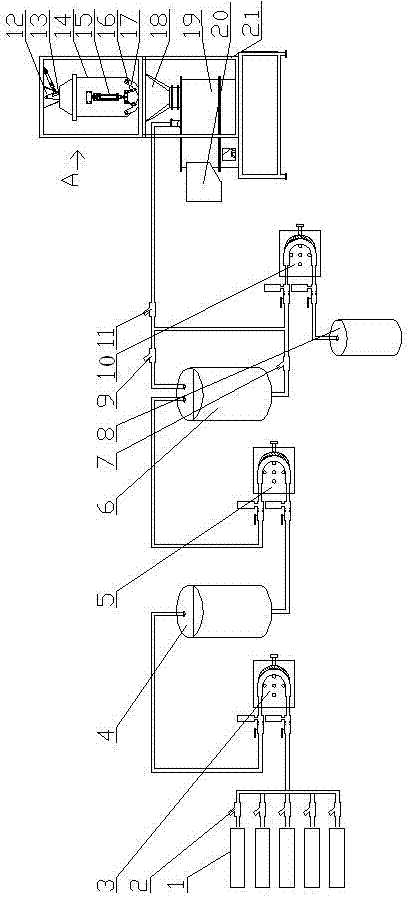

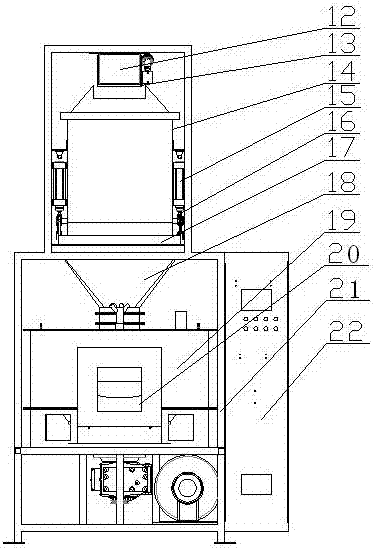

Batch continuous coating control method and coating machine with premixing function of seed coating agent

A coating machine and coating technology, applied in the direction of seed coating/seed dressing, etc., can solve the problems of increasing the work intensity of operators, affecting the seed coating effect, and damaging seeds, so as to avoid jamming or damage

- Summary

- Abstract

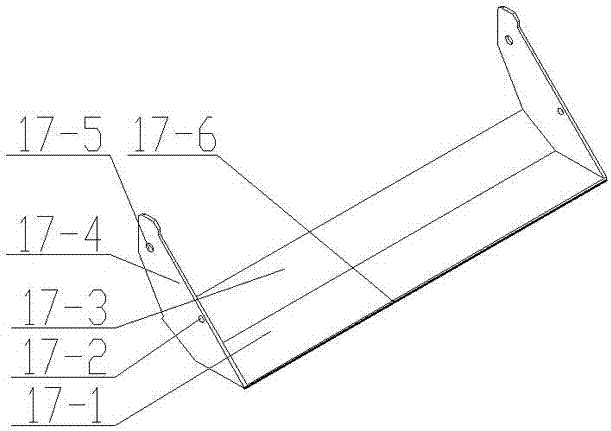

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] It is used for the coating process of 40 tons of corn seeds. The ratio of seed coating agent to seeds is 1:100. The seed coating agent is a commonly used corn seed coating agent in the market; a batch continuous type with the premixing function of seed coating agent Coating control method, comprises the following steps:

[0078] 1) Parameter setting: The set seed coating agent addition ratio is 1:100 and the formula of the seed coating agent, and the total weight of seeds to be coated is 40 tons, the weight of a single batch of coated seeds is 1 ton, and the stirring time is 6s ;

[0079] 2) Calculation of premixing program parameters: PLC controller calculates that the total amount of seed coating agent required is 400Kg, and the maximum loading capacity of dispensing metering tank 4 is: 400kg; The dosage of each original drug;

[0080] 3) Seed coating agent premixing: According to the calculation result of step 2), the PLC controller opens the valve guide group 2 an...

Embodiment 2

[0093] It is used for the coating process of 50 tons of rice seeds. The ratio of seed coating agent to seeds is 1:50. The seed coating agent is a commonly used rice seed coating agent in the market. It is a batch continuous type with the premixing function of seed coating agent. Coating control method operating steps are overall the same as in Example 1, the differences are as follows:

[0094] 1) Parameter setting: The set seed coating agent addition ratio is 1:50 and the formula of the seed coating agent, and the total weight of seeds to be coated is 50 tons, the weight of a single batch of coated seeds is 1 ton, and the stirring time is 12s ;

[0095] 2) Calculation of premixing program parameters: the PLC controller calculates the total amount of seed coating agent required to be 1000Kg, since the maximum loading capacity of the dispensing metering tank 4 is 400kg; the number of dispensing times is 3 times, and the weight of the first and second dispensing is 400Kg, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com