Plastic cone gear

A technology of bevel gears and plastics, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem that the transmission performance of the gear transmission system cannot reach the best, and achieve light weight and broad application prospects , the effect of easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

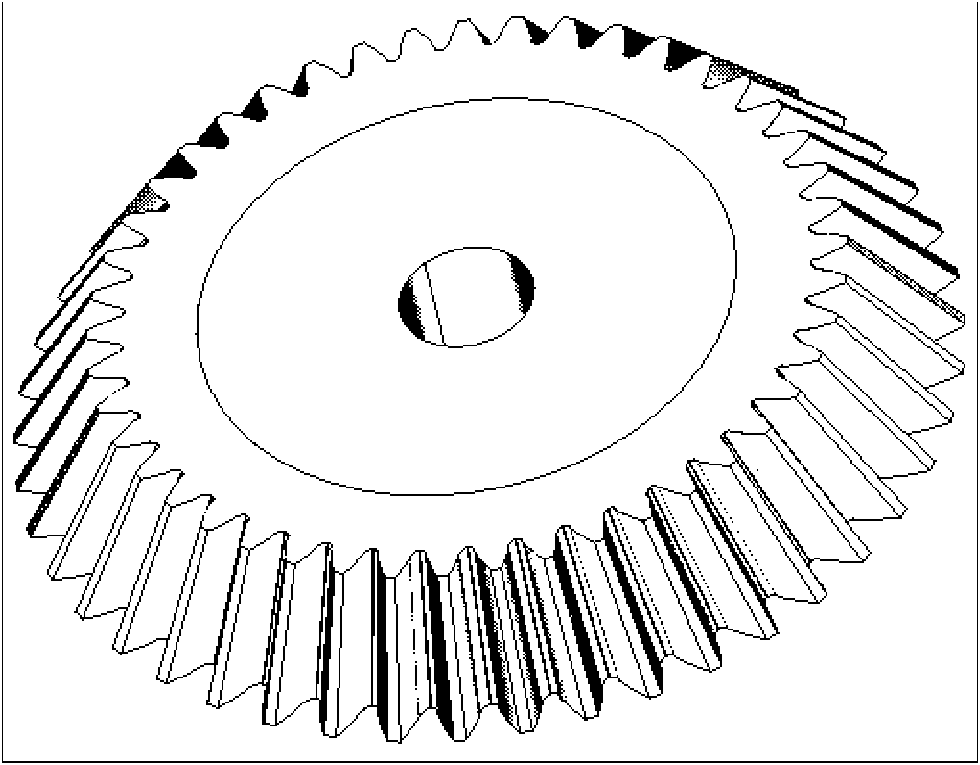

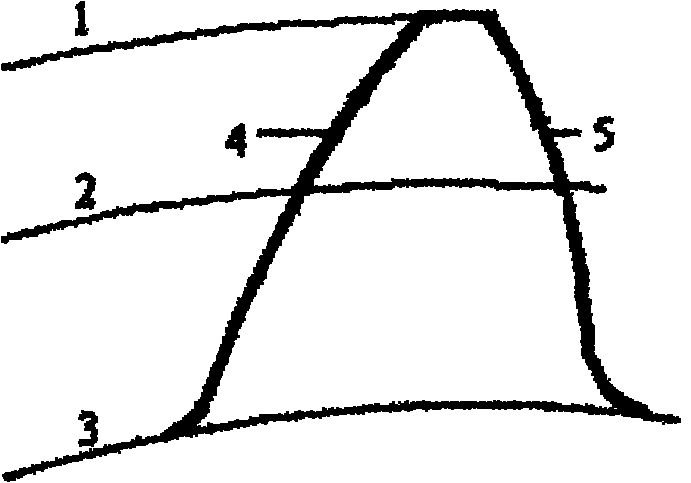

[0017] See Figure 1-2 , The tooth profile of the plastic bevel gear of the present embodiment mainly includes tooth top 1, dedendum 3, meshing side tooth profile 4, non-meshing side tooth profile 5 (large and small end tooth profiles have the same structure).

[0018] The principle of tooth profile surface generation is as follows:

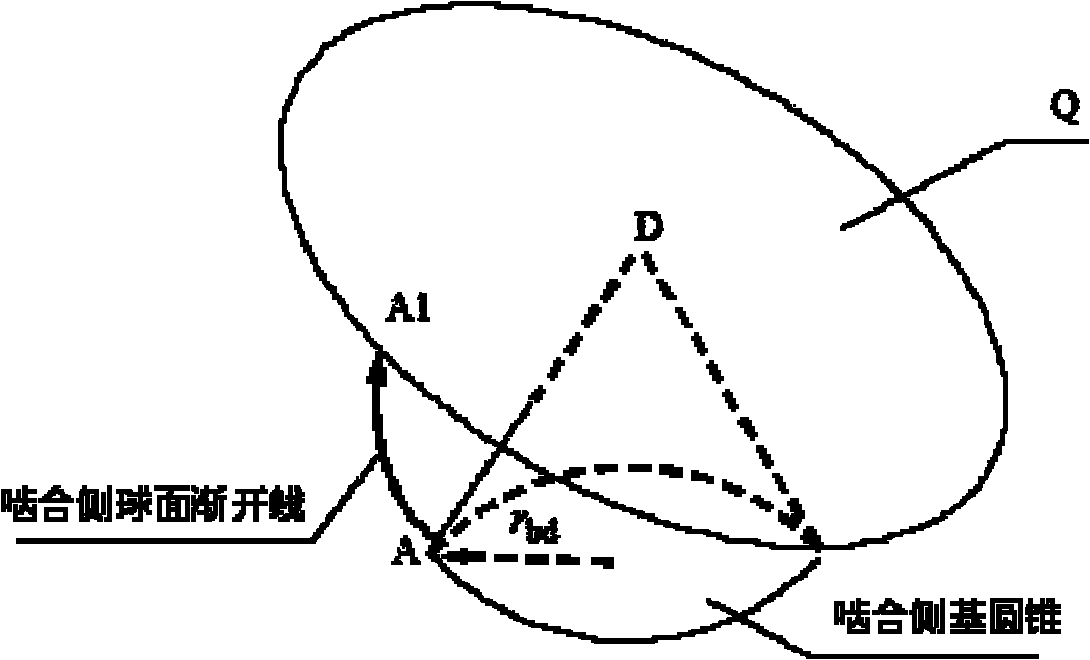

[0019] with r bd Make the meshing side base conical surface of the plastic bevel gear as the radius of the bottom surface, and there is a first occurrence surface Q that is tangent to the meshing side base conical surface, and a line segment is formed when the first occurrence surface Q is tangent to the meshing side base conical surface AD, where point A is on the bottom surface of the meshing side base cone, and point D is the apex of the meshing side base cone; when the first occurrence surface Q performs pure rolling without sliding along the meshing side base cone surface, the Trajectory AA 1 It is the tooth profile surface of the meshing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com