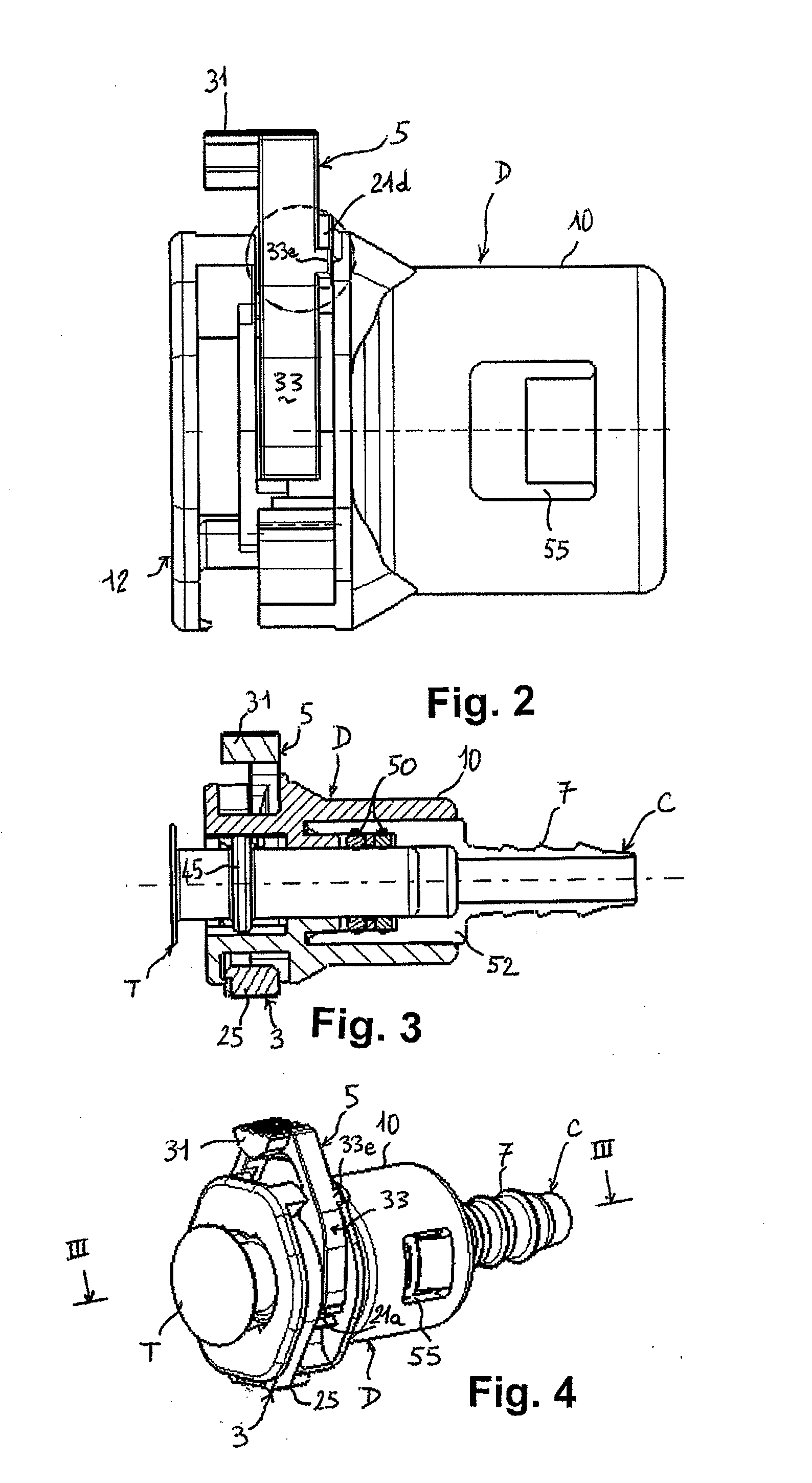

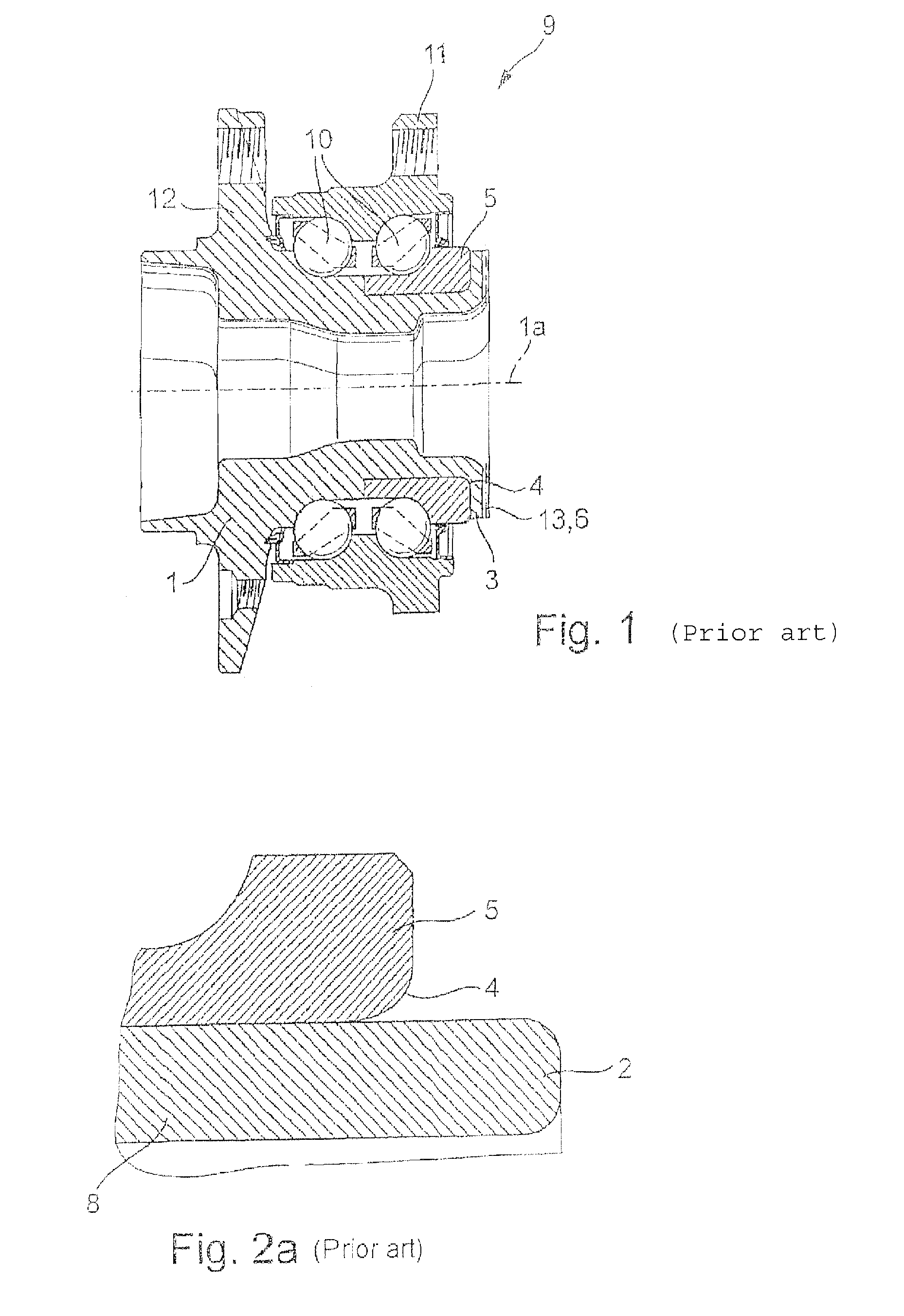

Collar having end-side teeth for a drivable wheel hub

A collar, made from plastically deformed material, of a hub. The collar holds at least one inner ring of a wheel bearing unit on the hub in an axially fixed manner. Also, end-side teeth, are formed in the collar for engaging in a mating toothing.

Owner:SCHAEFFLER TECH AG & CO KG

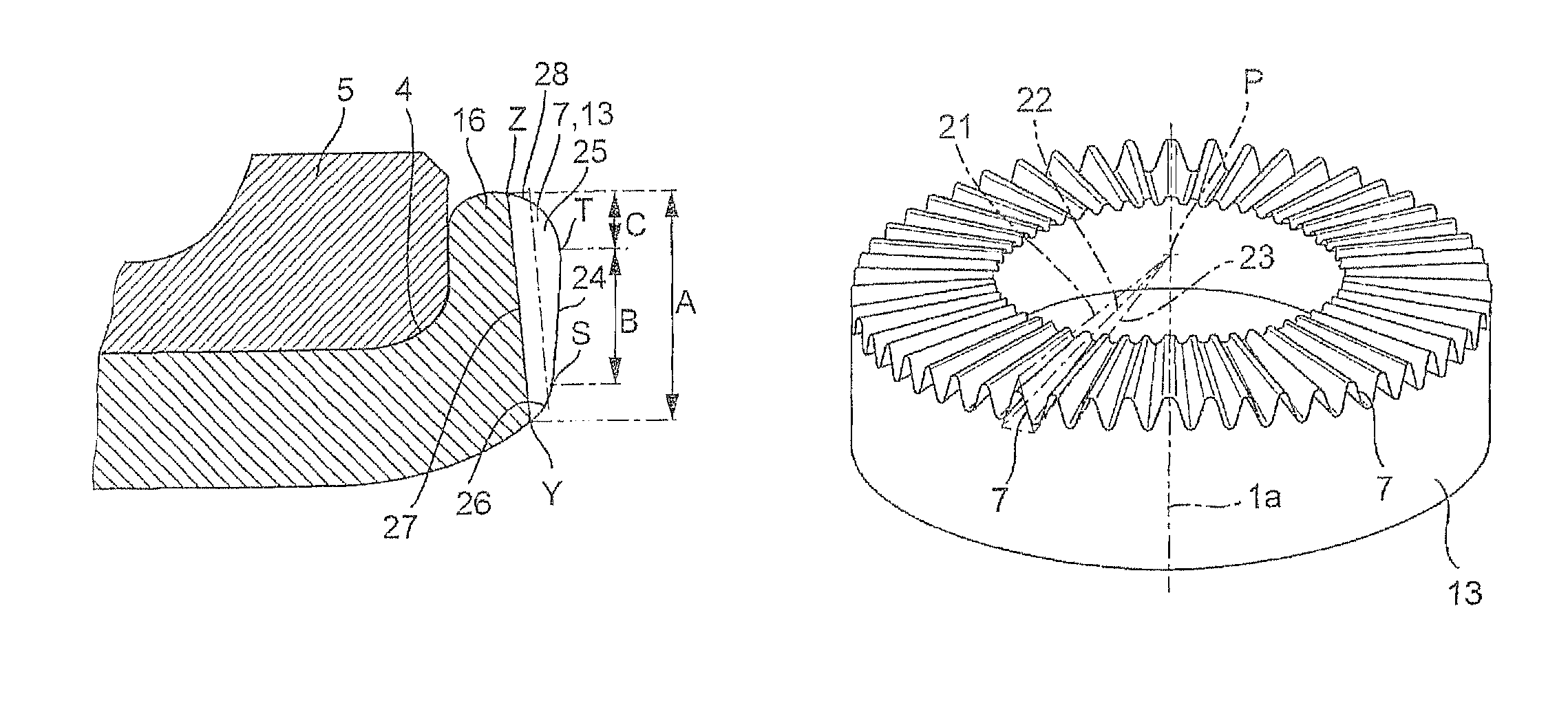

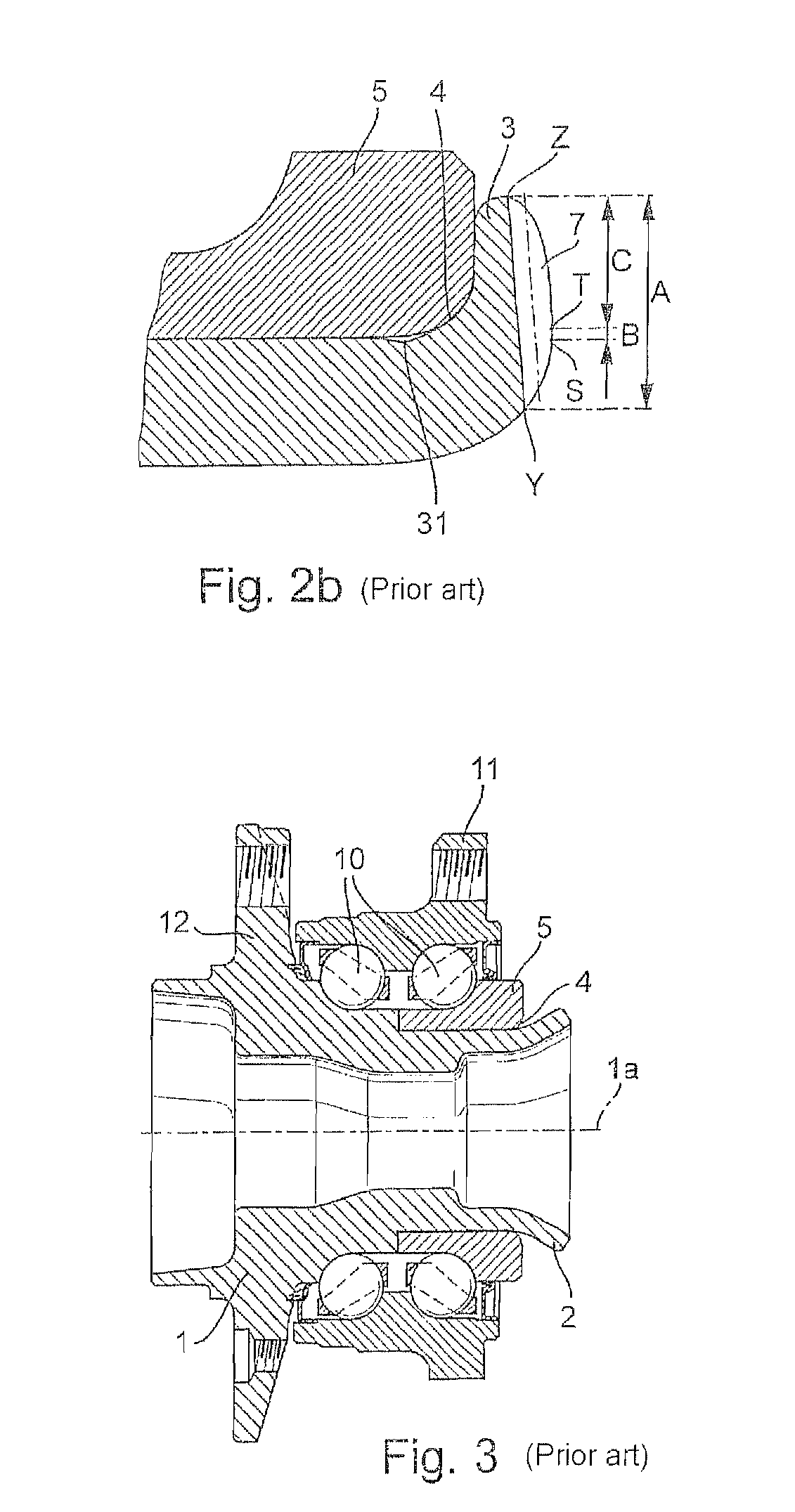

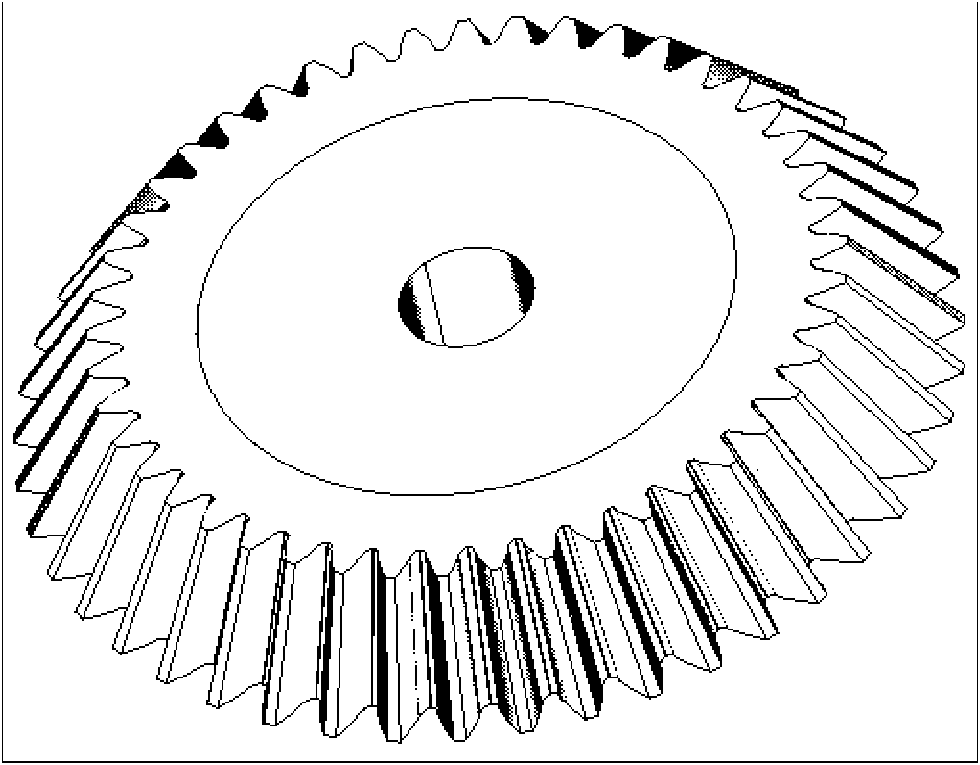

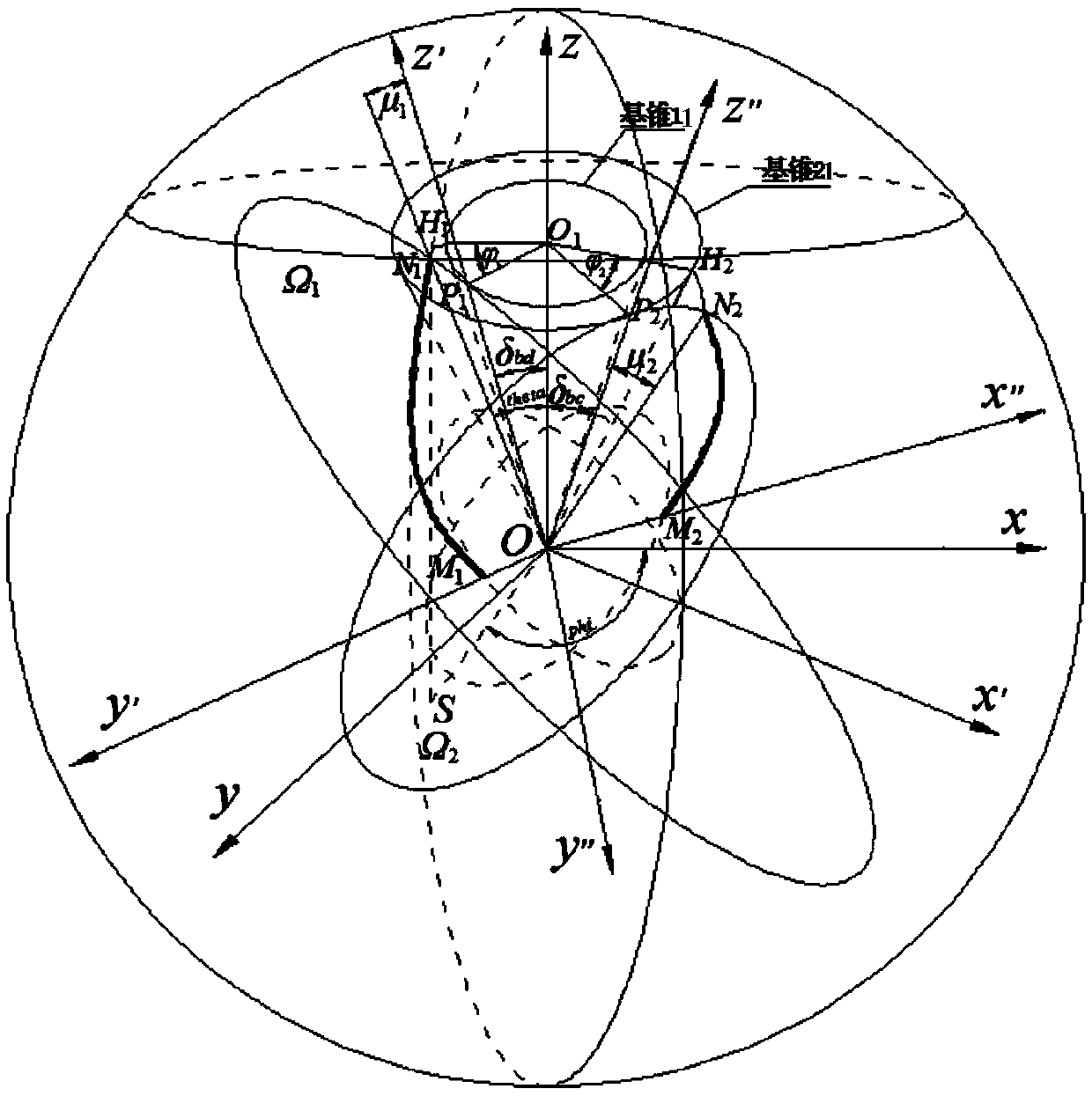

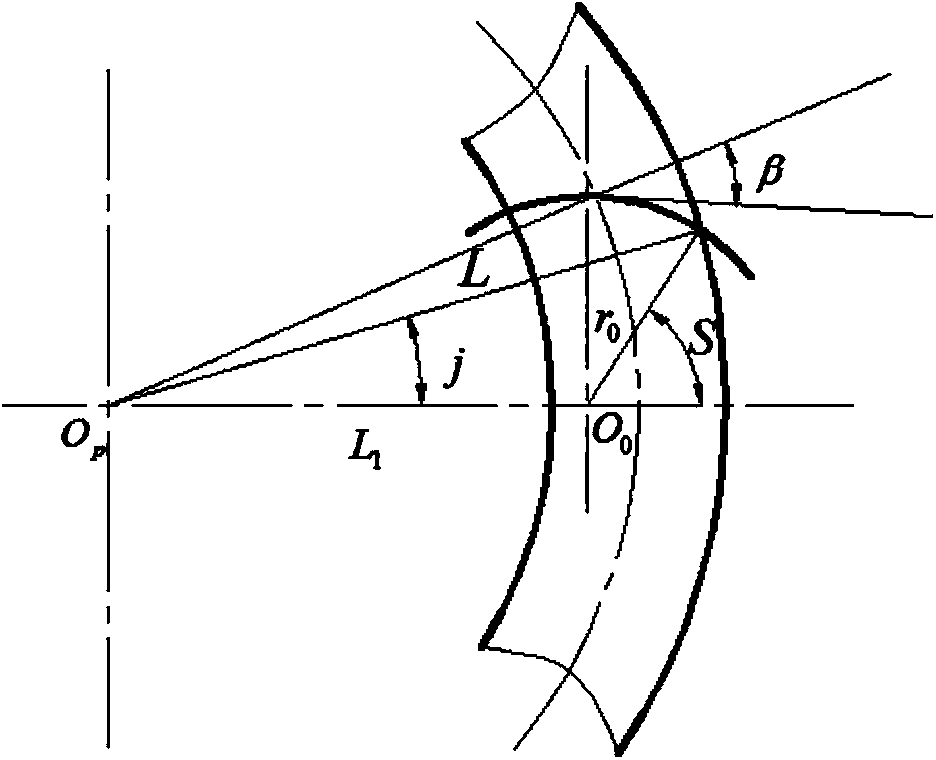

Design method of hypoid gear pair

InactiveCN101982673ASimplify the design processImprove tooth surface accuracyToothed gearingsPortable liftingState of artEngineering

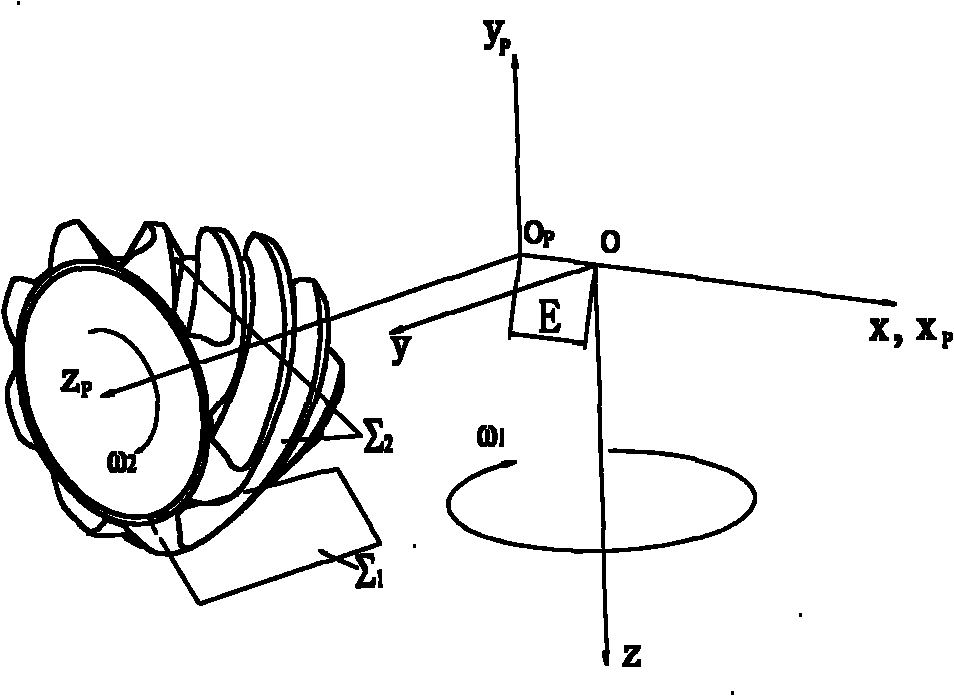

The invention discloses a design method of a hypoid gear pair, aiming at solving the problem of difficulty in designing the hypoid gear pair by using the prior art. The design method of the hypoid gear pair comprises the following steps: 1, taking a plane as a hypoid gear pair transmission forming principle for a big gear tooth surface; 2, determining the geometric technical parameters of a big gear tooth surface shape; 3, determining the geometric technical parameters of a small gear tooth surface shape; and 4, since the gear parameters refers to right-handed rotation of a big gear and left-handed rotation of a small gear, when the big gear is in right-handed rotation and the small gear is in left-handed rotation, dereferencing opposite numbers for the parameters related to the y axle in the parameters. The determination of the geometric technology parameters of the big gear tooth surface shape comprises the following steps: definition of representing the geometric parameters of the big gear tooth surface shape, determination of the coordinates of an M point, determination of the component expression formula of a vector shown in the specification, solution of a tooth-shaped unit vector shown in the specification, solution of another tooth-shaped unit vector shown in the specification, solution of the normal vector shown in the specification one side tooth surface sigma2, determination of the equation of the one side tooth surface sigma2, determination of the equation of the other side tooth surface sigma1, determination of the equation of a tooth surface sigma1theta and formation of the gear teeth of the gear in array.

Owner:JILIN UNIV

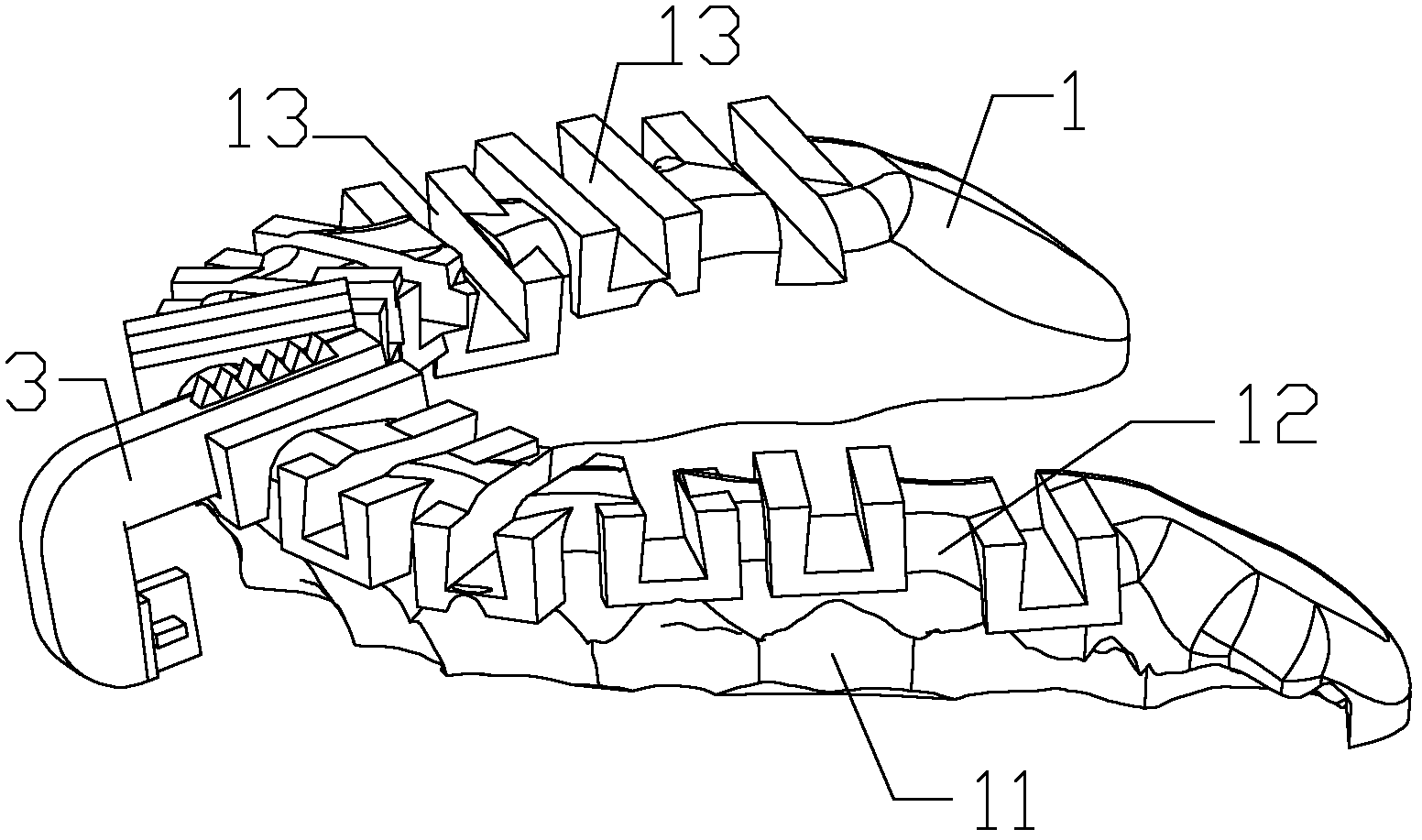

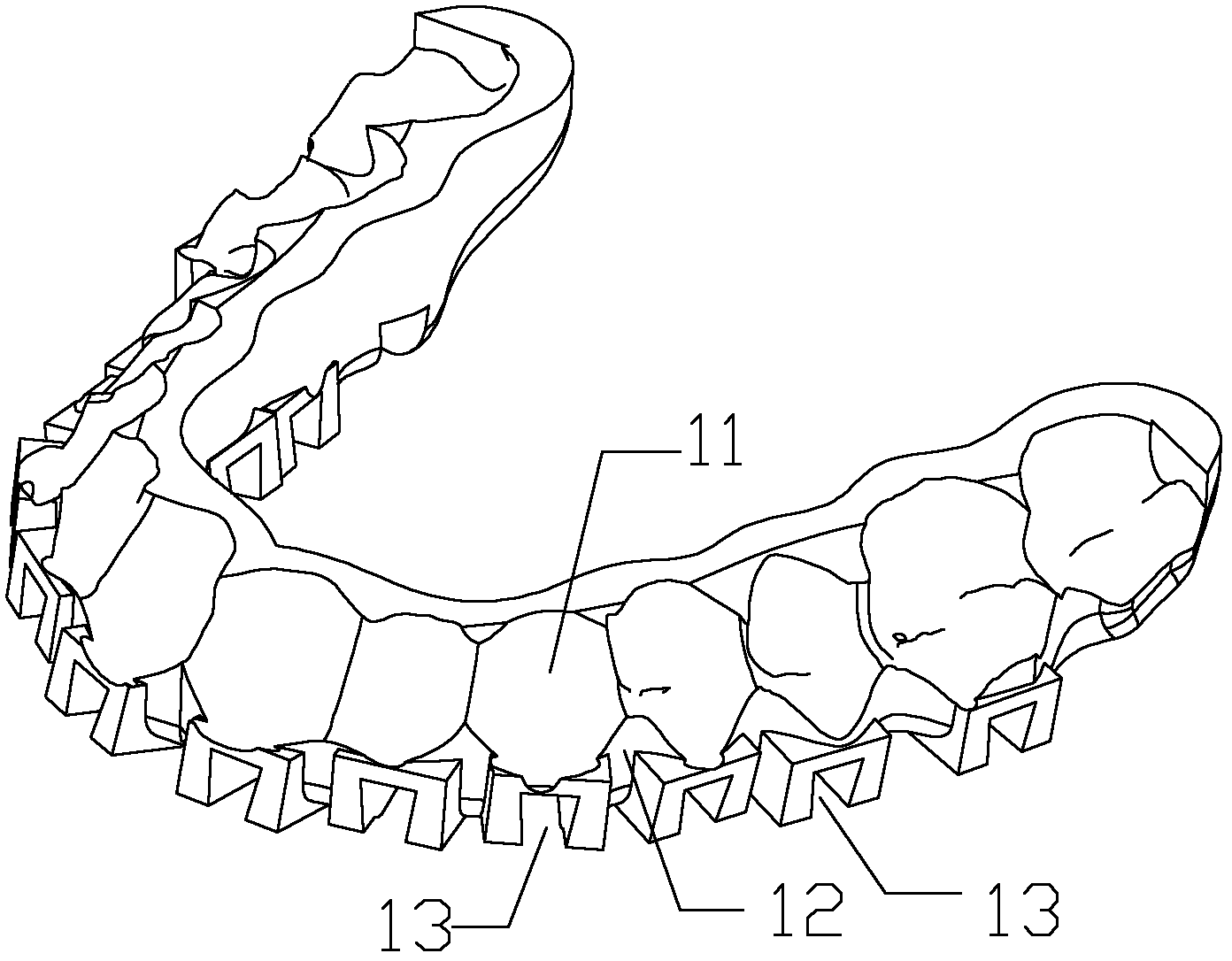

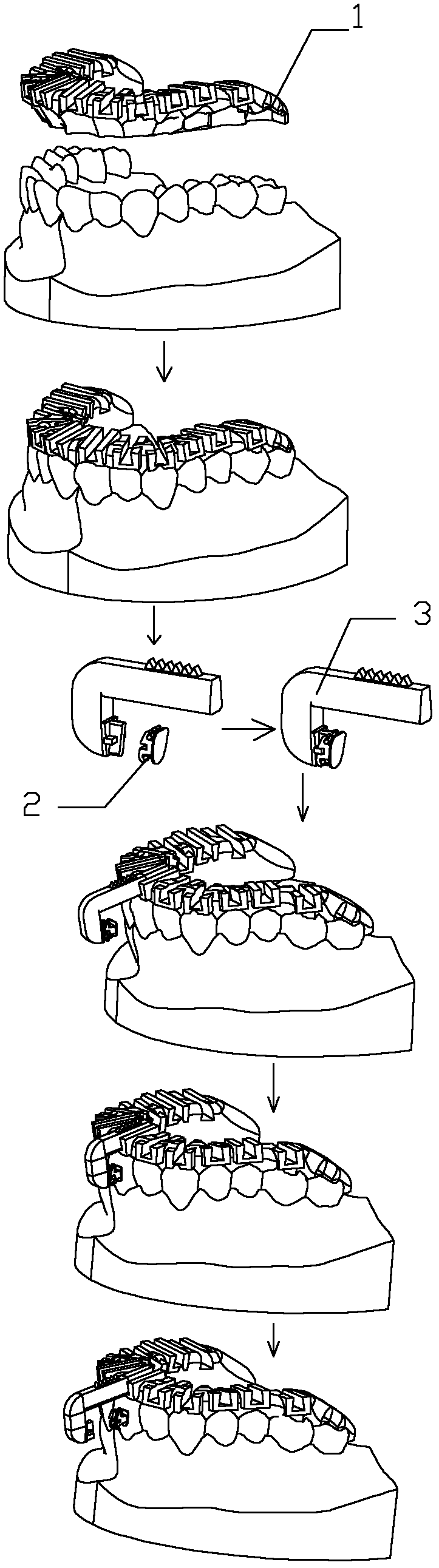

Digitalized guiding template for orthodontic bracket indirect bonding

A digitalized guiding template for orthodontic bracket indirect bonding comprises a substrate; the substrate comprises a side surface body which is attached to a tongue-side or palate-side tooth surface of a patient dentition, and a top surface body which is adapted to a top surface of the patient dentition; guiding slots which can determine that the bracket is at the lip and cheek side of the tooth surface are disposed on the top surface body; the guiding slots correspond to the bracket one by one; each guiding slot corresponds to a hook-shaped guiding rod which can determine the position ofthe bracket on the tooth surface; a straight rod part of the hook-shaped guiding rod is inserted into the guiding slots; a bending part of the hook-shaped guiding rod is detachably connected with thebracket; the hook-shaped guiding rod guides the bracket through the guiding slots and presses the bracket on the predetermined tooth surface of the patient. The invention has the advantages of convenient and simple operation, high accuracy, no dentition extrusion, and convenient treatment of leaked glue during bracket bonding.

Owner:6D DENTAL TECH

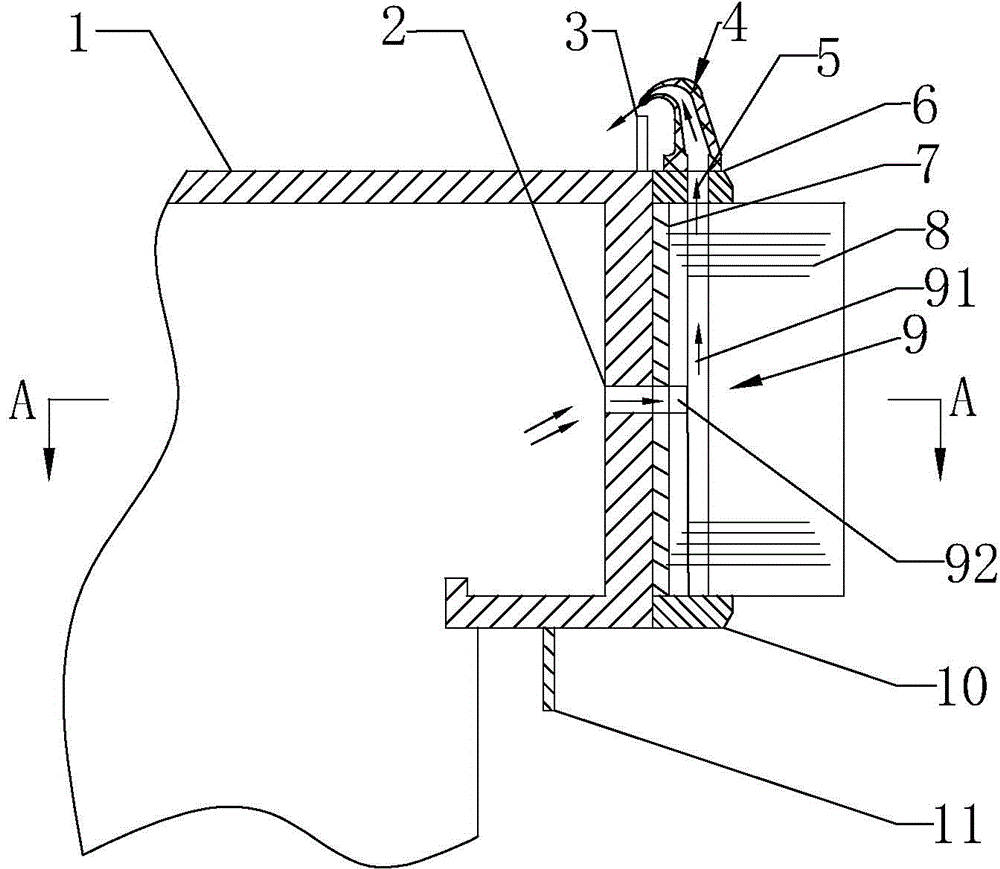

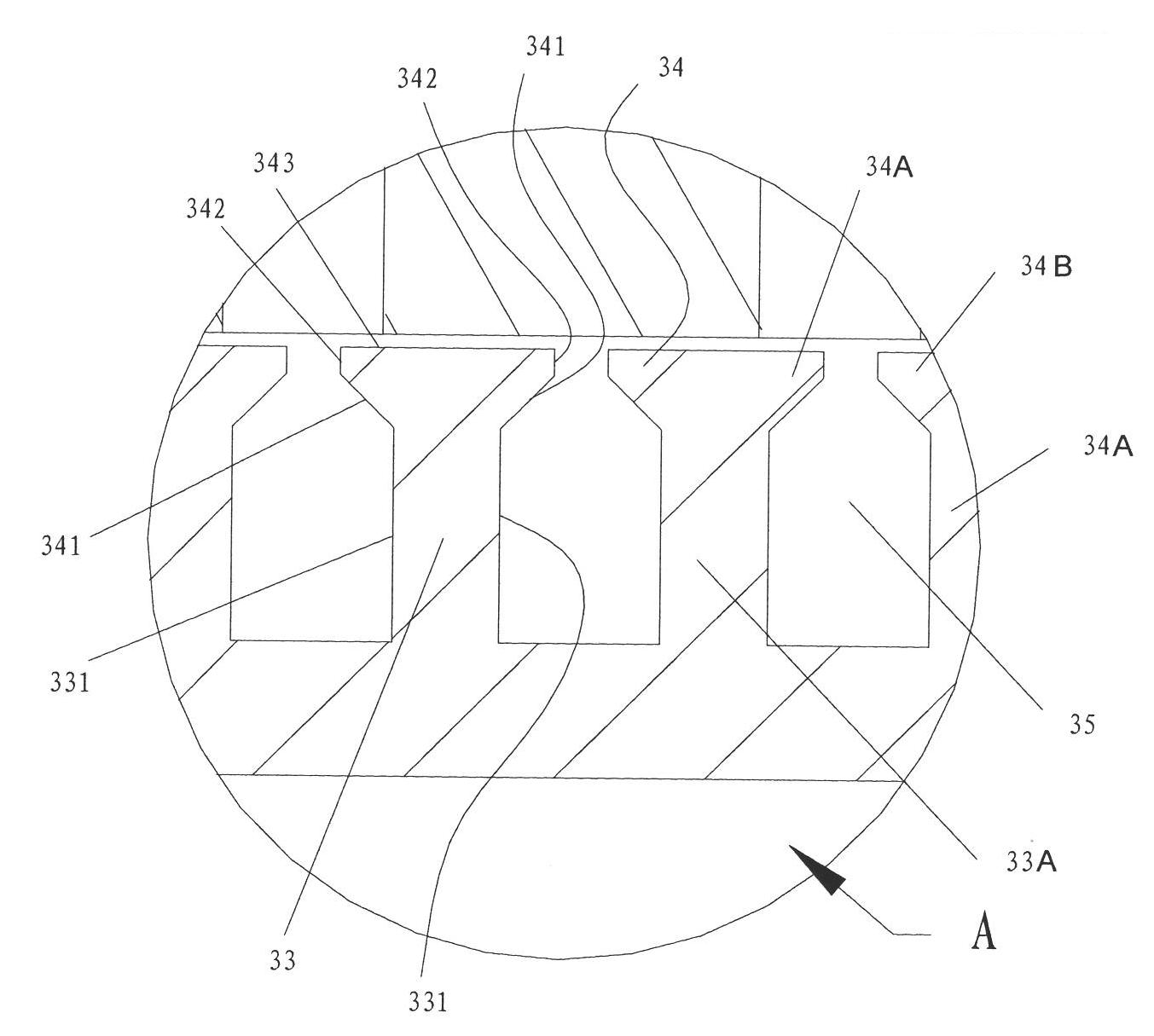

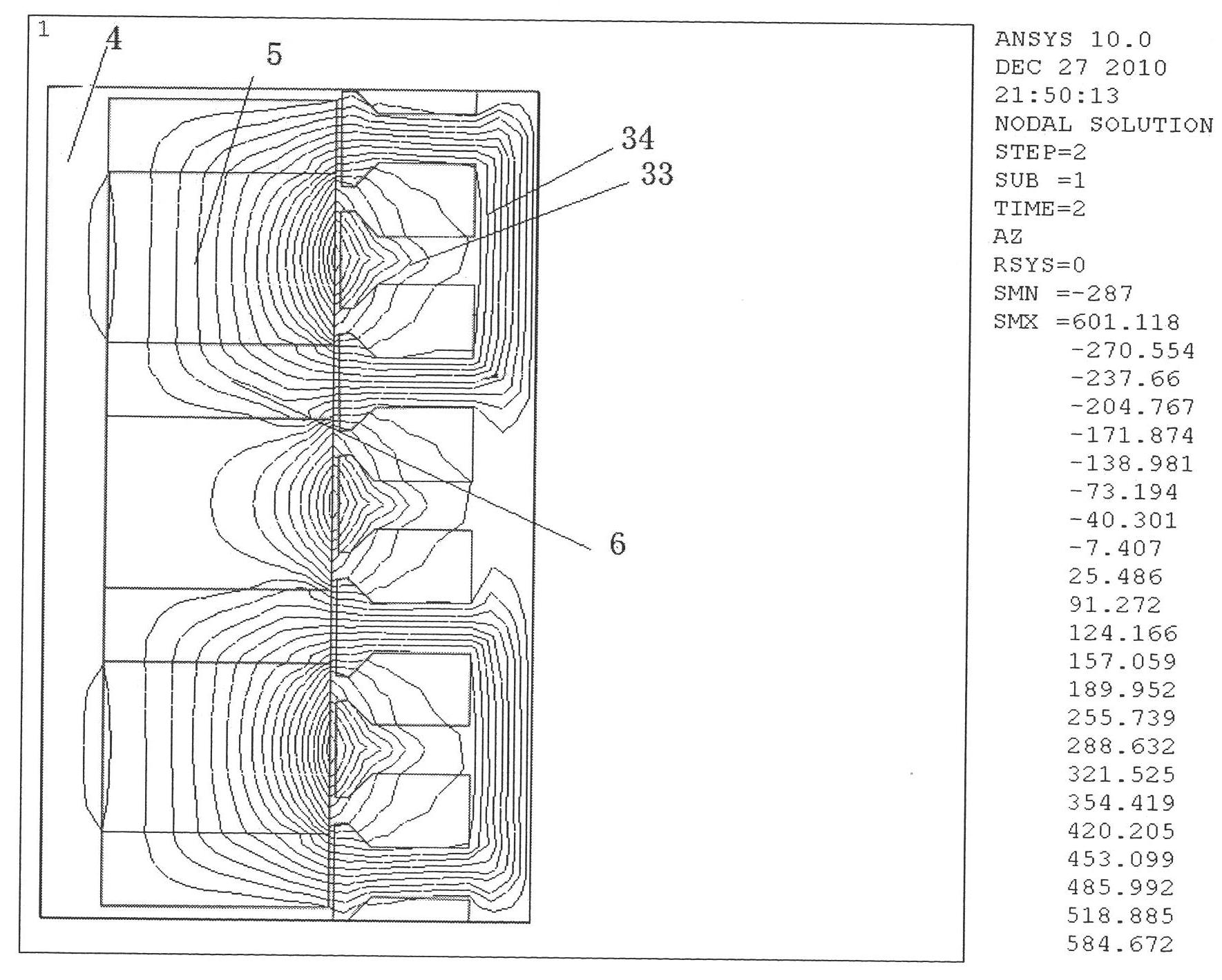

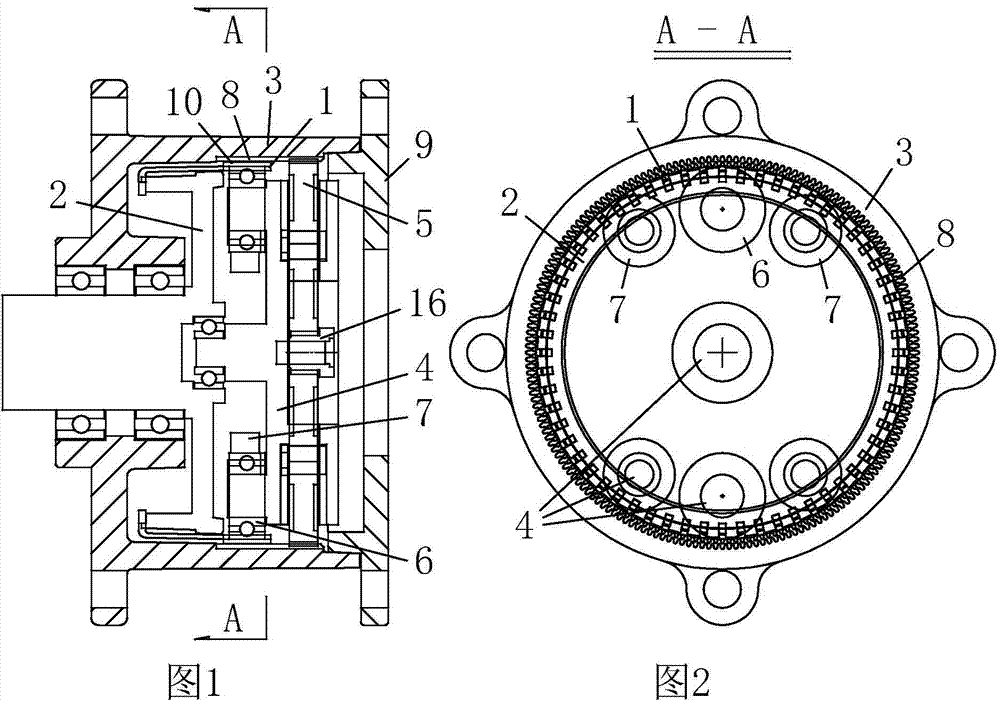

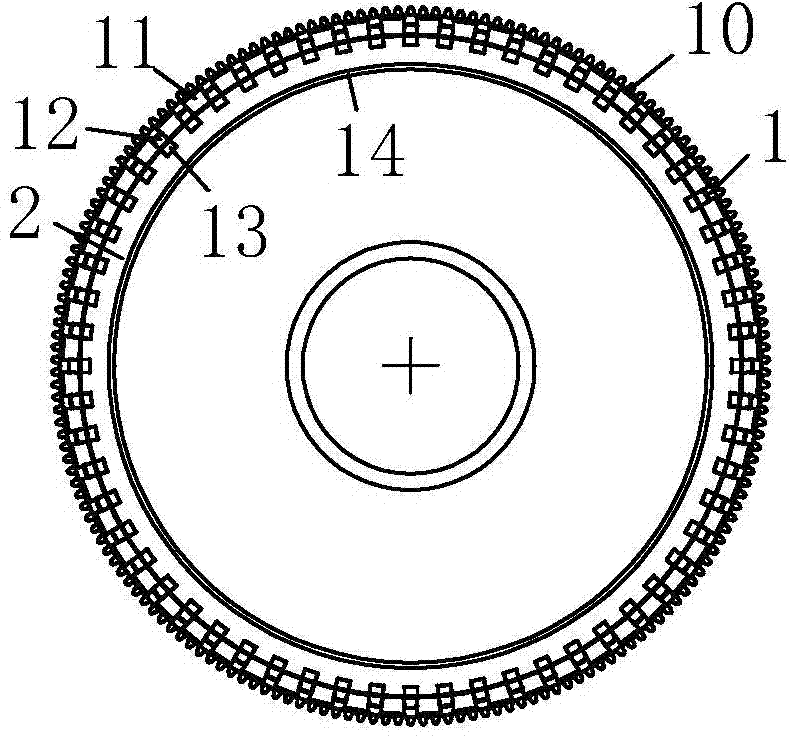

Direct drive permanent magnet wind generator, direct drive permanent magnet wind generator system and stator of direct drive permanent magnet wind generator

ActiveCN104600886AReduce risk of erosionGuaranteed insulation reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringTurbine

The invention provides a direct drive permanent magnet wind generator, a direct drive permanent magnet wind generator system and a stator of the direct drive permanent magnet wind generator. The stator comprises a stator support, a stator iron core arranged on the peripheral wall of the stator support, and a paddle side tooth support, wherein the paddle side tooth support is arranged on the paddle side axial end face of the stator iron core, at least one air hole is formed in the peripheral wall of the stator support, and at least one second air hole is formed in the paddle side tooth support. The stator further comprises at least one air flow passageway used for communicating the first air holes with the second air holes, wherein the air flow passageways penetrate through the stator iron core. The micro-positive pressure technology is used in the stator and a rotor of the airborne wind turbine, and therefore a motor can dry itself in a self-adaption mode, external severe air flow is prevented from entering the motor, the service life of permanent magnet poles is prolonged, the insulation level reduction of devices inside the motor is prevented, the risk that the motor is corroded by severe air flow is lowered, and the insulation reliability is improved.

Owner:XINJIANG GOLDWIND SCI & TECH

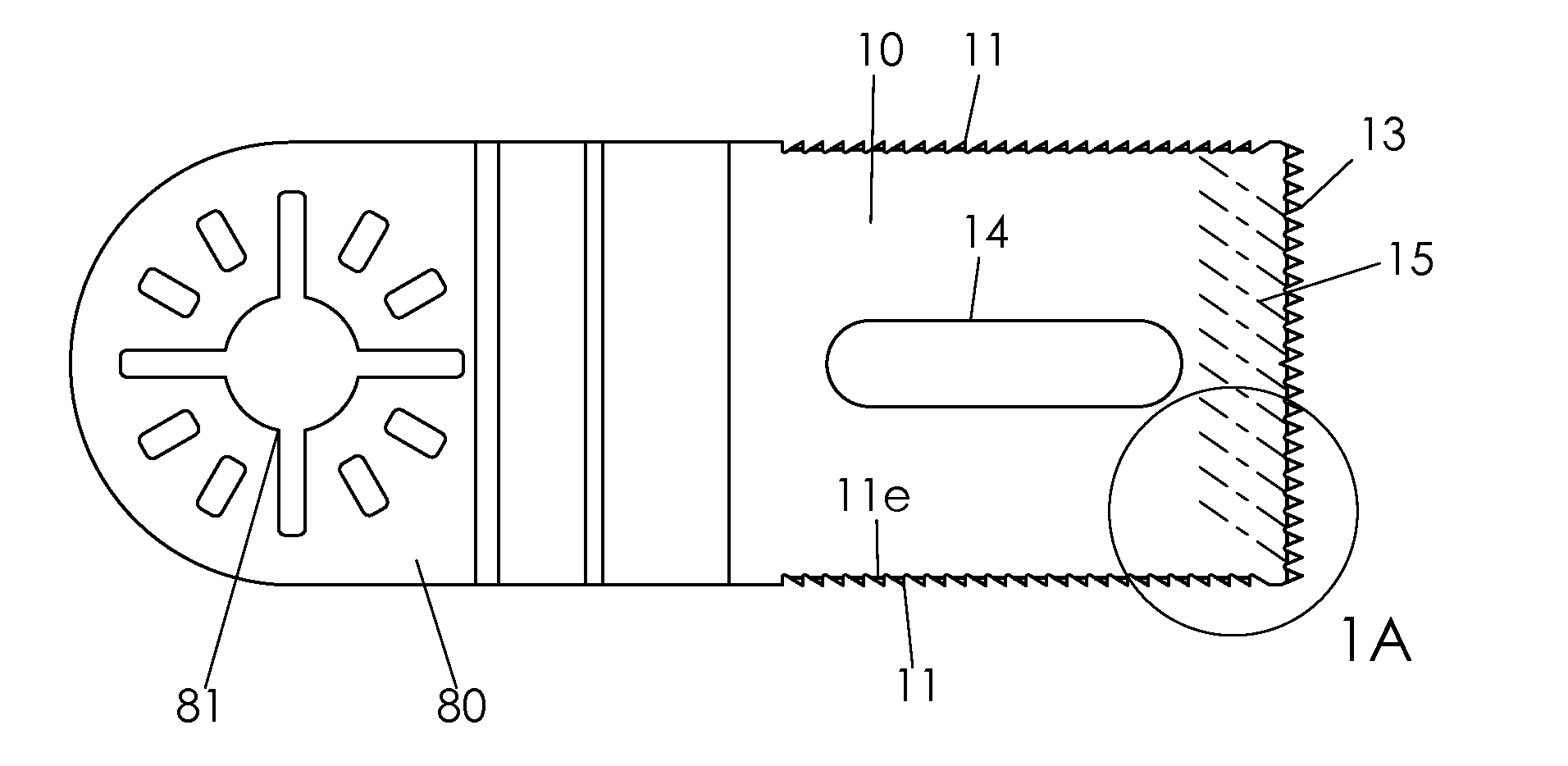

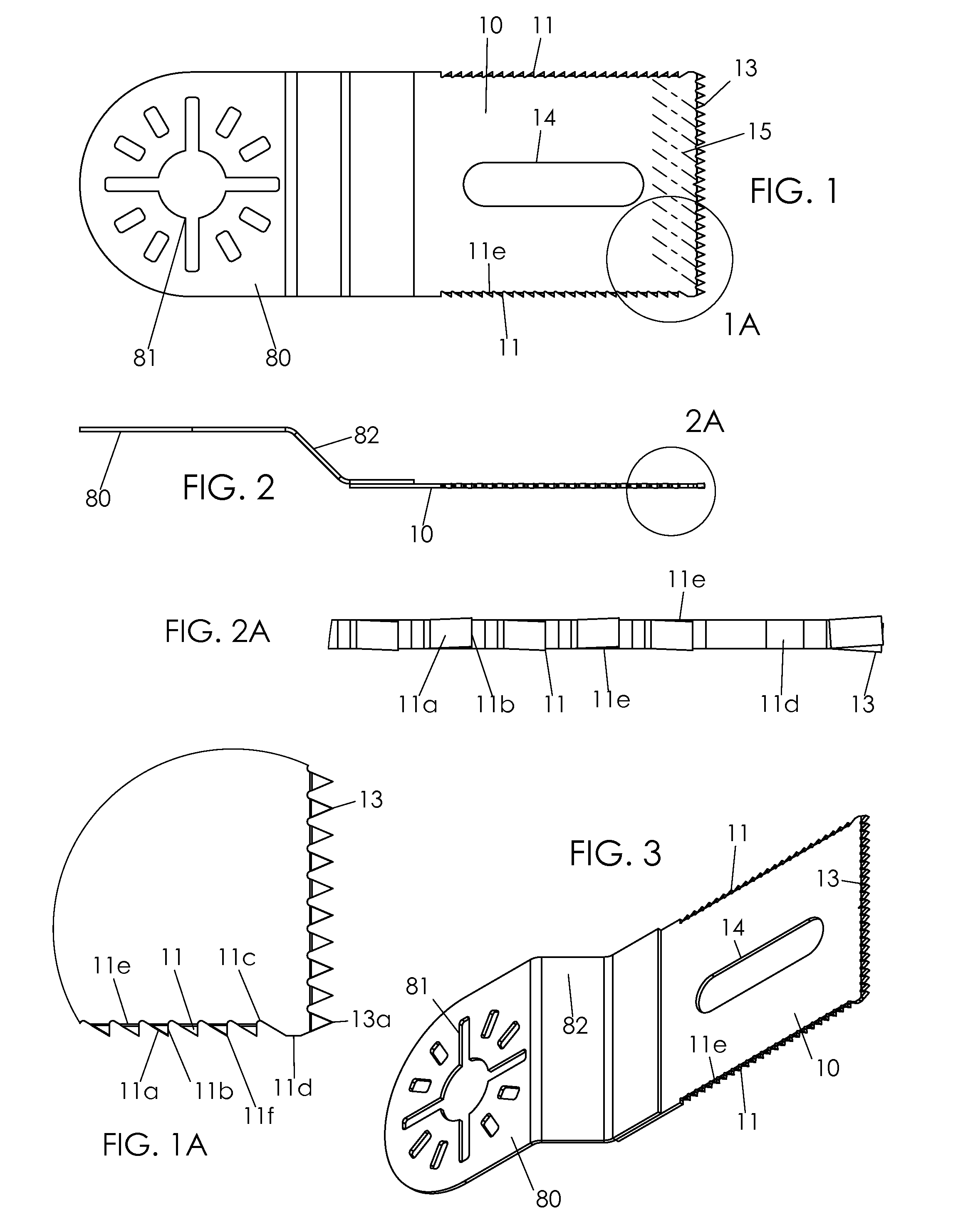

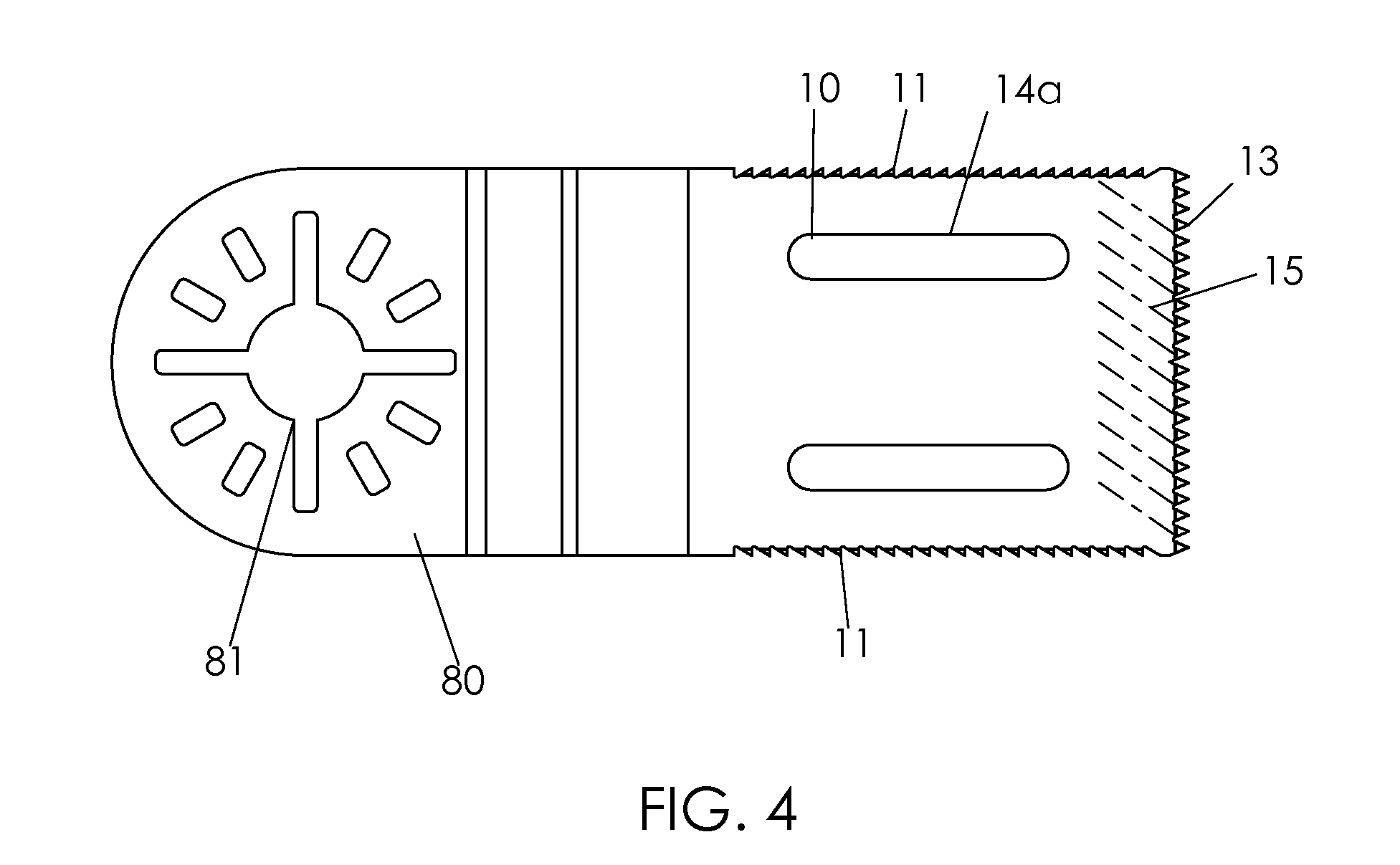

Cutting blade for oscillating tool

ActiveUS20160082605A1Smooth cutting actionFast and efficient cuttingPower driven reciprocating sawsMetal working apparatusEngineeringPower tool

An improved blade for use with an oscillating power tool is disclosed. A rectangular style blade includes side teeth to eject debris and allow rapid but well controlled blind plunge cuts. The side teeth are preferably asymmetric with a forward orientation to bias debris out and the blade inward. Preferably one or more openings or slots allow for additional debris removal. The side teeth also allow for controlled side cutting.

Owner:WORKTOOLS

Snap-on coupling for connecting a fluid pipe to a rigid end fitting with a connection indicator and method of inspecting this connection

The present invention relates to a snap-on coupling between a fluid pipe and a rigid tubular end fitting, this coupling having a sleeve mounted on a pipe to be coupled to an end fitting that has a peripheral connecting projection, a locking member engaging with this projection to retain the end fitting in the sleeve, and a visual indicator which engages with the projection behind the locking member and occupying an extended position and a depressed position in the sleeve, the member and the indicator each having a head and two elastically deformable side legs, each leg of the indicator having a retention arm engaging with a lower side tooth and with a bottom stop, both formed on the corresponding side of the sleeve, when the indicator occupies the depressed and extended positions, respectively.

Owner:HUTCHINSON SA

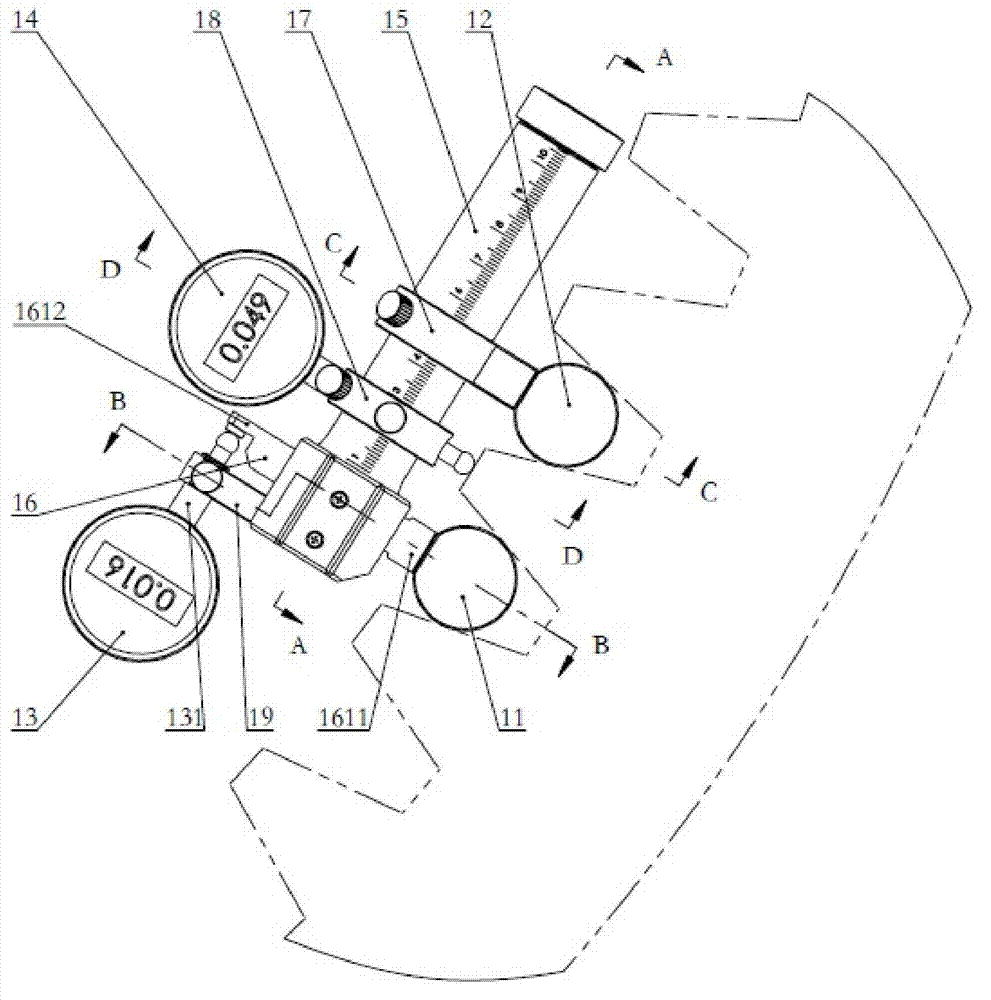

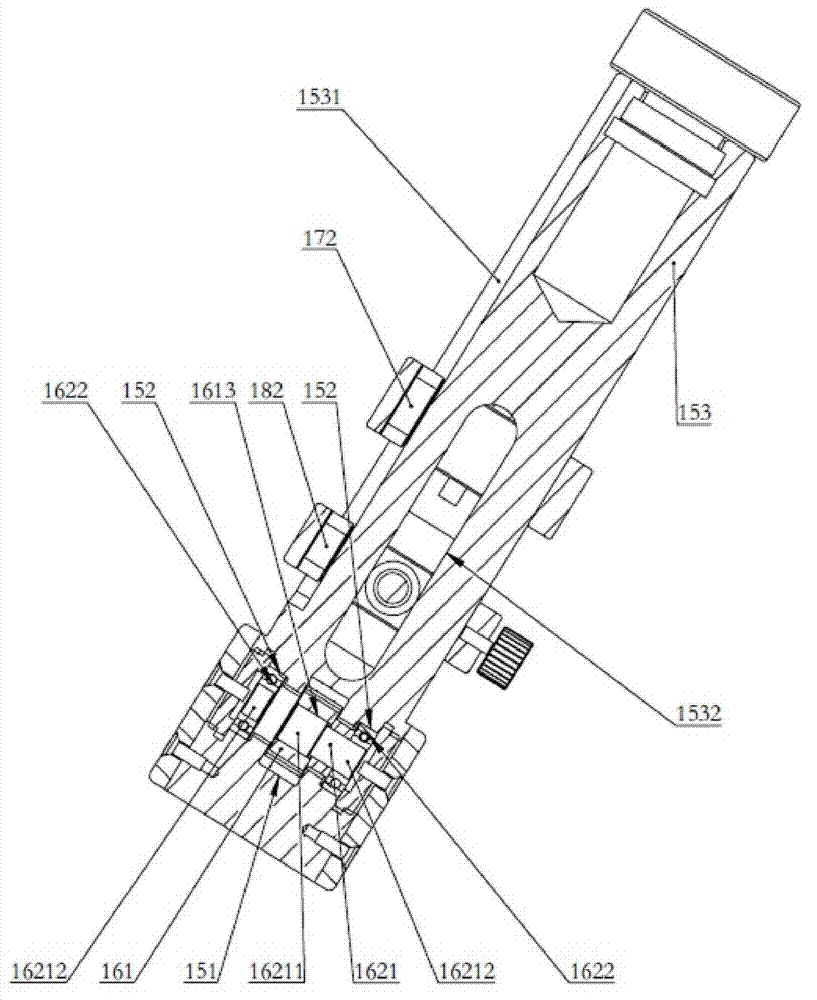

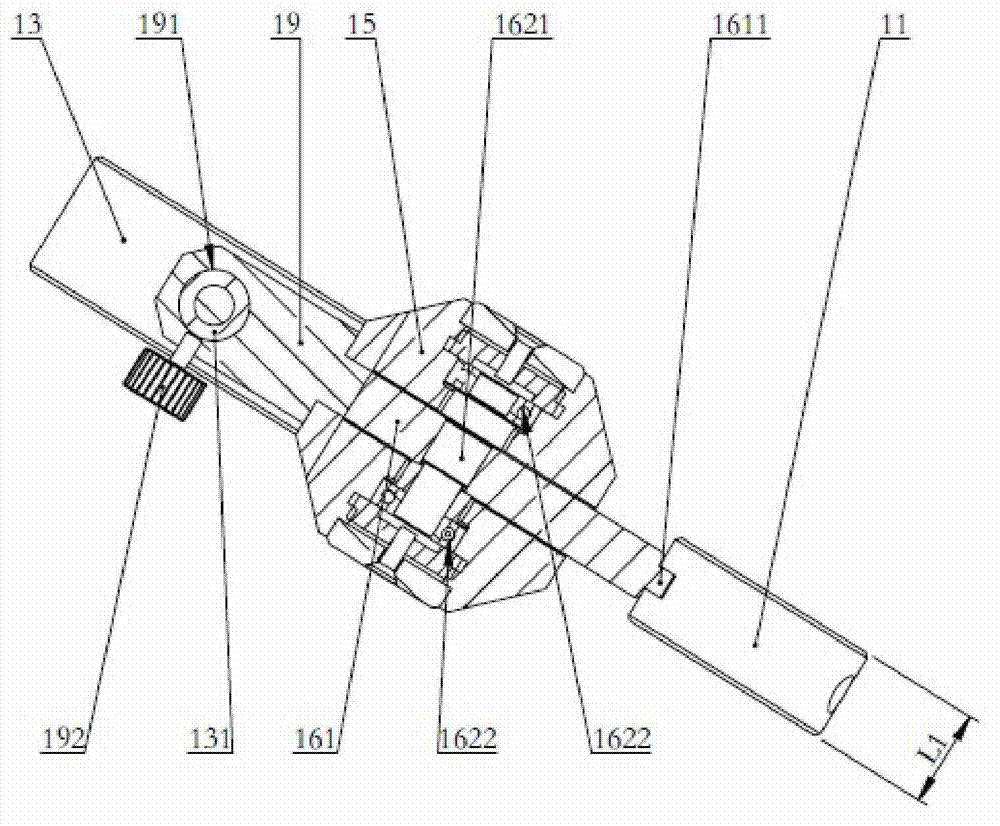

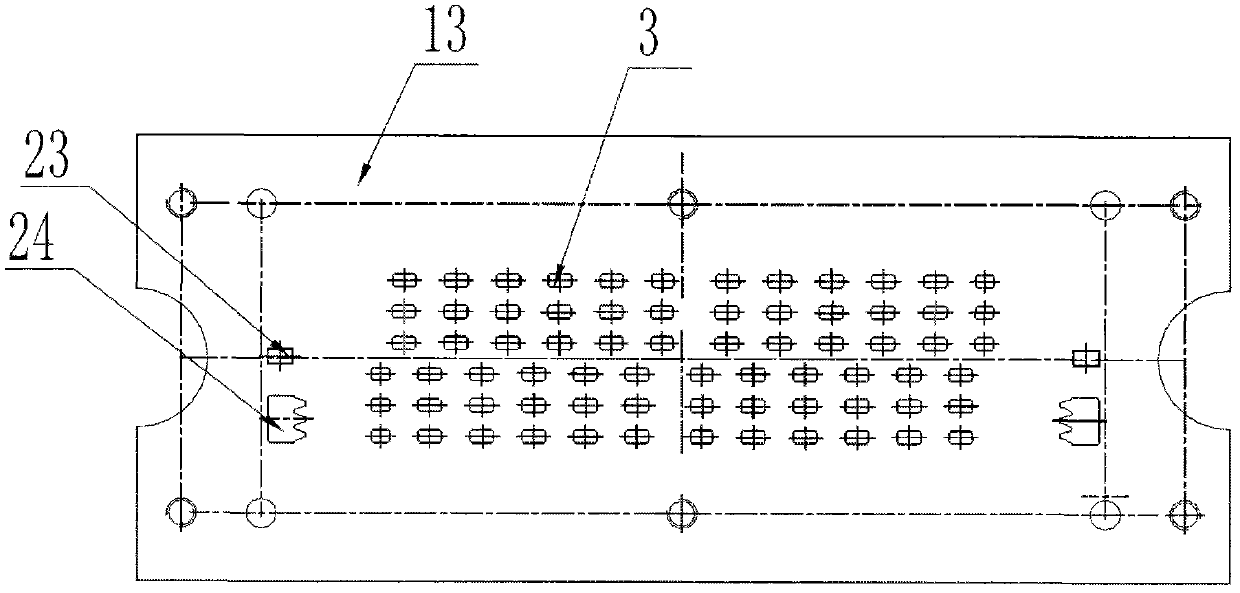

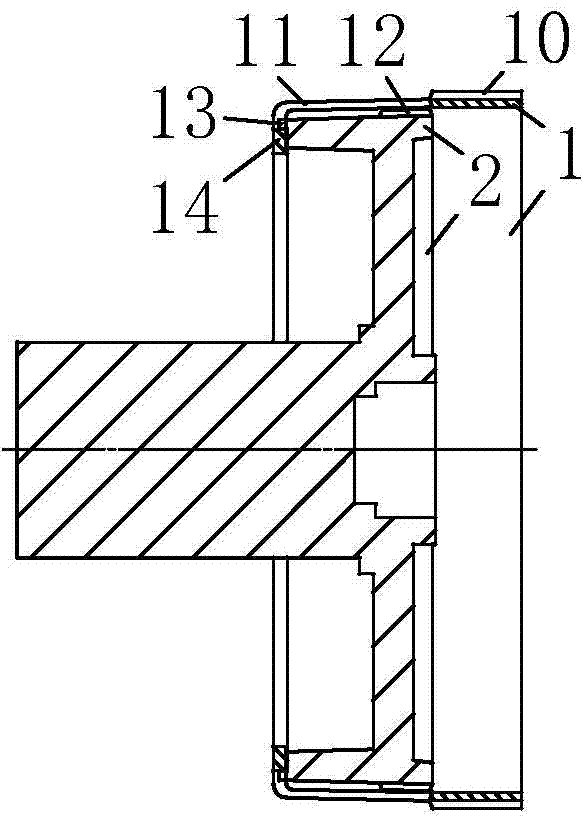

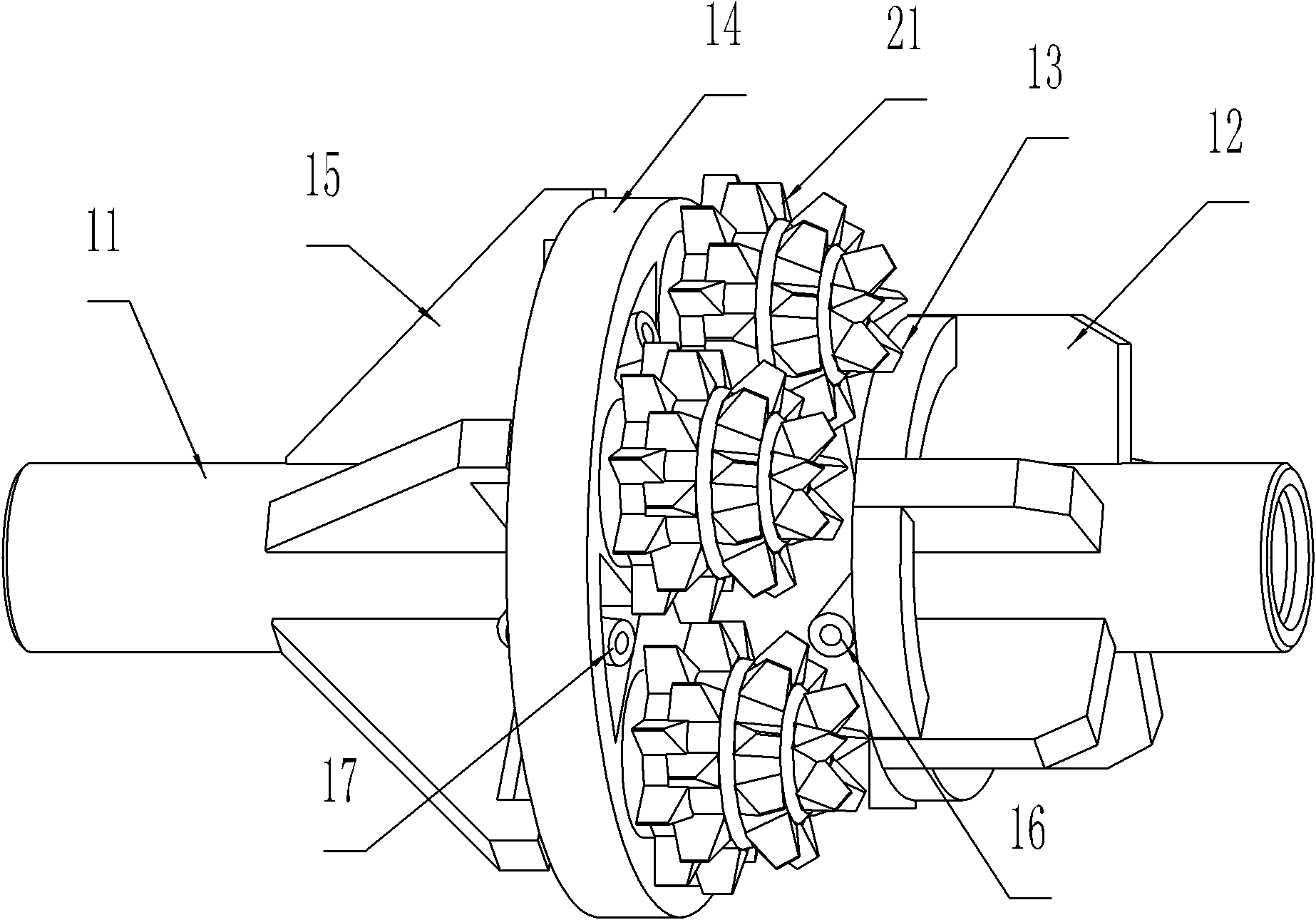

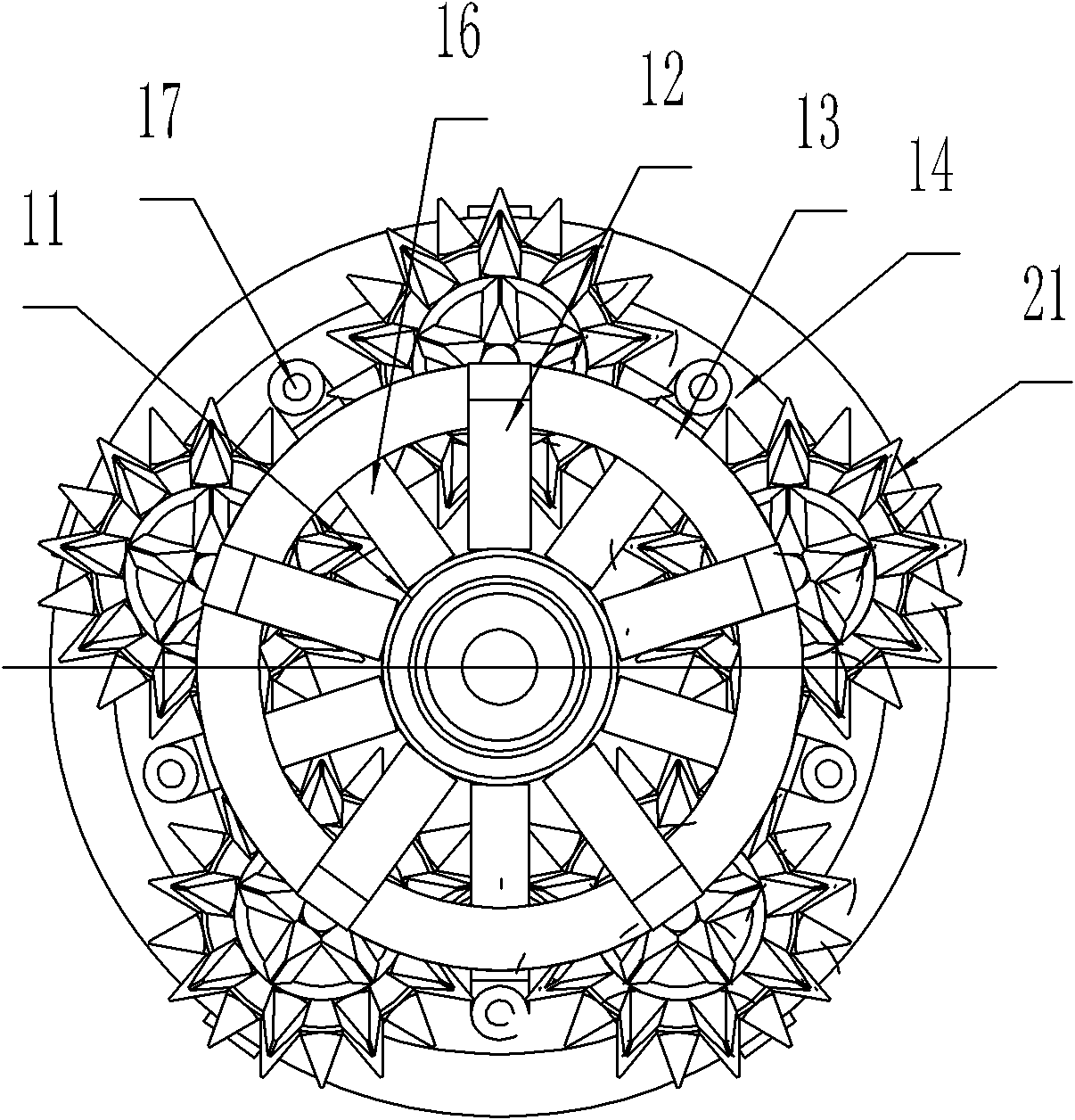

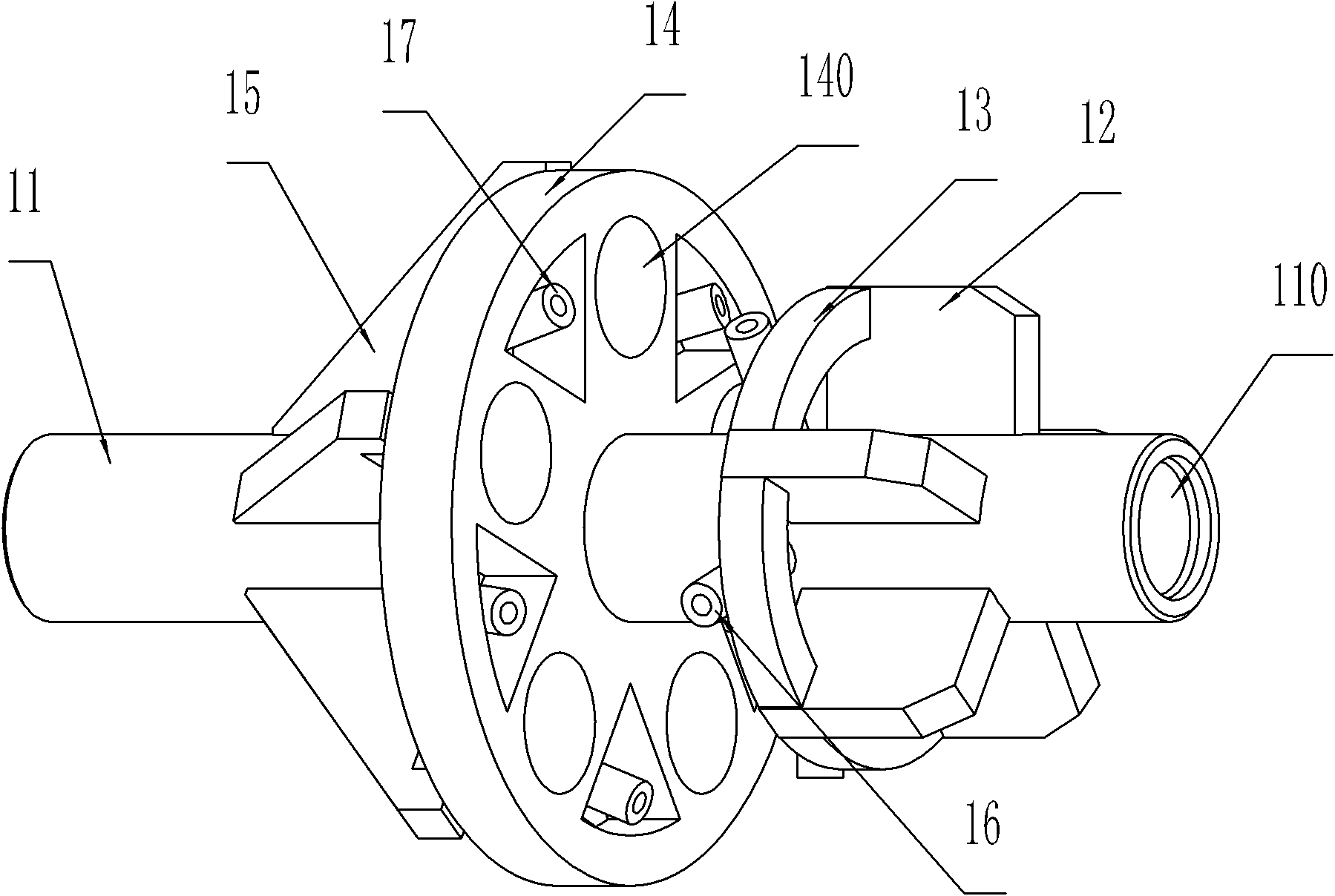

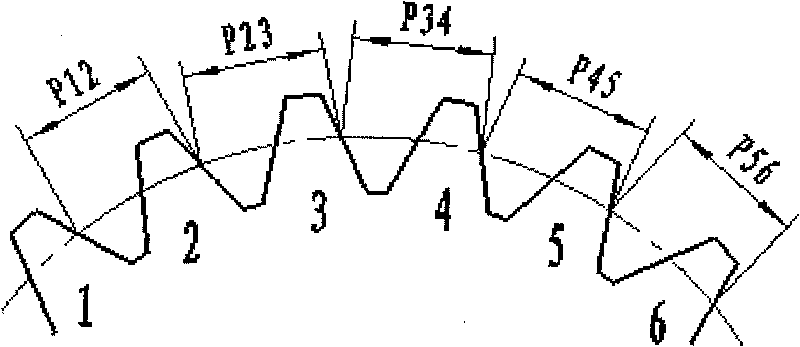

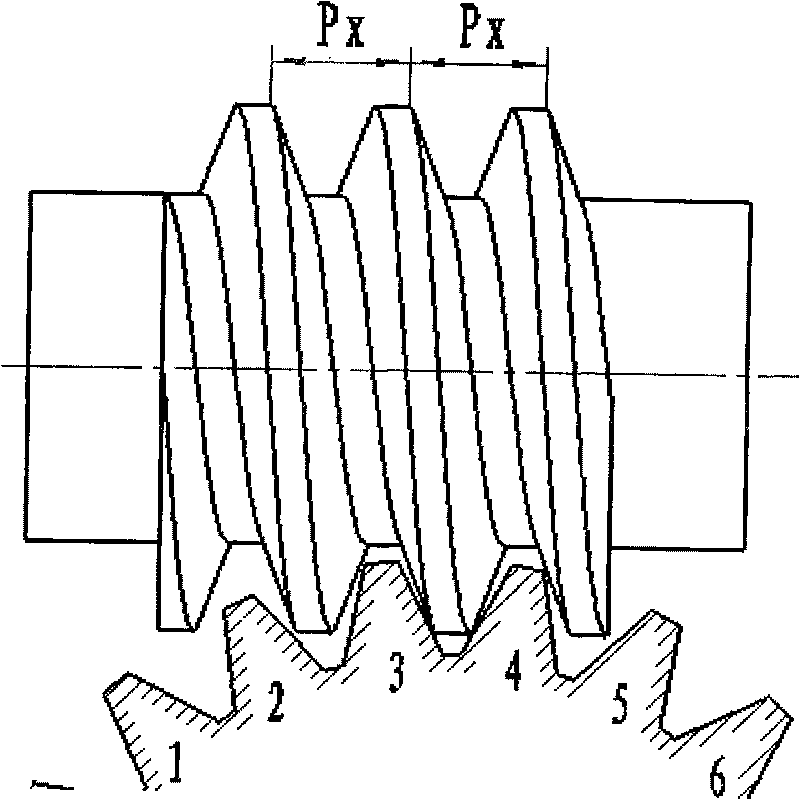

Pitch variation measuring device for large-size straight toothed spur gear

InactiveCN102927887AGood repeatabilityEasy to operateMechanical clearance measurementsMeasuring instrumentGear wheel

The invention relates to a pitch variation measuring device for a large-size straight toothed spur gear, which comprises a front positioning element 11, a rear positioning element 12, a center distance measuring gauge outfit 13, a radial measuring gauge outfit 14, a lever mechanism 16 and a body 15, wherein the center distance between the front positioning element 11 and the rear positioning element 12 can be changed and measured by the center distance measuring gauge outfit 13. When measurement is carried out, the front positioning element 11 and the rear positioning element 12 are respectively clamped between two teeth of a measured gear, and the radial measuring gauge outfit 14 contacts with the addendum circle or dedendum circle of the measured gear, so that the readings of the center distance measuring gauge outfit 13 and the radial measuring gauge outfit 14 at the time can be read. In such a way, the pitch variation of the measured gear can be calculated according to the obtained readings around a circle of the measured gear. Compared with the traditional pitch measuring instrument based on different principles, the pitch variation measuring device disclosed by the invention has the characteristics of easiness for operation, stable contact, good repeatability, and the like, ensures the measurement accuracy and can be used for measuring the pitch variation of two side tooth surfaces simultaneously obtained once.

Owner:SOUTHEAST UNIV

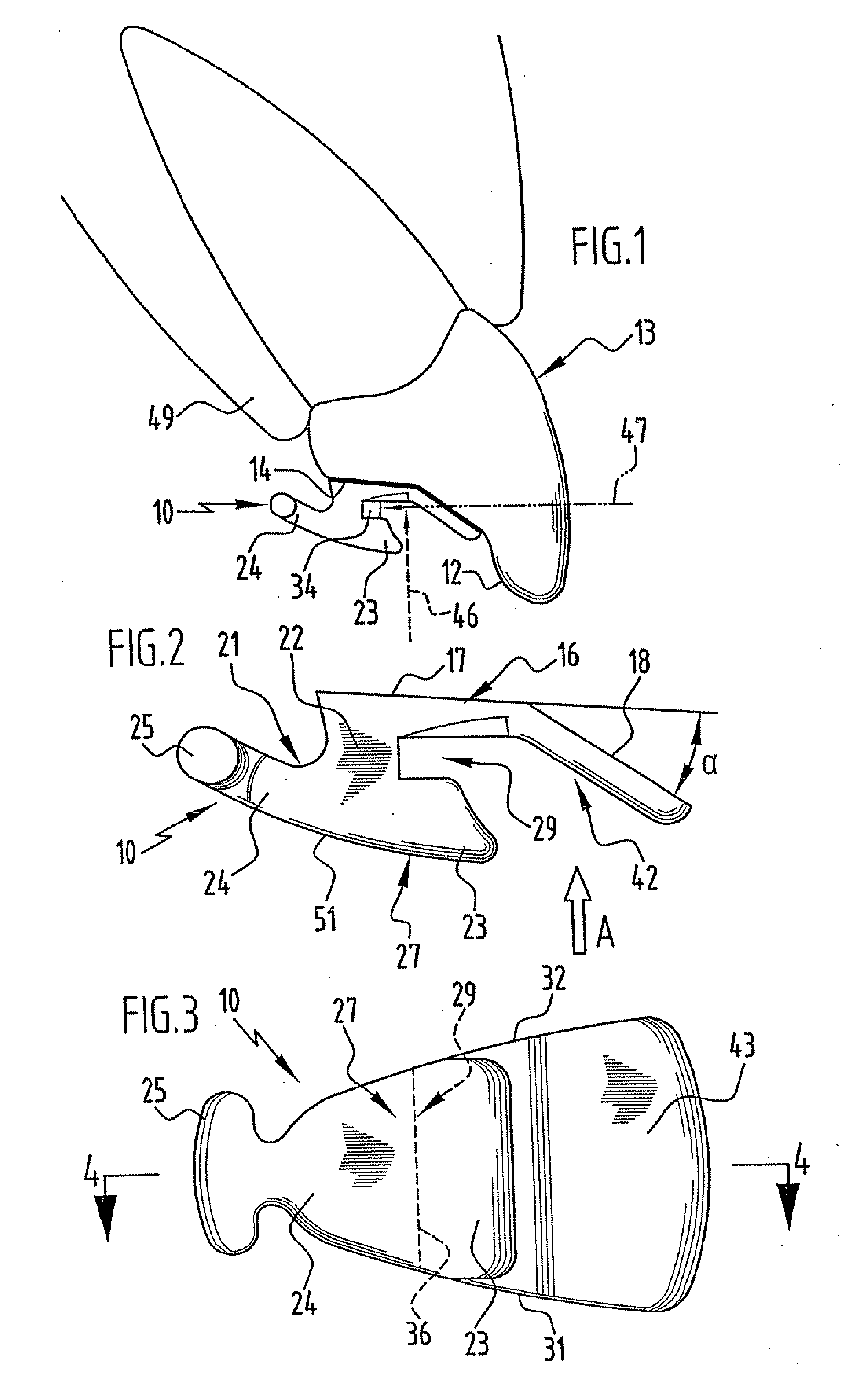

Lingual bracket

InactiveUS20070015103A1Reduce the overall heightEasy to placeBracketsDental toolsEngineeringCanine tooth

The invention relates to a lingual bracket for correcting the position of teeth, comprising a bracket base, which can be secured on the lingual side to a front or canine tooth, and comprising a bracket body, the bracket having a slot, which extends in the mesial-distal direction, delimited on the lingual side as well as on the gingival and occlusal sides, and which is intended for accommodating an archwire. In order to develop the bracket in such a way that an archwire can be easily inserted into the slot, by which even relatively small directional forces may be reproducibly exerted on the tooth and the risk of root resorption can be kept low, the slot is delimited on the gingival side by the bracket base and on the occlusal and lingual sides by the bracket body. Furthermore, a bracket system comprising a front or canine tooth bracket of this type and comprising a side tooth bracket is provided.

Owner:DENTAURUM J P WINKELSTROETER

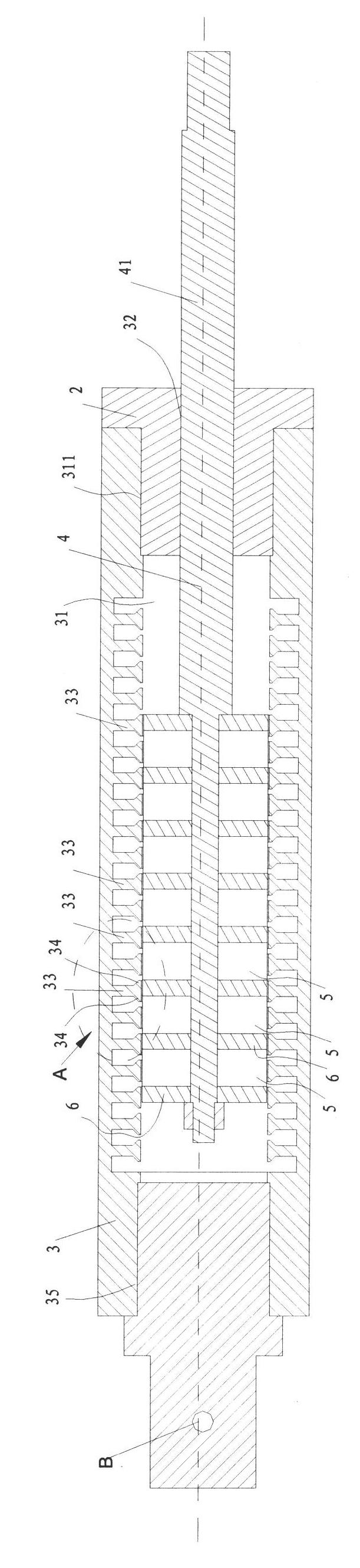

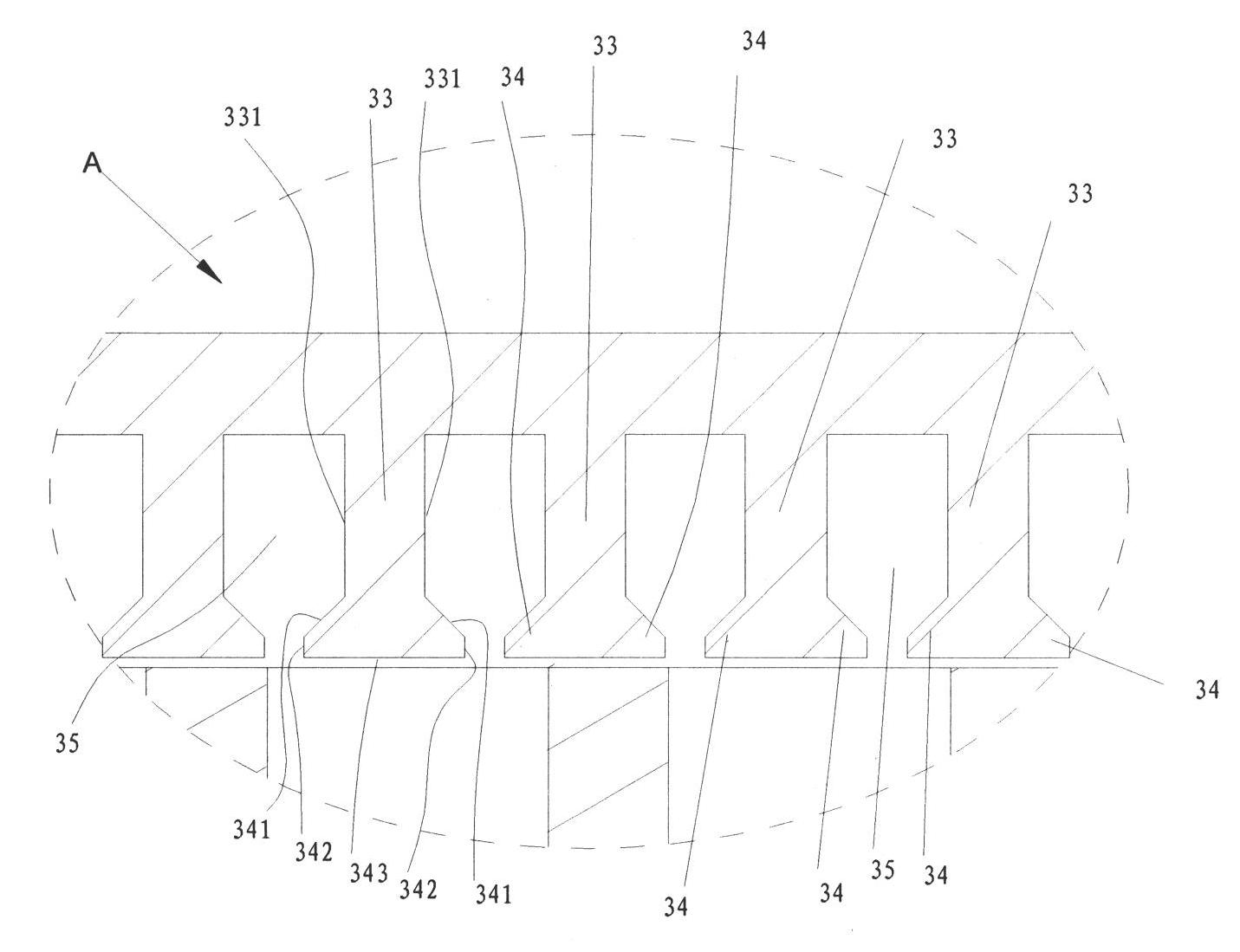

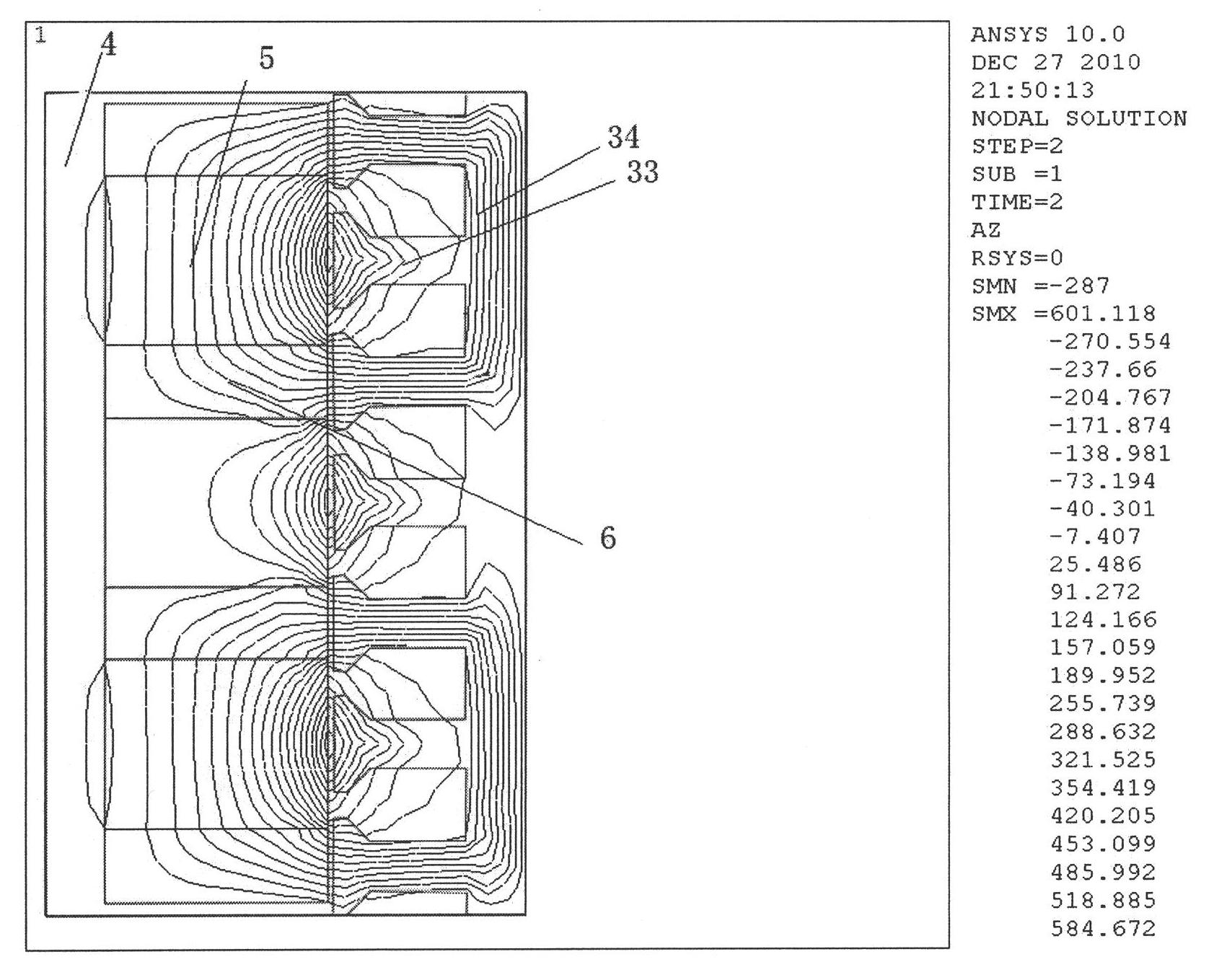

Self-powered electromagnetic rheological damper and its damping system

InactiveCN102278411ALow application costImprove the utilization of magnetic fieldNon-rotating vibration suppressionMagnetic currentMagnetic poles

Self-supplied electromagnetic rheological damper and magneto-rheological damping system, wherein, the self-supplied electromagnetic rheological damper includes a cylinder body, a piston rod, a stator, a connecting rod and several permanent magnets, and the cylinder body has a cavity with a first opening and a second opening Cavity structure, the cavity is filled with magnetorheological fluid; the piston rod is connected to a piston with a piston coil located in the cavity, and its first end extends out of the first opening, and its second end extends out of the second opening; the stator includes There is a housing cavity with a retractable opening, and a number of protruding teeth of high magnetic permeability materials are arranged at intervals on the inner wall of the housing cavity. The top of each protruding tooth extends along the axial direction to form side teeth, and the adjacent protruding teeth and side teeth form a housing and a piston. The groove of the electromagnetic coil electrically connected to the coil; the connecting rod is located in the accommodating cavity, and has a first connecting end protruding from the retractable opening and connected with the second end of the piston rod; several permanent magnets are connected with the connecting rod, correspondingly Magnetic poles are arranged between adjacent permanent magnets. The invention can realize self-power supply, and has high electromagnetic utilization rate.

Owner:JIAXING UNIV

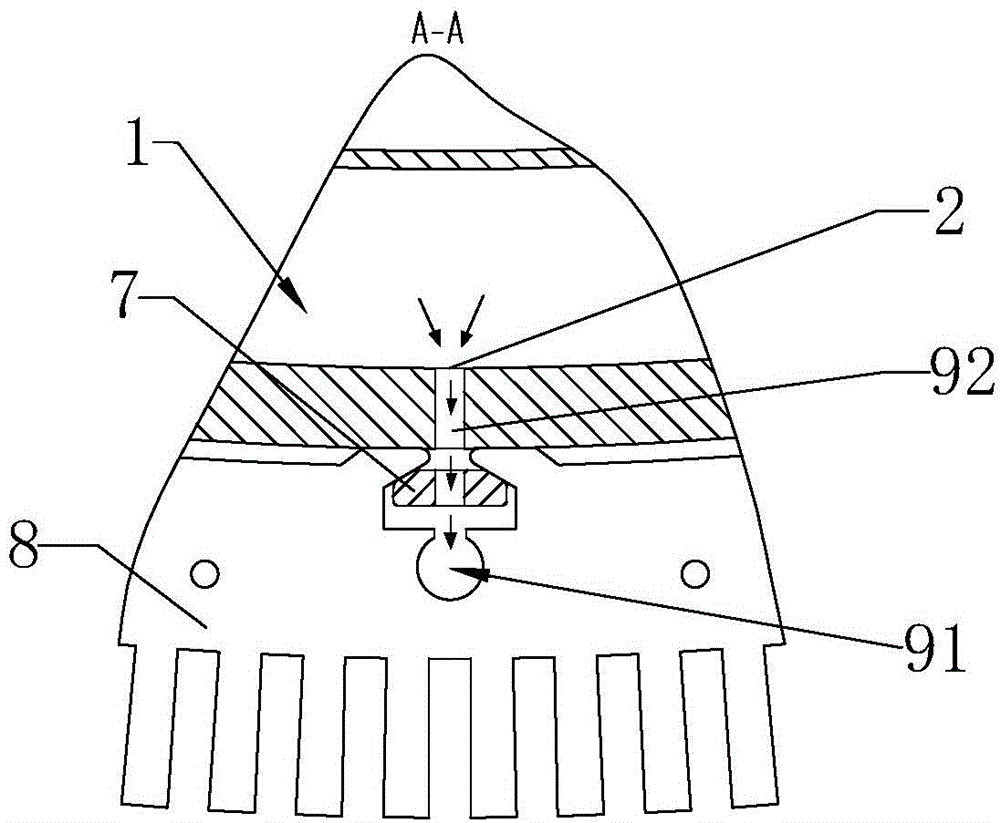

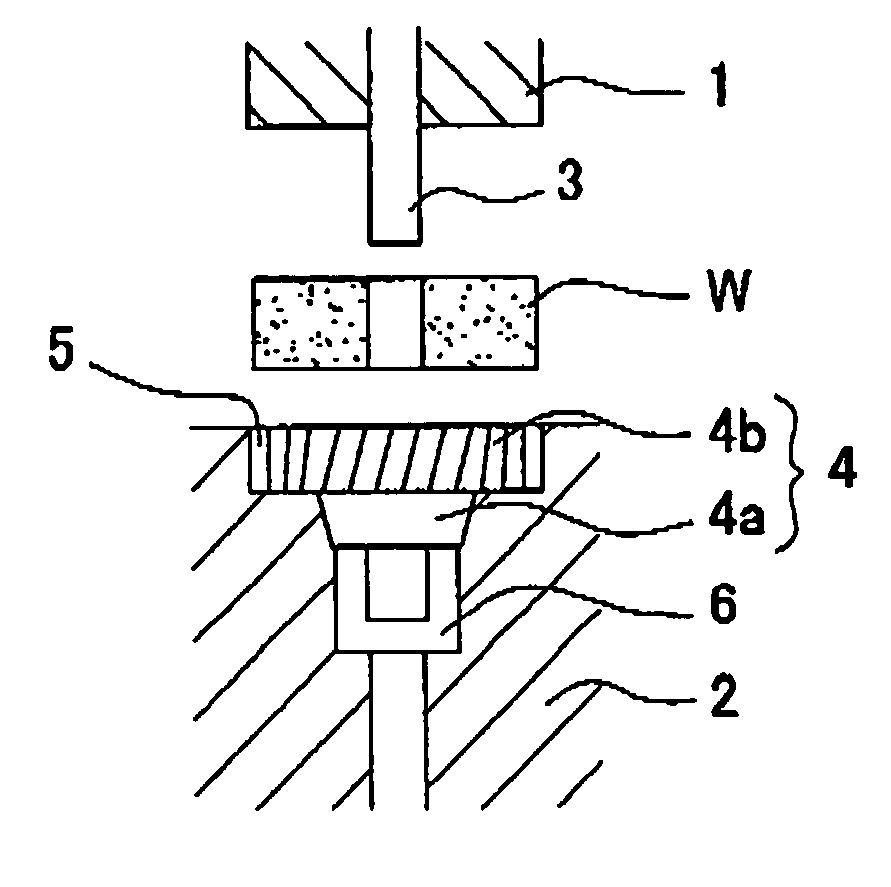

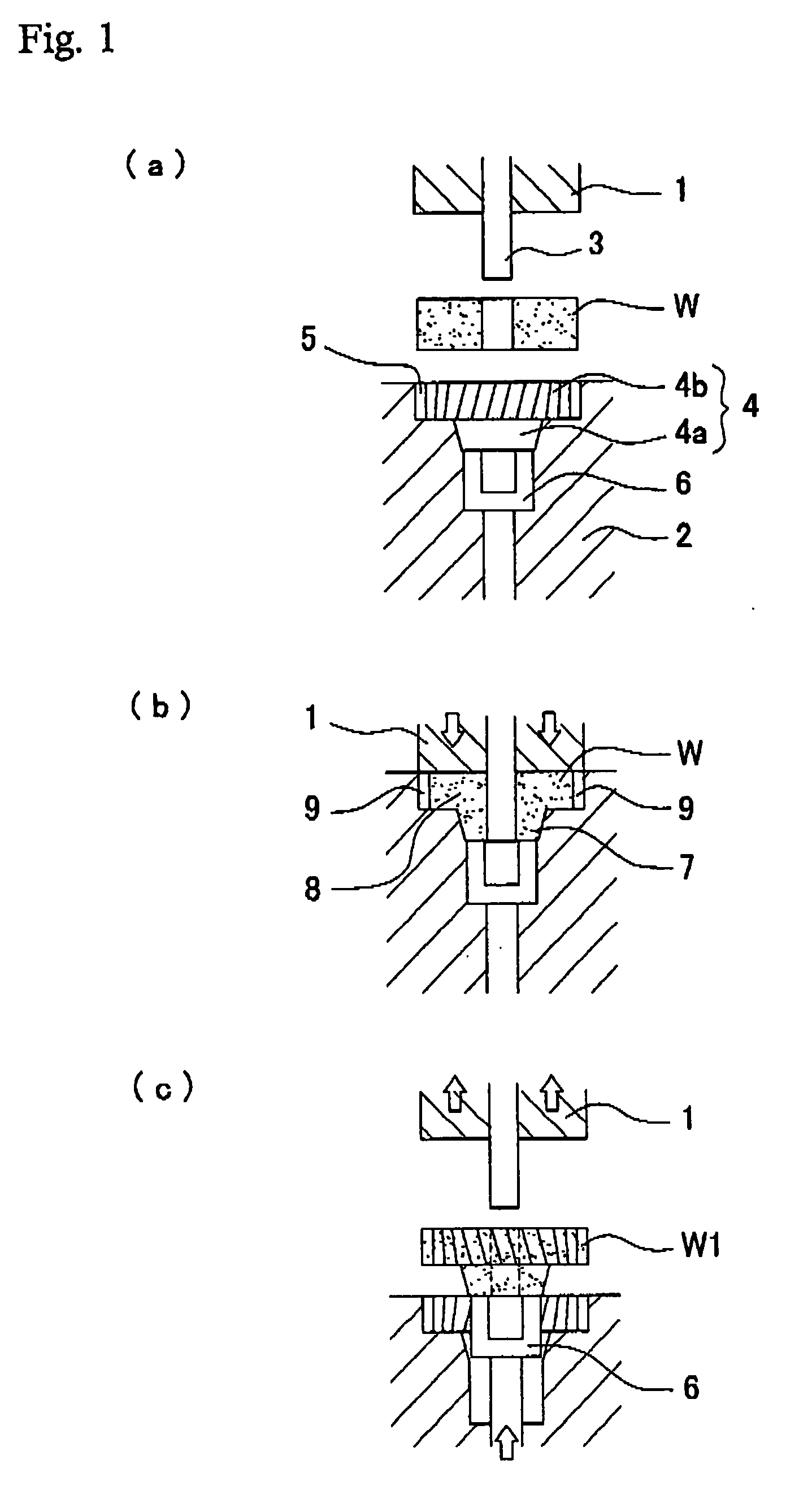

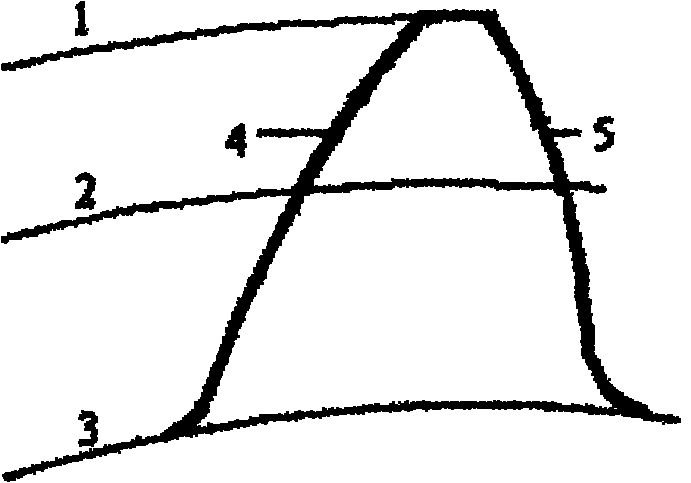

Gear product and method for manufacturing the same

InactiveUS20050278952A1Present inventionReduce processMetal-working apparatusPortable liftingEngineeringUpper teeth

In a gear product, a plurality of tooth having a crowning formed in a pattern unified to one pattern selected from fourteen patterns comprising four patterns in which a crowning is formed at one of an upper end part A or lower end part B of an upper inclined surface 91, an upper end part C or a lower end part D of a lower inclined surface 92, six patterns in which crownings are formed at two parts thereof and four patterns in which crownings are formed with three parts thereof, are formed at an equal pitch on an outer peripheral surface of a gear part. In a helical gear 9, a combination pattern of an upper part A of an upper side tooth surface 91 and a lower part D of a lower tooth surface 92 or a pair of an upper part C of the lower tooth surface 92 and a lower part D of the upper tooth surface 92 is formed by forging device.

Owner:O OKA CORP

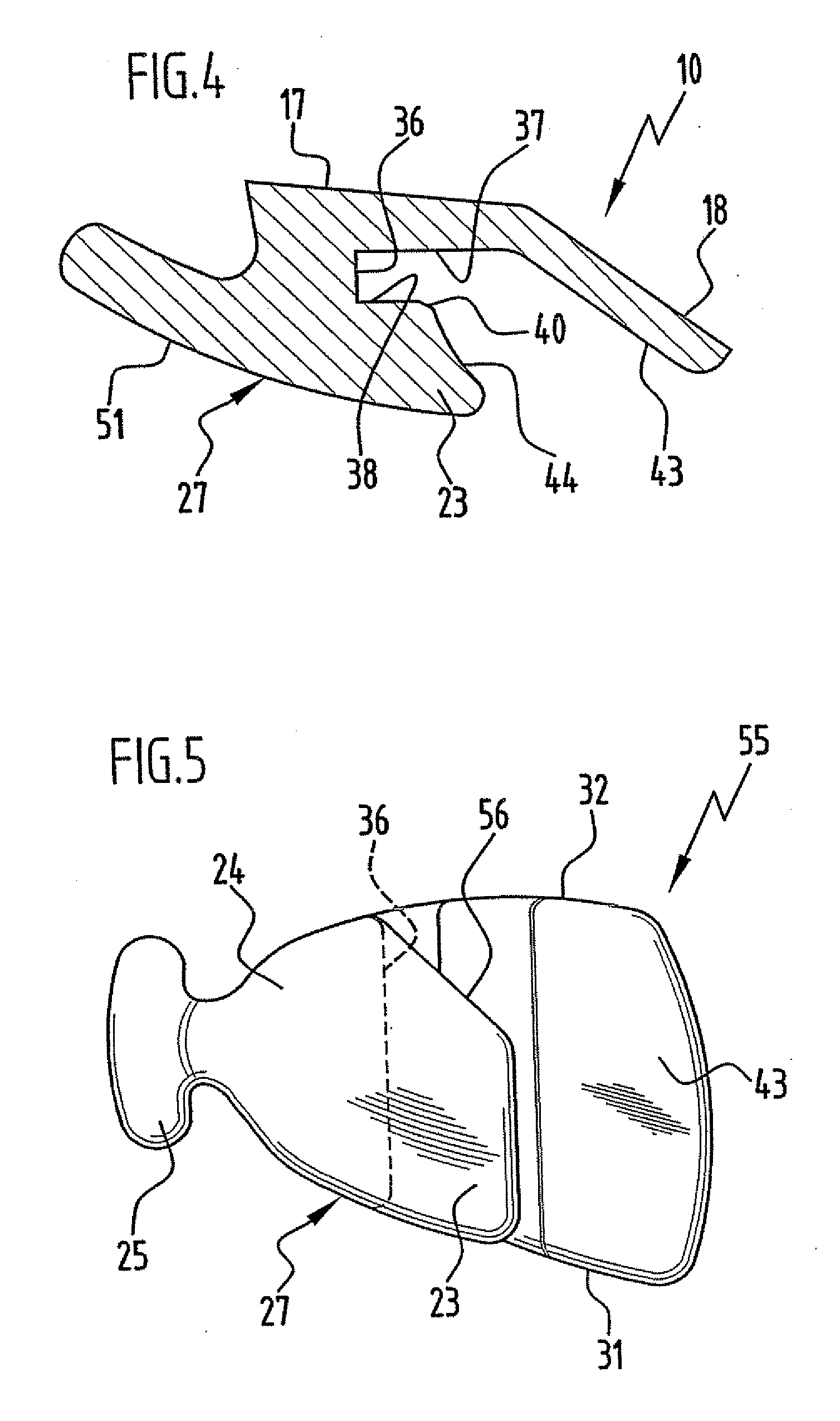

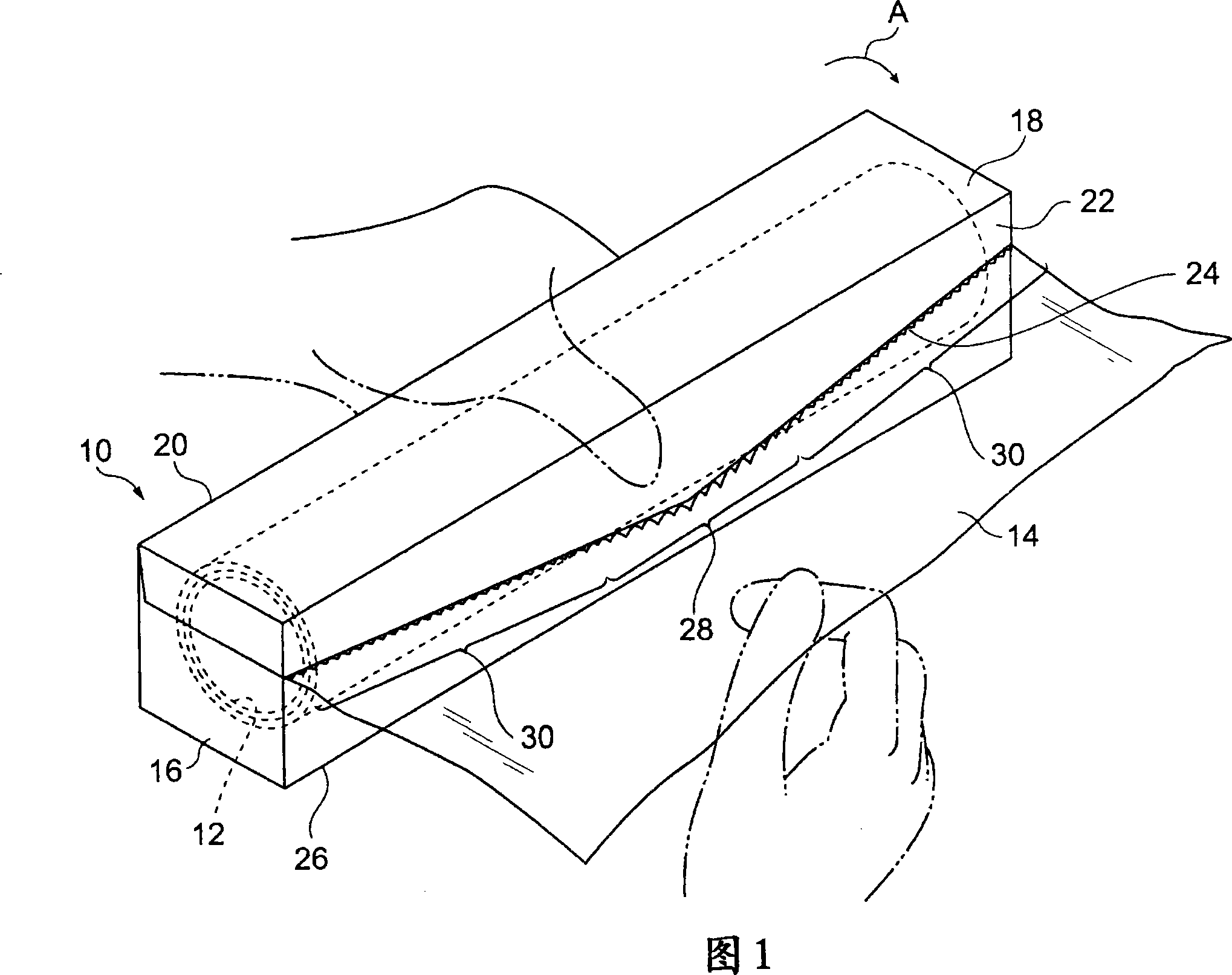

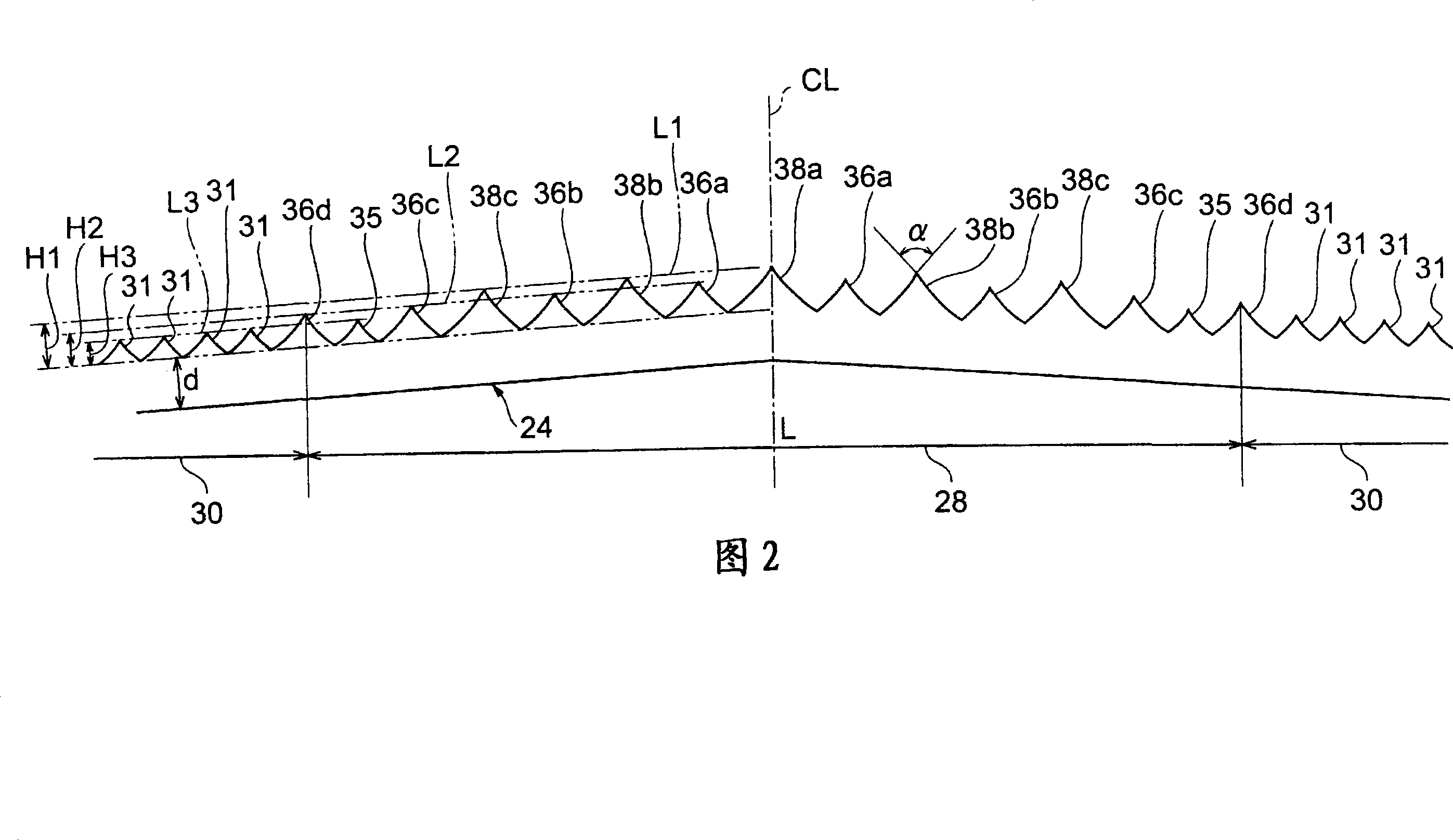

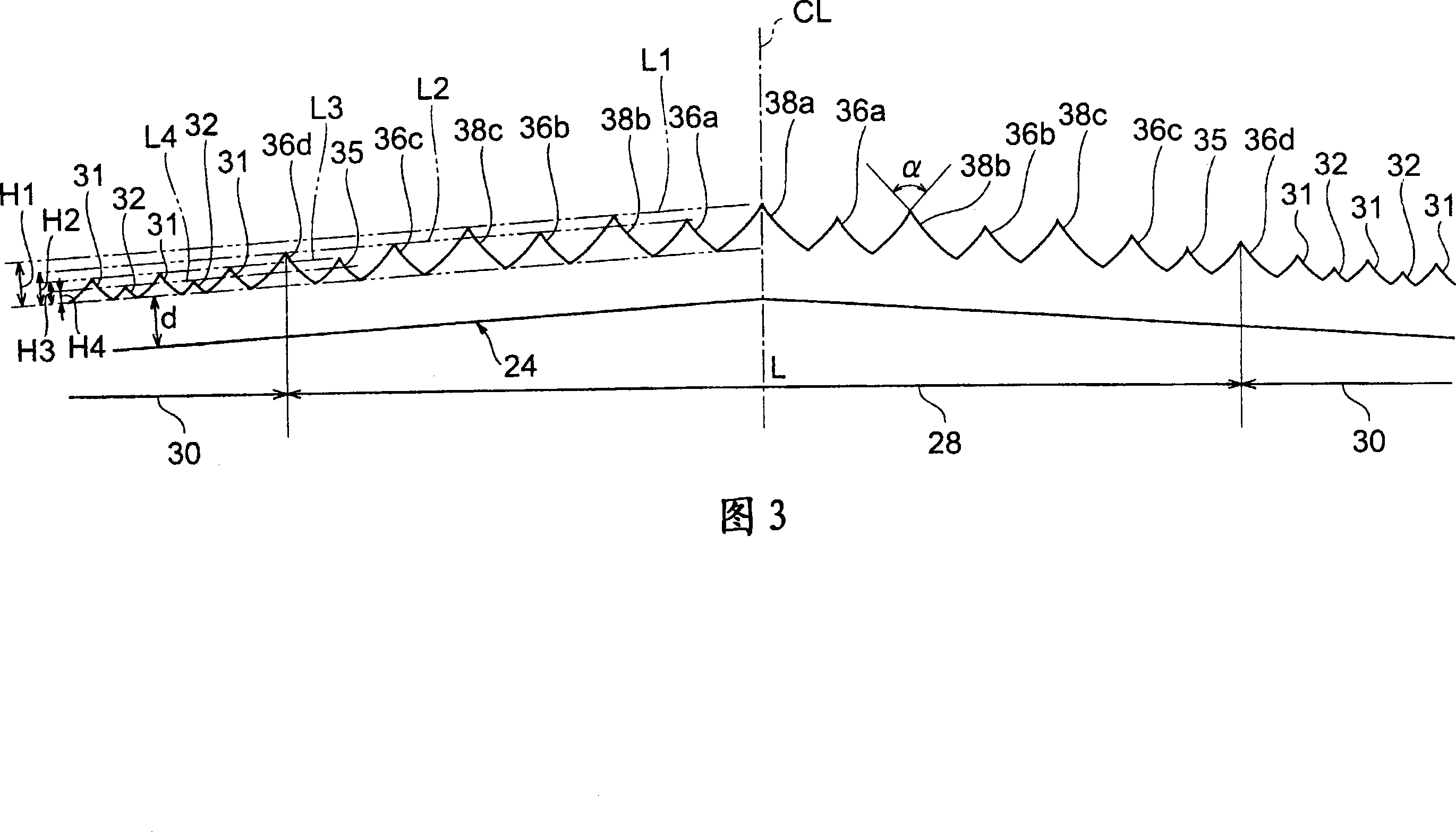

Cutting edge for package container and package container having the same

ActiveCN101081669AEasy to cutIncreased durabilityMetal working apparatusArticle deliveryLarge toothSide Tooth

Provided are a non-metallic V-shaped cutting blade capable of cutting roll-shaped packaging materials such as wrapping films with very light force, and a packaging container provided with the cutting blade. The cutting edge (24) of the present invention includes a central region (28) and side regions (30) that are arranged on both sides of the central region and are composed of a plurality of side teeth (31). A middle tooth (36) and a plurality of large teeth (38). One of the large and medium teeth is arranged at the apex of the V-shape, and the other large teeth are arranged at predetermined intervals so as to sandwich the teeth at the apex. The middle teeth are arranged between the large teeth. The large gear is more prominent than the middle gear. With this structure, when the cutting starts, the large teeth pierce the wrapping film (14) first, and then the middle teeth pierce the wrapping film. Since the wrapping film is pierced through such two stages, the force required for cutting is small.

Owner:KUREHA KAGAKU KOGYO KK +1

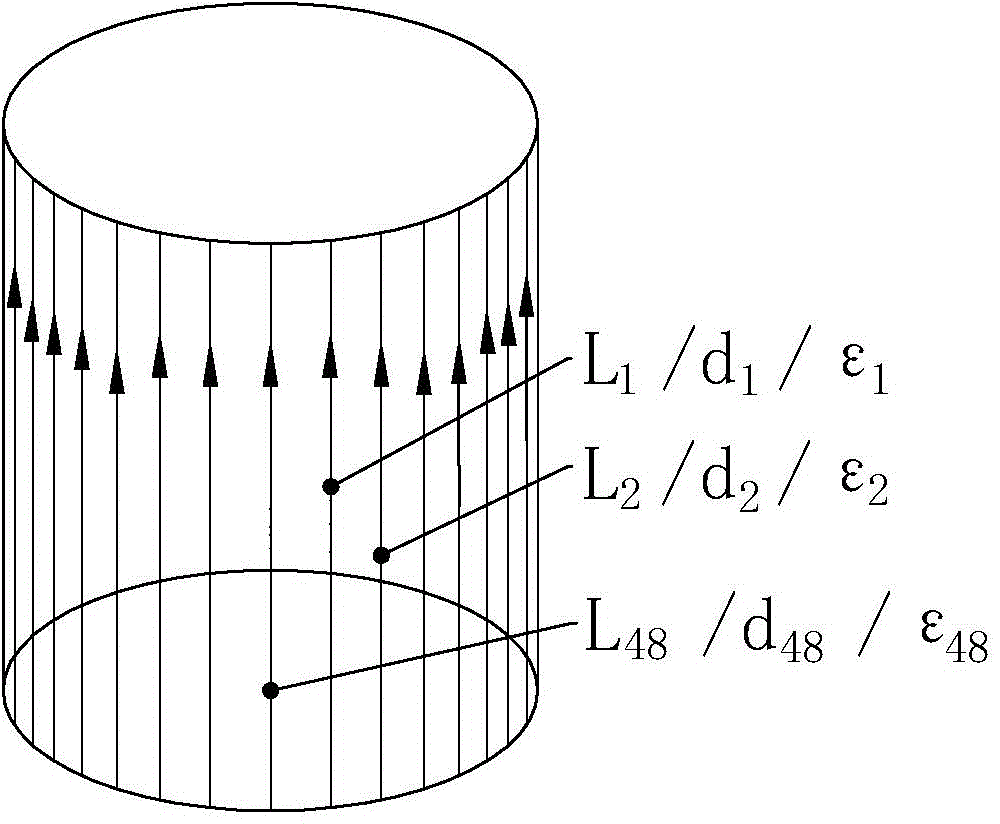

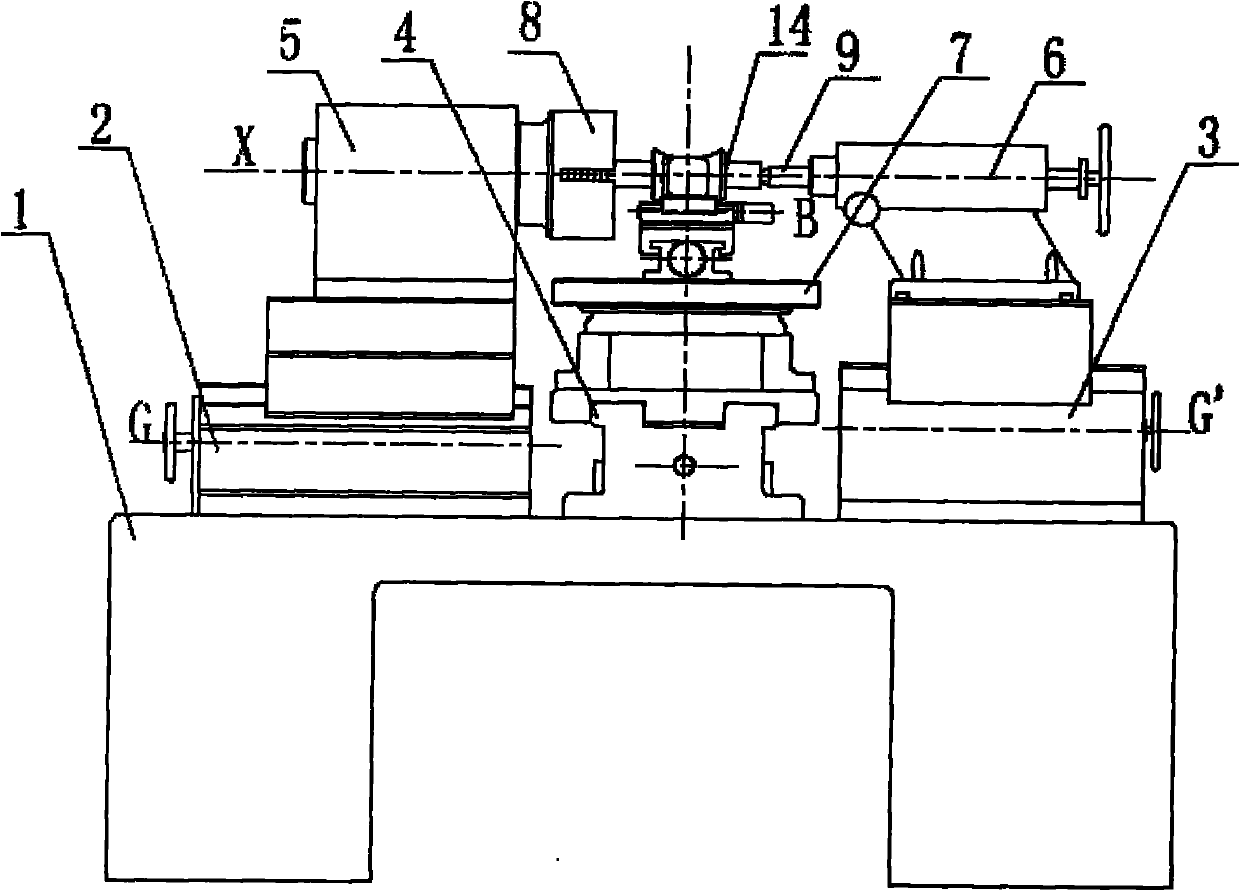

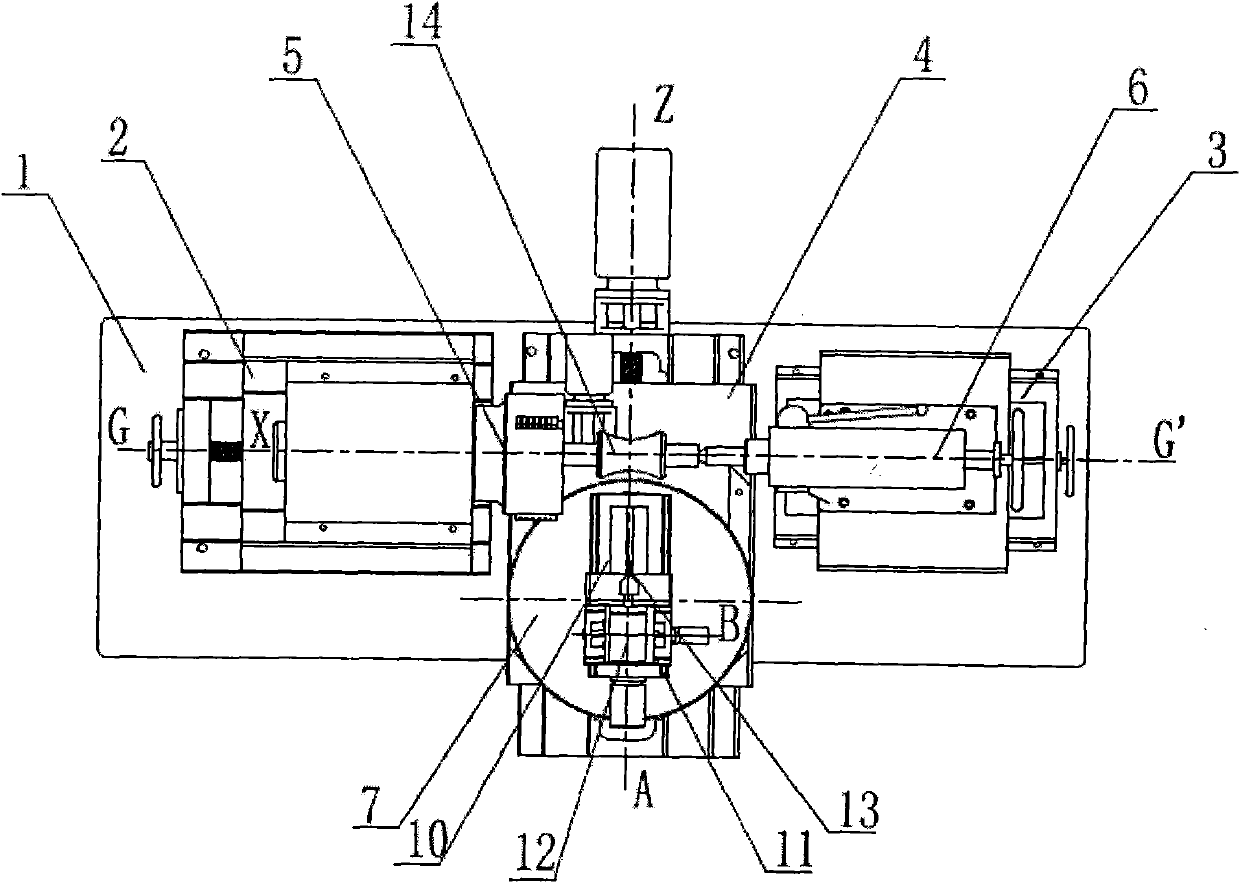

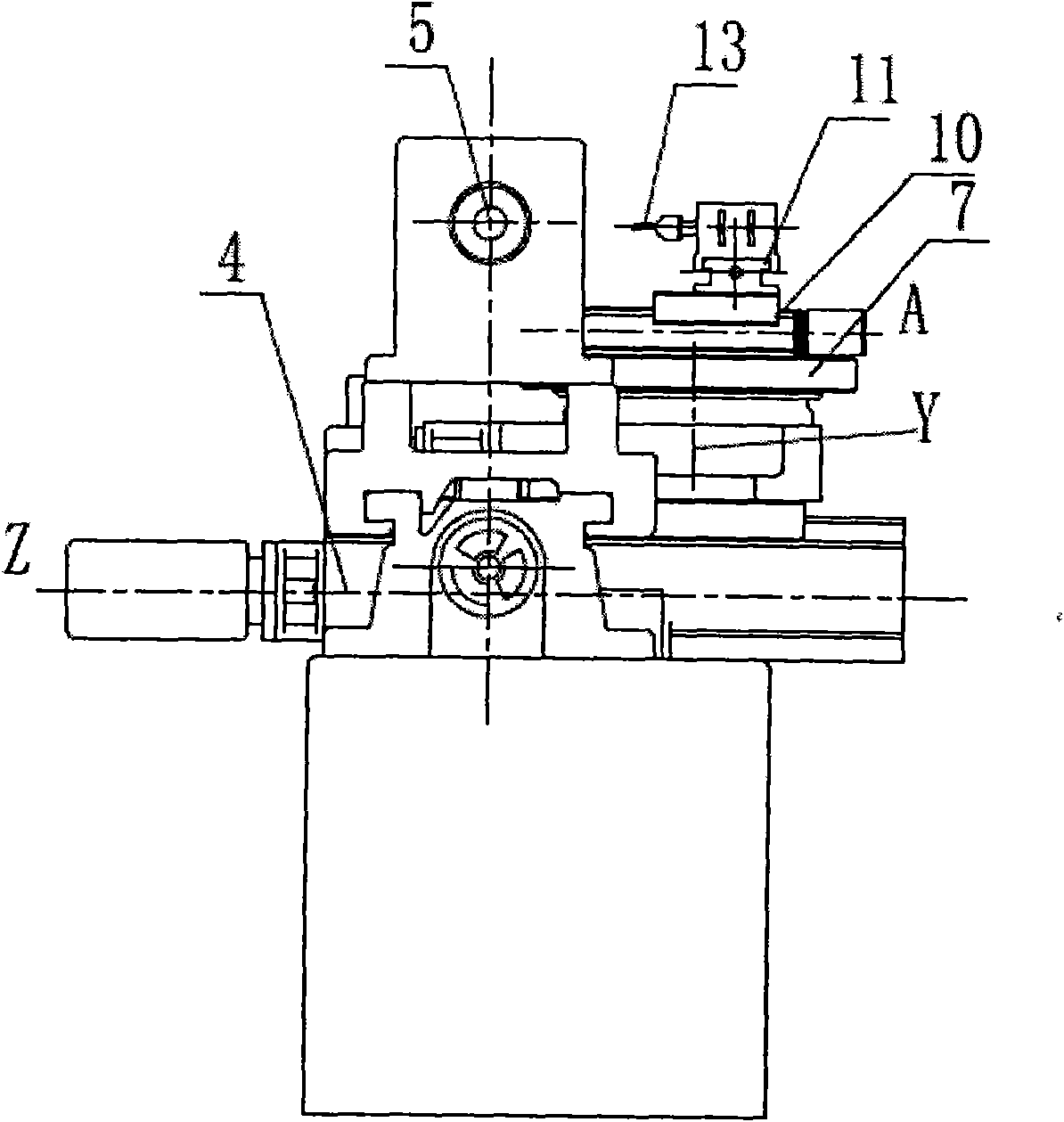

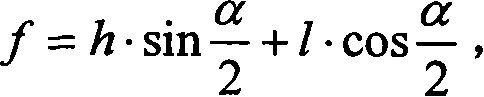

Numerical control relief grinding method for enveloping worm hob and machine tool for realizing same

InactiveCN101791772AAchieve precise CNC relief grindingMeet precise processing requirementsMilling cuttersNumerical controlEngineering

The invention discloses a numerical control relief grinding method for an enveloping worm hob and a machine tool. When relief grinding is carried out on side tooth faces of a hob, a main shaft and a rotary disk of the machine tool are synchronously rotated according to a worm pair transmission ratio, the rotation angle of the main shaft is thet0=2s / dl, the main shaft and the rotary disk are synchronously rotated to carry out the relief grinding on the tooth faces of the hob, the rotation angle of the main shaft satisfies the formula1, the transmission ratio of the main shaft and the rotary disk during the relief grinding of the right side tooth faces satisfies the a formula2, and the transmission ratio of the main shaft and the rotary disk during the relief grinding of the left side tooth faces satisfies the formula3, and the rotary disk is re-rotated with a compensation angle to finish the relief grinding of one tooth face, the compensation angle in the process of relief grinding of the right side tooth faces satisfies the formula 4, the compensation angle in the process of the relief grinding of the left side tooth face satisfies the formula 5; and when relief grinding is carried out on tooth backs, the main shaft and the rotary disk are firstly synchronously rotated, wherein the rotation angle of the main shaft is thet0= 2s / dl, the main shaft and the rotary disk are continuously rotated synchronously to enable a longitudinal feed carriage to carry out the relief grinding on the tooth backs along the longitudinal feeding, the rotation angle of the main shaft satisfies the formula 6, then the longitudinal feed carriage is reversely fed, the transmission ratio of the main shaft and the rotary disk is equal to the worm pair transmission ration in the whole process of the relief grinding of the tooth backs, and both the longitudinal feeding and the reverse feeding of the longitudinal feed carriage satisfy the formula7.

Owner:ZHEJIANG UNIV +1

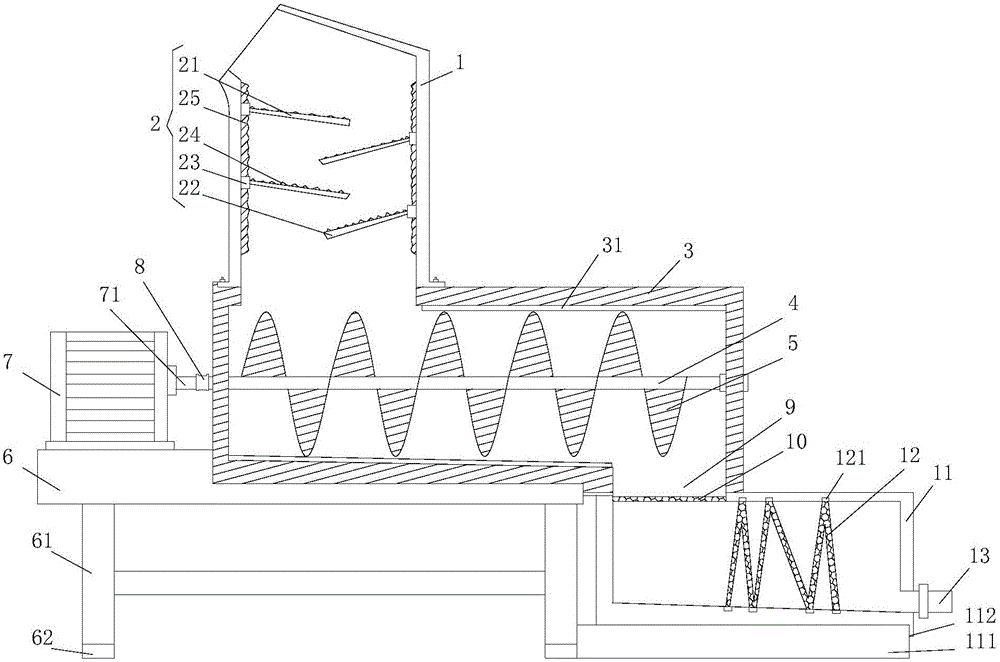

Purification device for primary sewage treatment

InactiveCN106277112AWell mixedIncrease contact areaSpecific water treatment objectivesTreatment involving filtrationEngineeringSewage

The invention discloses a purification device for primary sewage treatment. The purification device comprises a water inlet platform, a purification barrel and an impurity filter tank, wherein the inner wall of the water inlet platform is connected with an auxiliary stirring mechanism; the auxiliary stirring mechanism comprises a connecting block, bulging teeth, side teeth as well as an upper guide plate and a lower guide plate which are obliquely mounted; the bottom of the water inlet platform communicates with one side of the top of the purification barrel. When sewage is mixed with a flocculating agent, the sewage and the flocculating agent produce continuous collision contact and spirally downward force during flowing under the gravity effect, the contact area between the sewage and the flocculating agent is enlarged, the mixing effect and efficiency of the sewage and the flocculating agent is improved substantially, the sewage and the flocculating agent can be further stirred spirally and mixed more sufficiently within a short time, and the mixing effect of the sewage and the flocculating agent is improved to a great extent.

Owner:新昌县城关升华机械厂

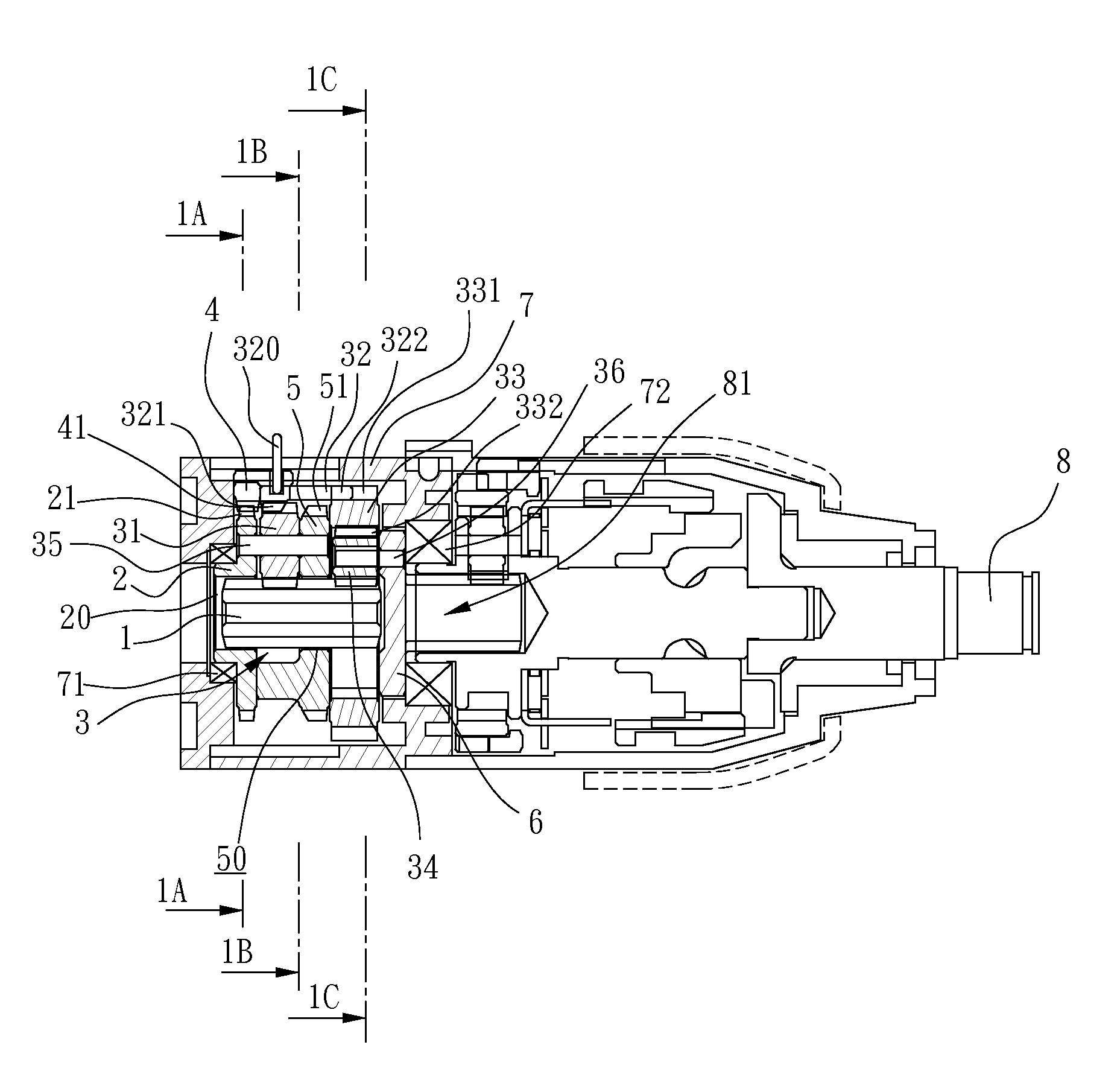

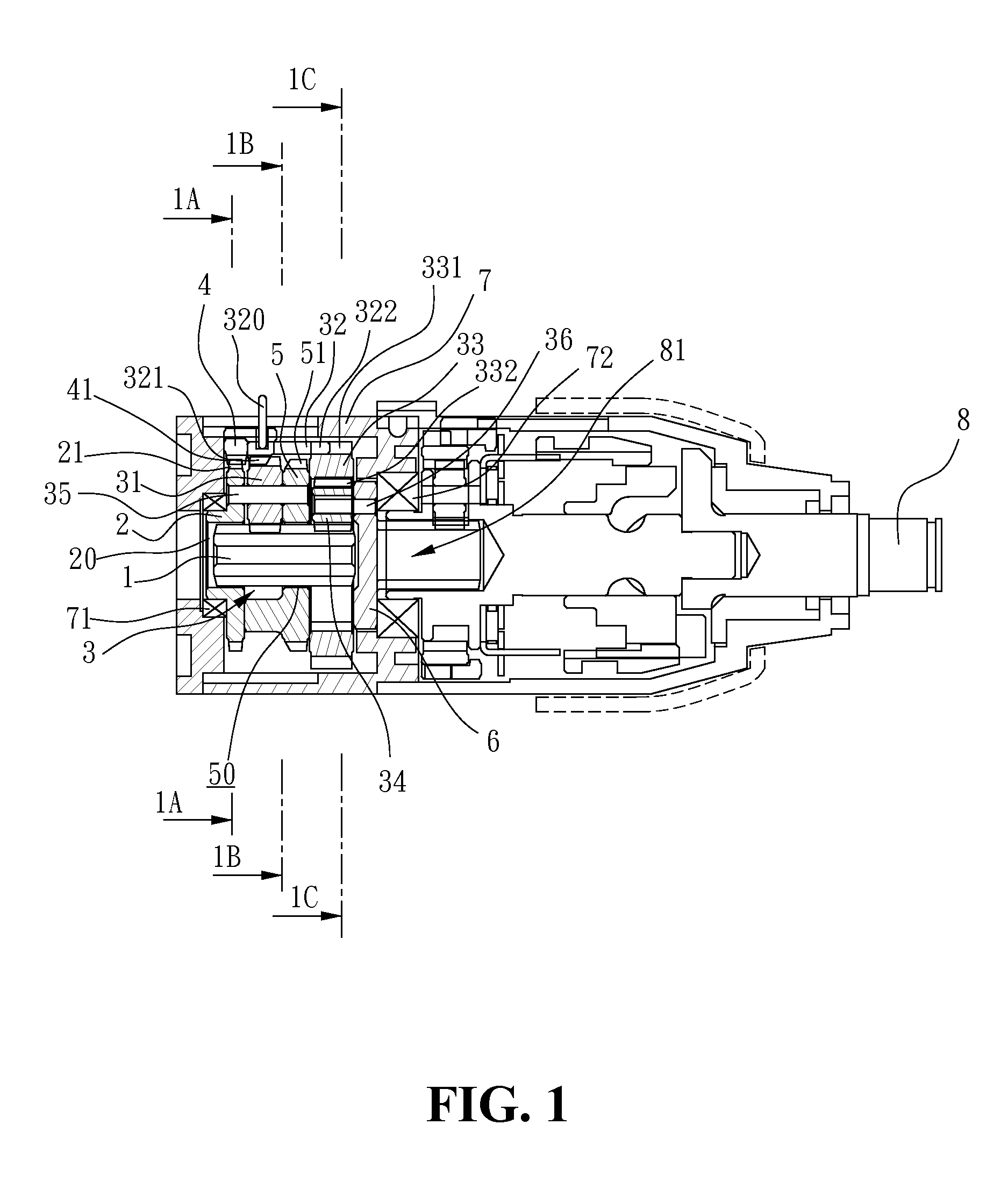

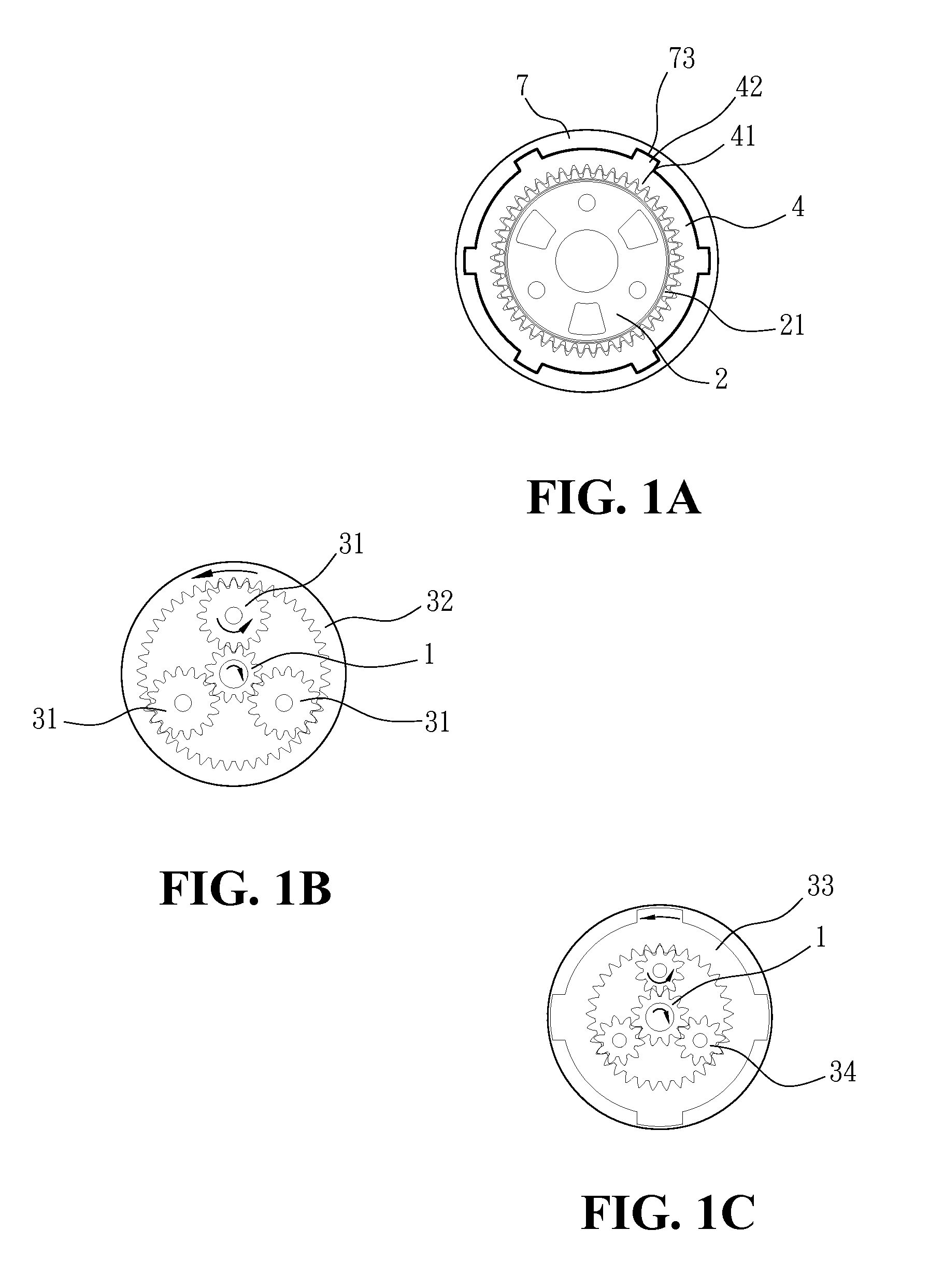

Multi-gear mechanism for power tools

A multi-gear mechanism includes first and second gear sets, an output set, multiple first planet gears pivotably connected between the first and second gear sets, a first gear ring having internal teeth and external teeth, multiple second planet gears cooperated with the internal teeth of the first gear ring, a second gear ring having internal teeth and side teeth, an operation gear ring and a motor gear. The motor gear extends through two central holes of the first and second gear sets, and the first and second planet gears are engaged with the motor gear. The operation gear ring is connected with the second gear ring which drives the operation gear ring to move axially. The motor gear drives the output set at low speed, constant speed or high speed when the operation gear ring and the second gear ring are operated to engage with different gears.

Owner:POWER NETWORK IND

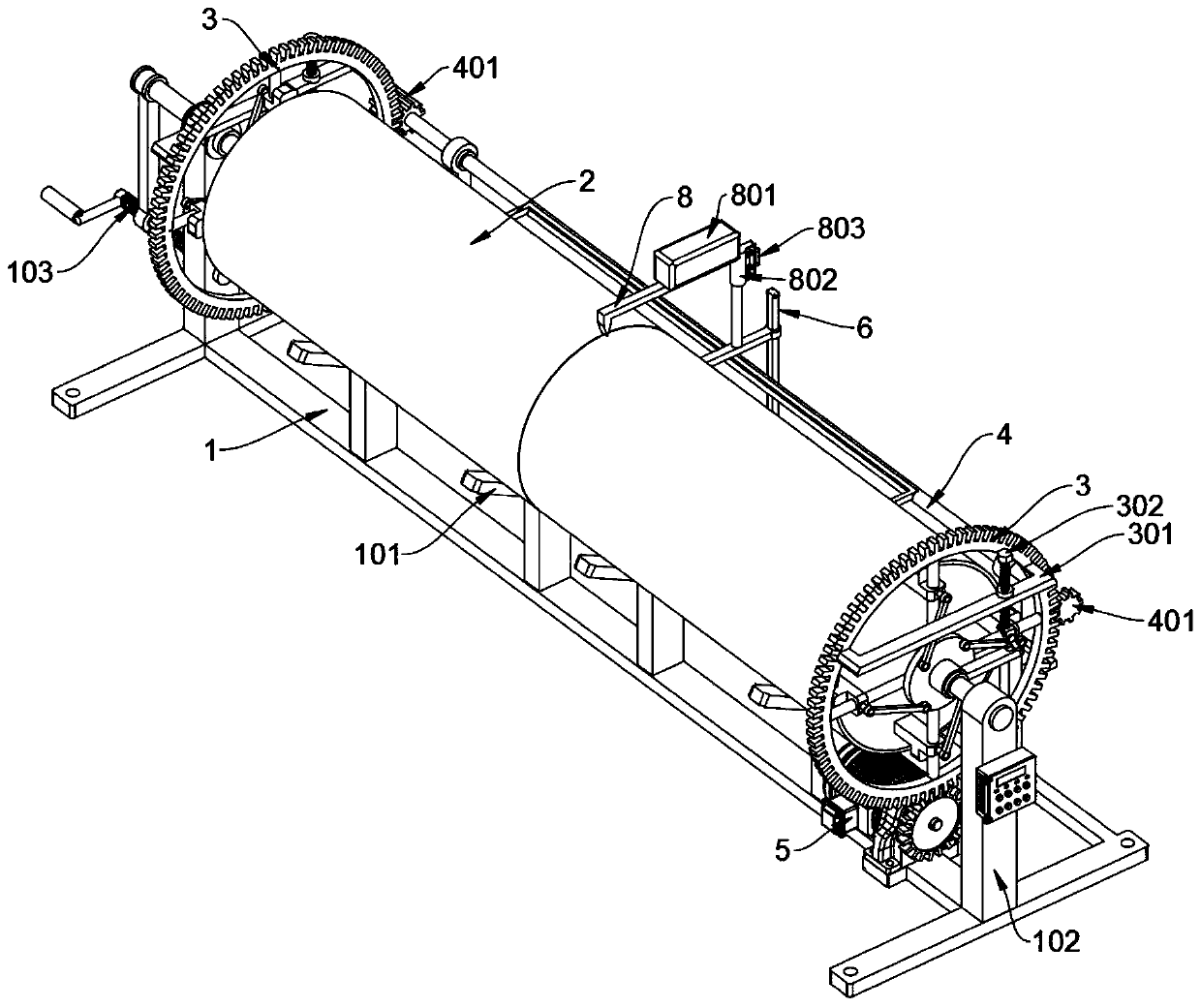

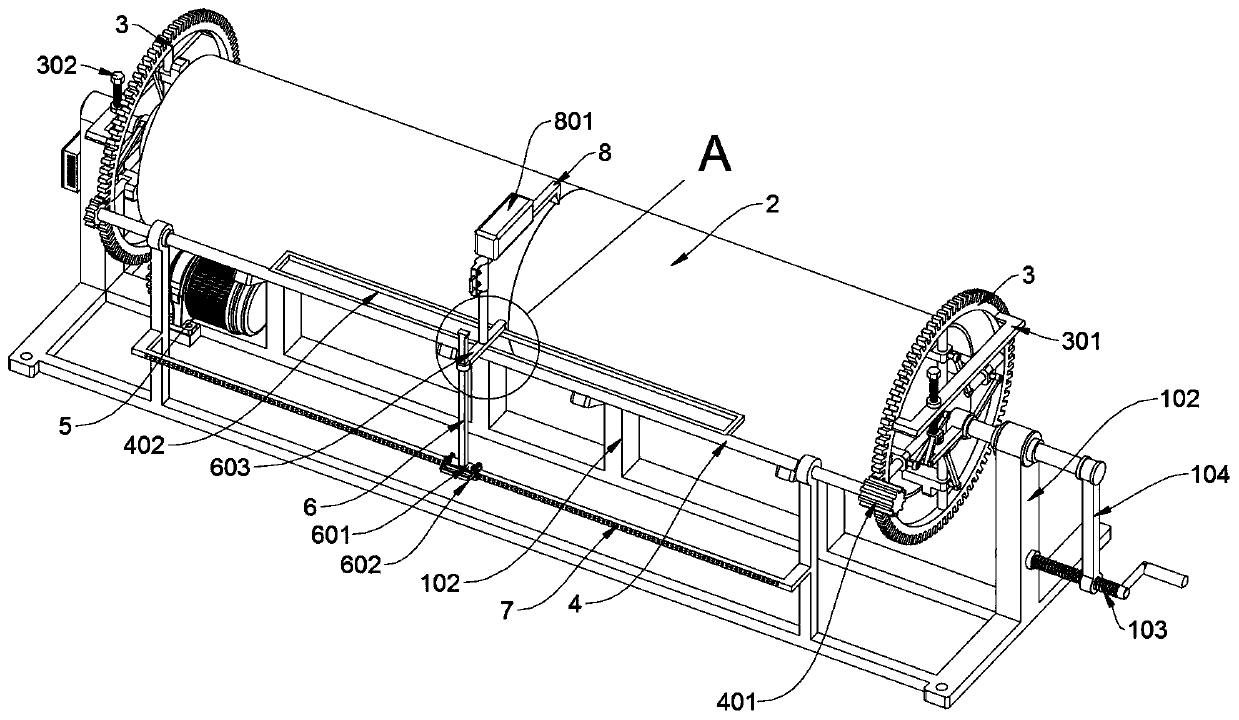

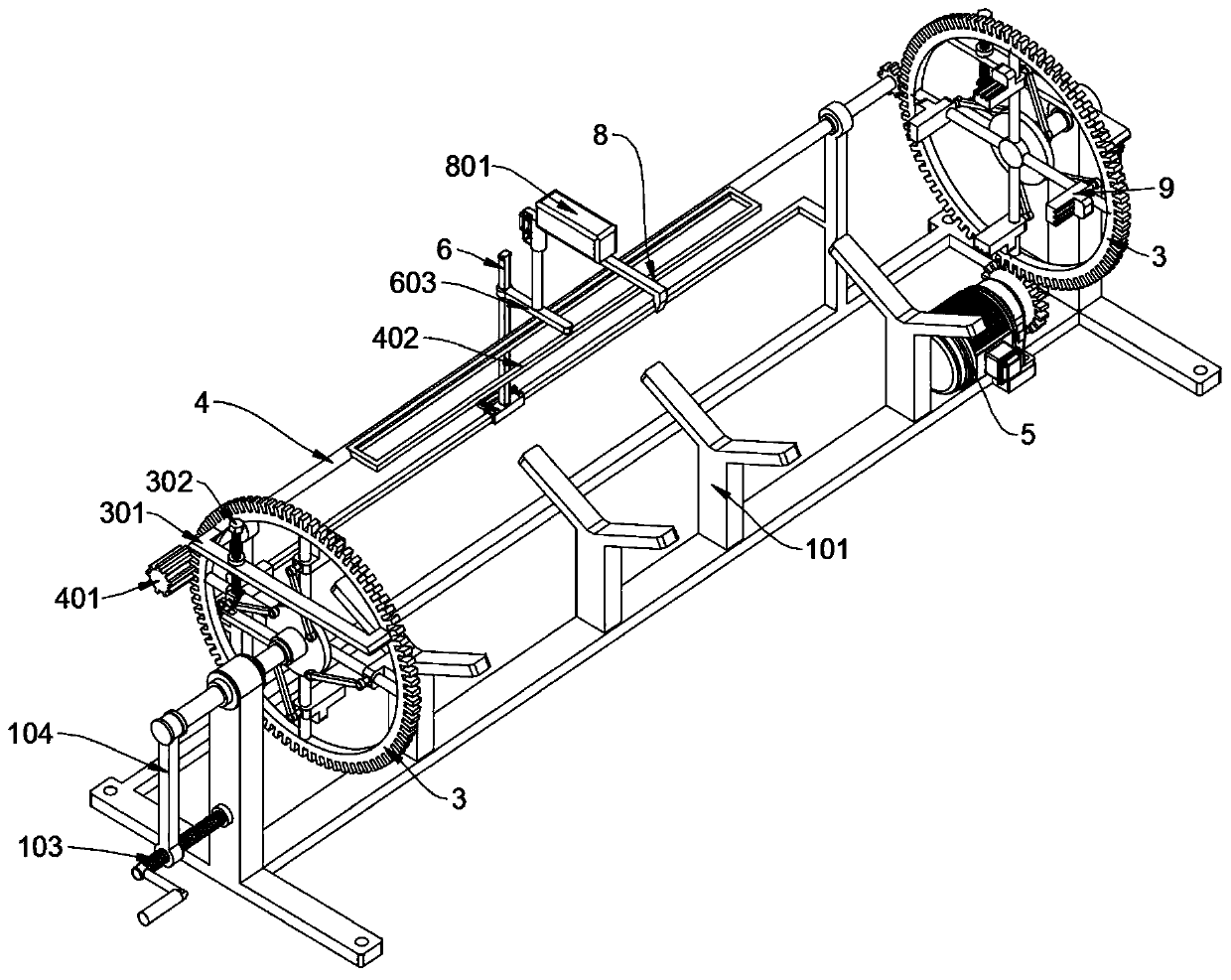

Multi-angle overturning welding device for long-distance large-diameter jacking pipe

InactiveCN111360479AEasy to assemble and disassembleAvoid obstaclesWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Butt welding

The invention discloses a multi-angle overturning welding device for a long-distance large-diameter jacking pipe, relates to the technical field of jacking pipe welding equipment, and solves the problems that according to an existing welding device, a welder needs to manually knock a welding slag coating after welding, the efficiency is low, manpower is wasted, and hand fatigue of the welder is likely to be caused by frequent knocking actions. The multi-angle overturning welding device for the long-distance large-diameter jacking pipe comprises a base and a positioning square rod, wherein thebase comprises a V-shaped supporting plate, vertical supporting rods, a lead screw and a connecting top plate, the base is integrally of an I-shaped structure, and the two vertical supporting rods aresymmetrically welded to the middles of the front side and the rear side of the base; and two gear rings are rotationally inserted and supported at the top ends of the two vertical supporting rods, and the front end side gear ring is movably mounted. According to the multi-angle overturning welding device, a knocking rod can slide left and right along a rail square rod through a square sliding sleeve to be adjusted and is inserted and positioned through the rail square rod, and the device is suitable for knocking welding slag on butt welds at different positions, is flexible to use and wide inapplication.

Owner:王伟

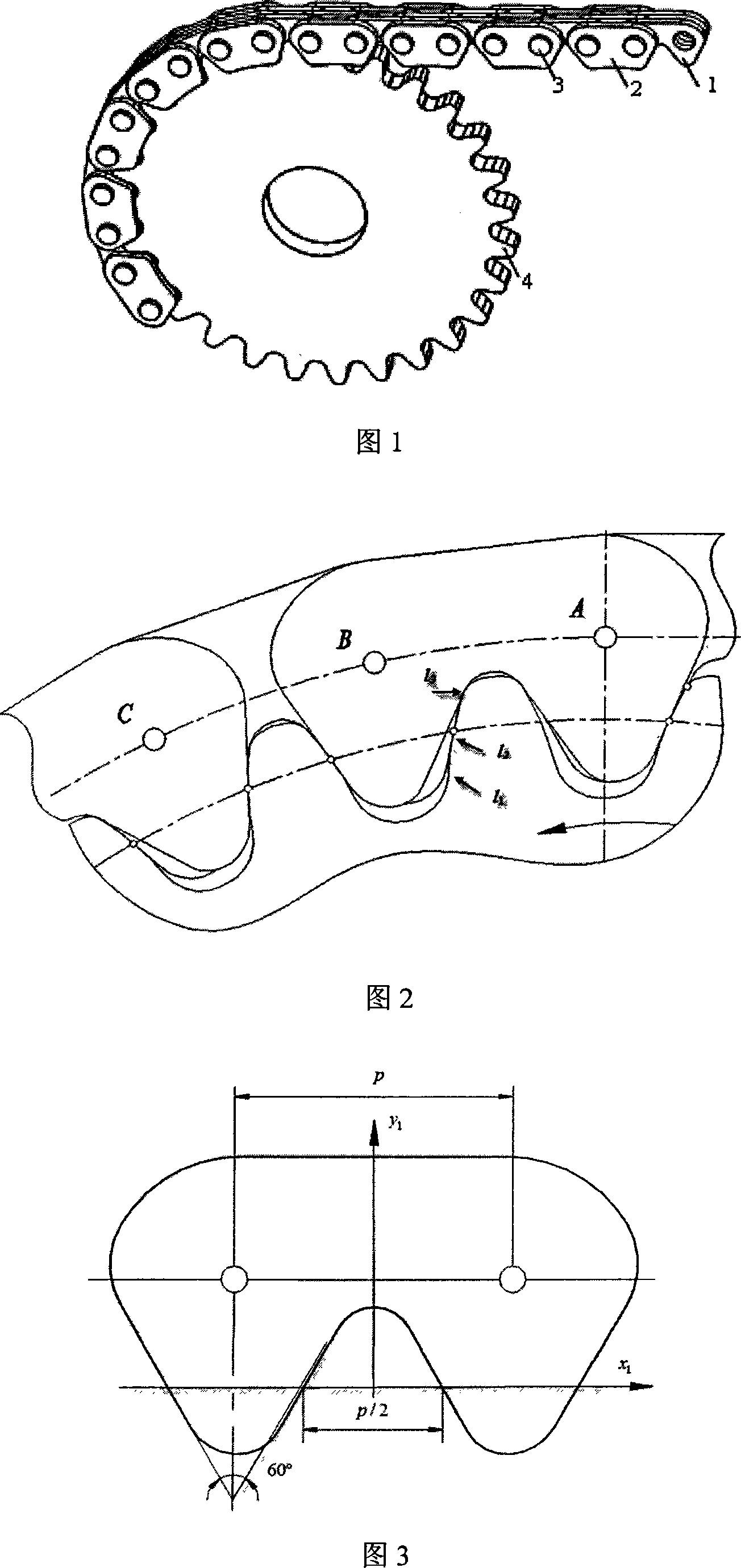

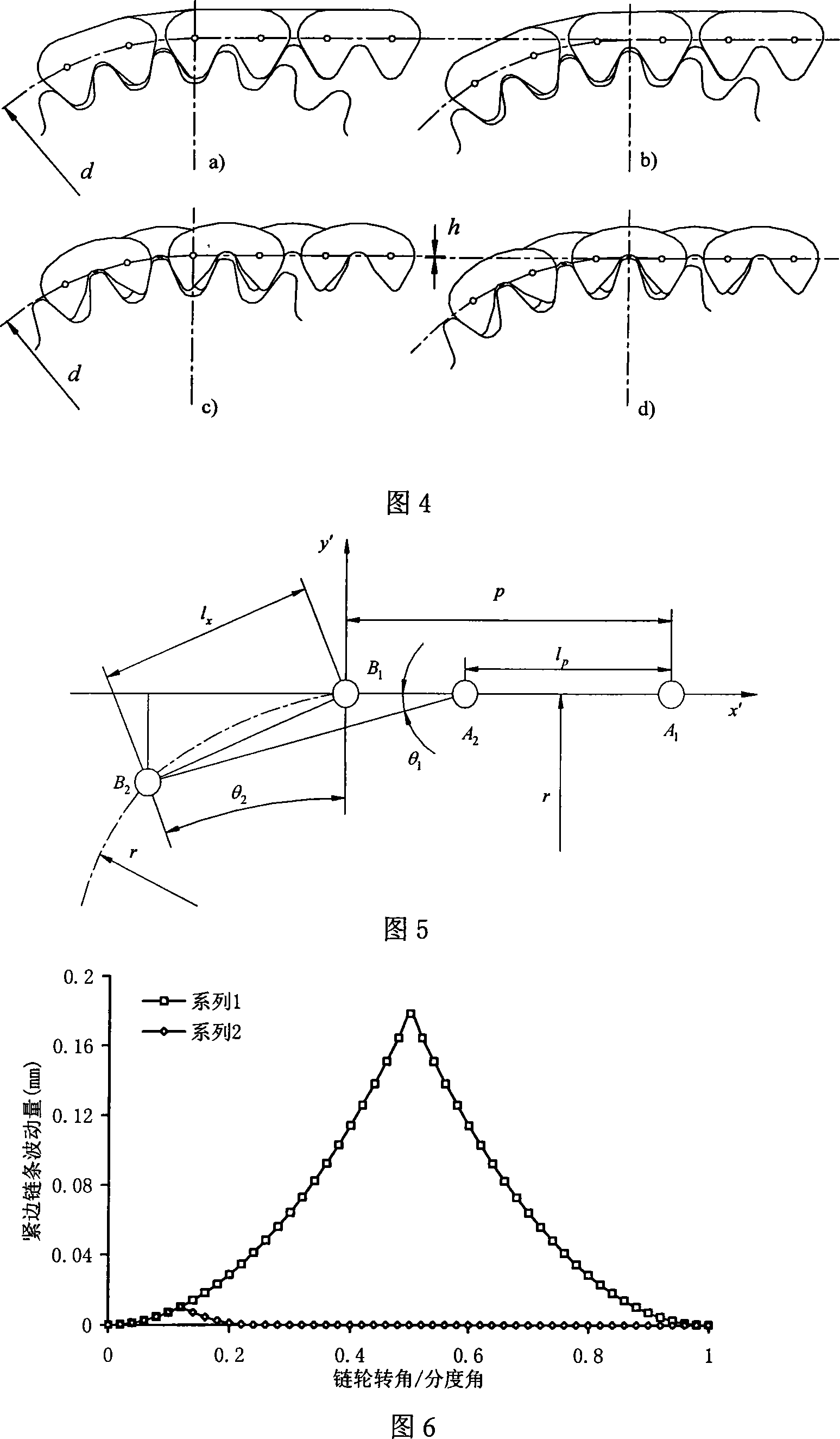

High speed transmission toothed chain and chain wheel

InactiveCN101101049AEliminate position changesEliminate lateral movementGearingPortable liftingLow noiseSprocket

This invention discloses high speed driving toothed chain and chain wheel. The inner and outer tooth profile of tooth link joint can be joggled with gear tooth of chain wheel. The link joint inner tooth profile is first joggled with chain wheel gear tooth. With chain wheel rotating, the link joint inner and outer tooth profile are joggled with chain wheel at the same time. At last, outer tooth profile is located on the gear tooth of chain wheel. The chain wheel single tooth single side tooth profile line is composed of transition curve, involute and correcting involute. The inner profile of inverted tooth chain link joint is convex in respect to outer profile. This invention has low shock and low noise.

Owner:SHANDONG UNIV

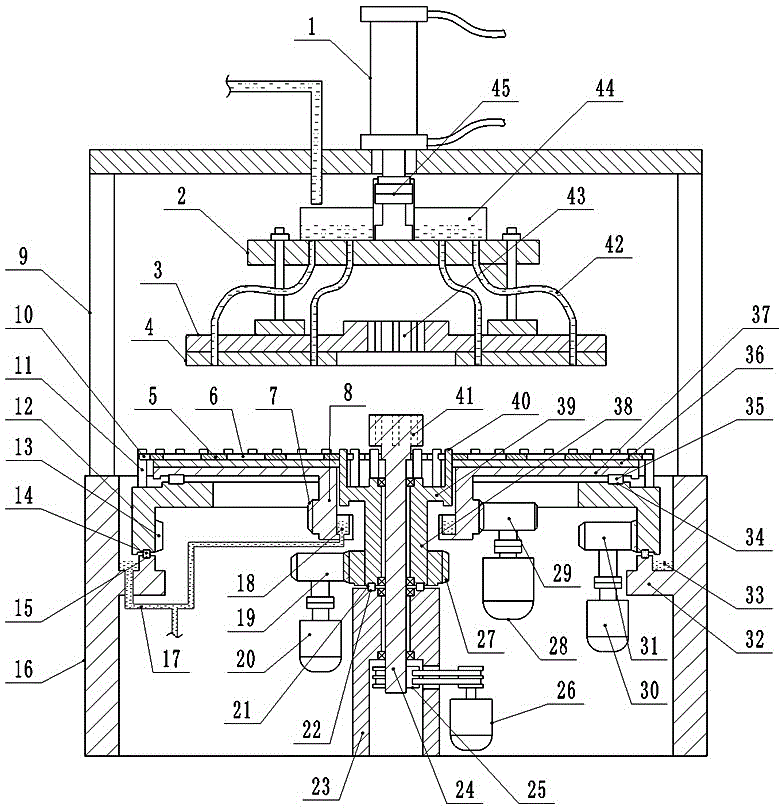

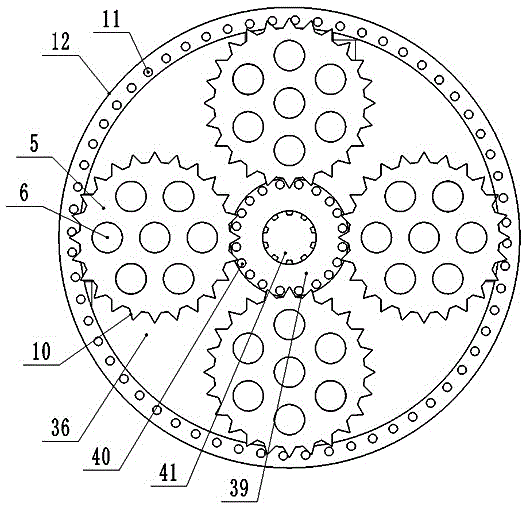

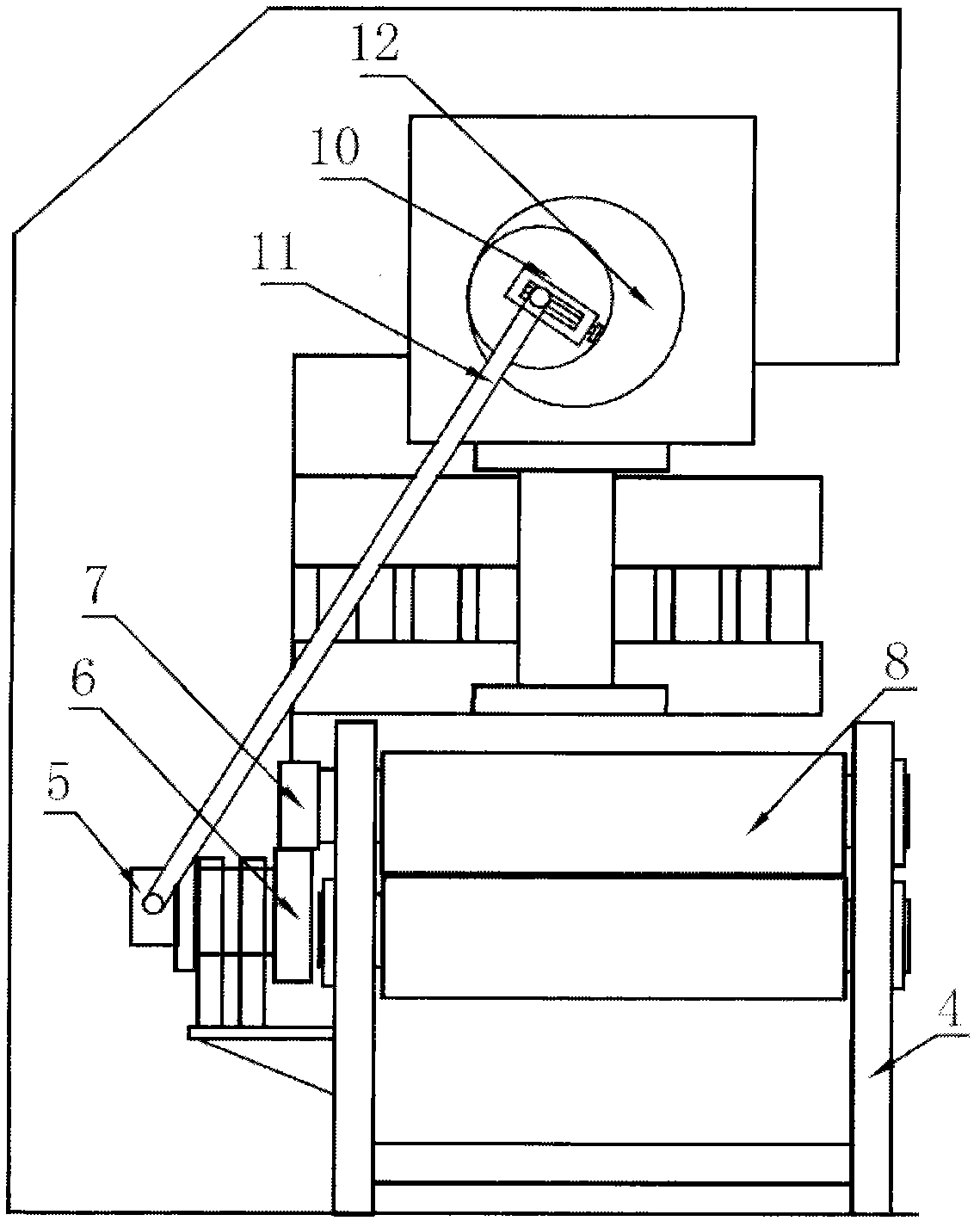

Four-drive two-face chip polishing machine

ActiveCN106312718ATurn fasterImprove polishing efficiencyGrinding carriagesGrinding bedsEngineeringSide Tooth

The invention relates to a four-drive two-face chip polishing machine. The four-drive two-face chip polishing machine is formed by a lower polishing device and an upper polishing device; a pressure disc and an upper polishing disc are installed below an air cylinder of the upper polishing device through rotation connectors, and a linkage hole is machined in the middle of the pressure disc; a first transmission column is installed on an outer rotary disc of the lower polishing device, a lower polishing disc is installed on a lower tray, a second transmission column is installed on an inner rotary disc, and a connector is installed on a linkage shaft; and the first transmission column, the lower polishing disc, the second transmission column and the connector are driven by a first motor, a second motor, a third motor and a fourth motor correspondingly; the pressure disc is driven by the connector on the linkage shaft, a chip containing hole is machined in a chip positioning liner, the chip positioning liner is placed on the lower polishing disc, and side teeth of the chip positioning liner are combined with the first transmission column and the second transmission column in a clamped manner. By means of the technology, the first transmission column and the second transmission column drive the chip positioning liner to rotate between the upper polishing disc and the lower polishing disc in two directions, and chips are polished for the first time; and meanwhile, when the upper polishing disc and the lower polishing disc rotate, the chips are polished for the second time, work of polishing at the two times are overlapped, and therefore the polishing efficiency of the chips is increased in a multiplied manner.

Owner:YUNNAN CRYSTALAND

Gear engagement detection method

InactiveCN102141472AReduce manufacturing costHigh densityMachine gearing/transmission testingAdhesive beltGear wheel

The invention provides a gear engagement detection method which is simple, accurate in detection and low in detection cost. The method is characterized by comprising the following steps: mixing red lead powder with machine oil, then coating the obtained mixture on the side surface of one of gears; rotating two gears; after the tooth surfaces of the two gears are completely contacted, covering the side tooth surface of the other gear by using an adhesive tape; and removing the adhesive tape, then observing the distribution situation of the red lead powder, if the red lead powder is fully distributed on the adhesive tape without gaps, showing that the gears are completely engaged, and if the red lead powder is distributed on the adhesive tape with light color and gaps or large gaps, showing that the gears are incompletely engaged or not engaged.

Owner:WUXI JULI HEAVY IND OFF

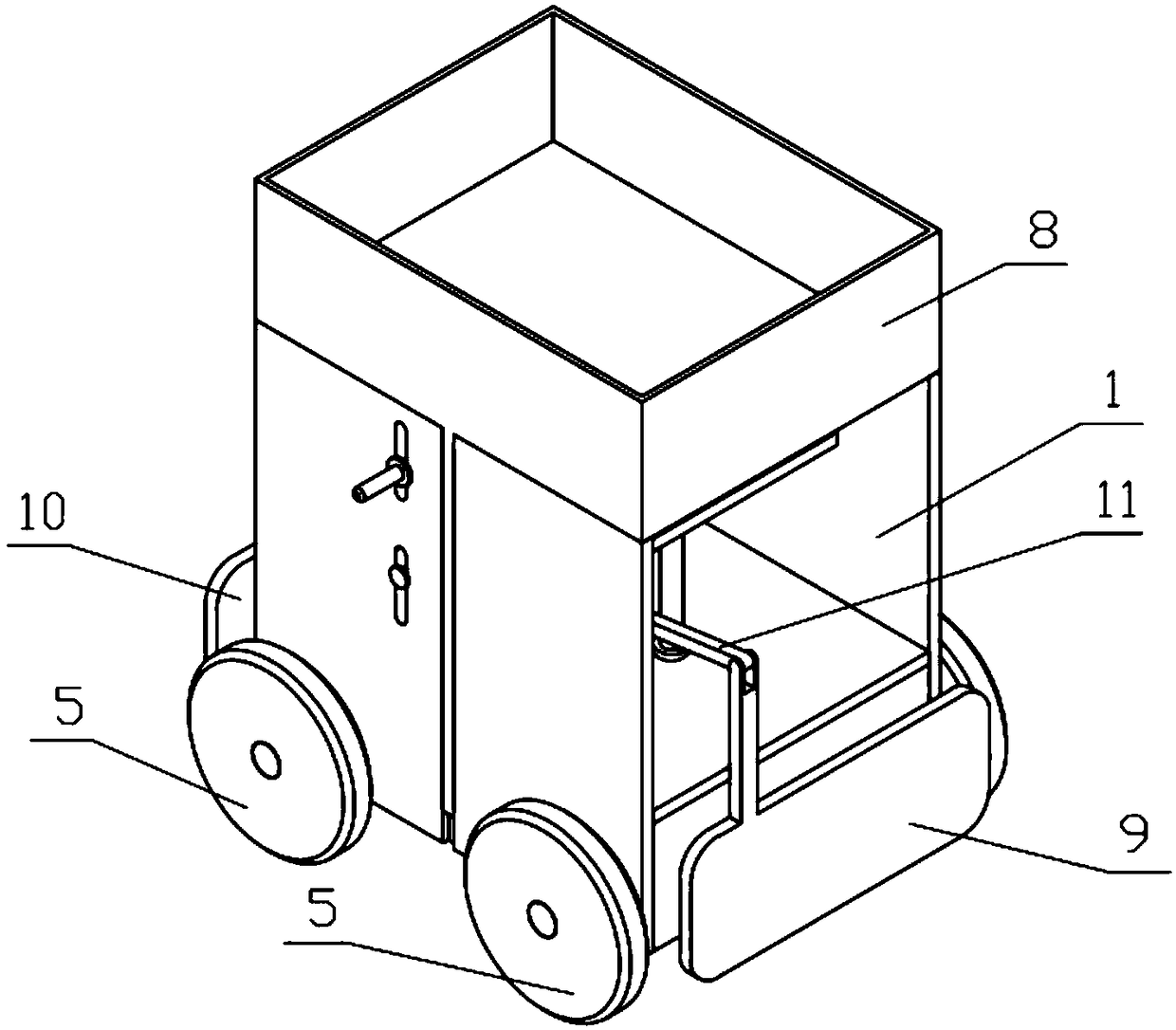

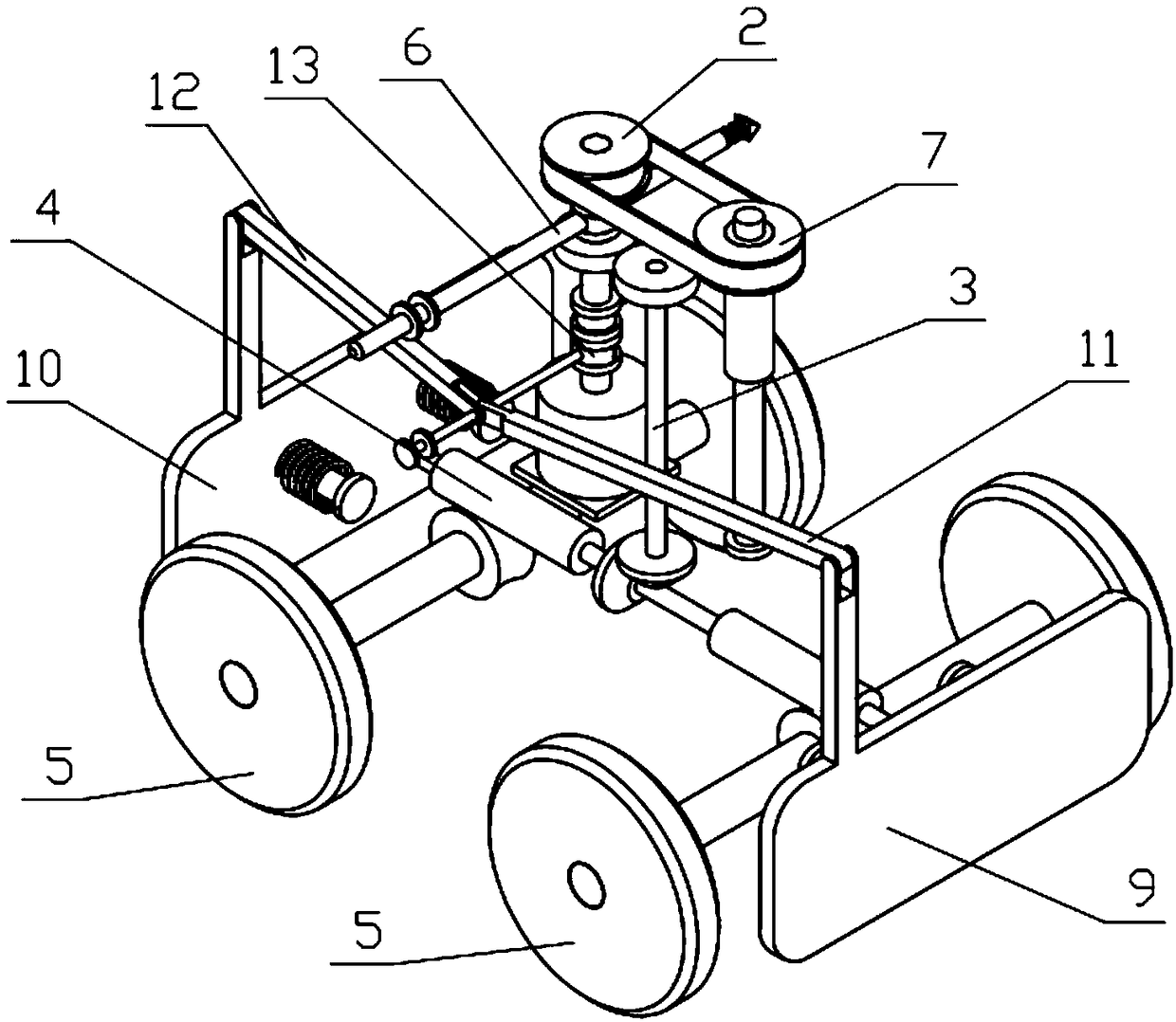

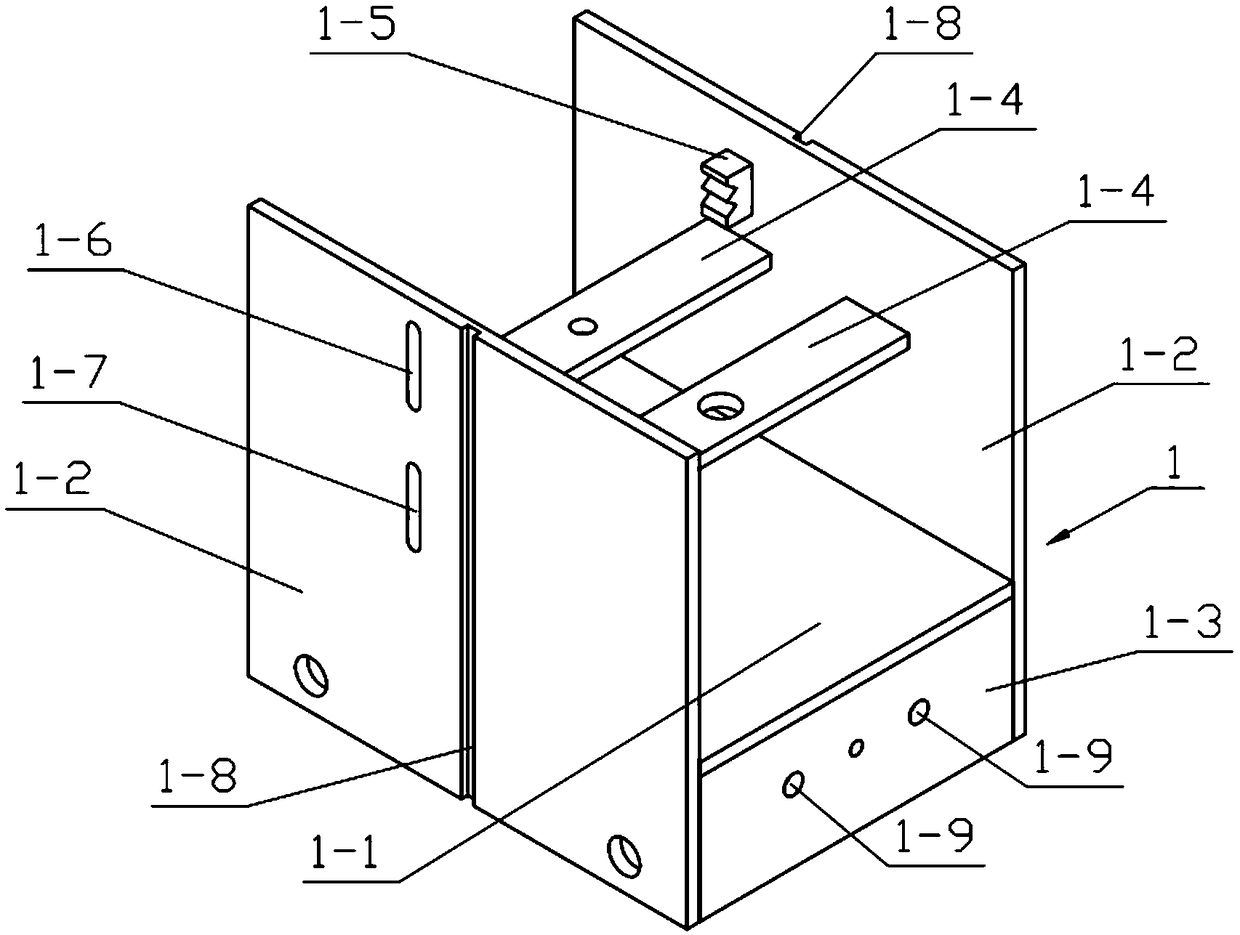

Scaffold for building

The invention relates to a building device, in particular to a scaffold for building. The scaffold comprises a whole bracket, a power mechanism, a transmission mechanism, a worm mechanism, movement mechanisms, a control mechanism, a lifting mechanism, a lifting plate, a touch front plate, a touch rear plate, a connecting rod I, a connecting rod II and a shifting fork. The scaffold can move, ascendand descend through power switching on the power mechanism; when the control mechanism is clamped at the upper end of a W-shaped clamping body, a sliding side tooth II and a power belt wheel on the power mechanism are engaged, and the lifting mechanism moves; when the control mechanism is clamped at the lower end of the W-shaped clamping body, the sliding side tooth II and a power gear on the power mechanism are engaged, and the movement mechanisms move to move the scaffold; and when the scaffold encounters obstacles during moving, the touch front plate or the touch rear plate squeezes a compression spring I or a compression spring II to push the shifting fork to move, a sliding side tooth I and a side tooth on the power mechanism are disengaged, power on the power mechanism is switched off, and thus the effect of protecting the scaffold is achieved.

Owner:浙江花园建设集团有限公司

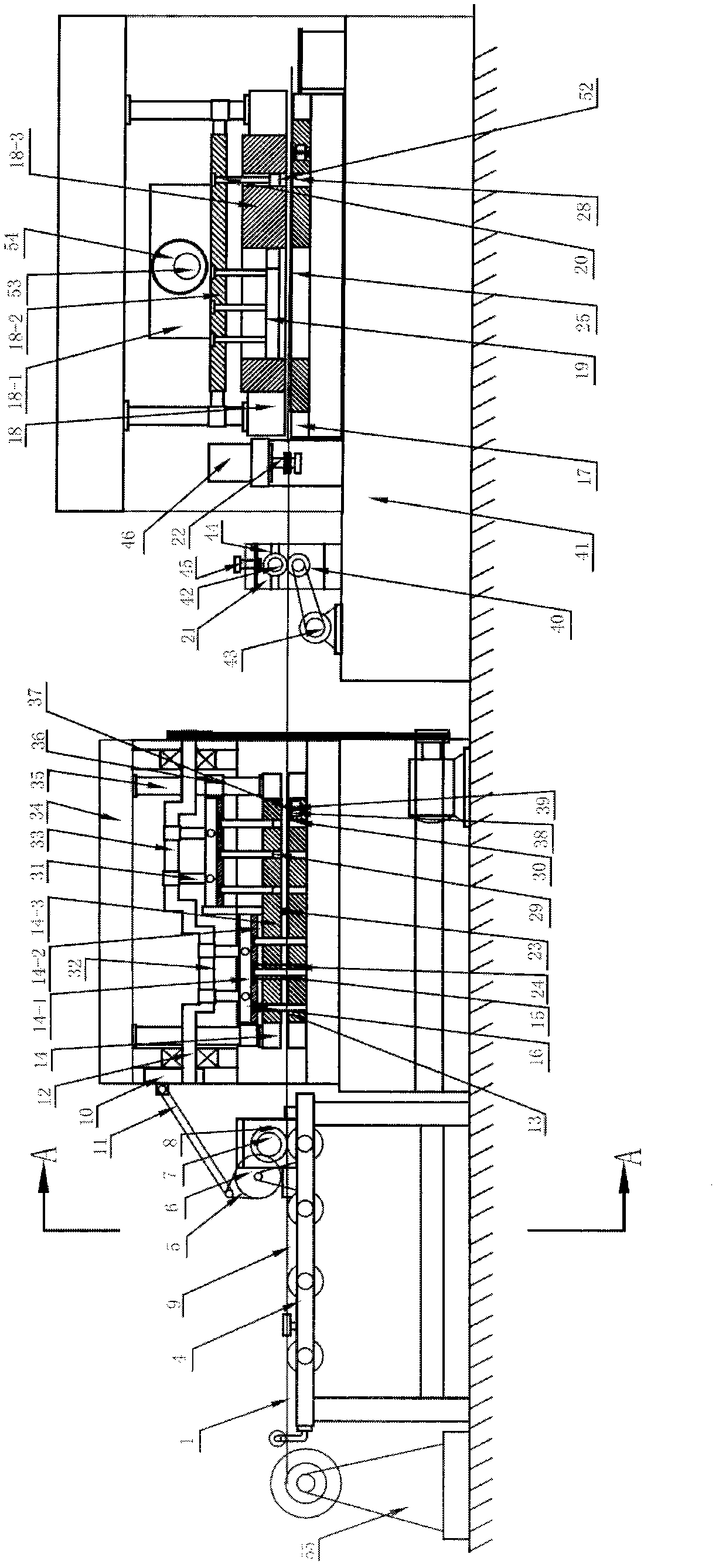

Stamping equipment for grid plates of lead-acid storage battery

ActiveCN103286188ASimple structureImprove work efficiencyPerforating toolsMetal-working feeding devicesPunch pressDrive shaft

The invention discloses stamping equipment for grid plates of a lead-acid storage battery. The stamping equipment comprises a first conveying mechanism for automatically conveying a rolled lead plate into a stamping machine, the stamping machine used for stamping the lead plate to generate side teeth and meshes, and a cutting and stamping machine used for cutting a continuous complete plate grid into the grid plates of the lead-acid storage battery, wherein the first conveying mechanism comprises a conveying platform; a second cam is arranged on one side of the conveying platform; the second cam and a first cam are hinged through a connecting rod to form a crank-rocker mechanism; the first cam is arranged at one end of a stamping machine drive shaft; a first female die and a first stamping die are arranged on the stamping machine; a stamping head used for stamping the side teeth and the meshes is arranged in the first stamping die; a second female die and a second stamping die are arranged on the stamping machine; a stamping head used for cutting off the side teeth and a stamping head used for cutting the complete plate grid into the grid plates of the lead-acid storage battery are arranged in the second stamping die; and a creasing mechanism and a second conveying mechanism for conveying materials into the stamping machine through the side teeth are arranged between the stamping machines.

Owner:JIANGSU DONGSHUN NEW ENERGY TECH

Planetary harmonic gear reducer

The invention provides a planetary harmonic gear reducer. The planetary harmonic gear reducer comprises a planetary harmonic inner gear ring, a gear frame, a flexible gear ring and an output shaft, wherein rigid inner teeth are arranged on the planetary harmonic inner gear ring; a harmonic coupling part is arranged on one side of the gear frame; the flexible gear ring is arranged in the harmonic inner gear ring; the harmonic coupling part is arranged on the position, corresponding to flexible outer teeth, on the flexible gear ring; the output shaft is provided with an outer gear ring; after being deformed by flexible side teeth or flexile inner teeth, the outer gear ring and the flexible gear ring are meshed with each other; the matching tooth number between the outer gear of the output shaft and the flexible side teeth or flexible inner teeth of the flexible gear ring is equal; the gear frame directly drives the harmonic coupling part to drive the flexible gear ring, so that after being deformed, the flexible gear ring is enabled to be subjected to harmonic meshing with the flexible inner teeth of the planetary harmonic inner gear ring, and meanwhile, after being deformed, the flexible gear ring is meshed with the outer gear ring of the output shaft, so that the output shaft is driven to finish reduction transmission. The working speed of the flexible gear ring is reduced, and the service life of the flexible gear ring is further prolonged.

Owner:朱祖良

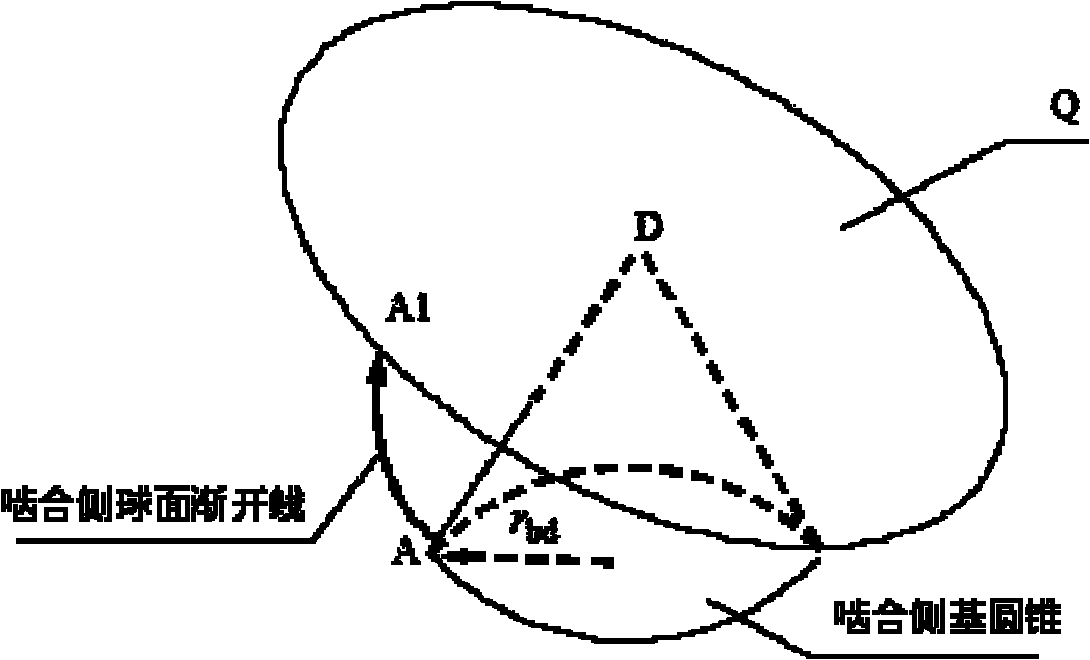

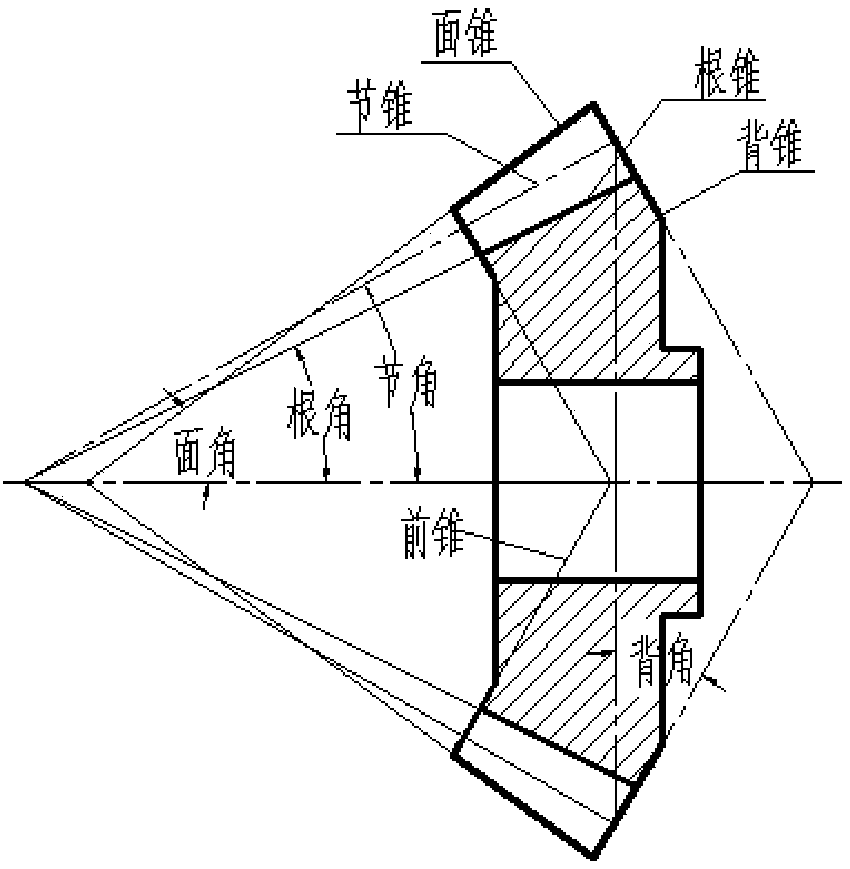

Plastic cone gear

InactiveCN102155528AGood transmission effectReduce volumePortable liftingGearing elementsGear wheelRooted tooth

The invention provides a plastic cone gear which can increase the fatigue resistance strength of a dedendum and basically does not affect the impact resistance performance of the dedendum; the plastic cone gear is characterized in that a meshing pendant group circular conical surface is worked out by taking rbd as a radius, a first occurrence surface is tangent to the meshing side base conical surface, and a line segment AD is a tangent line of the first occurrence surface and the meshing side base conical surface. When the first occurrence surface purely rolls without slipping along the meshing side base conical surface, the locus of a point A is a meshing side tooth profile curved surface of the plastic cone gear. A non-meshing side base conical surface is worked out by taking rbc as a radius, a second occurrence surface is tangent to a non-meshing side base conical surface, and a line segment BC is a tangent line of the second occurrence surface and the non-meshing side base conical surface. When the second occurrence surface purely rolls without slipping along the non-meshing side base conical surface, the locus of a point B is a non-meshing side tooth profile curved surface of the plastic cone gear. The wheel gear reference circle modulus and tooth depth modulus of the plastic cone gear are unequal; and the design method of big tooth addendum coefficients is adopted.

Owner:JIANGSU UNIV OF TECH

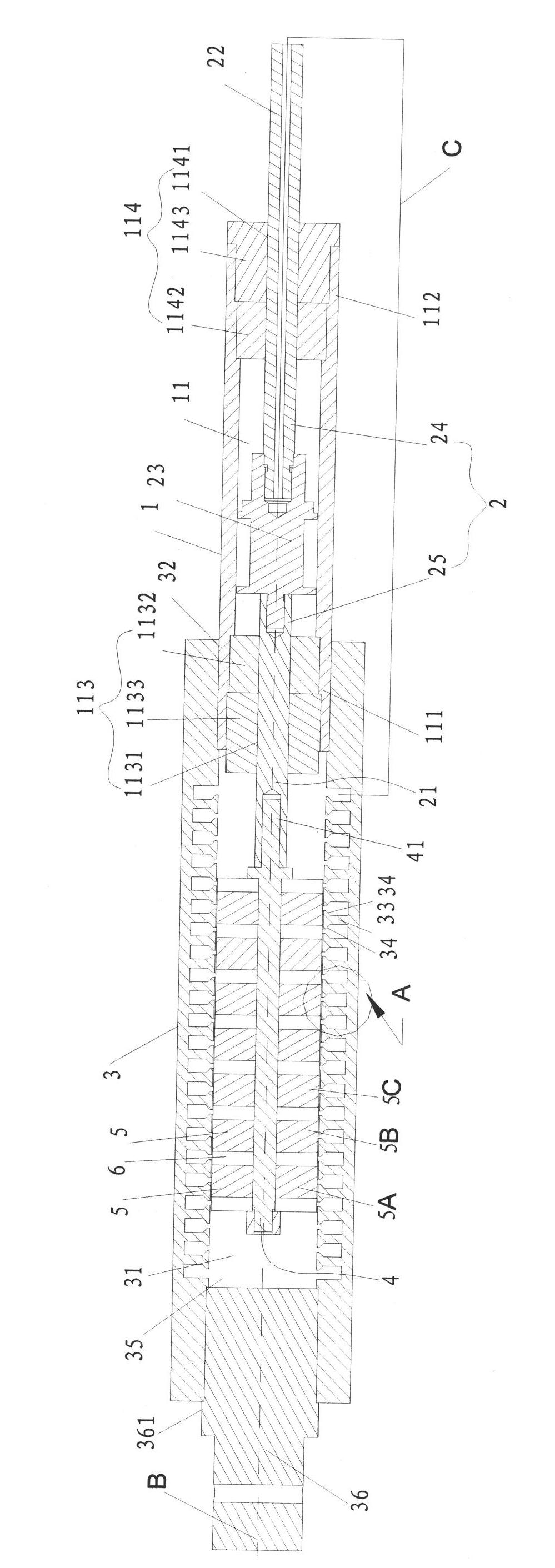

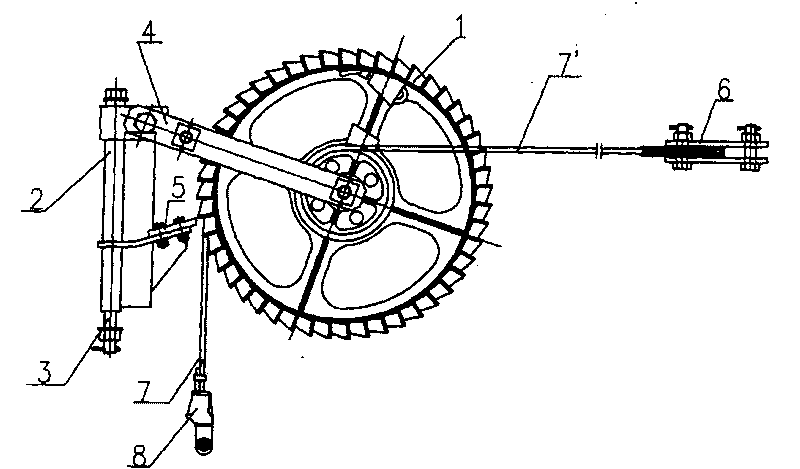

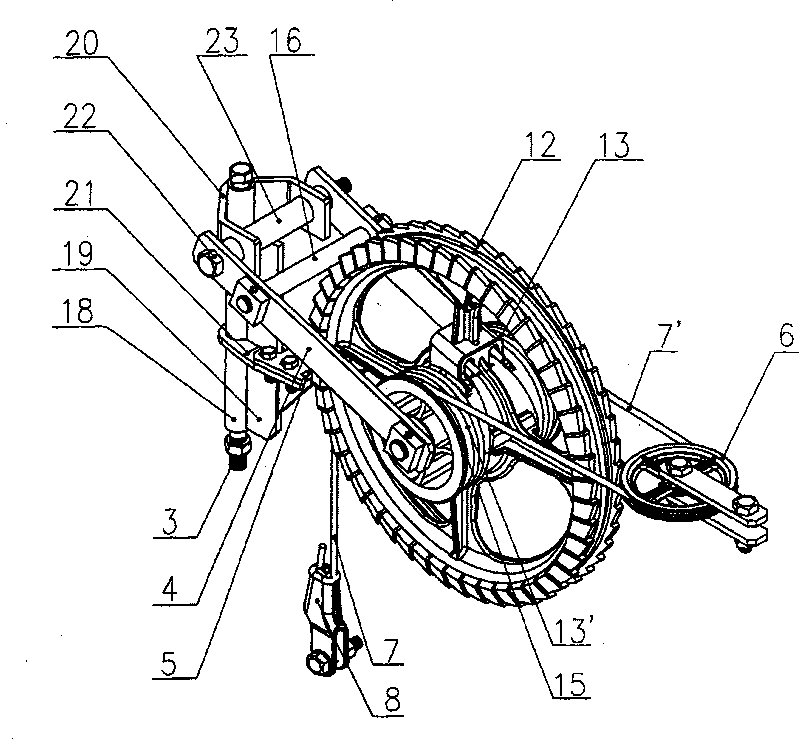

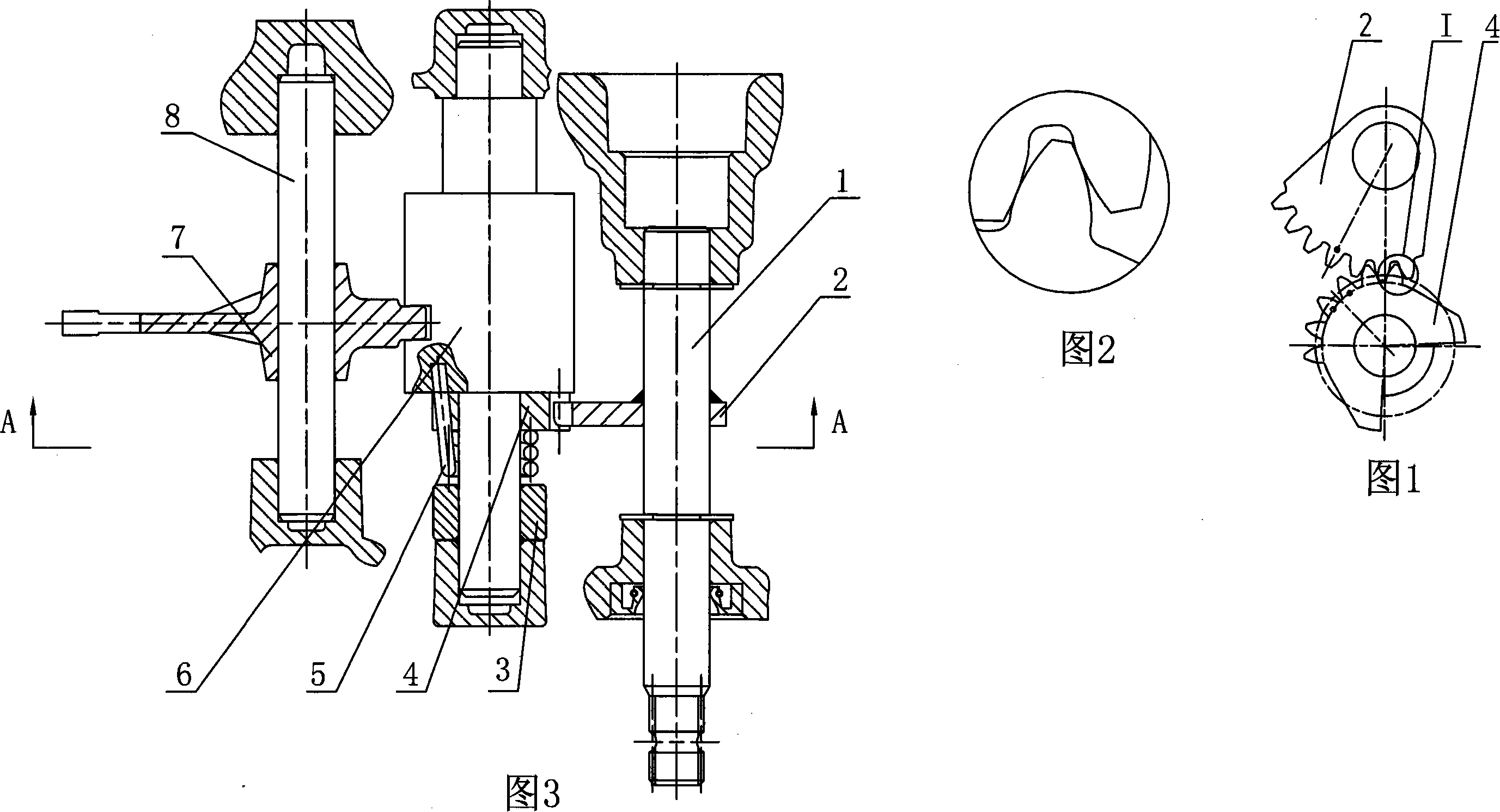

Bevel ratchet wheel compensating device

ActiveCN101716893AStrong impactComprehensive braking performance reliable insuranceTrolley linesManufacturing technologyEngineering

The invention provides a bevel ratchet wheel compensating device, comprising a ratchet wheel body (1), a ratchet wheel brake frame (2), a long bolt pin (3), a ratchet wheel framework connecting plate (4), a brake pallet (5), a balance wheel (6), a steel wire rope I (7), a steel wire rope II (7') and a cable clamp (8), wherein two rows of symmetrical bevel gears are arranged on the excircle of a bull wheel (12) of the ratchet wheel body (1), the bevel gear is composed of straight teeth (24) and side teeth (25), the straight teeth (24) are arranged at two sides of the circumference surface of the bull wheel (12), and side teeth (25) are arranged at the side wall of the bull wheel (12); and the front end of the brake pallet (5) is provided with a U-shaped brake port (26) of which the width is consistent with the spacing of the bottom parts of the two side teeth (25). In the invention, the ratchet adopts a bevel structure formed by the straight teeth and the side teeth; by optimizing the structure design, the manufacture technology is simplified, the safe use performance is improved so as to lead the working tension to reach 38.85kN and compensation distance to reach 800m, thus not only satisfying the requirements on high tension and large compensation distance for a high-speed electrified railway contact line, but also having convenient installation and maintenance.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

Side tooth gage reamer

The invention relates to a side tooth gage reamer which is characterized by mainly comprising a reamer body and toothed wheel assemblies comprising toothed wheels and toothed wheel seats, wherein the reamer body mainly comprises a body mandrel of which two ends are provided with drill rod joint threads, an annular plate, a main plate, a front guide plate, a rear guide plate, a radial water pipe and an inclined water pipe; the front guide plate, the annular plate, the main plate and the rear guide plate are sequentially and fixedly connected to the box mandrel from front to back; not less than three toothed wheel seat mounting holes are uniformly distributed on the circumference of the main plate; the radial water pipe is arranged behind the front guide plate and passes through the body mandrel; and the inclined water pipe is arranged between the toothed wheel assemblies at the front side of the main plate and radially passes through the body mandrel. The invention has the advantages that the replaceable toothed wheel assemblies are adopted, and the reamer can be continuously used only by replacing new toothed wheel assemblies; and in the toothed wheel assembly, the toothed wheel seat is used for replacing a palm back, thereby avoiding damages caused by rock debris and sediments at the bottoms of hole walls and indirectly protecting a sealing system of toothed wheel assembly bearings.

Owner:TIANJIN LILIN BIT

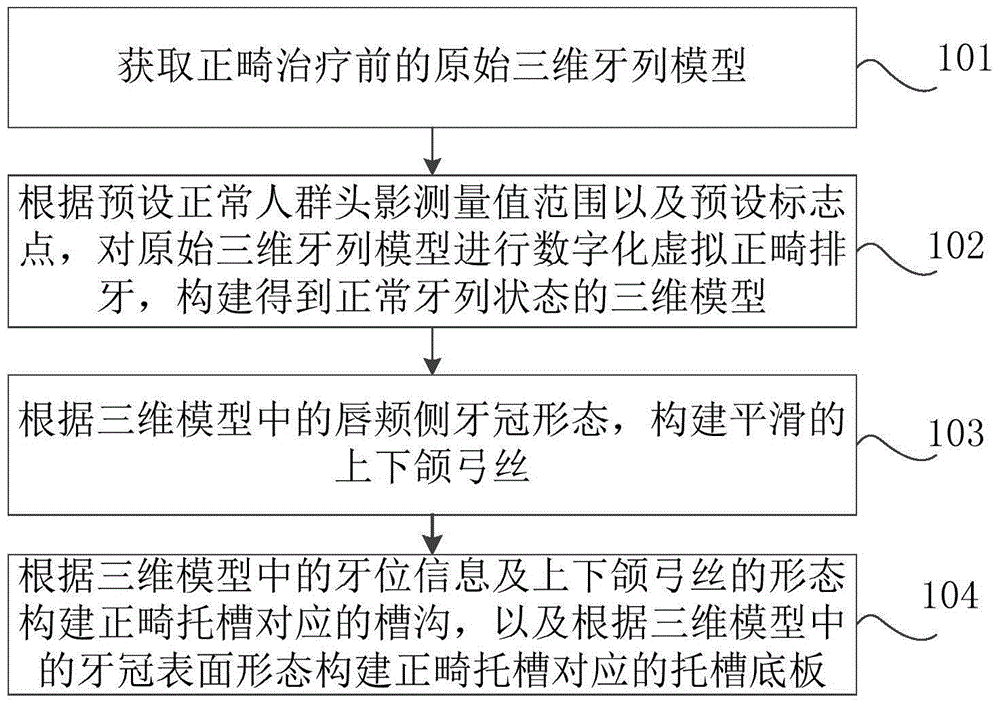

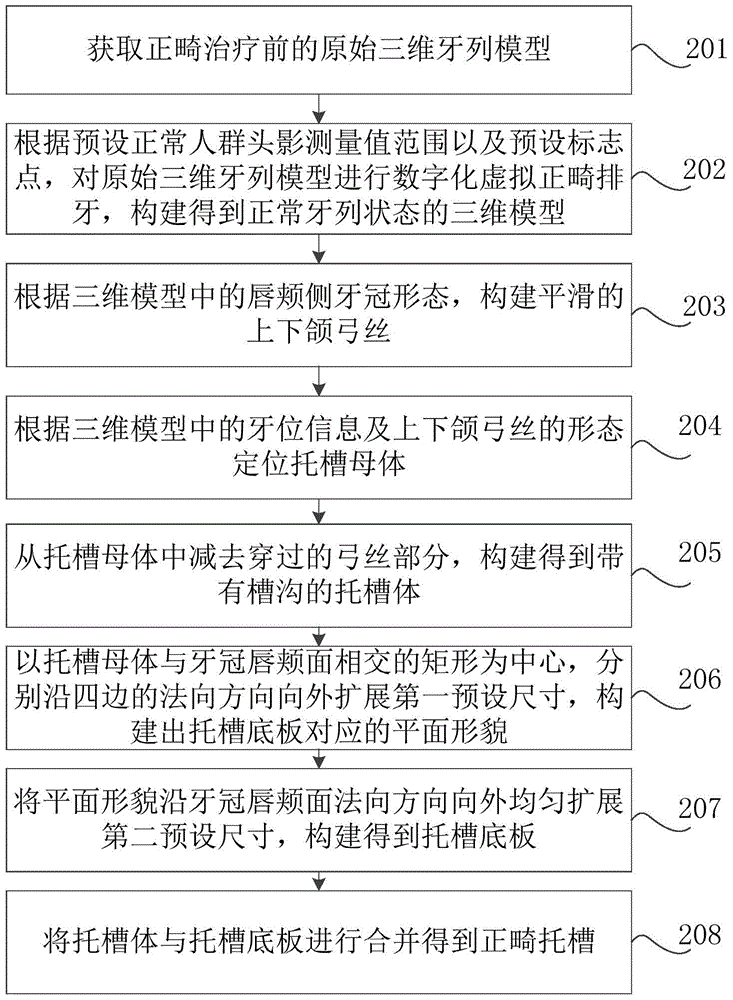

Method and device for manufacturing orthodontic bracket

InactiveCN105708565AGood effectImprove efficiencyBracketsAnatomical structuresManufacturing technology

The invention discloses a method and device for manufacturing an orthodontic bracket and relates to the technical field of orthodontic bracket manufacturing, by means of the method and device for manufacturing the orthodontic bracket, the personalized orthodontic bracket can be manufactured according to the unique tooth three-dimensional anatomical structure of each patient, and the effect and efficiency of orthodontic treatment can be improved.The method includes the steps that firstly, an original three-dimensional tooth column model before orthodontic treatment is obtained; then, digital virtual orthodontic tooth arrangement is conducted on the original three-dimensional tooth column model according to the preset head shadow measurement value range of normal people and preset mark points, and a three-dimensional model of a normal tooth column state is constructed; smooth maxillary arch wires and mandibular arch wires are constructed according to the lip buccal side tooth crown state in the three-dimensional model; finally, a bracket gutter corresponding to the orthodontic bracket is constructed according to the tooth position information in the three-dimensional model and the states of the maxillary arch wires and mandibular arch wires, and a bracket bottom plate corresponding to the orthodontic bracket is constructed according to the dental crown surface form in the three-dimensional model.The method and device are suitable for processing the orthodontic bracket.

Owner:北京正齐口腔医疗技术有限公司

Gear shift mechanism of engine speed changer

The invention discloses a gearshift for a gearbox of an engine. Wherein, a driving segment gear is fixed on a gear-shifting shaft, a driven segment gear is clearance fit on the shaft of a shifting hub, and forms flexible connection with the shifting hub through a torsional spring; the driven segment gear is engaged with the driving segment gear; a drive fork is clearance fit on a drive-fork shaft; one end of the drive fork is clearance fit on a cam slot provided on the shifting hub; the driven segment gear is in dovetail segment gear structure, the two sides of the dovetail are correspondingly intercrossed with the tooth profile evolvent of the side teeth at the head and tail of the gear at any location between the indexing circle and the tooth crest circle of the gear; the extended lines of the two sides of the dovetail extend toward the gear and intercrosses. By a driven segment gear to avoid over rotation of the driving segment gear, the invention can avoid the disengagement between the driving and driven segment gear, and guarantee the reliability in gear shifting.

Owner:LONCIN MOTOR

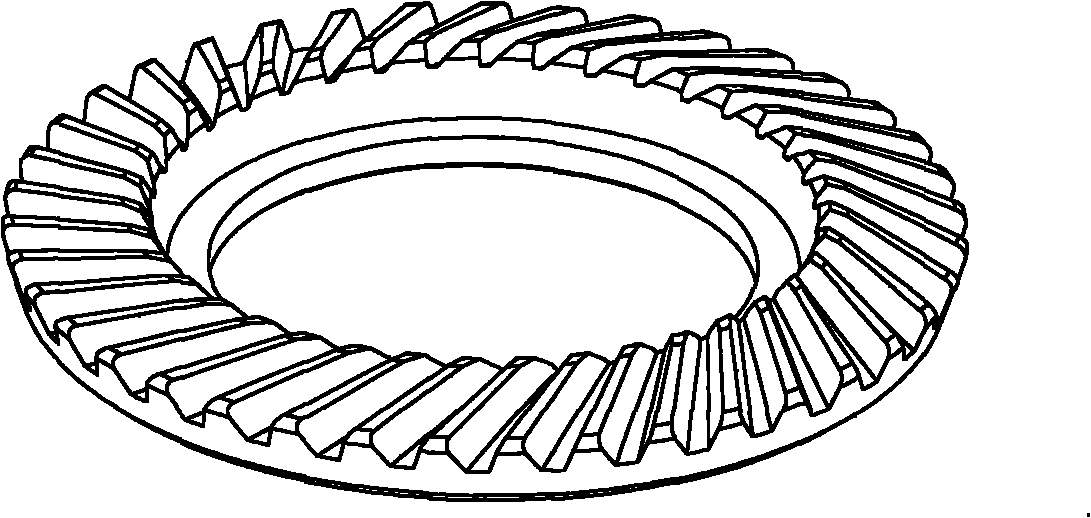

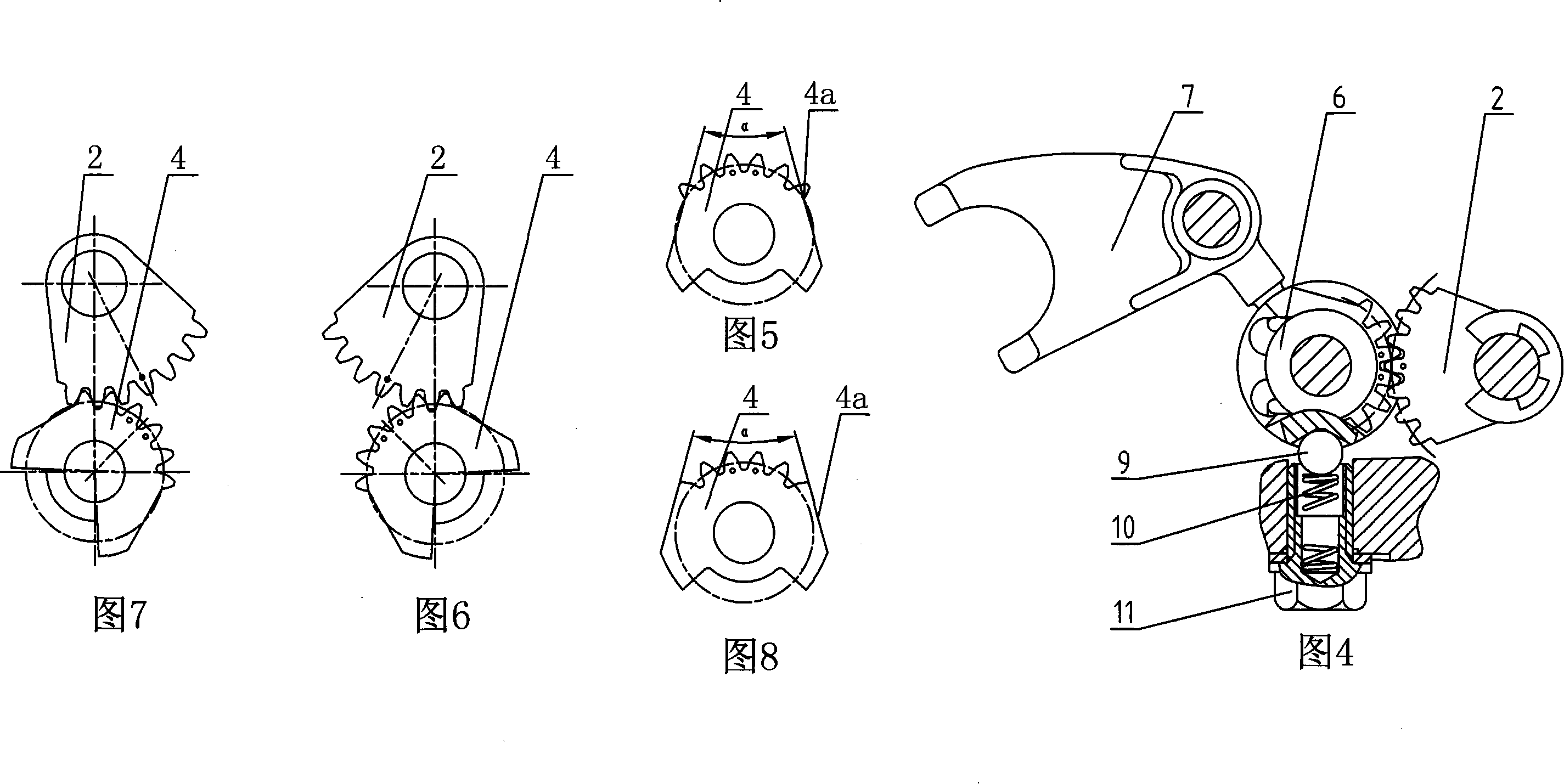

Design method for tooth profile of double-base cone spiral bevel gear

ActiveCN104196981AImprove performanceImprove carrying capacityPortable liftingGearing elementsLarge toothGear wheel

The invention provides a design method for a tooth profile of a double-base cone spiral bevel gear and relates to gears. According to the double-base cone spiral bevel gear, five conical surfaces, four cone angles and two base cones are arranged; the normal tooth profile of each gear tooth comprises an addendum circle, a root circle, a driving side tooth curve, a non-driving side tooth curve and a tooth directional line; the five cone surfaces are a surface cone, a root cone, a pitch cone, a back cone and a front cone respectively; the four cone angles are a face angle, a root angle, a pitch angle and a back angle respectively; for vehicles with gear transmission mechanisms mainly depending on one-way transmission, the property of the spiral bevel gear is improved; the design method for the tooth profile of the double-based cone spiral bevel gear provided by the invention has the advantages that as large tooth profile angles are adopted in the driving surface and small tooth profile angles are adopted in the non-driving surface, the bearing capacity of the gear in the driving direction is increased and the top of tooth is prevented from being tapered, the bearing capacity, fatigue life and output torque of the spiral bevel gear are improved effectively and the vibration and noise in the transmission are reduced.

Owner:XIAMEN ZHEN-WEI TECH CO LED

Permanent magnet linear generator, magnetorheological damper and magnetorheological damping system thereof

InactiveCN102223049AImprove the utilization of magnetic fieldIncrease power generation rateNon-rotating vibration suppressionDynamo-electric machinesForce linesClosed loop

The invention discloses a permanent magnet linear generator, a magnetorheological damper and a magnetorheological damping system. The permanent magnet linear generator comprises a stator, a connection rod and a plurality of permanent magnets; the stator comprises an accommodation chamber with a telescopic mouth; the inner wall of the accommodation chamber is provided with a plurality of convex teeth at intervals; two opposite sides of the top end of each convex tooth extend along an axial direction of the accommodation chamber to form side teeth; the convex teeth and the side teeth are made of a permeability material, and the adjacent convex tooth and side tooth form a groove for accommodating an electromagnetic coil; the connection rod is positioned in the accommodation chamber of the stator, and is provided with a first connection end extending out of the telescopic mouth; and the plurality of permanent magnets are connected with the connection rod, and a magnetic pole is arranged between the adjacent permanent magnets. By the design of the convex teeth and the side teeth, more magnetic force lines pass through an air gap to form a closed-loop circuit; the utilization rate of a permanent magnet magnetic field is improved; and a value of an induced electromotive force is increased, and the electricity generation rate is high.

Owner:JIAXING UNIV

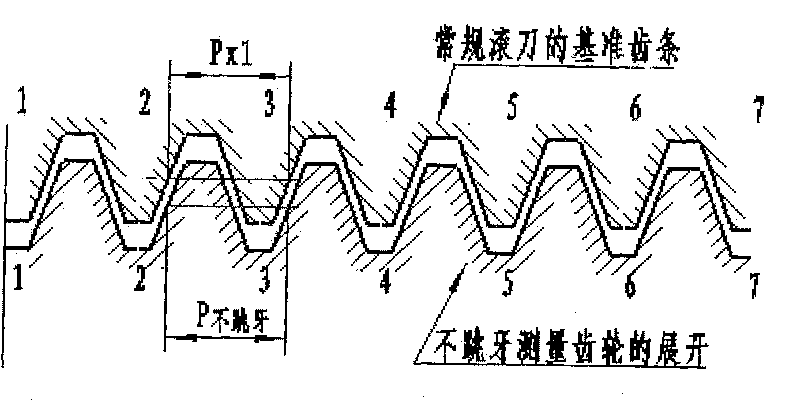

Method for manufacturing micro nth skipping-thread measuring gear

Owner:CHENGDU TOOL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com