Spray needle device of bottle washing machine with balanced water jet capacity

A bottle washing machine, water spraying technology, applied in the direction of spraying device, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of unclean bottle washing with spray needles and uneven water spraying volume, so as to prevent splashing and ensure The effect of cleaning quality, easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

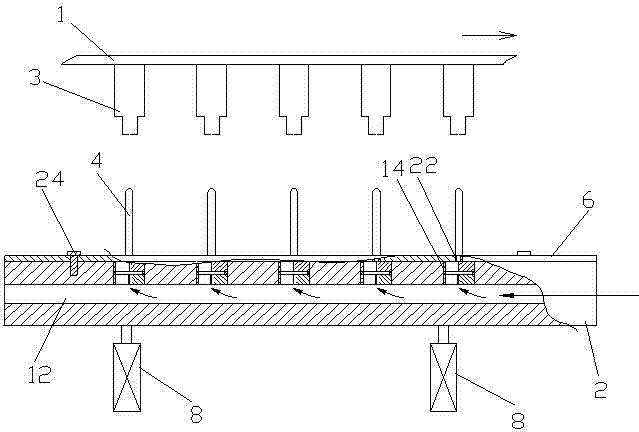

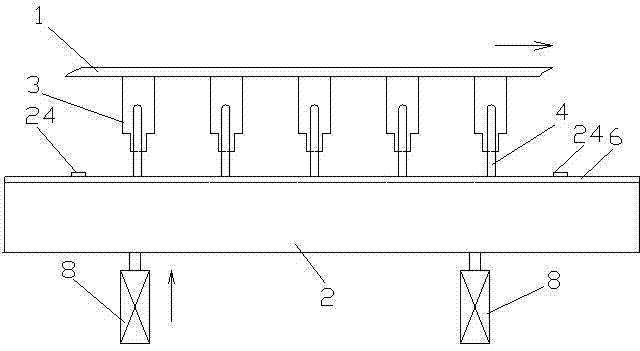

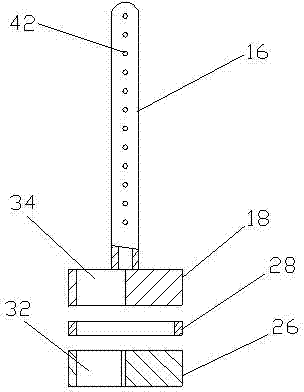

[0022] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0023] Such as Figure 1-6 As shown, a spray needle device for a bottle washing machine with a balanced water spray volume of the present invention includes a horizontally extending flat spray needle frame 2, a plurality of spray needles 4 vertically arranged on the spray needle frame 2, and a plurality of spray needles 4 arranged in parallel on the spray needle frame. One side of the frame 2 is used to fix the cover plate 6 of the spray needle 4 . Wherein, an air cylinder 8 is vertically arranged on the side of the needle holder 2 opposite to the needle 4 . The needle holder 2 includes a water flow channel 12 extending laterally and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com