Reinforcing reinforced concrete column and construction method thereof

A technology of reinforced concrete columns and concrete columns, which is applied in bridge reinforcement, building maintenance, erection/assembly of bridges, etc., can solve problems such as increased seismic force, long construction period, and reduced ductile deformation capacity, so as to improve bearing capacity, The effect of short construction period and rapid reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

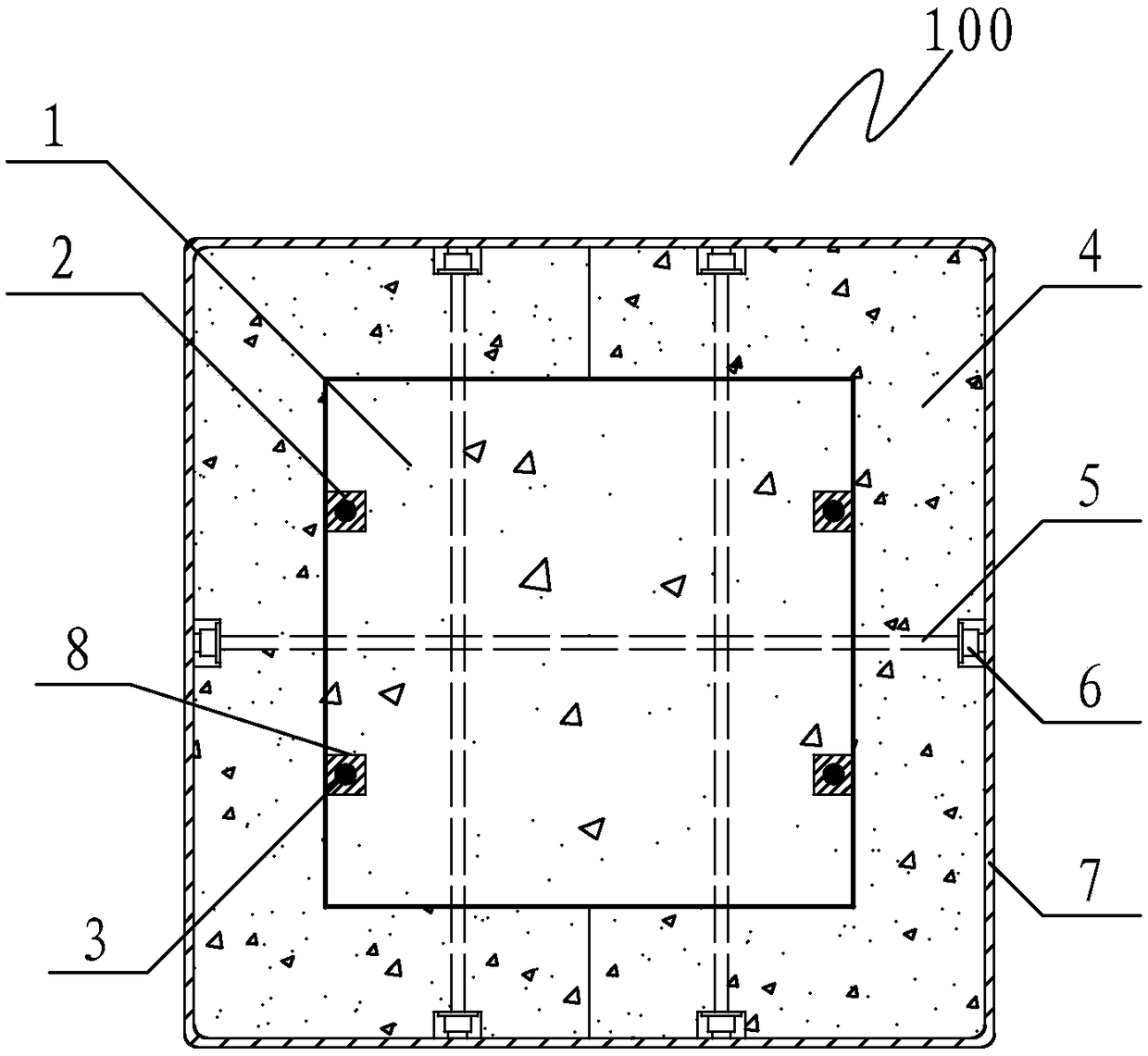

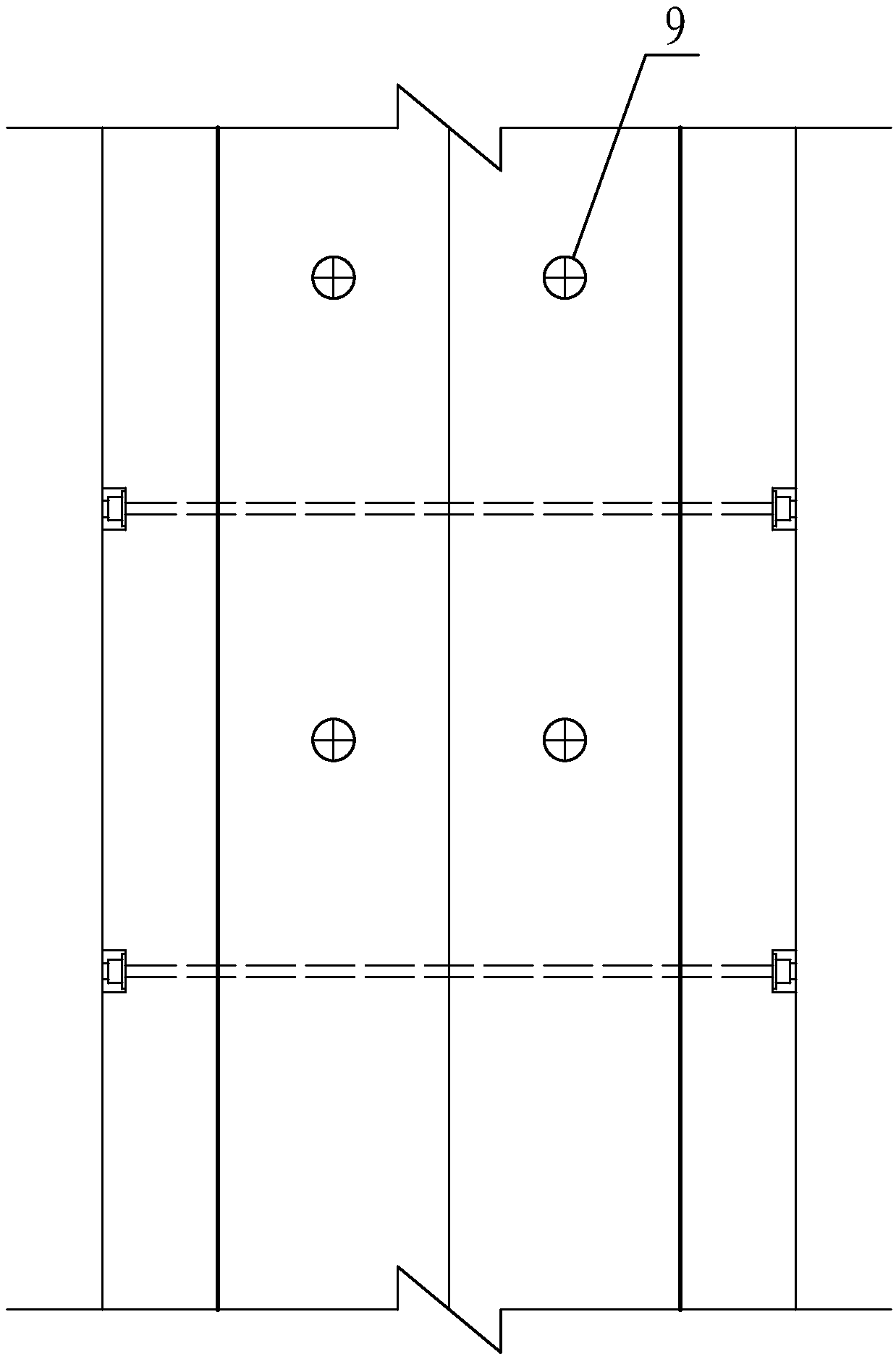

[0024] see figure 1 and figure 2 , a reinforced reinforced concrete column 100, comprising a concrete column body 1, two prefabricated fiber concrete segments 4 and a plurality of fiber cloth layers 7; the two prefabricated fiber concrete segments 4 embrace the periphery of the concrete column body 1, and The two prefabricated fiber concrete segments 4 and the concrete column body 1 are fastened and connected by a plurality of through bolts 5; the prefabricated fiber concrete segments 4 are groove-shaped; the material of the prefabricated fiber concrete segments 4 Fiberglass, carbon fiber or basalt fiber. The outer surface of the concrete column body 1 is sunken inwards to form a plurality of rib grooves 8, which extend from the bottom to the top along the height direction of the concrete column body 1, and each rib groove 8 is embedded with a A tendon3. The ribs 3 are steel bars, glass fiber bars, carbon fiber bars or basalt fiber bars. One of the fiber cloth layers 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com