Sugarcane juicing device

A technology for squeezing juice and sugarcane, which is applied in the field of juicing devices, which can solve the problems that sugarcane needs to be manually pushed, and only one sugarcane can be squeezed at a time, so as to improve the efficiency of juicing, reduce manual operations, and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A sugarcane juicer, such as figure 1 As shown, it includes a base 1, a special-shaped seat 2, a baffle plate 4, a collection frame 5, a pressing mechanism 6 and a feeding mechanism 7, and the middle part of the base 1 is equipped with a special-shaped seat 2, and the left side of the special-shaped seat 2 is uniformly provided with a runner groove 3, The front and rear sides of the special-shaped seat 2 are provided with baffle plates 4, the left side of the base 1 is provided with a collection frame 5, the collection frame 5 is located on the left side of the special-shaped seat 2, and a pressing mechanism 6 is installed between the front and rear sides of the special-shaped seat 2. 1 The right side is provided with a feeding mechanism 7, and the feeding mechanism 7 is connected with the pressing mechanism 6.

[0035] When the sugarcane needs to be squeezed into juice, one end of the washed sugarcane is manually placed between the parts of the feeding mechanism 7, and ...

Embodiment 2

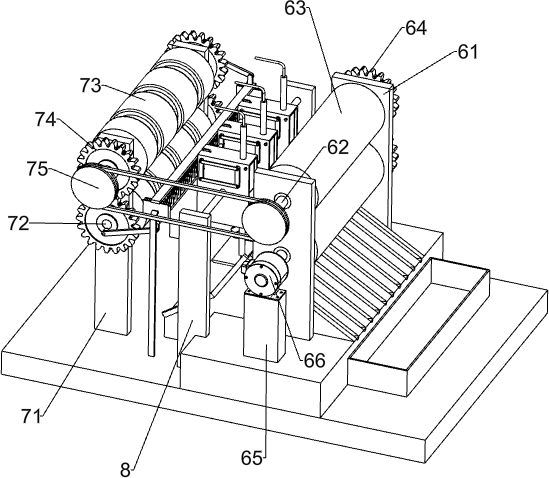

[0037] refer to Figure 1-2 As shown, the squeezing mechanism 6 includes a first bearing seat 61, a drive shaft 62, a cylinder 63, a first gear 64, a spacer 65 and a servo motor 66, and the first bearing seat 61 is installed on the front and rear sides of the top of the special-shaped seat 2. Two transmission shafts 62 are arranged between the upper parts of the first bearing seat 61 on the side, and a roller 63 is arranged on the transmission shaft 62. The front side of the transmission shaft 62 is connected with a first gear 64, and the two first gears 64 are meshed. A pad 65 is installed on the rear side of the top of the seat 2, and a servo motor 66 is arranged on the top of the pad 65, and the output shaft of the servo motor 66 is connected with the transmission shaft 62 rear end of the downside.

[0038] Manually put one end of the washed sugarcane between the parts of the feeding mechanism 7, and after keeping the sugarcane level, start the servomotor 66, the output sha...

Embodiment 3

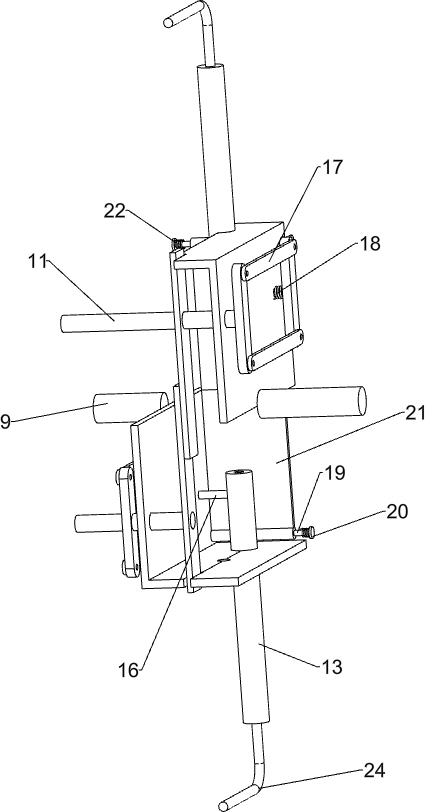

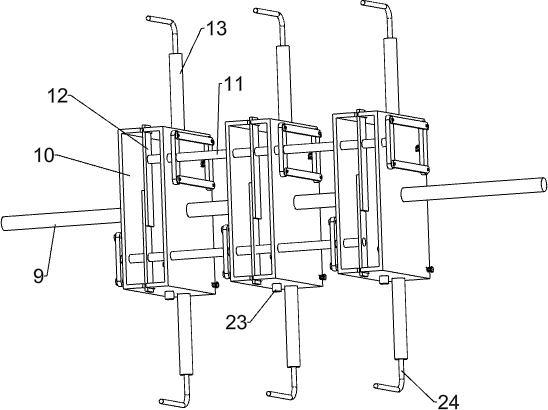

[0042] Specifically, such as Figure 3-6 As shown, it also includes a support plate 8, a connecting column 9, a box 10, a connecting shaft 11, a rotating plate 12, a nozzle 13, a water stop ball 14, a connecting rod 16, a plane four rod 17, a first elastic member 18, and a second rotating shaft 19, bump 20, gear door 21, second elastic member 22, leaking water flow channel 23 and water pipe 24, the front and rear sides of the right part of the special-shaped seat 2 are provided with support plates 8, and the support plates 8 tops on both sides are equipped with Connecting column 9, three boxes 10 are evenly arranged on the connecting column 9, and the upper and lower parts on the right side of the box 10 are all rotatably provided with connecting shafts 11, and rotating plates 12 are evenly installed on the connecting shafts 11, and the rotating plates 12 are located inside the box 10. In contact with the rotating plate 12 in the same box 10, the top and the bottom of the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com