Patents

Literature

544results about How to "Guaranteed cleaning quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

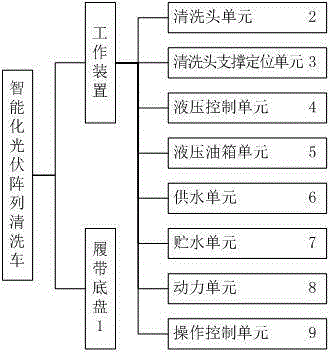

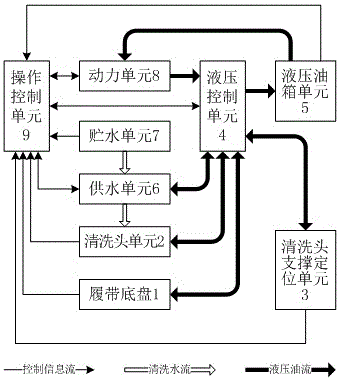

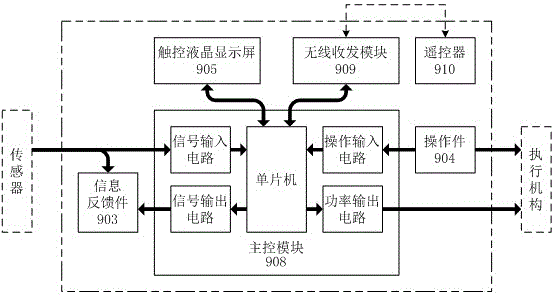

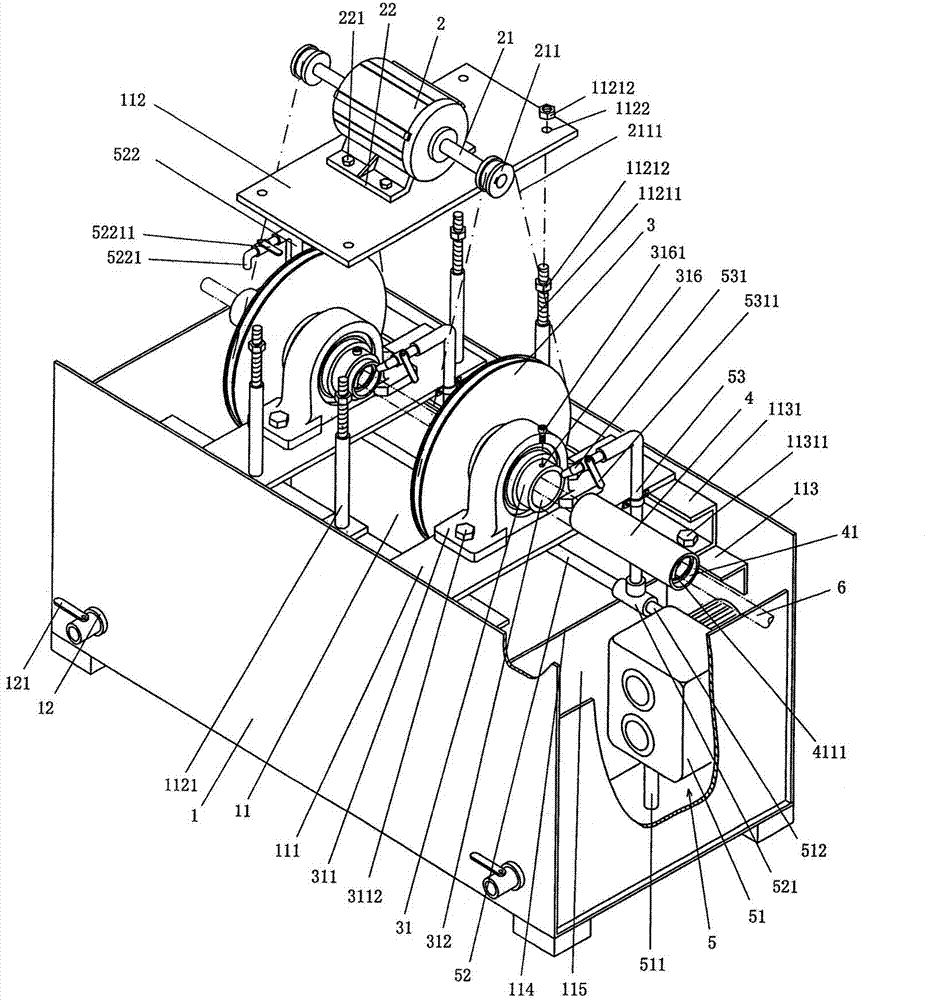

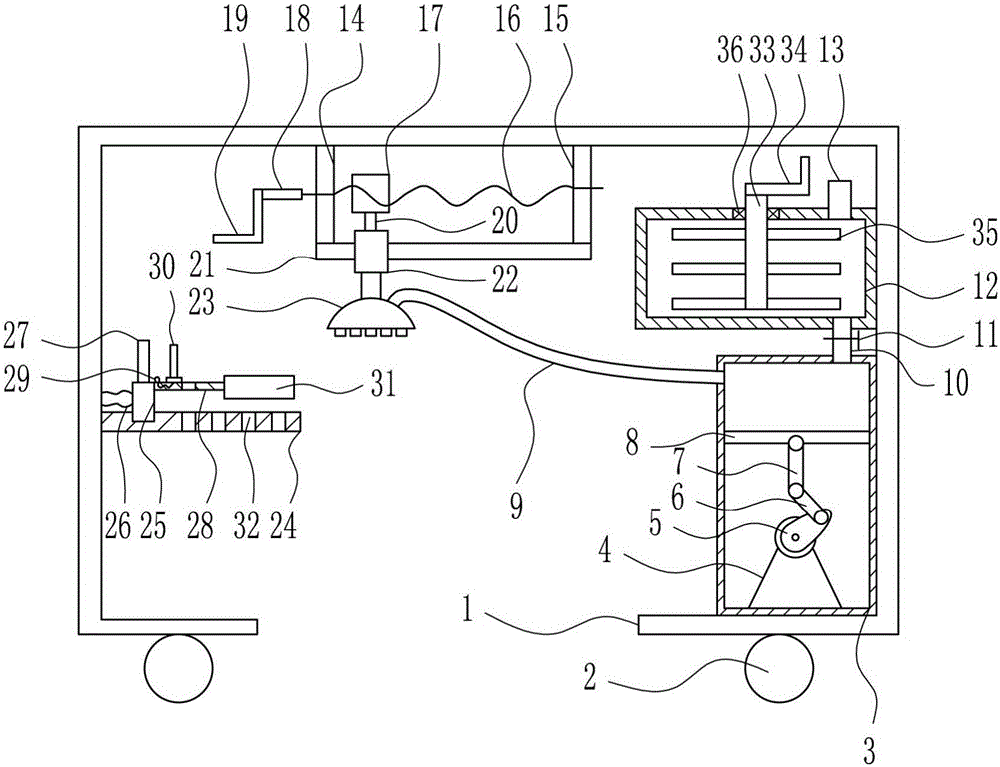

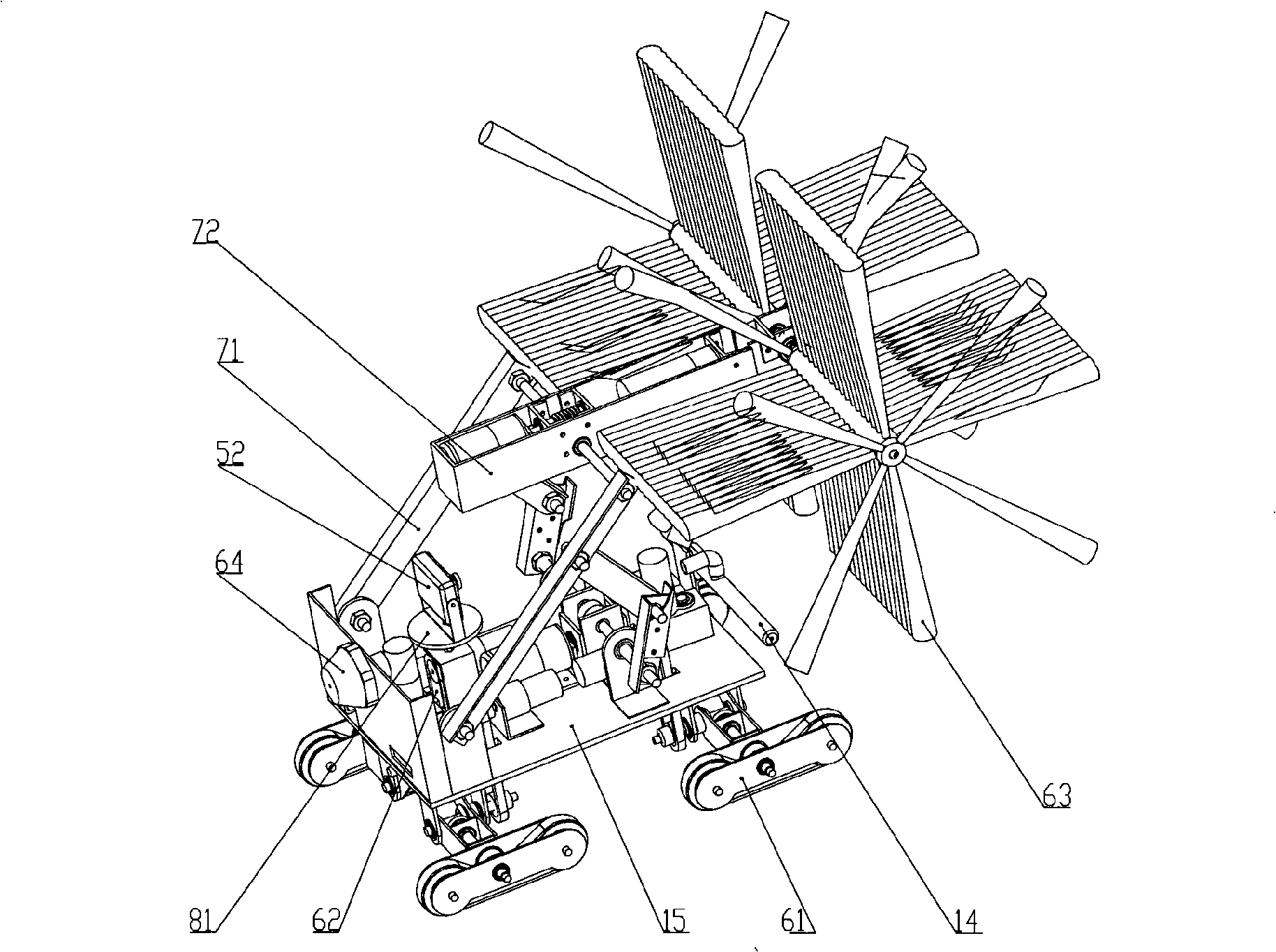

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

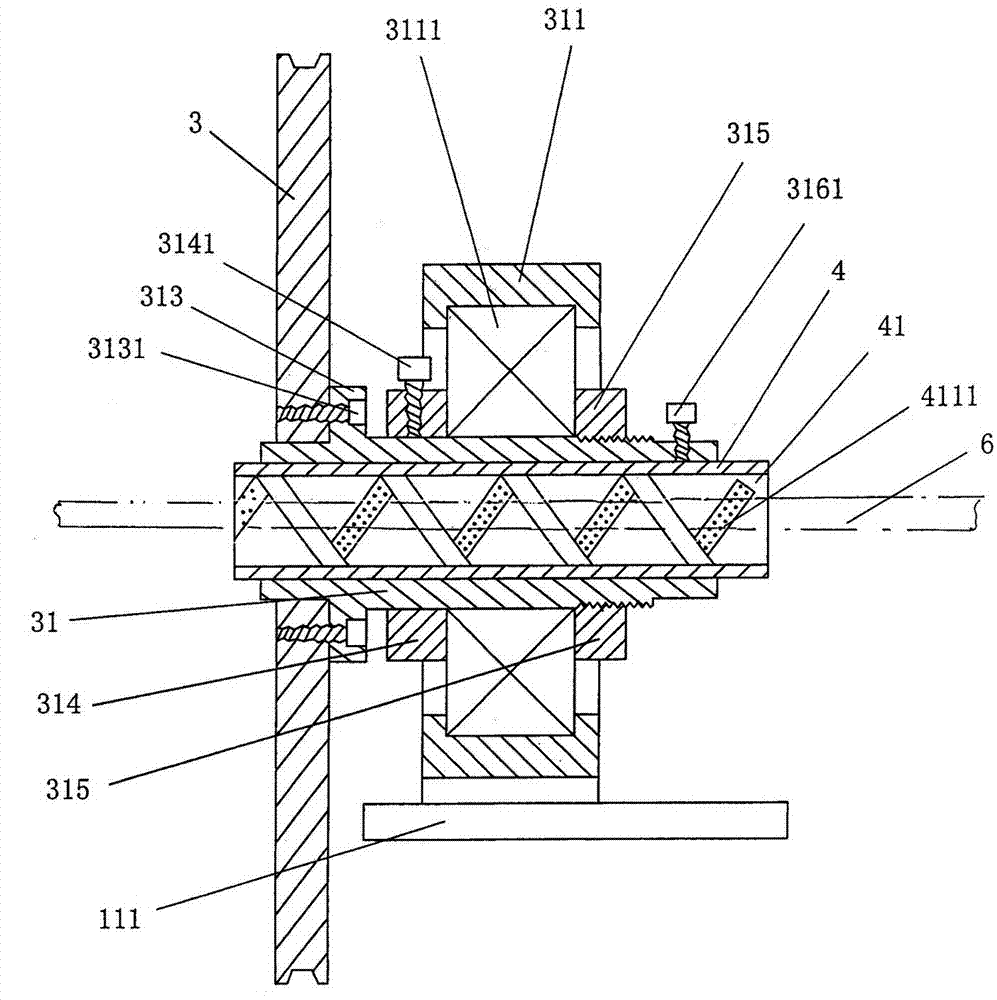

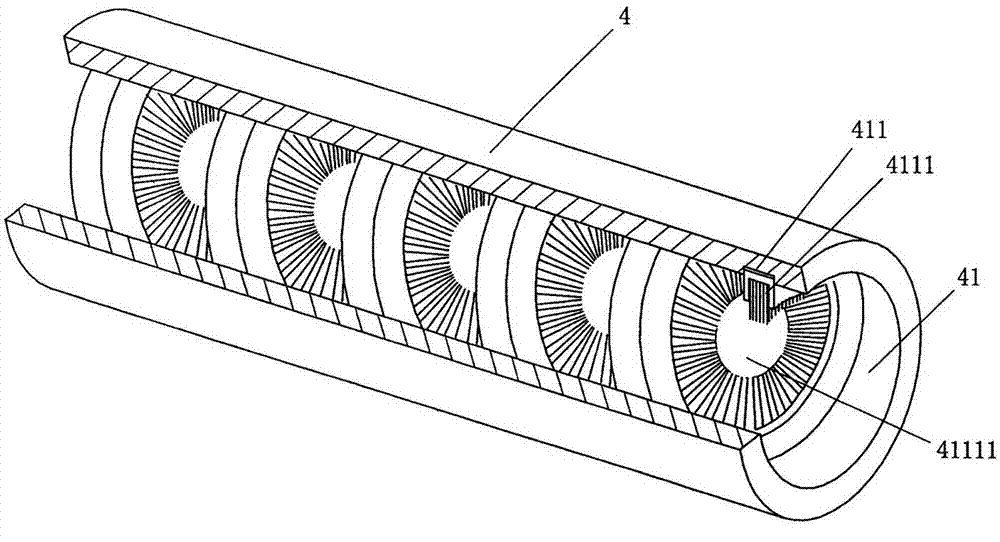

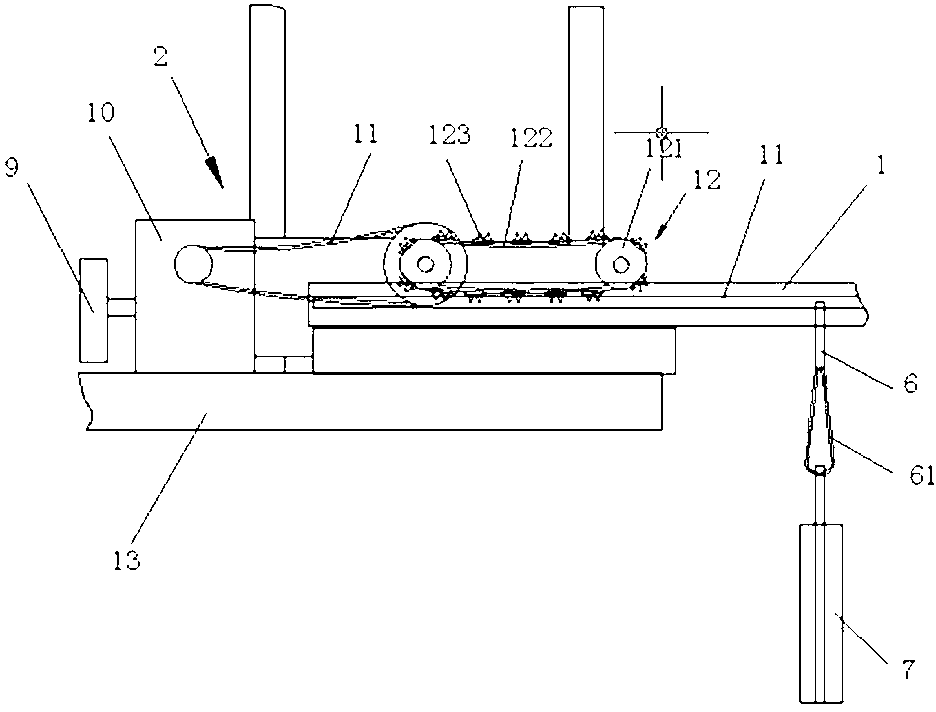

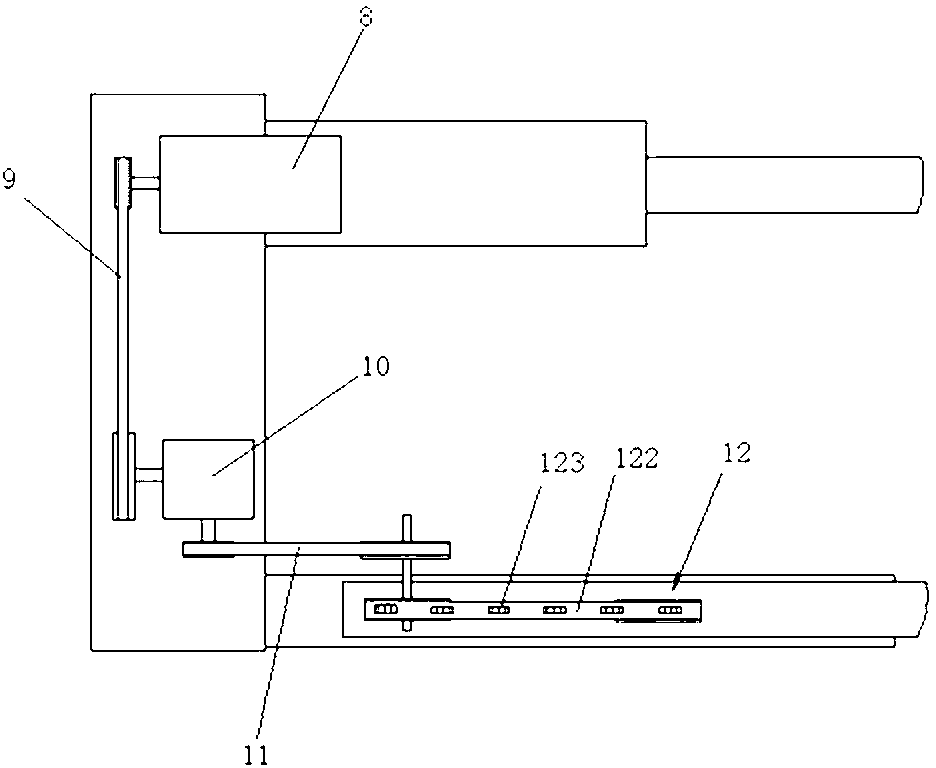

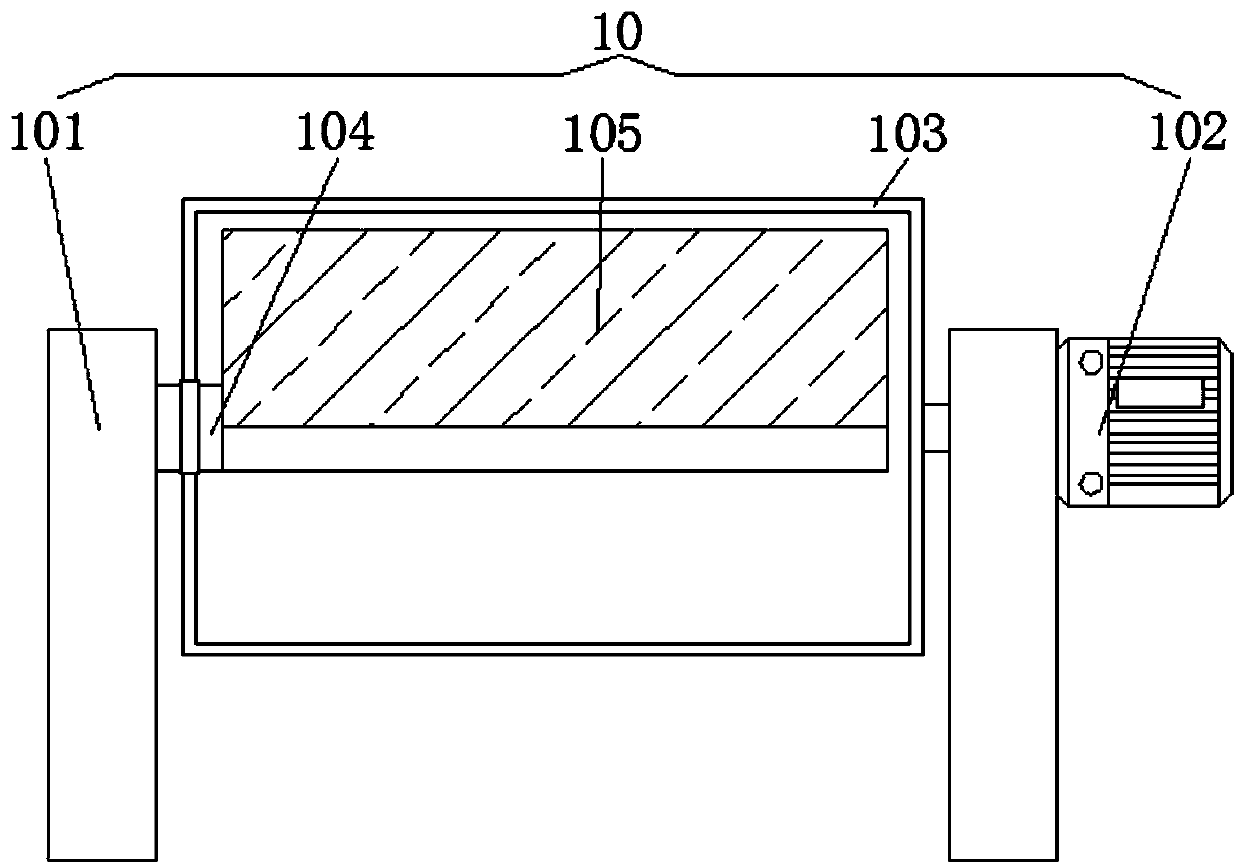

Steel pipe cleaning device

InactiveCN103920677ALong-lasting cleaning effectPlay a cleaning roleHollow article cleaningWork cleaning devicesDrive wheelControl engineering

The invention provides a steel pipe cleaning device, and belongs to the field of metal pipe cleaning machines. The steel pipe cleaning device comprises a cleaning fluid box body and a circulating fluid supply mechanism. A cleaning fluid recycling cavity is formed in the right end of a cavity of the box body, bearing block fixing plates and a motor supporting plate are fixed to the left end of the cavity, shaft sleeve driving wheels are arranged on the bearing block fixing plates, a motor is arranged on the motor supporting plate, motor shaft driving wheels are fixed to the two ends of a motor shaft, one end of a driving belt is arranged on the motor shaft driving wheels, the shaft sleeve driving wheels are sleeved with the other end of the driving belt, one end of each shaft sleeve is fixed to the center of the corresponding shaft sleeve driving wheel, the other end of each shaft sleeve is supported by a corresponding shaft sleeve bearing block, the shaft sleeve bearing blocks are fixed to the bearing block fixing plates, a brush pipe is fixed into shaft sleeve cavities, brush positioning grooves are formed in the inner wall of a brush pipe cavity and in the length direction, and brushes are embedded into the positioning grooves. The circulating fluid supply mechanism is arranged in the cleaning fluid recycling cavity. The structure is simplified, and the brushes make good contact with the outer wall of a steel pipe; transition links are fewer; the brushes have the permanent cleaning effect on the steel pipe, and the cleaning quality is good.

Owner:CHANGSHU WATER SUPPLY & SEWERAGE WORKS CO LTD

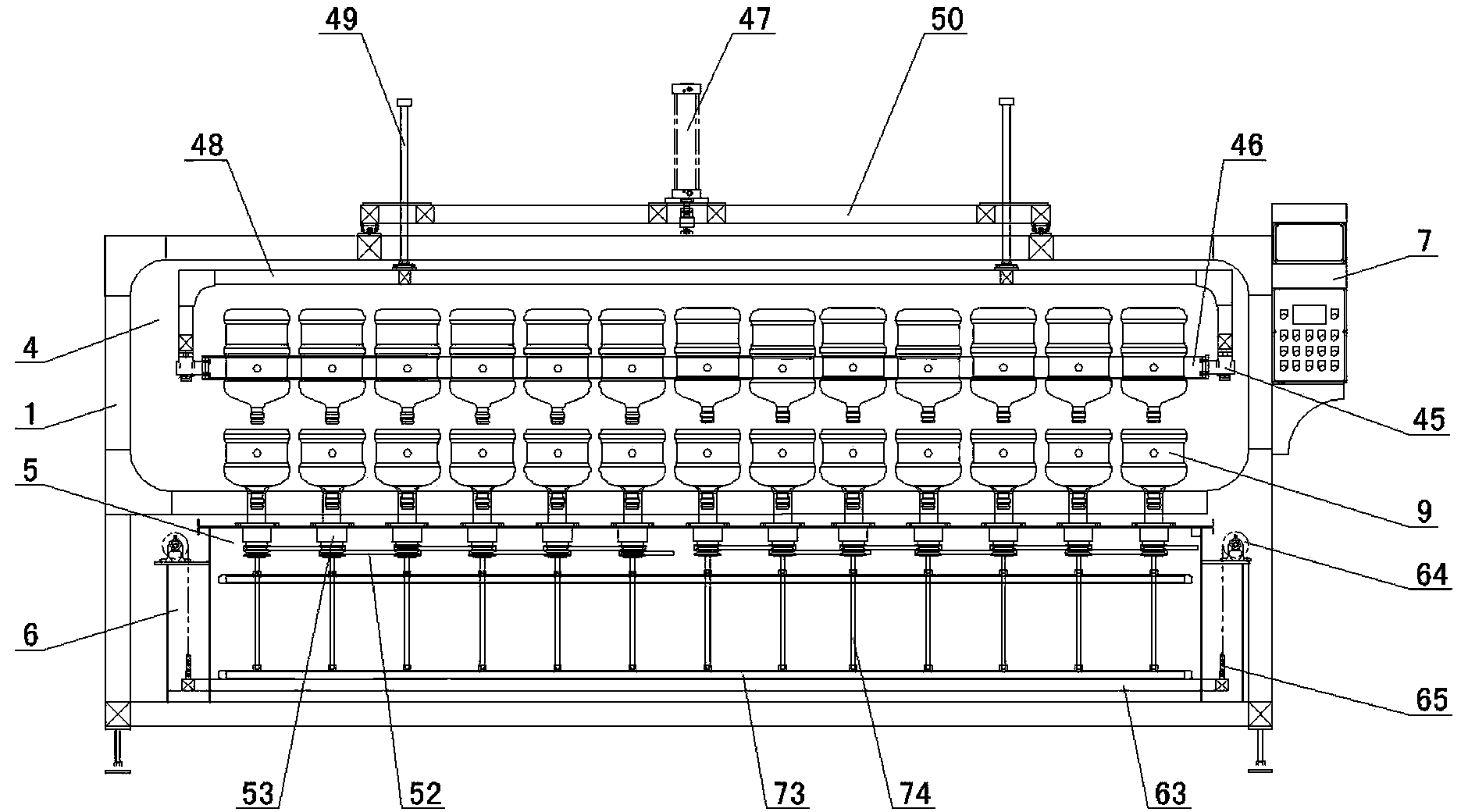

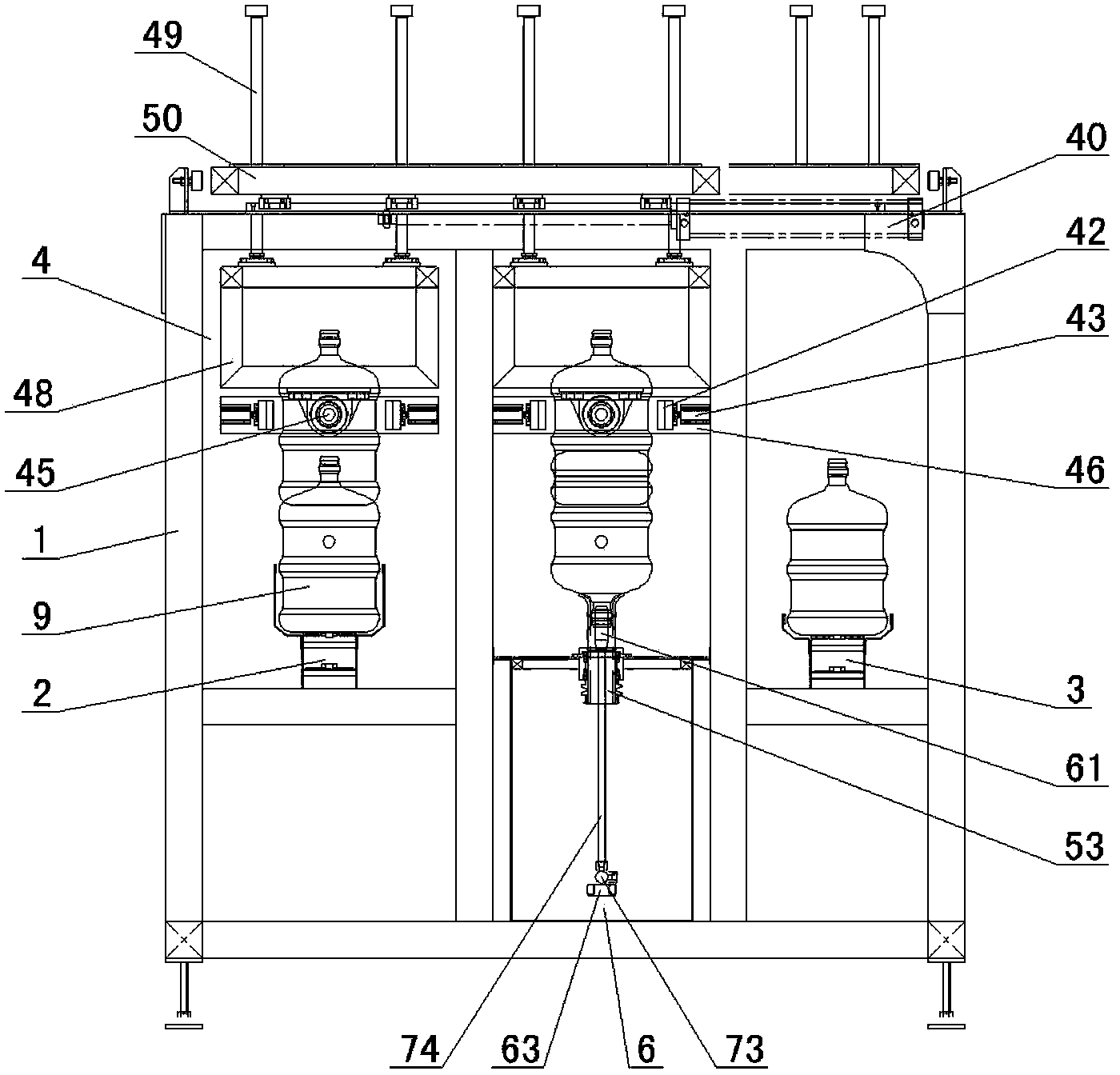

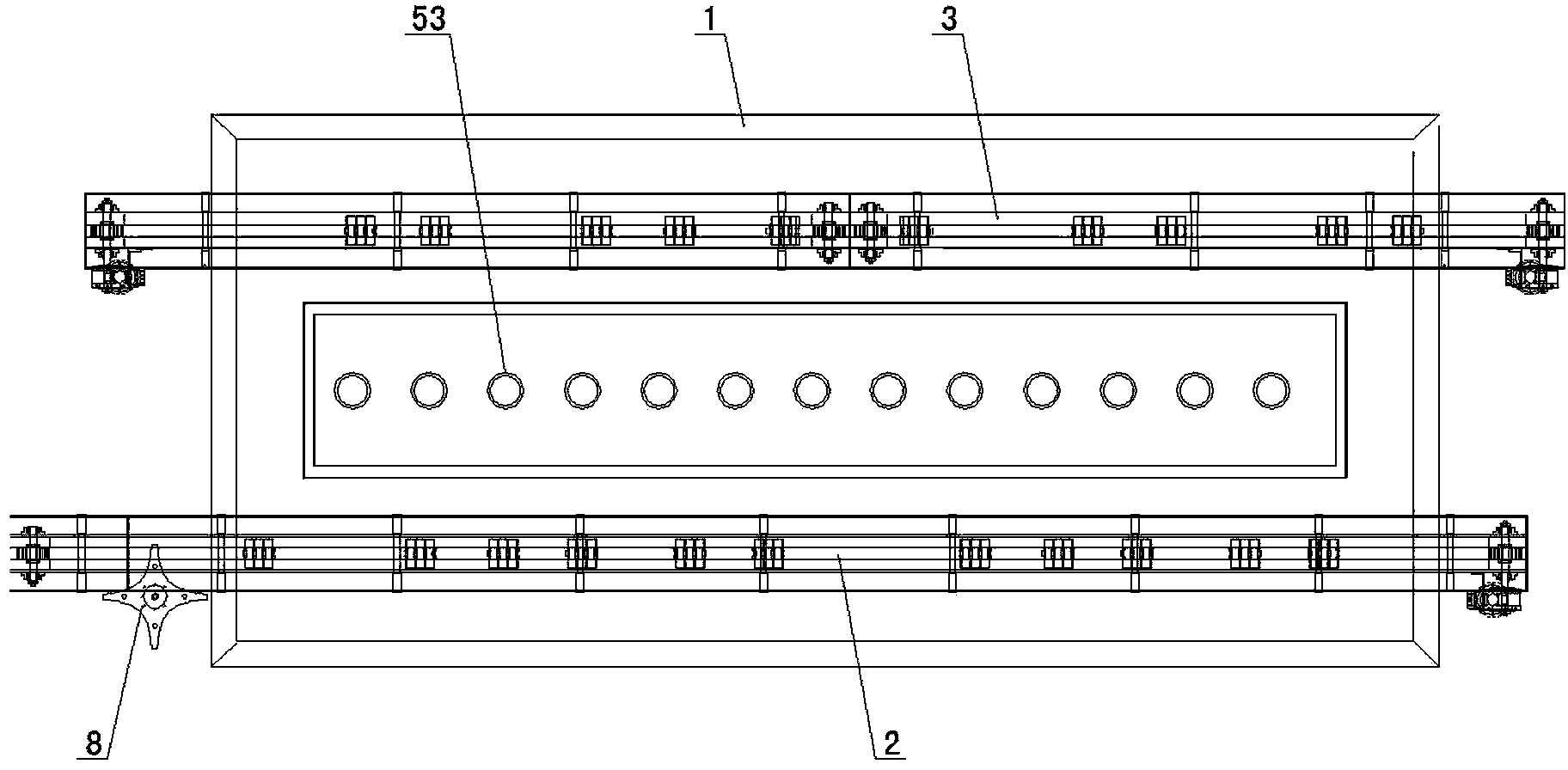

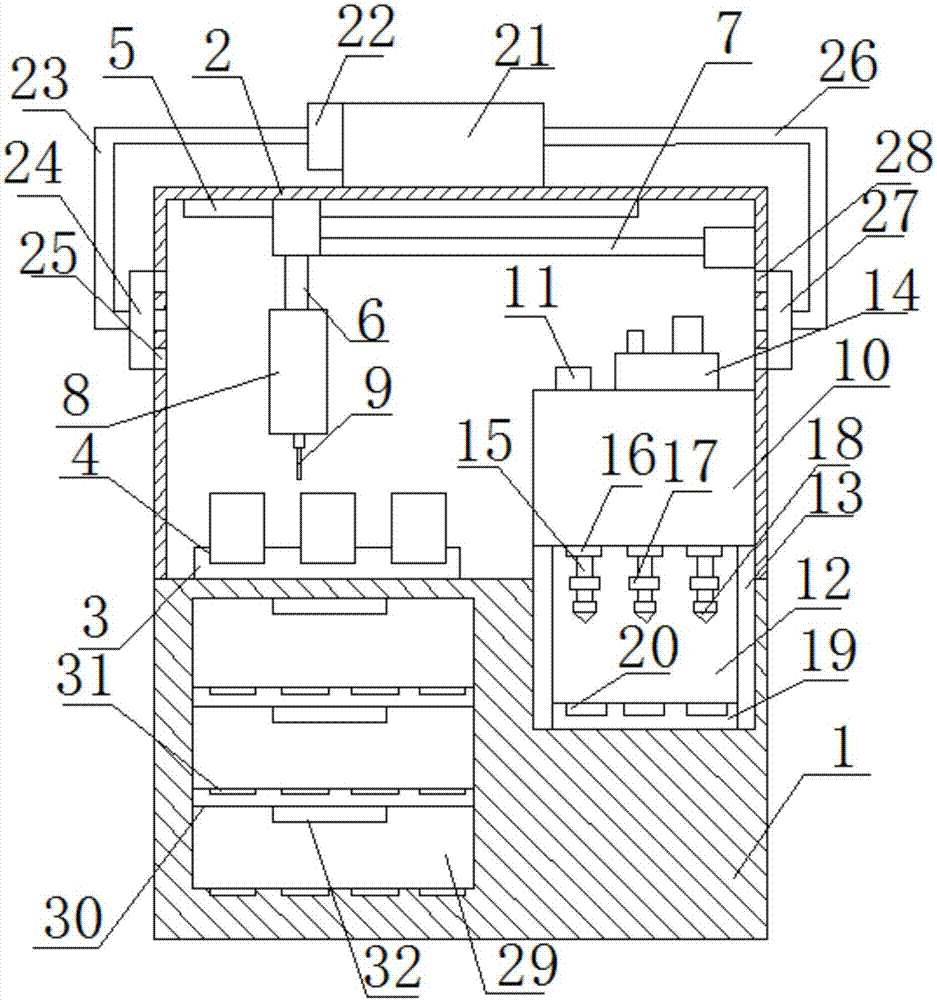

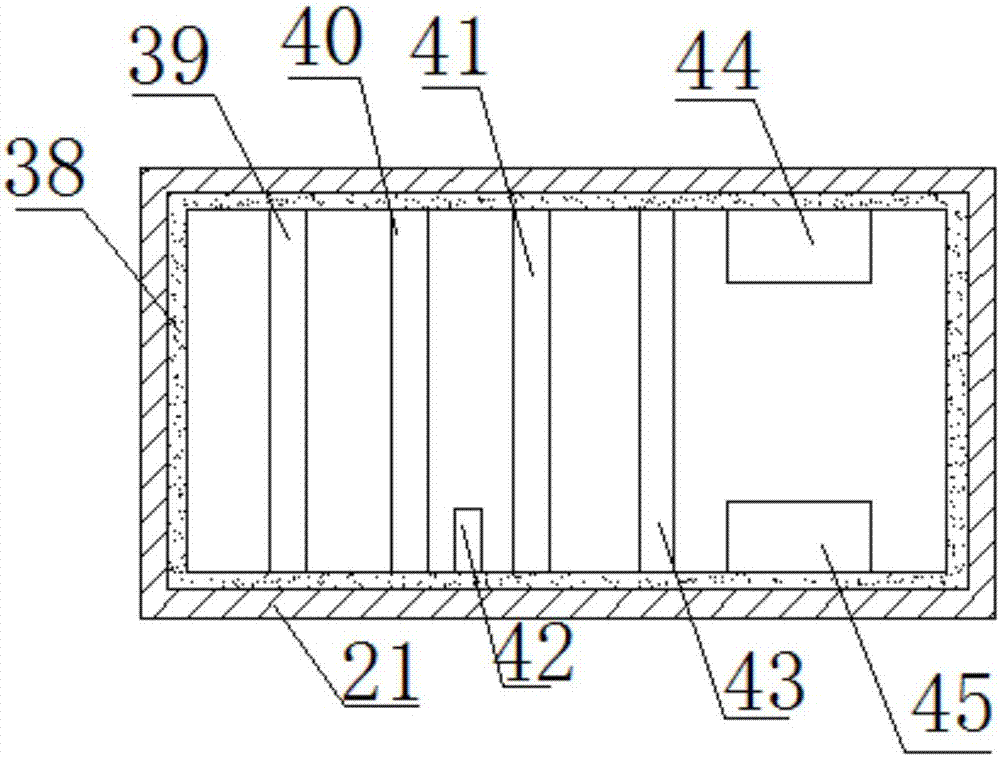

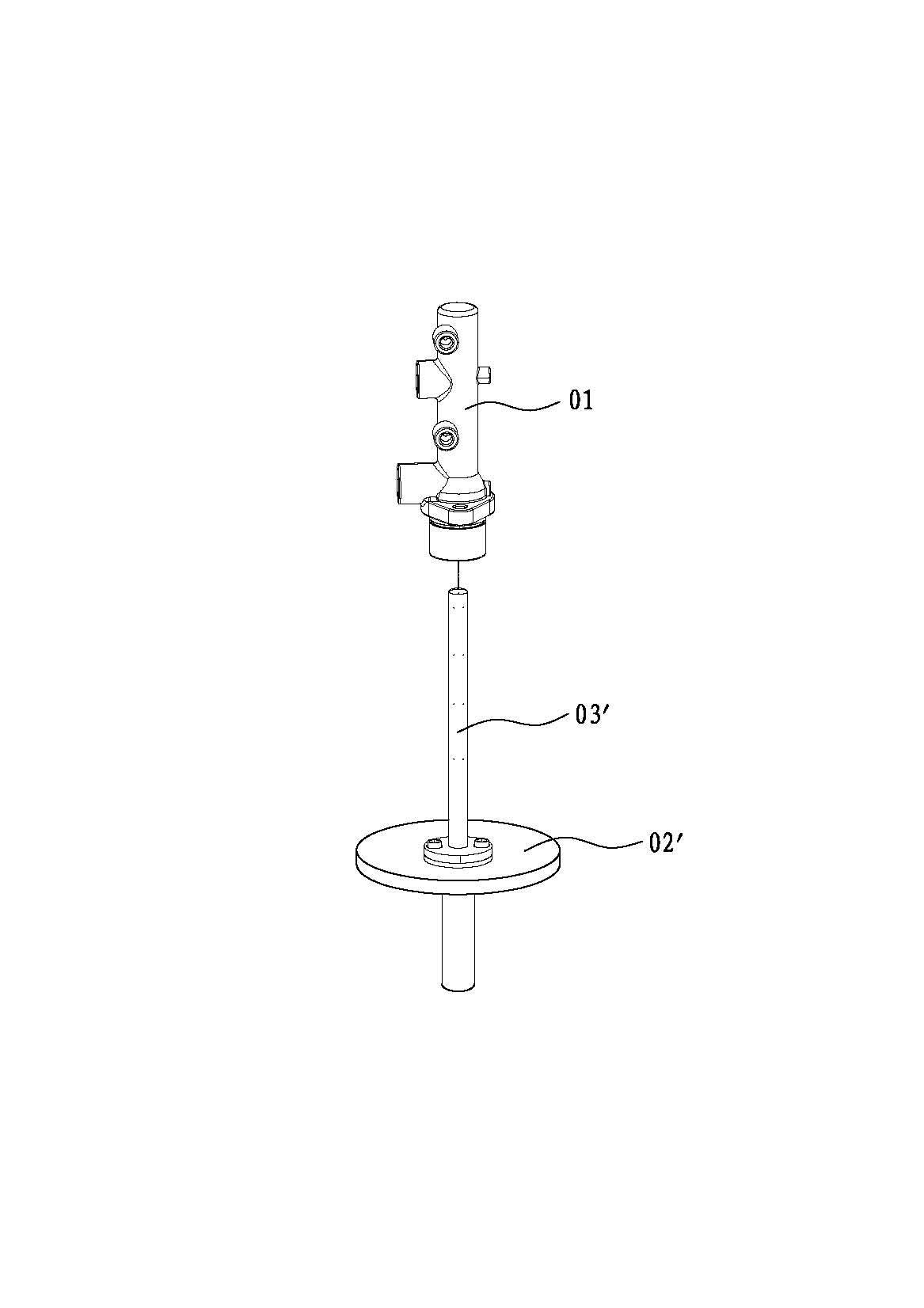

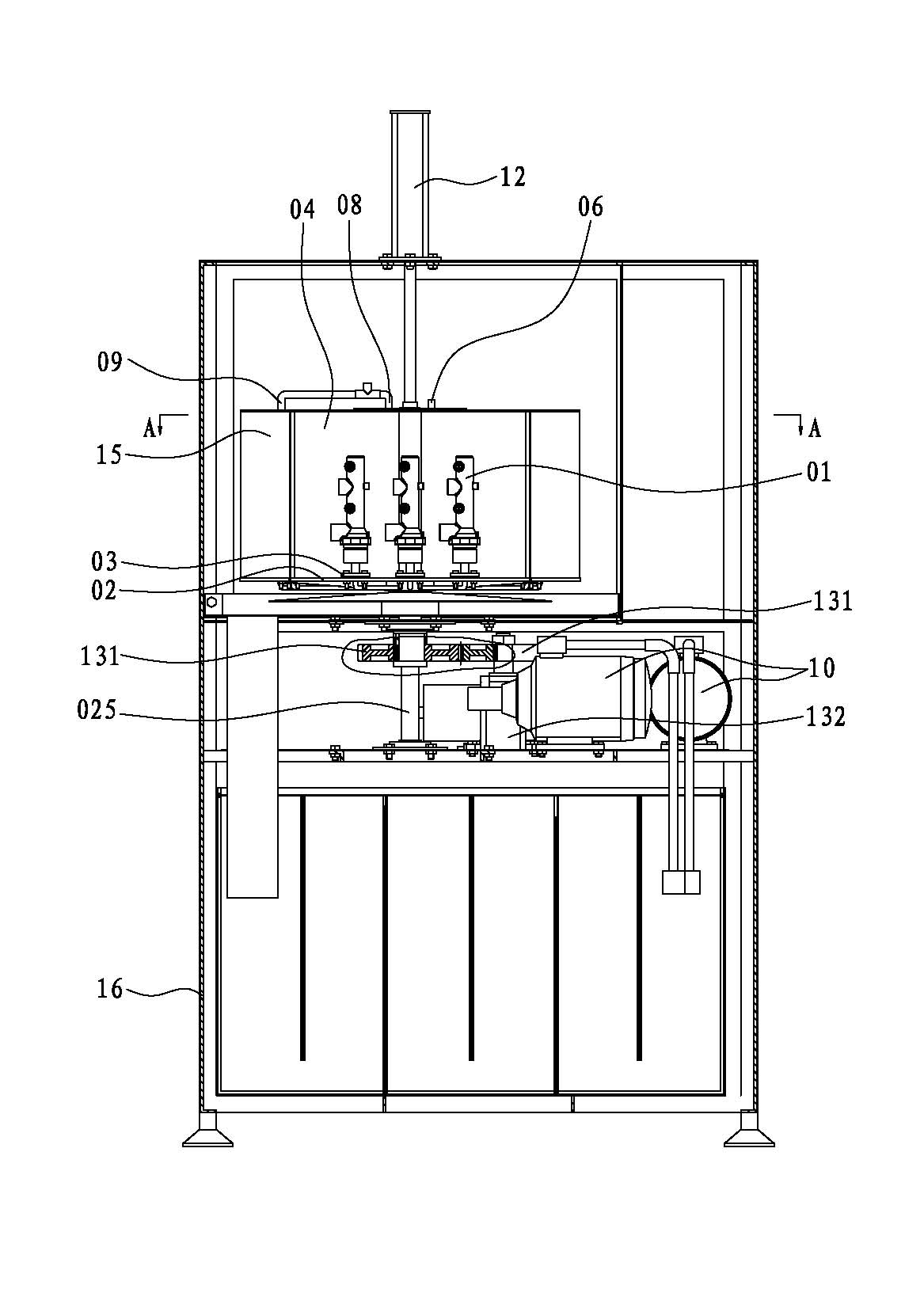

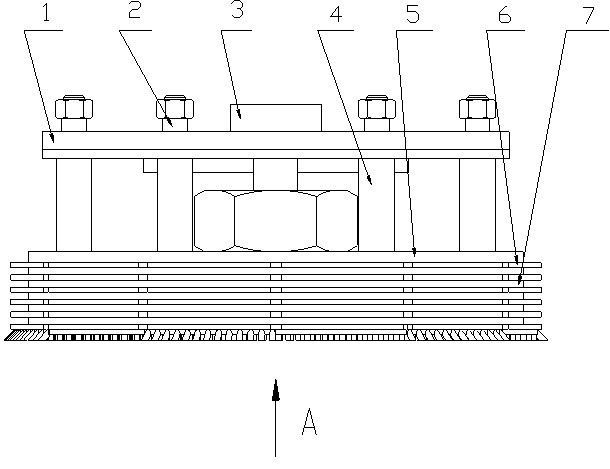

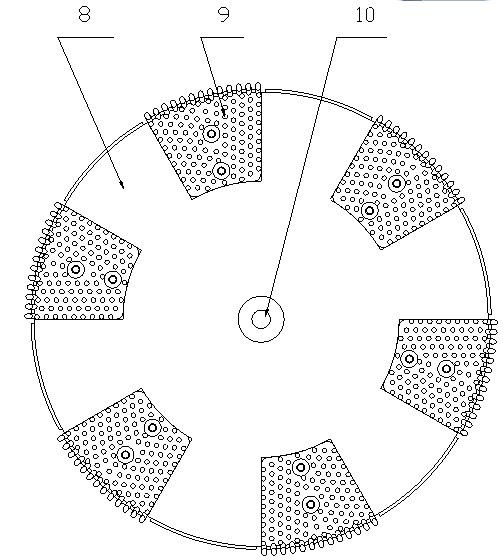

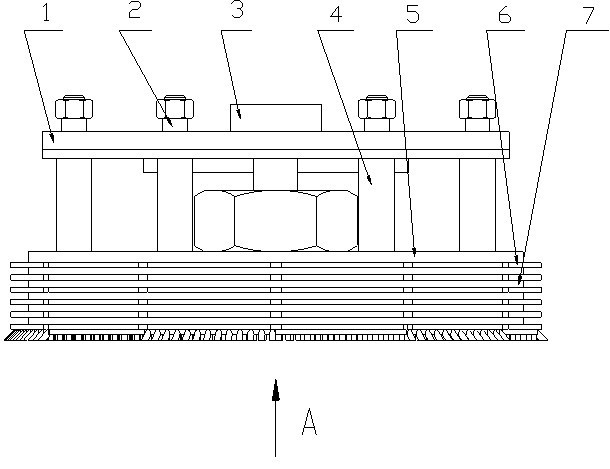

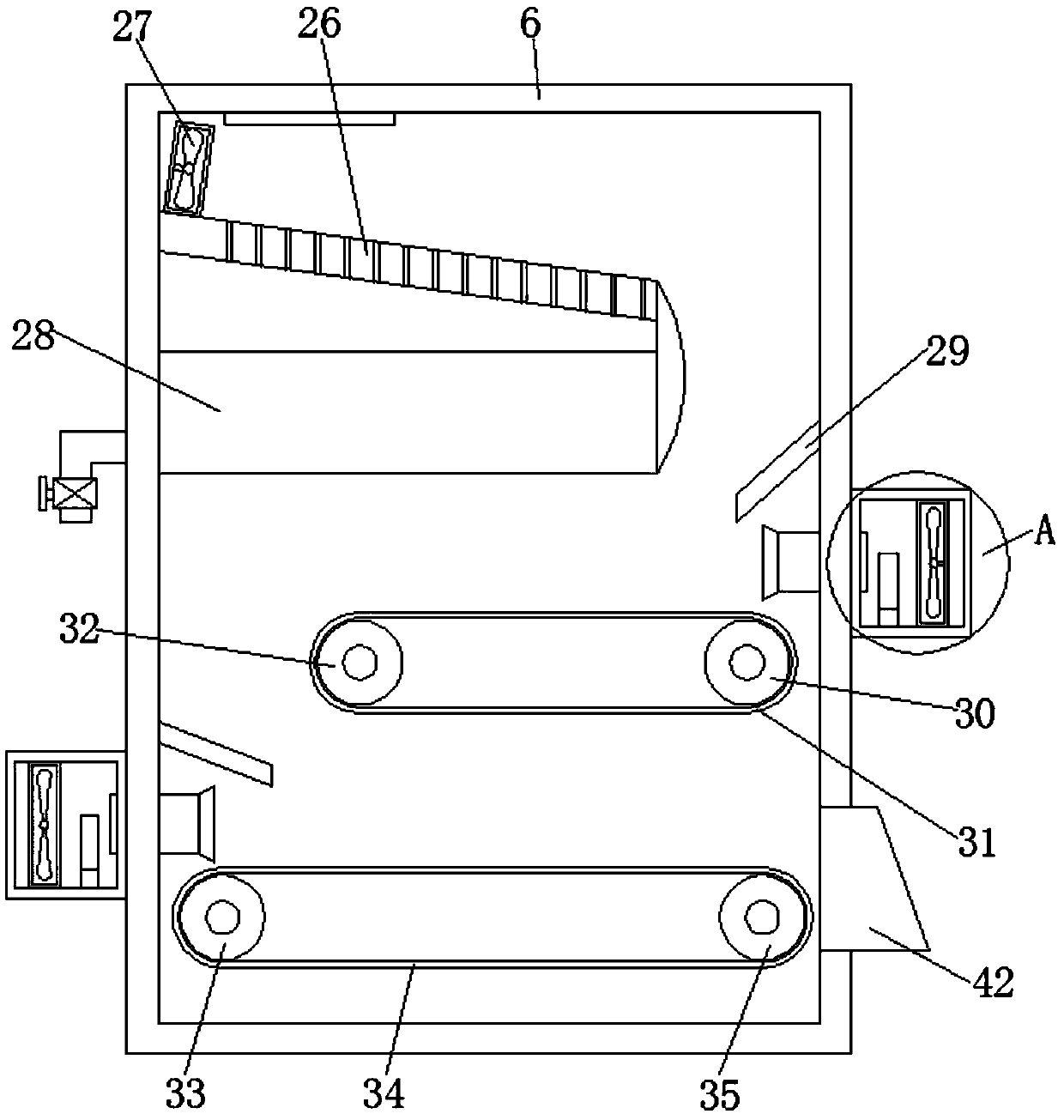

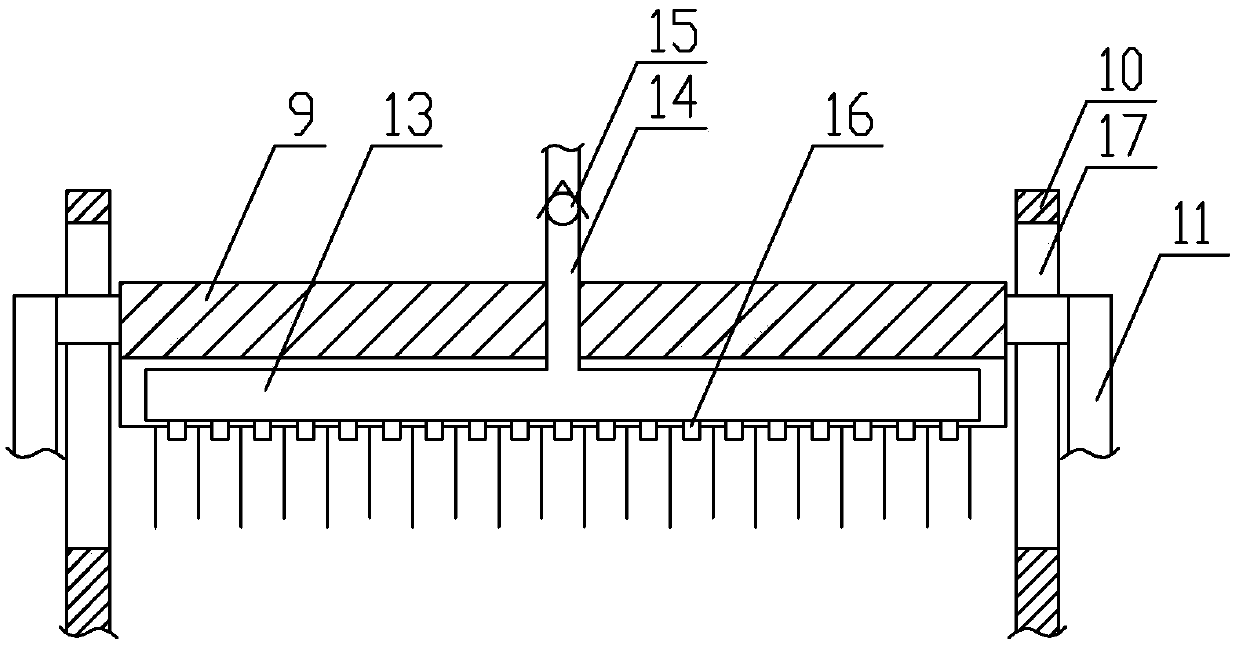

Machine for cleaning inner wall of barrel

ActiveCN103357629AGuaranteed cleaning qualityWork lessHollow article cleaningSpray nozzleEngineering

A machine for cleaning the inner wall of a barrel comprises a machine frame, a barrel inlet conveying chain, a barrel outlet conveying chain, a barrel clamping device, a barrel fixing rotary device, a high-pressure cleaning device and an operation control box, wherein the high-pressure cleaning device comprises a cleaning solution feeding device, a jet head and a pneumatic vertical lifting mechanism; the jet head is communicated with the cleaning solution feeding device through a liquid transport tube; the pneumatic vertical lifting mechanism is mounted on the machine frame and used for driving the jet head to move up and down vertically; at least three nozzles, which form different angles with the horizontal plane, are arranged on the jet head. According to the machine, the inner wall of the barrel of barreled water can be cleaned in an up-down 360 degrees' rotating isopiestic pressure cutting manner, so that each part of the inner wall of the barrel can be cleaned with high-pressure water proportionably, the effect of flushing the inner wall of the barrel completely is achieved effectively, the cleaning quality of the inner wall of the barrel is guaranteed, and the service life of the jet head is prolonged. The machine has the advantages that the structure is reliable; the running is stable; the cleaning efficiency is high; occupied production space is less; the labor cost, manufacture cost and running cost are low.

Owner:广东鼎湖山泉有限公司

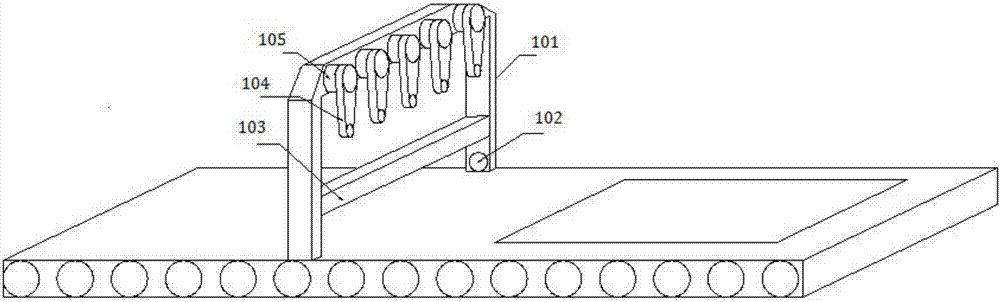

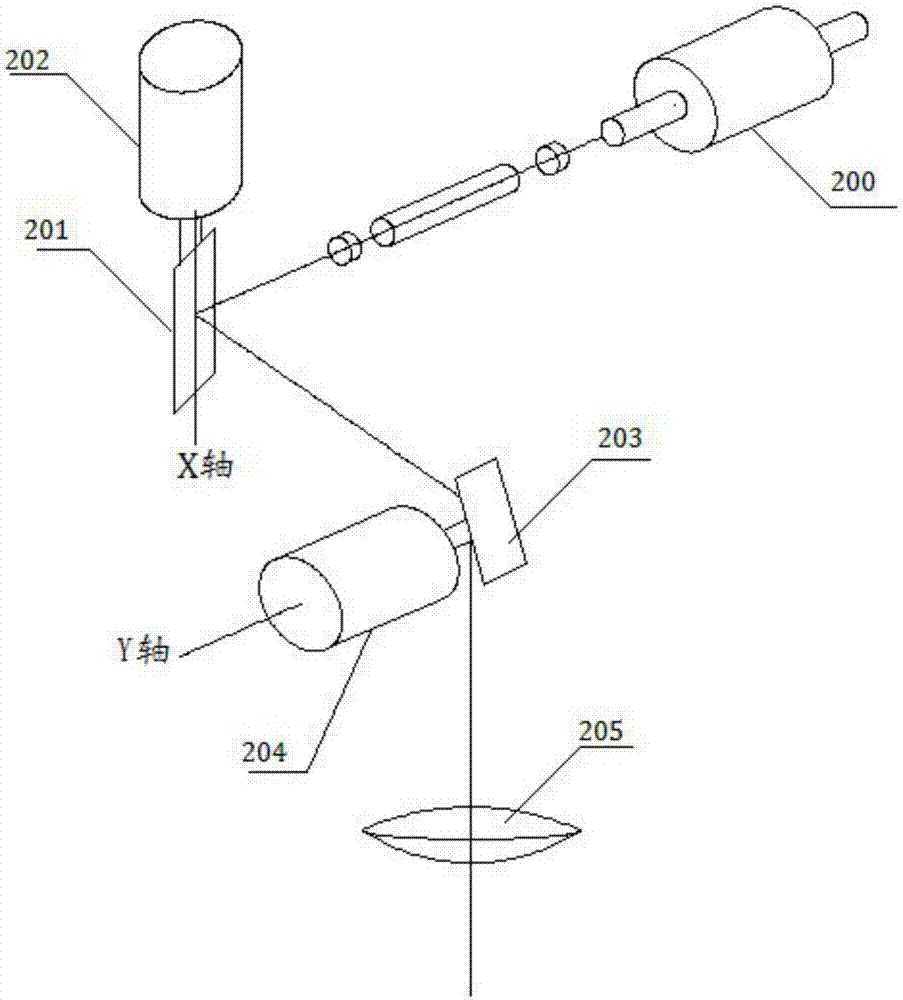

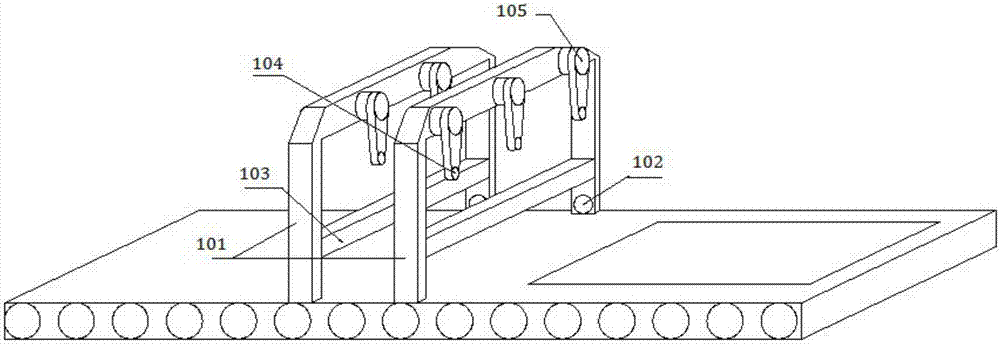

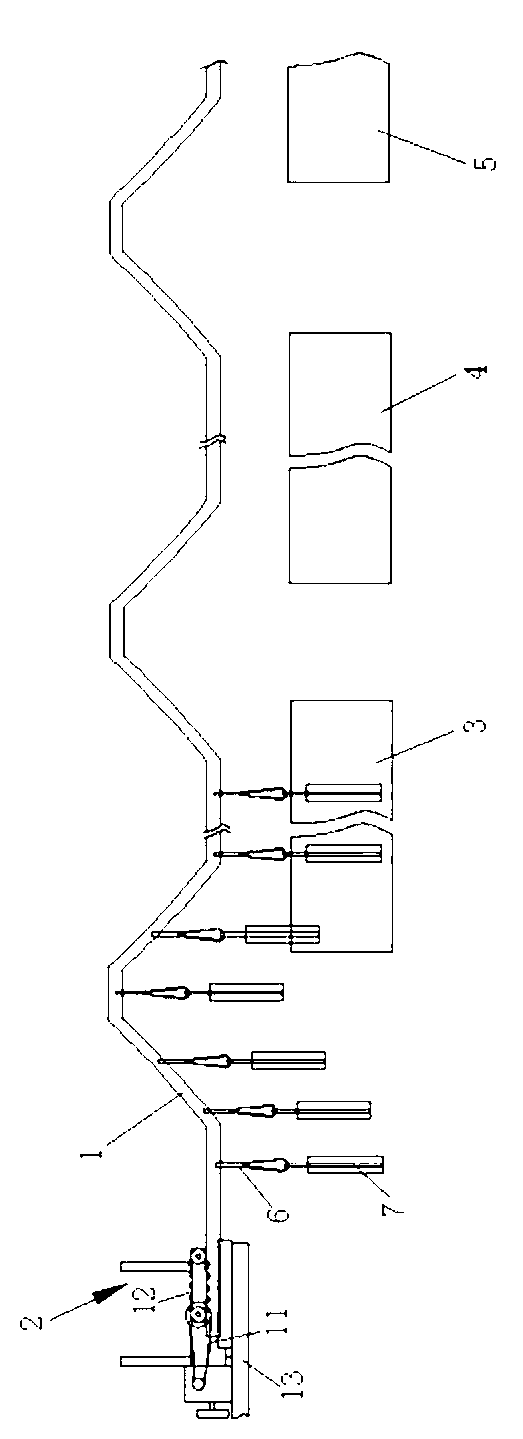

Laser cleaning device and cleaning method

ActiveCN107081312AEasy to cleanImprove cleaning efficiencyWork treatment devicesCleaning processes and apparatusProduction lineCleaning methods

The invention discloses a laser cleaning device and a cleaning method. Specifically, the device comprises a support, a position sensor, a controller, an oxide skin collecting device, multiple laser cleaning heads, multiple swing motors and multiple image sensors. The laser cleaning device is installed on a to-be-cleaned object conveying belt through the support, whether to-be-cleaned objects enter a cleaning zone or not is detected through the position sensor, cleaning of the to-be-cleaned objects on a production line can be achieved, laser cleaning is performed through the multiple laser cleaning heads, swing angle adjustment of the laser cleaning heads can be achieved through the swing motors, the cleaning efficiency and cleaning quality can be improved, images obtained after cleaning are analyzed through the image sensors, and the cleaning quality is thus ensured. By adopting the device and the device, fast and efficient cleaning of to-be-cleaned objects on the production line can be achieved.

Owner:武汉翔明激光科技有限公司

Acid pickling promotor for iron and steel

The acid pickling promoter for iron and steel consists of inorganic salt as reducing agent 10-80 wt%, organic metal ion chelating chelating agent 1-20 wt%, synergist 1-20 wt% and water 10-50 wt%. The acid pickling promoter is suitable for being added into acid pickling liquid to promote the elimination of dense oxide scale on the surface of steel, shapes and other iron and steel product. It can raise the surface quality of silicon steel plate after being acid pickled, shorten acid pickling period, reduce acid consumption and improve acid pickling environment.

Owner:HUAZHONG UNIV OF SCI & TECH +2

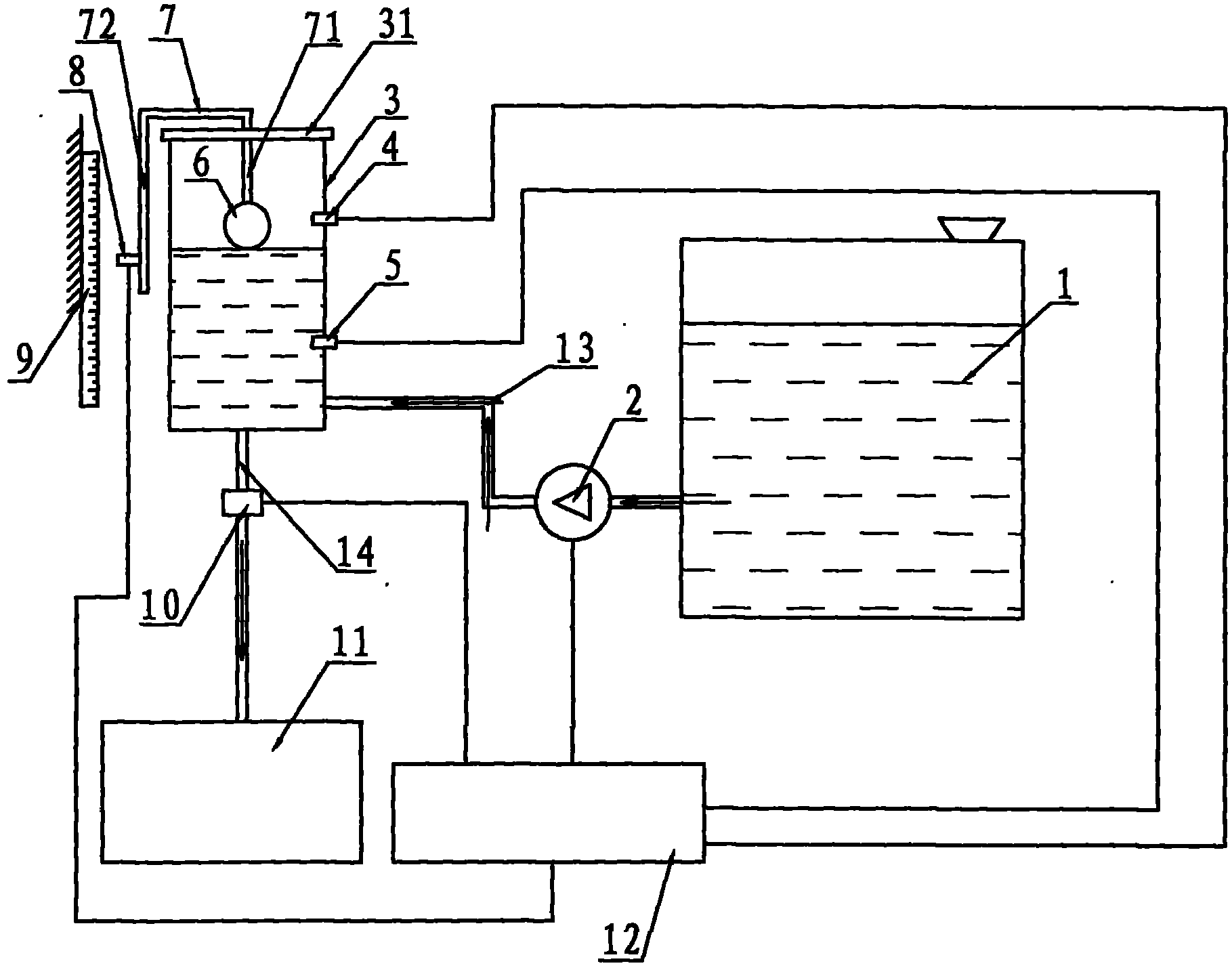

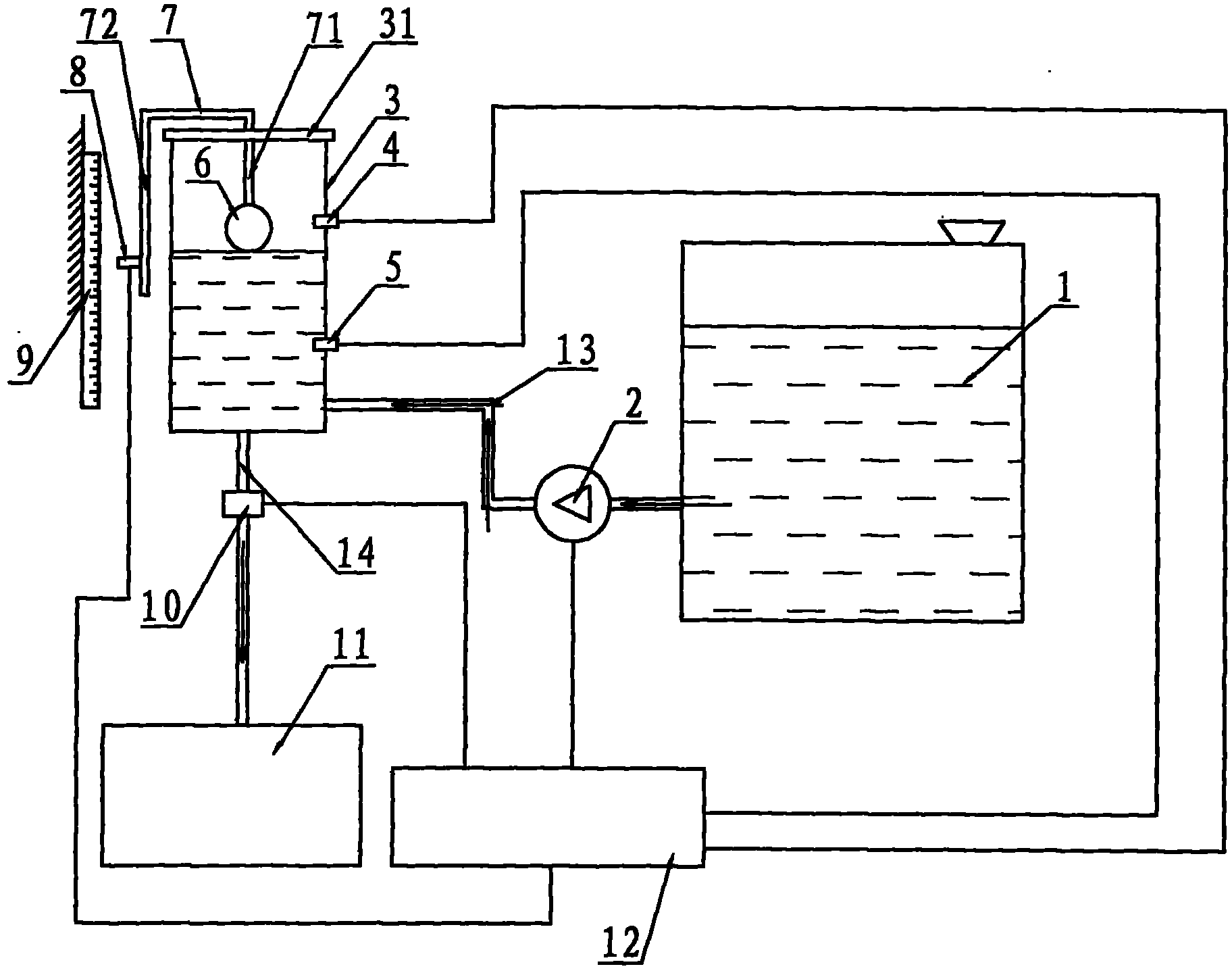

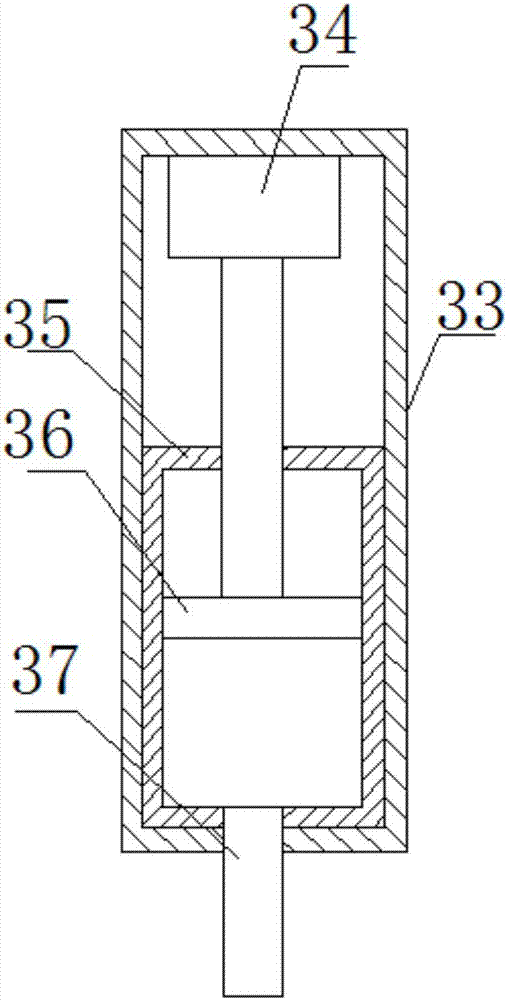

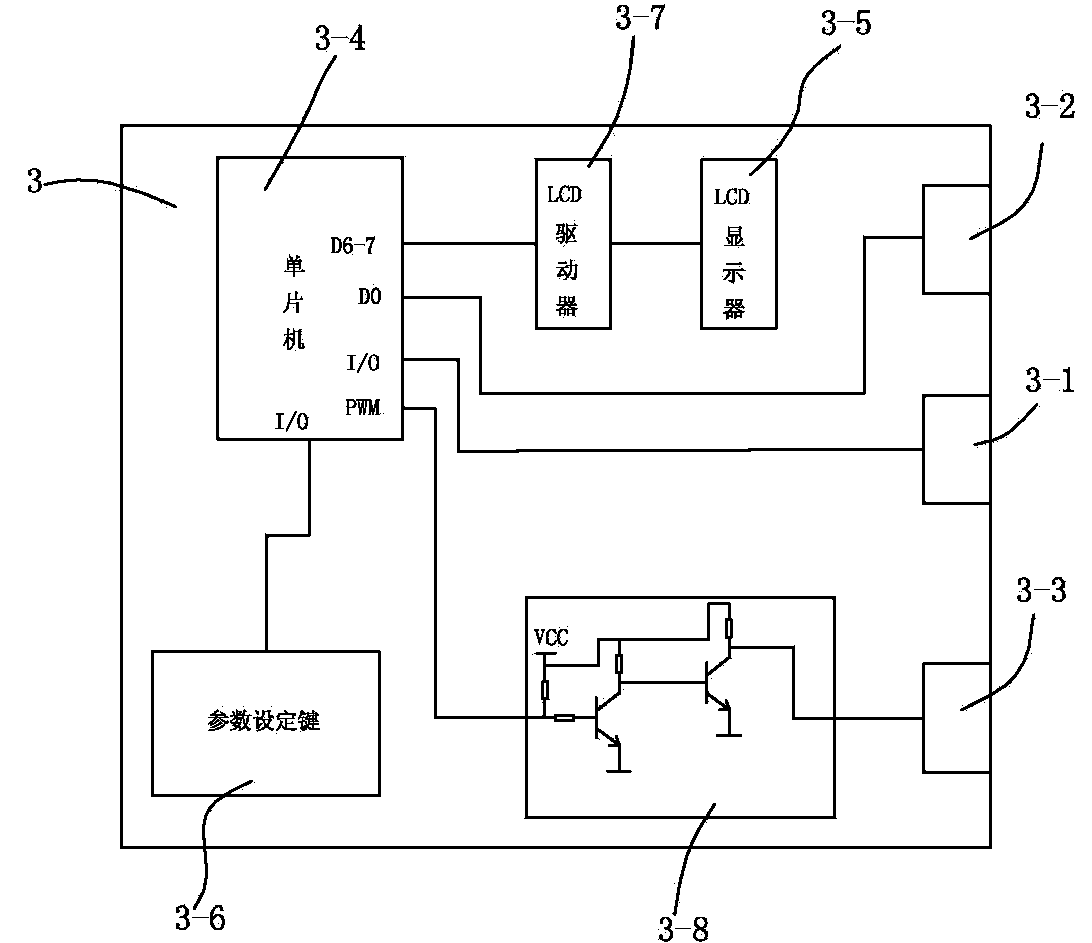

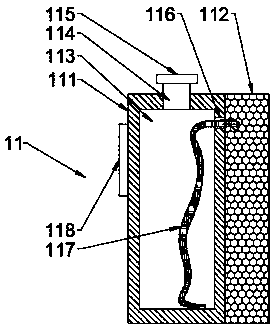

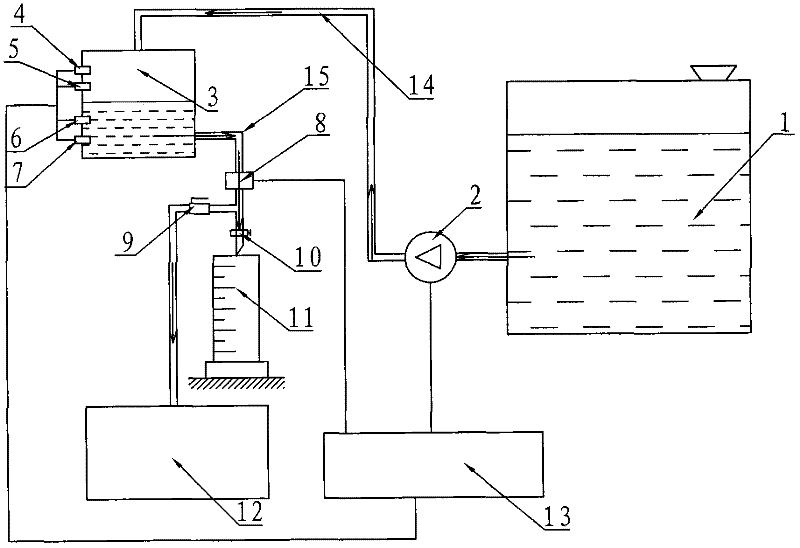

Constant volume type accurate automatic liquid replenishing device

ActiveCN102148285AStable concentrationGuaranteed cleaning qualityFinal product manufactureCleaning using liquidsControl systemLiquid storage tank

The invention discloses a constant volume type accurate automatic liquid replenishing device. The device comprises a liquid storage tank, a mechanical liquid replenishing pump, a sizing tank, an upper liquid level sensor, a lower liquid level sensor, a floating ball, a U-shaped floating ball rod, a constant volume sensor, a ruler, an electromagnetic directional valve, a cleaning groove and a control system, wherein the inner side wall of the sizing tank is provided with the upper liquid level sensor and the lower liquid level sensor; the primary liquid replenishing volume can be acquired through the diameter of the sizing tank and the drop distance of the floating ball; the drop distance of the floating ball is controlled by the constant volume sensor; the electromagnetic directional valve is opened during liquid replenishing; after the constant volume sensor drops for a predetermined distance, a signal is transmitted to the control system by the constant volume sensor and the electromagnetic directional valve is immediately closed, so that the liquid can be accurately replenished in the cleaning groove, the concentration of a solution in the cleaning groove is kept stable, and the cleaning quality of a silicon slice is substantially guaranteed.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

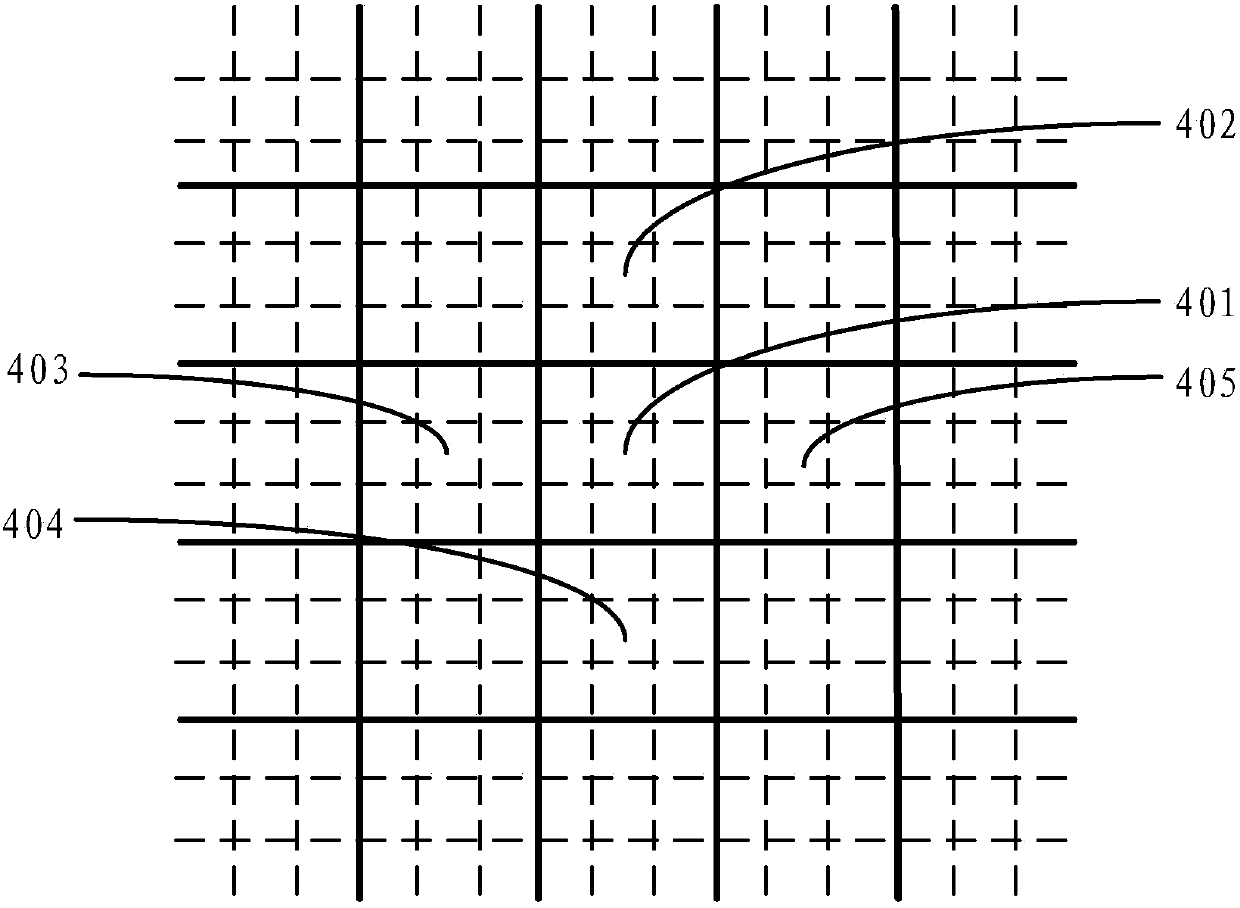

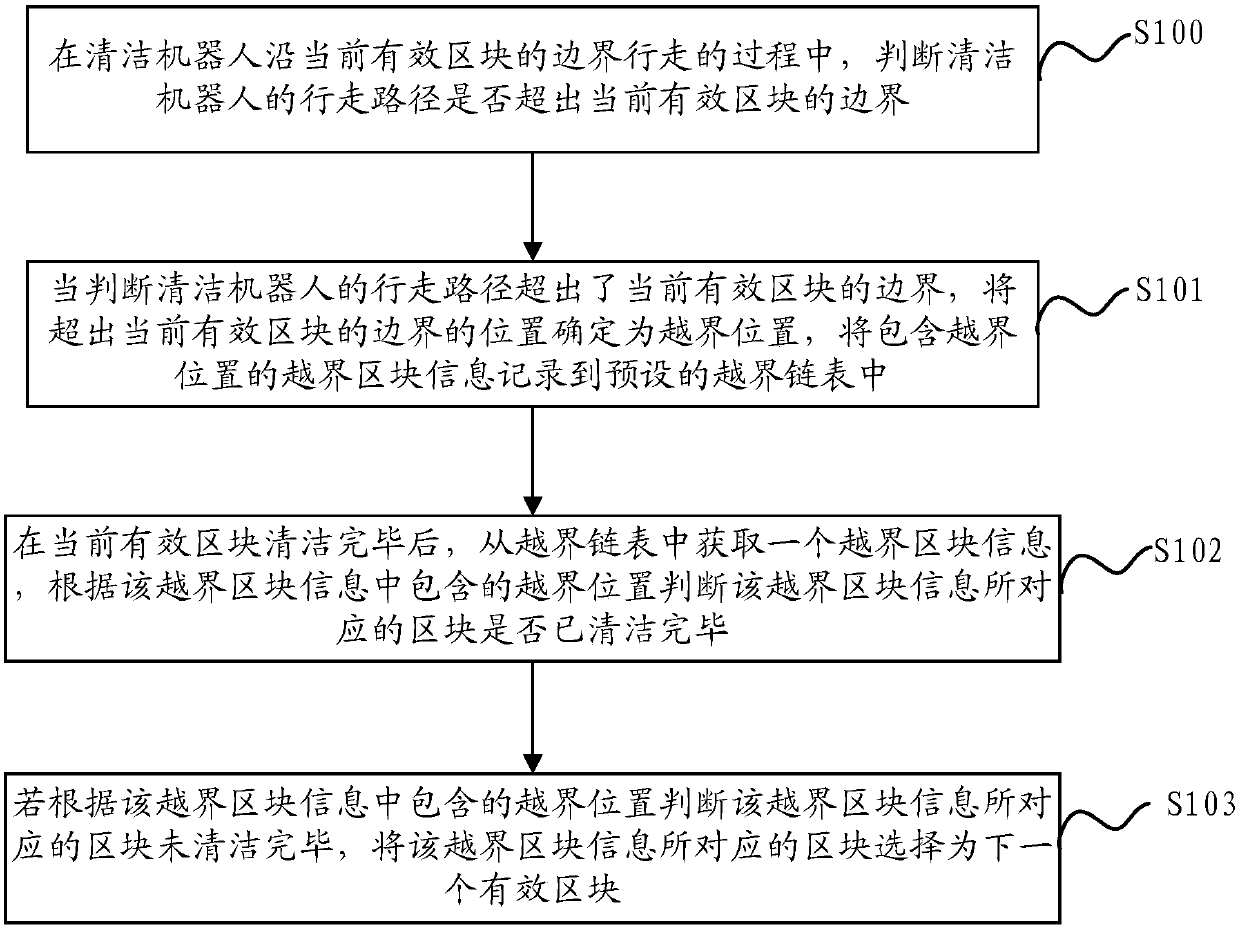

Cleaning robot and block selection method and device for same

ActiveCN107913039AAvoid repeated cleaningAvoid Uncleaned SituationsCarpet cleanersFloor cleanersCross-linkEngineering

The invention discloses a cleaning robot and a block selection method and a block selection device for the cleaning robot. The block selection method includes judging whether the walking path of the cleaning robot exceeds the boundary of the current effective block or not when the cleaning robot walks along the boundary of the current effective block; if so, then determining the position out of the boundary of the current effective block as a boundary-crossing position according to the judgement result, and recording boundary-crossing block information containing the boundary-crossing positionto a preset boundary-crossing linked list; after finishing cleaning of the current effective block, acquiring one boundary-crossing information from the boundary-crossing linked list, and judging whether the block corresponding to the boundary-crossing block information is cleaned or not according to the boundary-crossing position contained in the boundary-crossing block information; if no, thendetermining the block corresponding to the boundary-crossing block information as the next effective block. By the method, repeated cleaning of the block can be avoided, cleaning efficiency can be improved, omission of cleaning of the block can be avoided, and cleaning quality can be guaranteed.

Owner:BEIJING QIHOO TECH CO LTD

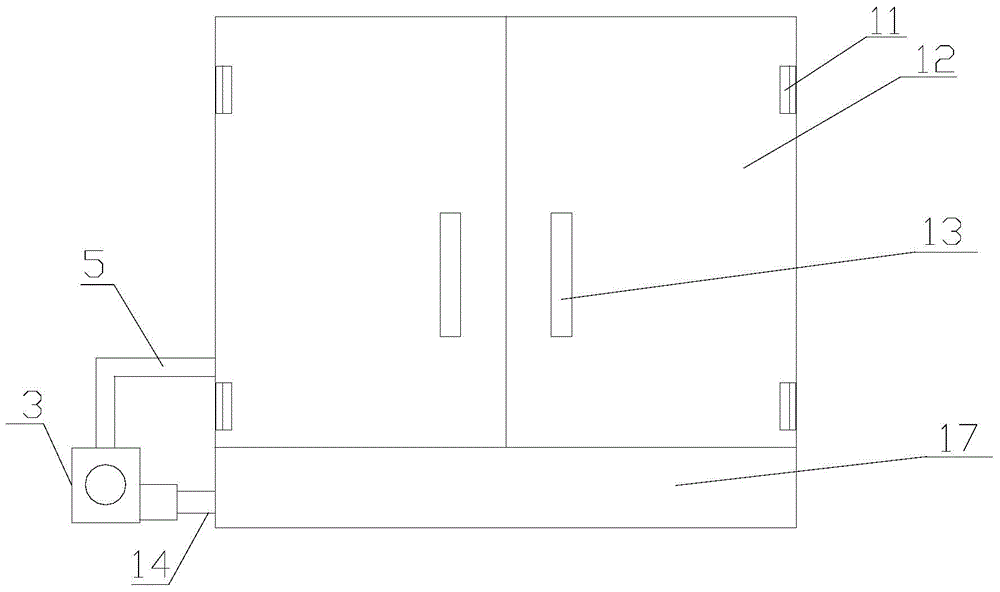

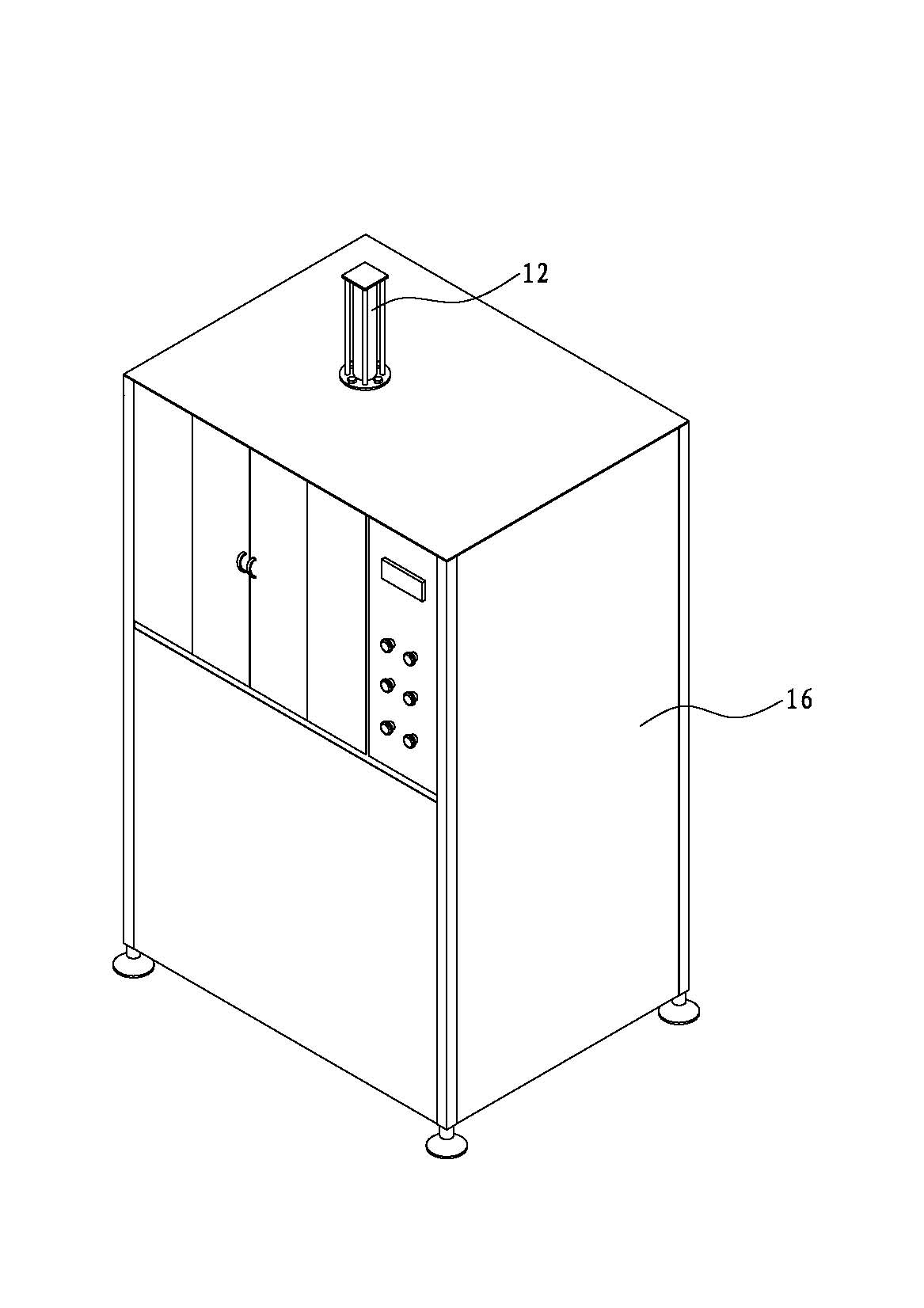

Bearing washing machine

InactiveCN105013737APrevent fallingGuaranteed cleaning qualityCleaning using liquidsWater storage tankWater resources

The invention provides a bearing washing machine. The bearing washing machine comprises a closed type box body, a first filter screen, a water pump, a rotary table, a first water pipe, a motor chamber rotary shaft and a hanging frame, and the bearing washing machine further comprises a hinge, a box door, a door handle and a water storage tank; and the box door is connected with the box body through the hinge, the door handle is located in the middle portion of the box door, and the water storage tank is located at the bottom of the box body. By means of the bearing washing machine, used water can be recycled to be reutilized, the water resource is saved, the water can be collected into the portion of a second water pipe by a sloping plate, water is convenient to recycle, bearing can be washed from multiple angles by means of the design of a nozzle, and the bearing washing quality is guaranteed; and the water cannot be splashed in the washing process due to the sealing structure of the box body, and dry of a working place is guaranteed. Compared with the prior art, the equipment investment cost can be reduced, the washing cost can be reduced, and the structure is simple.

Owner:XINCHANG COUNTY SANHE BEARING

Hanging-hook automatic deplating line

The invention provides a hanging-hook automatic deplating line which comprises a conveying rail, a driving device, a deplating groove, an oil removal groove and a cleaning groove, wherein the conveying rail is located above the deplating groove, the oil removal groove and the cleaning groove, the driving device drives a chain in the conveying rail to conduct operation along the conveying rail, hanging pillars which downwards overhang are connected to the chain, and the lower portions of the hanging pillars are provided with hanging rings for hanging and hooking hanging hooks. Under the control of a controller, the hanging pillars are driven by the chain to slowly advance along the conveying rail and sequentially pass through the deplating groove, the oil removing groove and the cleaning groove. The conveying rail has fluctuations in the height direction so as to enable the hanging hooks to ascend when the hanging hooks go out of the grooves and descend when the hanging hooks enter the grooves. The hanging-hook automatic deplating line can automatically carry out deplating processing, as long as the hanging hooks are hung on the hanging-hook automatic deplating line, the deplating process, the oil removal process and the cleaning process can be automatically carried out on the hanging hooks, manual work and fresh water are saved, the environment-friendliness requirement for saving water is met, energy is saved, environmental friendliness is achieved, and the labor intensity of workers is greatly reduced.

Owner:石狮市闽南五金塑料有限公司

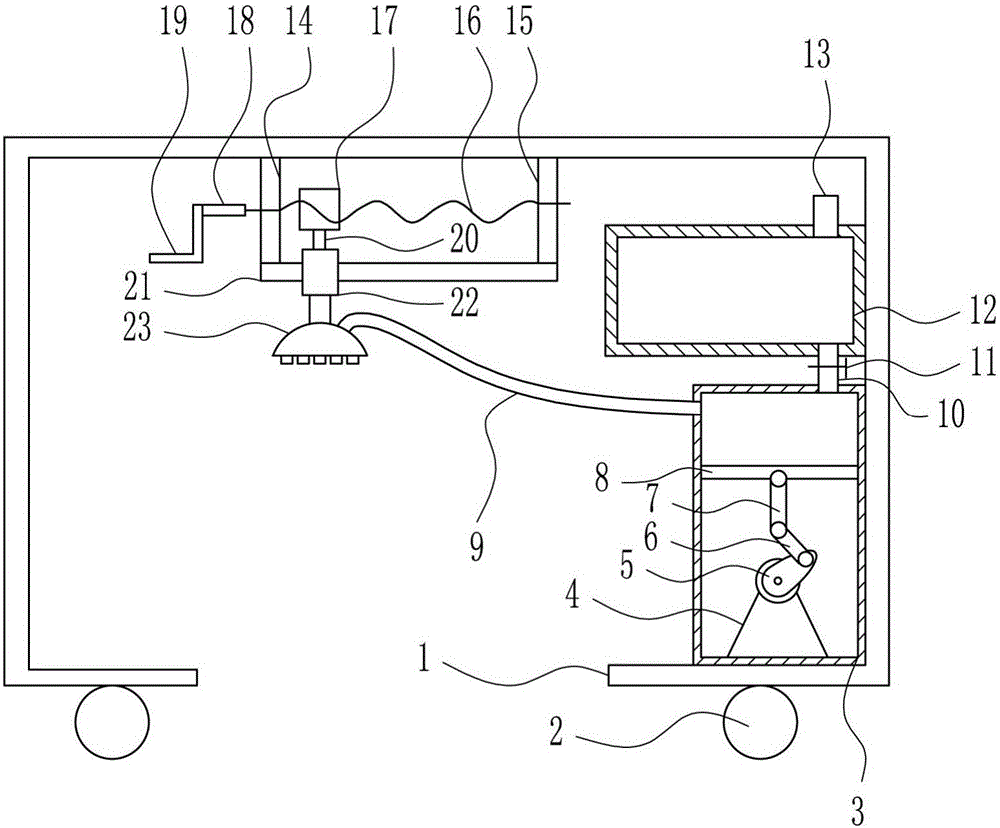

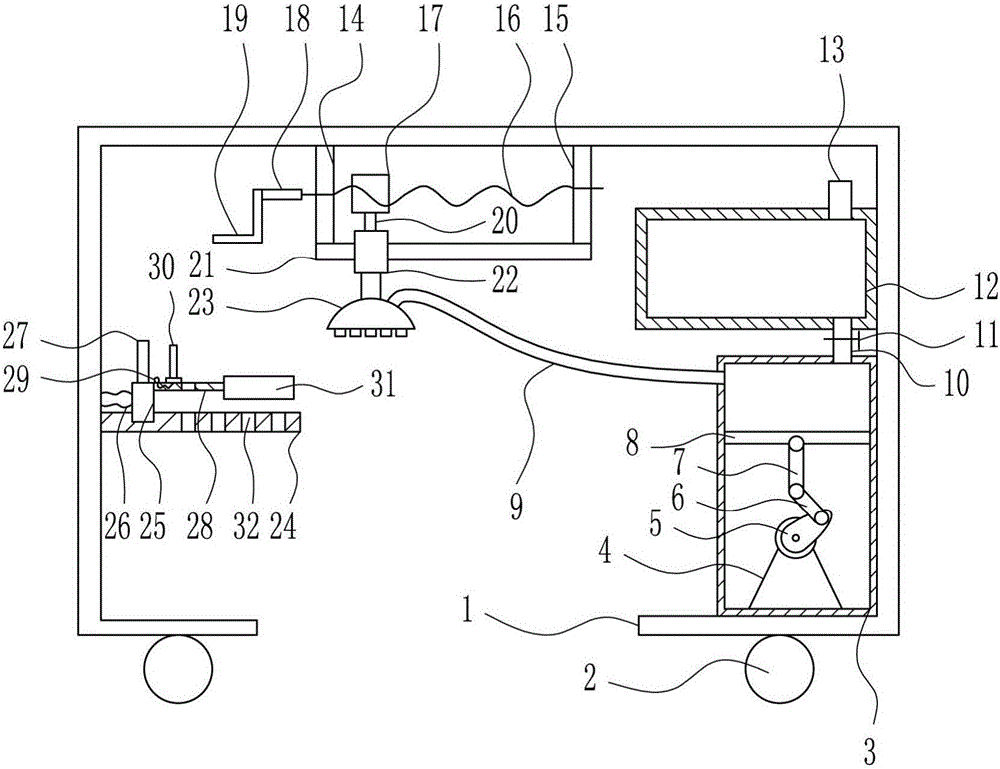

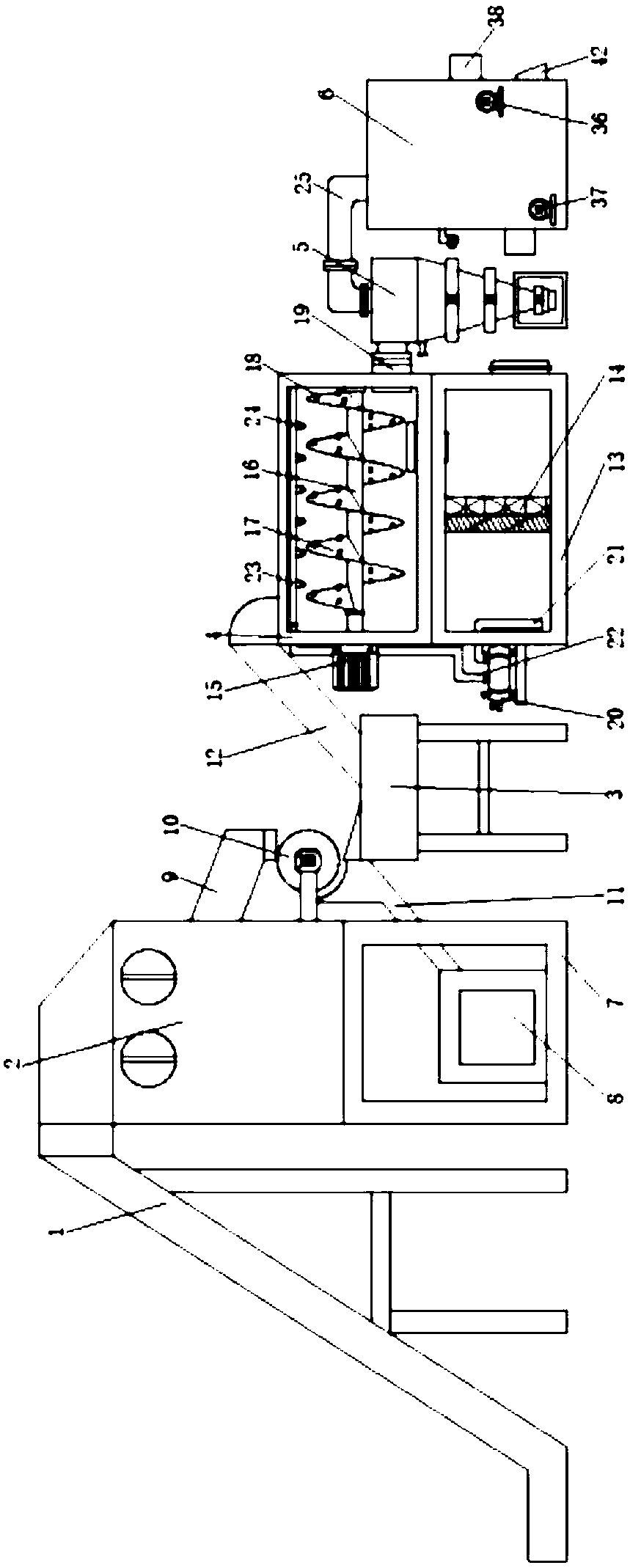

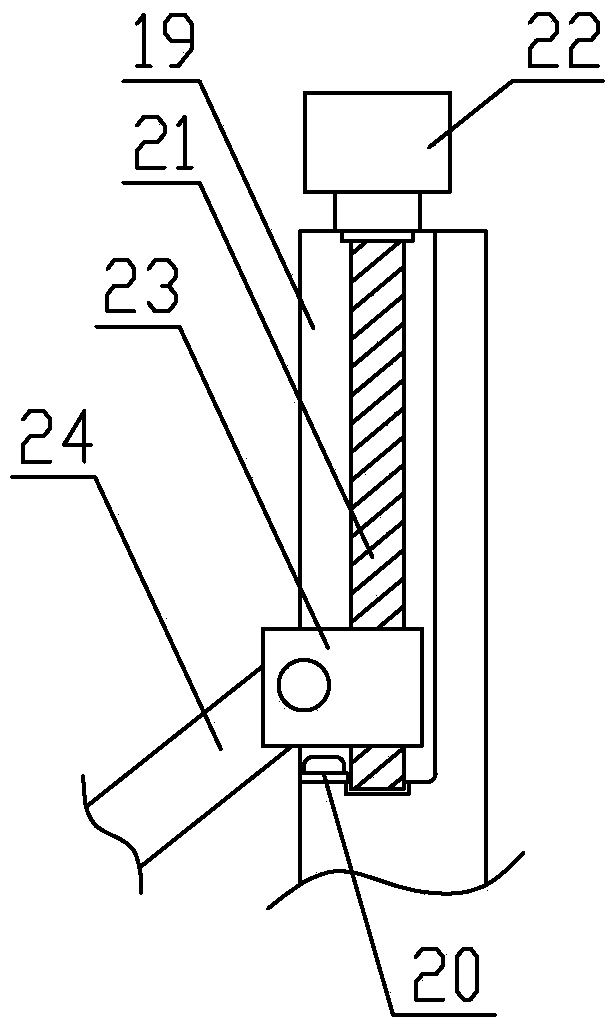

Cleaning equipment for cotton ramie wool primary processing

InactiveCN106670169AClean and comprehensiveImprove cleaning efficiencyCleaning using liquidsWater pipePiston

The invention relates to cleaning equipment, in particular to cleaning equipment for cotton ramie wool primary processing. In order to achieve the technical aims, the cleaning equipment for cotton ramie wool primary processing facilitates cleaning and has a drying function. To achieve the above technical aims, the cleaning equipment for cotton ramie wool primary processing comprises a mounting rack, universal wheels, a cylinder body, a motor, a crank, a swing rod, a lifting rod, a piston, a hose, a water outlet pipe, a valve, a water tank, a water inlet pipe, a left bearing pedestal and the like. The universal wheels are arranged on the left side and the right side of the bottom of the mounting rack. The cylinder body is arranged on the right side of the bottom in the mounting rack. The motor is arranged in the center of the bottom in the cylinder body. The crank is arranged on the front side of the motor. The swing rod is hinged to the right end of the crank. The lifting rod is hinged to the top end of the swing rod. According to the cleaning equipment for cotton ramie wool primary processing, an atomization spray head is driven by shaking a first rocking handle to move left and right, cleaning is more comprehensive, the cleaning efficiency is improved, and a drying machine is arranged.

Owner:湖州东方皮革有限公司

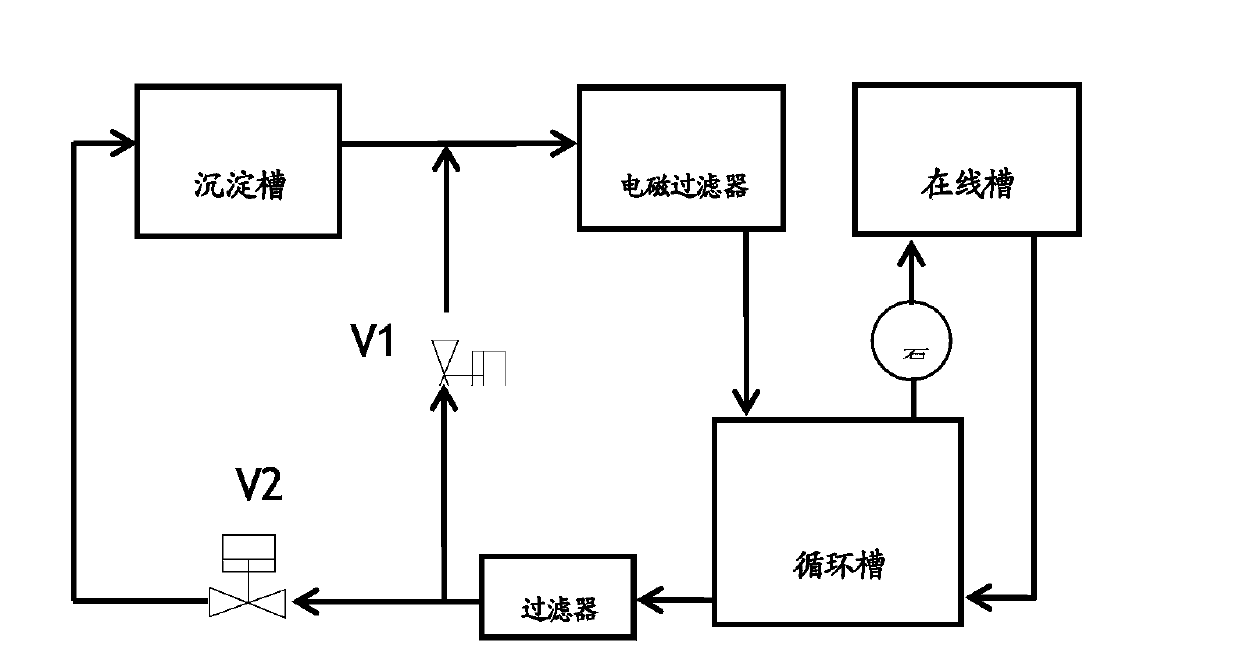

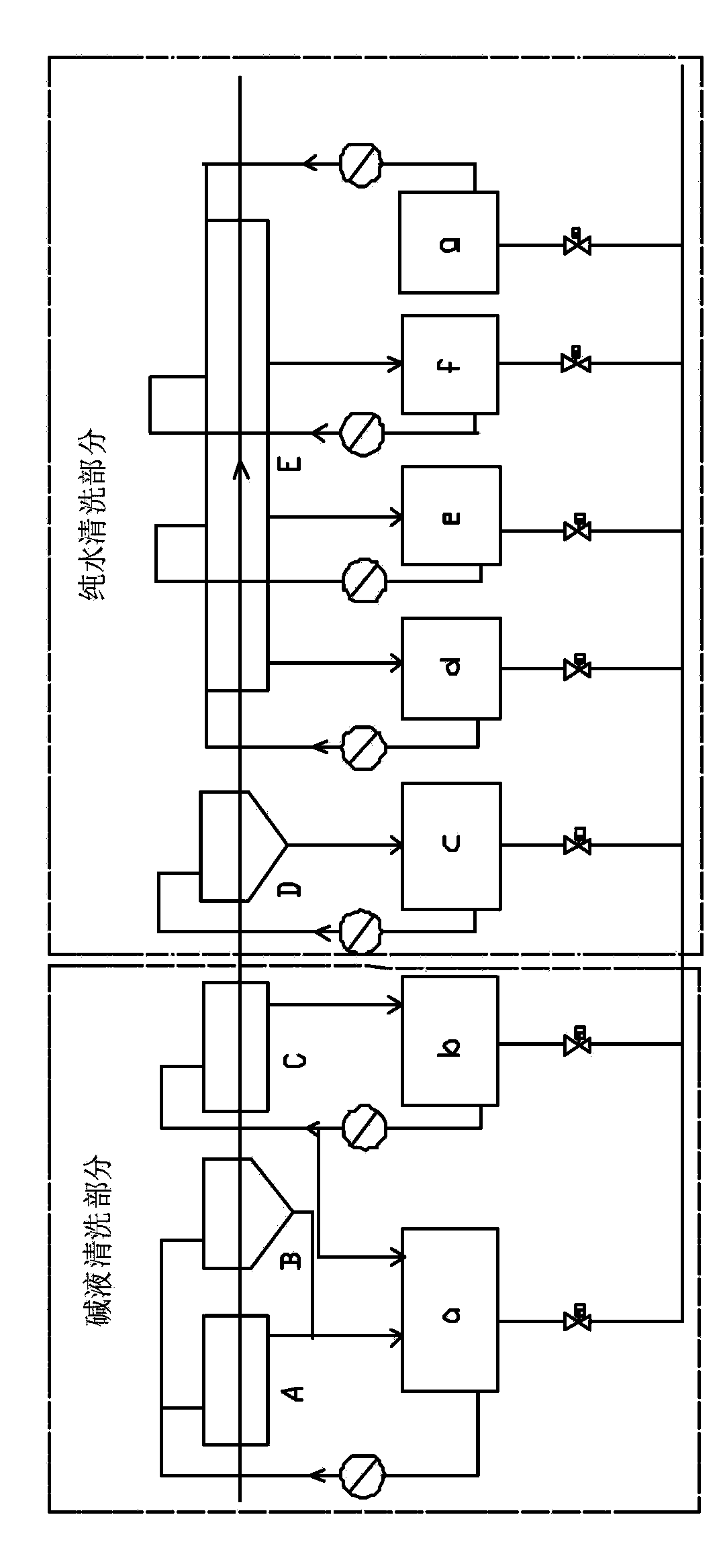

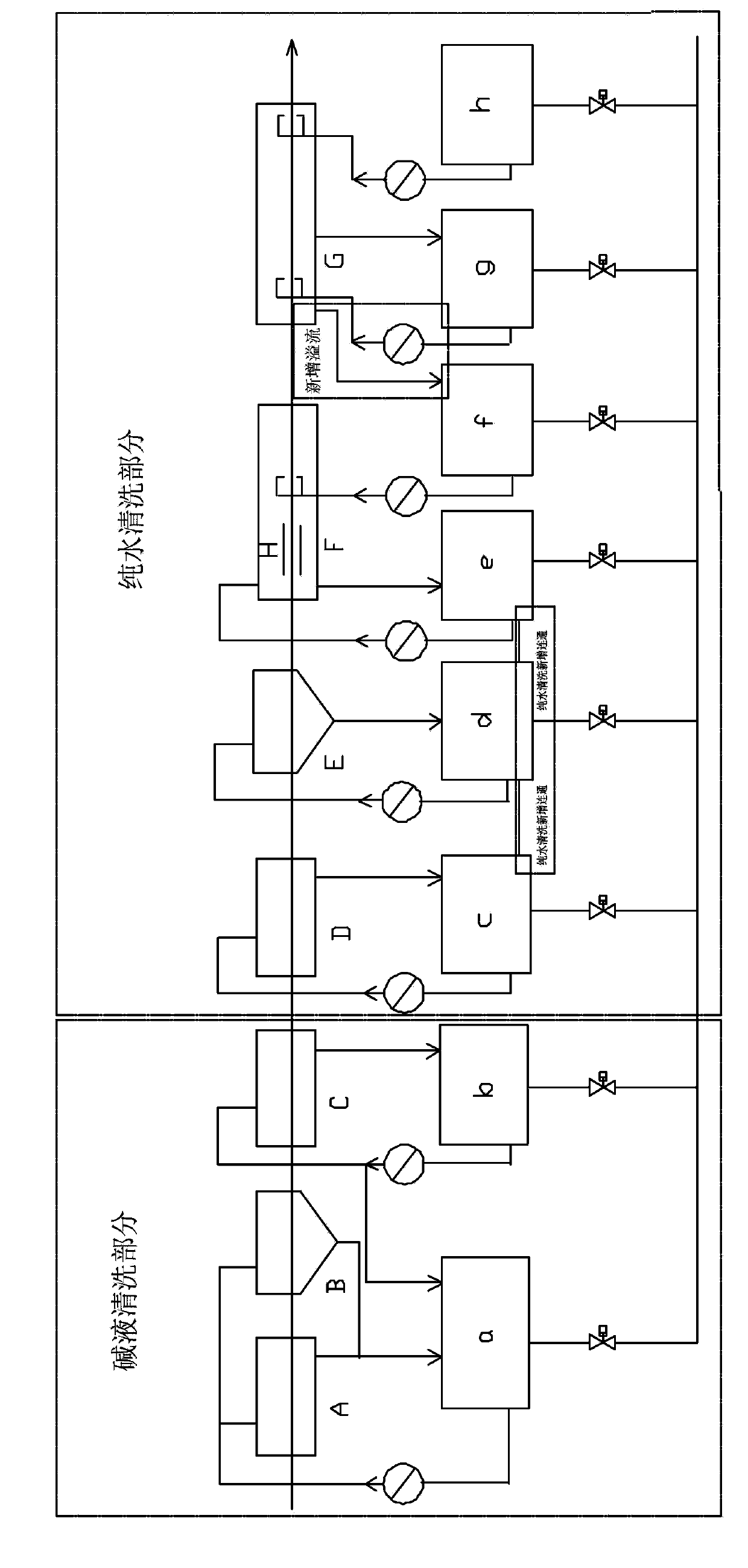

Device and method for cleaning surface of silicon steel

ActiveCN104117510AThoroughly remove residueEliminate residueWork cleaning devicesCleaning processes and apparatusElectrolysisHigh pressure water

The invention provides a device for cleaning the surface of silicon steel. The device comprises online grooves including the alkali liquor immersion groove, the alkali liquor brushing groove, the electrolysis cleaning groove, the high-pressure-water spraying groove, the water brushing groove, the hot-water rinsing groove, the hot-water spraying groove and the like and corresponding circulation grooves connected with the online grooves, wherein the online grooves are sequentially connected. The circulation grooves are provided with high-low liquid level water supplementing control devices respectively. The high-pressure-water spraying groove and the hot-water spraying groove are internally provided with vertically-arranged spraying nozzles respectively. The invention further provides a method for cleaning the surface of the silicon steel. The silicon steel is effectively cleaned by setting parameters such as the alkali liquor concentration, the alkali liquor temperature and the pure water temperature through the device. By means of the device and the method, the cleaning quality of the surface of rolled hard roll strip steel is improved in an electrical steel unit, it is guaranteed that the surface of furnace-entered strip steel is clean, inner-furnace dross is easily reduced, the quality of the surface of the strip steel is improved, and meanwhile pure water consumption is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic western medicine preparing device

InactiveCN107260539AQuality assuranceQuality improvementPharmaceutical containersMedical packagingWestern medicineEngineering

The invention discloses an automatic western medicine dispensing device, which comprises a workbench and a protective cover. A medicine placement plate is arranged on the left side of the upper side of the workbench. A plurality of drug cartridge placement grooves are arranged on the medicine placement plate. The inner upper end of the protective cover is arranged with a Slide rail, the first electric telescopic rod is arranged on the slide rail, the inner right upper end of the protective cover is provided with the second electric telescopic rod, the left end of the second electric telescopic rod is connected with the first electric telescopic rod, the first electric telescopic rod The lower end is equipped with a medicine taking device, the upper right part of the workbench is provided with a filling chamber, the left and right sides of the filling chamber are provided with pillars, the upper end of the pillar is provided with a dispensing box, and the upper left side of the dispensing box is provided with a dosing port The lower end of the dispensing box is provided with a number of filling pipes, the filling pipe is provided with a drug delivery pump and a flow meter, the lower end of the filling pipe is provided with a filling nozzle, and the upper end of the protective cover is provided with a purification box. The invention has the advantages of simple structure, convenient use, high degree of automation, high dispensing efficiency and good dispensing quality.

Owner:临泉县生产力促进中心

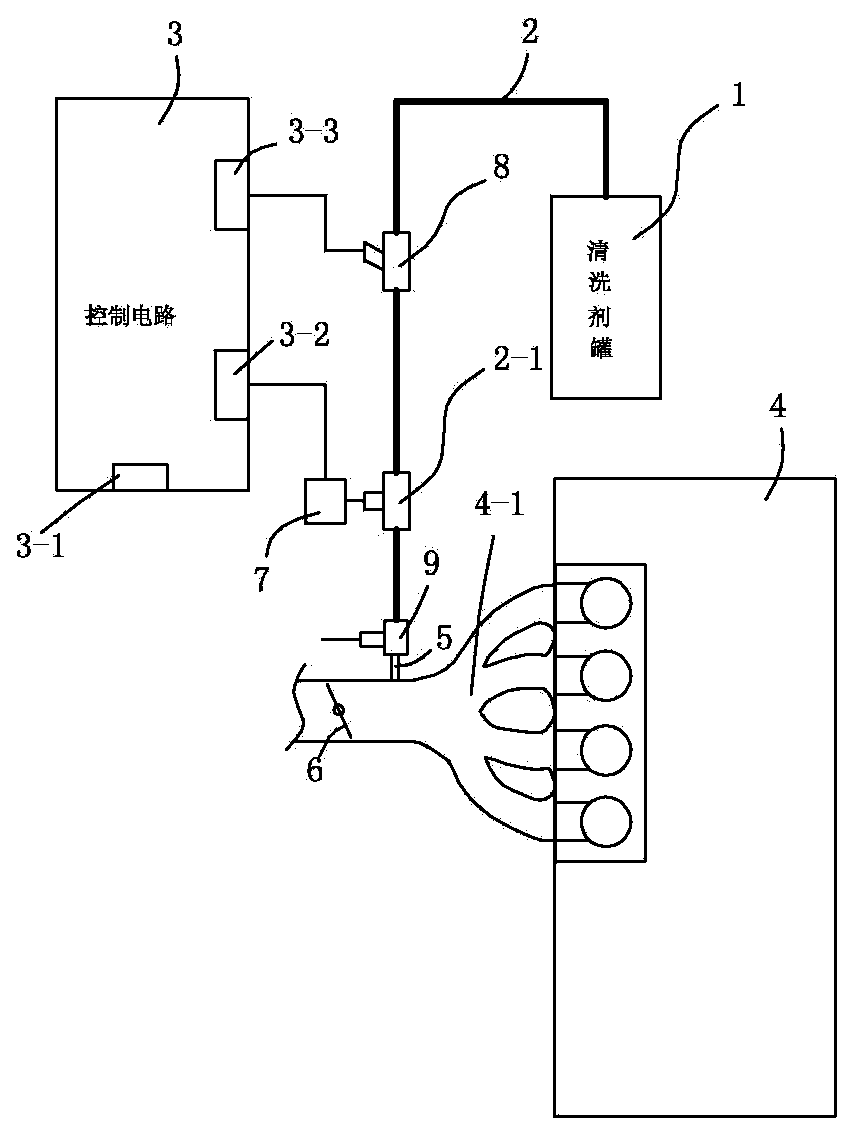

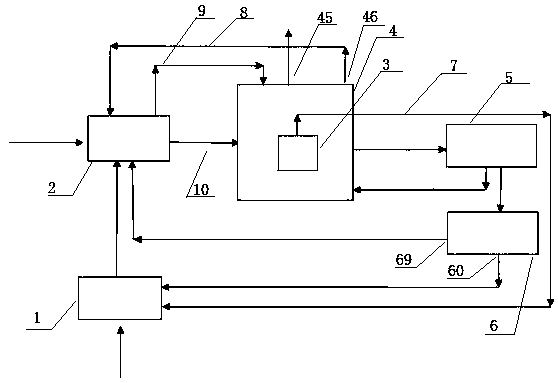

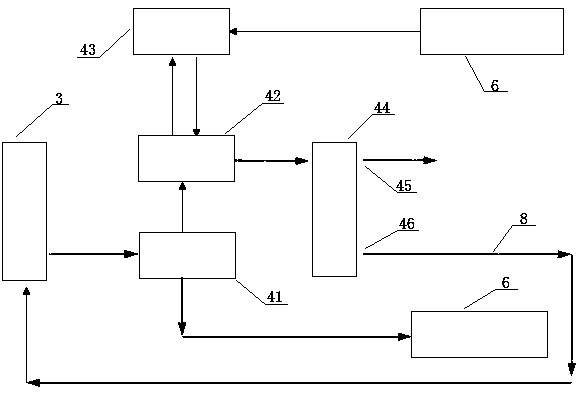

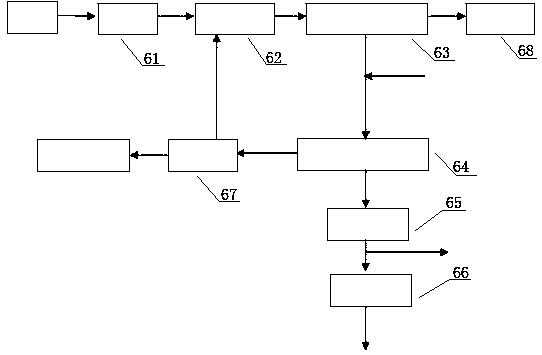

Online carbon deposit cleaning system for air inlet valve and combustion chamber of engine and control method

InactiveCN103422985ARealize online cleaningSimple control methodMachines/enginesEngine componentsCombustion chamberVacuum pressure

The invention discloses an online carbon deposit cleaning system for an air inlet valve and a combustion chamber of an engine and a control method. The system comprises a cleaning agent tank, a cleaning agent charging pipeline and a control circuit, wherein the control circuit comprises a cleaning working procedure; a cleaning starting circuit is arranged in the control circuit; the cleaning agent tank is arranged on a frame in an automotive engine hood; one end of the cleaning agent charging pipeline is connected with the cleaning agent tank, and the other end of the cleaning agent charging pipeline is connected with a vacuum pipeline of the engine; the vacuum pipeline is communicated with the air inlet valve of the automotive engine; a control signal in the running state of the automotive engine is connected with the starting circuit in the control circuit. According to the system and the method, the carbon deposit of the air inlet valve and the combustion chamber of the engine is cleaned on line on the premise of no changes in the conventional basic design of an automobile; the control method is simple and practical; automatic closed loop control over the inflow of a cleaning agent and vacuum pressure is realized; a cleaning process is safe and reliable, and the environment friendliness of engine emissions is improved.

Owner:刘新羽

Automatic cleaning device for automobile brake pump cylinder

InactiveCN102601093AImprove work efficiencyPlay a clearing roleDrying solid materials with heatHollow article cleaningSurface cleaningEngineering

The invention discloses an automatic cleaning device for an automobile brake pump cylinder, which comprises a rotary worktable divided into four working cavities by working cavity partition plates. The first working cavity is used for loading and unloading the brake pump cylinder, the second working cavity is used for cleaning an inner cavity of the brake pump cylinder, the third working cavity is used for cleaning the outer surface of the brake pump cylinder, the fourth working cavity is used for drying, the rotary worktable is separated from an outer surface cleaning nozzle or an outer surface drying nozzle, and the outer surface cleaning nozzle or the outer surface drying nozzle moves up and down along with extension and retraction of the cylinder above the nozzle, so that circulatory continuous cleaning operation can be realized. Loading, unloading, cleaning and drying are simultaneously realized, halting is omitted in loading and unloading, and working efficiency is greatly improved.

Owner:XIAMEN UNIV OF TECH

Clearing device

The invention discloses a clearing device, which comprises a rotary table. A coupler is arranged in the center of the rotary table, a plurality of connecting rods are further arranged on the rotary table, each connecting rod is matched with a spring which is connected with a close cover, a plurality of cutting pieces and crushing rings are arranged below the close cover, a circular brush disk is connected onto the coupler, six brush plates are uniformly distributed on the circumference of the brush disk, each crushing ring is arranged between each two cutting pieces, and a sensor is arranged in the center of the brush disk. The clearing device has the advantages of fine clearing effect, low cost, simple structure and the like.

Owner:NANTONG HAIOU LIFE SAVING & PROTECTION EQUIP

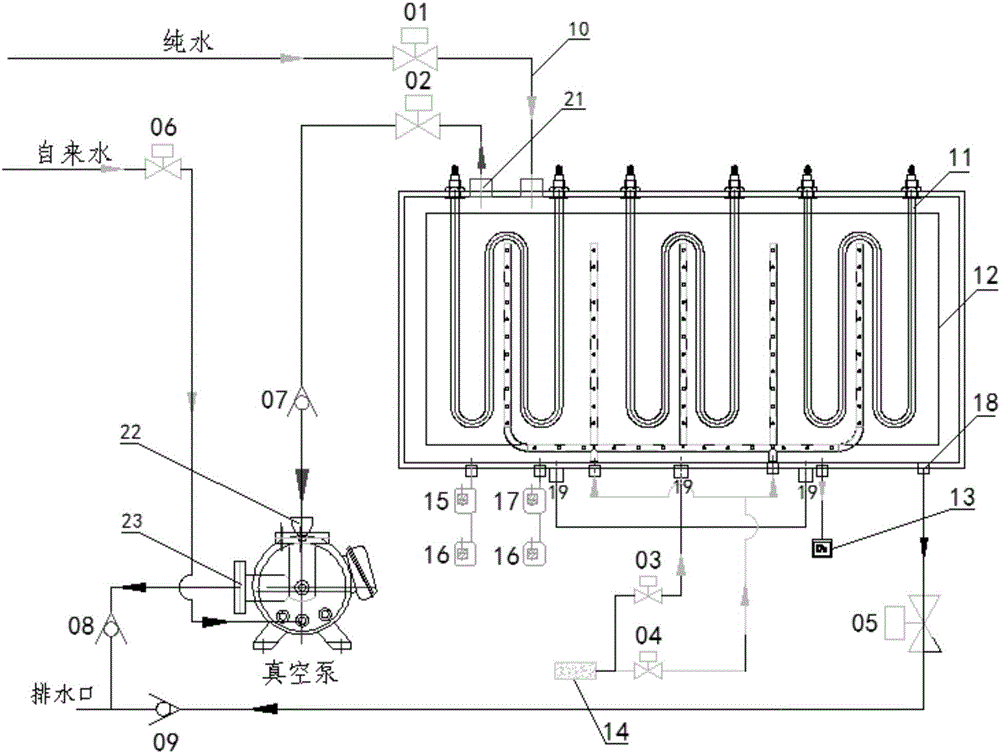

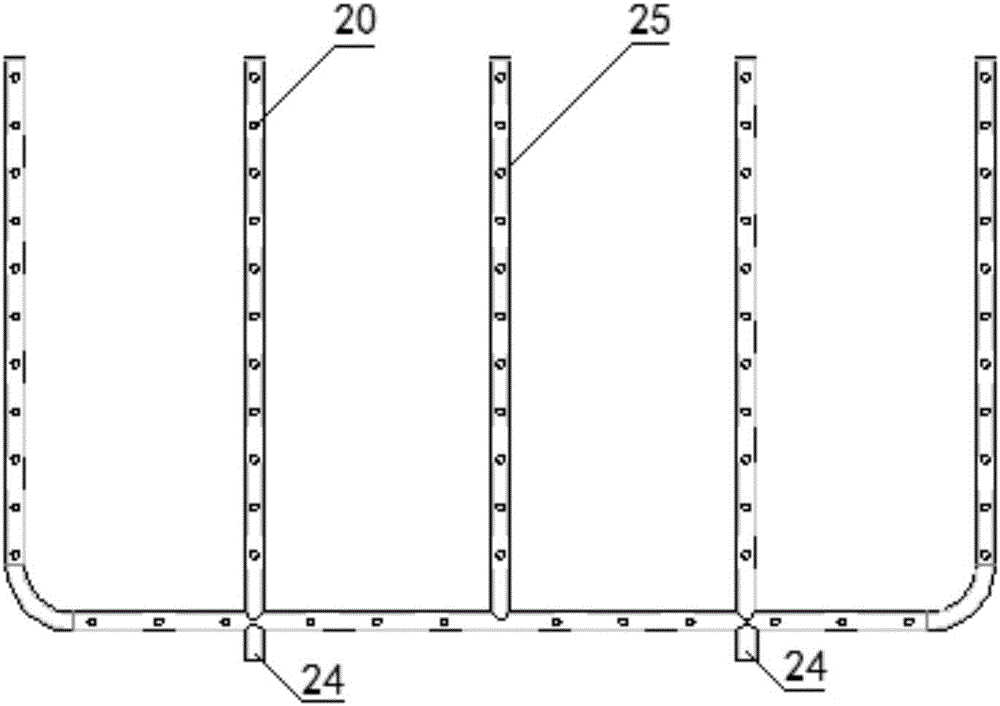

Multistage variable-pressure pulse washing system and washing method thereof

InactiveCN106269661AImprove cleaning efficiencyGuaranteed cleaning qualityDiagnosticsSurgeryVacuum pumpingBoiling point

The invention provides a multistage variable-pressure pulse washing system and a washing method thereof. The washing system mainly comprises a water charging system, a heating device, a washing cabin, a pressure detection device, a drainage system, a gas breaking system, a water level detection system and a vacuum pump circulation system. The washing method comprises the steps of putting an object to be washed into the washing cabin, closing a cabin door, and supplementing cleaning fluid; when the cleaning fluid reaches a set liquid level, starting to heat to be 45 DEG C to 55 DEG C; when the temperature reaches set temperature, starting a vacuum pump to pump out gas in the washing cabin; reducing the boiling point of the cleaning fluid in a tank along with the continuous reduction of the vacuum degree in the tank, starting to shaking and boiling the liquid in the tank when the liquid in the tank reaches the boiling point, after maintaining the state for a while, switching on a liquid breaking valve or a gas breaking valve for 1s to 30s, and quickly recovering the pressure in the washing tank; repeating the steps of vacuum pumping and switching on the liquid breaking valve or the gas breaking valve for washing; after the washing is finished, taking the washed object out. According to the multistage variable-pressure pulse washing system and the washing method thereof provided by the invention, the manpower is saved, the simplicity and the convenience in operation are realized, and the washing effect is good.

Owner:深圳市美雅洁技术股份有限公司

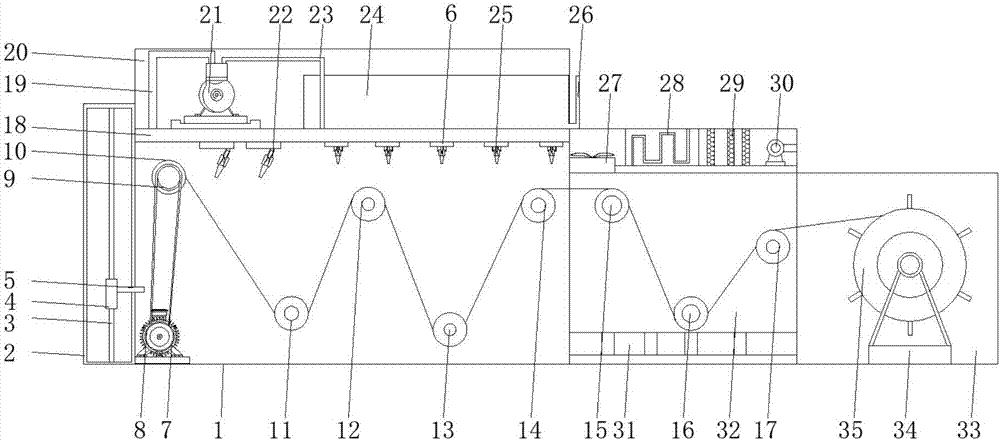

Automatic cleaning, drying and collecting integrated machine

ActiveCN107503052AAchieve the purpose of cleaningGuaranteed cleaning efficiencyLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to the technical field of textile machinery and discloses an automatic cleaning, drying and collecting integrated machine which comprises a chamber. A first motor is fixedly connected to one side of the inner wall bottom of the chamber through a motor mounting platform and is rotationally connected with a first belt pulley through an output shaft, the first belt pulley is in rotational connection with a second belt pulley through a belt, and the second belt pulley is in rotational connection with a first movable pulley through a rotating shaft. A water supply tank is fixedly connected to the upper portion of the inner wall of the chamber, and a water pump is fixedly connected to the inner wall bottom of the water supply tank through a water pump mounting platform. The automatic cleaning, drying and collecting integrated machine has advantages that automatic cleaning, drying and collecting of textile cloth are realized, cleaning quality and cleaning efficiency are guaranteed, operation efficiency is improved, labor amount of workers is decreased, production cost is reduced, suitableness for large-scale popularization is realized, all parts of the textile cloth can be cleaned, and operation efficiency can be guaranteed by cooperation with a drying device.

Owner:嘉兴市华阳纺织染整有限公司

Oil tank truck cleaning treatment system and technology

PendingCN108941107AGuaranteed uptimeAdjust the amount of waterFatty/oily/floating substances removal devicesTank vehiclesLiquid wastePollution

The invention discloses an oil tank truck cleaning treatment system and technology. The system comprises a boiler device, a cleaning device, an oil vapor trap device, a waste gas treatment device, a waste heat recycling device and a sewage treatment device. The boiler device is connected with the cleaning device, the oil vapor trap device is located in the middle of a spraying tower of the waste gas treatment deice, one part of waste liquid of the spraying tower is returned into the spraying tower through a circulation pump, the rest enters the sewage treatment device, and unabsorbed oil vaporenters the boiler deice through the top of the oil vapor trap device for secondary air combustion. The low-pressure vapor tank technology most advanced in China is adopted, the cleaning quality is ensured, scale cleaning is achieved, more than 200 oil tank trucks are treated daily, the efficiency can be greatly improved compared with retail investor extensive type cleaning, consumption of low-pressure steam amount of each truck is reduced by 55% or more, cleaning sewage is recycled after being treated, the cleaning cost of each truck is reduced, and economic benefits are improved. Waste gas is exhausted after being treated and reaching standards, no pollution is caused to surrounding, and great environmental and social benefits are produced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

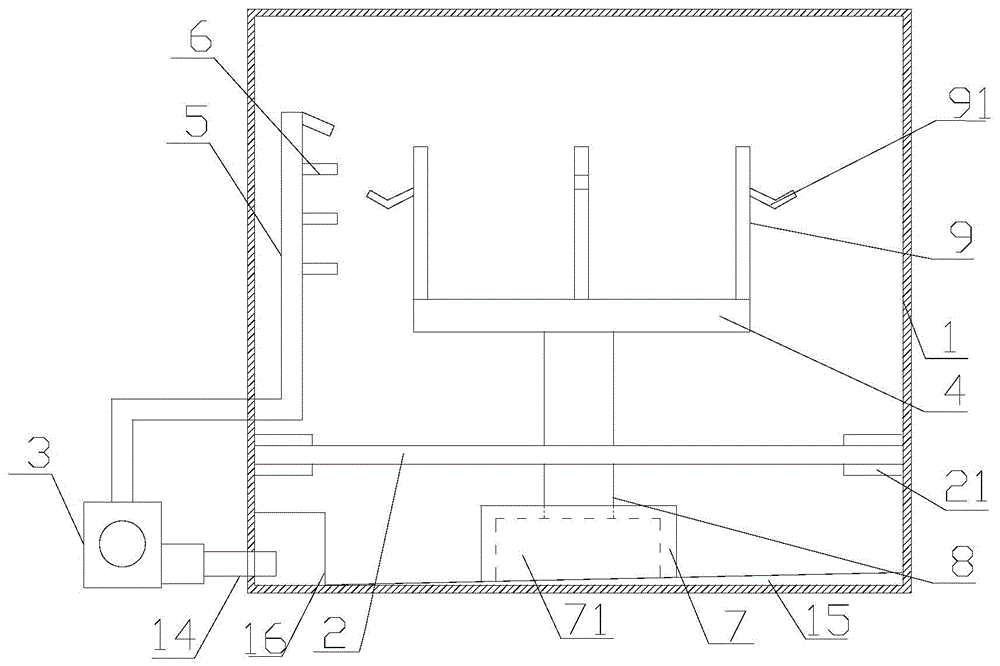

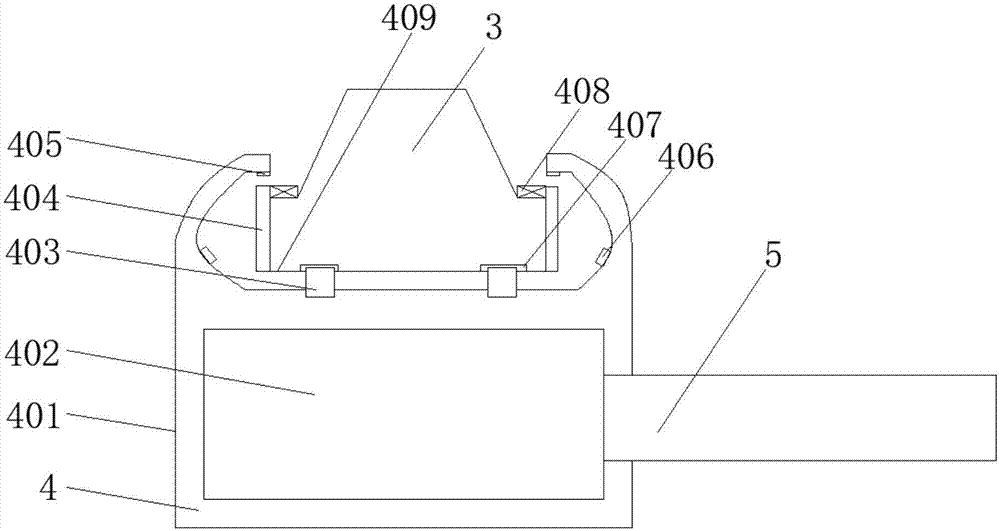

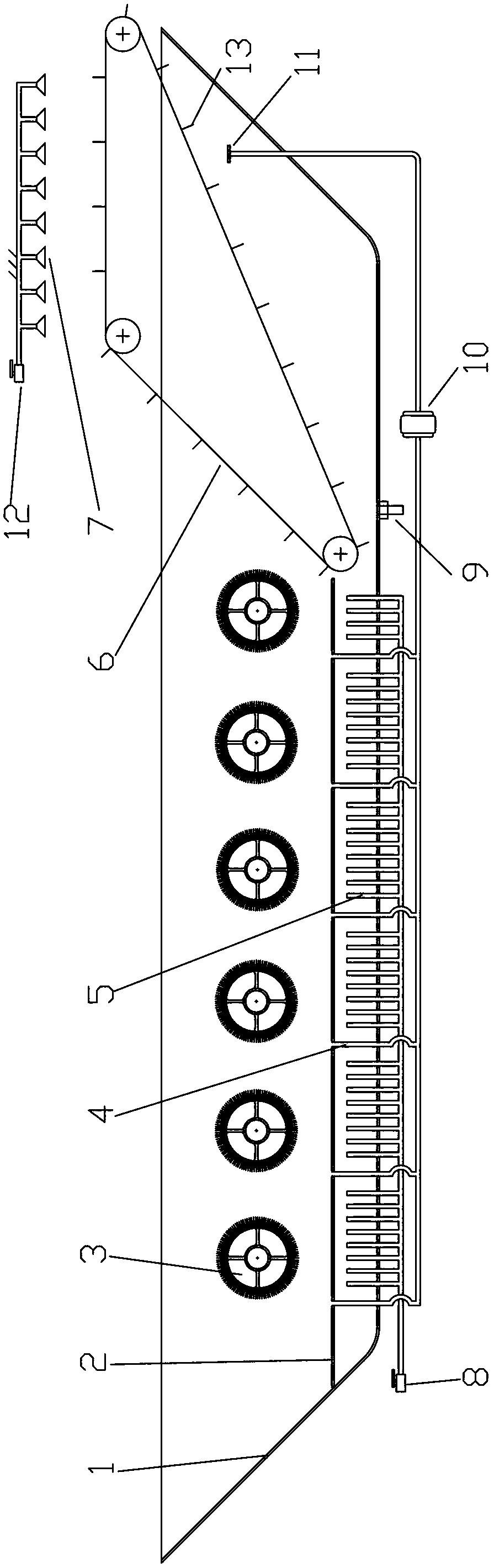

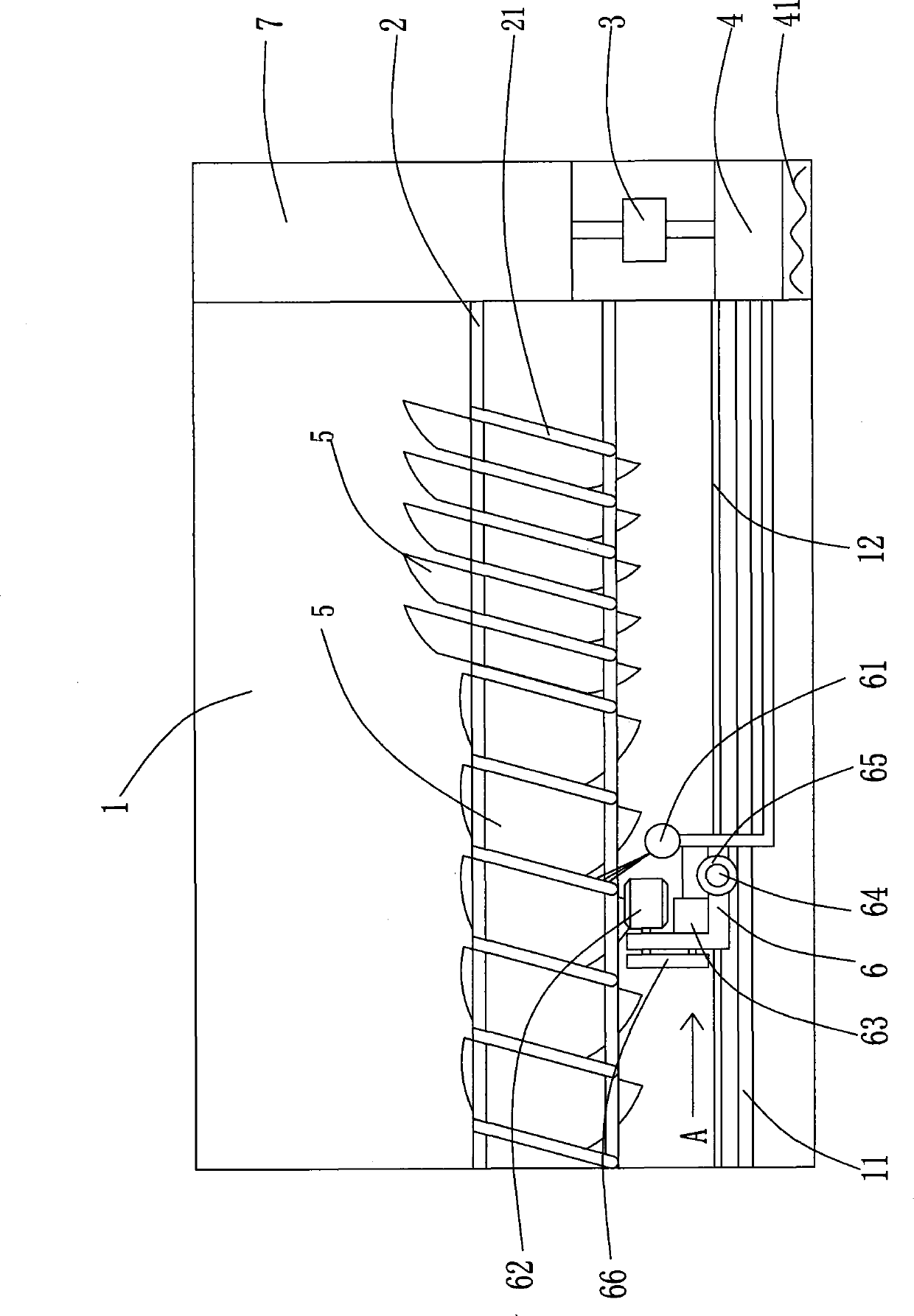

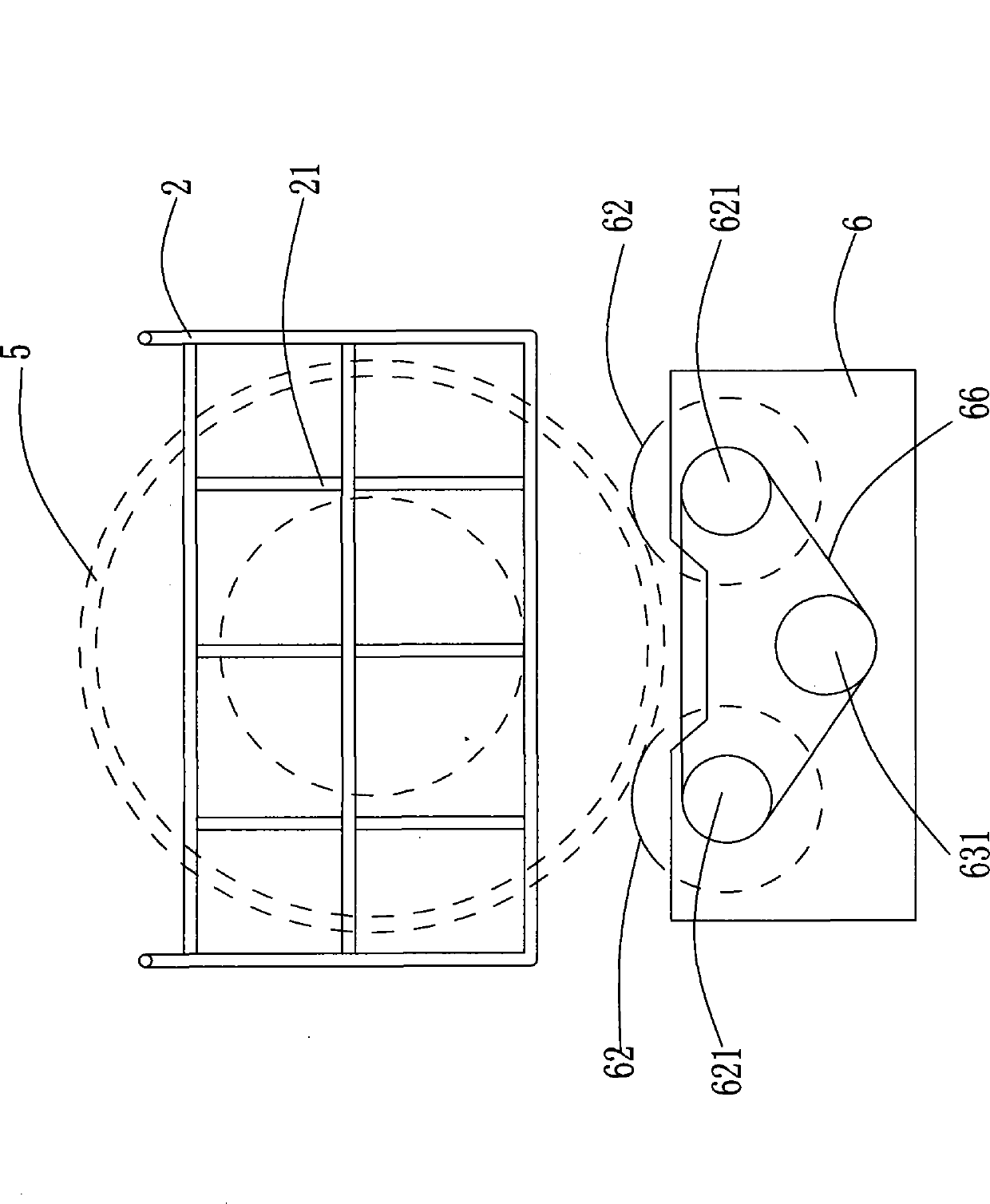

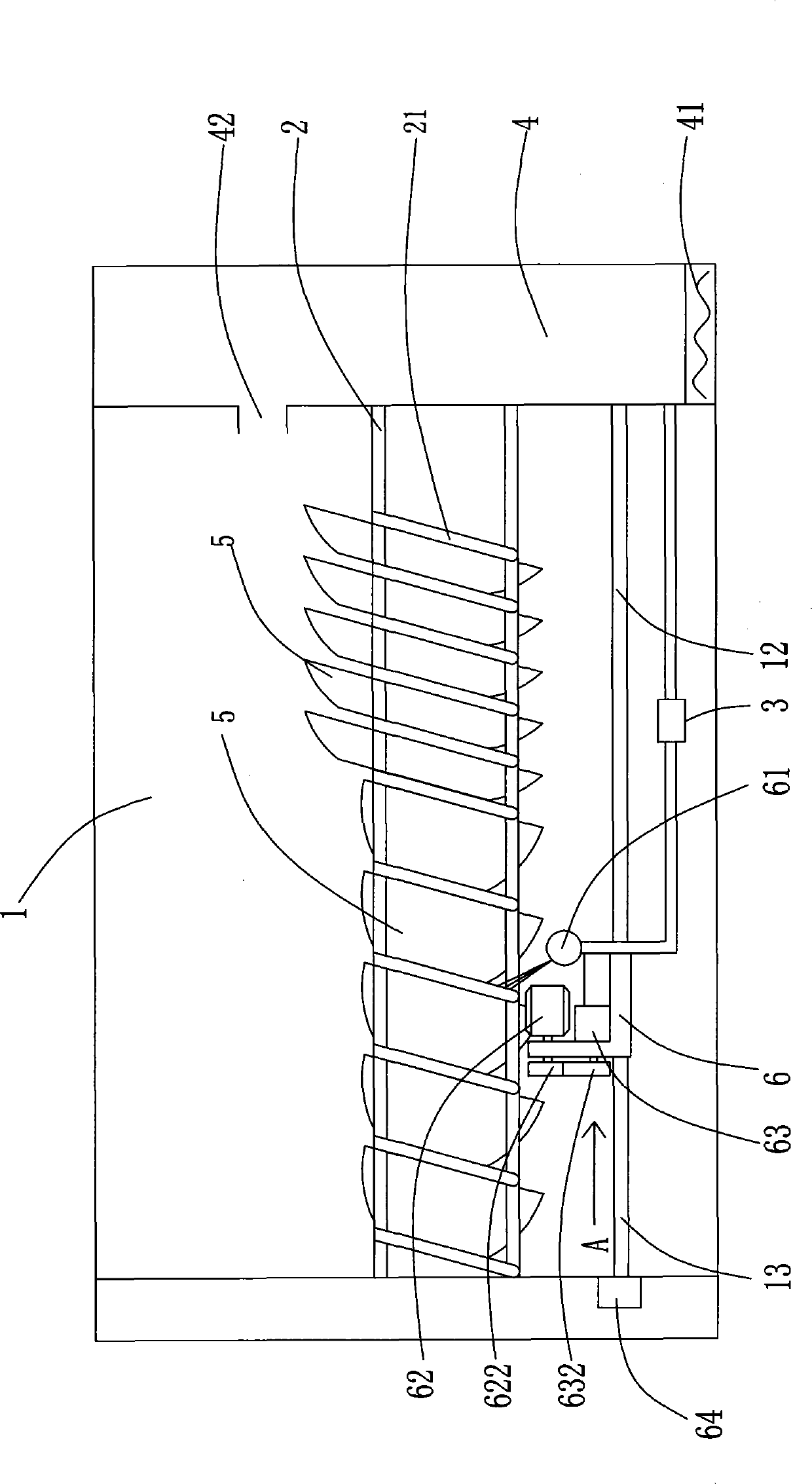

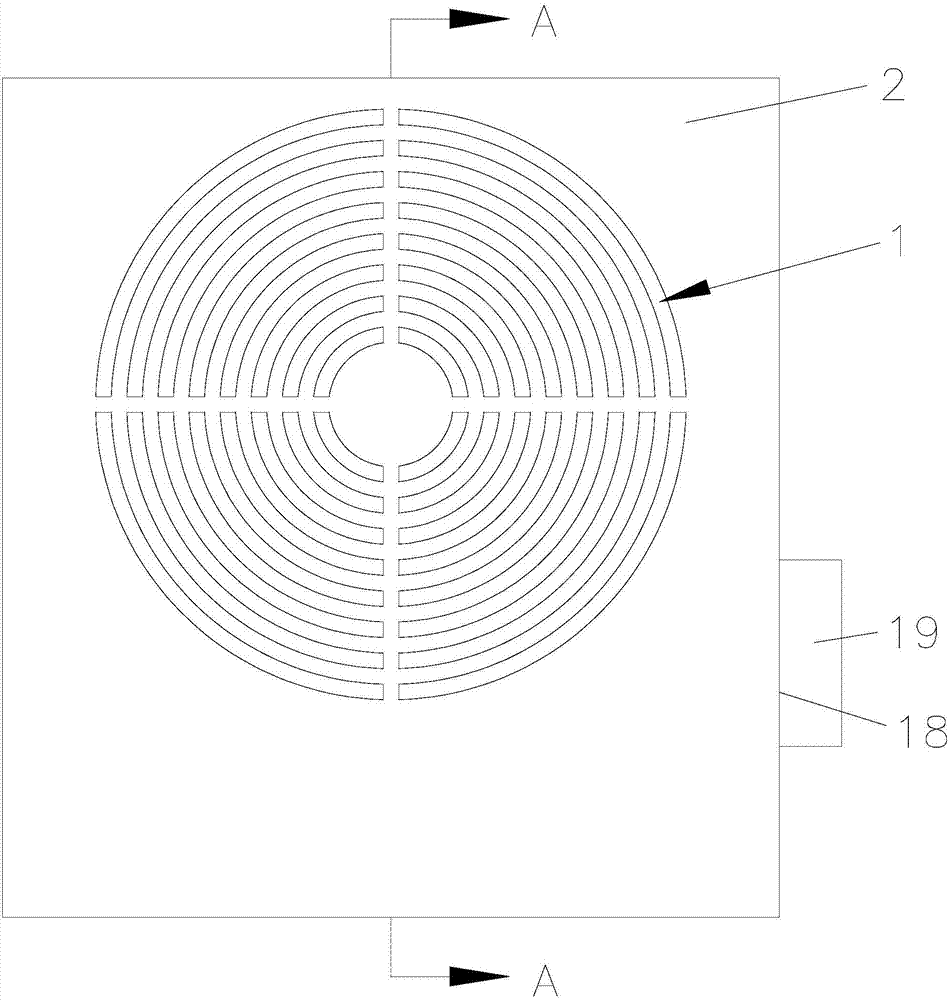

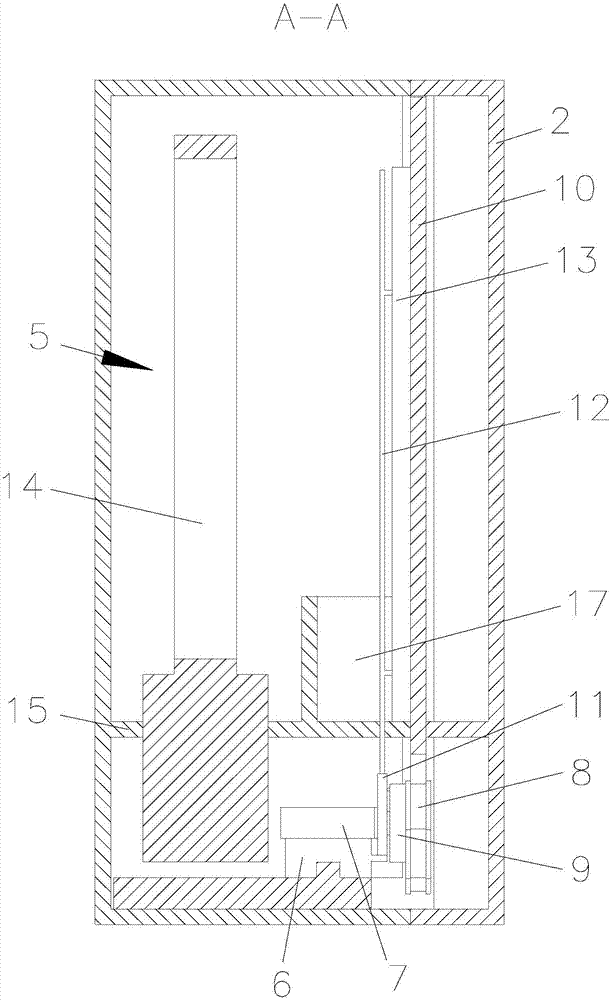

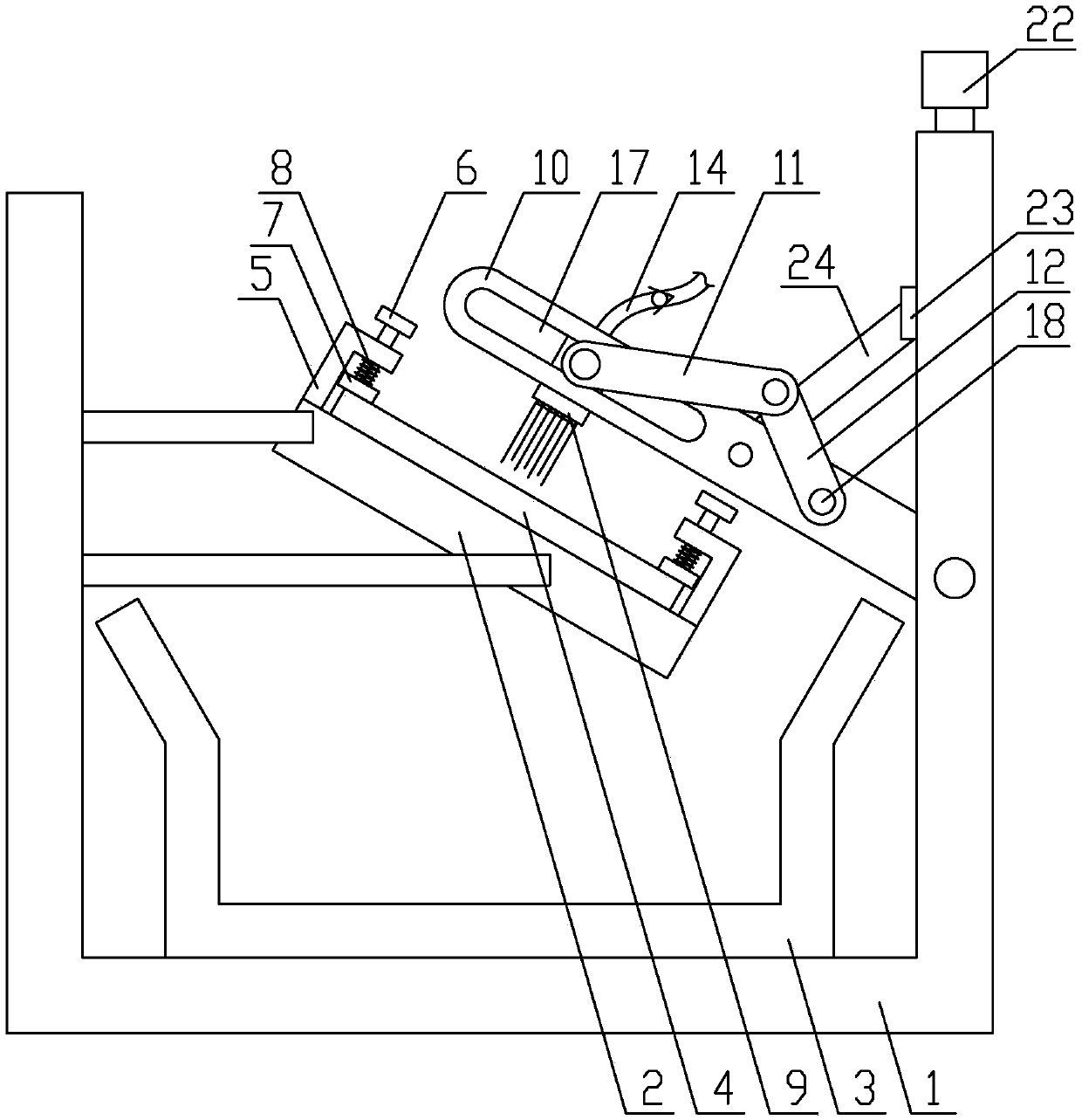

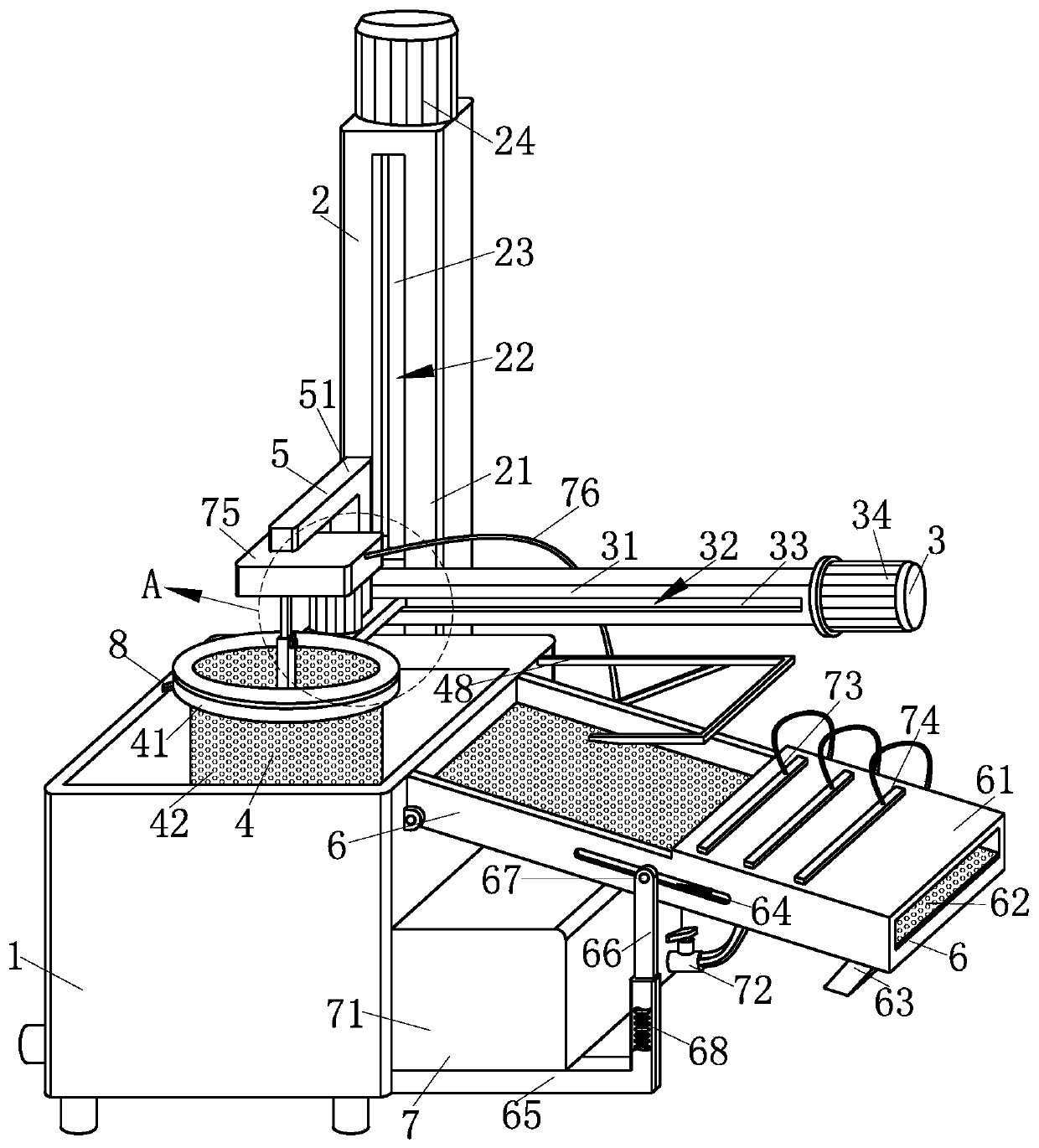

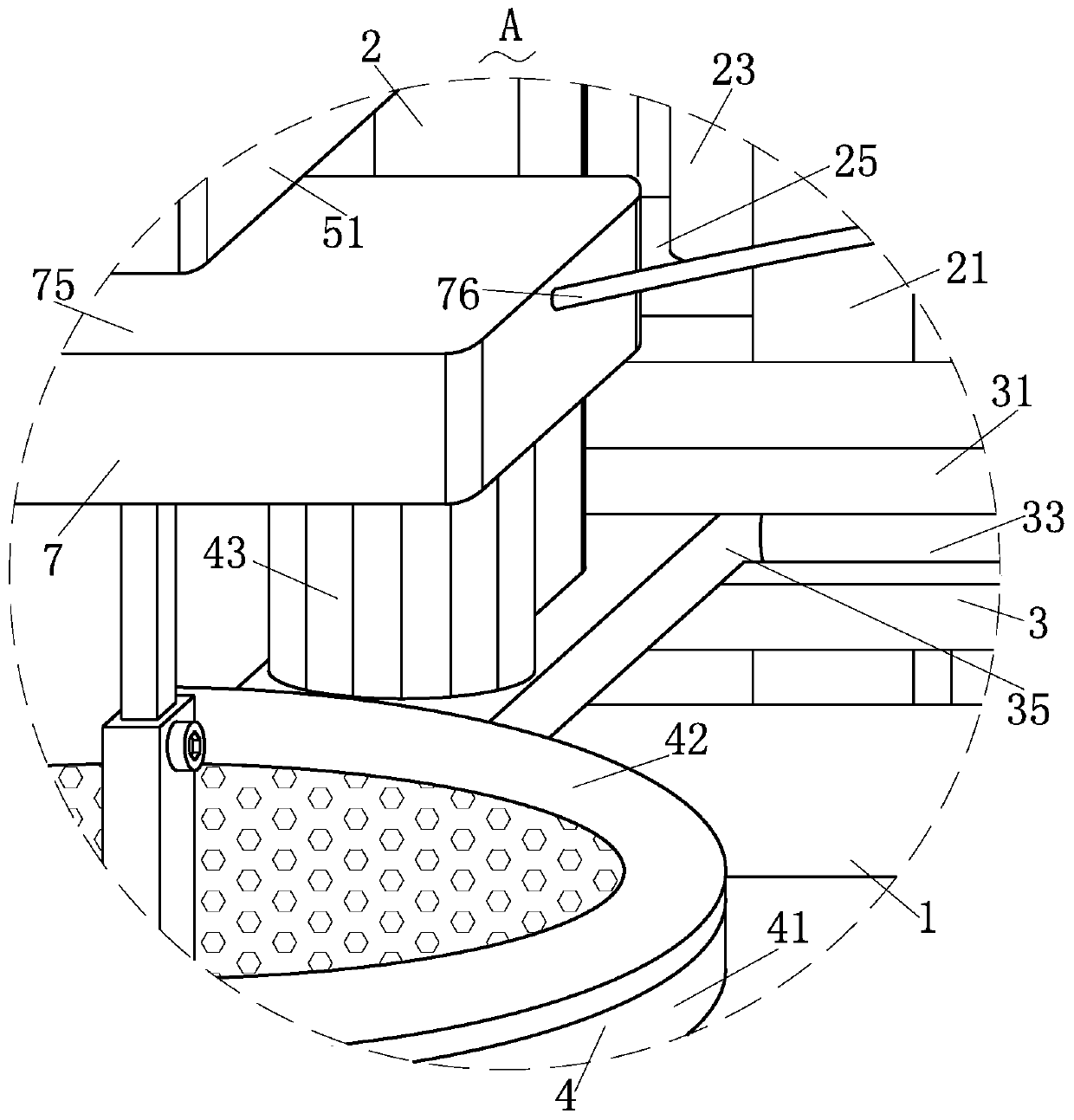

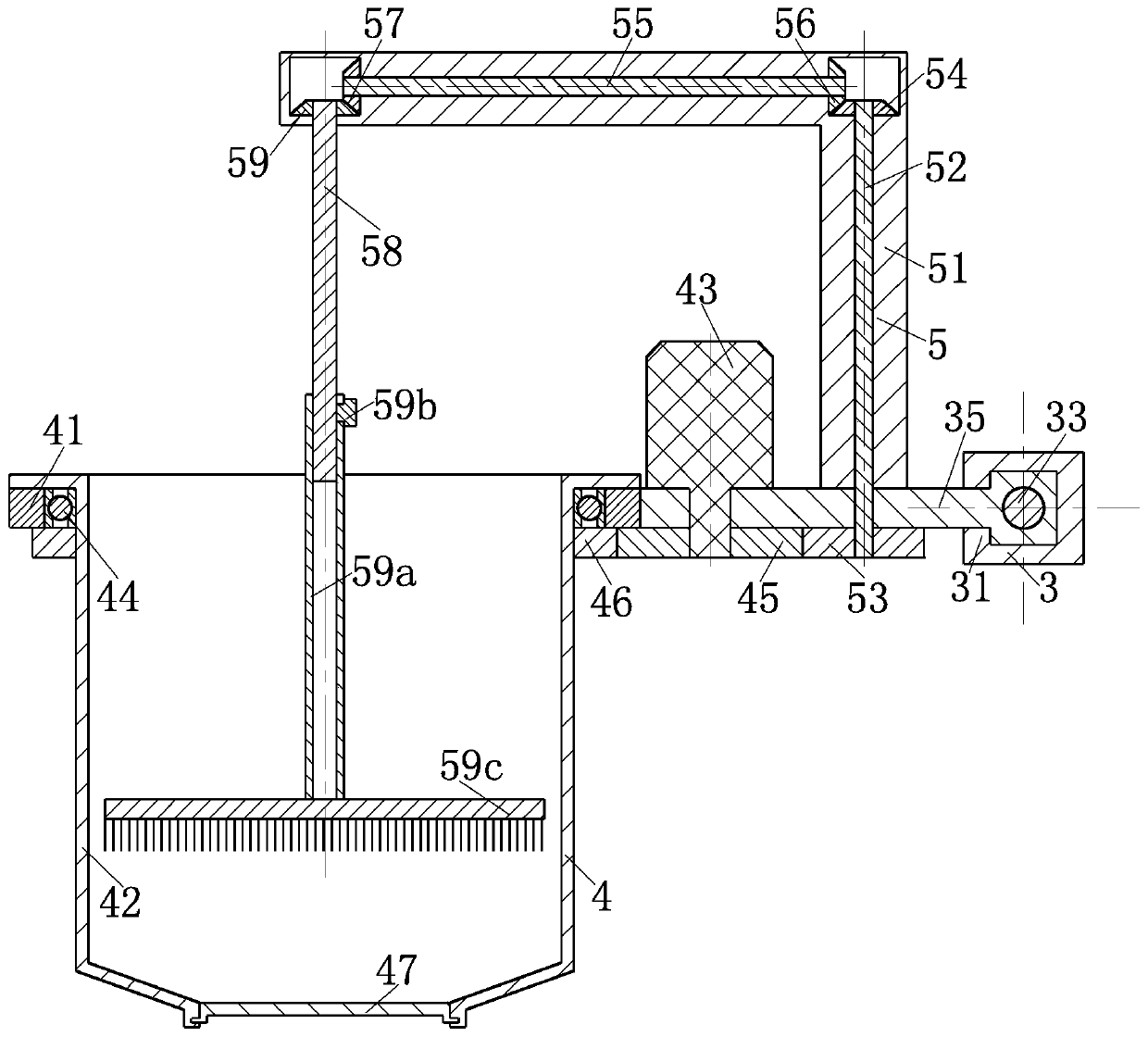

Multi-action type sea cucumber cleaning machine

ActiveCN103212555AGuaranteed cleaning qualityCleaning processes and apparatusWater dischargeTexture control

The invention discloses a multi-action type sea cucumber cleaning machine, comprising a soaking pond (1) with a water discharging port (9) at the bottom part, wherein a net partitioning plate (2) is paved at the middle-lower part of the soaking pond; rolling brushes (3) are arranged above the net partitioning plate at intervals; foaming pipes (5) are arranged under the net partitioning plates at intervals and are connected with an air pumping unit; surging pipes are also arranged under the net partitioning plate at intervals and are connected with a water body pumping unit; one side of the net partitioning plate is provided with a belt transmission unit; and a spraying unit is arranged above one section of a conveying belt. The multi-action type sea cucumber cleaning machine disclosed by the invention has the advantages that a multi-action mode is adopted to clean sea cucumber, so that the cleaning quality of the sea cucumber can be effectively ensured, and the multi-action type sea cucumber cleaning machine is applicable to the cleaning procedure before the texture control in the processing process of a sea cucumber product.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Swirling flow type waste plastic crushing sorting cleaning system

InactiveCN109551664AQuality improvementReduce metal magnetic impuritiesPlastic recyclingMechanical material recoveryWater resourcesPlastic recycling

The invention provides a swirling flow type waste plastic crushing sorting cleaning system. The swirling flow type waste plastic crushing sorting cleaning system includes a first transfer machine, a crushing machine, a transfer box, a cleaning device, a swirler, a box body and a fixing frame, and the top of the fixing frame is fixed to the bottom of the crushing machine. According to the swirlingflow type waste plastic crushing sorting cleaning system, metal magnetic impurities in waste plastic are reduced, the quality of waste plastic recycling is improved, meanwhile, the waste metal magnetic impurities are collected, post-processing and production of processing are convenient, multi-angle cleaning is realized, cleaning is more even, the efficiency and quality of cleaning are ensured, thus the recycling efficiency of the waste plastic is improved, reuse of water resources is improved, the cleanliness degree of the cleaning process is increased, thus the recycling quality of the wasteplastic is ensured, the water content of waste plastic recycling is decreased, and the quality of production is ensured, so that secondary processing is avoided.

Owner:开平市源成达塑胶制品有限公司

Water using wipe floor cleaning machine

InactiveCN1919134AGuaranteed cleaning qualityRealize automatic walkingCarpet cleanersFloor cleanersWater useDrive wheel

The invention discloses a water rag grazing cleaning machine, which comprises the following parts: walking, cleaning and water systems, wherein the walking part contains rack with back driving wheel and front guide wheel, fixing shaft with rotatable cleaning part, rotary disc rack, rag wiping and brushing device, wherein the rotary disc rack is encased on the fixing shaft, the rotary disc driving motor is set on the rack, which contains deceleration driving device from rotary disc rack, the rag can wipe device on the rotary disc rack, which contains brushing wheel, water squeezing pressure wheel and water sprayer, the water system supplies clear water and effluent reserving groove and cleaning groove, which provides clear water and gathers effluent in the effluent groove.

Owner:郑明珠

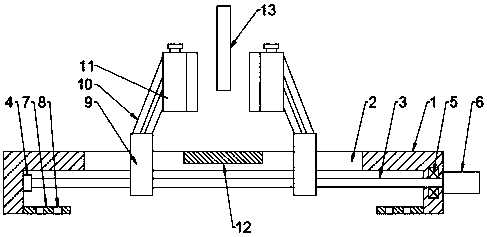

Novel dish-washing machine

ActiveCN103284675AFew partsEasy to assembleTableware washing/rinsing machine detailsSprayerEngineering

The invention provides a novel dish-washing machine which comprises a cabinet body, a support, a water pump, a heating chamber provided with a heating element and used for providing hot water or steam, a sprayer capable of spraying the steam or the hot water onto ware, and at least one rotary stick which is positioned below the support and can drive at least one ware to rotate, wherein the heating chamber is communicated with the sprayer. The dish-washing machine is characterized in that the dish-washing machine further comprises a workbench capable of moving left and right; the rotary stick is connected with a first motor and driven by the first motor to rotate; and the sprayer, the rotary stick, and the first motor are mounted on the workbench. Compared with the prior art, according to the dish-washing machine, an row of ware only needs one sprayer; only one ware is driven to rotate, sprayed and washed during washing; the workbench moves to the inferior of the next ware to wash after one ware is washed; and the dish-washing machine has the advantages of few parts, easiness in assembly, simple structure, strong spraying impact force, low cost and good washing quality.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD +1

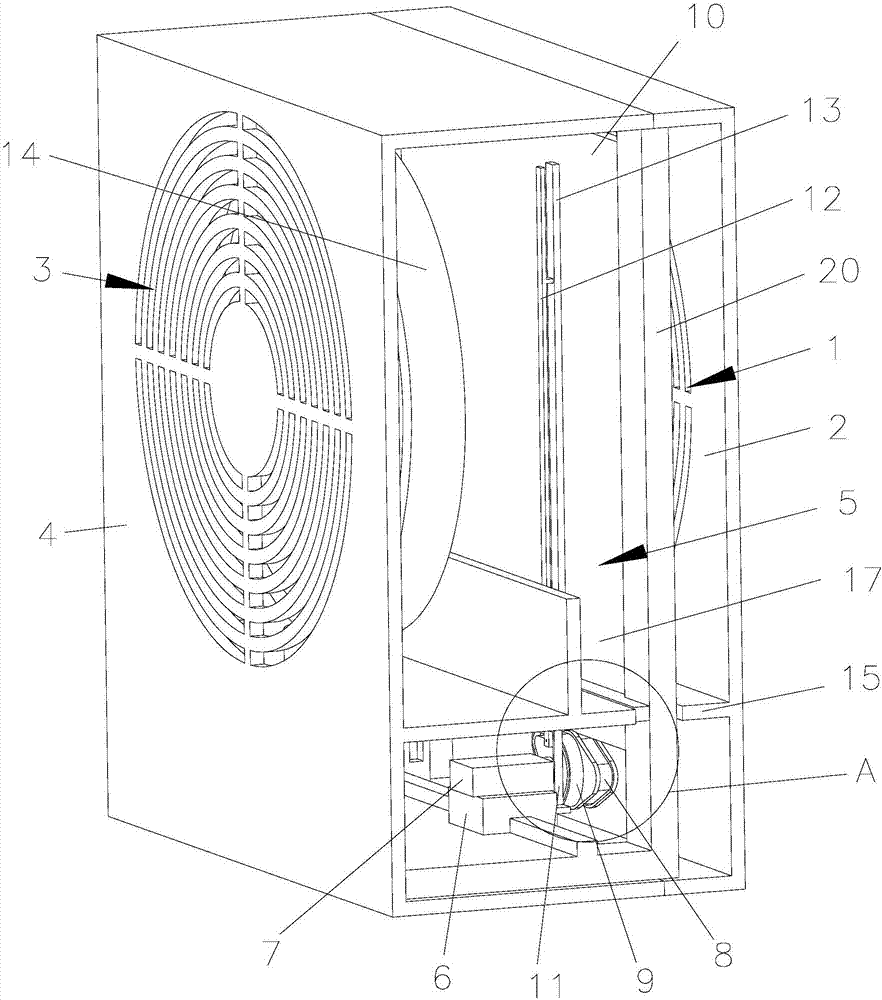

Self-cleaning air purifier

PendingCN107376539AGuaranteed cleaning qualitySave human effortDispersed particle filtrationTransportation and packagingMotor driveEngineering

The invention relates to a self-cleaning air purifier. With a motor driving a first cam to shake a filter screen, dust on the surface of the filter screen is shaken off into a dust collecting groove. With a motor driving a second cam to drive a brush holder, the brush holder drives a brush to move, and dust on the filter screen is swept into the dust collecting groove. Through self-shaking of the filter screen and with the brush brushing the filter screen, dust on the filter screen can rapidly fall into the dust collecting groove. While the first cam drives the filter screen to ascend, the second cam drives the brush to descend. With the filter screen and the brush moving opposite to each other, the brush sweeps dust on the filter screen more easily. With a pneumatic slide block driving the brush to move in the length direction of a filter, each part of the filter can be cleaned by the brush. Thus, cleaning quality is guaranteed. According to the invention, manpower is saved, dust on the filter screen can be cleaned timely, and purification efficiency and purification quality of the air purifier are guaranteed.

Owner:SUZHOU UNIV OF SCI & TECH

Shutdown method of fixed bed residual oil hydrogenation apparatus

ActiveCN104611012AEasy to disassembleAccelerated exclusionTreatment with hydrotreatment processesWaxPressure decrease

The present invention discloses a shutdown method of a fixed bed residual oil hydrogenation apparatus. The shutdown method comprises that: the apparatus is subjected to temperature decrease and amount decrease, hydrogenation tail oil enters the apparatus along the sequence opposite to the normal operation feeding sequence of the apparatus, wax oil is switched to wash the apparatus after the hydrogenation tail oil passes through the whole reaction system, the system is cooled after the washing with the wax oil is qualified, washing with diesel fuel is performed, the whole system is cooled after the apparatus washing with the diesel fuel is qualified, the diesel fuel feeding is stopped, hydrogen gas purging is performed, the whole apparatus is subjected to temperature decrease and pressure decrease after the hydrogen gas purging is performed for a certain time, nitrogen gas purging is performed, and the apparatus shutdown is completed. With the shutdown method of the present invention, the apparatus washing and the catalyst washing are easily achieved, and the catalyst disassembly is easily achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Circuit board cleaning device

InactiveCN111185410AGuaranteed cleaning qualityImprove cleaning qualityCleaning using toolsCleaning using liquidsElectric machineryEngineering

The invention provides a circuit board cleaning device. The circuit board cleaning device comprises a main body, a bearing platform, a collecting box and a cleaning mechanism arranged which is arranged above the bearing platform.A fixing mechanism for fixing a circuit board is arranged on the bearing platform, and the cleaning mechanism comprises a brush, supports, driven rods and driving rods; long-strip-like holes are formed in the supports, the two ends of the brush penetrate through the long-strip-like holes to be hinged to one ends of the driven rods respectively, and the other ends of the driven rodsare hinged to one ends of the driving rods; the other ends of the driving rodsare fixedly connected with a rotary shaft driven by a motor; the bearing platform is obliquely arranged, theends, away from the long-strip-like holes, of the supportsare hinged to the main body, and the main body is provided with an adjusting mechanism for adjusting the angles of the supports to make the supports parallel to the bearing platform; a water spraying pipe is arranged in the brush, and a plurality of nozzles are uniformly arranged on the bottom of the water spraying pipe. By arranging the brush above the bearing platform and using the driving rods and the driven rods to drive the brush to slide forth and back along the supports, repeated cleaning of the circuit board is achieved, and thecleaning quality is effectively improved.

Owner:江苏盐湖电子科技有限公司

Cleaning device for valve part degreasing treatment

ActiveCN111299235AWash thoroughlyEasy to cleanDrying solid materials without heatCleaning using toolsMachiningVALVE PORT

The invention relates to the field of valve part production and machining devices, in particular to a cleaning device for valve part degreasing treatment. The cleaning device for valve part degreasingtreatment comprises a box body, a feeding structure, a transverse moving structure, a rotating structure, a sweeping structure, a discharging structure, a flushing structure and a flapping structure.According to the cleaning device for valve part degreasing treatment, through the arrangement of the rotating structure, rotationally cleaning valve parts can be carried out, so that the cleaning time of the valve parts can be shortened, the valve parts can be cleaned more thoroughly, the cleaning quality of the valve parts is guaranteed; and the feeding structure is arranged at one end of the box body, the cleaned valve parts can be extracted from the inner part of the box body, and the valve parts extracted from the inner part of the box body can be transversely moved to the outer part of the box body in cooperation with work of the transverse moving structure so that draining work on the valve parts can be conveniently carried out, the valve parts can be taken out from the inner part of the box body conveniently, manual repeated fishing of parts in the inner part of the box body is avoided, and the effects of saving labor and improving efficiency can be further achieved.

Owner:浙江奥德华科技股份有限公司

Cleaning device for blade of packaging box cutting machine

InactiveCN109225959ARealize automatic movementGuaranteed cleaning qualityBox making operationsPaper-makingCarton

The invention discloses a cleaning device for a blade of a packaging box cutting machine, which comprises a base, wherein a chute is arranged at the middle part of the top end surface of the base, a screw rod is arranged in the inner cavity of the base, one end of the screw rod is rotatably connected with the left side wall of the inner cavity of the base through a bearing seat, the other side endof the screw rod passes through the right side wall of the base body and is fixedly connected on the motor shaft of a motor, the screw rod is rotatably connected to a machine body through a bearing,the left and right sides of the outer circle surface of the screw rod are symmetrically sleeved with moving seats matched with the chute, the top end of the moving seat is uniformly provided with a plurality of bracket rods, the other ends of the bracket rods are fixedly connected with a cleaning brush matched with a cutting tool; according to the invention, the two moving seats are matched with the screw rod so as to achieve the automatic movement of the cleaning brush, so that the cutting tool can finish the cleaning work in the running process, and the processing quality is ensured under the condition of ensuring normal operation of the cutting work; meanwhile, a frosted surface and a sponge surface are arranged on a cleaning body, the cleaning quality of the cutting tool is ensured.

Owner:温州磐石机械设备维修咨询有限公司

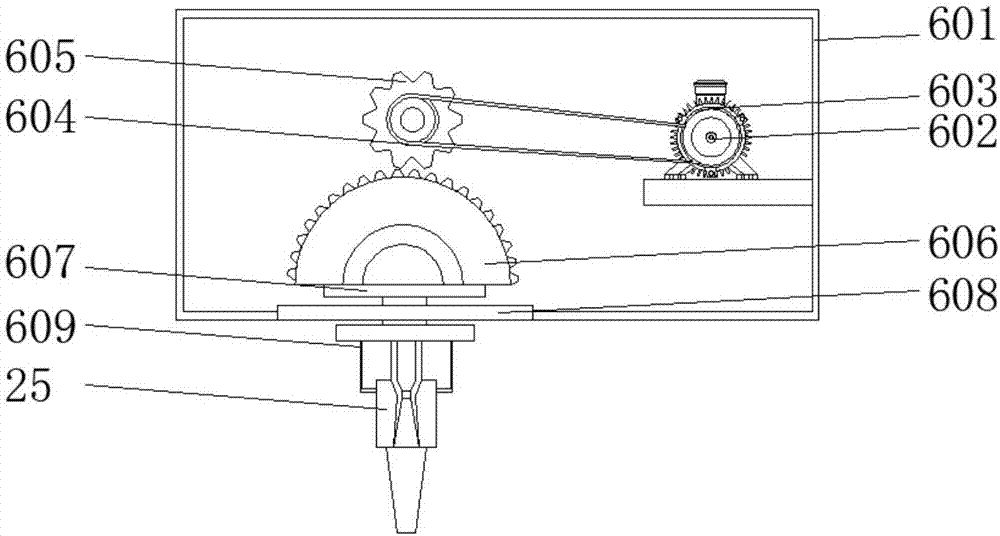

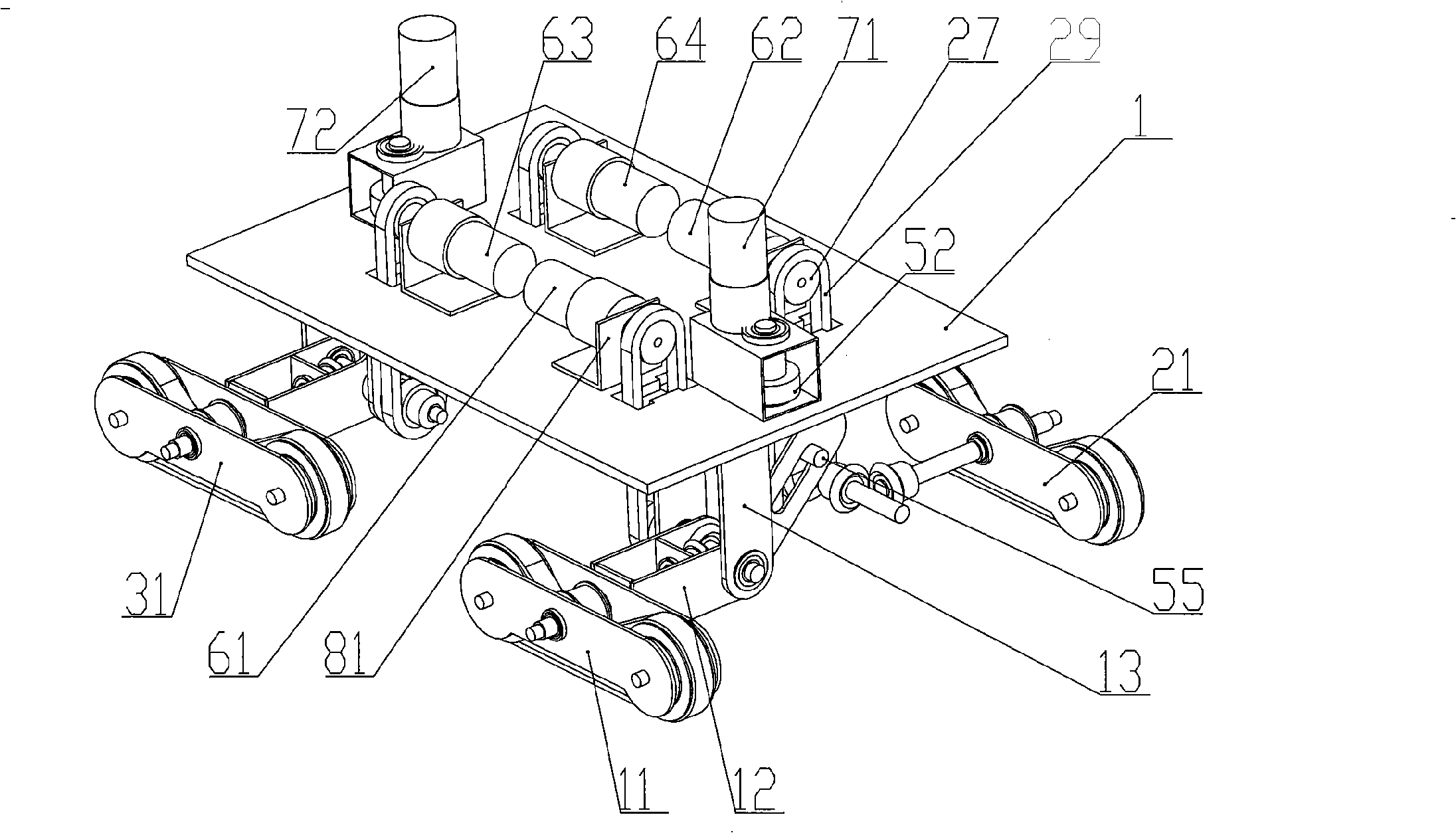

Pipeline cleaning and disinfecting vehicle for central air-conditioner

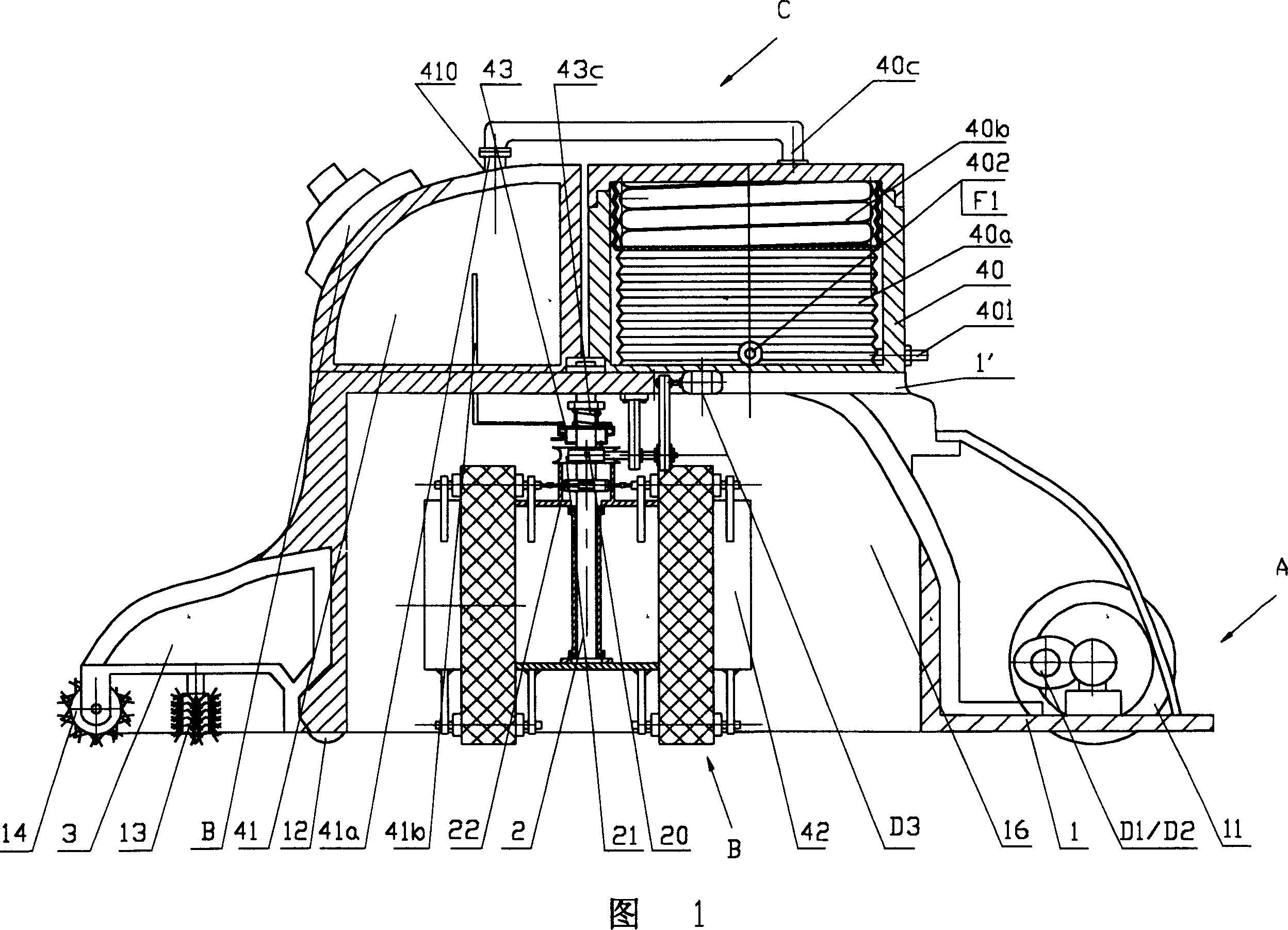

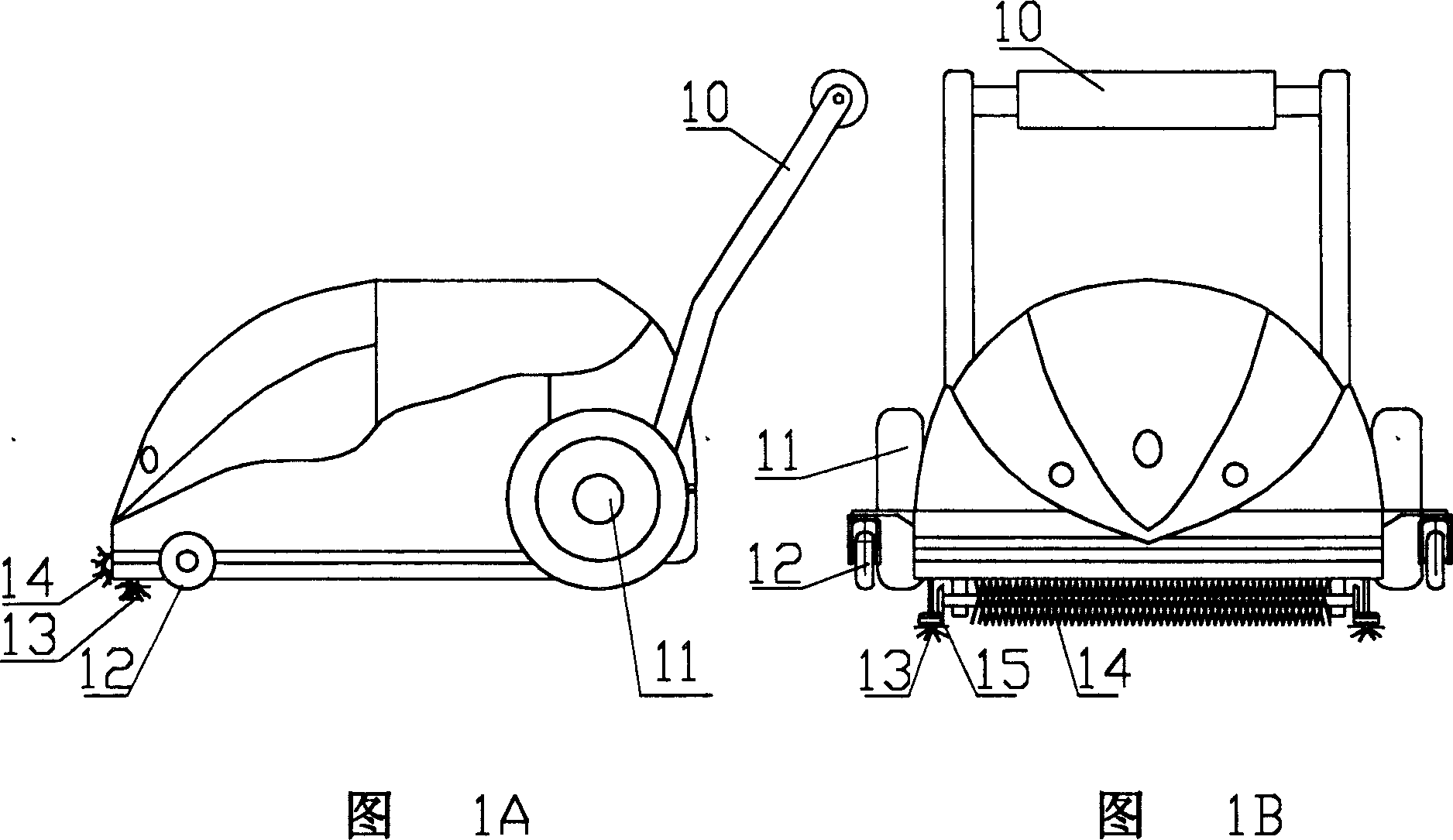

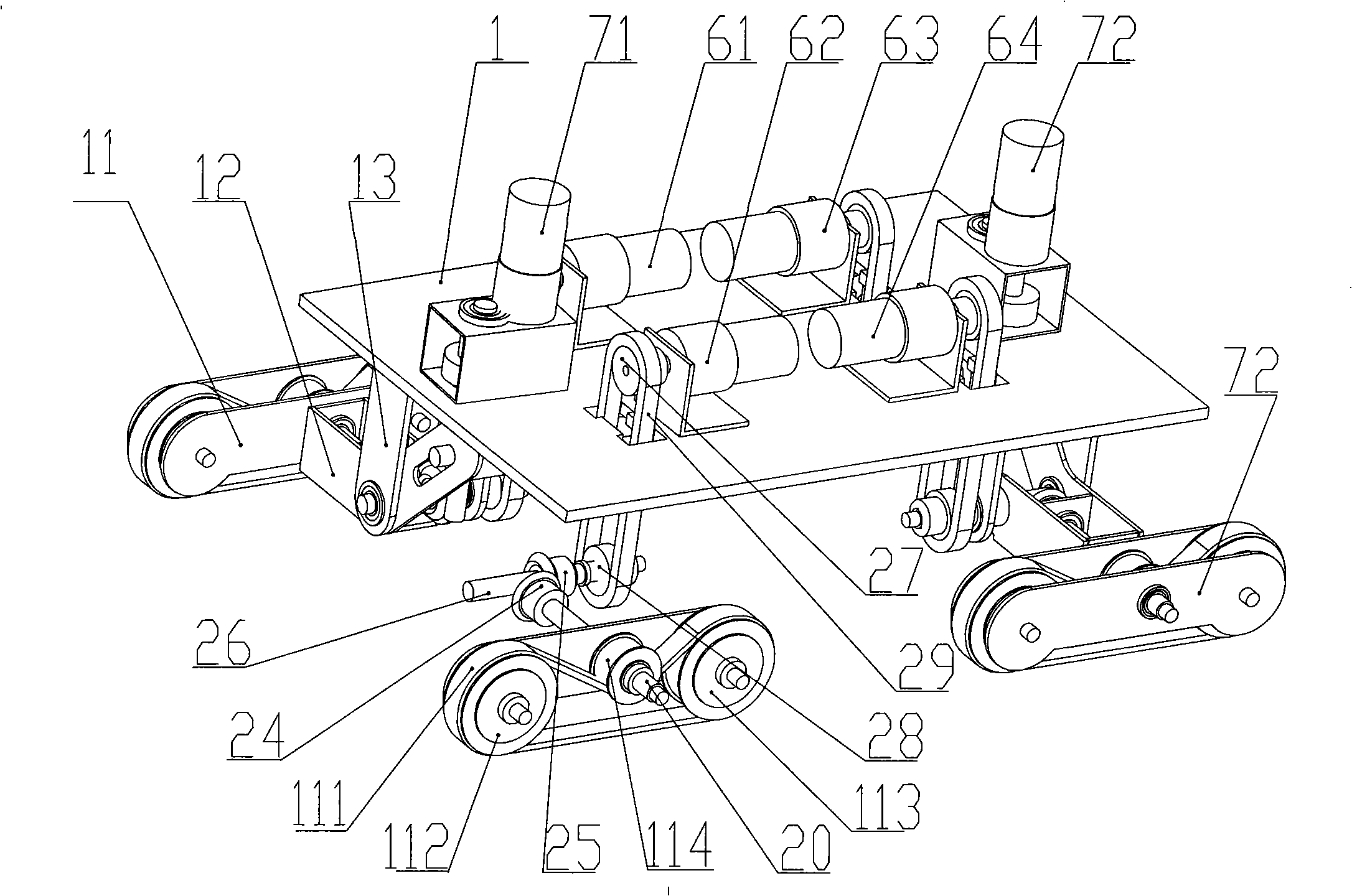

InactiveCN101269375AMeet the need to move forwardGuaranteed levelHollow article cleaningEndless track vehiclesCentral air conditioningSprocket

The invention relates to a cleaning and disinfecting vehicle for a central air-conditioning pipe, including a vehicle chassis, a walking mechanism, a cleaning mechanism and a disinfection interface; wherein, the walking mechanism is arranged under the vehicle chassis; the cleaning mechanism is arranged on the vehicle chassis; the walking mechanism comprises four mechanical legs, a pedrail foot and a walking and driving motor; each mechanical leg comprises an upper sprocket, a chain, a lower sprocket, a first transmission rod, a second transmission rod and a drive wheel; wherein, the drive wheel is in transmission connection with the pedrail of the pedrail foot; the walking mechanism also comprises two swaying mechanisms which are arranged between two mechanical legs respectively at the front and the back of the vehicle chassis; the swaying mechanism comprises a swaying motor, a drive gear, a driven gear and a screw transmission rod; the lower side of the screw transmission rod is sleeved on a fixed block with a screw hole; and the fixed block with a screw hole is arranged on a pressure lever; a connecting sheet with an arc trough is fixedly sleeved on the first transmission rod of various mechanical legs; the pressure lever penetrates the arc trough of every connecting sheet. The cleaning and disinfecting vehicle for a central air-conditioning pipe can be suitable for the cleaning of rectangular and circular pipelines.

Owner:ZHEJIANG UNIV OF TECH

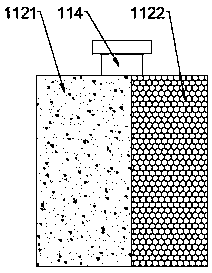

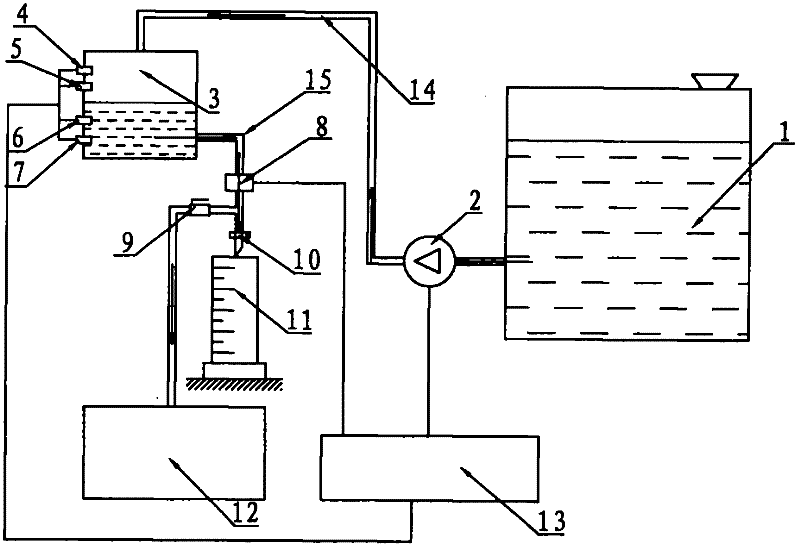

Flow type precise automatic liquid supplementing device

InactiveCN102172582AStable concentrationGuaranteed cleaning qualityCleaning using liquidsControl systemLiquid storage tank

The invention discloses a flow type precise automatic liquid supplementing device which comprises a liquid storage tank, a mechanical liquid supplementing pump, a constant-pressure tank, an upper alarm sensor, an upper liquid level sensor, a lower liquid level sensor, a lower alarm sensor, an electromagnetic reversing valve, a manual liquid supplementing valve, a manual calibration valve, a measuring jug, a cleaning tank and a control system, wherein the mechanical liquid supplementing pump is arranged between the constant-pressure tank and the liquid storage tank; the upper alarm sensor, the upper liquid level sensor, the lower liquid level sensor and the lower alarm sensor are sequentially arranged on the side wall of the constant-pressure tank from top to bottom and electrically connected with the control system; and a liquid supplementing pipe is divided into two branches through the electromagnetic reversing valve, wherein one branch is led into the cleaning tank through the manual liquid supplementing valve, and the other branch is led to the measuring jug through the manual calibration valve. The device can measure the flow of supplemented liquid, determine the liquid supplementing time according to the process requirements, and accurately supplement liquid to the cleaning tank in time so as to keep the concentration of a solution in the cleaning tank stable and fundamentally guarantee the cleaning quality of a silicon wafer.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

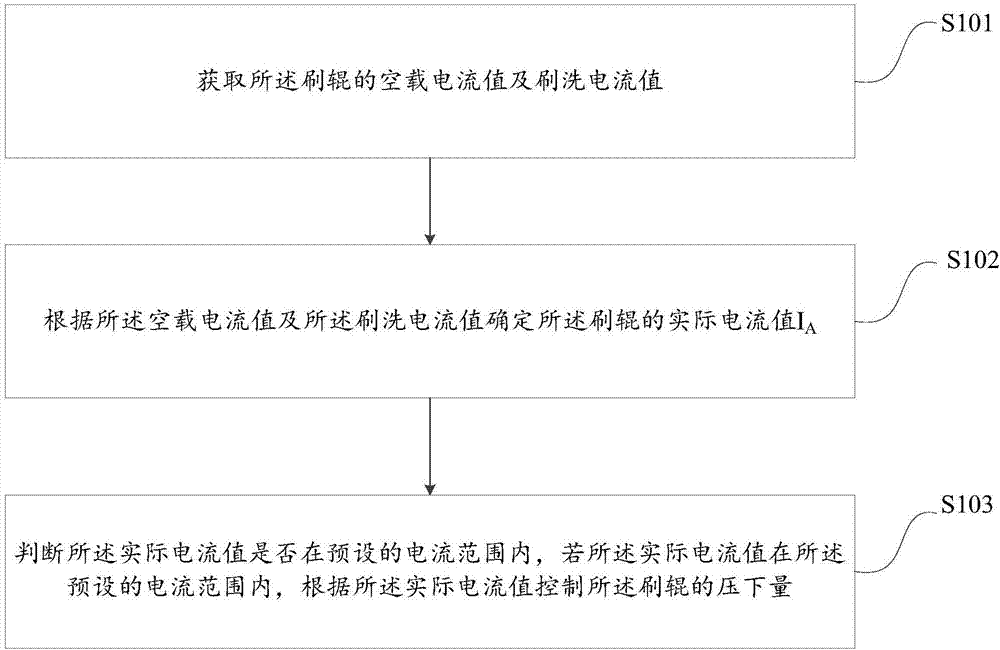

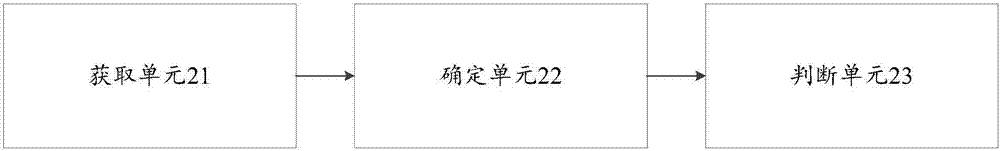

Method and device for controlling cleaning brush roll

ActiveCN106939397AStable and even outputReduce lossHot-dipping/immersion processesPower flowCurrent range

The invention provides a method and device for controlling a cleaning brush roll. The method includes the steps that the non-load current value of the brush roll is obtained; the cleaning current value of the brush roll is obtained; according to the non-load current value and the cleaning current value, the actual current value IA of the brush roll is determined; and whether the actual current value is within a preset current range or not is judged, and if the actual current value is within the preset current range, the rolling reduction of the brush roll is controlled according to the actual current value. In this way, when the roll diameter of the brush roll is reduced due to abrasion, on-line compensation can be conducted on the actual current value of the brush roll according to abrasion, and thus the brush roll can exert force stably and uniformly, the cleaning quality for strip steel is guaranteed, loss of the brush roll is reduced, and then production cost is lowered.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com