Hanging-hook automatic deplating line

It is an automatic technology that can be used in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids. Meet environmental protection requirements, save labor and clean water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

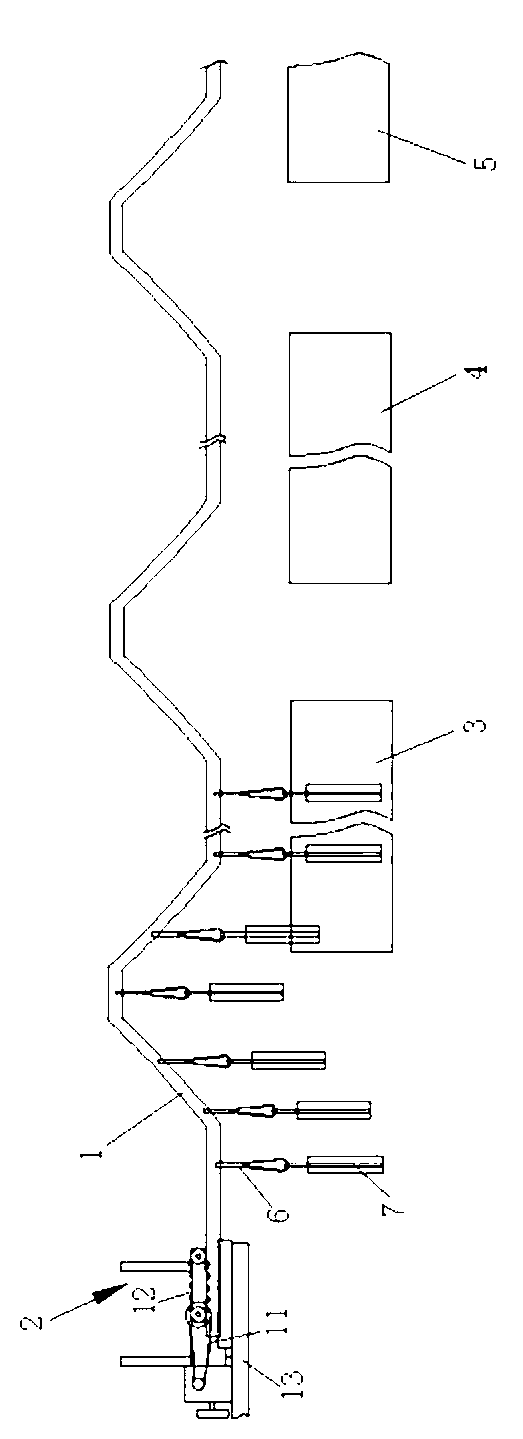

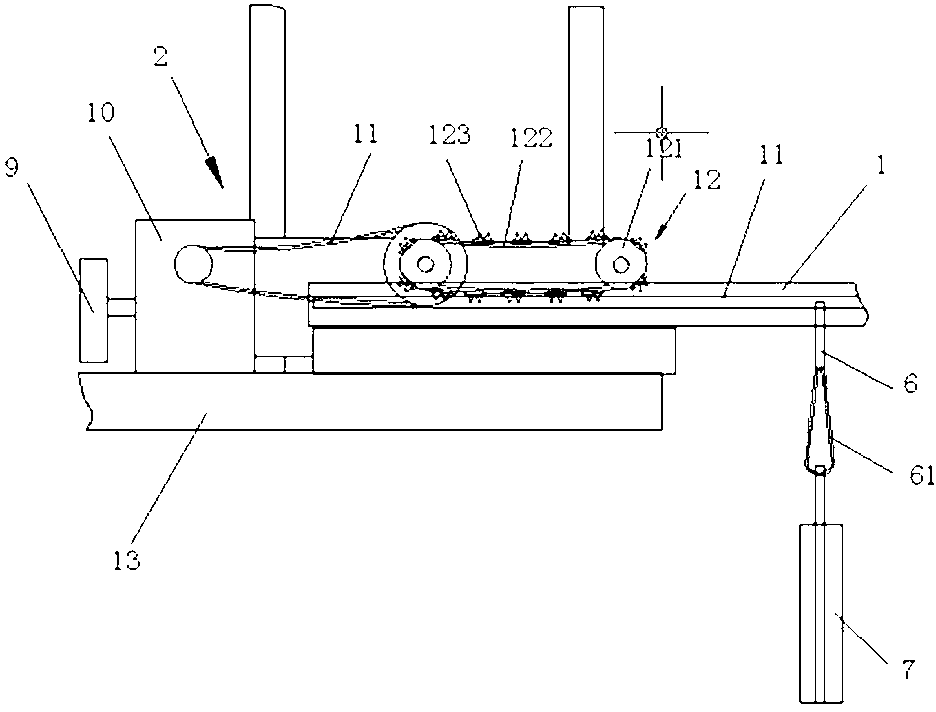

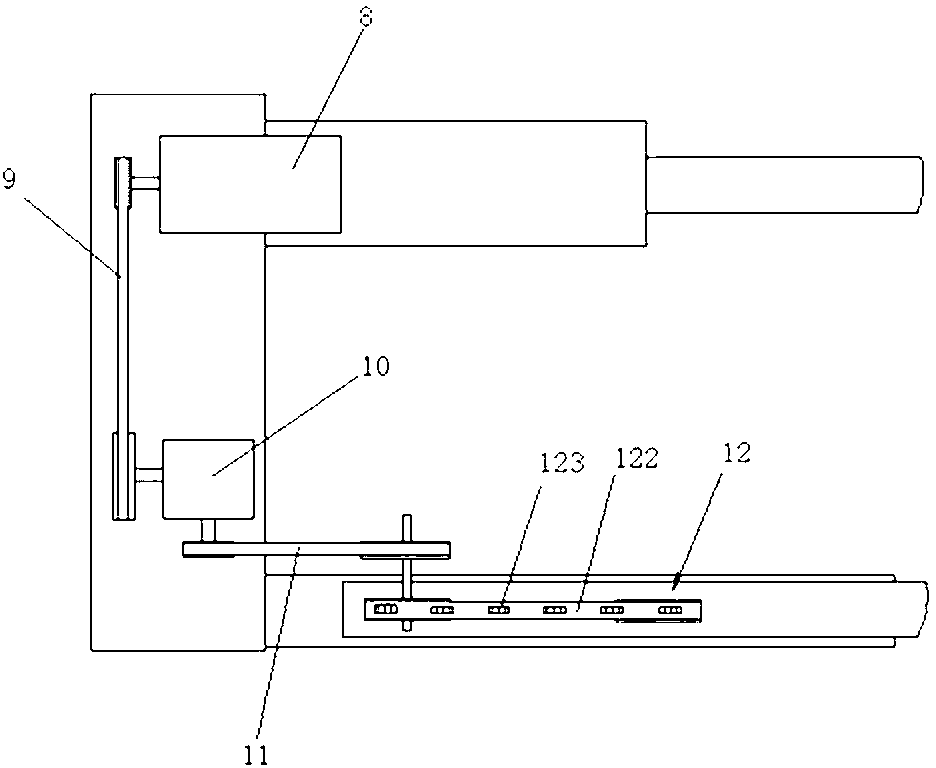

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, but the following specific implementations are not intended to limit the present invention. Such as Figure 1 to Figure 3 As shown, a hanger with automatic withdrawal and hanging line includes a conveying rail 1, a driving device 2, a deplating tank 3, a degreasing tank 4 and a cleaning tank 5, and the conveying rail 1 is located in the deplating tank 3, the degreasing tank 4 and the cleaning tank 5 above ( figure 1 The layout of the conveying rail 1 and each groove is a schematic diagram of the expansion. In practice, the position of each groove is arranged according to the site), the driving device 2 drives the chain 11 in the conveying rail 1 to run along the conveying rail 1, and the chain 11 is connected with a downward Hanging post 6, the lower part of the post 6 is provided with a hanging ring 61 for hooking the hanger 7; under the control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com