Cleaning device for blade of packaging box cutting machine

A cleaning device and cutting machine technology, applied in the cleaning method of using tools, packaging, transportation and packaging, etc., can solve the problems of rough cutting of paper, burrs, and affecting the quality of cardboard production, so as to ensure the cleaning quality and processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

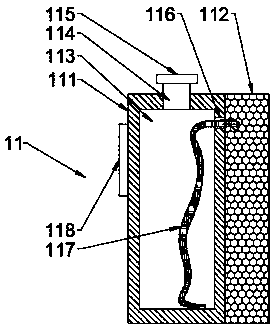

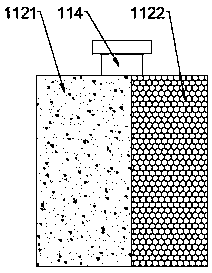

[0031] This embodiment is a further elaboration on the basis of Embodiment 1. The cleaning brush 11 includes a brush body 111 and a cleaning body 112. The right side end of the brush body 111 is provided with a cleaning body 112. The cleaning body 112 includes The frosted surface 1121 and the sponge surface 1122, the frosted surface 1121 is arranged on the front side of the sponge surface 1122, in the process of cleaning the cutting tool 13, the frosted surface 1121 first decontaminates the cutting tool, and then utilizes the sponge surface 1122 Clean up to ensure that the cutter is cleaned thoroughly; the inner chamber of the brush body 111 is provided with a water chamber 113, and the inner chamber of the water chamber 113 is provided with a communication hole 116 near the top of the side of the sponge surface 1122, and the communication hole 116 116 is provided with the water supply sliver 117 that cooperates with water chamber 113 and sponge surface 1122 respectively, throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com