Patents

Literature

65results about How to "Water balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

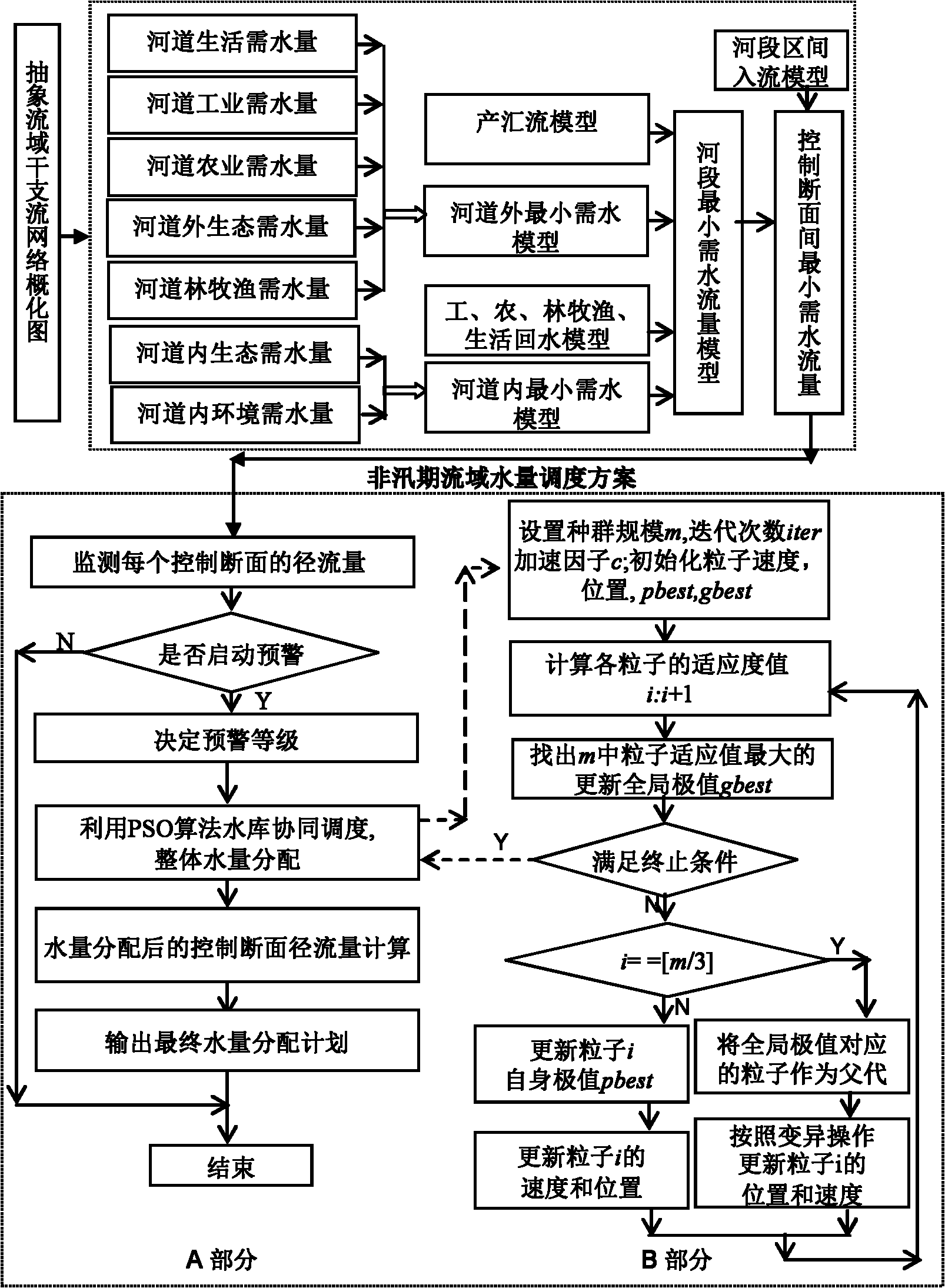

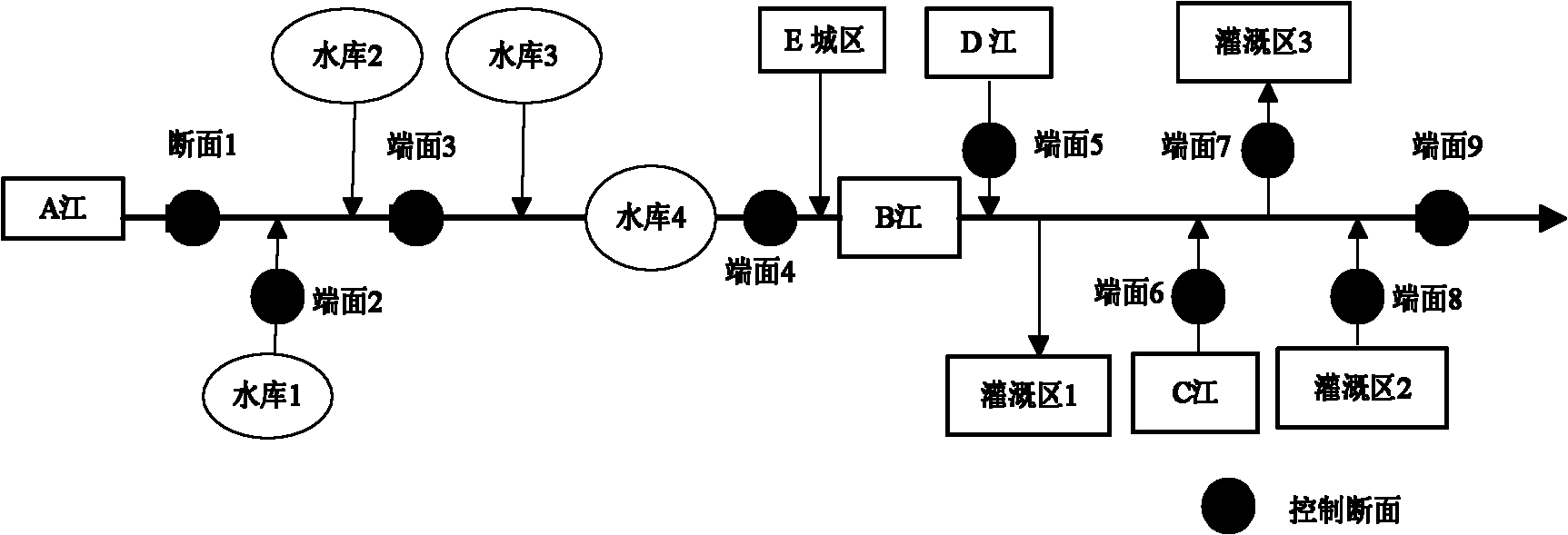

Method for cooperatively and optimally allocating water volume in non-flood season

InactiveCN102156914AWater balanceFull protectionData processing applicationsClimate change adaptationWater volumeStreamflow

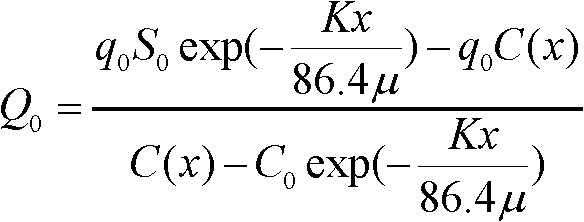

The invention relates to a method for cooperatively and optimally allocating the water volume in a non-flood season, which comprises the following steps of: firstly, obtaining the information of water consumption and water return of each aspect under the overall consideration including the aspects of ecology, livelihood, industry, agriculture, and the like of a river basin; secondly, determining and controlling the minimum water demand of a section by calculating the runoff of a river course, the water demand outside the river course and the lowest water demand in the river course; monitoring the water volume of the river course of the river basin at real time, and automatically outputting water shortage prewarning degrees when the flowrate of the control section is lower than the minimum water demand flowrate; and finally, dynamically and integrally adjusting and controlling groups of reservoirs through cooperative particle swarm intelligent optimization algorithms under different prewarning degrees, so as to achieve the functions of unified water allocation. The method thoroughly takes the water consumption of the ecology, the livelihood, the industry and the agriculture into consideration, and ensures the balanced water consumption of water-consuming aspects in the river basin according to the principle of firstly ensuring the livelihood and then meeting the requirements of the agriculture and the industry.

Owner:DONGHUA UNIV

Skin antibacterial agent and preparation method thereof

InactiveCN102552650AImprove the bactericidal effectPurification bactericidal spectrumPeptide/protein ingredientsAntisepticsDistilled waterMugwort

The invention relates to a skin antibacterial agent and a preparation method thereof. The skin antibacterial agent comprises components such as ginkgo leaf juice, white chrysanthemum juice, eggplant root juice, kudzuvine root juice, mugwort leaf juice, portulaca oleracea juice, fistular onion stalk juice, distilled water and the like. The preparation method for the skin antibacterial agent comprises the following steps of: mixing the ginkgo leaf juice, the white chrysanthemum juice, the eggplant root juice, the kudzuvine root juice, the mugwort leaf juice, the portulaca oleracea juice, the fistular onion stalk juice and the distilled water, stirring uniformly, heating for 6 to 8 hours at the temperature of 65 to 70 DEG C, adding an auxiliary raw material into the mixed solution to ensure that the mixed solution is subjected to catalytic reaction, and thus obtaining the skin antibacterial agent, wherein a biological monitor in a catalytic reaction device is used for automatically tracking and testing in the process of the catalytic reaction. The invention has the advantages that: the skin antibacterial agent has wide sterilization spectrum, is low in effective concentration, quick in response and stable in performance, greatly improves healing degree of wounds and relieves pain of patients in the process of changing and applying medicines; and in addition, the preparation method for the skin antibacterial agent is simple and convenient to operate.

Owner:侯悦倪

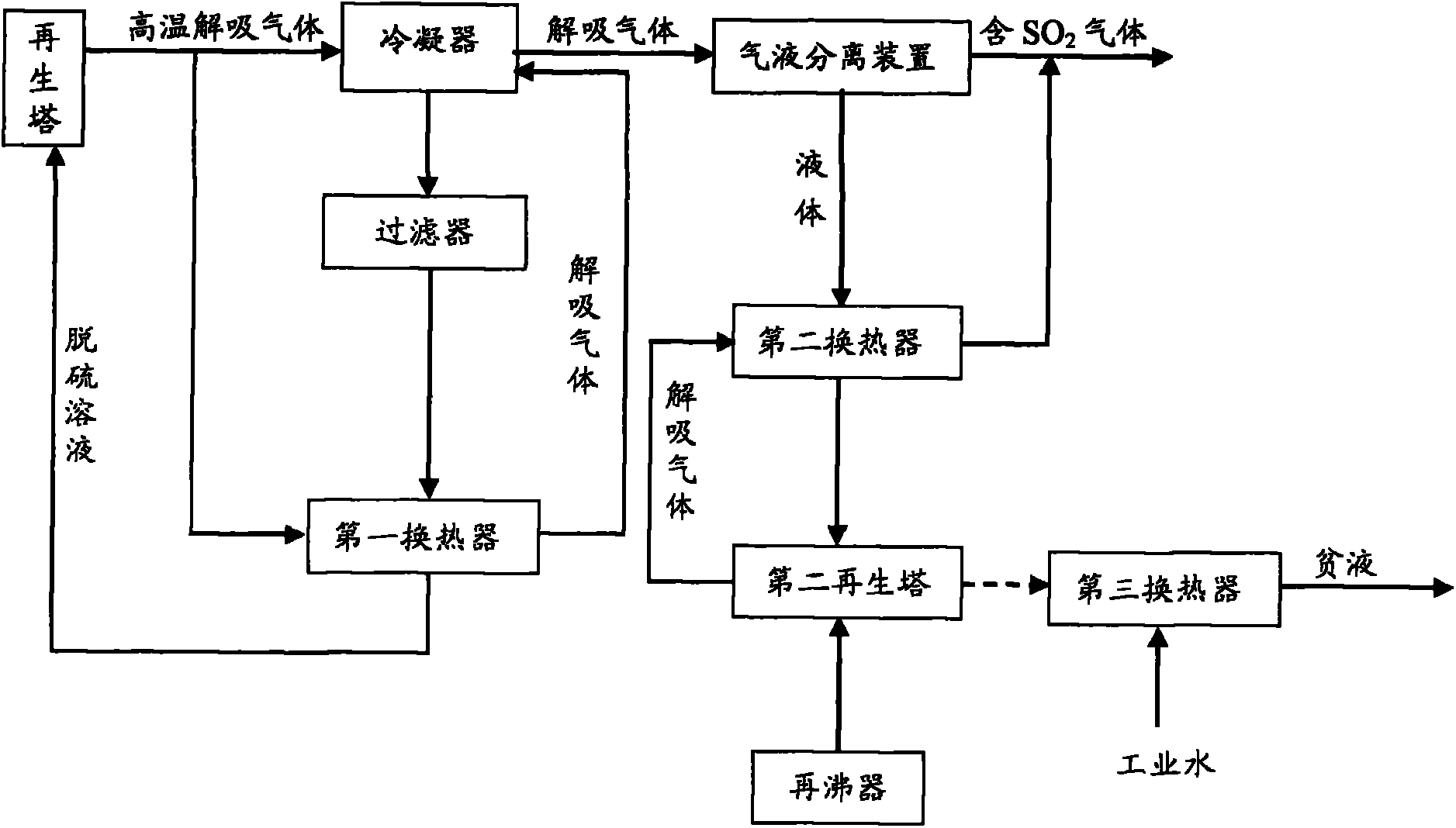

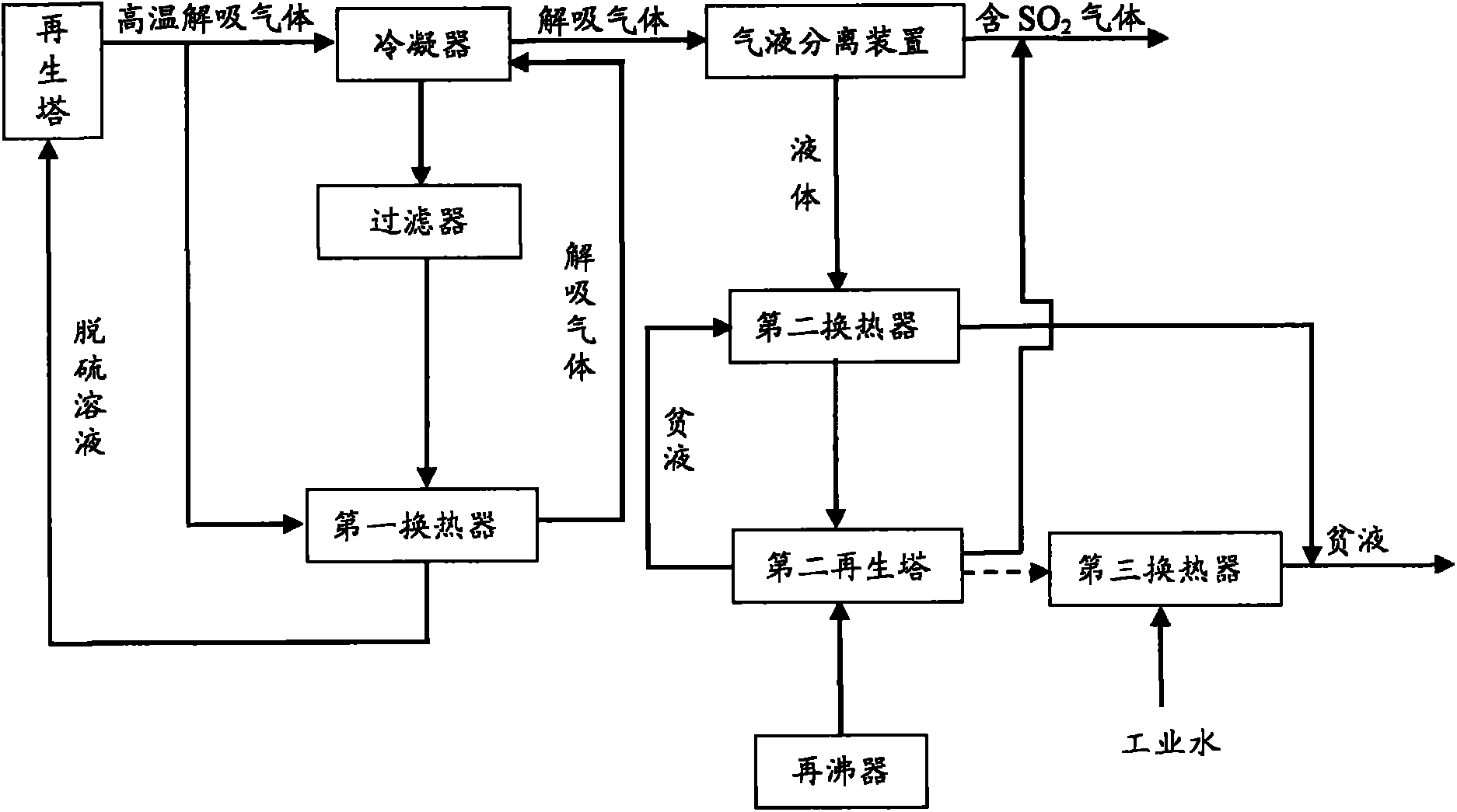

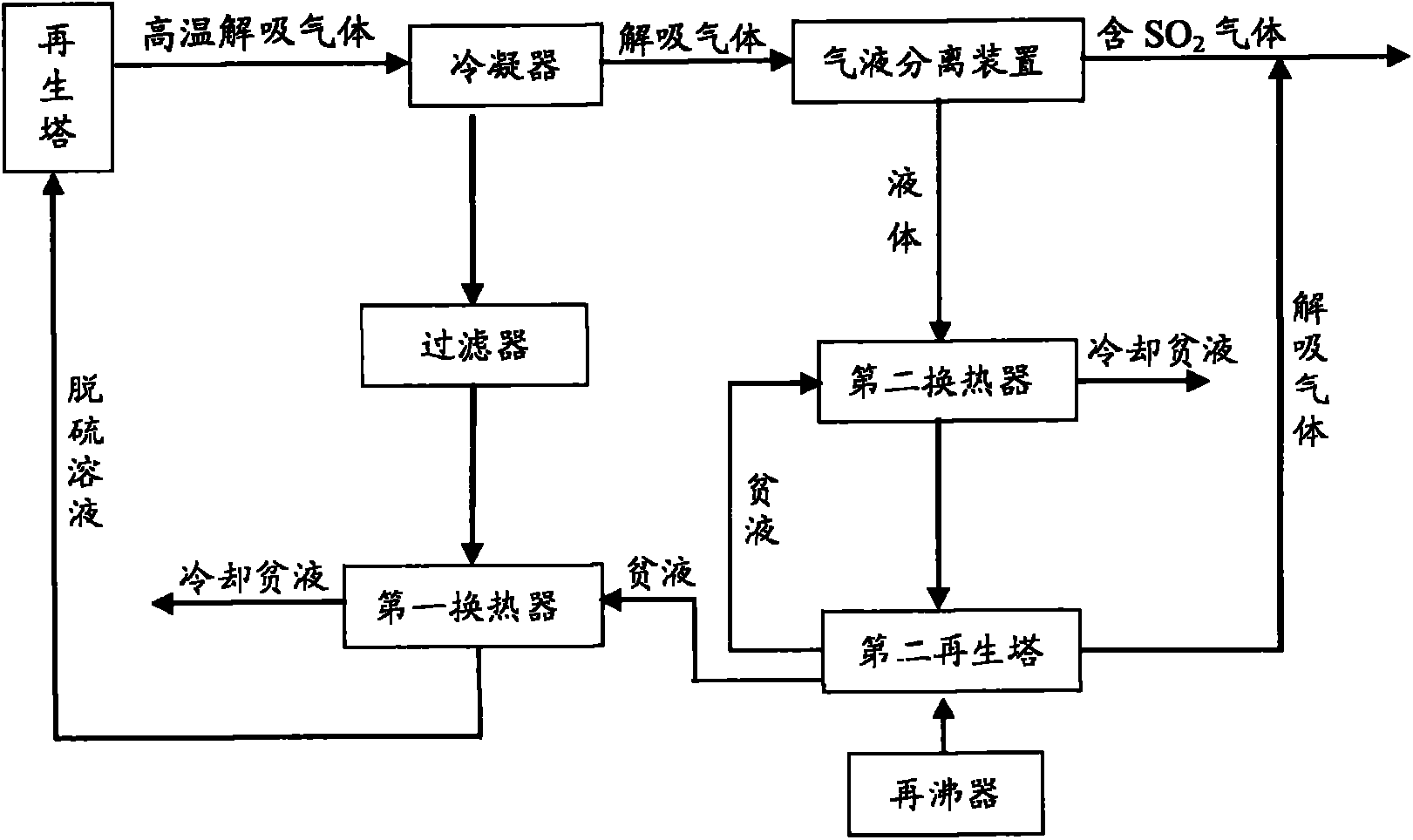

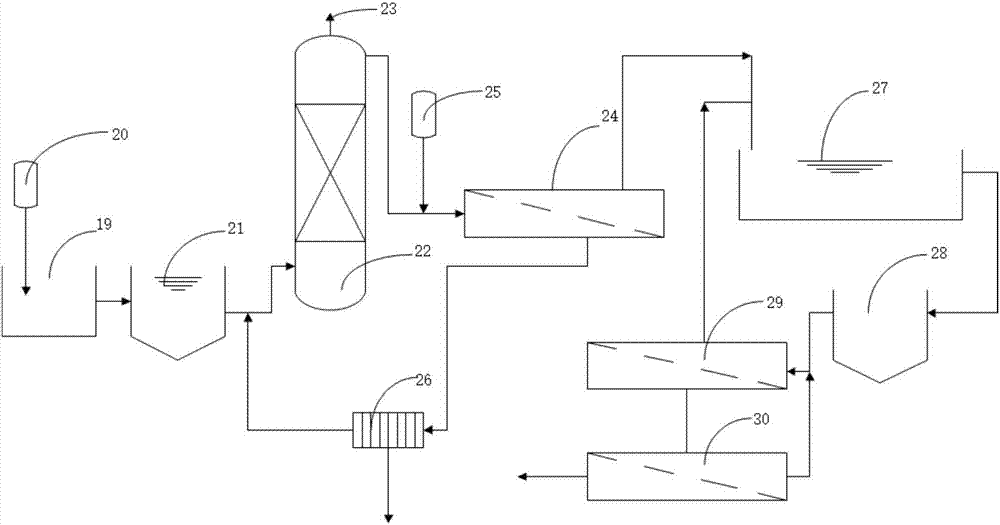

Method for dewatering desorption gas for flue gas desulfurization and recycling condensate

The invention provides a method for dewatering desorption gas for flue gas desulfurization and recycling condensate. The method comprises the following steps: supplying the desorption gas desorbed from a regeneration tower to a condenser for multistage condensation so as to generate the condensate containing a desulfurizer, water and impurities and the desorption gas containing water vapor, sulfur dioxide gas and a desulfurizer; supplying the condensate to a filter for filtration so as to remove the impurities, thus obtaining a desulfurization solution containing the desulfurizer and the water; carrying out heat exchange on the desulfurization solution in a heat exchanger, and then returning the heated desulfurization solution to the regeneration tower; and supplying the generated desorption gas to a gas-liquid separator for gas-liquid separation so as to generate a liquid and gas containing sulfur dioxide. The process provided by the invention has the beneficial effects of effectively maintaining water quantity balance of a desulfurization system, maximally lowering the loss of sulfur dioxide and further reducing the energy consumption of a desorption system.

Owner:PANZHIHUA IRON AND STEEL +2

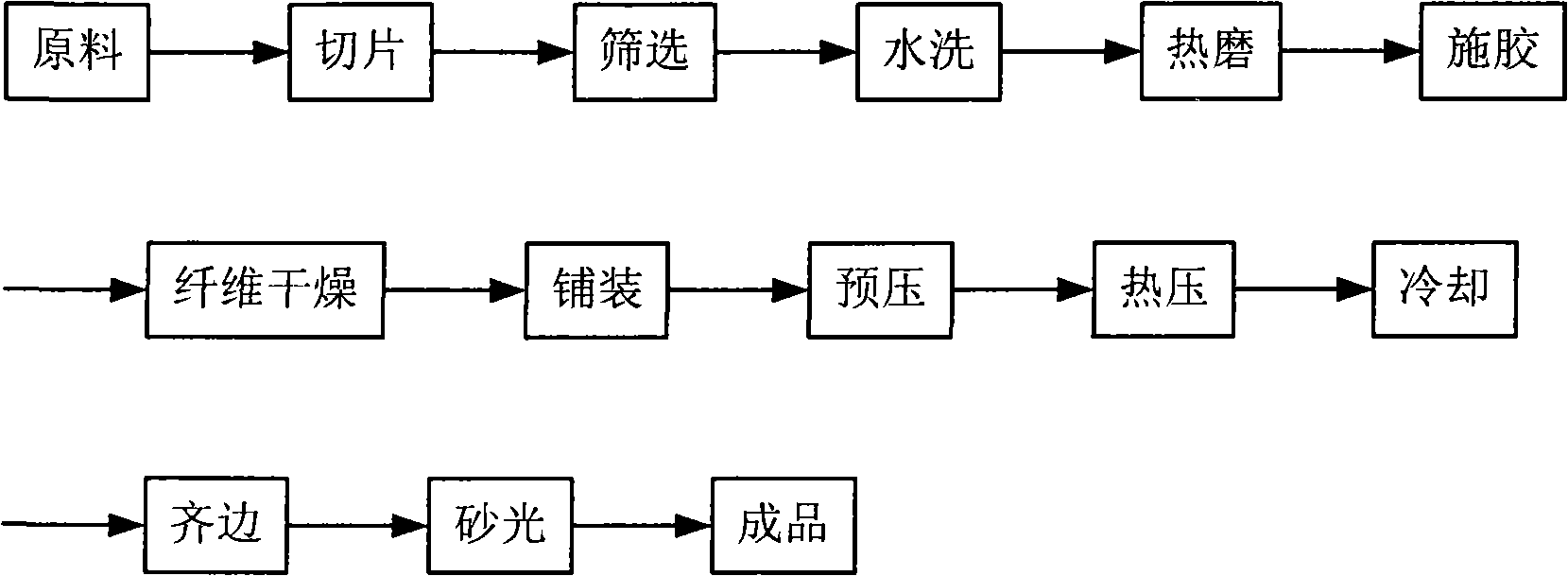

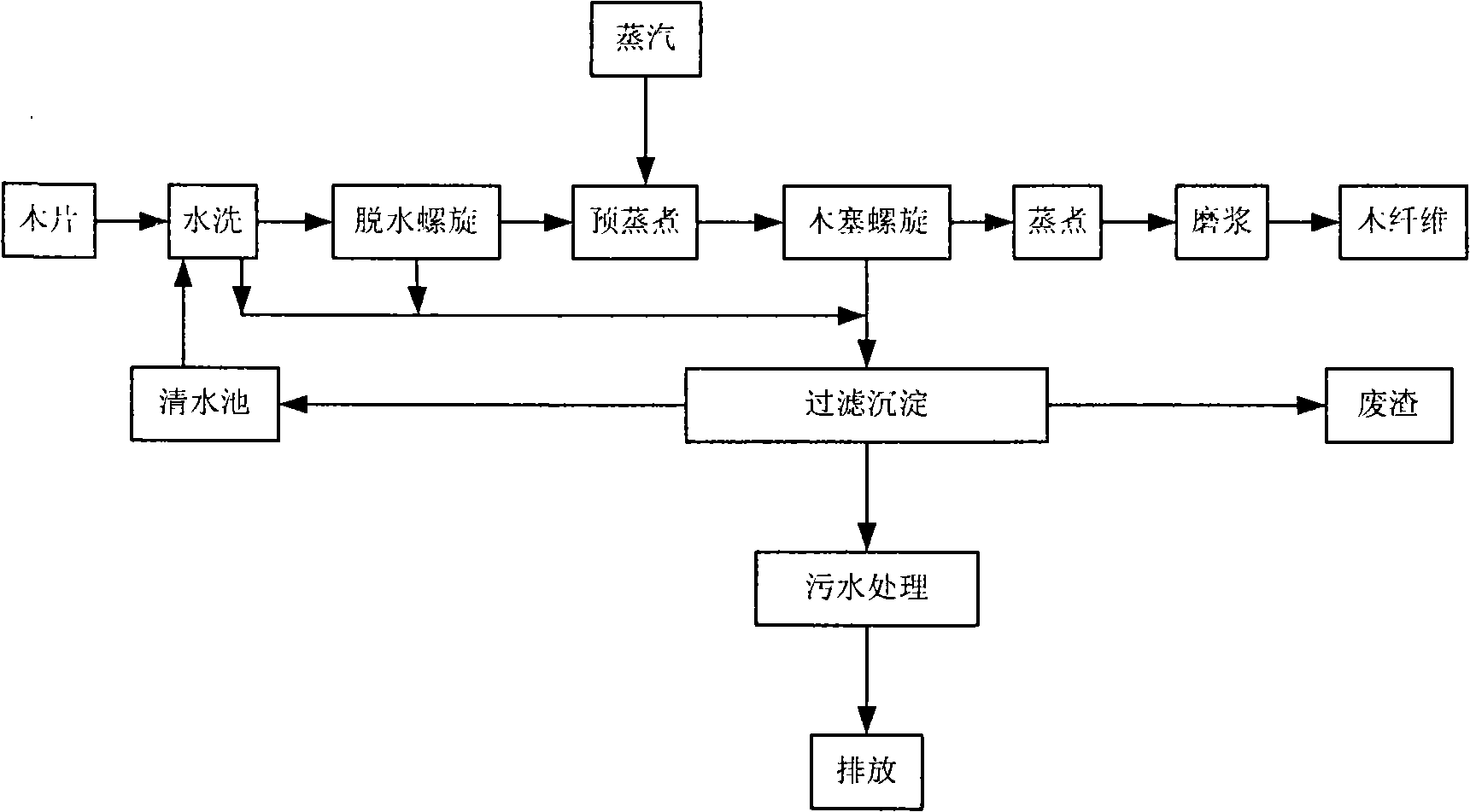

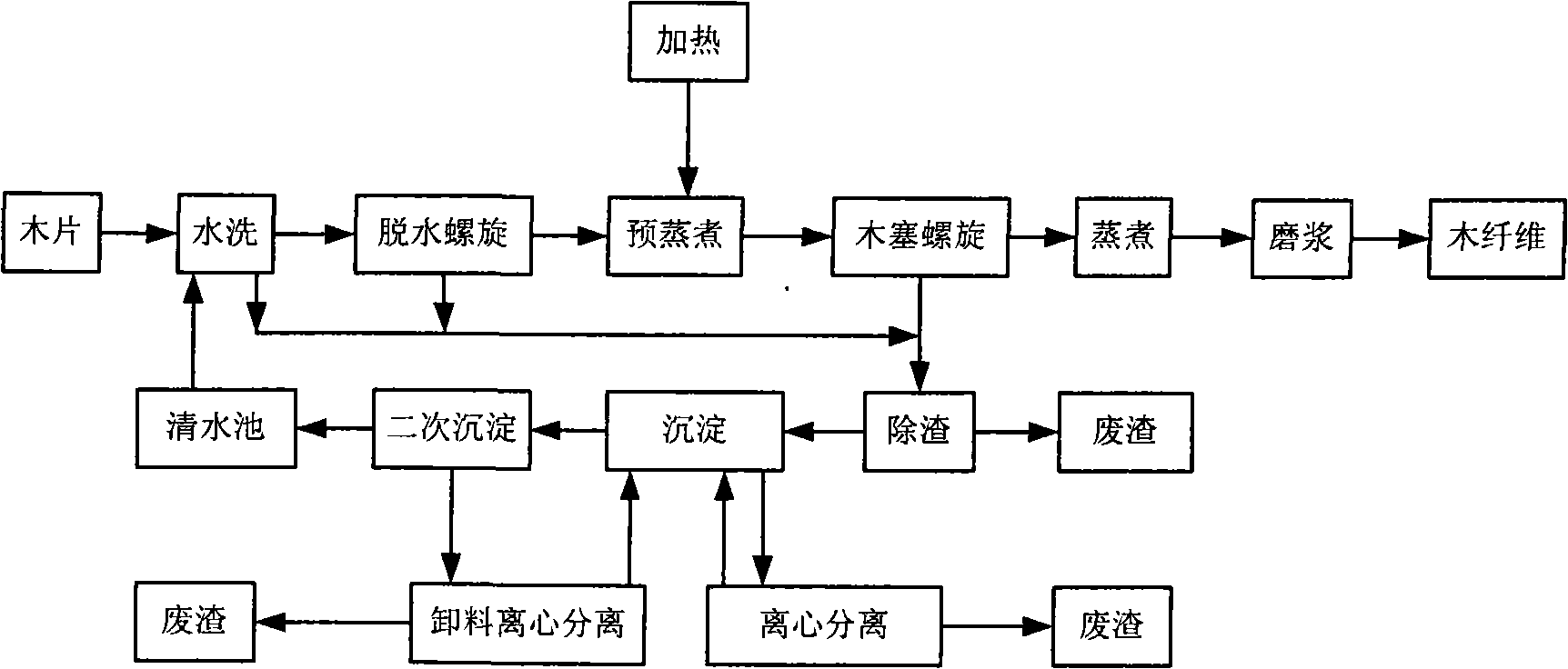

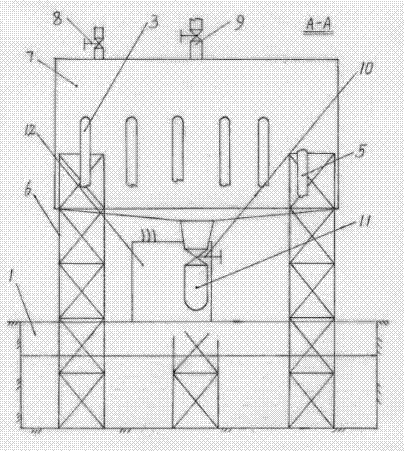

Medium-density fiberboard production waste drainage closed cycle loop back technique

InactiveCN101284393ARealize fully closed cycle reuseWater balancePulp liquor regenerationDigestersWater treatment systemMedium density

The invention discloses a fully enclosed recycle and reuse technique for the waste water in producing medium density fiberboards. In the prior production process, the waste water generated between water washing and hot grinding is collected and undergoes solid-liquid separation, the solid waste is discharged into a slag yard and the waste water after separation is led into a clean water tank for reuse. The invention is characterized in that a heating used heating agent carries out heat change heating to the material in an indirect heating manner in a pre-stewing step. As the heating used heating agent is not directly contacted with the material, no redundant condensed water is generated in the pre-stewing step, the quantity of water is balanced, all the waste water is reused, no redundant water is discharged, and no system for treating biochemical sewage is needed for realizing the totally enclosed recycle and reuse of the waste water in producing the medium density fiberboards. The totally enclosed recycle and reuse technique has the advantages of saving investment, saving water, saving energy, simple structure and feasibleness.

Owner:杨明杰 +2

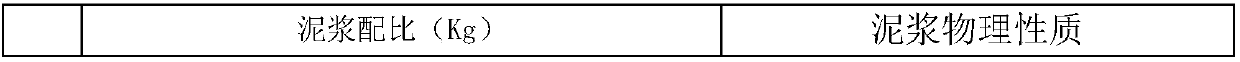

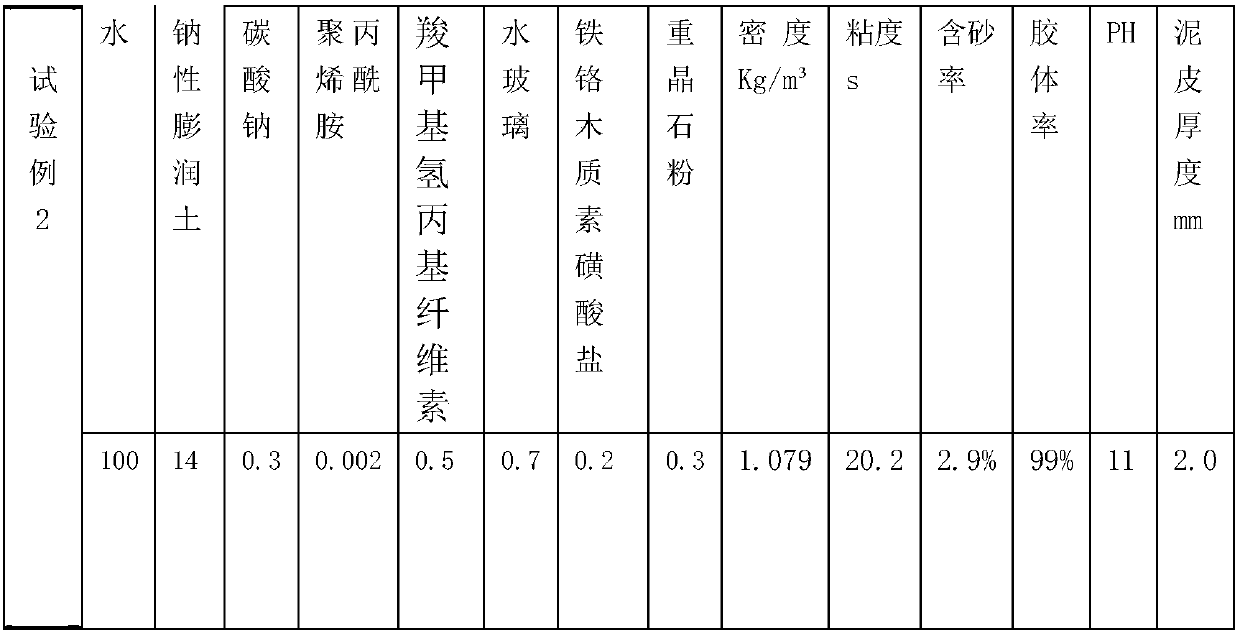

Alluvial plain karst developing district drilling pile formation wall protection mud and preparation method thereof

InactiveCN107739597AReduce construction riskMake up for technical defects in drillingDrilling compositionSodium BentoniteKarst

The invention discloses alluvial plain karst developing district drilling pile formation wall protection mud which is prepared from the components in parts by mass: 100 parts of water, 6-10 parts of clay, 5-14 parts of sodium bentonite, 0.2-0.3 part of sodium carbonate, 0.002-0.005 part of polyacrylamide, 0.5-0.6 part of carboxymethyl hydroxypropyl cellulose, 0.6-0.9 part of water glass, 0.1-0.3 part of ferric chromium lignin sulfonate, 0.1-0.3 part of barite powder and 0.25-0.5 part of potassium humate. The mud prepared by the invention is suitable for an alluvial plain karst developing district drilling pile formation technology and lowers the probability of occurrence of safety accidents of drilling pile formation. A result of interaction of the mud and a stratum is changed by changingthe performance index of the mud, so that the safety coefficient of construction is increased, and the technical defect of drilling a complex strata is made up.

Owner:SHENYANG POLYTECHNIC UNIV

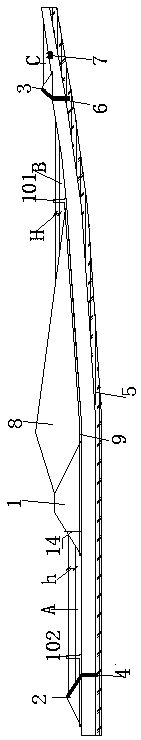

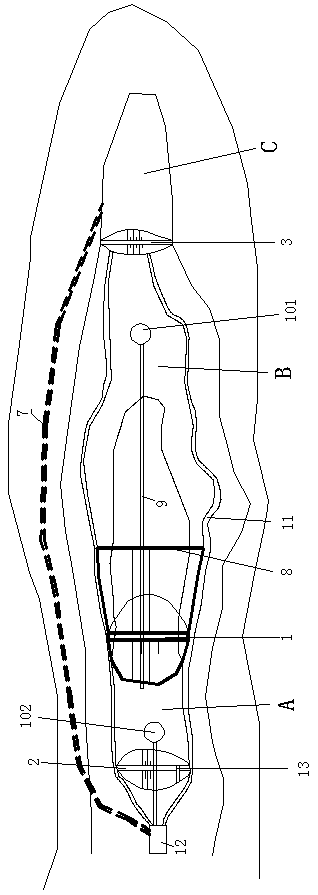

Zero-emission tailings pond system and implementation method thereof

ActiveCN108374384ARealize cleaning and diversionAchieving zero emissionsBarrages/weirsDamsTailings damWastewater

The invention discloses a zero-emission tailings pond system and an implementation method thereof, belongs to the field of tailings pond environment protection, and aims to solve the problems that rainwater in a wet-discharge tailings pond is hard to discharge, and complete wastewater cleaning and distributing cannot be achieved. The zero-emission tailings pond system comprises a seepage interception dam, a flood interception dam, flood interception channels and drainage wells, wherein the seepage interception dam is arranged below a tailings dam, the flood interception dam is arranged at theupstream of a tailings accumulation body, the flood interception channels are arranged between the seepage interception dam and the flood interception dam and on two sides of the tailings accumulationbody and the tailings dam, and one drainage well is arranged at the downstream of each of the flood interception dam and the tailings dam. The zero-emission tailings pond system has the advantages that a complete anti-seepage layer is formed in a tailings pond through the anti-seepage technology, tailing pond wastewater is collected and recycled at the seepage interception dam and prevented frompolluting underground water, flood outside the tailings pond is intercepted by the flood interception dam and the slope convergence flood interception channels and discharged, complete wastewater cleaning and distributing is achieved, rainfall in the tailings pond is stored in the tailings pond, and zero wastewater emission is achieved by using a regulating system in the tailings pond.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

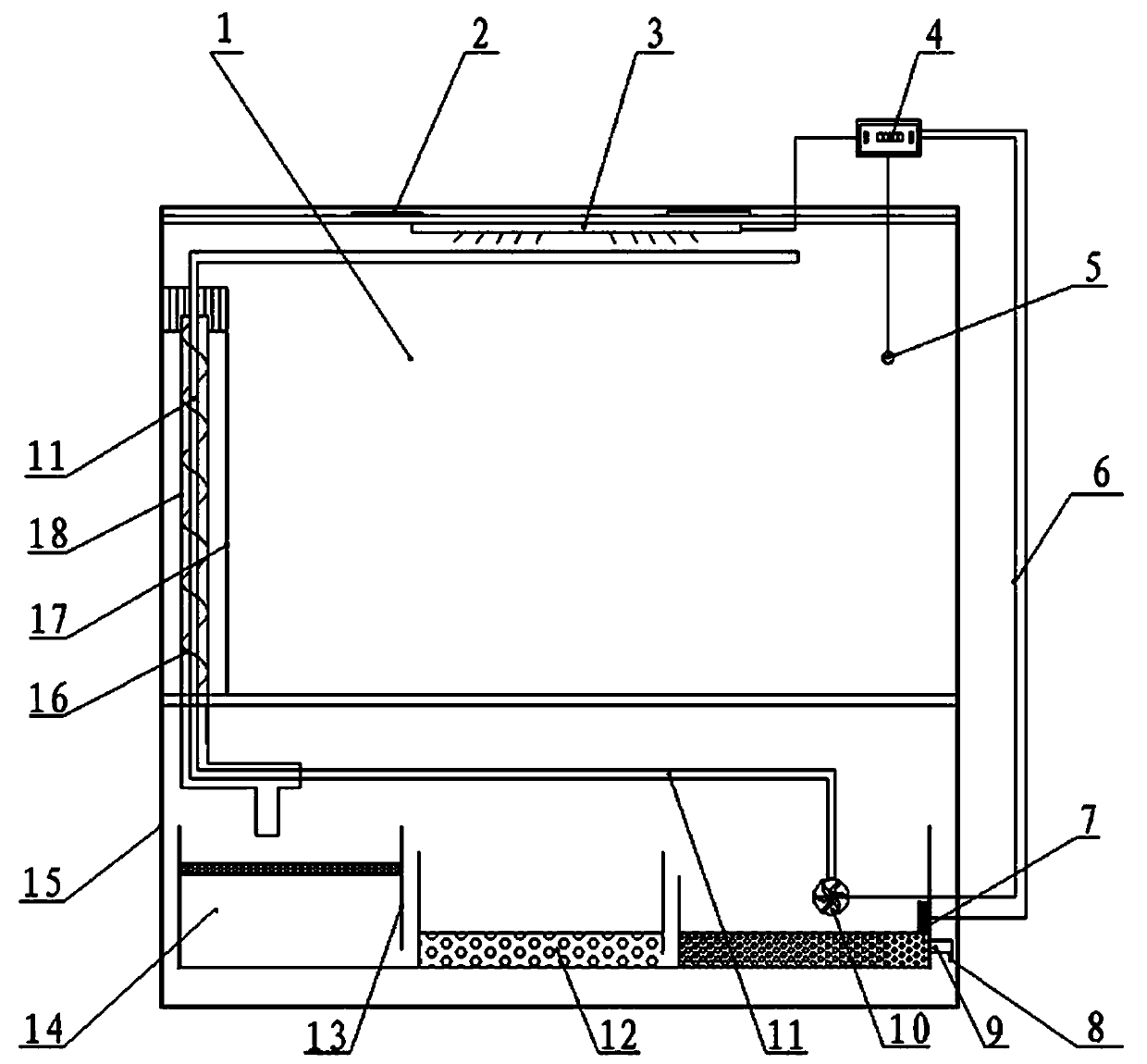

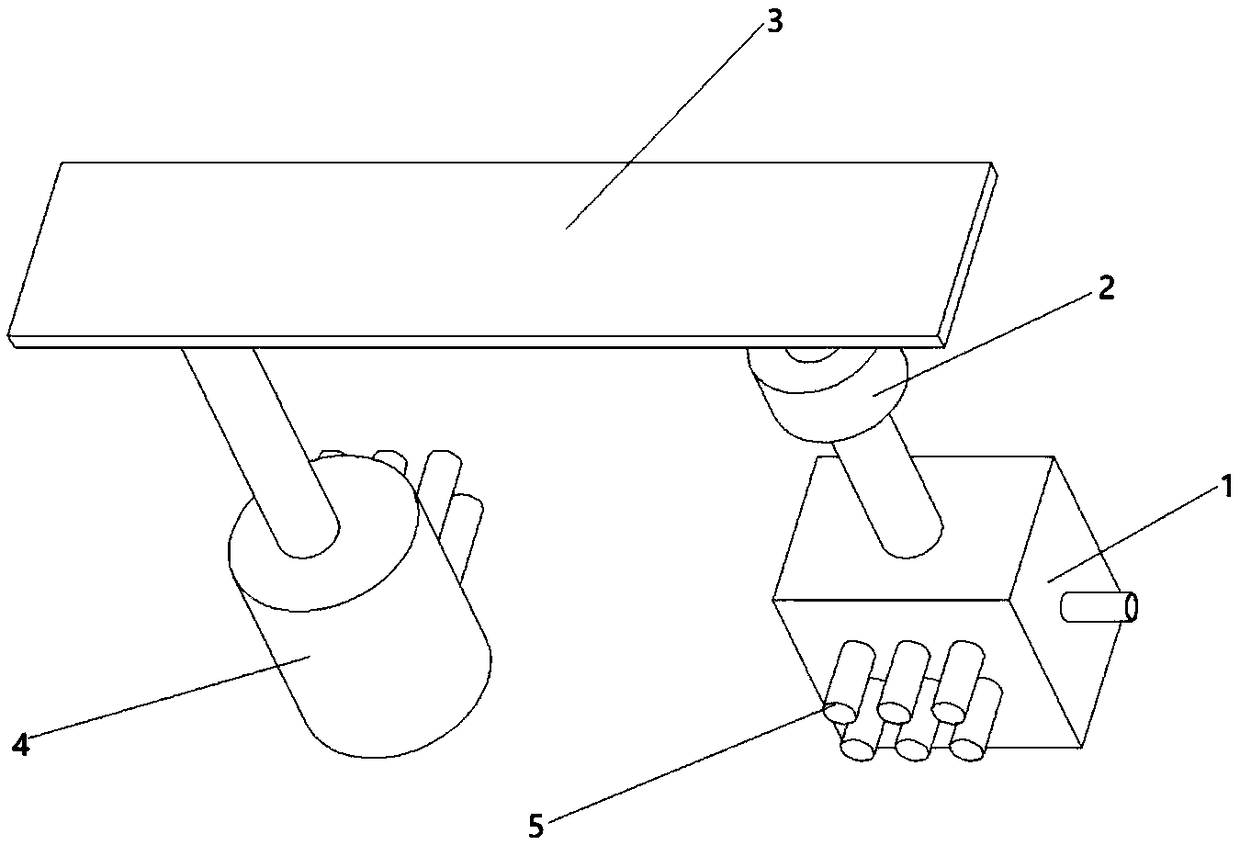

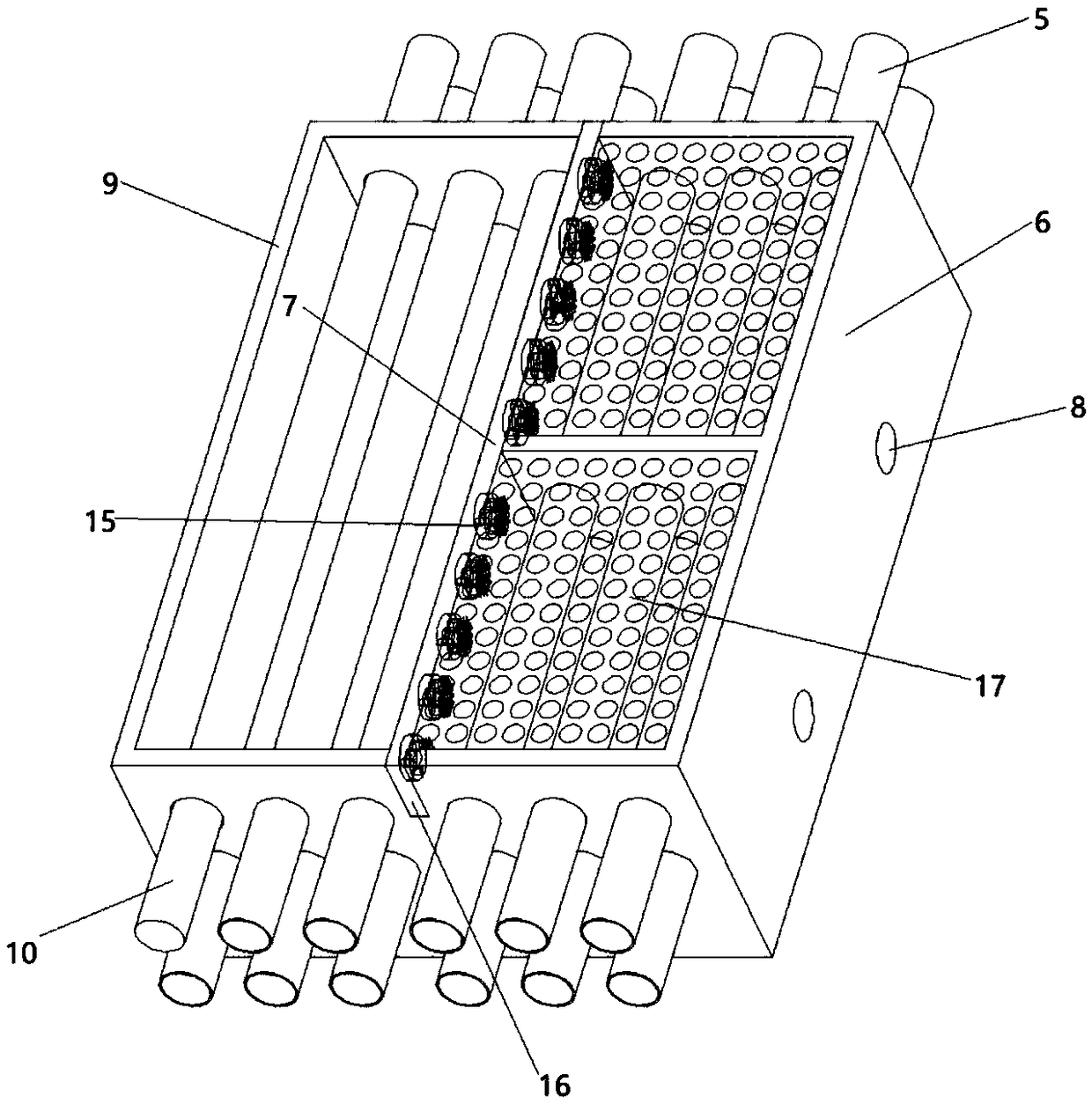

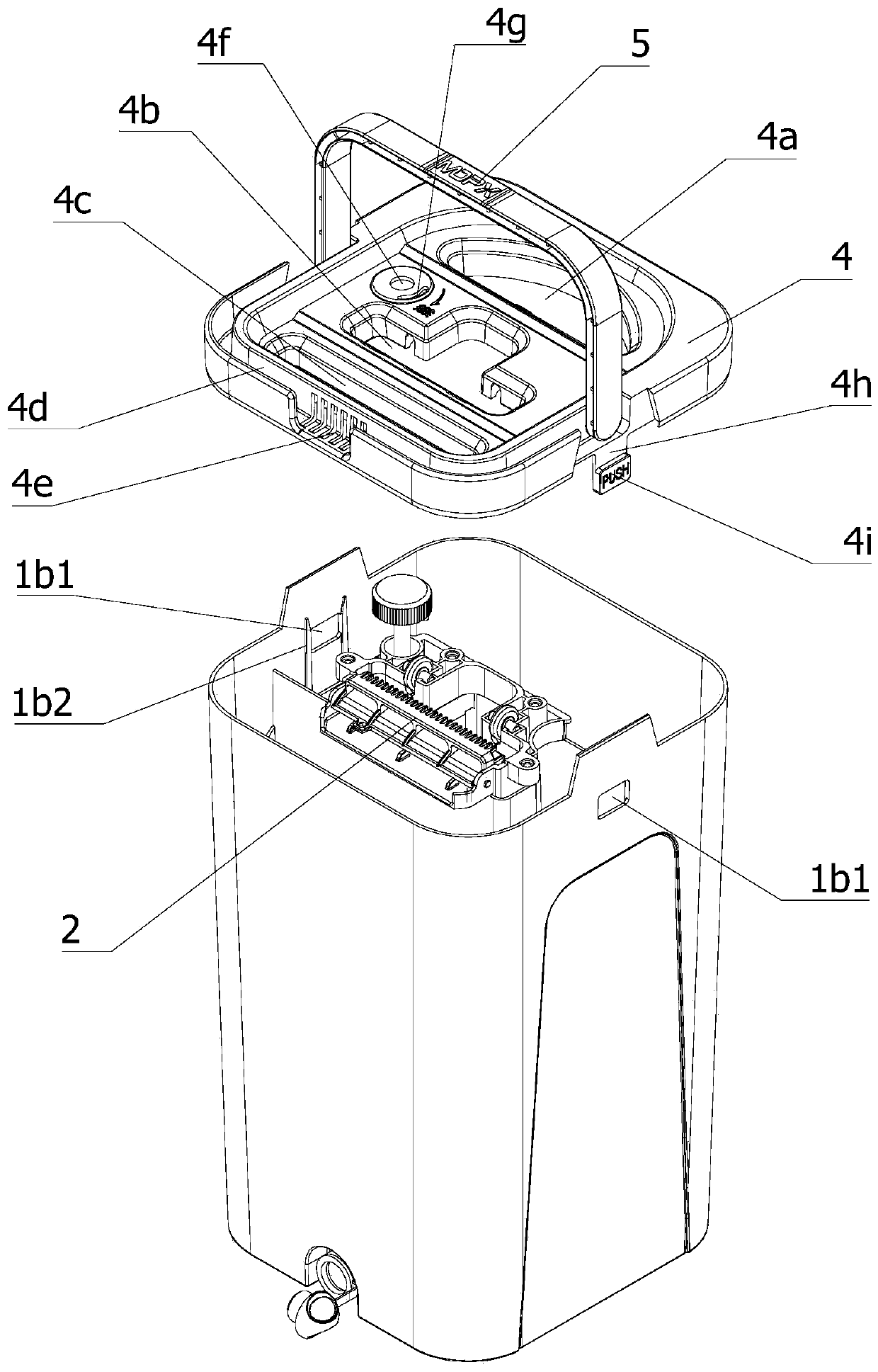

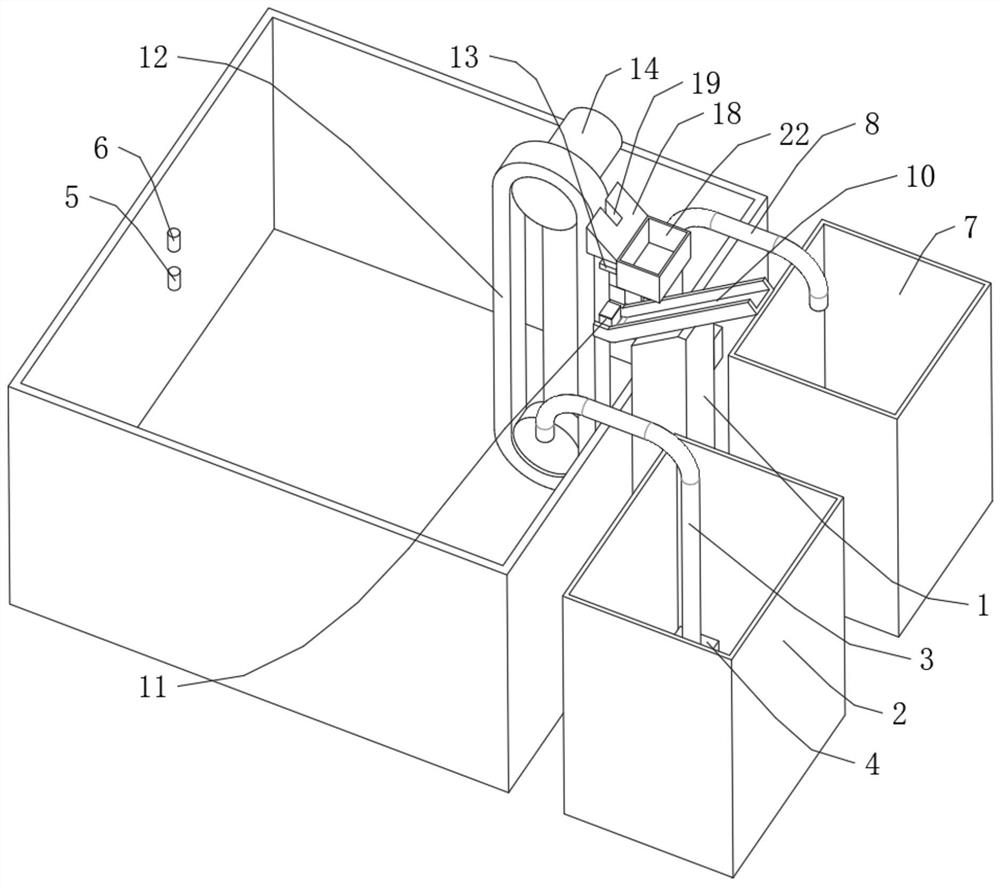

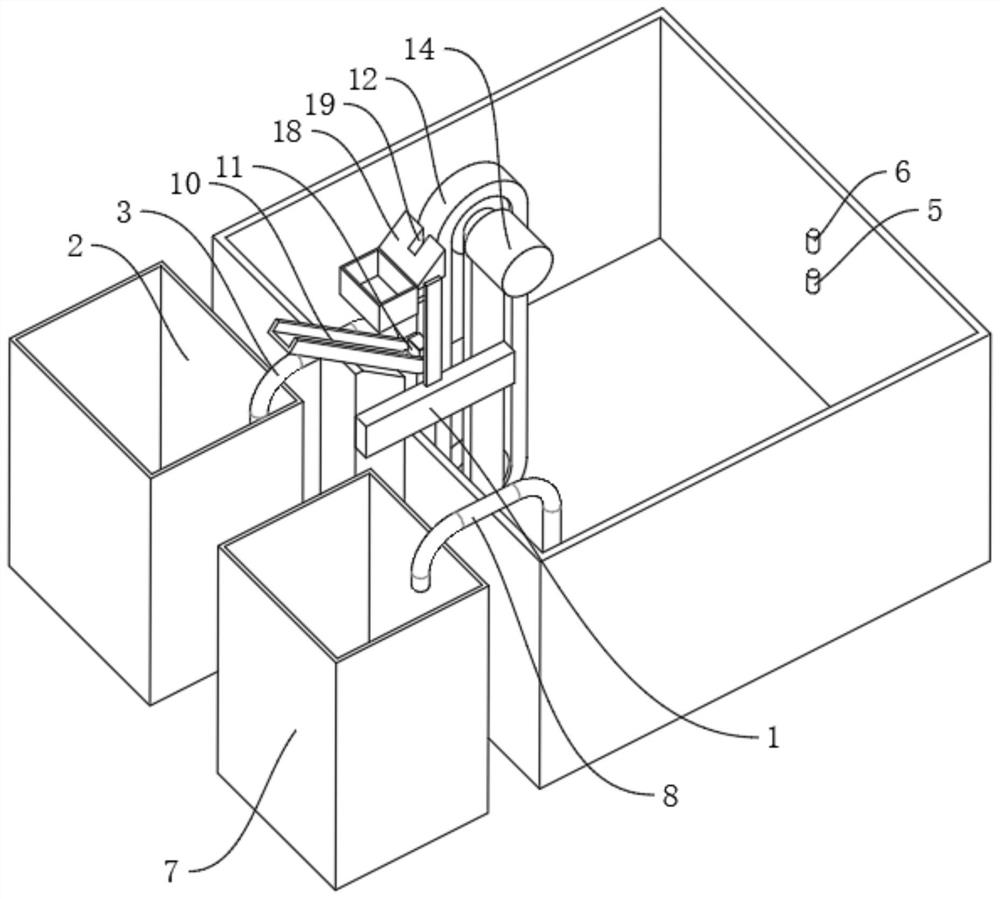

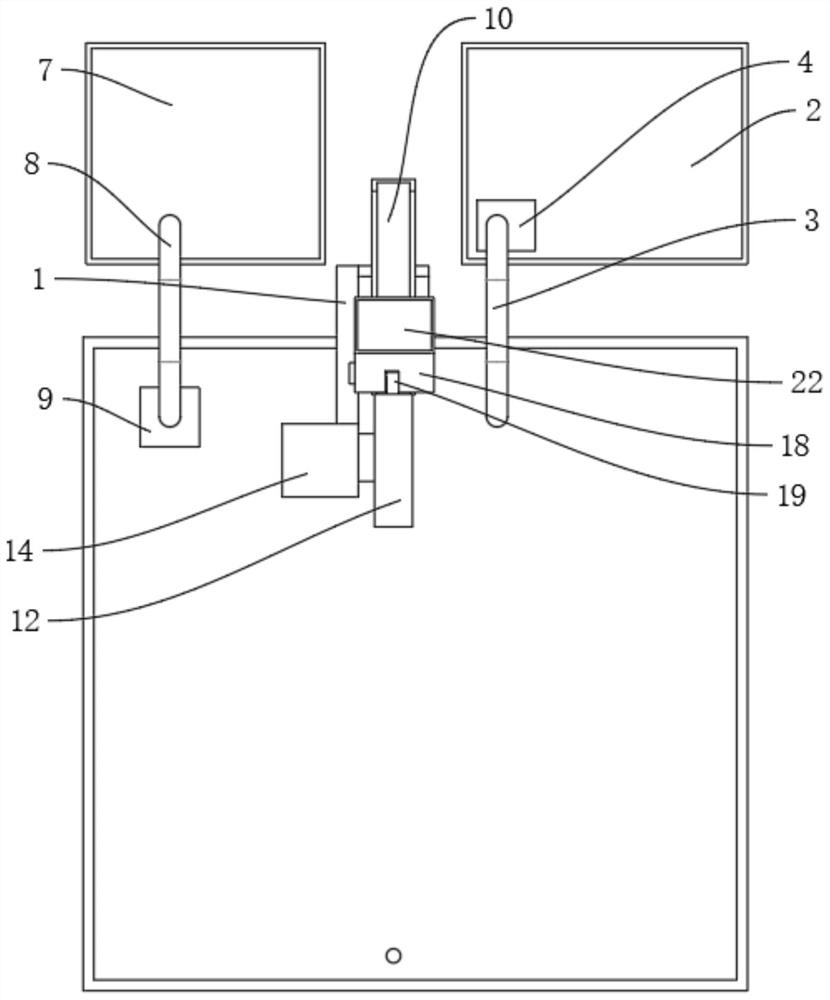

Ecological ornamental fish tank

The invention provides an ecological ornamental fish tank which is simple in structure and simple to operate, and solves the problem that an existing ecological ornamental fish tank is complex in water exchange and cleaning. The fish tank comprises a water box, a supporting bottom cabinet, auxiliary functional parts and a controller, wherein a filtering device is arranged in the bottom cabinet, the side portion of the water box is provided with three overflow pipes which include a water outlet pipe, a water inlet pipe and an anti-overflow pipe from inside to outside, the anti-overflow pipe is attached to the side wall of a tank body in an adhesive mode through a fixing edge vertical to the outer edge of the anti-overflow pipe, a spiral flow guide piece is disposed between the water outlet pipe and the water inlet pipe, the outer edge of the water outlet pipe is sleeved with the spiral flow guide piece, a submersible pump is arranged in the filtering device, the submersible pump is connected with the tail end of the water inlet pipe, the auxiliary functional parts comprise an illumination lamp, a temperature sensor, a control panel, an electric heating bar and an ultraviolet sterilization lamp, the control panel is provided with a temperature displayer and a parameter control key, control parameter data of the control panel are integrated on the controller, and the auxiliary functional parts are connected with functional modules corresponding to the controller through wires.

Owner:滨州鲲鹏工贸有限公司

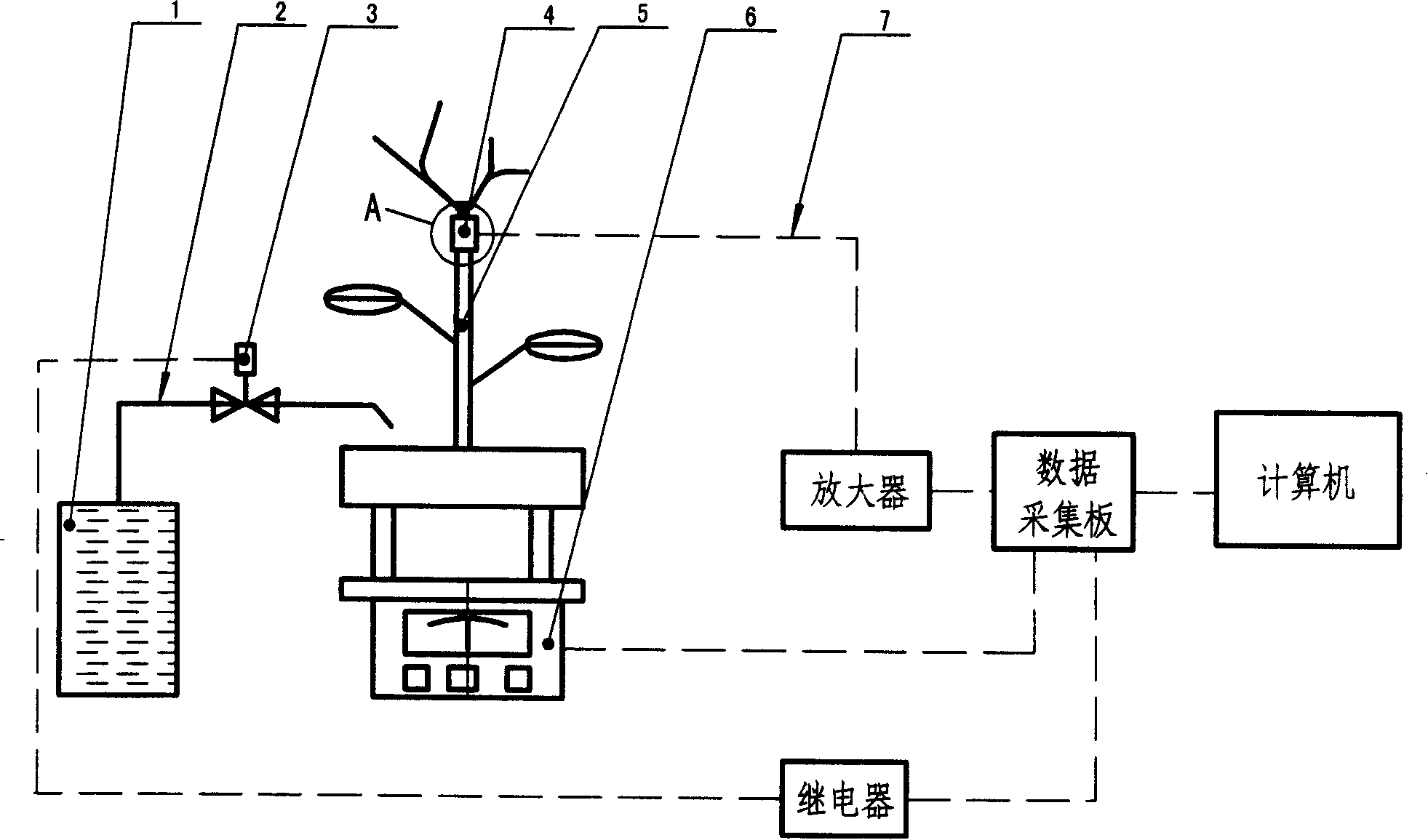

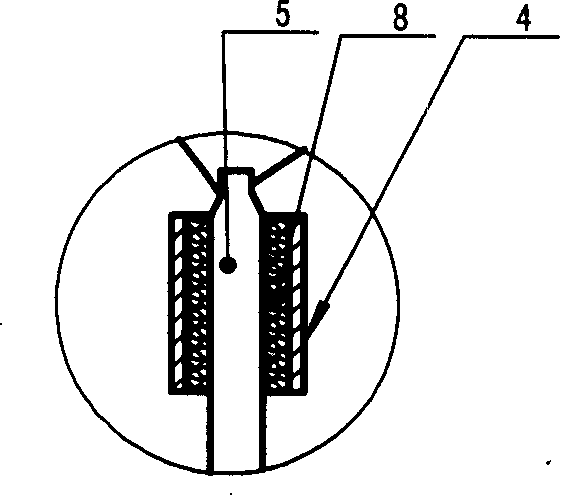

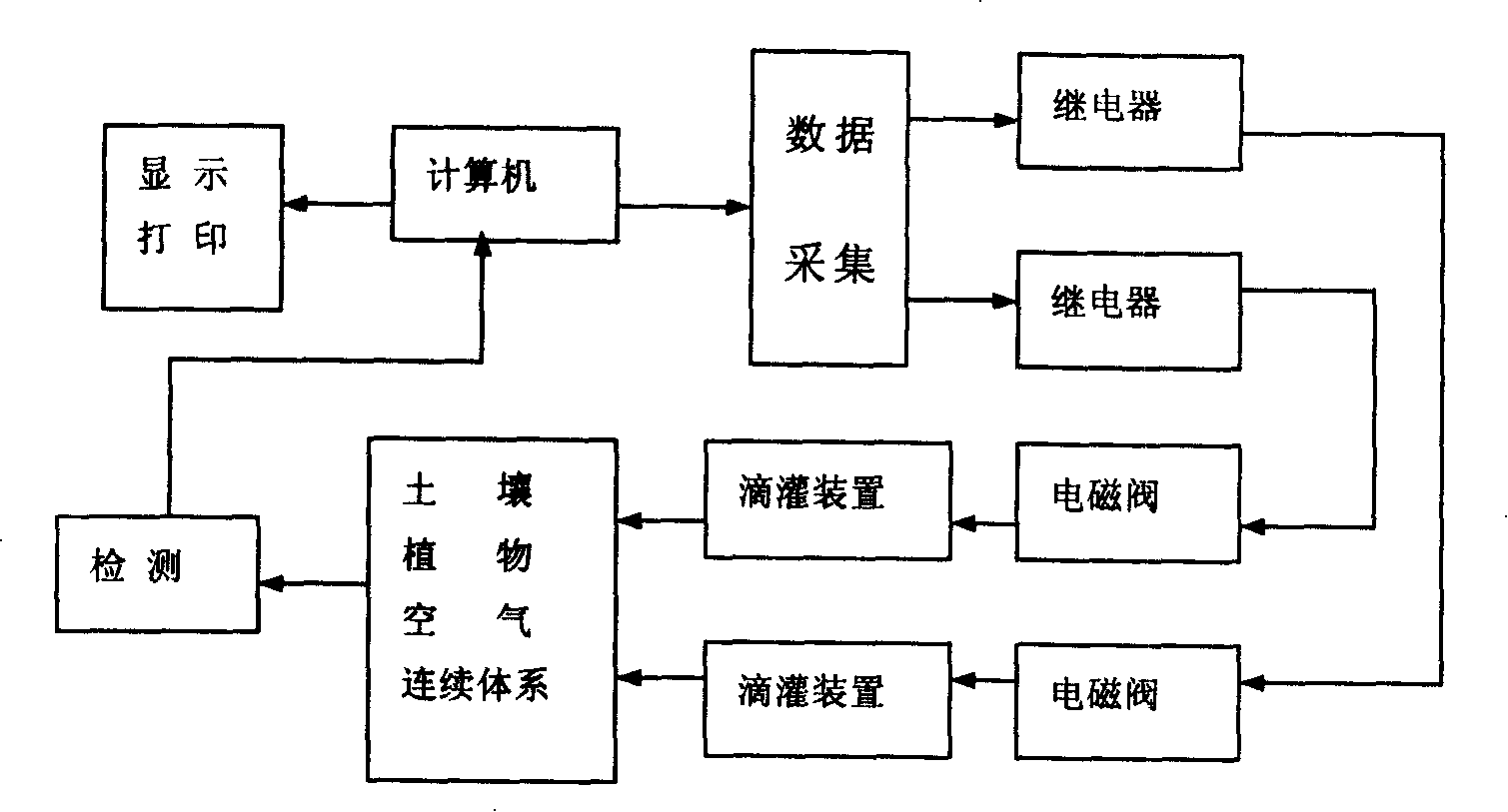

Vision irrigation system for detecting emission character based on crop water duress sound

InactiveCN101176419AWon't hurtImprove test accuracyClimate change adaptationWatering devicesAutomatic controlData acquisition

The invention relates to a condition irrigation system that detects by water stress acoustic emission characteristics of crops, which is mainly characterized in that an acoustic emission sensor is arranged on the main diameter of the crop plant on an electronic balance; the acoustic emission sensor is successively connected with a signal conditioner, a PCI data acquisition card and a computer system; the electronic balance is connected with a computer by a PCI control bus, and the condition irrigation system of crop is automatically controlled by the computer. The invention has the advantages that intelligent condition precision sprinkling irrigation and drip irrigation are implemented according to the woe signals and the transpiration changing signals emitted by the crop experiencing water stress; meanwhile according to various soil moisture needed by the crop in different growth periods, the water supply efficiency and the water supply time of the crop is determined and properly adjusted by a computer software; appropriate soil moisture for the growth of crop is guaranteed, and the objective of water saving is achieved; thus the growth of crop under best soil water condition is effectively ensured.

Owner:TIANJIN UNIV OF SCI & TECH

Closed cycle preparation new process of zinc sulfate and zinc oxide

ActiveCN106745195AImprove abilitiesComprehensive utilization of resources is highZinc sulatesZinc oxides/hydroxidesWaste treatmentSodium sulfate

The invention discloses a closed cycle preparation new process of zinc sulfate and zinc oxide, and belongs to the field of chemical engineering. The new process comprise a liquid preparing system procedure, a product preparation system procedure and a waste liquid treatment system procedure, wherein the liquid preparing system procedure is composed of the procedures of medium-acid leaching, oxidation for iron removal and oxidation for manganese removal of leaching agent, and replacement for impurity removal; the product preparation system procedure is composed of a preparation subsystem of zinc sulfate and a preparation subsystem of zinc oxide; the waste liquid treatment system procedure is composed of treatment procedures of generated waste liquid such as zinc sulfate separated mother liquid produced in the preparation sub-system of the zinc sulfate, an ammonium sulfate or sodium sulfate solution and basic zinc carbonate cleaning liquid produced in the preparation sub-system of the zinc oxide. The original production lines of singly producing the zinc sulfate and the zinc oxide are integrated and transformed into a closed cycle production system, the wastewater zero discharge is realized, the vicious circle of pollution-treatment-secondary pollution is avoided; the production of three-waste is controlled from the source so as to prevent the environment pollution, and the production cost is lowered, and the economic benefit is improved.

Owner:宁夏京成天宝科技有限公司

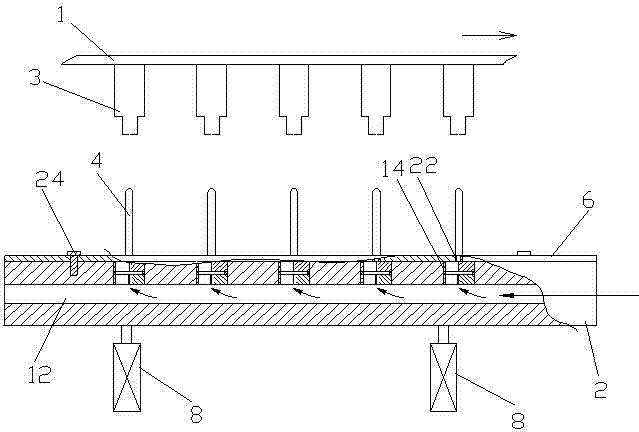

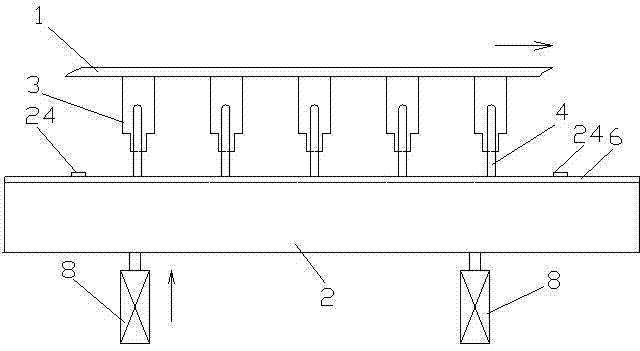

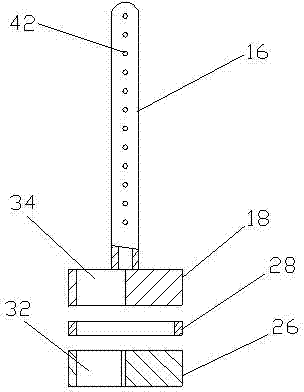

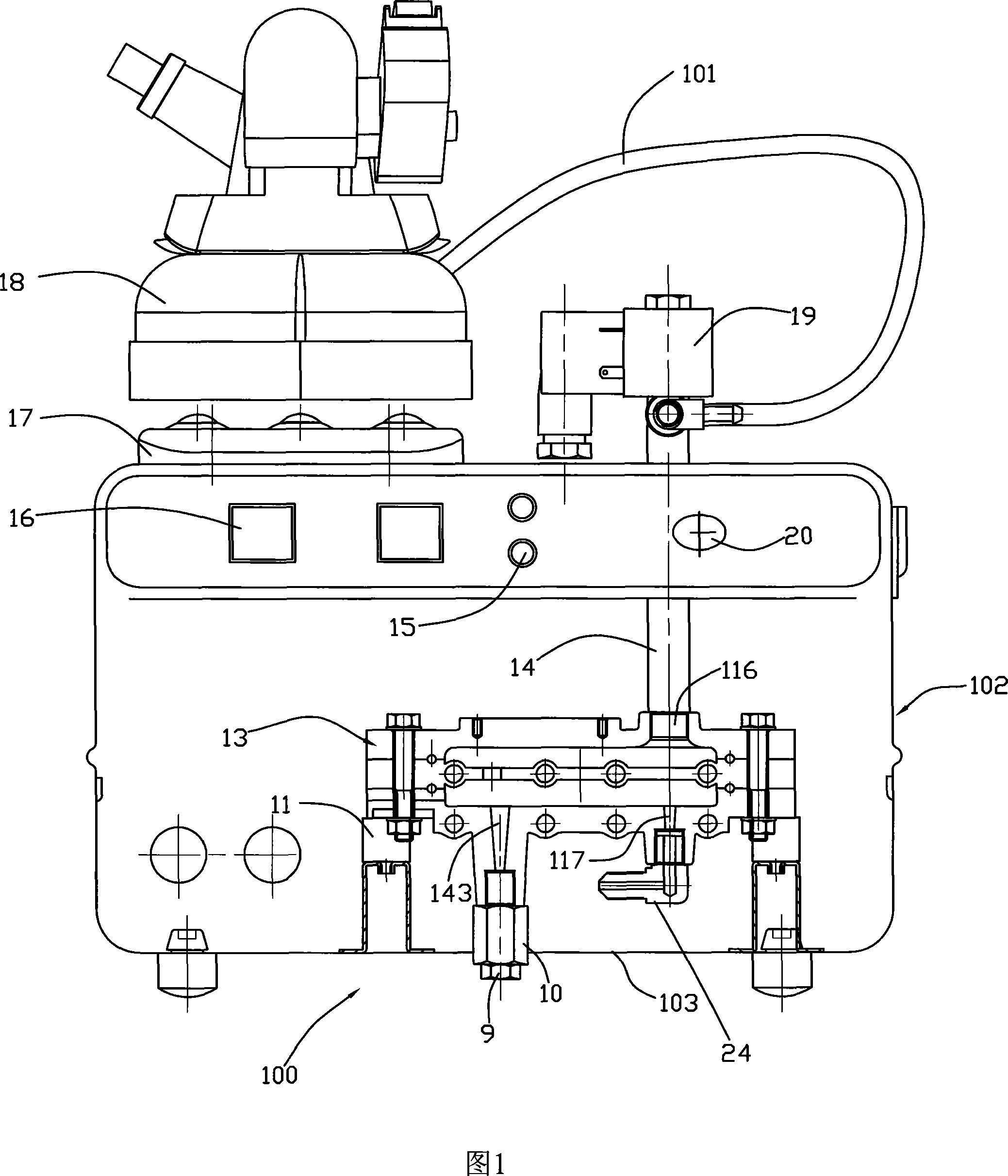

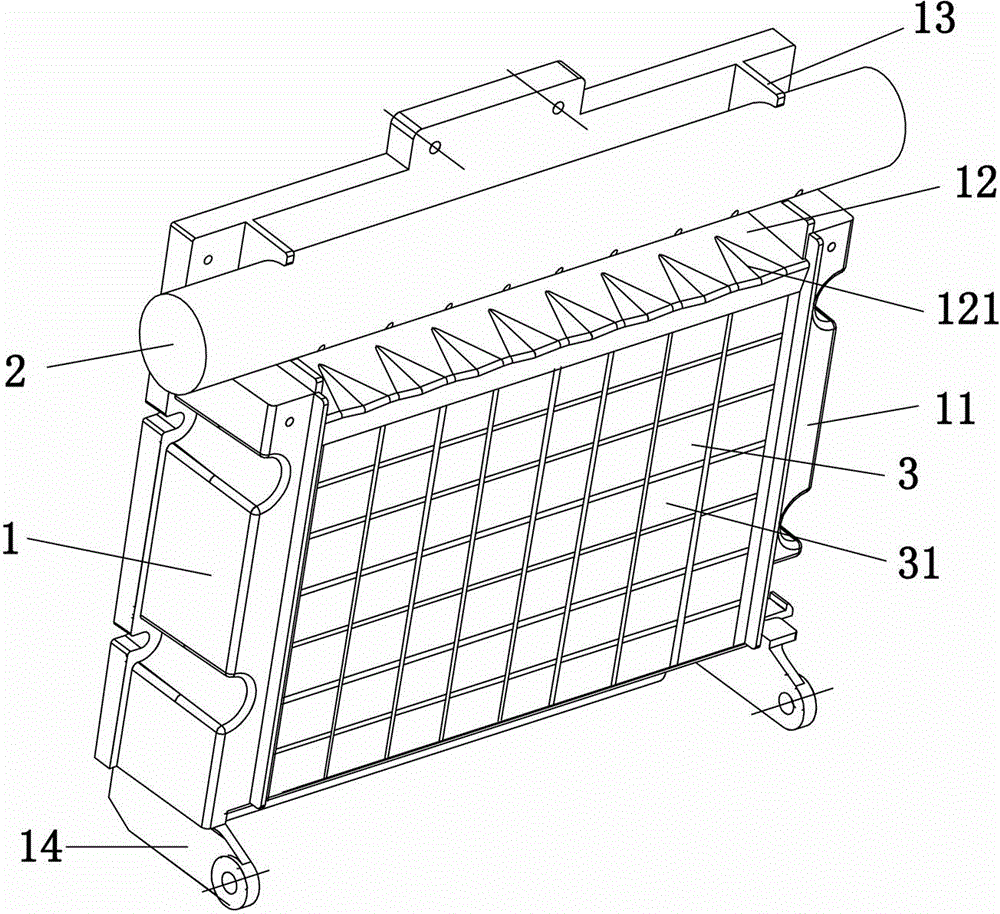

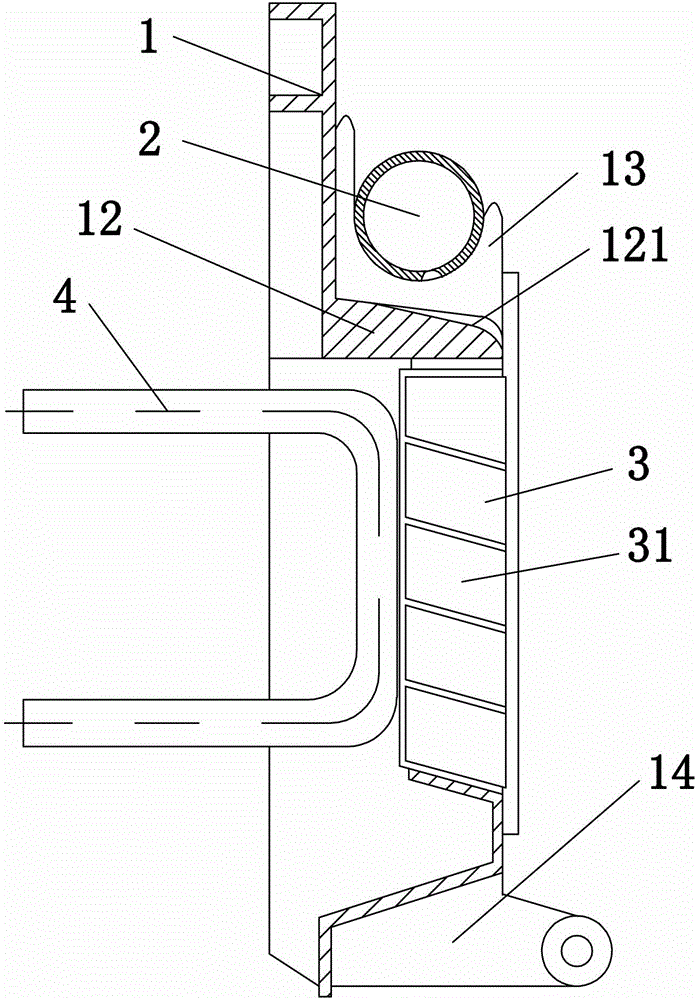

Spray needle device of bottle washing machine with balanced water jet capacity

InactiveCN102950075AEasy loading and unloadingPrevent splashHollow article cleaningSpraying apparatusWater jetEngineering

The invention relates to a spray needle device of a bottle washing machine with balanced water jet capacity. The spray needle device comprises a tabular spray needle frame which laterally extends and a plurality of spray needles which are vertically arranged on the spray needle frame, wherein the spray needle frame comprises a water flow channel which laterally extends and a plurality of round grooves which are vertically formed respectively and have one ends being communicated with the water flow channel, each spray needle comprises a hollow needle bar and a round base which is positioned on the tail end of the needle bar, and bases are respectively arranged in the grooves; and the spray needle device is characterized in that in the grooves, sealing gaskets and throttling orifices are also sequentially arranged on the bottom ends of the bases which correspond to the spray needles, a first through hole with a sectorial cross section is formed in each throttling orifice, and a second through hole with the sectorial cross section is formed in each base. The spray needle device can adjust the peripheral relative positions of the bases and the throttling orifices through rotating the spray needles, so that the spray water pressure is changed, the water jet capacities of all the spray needles are maintained balanced, and on the basis of ensuring the cleaning effects of all the spray needles, a water-saving effect of a certain degree can also be realized.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Disposing method and device of papermaking waste water

ActiveCN107311391AAvoid destructionReduce pollutionWater contaminantsTreatment involving filtrationFiltration membraneReverse osmosis

The invention relates to a disposing method and device of papermaking waste water, and belongs to the technical field of water disposal. The disposing method includes steps of initially settling waste water for pulping and papermaking, and then adding biodegradable flocculating agent to perform the flocculating reaction; settling the flocculate; delivering the disposed waste water to an anaerobic reaction tower to react; after adding sodium carbonate precipitant in the produced water at the upper part of the anaerobic reaction tower, delivering to a tubular ceramic micro-filtration membrane filter to filter; delivering concentrated fluid of the tubular ceramic micro-filtration membrane filter to a plate frame type filter to perform filter pressing; returning the waste water after filter pressing to an anaerobic reaction tower to dispose; delivering the produced water of the tubular ceramic micro-filtration membrane filter to an aerobiotic pond to react; after settling the produced water of the aerobiotic pond through a settling pond, delivering the waste water to the ceramic micro-filtration membrane filter to filter; delivering penetrated liquid of the ceramic micro-filtration membrane filter to a reverse osmosis membrane to filter.

Owner:贵州西部环保科技股份有限公司

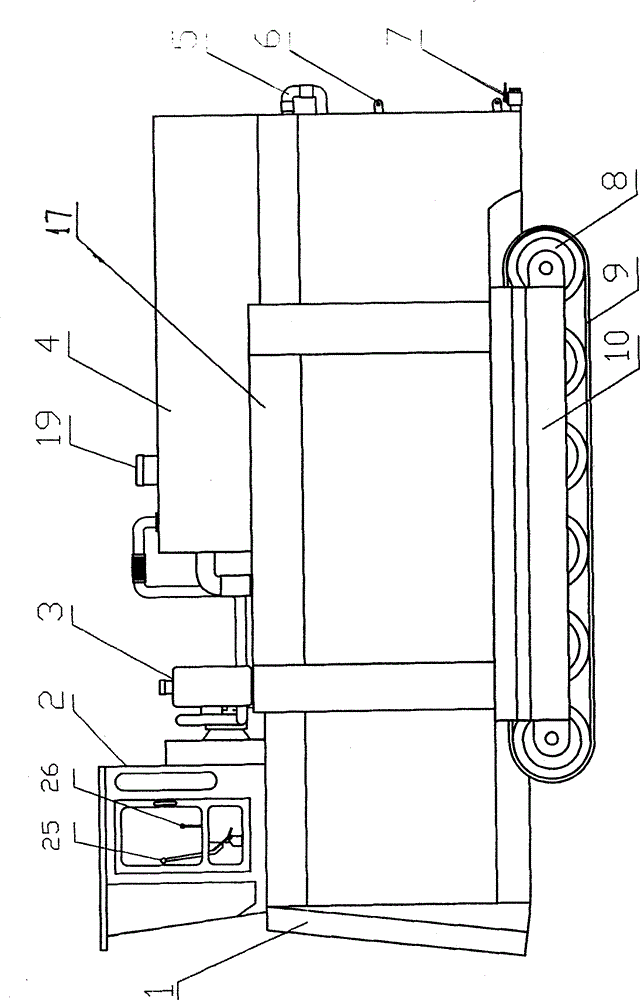

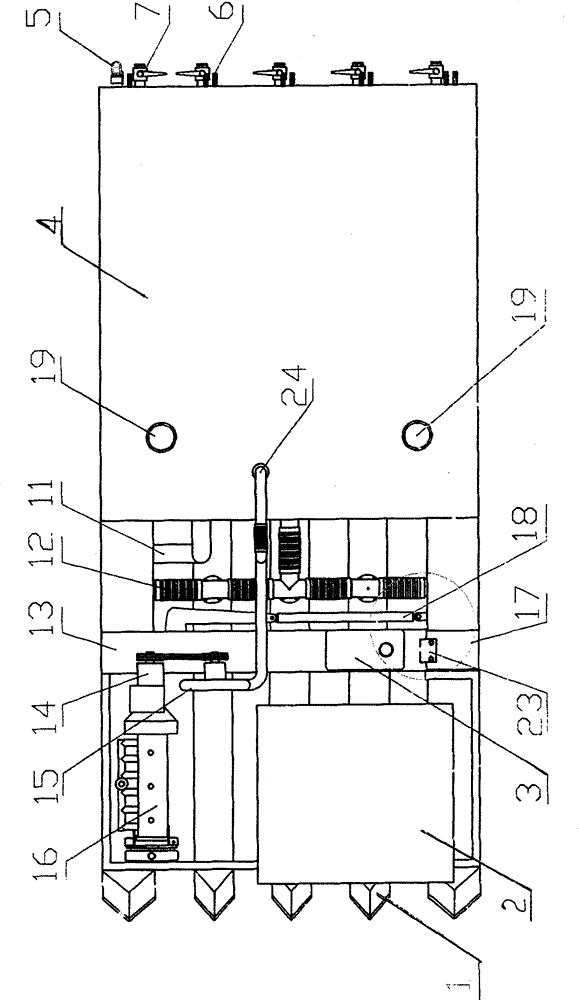

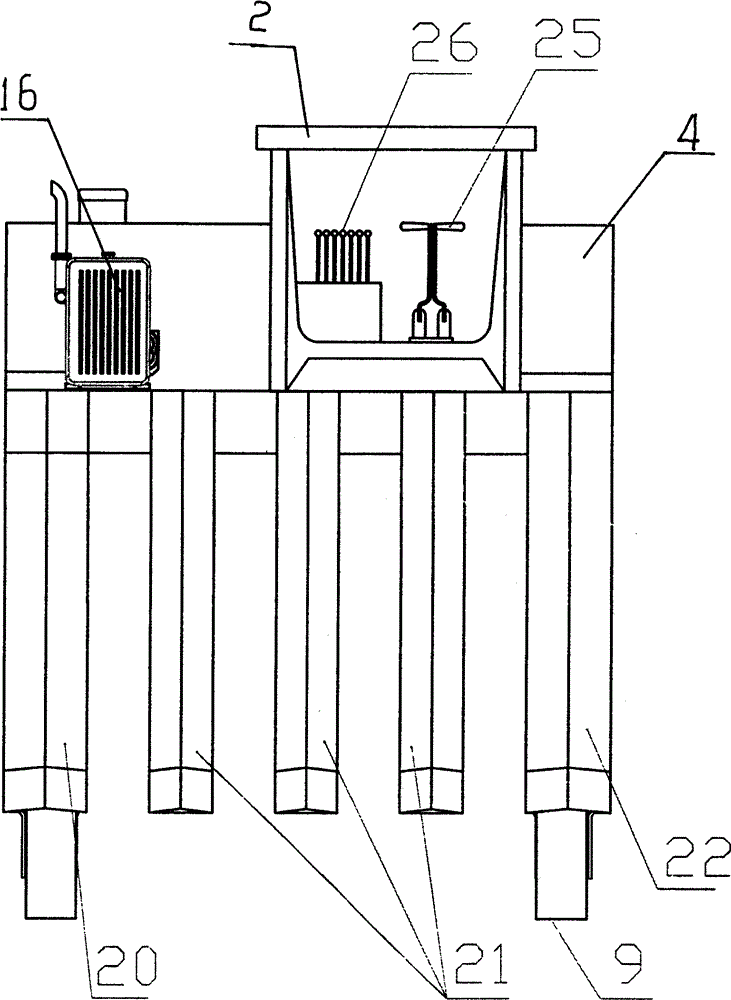

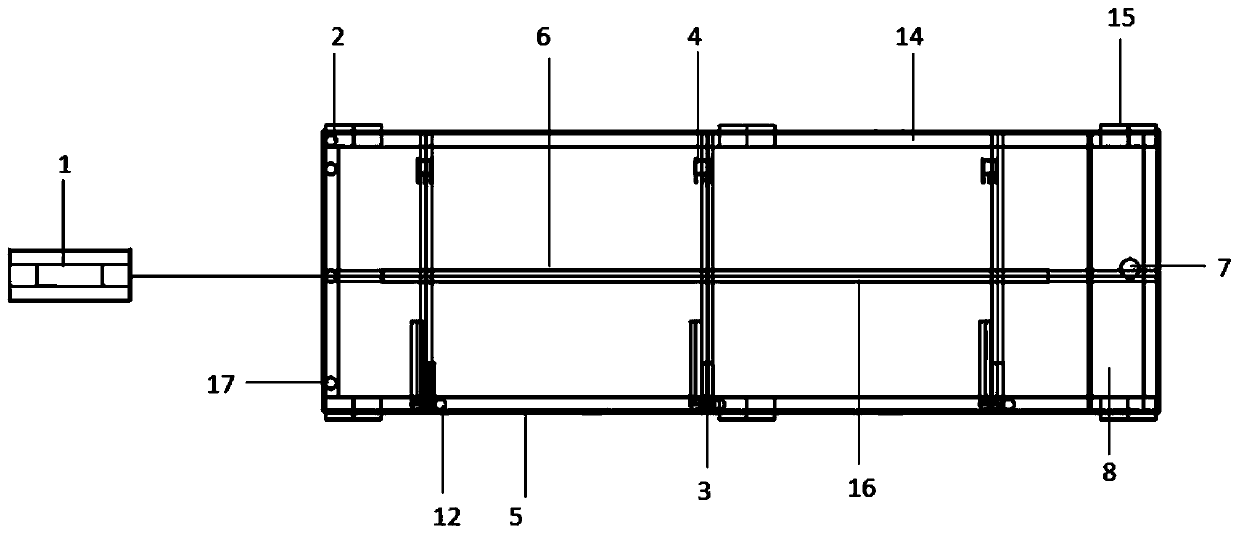

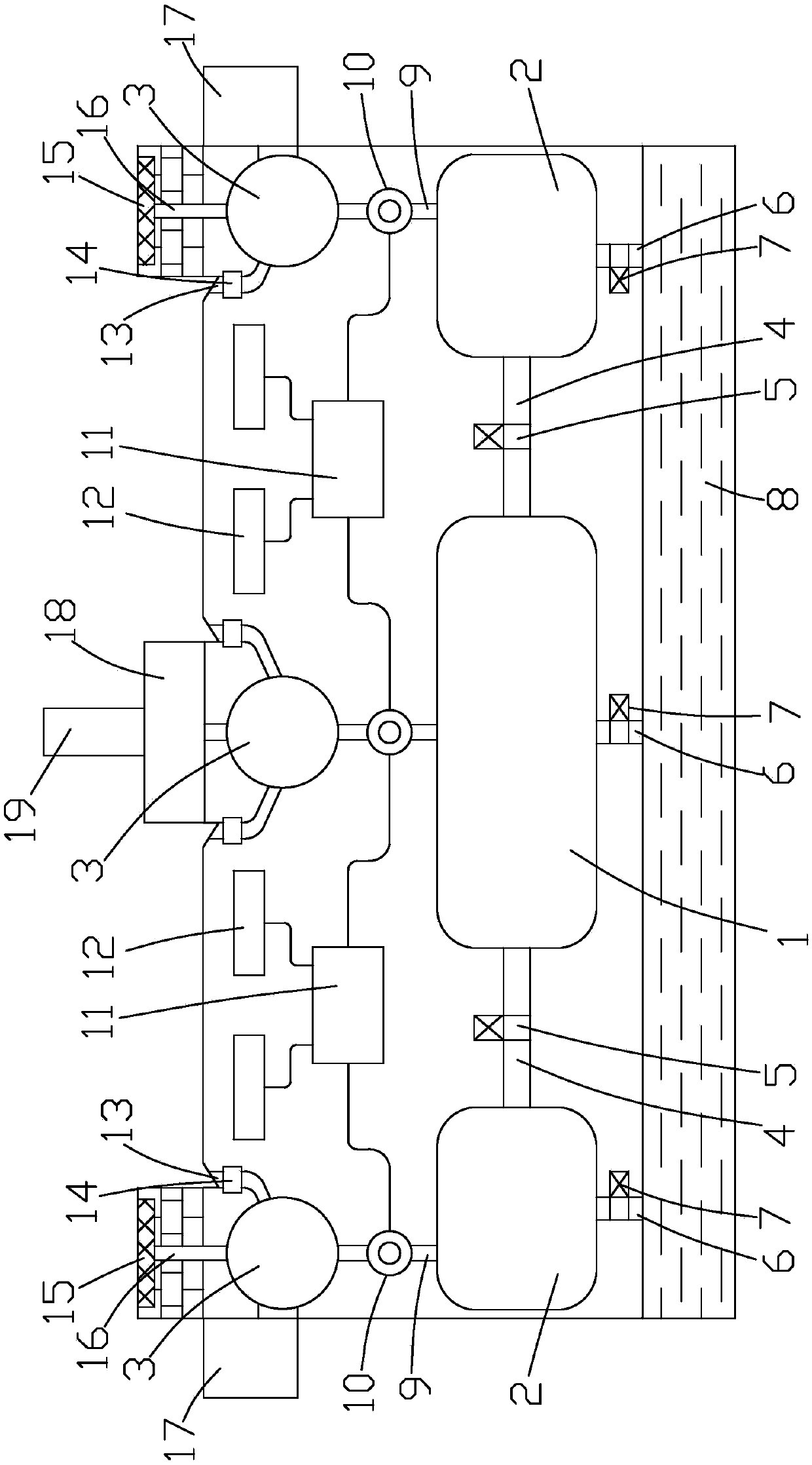

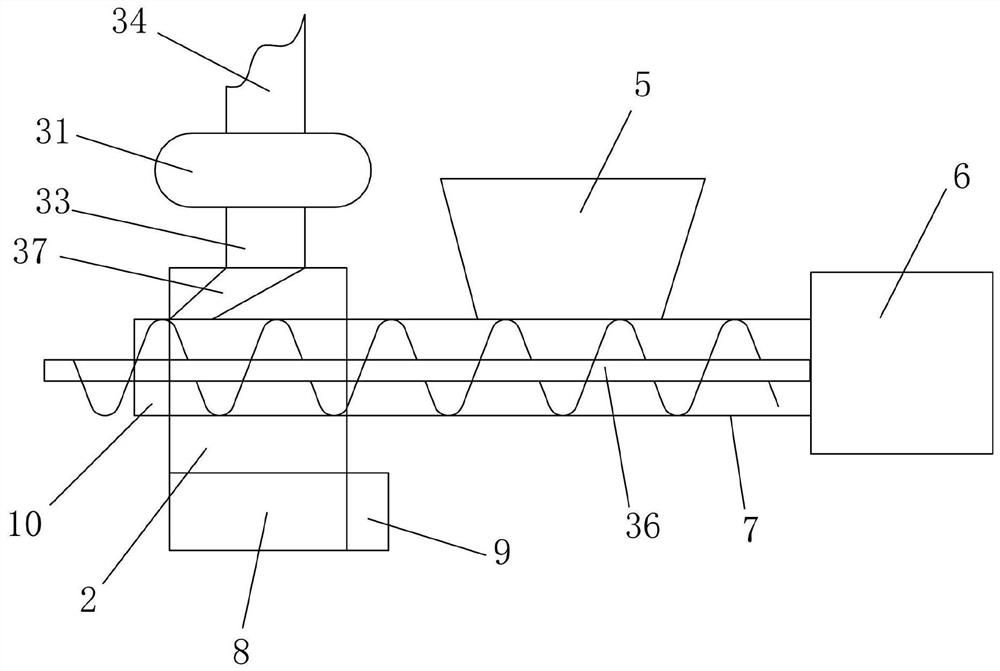

Self-propelled type crawler belt type water saving irrigation machine

ActiveCN104813905AImprove walking abilityRelieve pressureWatering devicesCultivating equipmentsAgricultural engineeringFuel tank

Disclosed is a self-propelled type crawler belt type water saving irrigation machine which belongs to agricultural machinery. An n-shaped rack assembly formed by a left rack and a right rack is equipped with dividers, a cab, a hydraulic oil tank, a main water tank, a walking crawler belt assembly, a hydraulic oil pump and a motor, wherein a right side water tank and N middle water tanks are hanged on the right rack, a left side water tank is hanged on the left rack, the hydraulic motor is installed on a drive shaft of the walking crawler belt assembly, the motor is connected with the hydraulic oil pump and a booster fan, the booster fan is communicated with the main water tank through a high pressure air pipe, the main water tank is communicated with the right side water tank through a water pipe, the right side water tank is communicated with the N middle water tanks and the left water tank through a distributive pipe, drain valves are fixedly arranged on the lower portions of the rear sides of the right water tank, the left water tank, and the N middle water tanks, the hydraulic oil tank, the hydraulic oil pump, the hydraulic motor and a manual multichannel control valve are communicated with one another through a hydraulic oil pipe. The self-propelled type crawler belt type water saving irrigation machine is simple and reasonable in structure, low in power consumption, good in water supply quality, and high in working performance.

Owner:刘伟生

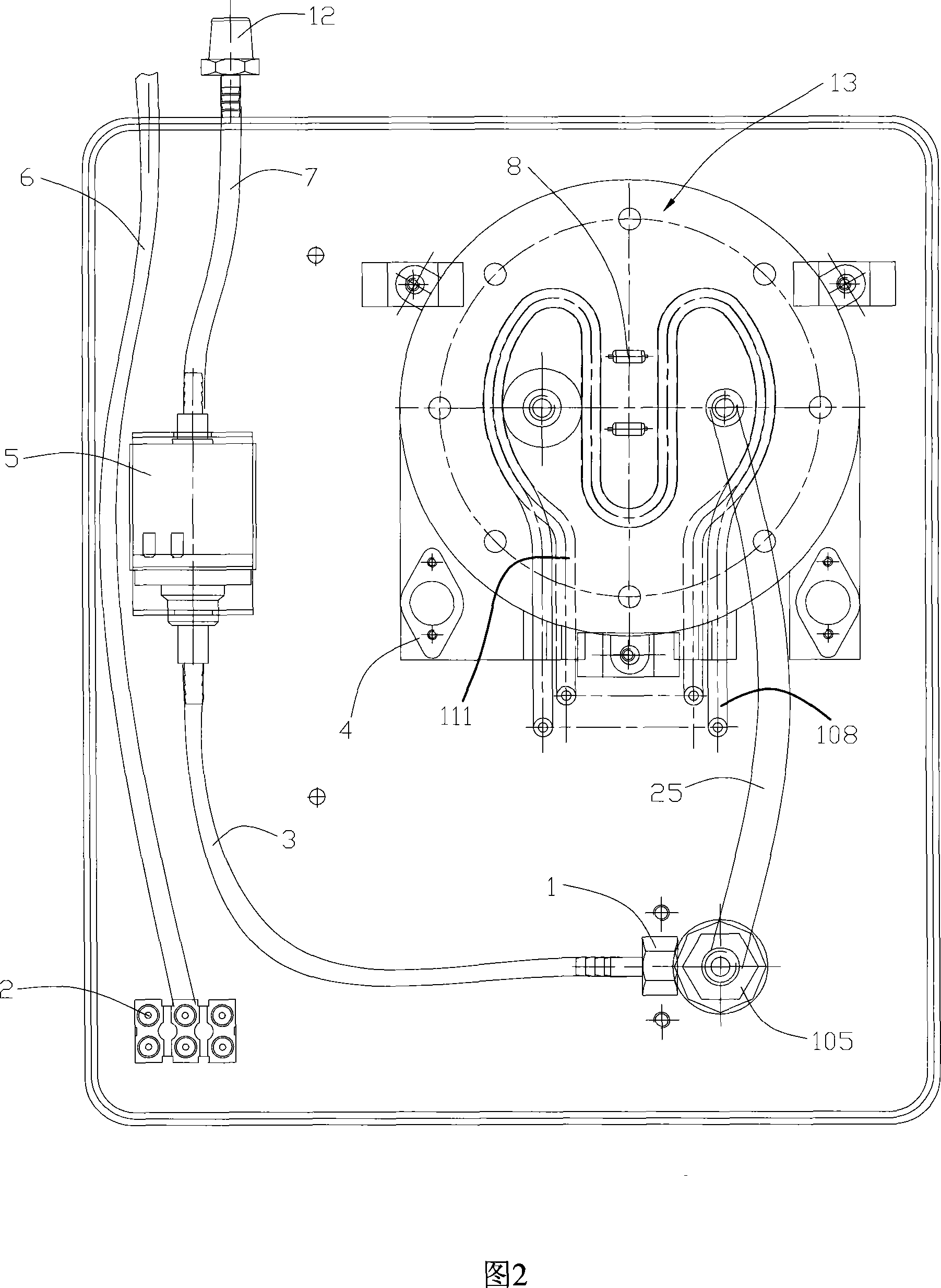

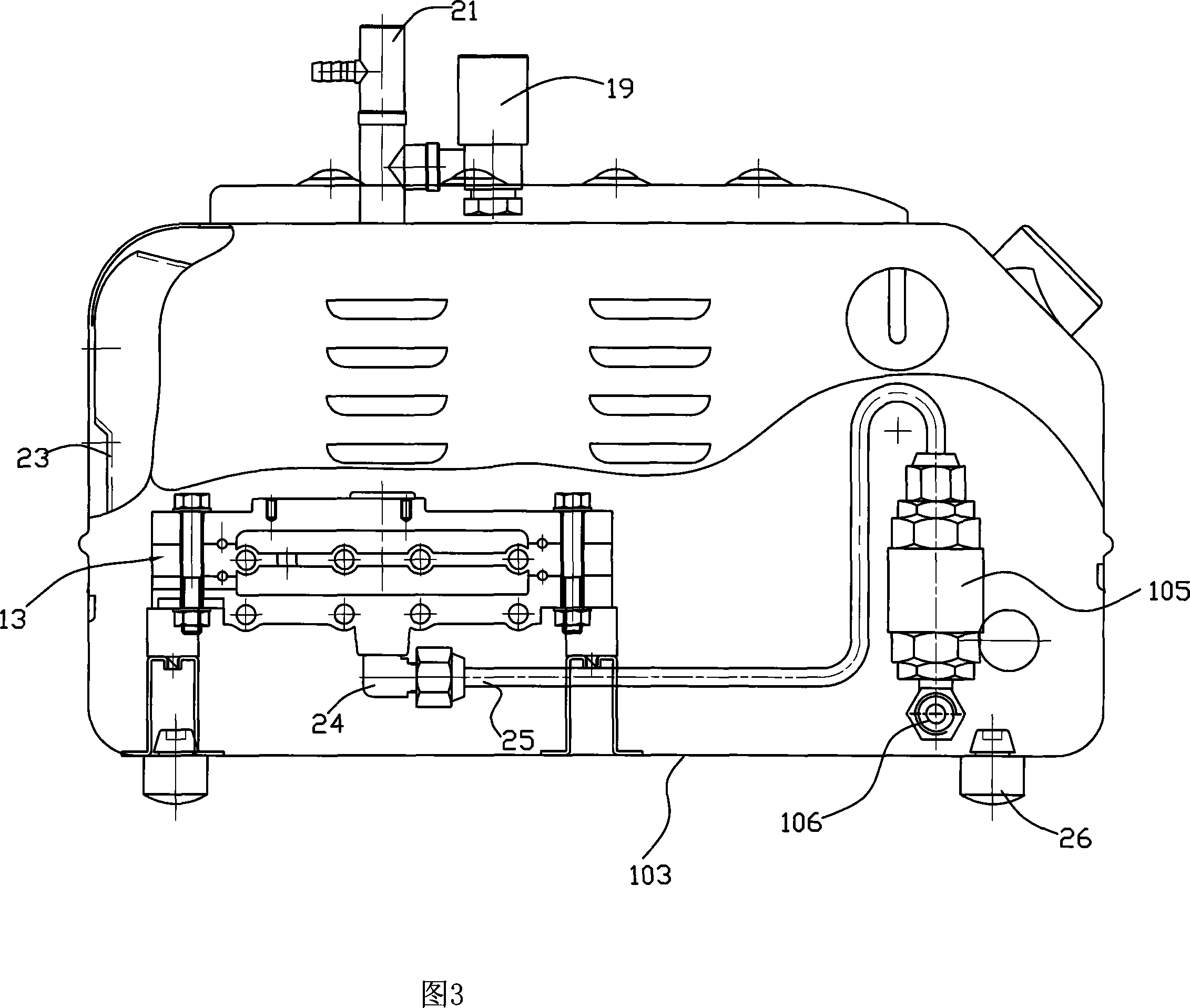

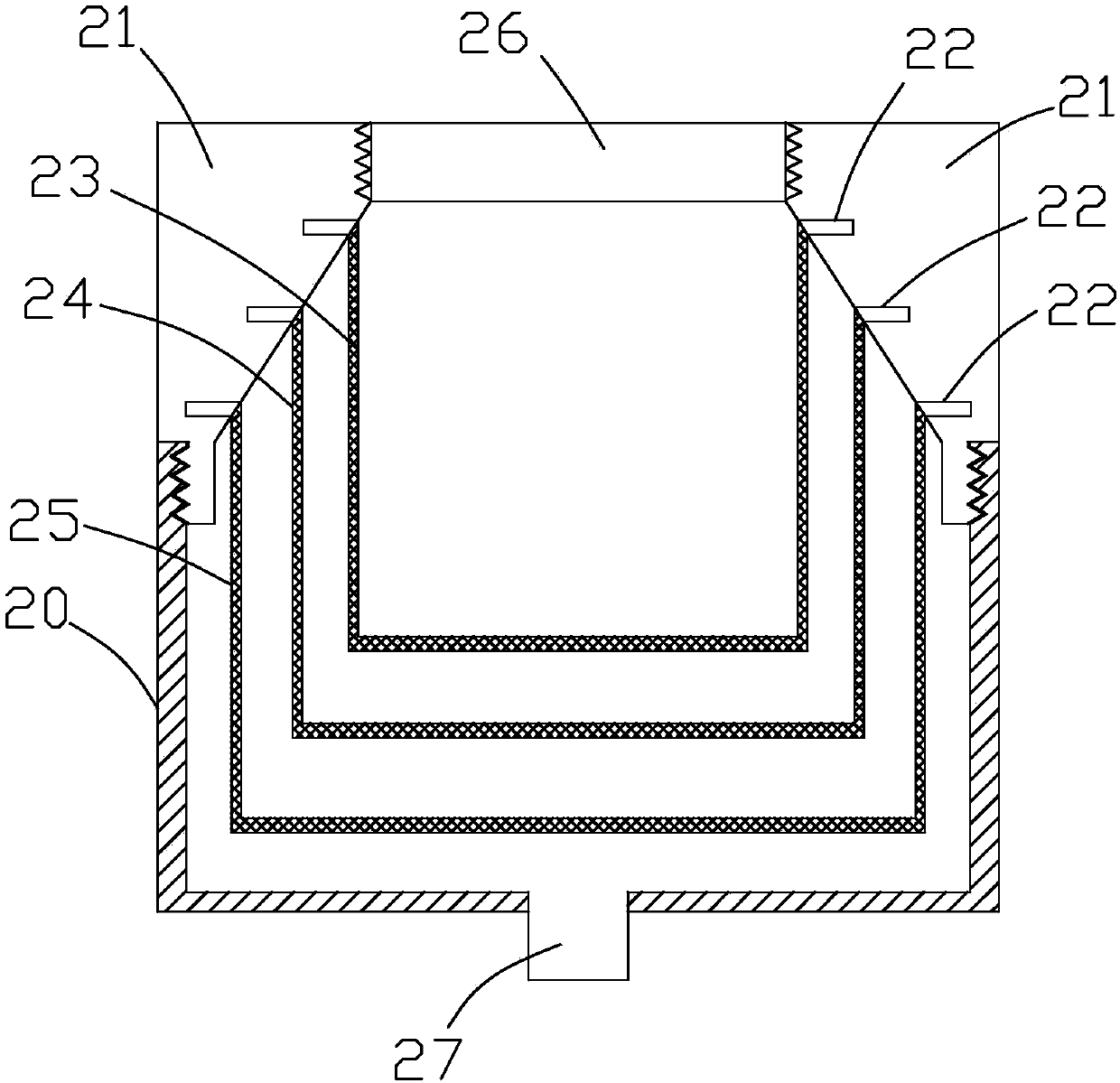

Steam generator

The invention provides a steam generator, comprising a case. The case is internally provided with a water pump which is used for pumping water outside the case into the case, and a liner which is communicated with the water pump so as to heat and gasify the water pumped into the case by the water pump. Two mutually separated and communicated steam containing spaces which are communicated with the water pump are formed in the liner. The water feeding speed and the steam output speed of the steam generator can be balanced automatically, thereby balancing the water quantity entering into the steam generator and the steam quantity produced by heating continuously and constantly, further shortening the heating time and avoiding long-time dry burning phenomenon.

Owner:广州市立本电器有限公司

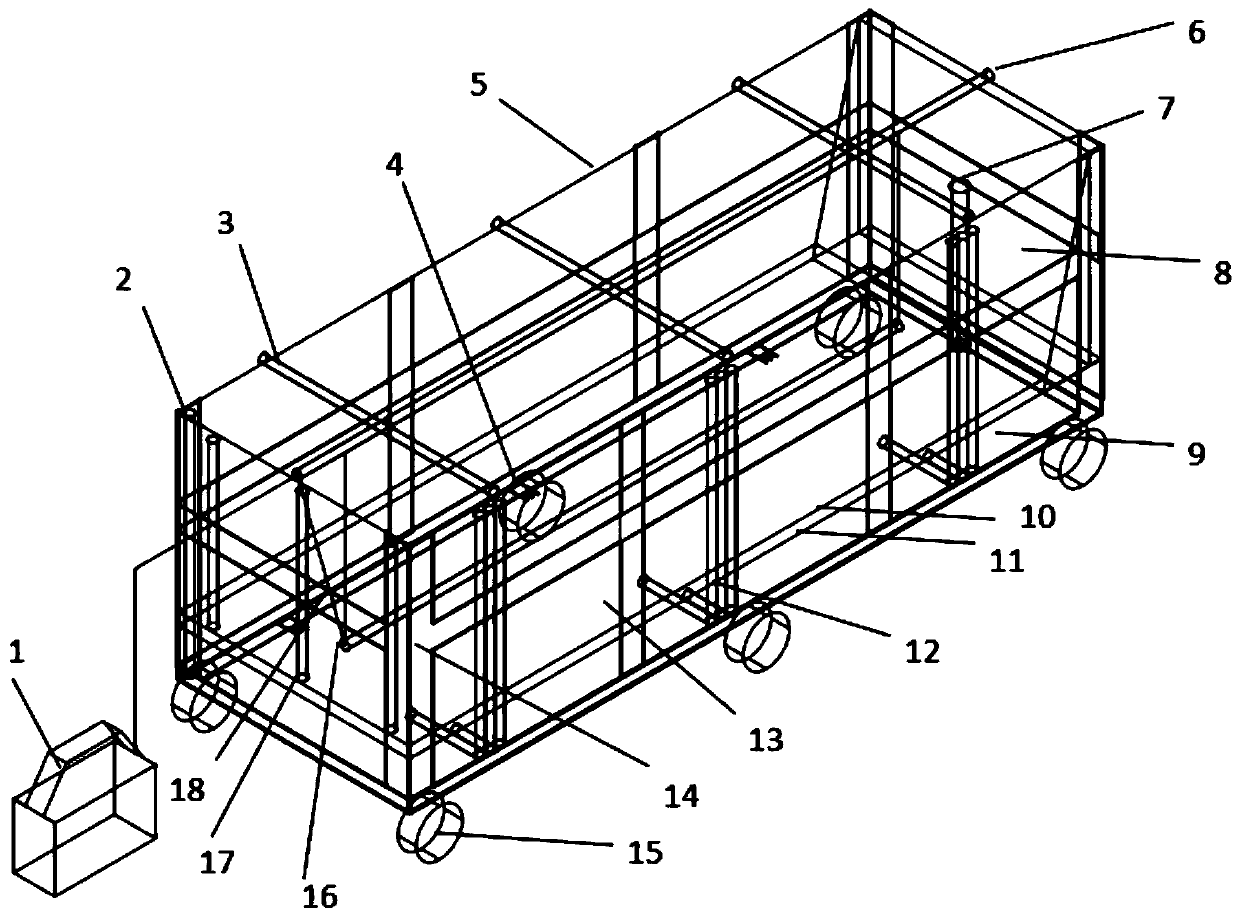

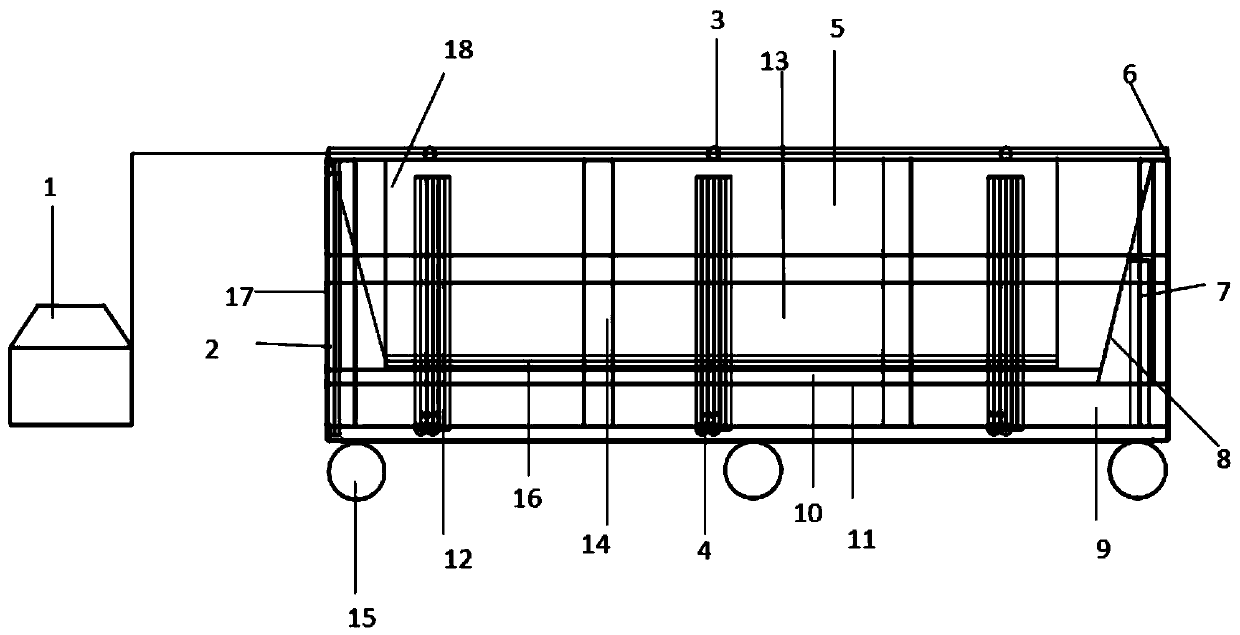

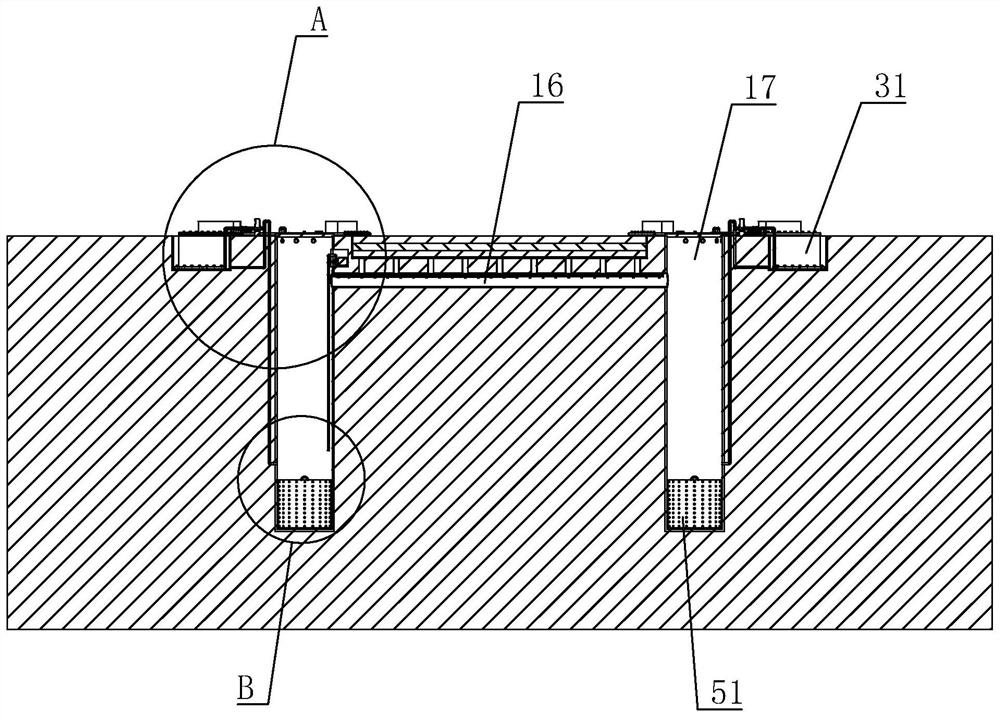

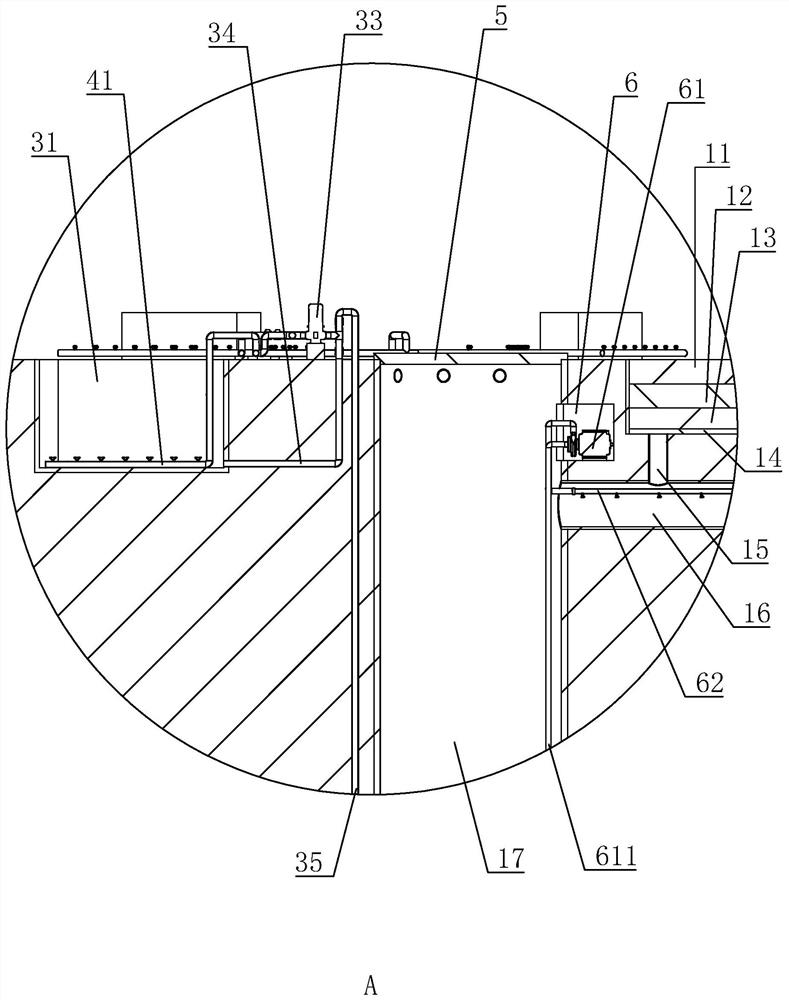

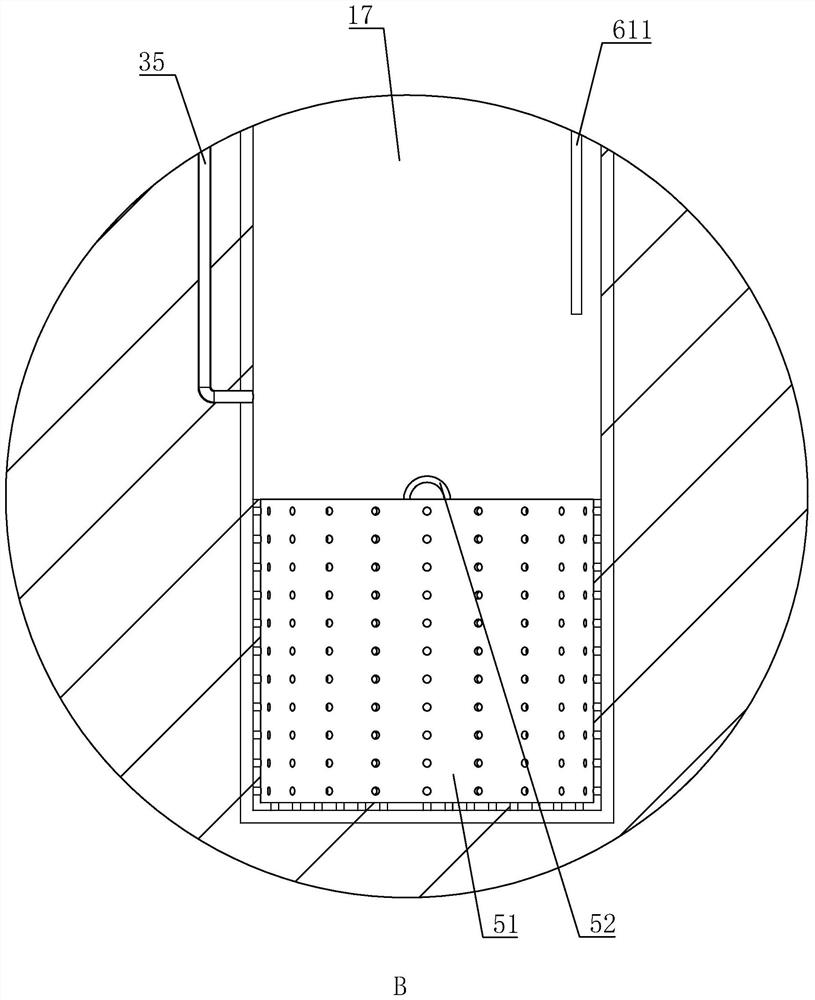

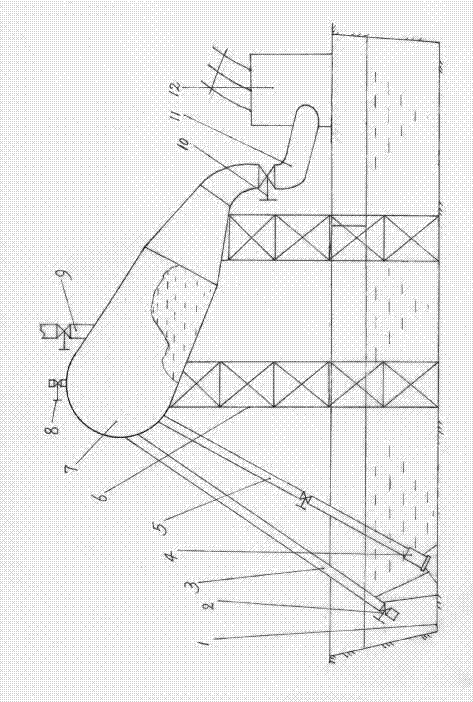

Simulation platform, experiment system and method for reservoir leakage detection experiment

ActiveCN111366303AHigh simulationAvoid frequent transfersDetection of fluid at leakage pointEarth material testingWater storageWater use

The invention relates to a simulation platform, an experiment system and a method for reservoir leakage detection experiments, and the platform comprises a sand box, and the upper part of the sand boxis provided with an opening so as to expose an inner cavity of the sand box. An earthing layer is laid on the upper surface of the bottom wall of the sand box. A simulated dam body is arranged at oneend of the sand box, the simulated dam body is supported by a soil covering layer, a water storage tank is defined by the side face, close to an inner cavity of the sand box, of the simulated dam body and the inner wall of the sand box, and the relative position of the simulated dam body and the sand box can be adjusted to change the size of the water storage tank. The water storage tank can be filled with experimental water so as to simulate water resources stored in a reservoir. A drainage device is arranged on the bottom wall of the sand box so as to drain accumulated water leaked from thesoil covering layer.

Owner:SHANDONG UNIV

Urban road rainwater penetrating system and construction method for same

ActiveCN107044150AQuick collectionAvoid traffic jamsFatty/oily/floating substances removal devicesSewerage structuresWater storageWater storage tank

The invention discloses an urban road rainwater penetrating system and a construction method for the same. The urban road rainwater penetrating system comprises a first water storage tank, second water storage tanks, drainage pipe channels, road heating devices and current generating devices, wherein the drainage pipe channels are all connected to the underground water layer via first water seepage pipes; storage batteries are arranged under the road heating devices; the storage batteries are connected with the road heating devices and the current generating devices via leads; and the current generating devices are fixed on second water seepage pipes. The construction method comprises steps of digging a base pit, installing a water storage tank, constructing the road heating devices and laying road surface pitch. The construction method is simple and can meet road surface construction in regardless of lengths and widths; a rainwater penetrating system has great drainage effect; obvious economic effects can be achieved; construction time is shortened; construction cost is lowered; and construction safety can be enhanced.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

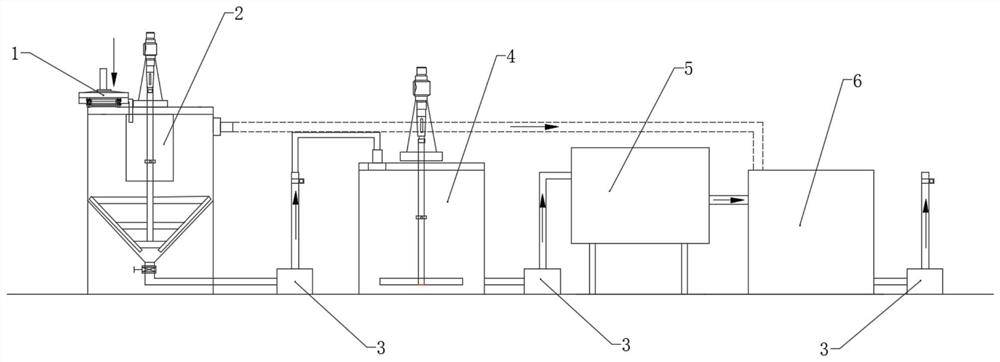

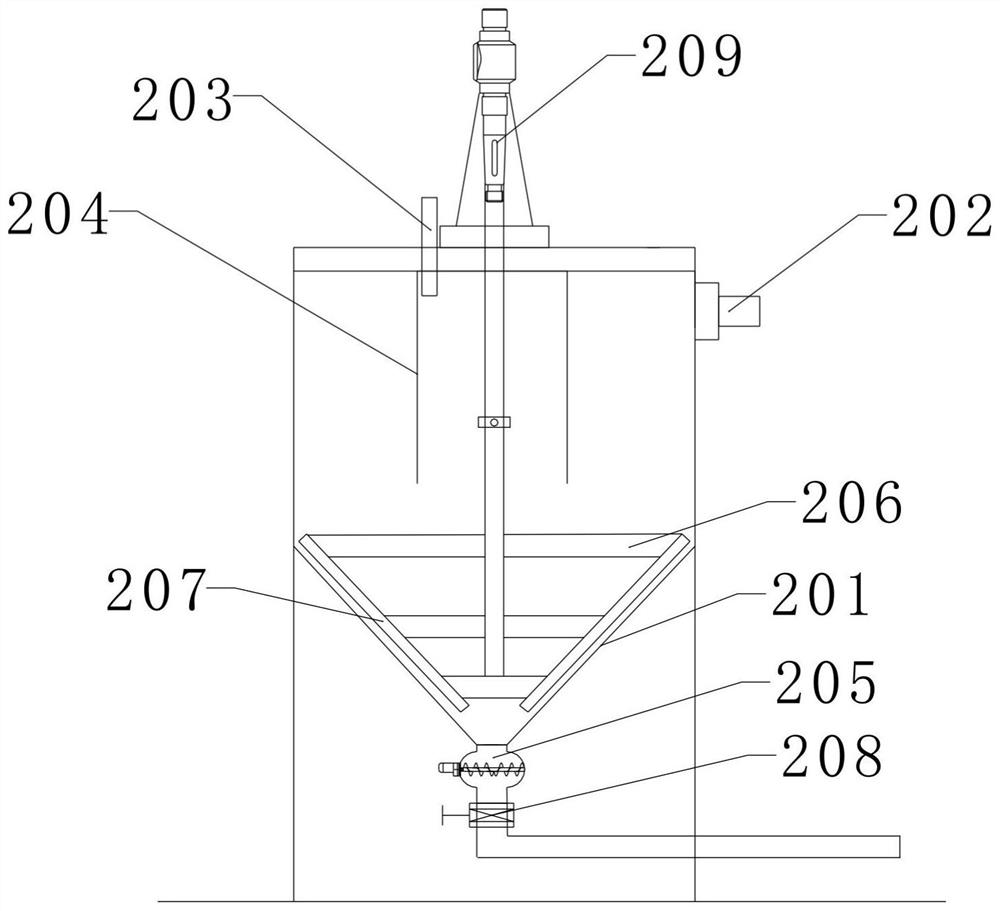

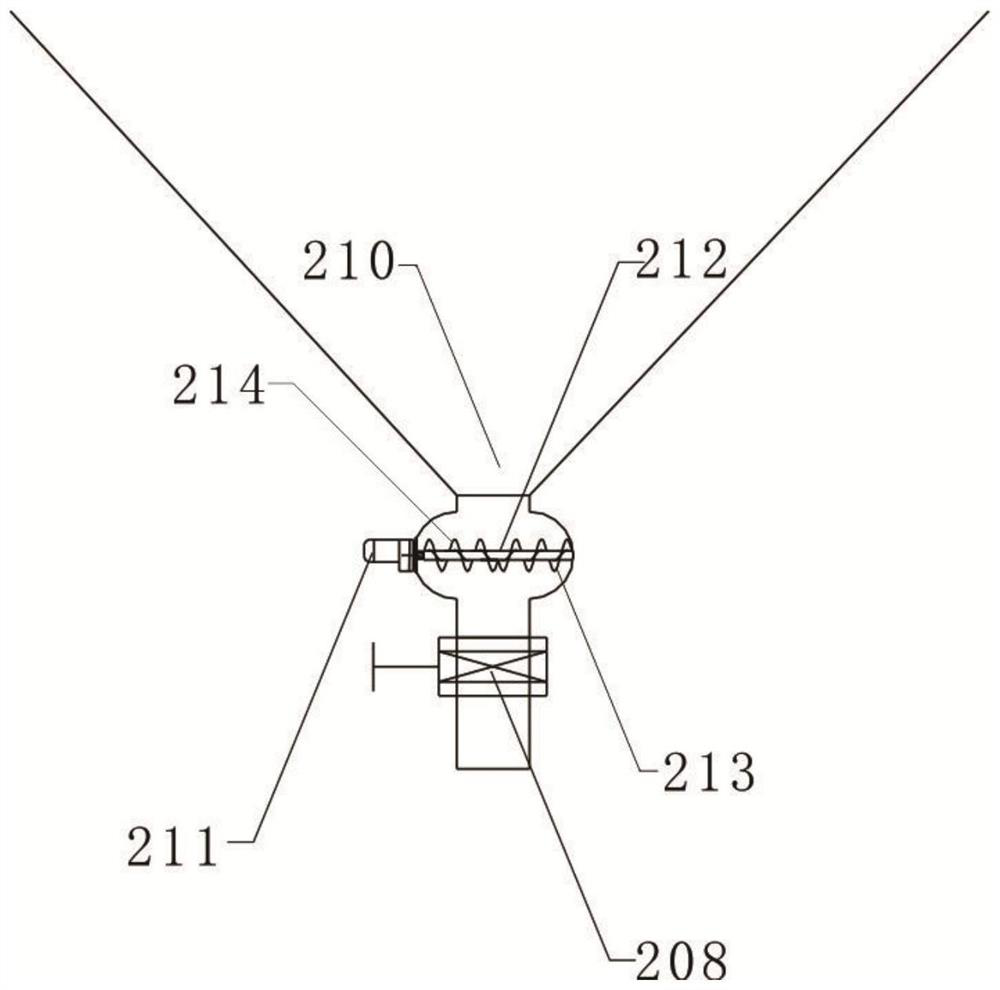

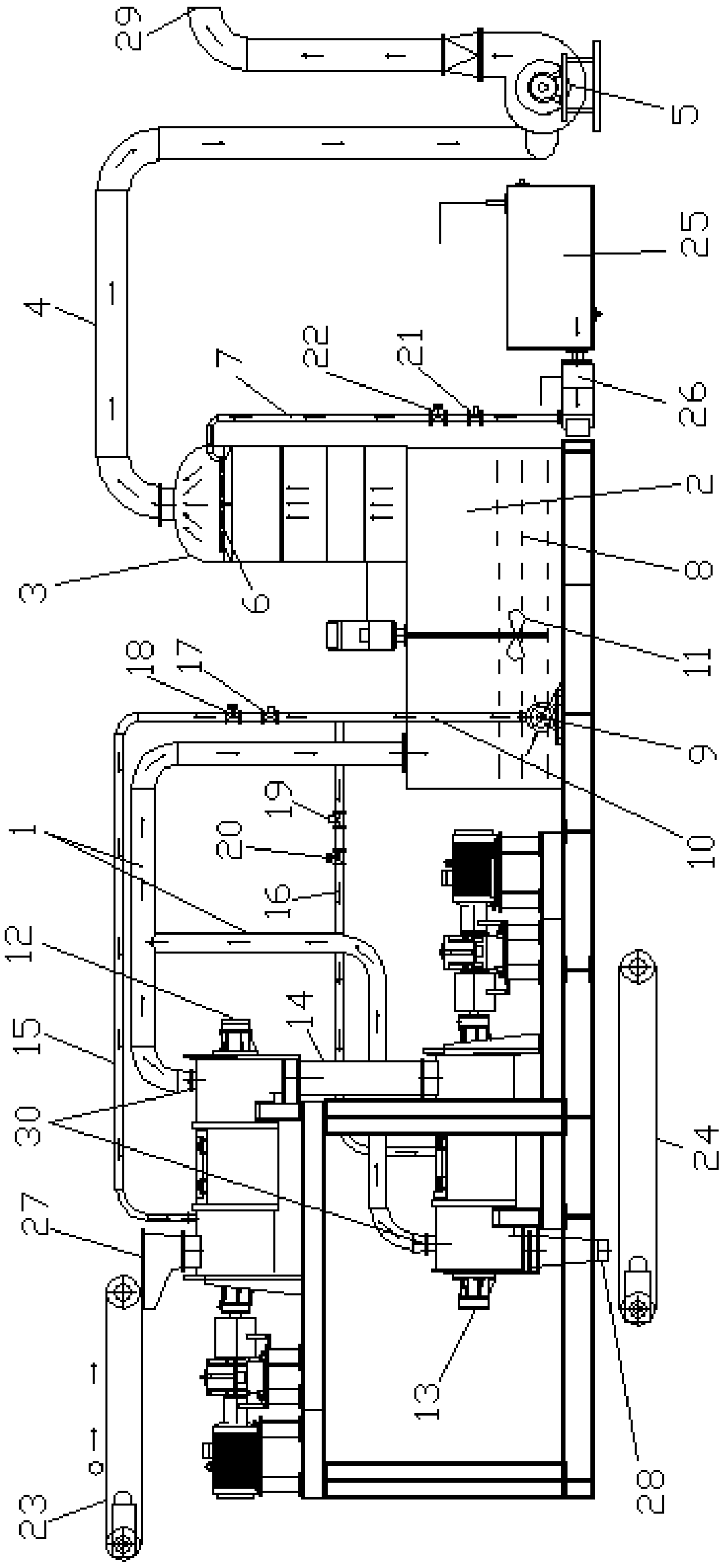

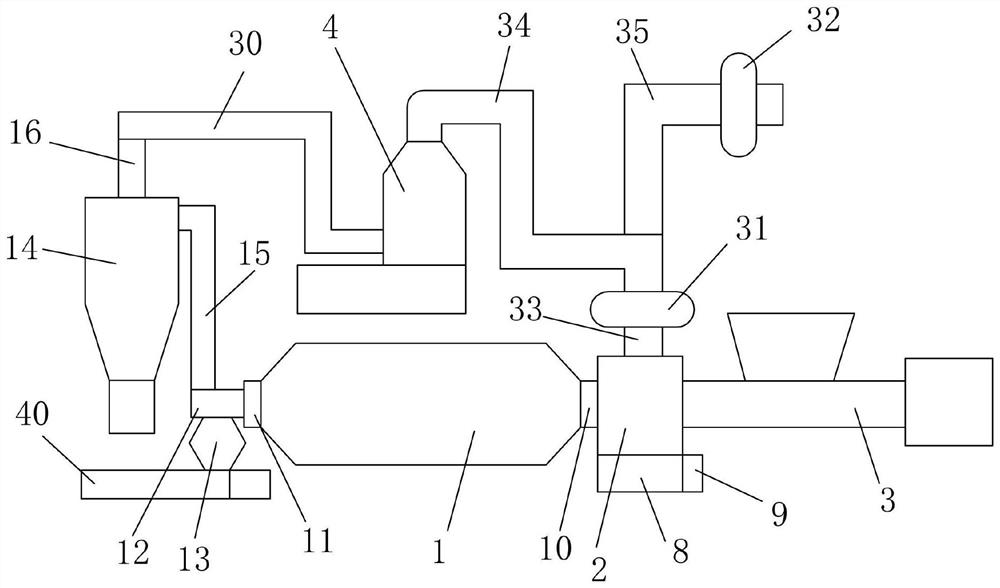

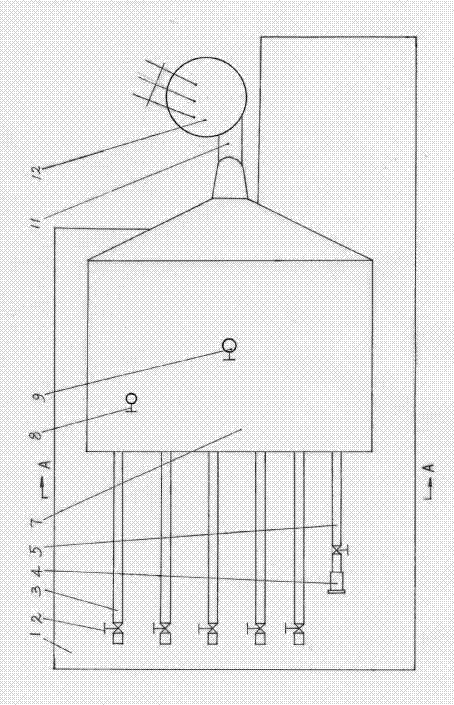

Mixing station waste slurry recycling process and device

PendingCN113232157AEfficient reductionSignificant reductionSludge treatment by de-watering/drying/thickeningCement mixing apparatusSlurryHolding tank

The invention discloses a mixing station waste slurry recycling process and device. The process comprises the following steps of: S1, separation; S2, concentration; and S3, vacuum desliming. The device comprises a screening device, a concentrator, a waste slurry storage tank, a desliming machine and a clear water tank which are sequentially communicated. The mixing station waste slurry recycling process and device can treat and recycle mixing station waste slurry, the mixing station waste slurry enters the concentrator for rapid water-slurry separation after being treated by sand-stone separation equipment, overflow clear water can be directly used for concrete production and equipment and site cleaning, high-concentration waste slurry at the bottom enters efficient desliming equipment for water-solid separation, separated solid residues are loose and scattered and are directly recycled for production, and separated water is directly used for production or equipment and site cleaning. The mixing station waste slurry recycling process and device have the characteristic of efficiently treating mixing station solid waste at high value, and have the advantages of low treatment cost, zero solid waste emission, complete recycling, intelligent monitoring and control, environmental protection and the like.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Micro-hydro generator

ActiveCN101892937ALow rotational resistanceReduce the problem of low power generation efficiencySpray nozzlesMachines/enginesEngineeringMicro hydro

The invention discloses a micro-hydro generator, which comprises an upper cover and a lower cover. A water storage cavity and a rotor cavity are formed on the upper cover; a shared wall is formed between the rotor cavity and the water storage cavity; the wall is provided with a flushing port communicated with the water storage cavity and the rotor cavity; a water inlet is formed on the lower cover and used for injecting water into the water storage cavity; a water outlet is formed on the upper cover and positioned in the rotor cavity and is opposite to the wall; a rotatable rotor is arranged in the rotor cavity; the lower cover is provided with a stator matched with the rotor; and the rotor cavity has a shape of which the cross sectional area is gradually reduced from the wall to the water outlet. The micro-hydro generator solves the technical problems that a blade undergoes relatively large resistance and the generation efficiency is influenced because water in an accommodating cavity flows back to a water inlet cavity and forms flowback water in the micro-hydro generator of the prior art; besides, the micro-hydro generator is suitable for showers, faucets and the like.

Owner:ZHUHAI EDISON ECOTECH CORP CO LTD

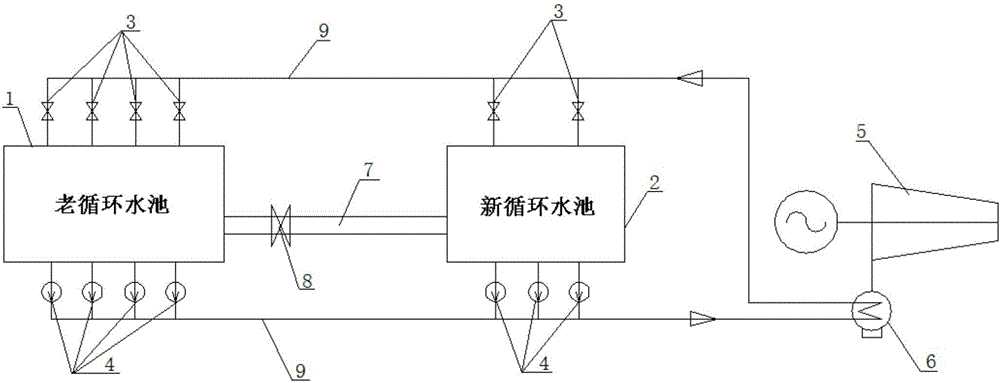

Extension method for circulating water system of power plant

ActiveCN106088214APrevent overflowOperation impactService pipe systemsWater mainsWater resourcesStop time

The invention discloses an extension method for a circulating water system of a power plant. A new circulating water pool is independently built beside an old circulating water pool, and is communicated with the old circulating water pool through a communicating pipe, the new circulating water pool and the old circulating water pool are connected in parallel with a main pipe, running of an existing circulating water system is not influenced in a process of building the new circulating water pool, safe and stable running of original equipment is ensured, and a turboset and the circulating water system are required to be stopped only in a process of communicating the new circulating water pool with the old circulating water pool. According to the method, the stopping time is greatly shortened, economic loss caused by stopping is reduced, and process design requirements are met; the communicating pipe is arranged between the new circulating water pool and the old circulating water pool, so that problems about water level balance between the new circulating water pool and the old circulating water pool are solved, and overflow of the circulating water pools and waste of water resources are avoided.

Owner:武汉钢铁有限公司

Control method for trinity structure wastewater treatment

ActiveCN109502868AGuarantee the balance of water intake and evaporationWater balanceWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsBalance equationHeat flow

The invention discloses a control method for trinity structure wastewater treatment. The method comprises the following steps: initializing heat provided by a single heat flow pipe; establishing a balance equation between water inflow and evaporation capacity; establishing a heat collecting efficiency equation of a solar plate thermal collector in different environment conditions; ensuring that anelectrothermal compensator performs thermal compensation to the solar plate thermal collector according to the second and third steps and the current environment condition; adjusting the wastewater flow rate according to the steps, and further adjusting the water inflow, so as to ensure that the water inflow and the evaporation capacity always keep balanced, so as to realize control for the trinity structure wastewater treatment. The method degrades organic pollutants in wastewater through an ultrasonic technology and a cavatition effect of ultrasonic wave, evaporates the wastewater into water vapor through high temperature of heat flow pipes, condenses the water vapor into purified water, performs determination according to the balance equation between the water inflow and the evaporation capacity through wastewater inlet flow rate, and is convenient for the water inflow and the evaporation capacity to always keep balanced.

Owner:合肥庐阳科技创新集团有限公司

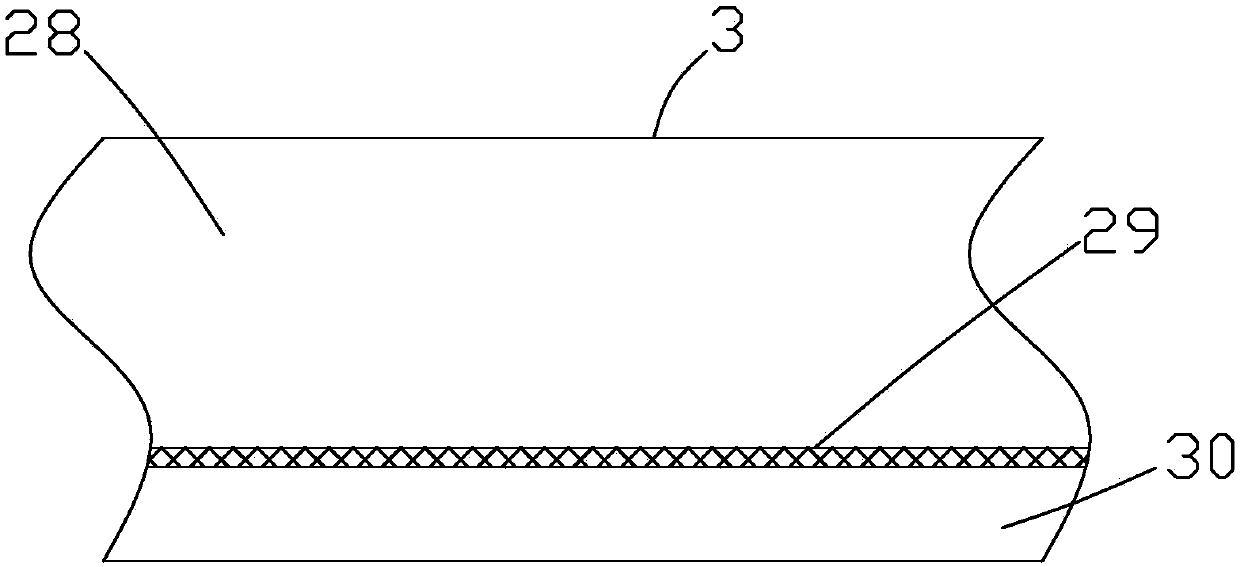

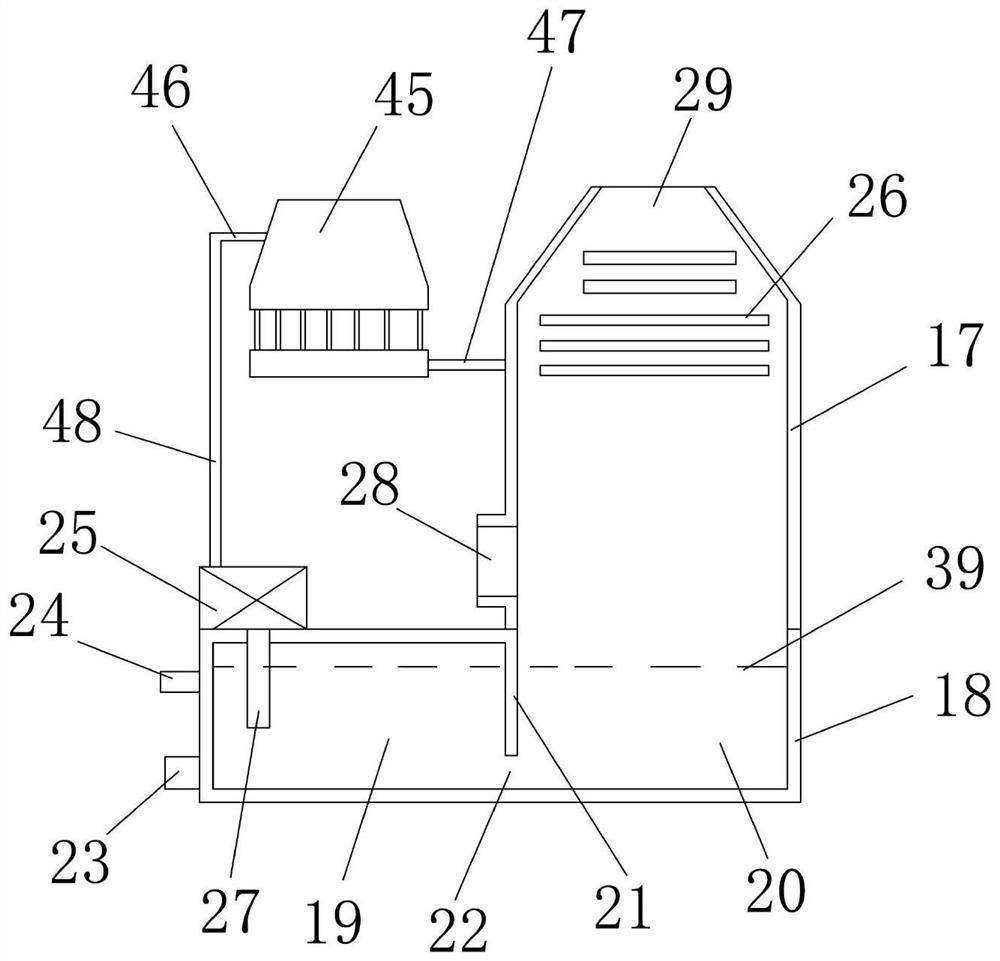

Running form evaporator for ice machine

InactiveCN105222452AProduct design layout moreReasonable and portable product designIce productionEvaporators/condensersEvaporatorEngineering

The invention relates to a running form evaporator for an ice machine. The running form evaporator comprises a shell body, a water spraying pipe arranged on the upper portion of the shell body, an ice disc arranged in the shell body and an evaporating pipe arranged on the back of the ice disc. The shell body is an injection member of a rectangular frame of which an inner cavity is formed for installing the ice disc and the evaporating pipe. A water spraying area is arranged at the top of the shell body. The water spraying area is provided with outflow outlets which are matched with the ice disc arranged under the outflow outlets. The structure of the outflow outlets is a water flowing outlet bottom face composed of N same concave grooves which are formed corresponding to transversely arrayed ice grids on the ice disc in number and are evenly distributed to be connected into a whole. The center line of each concave groove corresponds to the center line of a water inlet of the corresponding ice gird. Compared with the prior art, the running form evaporator for the ice machine has the beneficial effects that 1, the shell body is the integrated injection member, so that the design and arrangement of the product is more reasonable; portability is achieved; the production is simple and convenient; and 2, the design of a grid-divided water curtain is adopted, so that the water inflow of each ice gird is even, and the quality of ice blocks is ensured.

Owner:CHANGZHOU YOUHAO ELECTRIC APPLIANCE

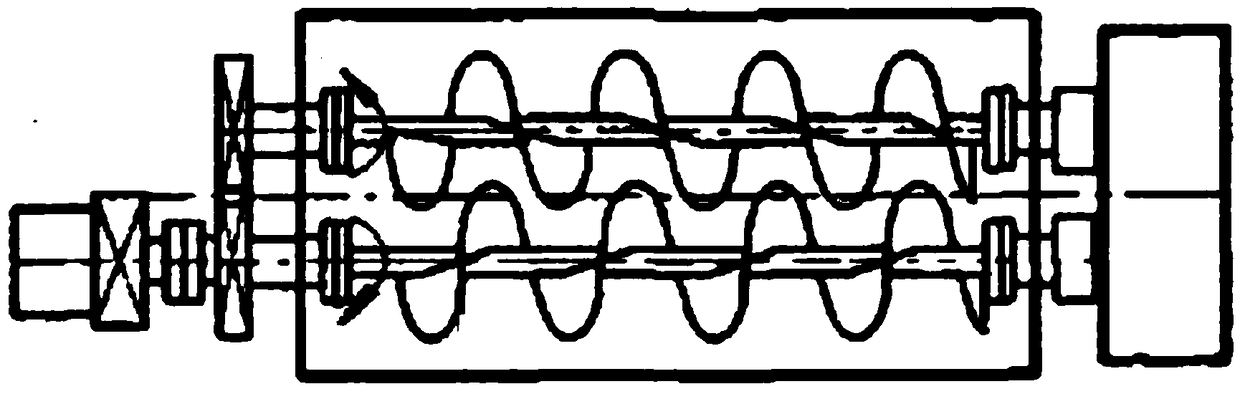

Quicklime slaking equipment system

The invention discloses a quicklime slaking equipment system which comprises horizontal powerful mixing machines. A waste gas pipeline, a closed filter pond, a spray tower, a purified air pipeline anda fan are sequentially connected onto waste gas exhaust openings of the horizontal powerful mixing machines according to waste gas output and treatment sequences, the spray tower is arranged on the upper portion of the closed filter pond, a waste gas output end of the waste gas pipeline and the bottom of the spray tower are communicated with the upper portion of the closed filter pond, a spray head is arranged on the upper portion of the spray tower, a purified air outlet in the top of the spray tower is connected with the purified air pipeline, a clear water supply pipe is connected onto thespray head, and filter water in the closed filter pond can be delivered onto water adding openings of the horizontal powerful mixing machines by a filter water delivery pump and a filter water delivery pipe. The quicklime slaking equipment system has the advantages that the quicklime slaking rate can be increased, the equipment operation reliability can be improved, quicklime slaking and dust removal can be integrated, and waste gas and waste water zero-discharge effects can be realized.

Owner:江阴市创裕机械有限公司

Fish feed containing Chinese herbal medicine formula and preparation method of fish feed

InactiveCN106343268AImprove immunityFast growthFood processingClimate change adaptationDiseasePlant disease

The invention discloses a fish feed containing a Chinese herbal medicine formula. The fish feed comprises the following components in parts by weight: 4-6 parts of green tea, 5-7 parts of residues of Fructus Hippophae, 2-4 parts of Radix Et Rhizoma Rhei, 1-3 parts of Cortex Phellodendri, 2-3 parts of Radix Scutellariae, 1-3 parts of Cortex Eucommiae, 6-8 parts of branches and leaves of Melia azedarach L., 1-2 parts of garlicin, 2-4 parts of vitamin, 110-130 parts of silkworm chrysalis, 70-90 parts of fish meal, 340-360 parts of bean pulp, 60-80 parts of peanut residues, 190-210 parts of wheat bran, 160-180 parts of corn and 8-12 parts of salt. The invention further provides a preparation method of fish feed containing the Chinese herbal medicine formula. The fish feed does not have side effect, does not have chemical drug residues, does not damage micro-ecological balance in water, further can enhance fish immunity, prevents diseases, reduces morbidity, effectively reduces use amount of medicines, and guarantees safety of quality of aquatic water.

Owner:上林县维度食品有限公司

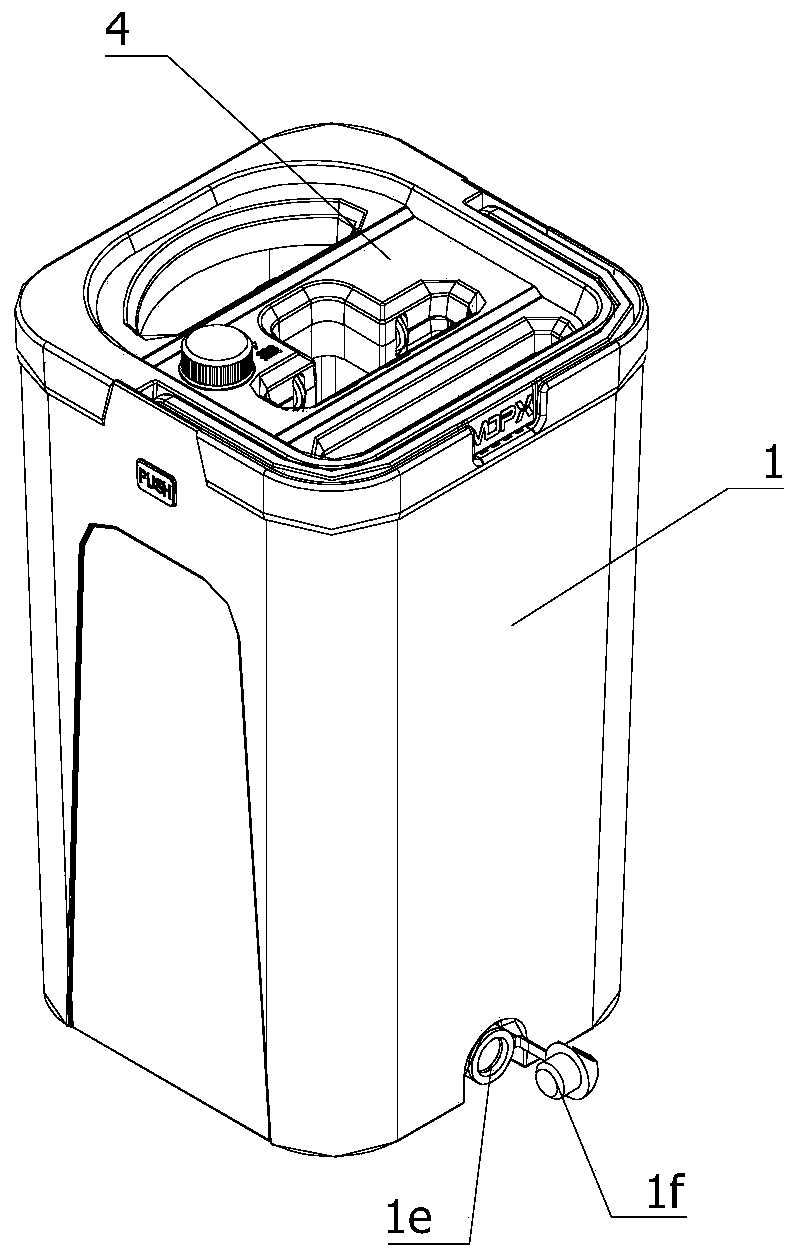

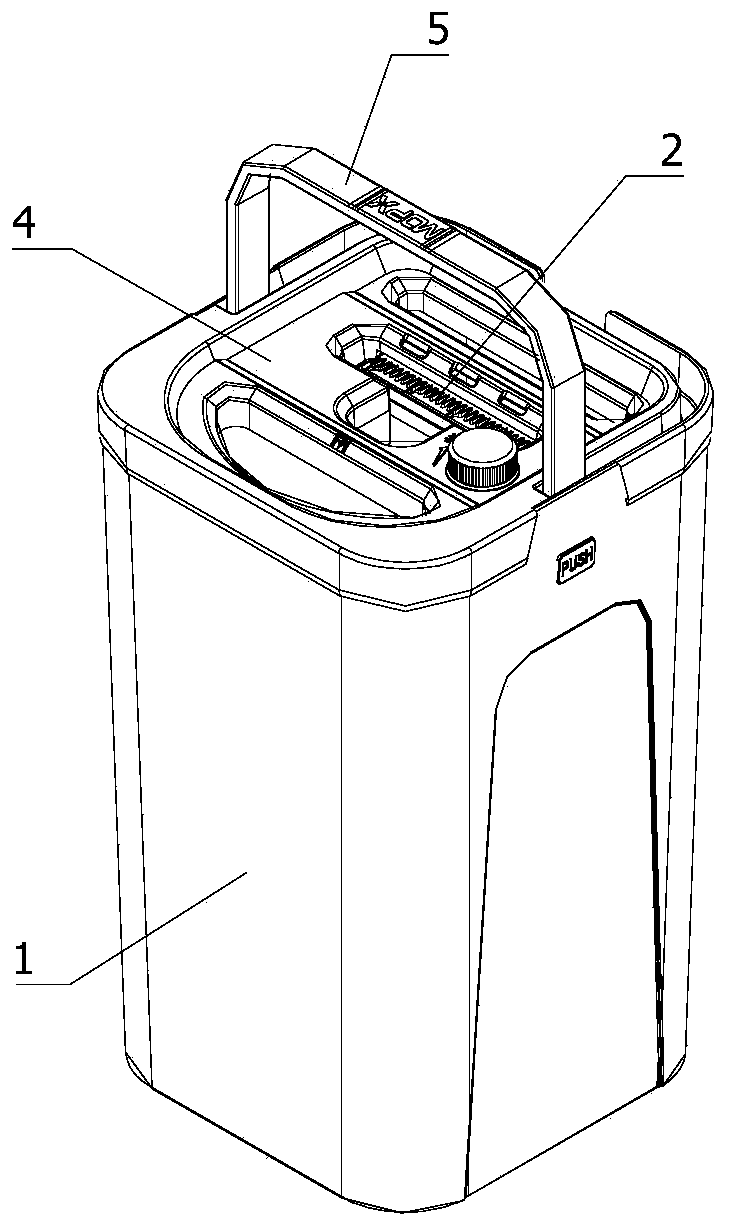

Flat mop cleaning barrel and flat mop cleaning method

The invention relates to the technical field of mop barrels, and particularly relates to a flat mop cleaning barrel and a flat mop cleaning method. The flat mop cleaning barrel comprises a barrel body, wherein a clean water region, a sewage cleaning and dewatering region, a sewage region and a heightening region which are independent of each other are arranged in the barrel body; the clean water region, the sewage cleaning and dewatering region and the sewage region are adjacently arranged in the horizontal direction; the clean water region and the heightening region are adjacently arranged inthe vertical direction; the heightening region is located below the clear water region, and the bottom height of the sewage cleaning and dewatering region is flush with that of the heightening region; a sewage cleaning and water squeezing device with the water outlet direction facing the sewage region is mounted at the top end of the sewage cleaning and dewatering region; a water passing hole communicated with the clean water region and the sewage cleaning and dewatering region is formed in the barrel body; the water passing hole is formed in the position close to the bottom of the clear water region; and the barrel body is provided with a control valve assembly for opening and closing the water passing hole. The mop cleaning barrel is combined with the flat mop cleaning method, clear water and sewage can be effectively isolated, a situation that sewage water flows reversely to contaminate the clean water is avoided, and the clean water utilization rate of the mop cleaning barrel is high.

Owner:王玉龙

Sponge city seepage structure and sponge city water circulation system

ActiveCN110952640BReduce cloggingLarge coverage areaFatty/oily/floating substances removal devicesSewerage structuresSoil scienceWater circulation

Owner:南京金海设计工程有限公司

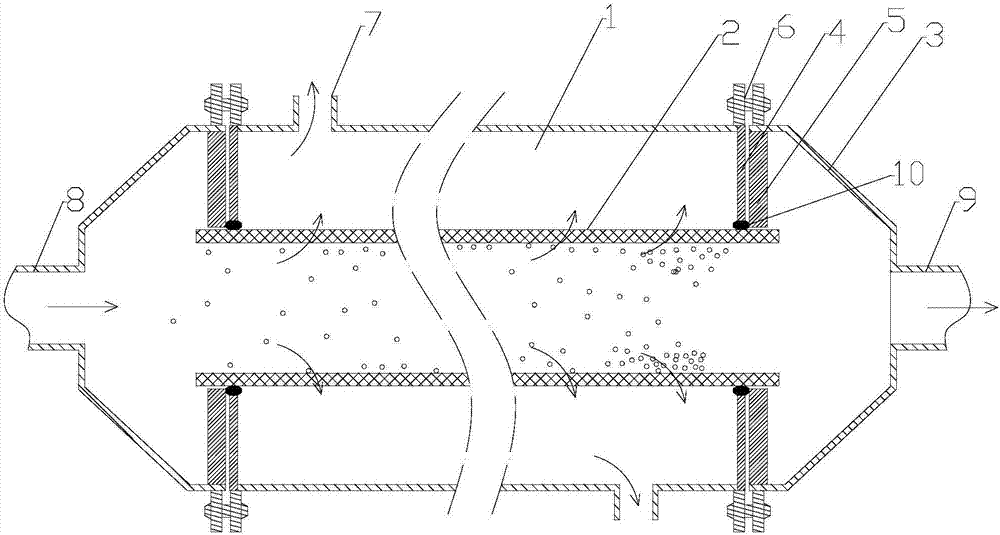

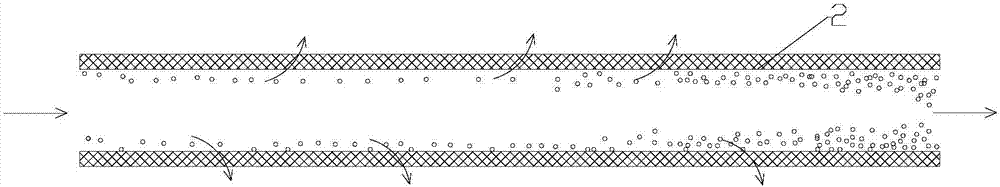

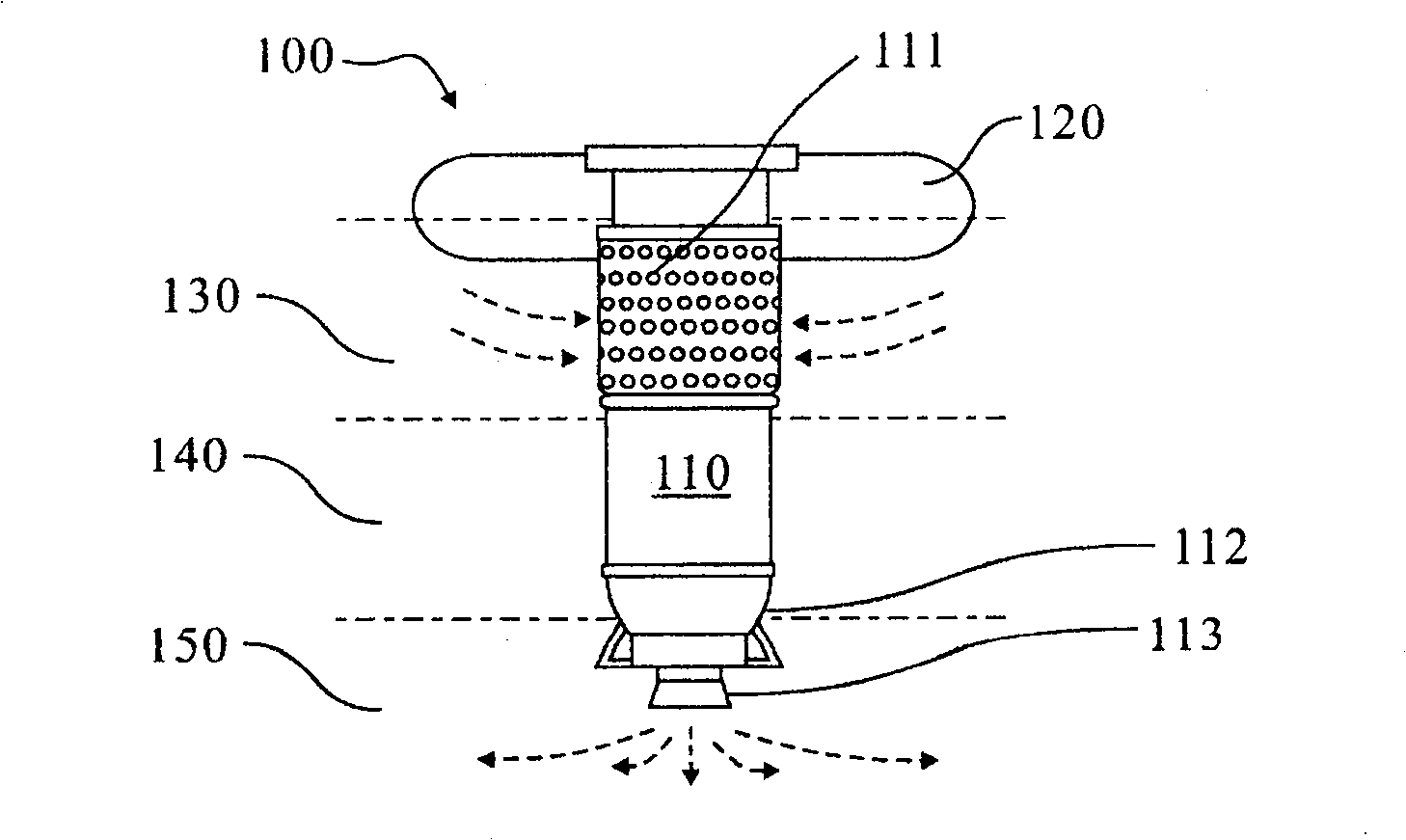

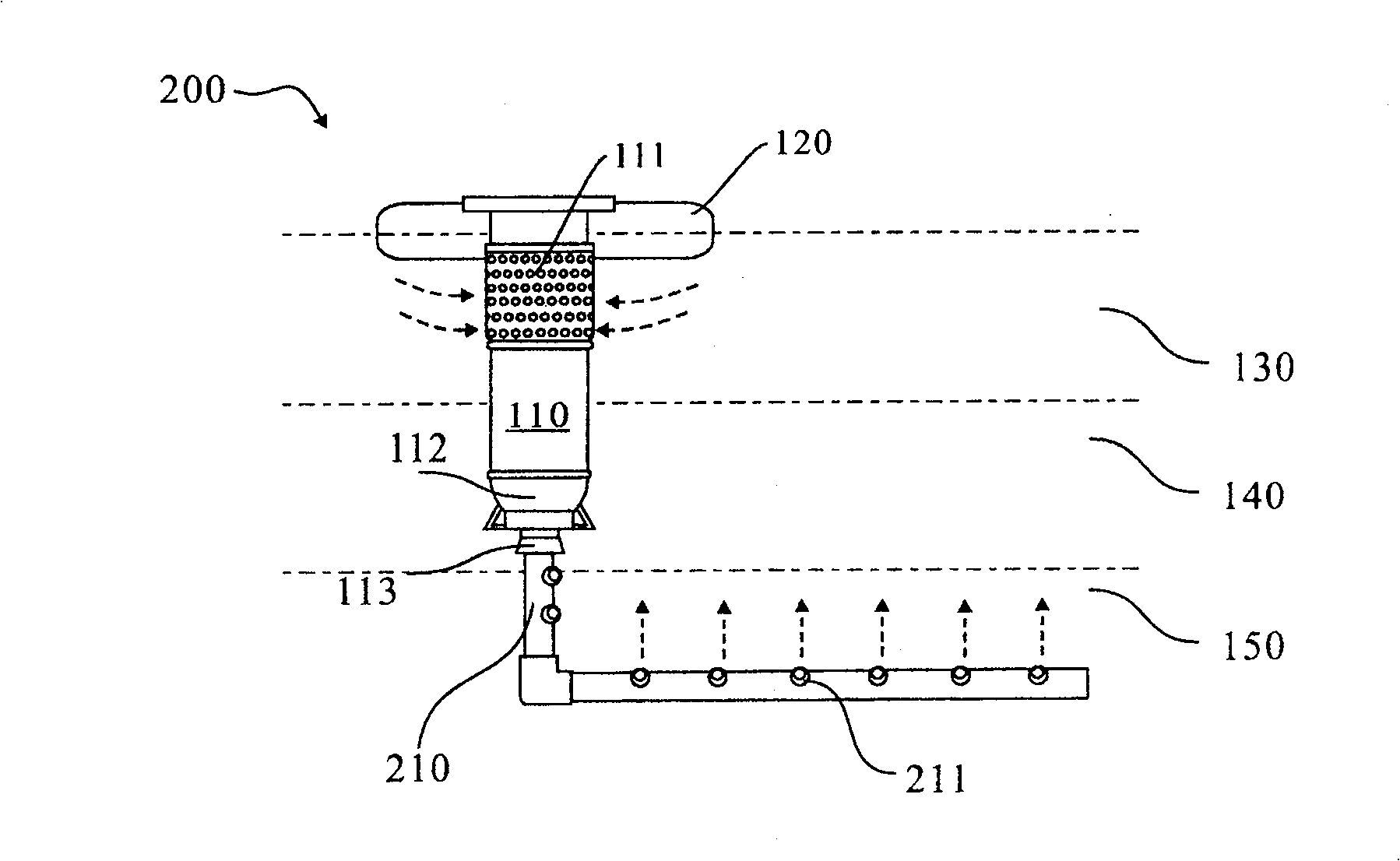

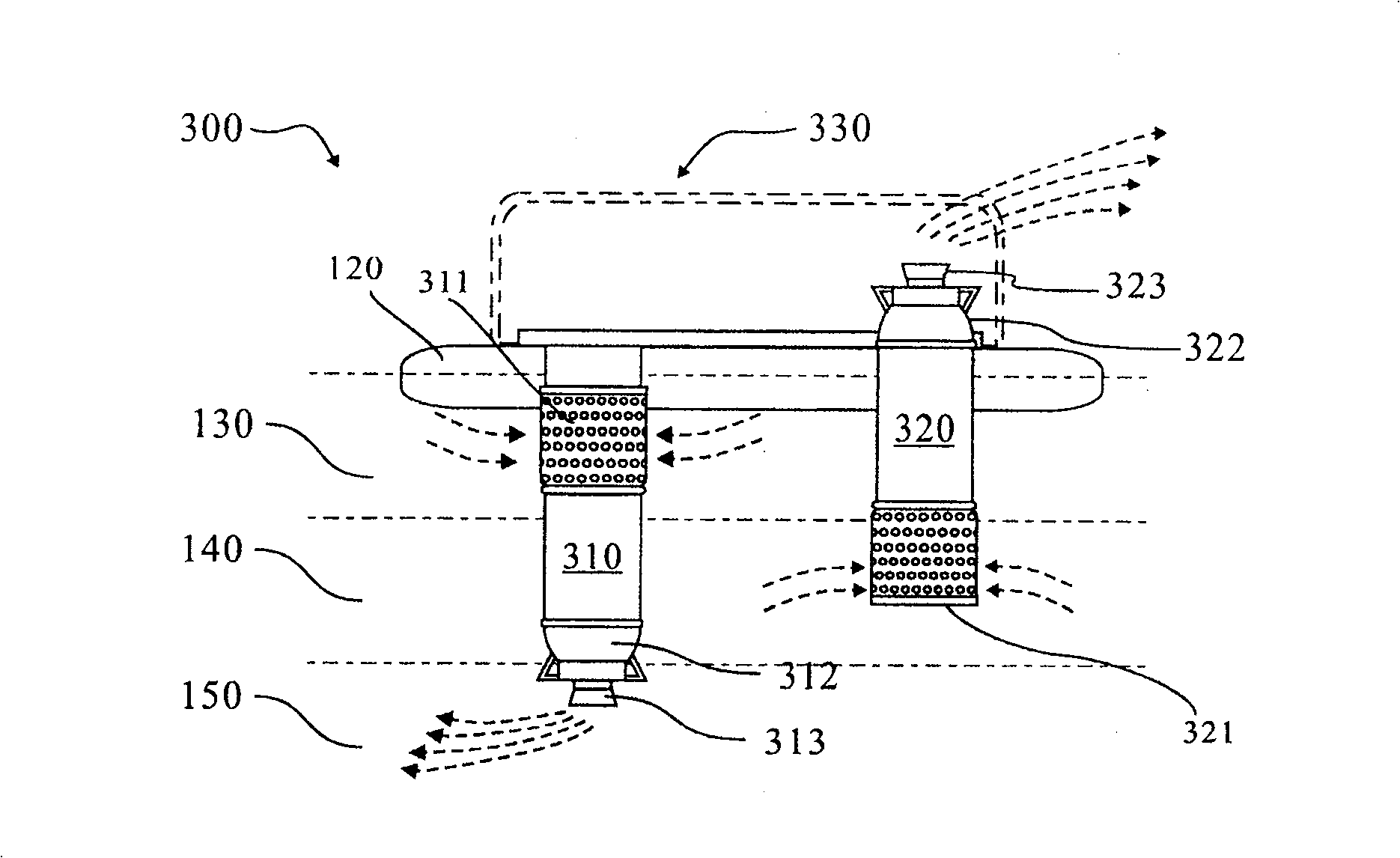

Aeration device and aeration equipment

InactiveCN100528773CReduce headIncrease dissolved oxygenFlow mixersTransportation and packagingLiquid jetAeration

The present invention relates to a kind of aeration equipment, which is used in a pool, which includes: a support; at least one upright aeration device, which is arranged on the support, and the or these upright aeration devices include A first pump, a first water inlet and a first water outlet; at least one reverse aeration device, set on the support, the or these reverse aeration devices include a second pump, a a second water inlet and a second water outlet, wherein the second water inlet is connected to the second pump; and a controller for controlling the switches of the positive aeration devices and the reverse aeration devices, Asymmetric liquid jets are generated to form thrust, so that the aeration equipment can circulate and move in the pool by itself. The present invention can not only adjust the oxygen content rate of pool water with different depths in the pool, but also move circularly in a specific direction in the pool, thereby reducing the demand for aeration equipment per unit area.

Owner:蔡荣锋 +1

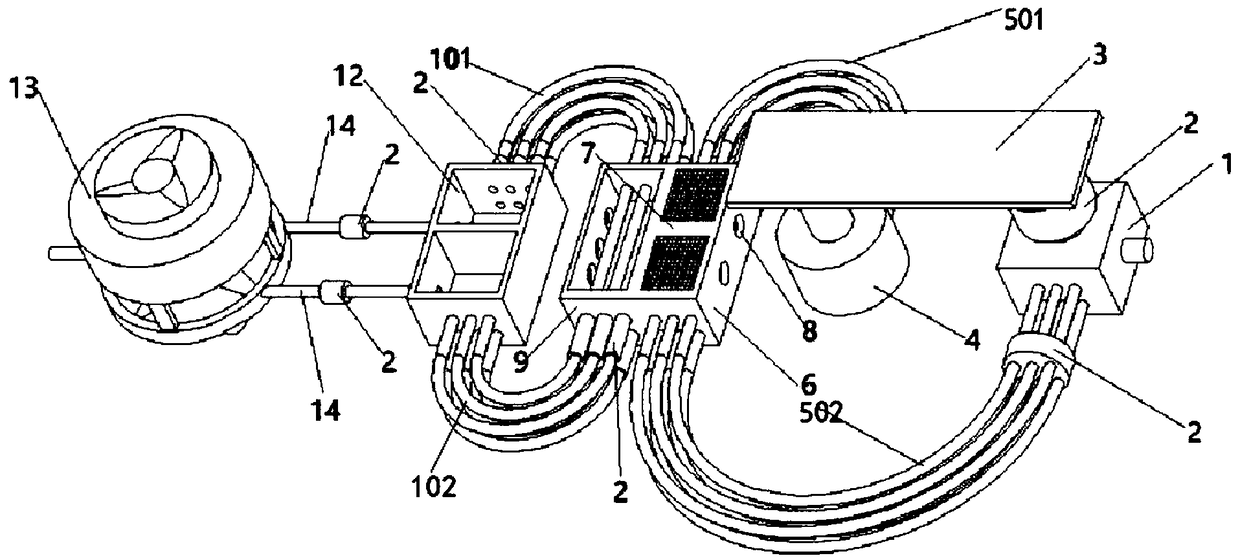

Dedusting and dehumidifying hot air circulation drying system

InactiveCN111964393AAchieve recyclingRealize the effect of condensation and dehumidificationDrying gas arrangementsDrying solid materialsWater storage tankDust control

The invention discloses a dedusting and dehumidifying hot air circulation drying system, and belongs to the technical field of drying equipment. A hot air circulation system is composed of a hot air furnace, a drying roller, a first discharging pipe, a first air conveying pipe, a cyclone dust collector, a second air conveying pipe, a condenser, a third air conveying pipe, a first draught fan, a fourth air conveying pipe and a fifth air conveying pipe, and the purpose of recycling air heated by a burner is achieved; the first draught fan, a second draught fan and a combustion furnace are started, the combustion furnace sucks external air into a hot blast stove, and external high-temperature steam is connected into a high-temperature steam connector, so that the high-temperature steam entersthe hot blast stove, and the the air heated by the combustion furnace and the high-temperature steam are mixed and then enter the drying roller together; and the water level of cooling water in a water storage tank can be continuously increased along with the condensation process, the cooling water is drained through a drain pipe at the moment, and the temperature of the cooling water after beingheated by the high-temperature steam is about 98 DEG C, so that the drained cooling water is utilized at most, and the effect of utilizing residual water is achieved.

Owner:ZHEJIANG YOUPIN BIOTECH CO LTD

Improved siphon circulation hydroelectric generation device

InactiveCN103790758AOperation is basically the sameRun consistentlyHydro energy generationMachines/enginesSiphonBlowoff valve

The invention relates to an improved siphon circulation hydroelectric generation device which is composed of a water storage tank, a siphon pipe, a buffering water tank and an electric generator. The water storage tank is arranged above the buffering water tank, the siphon pipe is a slant pipe connected between the water storage tank and the buffering water tank, the low end of the siphon pipe is provided with a siphon pipe bottom valve, the bottom of the water storage tank is provided with a water inlet pipe connected with the electric generator, a blowoff valve is arranged at the top of the water storage tank, a water feeding pipe is connected between the water storage tank and the buffering water tank, the low end of the water feeding pipe is provided with a pump and a gate valve, the water passing cross sectional area of the siphon pipe is larger than or equal to the water passing cross sectional area of the water inlet pipe, and the blowoff valve is an automatic stopping valve in water level signal linkage with the water storage tank. When water is fed into the water storage tank, the blowoff valve is opened, air in the water storage tank is discharged, and the blowoff valve is automatically closed when the water storage tank is filled with the water and the water is overflowed. According to the improved siphon circulation hydroelectric generation device, the surging hidden dangers of the negative pressure in the electric generation process are eliminated, the amount of the water coming in and going out of the water storage tank is basically balanced, generation of the in-tank vacuum negative pressure is avoided, gentle releasing of water energy in the water storage tank is guaranteed, the electric generation quality is improved, the potential safety hazard that the water storage tank is cracked is eliminated, and the personal and property safety is guaranteed.

Owner:何其兴

Water supplementing and changing device and water supplementing and changing method for seawater tank

ActiveCN113133427AAvoid high or low salinityEnsure salinityPisciculture and aquariaMachines/enginesSea saltSeawater

The invention discloses a water supplementing and changing device and a water supplementing and changing method for a seawater tank. According to the technical scheme, the water supplementing and changing device for the seawater tank is characterized by comprising a mounting frame mounted at the bottom of the seawater tank, and the mounting frame is provided with a water supplementing mechanism for supplementing water, a water changing mechanism for changing seawater, and a control device which is arranged on the mounting frame and is used for controlling the water supplementing mechanism and the water changing mechanism. Water supplementing is achieved through the water supplementing mechanism, and it is ensured that the water amount of the seawater tank is generally kept relatively balanced; Quantitative seawater drainage is achieved through the water changing mechanism, clear water and sea salt are supplemented, it is guaranteed that after seawater is changed, the salinity in water is kept relatively stable all the time, and the condition that after seawater is changed, the salinity is too high or too low is avoided.

Owner:张孟哲

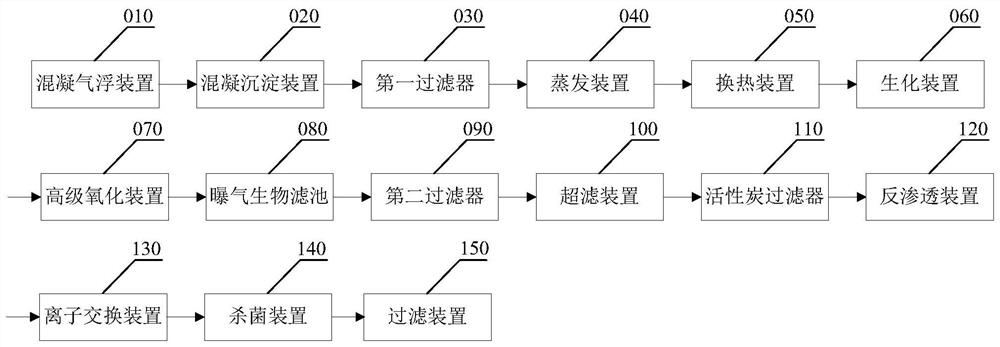

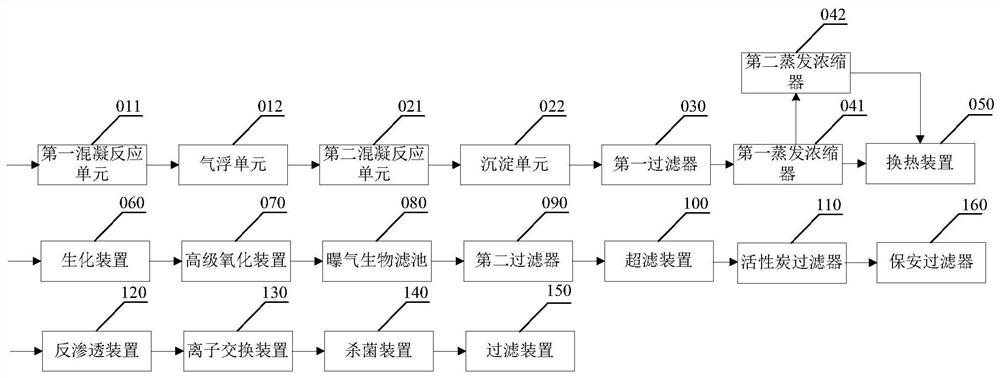

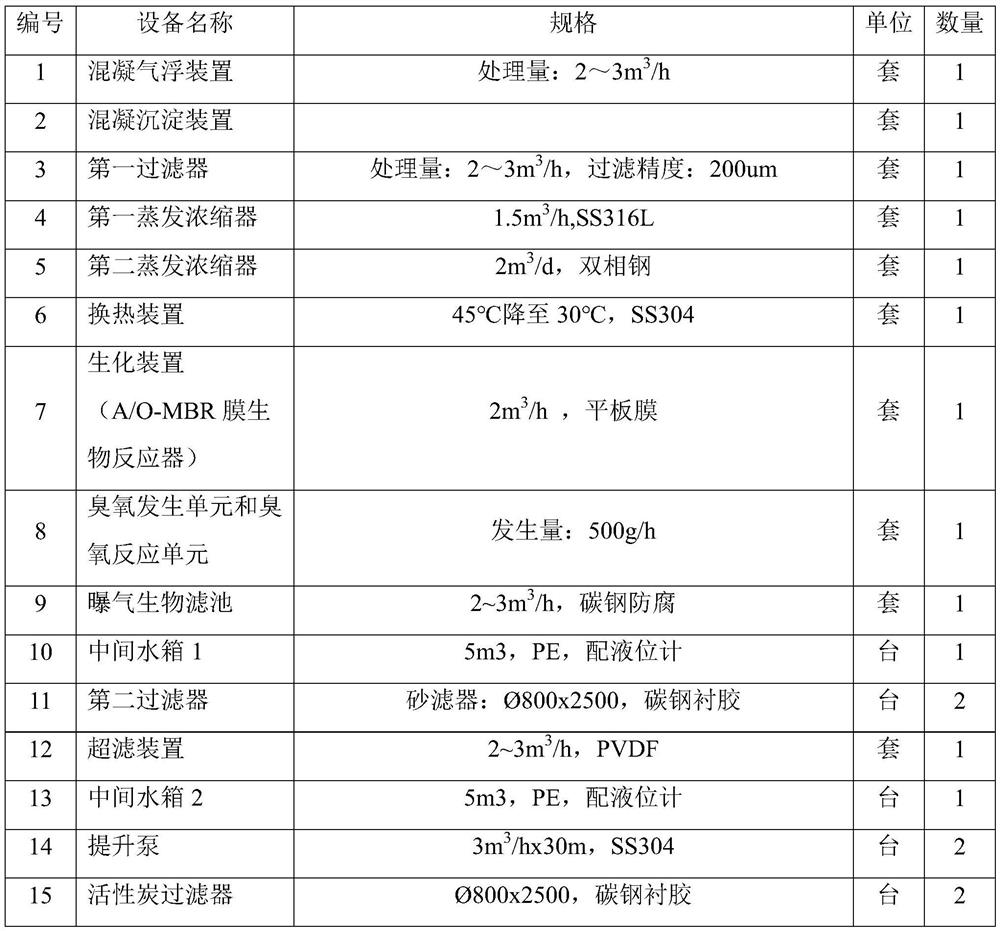

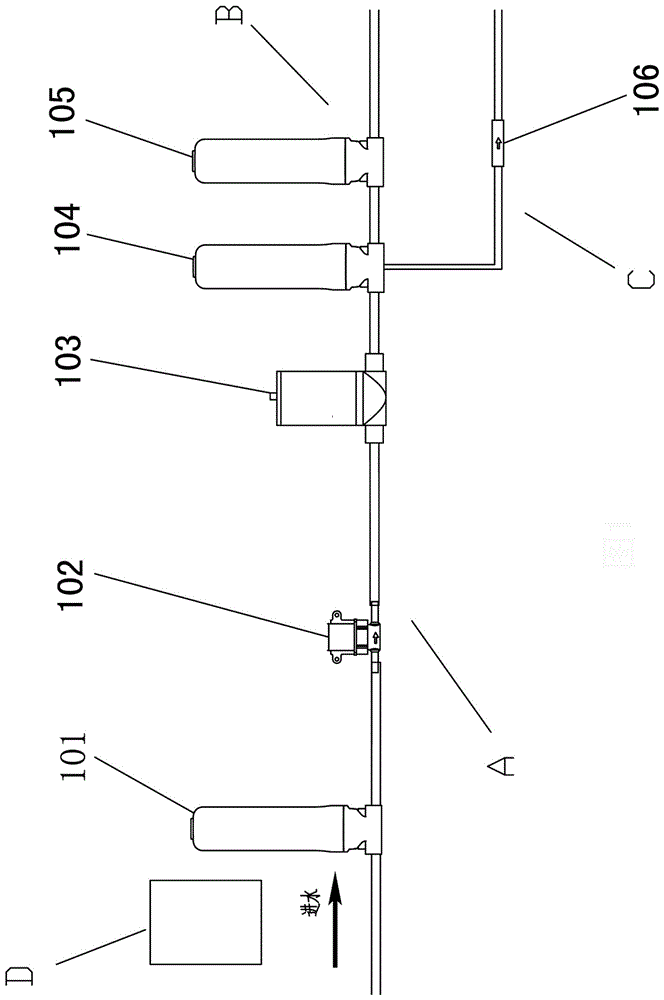

Treatment and reuse system and treatment and reuse method for wastewater produced during cleaning of finished products and/or raw materials of automobile parts

PendingCN112225386AWater balanceGuaranteed uptimeTreatment involving filtrationWaste water treatment from metallurgical processWater treatment systemActivated carbon filtration

The invention provides a treatment and reuse system and a treatment and reuse method for wastewater produced during cleaning of finished products and / or raw materials of automobile parts. The treatment and reuse system comprises a coagulation air floatation device, a coagulation sedimentation device, a first filter, an evaporation device, a heat exchange device, a biochemical device, an advanced oxidation device, a biological aerated filter, a second filter, an ultrafiltration device, an activated carbon filter, a reverse osmosis device an ion exchange device, a sterilization device and a filtering device which are in fluid communication in sequence. According to the invention, the automobile part finished product and / or raw material cleaning wastewater is subjected to advanced treatment and is reused for cleaning the automobile part finished product and / or raw material, an original pure water treatment system device is replaced to achieve the purposes of energy conservation and emission reduction, and the surface of the finished product and / or raw material cleaned by the water has no white spots, water stains and other undesirable quality.

Owner:SHANGHAI YIKE GREEN ENG

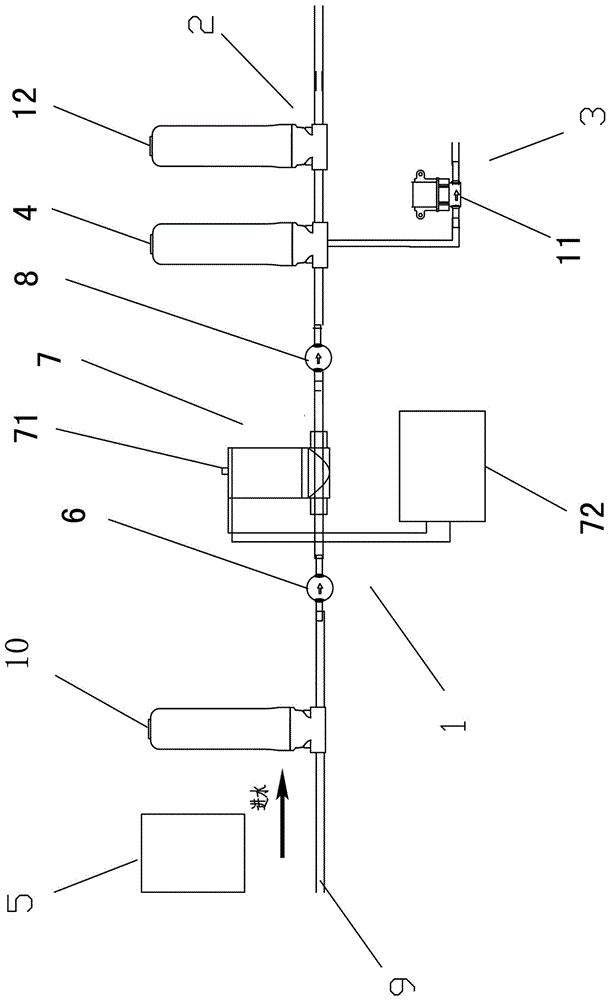

Water purifying system and automatic working pressure adjusting method thereof

ActiveCN105797587AImprove reliabilityExtended service lifeTreatment involving filtrationReverse osmosisReverse osmosisEngineering

The invention discloses a water purifying system and an automatic pressure adjusting method thereof. The water purifying system comprises a filtering part, a pure-water part, a concentrated-water part, a reverse-osmosis filtering core and an electric control device, wherein the filtering part is divided into two paths for output by the reverse-osmosis filtering core, one path goes to the pure-water part, and the other path goes to the concentrated-water part; the filtering part is provided with an inflow-water pressure sensor, a pressure adjusting device and a membrane-front water pressure sensor; the electric control device is electrically connected with the inflow-water pressure sensor, the pressure adjusting device and the membrane-front water pressure sensor. The water purifying system disclosed by the invention has the advantages that the electric control device detects the inflow-water pressure condition of the filtering part according to the inflow-water pressure sensor, the pressure of water about to enter the reverse-osmosis filtering core is adjusted by controlling the pressure adjusting device, and the membrane-front water pressure sensor detects whether the pressure of water about to enter the reverse-osmosis filtering core meets the set value, so that the electric control device can control the pressure adjusting device to work, the balance of the amount of outflow water can be guaranteed, the working reliability also can be improved, and the service life can be prolonged; and the working condition of the pressure adjusting device can be adjusted intelligently, so that an optimum working pressure is provided for the pressure of water about to enter the reverse-osmosis filtering core.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com