Intelligent deep hole rope winch driven by variable frequency motor

A frequency conversion motor and winch technology, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of complex hydraulic system, low hydraulic transmission efficiency, difficult equipment maintenance, etc. The effect of salvage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

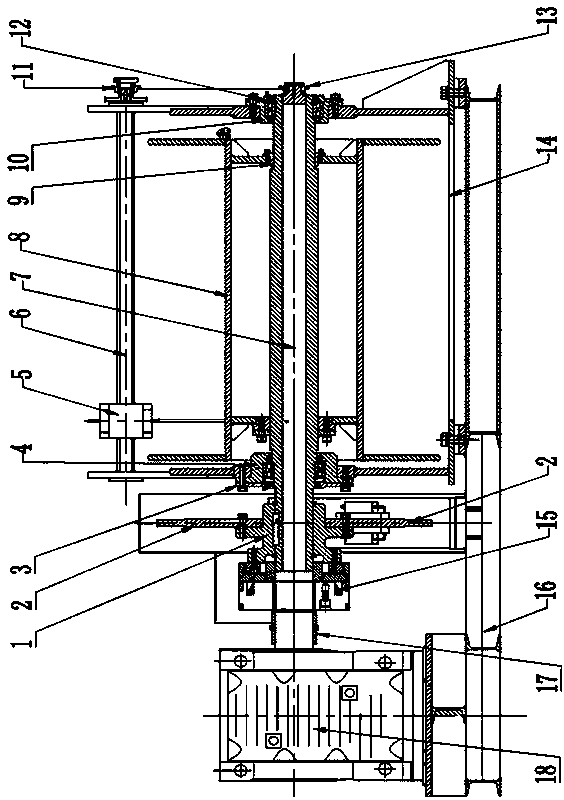

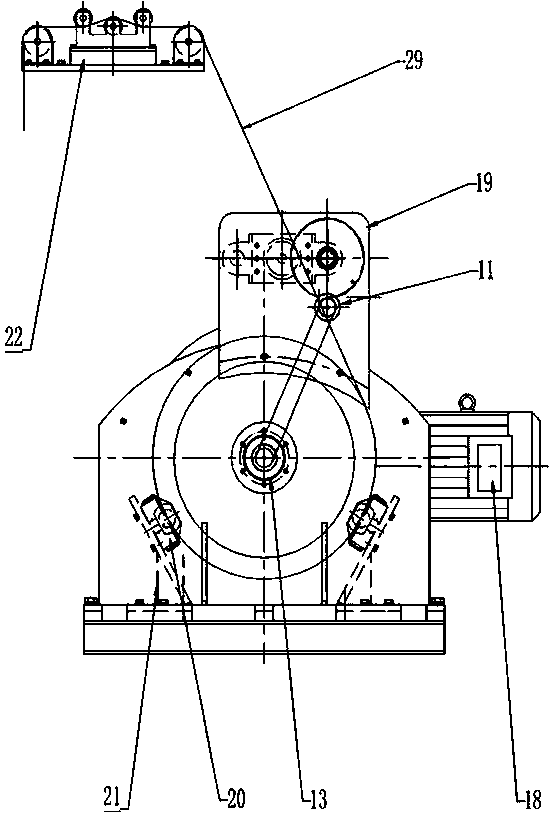

[0030] Such as figure 1 , figure 2 and image 3 Shown, the present invention is a kind of intelligent deep hole rope winch driven by frequency conversion motor, and this winch is provided with frequency conversion motor 18, winch frame 16, reel frame 14, rowing mechanism 19 and monitoring system, frequency conversion motor 18 and reel The drum frame 14 is arranged on the left side and the right side of the winch frame 16 respectively; The reel 8 connected to the radially outer side of the shaft 7; in order to realize the high-efficiency drive and control of the winch operation using the motor, the left end of the winch central axis 7 extends out of the reel frame 14 and is connected with the driven plate of the electromagnetic clutch 15 through the connecting plate 1, and the frequency conversion The output shaft of the motor 18 is connected with the input shaft of the reduction box, and the output shaft of the reduction box is connected with the active plate of the electro...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to be able to control the rotating speed of the reel 8 and brake the reel 8 in the present invention, in a preferred embodiment, the winch is also provided with a hydraulic disc brake 20 for braking the reel 8, which The hydraulic disc brake 20 is connected to the outer side of the connecting plate 1 through bolts. The hydraulic disc brake is provided with a brake disc 2. In order to improve the braking effect of the disc brake, the winch is also provided with a disc brake frame 21 for cooperating with the hydraulic disc brake 20. The disc brake frame 21 is arranged on the winch frame 16 through bolts; in order to realize the control of the monitoring computer for the hydraulic disc brake 20, the winch is also provided with a hydraulic disc brake controller for controlling the hydraulic disc brake 20 to brake. The disc brake controller is connected with the monitoring computer through the control circuit, and the other parts are ide...

Embodiment 3

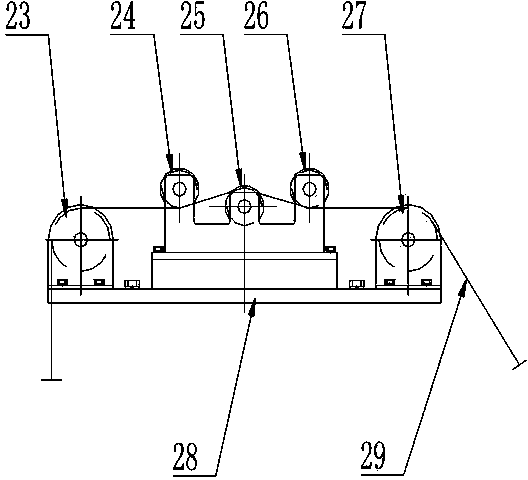

[0034] On the basis of Embodiment 2, in order to orderly wind up and unwind the rope during the retracting and unwinding process of the present invention, a preferred embodiment also includes that the rope arranging mechanism 19 is connected to the upper end of the reel frame 14 by bolts, The rope row rotating shaft 6 is arranged parallel to the reel 8, and the rope row rotating shaft 6 is provided with a rope row pulley 5 for arranging the ropes 29; The rope sprocket 11 on the frame 14 outsides; the winch central shaft 7 right-hand side is provided with the power output sprocket 13 that stretches out the reel frame 14, and this power output sprocket 13 is connected with the rope sprocket 11 by transmission chain, and other parts are connected with the rope sprocket 11. Example 2 is exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com