Patents

Literature

180results about How to "Fast reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

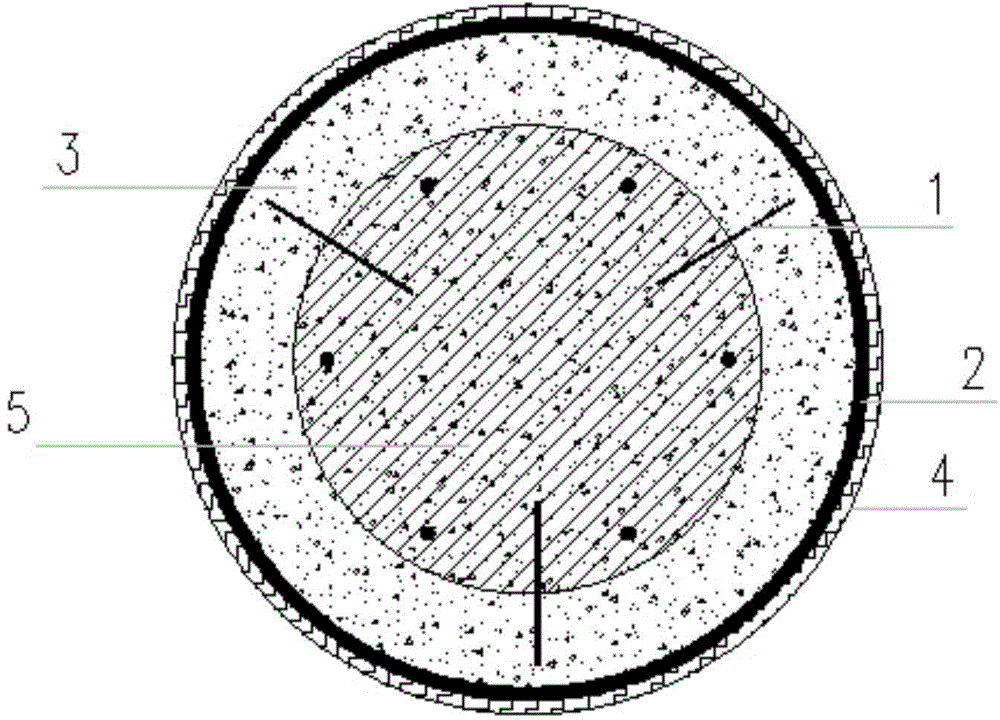

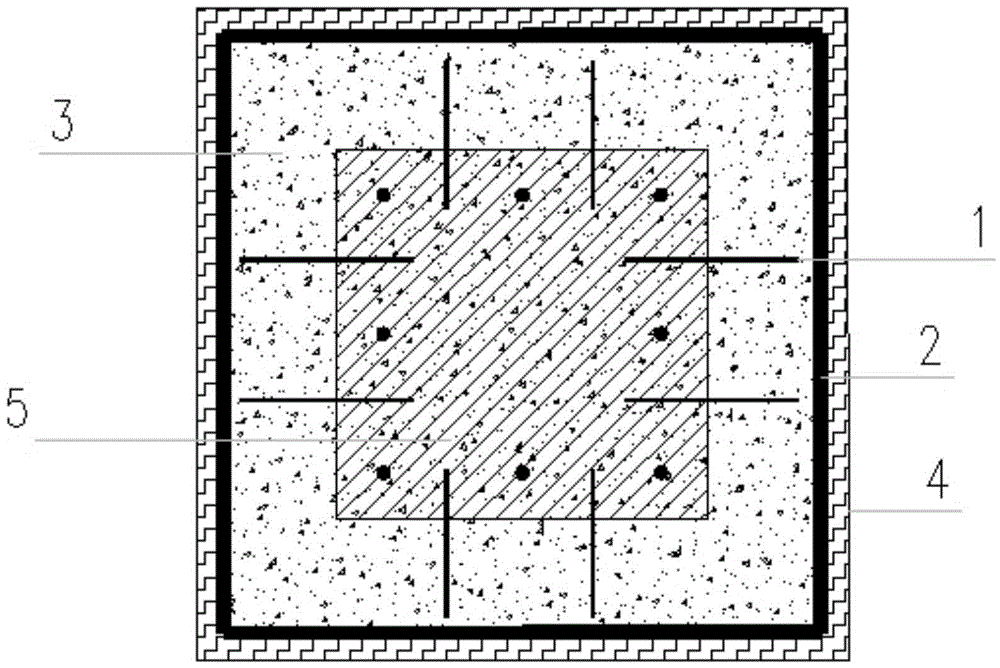

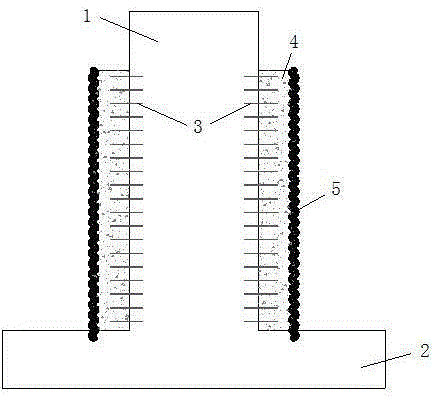

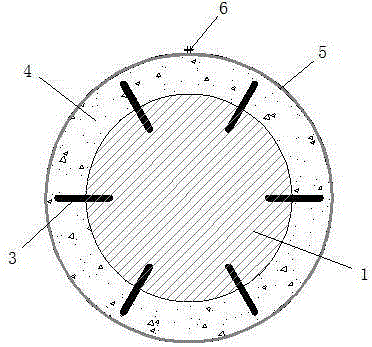

Ultra-high-performance concrete reinforced concrete column with fiber reinforced polymers wound around steel pipe

The invention provides an ultra-high-performance concrete reinforced concrete column with fiber reinforced polymers wound around a steel pipe, and relates to the technical field of novel combination column reinforced existing structures. FRP cloth is wound around the steel pipe and used for wrapping around and reinforcing existing reinforced concrete columns. A combination column comprises planting ribs, the steel pipe, ultra-high-performance concrete, the FRP cloth and an original reinforced concrete column. Compared with the method for expanding the section of traditional reinforced concrete, high-strength steel pipe concrete (steel pipe self-compaction concrete and steel pipe common fiber concrete) and an angle steel reinforced column, the component can effectively improve carrying capacity, deformability, seismic-resistance and antiseptic durability. Besides, the ultra-high-performance concrete reinforced concrete column is especially suitable for reinforcing high-rise and ultra-high-rise underlying columns, large-span bridge pier columns, structural engineering in a bad environment and industrial factory buildings in a corrosion environment.

Owner:BEIJING UNIV OF TECH

Silicate modified polyurethane high molecular material and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a silicate modified polyurethane high molecular material for the reinforcing and plugging of coal-rock mass and a preparation method thereof. The silicate modified polyurethane high molecular material consists of a component A and a component B at a volume ratio of 1:1, wherein the component A is liquid sodium silicate water glass; and the component B consists of 40-50 parts of polyaryl polymethylene isocyanate, 40-50 parts of modified MDI and 0-10 parts of viscosity reducer by weight. The preparation method comprises the following steps of: adding the raw materials of the component B into a reaction kettle and stirring uniformly, and performing nitrogen displacement encapsulation; and mixing the component A and the component B and grouting by a double-liquid grouting pump to obtain the product. Through the invention, the product has good flame retardance; the raw material liquid has low viscosity and good permeability in the coal-rock mass; cohesiveness between the consolidating body and the coal-rock mass is good; the silicate modified polyurethane high molecular material is suitable for the quick reinforcing and plugging treatment of the broken coal bed and rock stratum in various coal mines and tunnels in poor ventilation; and the preparation method adopts the pressure grouting of a double-liquid grouting pump, realizes an excellent pumping property, and is convenient to use.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Cement-polyurethane composite grouting process capable of blocking water fast

InactiveCN105332719APrevent backflowNot easy to diluteUnderground chambersTunnel liningWater leakageSlurry

The invention discloses a cement-polyurethane composite grouting process capable of blocking water fast. The cement-polyurethane composite grouting process includes the steps of a, performing engineering exploration, to be more specific, designing a plurality of holes after the optimal reaction positions of polyurethane grout are determined according to the stratum cracks or the flowability of flowing water, wherein the holes should communicate water leakage points as much as possible or penetrate a plurality of stratum cracks to allow one hole to penetrate multiple stratums; b, drilling; c, grouting, to be more specific, simultaneously and alternately grouting the polyurethane grout and cement grout into all holes, using the instant foaming and curing feature, which uses water to stop water, of the polyurethane grouted first to stop and block water, using the cement grout grouted later to stop the backflow of the polyurethane so as to form a structure with grouted holes and front blocking and back protection, and repeatedly and alternately grouting for multiple times until water burst is blocked; d, continuing grouting for a certain period of time after the water burst is blocked to guarantee that blocking is completed. By the arrangement, the cement-polyurethane composite grouting process is simple in procedures, capable of blocking water fast, and capable of integrating blocking and reinforcing.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Production method for white carbon black with high additive amount

ActiveCN104291344AIncrease product additionSmall specific surface areaSilicaSeed crystalCarbon black

The invention relates to a production method for an inorganic powder material, in particular to a production method for white carbon black with high additive amount applied to high-elastic silicone rubber. The production method comprises the processes of dissolution and refining of water glass, synthesis reaction of the water glass and dilute sulphuric acid, pressure filtration, washing, pulping and drying; the reaction of the water glass and the dilute sulphuric acid comprises the following three steps: generating seed crystal, conducting synthesis reaction and adjusting integral pH value. According to the invention, the synthesis process of three steps is adopted; the specific surface area of the product is reduced by adding a sodium sulfate additive; reaction conditions are controlled strictly; the particle diameter of secondary particles of the product is controlled effectively; the characteristics of small specific surface area, low oil absorption value, high additive amount, high reinforcing performance and short mixing time during mixing with silicone rubber are provided; the raw materials are easy to obtain; the process is easy to control; no extra equipment is needed; the production can be conducted on an original production line.

Owner:江西双龙硅材料科技有限公司

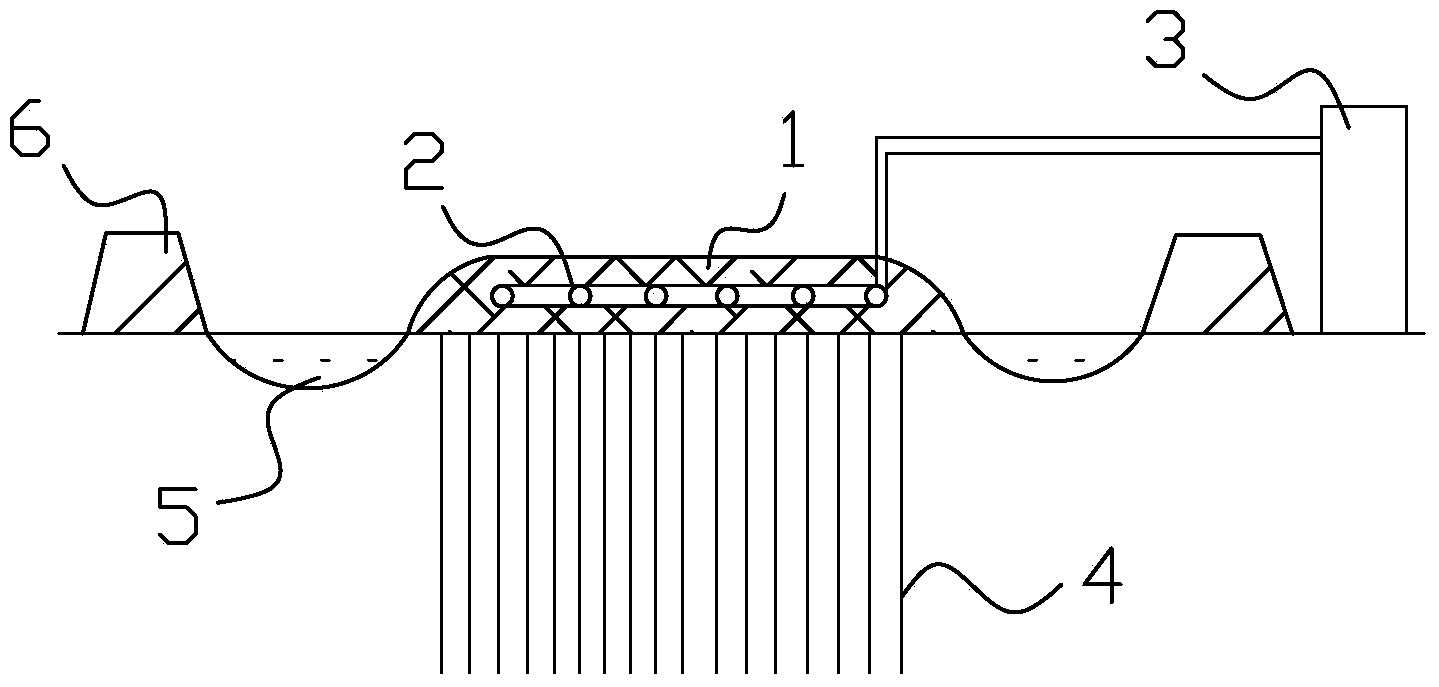

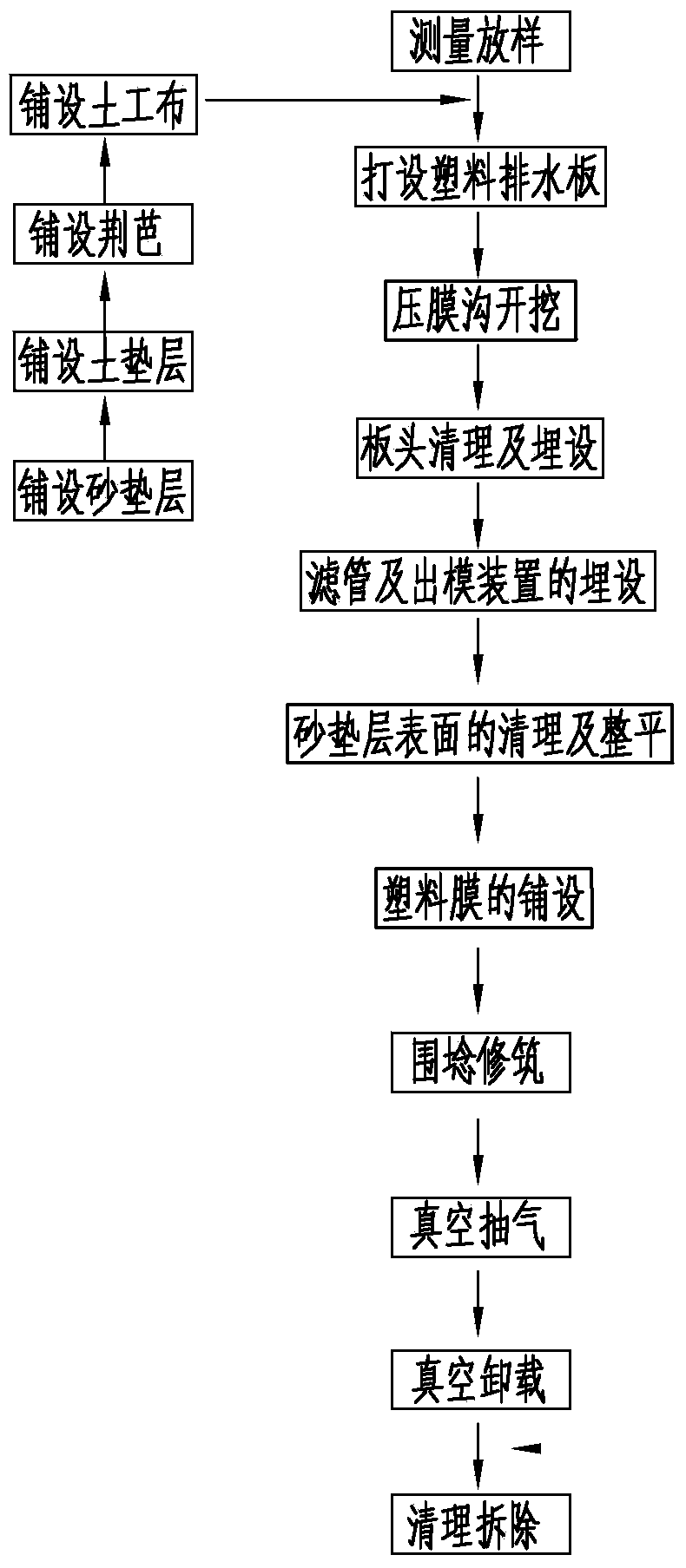

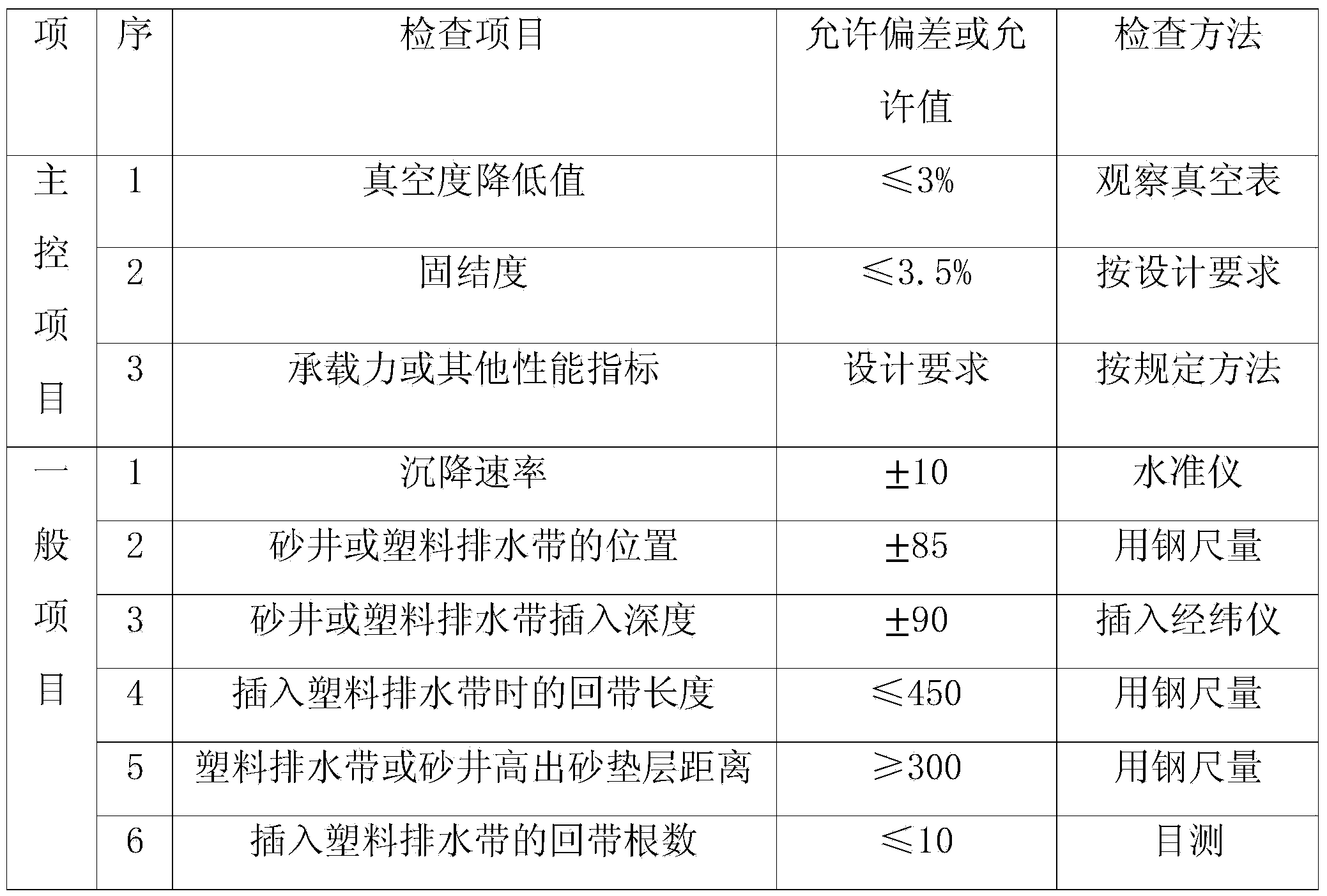

Vacuum preloading foundation treatment construction method

ActiveCN103643672AIncrease stiffnessImprove stabilitySoil preservationVacuum pumpingArchitectural engineering

The invention discloses a vacuum preloading foundation treatment construction method. The method includes the first step of conducting survey staking out, the second step of laying geotechnical cloth, the third step of laying vitex fences, the fourth steps of laying a soil cushion layer, the fifth step of laying a sand cushion layer, the sixth step of arranging a plastic drain plate in a striking mode, the seventh step of excavating a pressed film ditch, the eighth step of cleaning and embedding a plate head, the ninth step of embedding filter tubes and a film outlet device, the tenth step of cleaning and leveling the surface of the sand cushion layer, the eleventh step of laying a plastic film, the twelfth step of constructing a dam, the thirteenth step of vacuum air exhaust, the fourteenth step of vacuum unloading, and the fifteenth step of conducting cleaning and disassembly. According to the method, the strength and the rigidity of a foundation are improved, the reinforcing speed is high, the densification effect is good, the strength increase rate is high, the density of the foundation is improved, the foundation is made to be more stable, and the settling volume of the foundation is reduced. Vacuum is generated through air exhaust, the pore water pressure is effectively reduced, negative excess pore water pressure is generated to increase the effective stress of a soil body, reinforcing is conducted through the pore water pressure so that sphere effective stress increment can be generated, and the construction speed is effectively increased.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

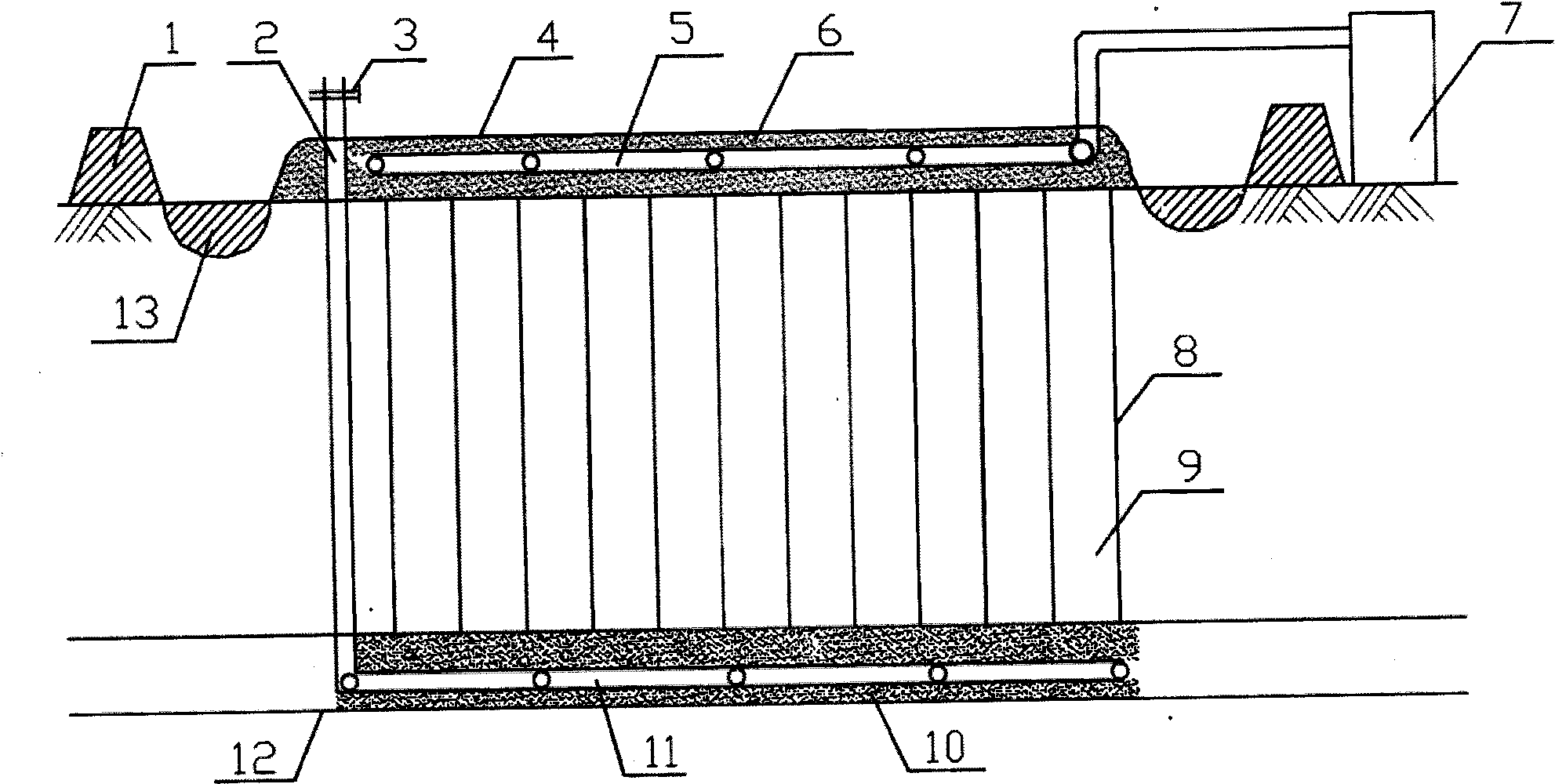

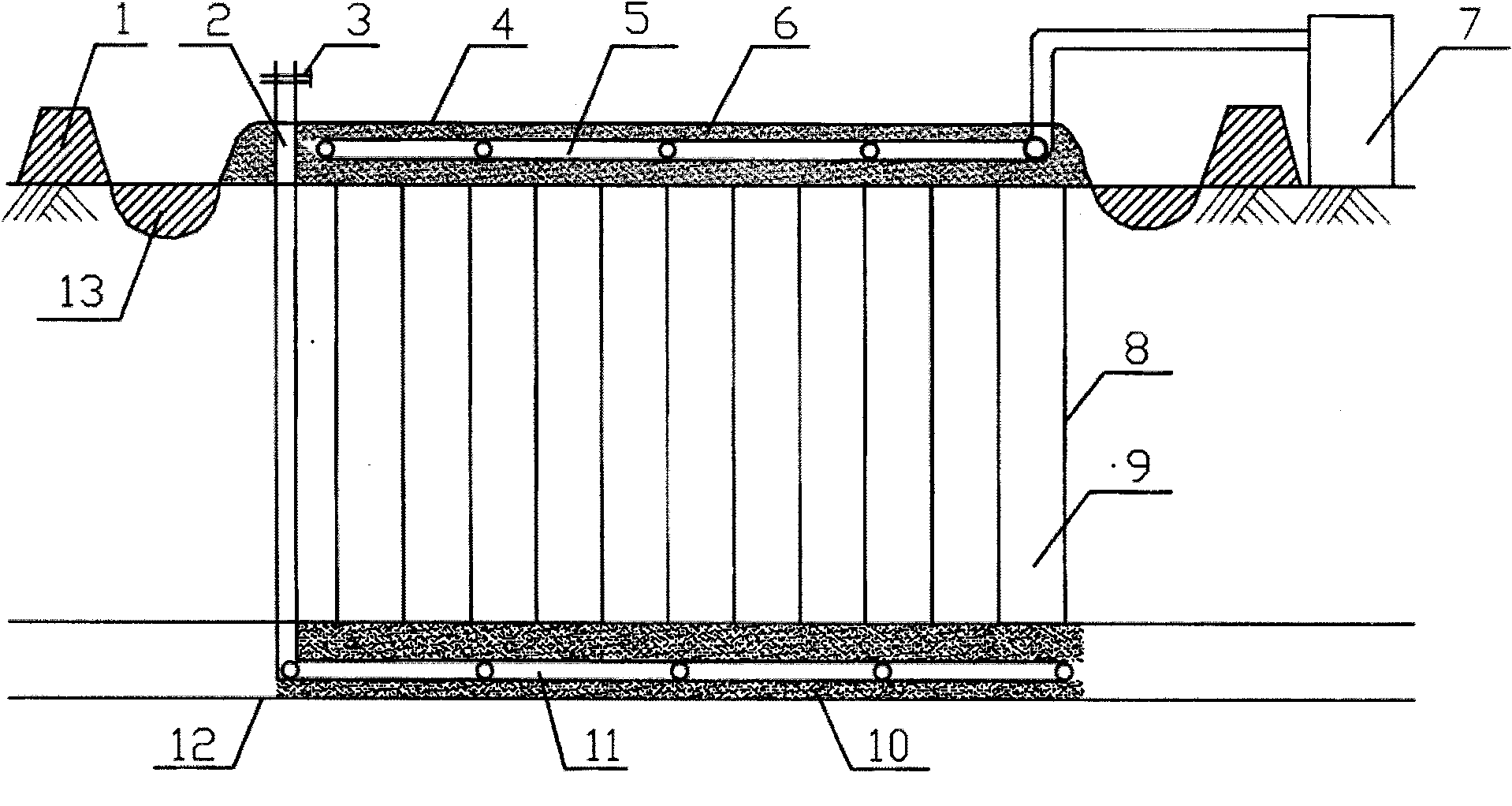

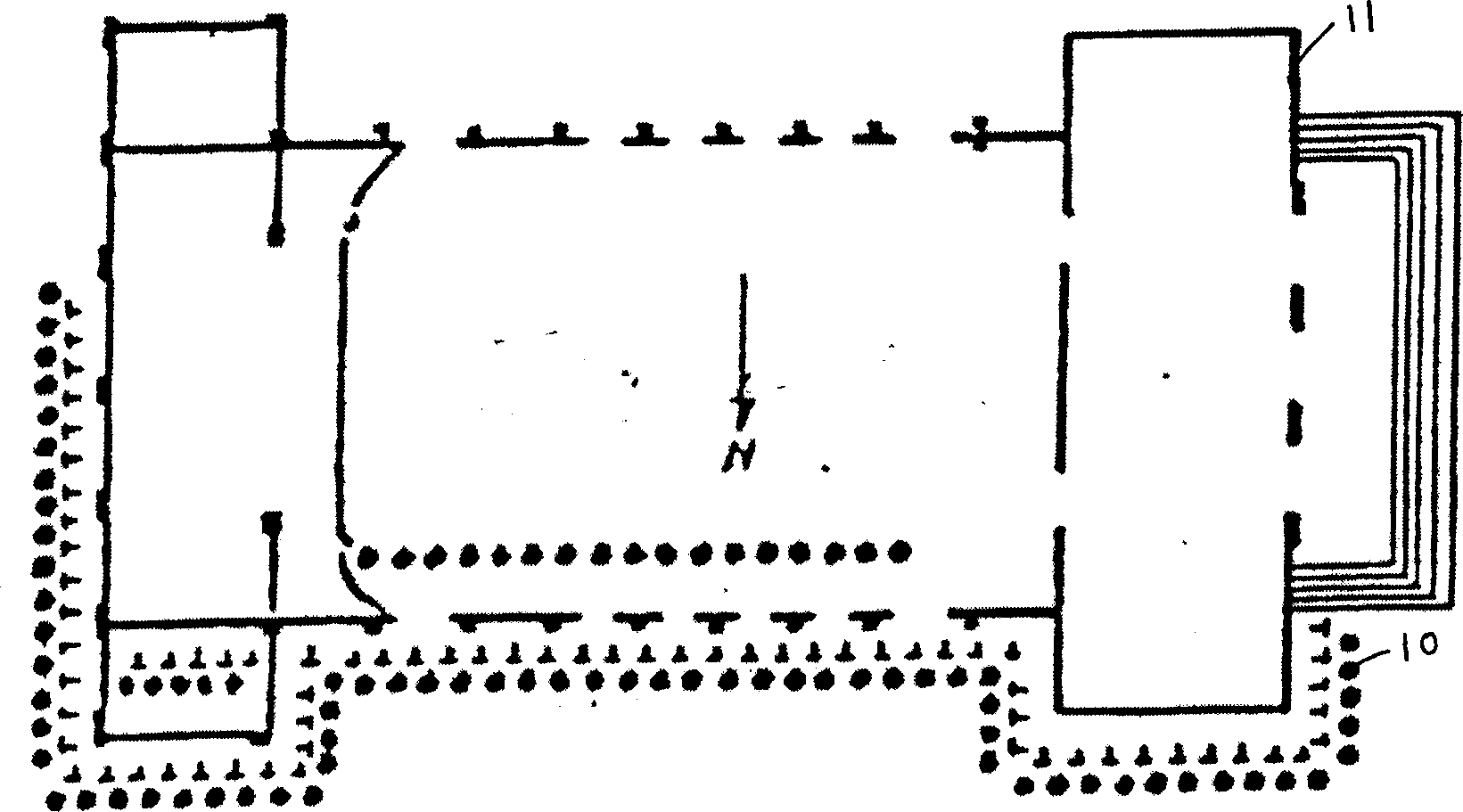

Method for regulating and controlling ventilating transformation and quickly reinforcing dredger fill in vacuum

InactiveCN101851914AReduce moisture contentWide range of construction applicationsSoil preservationVacuum pressureEngineering

The invention discloses a method for regulating and controlling ventilating transformation and quickly reinforcing dredger fill in vacuum. The process of the method comprises the steps of: sequentially hydraulically filling a bottom sand cushion layer, a hydraulically filling mud layer, and an upper sand cushion layer on a primary natural foundation; laying a ventilating filter pipe net, a ventilating pipe and a ventilating valve in the bottom sand cushion layer; laying a drainage filter pipe in the upper sand cushion layer; connecting the drainage filter pipe with a vacuumizing device; arranging a drainage plate between the upper sand cushion layer and the lower sand chusion layer in a striking way; finally seal-capping with geotextile and a plastic sealing film; opening the vacuumizing system; and repeatedly carrying out the operations of closing the ventilating valve, stabilizing vacuum pressure, and draining water bodies in soil bodies and the operation of opening the valve to exhaust added airflows so as to quickly drain the water bodies in the bottom sand cushion layer, the drainage plate and the upper sand cushion layer. The method has the advantages of simple and quick construction, high speed of reinforcement and drainage, and fund saving.

Owner:TIANJIN UNIV

Quick repairing polymer cement base material and its preparing method

The present invention is one polymer and cement-base quick repairing material for water engineering and building engineering. The material consists of portland cement, high-alumina cement, re-dispersed latex powder, high efficiency water reducing adhesive, sodium carbonate and other material in certain proportion. The material has high adhering strength and wide construction adaptability, and is suitable for construction in damp base especially.

Owner:TONGJI UNIV

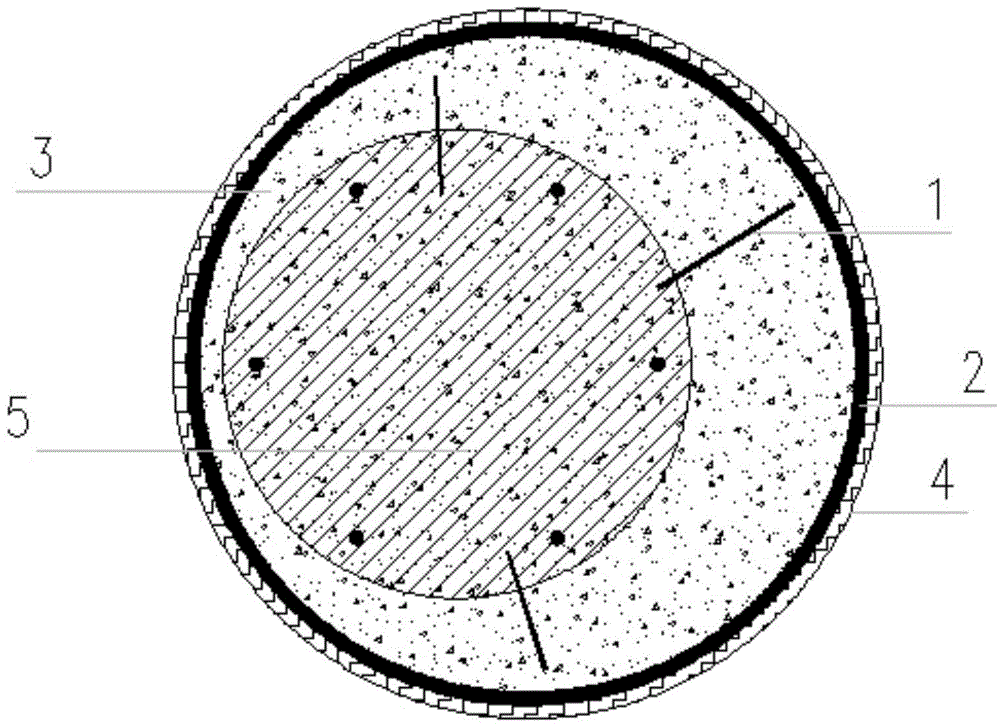

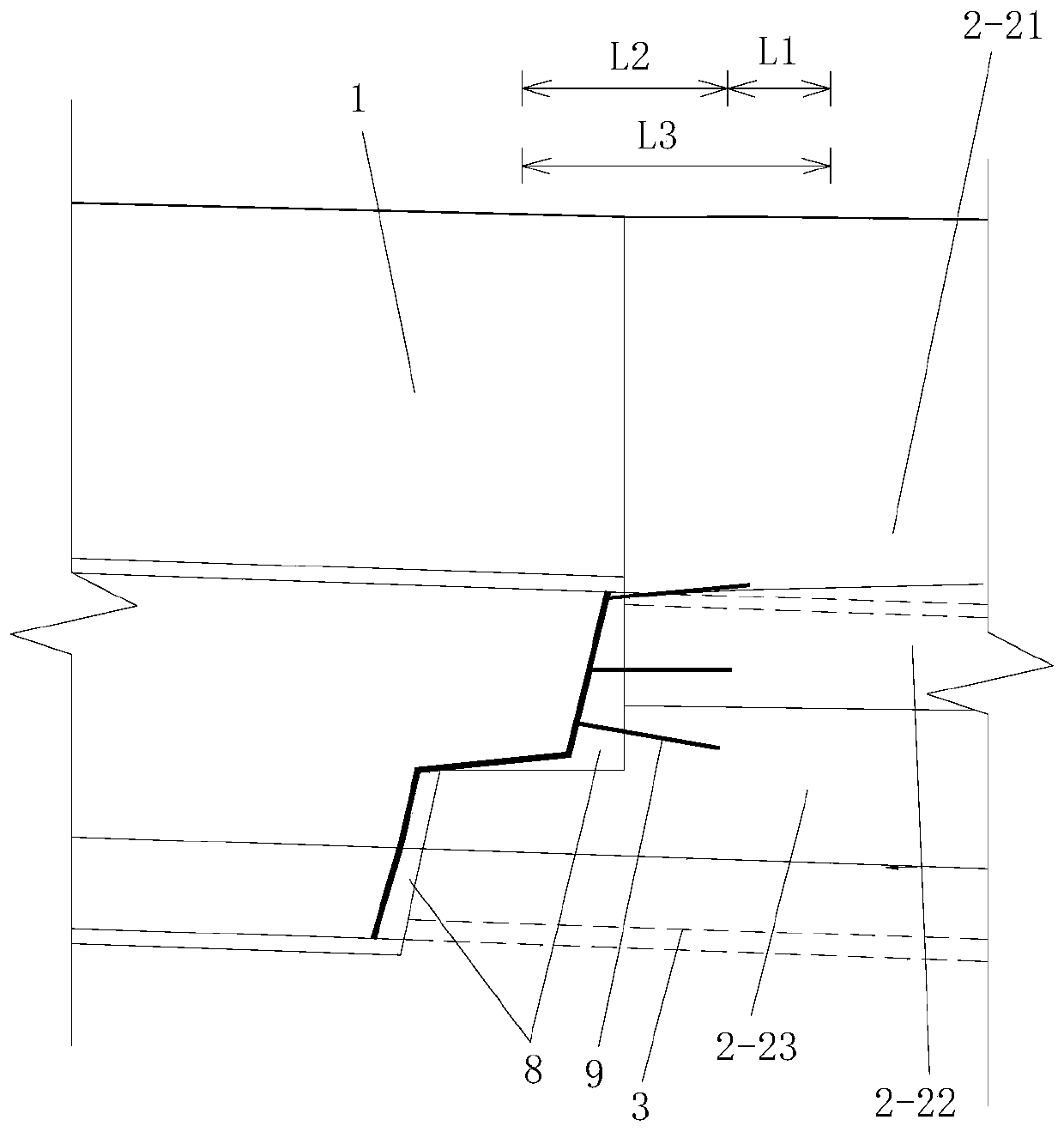

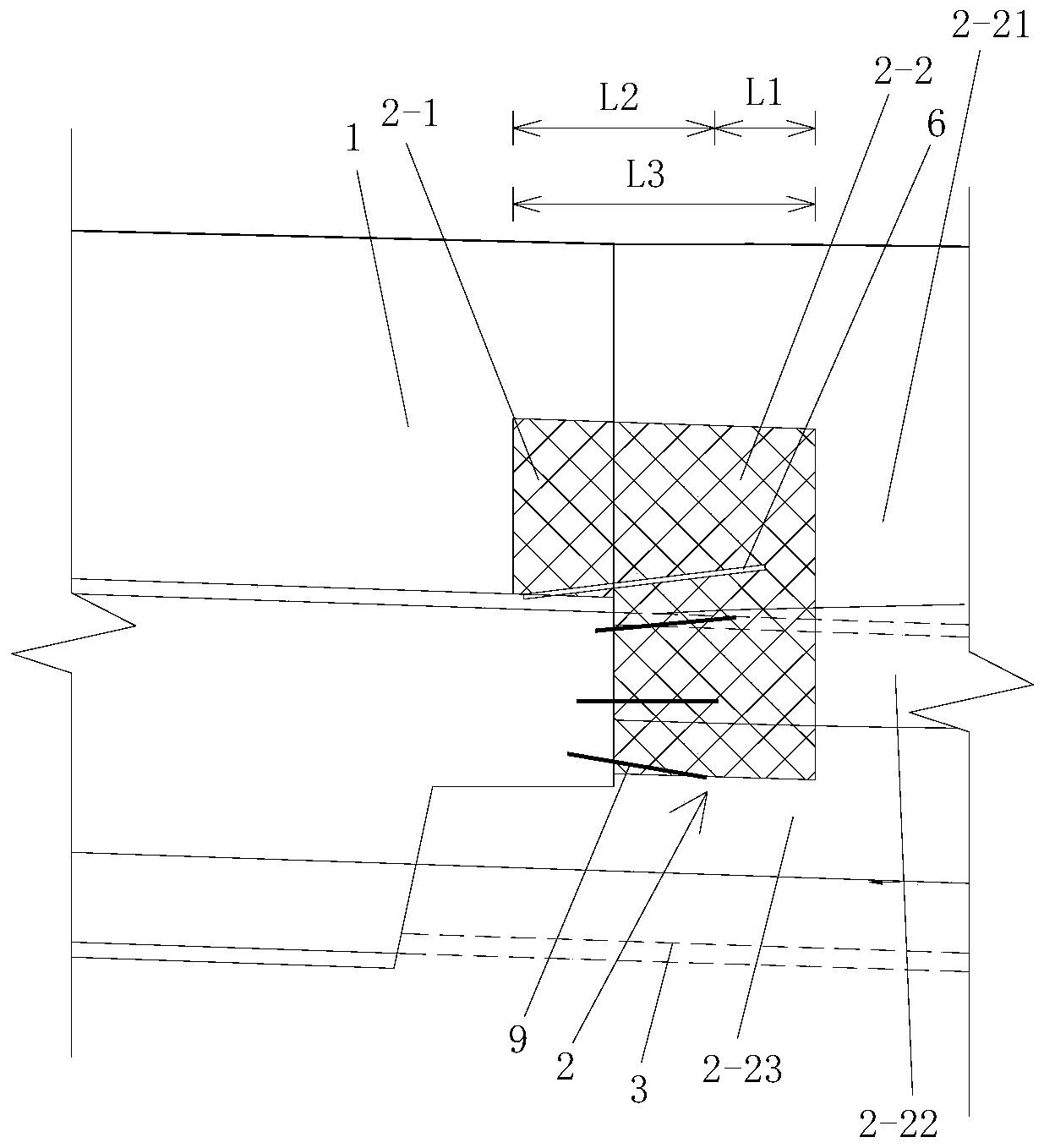

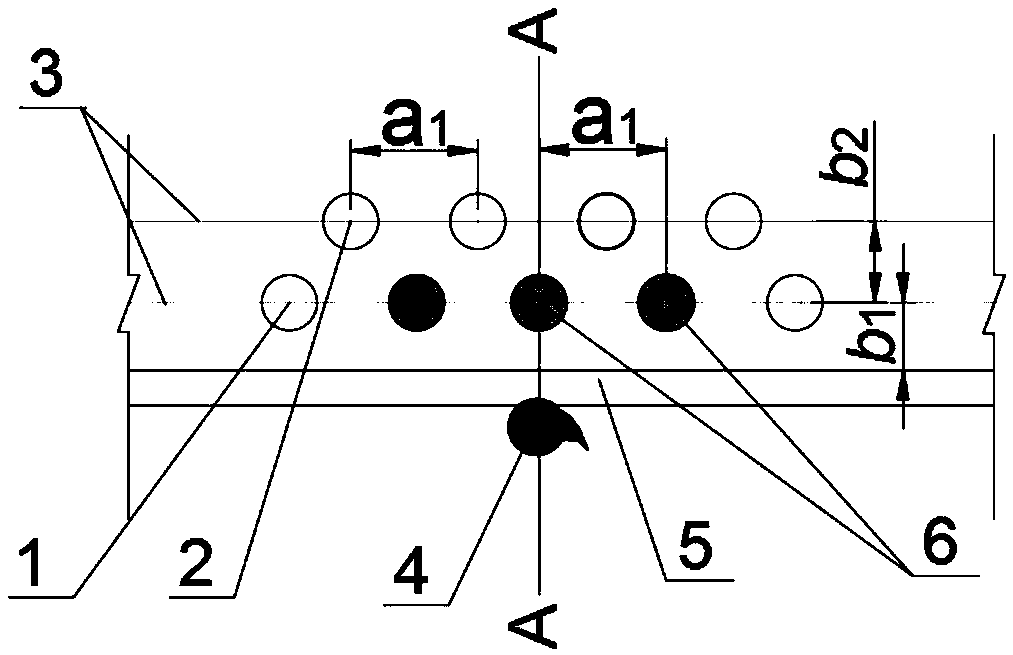

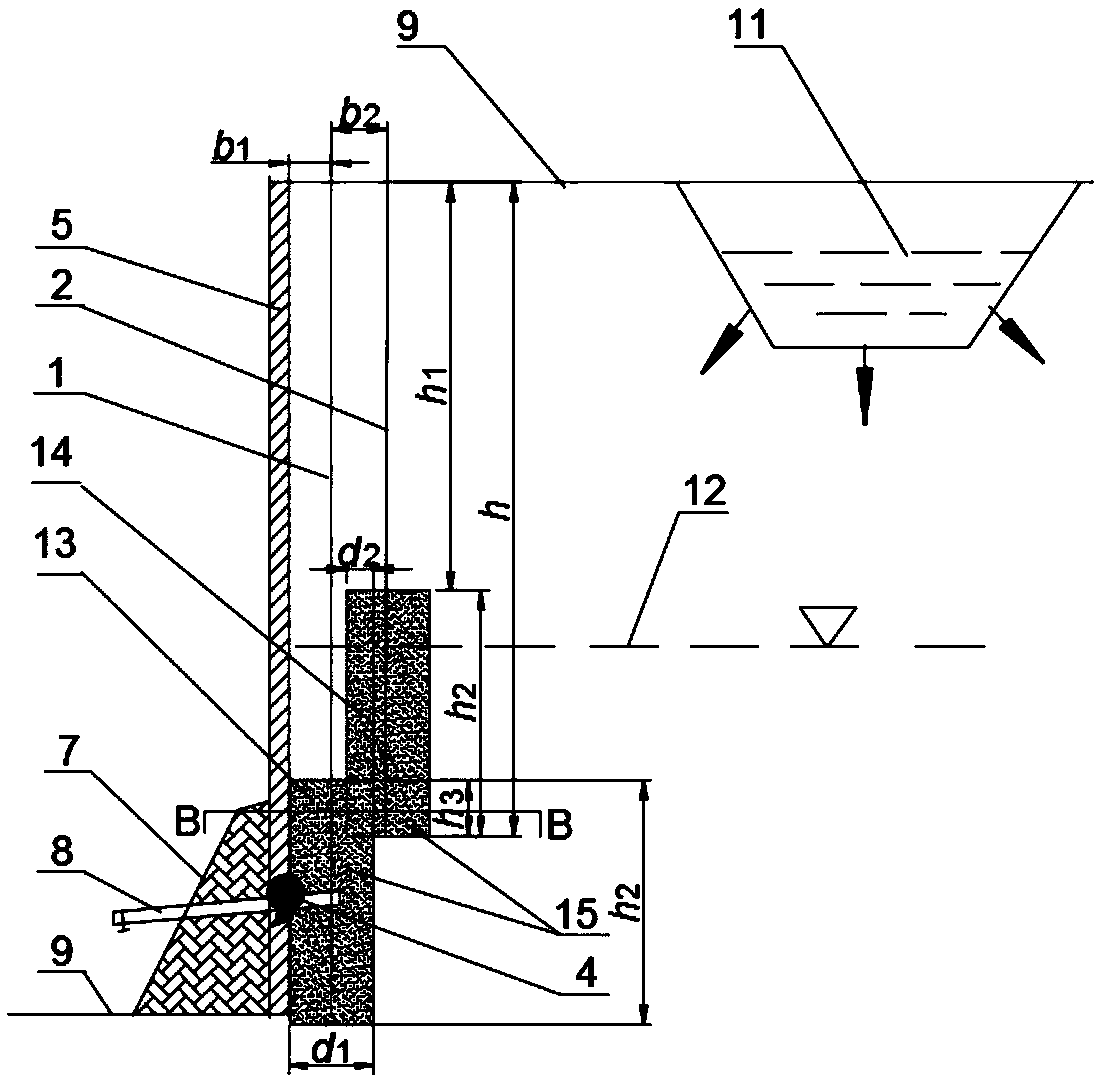

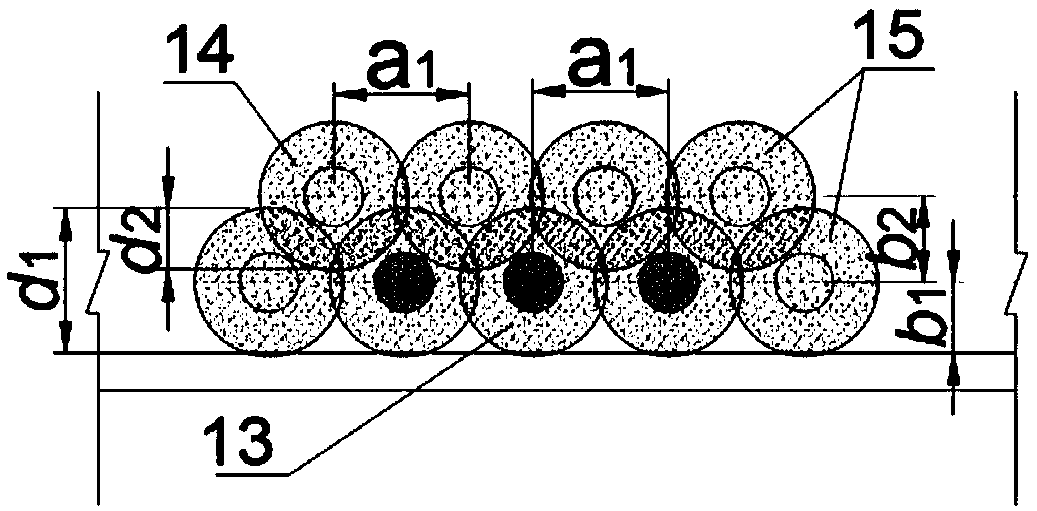

Method for reinforcing concrete pier through combination of corrugated steel pipes and fiber reinforced powder concrete

InactiveCN105178202ALow costReduce dismantling processBridge erection/assemblyBridge strengtheningSteel barShock resistance

A method for reinforcing a concrete pier through combination of corrugated steel pipes and fiber reinforced powder concrete comprises the following steps of (1) carrying out grinding and rough chiseling on the surface of a concrete pier reinforcing area; (2) determining the steel bar embedding positions on the surface of the concrete pier reinforcing area, and embedding transverse structure bars through drilling, hole clearing and gluing; (3) arranging the corrugated steel pipes embedded in a bearing platform on the outer side of the concrete pier reinforcing area; and (4) pouring the fiber reinforced powder concrete wrapping the transverse structure bars between the corrugated steel pipes and the concrete pier. By means of the method, not only can the bearing capacity and the shock resistance of the original concrete pier be improved, but also the method has the advantages that the number of construction procedures is small, the construction speed is high, and combination between new and old concrete materials is good.

Owner:EAST CHINA JIAOTONG UNIVERSITY

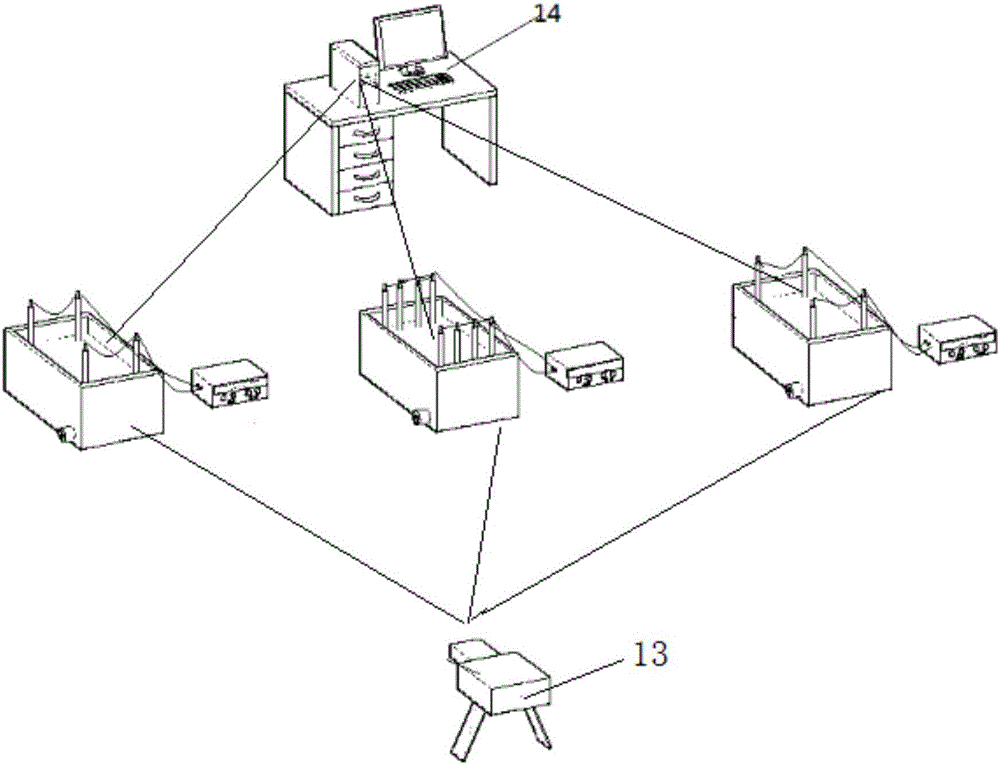

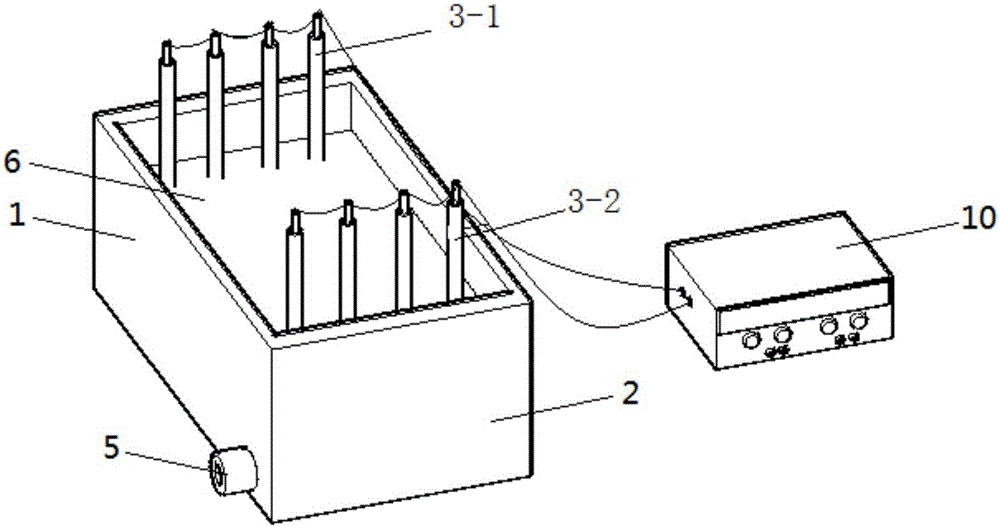

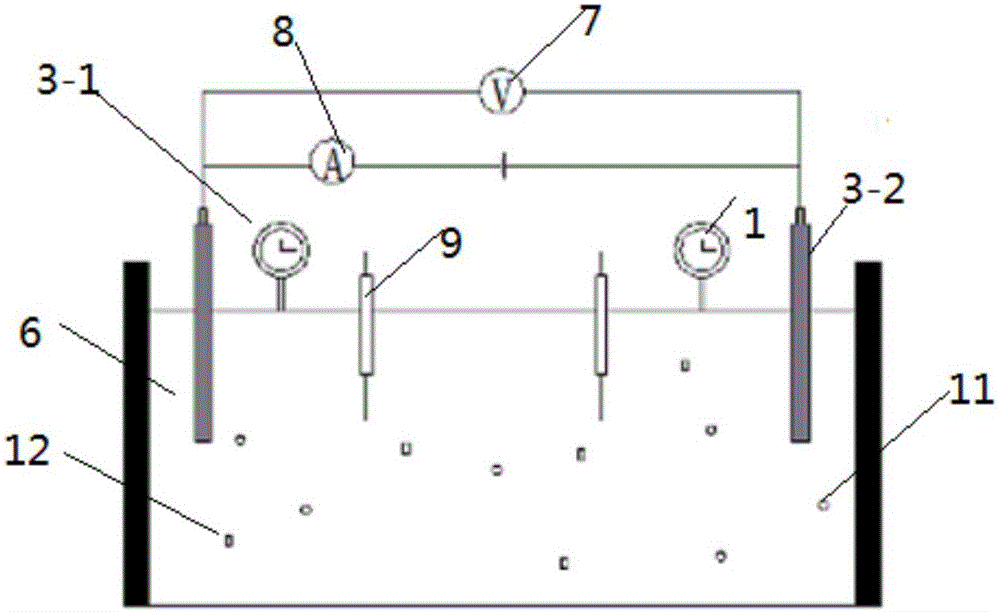

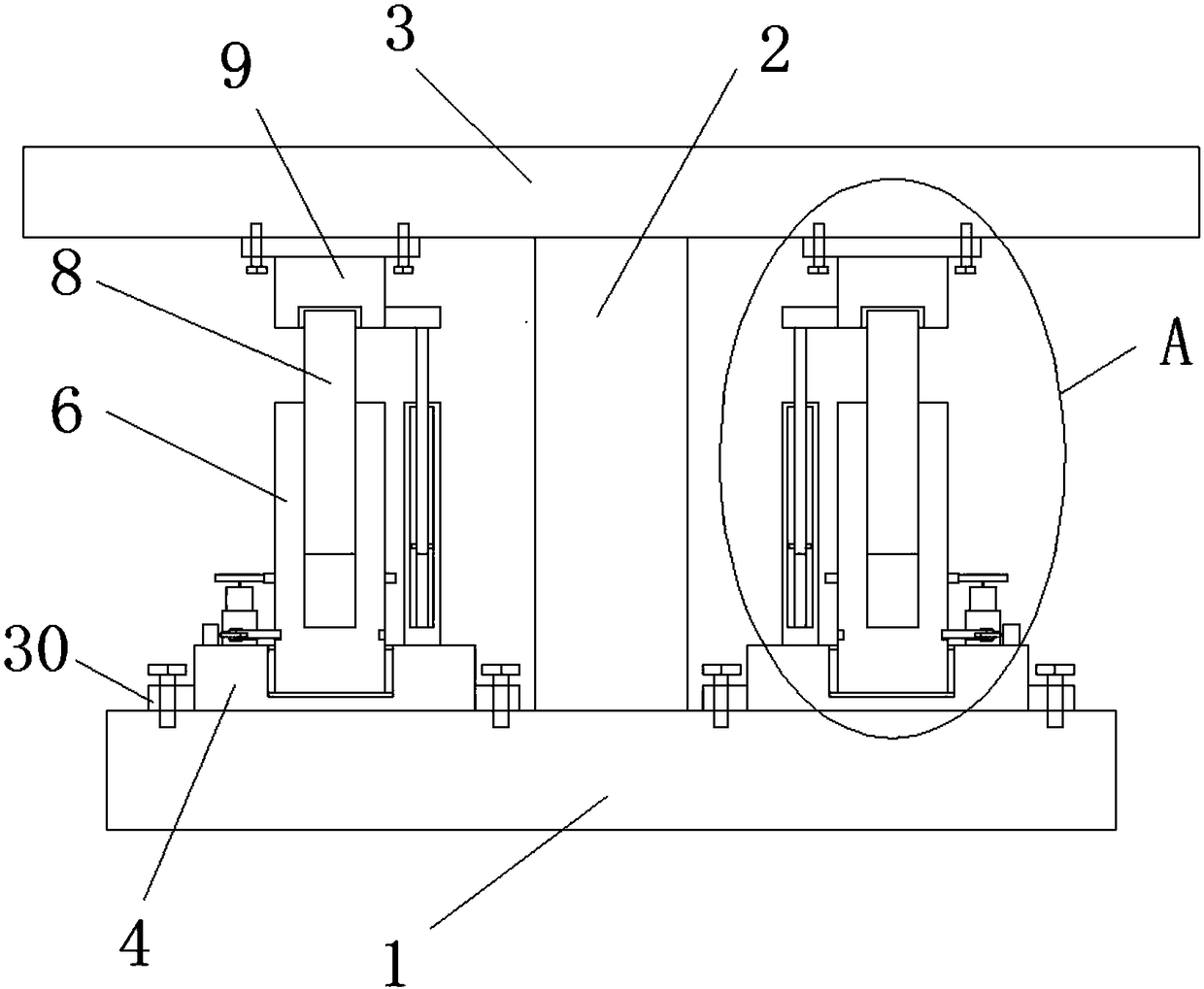

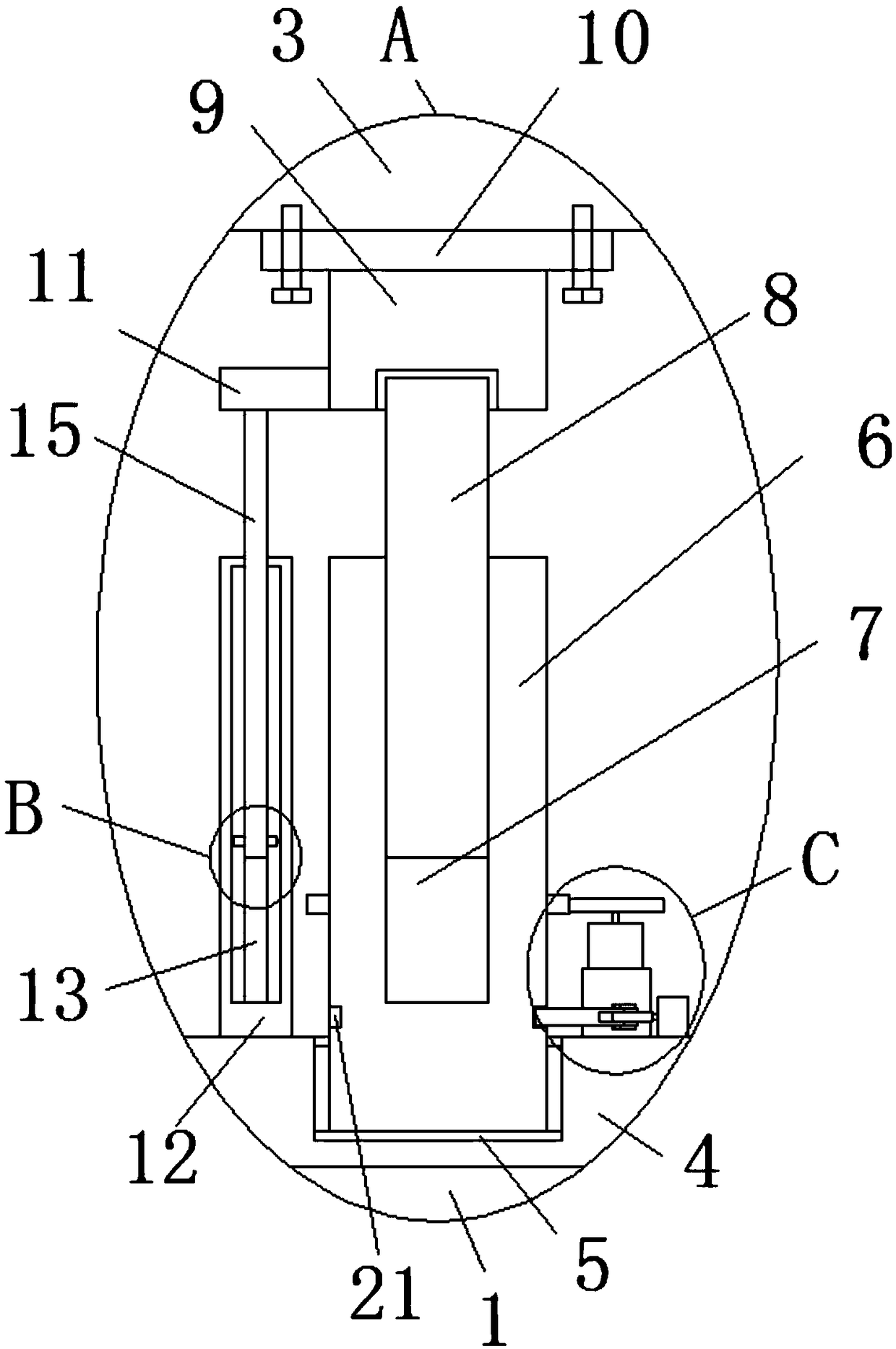

Electro-osmotic consolidation test device and method for consolidating soft clay foundation

InactiveCN105866382ARealize visualizationFast reinforcementEarth material testingHeight/levelling measurementPower flowSoft clay

The invention discloses an electro-osmotic consolidation test device and method for consolidating a soft clay foundation. The device comprises an external visual main body, measuring electrodes used for measuring the voltage and the current of a clay body and potential measuring needles are arranged in the external visual main body, the bottom of the external visual main body is provided with a drainage channel, and a real-time image collecting system is arranged outside the external visual main body; power is supplied to the measuring electrodes by a power supply, and a voltmeter and an ammeter are connected to a loop connected with the measuring electrodes. According to the device and the method, omnidirectional comprehensive measuring is conducted on the conductivity, the clay pressure, the settlement volume, the displacement, the voltage and the current, data is automatically processed with the help of a computer, the electro-osmotic effects under the different factors are visually compared, and compared with a previous device, the device has more practicability and comprehensiveness.

Owner:SHANDONG UNIV

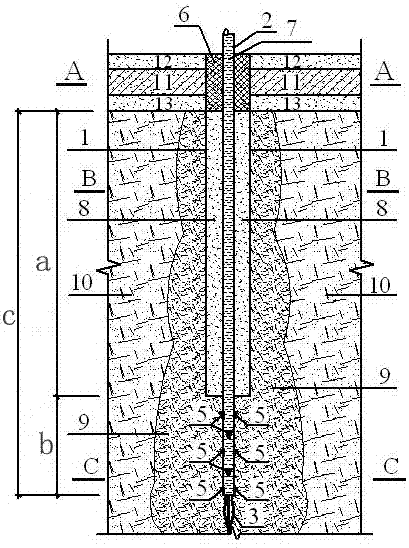

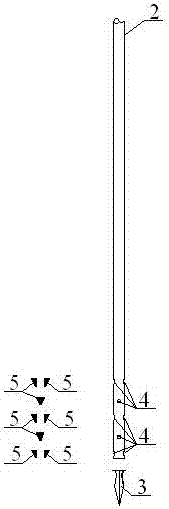

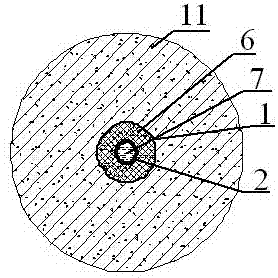

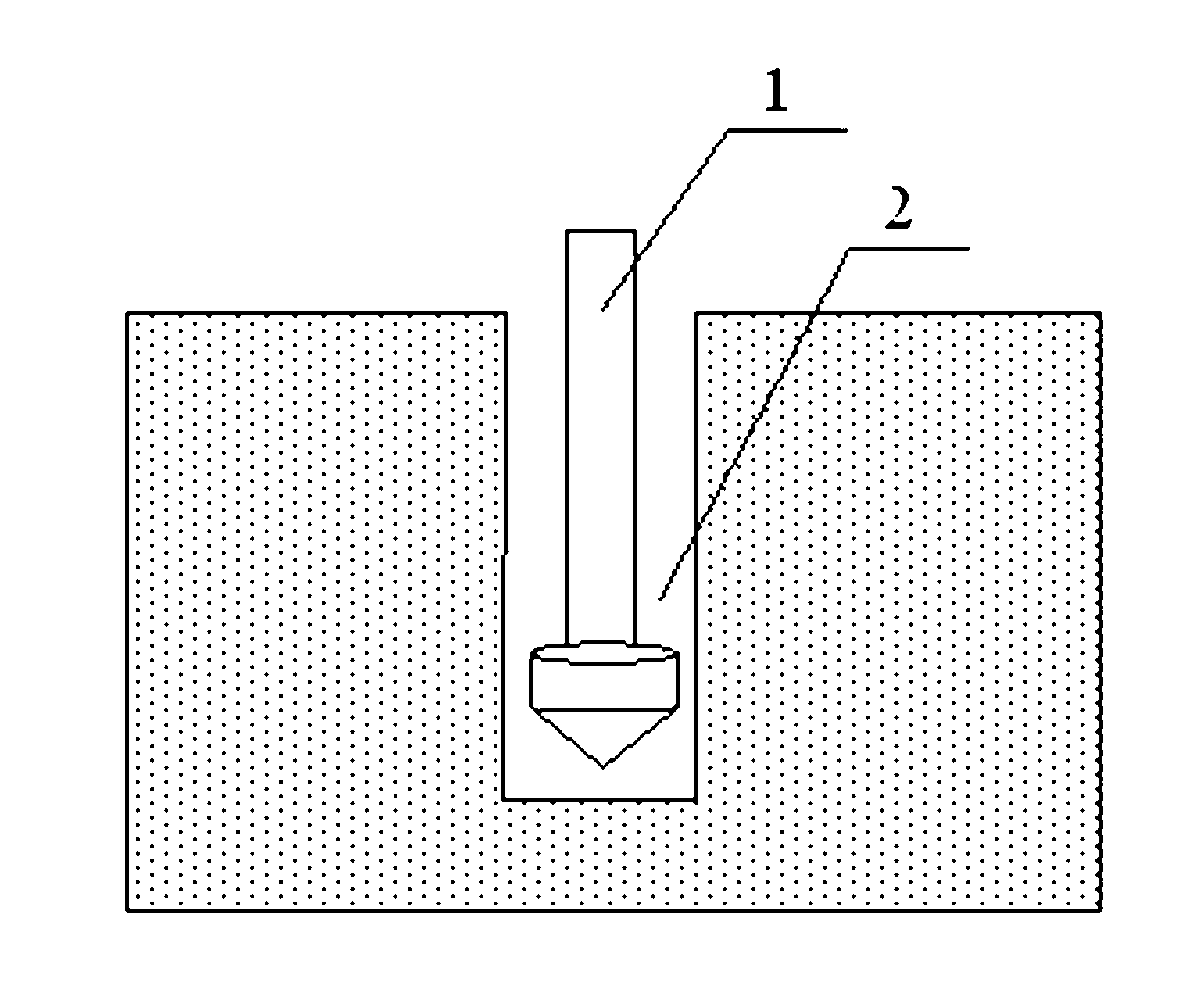

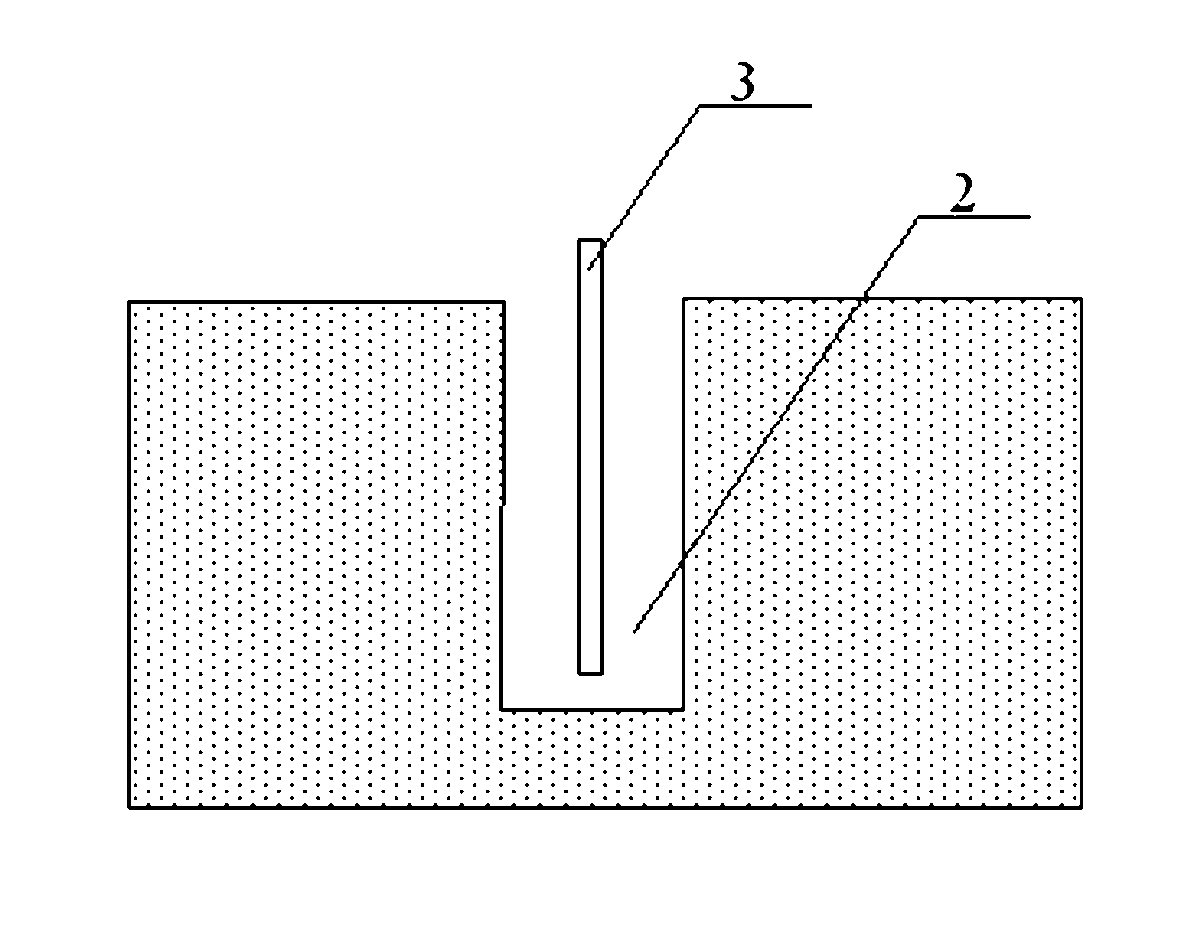

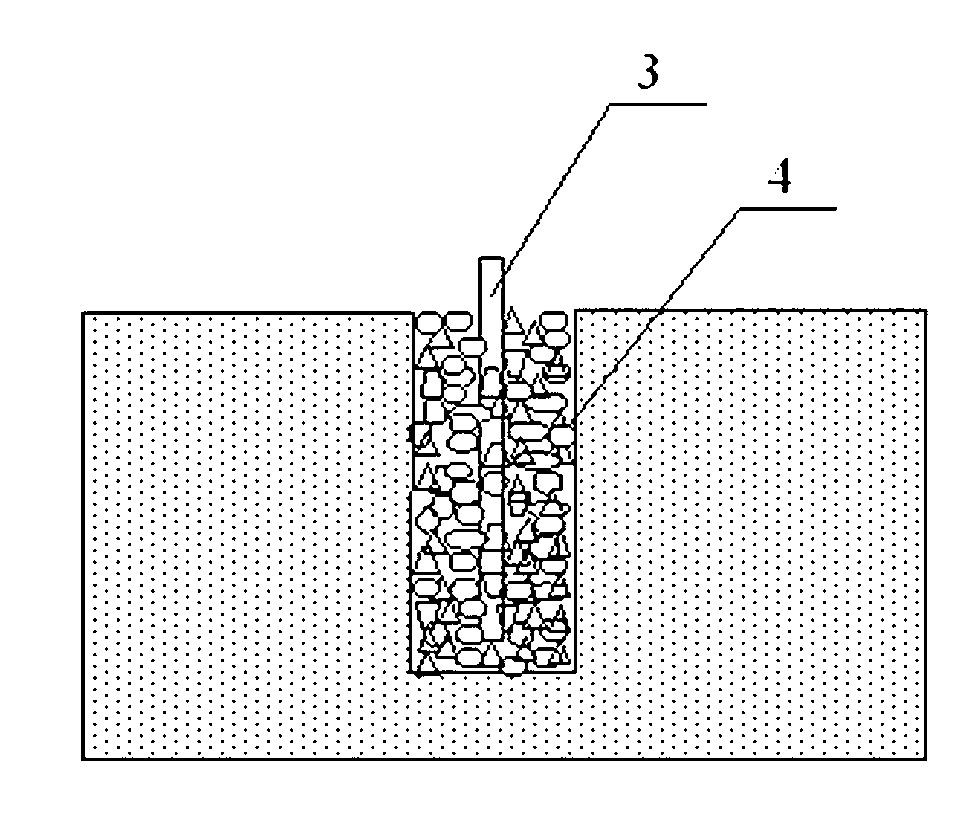

Expansive-type high-polymer cement paste, grouting reinforcement device and grouting reinforcement method

ActiveCN107417182AImprove mechanical propertiesImprove bearing capacityDrilling compositionSoil preservationDynamic compactionWhole body

The invention provides expansive-type high-polymer cement paste, a grouting reinforcement device and a grouting reinforcement method, aiming to solve the technical problems that dynamic compaction is not uniform, partial compactness does not meet requirements and differential settlement of buildings occur when a dynamic compaction substitution method is used for miscellaneous fill foundation treatment. The expansive-type high-polymer cement paste comprises, by weight, 91-95 parts of Portland cement, 2-4 parts of soundless cracking agents and 3-5 parts of polypropylene fibers. The expansive-type high-polymer cement paste is injected into stratum evenly through a steel grouting pipe, original cracks are filled with grout in the mode of filling, permeating, swelling and compacting, originally-loose soil particles are rapidly solidified into a whole body, and a mini pile is formed in a drill hole, so that mechanical property of foundation soil is improved, and the effects of improving bearing capacity of the foundation soil and consolidating the foundation are achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

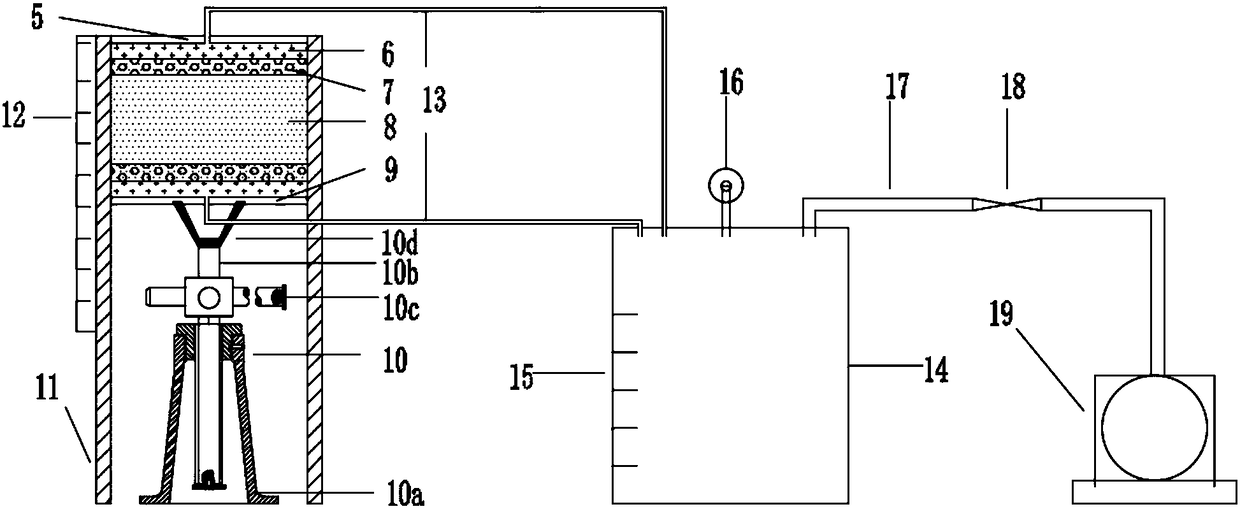

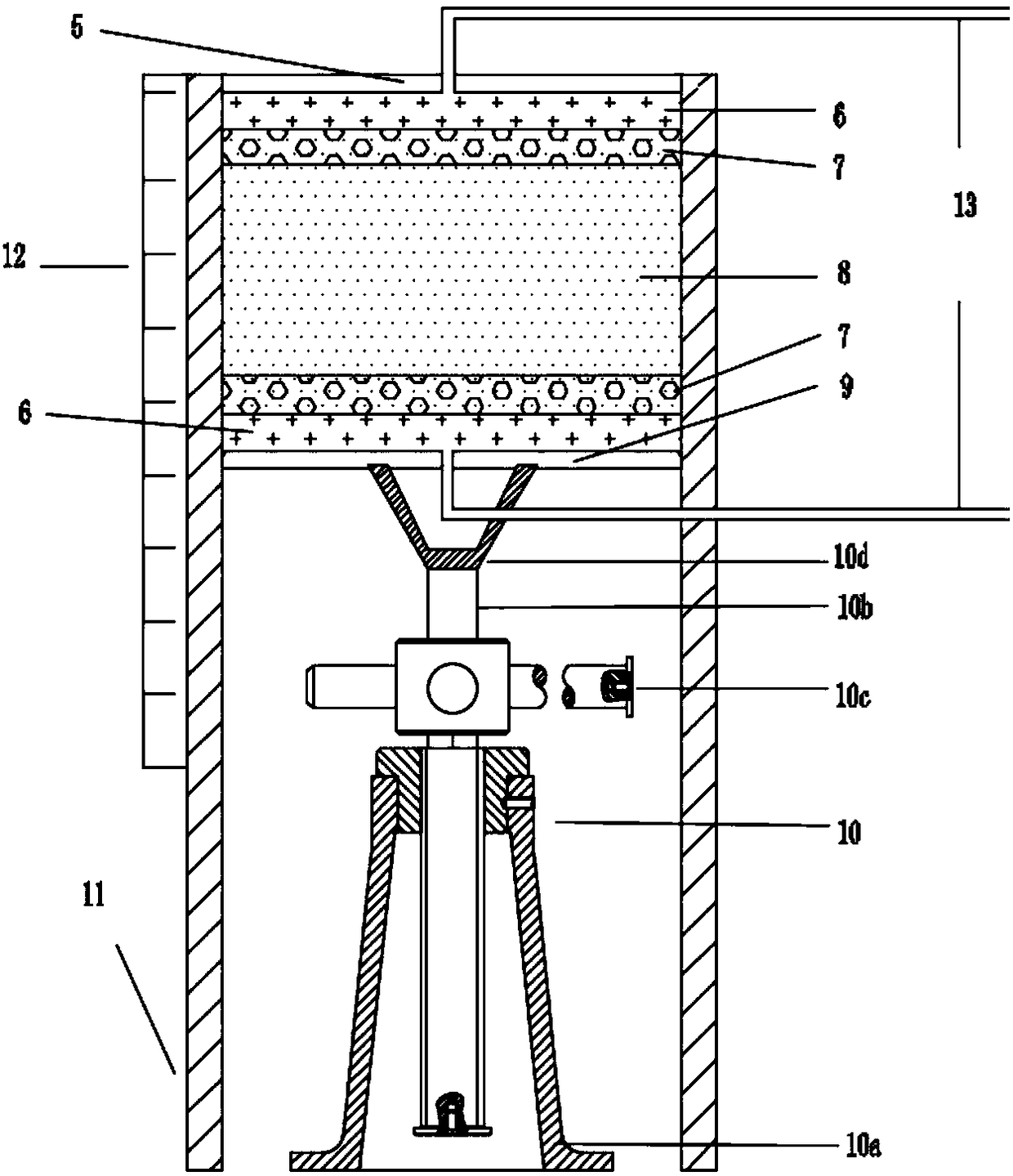

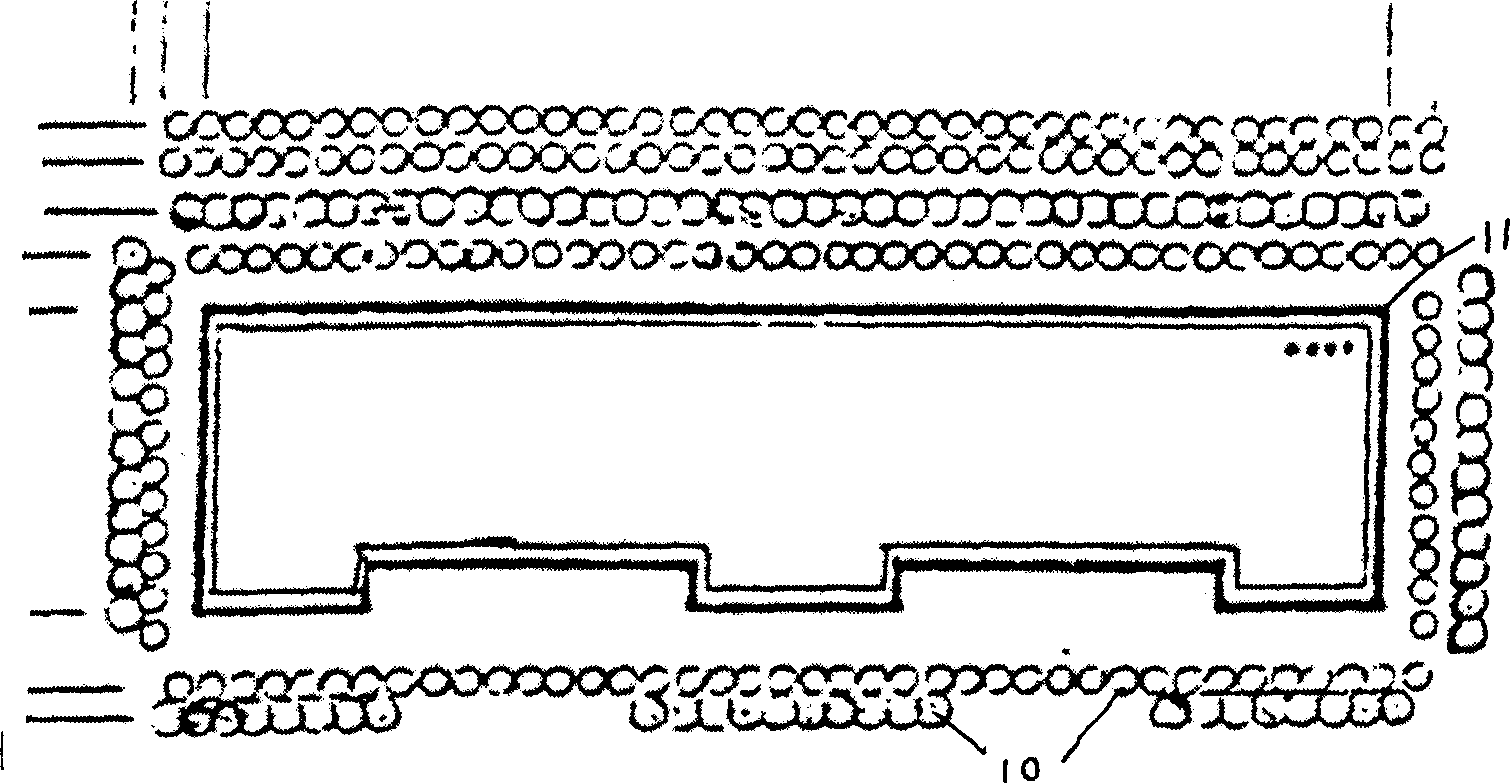

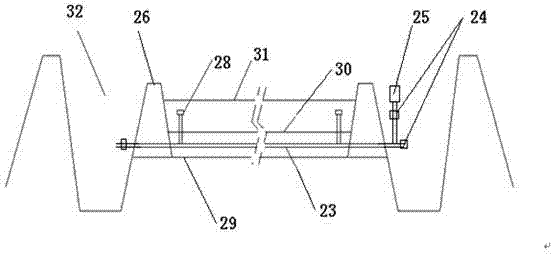

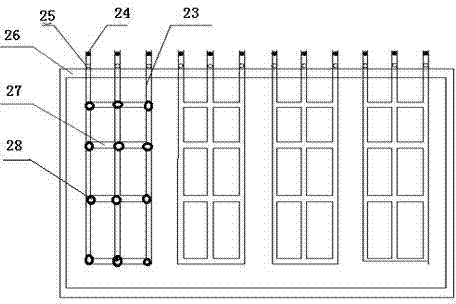

Fast mud dehydrating device

InactiveCN108101341AConsolidation has a significant effectVacuum pressure is evenly distributedSludge treatment by de-watering/drying/thickeningFiltrationPulp and paper industry

The invention discloses a fast mud dehydrating device, and is suitable for indoor experiments. The fast mud dehydrating device mainly comprises a mud dehydrating tank, a hydraulic jack and a two-way vacuum suction filtration system; sand cushions with certain thicknesses are arranged on and under the mud in the mud dehydrating tank, and are matched with a geotextile layer, a waterproof top plate and a waterproof bottom plate to form a whole, meanwhile, vacuum suction filtration channels allowing suction filtration pipes to go through are reserved on both the top plate and the bottom plate, thelifting hydraulic jack is arranged under the bottom plate, the mud is then rapidly dehydrated under the co-action of the vacuum negative pressure and the pressure load; a vacuum pump is connected toa liquid collecting barrel with the containing mark through a vacuum pipe in the two-way vacuum suction filtration system, the liquid collecting barrel is additionally provided with two suction filtration pipes, and the two suction filtration pipes are respectively communicated with the vacuum suction filtration channels on the top plate and the bottom plate. The fast mud dehydrating device has the advantages of two-way vacuum prepressing, the load of the external force can be applied, and the dehydrating efficiency is high.

Owner:WUHAN UNIV

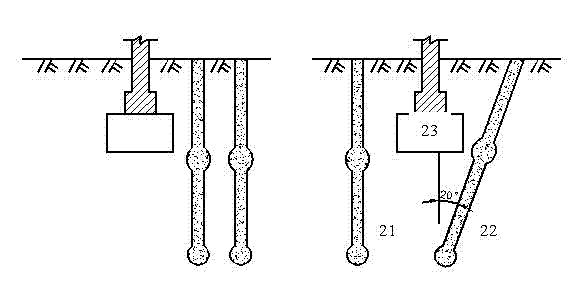

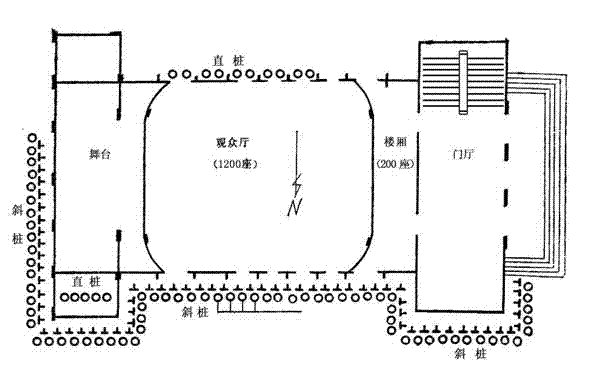

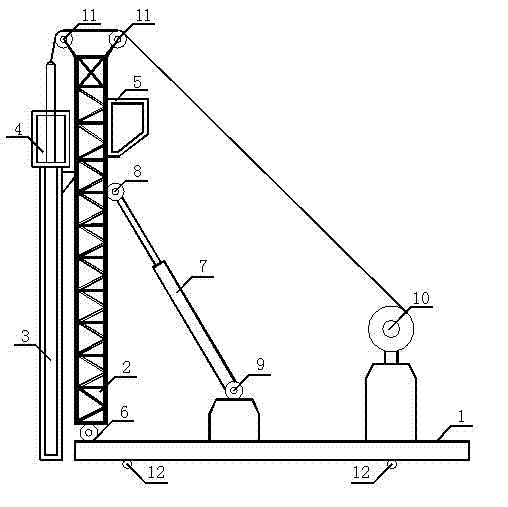

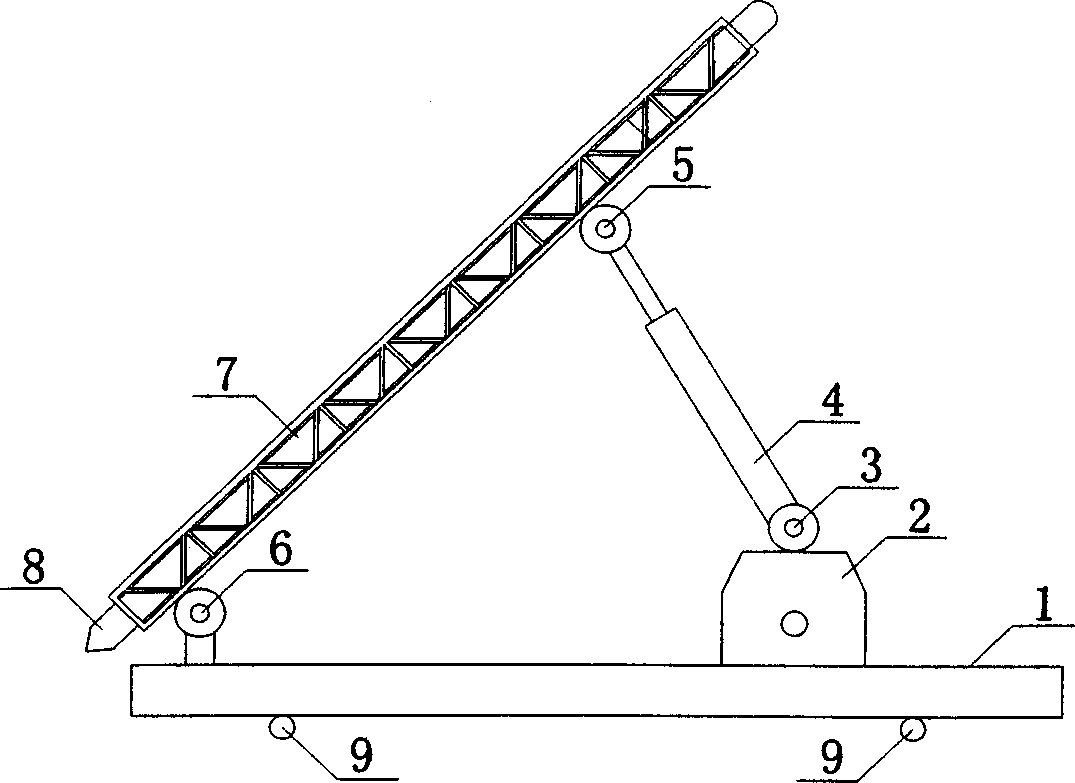

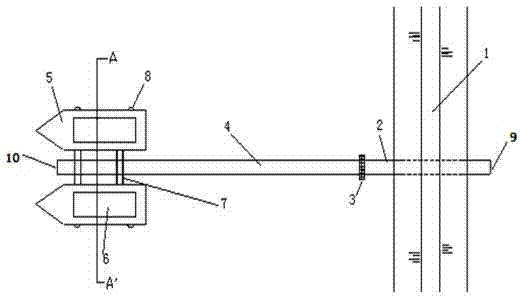

Given force variable stiffness discrete material pile ramming and expanding machine and application thereof

InactiveCN102392447AMeet the trait requirementsFast reinforcement effectBulkheads/pilesSoil preservationVariable stiffnessElectricity

The invention relates to a given force variable stiffness discrete material ramming and expanding machine which comprises a chassis, a traveling part, a control system, a hoist system, a portal steel frame and a pile pipe ramming and expanding system. The pile pipe ramming and expanding system comprises a straight-through ramming hammer head, a hammer cushion and inner and outer sleeve pile pipes. The portal steel frame for supporting and stabilizing the inner and outer sleeve pile pipes is arranged on the chassis. A telescopic pull rod for controlling a piling angle is also connected onto the portal steel frame. The hoist system comprising lifting inner and outer pile pipes, a lifting straight-through ramming hammer head and a lifting vibrator part and the control system comprising an electric motor and an electrohydraulic linking and illuminating device are also arranged on the chassis. The straight-through ramming hammer head is positioned at the upper part of double layers of pile pipes in the sleeve structure. The given force variable stiffness discrete material ramming and expanding machine not only can be used for piling a multi-section enlarged head discrete material flexible pile, but also can be used for piling a concrete rammed and expanded rigid pile. The machine can be suitable to be applied to piling of a new construction, an extension project, a reconstruction project and the engineering for treating pathological accidents on weak or poor foundations such as interlayer soft clay, loose fine sandy soil, plain fill, miscellaneous fill, collapsed loess and the like.

Owner:苏州予力再生建材有限公司 +1

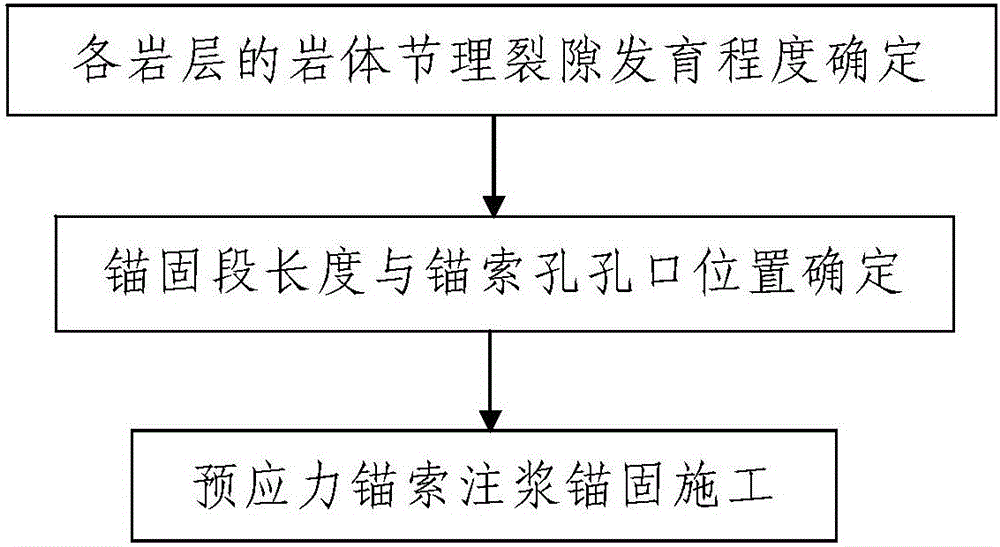

Fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method

ActiveCN106522243AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressHigh pressure

The invention discloses a fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method. Multiple prestressed anchor cables uniformly distributed on the same one plane are adopted to reinforce a slope to be reinforced; the method comprises the following steps: (1) the rock mass joint fissure development degree of each rock stratum is determined; (2) the lengths of anchoring sections and the hole port positions of anchor cable holes are determined; the prestressed anchor cables include anchor cable bodies, primary grouting pipes and secondary grouting pipes; anchoring tools are mounted at the back ends of the anchor cable bodies; and the anchor cable bodies include multiple steel strands; and (3) the prestressed anchor cables are grouted and anchored: when any one prestressed anchor cable is grouted and anchored, the construction includes the steps of drilling, placement of the anchor cables, normal-pressure grouting, high-pressure grouting, tensioning of the anchor cables and anchor sealing. The method is simple in steps, reasonable in design, convenient to construct, high in construction efficiency and excellent in use effect, and can conveniently and quickly finish the reinforcing process of the slope to be reinforced; and the adopted prestressed anchor cables are low in cost and higher in anchoring force, and can effectively reinforce the slope to be reinforced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for processing ultra-soft soil through combining shallow-surface-layer intermittent strong water-pumping/draining with short-term air-curing

The invention discloses a method for processing ultra-soft soil through combining shallow-surface-layer intermittent strong water-pumping / draining with short-term air-curing. The method comprises the following steps of: arranging horizontal water-pumping / draining pipe networks in a shallow-surface layer of an ultra-soft soil body, arranging water-draining pipe trenches in the surface layer and connecting the horizontal water-pumping / draining pipe networks and the water-draining pipe trenches with water-pumping / draining equipment so as to form a three-dimensional surface-layer water-pumping / draining system for shallow-surface-layer ultra-soft soil; carrying out intermittent strong water-pumping / draining and being aided with surface-layer drainage by using the water-pumping / draining equipment; and meanwhile, combining with the short-term air-curing by using the climate characteristics of strong sunlight and strong wind of coastal areas. According to the invention, the reinforcement for the shallow-surface-layer ultra-soft soil can be effectively and rapidly achieved, thus the invention provides a reinforcement treatment method which is applied to ultra-soft foundations, the shallow-surface layer of which is made of sludge or hydraulic-filled sludge and can greatly save cost.

Owner:CCCC FOURTH HARBOR ENG INST +3

Fast concrete road and bridge repairing material

The fast concrete road and bridge repairing material has the composition of:early strength aluminosulfate cement 75-95 wt%, portland cement 5-25 wt%, naphthalene water reducing agent 1.5-3.5 wt%, lithium salt below 0.5 wt% and boric acid below 0.5 wt%. it has the features of fast solidification, fast hardening, high strength, less swelling, corrosion resistance, etc. It is used in mixing mortar and concrete without need of other supplementary material. It results in 4H break strength higher than 4 MPa and compression strength higher than 25 MPa of mortar as well as 6H break strength higher than 4 MPa and compression strength higher than 30 MPa of concrete. When used to repair road and bridge, the traffic may be opened after 6 h. It may be also used in reinforcement of other concrete member.

Owner:李乃珍

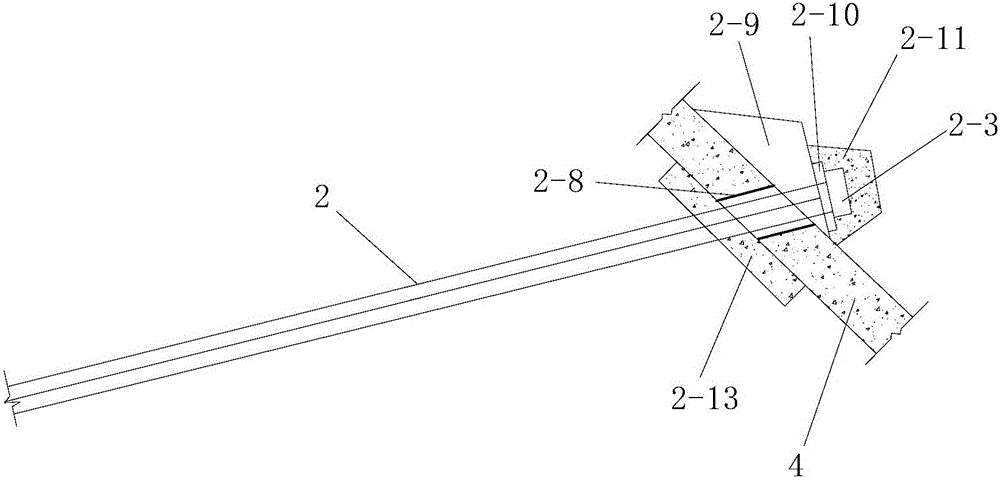

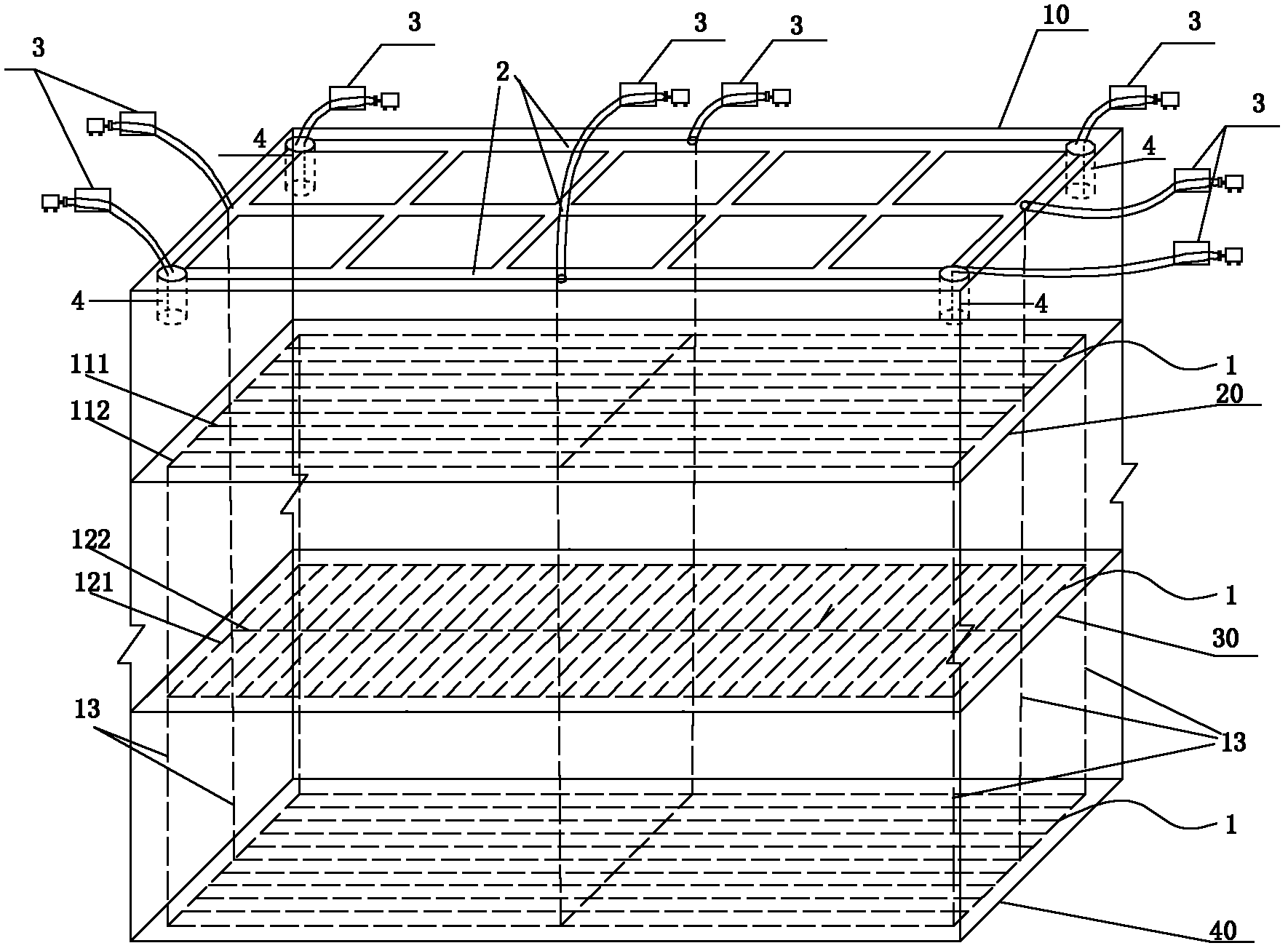

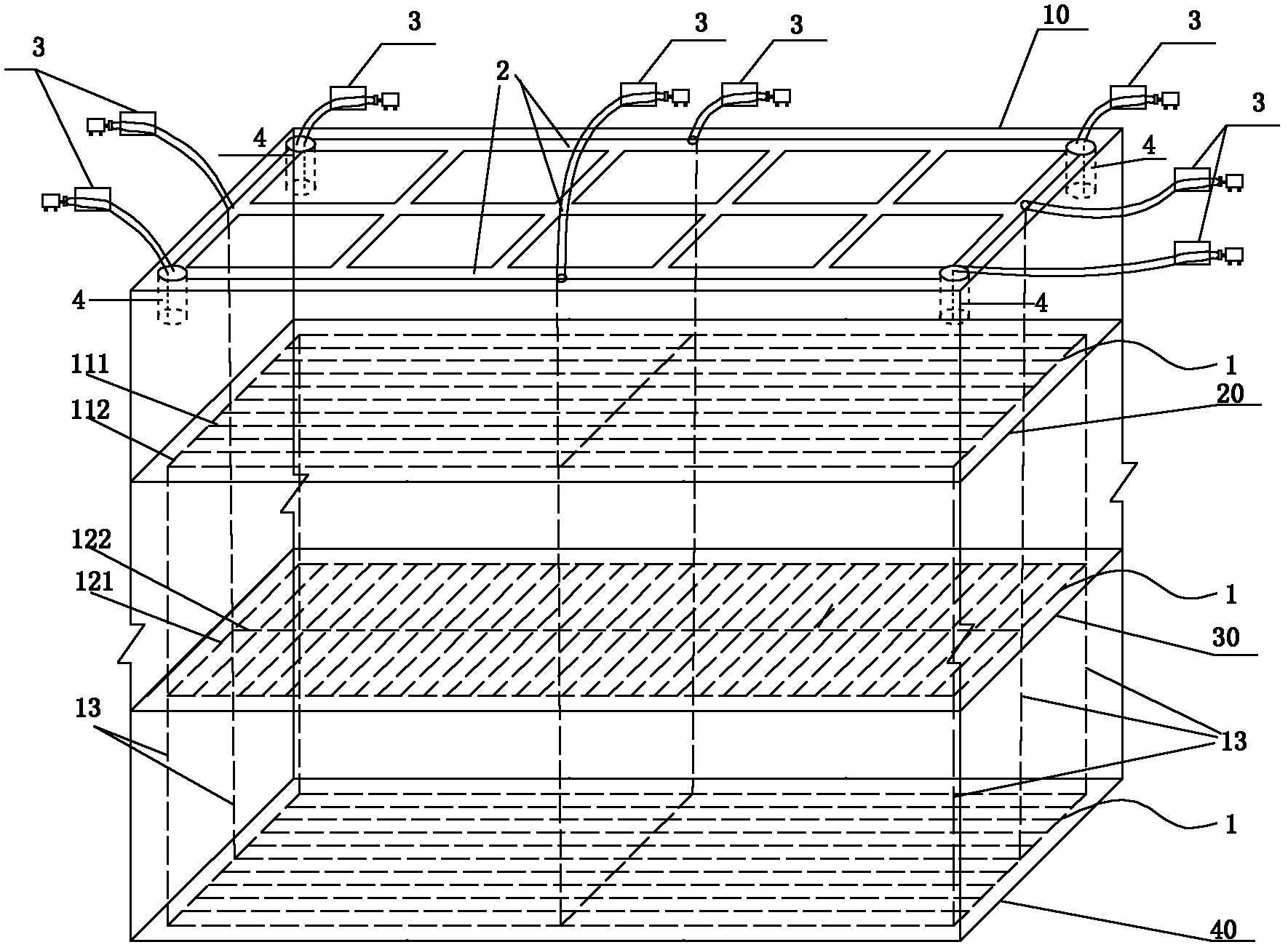

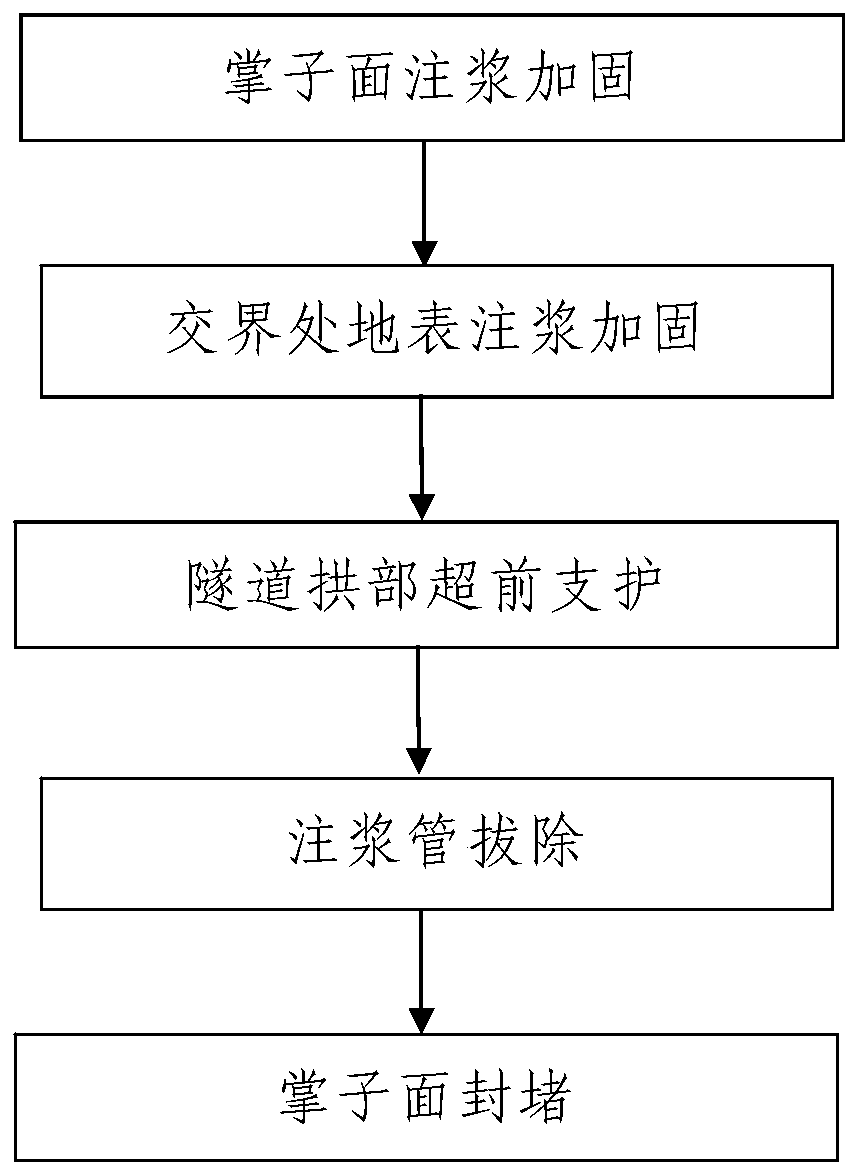

Surrounding rock reinforcement method for junction tunnel section in upper-soft lower-hard stratum constructed adopting shield method and mining method

ActiveCN110878696AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructural engineeringGround settlement

The invention discloses a surrounding rock reinforcement method for a junction tunnel section in an upper-soft lower-hard stratum constructed adopting a shield method and a mining method. The method comprises the steps that 1, tunnel face grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on stratum in front of an excavation face of an upper tunnel body by adopting grouting pipes; 2, junction surface grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on the reinforced stratum by adopting sleeve valve pipes; 3, tunnel arch part advanced support is carried out, specifically, advanced support is carried out on an arch part of the junction tunnel section; 4, grouting pipe removal is carried out; and 5, tunnel faceplugging is carried out, specifically, a tunnel face is plugged through concrete backfilling, and a tunnel face plugging structure is obtained. The method is reasonable in design, simple and convenient to construct and good in use effect, and surrounding rock of the junction tunnel section is effectively reinforced by the method of combining the surface grouting reinforcement with the in-tunnel reinforcement so that the mechanical property of the surrounding rock can be effectively improved; and the tunnel face of the junction tunnel section is reliably plugged before and after reinforcement so that tunnel safety construction can be effectively guaranteed, and ground settlement caused by excavation can be effectively reduced.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Highway bridge reinforcing device

ActiveCN108517791AGuaranteed up and down motionStable supportBridge erection/assemblyBridge strengtheningStructural engineeringEngineering

Owner:张晓强 +9

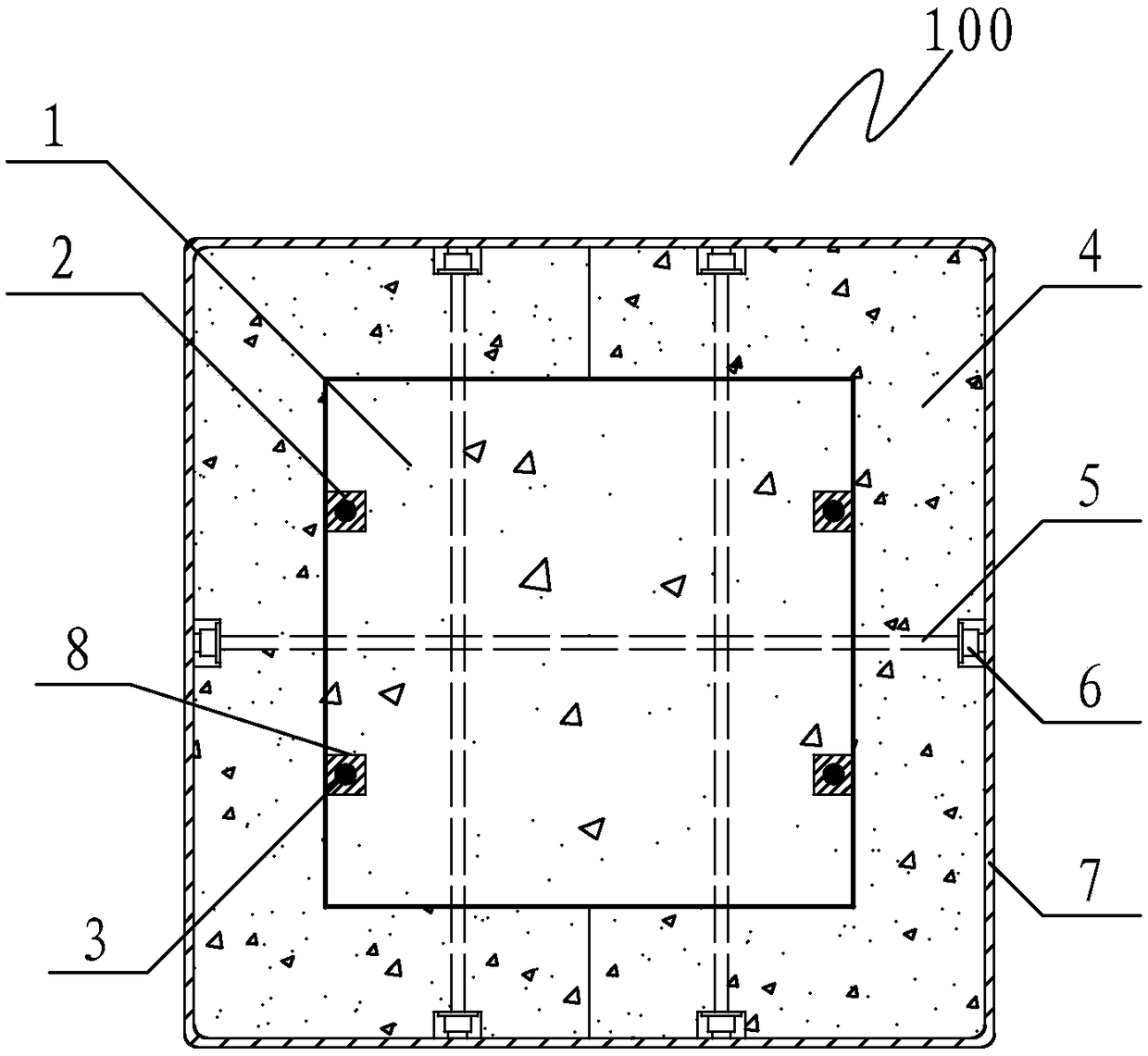

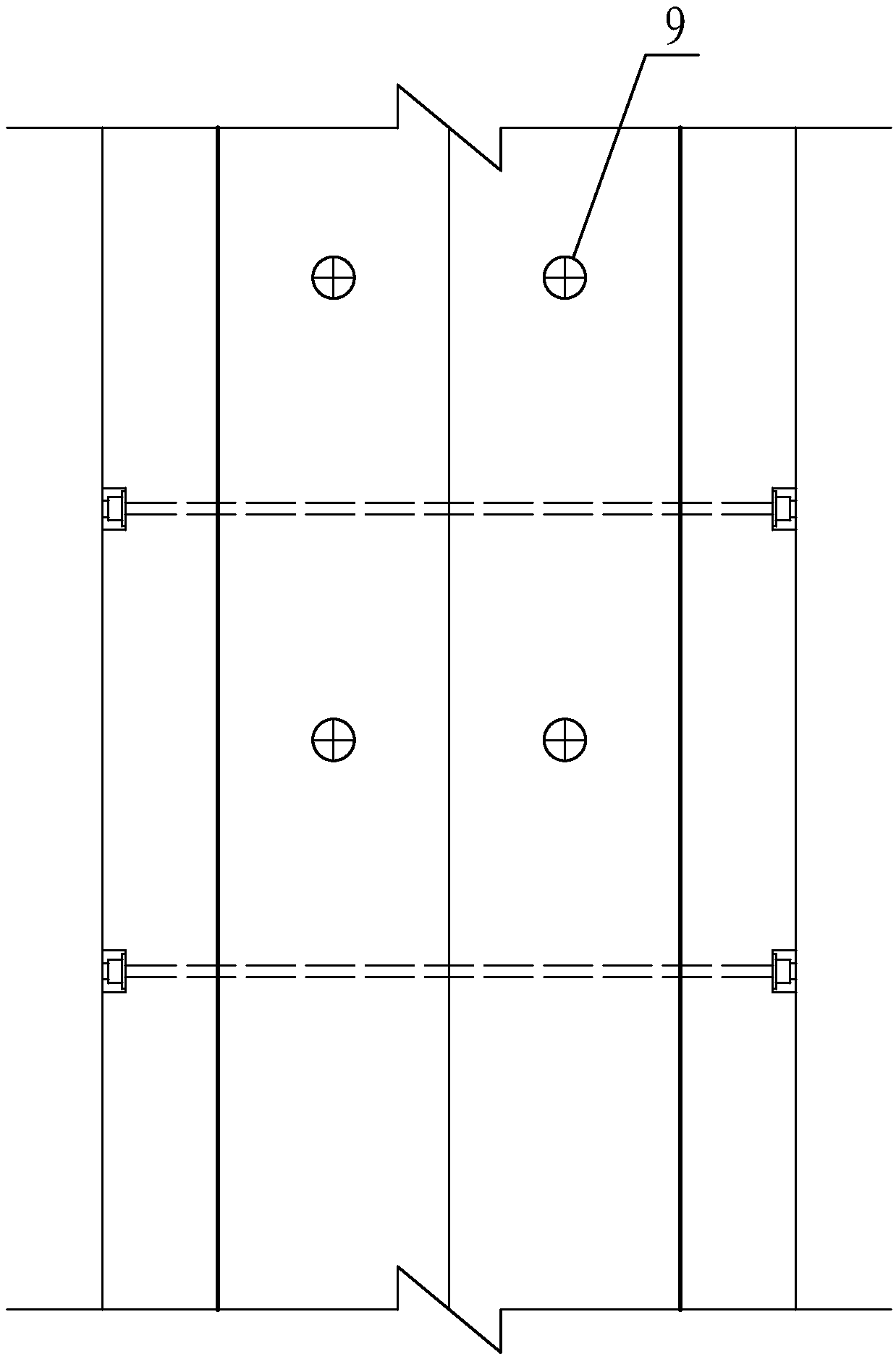

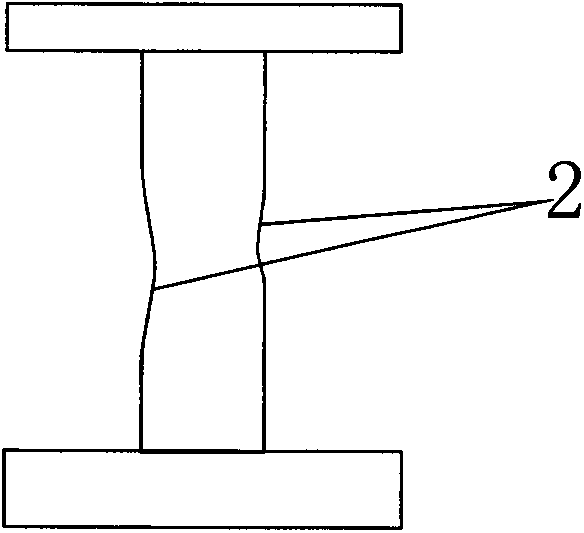

Reinforcing reinforced concrete column and construction method thereof

InactiveCN108547468AFast reinforcementImprove bearing capacityBuilding repairsBridge erection/assemblyReinforced concrete columnAdhesive

The invention provides a reinforcing reinforced concrete column and a construction method thereof. The reinforcing reinforced concrete column includes a reinforced concrete column body, two prefabricating fiber reinforced concrete duct pieces and a plurality of fiber cloth layers; the two prefabricating fiber reinforced concrete duct pieces are embraced together around the periphery of the reinforced concrete column body and the two prefabricating fiber reinforced concrete duct pieces and the reinforced concrete column body are fixedly connected by a plurality of penetrating bolts; the fiber cloth layers are tightly arranged on the outer surfaces of the two prefabricating fiber reinforced concrete duct pieces in a surrounding mode; and the rest of fiber cloth layers are successively surrounded on the periphery of the fiber cloth layers and the fiber cloth layers are connected in an adhesive mode by adhesives. The construction method includes the following steps of manufacturing the prefabricating fiber reinforced concrete duct pieces, drilling bol holes, chiseling grooves, injecting glue, planting bars, mounting the prefabricating fiber reinforced concrete duct pieces and twining cloth. According to the reinforcing reinforced concrete column and the construction method thereof, the construction period is short, bearing capacity, rigidity and ductility deformability of the reinforced concrete column can be effectively improved, and the reinforcing column has the rigidity and the ductility at the same time.

Owner:FUJIAN UNIV OF TECH

Screen cloth reinforcing method

ActiveCN107675505AImprove heat resistanceGood weather resistanceFibre treatmentWeather resistanceHeat resistance

The invention relates to a screen cloth reinforcing method. The screen cloth reinforcing method comprises the following steps: embedding unfoamed EVA particles into meshed holes of the screen cloth, fixing the EVA particles into the screen net through thermal foaming or hot pressing, and reinforcing the screen cloth. Compared with the prior art, the screen cloth reinforcing method has the following advantages: the screen cloth is reinforced by the EVA particles subjected to foaming or hot pressing, the EVA is a polymer of ethylene vinyl acetate, the heat resistance, the weather resistance, thehardness, the tensile force, the elasticity and the like of the screen cloth are improved by using the characteristics of ethylene vinyl acetate, and the method is high in reinforcing speed, remarkable in effect and stable in reinforcement. Different parts of sport shoe fabric can be subjected to different-strength screen net reinforcement according to requirements, different tensile forces and different control forces of different parts of the sport shoe fabric can be realized, and the use range of the screen cloth is enlarged.

Owner:FUJIAN HUAFENG SPORTING GOODS TECH CO LTD

Force-given effect flexible stake composite presser for groundsill and its uses

InactiveCN1884717AFast reinforcement effectEasy to handleBulkheads/pilesSoil preservationElectricityControl system

The invention relates to a flexible pile composite foundation compress machine, formed by chassis, stabilize leg, walking device, compress tube, pile support, angle control flexible drawing rod, hydraulic system formed by hydraulic device and oil tube, control system formed by motor, hydraulic electric linkage and lighting device, and weight, wherein the chassis is arranged with pile support, support pile support and angle control flexible drawing rod, which are connected via pins or bolts; another end of flexible drawing rod is connected to the pile support via pin or bolt; the compress support and relative fixing pile support form compress part; and the hydraulic system is formed by compress tube jack, oil pump and oil tube; the hydraulic output of hydraulic system is fixed on the pile support and connected to the compress tube, to extend and contract the compress tube, to form hole in soil and compress pile.

Owner:NANJING UNIV OF TECH +1

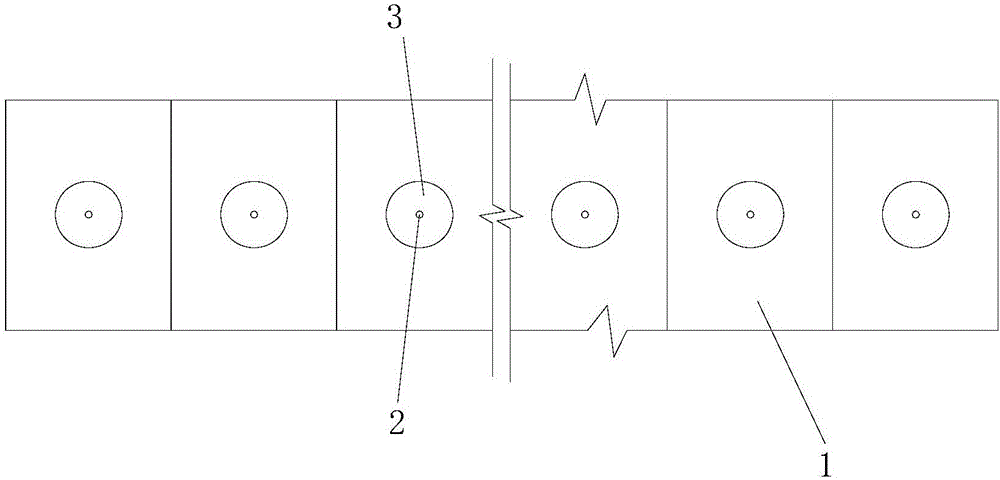

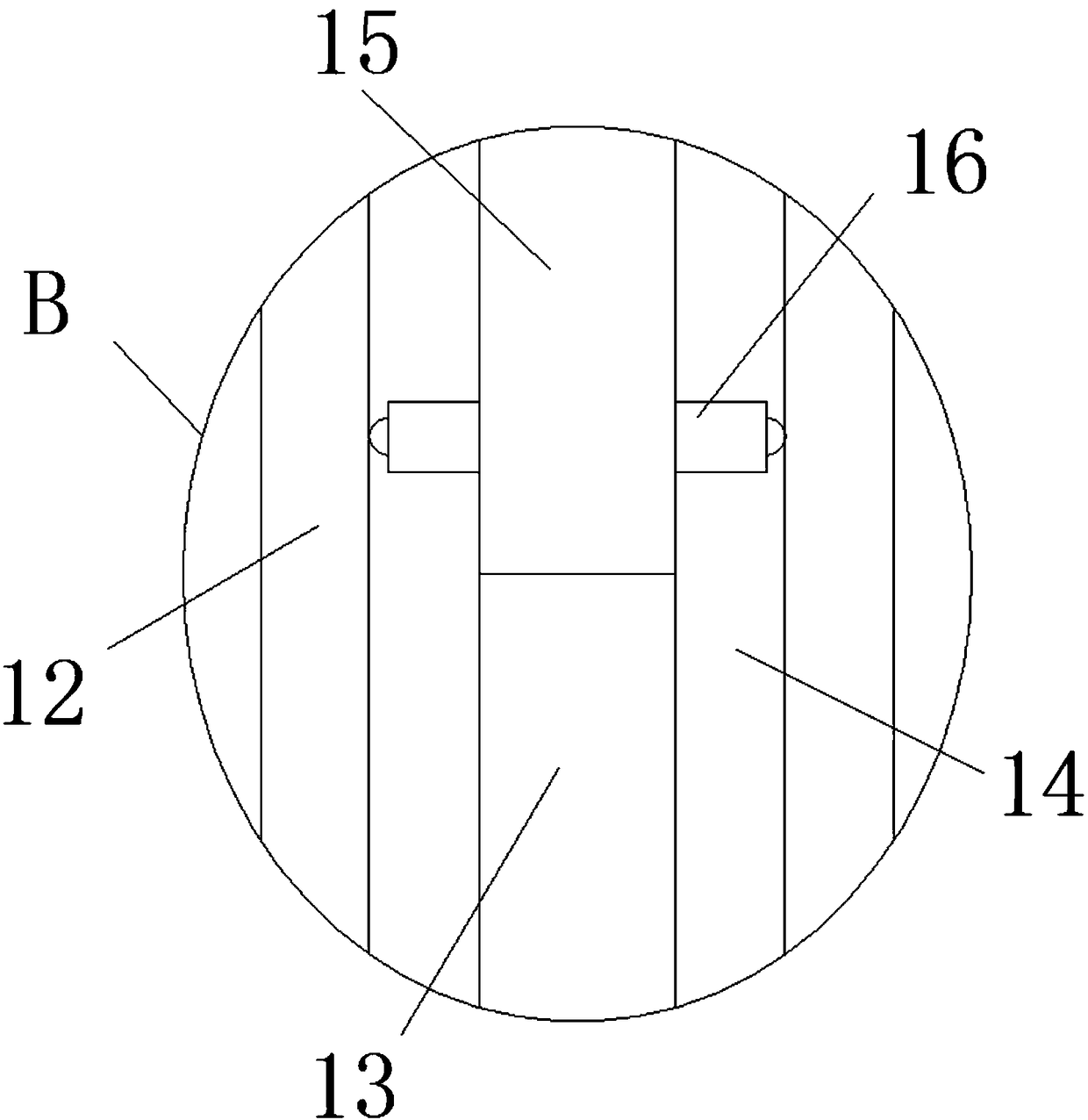

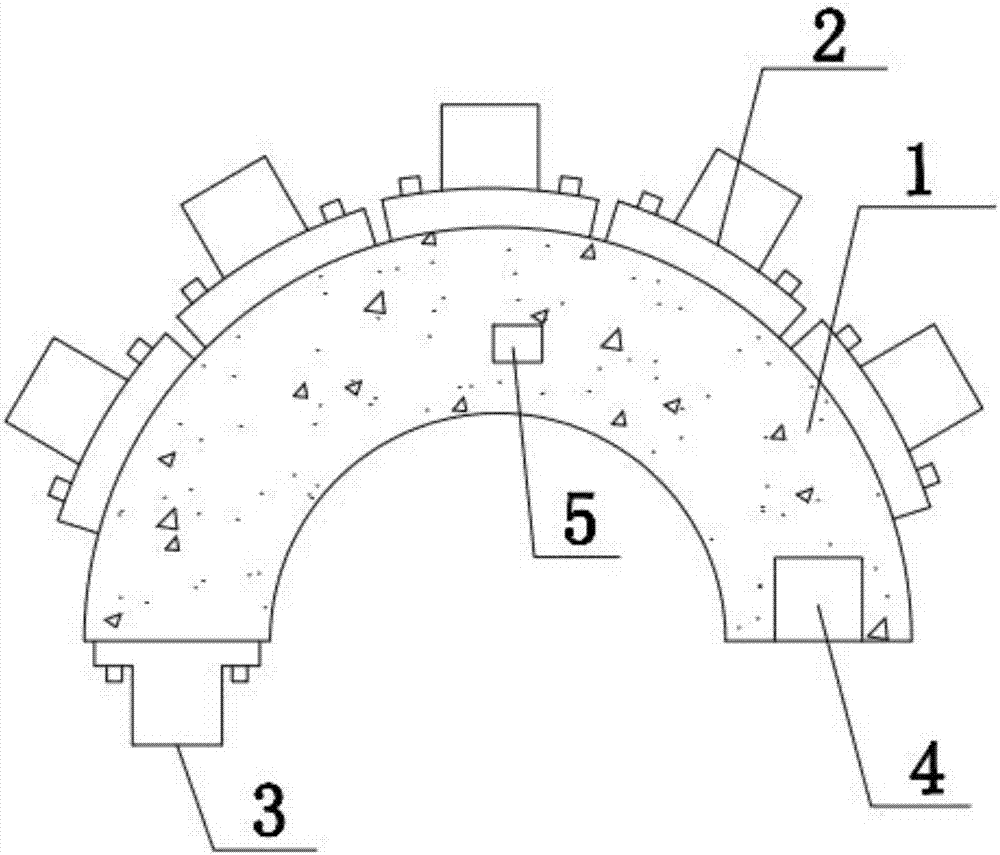

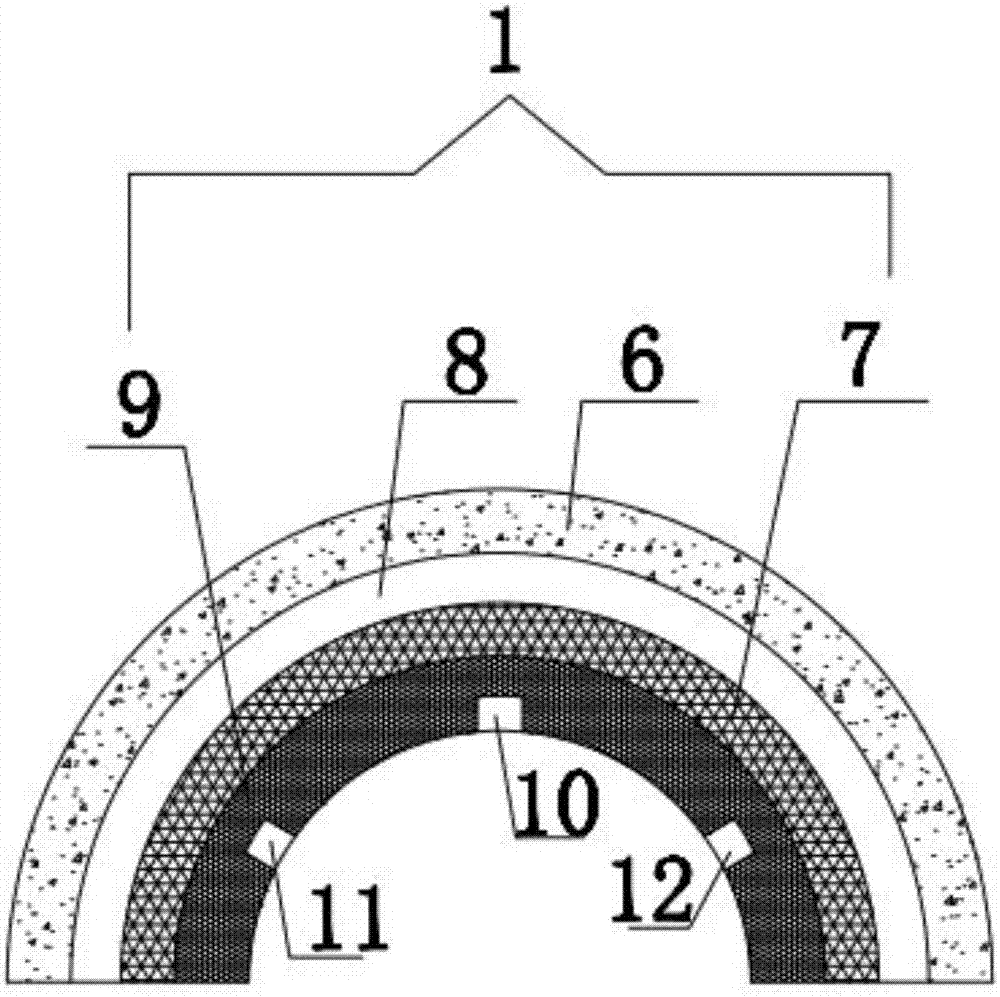

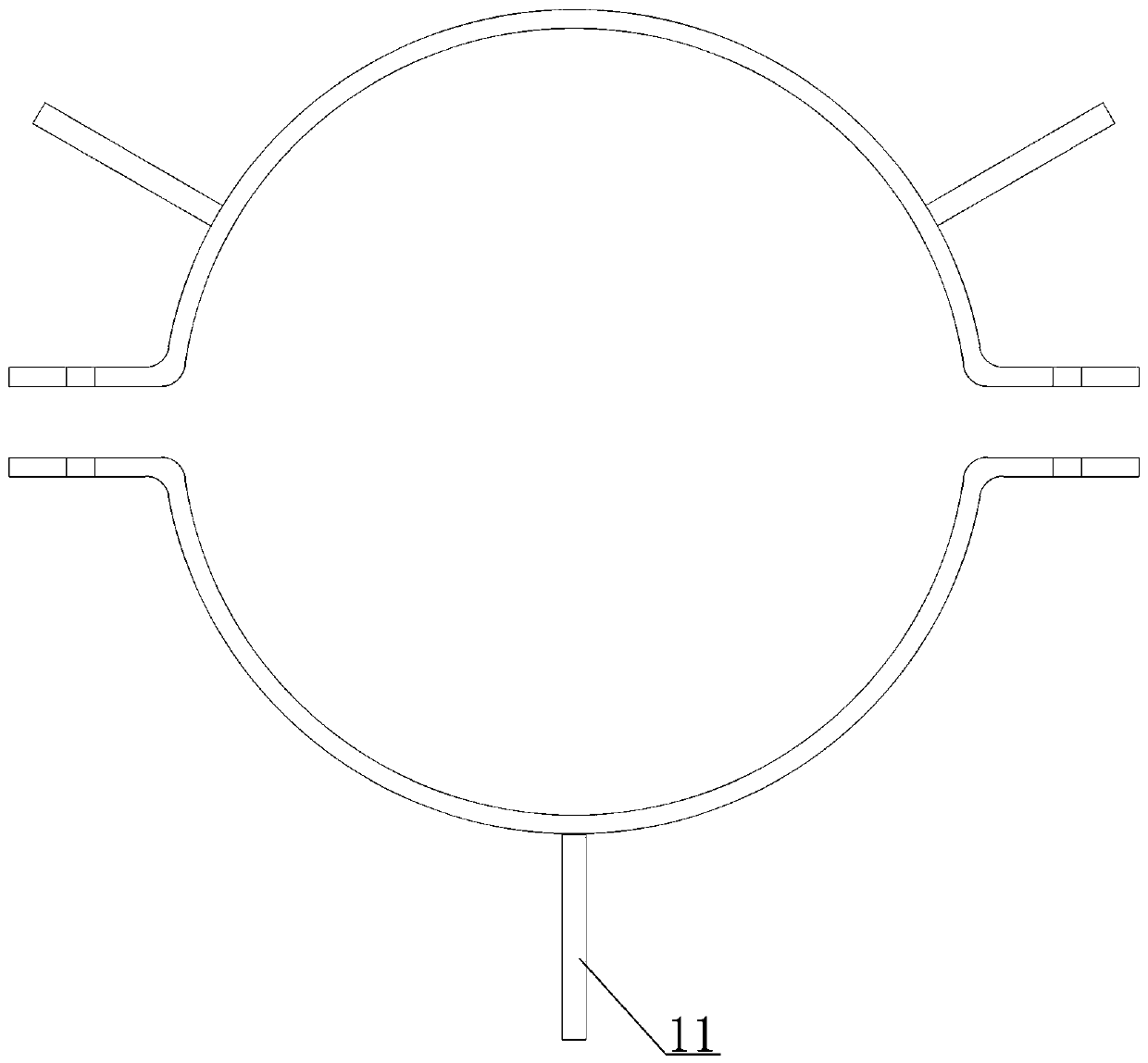

Circumferential intellectualization reinforcing structure and reinforcing method for shield tunnel

InactiveCN106907163AImprove carrying capacityIncrease stiffnessMining devicesUnderground chambersFiberStress sensor

The invention discloses a shield tunnel circumferential intelligent reinforcement structure and a reinforcement method in the field of tunnel reinforcement technology, including a reinforcement structure body, the top of the reinforcement structure body is evenly fixed and installed with shield segment connecting columns by bolts, so that The bottom left end of the reinforcement structure body is fixedly connected with a support column by bolts, and the bottom right end of the reinforcement structure body is provided with a fixing groove, and the fixing groove and the support column cooperate with each other. This kind of shield tunnel circular intelligent reinforcement structure and reinforcement method, the design is reasonable, and the mortar layer, steel plate and carbon fiber composite molding are used to improve the ultimate bearing capacity and rigidity of the shield tunnel, and can realize rapid reinforcement of the tunnel under harsh conditions such as narrow space and short reinforcement time, and adopt CCD The image sensor, stress sensor and water seepage sensor can monitor the image inside the shield tunnel in real time, and monitor the strain distribution and water seepage of the reinforced structure.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

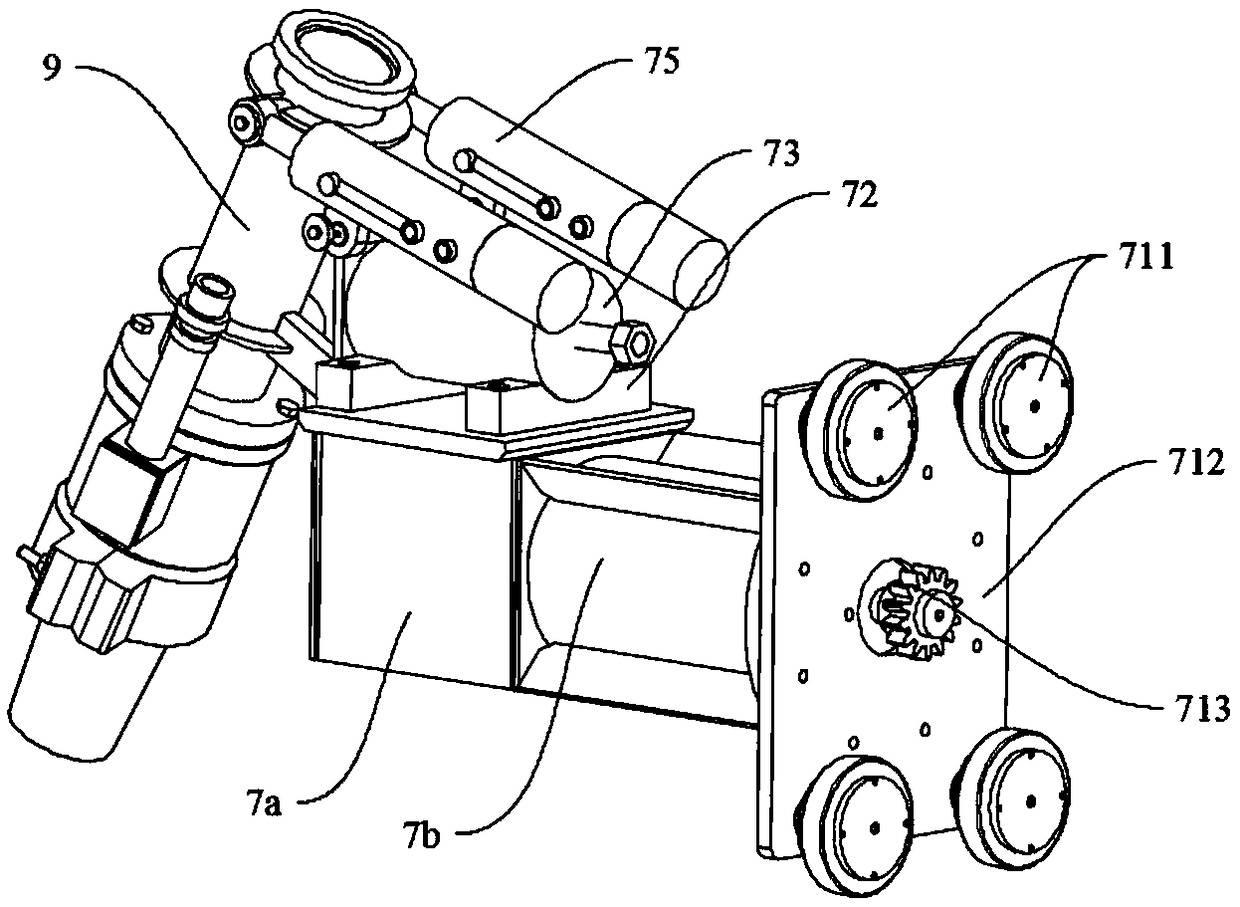

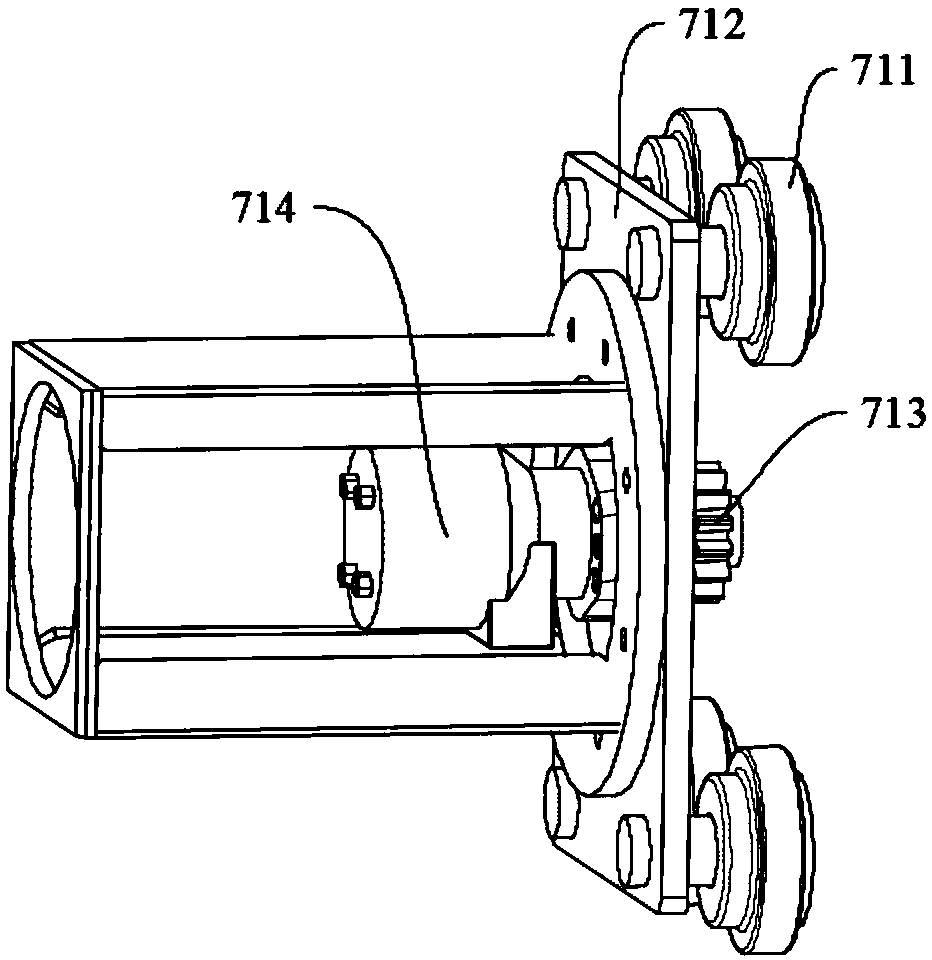

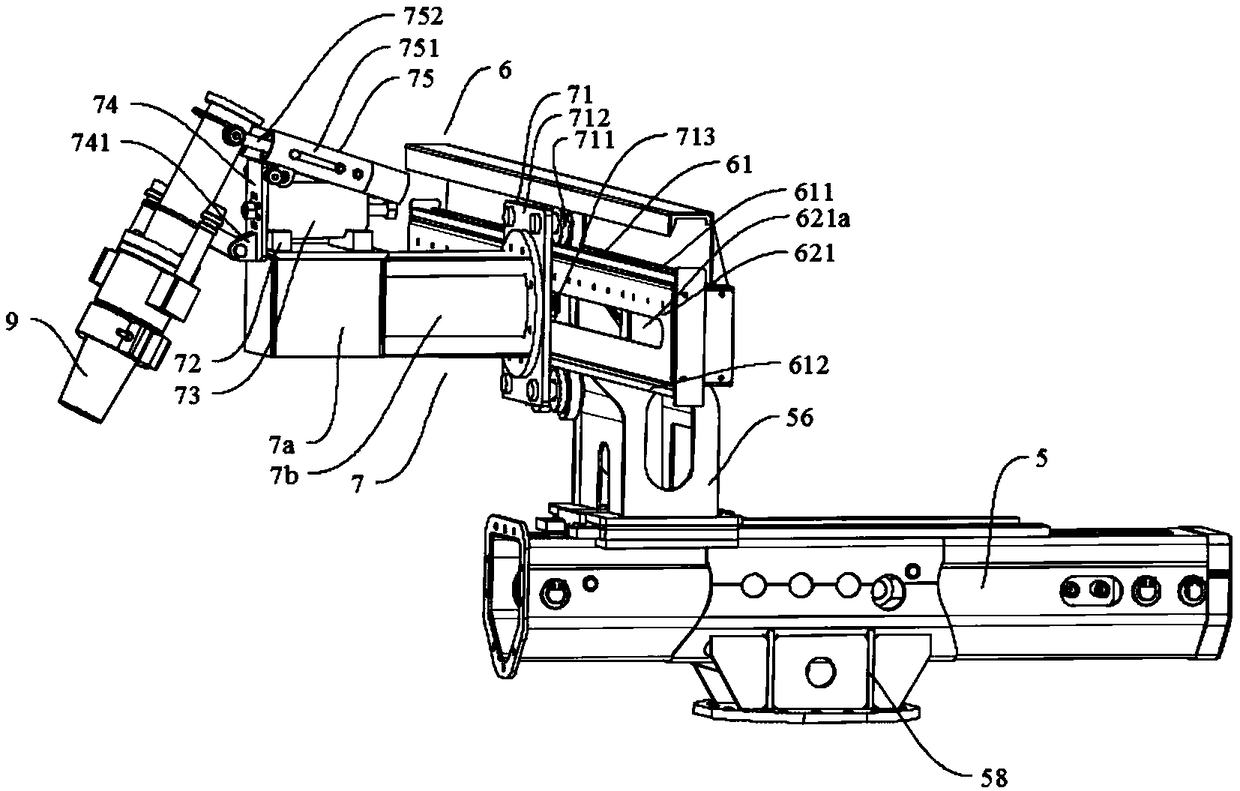

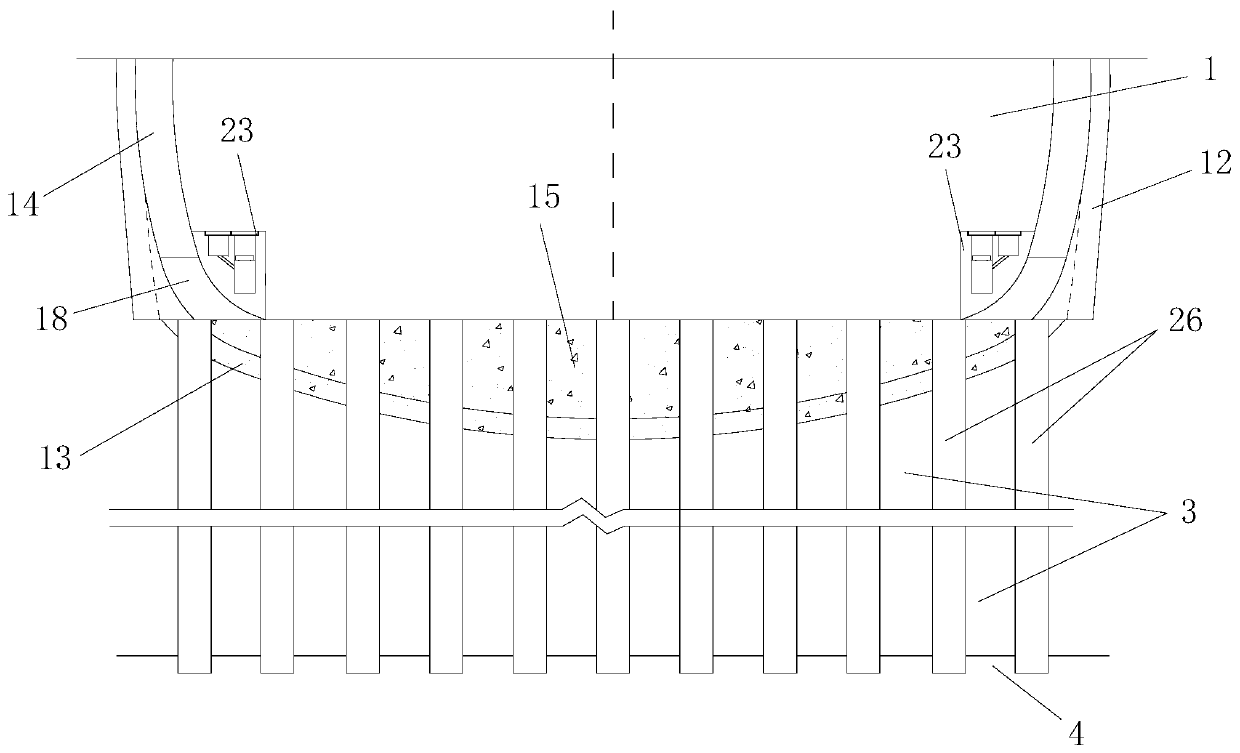

Tunnel supporting layer mold spraying mechanism and method

PendingCN109404014AMeet control requirementsImprove coordinationUnderground chambersTunnel liningMechanical engineeringEngineering

The invention discloses a tunnel supporting layer mold spraying mechanism and method. The mold spraying mechanism comprises a spray head assembly, a mold plate mechanism and an injection system, wherein the injection system is connected with the spray head assembly; the spray head assembly is arranged on the upper part of the mold plate mechanism, and a mold cavity to be poured is formed by the mold plate mechanism and a rock wall; the injection system conveys concrete to the spray head assembly, and the spray head assembly sprays the concrete into the mold cavity from the upper part of the mold plate mechanism in the direction not perpendicular to the rock wall. According to the innovatively designed tunnel supporting layer mold spraying mechanism and method and based on the actual situation of the mold cavity between the mold plate mechanism and the excavated rock wall, the displacement, the angle, the direction, the height and the like of the spray head assembly can be adaptively adjusted, the controlling difficulty is lowered, and the controlling accuracy is improved; meanwhile, a mold spraying material agent injection system enables the concrete and an accelerator to be mixedquickly, adequately and evenly; and then the mixed concrete can be sprayed into the mold cavity and a supporting layer is formed rapidly, and the purpose of quickly reinforcing the tunnel rock wall isachieved.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

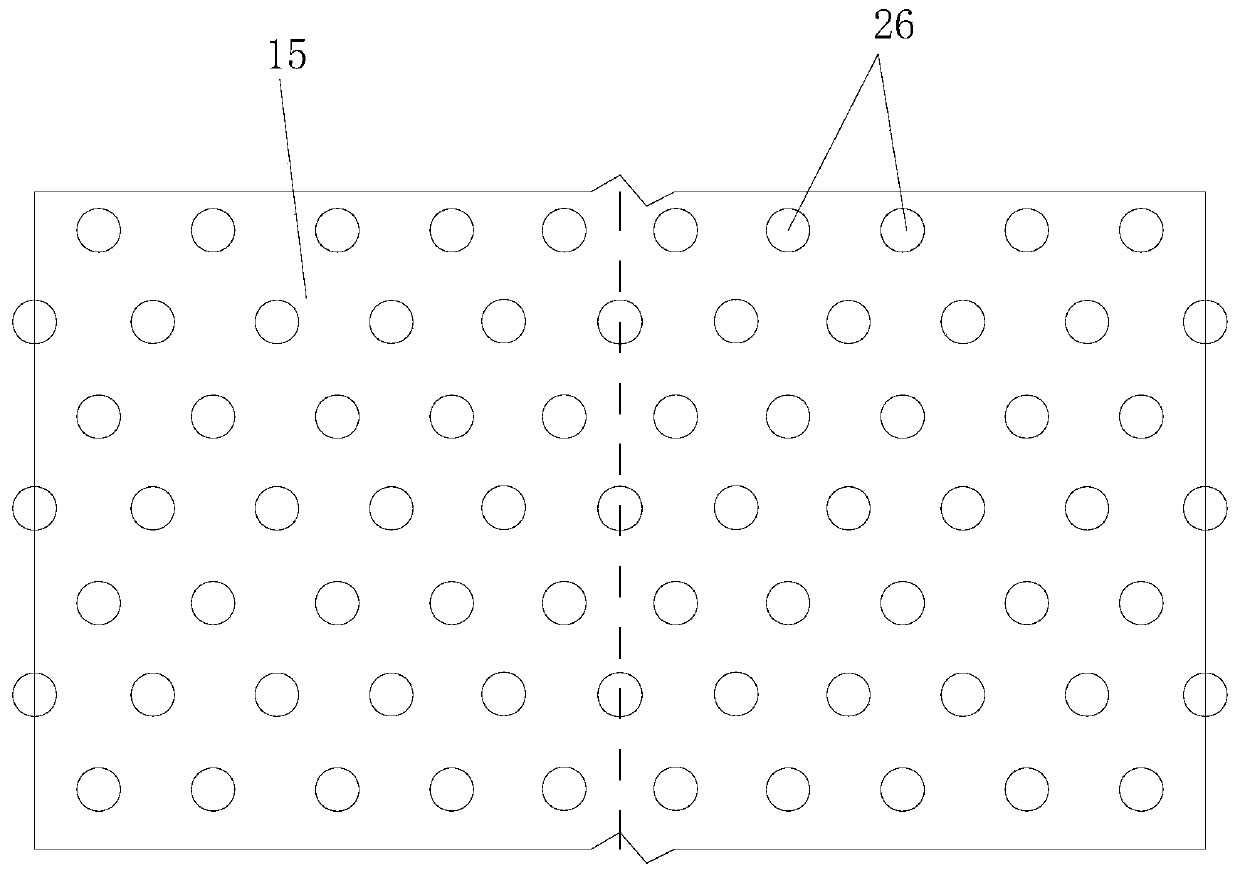

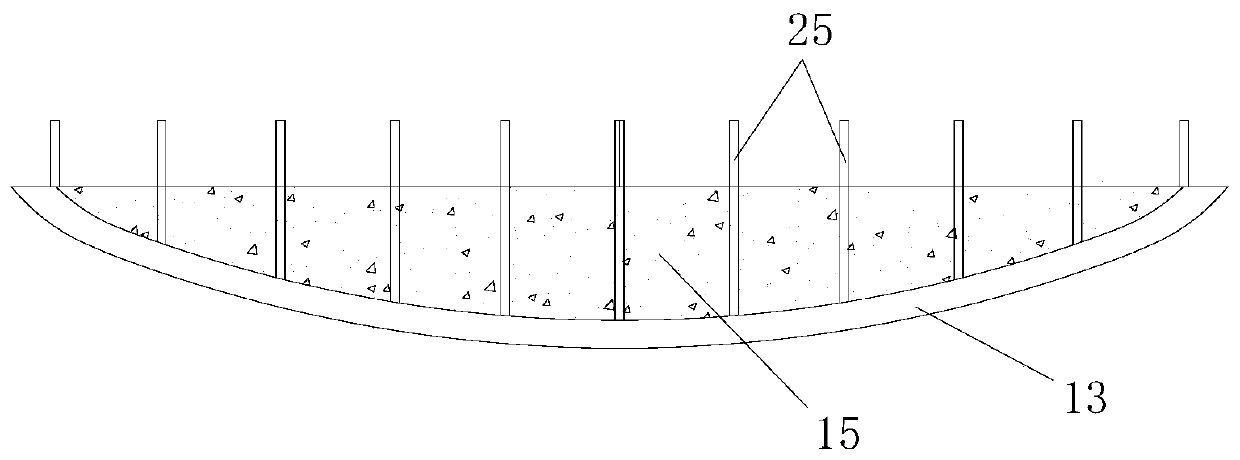

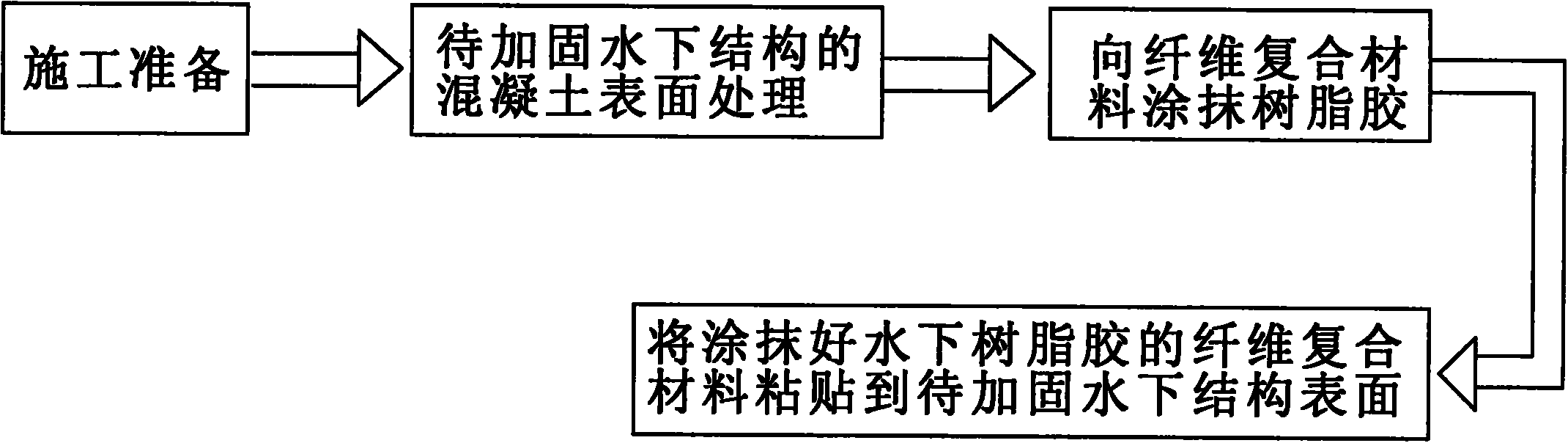

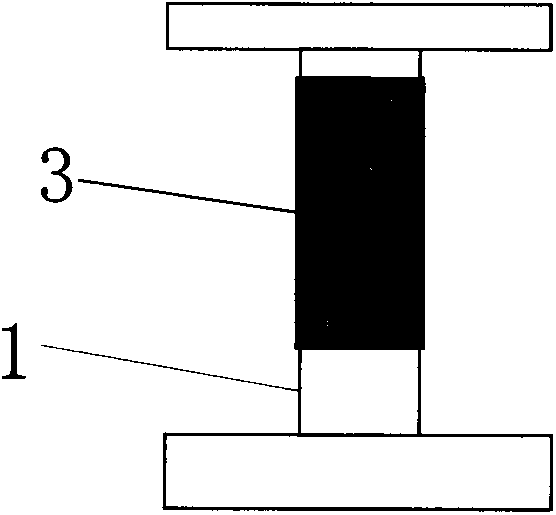

Method for reinforcing underwater structure through fiber composite materials

InactiveCN103397657AMeet emergency repairsSmall sizeArtificial islandsFoundation repairEpoxyUnderwater

The invention discloses a method for reinforcing an underwater structure through fiber composite materials. The method comprises the following steps that the concrete surface of an underwater structure to be reinforced is processed; underwater epoxy resin or underwater non-dispersed concrete or underwater non-dispersed mortar is utilized to repair and restore on a cleaned up damage portion of the underwater structure to be reinforced, and protruding portions of the surface of the structure are polished smooth; underwater resin adhesive is uniformly daubed on the fiber composite materials with the size cut well; at lest one layer of the fiber composite materials daubed by the resin adhesive are annularly pasted to the surface of the damage repairing portion of the underwater structure to be reinforced, the fiber composite materials are pasted on the surface of the underwater structure to be reinforced layer by layer, and annular lap joint portions of the layers are mutually staggered. According to the method, the reinforcing speed is high, the construction period is short, the process is simple, water repellent treatment is carried out because cofferdam water abandoning is not needed in construction, the construction has small influences on a navigation channel, abrasion of acid and alkali to the concrete structure can be prevented after reinforcing, and the service life of the underwater structure to be reinforced is prolonged.

Owner:上海其军加固工程有限公司

Polymer gravel pile grouting method

Owner:HENAN POLYTECH INFRASTRUCTURE REHABILITATION

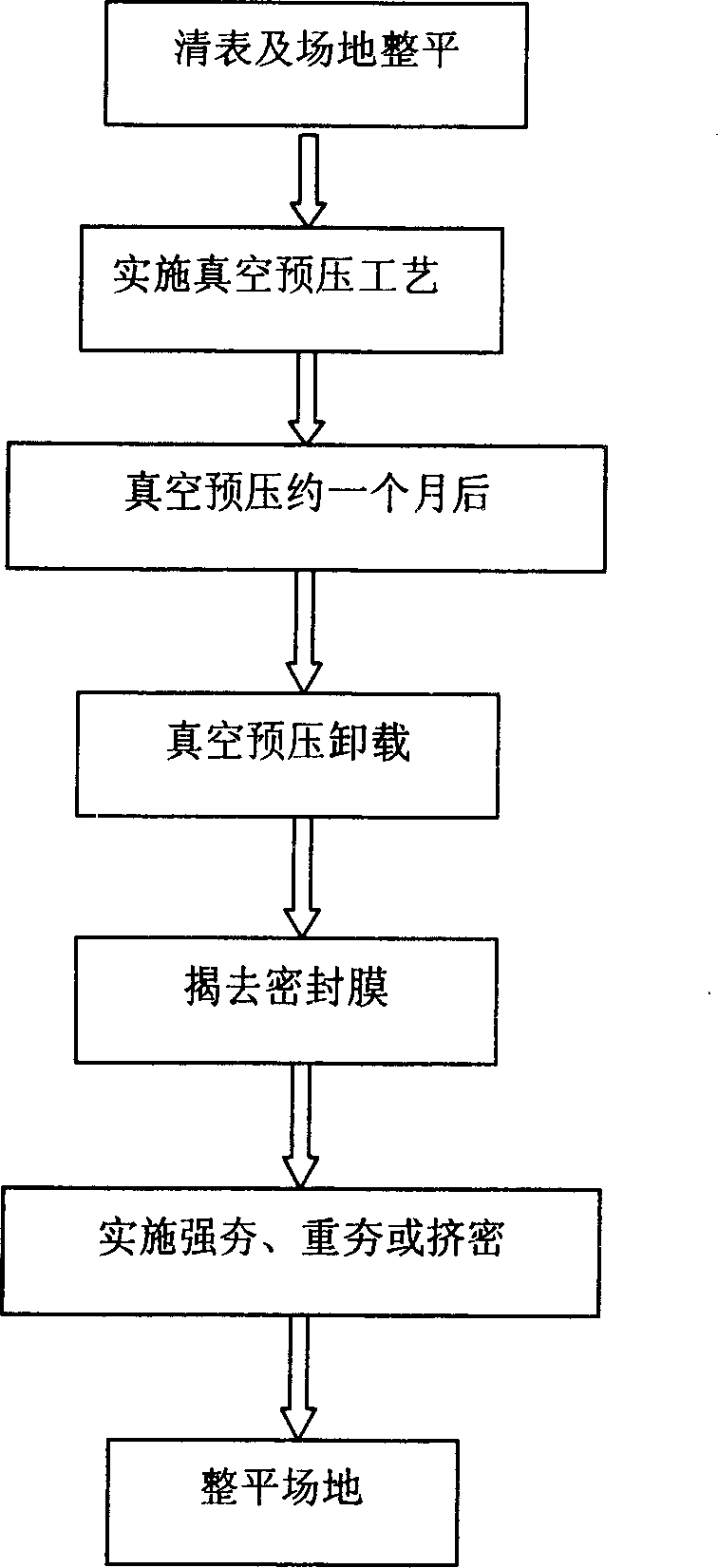

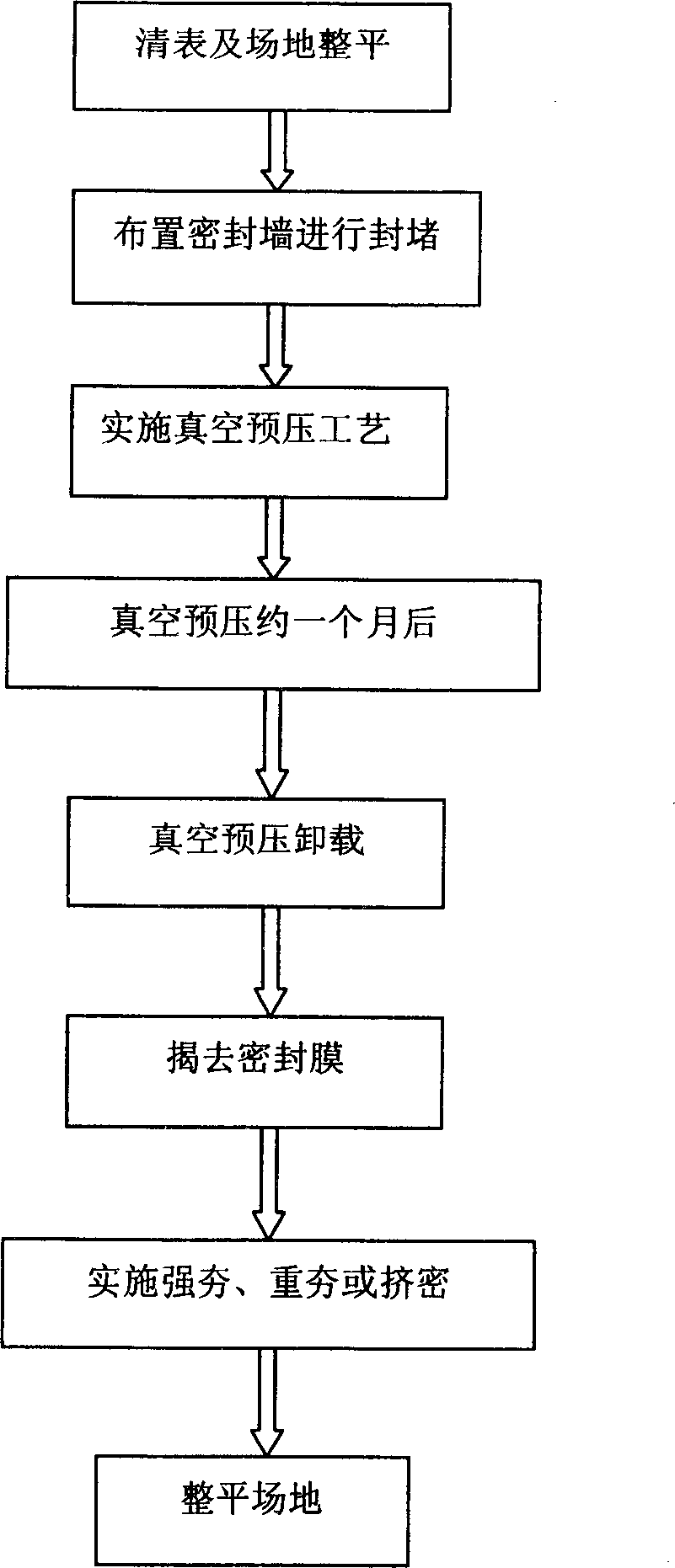

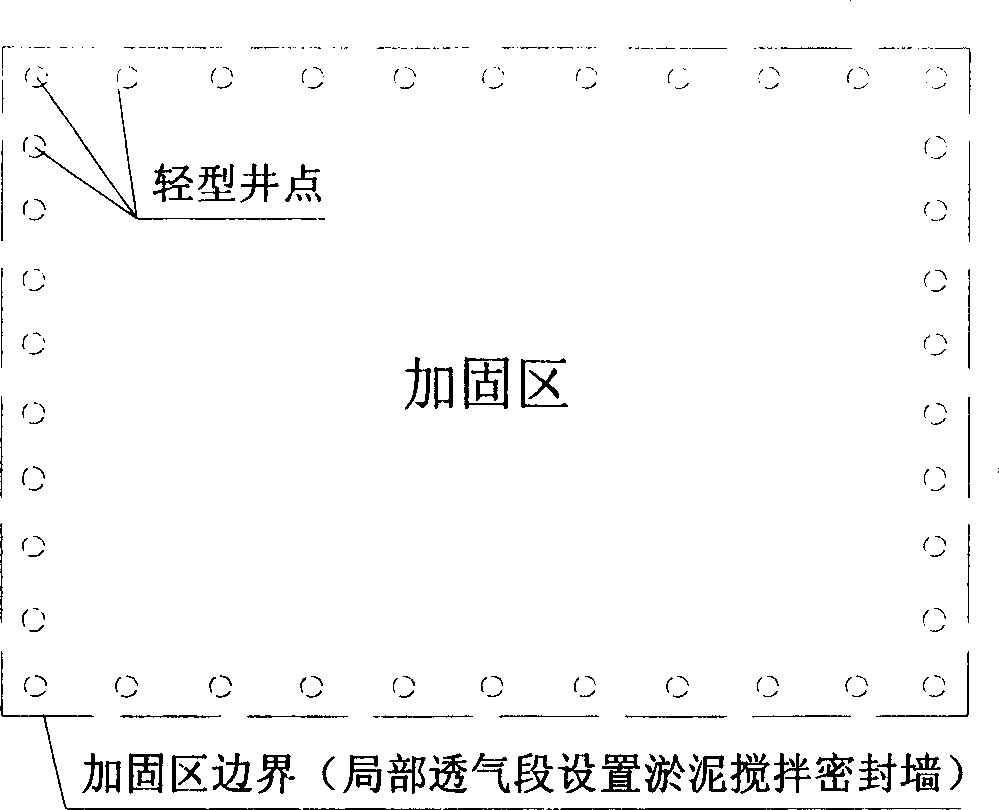

Technique for quickly reinforcing soft soil foundation

InactiveCN1837499AImprove bearing capacityImprove stabilitySoil preservationWater dischargeEngineering

The invention relates to a soft ground quick solidifying method, which comprises following steps: 1, vacuum pre-compress discharging water and solidifying the soft ground for 30 days to reach more than 70% of solidify degree;, b, removing the vacuum pre-compress sealing film, to process power solidifying treatment as compressing, etc. the invention combines the vacuum pre-compress water discharge solidifying method and the power solidify method, to improve the efficiency, reduce the cost and time as 1 / 3-3 / 2 reduced time of before. It can be used in non-sand ventilating layer of soft ground and the sand-interlayer ventilating layer.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

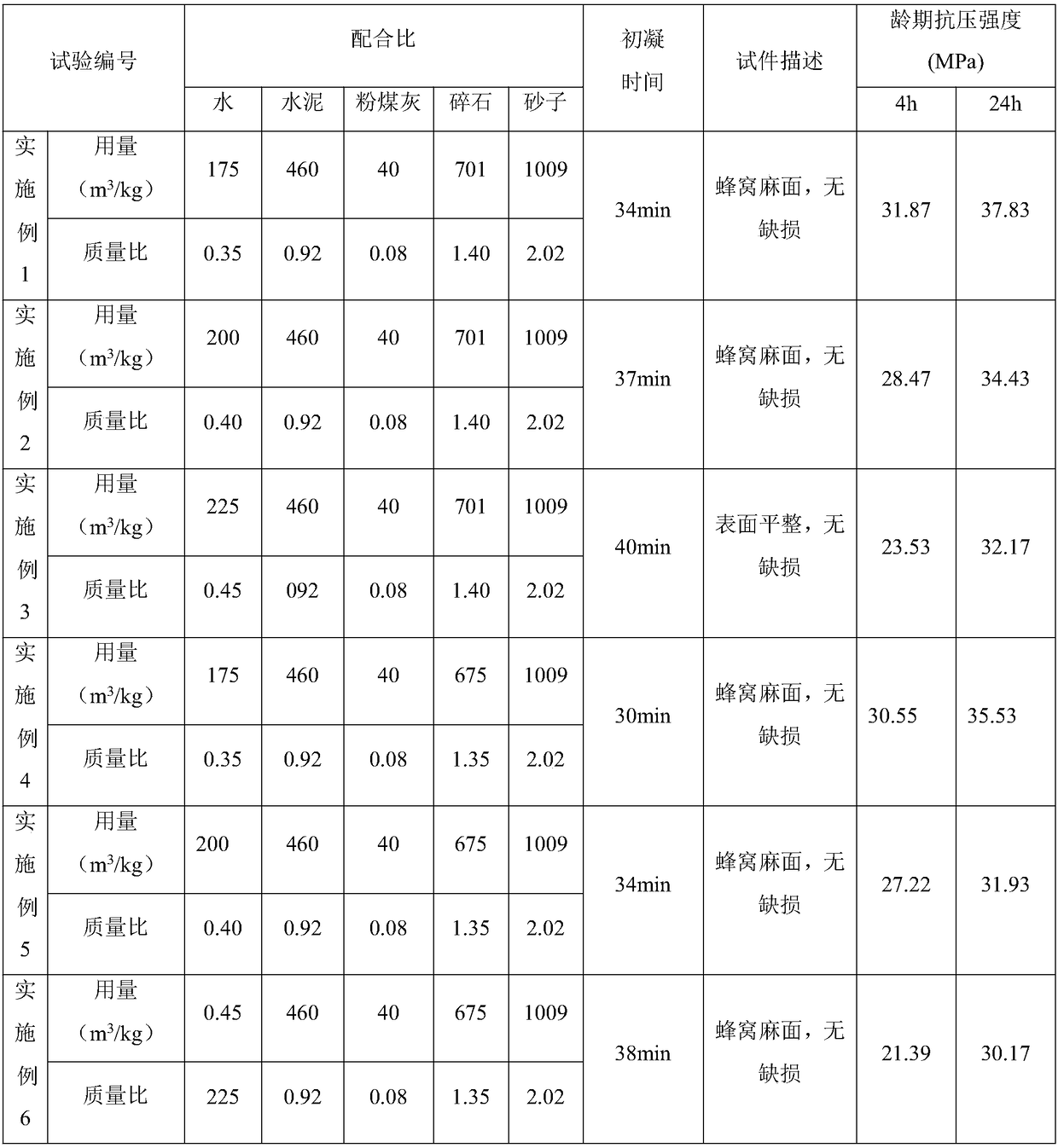

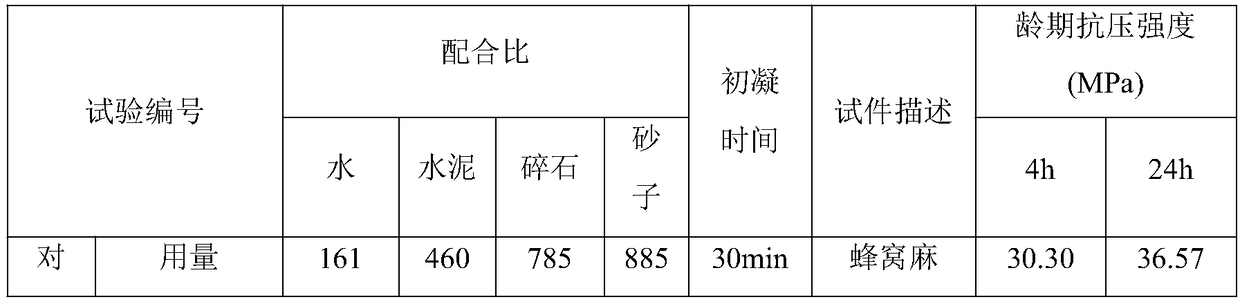

High-strength and quick-hardening shotcrete and soft-rock tunnel surrounding rock closing and strengthening method

The invention discloses high-strength and quick-hardening shotcrete and a soft-rock tunnel surrounding rock closing and strengthening method. The high-strength and quick-hardening shotcrete compriseswater, cement, fly ash, gravel and sand, wherein the weight ratio of the fly ash to the cement is 0.92:0.08, the ratio of the weight of water to the total weight of the cement and the fly ash is (0.35-0.45):1, the ratio of the weight of the gravel and the total weight of the cement and the fly ash is (1.35-1.4):1, and the ratio of the weight of the sand and the total weight of the cement and the fly ash is 2.02:1. The high-strength and quick-hardening shotcrete is high in setting speed, can achieve initial setting within 35min plus or minus 5min, has the cubic average compressive strength being higher than or equal to 20MPa at 4h, has the cubic average compressive strength being higher than or equal to 30MPa at 24h, can timely and quickly close and strengthen an excavated surface, and hashigh early strength. In tunnel construction, the high-strength and quick-hardening shotcrete is sprayed first and then ordinary shotcrete is sprayed, so that effective connection of the low-age strength and the high-age strength of the shotcrete is achieved, and optimization of the functionality and the economy of the shotcrete is achieved.

Owner:CHANGAN UNIV

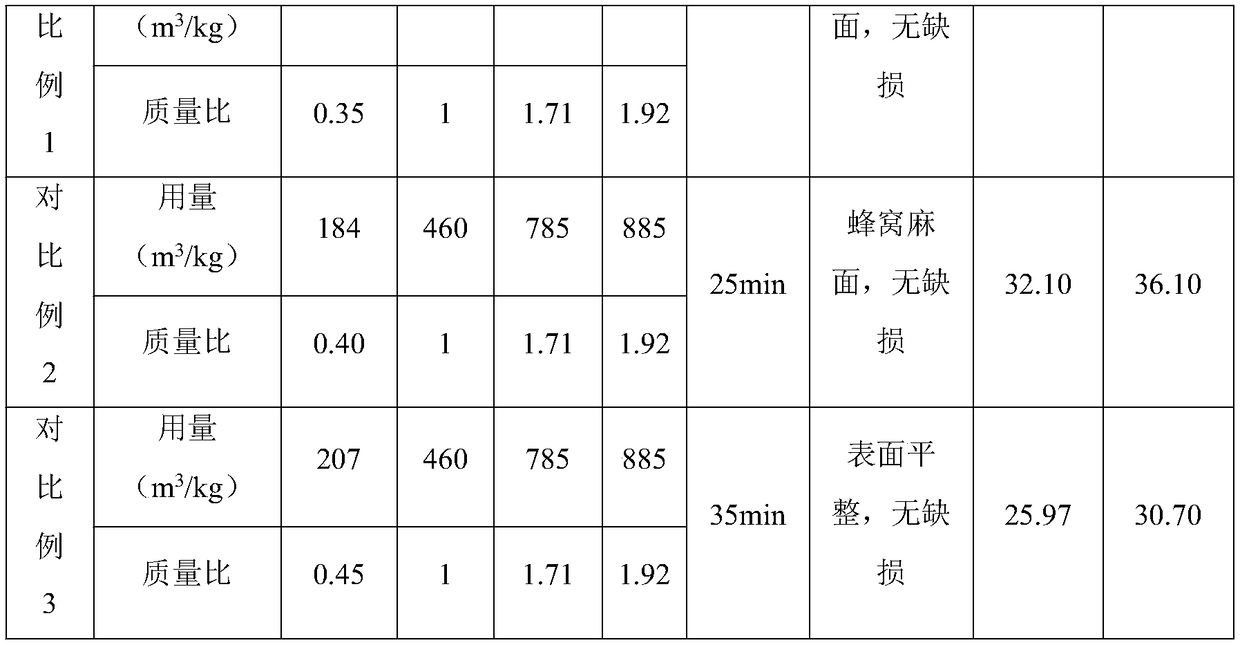

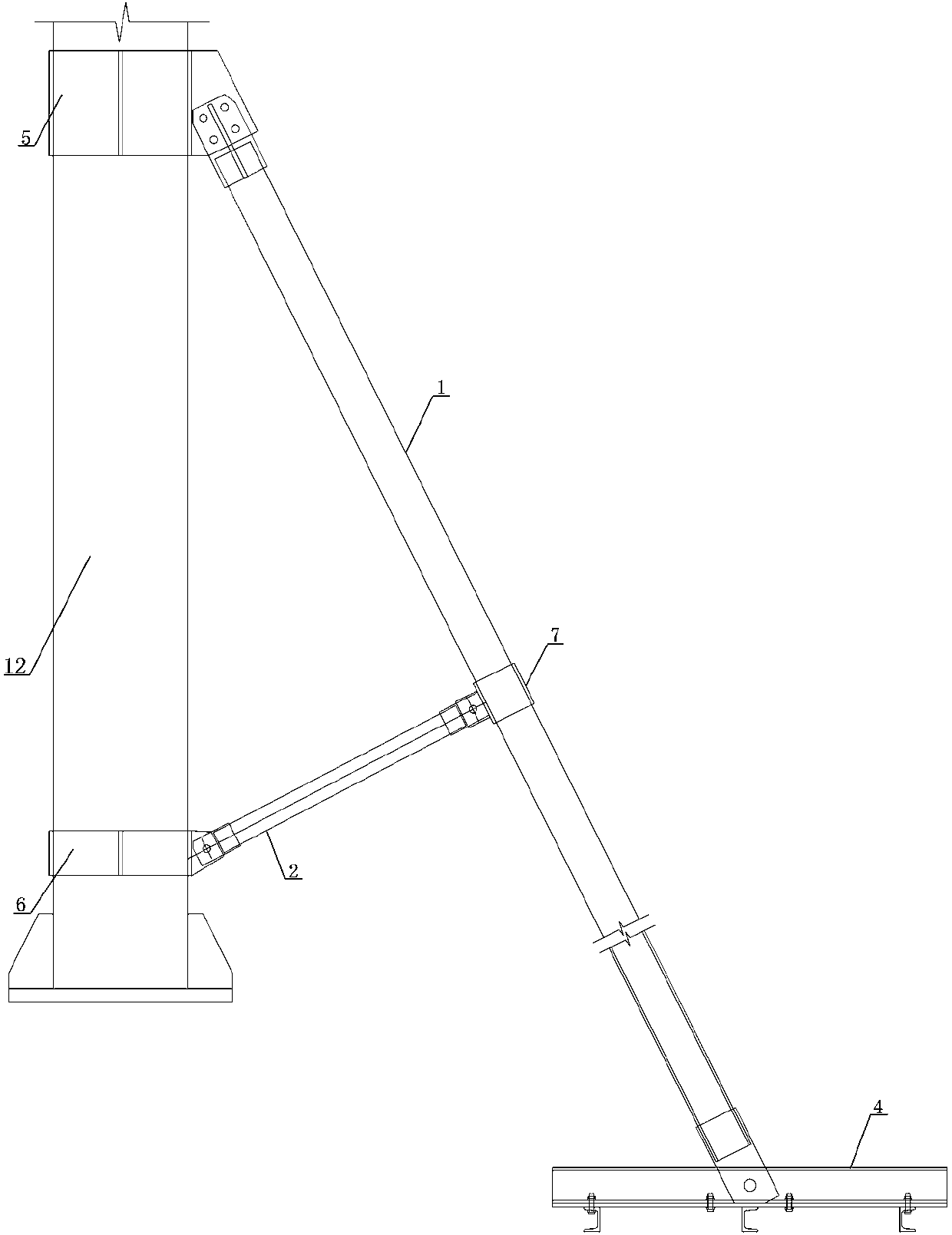

Reinforcing structure for single-tube communication tower

InactiveCN109594838AReduce bending momentSolve the problem that the anti-overturning does not meet the specification requirementsTowersExcavationsEngineeringTower

The invention provides a reinforcing structure for a single-tube communication tower. The reinforcing structure comprises a plurality of diagonal bracing, wherein each diagonal bracing is connected with a tower body through a first hoop arranged at the upper section of the diagonal bracing, the lower end of each diagonal bracing is connected with a base structure, and a cross bracing is transversely arranged between the adjacent diagonal bracings. The invention aims to solve the technical problem that tower body bearing capacity and foundation overturning resistance of the single-tube communication tower before reinforcement do not meet the standard requirement.

Owner:HENAN INFORMATION CONSULTATION DESIGN & RES

Negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method

The invention discloses a negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method. The negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method mainly comprises the steps that a dredger fill area is cleaned and flattened; a ditch is horizontally formed in the dredger area or a horizontal water seepage pipe is arranged by inclining by 0.5-5 degrees, and backfilling is conducted through medium and rough sand-gravel aggregate; a dam and a drainage canal are constructed on the periphery of the dredger fill area, and a water diversion pipe and an automatic-flowing drainage pipe are pre-buried; a dredger fill pipeline is led into the dredger fill area in the dam; slurry is guided into the surface layer of the dredger fill area and underground water is guided into the drainage canal after silt deposits; a water suction pump is connected to the outer port of the drainage pipe, and then forced drainage is conducted. Meanwhile, the invention creatively provides a suspension controllable dredger fill area drainage device, a movable multifunctional integrated well tube draining and vibrating-flushing device and technologies matched with the suspension controllable dredger fill area drainage device and the movable multifunctional integrated well tube draining and vibrating-flushing device. Compared with the prior art, the reinforcing period can be shorted by about 50% and the comprehensive unit cost can be reduced by about 45% under the same condition, and the bearing capacity of a fill stratum within the overall depth range can reach 60-80 kPa after treatment.

Owner:江苏楚匠建设工程有限公司

In-stratum stepped-heaped-weir-type safe grouting construction process for blocking large water gushing from sidewall of deep foundation pit

The invention discloses an in-stratum stepped-heaped-weir-type safe grouting construction process for blocking large water gushing from a sidewall of a deep foundation pit. The safe grouting construction process comprises the following steps: the amounts of gushed water and silt from the sidewall at the deep part of the foundation pit are observed and calculated; a water drain pipe is arranged ina water gushing point to drain water; backpressure bodies are arranged around the water gushing point to form backpressure on the sidewall, of the foundation pit, around the water gushing point; holesare drilled in the surface of the sidewall where the water gushing point is positioned, the holes are divided into at least two rows, the depths of the first row of holes and the second row of holesare arranged in a vertically-stepped form, the first row of holes is near a supporting protective body of the sidewall, and the depths of the drilled holes decrease sequentially from inward to outward; and grouting is performed for blocking. Vertical drilling is carried out quickly in the surface on the outer side of the sidewall, where the water gushing point in the the deep part of the foundation pit is positioned; aggregate and anti-dispersion high-early-strength rapid-hardening grout are injected into a water guide channel or a formed cavity through the drilled holes to rapidly form a water-blocking curtain in a stratum where water gushes out, so as to block an underground water gushing channel and achieve the purposes of quickly controlling water gushing and by grouting, reinforcing the stratum damaged by water gushing.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com