Patents

Literature

103results about How to "Stable positional relationship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

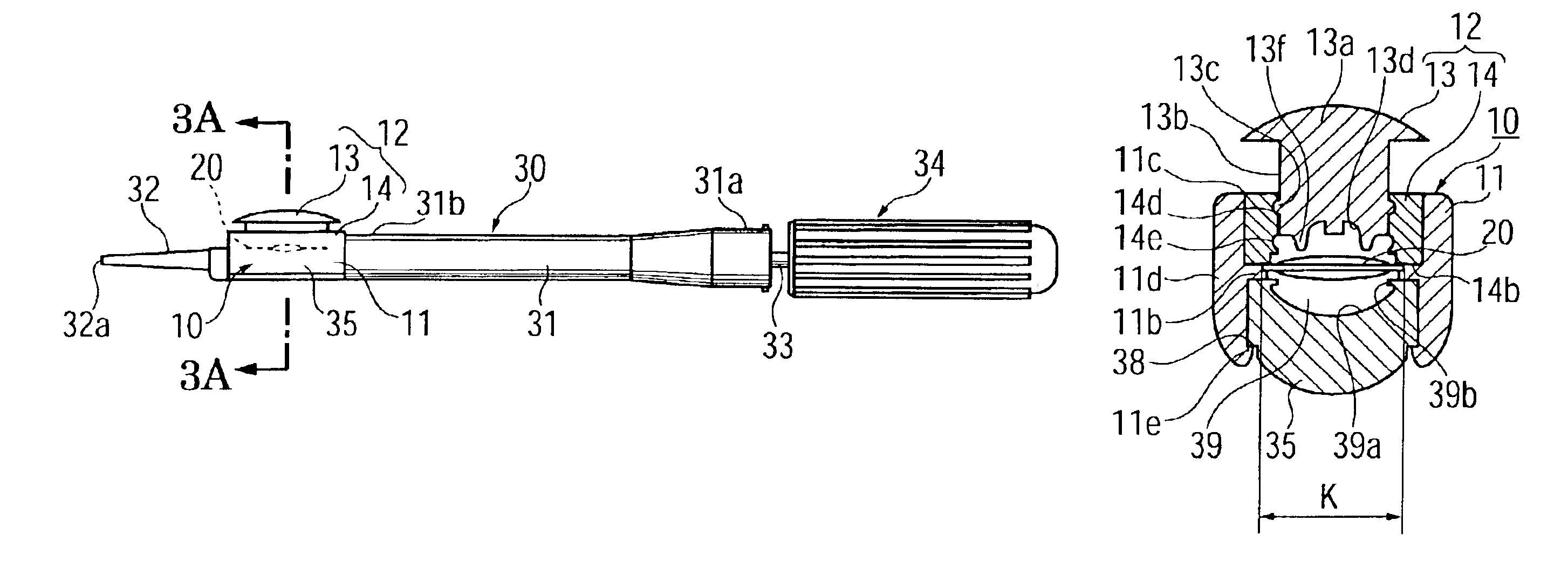

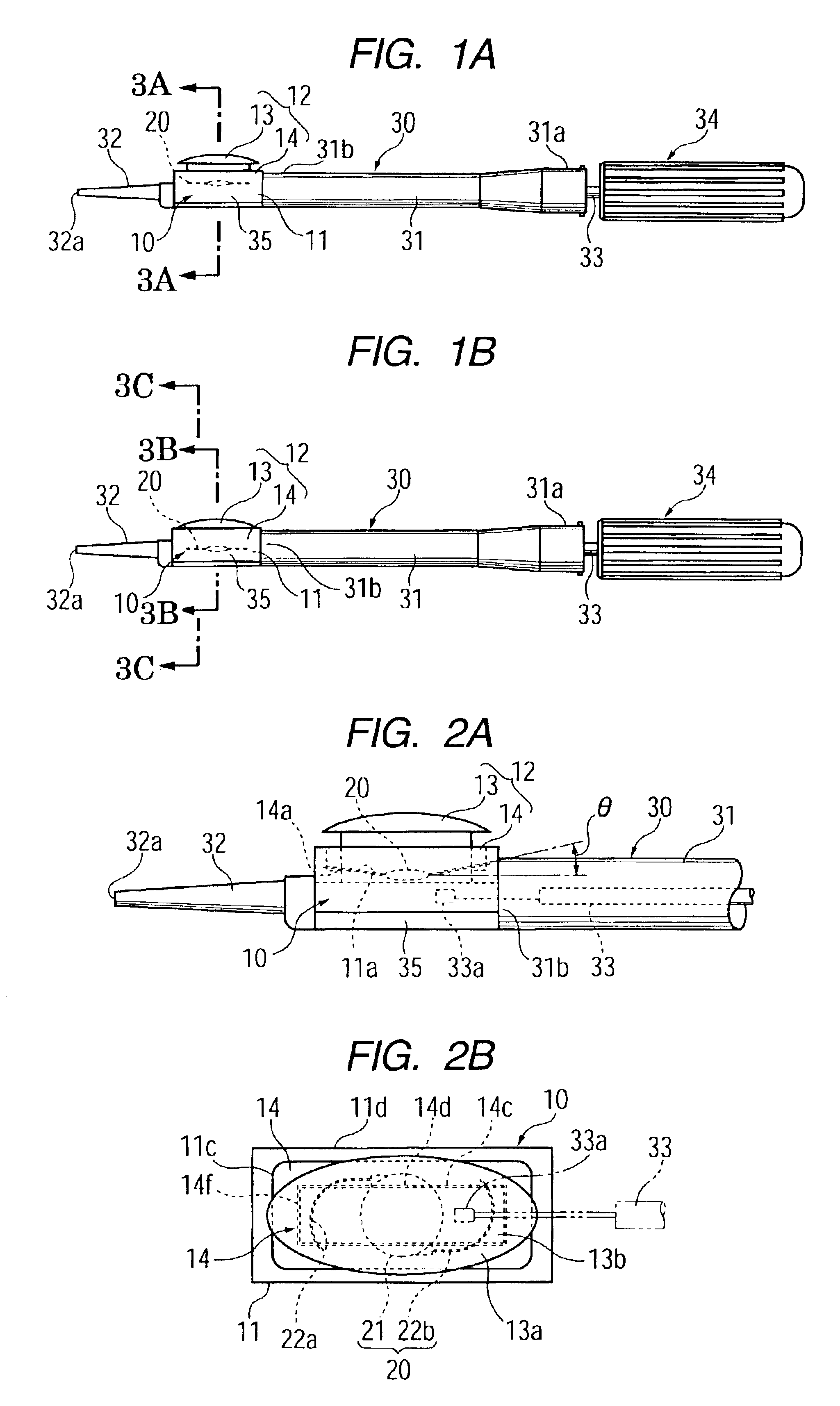

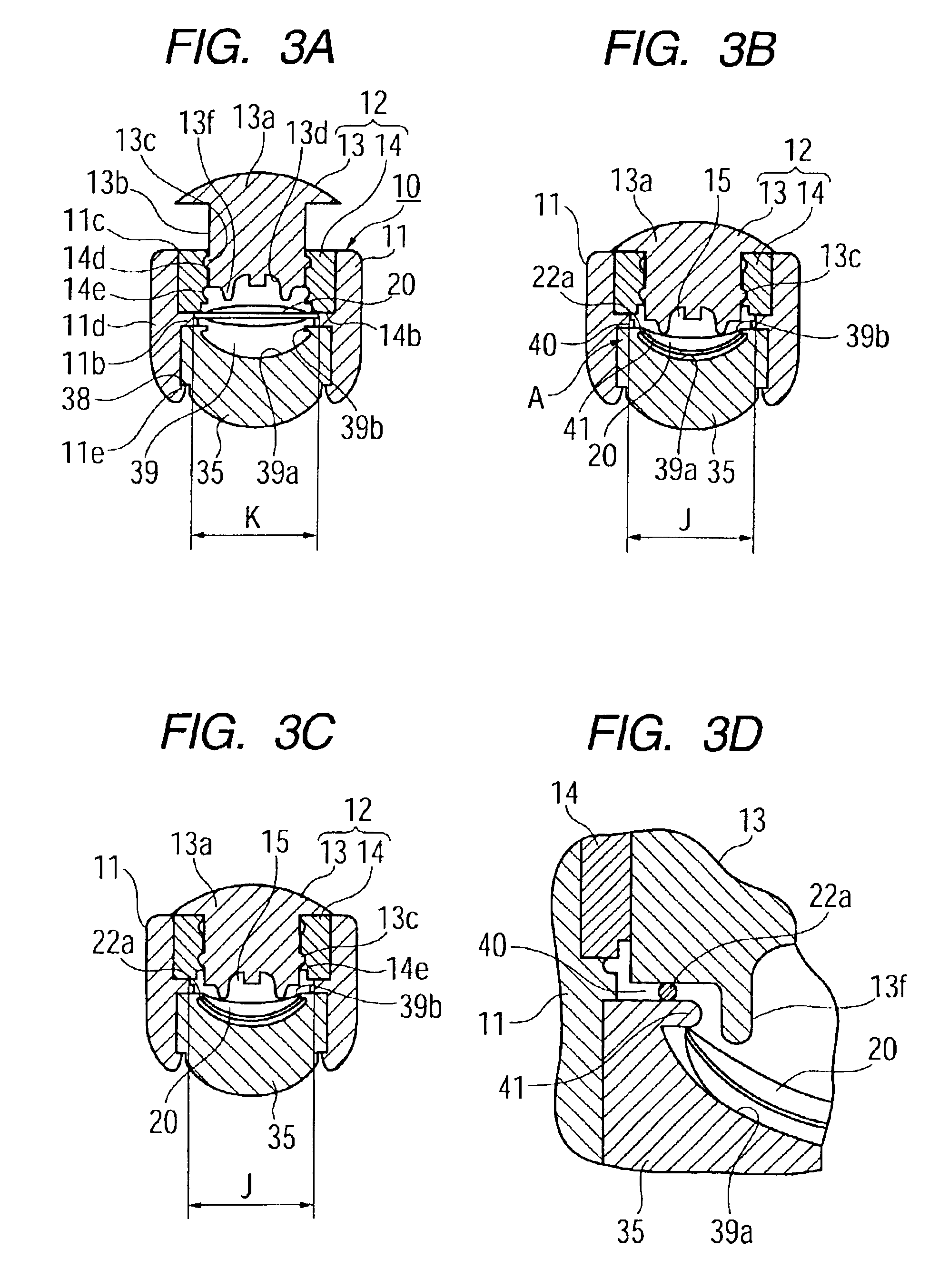

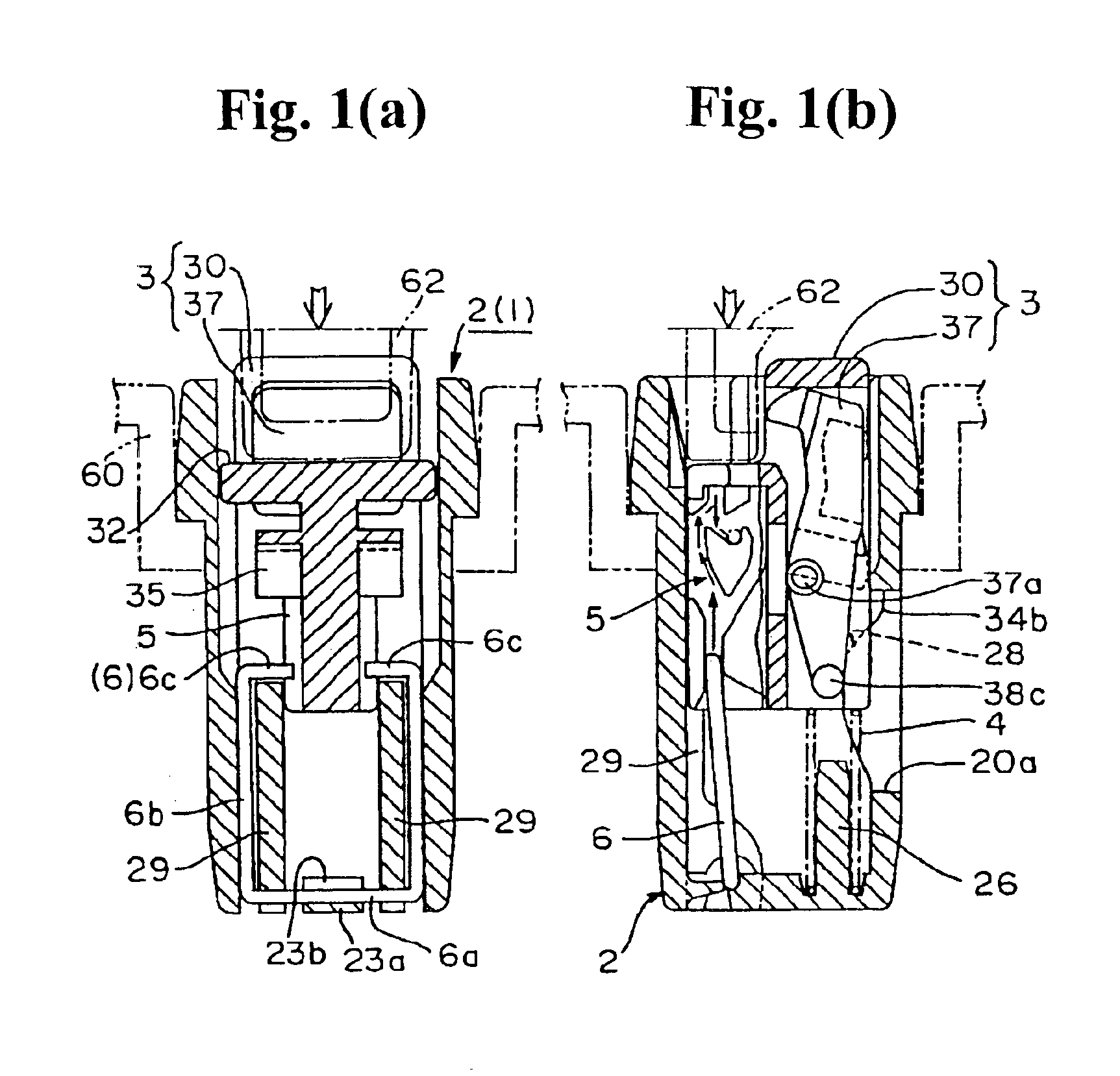

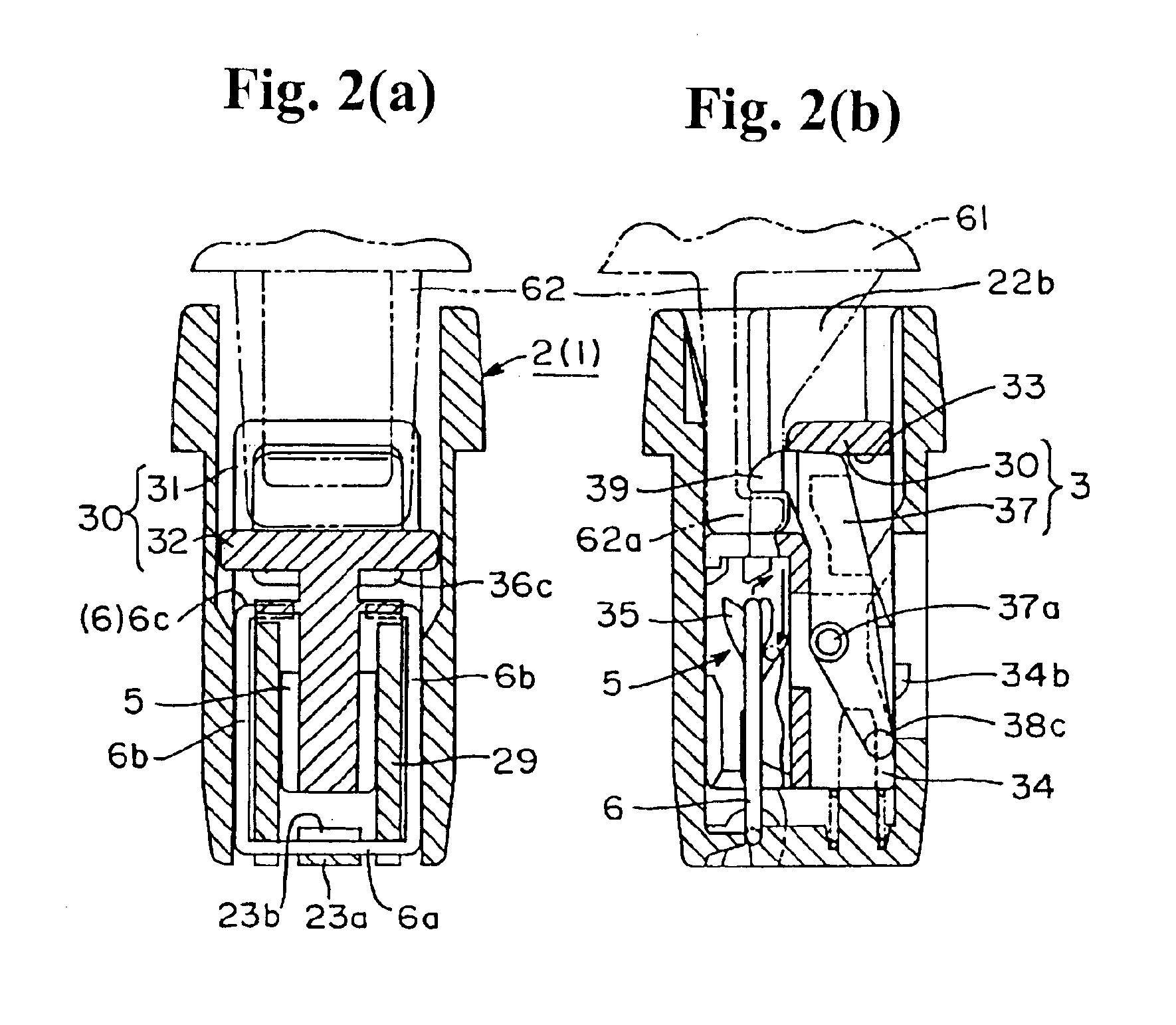

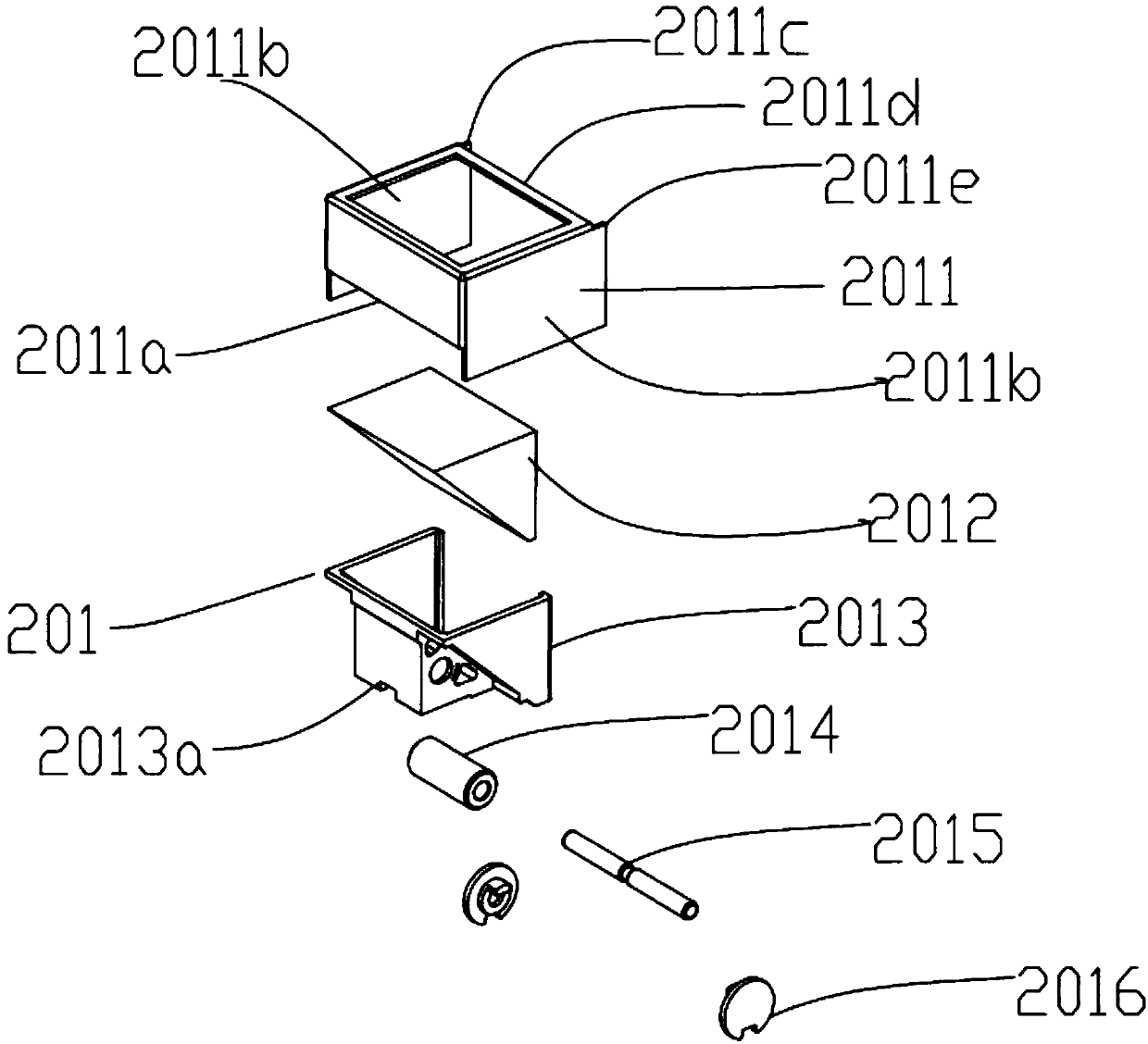

Insertion system for intraocular lens

InactiveUS6858033B2Stable positional relationshipReduce necessityEye surgeryIntraocular lensCamera lensIntraocular lens

An insertion system for an intraocular lens having a deformable optical portion and loop-shaped support portions for supporting the optical portion within an eye includes a holding member for holding the intraocular lens at a standby position in a state in which no stress acts on the optical portion of the lens; a deforming member for deforming the lens to a reduced size; an insertion tube through which the deformed lens is inserted into the eye; a pusher mechanism having a push rod for pushing and inserting the lens into the eye; and a lens moving mechanism for moving the lens from the standby position to an insertion position at which the pusher mechanism can push and insert the lens into the eye. When the lens is moved to the insertion position, the optical portion and the support portions of the lens are placed in different spaces in order to fix the positional relationship between the optical portion and the support portions of the lens.

Owner:STAAR JAPAN

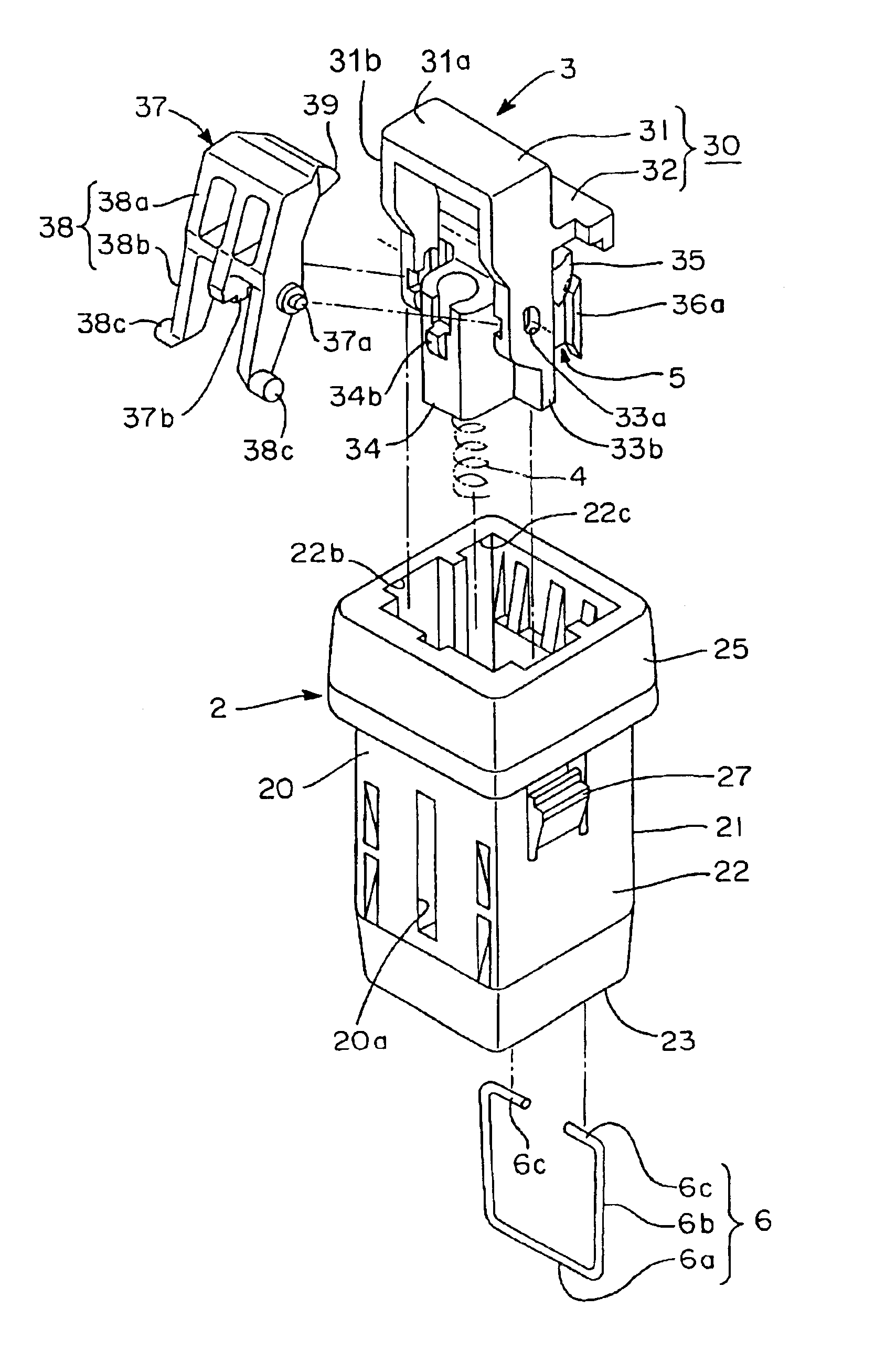

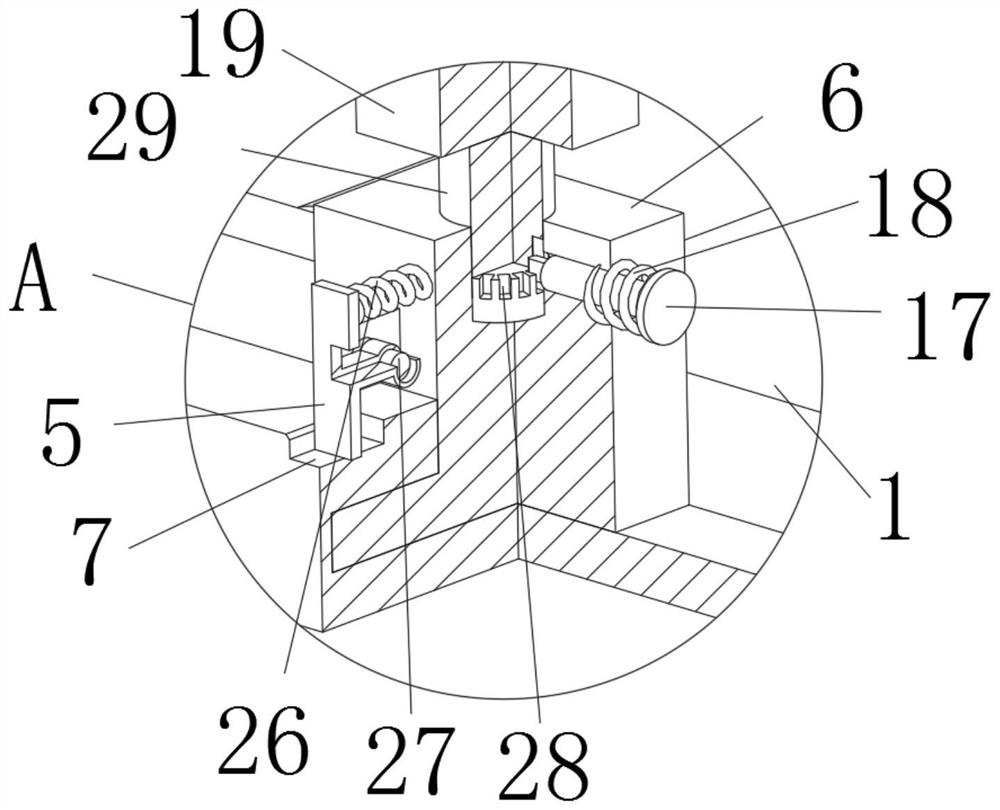

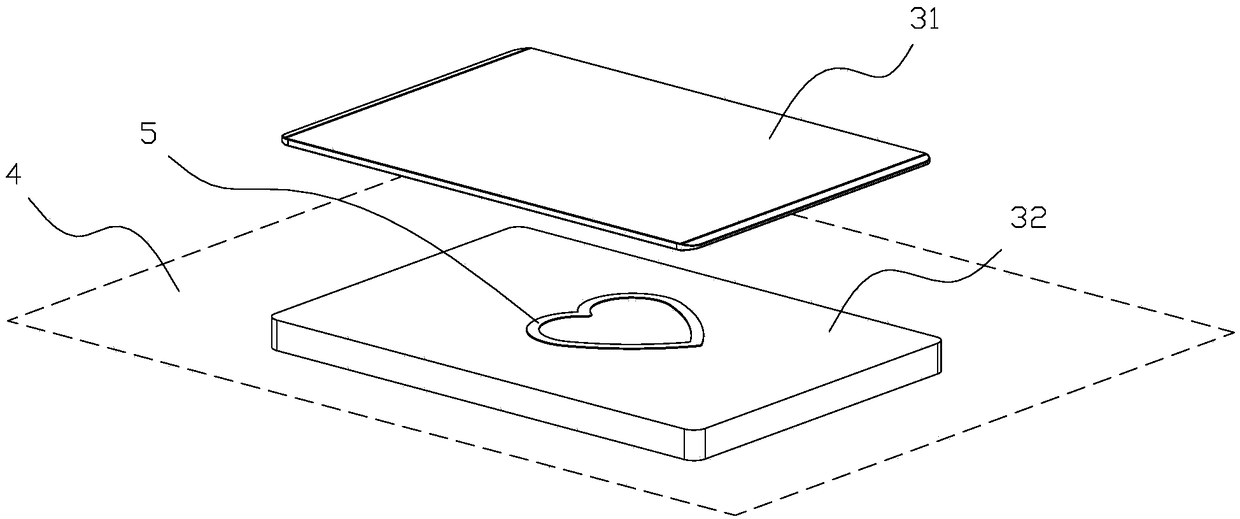

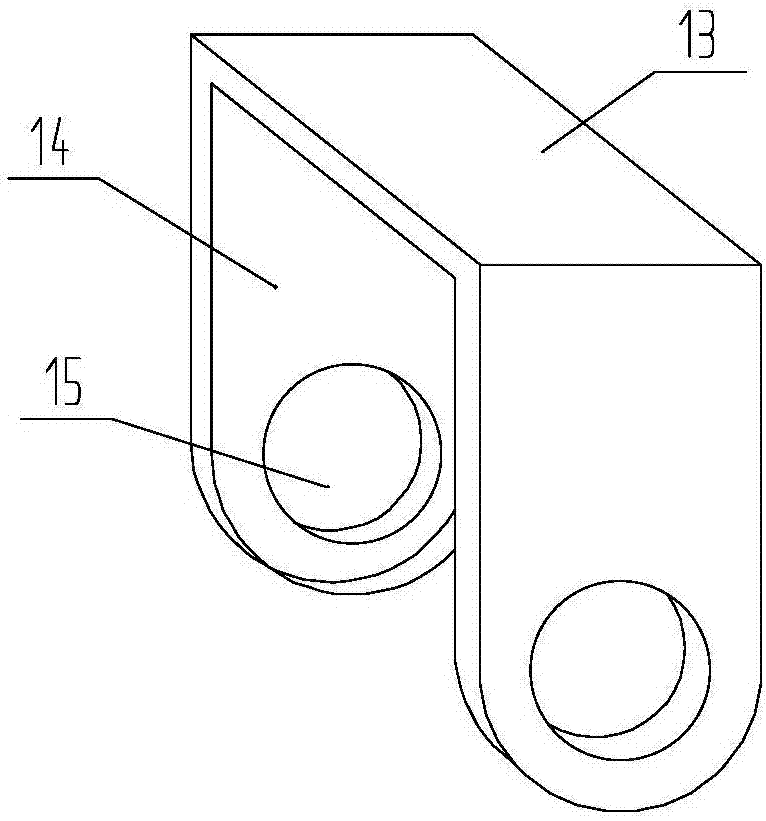

Latch device

A latch device engages and releases a striker by push-and-push operations. The latch device includes a case having an opening for receiving the striker therethrough, a latch member disposed inside the case and being able to be switched between an engagement position where the striker is prevented from being removed and a release position where the striker can be removed, a spring member for urging the latch member to the release position, generally heart-shaped cam grooves symmetrically provided on two sides of the latch member, and a pin member having a general U-shape and disposed inside the case. The pin member includes a U-shape intermediate portion disposed on a side opposite to the opening of the case, and edges formed at U-shape side portions. The edges project toward each other to engage and trace the cam grooves.

Owner:NIFCO INC

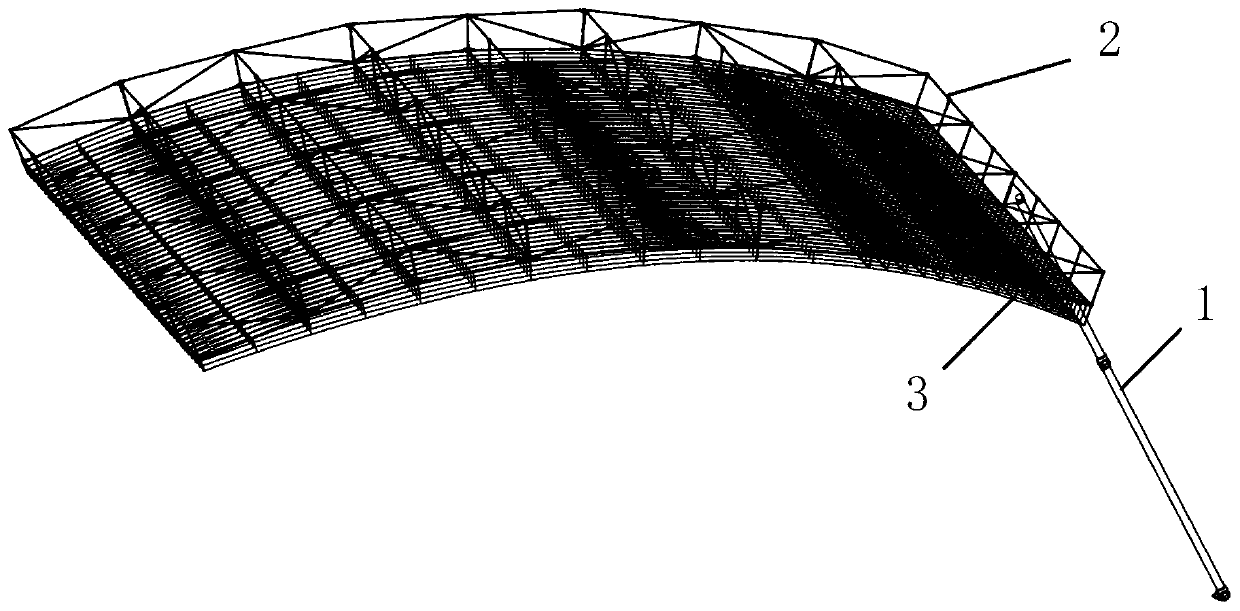

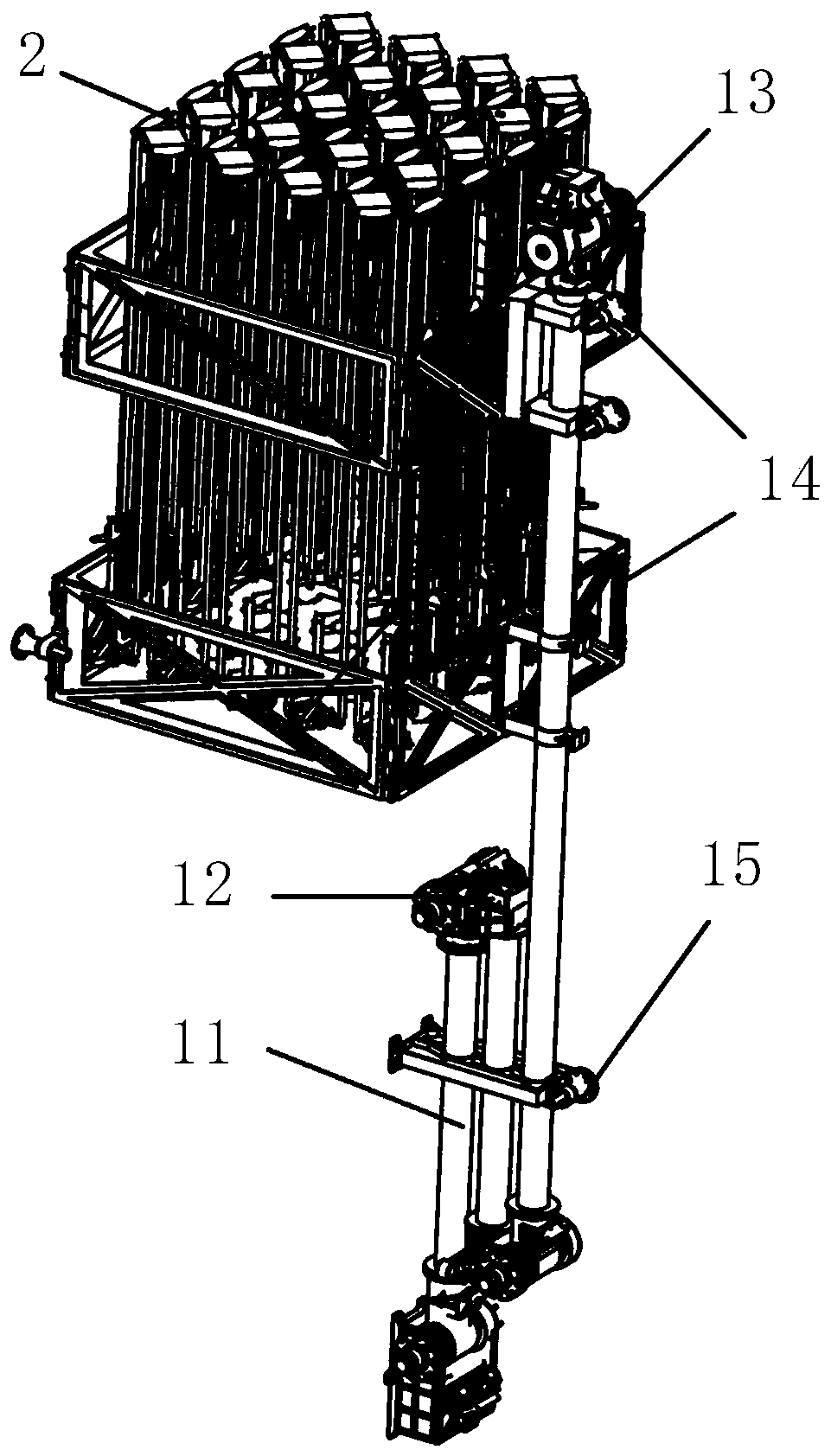

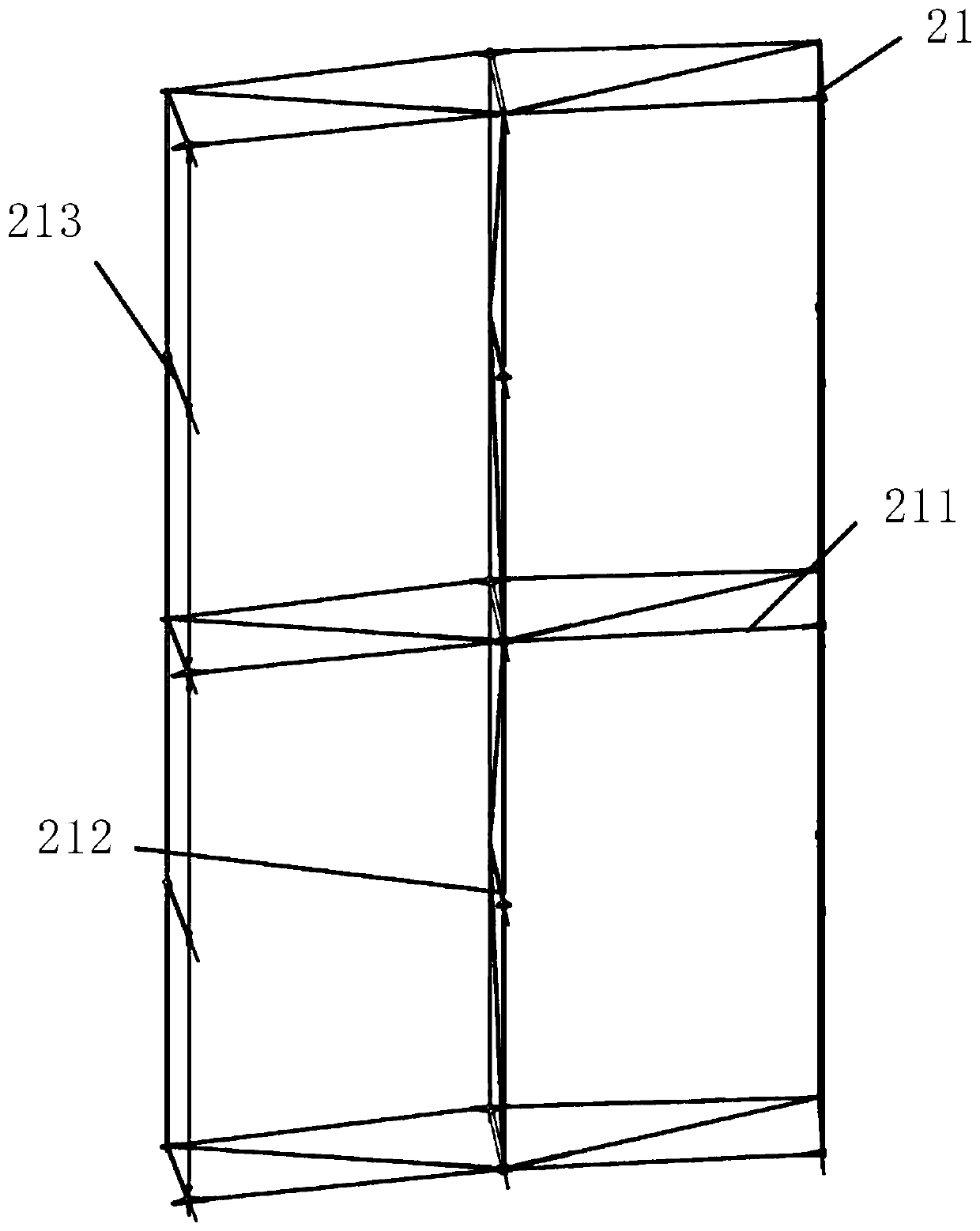

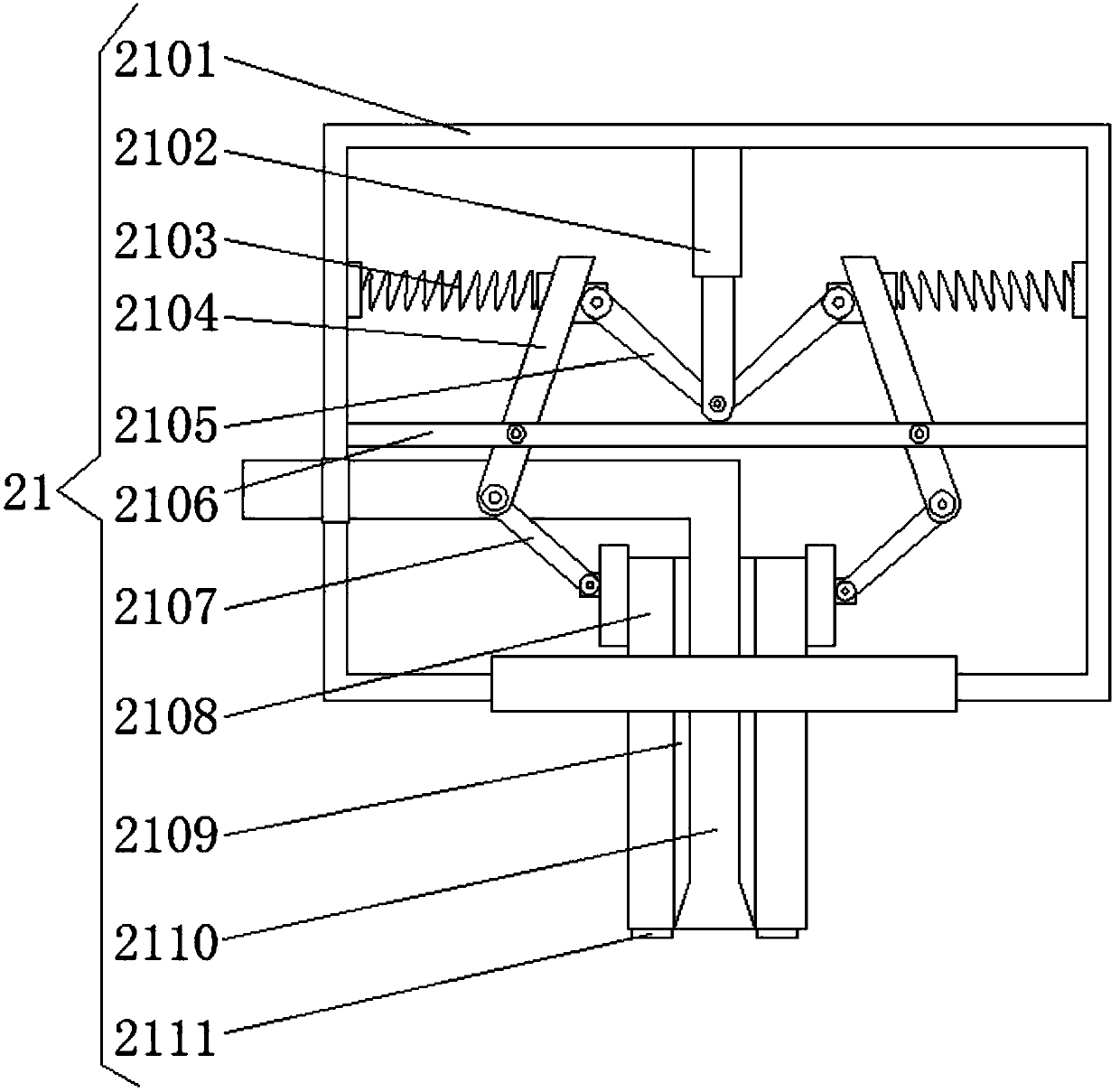

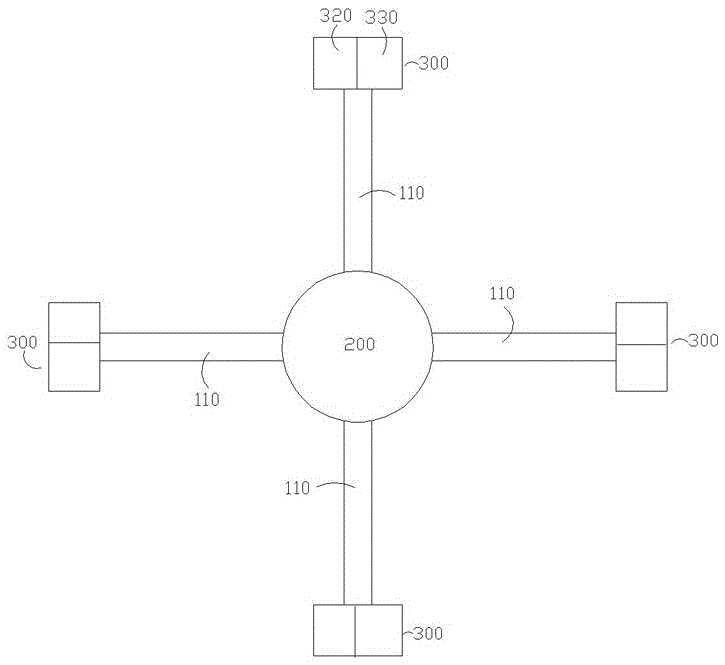

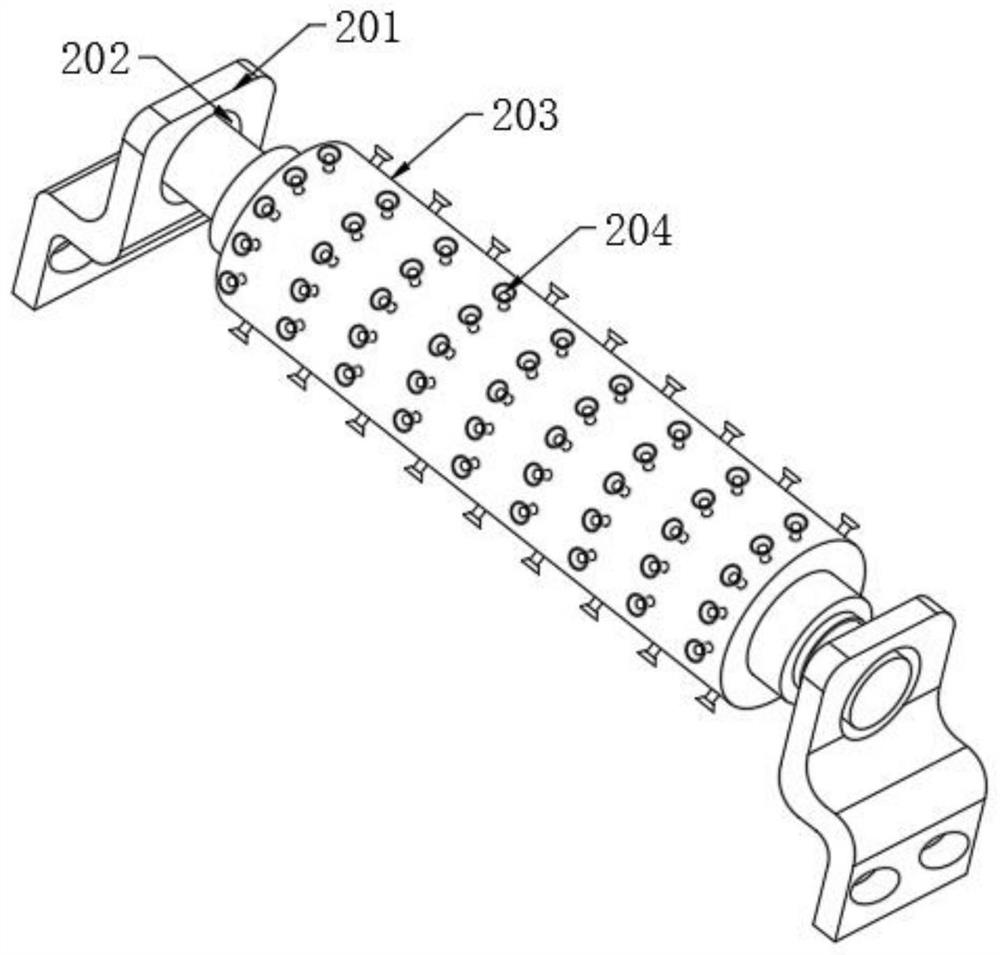

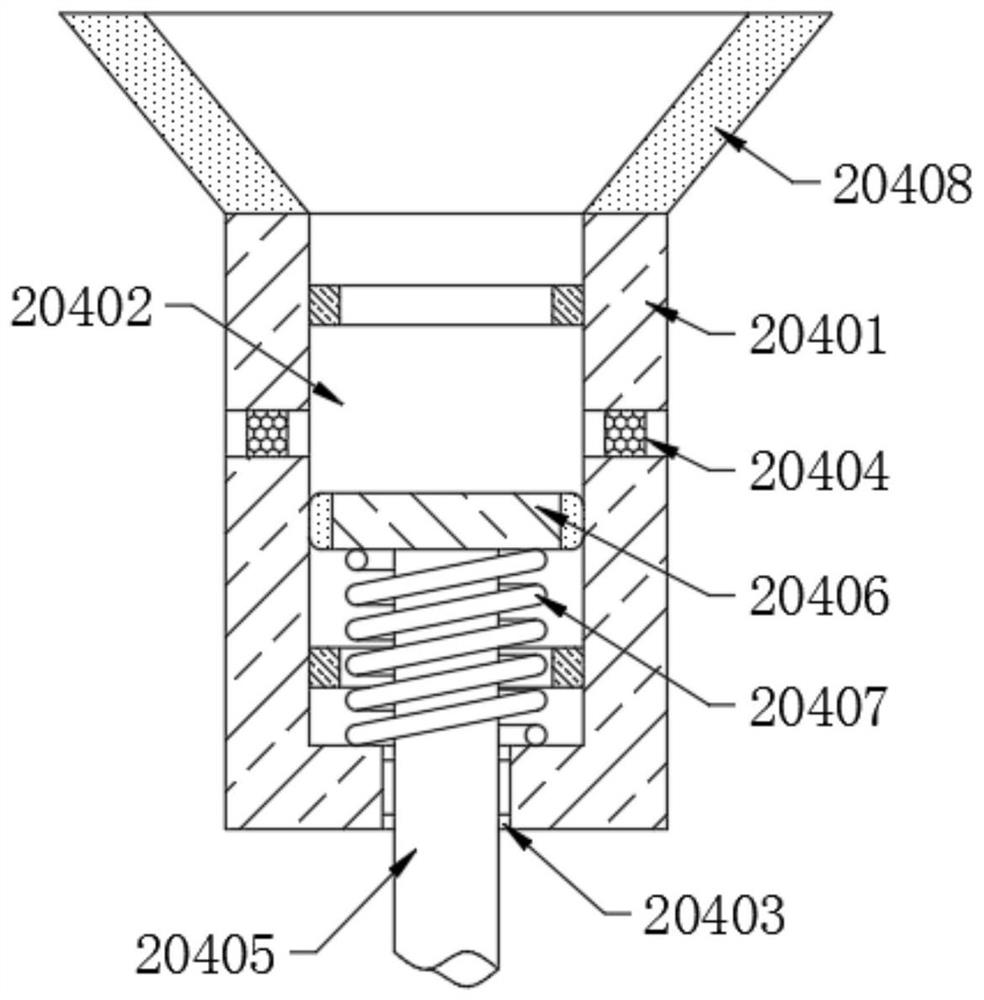

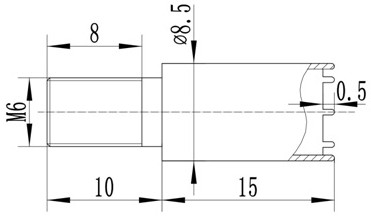

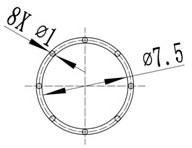

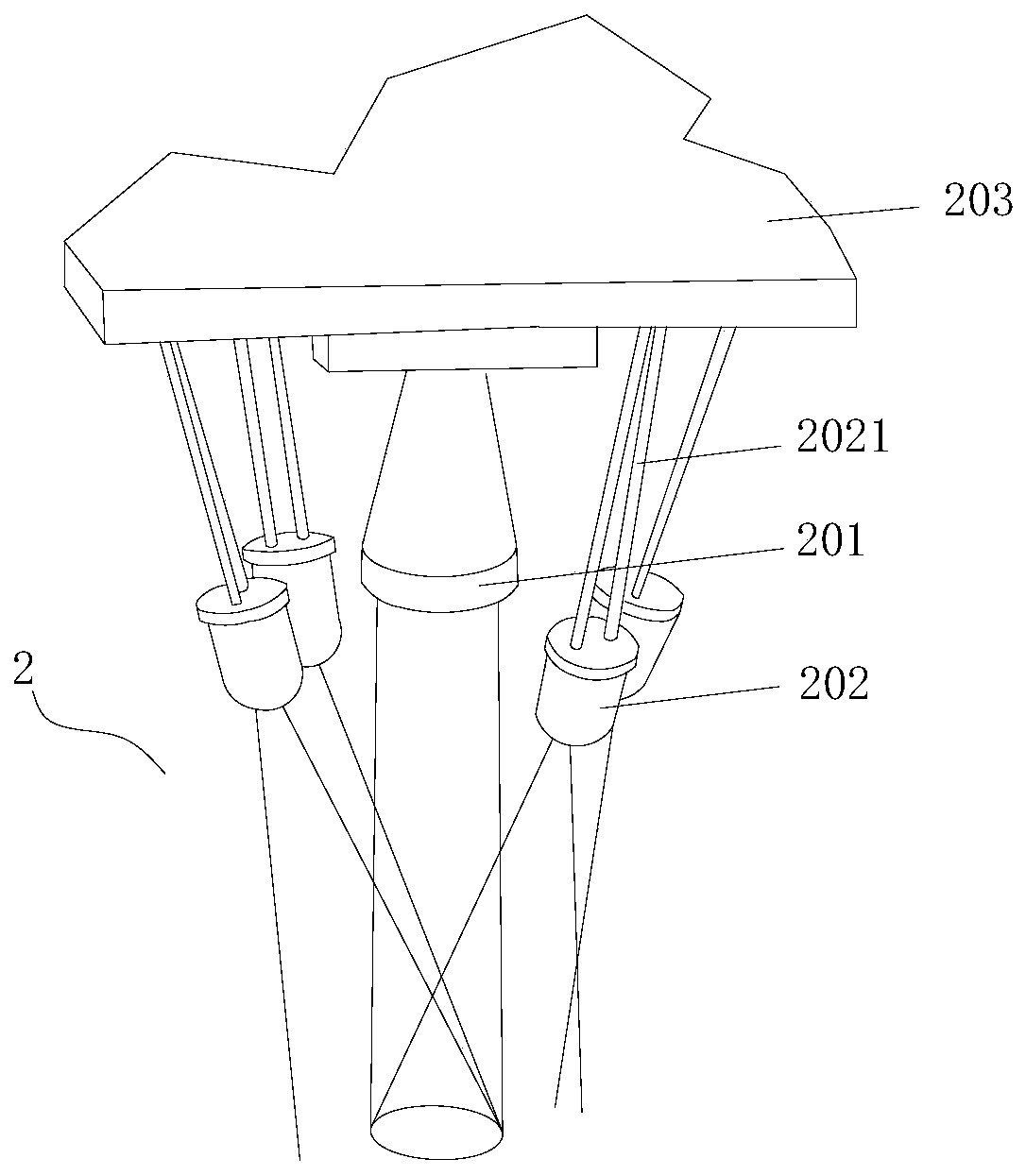

Satellite-borne deployable mesh antenna

ActiveCN109818151AHigh precisionLightweight structureCollapsable antennas meansAntenna adaptation in movable bodiesMicrowaveThermal deformation

The invention discloses a satellite-borne deployable mesh antenna. The satellite-borne deployable mesh antenna comprises an antenna reflecting surface extending arm (1), an antenna reflecting surfacedeployable supporting assembly (2) and a cable net structure (3). The antenna reflecting surface extending arm adopts a carbon fiber composite material hollow round rod design, so that the weight of the extending arm and the in-orbit thermal deformation of the extending arm are reduced, and the antenna pointing accuracy is ensured. The antenna reflecting surface deployable supporting assembly (2)is composed of module units, can be increased or decreased according to the aperture requirement of the antenna reflecting surface, and is high in expandability. The cable net structure is designed ina multi-layer cable net mode, ground adjustment of the profile precision of the reflecting surface is achieved, and the requirement of microwave antenna detection for the profile precision of the reflecting surface is met. According to the invention, factors such as antenna emission folding and in-orbit unfolding, antenna reflecting surface function and performance testing and antenna reflectingsurface profile precision adjusting are comprehensively considered for design, and the requirement of satellite in-orbit ground detection can be met.

Owner:SHANGHAI SATELLITE ENG INST

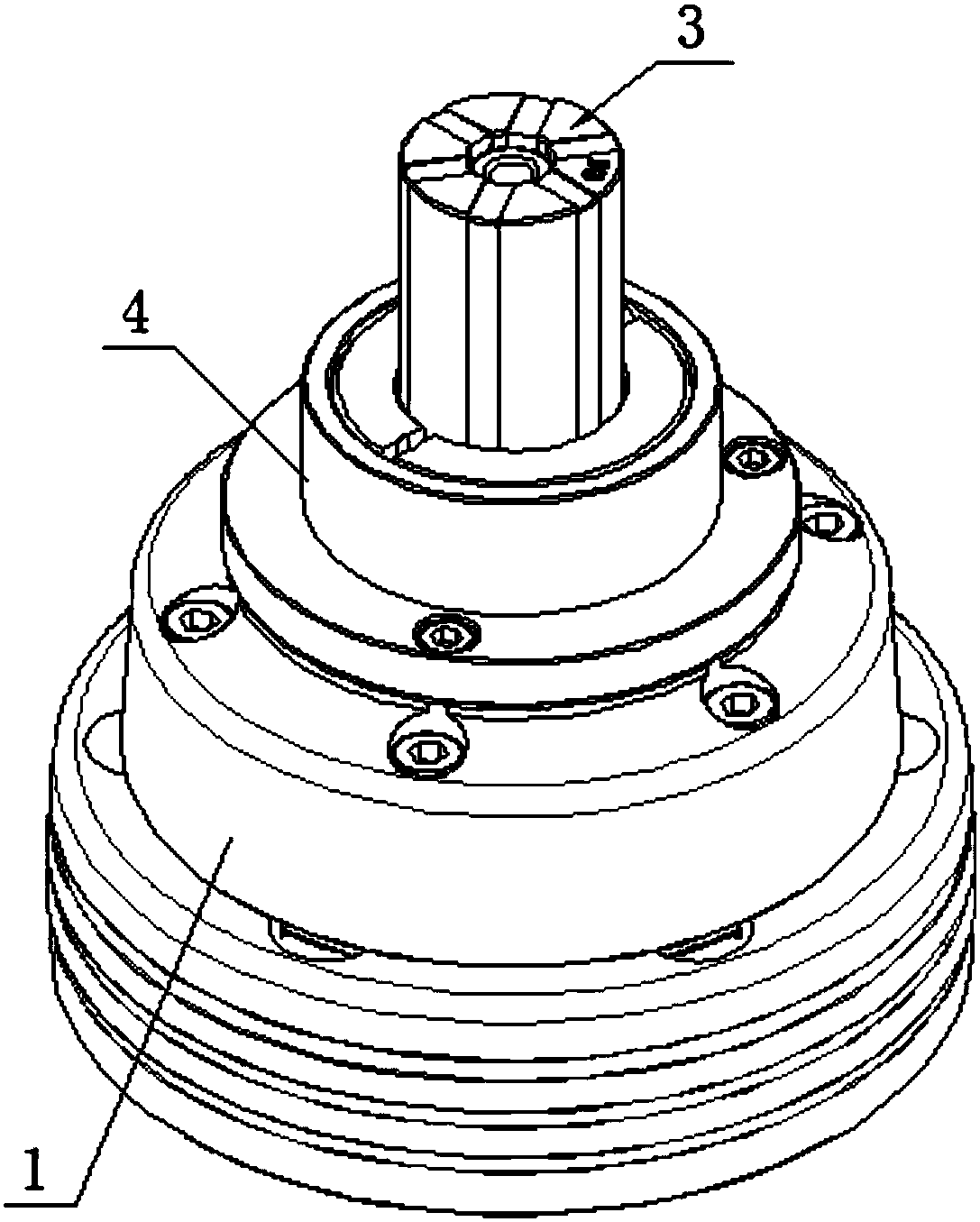

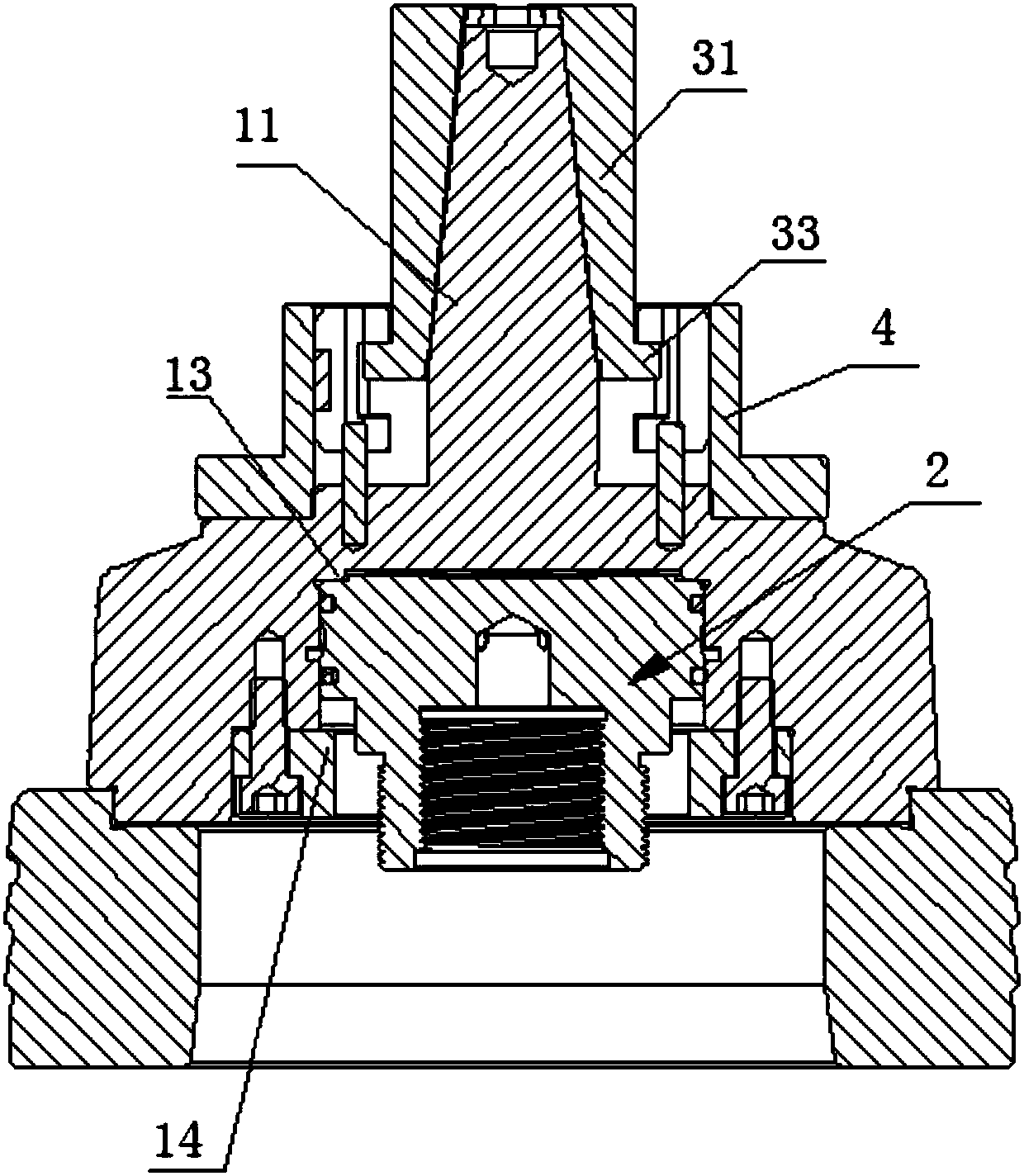

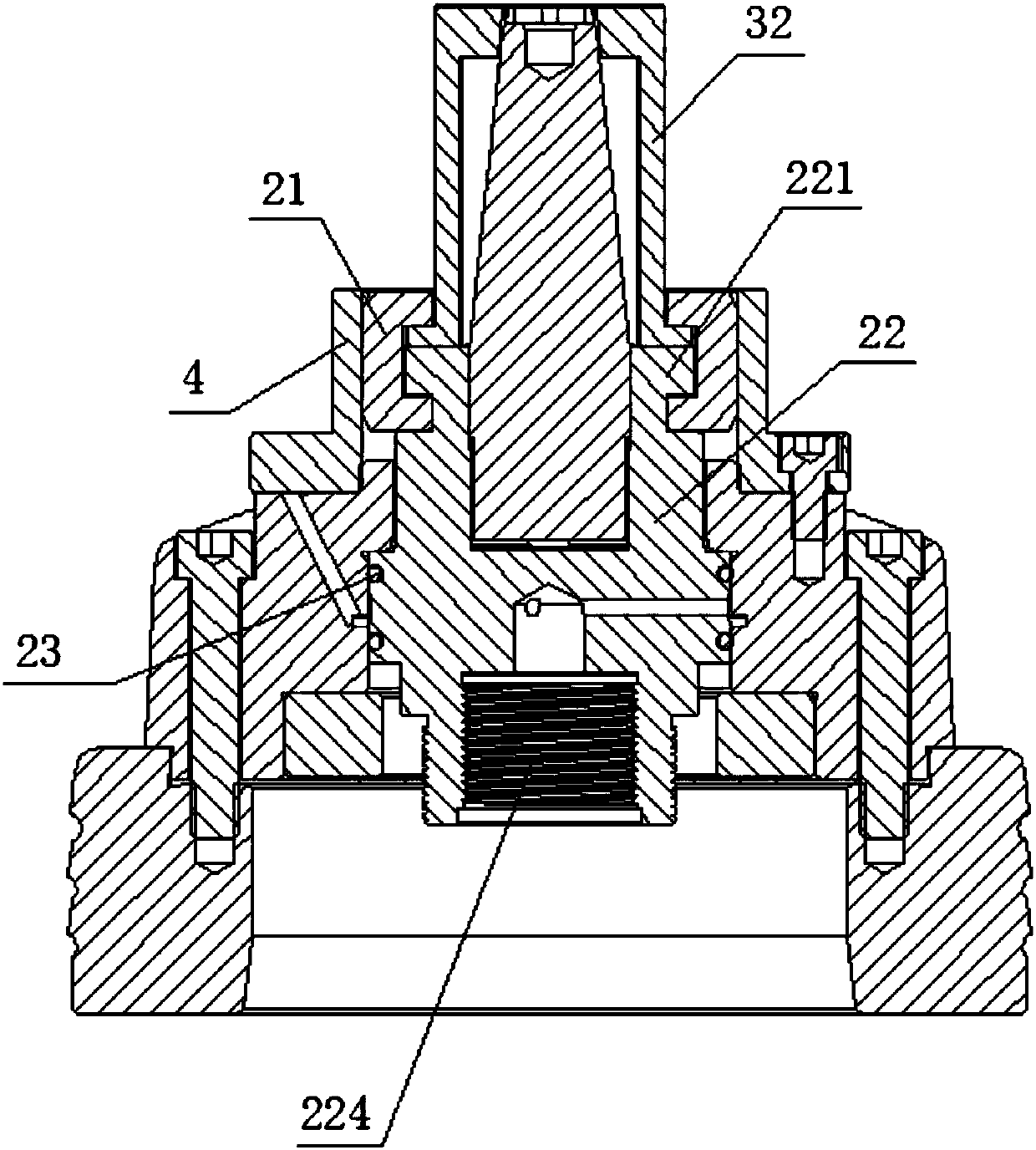

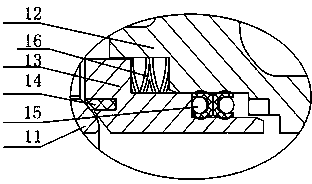

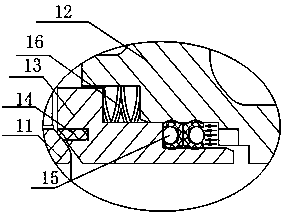

Internal expanding chuck

The invention relates to the technical field of internal expanding chuck equipment, in particular to an internal expanding chuck. The internal expanding chuck comprises a chuck body, an annular integrated expanding sleeve and a push-pull assembly, wherein the integrated expanding sleeve comprises at least two fan-shaped clamping jaws and at least two elastic structural components; one elastic structural component is fixedly connected between every two adjacent fan-shaped clamping jaws; the chuck body is connected with a machine tool; a conical shaft is arranged at the top part of the chuck body; the conical shaft is in a conical shape or a circular truncated cone shape; the integrated expanding sleeve is arranged on the conical shaft in a sleeving way; the inner side wall of the integratedexpanding sleeve is matched with the conical shaft in a sliding way; the outer side wall of the integrated expanding sleeve is in a cylindrical surface shape which is coaxial with the conical shaft;the outer side wall of the integrated expanding sleeve can be fitted with an inner circle of a workpiece; the push-pull assembly is used for pulling and limiting the integrated expanding sleeve to move along the axis of the conical shaft. According to the internal expanding chuck provided by the invention, the damage to the workpiece is reduced, the repeated positioning accuracy is high, and the service life is longer.

Owner:NINGBO FENGZHOU MACHINERY

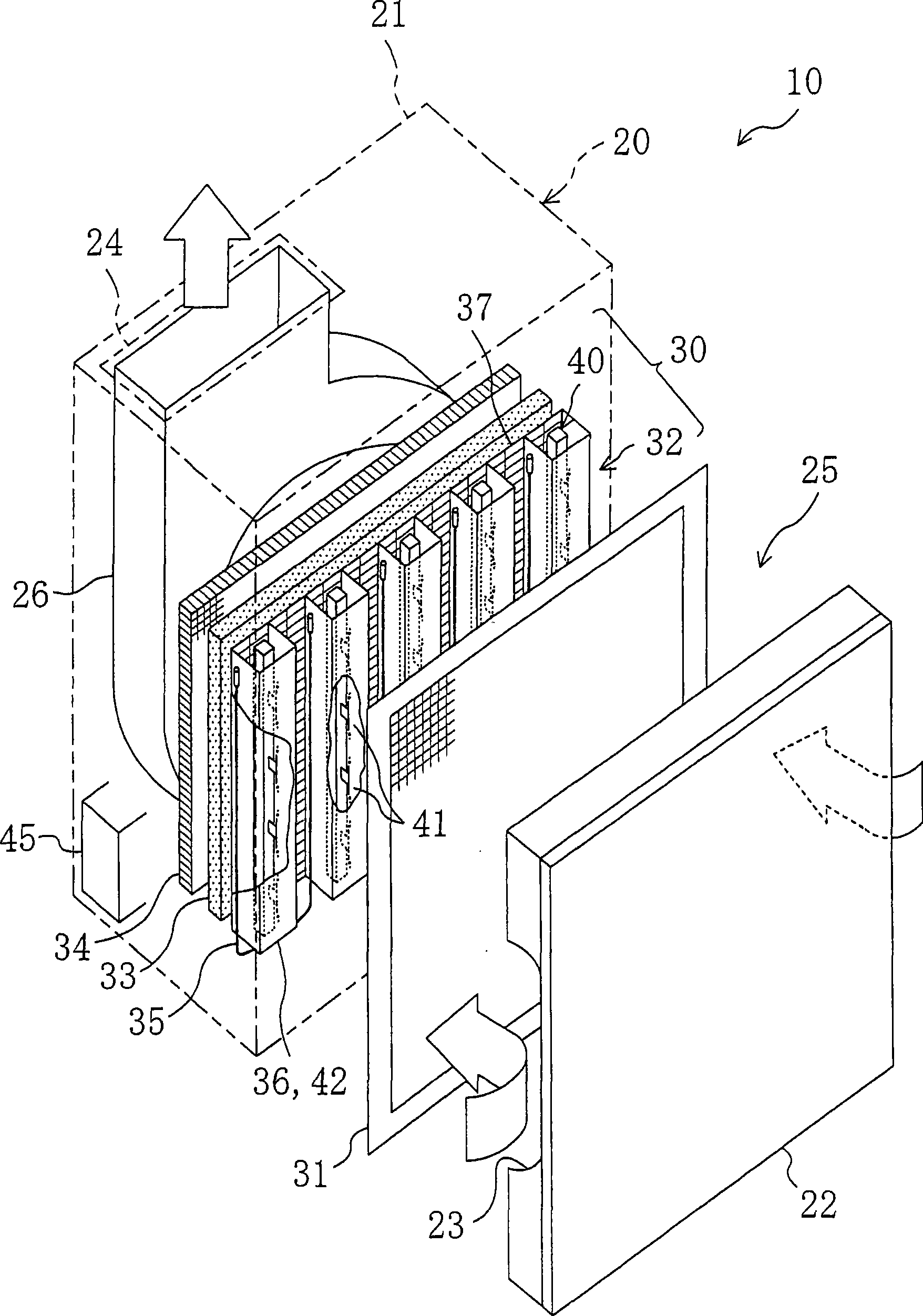

Recording device

ActiveUS8066283B2Effective holdingImprove air tightnessOther printing apparatusArticle feedersEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

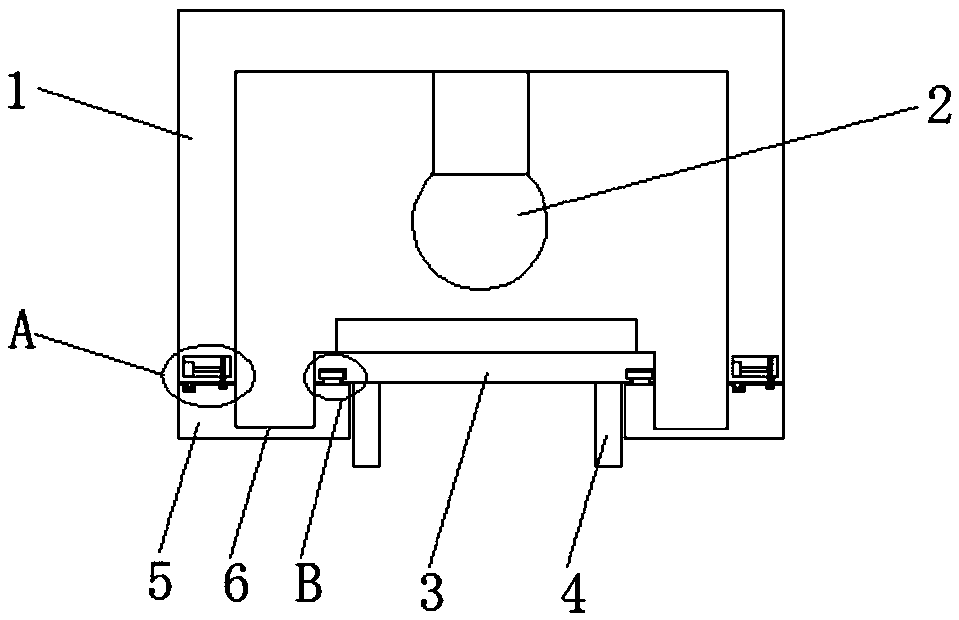

Metal cutting machine tool capable of preventing metal chips from splashing

ActiveCN107671595AClean up in timeEasy to moveMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a metal cutting machine tool capable of preventing metal chips from splashing. The metal cutting machine tool comprises a shell; the shell is of a hollow structure opened at the bottom end; a metal cutting tool is fixedly mounted on the inner wall of the top end of the shell; a console is arranged below the metal cutting tool; two support legs are fixedly mounted at the bottom end of the console; the console and the bottom end of the shell are positioned on the same horizontal plane; placing blocks are arranged on two sides of the bottom end of the console, and are positioned below the shell; a moving mechanism for shifting the placing blocks is arranged between the placing blocks and the bottom end of the shell; the moving mechanism comprises a first cavity formedin the shell; and a rotating motor is fixedly mounted on the inner wall of one side of the first cavity. The metal cutting machine tool can conveniently collect the splashing metal chips through a collecting box, meanwhile, can conveniently and stably mount and disassemble the collecting box, is convenient to timely remove the metal chips in the collecting box, and is simple in structure and convenient to use.

Owner:江苏沃尔森自动化装备有限公司

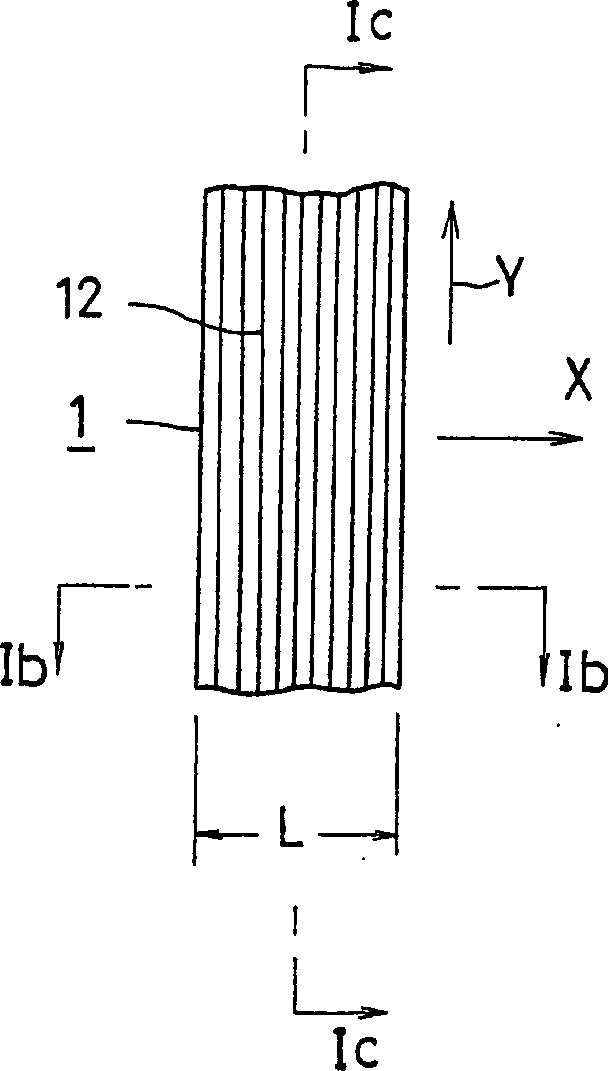

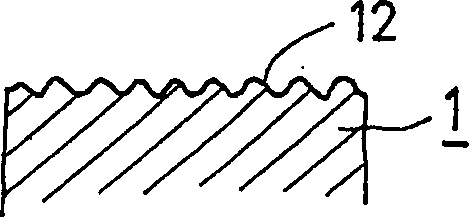

Aluminum pipe having excellent surface quality, method and apparatus for manufacturing the aluminum pipe, and photosenstive drum base body

InactiveCN1819879AEfficient preparationPrevent heat stickingDrawing mandrelsDrawing diesMaterials scienceAluminium

In a manufacturing method in which an aluminum bullet is extruded to obtain an extruded raw pipe 4 and then the extruded raw pipe 4 is subjected to a drawn process, the aluminum extruded raw pipe 4 is cut at a position within 10m from a discharge position M of an extruding die to obtain an aluminum extruded raw pipe 4 with a length of 10m or shorter, and the extruded raw pipe 4 is subjected to a drawing process. With this, an aluminum pipe excellent in surface quality having no surface defect such as white peeling can be manufactured at high manufacturing efficiency.

Owner:RESONAC HOLDINGS CORPORATION

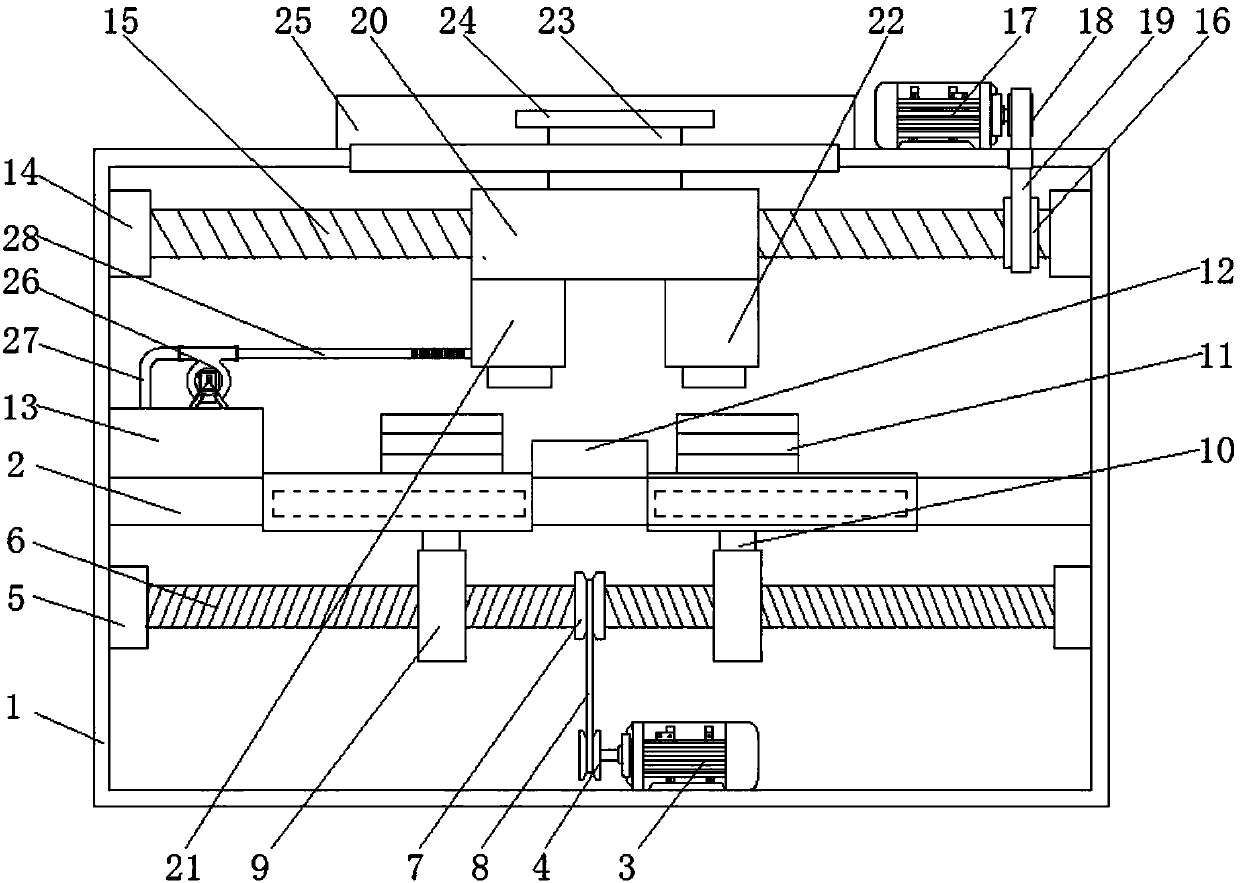

Connecting device for nylon ribbons

The invention discloses a connecting device for nylon ribbons. The connecting device comprises a box body; a working platform is fixedly connected between two opposite sides of the inner wall of the box body; a first motor is fixedly connected at the bottom of the inner wall of the box body; a first screw is in transmission connection with the output shaft end of the first motor; clamping devicesare fixedly connected on the surface of the first screw through first sliding blocks; a waste box is fixedly connected in the position located at the top of the working platform and close to one sideof the inner wall of the box body; a second motor is fixedly connected at the top of the box body; a second screw is in transmission connection with the output shaft end of the second motor; a cuttingdevice and a connecting device body are fixedly connected on the surface of the second screw through a second sliding block; the top of the waste box communicates with a dust suction pump; and one end, far away from the dust suction pump, of a suction pipe communicates with the cutting device. The invention relates to the technical field of printing consumable production. By the aid of the connecting device for the nylon ribbons, the problems of low connecting speed, uneven connections and the like of traditional nylon ribbons are solved, and the subsequent cleaning work is reduced.

Owner:湖州天骊正隆电子科技有限公司

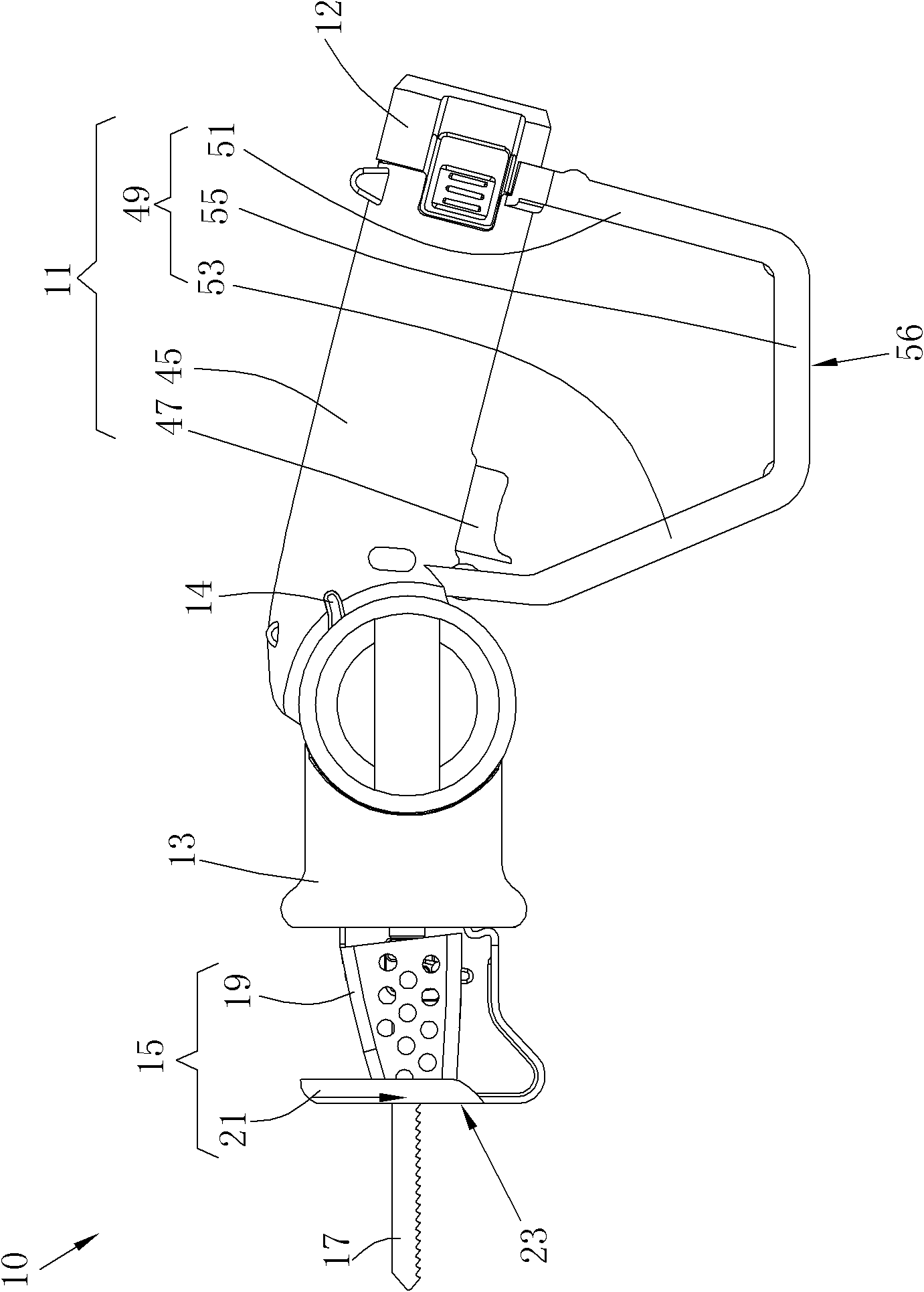

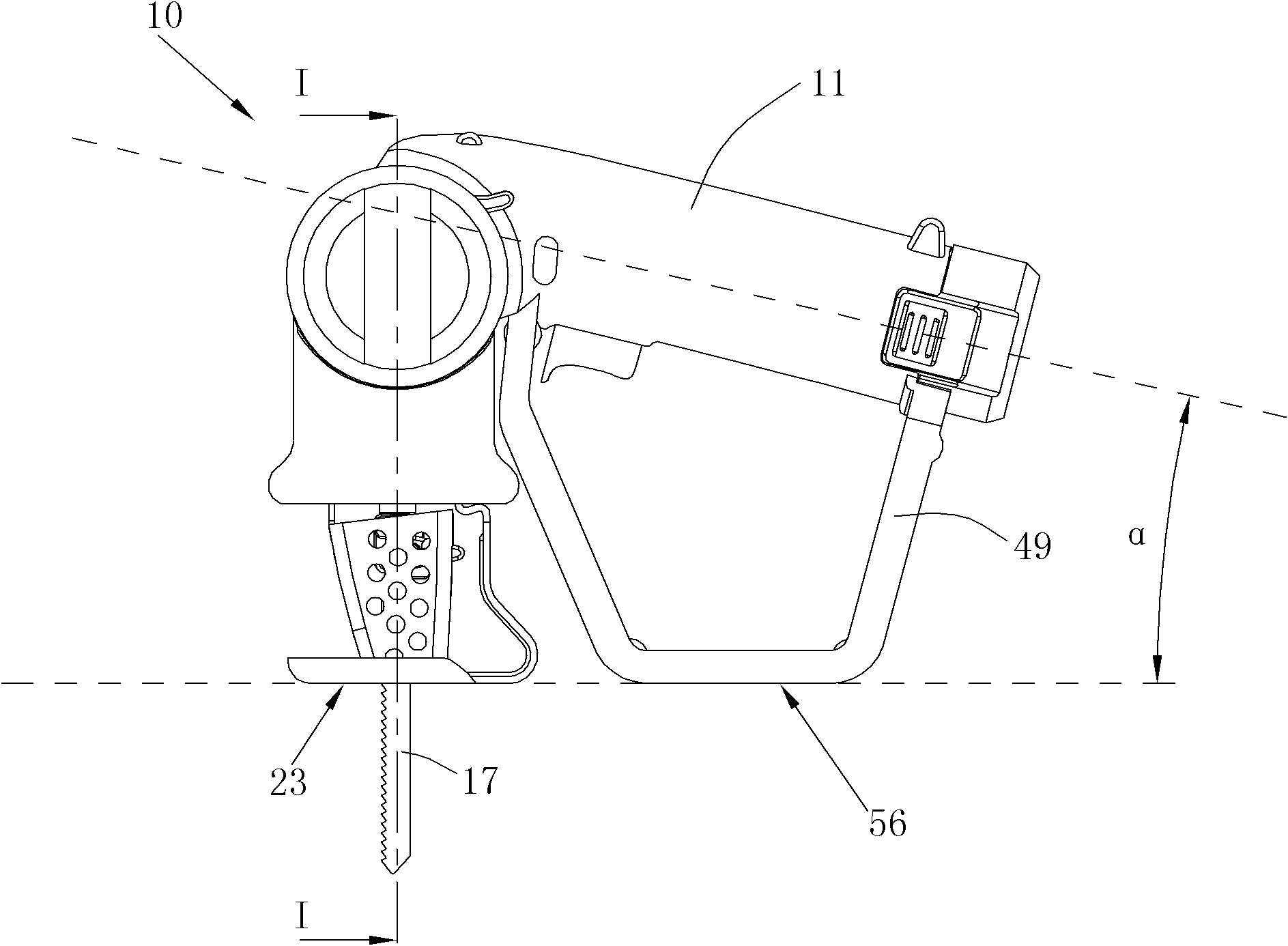

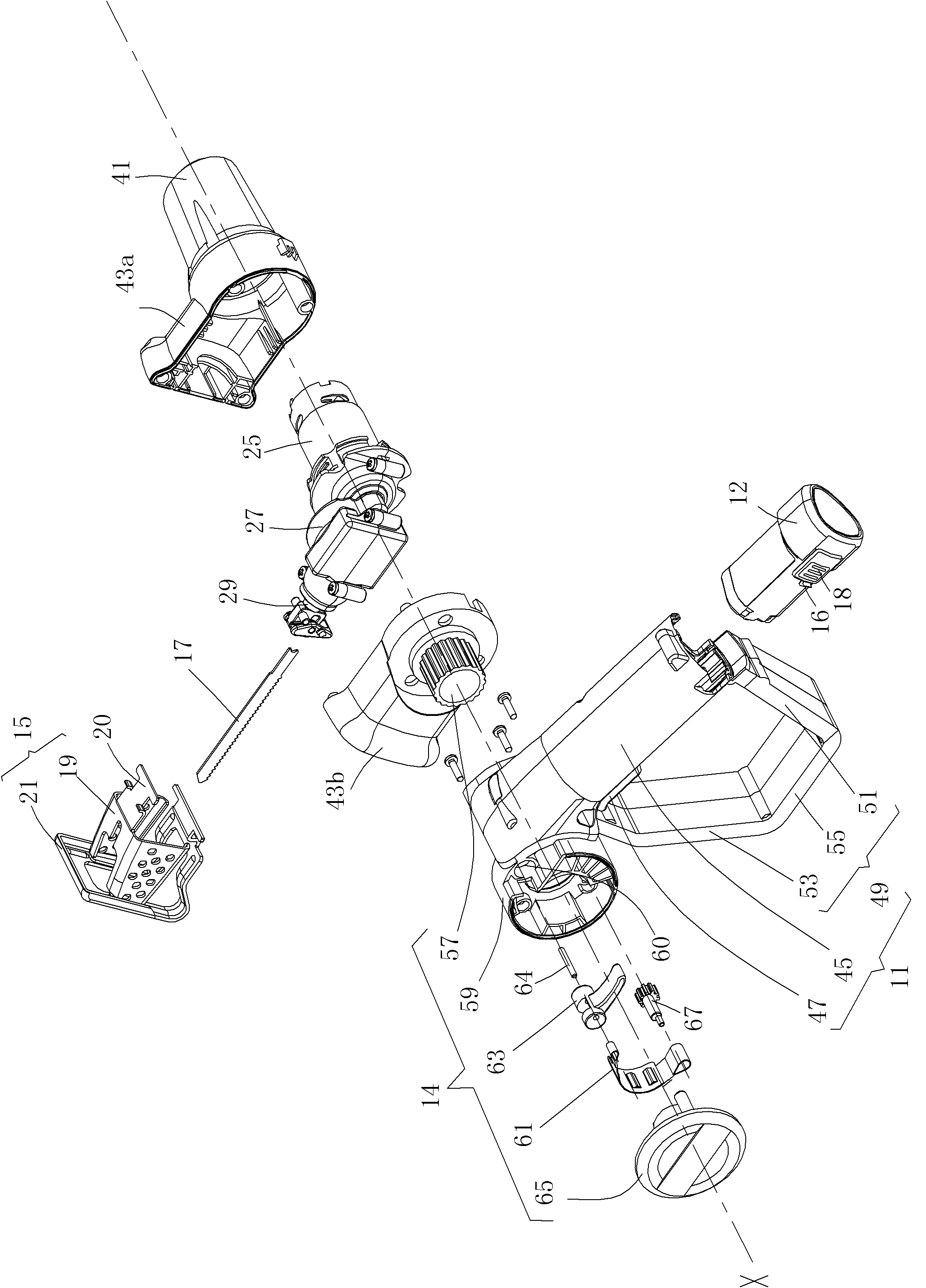

Reciprocating cutting tool

ActiveCN102581377AIncrease rotational resistanceStable positional relationshipMetal sawing devicesReciprocating motionEngineering

The invention provides a reciprocating cutting tool, which is used for cutting workpieces and comprises a handle, a casing, a motor, a reciprocating lever and a limiting part, wherein the casing is pivotally connected with the handle, the motor is contained in the casing, the reciprocating lever is driven to reciprocate by the motor, and the limiting part is arranged on the casing. A locking part is detachably mounted on the handle, can be matched with the limiting part and is operably placed at a locking position and a releasing position, wherein the locking position is used for limiting relative rotation of the casing and the handle, the releasing position is used for allowing relative rotation of the casing and the handle, and the locking part at least partially encloses the limiting part. The reciprocating cutting tool has the advantages that the rotary resistance between the locking part and the limiting part is increased, and the positions of the locking part and the limiting part are stably locked.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

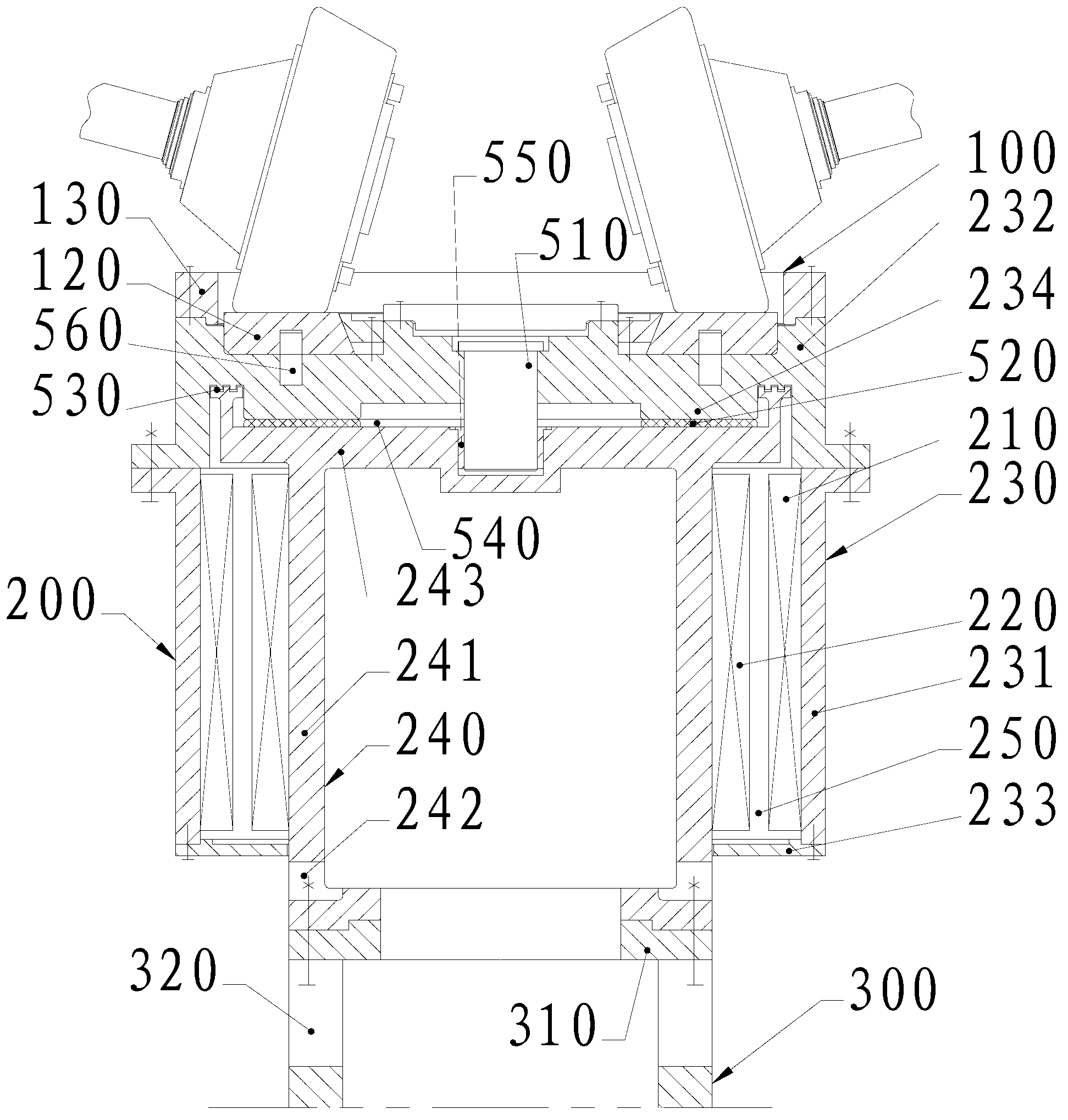

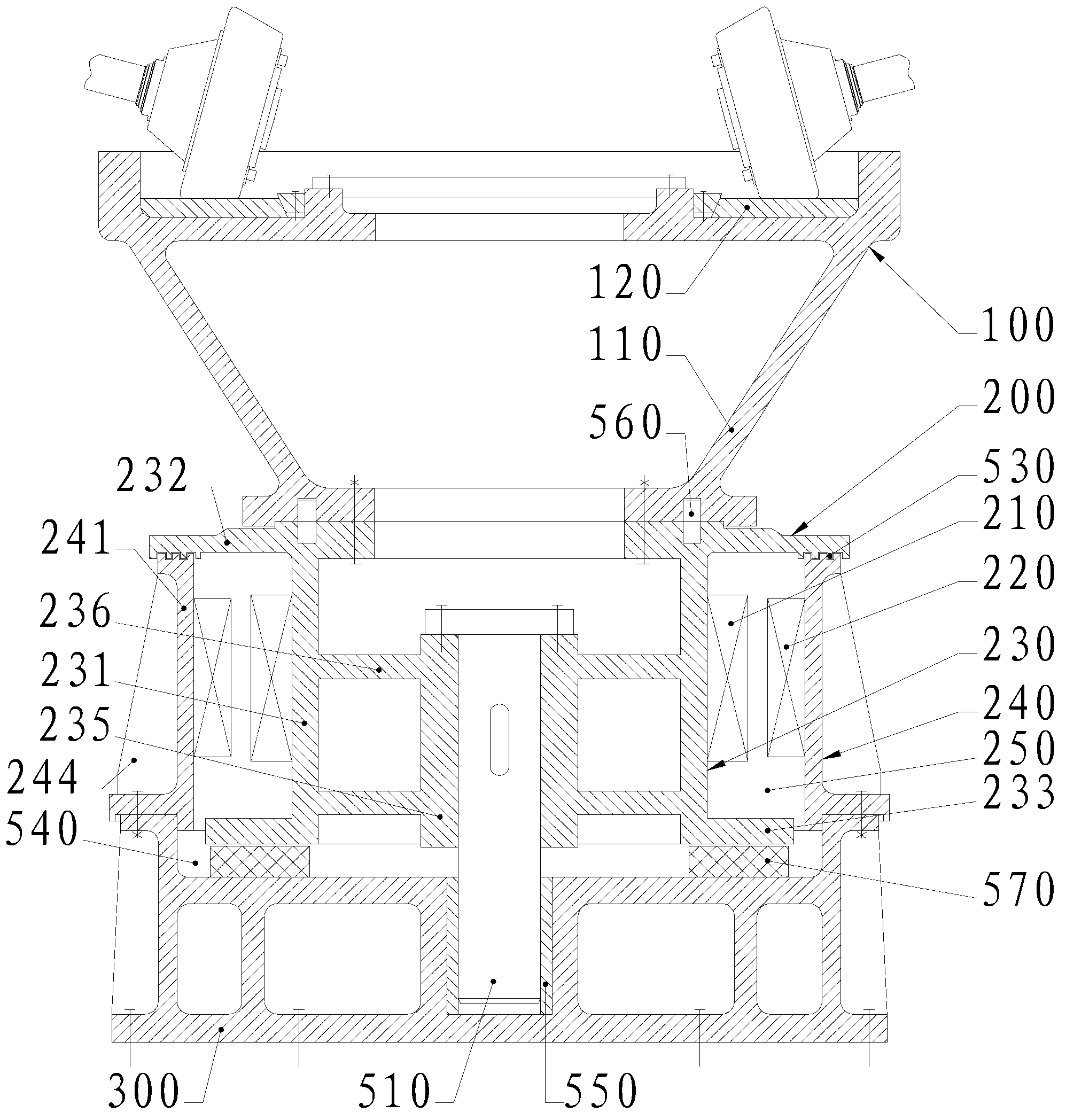

Vertical roller mill

ActiveCN103191803AReduce risk of damageStrong resistanceGrain treatmentsSupports/enclosures/casingsSlagMechanical engineering

The invention relates to grinding equipment, and in particular relates to a vertical roller mill which is widely used in a building material industry for grinding cement raw materials, cement clinker, slag and fire coal powder. A motor base comprises a cylinder for containing a stator; a motor rotating body comprises a rotary drum for containing a rotor, and a top installation plate; the top of the rotary drum is fixedly connected with the top installation plate; the cylinder and the rotary drum are sleeved; the bottom of the base is fixedly connected with a bottom seat; the top installation plate is in contact with and supported by the top of the base or by the bottom seat through the rotary drum; the supporting position of the top installation plate corresponds to the rolling position of a milling disk device; a centering device adopts a centering shaft which is arranged between the base and the rotating body or between the bottom seat and the rotating body; and the milling disk device is fixedly arranged on the top installation plate, and is directly driven by a motor to axially rotate around the motor. The top installation plate is supported by a cylindrical structure without influence of bending moment, and thus the vertical roller mill steadily operates, and is convenient to process, low in cost, energy-saving and environment-friendly; and the risk of damage to the centering shaft is extremely low.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

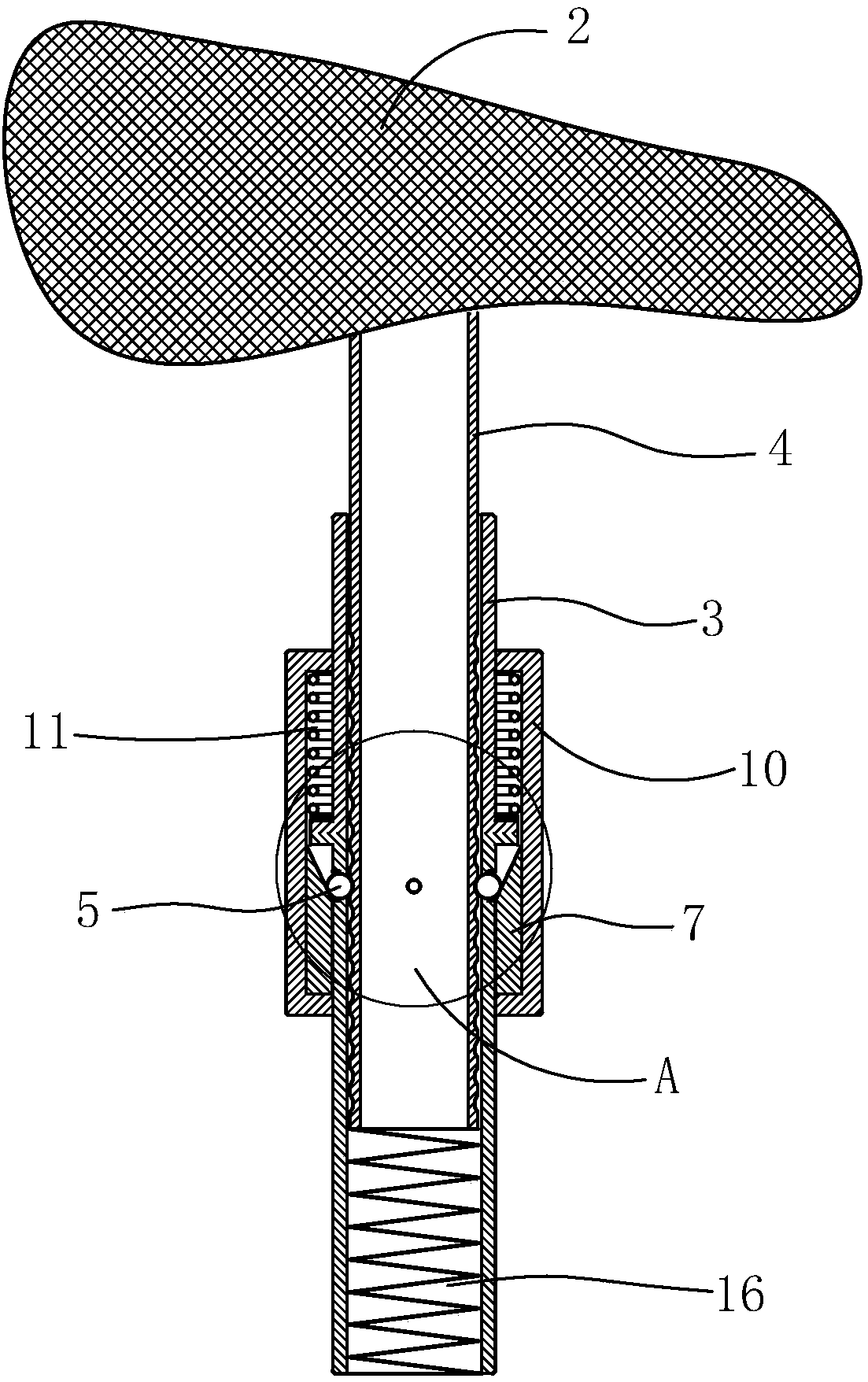

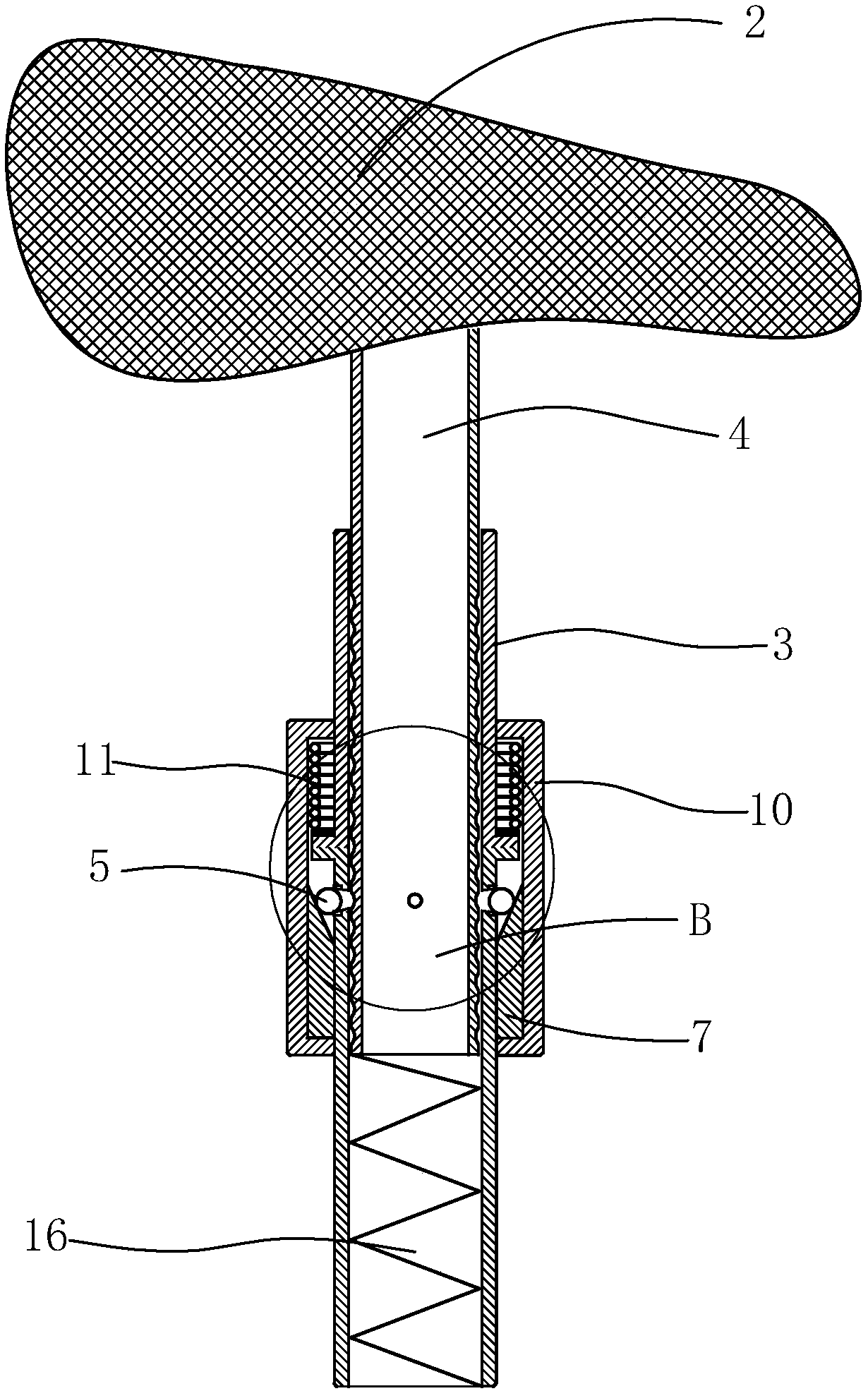

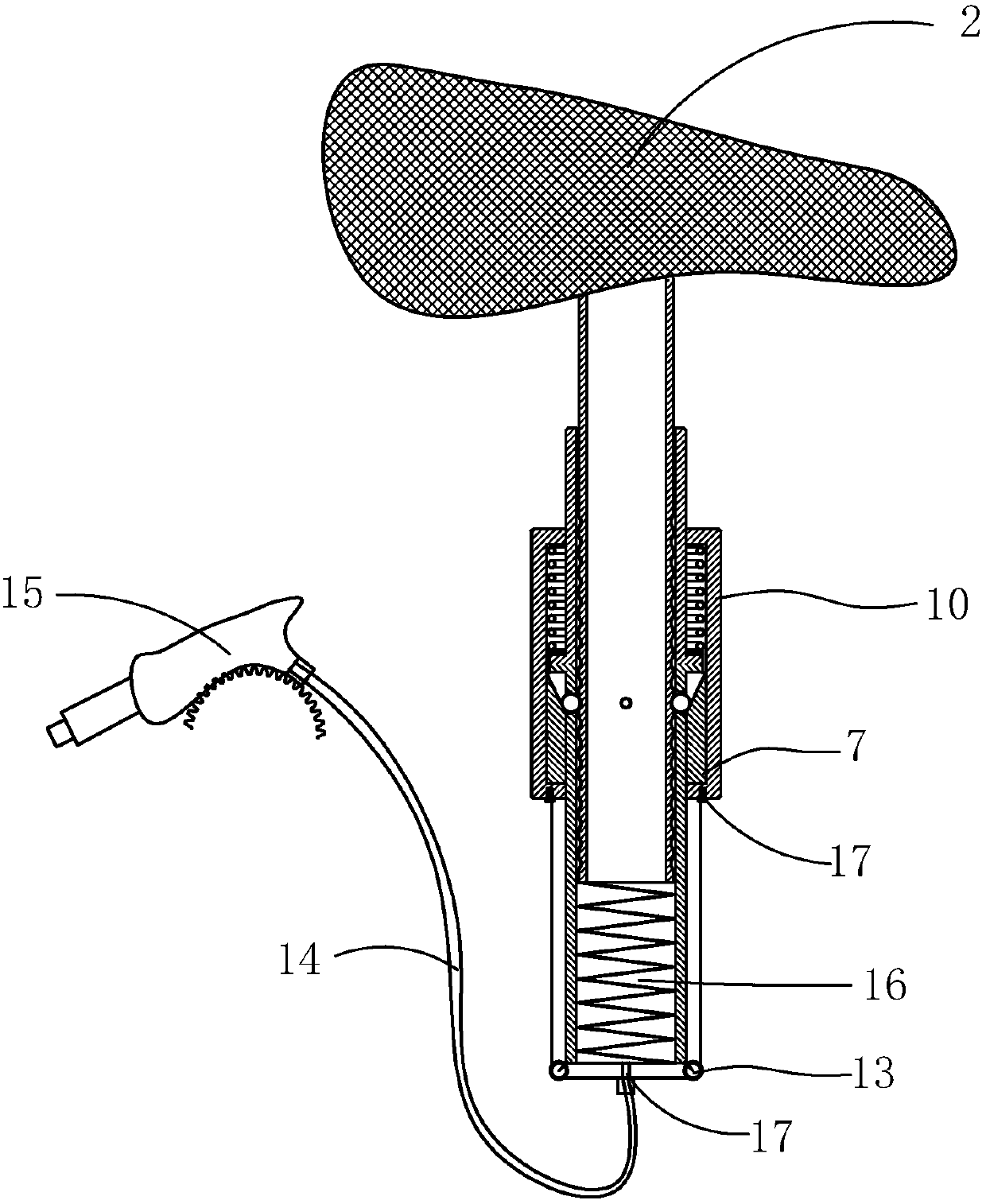

Locking device of bicycle saddle and bicycle thereof

InactiveCN107600235AImprove enduranceUniform bearing capacityCycle saddlesVehicle frameArchitectural engineering

The invention discloses a bicycle which comprises a frame and a saddle. A vertical pipe is arranged on the frame, a core pipe is arranged below the saddle, a locking device is arranged between the core pipe and the vertical pipe and comprises multiple limiting steel balls annularly distributed on the vertical pipe and capable of transversely moving in a limited-amplitude manner, the limiting steelballs can be constantly held in the vertical pipe, and annular grooves in longitudinal arrangement and an inner taper sleeve sleeving outside the vertical pipe, capable of moving up and down and provided with an oblique pushing face are arranged on the outer wall of the core pipe. When the oblique pushing face on the inner taper sleeve inwards pushes and presses the limiting steel balls to enterone annular groove of the core pipe, height of the saddle is fixed; when the oblique pushing face of the inner taper sleeve leaves the limiting steel balls, the limiting steel balls move out of the annular groove of the core pipe, and the core pipe of the saddle and the vertical pipe on the frame can move up and down relatively. Relative position of the core pipe and the vertical pipe are limitedby utilizing the limiting steel balls in annular distribution, so that the locking device is higher in bearing capacity, and the saddle is less prone to deviation and more stable.

Owner:NINGBO UNIV

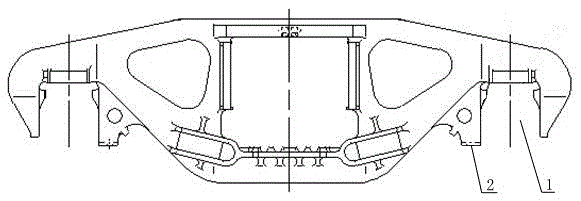

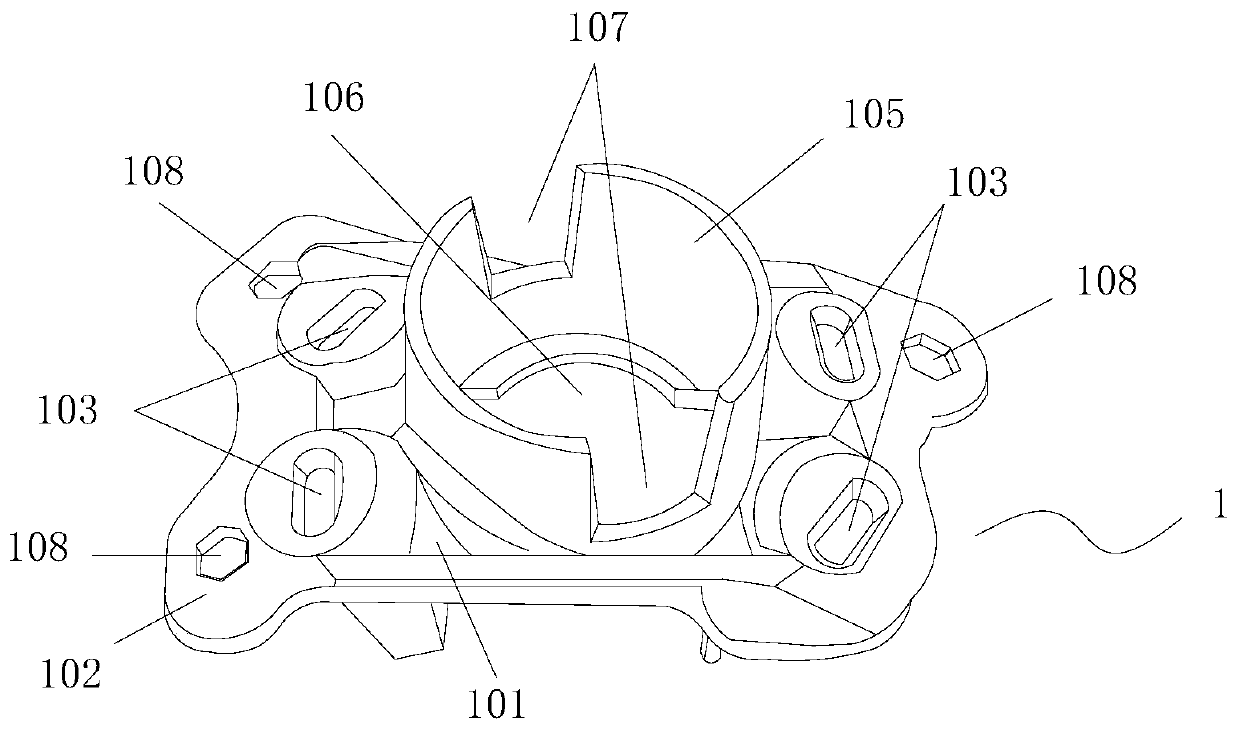

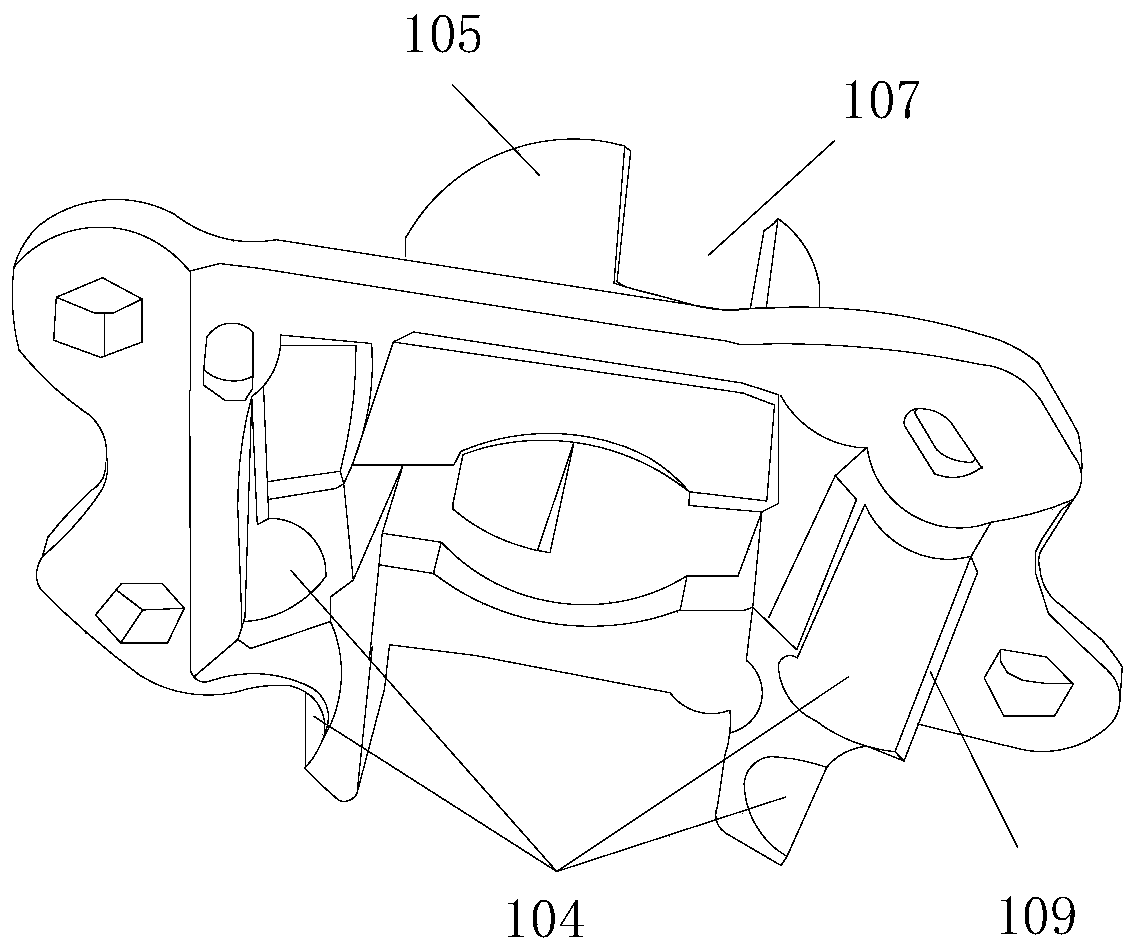

Integrated sand core for integrated molding of railway wagon side frame guiding frame and stop key mounting surface as well as production method of integrated sand core

ActiveCN105537529AStable positional relationshipSmall sizeFoundry mouldsFoundry coresTruckEngineering

The invention discloses an integrated sand core for integrated molding of a railway wagon side frame guiding frame and a stop key mounting surface as well as a production method of the integrated sand core. The integrated sand core comprises a sand core part A for molding the railway wagon side frame guiding frame and a sand core part B for molding the stop key mounting surface, wherein the sand core part B is the part that the sand core part A extends in the vertical direction of the sand core part A and enlarges in the width direction to contain the stop key mounting surface, and the sand core part A and the sand core part B constitute the sand core adopting an integrated structure. Different from the technological method for molding the guiding frame and the stop key mounting surface respectively by using a sand core and a contour, the integrated sand core is used for molding the side frame guiding frame and the stop key mounting surface, that is, the side frame stop key mounting surface is molded while the side frame guiding frame is molded integrally by the aid of the integrated sand core, so that the side frame stop key mounting surface is free of draft angles, steps and trimming, the appearance quality and the inherent quality of the stop key mounting surface are effectively improved, and the cleaning work intensity of repair welding, polishing and the like caused by appearance molding is reduced.

Owner:CRRC MEISHAN

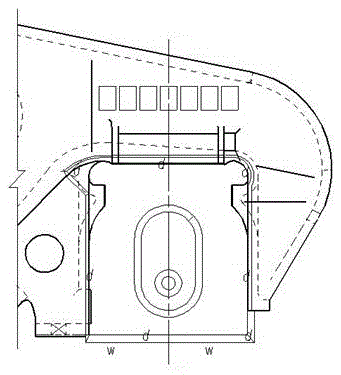

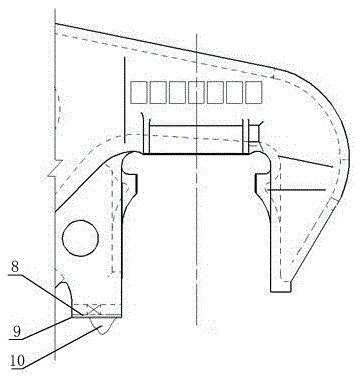

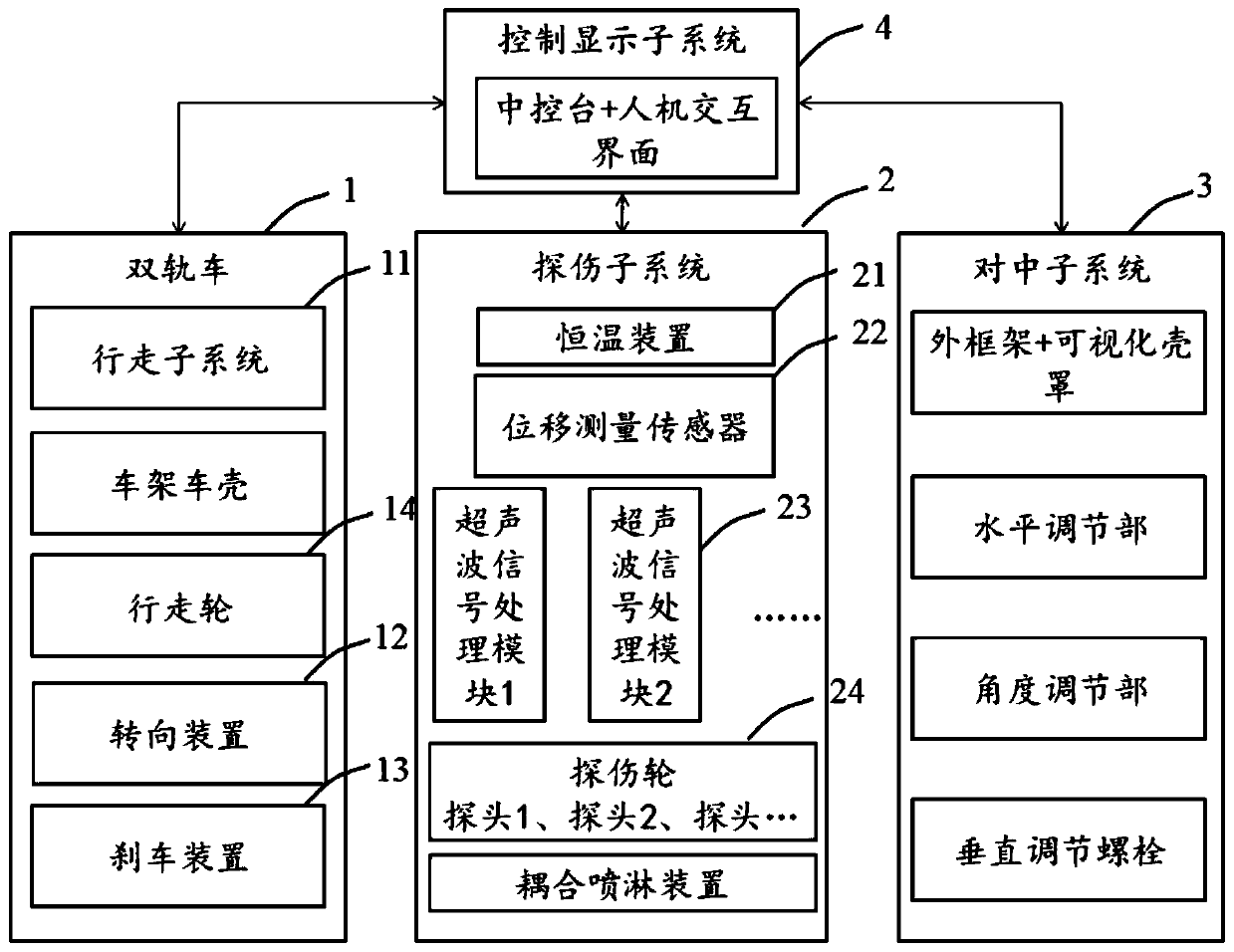

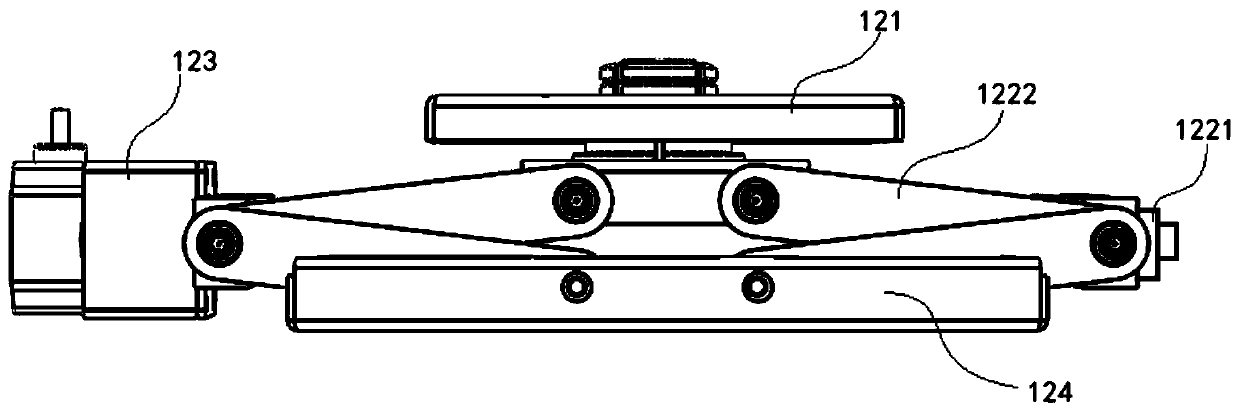

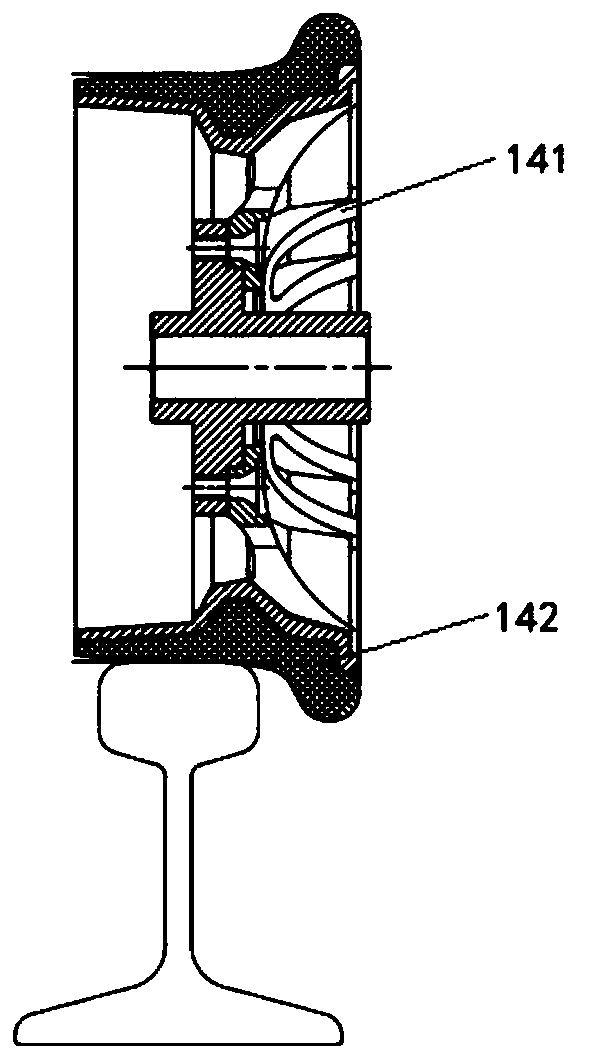

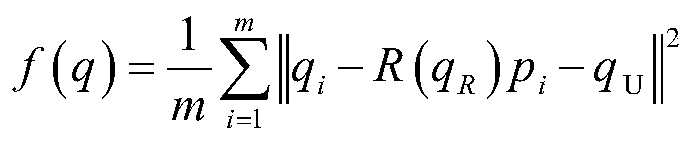

Double-track type high-speed stable ultrasonic flaw detector

PendingCN111497894ADoes not affect flaw detection operationsRealize U-turn in situAnalysing solids using sonic/ultrasonic/infrasonic wavesRailway auxillary equipmentEngineeringSlow speed

The invention discloses a double-track type high-speed stable ultrasonic flaw detector. The flaw detector comprises a double-track vehicle provided with a walking subsystem, a flaw detection subsystem, a centering subsystem and a control display subsystem, and a steering device used for pivot steering is arranged on a chassis of the double-track vehicle; the flaw detection subsystem comprises a plurality of ultrasonic signal processing modules; the plurality of ultrasonic signal processing modules are used for respectively processing data of different probes of a flaw detection wheel; the centering subsystem comprises a horizontal adjusting part and an angle adjusting part; and the horizontal adjusting part and the angle adjusting part are respectively used for detecting and automaticallyresetting the horizontal position and angle of the flaw detection wheel. The detection speed is integrally improved, the problems of missed detection, low detection rate, increased jittering of flaw detection wheels, poor equipment safety, difficult equipment maintenance and the like caused by speed increase are solved, the problems that reversing detection is not safe and not beneficial to observation, the detection speed is low, reversing detection is not suitable for long-distance driving and the like are solved, and the technical characteristics of high detection speed, high detection stability and convenient steering are achieved.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

Three-dimensional laser scanning and GPS-PPK combined measurement method

ActiveCN111561908AImprove coordinate absolute position accuracyAchieve integrationHeight/levelling measurementPoint cloudLaser scanning

The invention discloses a three-dimensional laser scanning and GPS-PPK combined measurement method which is suitable for the field of surveying and mapping. An observation station is arranged at the central position of a to-be-tested area, and GPS targets are averagely arranged in the to-be-tested area to ensure that the included angle of connecting lines between the targets is 30-60 degrees; GPSdata of a plurality of time periods are acquired according to the single-station acquisition time of unit time; three-dimensional laser scanning point cloud data of the to-be-tested area and GPS dataof the GPS target are obtained; high-precision target control point coordinates are provided by GPS-PPK measurement, three-dimensional laser scanning is carried out to obtain high-precision point cloud relative coordinate data, and the GPS coordinate data as a standard is substituted into the three-dimensional laser point cloud data coordinates of the GPS target points, so that the point cloud data of the observation station and the GPS data of the GPS targets are fused, and finally the high-precision absolute coordinate information of the point cloud data of the to-be-tested area is obtained.Three-dimensional laser scanning and GPS-PPK measurement can be effectively fused, and an effective, high-precision and reliable data basis can be provided for mining subsidence large-range deformation monitoring work.

Owner:CHINA UNIV OF MINING & TECH

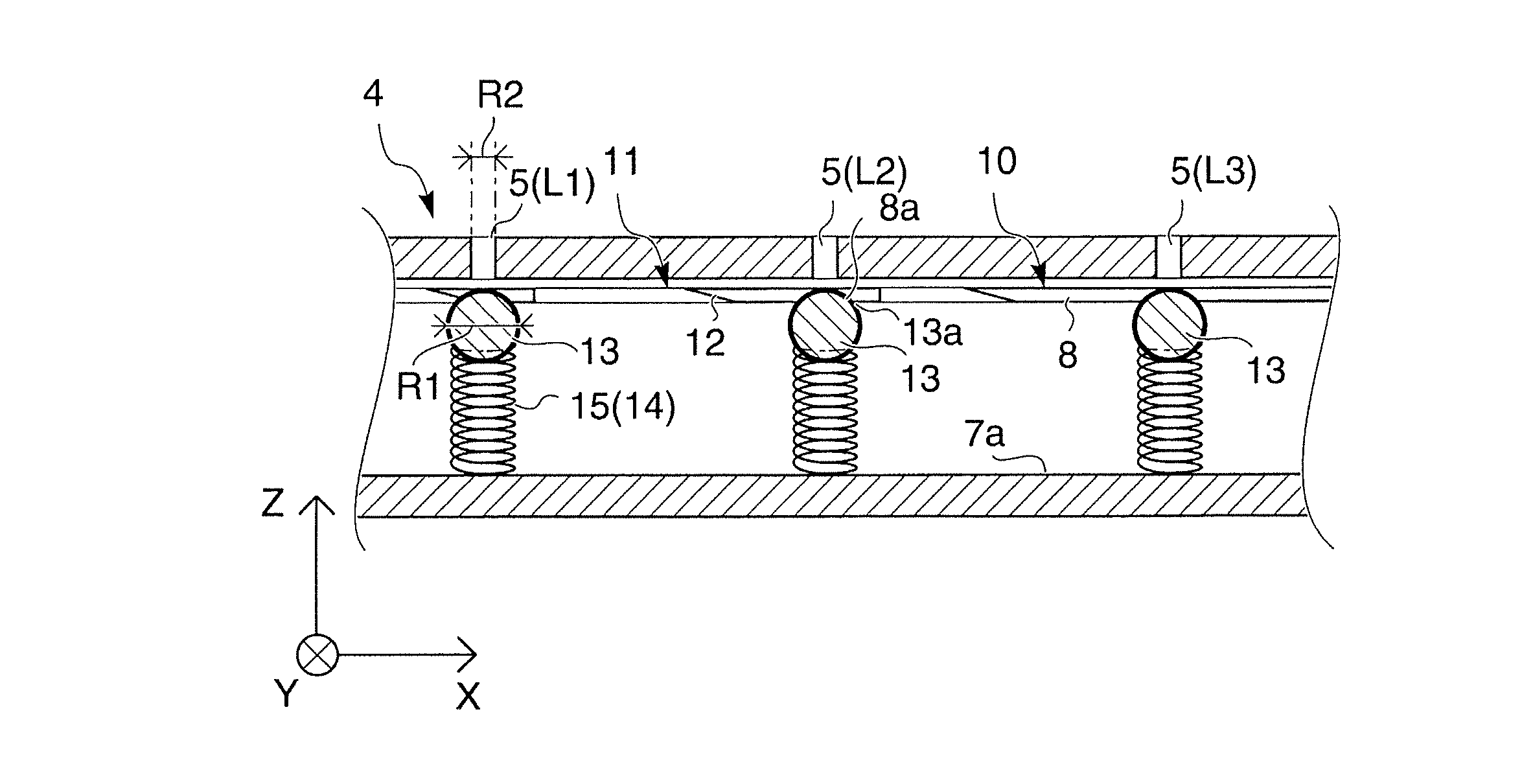

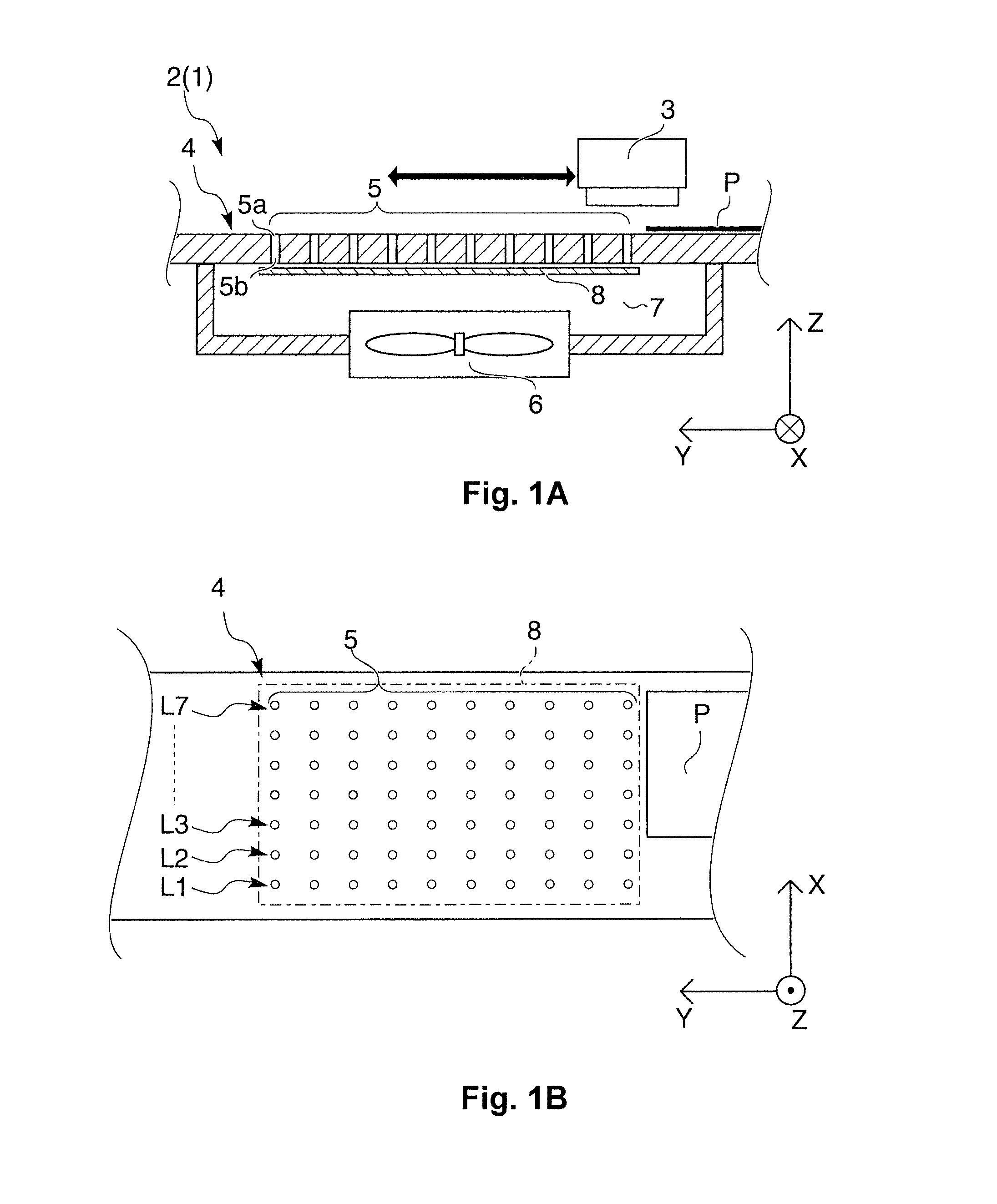

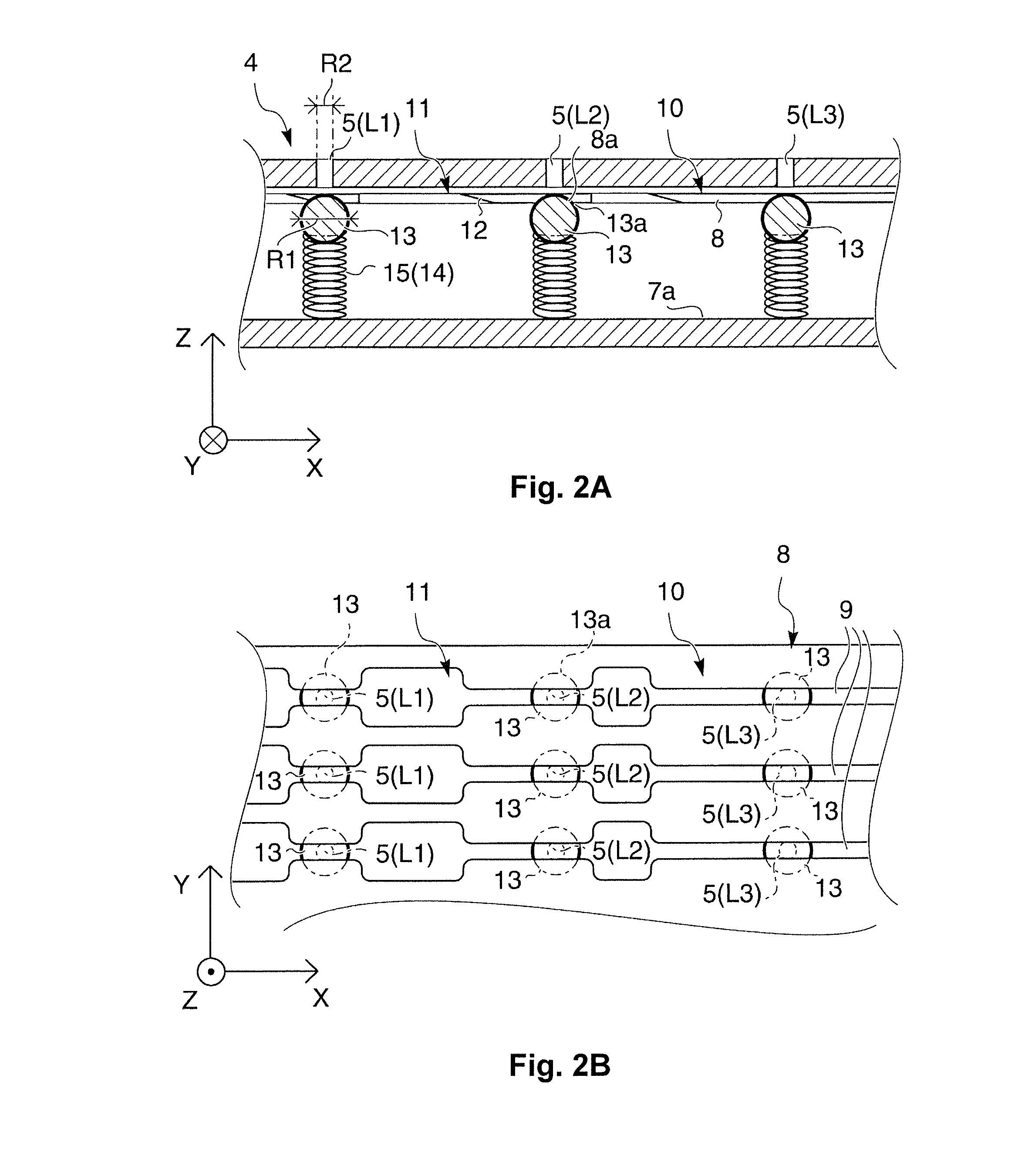

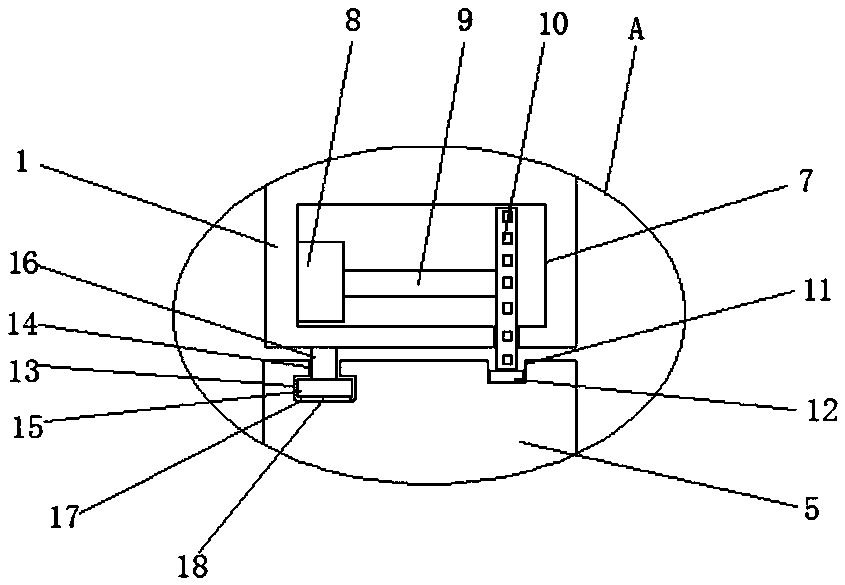

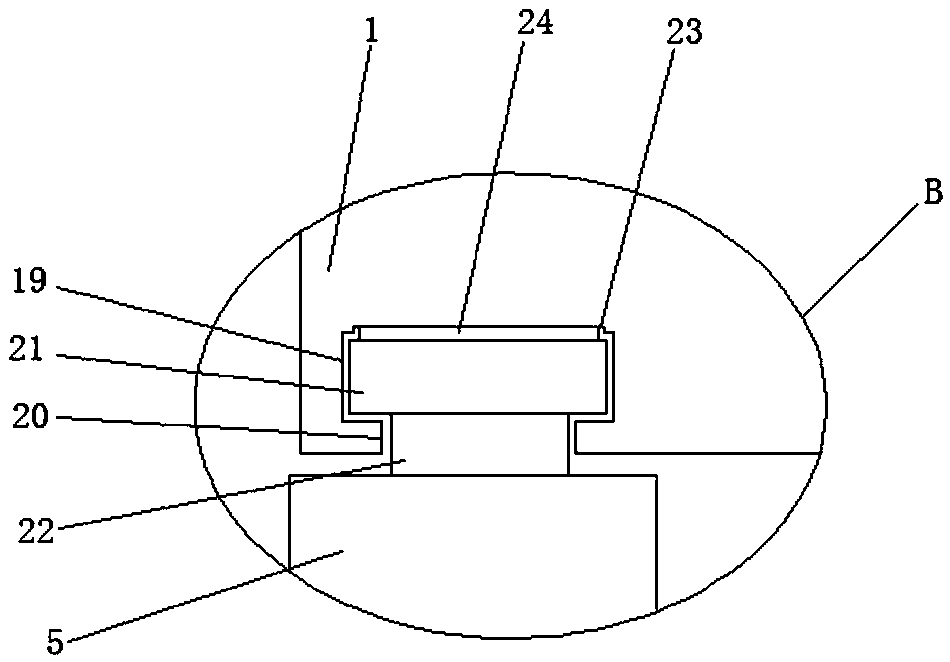

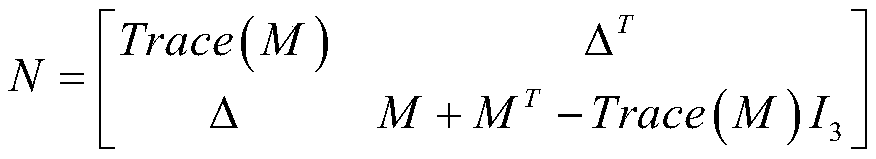

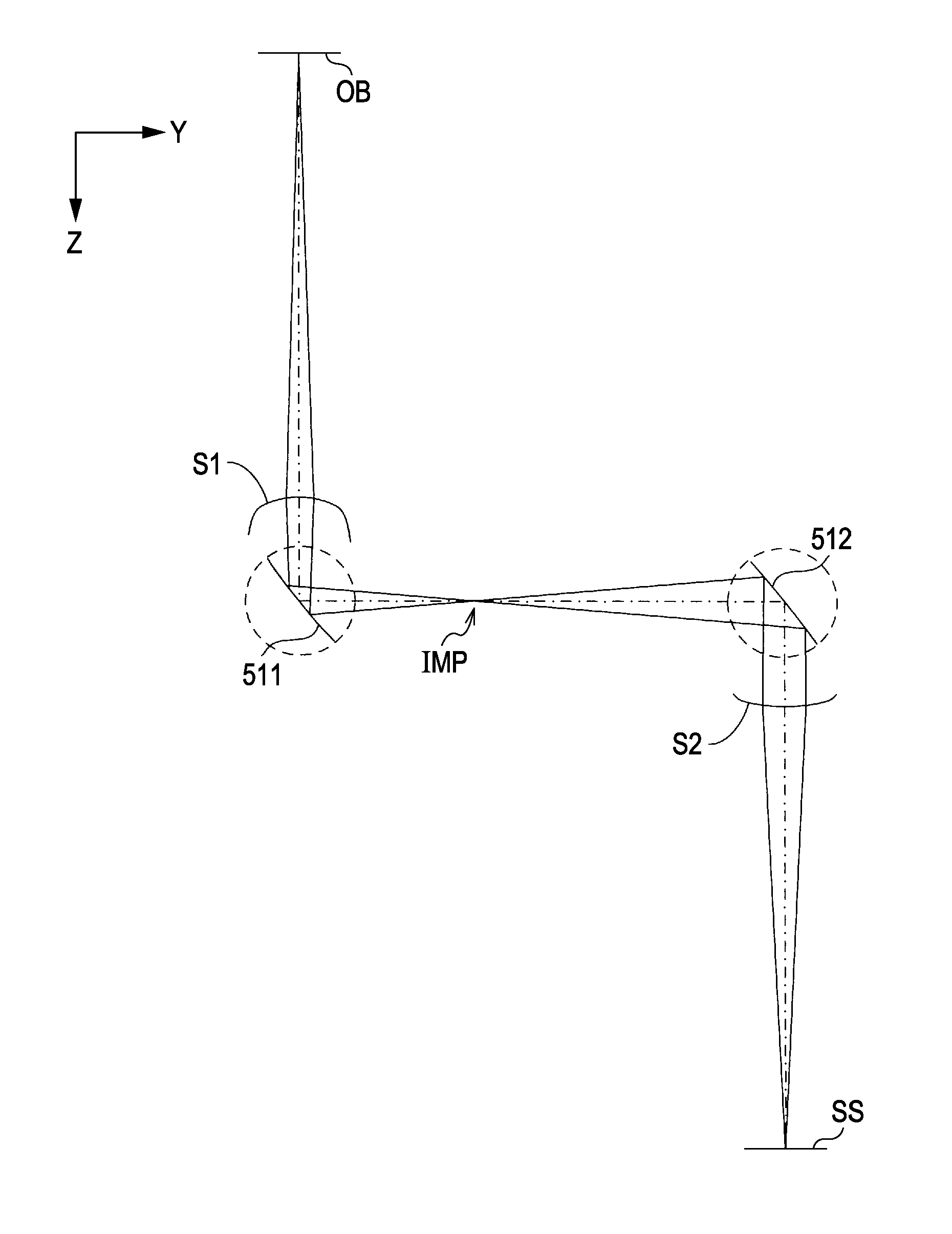

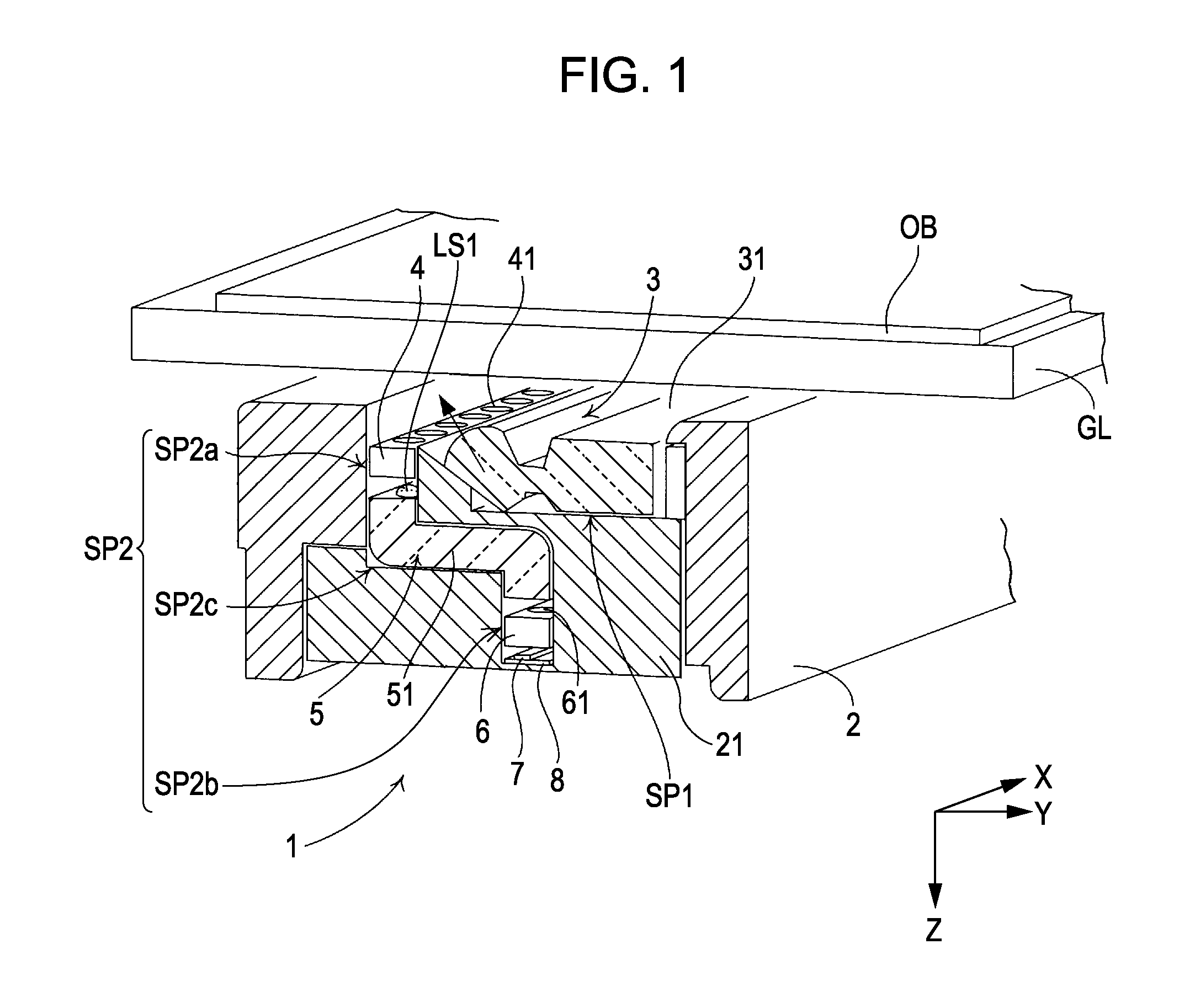

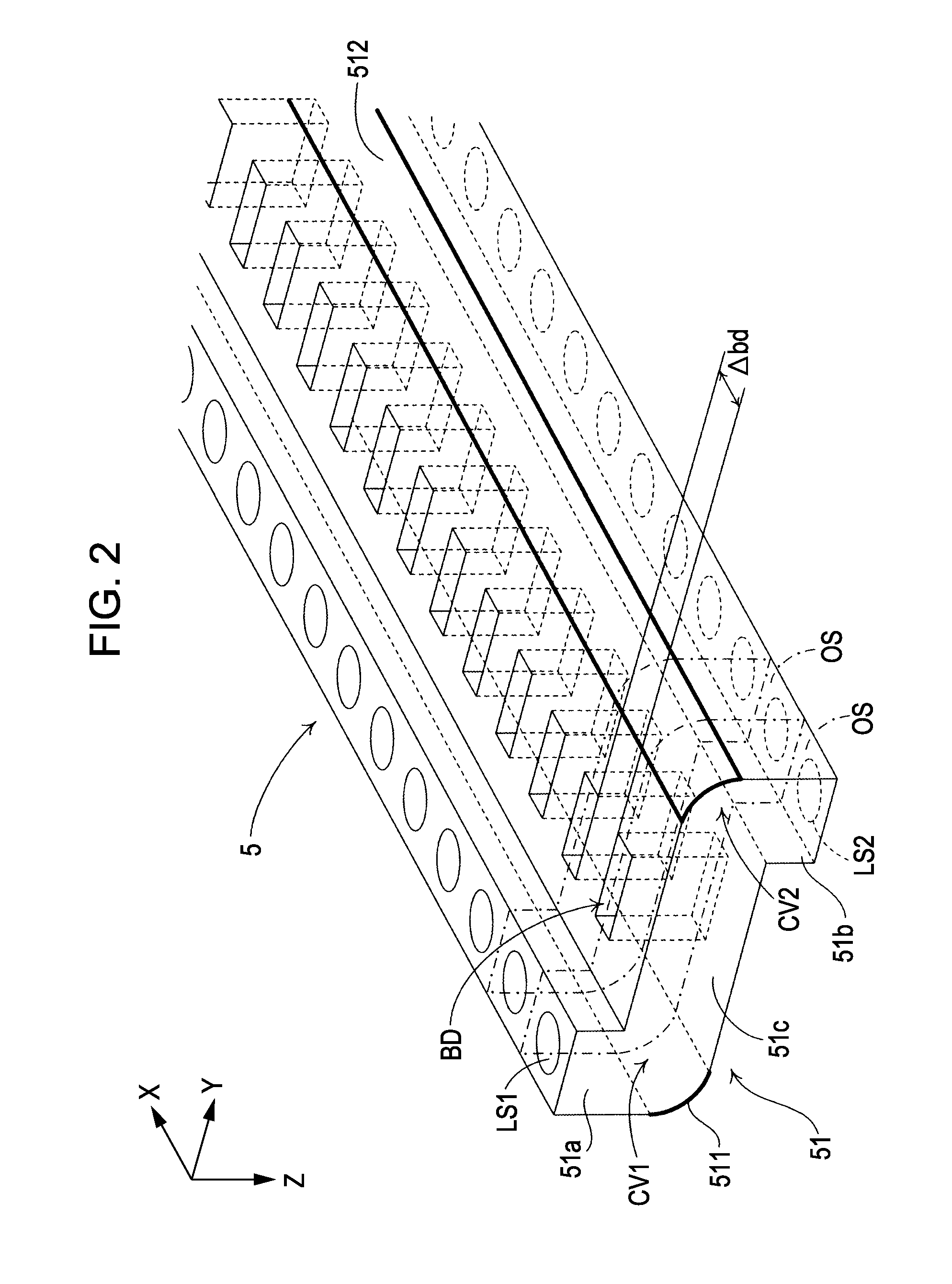

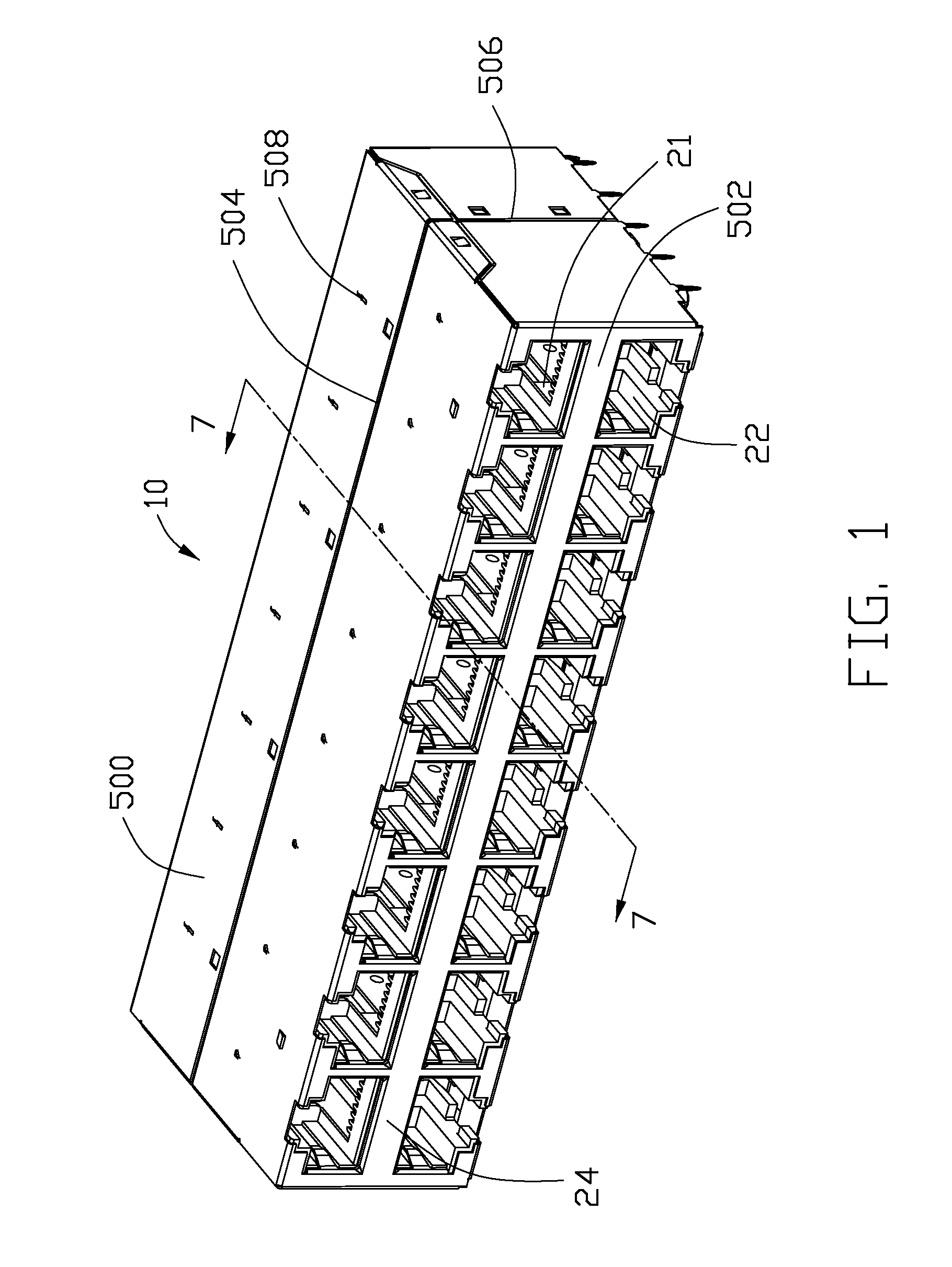

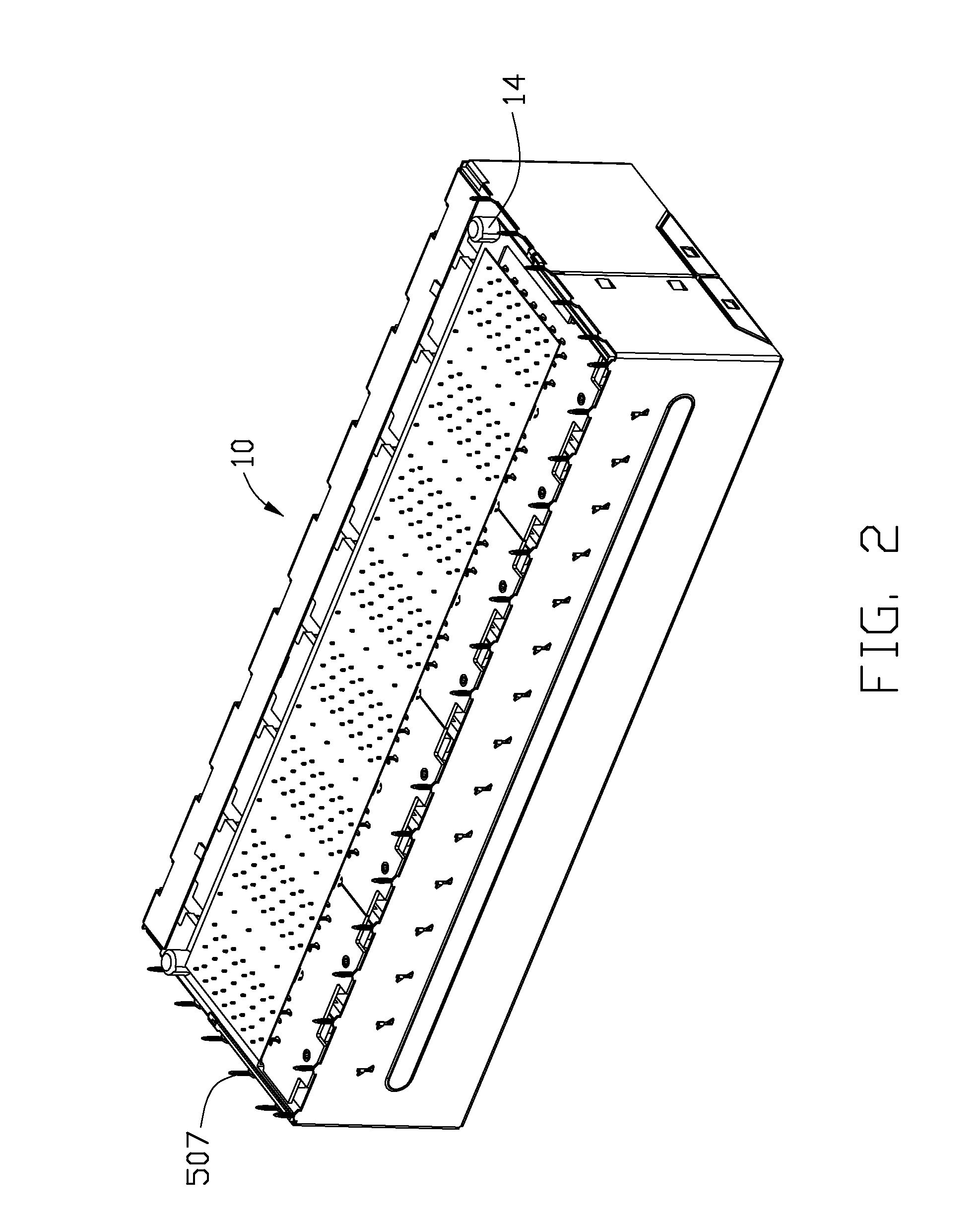

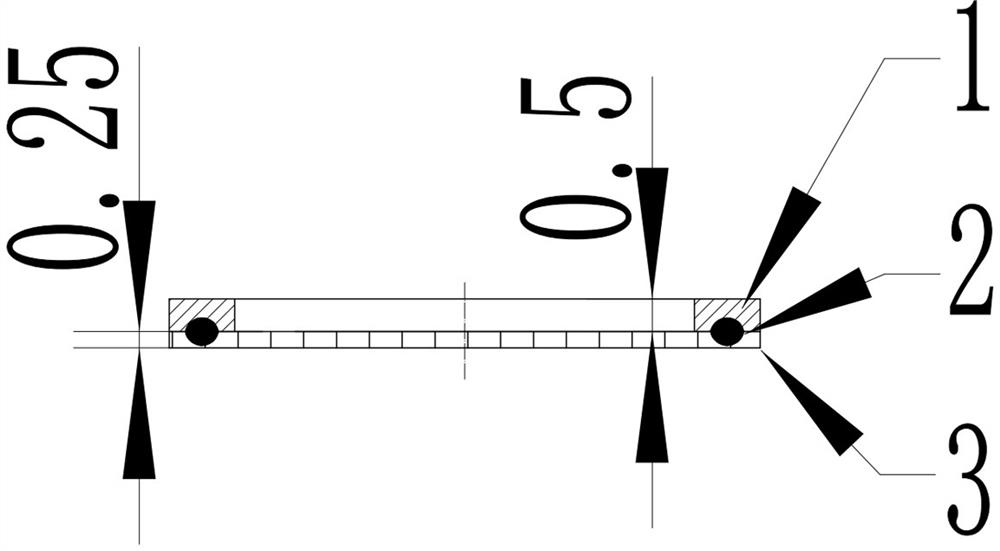

Imaging Optical Array And Image Reading Device

InactiveUS20120200900A1Stable positional relationshipStable relationshipPictoral communicationLight guideMagnification

An imaging optical array includes a plurality of imaging optical elements, which is arranged in a line in an arrangement direction, each including incidence lens to which light from an object is incident, an emission lens that emits light, and a light guiding portion that connects the incidence lens and the emission lens and that guides the light incident from the incidence lens to the emission lens, and which images an erect equal-magnification image of an object by the incidence lens and the emission lens, in which the plurality of imaging optical elements is integrally formed of a transparent medium in a state where the respective light guiding portions of the plurality of imaging optical elements are arranged in a line in the arrangement direction, and a void between the light guiding portions of the imaging optical elements adjacent to each other is empty in the transparent medium.

Owner:SEIKO EPSON CORP

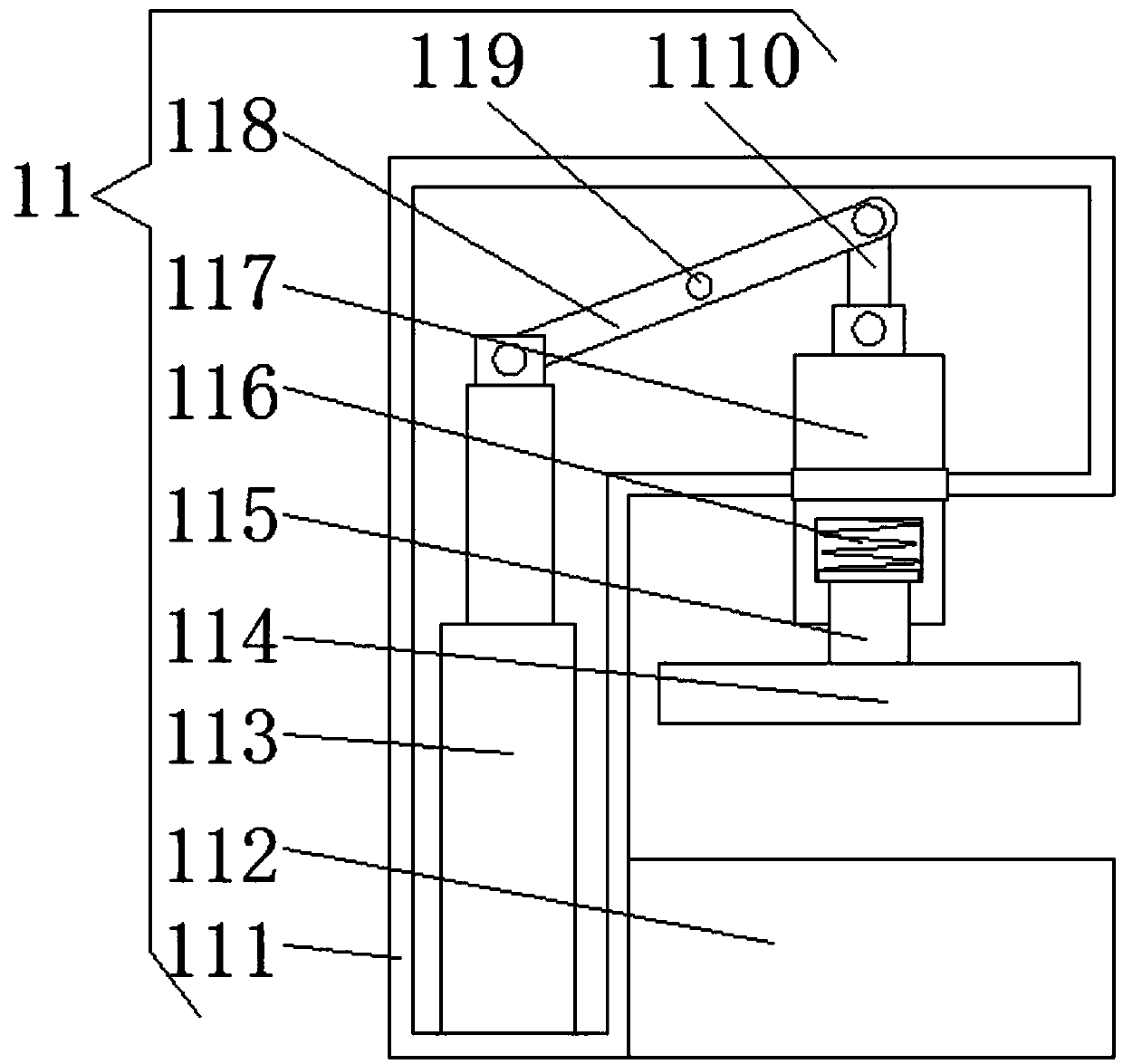

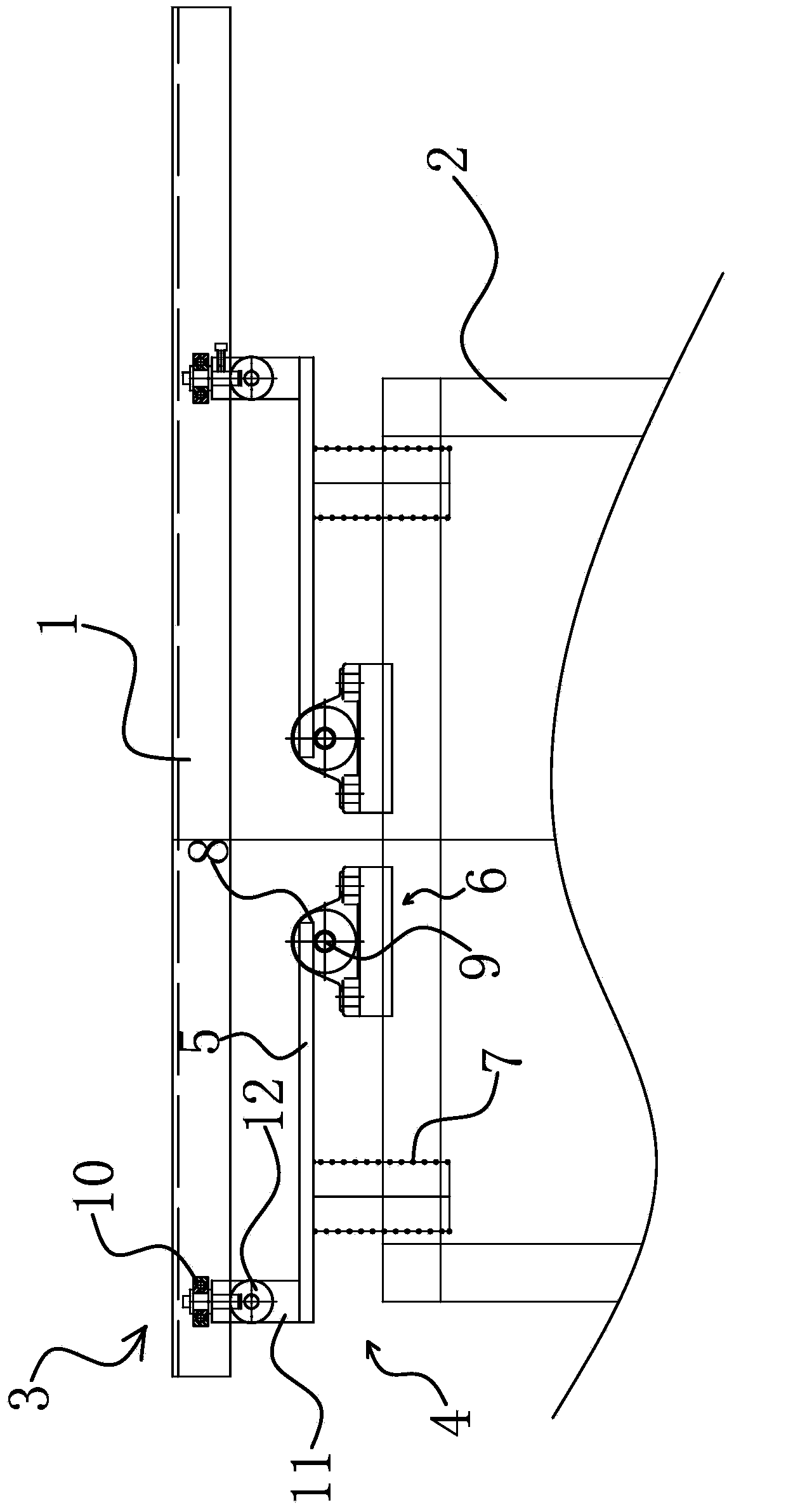

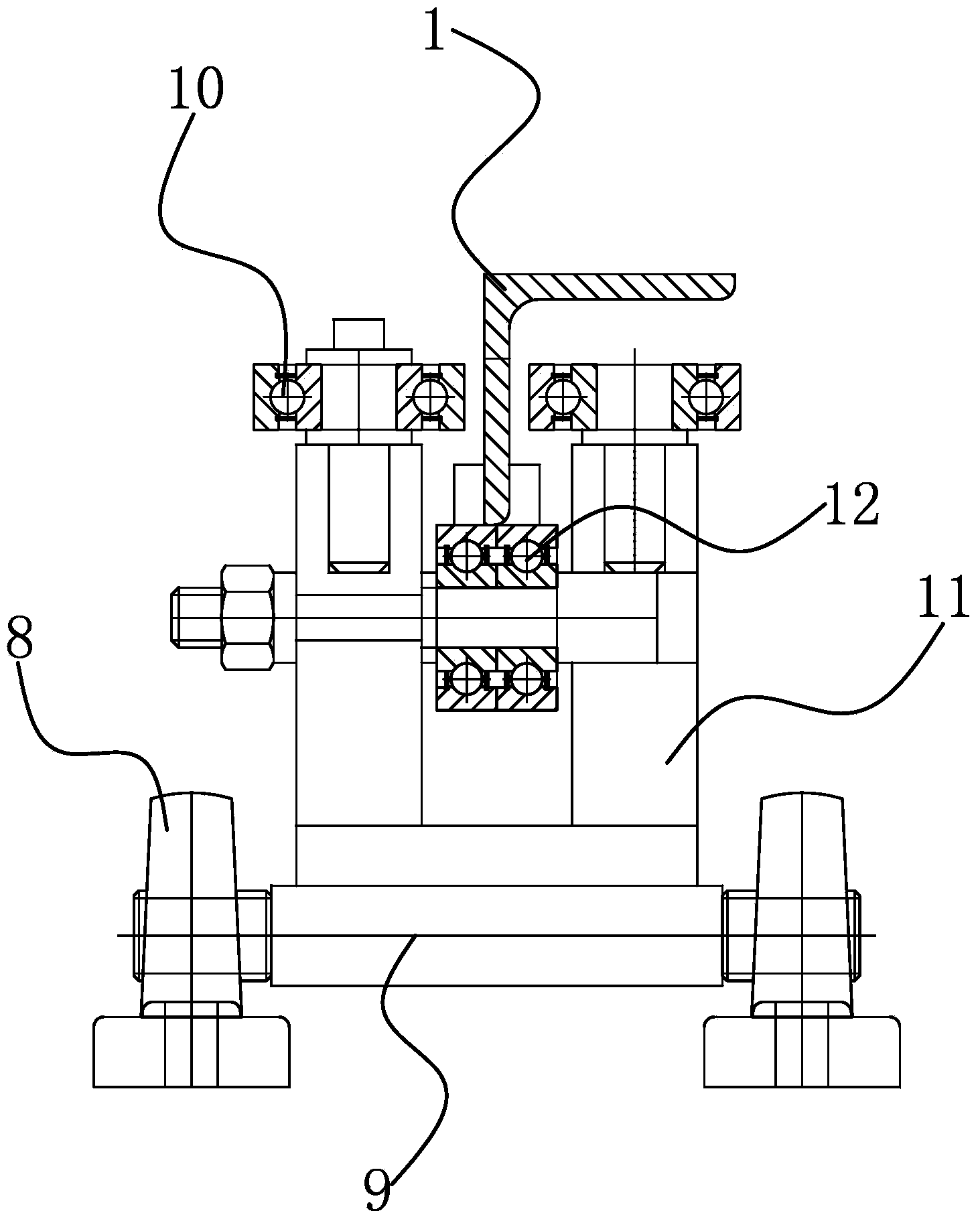

Swinging-type floating support structure

InactiveCN103962358ATroubleshoot difficult situationsGuaranteed uptimeCleaning processes and apparatusTemperature differenceEngineering

The invention belongs to the technical field of equipment cleaning, and particularly relates to a swinging-type floating support structure. The swinging-type floating support structure solves the technical problem that a cleaning machine operates difficultly in an environment with large temperature differences due to thermal expansion and cold contraction of a machine frame. The swinging-type floating support structure is arranged between an upper guide rail and the machine frame and is characterized in that the upper guide rail is provided with a guide wheel set capable of moving along the upper guide rail, and an elastic floating supporting mechanism making the guide wheel set to be attached to the upper guide rail tightly is arranged between the guide wheel set and the machine frame. The swinging-type floating support structure has the advantages that the upper guide rail can be supported in a floating mode, the guide wheel set is always in contact with the upper guide rail under certain pressure, the relative position relation of the guide wheel set and the machine frame maintains stable, the cleaning machine operates stably and reliably in the operating process, the situation that the upper guide rail derails due to installation errors is avoided, the problem that the cleaning machine operates difficultly in the environment with large temperature differences due to thermal expansion and cold contraction of the machine frame can be well solved, normal operation of the cleaning machine is guaranteed, the design is reasonable, the structure is simple and practicability is high.

Owner:江苏科能电力机械有限公司

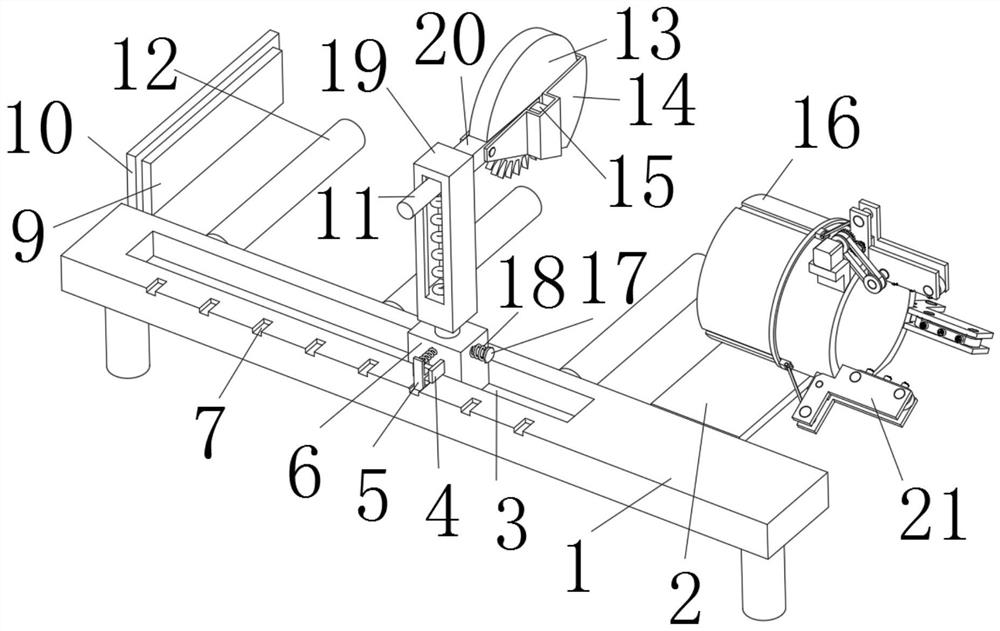

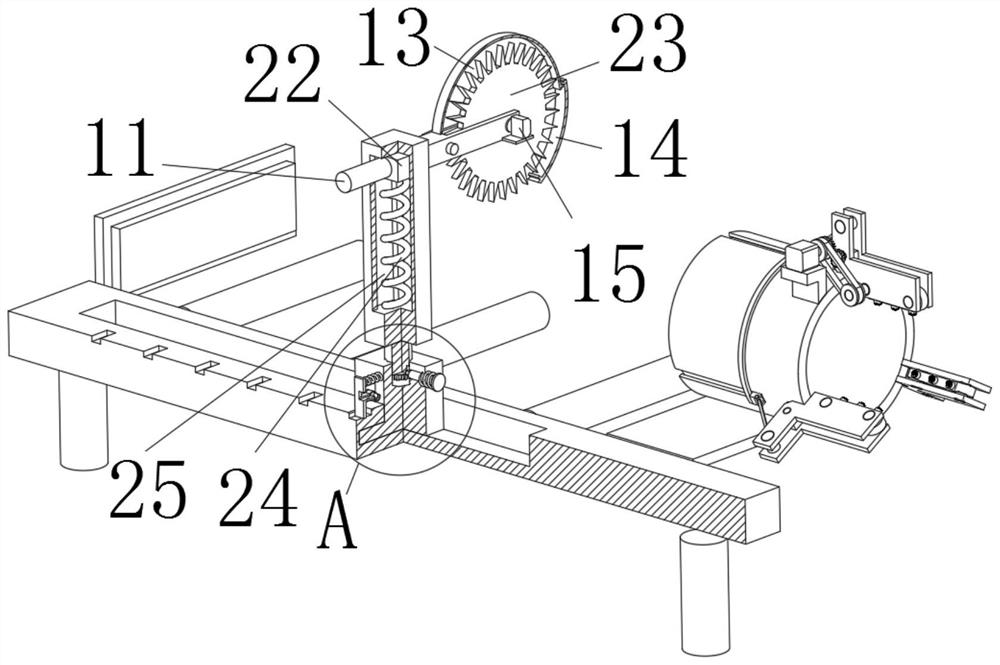

Efficient cutting equipment for PVC pipe production and PVC pipe production process

ActiveCN113103324AGuaranteed stabilityReasonable structureMetal working apparatusGear wheelElectric machinery

The invention discloses efficient cutting equipment for PVC pipe production and a PVC pipe production process, and relates to the field of cutting devices. The efficient cutting equipment comprises a base, a mounting plate is fixedly connected to one side of the base, a mounting ring is fixedly connected to the top of the mounting plate, and a PVC pipe clamping mechanism is mounted on the side wall of the mounting ring. A PVC pipe conveying mechanism is mounted on the PVC pipe clamping mechanism, a plurality of round rod shafts are fixedly connected to one side of the base, and hollow rods rotationally sleeve the round rod shafts. The efficient cutting equipment for the PVC pipe production is reasonable in structure, a conveying motor drives a first gear to rotate clockwise, the first gear is matched with a second gear and a third gear to rotate, a half gear is driven to rotate clockwise, when the half gear rotates clockwise, a clamping plate is driven to rotate, and when meshing of the second gear and the half gear is finished, the clamping plate rotates to a limiting position; and at the moment, the second gear is in a continuous tangent process with a last tooth of the half gear during rotation.

Owner:唐山冀鸿节水科技有限公司

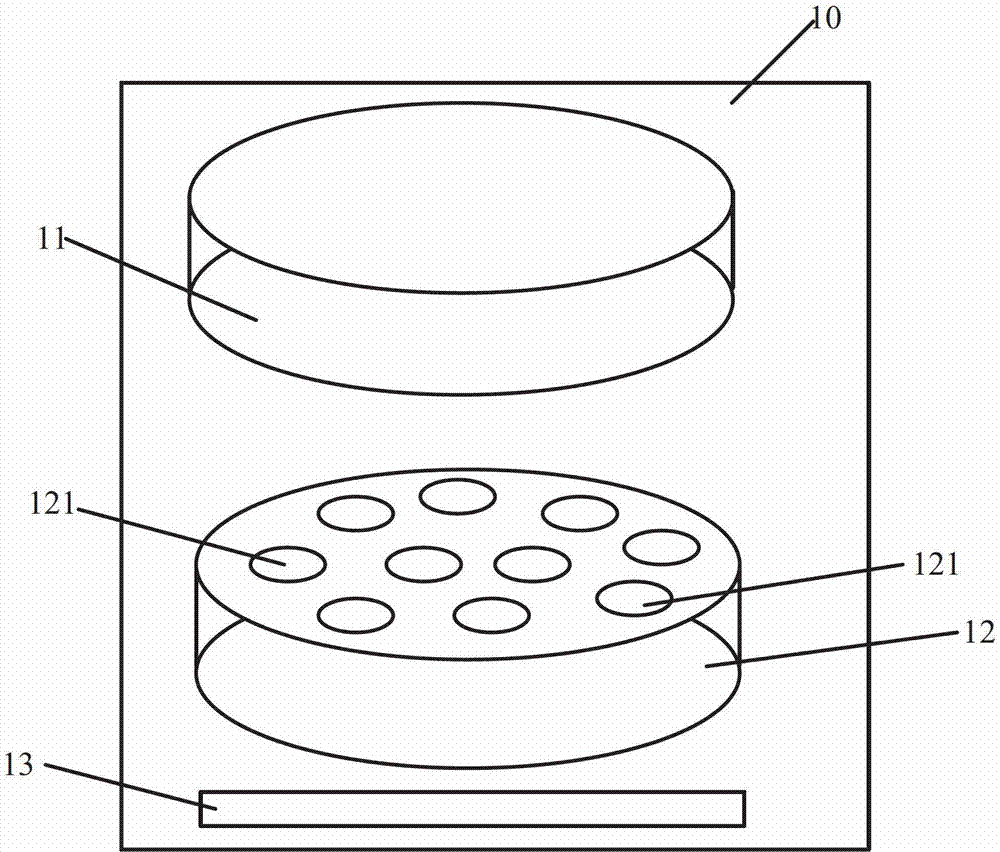

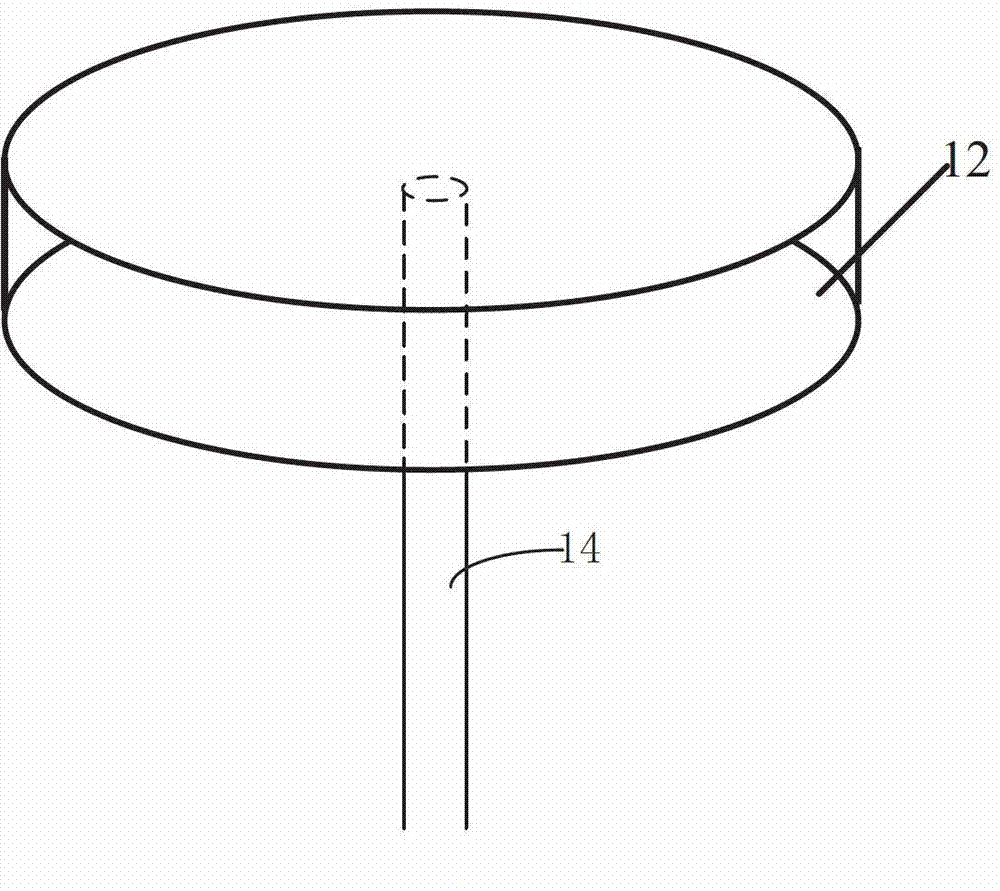

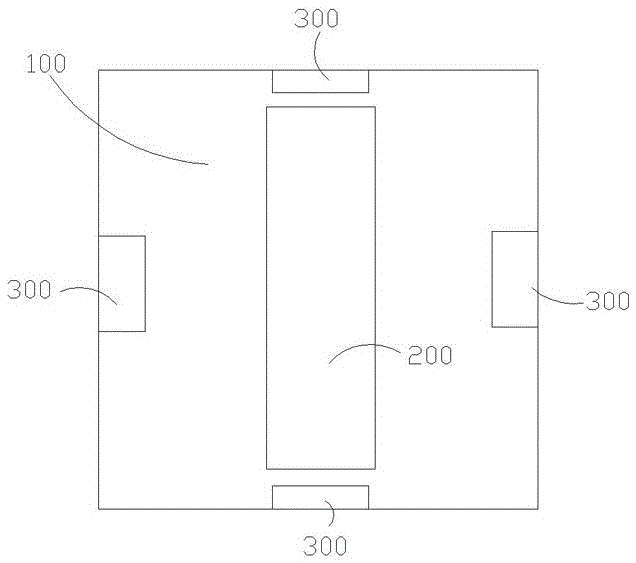

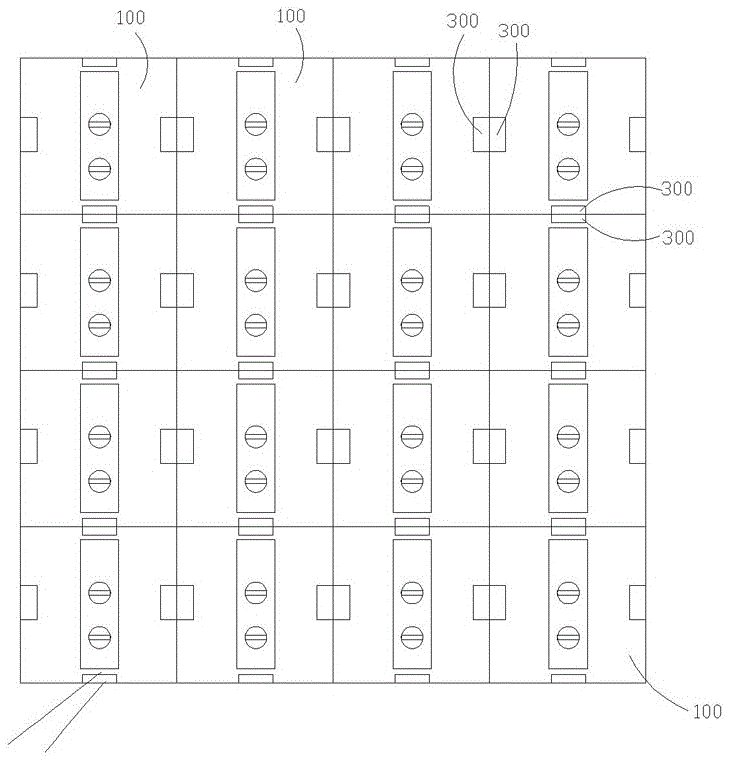

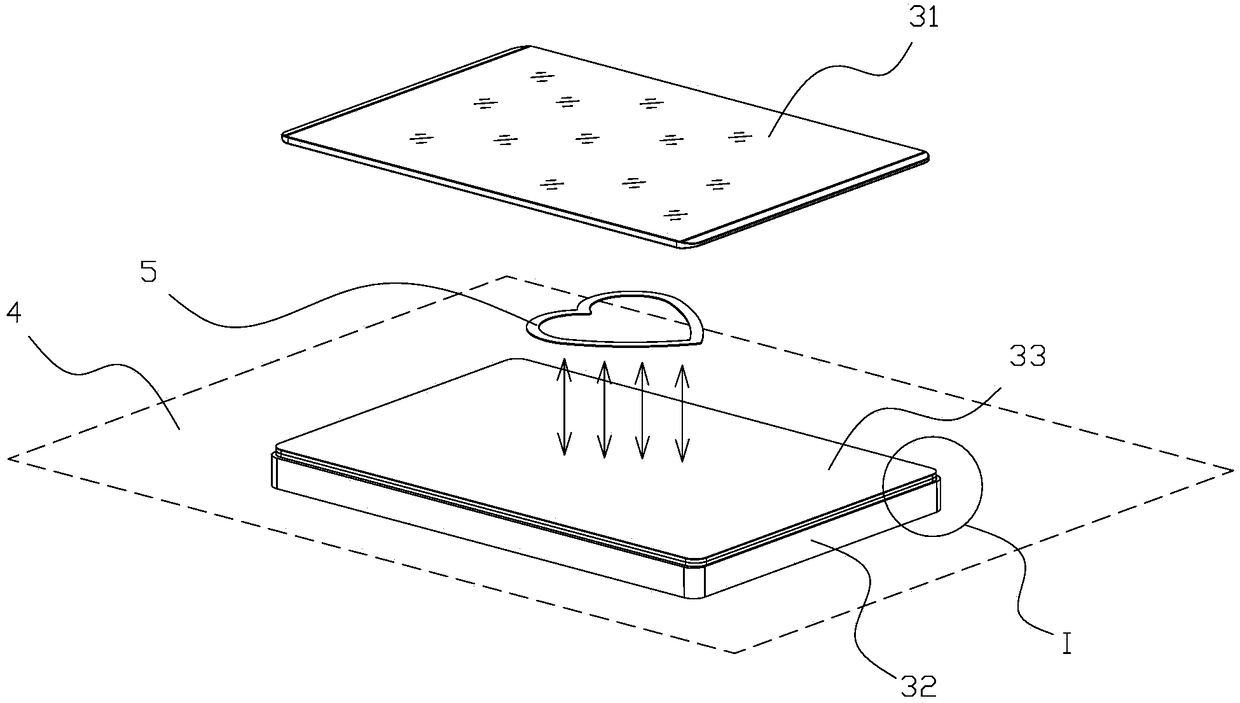

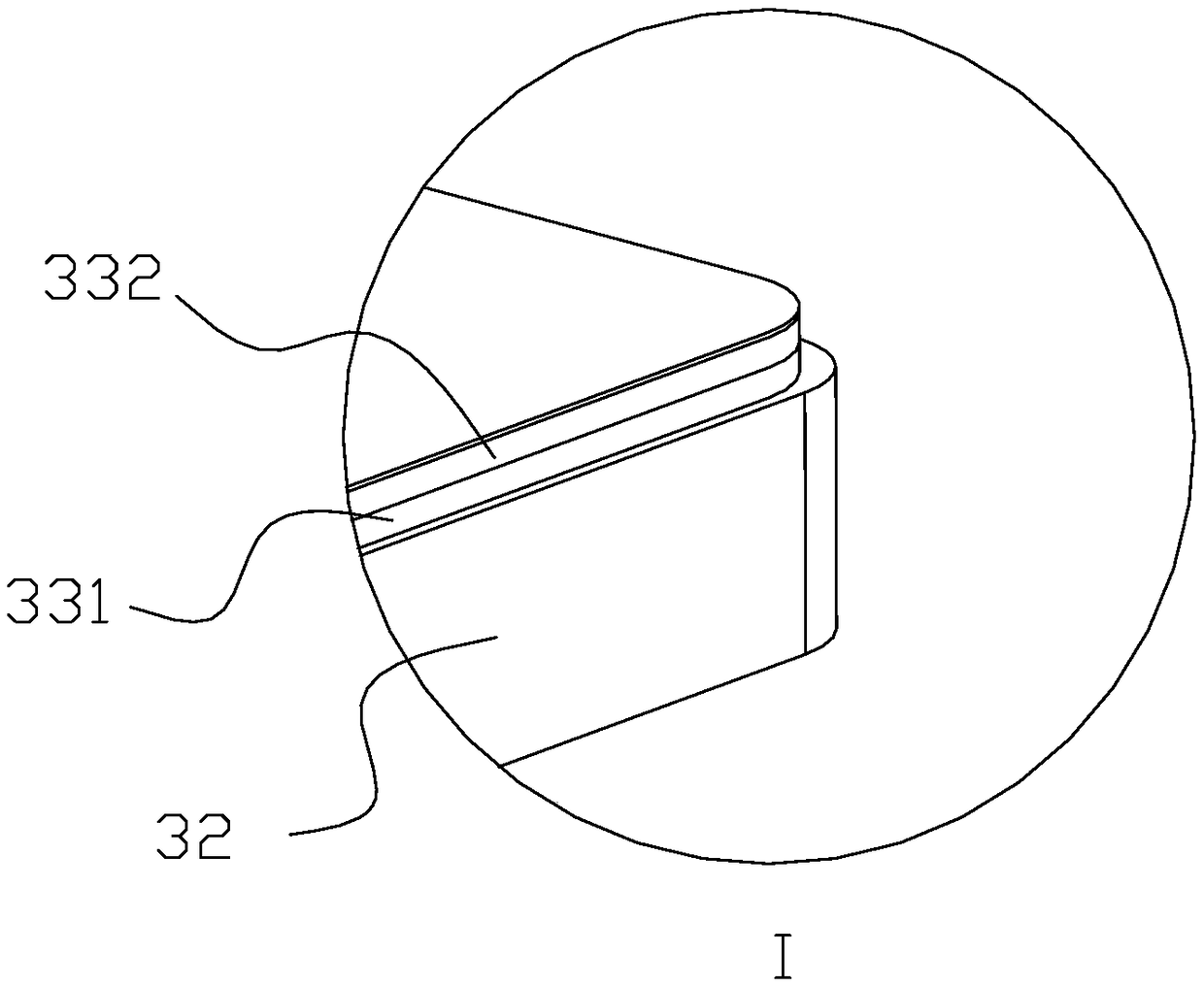

Substrate supporting structure and reaction chamber containing the same

InactiveCN103074610AStable positional relationshipImprove uniformityChemical vapor deposition coatingEngineeringMechanical engineering

The present invention provides a substrate supporting structure and a reaction chamber containing the substrate supporting structure. The substrate supporting structure comprises a substrate supporting disc and a cylindrical supporting member, wherein the cylindrical supporting member is vertically arranged, the substrate supporting disc is supported on the top end of the cylindrical supporting member, the top end of the cylindrical supporting member is provided with a supporting member projection or a supporting member recess, the substrate supporting disc is provided with a supporting disc recess corresponding to the supporting member projection or a supporting disc projection corresponding to the supporting member recess, and the supporting member projection and the supporting disc recess are matched or the supporting member recess and the supporting disc projection are matched so as to lock the substrate supporting disc on the cylindrical supporting member. With the present invention, the problems that the substrate-placed substrate supporting disc easily fly out during a rotation process and rotation of the substrate supporting disc is not stable are solved.

Owner:BRILLIANT LIGHT TECH

Integrated connector for power supply transmission lines, signal transmission lines and lock bodies and integrating method

InactiveCN105552644AStable positional relationshipSimple and efficient construction and installation workCoupling device engaging/disengagingCoupling device detailsConnection - actionEngineering

The invention relates to an integrated connector for power supply transmission lines, signal transmission lines and lock bodies and an integrating method. The connector comprises a plurality of connecting lock bodies, wherein each connecting lock body is connected with a screen power signal module through an internal line; the connecting lock bodies are used for determining the connection relationship between any adjacent display screens; meanwhile, the connecting lock bodies are also used for transmitting signals and currents between any adjacent display screens; the connecting lock bodies are divided into plug bodies and socket bodies; each plug body comprises a locking unit and a plug unit; an action unit drives each locking unit to finish a connecting lock action between any adjacent display screens; and the action unit can also drive each plug unit to finish signal and current connection actions between any adjacent display screens.

Owner:刘剑冰

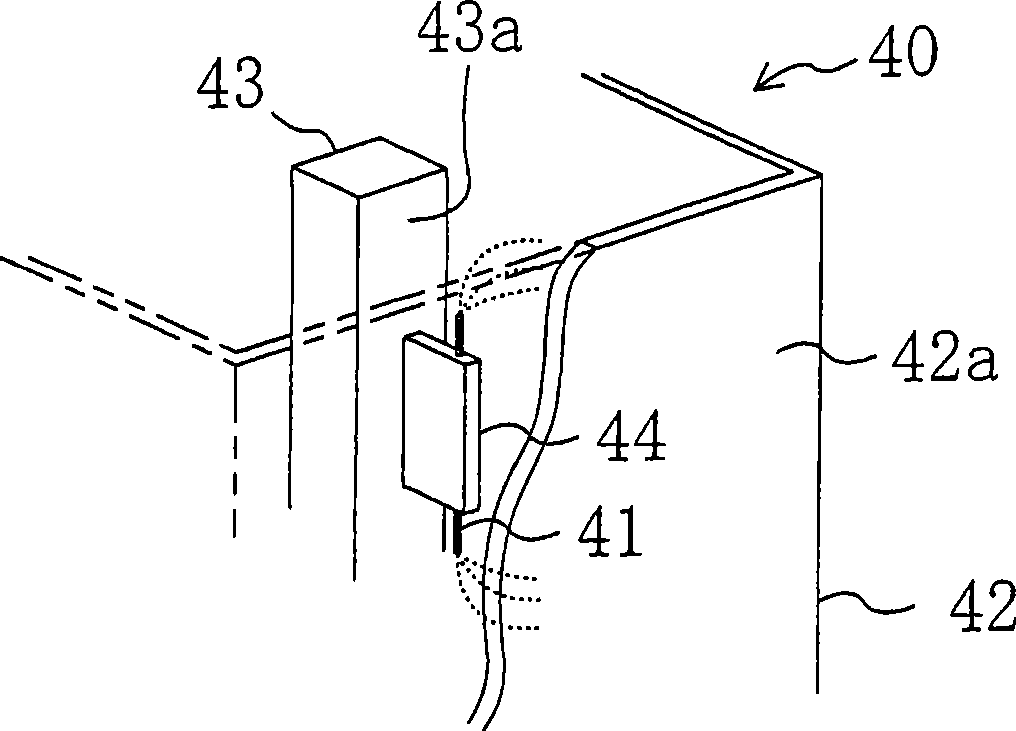

Electric discharge device and air purifier device

ActiveCN101425660AMaintain discharge characteristicsStable Streamer DischargeDispersed particle separationDeodrantsElectric dischargeAir purifiers

In an electric discharge device (40) performing streamer discharge from the top of a discharge electrode (41) toward an opposing electrode (42), the discharge electrode (41) with a liner or bar-like shape is placed substantially parallel to the opposing electrode (42). The structure results that the shape of the top of the discharge electrode (41) does not change even if the top wears and the distance between the discharge electrode (41) and the opposing electrode (42) also does not change. This prevents stability of streamer discharge from lowering even if the top of the discharge electrode (41) wears.

Owner:DAIKIN IND LTD

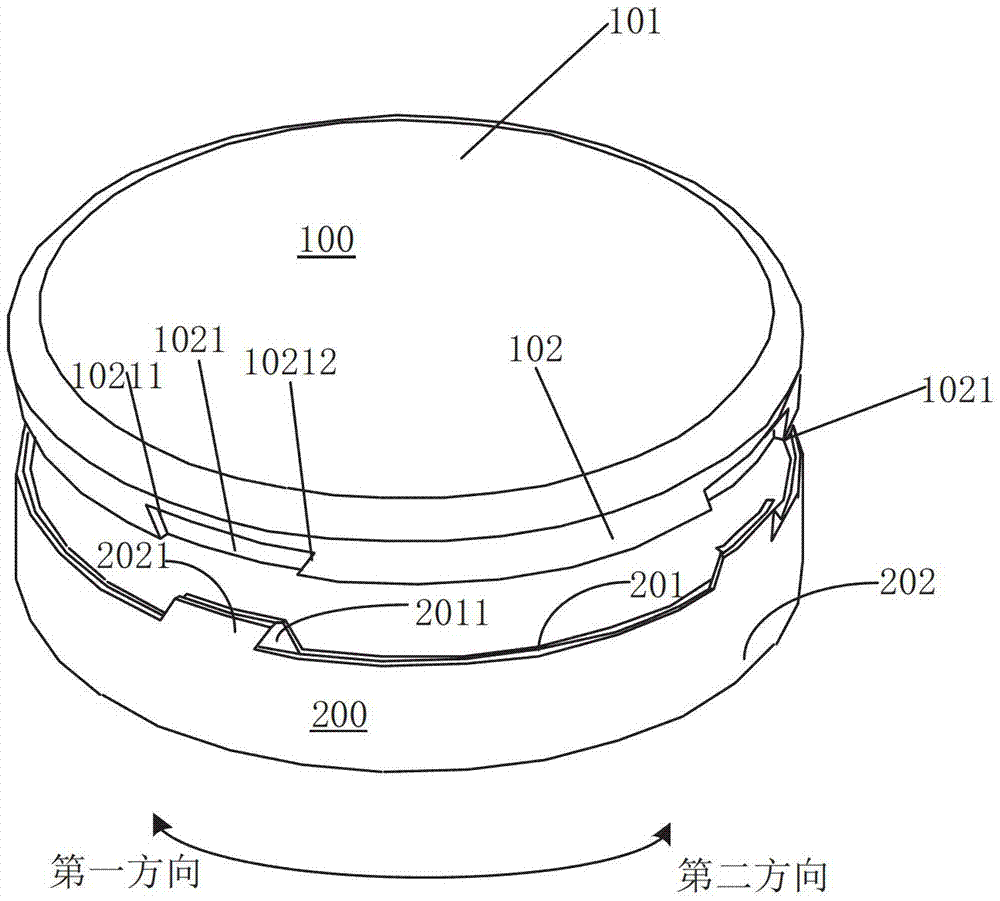

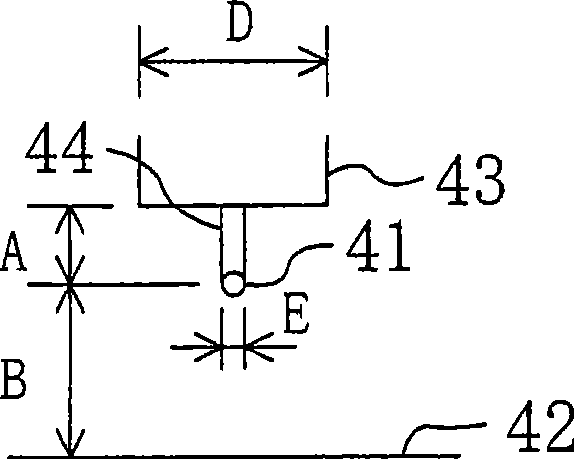

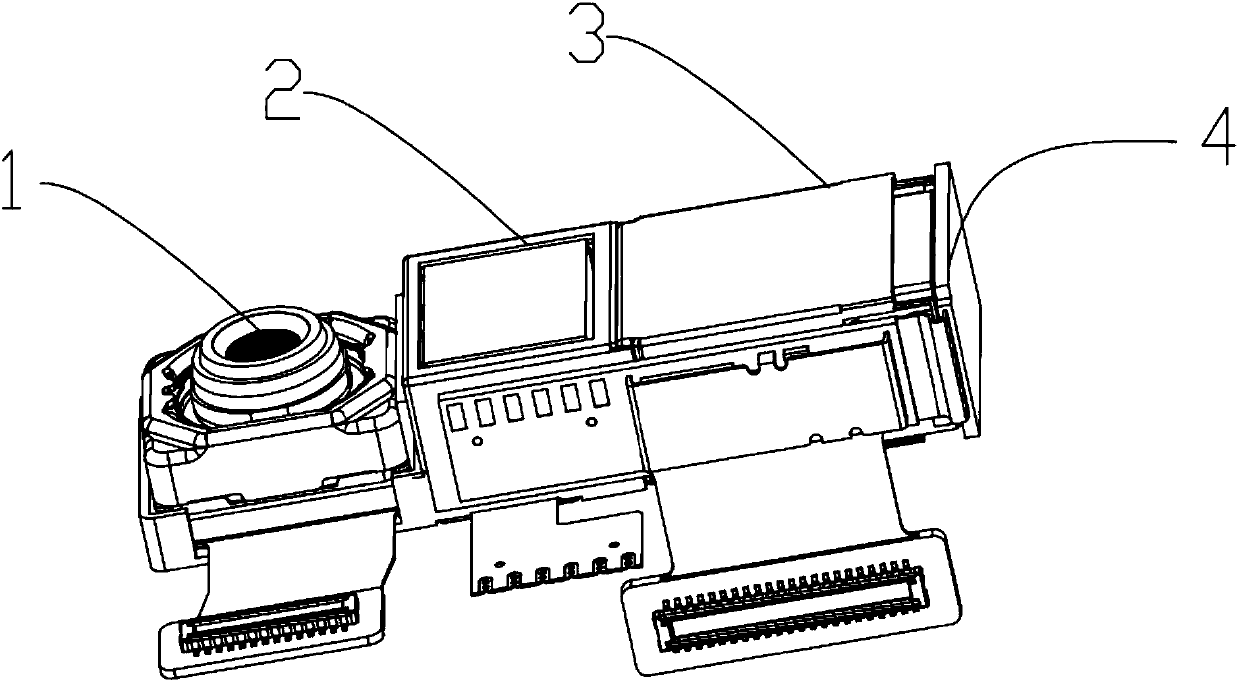

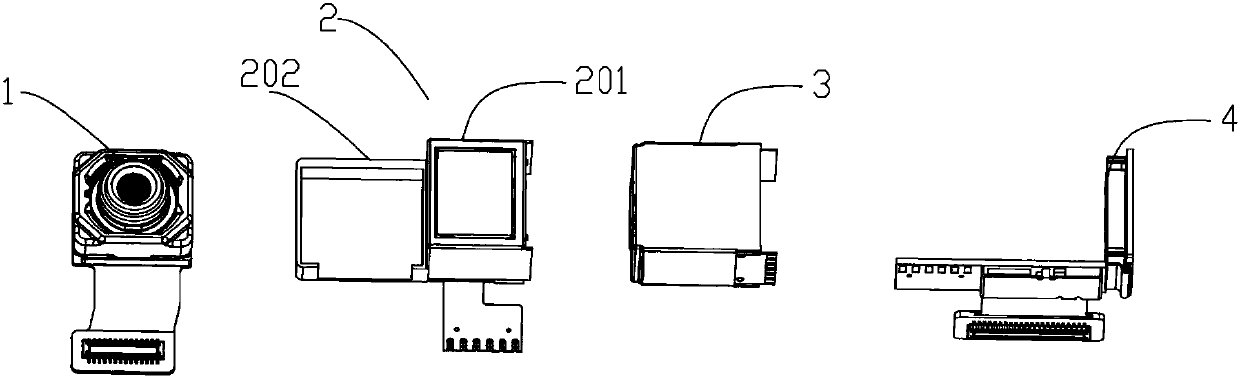

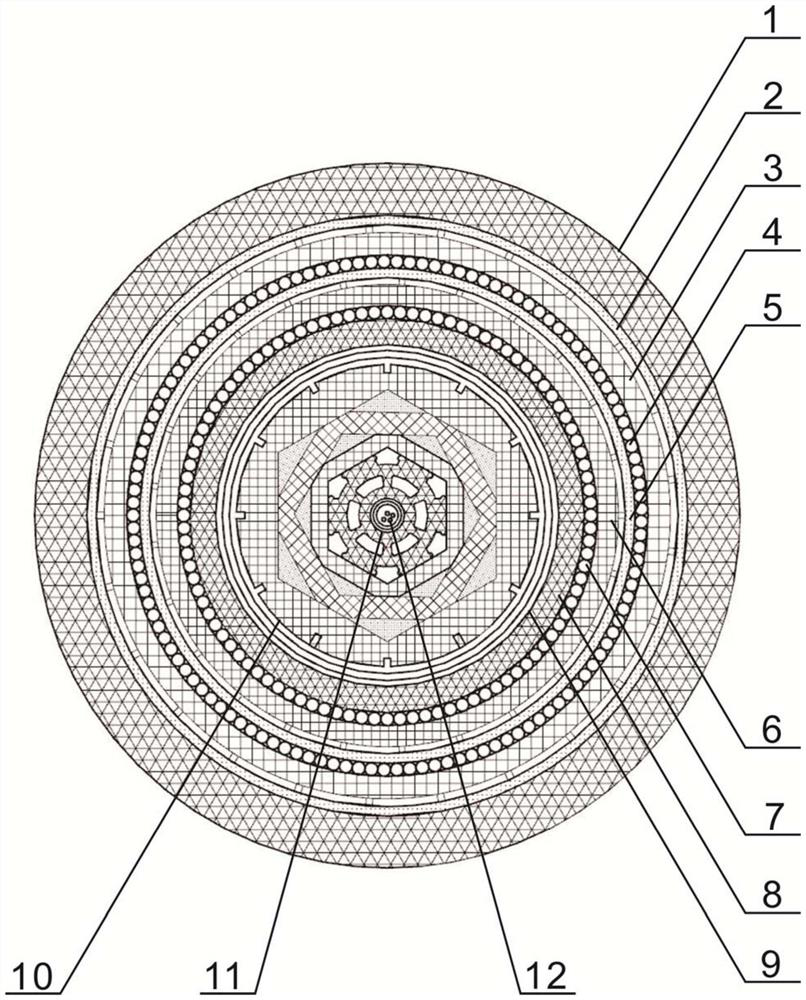

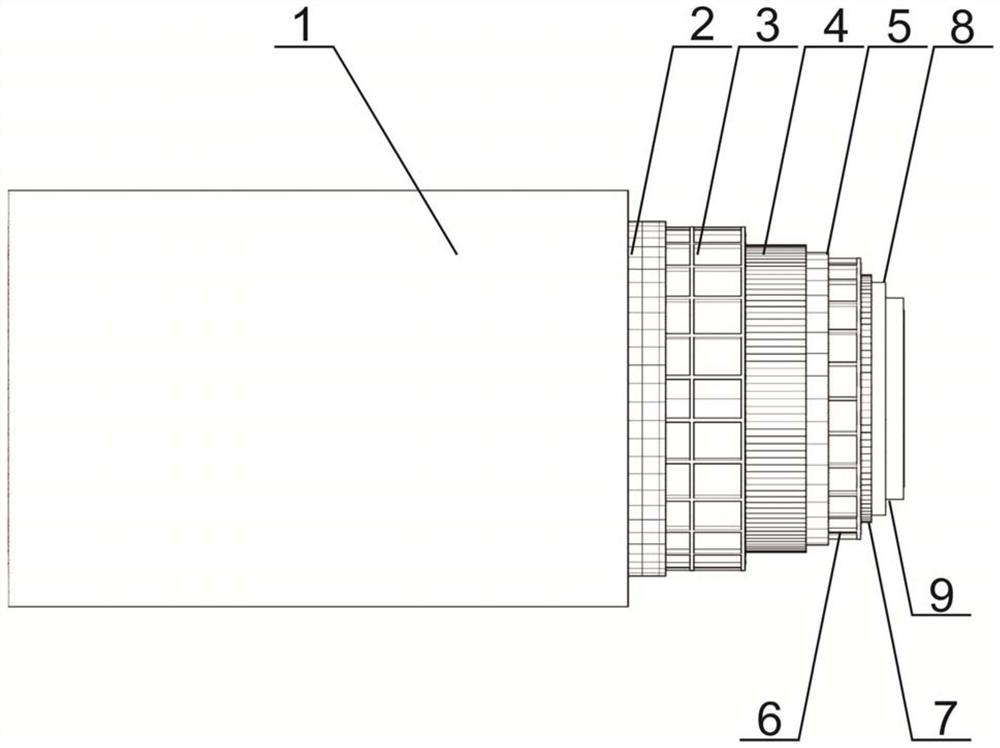

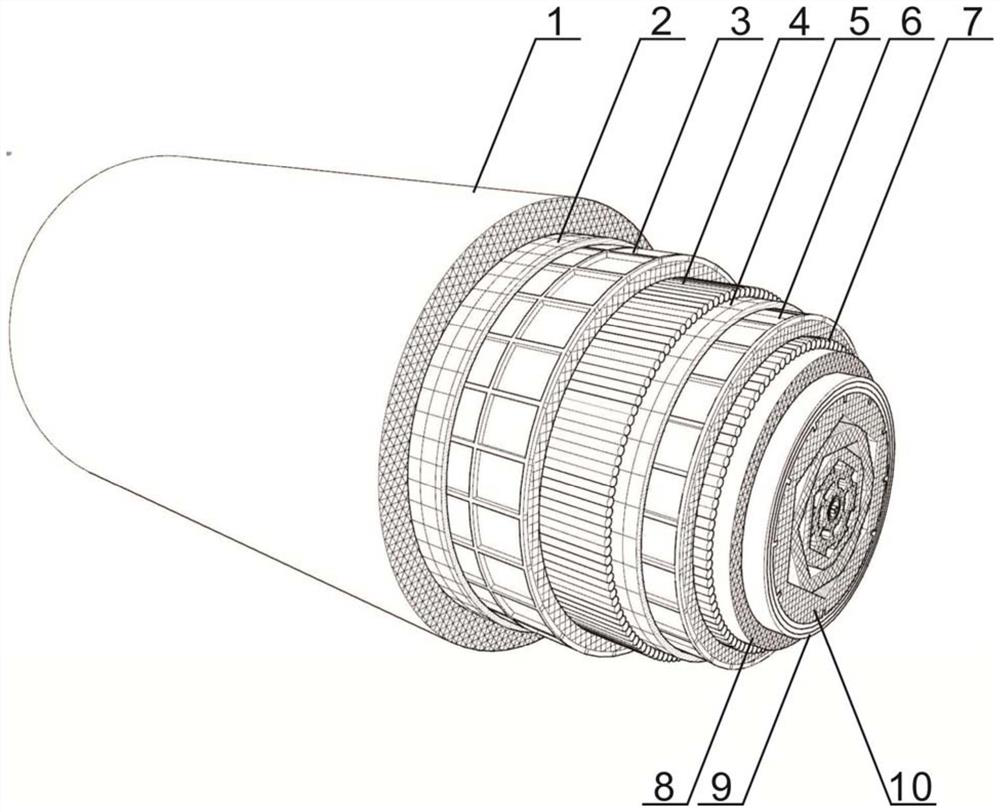

Double-shooting zooming module

PendingCN107783246AGuaranteed image qualityImprove rigidityMountingsFocusing aidsMating connectionOptical axis

The invention relates to a double-shooting zooming module. The double-shooting zooming module comprises a first shooting module, a prism module, a second shooting module and a circuit board. The double-shooting zooming module is characterized in that the first shooting module and the prism module are arranged in a co-plane mode, and the prism module and an optical axis of the second shooting module are coaxially arranged. According to the double-shooting zooming module, a prism base is provided with an intermediate reinforcing plate to reinforce the prism base, the prism base is further provided with a positioning projection, the second shooting module is provided with a positioning hole, the positioning projection and the projection hole are in matching connection to guarantee that the mutual position relationship is correct, and imaging quality is improved. The double-shooting zooming module is advantaged in that the split structure is employed, different components are divided intodifferent units, the different parts are then assembled into one body, so the parts can be flexibly changed, and cost and maintenance expenditure are saved.

Owner:NINGBO SUNNY OPOTECH CO LTD

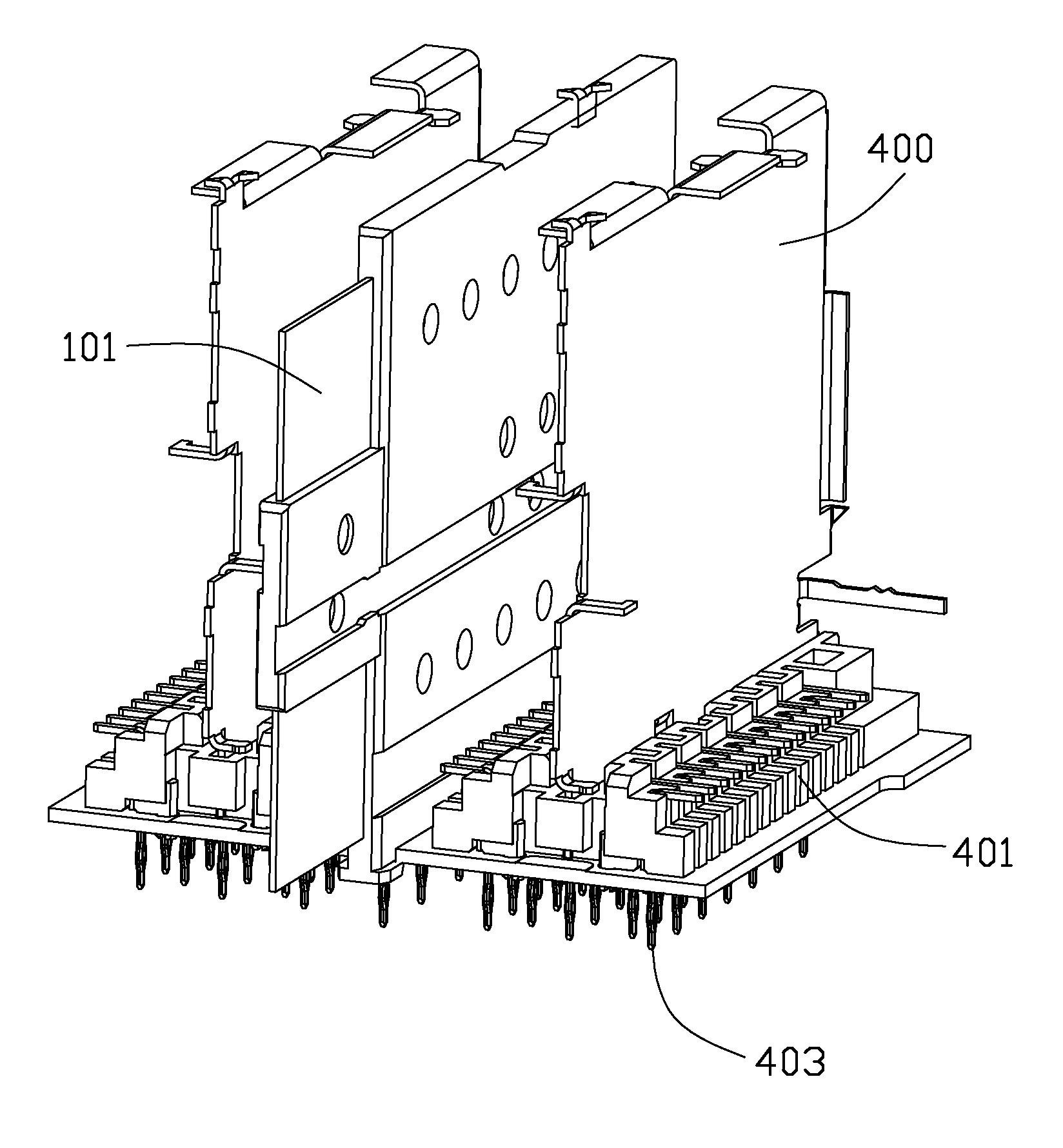

Electrical connector having position fixer for conductive terminals

ActiveUS20130252457A1Easy to insertStable positional relationshipLine/current collector detailsElectrically conductive connectionsPrinted circuit boardElectrical connector

An electrical connector (10) adapted for being mounted onto a printed circuit board (PCB) including a number of vias. The electrical connector includes an insulative housing (200) having a board mounting surface (12), a contact module (400) assembled to the insulating housing (200) and including a number of conductive terminals (403), and a positioning fixer (300) mounting to the conductive terminals. Each of the conductive terminals includes a pin end extending beyond the mounting surface for being inserted into one of the PCB vias. The position fixer (300) has a plurality of through holes (301) each retaining to a corresponding pin end (405) prior to the position fixer (300) being moved up to the mounting surface when the electrical connector is mounted to the PCB.

Owner:HON HAI PRECISION IND CO LTD

Submarine optical cable

ActiveCN113671646AHigh compressive strengthStable positional relationshipFibre mechanical structuresStructural engineeringProtection layer

The invention belongs to the technical field of optical cables and particularly relates to a submarine optical cable. The submarine optical cable comprises an outer protection layer, a middle protection layer, an inner protection layer and a cable core assembly, wherein the cross section of the middle protection layer is annular, the middle protection layer comprises a first tearing net attached to the outer protection layer and a first damage layer attached to an inner wall of the first tearing net, the first tearing net is formed by weaving steel wires, the first damage layer comprises a base layer I and grid strips I located on the periphery of the base layer I, and the grid strips I are embedded into an inner wall face of the first tearing net; and the middle protection layer further comprises a first steel strand protection layer. The submarine optical cable is advantaged in that the first tearing net woven by the steel wires is attached to the periphery of the first damage layer, a reserved space is formed between the first tearing net and the base layer I of the first damage layer, and when the outer protection layer is destroyed by an external force and the first tearing net is impacted by the external force, deformation of the first tearing net consumes a part of the external force; and the first damage layer can continue to consume the external force through self-destruction, so the destructive force and the damage area of the external force are reduced.

Owner:FUTONG GRP JIASHAN COMM TECH CO LTD +1

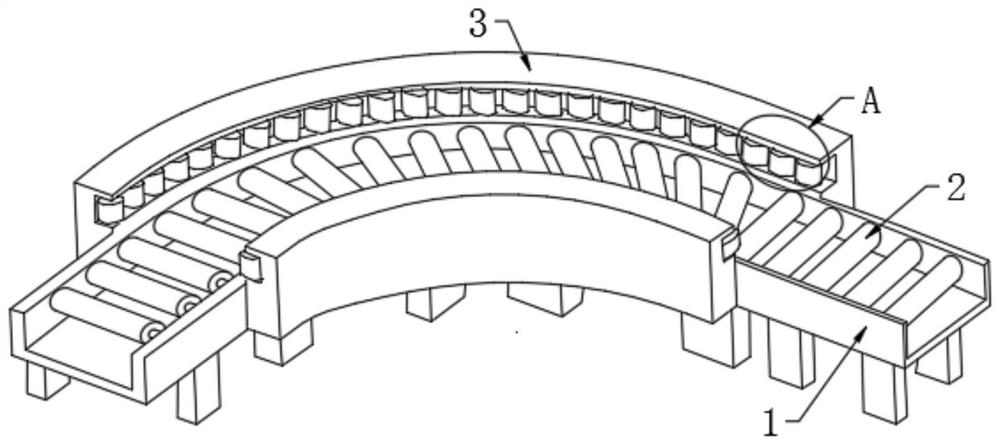

Conveying equipment for glass processing production line

InactiveCN111824773AStable positional relationshipNo shakingCharge manipulationConveyor partsManufacturing lineManufacturing engineering

Owner:马鞍山楚锐科技信息咨询有限公司

Low-power resistance spot-welding process adopting multi-end electrode

PendingCN113351976AStable positional relationshipEliminate position changesResistance welding apparatusElectrical resistance and conductanceSpot welding

The invention discloses a low-power resistance spot-welding process adopting a multi-end electrode. The low-power resistance spot-welding process adopting the multi-end electrode is used for solving the problems of welding spatter, high welding penetration rate and the like caused by unstable single-point welding and excessive instantaneous welding heat input in an existing resistance spot-welding connection technology for thin-wall parts and filter screen parts. The low-power resistance spot-welding process adopting the multi-end electrode comprises the steps of cleaning and assembling for a welding test piece, pressing before welding, preheating before welding, welding, pressure maintaining after welding and the like, wherein the multi-end electrode is used for welding the welding test piece, the welding process of pressurizing, preheating, welding and maintaining is adopted, the whole welding process lasts for about 5 ms, the time of heat accumulation in a welding pressing process is shortened, the welding efficiency is increased, and the stability of product assembling is improved; and the spatter generated in the welding process can be effectively avoided, collapse, welding penetration and the like in the welding process are greatly reduced, resistance spot-welding connection for thin-wall filter screens and gaskets can be stably, efficiently and excellently realized, and a new technological reference is provided for welding for thin-wall filter screen parts.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

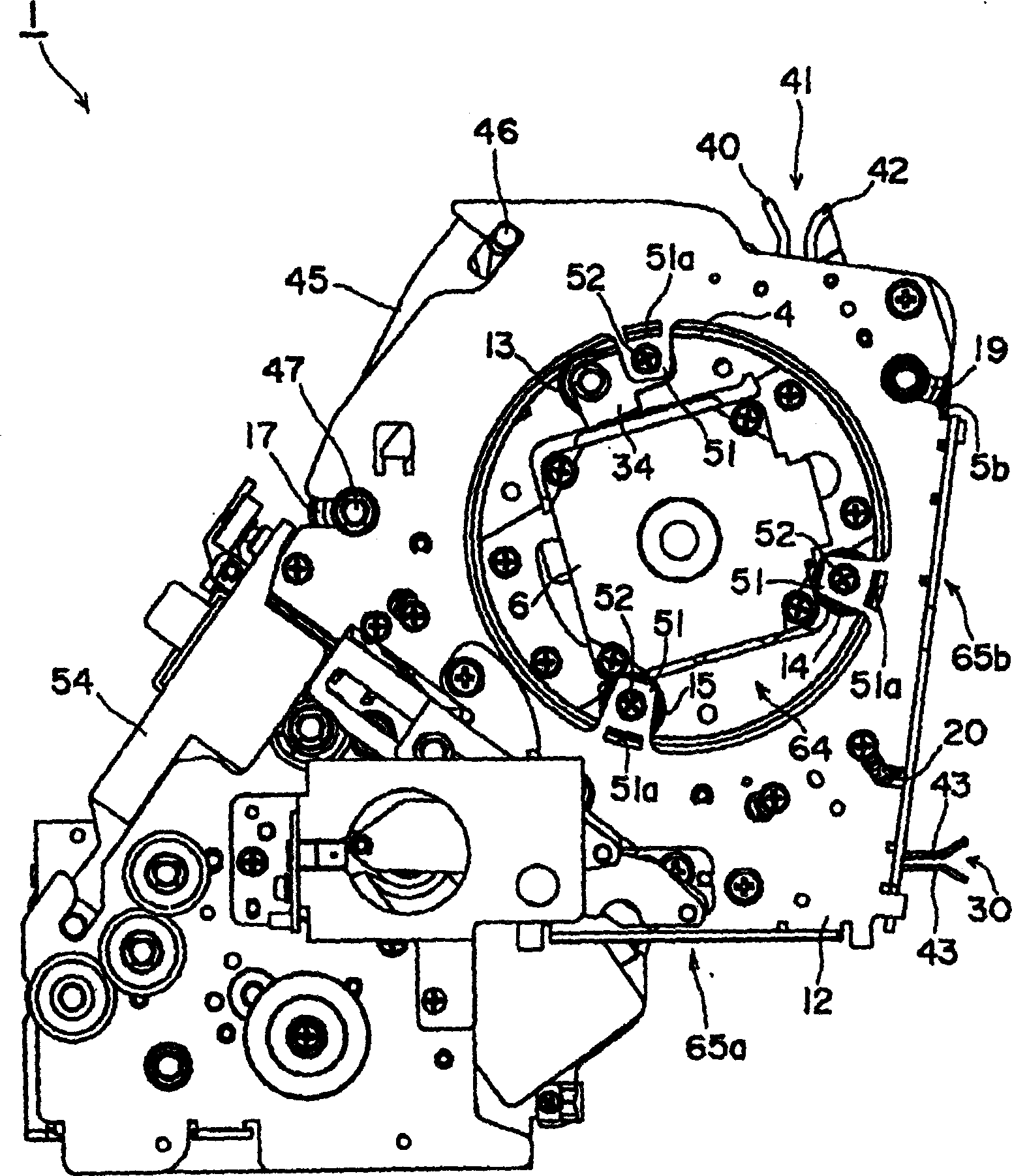

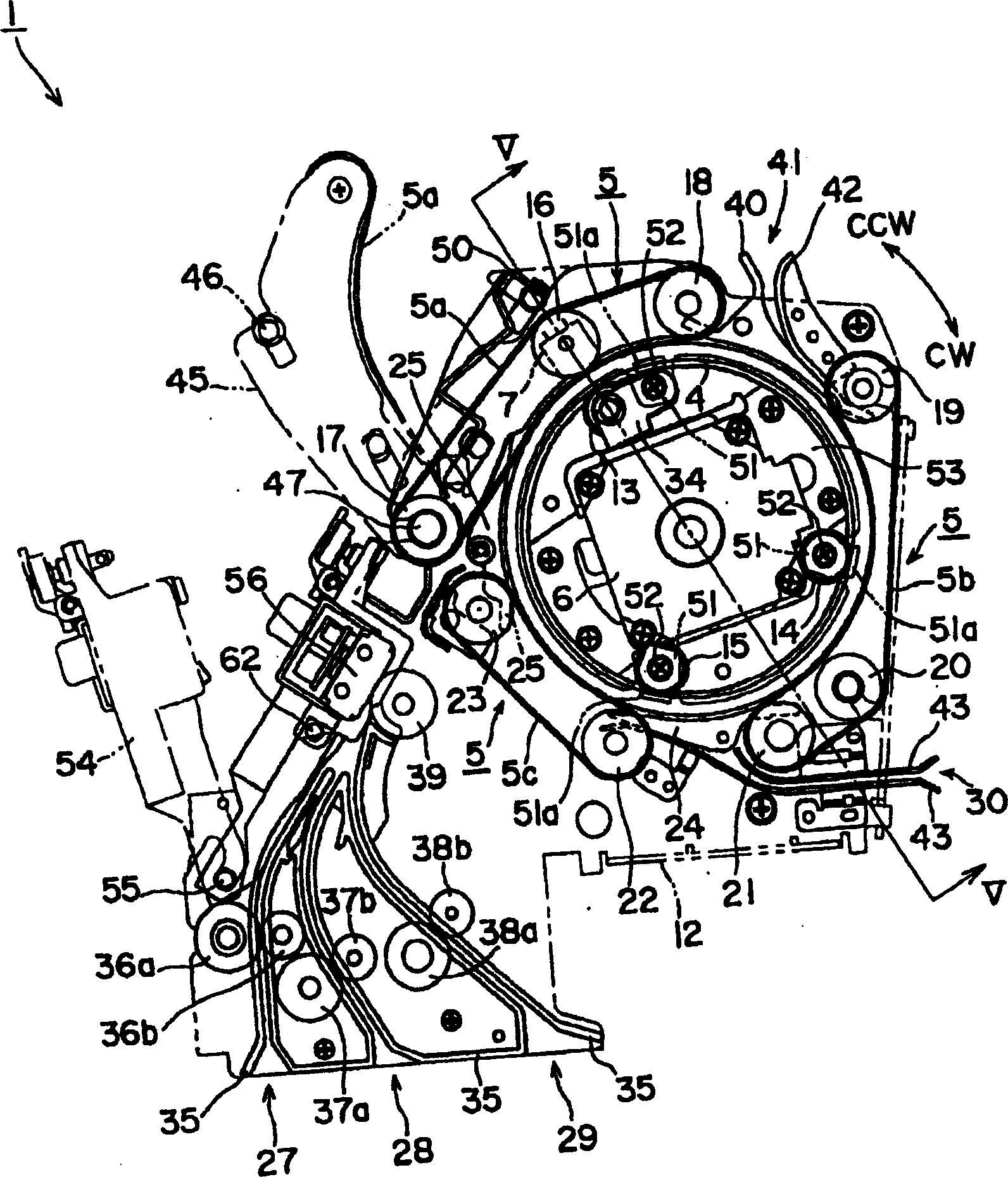

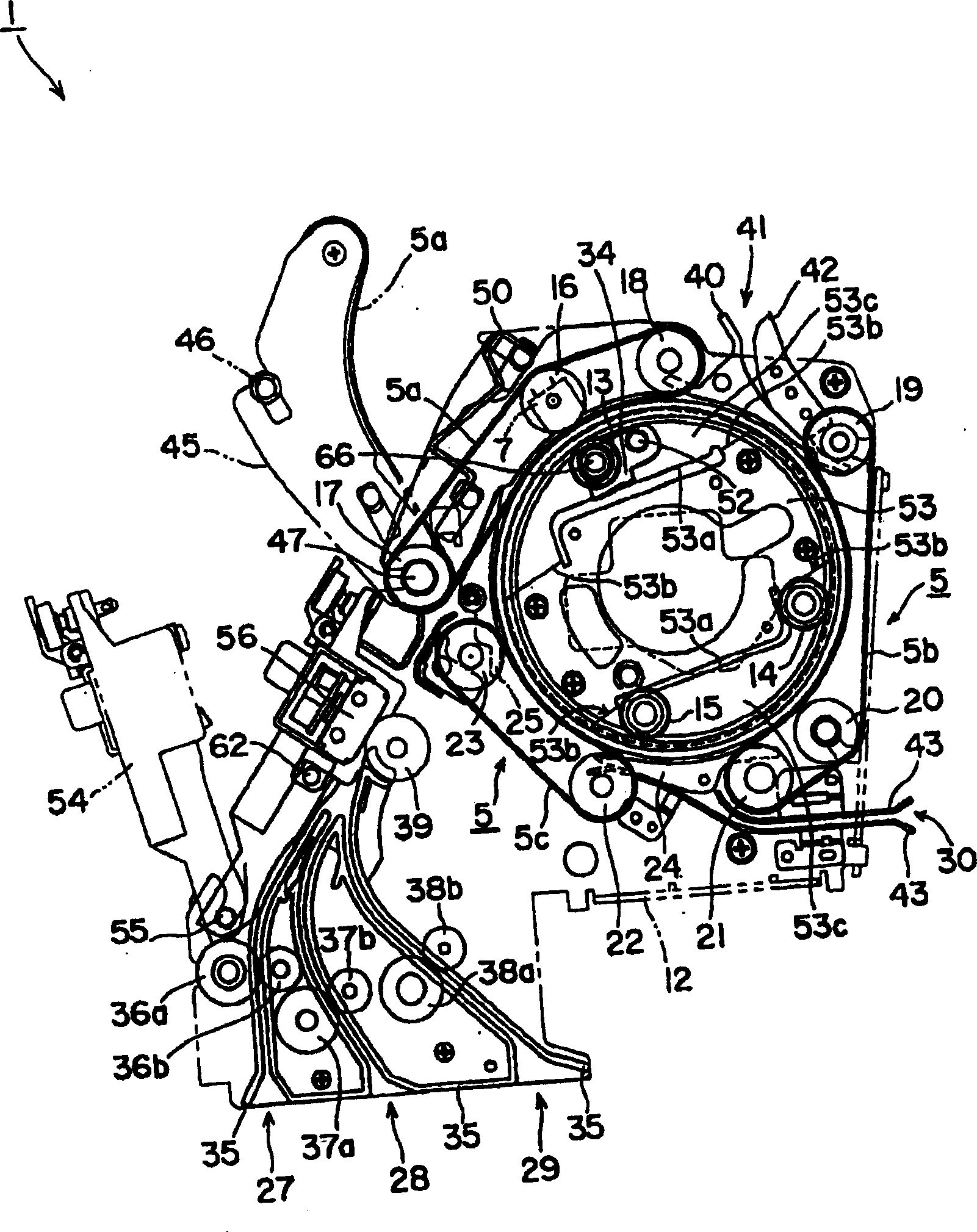

Magnetic information medium recording/reproducing device

InactiveCN1801363ARotational Vibration SuppressionCheap manufacturingRecord information storageRecord carrier guidanceEngineeringMechanical engineering

Owner:SANKYO SEIKI MFG CO LTD

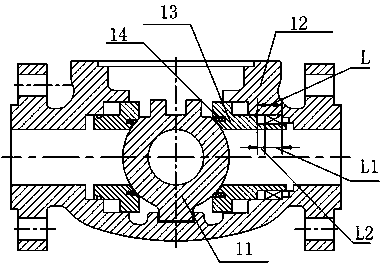

Ball valve

The invention relates to a ball valve. The ball valve comprises a fixer positioned between a valve ball and a valve body, and a limiting piece sleeved on the fixer, wherein the fixer is hermetically connected with the valve body through a sealing element; the valve ball is hermetically connected with the fixer; the limiting piece is connected with the valve body in an anti-rotation way; the sealing element is arranged between the radial end face of the limiting element and the radial inner end face of the valve body; an elastic piece is arranged between the limiting piece and the radial end face of the fixer; a plurality of second grooves are molded on the end face, which faces the fixer, of the limiting piece; a plurality of bosses are molded at positions where the fixer is matched with the second grooves; at an assembling position, the bosses are inserted into the second grooves; at a working position, the bosses retreat from the second grooves under the action of the resilience force of the elastic piece, the fixer can move towards the valve ball and be pressed against the valve ball, and the bosses are pressed against the outer end face of the limiting piece after rotating by certain angles on the fixer. The assemblies cannot move relatively at the working position, thereby achieving a reliable sealing effect between the fixer and the valve body and simplifying the structure.

Owner:NEWAY VALVE SUZHOU

Magnetic hobbing and pressing pad and pattern hobbing press with magnetic hobbing and pressing pad

PendingCN108858452AImprove connection strengthImprove convenienceMetal working apparatusHobbingEngineering

The invention discloses a magnetic hobbing and pressing pad. The magnetic hobbing and pressing pad comprises a magnetic layer. The magnetic hobbing and pressing pad faces a pattern medium, and a magnetic field passes through a pattern medium to adsorb a cutter, so that the pattern medium is stably clamped between the cutter and the magnetic hobbing and pressing pad, and the mutual location of thecutter and the pattern medium is stable and does not skew. The invention also discloses a pattern hobbing press. The pattern hobbing press comprises an upper hobbing and pressing plate and a lower hobbing and pressing plate, wherein the pattern medium and the cutter are clamped between the upper hobbing and pressing plate and the lower hobbing and pressing plate. The pattern hobbing press also comprises the magnetic hobbing and pressing pad, wherein the magnetic hobbing and pressing pad is connected to the upper hobbing and pressing plate or the lower hobbing and pressing plate; the pattern medium is laid on the surface of the magnetic hobbing and pressing pad; the magnetic field generated by the magnetic hobbing and pressing pad passes through the pattern medium to adsorb the cutter; compression rollers of the pattern hobbing press compress the upper hobbing and pressing plate and the lower hobbing and pressing plate, thereby compressing the cutter to cut off the pattern from the pattern medium; and by arranging the magnetic hobbing and pressing pad on the pattern hobbing press, the operating accuracy and using convenience of the pattern hobbing press are improved.

Owner:PARRIC NINGBO STATIONERY & GIFTS MFG

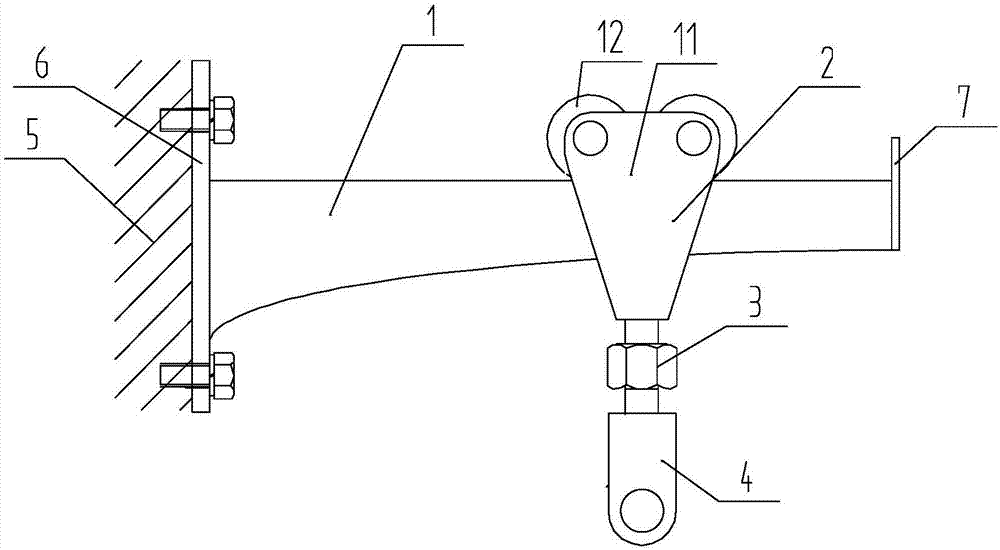

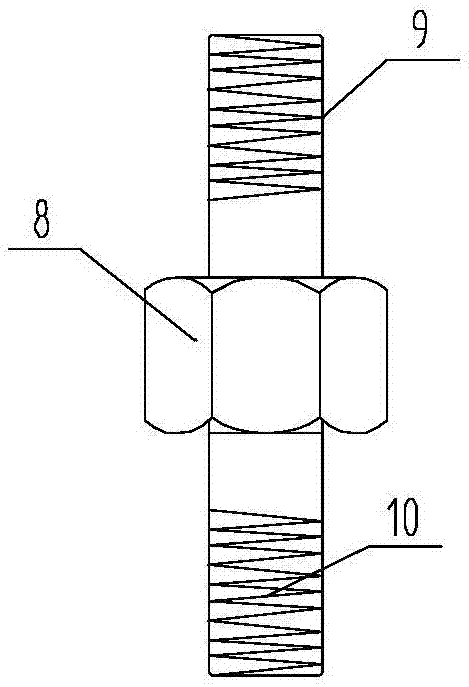

Oil transfer arm rotary joint sealing ring translation replacing device and application thereof

InactiveCN107263360AStable positional relationshipCreate simple structuresWork holdersDevices fixationEngineering

The invention provides an oil transfer arm rotary joint sealing ring translation replacing device and application thereof. The device comprises a translation beam, a translation frame and a connection block, wherein the translation frame is horizontally and slidably installed on the translation beam, and the connection block is installed at the lower end of the translation frame through a connector; one end of the translation beam is provided with an installation plate for being connected with an equipment fixing end, and the other end of the translation beam is provided with a limiting plate for preventing the translation frame from falling off; the connector comprises an adjustment nut, the upper end of the adjustment nut is provided with an upper threaded rod for being connected with the translation frame, and the lower end of the adjustment nut is provided with a lower threaded rod for being connected with the connection block; and the upper threaded rod and the lower threaded rod are opposite in direction of spiral. The oil transfer arm rotary joint sealing ring translation replacing device is simple in structure and convenient to use, the translation beam shares the weight of a rotating segment of a rotary joint, a positioning role is played through a long pole, and stability of the relative position relation between the rotating segment and a fixed segment of the rotary joint is always maintained; besides, the translation frame linearly moves on the translation beam, and resetting precision is effectively guaranteed; and when a sealing ring is replaced, operation difficulty is low, and time and labor are saved.

Owner:天津吉森机电设备工程有限公司

Sensor module and mobile cleaning robot

ActiveCN110233956AUniform lightCapture clearlyAutomatic obstacle detectionTelevision system detailsAcute angleEngineering

The invention discloses a sensor module, and the module comprises a camera module which comprises an optical range camera, a plurality of illumination elements disposed around the optical range camera, and a circuit board which is electrically connected with the optical range camera and the illumination elements; a first mounting seat, provided with a limiting hole used for limiting the position of the optical range camera and a first limiting part arranged on the periphery of the limiting hole and used for limiting the position of the illumination element. The illumination element is limitedby the first limiting part to enable the included angle between the optical axis of each illumination element and the optical axis of the optical range camera to be an acute angle. The invention further discloses a mobile cleaning robot. The mobile cleaning robot comprises a robot body and the sensor module. The relative fixation of the optical range camera and each illumination element is realized, the change of the relative position between the camera and the illumination element in the assembly process is avoided, and the optical range camera can clearly and accurately capture the image ofthe to-be-tracked surface.

Owner:SHARKNINJA CHINA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com