Device and method for cleaning surface of silicon steel

A technology for surface cleaning and silicon steel, which is applied in the direction of workpiece cleaning devices, cleaning methods and tools, chemical instruments and methods, etc., can solve the problems of poor cleaning quality of strip steel surface, easy generation of spots, waste of pure water, etc., and achieve surface cleaning , good surface cleaning quality, the effect of saving pure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

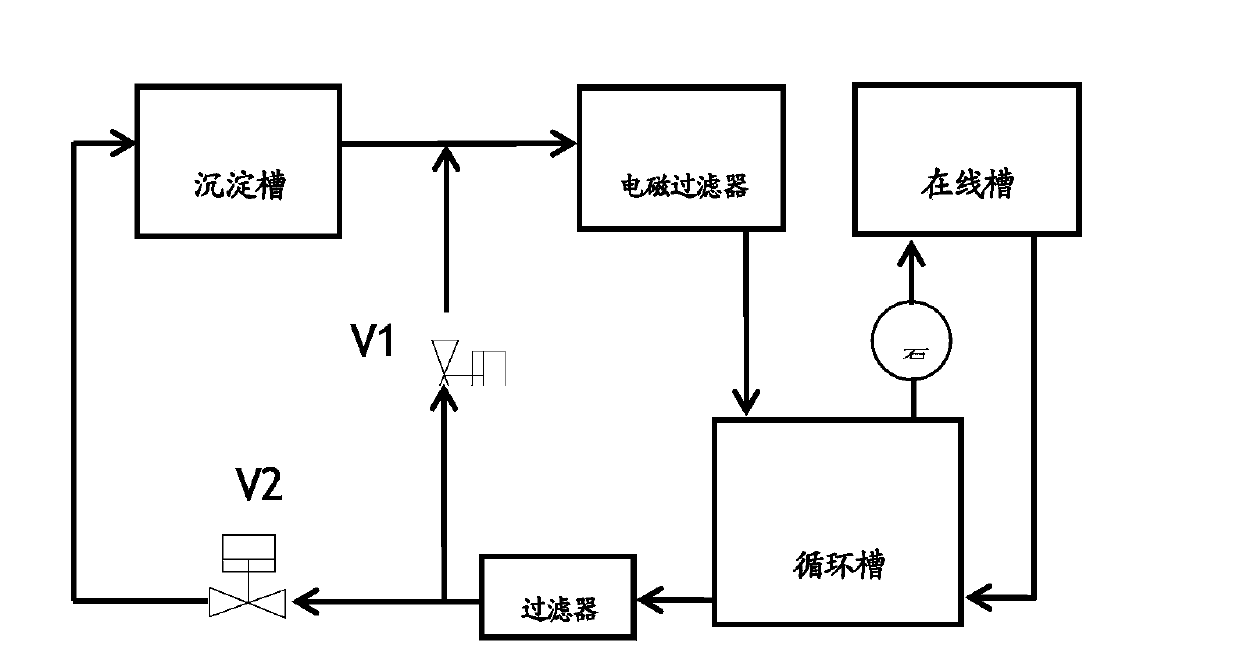

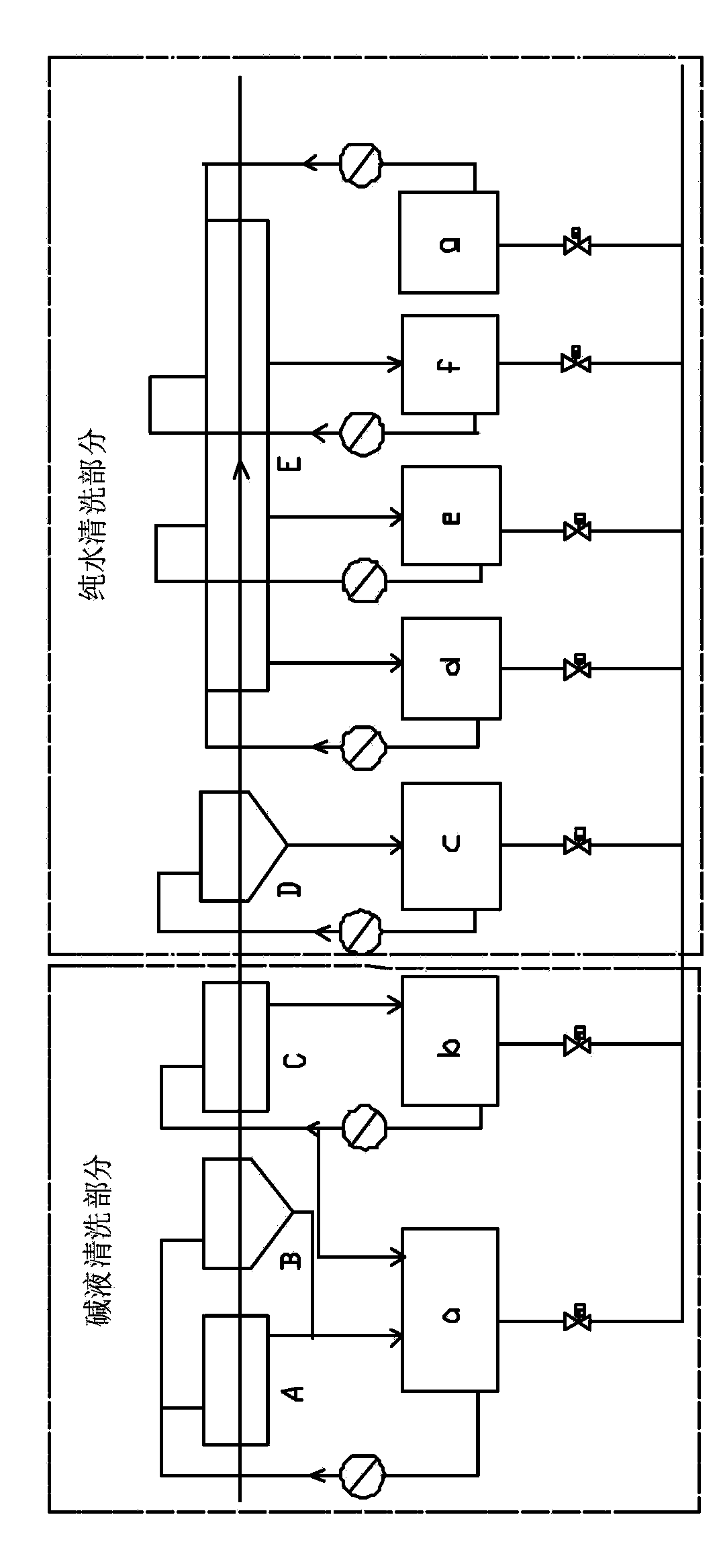

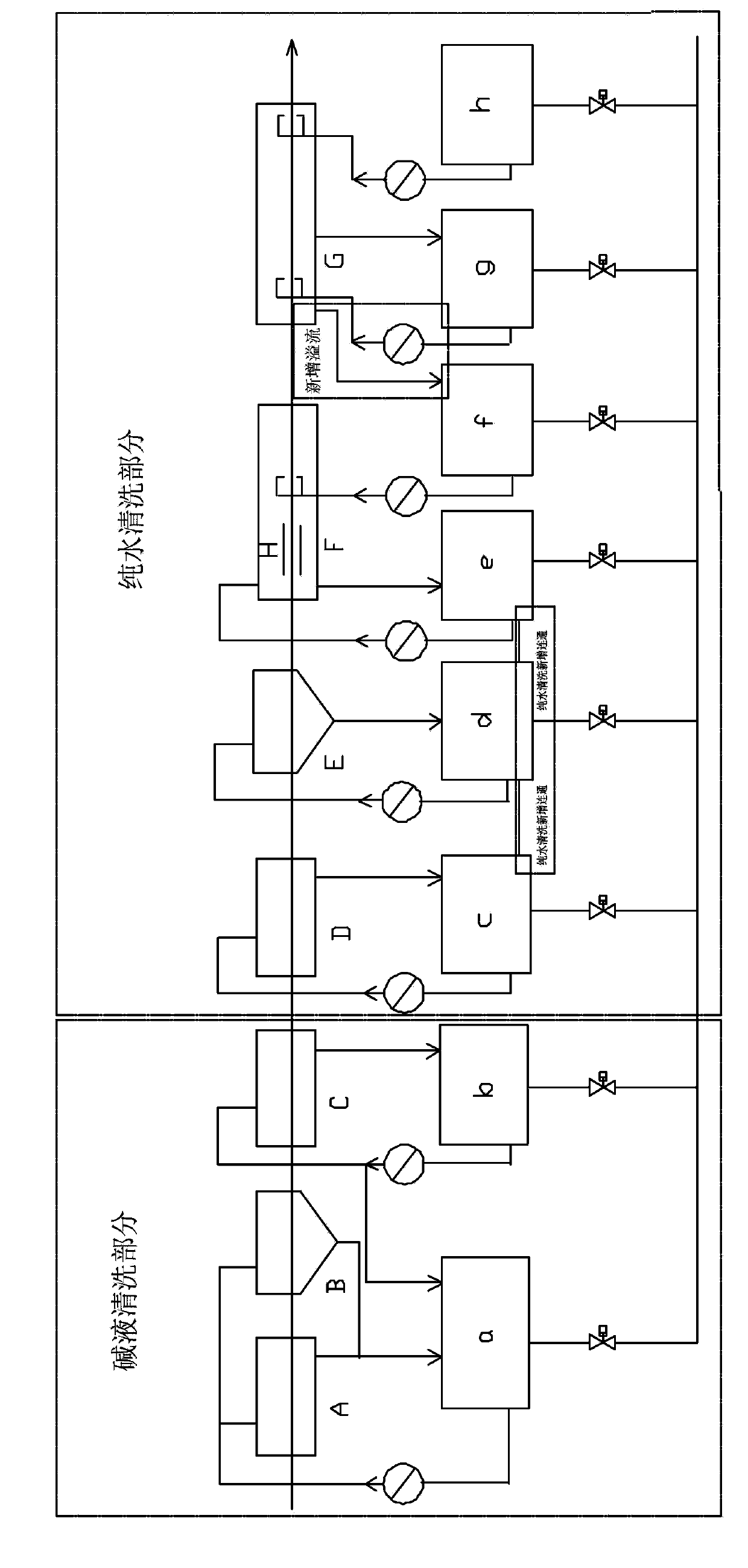

[0035] Such as figure 2 As shown, the cleaning equipment of the present invention mainly includes three lye online cleaning tanks and four pure water online cleaning tanks, and includes two lye circulation tanks and six pure water supply tanks. Among them, A-G respectively represent lye immersion tank, lye scrub tank, electrolytic cleaning tank, high-pressure water spray tank, water scrub tank, hot water rinse tank and hot water spray tank.

[0036] Circulation tank composition: a-h represent the first lye circulation tank, the second lye circulation tank, the high-pressure water spray circulation tank, the water brushing circulation tank, the third pure water circulation tank, the second pure water circulation tank, the first pure water circulation tank Water circulation tank and pure water supply tank. Each circulation tank has high and low liquid level water replenishment control functions, low liquid level replenishment, and high liquid level automatic stop water repleni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com