Oil tank truck cleaning treatment system and technology

A processing system and technology for oil tankers, applied in the field of oil tanker cleaning, can solve the problems of extensive management, low cleaning efficiency, consumption of large water resources, etc., achieve great environmental and social benefits, reduce cleaning costs, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

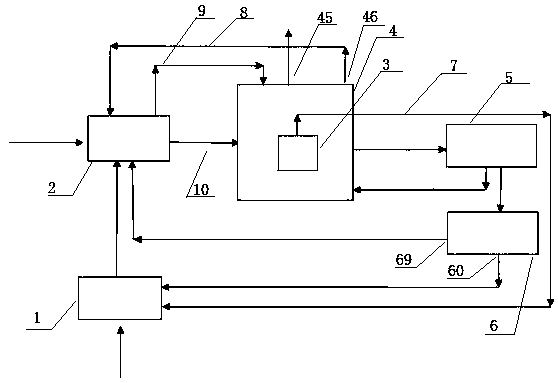

[0038] figure 1 Among them, an oil tanker cleaning treatment system includes a boiler device 1, a cleaning device 2, an exhaust gas treatment device 4, a waste heat recovery device 5, and a sewage treatment device 6 connected in sequence; the boiler device 1 is connected to the cleaning device 2, which is a cleaning device 2 to provide low-pressure steam; the exhaust gas generated by the cleaning device 2 enters the exhaust gas treatment device 4.

[0039] Boiler device 1 includes a boiler main unit, boiler supporting auxiliary machines, and boiler supporting instrument valves. The boiler main unit is a horizontal gas-fired steam boiler; the boiler unit generates low-pressure steam.

[0040] The cleaning device 2 includes a manhole cover, a quick connection of the discharge port, a spray gun, a rubber hose, a water pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com