In-stratum stepped-heaped-weir-type safe grouting construction process for blocking large water gushing from sidewall of deep foundation pit

An intra-stratum, safe injection technology, applied in basic structure engineering, construction, excavation, etc., can solve the problems of small slurry diffusion range, long construction period, small grouting amount, etc., to achieve rapid water plugging system reinforcement, saving grouting Slurry, the effect of reducing the speed of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

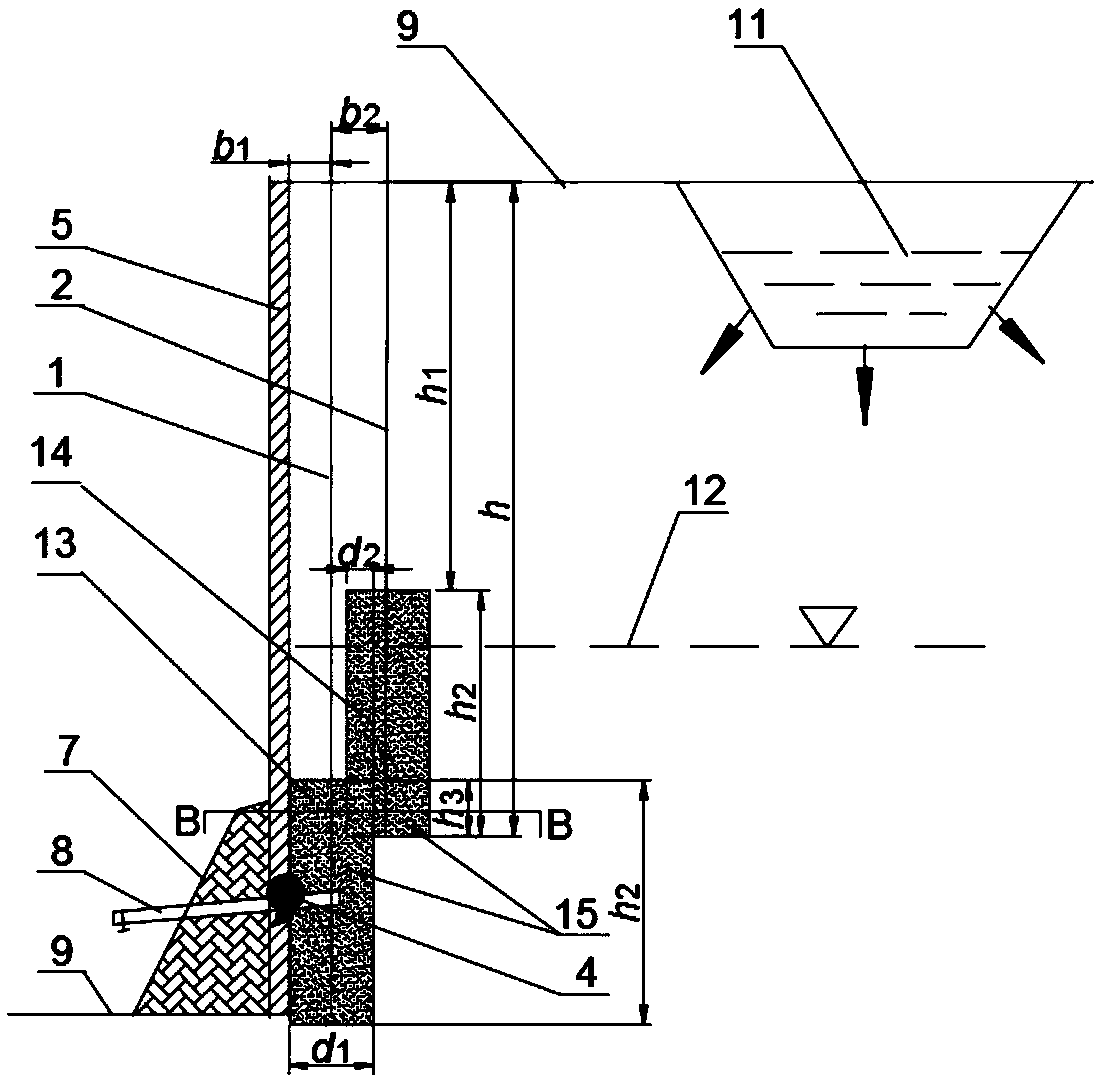

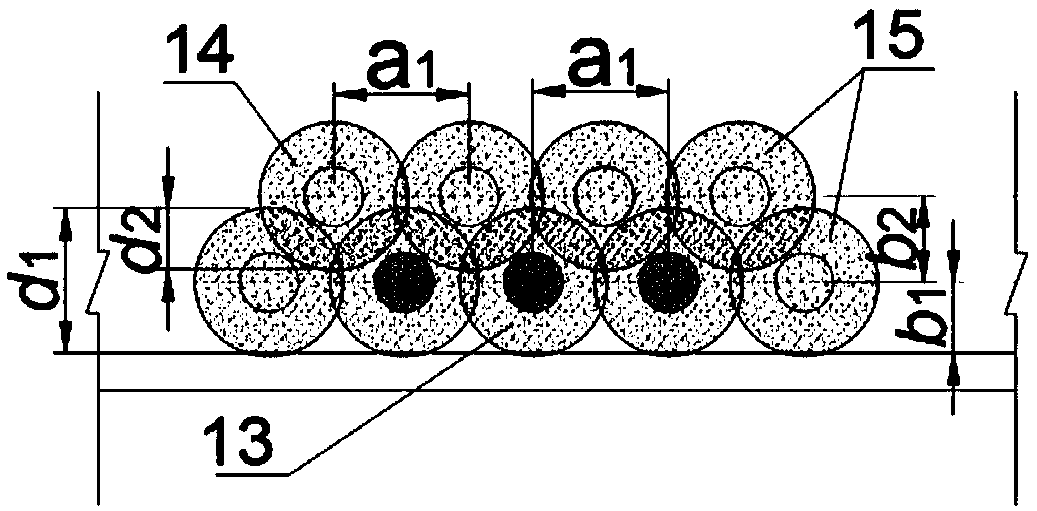

[0055] 1. Observation and calculation of water gushing volume and carried sediment volume. When strand-shaped water gushing appeared on the deep side wall of the foundation pit, a water accumulation pit was set up at the bottom of the foundation pit, and the pumping volume of the submersible pump was used to measure and calculate. According to the calculation, the water inflow on the side wall is about 16.7m 3 / h, the water volume remained stable during the 5 hours observed. And the water quality is mixed, the sediment content is about 13% (volume content). The water gushing point is located in the silt layer, and the bottom of the silt layer is clay layer. According to the analysis, the source of the gushing water is underground diving, but the possibility of replenishment by a river 200 meters away is not ruled out. The aqueduct is in the silt layer, and there is no possibility of downward transfer. The overlying rock layers on the silt layer are gravel layer, silt layer ...

Embodiment 2

[0071] On April 5, 2017, during the construction of the foundation pit of Hengdacheng Station of Jinan Metro Line R3, water gushed out suddenly at a depth of 13m from the south side wall of the foundation pit, and the water gushing volume was about 50-70m according to visual inspection 3 / h, after measurement, the water volume is 37m 3 / h, the amount of water did not change after 6 hours of observation. The water quality is black and contains silt, and the silt content is about 10-15%. Based on the analysis of the survey data, the possibility that the water source is the confined water in the gravel layer at a depth of 17m below the surface has been ruled out. After testing the water quality, the water quality was the same as that of the underground diving water, and the possibility of pipeline leakage was also ruled out. After investigation, it was found that the water source was the water in the ancient river channel buried underground, and the possibility that the supplem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com