Negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method

A three-dimensional technology of filling and filling, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of difficult foundation treatment, long period, long settlement time, etc., to achieve outstanding drainage and soil preservation performance, and improve foundation bearing capacity. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

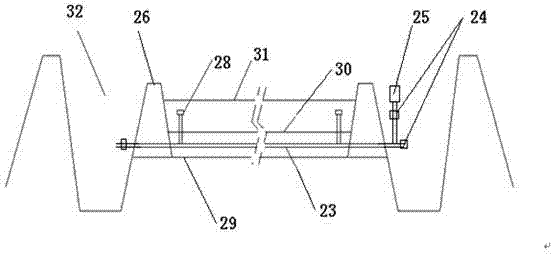

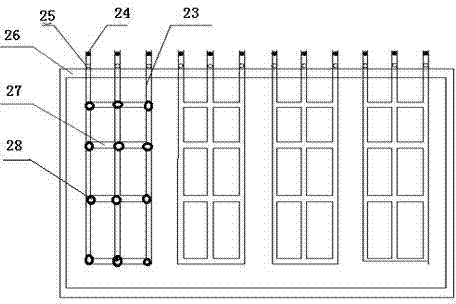

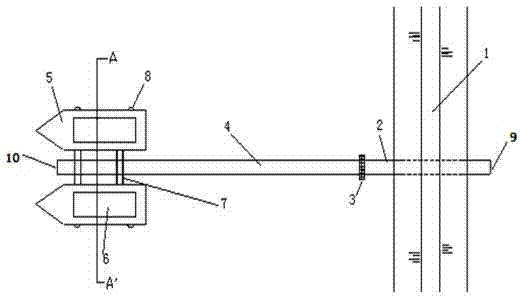

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

[0033] Refer to attached figure 1 and 2 , a negative pressure three-dimensional diversion disturbance impact consolidation dredging filling method, comprising the following steps:

[0034] (1) Clean up and level the reclamation area according to the design requirements, and then use a scarifier to loosen the ground by about 0.5m as a water-permeable layer; for some areas with silt, peel off the surface silt to the original soil layer.

[0035] (2) Design the drainage system according to the area, length, width and height of the dredging reclamation area and the location of the drainage ditch, and reasonably distribute the drainage area of each group of seepage pipes and the length and spacing of the seepage pipes to achieve Capable of collecting and draining water quickly and efficiently. Use a ditching machine to ditch in the reclamation area, and the depth and width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com