Locking device of bicycle saddle and bicycle thereof

A bicycle seat and locking device technology, applied in bicycle saddles, bicycle accessories, transportation and packaging, etc., can solve the problems of reducing the service life of steel balls, insufficient bearing capacity of a single positioning steel ball, and accelerating the wear of steel balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

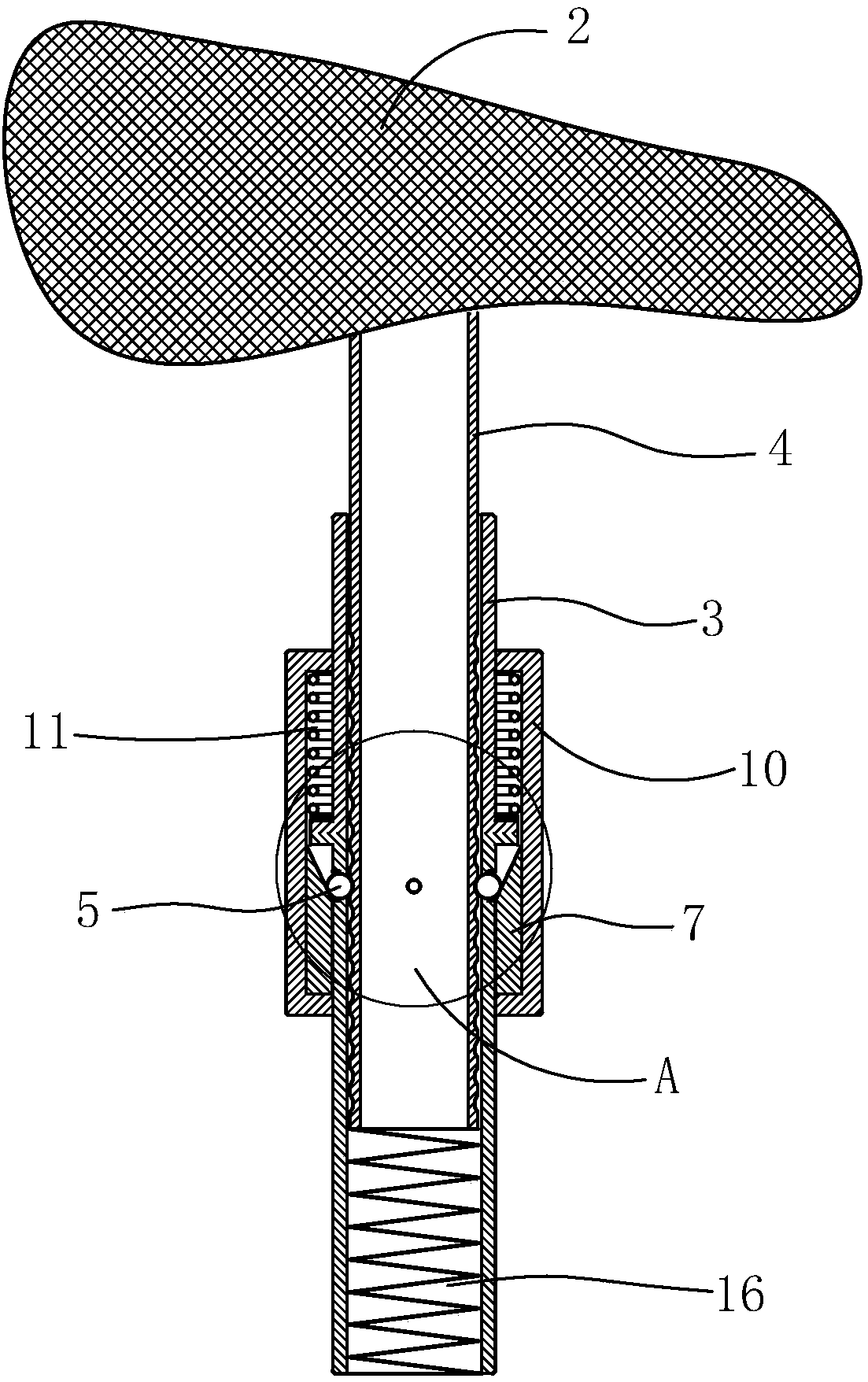

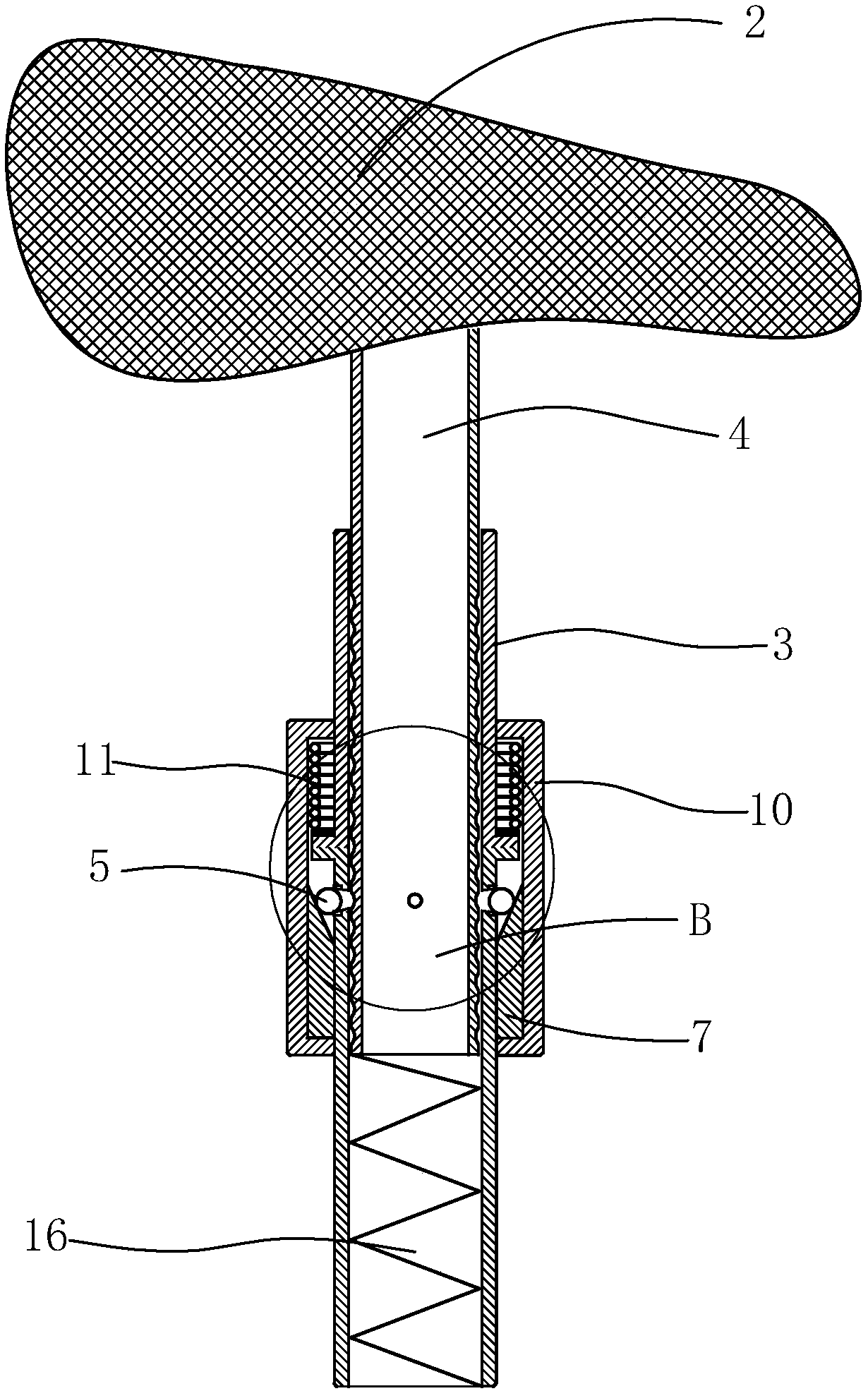

[0027] The locking device 1 includes a plurality of limit steel balls 5 annularly distributed on the standpipe 3 that can move laterally and remain in the standpipe all the time, an annular groove 6 arranged longitudinally on the outer wall of the core pipe 4 and sleeved The inner taper sleeve 7 with inclined push surface 71 that can move up and down outside the standpipe 3, the inner taper sleeve 7 is used to push the limit steel ball 5 into the annular groove 6, thereby locking the relative position of the core tube 4 and the standpipe 3, Thereby the height of vehicle seat 2 is fixed. Specifically, the first state, such as figure 1 , Figure 4 As shown, the inclined push surface 71 on the inner tapered sleeve 7 pushes the limit steel ball 5 inwardly into one of the annular grooves 6 of the core tube 4, and the height of the seat 2 is fixed; the second state, such as figure 2 , Figure 5 As shown, the inclined push surface 71 of the inner tapered sleeve 7 leaves the limit...

Embodiment 2

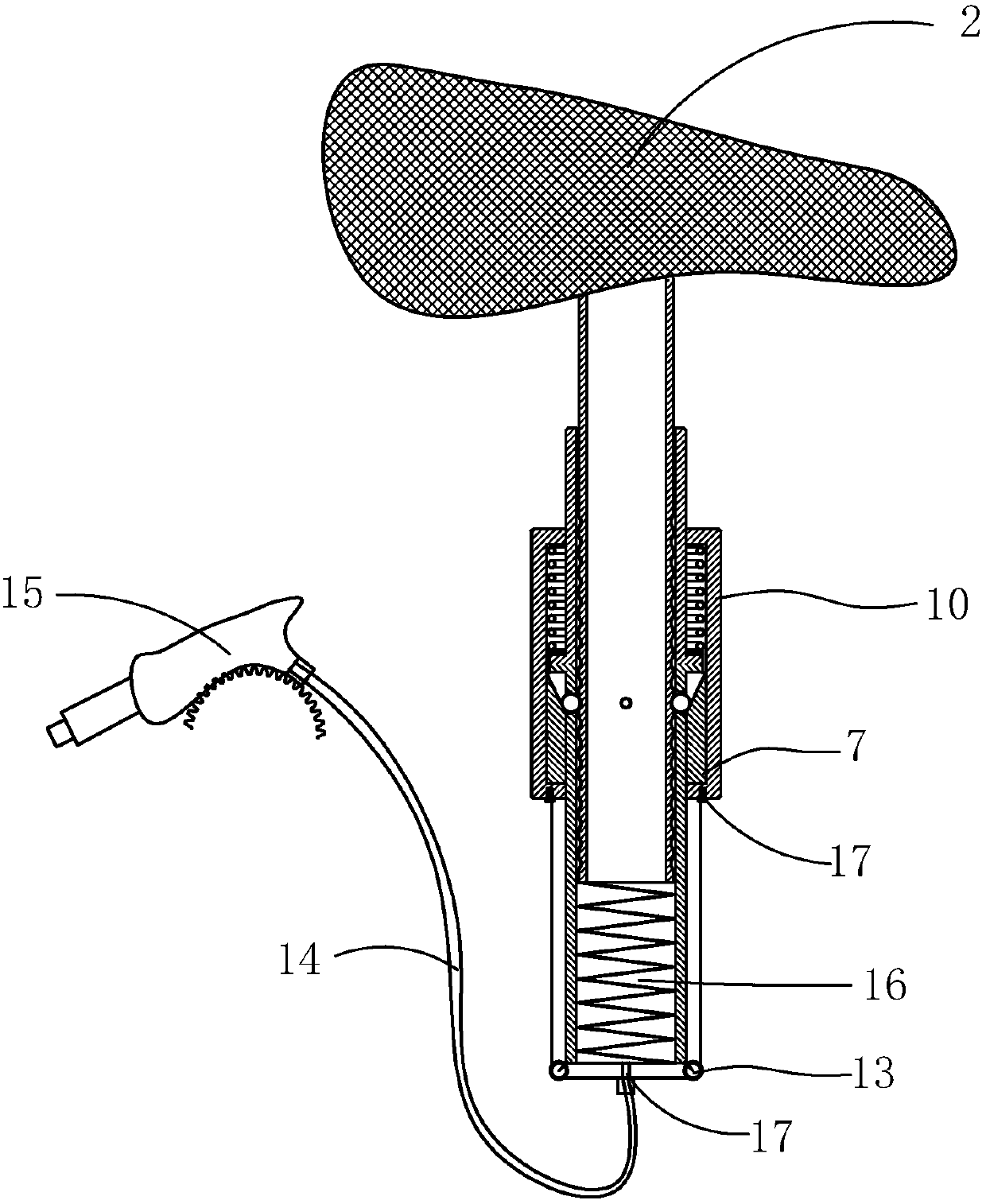

[0033] All the other parts are the same as Embodiment 1, the difference is: as image 3 As shown, the two ends of the bottom of the standpipe 3 are symmetrically provided with pulleys 13, and the two ends of the bottom of the stretch coat 10 are symmetrically fixed with stay ropes 14, and the two strands of stay ropes 14 are connected together after bypassing the pulleys 13. Preferably, It can be connected to a stay rope fixed mount 17, which is connected to the outer wall of the standpipe 3 bottom, and then the stay rope 14 is connected to the joystick 15, which is installed on the vehicle frame Or seat 2. In this embodiment, the user only needs to use the joystick 15 to pull the pull cord 14 so that the stretch coat 10 moves up or down, and finally controls the inclined push surface 71 to push the limit steel ball 5 or leave the limit steel ball 5, Adjust the relative positional relationship between the core tube 4 and the vertical tube 3 . The stay cord 14 is fixed on the...

Embodiment 3

[0036] The remaining parts are the same as in Embodiment 1, except that: preferably, the standpipe 3 is provided with annularly distributed through grooves 8, and a plurality of steel ball cages (not shown) are installed in the annularly distributed through grooves 8, limiting The position steel ball 5 is installed in the steel ball cage, and the limit steel ball 5 can move laterally in the steel ball cage in a limited range. When the inclined push surface 71 leaves the limit steel ball 5, the limit steel ball 5 leaves the core tube 4 under the action of its own weight The annular groove 6 will not completely break away from the through groove 8; specifically: as Figure 4 As shown, when the inclined push surface 71 pushes the limit steel ball 5 inward, the limit steel ball 5 moves inward in the steel ball holder and a part of the limit steel ball 5 enters the annular groove 6, thereby locking the core tube 4 and the vertical The relative position of pipe 3, fixes the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com