High speed transmission toothed chain and chain wheel

A high-speed transmission, toothed chain technology, applied in the direction of transmission chain, belt/chain/gear, transmission device, etc., can solve the problems of high cost, difficult to popularize and apply, complicated process, etc., and achieve the effect of eliminating the position change of the meshing line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the patent of the present invention will be further explained below in conjunction with the drawings.

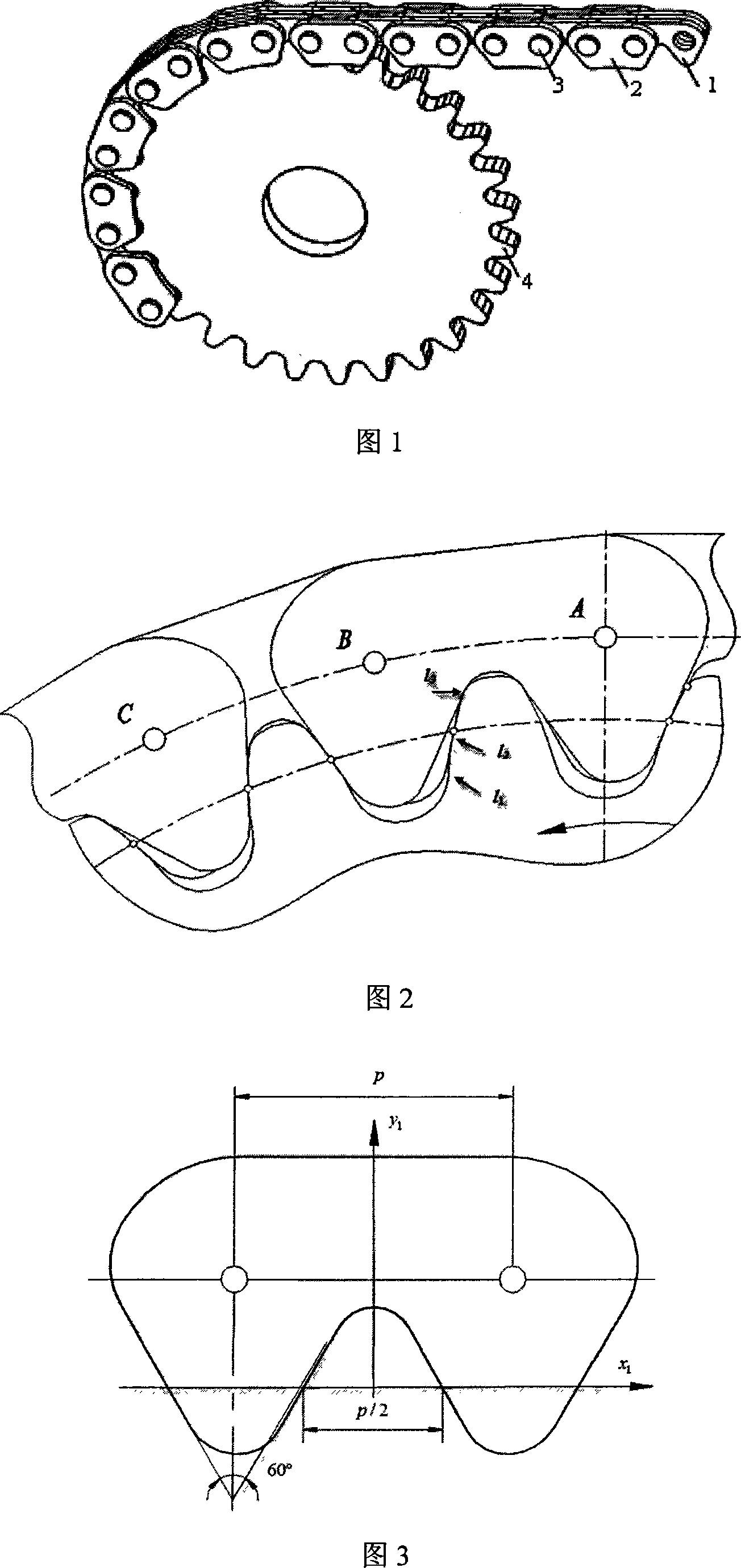

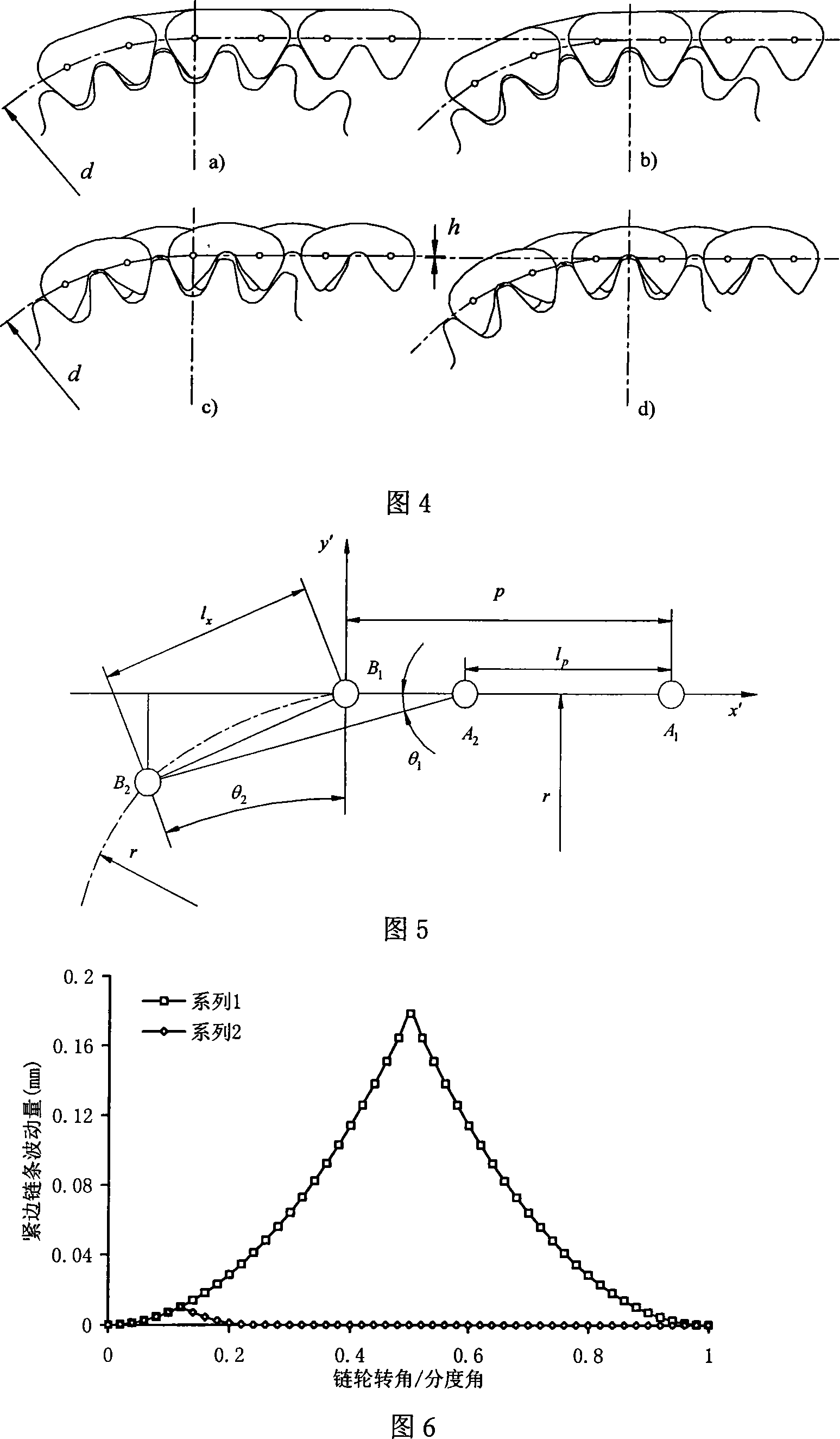

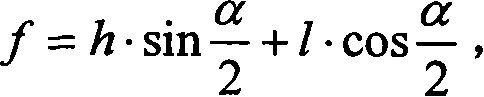

[0026] The toothed chain drive includes a double-sided meshing chain plate, an outer guide plate, a cylindrical pin, a driving sprocket and a driven sprocket. The inner and outer tooth profiles of the double-sided meshing chain plate 1 are linear, and the inner and outer tooth profiles can be meshed with the new toothed sprocket during the meshing process. The outer guide plate 2 enables the chain to be positioned on both sides of the sprocket in the axial direction, which can avoid the chain's axial movement. The cylindrical pin 3 connects the chain plate and the guide plate at the same position in the axial direction of the sprocket. The tooth profile of the new sprocket 4 is composed of a transition curve, an involute, and a modified involute except for the tooth profile of the tooth root and the tooth tip. The sprocket can reduce the impact at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com