Patents

Literature

52results about How to "Uniform bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

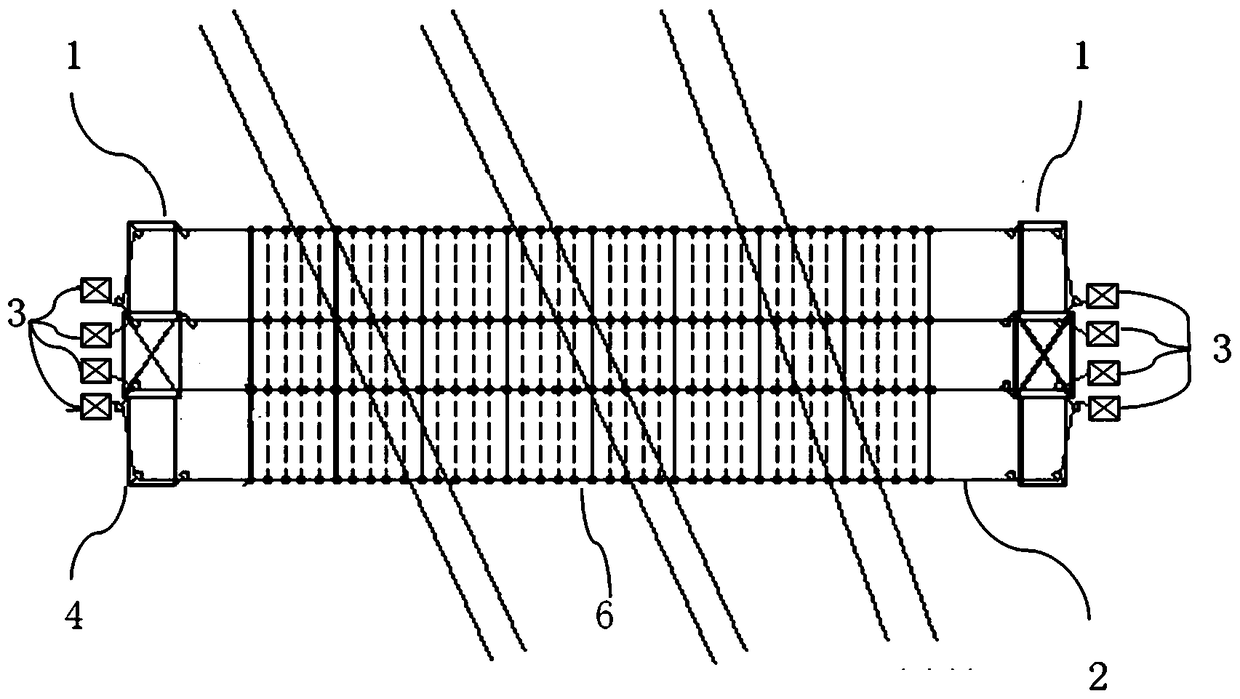

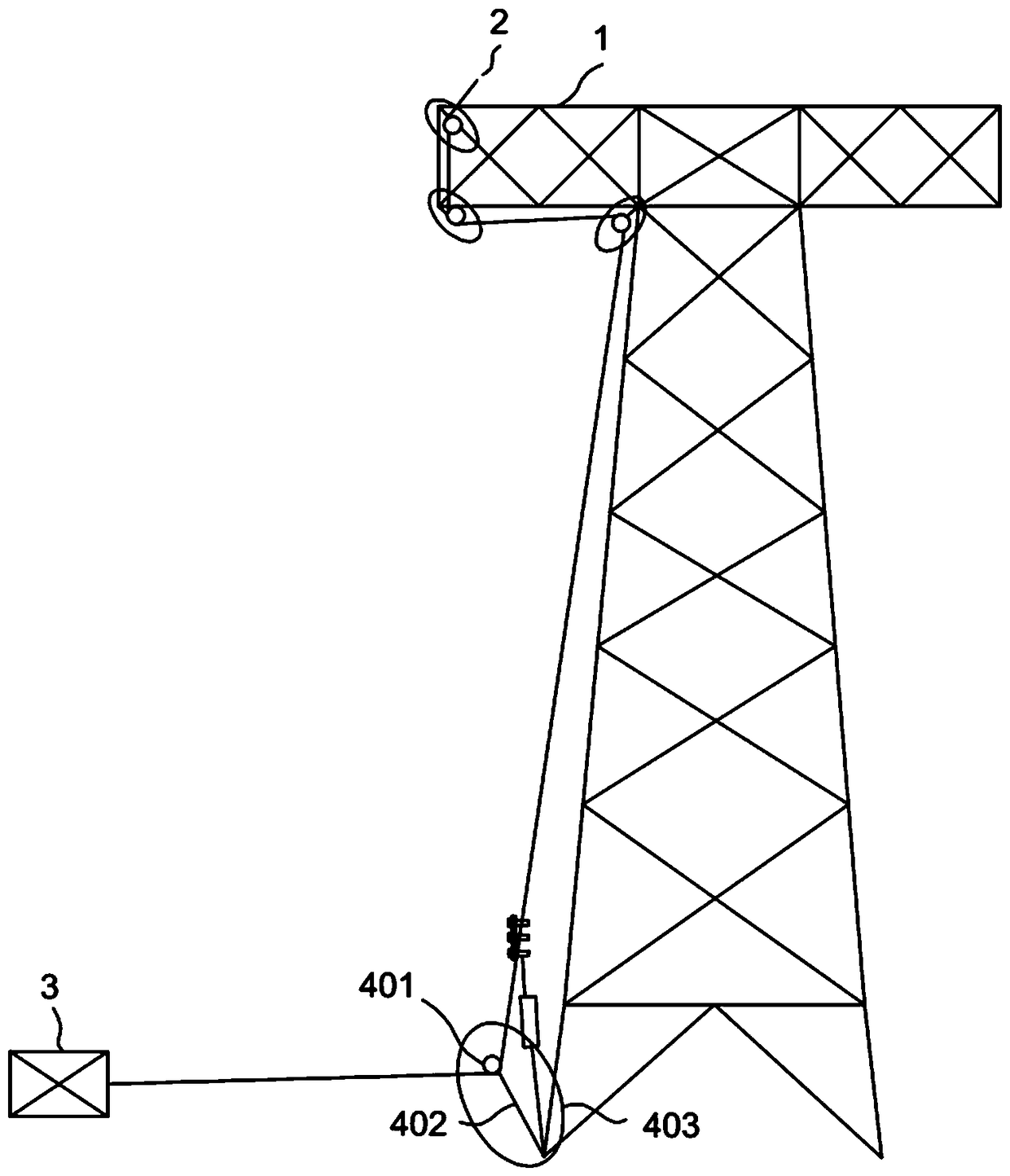

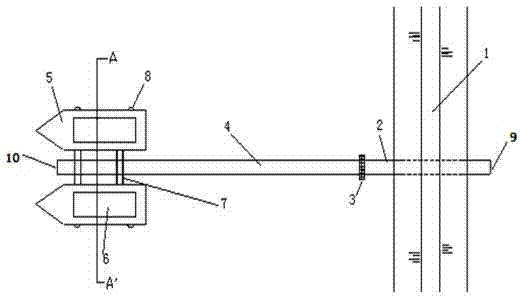

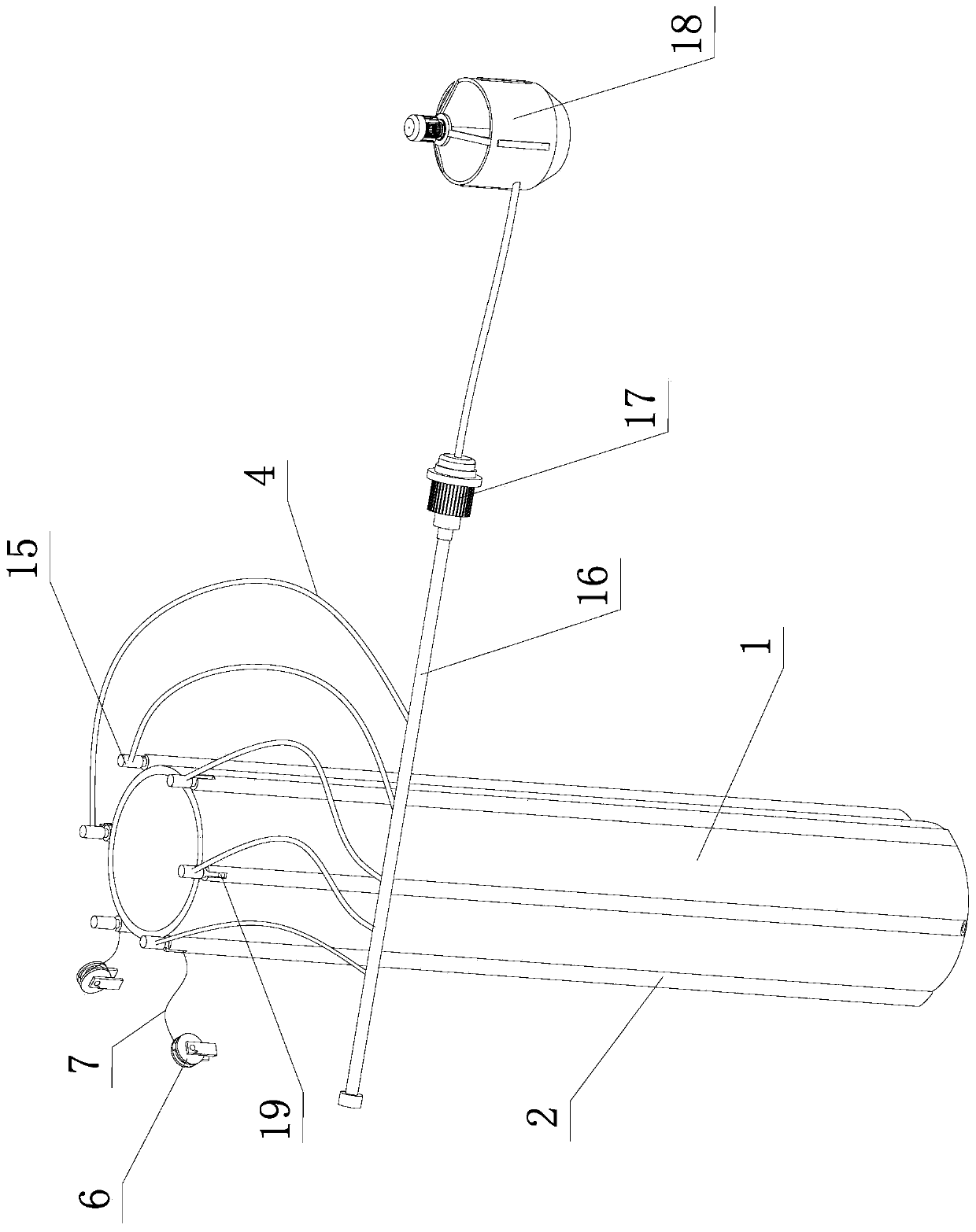

Net blocking system for crossing power line by using auxiliary cross arms and mounting and dismounting method of net blocking system

PendingCN108512115AEasy to install and disassembleSolve the problem that it is impossible to set up the reverse side landing cableApparatus for overhead lines/cablesStop timeEngineering

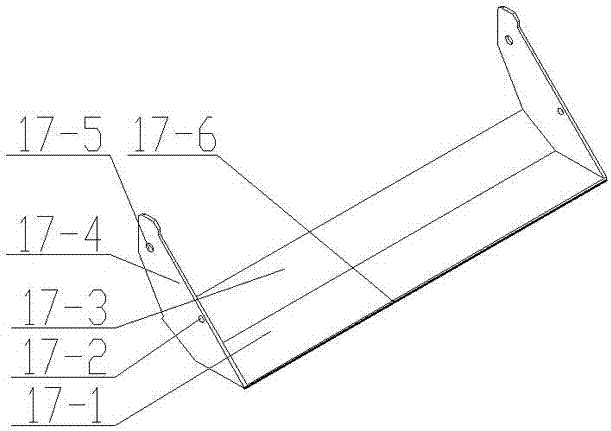

The invention discloses a net blocking system for crossing a power line by using auxiliary cross arms, and relates to the field of construction of power transmission line projects. An existing crossing mode is very hard to implement and difficult to perform. The net blocking system comprises the auxiliary cross arms arranged on iron towers on two sides of the power line, steel wire rope main cables, a main cable fixing device and a blocking net, wherein the auxiliary cross arms are symmetrically and detachably arranged on two sides of the iron towers; the steel wire rope main cables are detachably fixed on the auxiliary cross arms and the iron towers through the main cable fixing device; the blocking net is arranged on the steel wire rope main cables; the steel wire rope main cables and the blocking net are located above the power line. The net blocking system disclosed by the invention is convenient to mount and dismount; under the condition that the allowable maximum single lateral horizontal tension of the auxiliary cross arms can bear the tension of the blocking net, backside ground stay wires of the auxiliary cross arms and the iron towers can be canceled; the problem that thebackside ground stay wires cannot be erected due to mountain steepness is solved; by adoption of a high-altitude net blocking mode, the net blocking is easier and more convenient, and the time can besaved; the accompanying stop time of a power line below is shortened; and the overall construction cost of the net blocking system is reduced.

Owner:浙江省送变电工程有限公司 +4

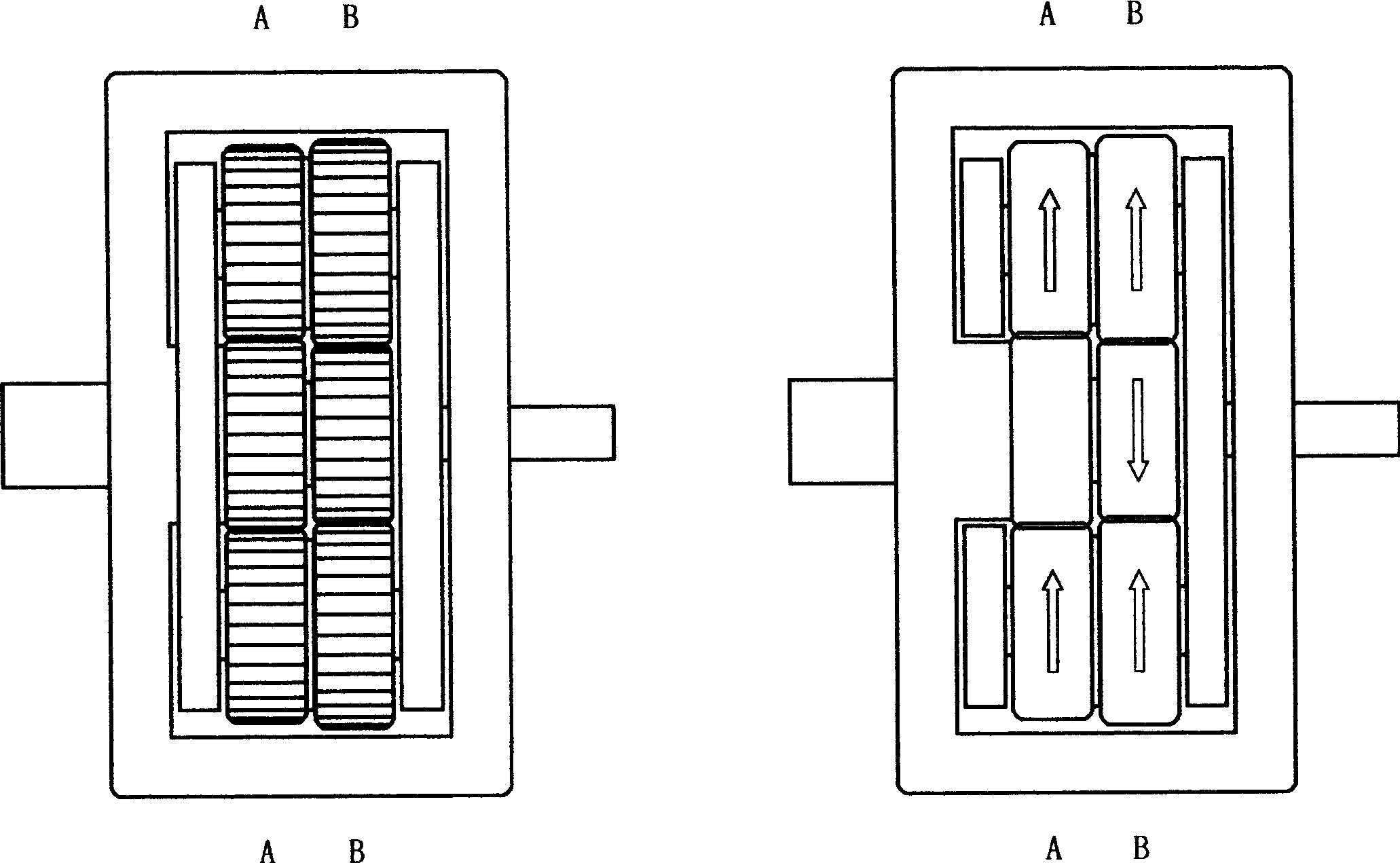

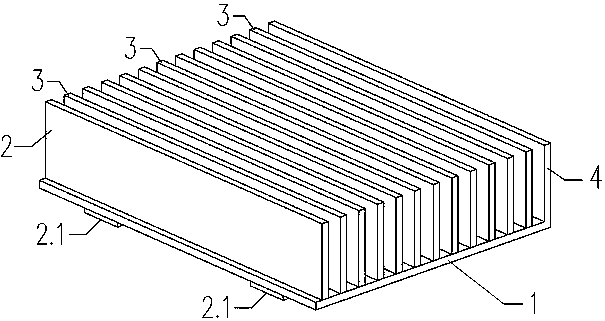

Linear guide rail pair and machining technology thereof

The invention provides a linear guide rail pair and a machining technology thereof, and belongs to the technical field of linear guide rail pairs. The linear guide rail pair comprises a sliding block body. The linear guide rail pair is characterized in that the body is in a U shape; a guide rail groove is formed in the bottom of the body, an installing groove is formed in the upper end face of the body, and two arc load grooves for supporting balls are formed in the inner walls of the two sides of the guide rail groove respectively; the two corners of the bottom of the guide rail groove are circular chamfers; and steps are arranged at the opening ends of the guide rail groove. The machining technology of the linear guide rail pair comprises the following steps of raw material preparing, head cutting, head rolling, head grinding, polishing, parkerising, saponifying and drawing. According to the linear guide rail pair, a unique double-arc structure is adopted in the load grooves, and when the impact load and the heavy load are borne, the bearing contact area is enlarged, and the rigidity of the system is improved. According to the machining technology of the linear guide rail pair, one-time joint forming is achieved during drawing, a plurality of later machining procedures are omitted, and cost, labor and the production time are saved.

Owner:浙江建鑫型钢科技股份有限公司

Concrete solid pile body

The invention provides a concrete solid pile body, belongs to the technical field of building, and solves the problems of conventional pile bodies all have insufficient bearing strength and poor tension stability, and raw materials are lack of activity and self-hardening property. The concrete solid pile body comprises a steel reinforcement cage as a central skeleton and a concrete entity poured in the steel reinforcement cage; the concrete entity comprises cement, gravels, slag, sand, high-calcium fly ash and low-calcium fly ash, the content proportion of the high-calcium fly ash is 25%-40%, the calcium content in the high-calcium fly ash is 10%-15%, the content proportion of the low-calcium fly ash is 10%-40% that of the high-calcium fly ash, and the calcium content in the low-calcium fly ash is 1%-5%. In a whole base pile manufacturing process, a number of process control indexes can be achieved, and the compressive strength and the tension stability of base piles are enhanced with utilization of characteristics of the high-calcium fly ash; and with utilization of the ability of the low-calcium fly ash to inhibit AAR, the concrete harm caused by an alkali aggregate reaction can be eliminated.

Owner:QINGDAO XINGHE BUILDING MATERIAL

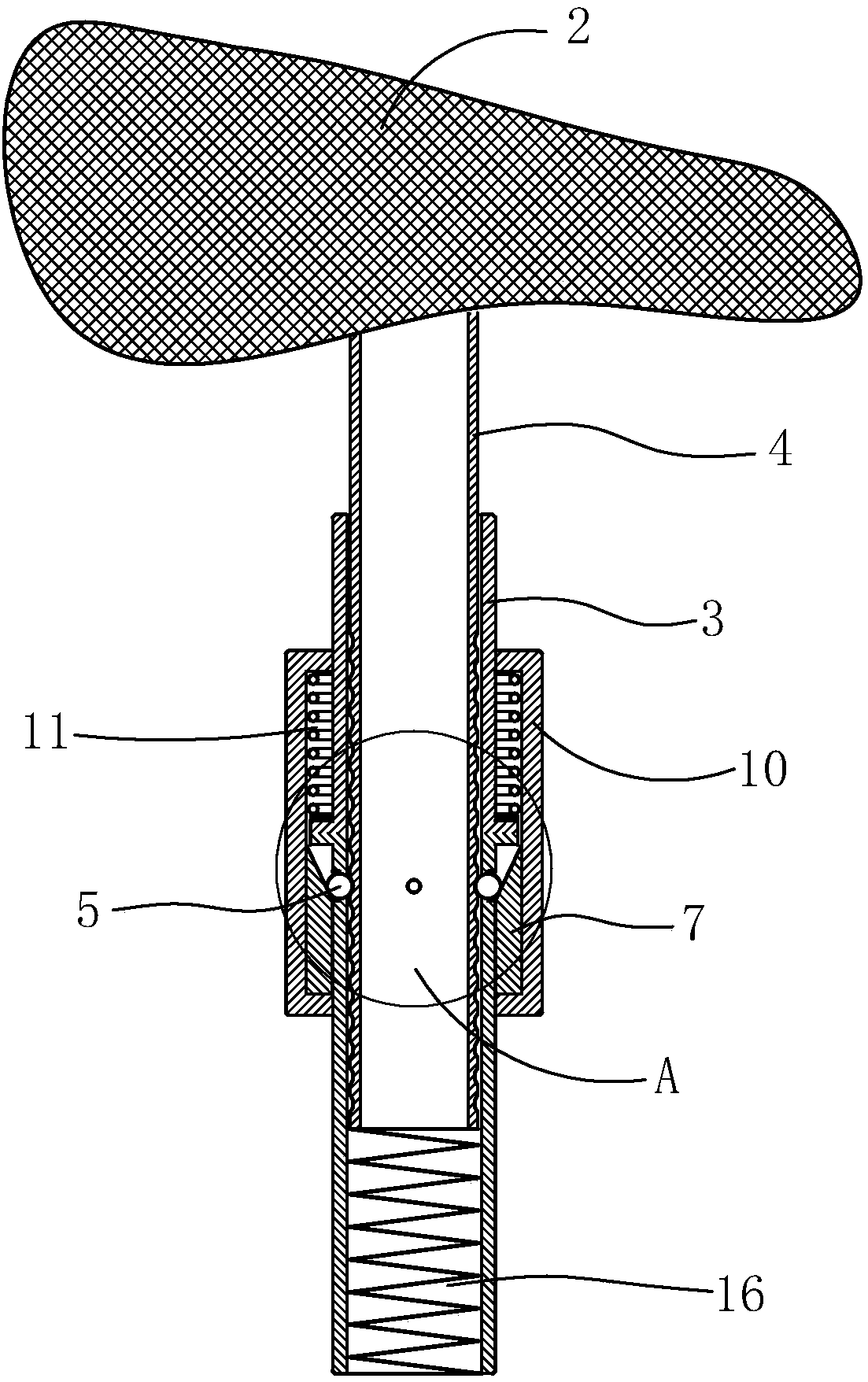

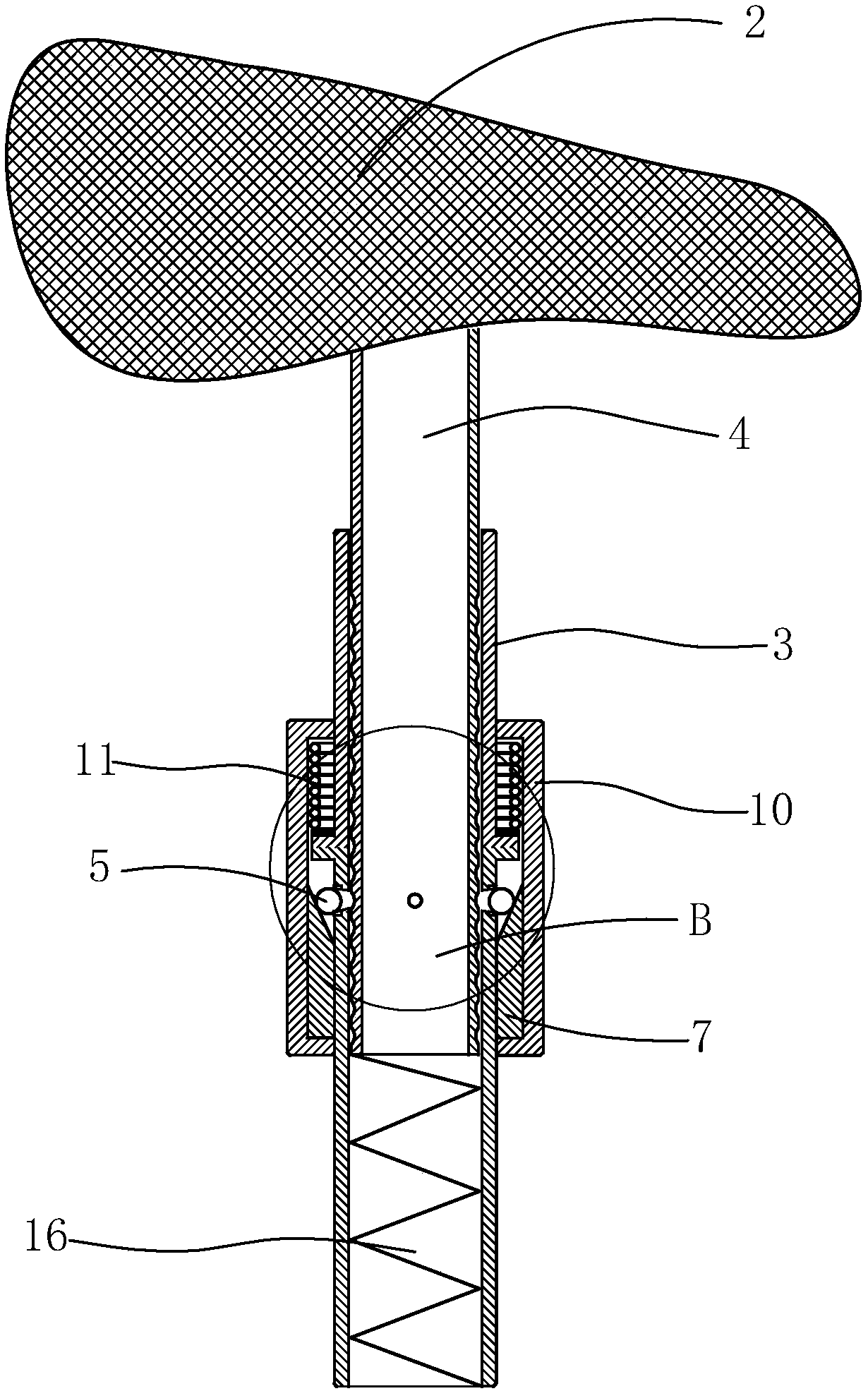

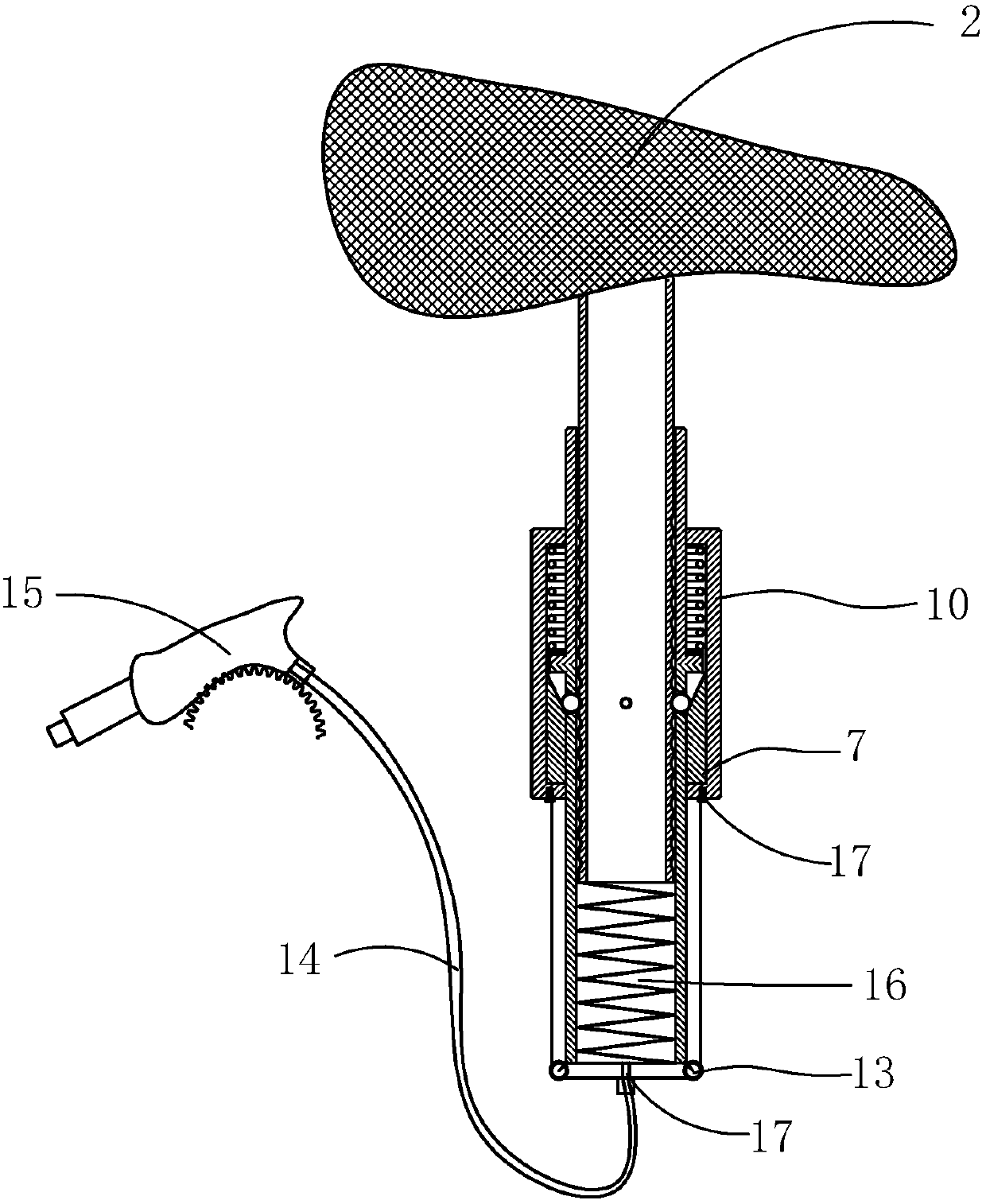

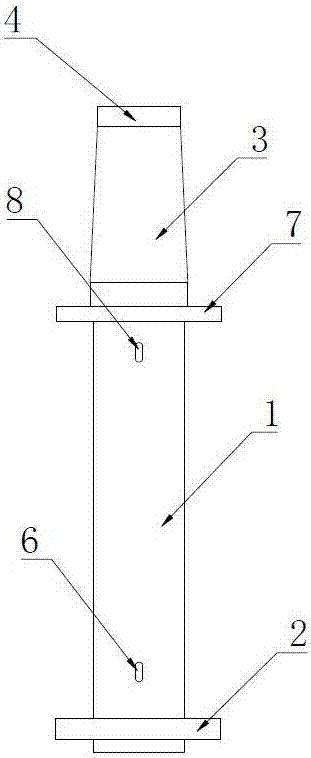

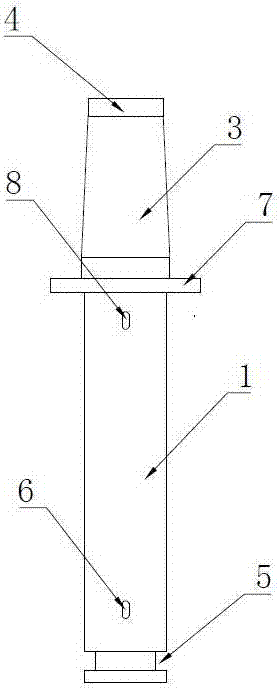

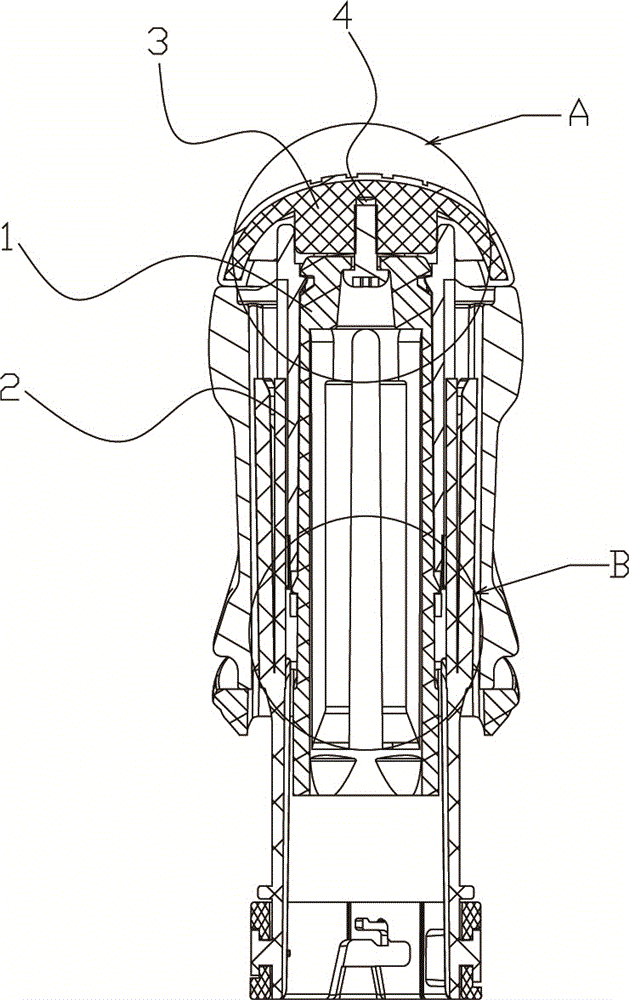

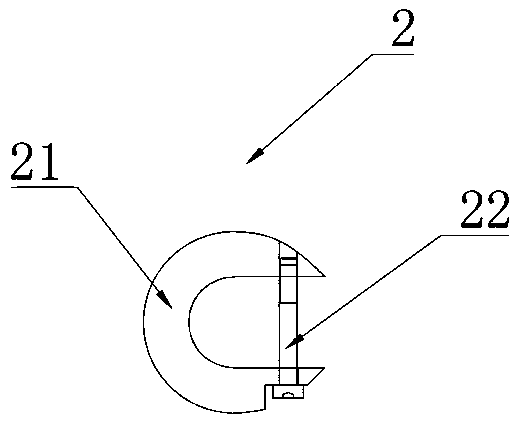

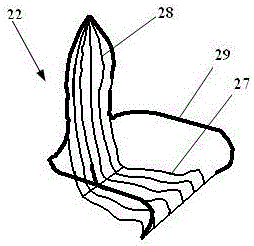

Locking device of bicycle saddle and bicycle thereof

InactiveCN107600235AImprove enduranceUniform bearing capacityCycle saddlesVehicle frameArchitectural engineering

The invention discloses a bicycle which comprises a frame and a saddle. A vertical pipe is arranged on the frame, a core pipe is arranged below the saddle, a locking device is arranged between the core pipe and the vertical pipe and comprises multiple limiting steel balls annularly distributed on the vertical pipe and capable of transversely moving in a limited-amplitude manner, the limiting steelballs can be constantly held in the vertical pipe, and annular grooves in longitudinal arrangement and an inner taper sleeve sleeving outside the vertical pipe, capable of moving up and down and provided with an oblique pushing face are arranged on the outer wall of the core pipe. When the oblique pushing face on the inner taper sleeve inwards pushes and presses the limiting steel balls to enterone annular groove of the core pipe, height of the saddle is fixed; when the oblique pushing face of the inner taper sleeve leaves the limiting steel balls, the limiting steel balls move out of the annular groove of the core pipe, and the core pipe of the saddle and the vertical pipe on the frame can move up and down relatively. Relative position of the core pipe and the vertical pipe are limitedby utilizing the limiting steel balls in annular distribution, so that the locking device is higher in bearing capacity, and the saddle is less prone to deviation and more stable.

Owner:NINGBO UNIV

Negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method

The invention discloses a negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method. The negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method mainly comprises the steps that a dredger fill area is cleaned and flattened; a ditch is horizontally formed in the dredger area or a horizontal water seepage pipe is arranged by inclining by 0.5-5 degrees, and backfilling is conducted through medium and rough sand-gravel aggregate; a dam and a drainage canal are constructed on the periphery of the dredger fill area, and a water diversion pipe and an automatic-flowing drainage pipe are pre-buried; a dredger fill pipeline is led into the dredger fill area in the dam; slurry is guided into the surface layer of the dredger fill area and underground water is guided into the drainage canal after silt deposits; a water suction pump is connected to the outer port of the drainage pipe, and then forced drainage is conducted. Meanwhile, the invention creatively provides a suspension controllable dredger fill area drainage device, a movable multifunctional integrated well tube draining and vibrating-flushing device and technologies matched with the suspension controllable dredger fill area drainage device and the movable multifunctional integrated well tube draining and vibrating-flushing device. Compared with the prior art, the reinforcing period can be shorted by about 50% and the comprehensive unit cost can be reduced by about 45% under the same condition, and the bearing capacity of a fill stratum within the overall depth range can reach 60-80 kPa after treatment.

Owner:江苏楚匠建设工程有限公司

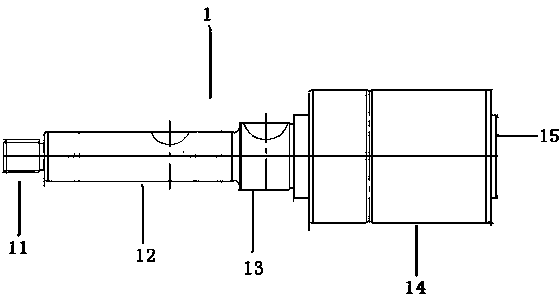

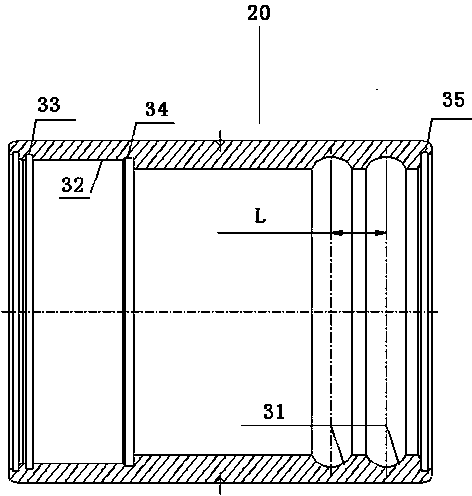

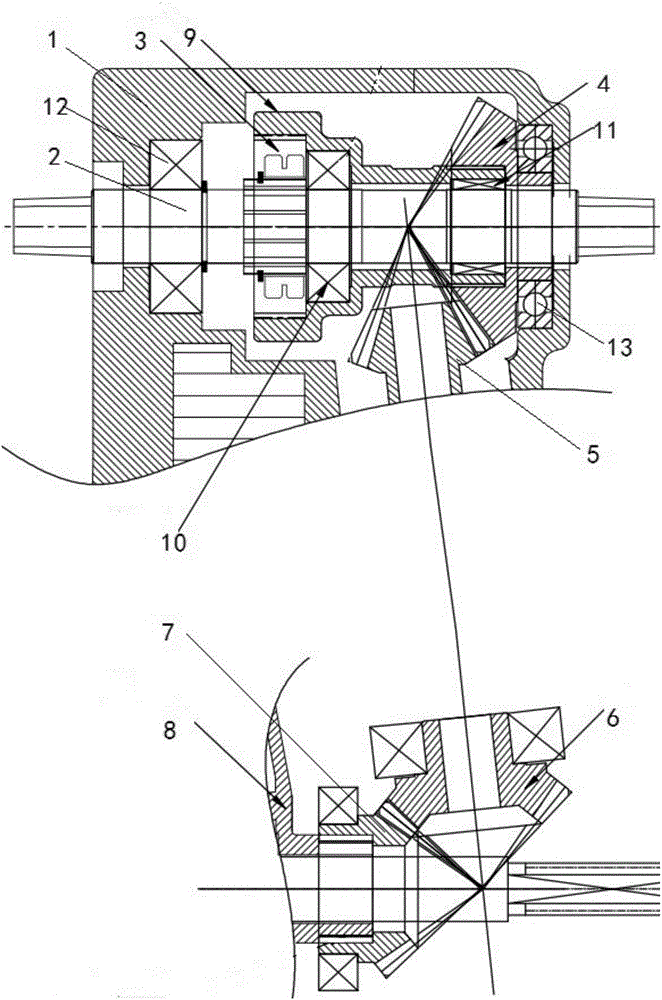

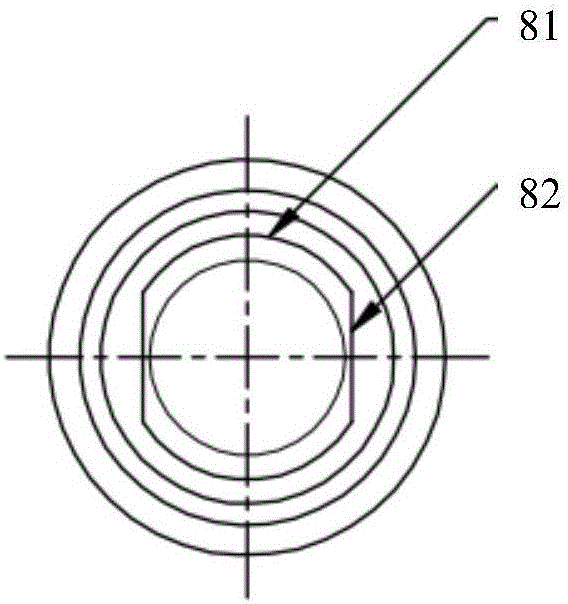

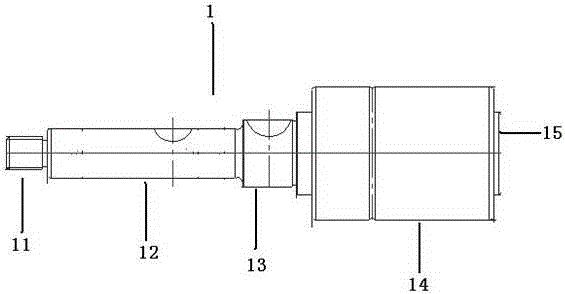

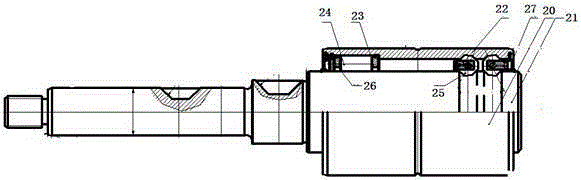

Integral shaft-connect type fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

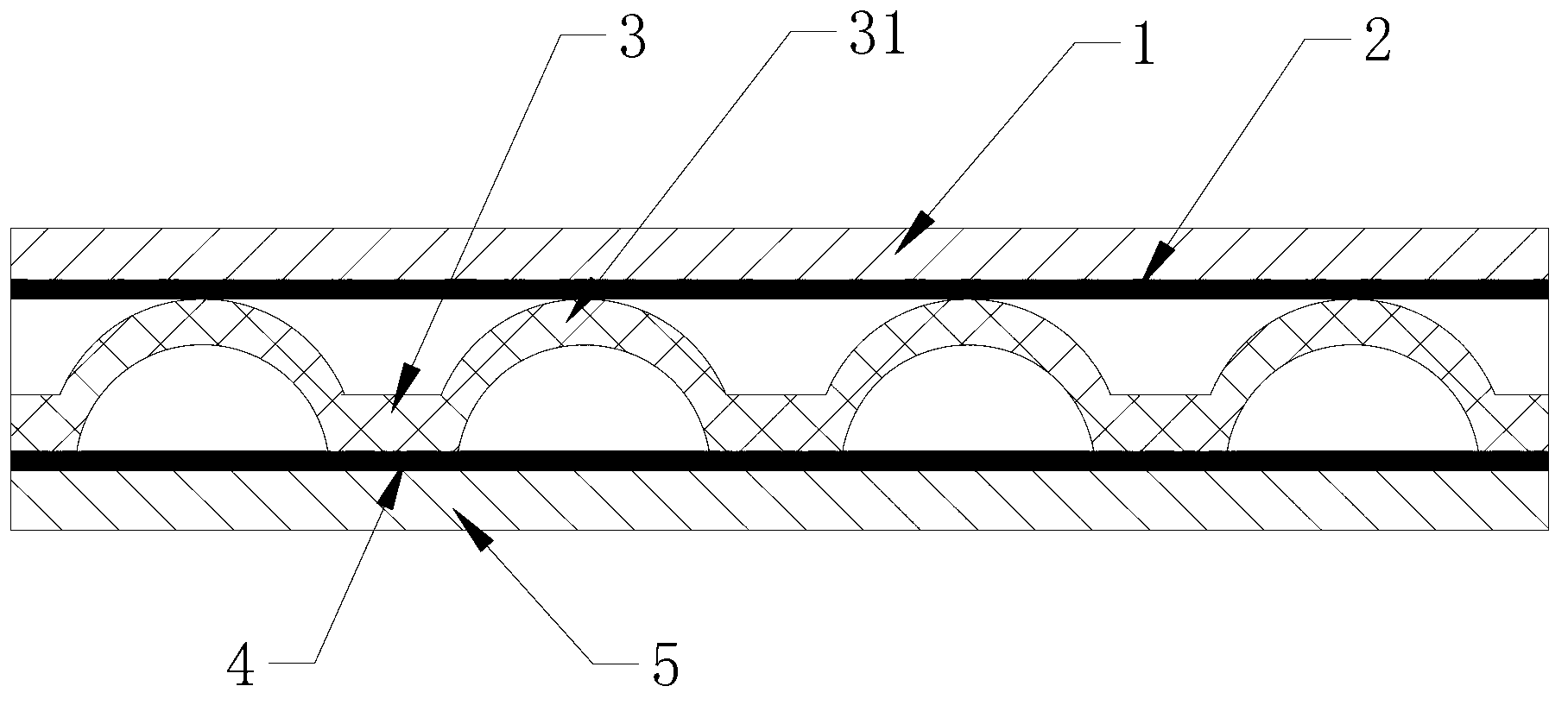

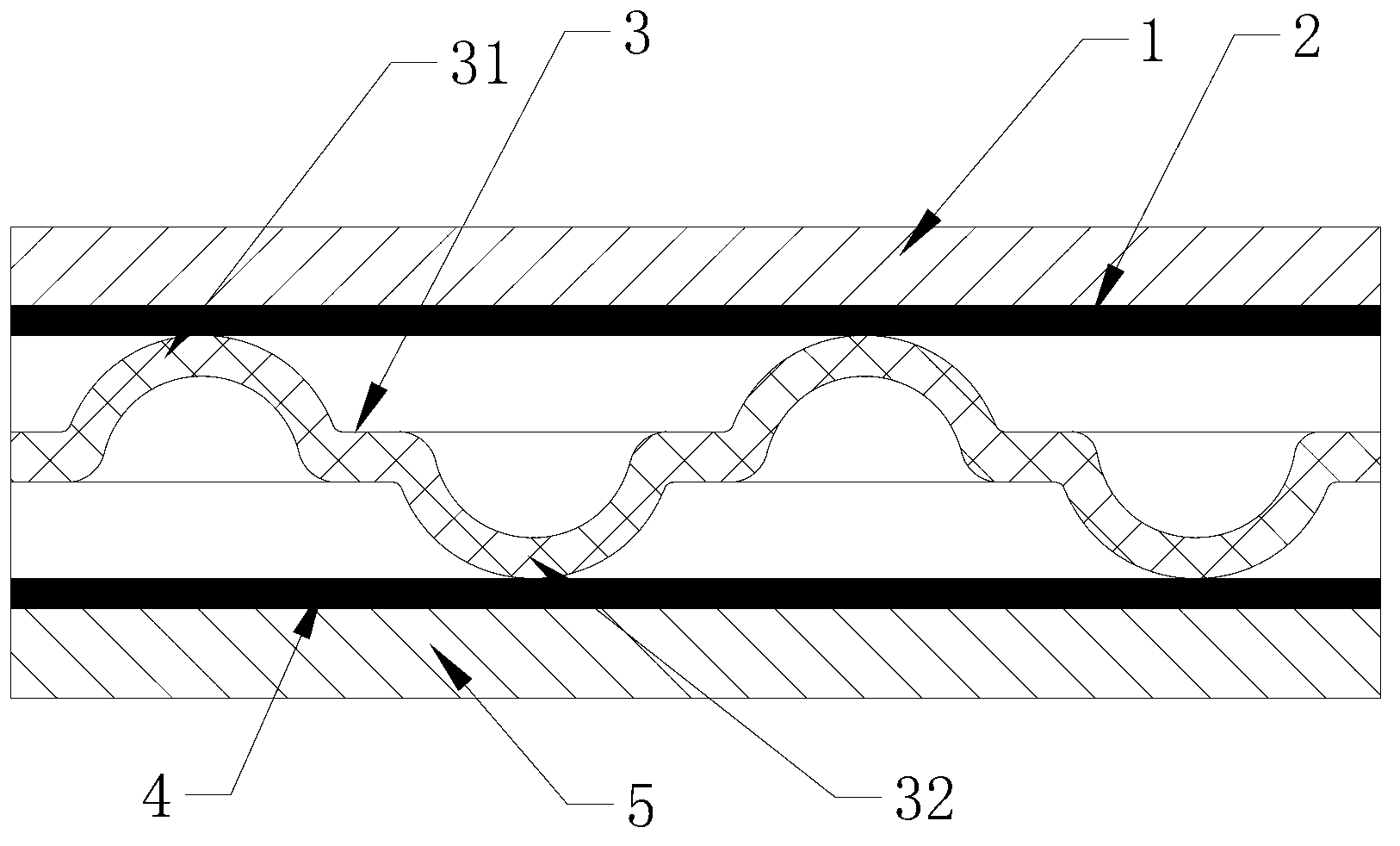

Aluminum composite plate

InactiveCN103213343AIncreasing the thicknessHigh strengthMetal layered productsSurface layerEngineering

The invention discloses an aluminum composite plate comprising a core-layer plate as well as a bottom-layer plate and a surface-layer plate which are adhered to two sides of the core-layer plate, wherein the core-layer plate, the bottom-layer plate and the surface-layer plate are made of aluminum; a plurality of first bulges are uniformly formed on the core-layer plate in a pressing manner; the protruding heights and the protruding directions of the first bulges are same; and the bottom-layer plate and the surface-layer plate are adhered to the core-layer plate through adhesive layers. The aluminum composite plate has the advantages of good flatness and processability, high strength, light weight and fire prevention.

Owner:ZHANGJIAGANG MUZI MACHINERY TECH

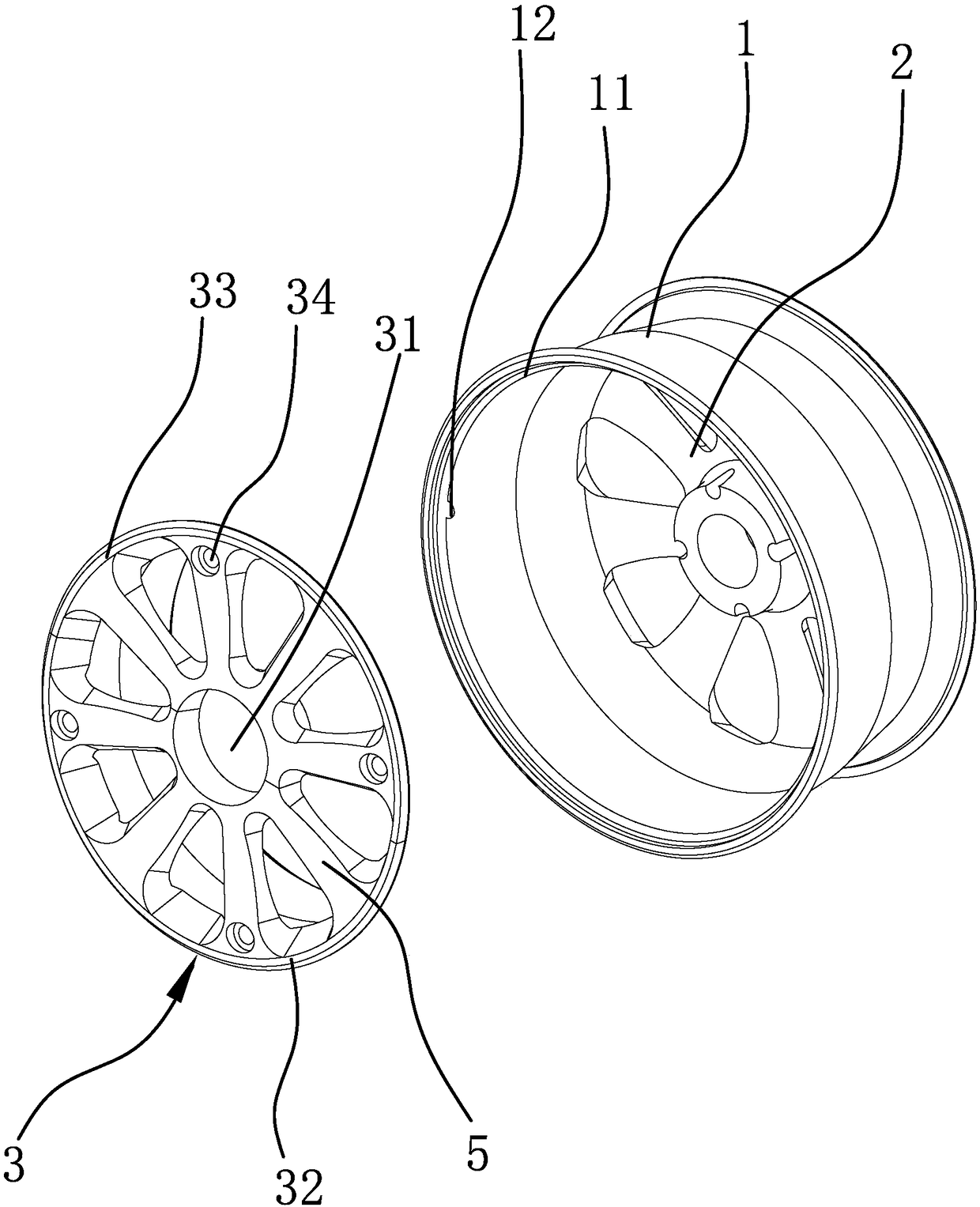

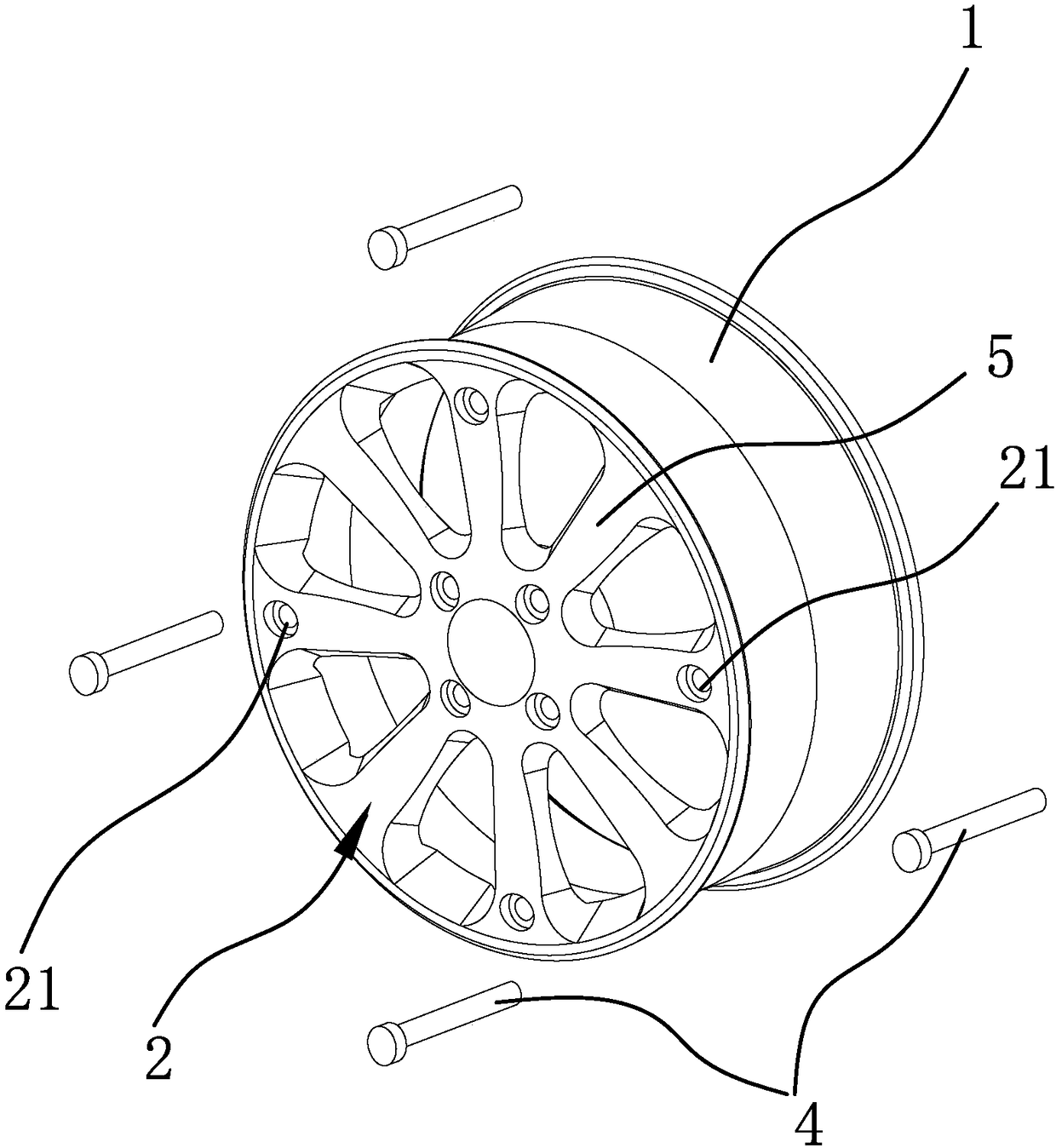

Multi-spoke movable wheel hub

ActiveCN108382129AImprove support strengthUniform dispersionHubsDisc wheelsCar manufacturingEngineering

The invention provides a multi-spoke movable wheel hub and belongs to the technical field of automobile manufacturing. The multi-spoke movable wheel hub solves the technical problem of stress non-uniformity of existing wheel hubs. The m multi-spoke movable wheel hub comprises a drum-shaped wheel rim, the outside of the wheel rim is fixedly provided with a spoke I, the inside of the wheel rim is provided with a detachable spoke II, the middle of the spoke II is provided with a through hole, the spoke II comprises a section I and a section II which are in central symmetry, both the section I andthe section II are in a semicircular shape, and the two sections are oppositely connected to form the entire spoke II; the position close of the inner wall of the wheel rim, which is close to the inner edge of the wheel rim, is provided with a ring-shaped stepping surface, and the spoke II is embedded inside the wheel rim and abuts against the stepping surface; the positions of the spoke I, whichare close to the outer circumferential surface of the spoke I, are provided with mounting holes I, the positions of the spoke II, which are close to the outer circumferential surface of the spoke II,are provided with mounting holes II, the mounting holes I and the mounting holes II are in one-to-one correspondence, and fastening bolts are inserted into the mounting holes I and the mounting holesII. According to the multi-spoke movable wheel hub, the left and the right of the wheel rim are provided with the spokes, so that force born by the wheel hub can be uniformly dispersed, and the support strength and the safety and comfort performance of the multi-spoke movable wheel hub can be improved.

Owner:ZHEJIANG YUELING

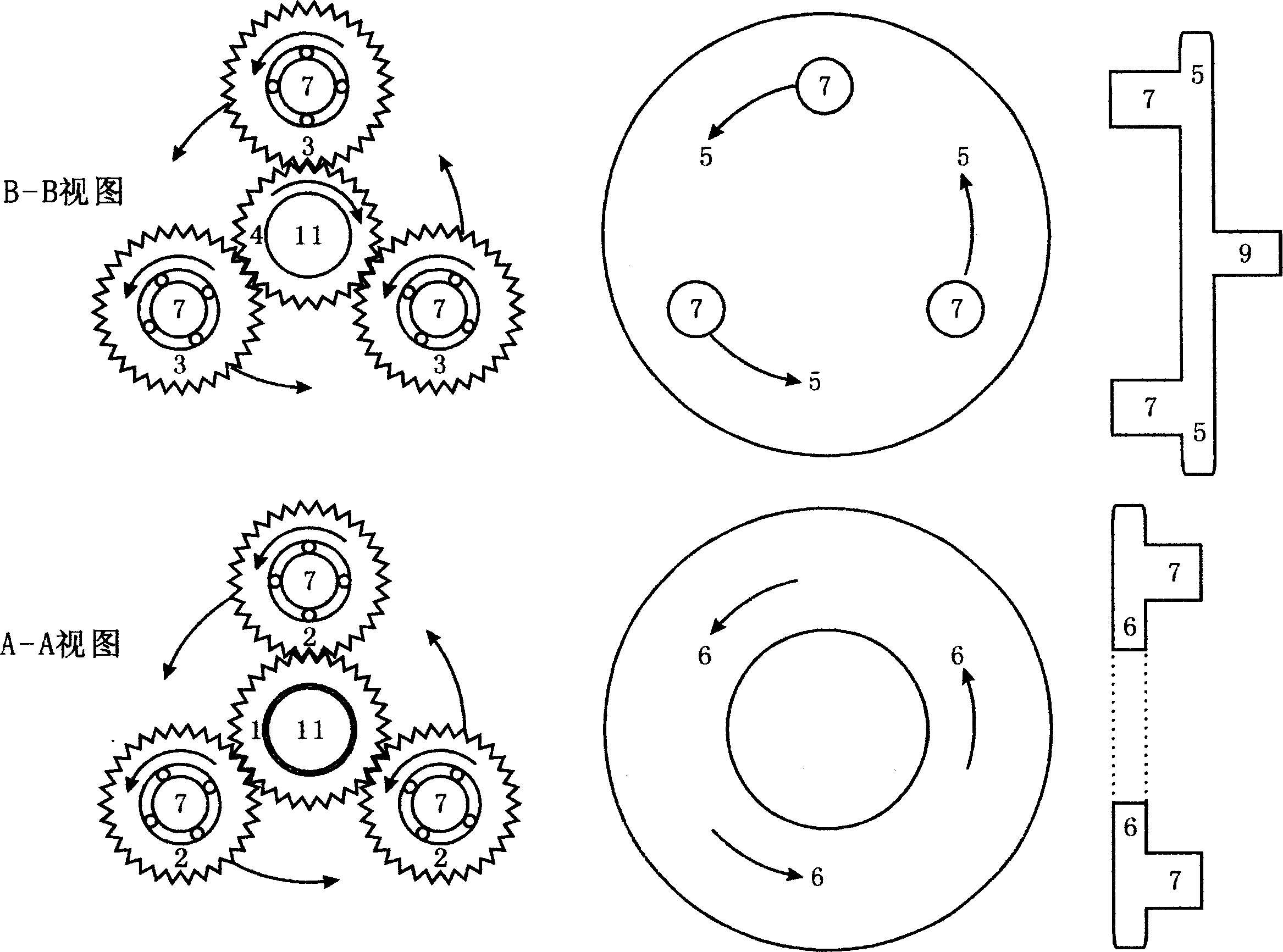

Direct-driving (external-toothing) gear speed reducer

A direct driving (outer engaging) gear speed reducer, only adjusting the diameter ratio of two gears, various transmission ratio from tens to tens of thousands, in any transmission ratio, every gear driving output axle in minimum friction coefficient all the time, the loaded force in each gear is uniform by driving planetary gear set in accurate position. Said invention also can be used as speed increaser with increased bearing ability, simple structure, small volume and light weight.

Owner:王维民

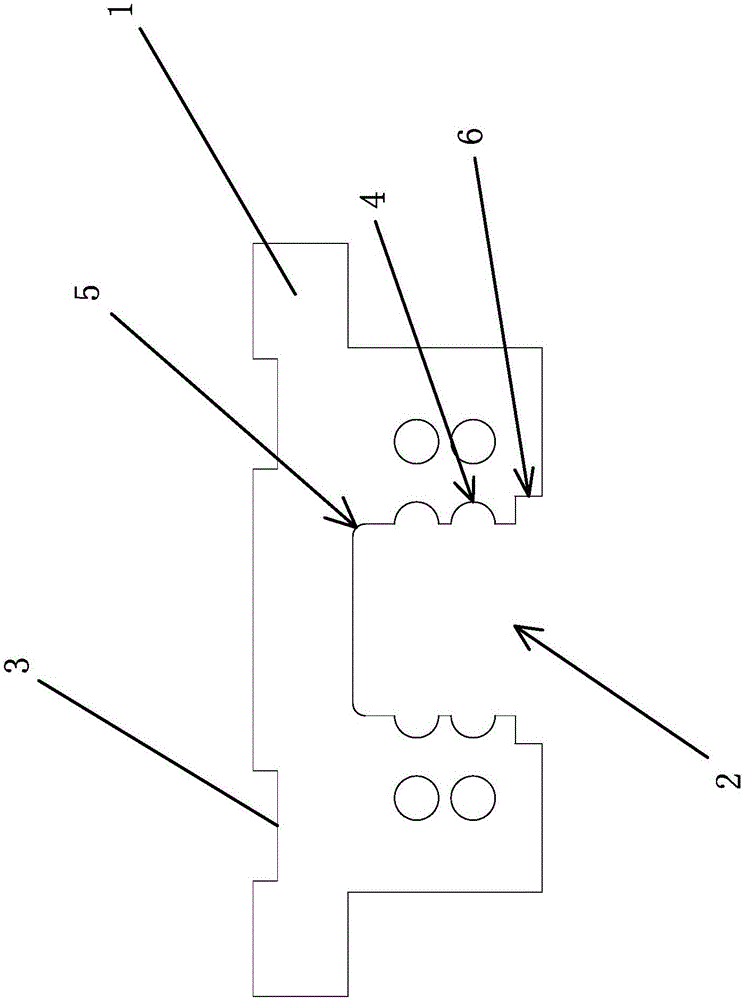

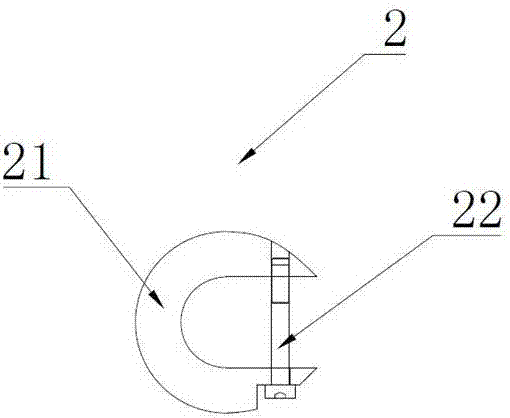

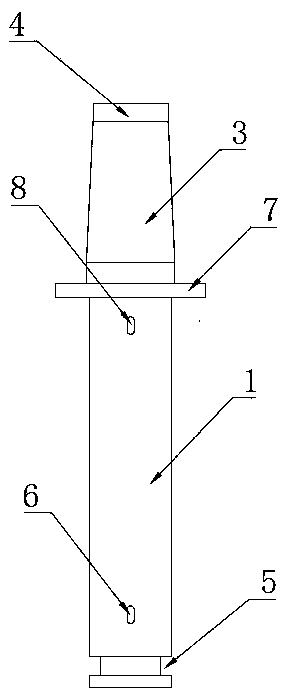

Scraper discharger for plane scraping of fitting bolt

The invention discloses a scraper discharger for plane scraping of a fitting bolt, and belongs to the technical field of ship construction. The scraper discharger comprises a scraper discharger body and a positioning clamp. The scraper discharger body is in a cylinder shape. A conical handle is arranged at the upper end of the scraper discharger body. A protruding strip is arranged on the top faceof the conical handle. An annular groove is formed in the lower end of the scraper discharger body. The positioning clamp is arranged in an annular groove of the scraper discharger body in a sleevedmanner. The top face of the positioning clamp is perpendicular to the center line of the scraper discharger body. A first key groove is formed in the lower end of the side face of the scraper discharger body. The first key groove is arranged above the annular groove. The positioning clamp is arranged in the annular groove, loosening disengaging of the positioning clamp due to high-speed rotation and scraper rotation are avoided, and safety is high. The top face of the positioning clamp is perpendicular to the center line of the scraper body, the bearing force of the positioning clamp to the scraper is uniform, and the situation that in the scraper scraping process, inclination happens, and consequently the scraping precision is reduced is prevented.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

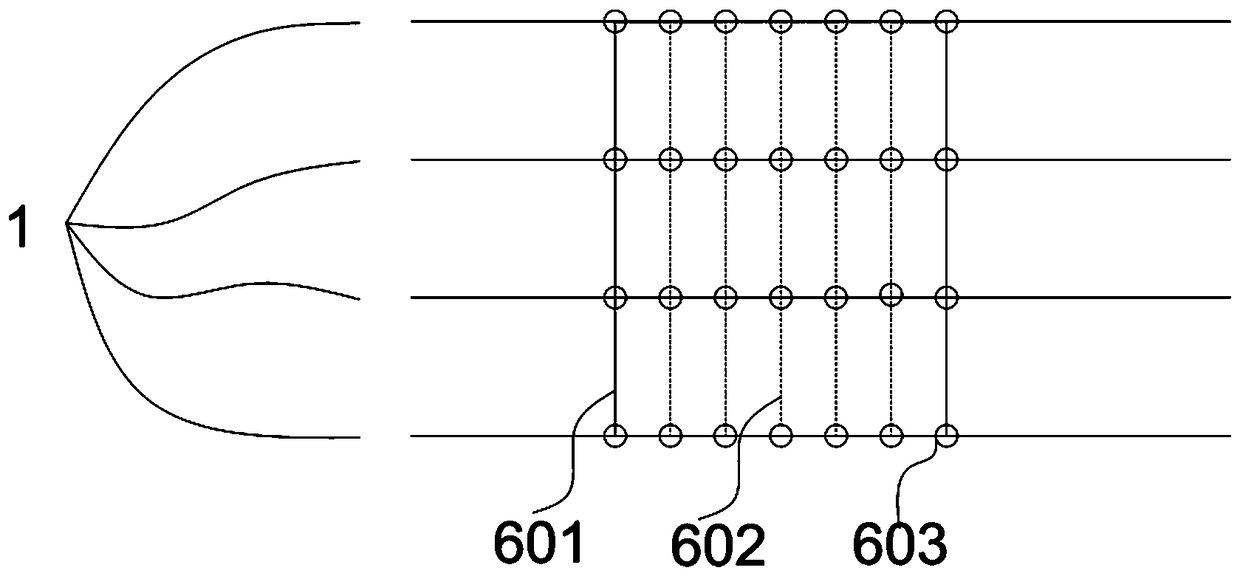

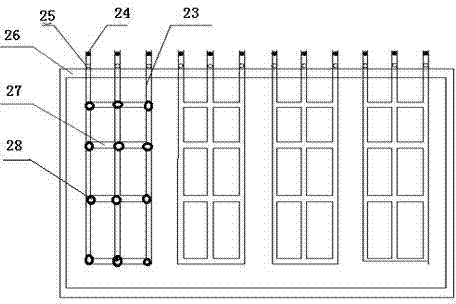

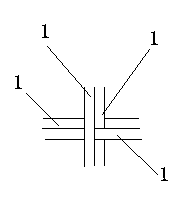

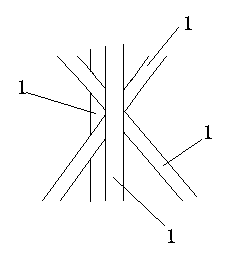

Carbon fiber bar skeleton of composite material in four-dimensional carbon fiber bar

The invention relates to a carbon fiber bar skeleton of a composite material in a four-dimensional carbon fiber bar. The carbon fiber bar skeleton is characterized in that: four groups of the carbon fiber bar skeletons are arranged and comprises a left group, a right group, a front group and a back group, each group of the carbon fiber skeletons is composed of a plurality of rows, the rows are parallel with each other, each row is composed of a plurality of round carbon fiber bars, the round carbon fiber bars are parallel with each other, all the carbon fiber bars between adjacent groups are mutually perpendicular to each other on a vertical projection surface, each group of the carbon fiber bars form same included angle with a horizontal plane, the four groups of the carbon fiber bars skeletons lie on a same horizontal plane, row spacing of the four groups of the carbon fiber bars skeletons are all equal to that of the carbon fiber bars in each row, four carbon fiber bars of the four groups of the carbon fiber bars skeletons on a same row is tangent at a point, and the tangent points among the four carbon fiber bars in the same row lie on a same horizontal plane. The advantages reside in that: a unit of the carbon fiber bar is in a rectangular pyramid shape, a structural body is difficult to be distorted and deformed; incised from whatever the direction is, the carbon fiber bars form a net shape, accordingly the carbon fiber bars bear uniform force and multidirectionally resist impact force. Open channels is existed between all the carbon fiber bar skeletons, so has big a space duty ratio, are extended to a CVD process, and make the treatment of the filling very smooth.

Owner:颜本善

Operation platform for drilling pile movable construction

ActiveCN106087698ASmooth connectionAccurate locationConstructionsResource savingStructural engineering

The invention provides an operation platform for drilling pile movable construction. The operation platform comprises supporting beams, a standing platform / standing platforms arranged at one ends or two ends of the supporting beams, a cover plate arranged on the supporting beams and a discharging hole formed in the cover plate. The cover plate is jointed to the supporting beams through a joint mechanism and is made of an iron plate with the thickness of 6-14 cm. A guide pipe is fixed when lowered so that a next guide pipe can be conveniently connected; a platform on a drilling cast-in-place pile machine is replaced, the shaping standardization level of the operation platform is high, materials commonly used in a construction field are fully utilized, the requirements for easy manufacturing, convenient operation and implementation, firmness, durability and circular use are met, and the effects of standardization, canalization, resource saving and convenient wide application and popularization are achieved.

Owner:NINGBO HOUSING CONSTR GRP

Concrete solid pile

InactiveCN104418550AAdjustable clotting timeHigh compressive strengthSolid waste managementSlagEngineering

The invention provides a concrete solid pile, belonging to the technical field of buildings. The concrete solid pile solves the problems that an existing pile body has insufficient bearing strength, poor tension stability, lack of activity and self-hardening property in raw materials, incapability of realizing multiple process regulation and control indexes in manufacturing processes and the like. The concrete solid pile comprises a steel bar cage as a middle framework and a concrete solid poured onto the steel bar cage, wherein the concrete solid comprises cement, gravel, slag, sand and high-calcium fly ash, the content by specific weight of high-calcium fly ash is 30%-45%, and the calcium content in high-calcium fly ash is 10%-15%. According to the concrete solid pile, high-calcium fly ash and a corresponding modifier are added in the traditional component formula and are subjected to specific weight adjustment again, so that multiple process regulation and control indexes can be realized in the manufacturing processes of a whole base pile, the compressive strength and tension stability of the whole base pile are effectively strengthened by utilizing the characteristics of high-calcium fly ash, and the concrete solid pile further has the characteristics of activity of volcanic ash, small fineness, small weight of screen residue and the like.

Owner:QINGDAO XINGHE BUILDING MATERIAL

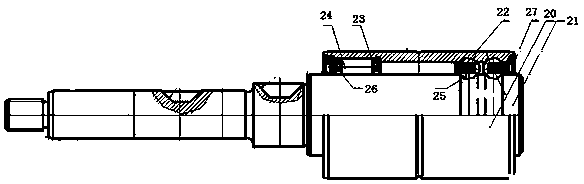

Novel connecting structure for five-way joint center shaft bevel gear and bicycle rim

InactiveCN106542042ACompact structureDoes not affect aestheticsWheel based transmissionFreewheel clutchesEngineeringBevel gear

The invention discloses a novel connecting structure for a five-way joint center shaft bevel gear and a bicycle rim. The novel connecting structure for the five-way joint center shaft bevel gear and the bicycle rim comprises a bicycle five-way joint, a five-way joint center shaft, a clutch, the five-way joint center shaft bevel gear, a first transmission bevel gear, a second transmission bevel gear, an output bevel gear and the bicycle rim. The five-way joint center shaft is rotationally connected with the bicycle five-way joint. The five-way joint center shaft bevel gear can rotate relative to the five-way joint center shaft. The clutch is arranged between the five-way joint center shaft and the five-way joint center shaft bevel gear. The five-way joint center shaft bevel gear is meshed with the first transmission bevel gear. The second transmission bevel gear is meshed with the output bevel gear. The first transmission bevel gear and the second transmission bevel gear synchronously rotate. The output bevel gear is fixedly connected with the bicycle rim. The novel connecting structure for the five-way joint center shaft bevel gear and the bicycle rim is compact in structure, does not change the existing structure of a rear wheel of a bicycle and does not influence the attractiveness of an original product, and meanwhile because the clutch of a bicycle bevel gear structure is arranged on the five-way joint center shaft, the transmission space of the back wheel is greatly reduced.

Owner:慈溪浩然驱动科技有限公司

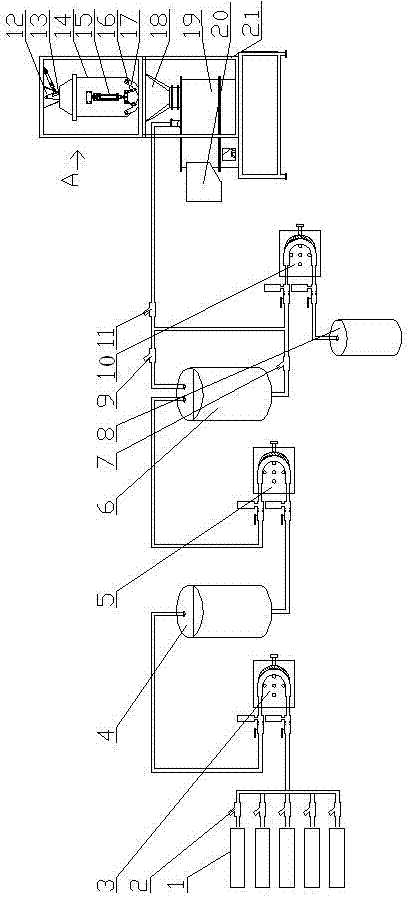

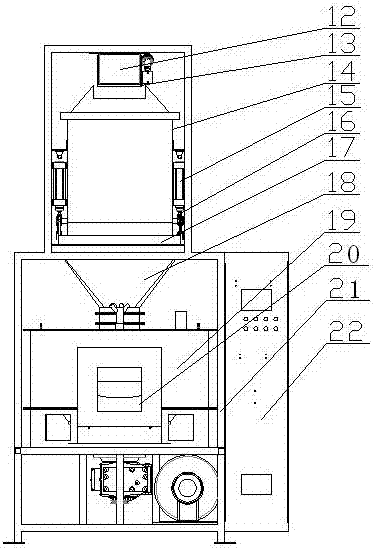

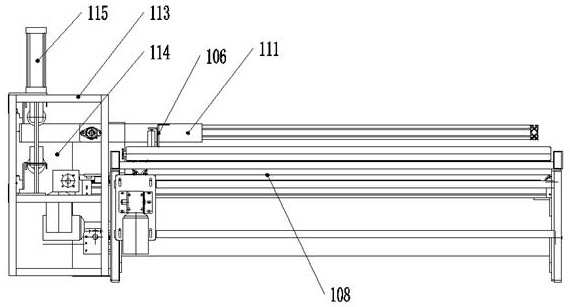

Batch continuous coating control method and coating machine with premixing function of seed coating agent

ActiveCN104855002BAvoid jammingAvoid breakingSeed coating/dressingAgricultural engineeringBatch method

The invention discloses a batch continuous seed coating machine with the function of seed coating agent premixing, comprising a seed coating agent premixing device, a metering hopper, a two-way feeding funnel, a coating chamber, a coating frame and a discharge port; The seed coating agent premixing device transports the formulated seed coating agent to the coating room through pipelines, and the coating room is fixed on the coating frame; a two-way feeding funnel is arranged above the coating room; A bidirectional feeding funnel is installed above the coating chamber; a metering hopper is installed above the bidirectional feeding funnel; a feeding hopper is arranged above the metering hopper; a discharge port is arranged on one side of the coating chamber. The invention also discloses a batch continuous coating control method with the premixing function of the seed coating agent. The present invention is a batch continuous seed coating machine with a seed coating agent premixing device, which is simple in structure, practical and convenient, realizes simultaneous delivery of seeds and agents, synchronous contact and full mixing, and precisely controls the uniformity of feeding and drug supply , The seed coating film is uniform.

Owner:HUNAN LIBEN SEED TECH

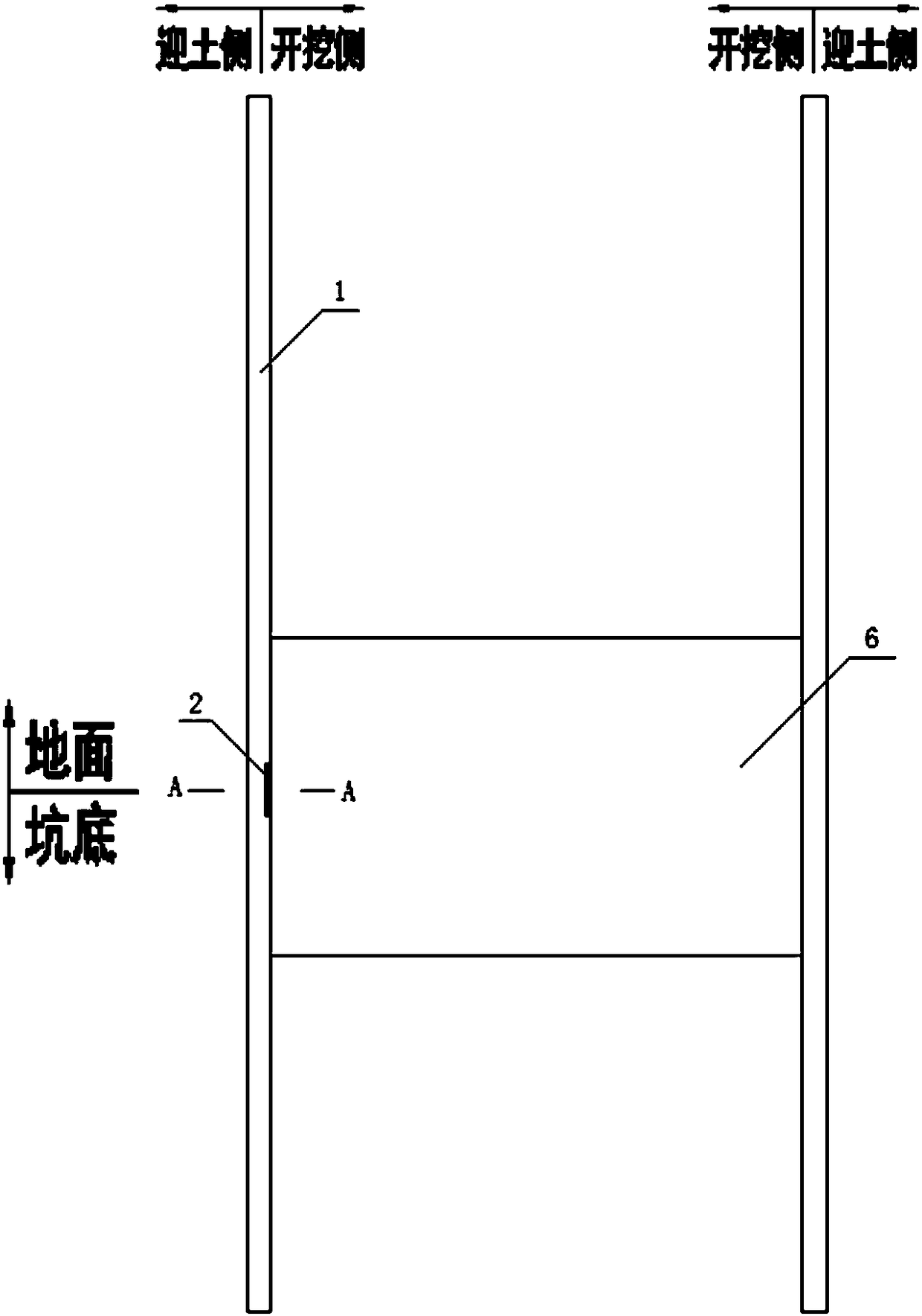

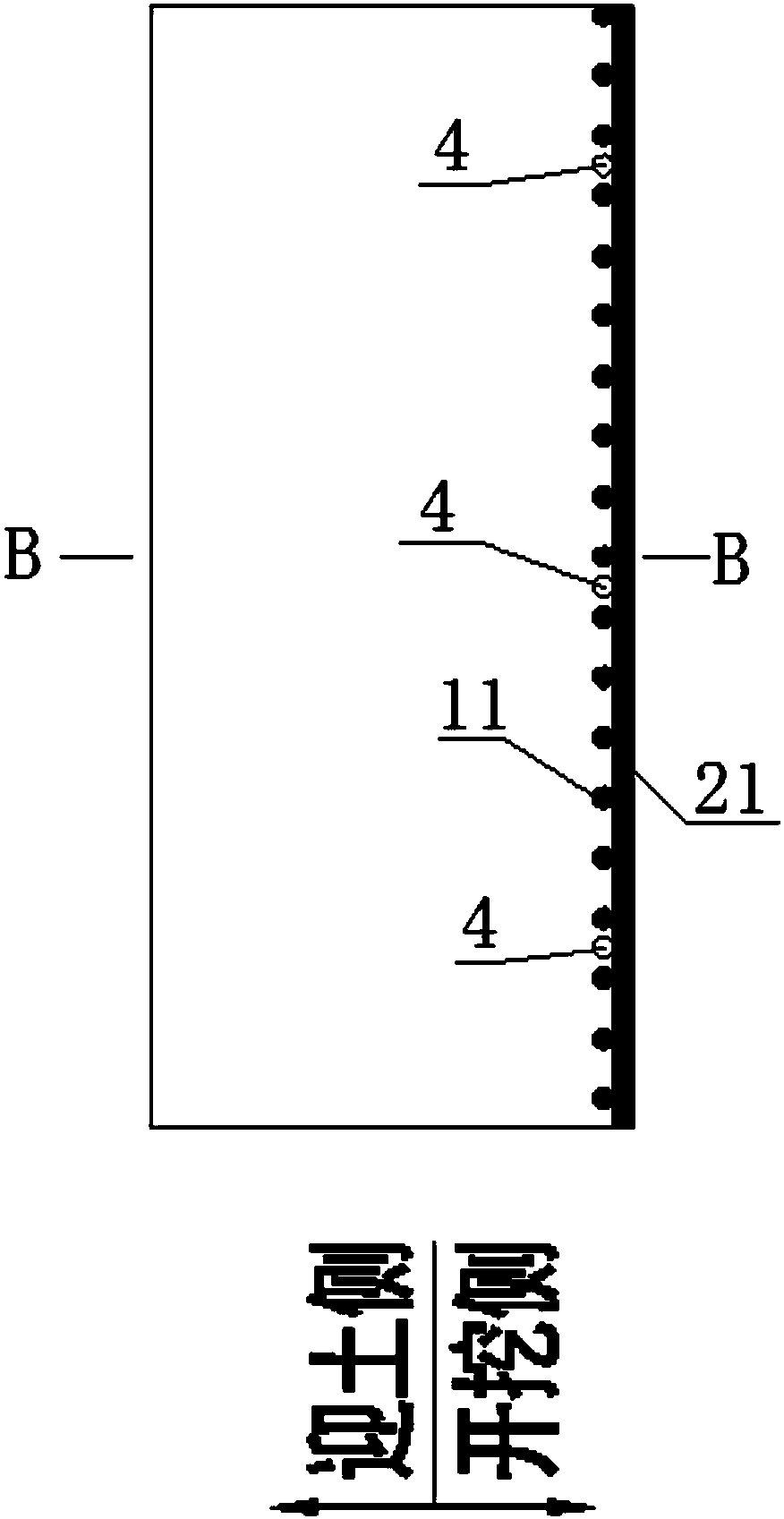

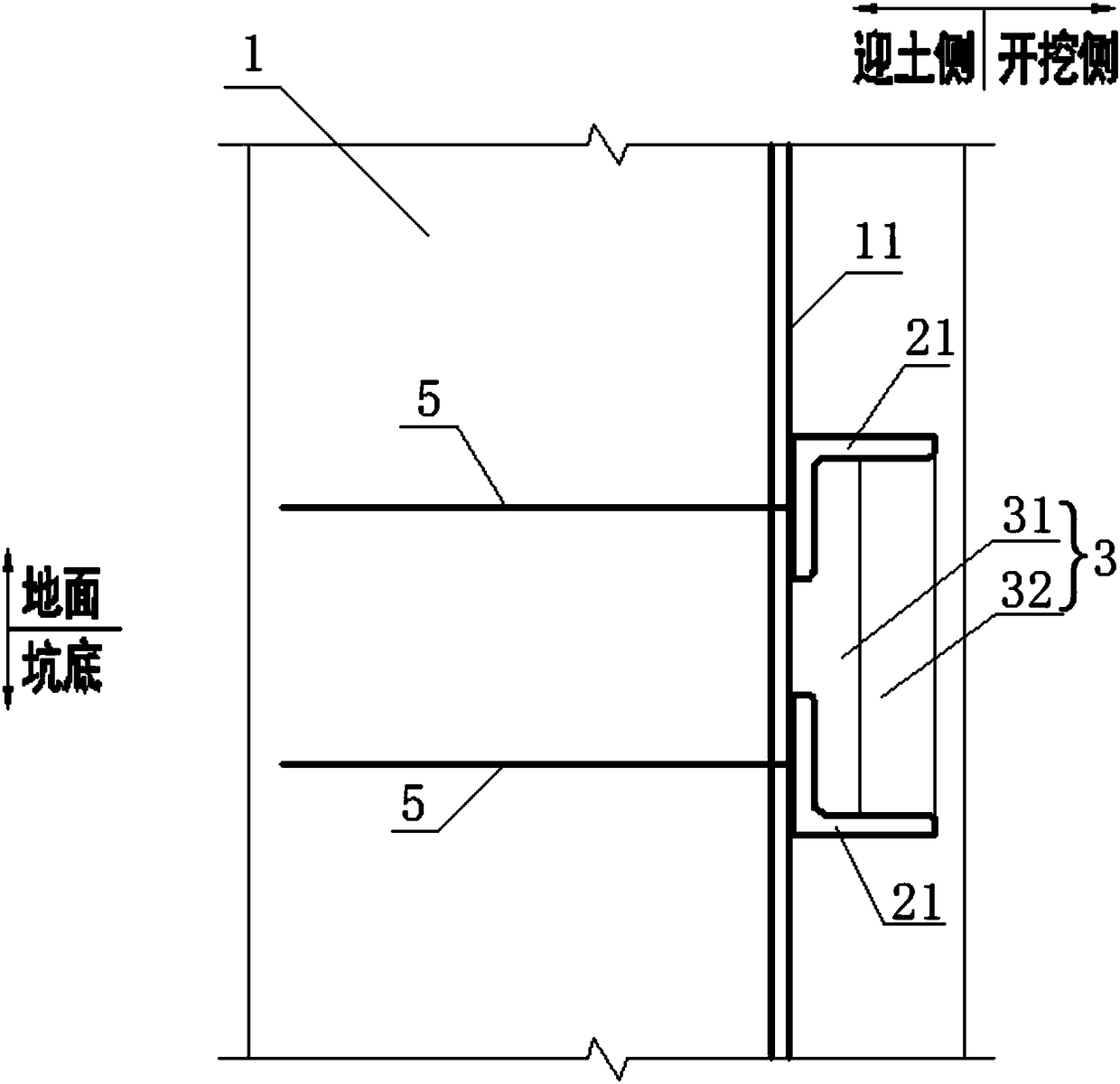

Shearing force groove structure for underwater concrete bottom sealing and construction method of shearing force groove structure

PendingCN108301414AReliable connectionGuaranteed watertightnessFoundation engineeringRebarShear force

The invention relates to a shearing force groove structure for underwater concrete bottom sealing and a construction method of the shearing force groove structure. The shearing force groove structurecomprises a foundation pit excavated on the ground, an enclosure structure is arranged around the foundation pit in a surrounding manner, and the shearing force groove structure further comprises steel angle pairs, transition plates and pre-buried flushing pipes, wherein the steel angle pairs are arranged on the inner side of the enclosure structure at intervals and in a surrounding mode, and thetwo steel angles in each steel angle pair are arranged oppositely at intervals; two rows of anchoring steel bars corresponding to the steel angles are embedded in the enclosure structure in an up-and-down interval mode, and the ends, close to the steel angle pairs, of the anchoring steel bars extend out of the enclosure structure and then are fixedly connected with the corresponding steel angles;each transition plate is arranged between the two steel angles in each steel angle pair, the pre-buried flushing pipes are arranged in the enclosure structure, and a plurality of water outlet holes are formed in the positions, corresponding to the steel angle pairs, of the pre-buried flushing pipes and the holes face the transition plates. According to the shearing force groove structure, reliableconnection between the bottom sealing concrete and the enclosure structure is achieved, the water tightness of the bottom sealing concrete is guaranteed, and huge water pressure at the bottom of thepit can be borne.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

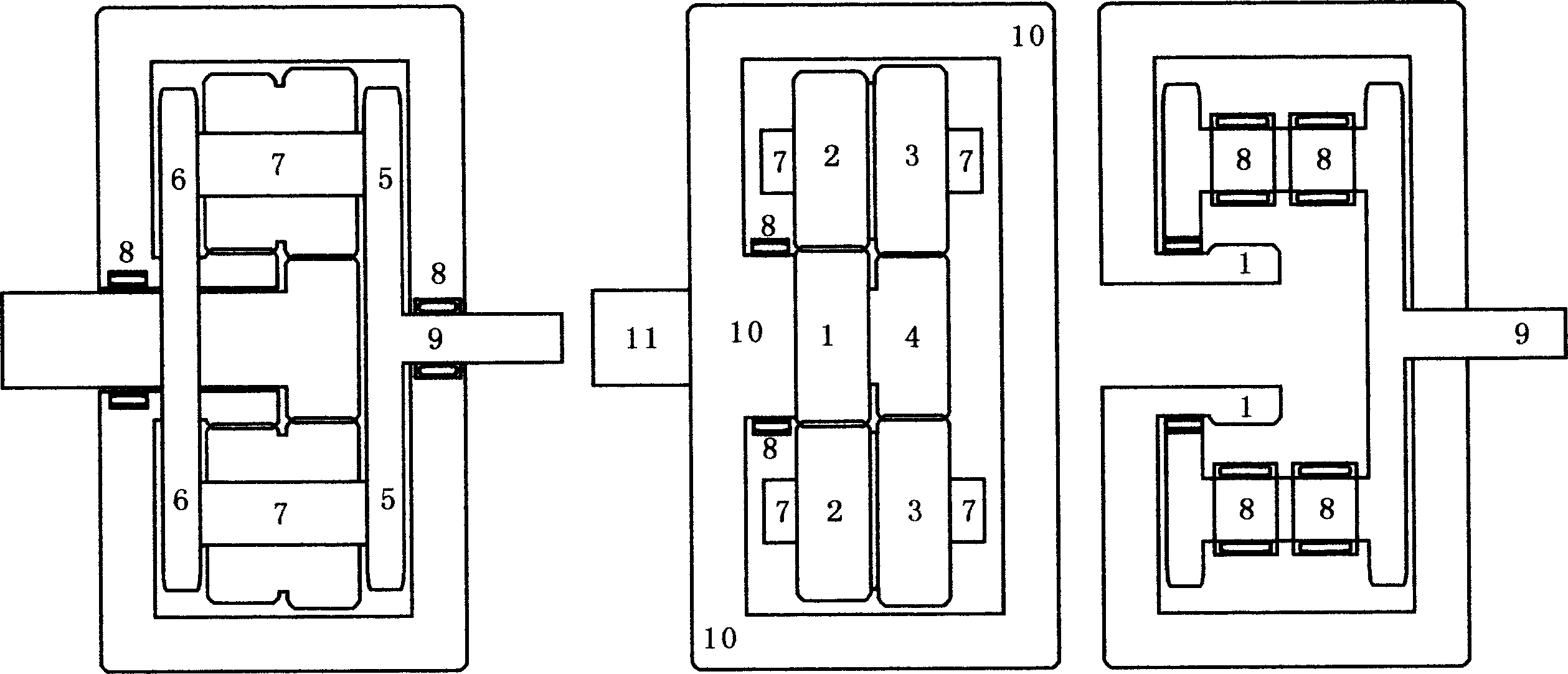

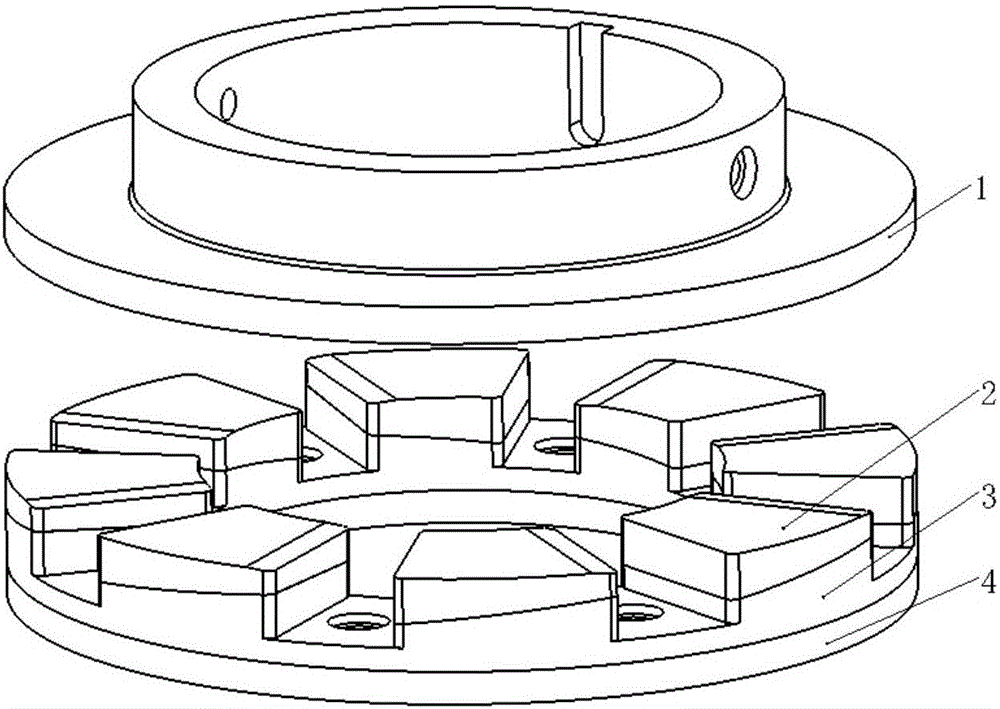

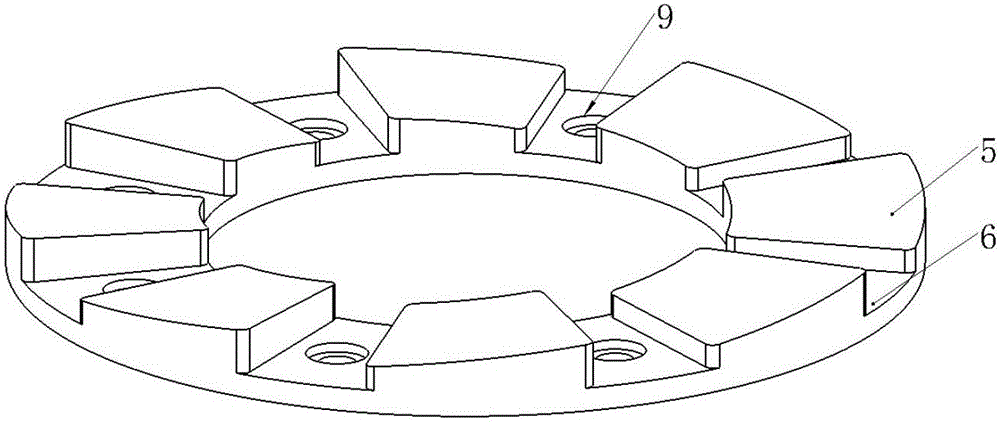

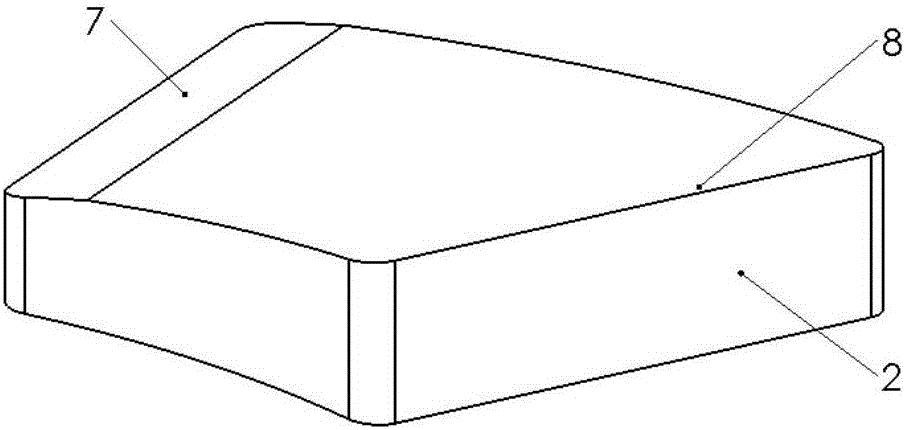

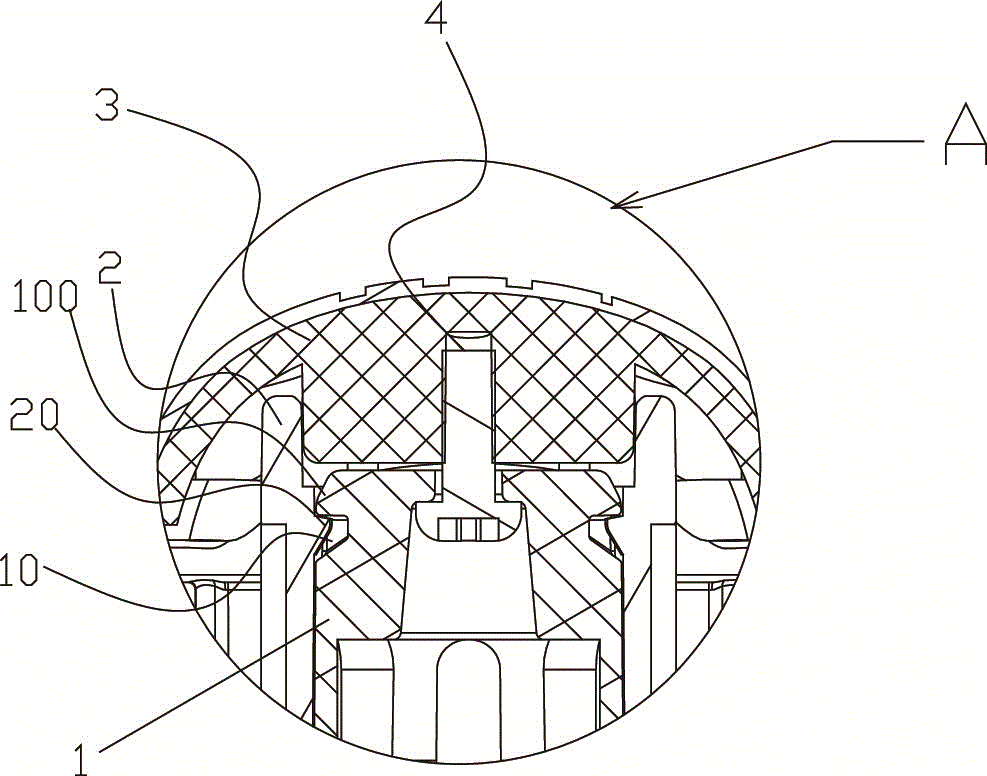

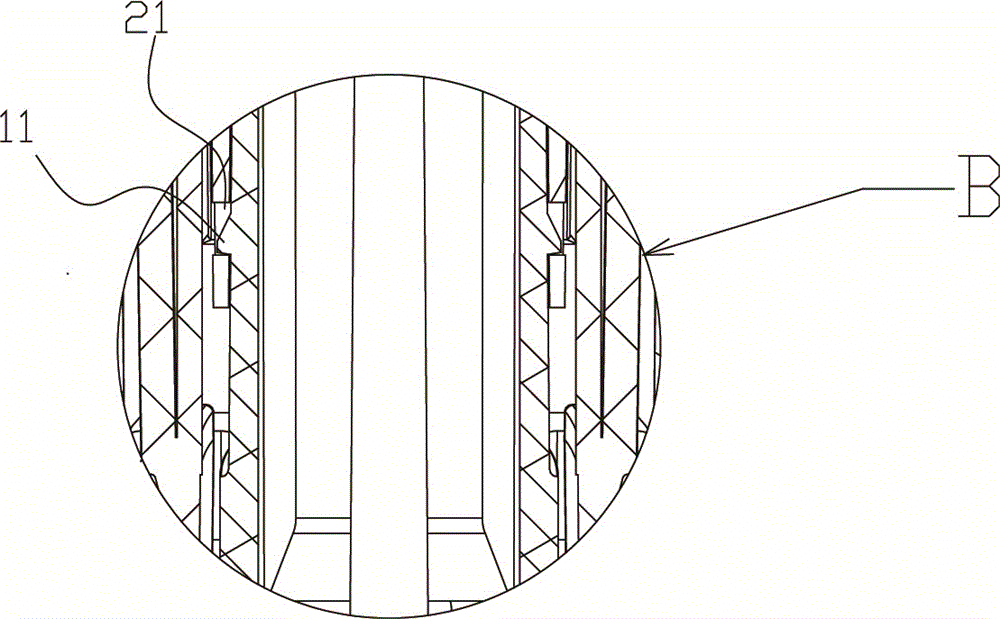

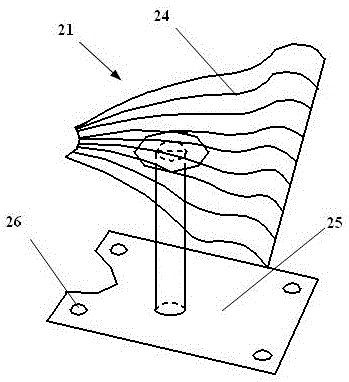

Tilting-pad thrust bearing supported through elastic disc

ActiveCN106438675ASimple structureFew partsBearing componentsSliding contact bearingsThrust bearingAxial thrust

The invention discloses a tilting-pad thrust bearing supported through an elastic disc. The tilting-pad thrust bearing is mainly composed of a thrust disc (1), a tilting material layer (2), the elastic disc (3) and a copper ring (4). The copper ring (4) is bonded to the lower surface of the elastic disc (3) and has the functions of supporting the elastic disc (3) and improving the strength of the elastic disc (3). The tilting material layer (2) is bonded to bosses (5) of the elastic disc and used for bearing axial thrust from the thrust disc (1). The tilting-pad thrust bearing has the beneficial effects of being simple in structure, convenient to machine and the like; the integral machining manner is adopted in the elastic disc, and it can be guaranteed that tiles have high planeness; and according to the thrust bearing, the character of deformation coordination of elastic materials is ingeniously utilized, and the thrust bearing has outstanding performance in the aspects of vibration reducing, noise lowering, tile load equalizing, lubricating and the like.

Owner:WUHAN UNIV OF TECH

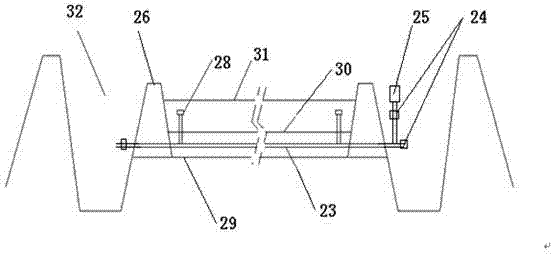

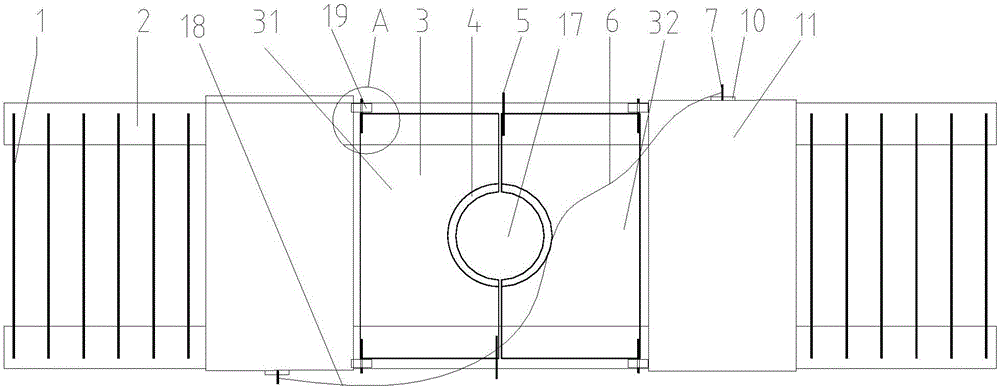

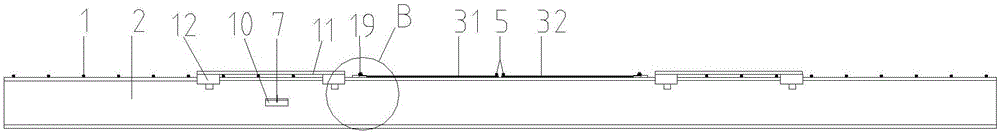

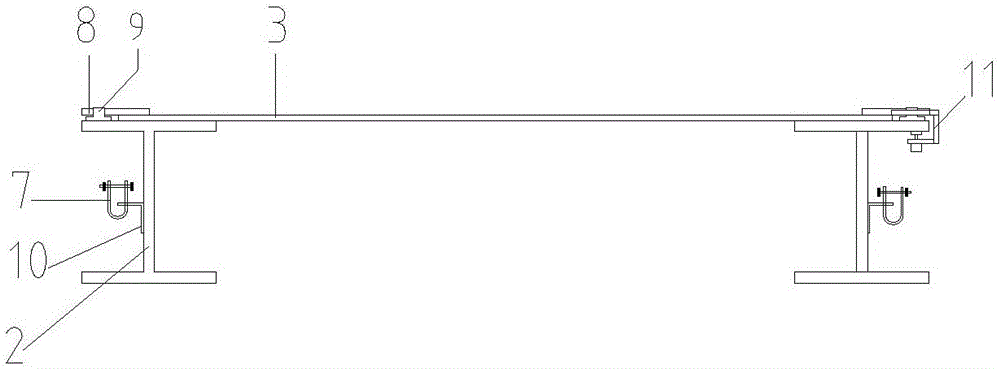

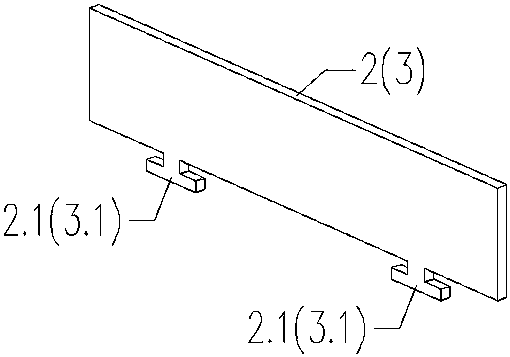

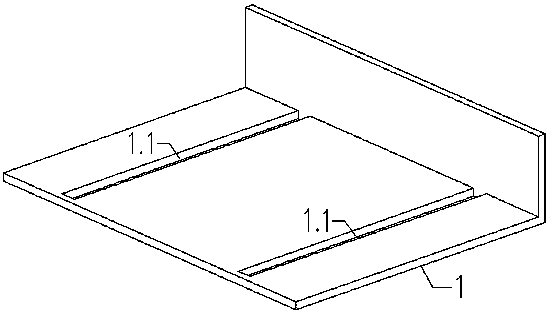

Expansion deformation connecting device and processing method thereof

ActiveCN108221653ASolve telescopic deformationAvoid being compressed and bulged,Bridge structural detailsBuilding insulationsGap fillingBearing capacity

The invention discloses an expansion deformation connecting device and a processing method thereof. The device comprises a horizontal supporting piece and multiple vertical supporting pieces perpendicularly arranged on the horizontal supporting piece. The vertical supporting pieces comprise the movable end vertical supporting piece, the fixed end vertical supporting piece and the movable middle vertical supporting pieces, wherein the movable end vertical supporting piece and the fixed end vertical supporting piece are located at the two ends of the horizontal supporting piece separately, and the movable middle vertical supporting pieces are located in the middle; and the movable end vertical supporting piece and the movable middle vertical supporting pieces can transversely slide on the horizontal supporting piece, the fixed end vertical supporting piece and the horizontal supporting piece are fixedly connected at the end, and elastic stuffing is arranged between every two adjacent vertical supporting pieces. The purpose of even expansion deformation between connected objects is effectively achieved, meanwhile, certain vertical even bearing capacity is achieved, and the problem that gap stuffing is compressed to bulge or stretched to collapse in a traditional gap filling method is solved.

Owner:CHINA MCC5 GROUP CORP

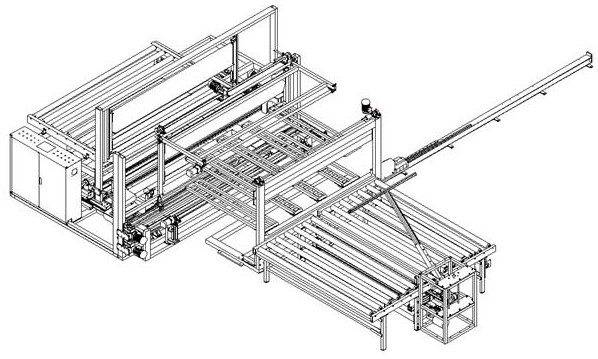

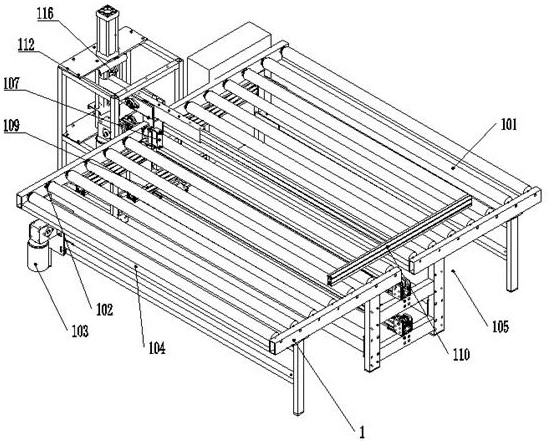

Bagging system for sponge inner sleeve

PendingCN111731565AReduce manual laborImprove work efficiencyWrapper twisting/gatheringYarnIndustrial engineering

The invention relates to a bagging system for a sponge inner sleeve. The bagging system comprises a feeding unit, a bagging unit, a cutting and overseam unit and a discharging unit sequentially arranged. The bagging system has the following advantages: through mutual cooperation of the feeding unit, the bagging unit, the cutting and overseam unit and the discharging unit, automatic conveying and bagging of sponge and automatic cutting and overseam unit of a yarn bag are realized, manual labor is greatly reduced during the entire process, effectively saves the labor force and correspondingly improves the working efficiency.

Owner:南通恒康数控机械股份有限公司

Handball convenient to insert and extract

The invention discloses a handball convenient to insert and extract. The handball comprises a clamping sleeve, a handle arranged in the clamping sleeve in a sleeving manner, and an end cover fixed to the upper end of the handle through a fastener, wherein the upper end of the handle is provided with a first ring-shaped clamping slot; the position, which corresponds to the first ring-shaped clamping slot, of the clamping sleeve is provided with a limiting baffle block which is protruded out of the side wall of the clamping sleeve; a ring-shaped bump part which is protruded out of the side wall of the handle is arranged on the middle part of the handle; and the position, which corresponds to the ring-shaped bump part, of the clamping sleeve is provided with a second ring-shaped clamping slot which is sunken into the side wall of the clamping sleeve. According to the handball, a three-section fixing mode is adopted for decomposing force which must be originally borne by one section of a buckle, so that the handball is more uniformly in stress, and is stable; by decomposing, the clamping amount of each buckle can be reduced, so that the assembly force is reduced, and therefore, the handball can be operated by virtue of a simple tool; besides, an oiling process is avoided.

Owner:FUCHENG AUTO PARTS

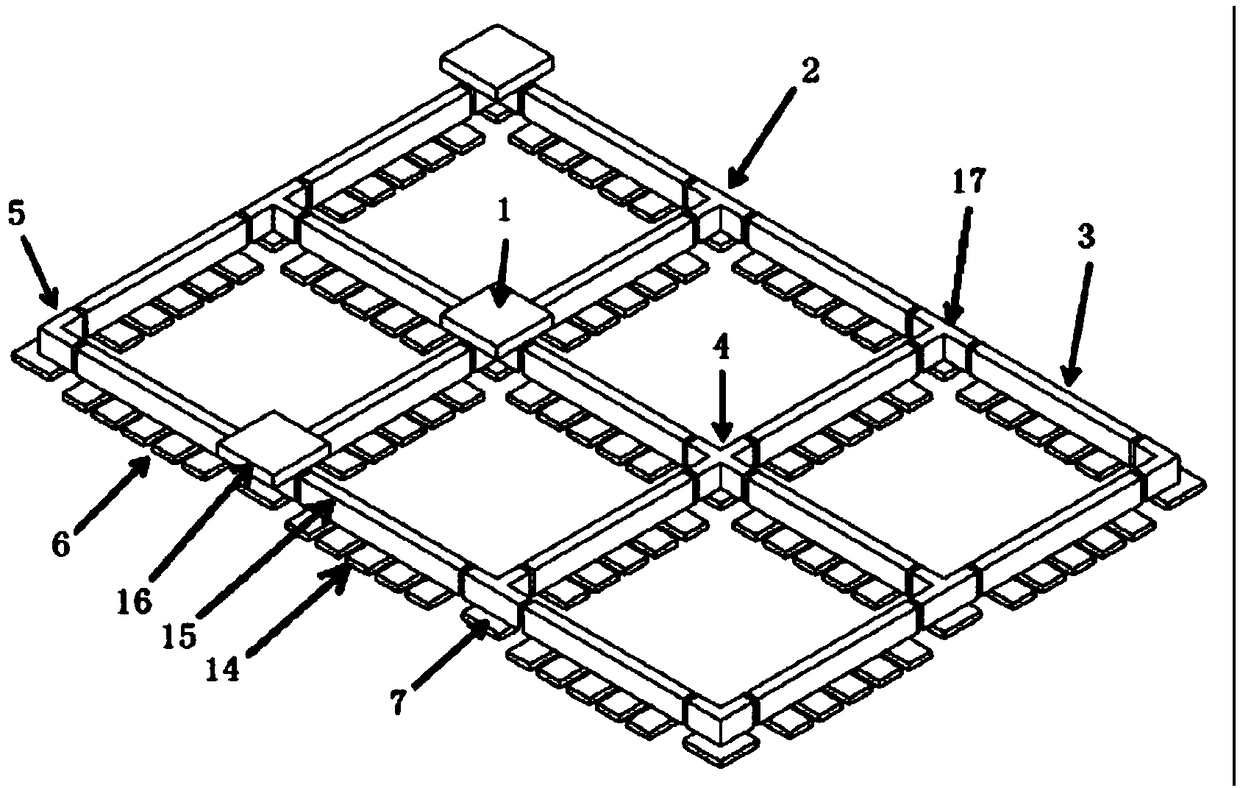

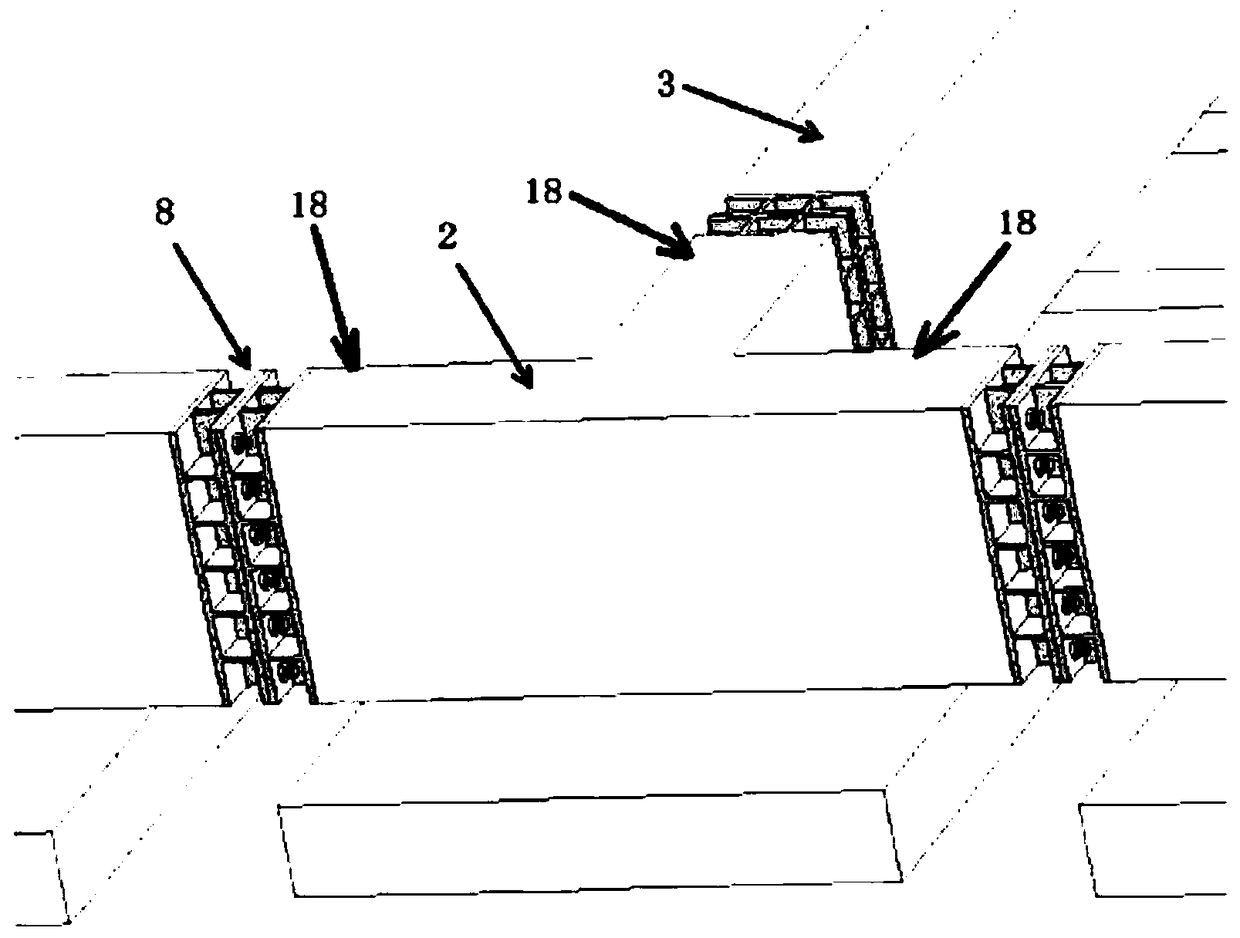

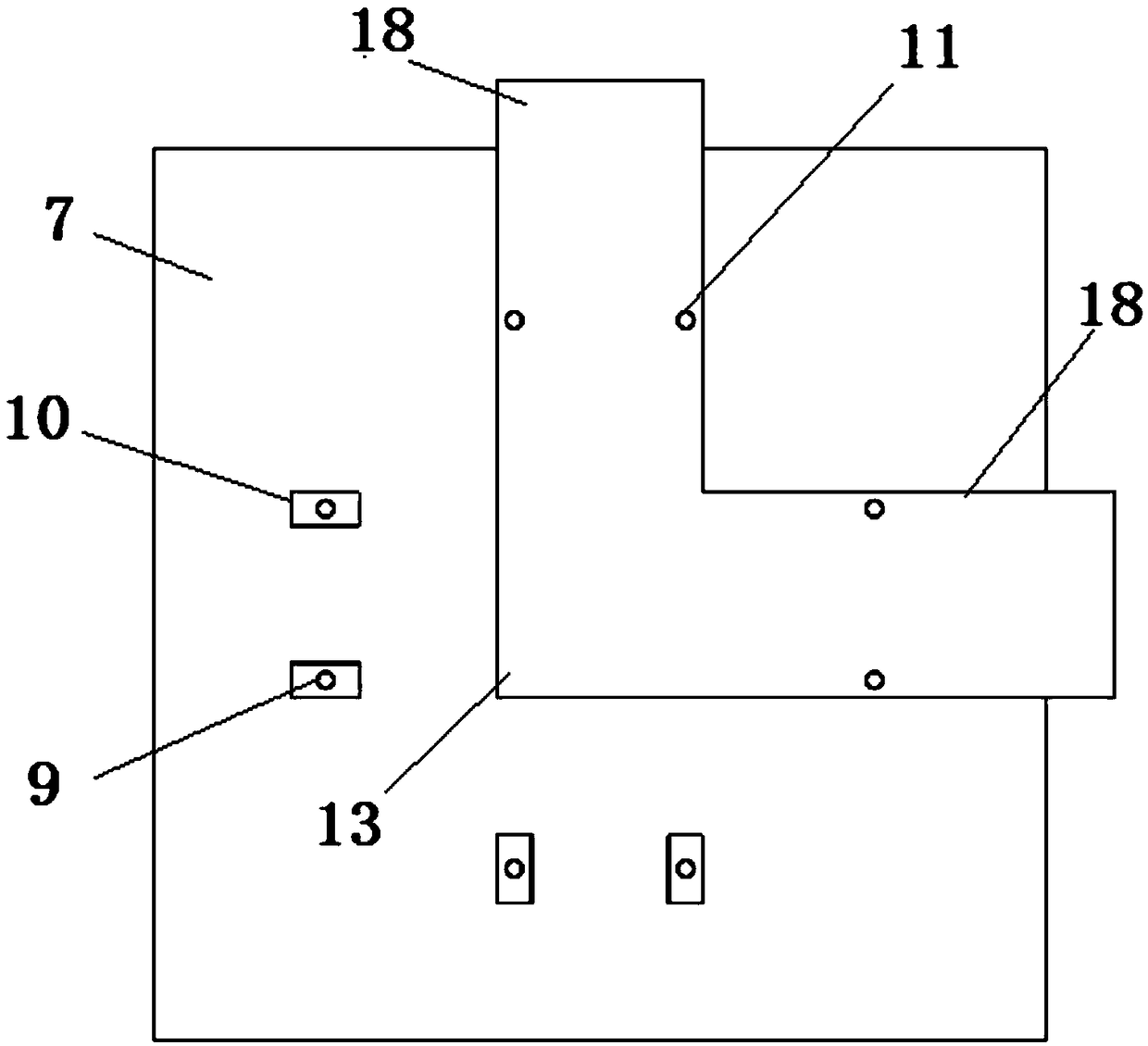

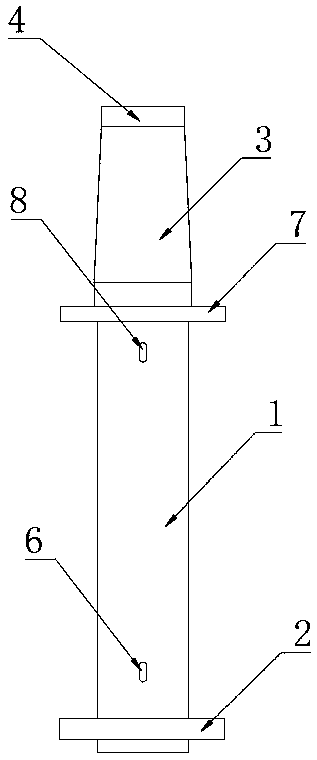

Equipment fabricated beam foundation and construction method thereof

PendingCN108755743AQuick buildBuilding security and stabilityFoundation engineeringEngineeringAbutment

Provided are an equipment fabricated beam foundation and a construction method thereof. A bottom plate layer, a connecting beam layer and an abutment layer are sequentially arranged from bottom to top. Each layer of component is assembled and spliced on site through a modular component. The bottom plate layer is formed by sequentially splicing a modular straight beam bottom plate and a joint beambottom plate block by block. Straight beam bottom plates and joint beam bottom plates are connected with beams through vertically through bolt holes, the horizontal degree of the beams is adjusted, the lower portions of corner beam sections are connected with the joint beam bottom plates, and the lower portions of straight beams are connected with straight beam bottom plates. Abutments are arranged above corner beam sections and fixedly connected with the corner beam sections below the abutments, and are used for containing equipment. A brand-new equipment foundation construction manner is provided, so that construction of the equipment foundation is very fast, safe, stable and extremely small in differential settlement, full-modular and on-site fabricated type dry construction can be achieved, and the construction cost is greatly reduced.

Owner:HUBEI BIEYIGE STEEL STRUCTURE TECH DEV

A kind of scraper used for scraping the flat surface of tightly fitted bolts

The invention discloses a scraper discharger for plane scraping of a fitting bolt, and belongs to the technical field of ship construction. The scraper discharger comprises a scraper discharger body and a positioning clamp. The scraper discharger body is in a cylinder shape. A conical handle is arranged at the upper end of the scraper discharger body. A protruding strip is arranged on the top faceof the conical handle. An annular groove is formed in the lower end of the scraper discharger body. The positioning clamp is arranged in an annular groove of the scraper discharger body in a sleevedmanner. The top face of the positioning clamp is perpendicular to the center line of the scraper discharger body. A first key groove is formed in the lower end of the side face of the scraper discharger body. The first key groove is arranged above the annular groove. The positioning clamp is arranged in the annular groove, loosening disengaging of the positioning clamp due to high-speed rotation and scraper rotation are avoided, and safety is high. The top face of the positioning clamp is perpendicular to the center line of the scraper body, the bearing force of the positioning clamp to the scraper is uniform, and the situation that in the scraper scraping process, inclination happens, and consequently the scraping precision is reduced is prevented.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

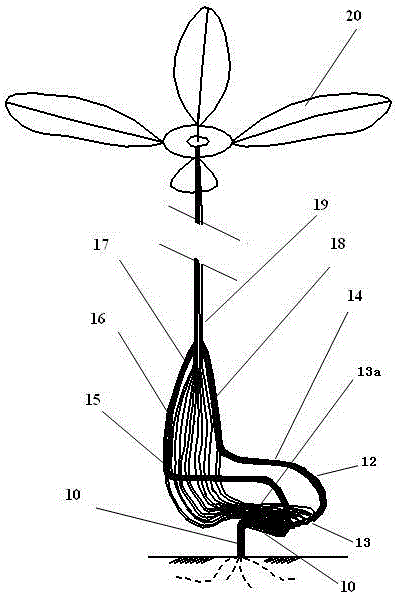

Modelling method of multiple-tree-in-one-pillar tree seat

The invention discloses a modeling method of a multiple-tree-in-one-pillar tree seat, and belongs to the field of forestry. The trunks of a plurality of trees, which are 25-35cm high and are strong in toughness, are mutually stuck and connected, so that a tree seat leg is formed; the plurality of trunks are bent forwards and are bent backwards on parts of 35-45cm; a base of the tree seat is bent backwards to 35-45cm and is bent upwards by 75-105 degrees; armrests are higher than the base; trunks of the armrests are stuck with and connected to adjacent base trunks, so that the edge of a backrest is formed; and the trunks of the trees are gathered in the center of the edge of the upper side of the backrest and perpendicularly grow upwards, and a crown is formed by virtue of a crown bracket. The tree seat structure provided by the invention is conducive to pedestrians to take a rest, tourists to relax and lovers to enjoy a secret meeting; a particular scenery can be offered to such places as a city, a park, a scenic area and the like; and an environment can be kept in green ecology; therefore, the tree seat is beneficial for air purifying and environment beautifying and is conducive to body heath of residents.

Owner:雷敏

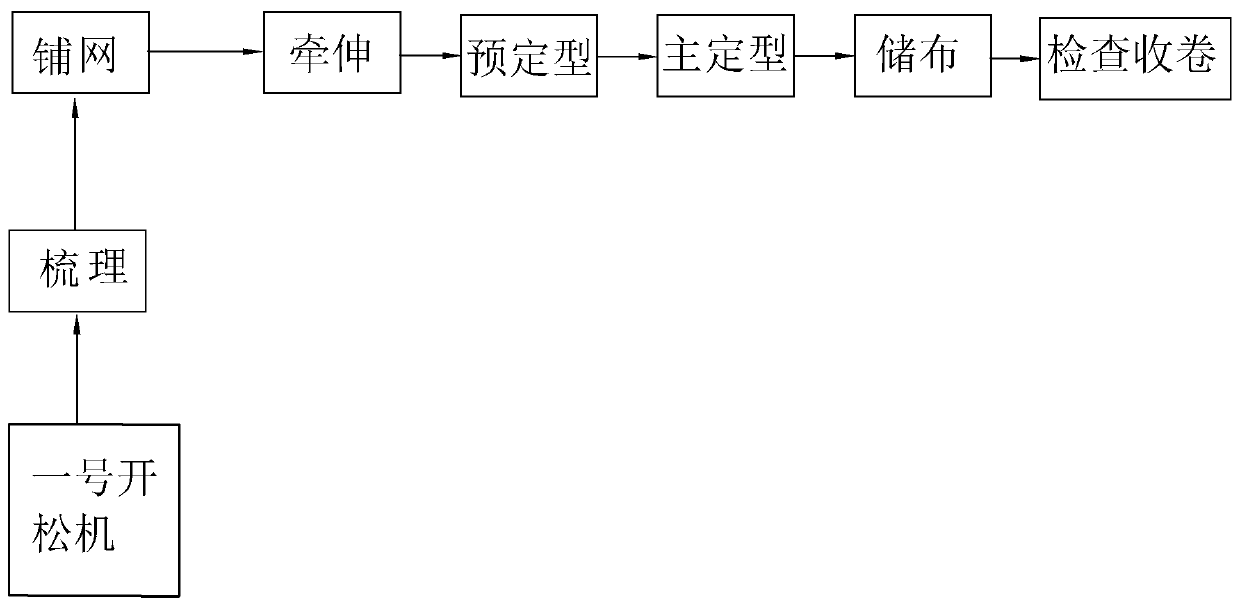

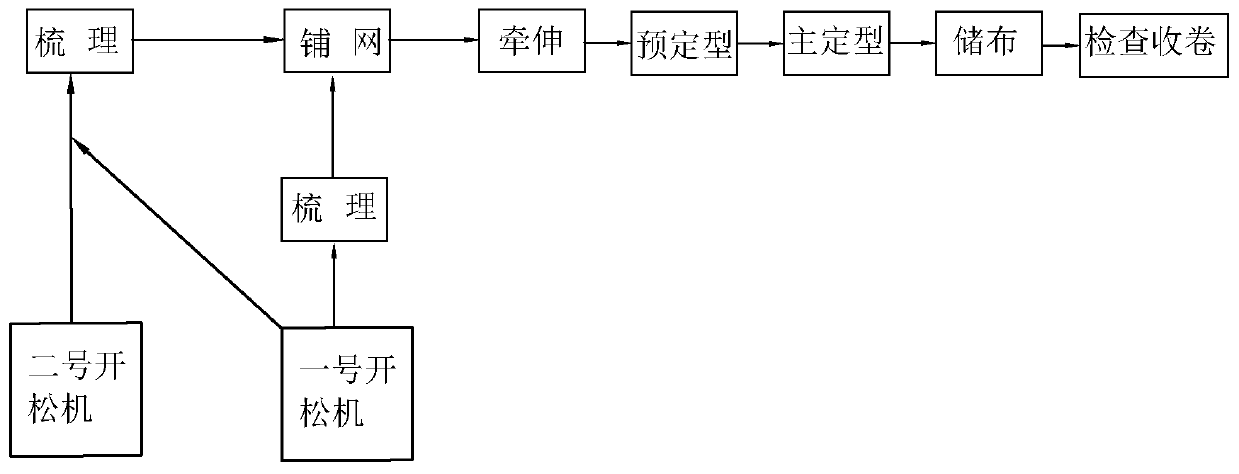

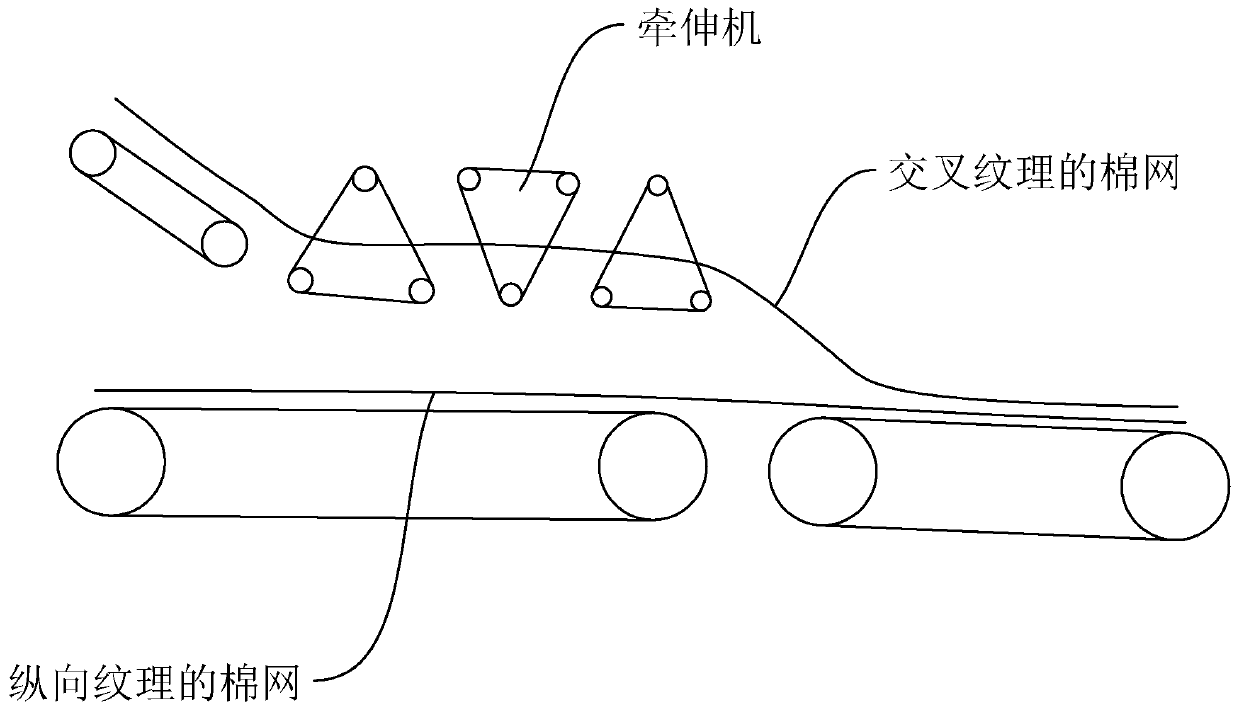

A light and high-strength non-woven fabric production process

The invention discloses a light and high-strength non-woven fabric production process and aims to solve the problem that traditional non-woven fabric is thick and not enough in strength. According tothe technical scheme, the process mainly includes the following steps of opening, cotton blending, carding, cross lapping, drawing, shaping, cloth storage, rolling and slitting; cross lapping includesthe step that a cotton web is sent from a first carding machine to a lapping machine, the discharge direction of the lapping machine is perpendicular to the feeding direction of the lapping machine,and the web sent from a cross lapping machine is a web having cross texture. According to the light and high-strength non-woven fabric production process, the produced non-woven fabric has the advantages of being light and uniform in strength, meanwhile reinforcement is conducted in the longitudinal direction, and the process is widely applied to packaging and other fields.

Owner:JIAXING HUALI NON WOVEN FABRIC CO LTD

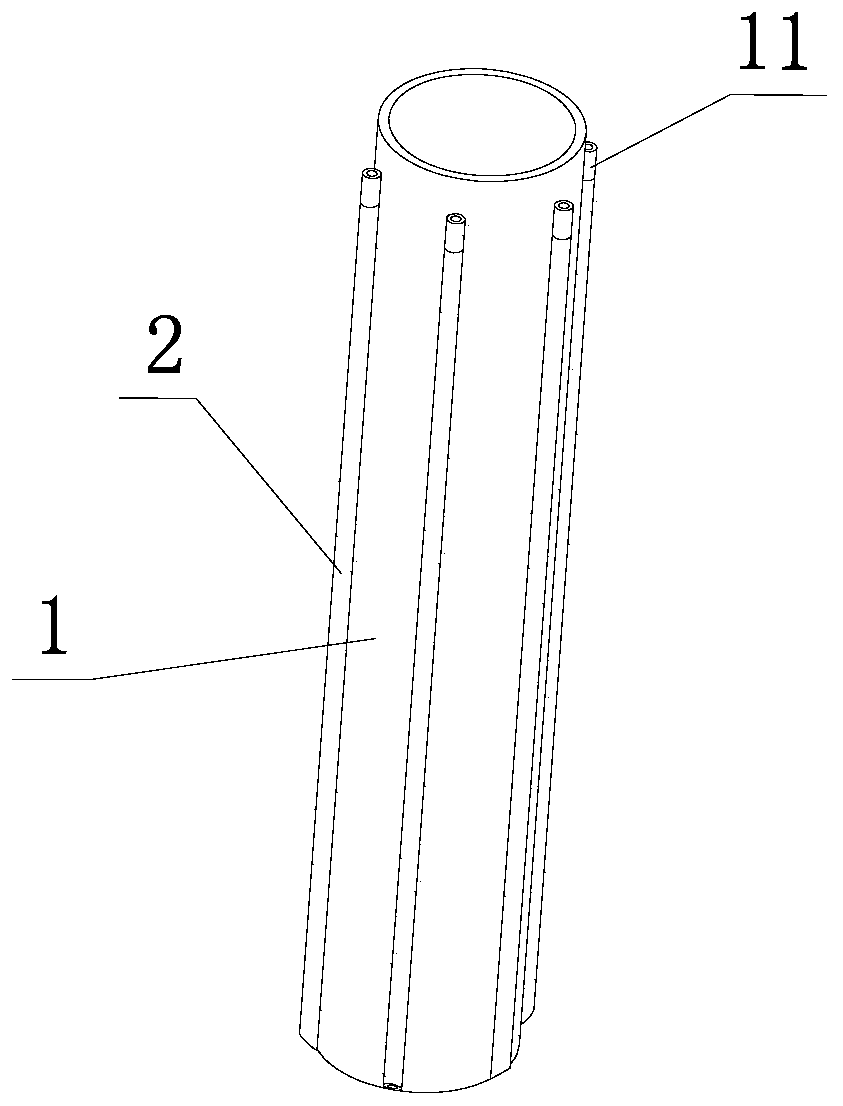

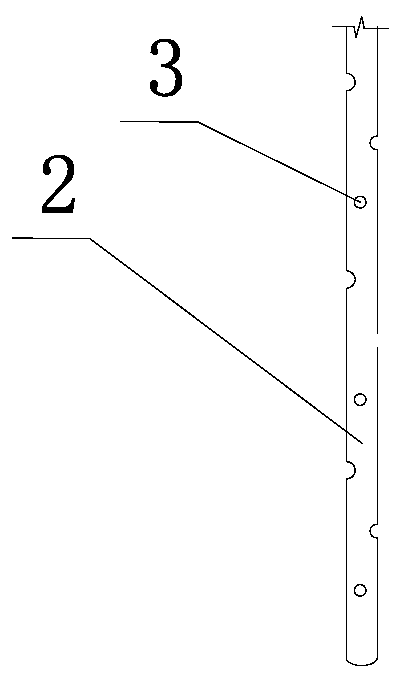

Device and method for enhancing stability of steel casing during pore-forming construction

ActiveCN110528516AImprove strength bearing capacityAvoid being unable to drill downFoundation testingBulkheads/pilesArchitectural engineeringCement slurry

The invention discloses a device and method for enhancing the stability of a steel casing during pore-forming construction. The device comprises the steel casing. A plurality of grouting guide pipes used for filling cement slurry to a soil mass are welded to the outer sidewall of the steel casing. Each grouting guide pipe is provided with a plurality of slurry delivery holes at different heights.The device further comprises a plurality of slurry delivery branch pipes used for communicating with upper ports of the grouting guide pipes. Each grouting guide pipe is provided with a pressure sensor used for measuring the stress of the bottom of the grouting guide pipe. The device further comprises a plurality of pay-off length adjustable rope sheaves in one-to-one correspondence with the grouting guide pipes. A steel wire rope is led out from each rope sheave, and the tail end of the steel wire rope is provided with an end cap used for falling into the corresponding grouting guide pipe tocontrol the grouting height of the grouting guide pipe. The key of the method is to set the pay-off lengths of the rope sheaves in a compensatory mode according to reading numbers of the pressure sensors of the grouting guide pipes to obtain different reinforcement height. Through the device and method for enhancing the stability of the steel casing during pore-forming construction, the steel casing can be protected against transverse and vertical displacement.

Owner:浙江易通特种基础工程股份有限公司

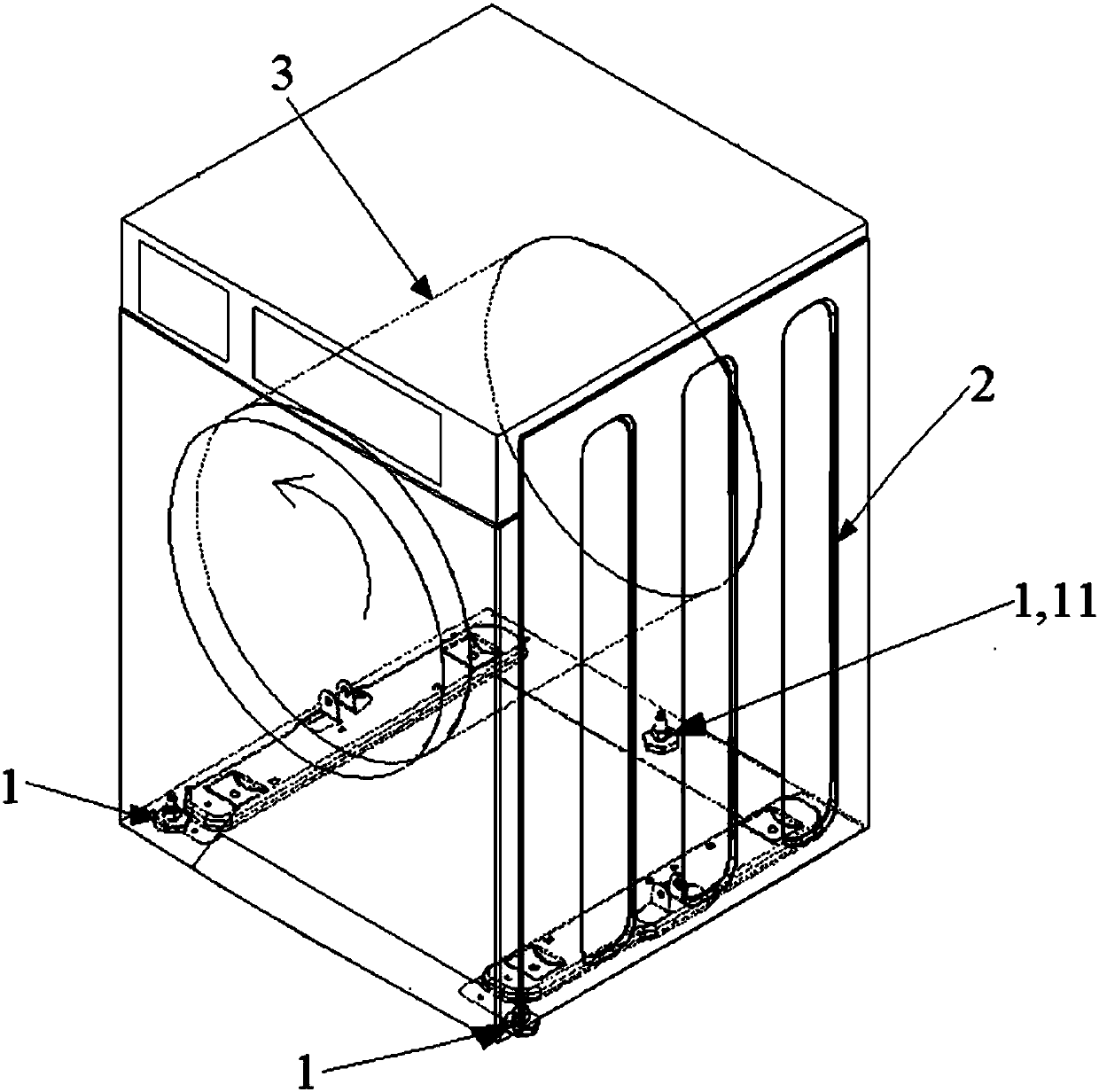

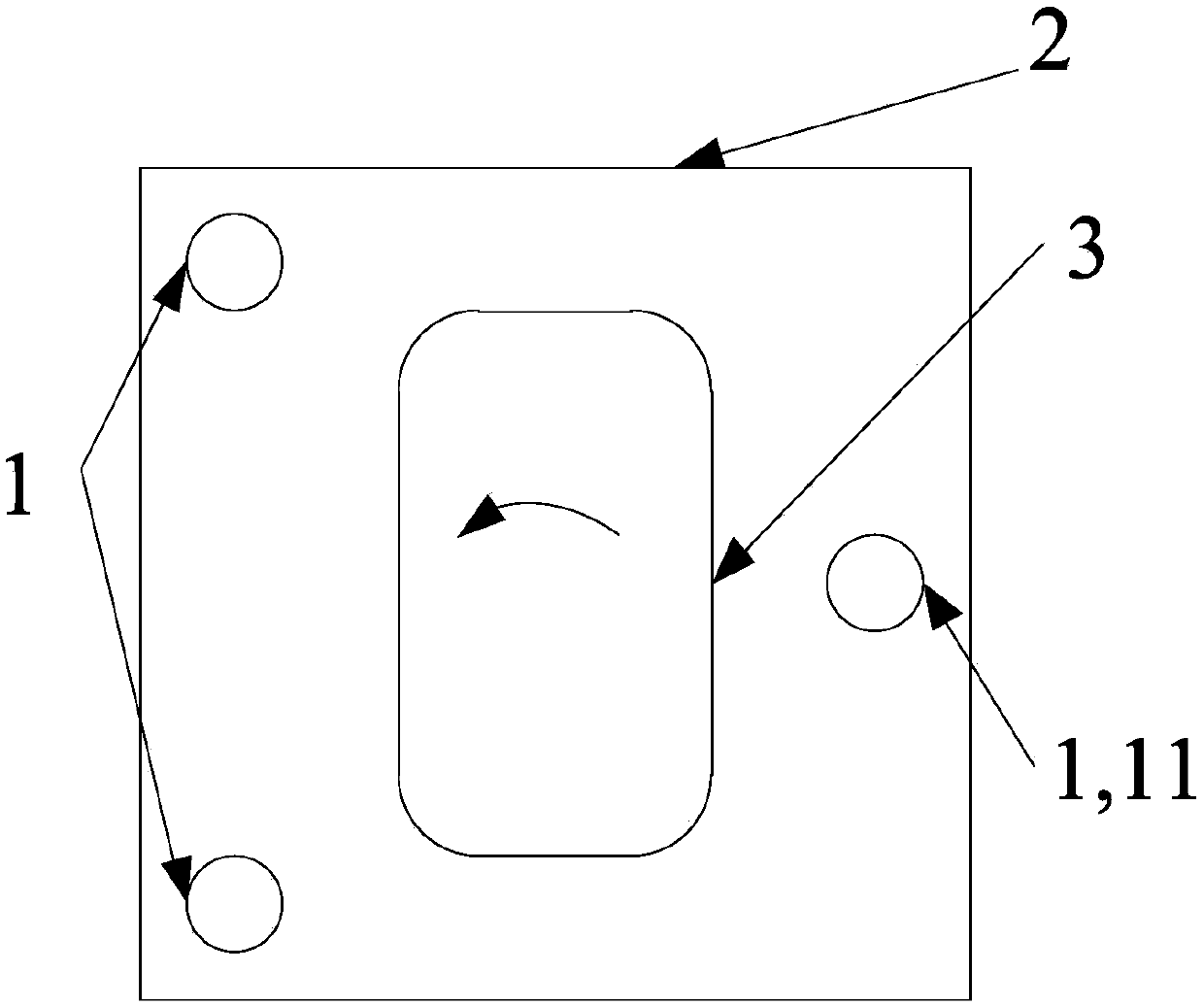

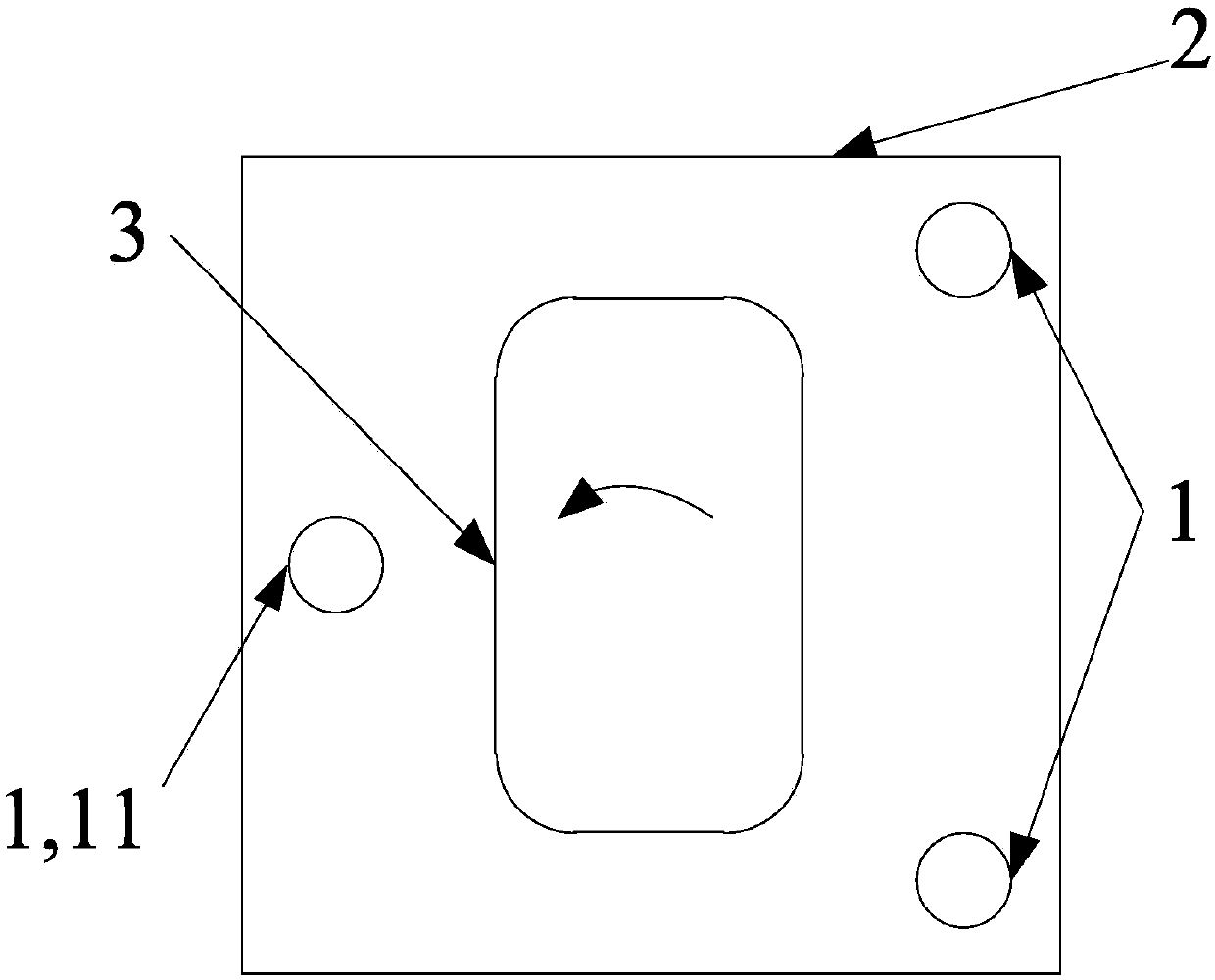

Clothing handling device

PendingCN109811500APlace stableUniform bearing capacityOther washing machinesWashing machine with receptaclesGround contactEngineering

The invention relates to the technical field of washing machines, in particular to a clothing handling device. The clothing handling device comprises a box and bottom feet, the box is internally provided with a washing cylinder and a motor, the bottom feet are arranged on the bottom surface of the box, the two linearly-arranged bottom feet are arranged on the side close to the bottom surface of the box, a bottom foot is arranged on the other side opposite to the side close to the bottom surface of the box, all the bottom feet and ground contact points are located on the same plane, and thus the clothing handling device is stably placed on the ground through the bottom feet located on the same plane. The clothing handling device provided by the invention is provided with the three or more bottom feet which are sequentially connected and arranged into a triangle, the process required by leveling is reduced, and the clothing handling device can be stably placed on the ground through simple adjustment.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

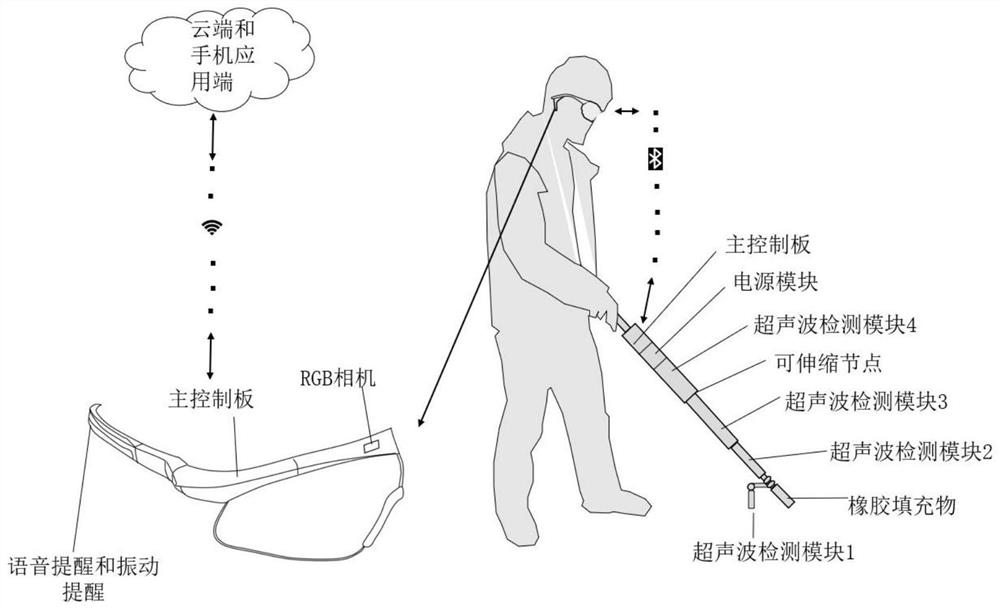

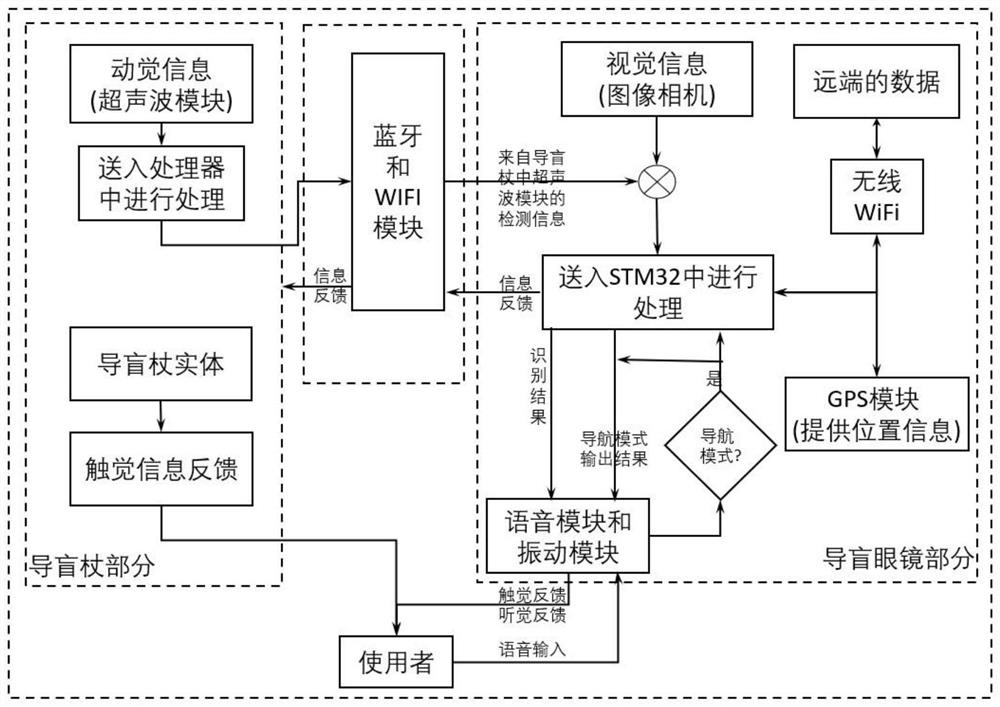

Blind guide stick mirror visual aid system and method for mixing visual touch sense information

PendingCN114831860AImprove adaptabilityReduce weightTelevision system detailsInstruments for road network navigationTouch PerceptionNerve network

The invention provides a blind guiding crutch mirror visual aid system and method for mixing visual sense and visual sense information. The blind guiding crutch mirror visual aid system comprises a module M1, a module M2 and a module M3, wherein the module M1 obtains visual information perceived in real time by the environment through a visual aid glasses body; the module M2 is used for acquiring touch and kinesthetic information perceived by the environment by utilizing the blind guiding stick body; the module M3 is used for integrating the touch and kinesthetic information perceived by the environment and the visual information perceived by the environment in real time, identifying the real-time position of an external environment object, judging by using a neural network model based on the real-time position of the environment object, and transmitting a judgment result to a wearer, so as to realize path guide for the blind.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

An integral shaft-connected fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

Storage pot shock insulation rubber support

ActiveCN101660585BCompact structureSimple installation and constructionNon-rotating vibration suppressionDislocationPetroleum engineering

The invention discloses a storage pot shock insulation rubber support which comprises an upper support plate, a lower connecting plate and high-elasticity rubber arranged between the upper support plate and the lower connecting plate, wherein a plurality of high damping materials and inner strengthening steel plates are embedded inside the high-elasticity rubber; the high damping materials, the inner strengthening steel plates, the upper support plate, the lower connecting plate and the high-elastiicty rubber form a shock insulation body; slideways are arranged at both ends of the outside of the shock insulation body; and inclined anti-toppling devices are arranged between the slideways and a basic surface. The invention has the advantages of compact structure, simple installation and construction, strong bearing capacity and good shock insulation and damping effect, and solves the problems of displacement dislocation or turnover of the storage pot caused by earthquake.

Owner:西安达盛隔震技术有限公司

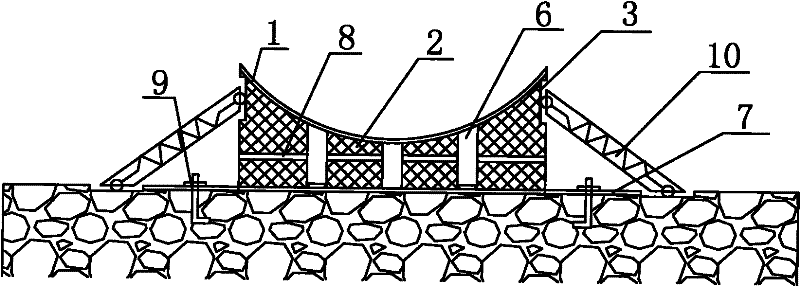

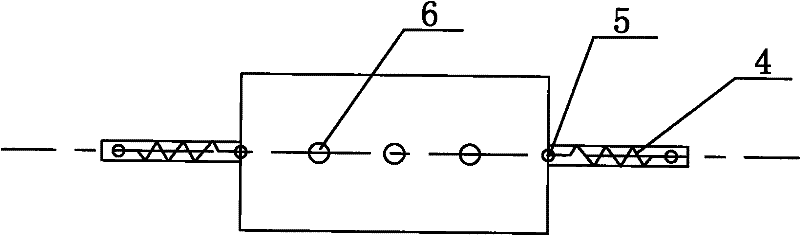

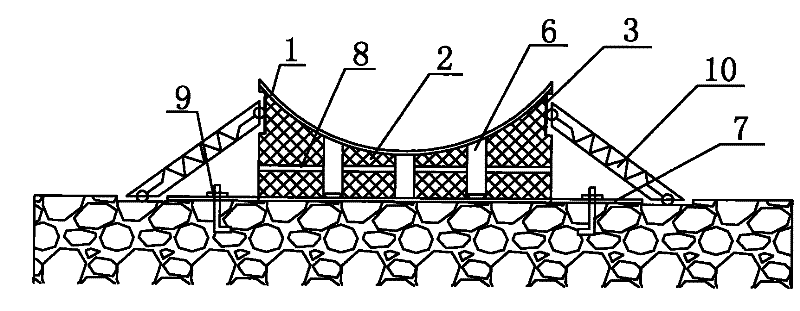

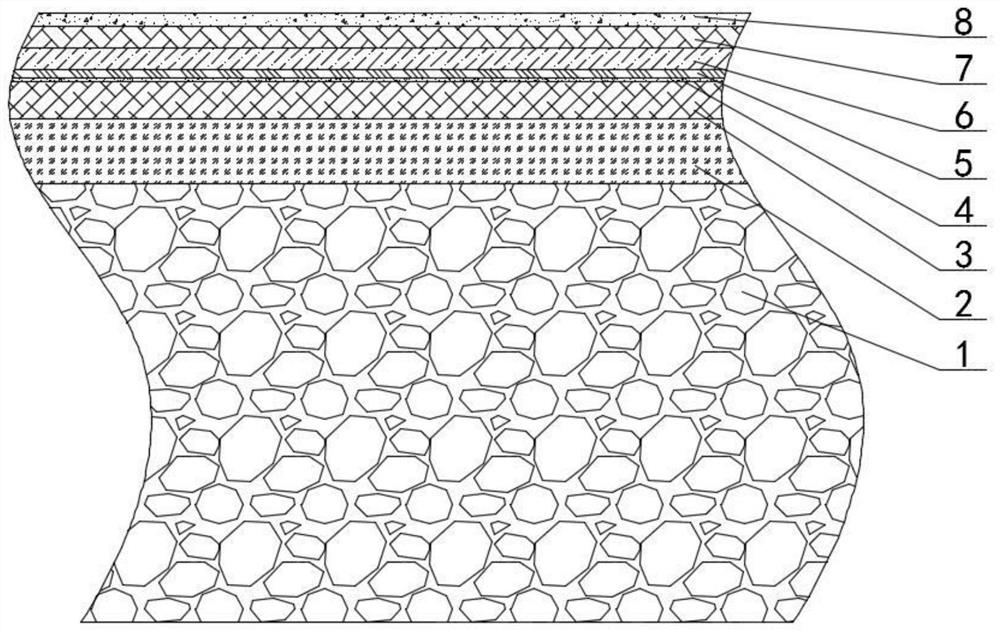

A method for paving full asphalt pavement of large particle size rock-filled subgrade

ActiveCN111501466BImproved deformation coordinationReduce stiffnessIn situ pavingsPaving gutters/kerbsCrushed stoneStructural engineering

Owner:CHINA CONSTR EIGHTH ENG DIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com