Patents

Literature

41results about How to "No deflagration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

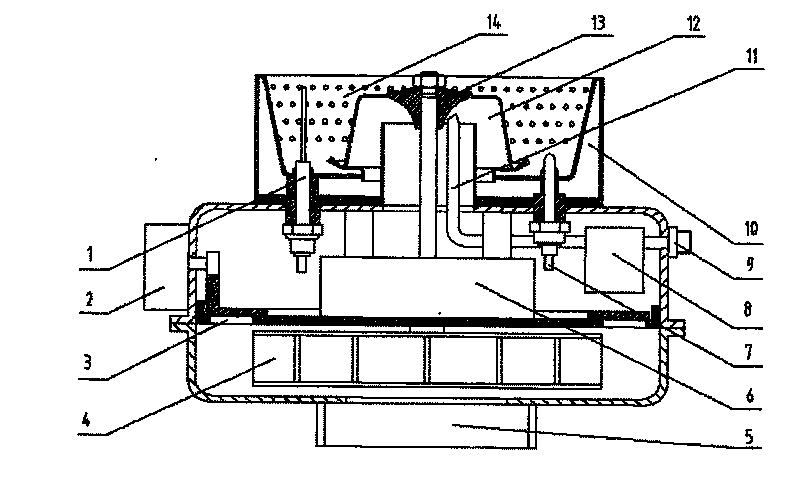

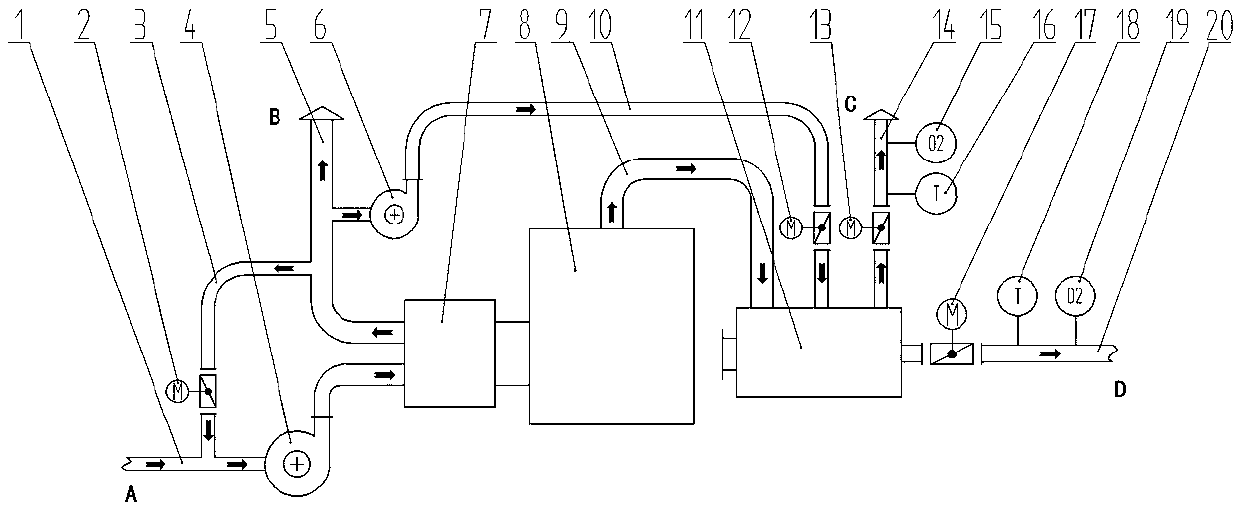

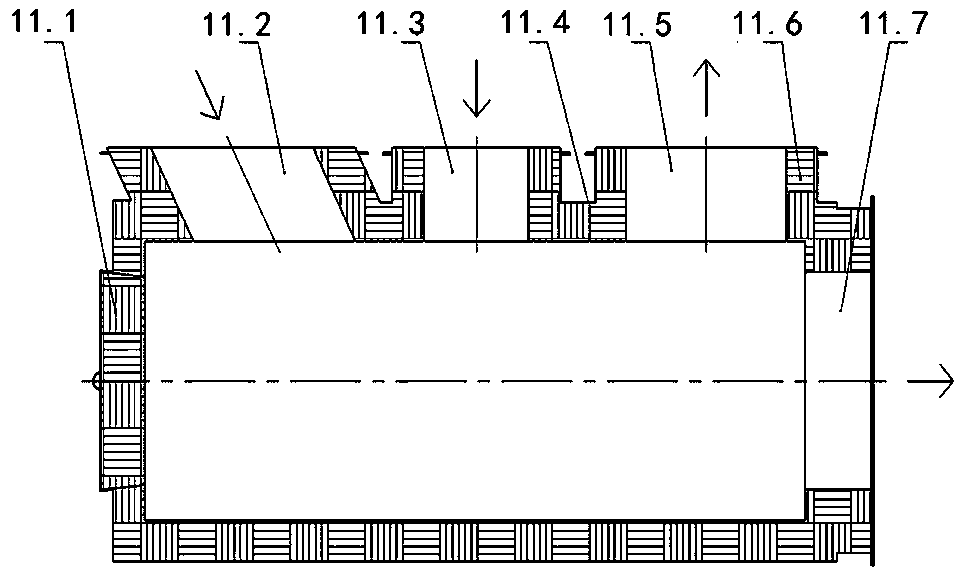

Oil tank truck cleaning treatment system and technology

PendingCN108941107AGuaranteed uptimeAdjust the amount of waterFatty/oily/floating substances removal devicesTank vehiclesLiquid wastePollution

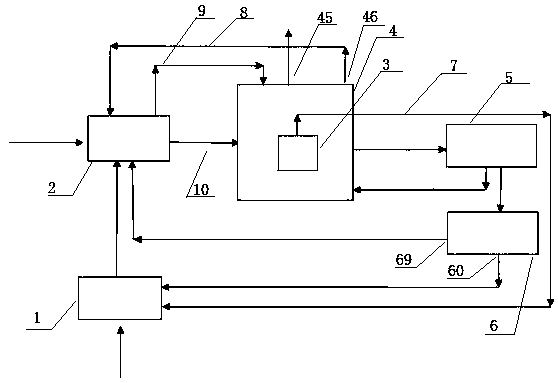

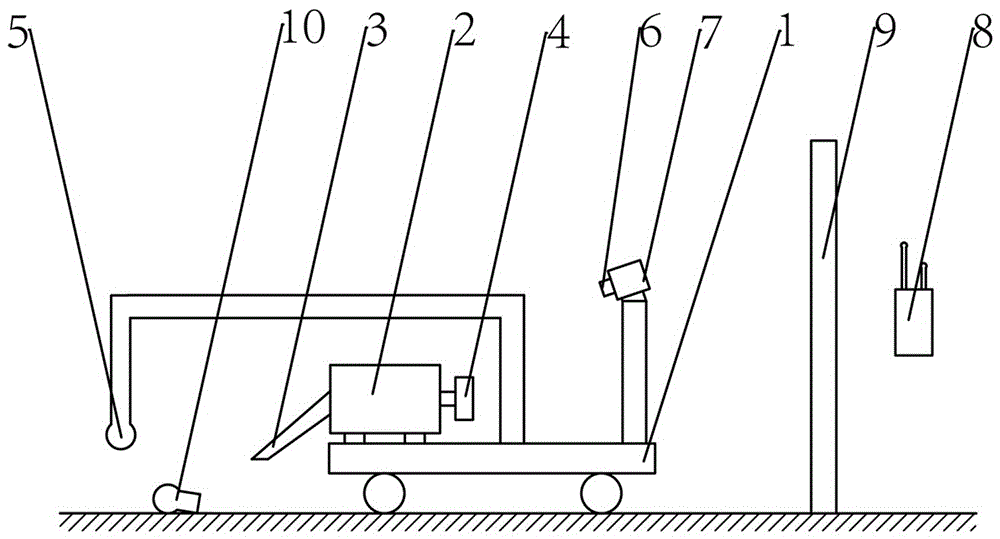

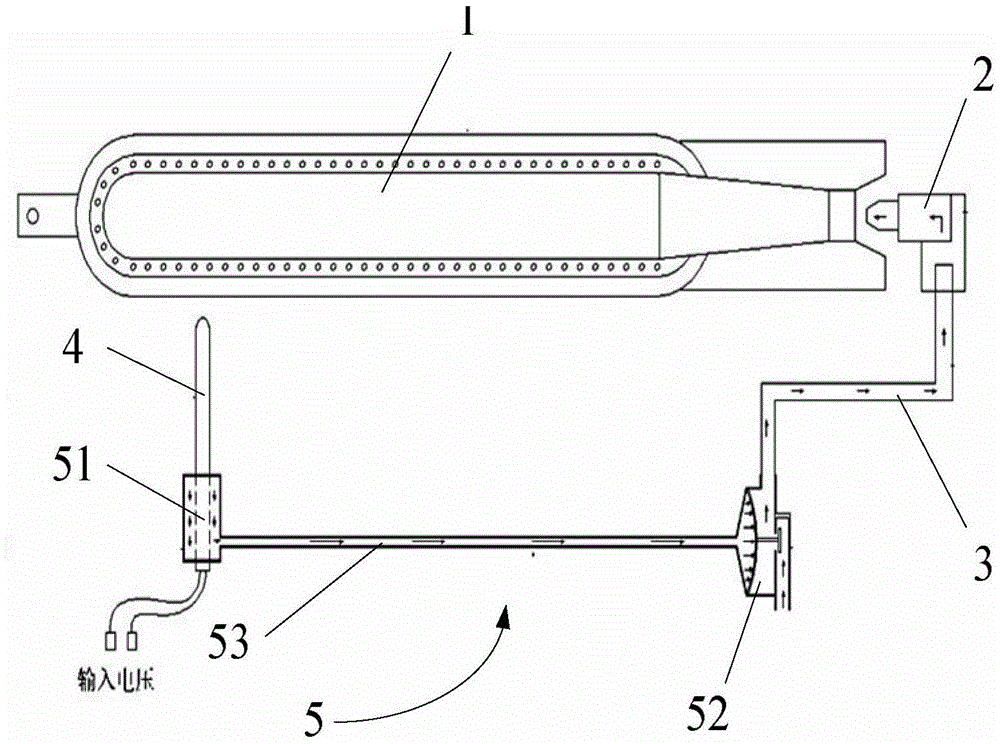

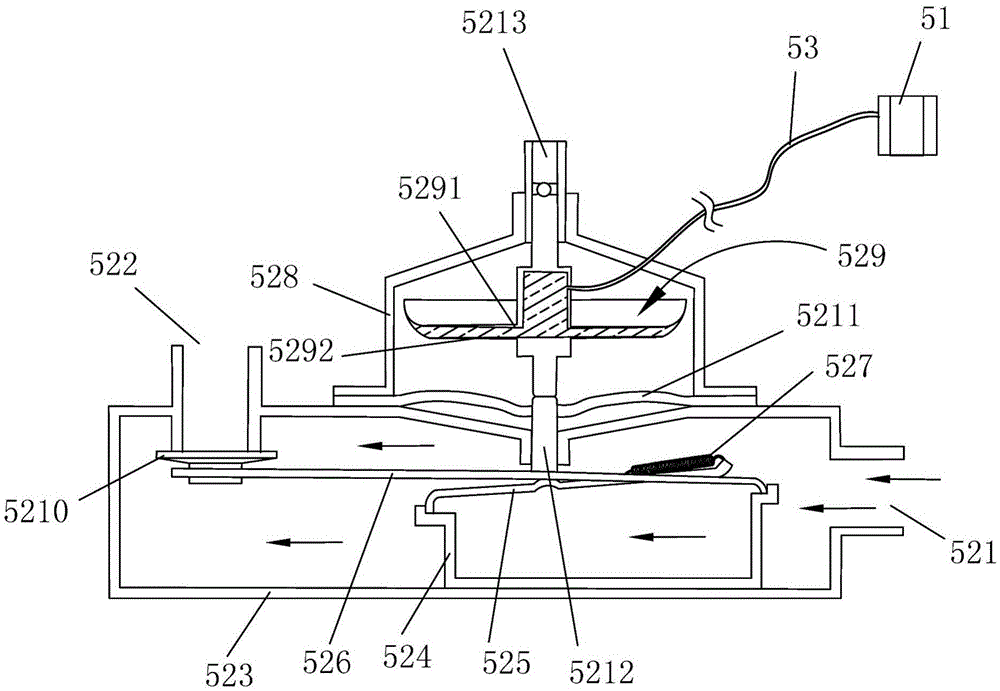

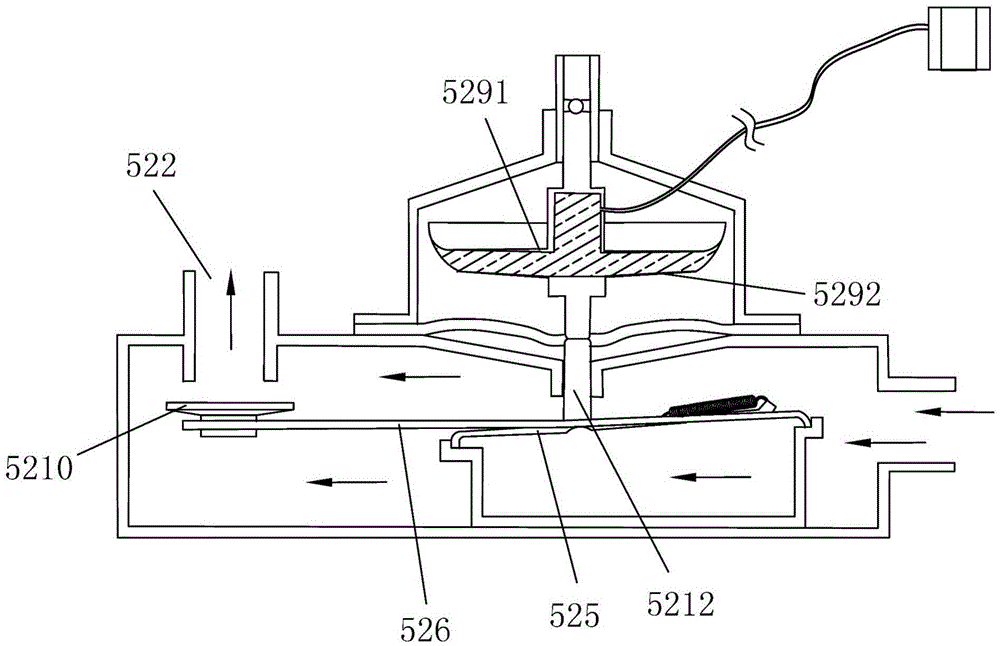

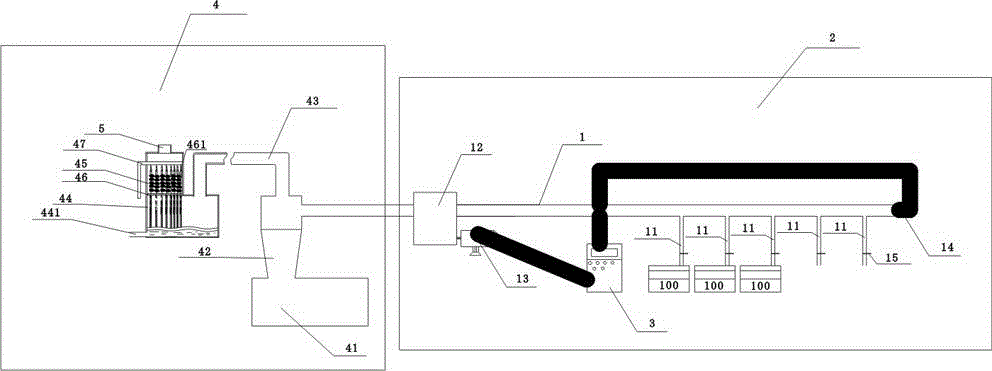

The invention discloses an oil tank truck cleaning treatment system and technology. The system comprises a boiler device, a cleaning device, an oil vapor trap device, a waste gas treatment device, a waste heat recycling device and a sewage treatment device. The boiler device is connected with the cleaning device, the oil vapor trap device is located in the middle of a spraying tower of the waste gas treatment deice, one part of waste liquid of the spraying tower is returned into the spraying tower through a circulation pump, the rest enters the sewage treatment device, and unabsorbed oil vaporenters the boiler deice through the top of the oil vapor trap device for secondary air combustion. The low-pressure vapor tank technology most advanced in China is adopted, the cleaning quality is ensured, scale cleaning is achieved, more than 200 oil tank trucks are treated daily, the efficiency can be greatly improved compared with retail investor extensive type cleaning, consumption of low-pressure steam amount of each truck is reduced by 55% or more, cleaning sewage is recycled after being treated, the cleaning cost of each truck is reduced, and economic benefits are improved. Waste gas is exhausted after being treated and reaching standards, no pollution is caused to surrounding, and great environmental and social benefits are produced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

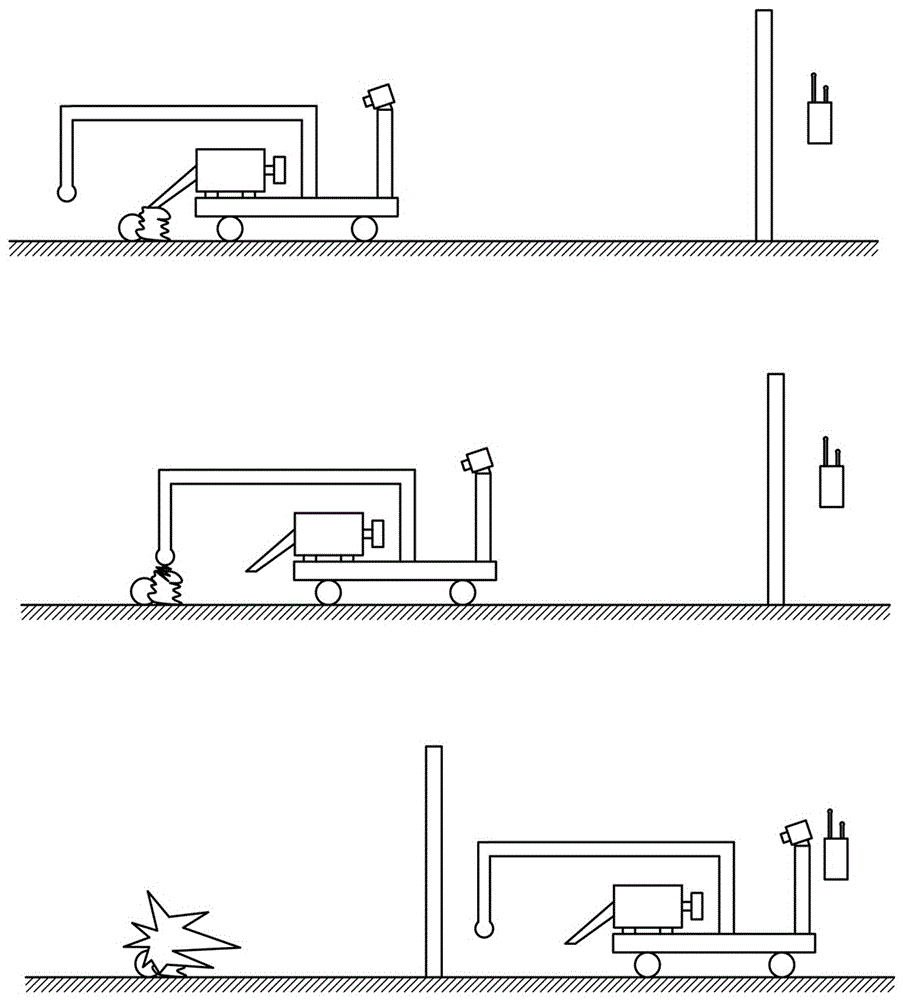

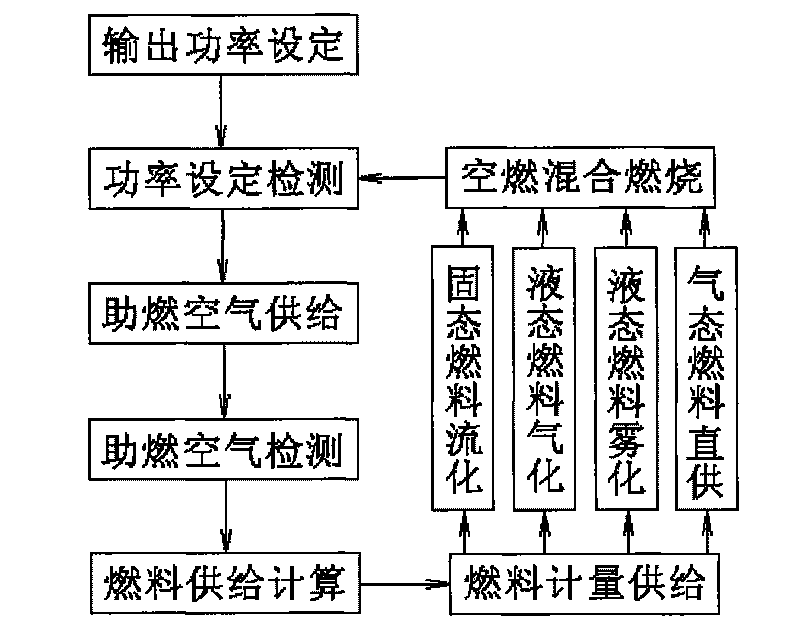

Combustible glue used for destroying unexploded ordnance and preparation method and application thereof

The invention provides combustible glue used for destroying unexploded ordnance and a preparation method and application thereof. The combustible glue is prepared through the following steps that Al powder and Fe3O4 powder are evenly mixed to obtain Al / Fe3O4 mixed powder; lac is dissolved in absolute ethyl alcohol to obtain a lac absolute ethyl alcohol solution with the mass concentration being 5%-6%; the Al / Fe3O4 mixed powder is added into the lac absolute ethyl alcohol solution, and the Al / Fe3O4 mixed powder and the absolute ethyl alcohol solution are stirred to be evenly mixed; glass fiber powder is added and stirred to be evenly mixed; and expandable graphite is added and stirred to be evenly mixed to obtain the combustible glue. The mass ratio of the Al powder to the Fe3O4 powder is 7-8 to 15. The massic volume ratio of the Al / Fe3O4 mixed powder to the lac absolute ethyl alcohol solution is 1g to 2-3 mL. The adding amount of the glass fiber powder is 1%-3% of the Al / Fe3O4 mixed powder by mass. The adding amount of the expandable graphite is 1%-3% of the Al / Fe3O4 mixed powder by mass. The combustible glue is low in combustion speed, large in combustion heat output and long in combustion duration, and can heat explosives in the unexploded ordnance once being ignited, and it can be ensured that the explosives in the unexploded ordnance are reliably detonated.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

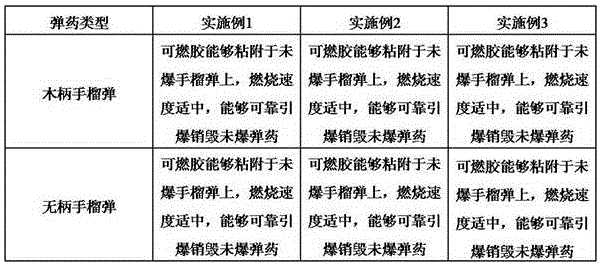

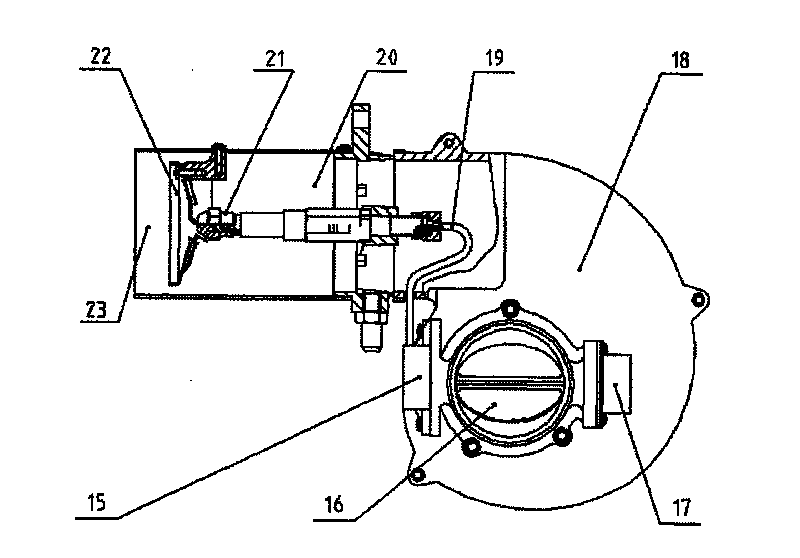

Output power control method of combustion apparatus

InactiveCN101691930ANo deflagrationEnsure safetyFuel supply regulationAuto regulationProcess engineering

The invention relates to an output power control method of a combustion apparatus for realizing continuous or segmental one key adjustment or automatic adjustment of the output power, meeting requirement of different heating loads when in operation and ensuring full and stable burning in the adjusting and heating process. By presetting combustion-supporting air amount and detecting combustion-supporting air flow rate, the fuel metering supplying is controlled according to the optimal air-fuel ratio requirement by utilizing the detecting result, fuel mixed combustion is provided accurately, and the fuel duty is changed along with the combustion-supporting air amount, and the output power of the combustion apparatus can be adjusted by only adjusting the combustion-supporting air amount, the operation is convenient, the combustion has high efficiency, the usage is safe and the operation is reliable.

Owner:YUNNAN AEROSPACE IND

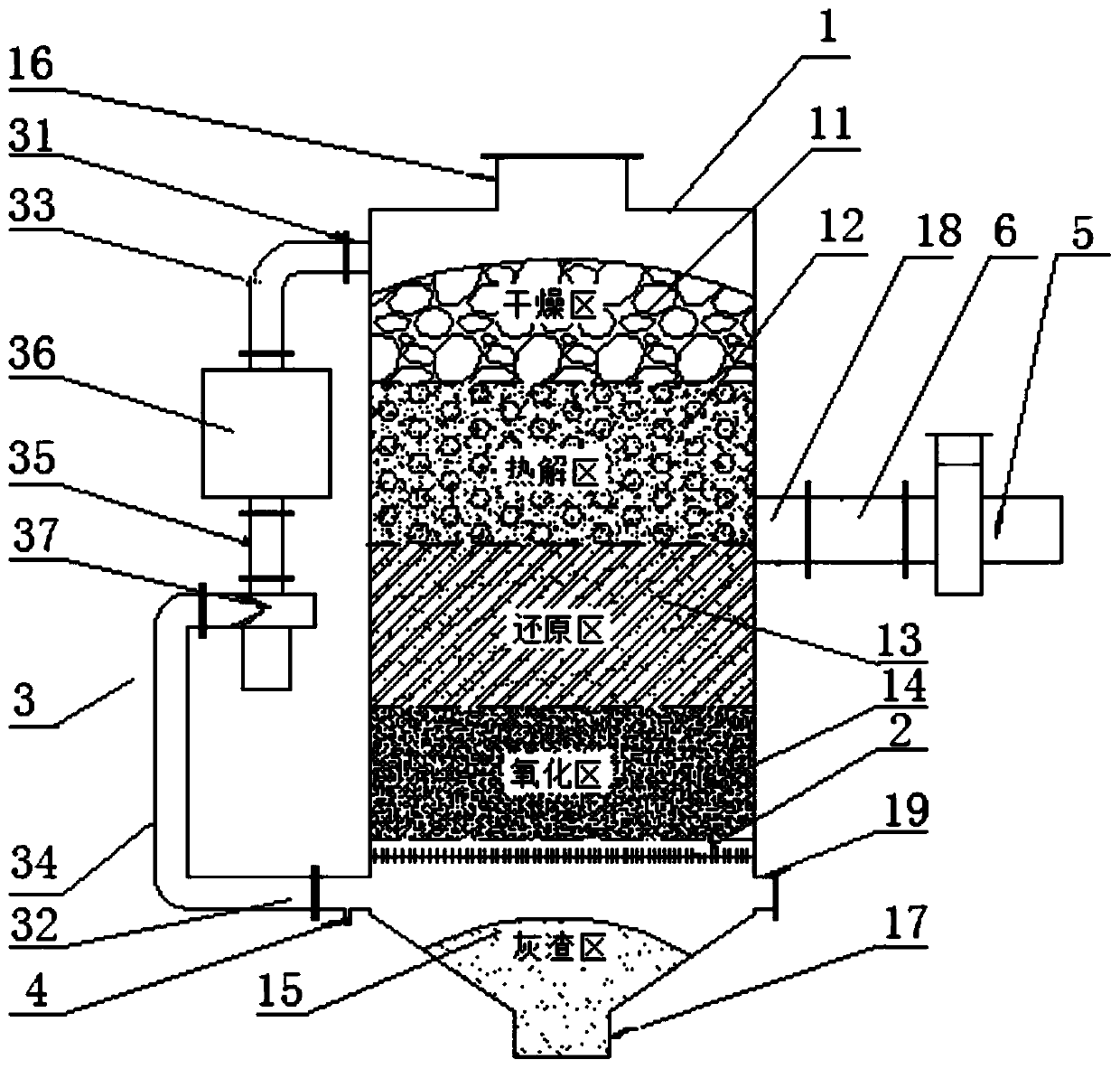

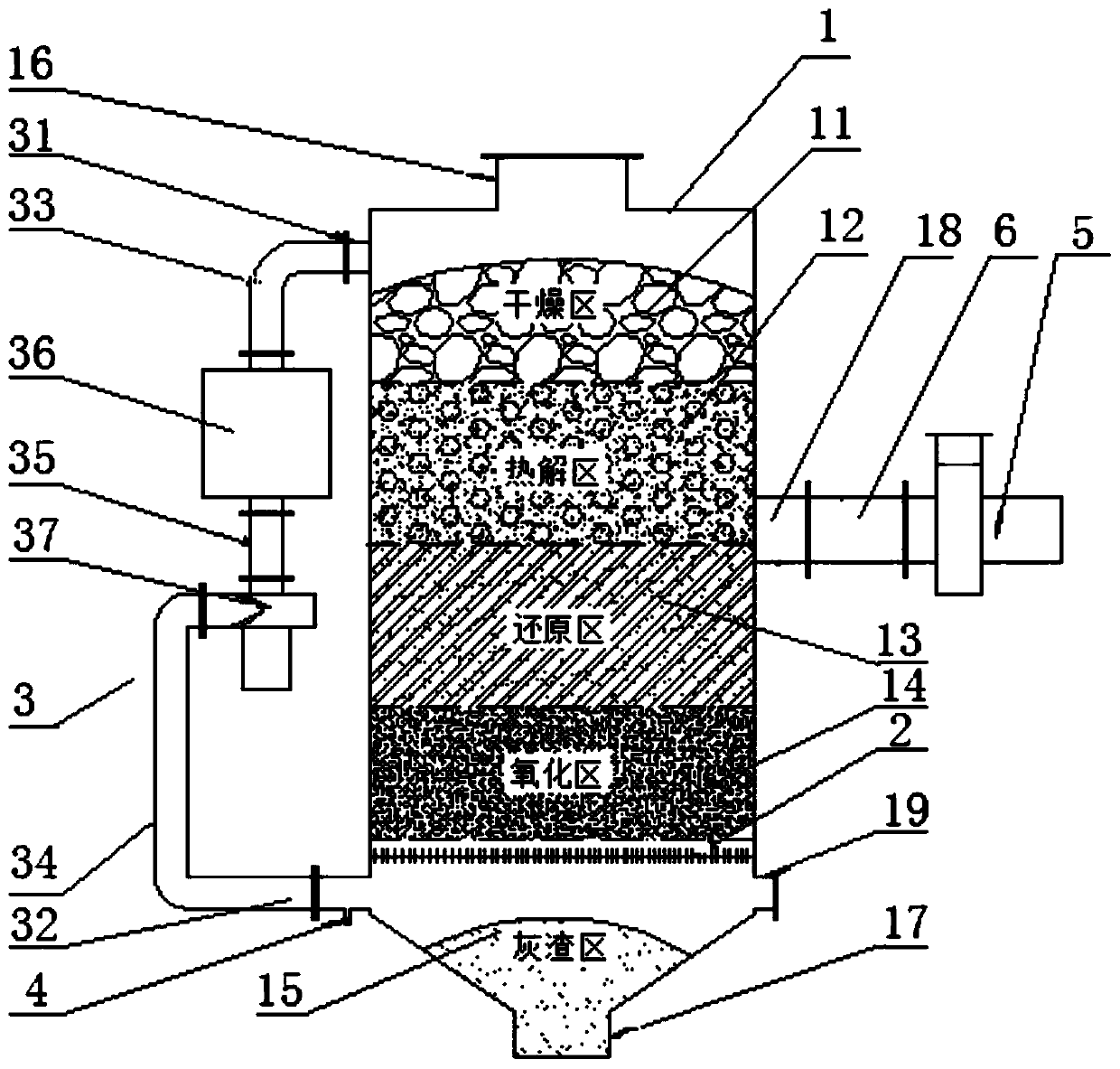

Domestic waste gasification device and process

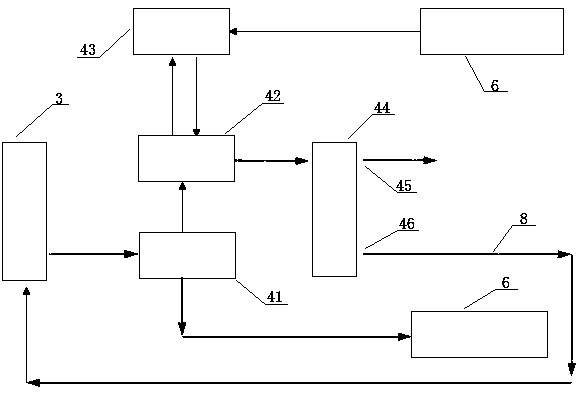

InactiveCN109705923AEliminate exhaust gasIncrease heatGranular/pulverulent flues gasificationSlagProcess engineering

The invention relates to the technical field of humidity regulation, more particularly to a domestic waste gasification device and a process. The domestic waste gasification device comprises a gasification furnace; a material inlet is arranged at that top of the gasification furnace, an ash-slag outlet is arranged at the bottom of the gasification furnace, a gasification gas outlet is arranged atthe side wall of the gasification furnace, and domestic garbage enters a drying zone, a pyrolysis zone, a reduction zone and an oxidation zone in turn for treatment, so that the obtained ash-slag is discharged through the ash-slag outlet and the obtained gasification gas is discharged through the gasification gas outlet; a fire grate is arranged at the junction of the oxidation zone and the ash-slag zone, a backdraft device for drying and filtering the gas is communicated between the drying zone and the ash-slag zone, the backdraft device is provided with a backdraft suction port communicatingwith the drying zone and a backdraft air outlet communicating with the ash-slag zone, the backdraft air outlet is arranged below the grate, and an igniter is arranged besides the side of the backdraft air outlet. The invention extracts the mixed gas at the top of the gasification furnace, dries and removes water vapor, thereby facilitating the continuous gasification reaction of the gasificationfurnace; the gasified gas after filtration and purification is ignited and then enters the furnace to effectively avoid the deflagration phenomenon.

Owner:GUANGDONG UNIV OF TECH

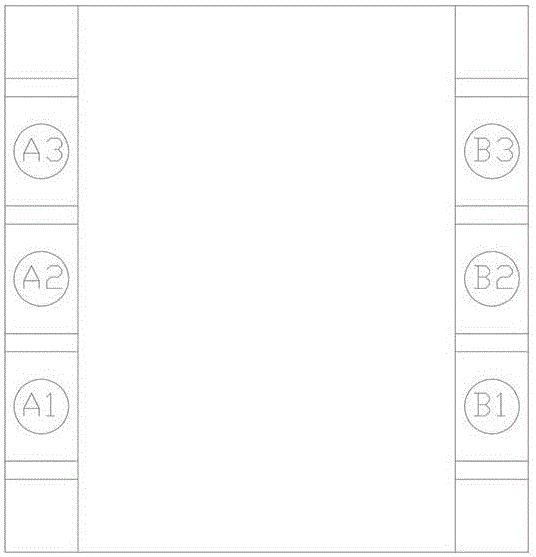

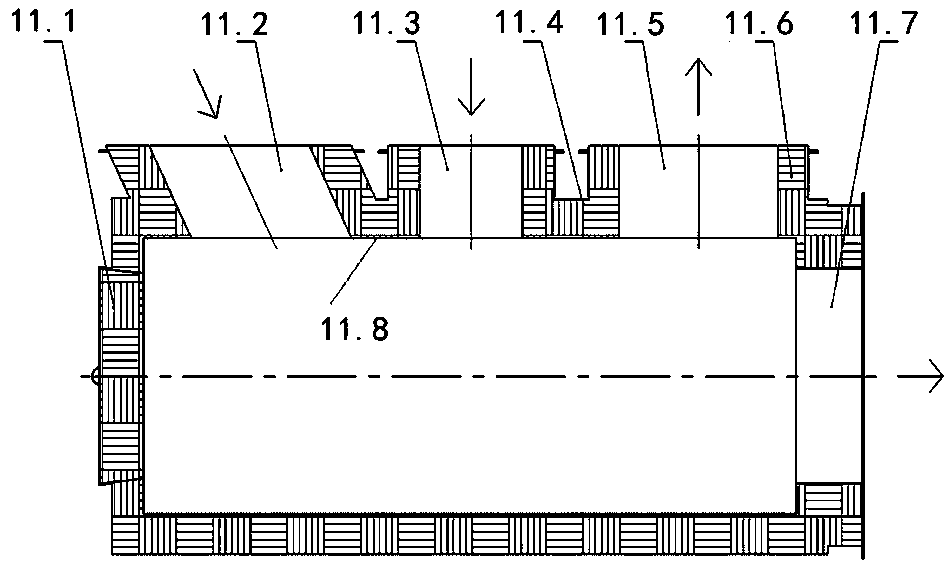

Opposed firing boiler with thermal power flexibility regulating function and regulating method thereof

InactiveCN106287672AImprove the ability of deep peak shavingThe improvement of deep peak shaving ability is outstandingCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorEngineering

The invention relates to a boiler with a thermal power flexibility regulating function and a regulating method thereof, in particular to the field of opposed firing boilers. The boiler is characterized in that upper burners are burners located on the first layer and the second layer from the top of the boiler; in the upper burners, the front wall and the back wall which are located on the same layer are both provided with the burners, and the burners located on the uppermost layer are set to be peak regulating burners; lower burners are burners located on the first layer from the bottom of the boiler; in the lower burners, any burners on the front wall and / or the back wall are peak regulating burners; the peak regulating burners are internal burning type burners, coal powder can be ignited in the peak regulating burners, and stable burning can be achieved; and the other burners are ordinary burners which are internal burning type burners or external burning type burners. The boiler with the thermal power flexibility regulating function has the beneficial effects that the thermal power operation flexibility and the fuel flexibility of the boiler can be improved, the deep peak regulating capacity of the boiler is remarkably improved, the rapid climbing capacity is achieved, and the boiler can be rapidly started or stopped.

Owner:CHONGQING FURAN TECH

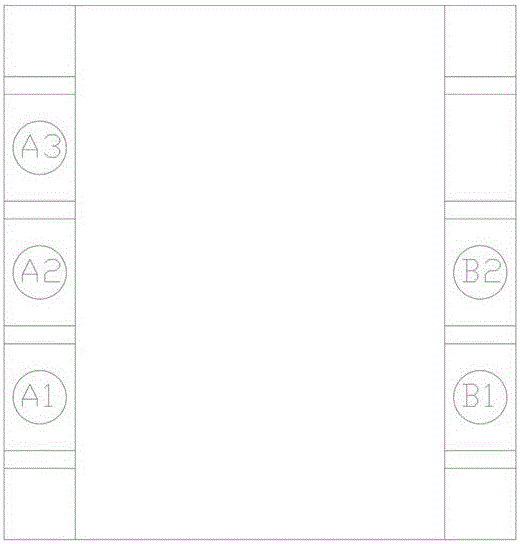

W-type combustion boiler with thermal power flexibility adjusting function and adjusting method of boiler

InactiveCN106287673AIncrease temperatureImprove the ability of deep peak shavingCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorEngineering

The invention relates to a W-type combustion boiler with a thermal power flexibility adjusting function and an adjusting method of the boiler. The boiler is characterized in that combustors can be divided into front arch combustors and rear arch combustors according to installation positions and types; the front arch combustors comprise front arch common combustors and front arch peak regulation combustors, and the rear arch combustors comprise rear arch common combustors and rear arch peak regulation combustors; one or two front arch peak regulation combustors are arranged in the front arch combustors every two or three front arch common combustors; one or two rear arch peak regulation combustors are arranged in the rear arch combustors every two or three one or two rear arch common combustors; the rear arch peak regulation combustors correspond to the front arch common combustors, and the rear arch common combustors correspond to the front arch peak regulation combustors. The combustion boiler has the advantages that thermal power operation flexibility and fuel flexibility of the boiler can be improved, the deep peak regulation capacity of the boiler is obviously improved, the quick gradeability is achieved, and the boiler can be quickly started and stopped.

Owner:CHONGQING FURAN TECH

Liquid gasifying and flow control device for measuring combustion limit of combustible liquid steam

InactiveCN103616411AFlammability limitGuaranteed feasibilityMaterial flash-pointInvestigating phase/state changeTemperature controlCombustion

The invention provides a liquid gasifying and flow control device for measuring the combustion limit of combustible liquid steam. The liquid gasifying and flow control device comprises a liquid storage pipe, a gas storage pipe, a measuring pipe, a heating and temperature-control device, ignition equipment, a high-temperature-resistant pipeline, a vacuum pressure gauge, a high-temperature-resistant valve and a vacuum pump, wherein the liquid storage pipe, the gas storage pipe and the measuring pipe are connected in sequence by pipelines; the liquid storage and the measuring pipe are respectively provided with a safety valve. The liquid gasifying and flow control device provided by the invention has the advantages that the promotion is high, not only can multiple combustible liquid steam be measured, but also the measurement under different pressures can be carried out simultaneously.

Owner:UNIV OF SCI & TECH OF CHINA

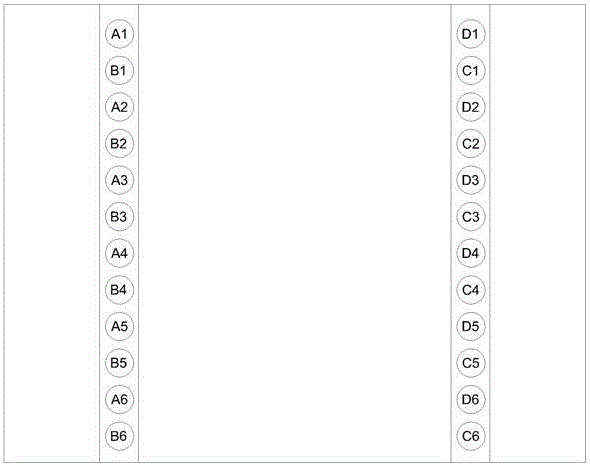

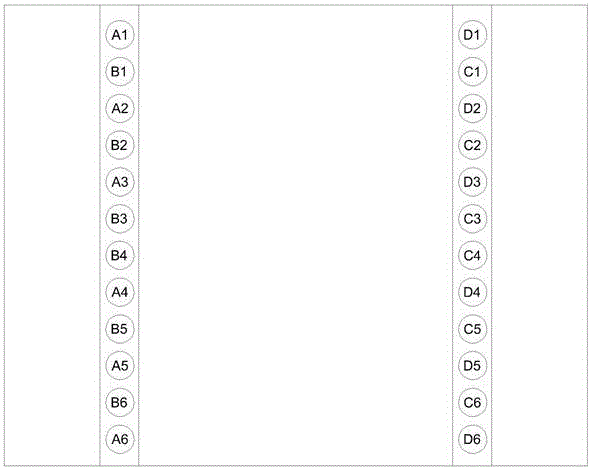

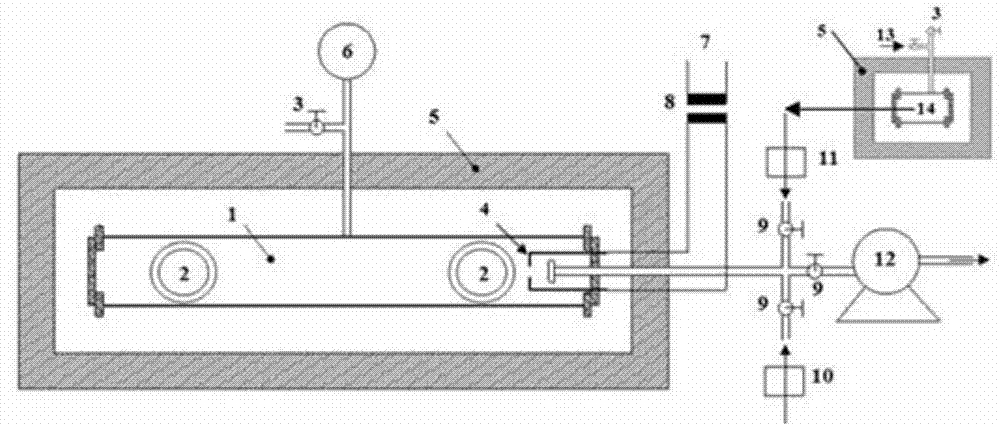

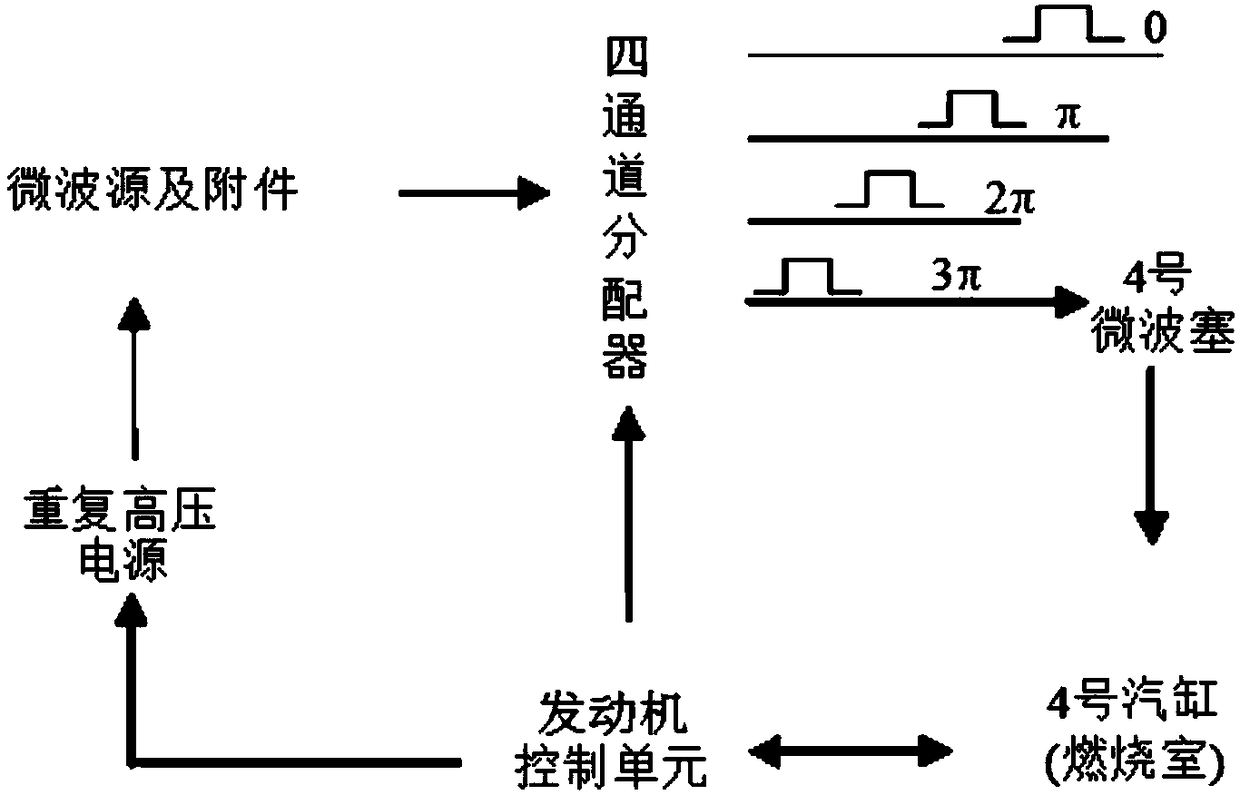

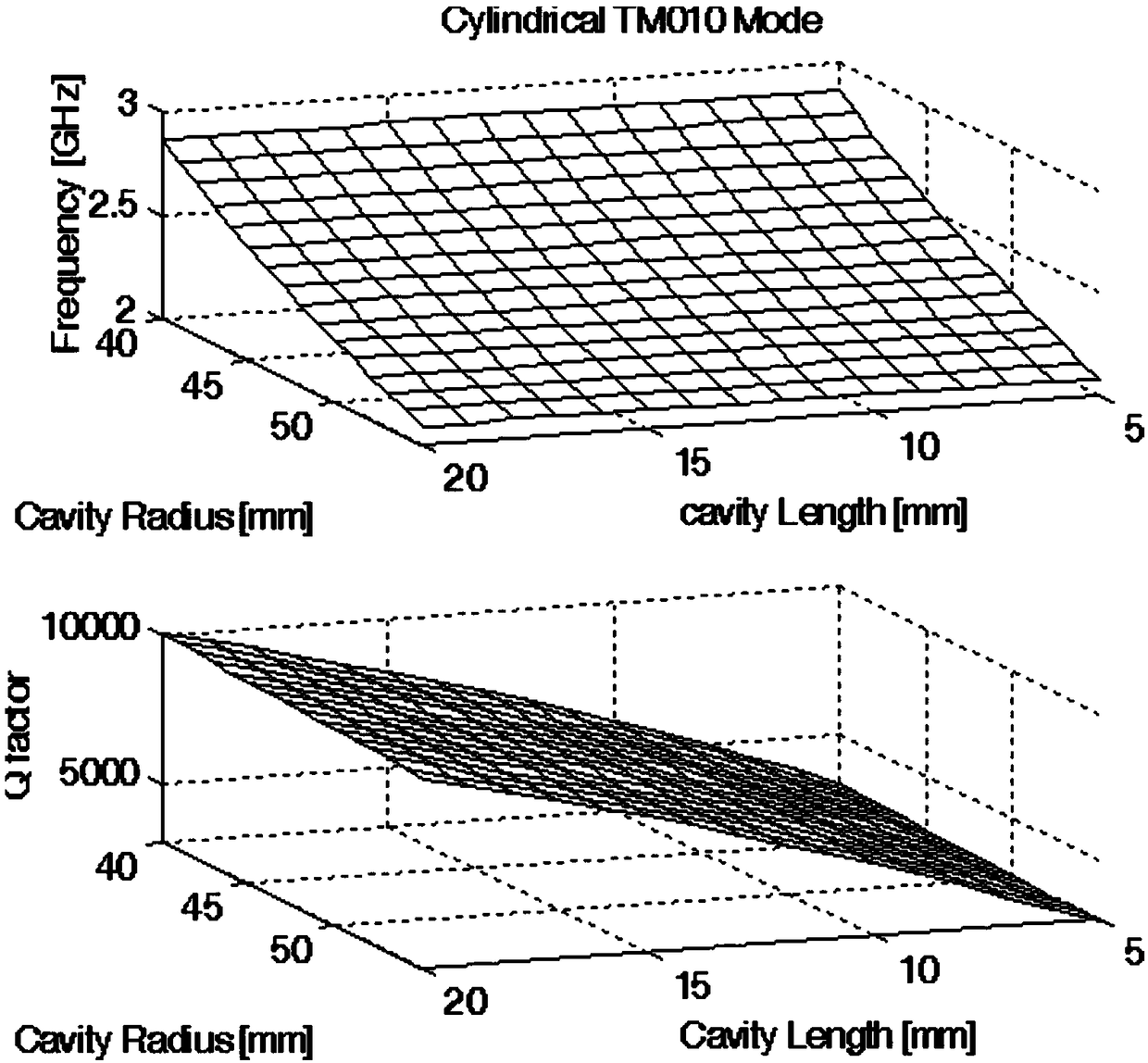

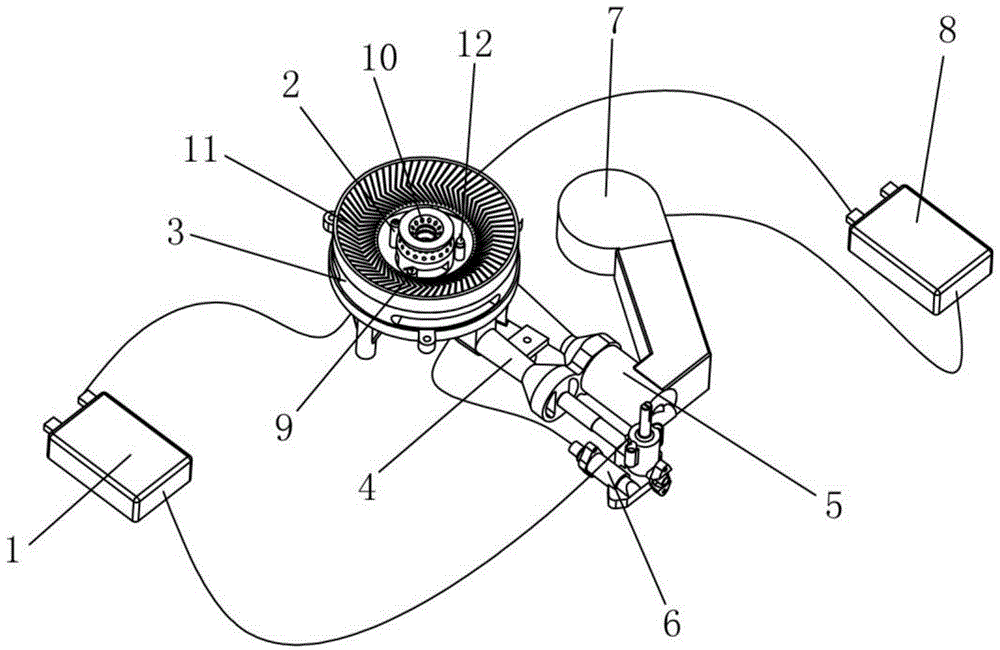

Microwave ignition system and method capable of being applied to engine combustor

InactiveCN109209729ABurn completelyIdeal body ignites purposeEngine ignitionMachines/enginesMicrowave frequencyCombustion chamber

The invention discloses a microwave ignition system capable of being applied to an engine combustor. The microwave ignition system comprises an engine control unit, a microwave source, a microwave distributor and combustors. The microwave source communicates with the multiple combustors through the microwave distributor. A microwave plug is installed in each distribution channel of the microwave distributor. The engine control unit is in control connection with a repeated high voltage power supply, the microwave distributor and a burner. The repeated high voltage power supply is electrically connected with the microwave source. In the microwave ignition system, the microwave frequency is consistent with a certain electromagnetism eigenfrequency of the combustors, and thus microwave energycan be coupled into the combustors in a resonance mode. When an engine works, microwave energy of a certain frequency is coupled into an air cylinder of the engine, and oil-gas mixed gas in the enginecombustor is ignited at an appropriate moment. After ignition, residual microwave energy interacts with plasma generated by burning in the combustor, thus overall burning in the combustor is achievedextremely quickly, more complete burning of the oil-gas mixture is facilitated, and tail gas discharge is reduced.

Owner:深圳市奥谱太赫兹技术研究院

Device and method for reducing oxygen content of coal slime drying hot air in gas oxidation furnace

The invention relates to a device and a method for reducing oxygen content of coal slime drying hot air in a gas oxidation furnace. The technical scheme is that the device comprises a gas oxidation system and a drying hot air oxygen content control system, wherein a gas pipeline is connected with an inlet of an air blower; an outlet of the air blower is connected with an inlet of a reversing valveand the gas oxidation furnace in sequence; an outlet of the reversing valve is connected with a chimney of the oxidation furnace; two ends of a backflow pipeline are connected to the gas pipeline andthe chimney of the oxidation furnace; and an oxygen content adjusting valve is arranged in the middle of the backflow pipeline. The device and the method have the beneficial effects that the popularization and adaptation range is expanded; by recycling oxidation flue of the device, the oxygen content of the drying hot air is reduced and is adjustable according to an actual situation; the construction and operation of a project are not affected even if an available resource condition for reducing oxygen by blending inert gas does not exist on site; the heat utilization rate of the oxidation furnace is high; about 15 percent of low-temperature flue at about 85 DEG C in the oxidation furnace is refluxed for utilizing, the gas oxidation heat is further utilized; and therefore, the device is more economic and reasonable compared with the original technology by arranging a low-temperature flue heat regenerator.

Owner:山东科美人和新能源科技有限公司

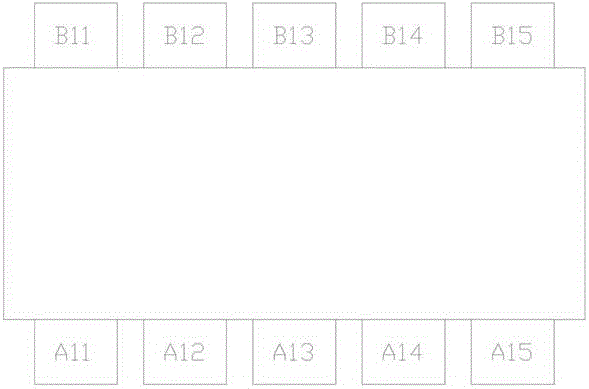

Corner tangential boiler with thermal power flexibility adjusting function and adjusting method of corner tangential boiler

InactiveCN106287675AImprove the ability of deep peak shavingThe improvement of deep peak shaving ability is outstandingCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorEngineering

The invention relates to a corner tangential boiler with a thermal power flexibility adjusting function and an adjusting method of the corner tangential boiler, in particular to the field of the corner tangential boiler. Combustors are divided into upper part combustors, middle part combustors and lower part combustors according to the mounting position levels, and are characterized in that the upper part combustors are combustors of a first layer and a second layer by counting from top to bottom of the boiler and the combustors of any one layer or two layers are peak-regulating combustors; the lower part combustors are combustors of a first layer and a second layer by counting from bottom to top of the boiler and the combustors of any one layer or two layers are peak-regulating combustors; the peak-regulating combustors are internal combustion type combustors; pulverized coal can be ignited in the combustors and can be combusted stably; other combustors are common combustors; and the common combustors are internal combustion type combustors or external combustion type combustors. The invention has the beneficial effects that thermal power operation flexibility and fuel flexibility of the boiler can be improved; the deep peak-regulating ability of the boiler is improved prominently; quick climbing ability is achieved; and the boiler can start / stop quickly.

Owner:CHONGQING FURAN TECH

Low-toxicity flame-retardant normal-temperature solvent marked line paint and preparation method thereof

PendingCN106280790AIncrease elasticityGood compatibilityFireproof paintsPolyurea/polyurethane coatingsAdditive ingredientRaw material

The invention discloses low-toxicity flame-retardant normal-temperature solvent marked line paint, which is prepared from the following raw materials in parts by weight: 190 to 275 parts of solid resin, 25 to 150 parts of pigments, 225 to 500 parts of filling materials, 27.5 to 39 parts of auxiliary agents, 210 to 425 parts of dimethyl carbonate and / or aromatic hydrocarbon, 10 to 20 parts of acetone, 10 to 20 parts of butyl acetate, 100 to 250 parts of chlorohydrocarbon and 16 to 27 parts of low-level saturated monobasic alcohol. The low-toxicity flame-retardant normal-temperature solvent marked line paint provided by the invention has the advantages that the recipe of the paint is scientific and reasonable; all ingredients are matched in a synergistic way; the excellent performance of a product is improved; the solvent selection toxicity is greatly reduced than that in the prior art; the marked line paint is safer and achieves a better environment-friendly effect. The marked line paint has the advantages that the flammable and explosive features of the existing paint are changed into combustible performance; good flame-retardant effects are achieved; the production process solves the problem of flammable and explosive risk of the normal-temperature solvent marked line paint; the harm of toxic solvents is reduced; the life safety of protection, transportation and construction personnel and relevant personnel in contact with products can be effectively protected.

Owner:王建周

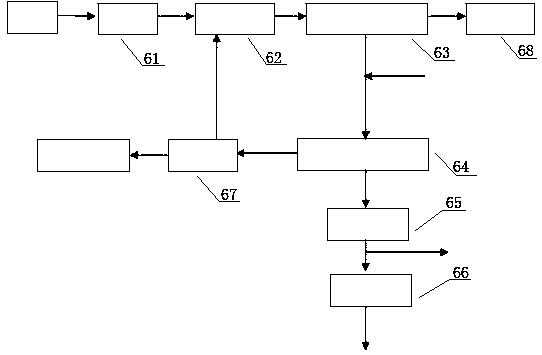

Control method of tail oxygen content in oxygen-enriched oxidation process of cyclohexane

InactiveCN102029134AEnsure safetyNo deflagrationChemical/physical/physico-chemical processesCyclohexanoneGas phase

The invention relates to a control method of tail oxygen content in an oxygen-enriched oxidation process of cyclohexane. The control method is used for controlling the tail oxygen content through online monitoring of gas phase tail oxygen content and in-time treatment when the oxygen content is super-high by using reaction kettles. The control method is characterized in that: in a cyclohexanone device, tail gas pipelines and a total tail oxygen pipeline of the first three reaction kettles from an upper position to a lower position according to a procedure are respectively provided with an online oxygen analyzer; when the numerical value of any one of the online analyzers exceeds a standard, an alarm or interlocking is started to emergently inject nitrogen into the reaction kettles. Through the perfect control method of the tail oxygen content, the invention ensures that the gas phase oxygen content of the reaction kettles in the oxygen-enriched oxidation process of the cyclohexane cannot exceed the standard, thereby controlling explosion hazards.

Owner:CHINA PETROLEUM & CHEM CORP +1

Epoxy solvent free paint and preparation method thereof

The invention relates to an epoxy solvent free paint and a preparation method thereof. The paint comprises the following components and contents in parts by weight: 35-45 parts of epoxy resin, 10-20 parts of curing agent, 30=45vparts of inert pigment filler, and 5-10 parts of additive. Compared with the prior art, the solid content of the epoxy solvent free paint in the invention is 100%, VOC content thereof is 0, and solvent evaporation does not exist, environment protection property is good, influence of pollutant property to the environment is reduced, and the epoxy solvent free paint has characteristics of excellent acid, alkali, oil and chemicals corrosion resistance, construction can be carried out in closed space without hazards such as explosion, suffocation and the like, the primary filming thickness of the invention is 3-4 times of common paint, construction procedures are reduced, and concrete structure and steel structure can be protected from being corroded under carbon dioxide and corrosive conditions.

Owner:SHANGHAI DATONG HIGH TECH MATERIALS

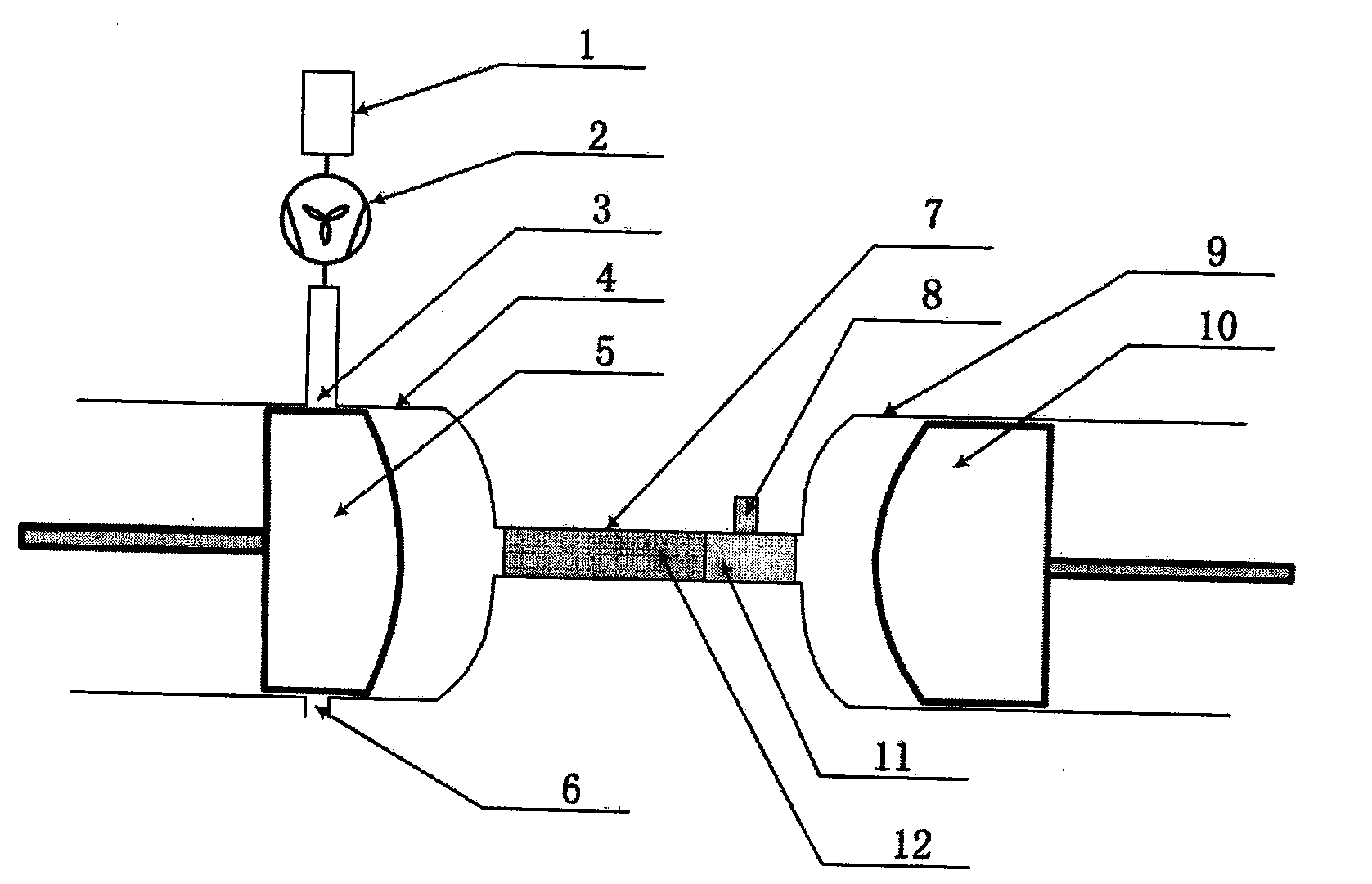

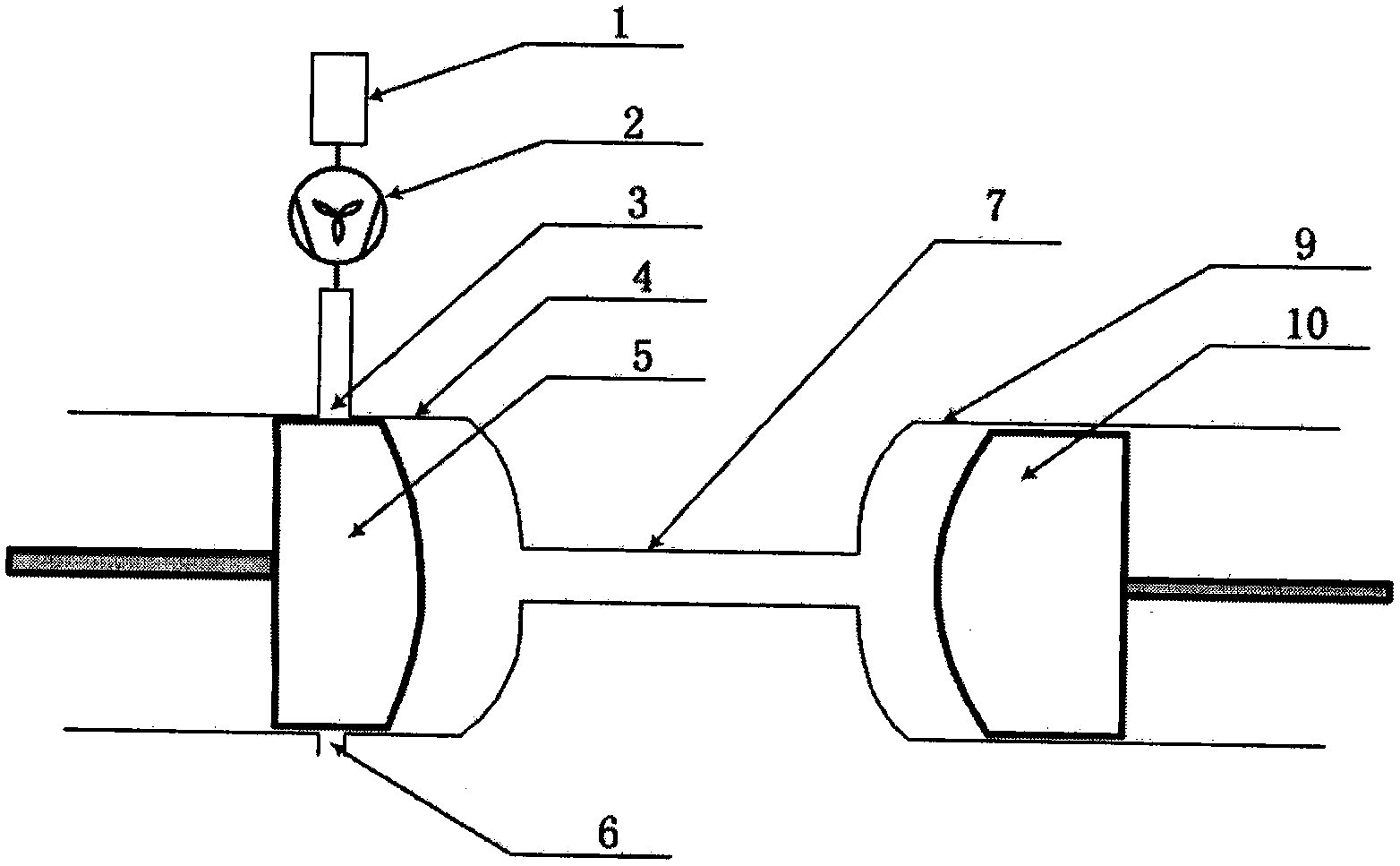

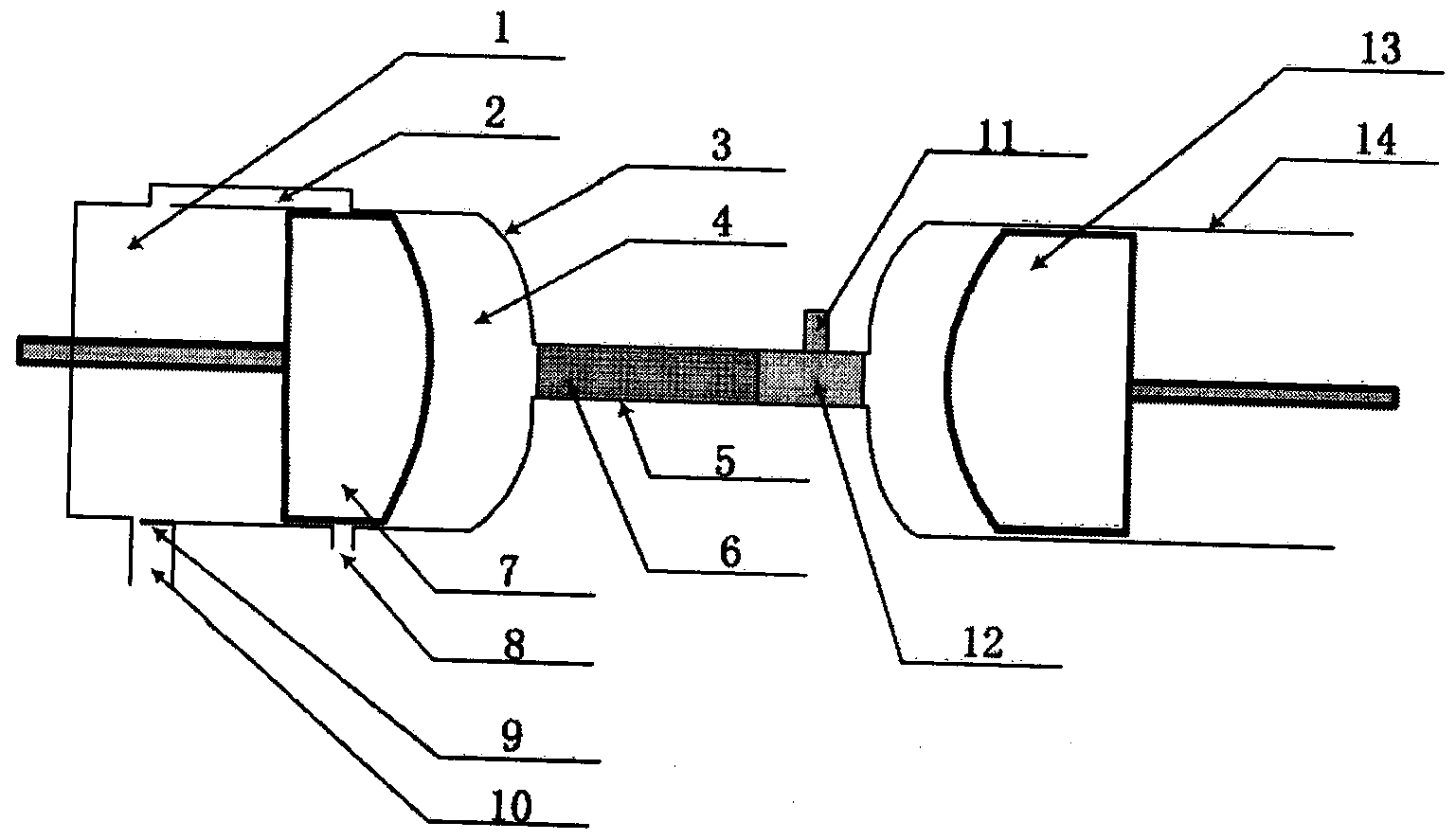

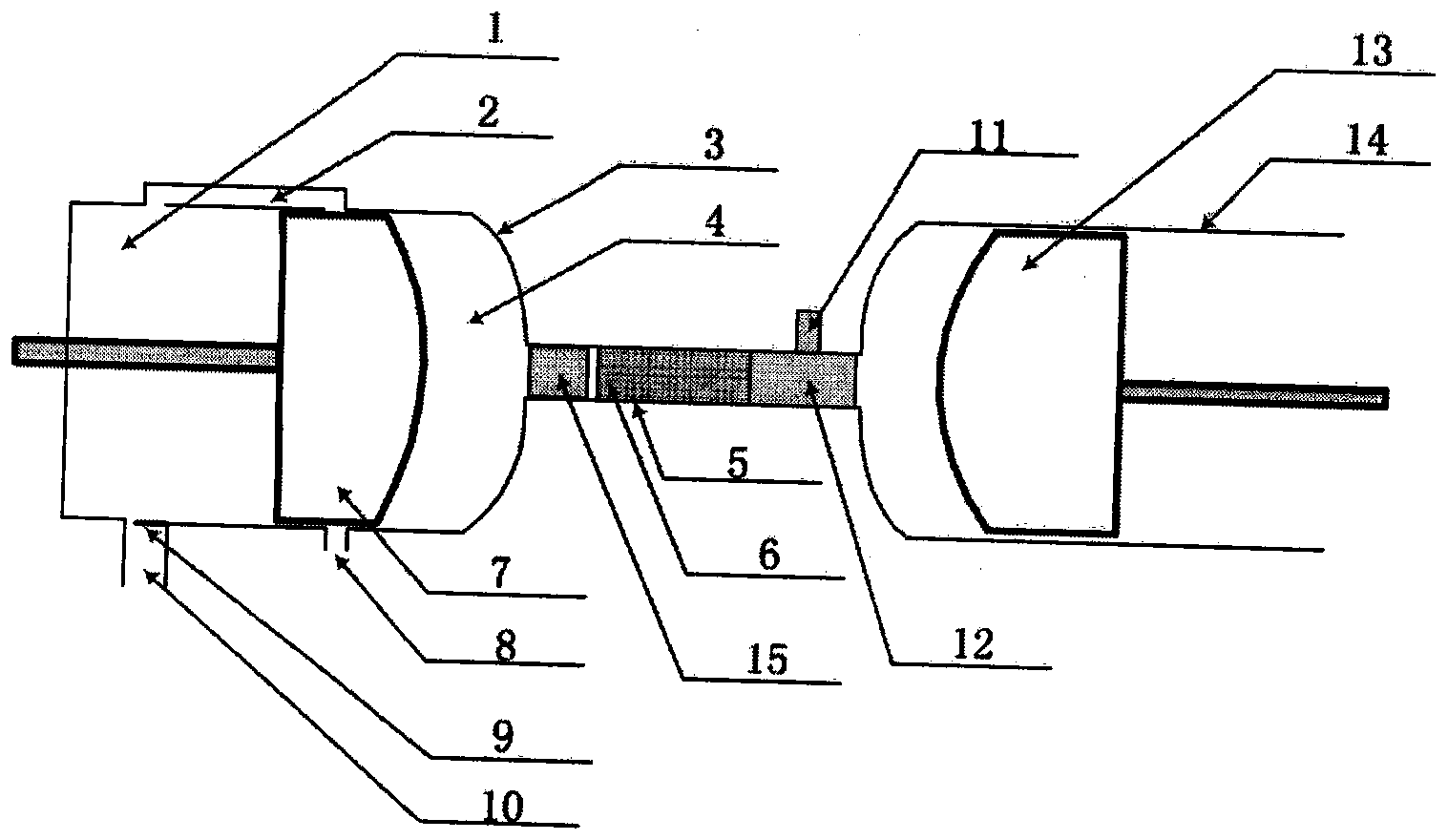

Reciprocating heat accumulating type internal combustion engine using scavenging pump for auxiliary intake and exhaust

InactiveCN104018931AInsulate the influenceReduce consumptionExhaust apparatusCombustion enginesComing outCombustor

A reciprocating heat accumulating type internal combustion engine using a scavenging pump for auxiliary intake and exhaust comprises the scavenging pump, a compression cylinder, a heat accumulator, a communicating pipe, a combustion chamber and an expansion cylinder. The internal combustion engine is structurally characterized in that the heat accumulator is located in a channel of the communicating pipe which connects the compression cylinder and the expansion cylinder, and the middle of the compression cylinder is provided with a scavenging port and a waste gas exhaust port. According to the basic working principle, when a compression cylinder piston moves from a lower dead center to an upper dead center, air in the compression cylinder is compressed, the compressed air is heated when flowing through the heat accumulator, enters the combustion chamber and is mixed with fuel for combustion, an expansion cylinder piston moves downwards from the upper dead center, and fuel gas expands and does work. When the expansion cylinder piston moves upwards, the compression cylinder piston moves downwards, the fuel gas comes out of the expansion cylinder after doing work, passes through a combustor and the heat accumulator in the reverse direction, heats the heat accumulator, lowers the temperature of itself, enters to a compression cavity and is exhausted through the waste gas exhaust port; air pre-compressed by the scavenging pump enters the compression cylinder through the scavenging port and further makes waste gas be discharged.

Owner:杨浩仁

Domestic gas blasting stove with safety control system

ActiveCN104315553AImprove combustion thermal efficiencySolve the ignition problemBurner safety arrangementsDomestic stoves or rangesCombustorControl system

The invention discloses a domestic gas blasting stove with a safety control system. The domestic gas blasting stove comprises an igniter, a combustor, at least two injection pipes communicated with the combustor, and a valve for controlling the injection pipes to open and close, wherein an ignition needle connected with the igniter is arranged on the combustor; at least one of the injection pipes is a natural air inlet type injection pipe, and at least one of the injection pipes is a blasting injection pipe; the domestic gas blasting stove also comprises a blasting device, a controller and an induction needle; the induction needle is used for inducing the gas combustion state; the blasting device is used for inputting air into the blasting injection pipe; and the controller is respectively connected with the induction needle and the blasting device and controls the blasting device to start, stop and regulate the air according to an induction signal of the induction needle. According to domestic gas blasting stove disclosed by the invention, the potential safety hazard problems caused by ignition difficulty and floating flames or blow-off of the domestic gas blower are effectively solved.

Owner:宁波丹沃思厨卫科技有限公司 +1

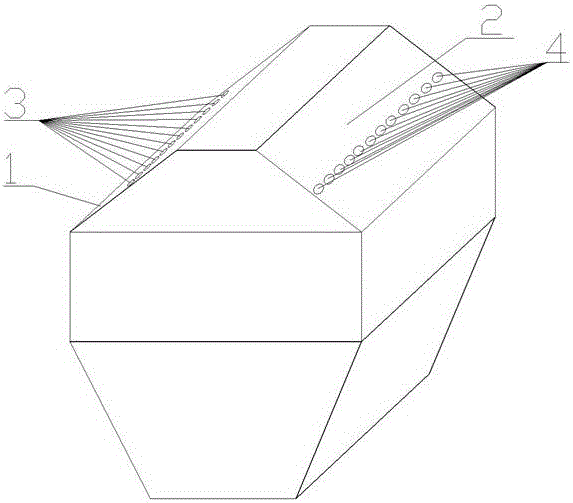

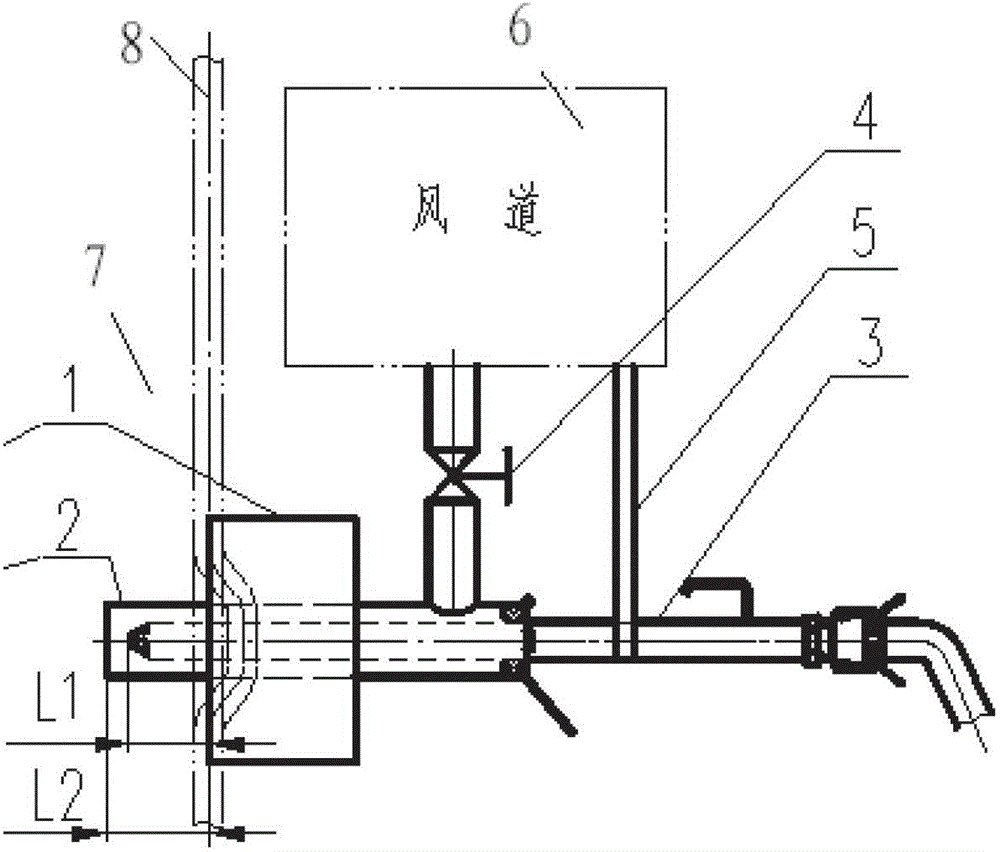

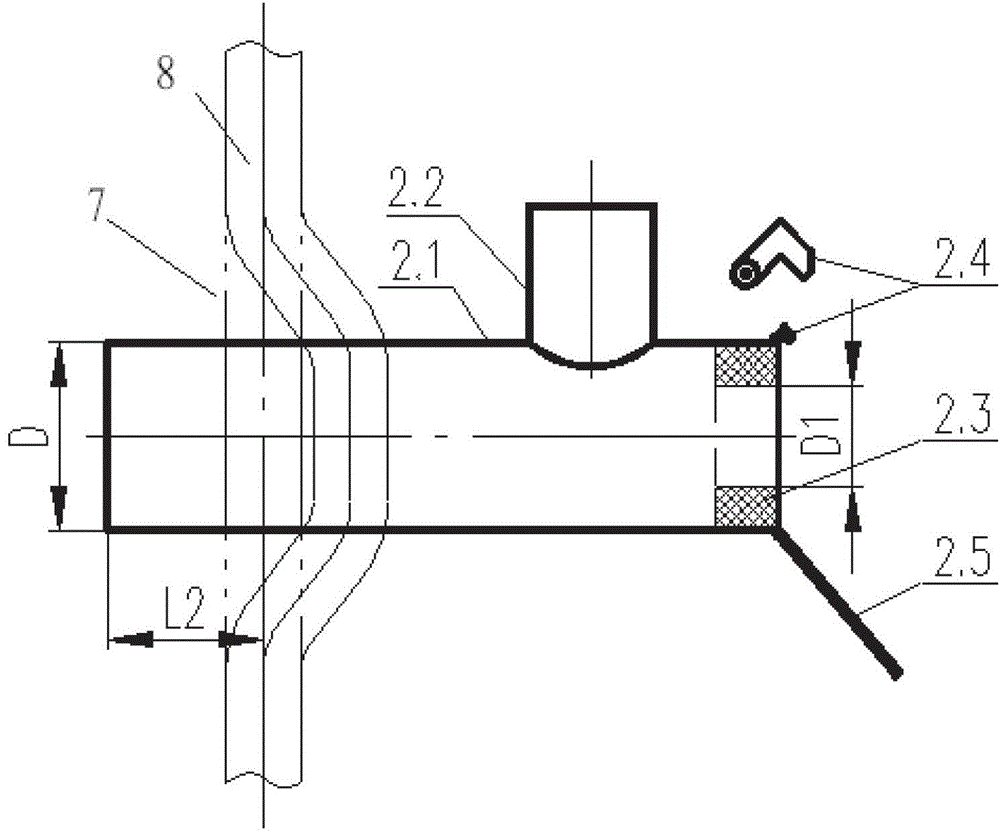

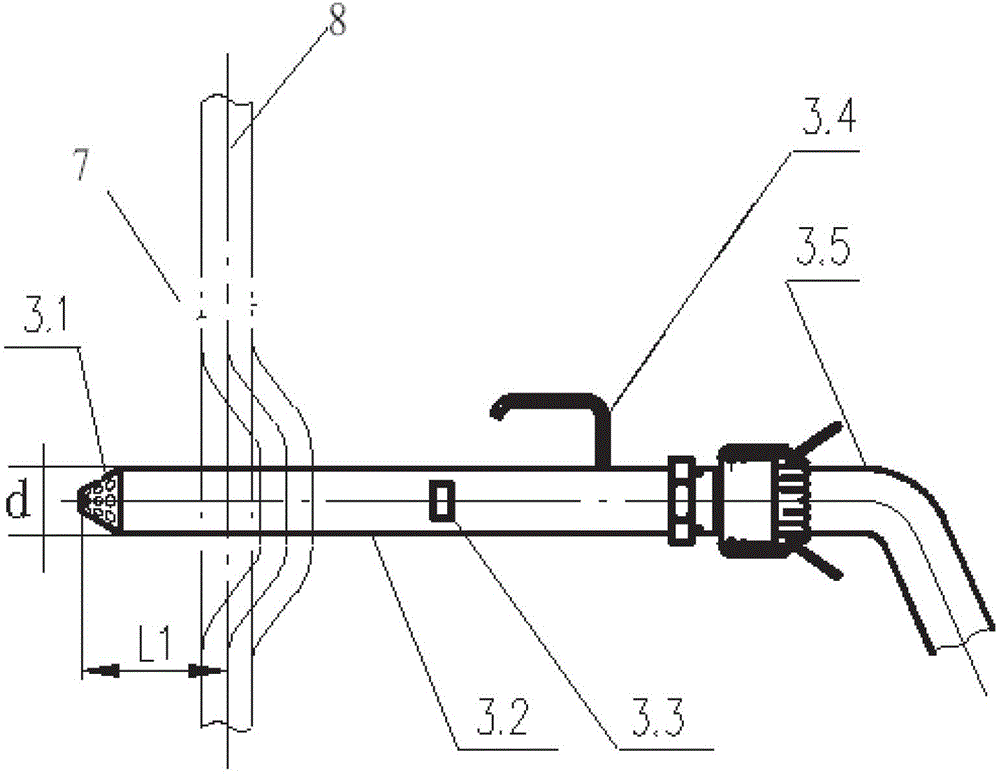

High-concentration odor combustion device with jacket cooling air

InactiveCN102913910APrevent backfireFully contactedCombustion technology mitigationIncinerator apparatusHigh concentrationCombustion

The invention discloses a high-concentration odor combustion device with jacket cooling air. The high-concentration odor combustion device comprises a gun barrel, wherein a handle is arranged on the gun barrel; the rear end of the gun barrel is communicated with a metal hose; the high-concentration odor combustion device also comprises a sleeve; two ends of the sleeve are provided with holes; the front part of the gun barrel is sleeved in the sleeve; the front end of the gun barrel is connected with a gun head; the gun head is arranged in the sleeve; a cooling air channel is formed between an inner wall of the sleeve and an outer wall of the gun barrel; a cooling medium air inlet pipe is arranged on the wall of the sleeve; and a hole formed in the rear end of the sleeve and the wall of the gun barrel are sealed. The high-concentration odor combustion device is simple in structure and convenient to operate, detach and maintain; the combustion gun is cooled and protected and is prevented from being burnt when the high-concentration odor amount is insufficient, and the service life of the combustion gun is prolonged; the high-concentration odor is fully and stably combusted, detonation is avoided, tempering is avoided, and the safety coefficient is high; and moreover, according to the sleeve, the phenomenon that the combustion gun head is polluted by alkali ash in the furnace, so that the blocking of the combustion hole can be avoided.

Owner:武汉锅炉集团工程技术有限公司

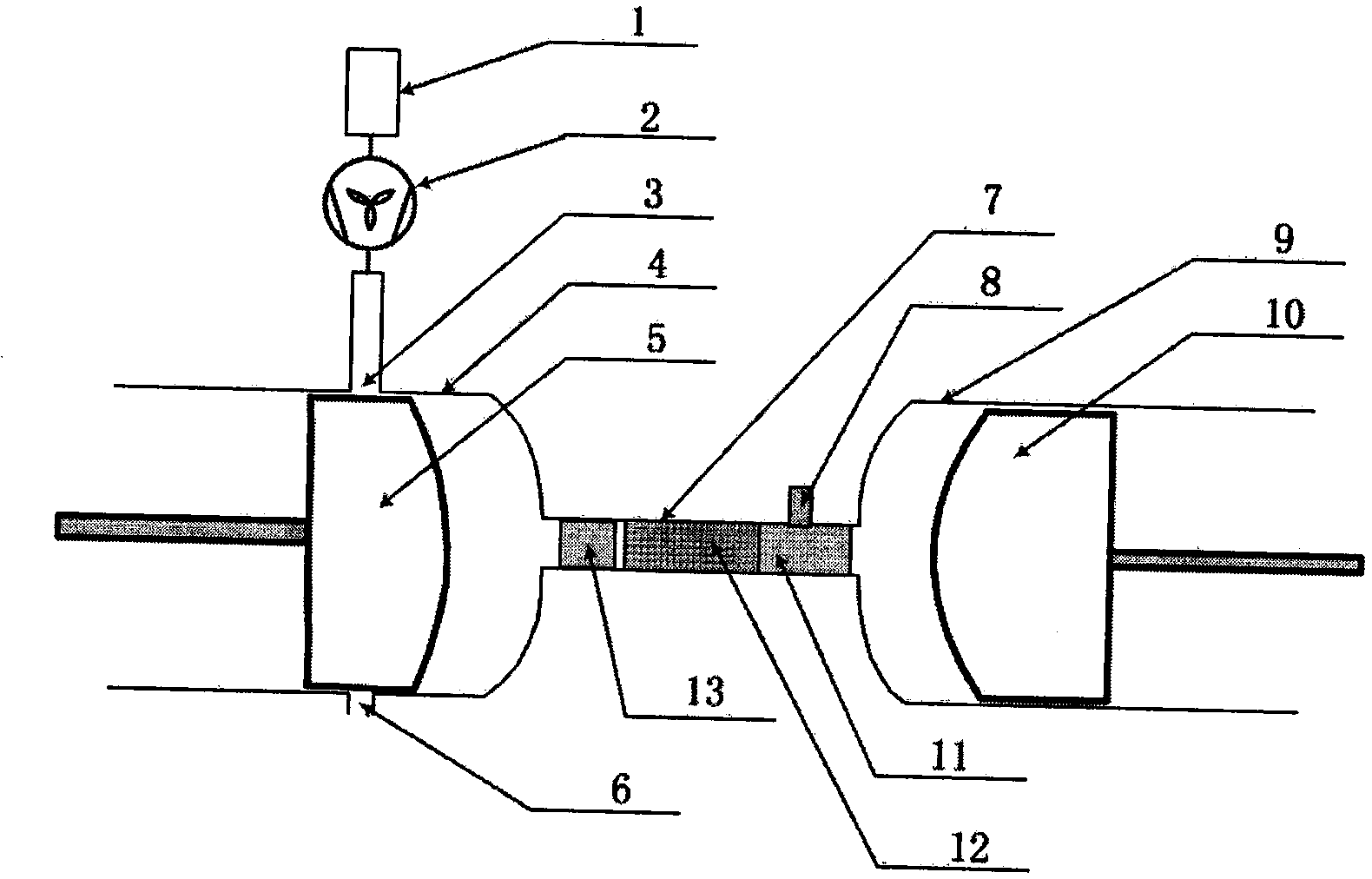

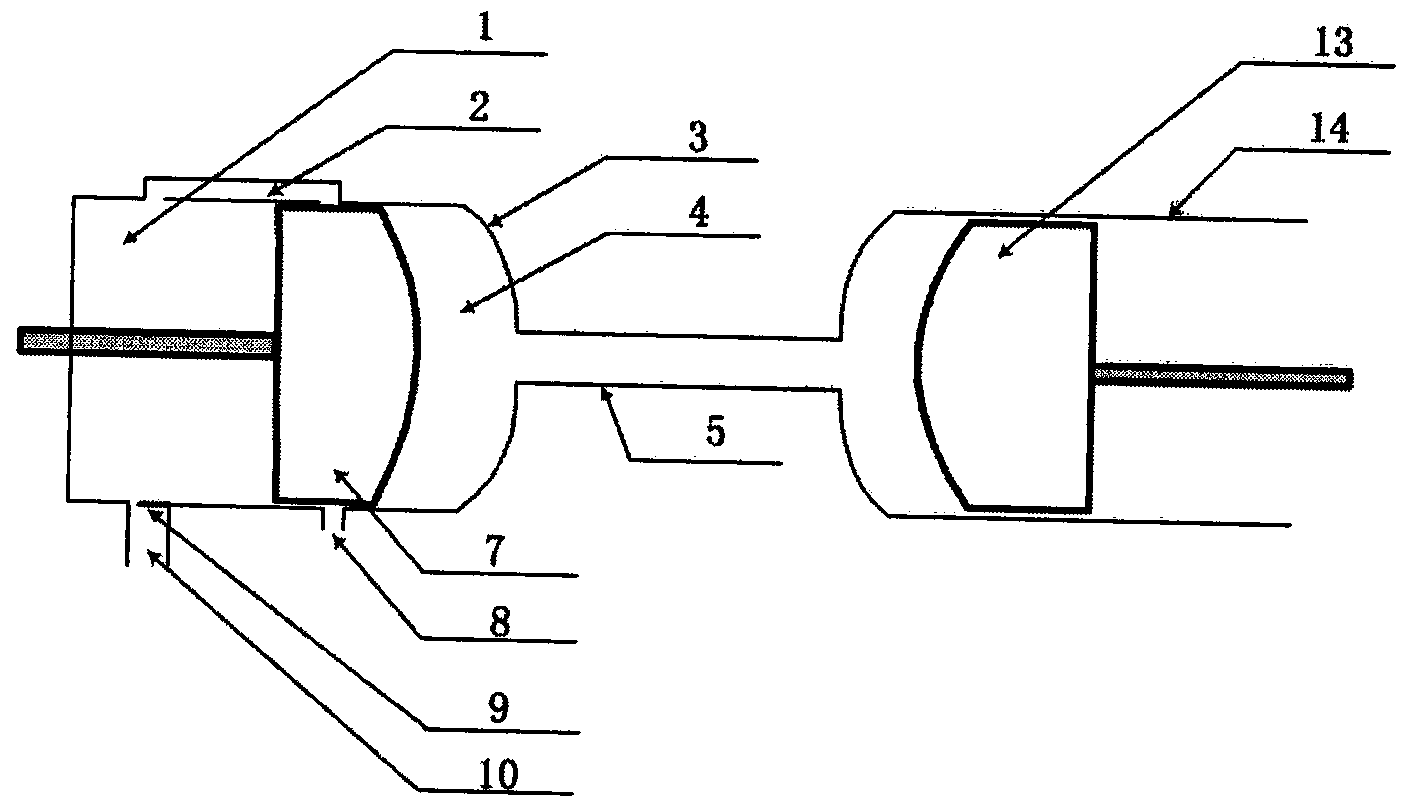

Reciprocating heat accumulating type internal combustion engine for air inlet and air outlet through scavenging duct

InactiveCN104018932AIncrease temperatureHigh thermal efficiencyCombustion enginesThermal treatment of fuelCombustorCombustion chamber

A reciprocating heat accumulating type internal combustion engine for air inlet and air outlet through a scavenging duct comprises a compression air cylinder, a heat accumulator, a communicated pipe, a combustion chamber and an expansion air cylinder. The reciprocating heat accumulating type internal combustion engine is characterized in that the heat accumulator is located in a channel of the communicated pipe connecting the compression air cylinder and the expansion air cylinder, the compression air cylinder is divided into a pre-compression cavity and a compression cavity through a piston, and the pre-compression cavity and the compression cavity are connected through the scavenging duct. According to the basic operating principle, when the piston of the compression air cylinder moves towards the upper stopping point from the lower stopping point, the air is fed into the pre-compression cavity, the air in the compression cavity is compressed, the compressed air flows through the heat accumulator to be heated and enters the combustion chamber to be burned with the fuel, a piston of the expansion air cylinder moves downwards from the upper stopping point, and fuel gas expands and acts. When the piston of the air cylinder moves upwards, the piston of the compression air cylinder moves downwards, the acting fuel gas gets out of the expansion air cylinder and reversely passes a combustor and the heat accumulator reversely to heat the heat accumulator, the fuel gas temperature is reduced, the fuel gas enters the compression cavity and is exhausted through an exhaust outlet, fresh air enters the compression cavity through the scavenging duct, and a power circulation is finished.

Owner:杨浩仁

Method for determining TiB2-ceramic-particle-enhanced aluminium-based composite material component

ActiveCN108387571AGuaranteed completenessNo deflagrationAnalysis by thermal excitationSiliconMaterials science

The invention provides a method for determining a TiB2-ceramic-particle-enhanced aluminium-based composite material component. The method comprises preparing a to-be-determined sample by adopting a method of dissolving an in-situ synthesized TiB2-ceramic-particle-enhanced aluminium-based composite material, and determining ICP-AES elements in the clear to-be-determined sample solution. The in-situsynthesized TiB2-ceramic-particle-enhanced aluminium-based composite material is dissolved via a strong alkali solution, and then low temperature oxidation is carried out to obtain the to-be-determined sample, so that a TiB2 ceramic particle component and silicon components with different silicon contents in the in-situ synthesized TiB2-ceramic-particle-enhanced aluminium-based composite materialcan be smoothly dissolved. In the whole process, high temperature oxidation is not required, explosion, burning, and splashing loss of the sample can be prevented, and the completeness of the sampleis efficiently ensured, which establishes the material base of accurately determining the content of various elements in the composite material in such series via ICP-AES and controlling and improvingthe quality of products.

Owner:SHANGHAI JIAO TONG UNIV +1

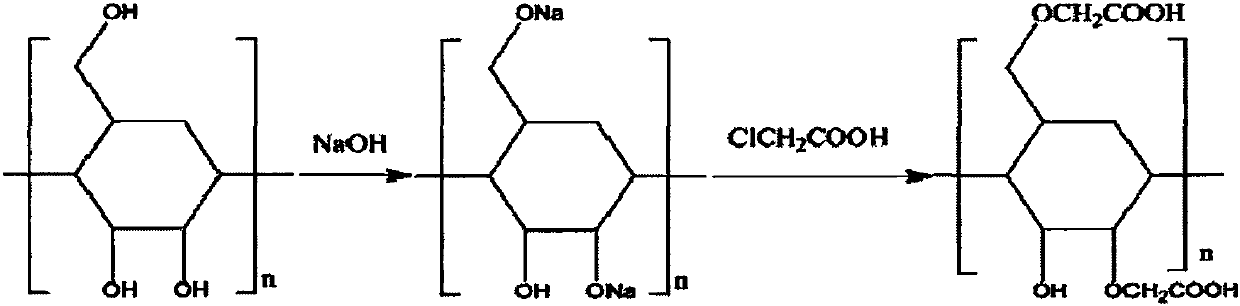

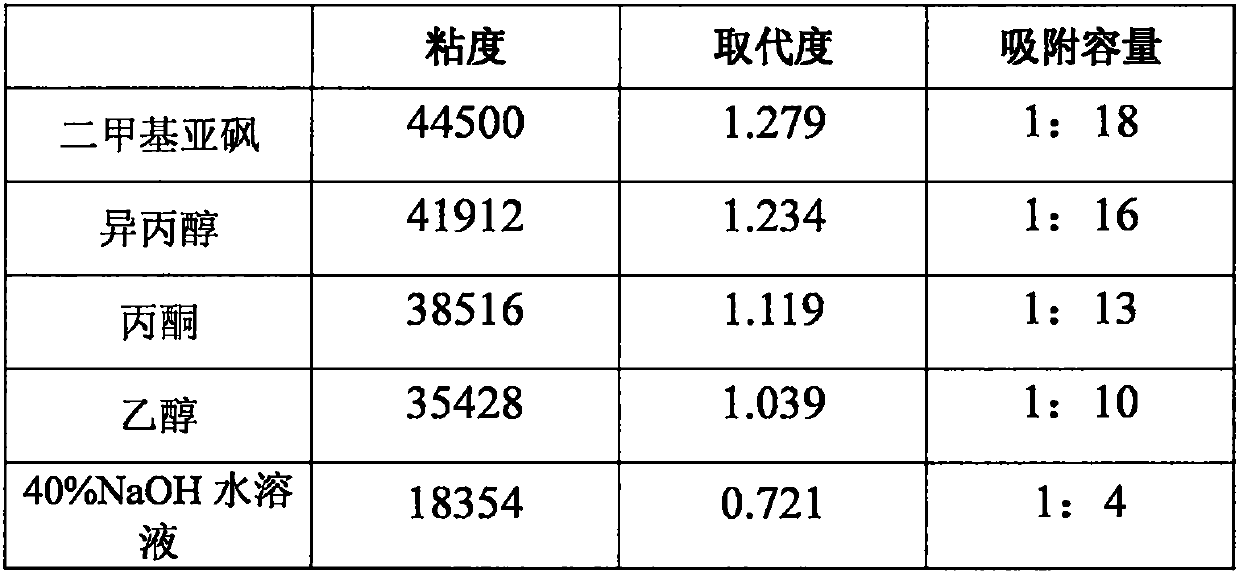

Preparation method of solid decontaminant for removing unsymmetrical dimethylhydrazine

InactiveCN111269327ANo deflagrationHas a dissolving effectChemical liquid solidificationDimethylhydrazineOrganosolv

The invention relates to a preparation method of a solid decontaminant for removing unsymmetrical dimethylhydrazine. The preparation method comprises the following steps: fully swelling cellulose in an organic solvent; mixing the fully swollen cellulose with alkali liquor for alkalization to obtain alkalized cellulose; mixing the alkalized cellulose with an acidifying agent for acidifying modification, and performing solid-liquid separation to obtain acidified cellulose, namely the so-called solid decontaminant. The solid decontaminant prepared by the invention has large adsorption capacity onunsymmetrical dimethylhydrazine, and a gelatinous solid is obtained after adsorption, so that unsymmetrical dimethylhydrazine can be prevented from flowing, spreading and volatilizing, detonation isprevented, and the solid decontaminant is easy to clean, quick, safe and convenient.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

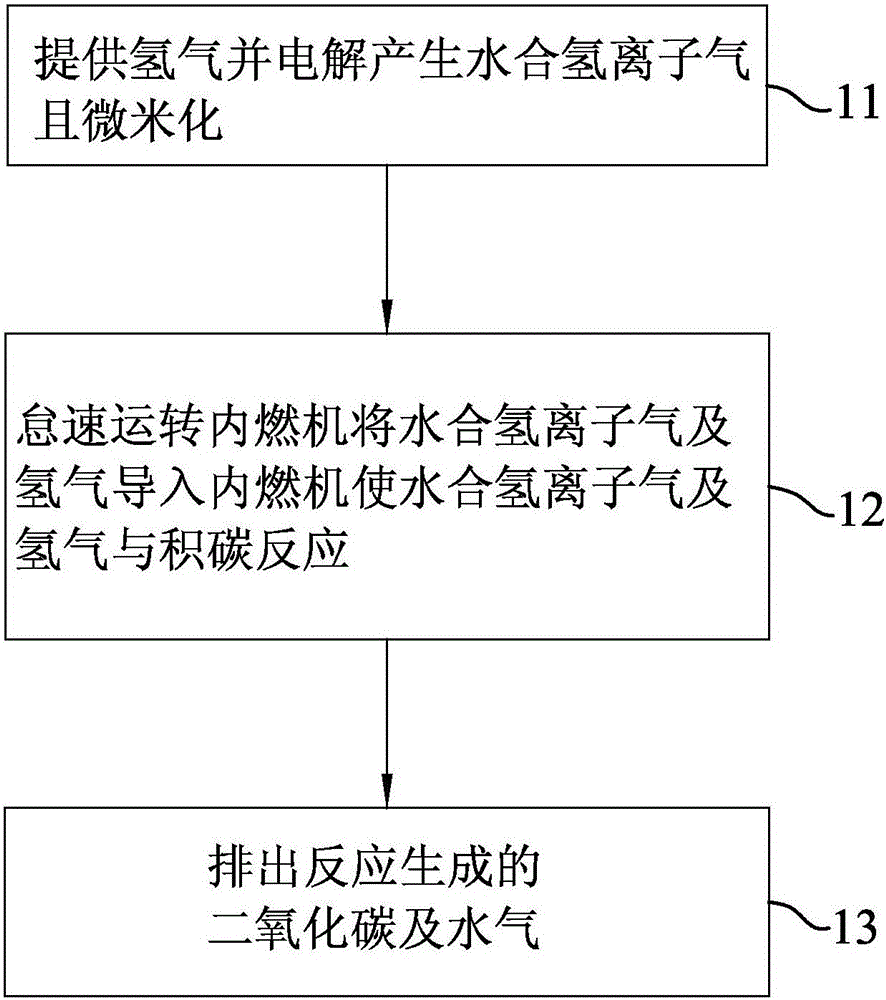

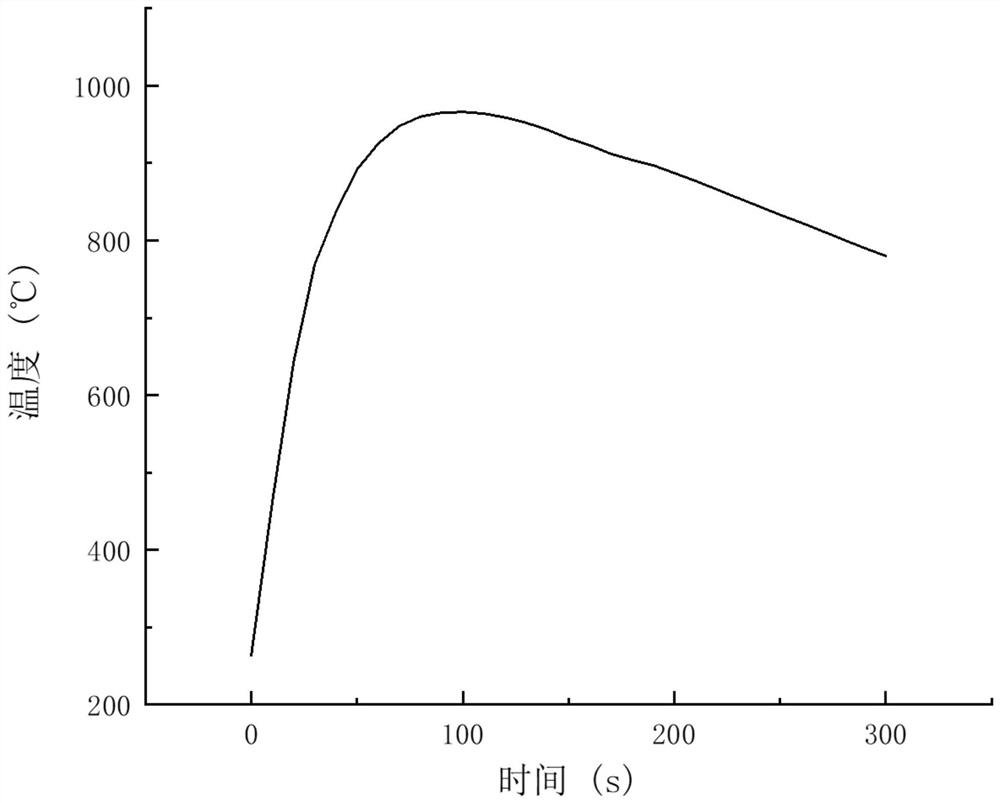

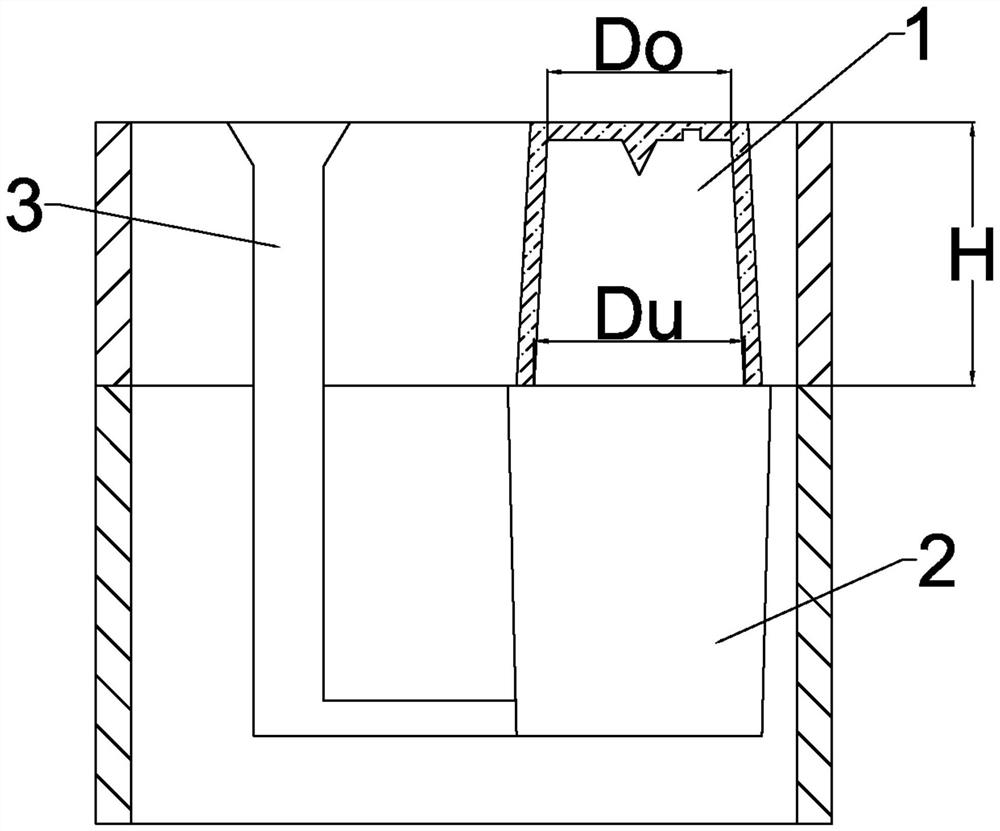

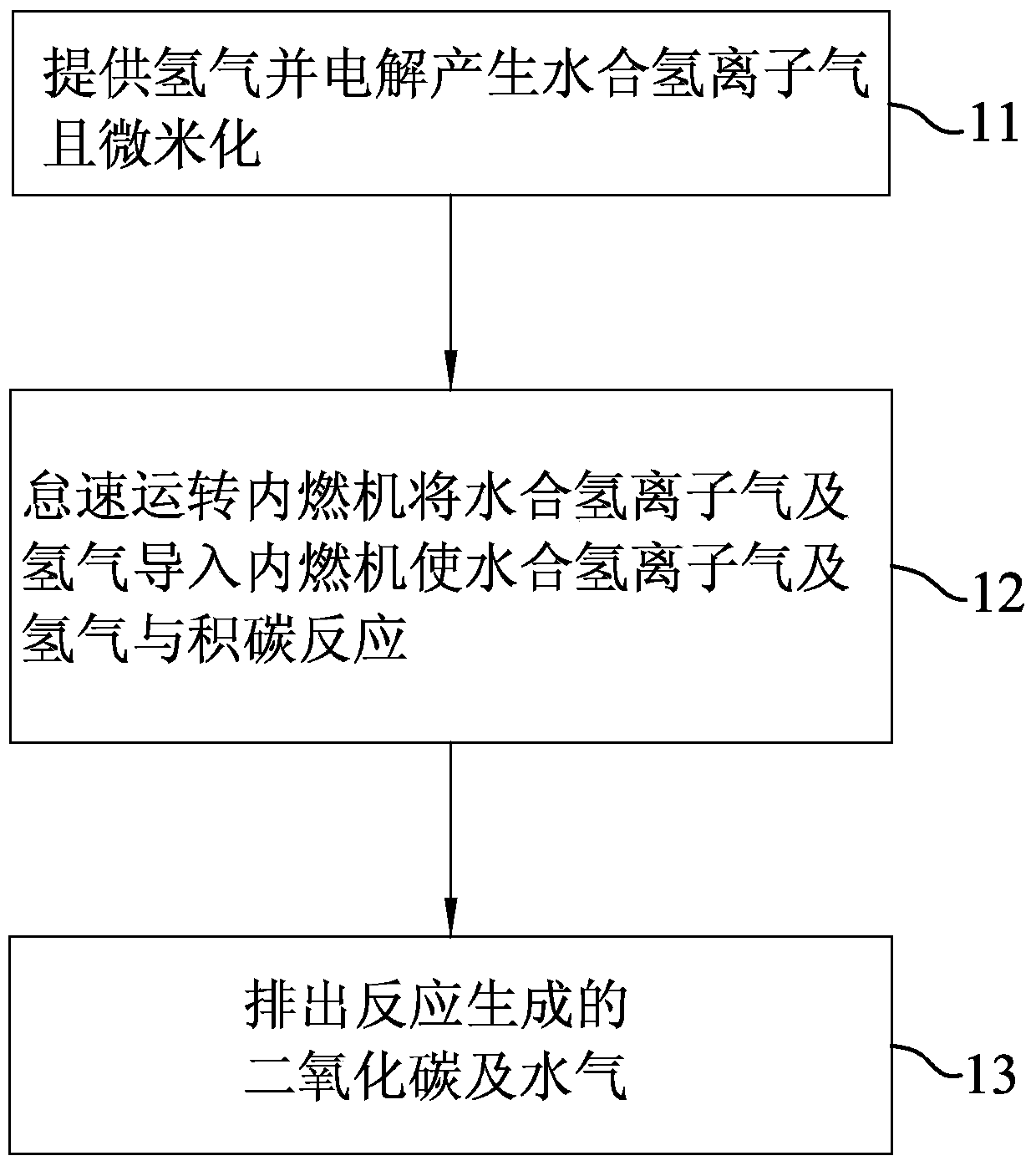

Carbon deposits removal method for internal combustion engine

ActiveCN106567781AWon't hurtImprove combustion characteristicsInternal combustion piston enginesEngine componentsHydronium ionDetonation

A carbon deposits removal method for internal combustion engine suitable for removing carbon deposits in an internal combustion engine includes the following steps: A. providing hydronium ions gas containing hydronium ions and hydrogen; B. continuing the idle operation of internal combustion engine to continuously introduce the hydronium ions gas and hydrogen into the internal combustion engine for reaction of the hydronium ions gas and hydrogen with the carbon deposits; and, C. waiting for the discharge of substance after reaction. By the present invention, there is no need to disassemble the engine and the hydronium ions gas may soften the carbon deposits and react with the carbon deposits to generate water gas to be burned with hydrogen to consume the carbon deposits. The hydronium ions gas can prevent the occurrence of detonation phenomenon without the concern of engine damage. Furthermore, the substance after reaction of the hydronium ions gas and hydrogen used by the present invention with the carbon deposits is non-toxic and environmental friendly.

Owner:唐暐轩

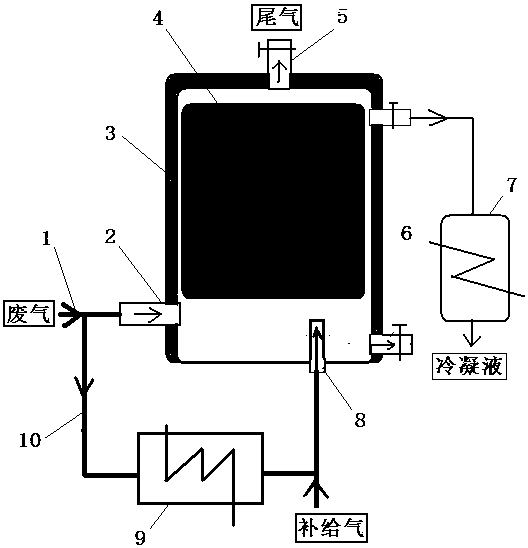

Regenerating system using waste gas itself as heating carrier

PendingCN107824007AGood securityLow costGas treatmentDispersed particle separationEngineeringEnvironmental geology

The invention discloses a regenerating system using waste gas itself as a heating carrier, which is provided with an absorption and desorption tank with an absorbing filler; the absorption and desorption tank is provided with a waste gas inlet, an absorption and desorption inlet, a purified gas outlet, a regenerating gas outlet; the waste gas is desorbed and absorbed by itself; a heating device isarranged on the pipeline between the waste gas source and the absorption and desorption gas inlet. By using the waste gas itself as the absorption and desorption gas source, no detonation is happened; the safety is good and the cost is low.

Owner:SHANGHAI YIJING ENERGY TECH

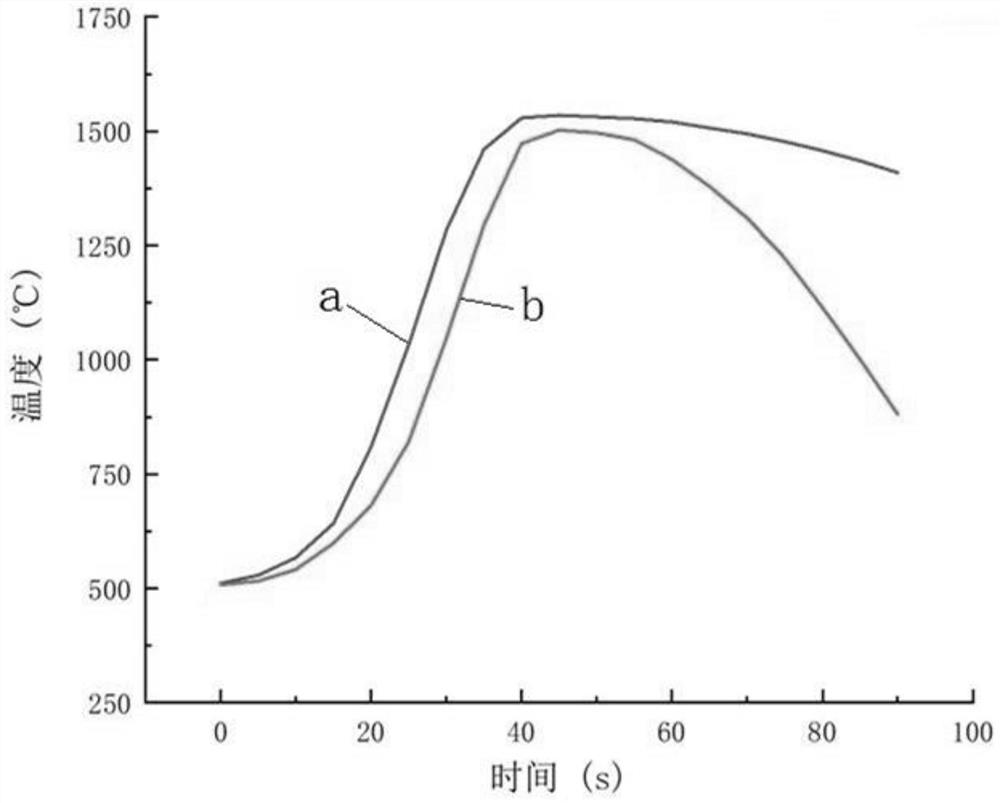

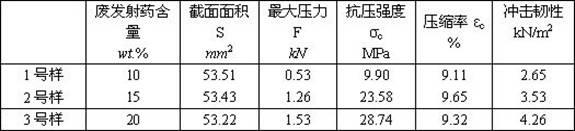

Organic silicon slag exothermic and insulating riser sleeve and preparation method thereof

The invention provides an organic silicon slag exothermic and insulating riser sleeve and a preparation method thereof. The insulating riser sleeve comprises the following raw materials of organic silicon slag, an oxidizing agent, refractory aggregate, an ignition material, a fluxing agent and a binder. According to the organic silicon slag exothermic and insulating riser sleeve, the organic silicon slag is used as a heating agent to partially or completely replace aluminum powder and aluminum slag, so that the riser sleeve has the advantages of energy conservation and emission reduction, low cost, low ignition temperature, short ignition time, excellent heating stability, no deflagration, long heat-insulating time, easiness in storage and the like; the problems of high cost, short storage period, deflagration and the like of the existing exothermic and insulating riser are solved; and during casting, under the combined action of heating and long heat preservation, the temperature of molten metal in the riser is increased through released heat, the solidification time of the molten metal in the riser is prolonged, the feeding time is prolonged, and the metal feeding rate in the riser is greatly increased.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

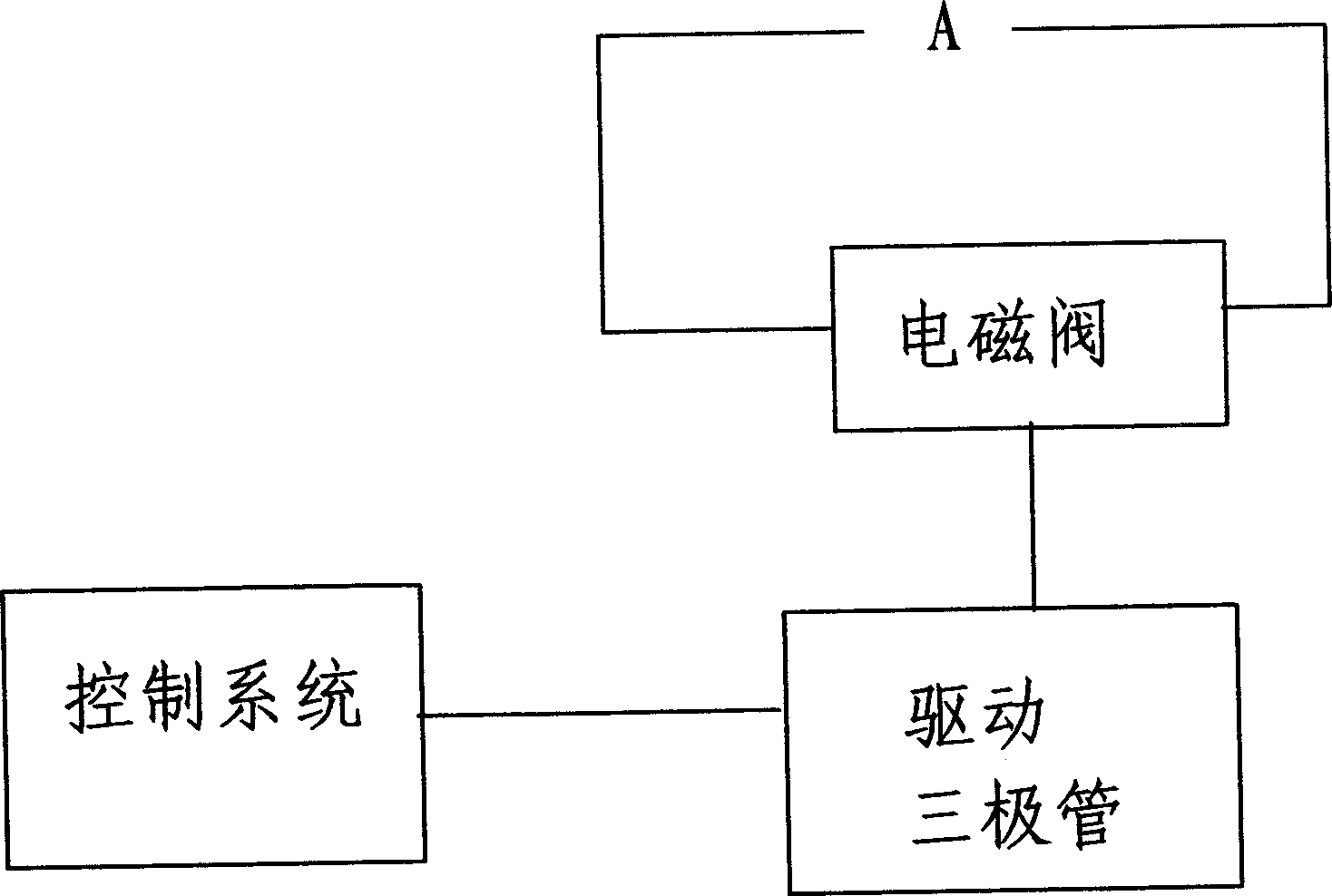

Method for controlling gas quantity in combustion charnber in lighting stage of gas water heater

The control method of gas dose in combustion chamber in lighting stage of gas wter-heater includes control system, drive triode and electromagnetic valve mounted on the gas pipe. The control system outputs the signal to drive triode, then the signal can be transferred into electromagnetic valve by means of the drive triode. In the lighting period, the signal outputted by control system is pulse signal so as to make the electromagnetic valve circularly act between opening and closing and make the gas channel be in opening and closing circulation state, so that the gas consumption dose before lighting can be reduced, after it is lighted, the signal outputted by control system is an opening signal, the gas channel is in opening state, the water-heater can be worked normally.

Owner:张卓文

Heatproof coating layer and preparation method thereof

ActiveCN110205018ARemove the force of aggregationExcellent heat shrinkage resistanceFireproof paintsSecondary cellsSolventCapacitance

The invention relates to a heatproof coating layer and a preparation method thereof. The heatproof coating layer is mainly composed of an inorganic inert nanopowder, an amino-terminated benzenesulfonamide surfactant and a matrix material, wherein a molar ratio of amino groups at the end to sulfonyl groups of the amino-terminated benzenesulfonamide surfactant is 1:(5-8). The heatproof coating layerhas a thickness of 0.5-15 [mu]m and a porosity of 50-80%, and the heatproof temperature of a porous film containing the heatproof coating layer can reach 300 DEG C. The preparation method of the heatproof coating layer comprises the following steps: dissolving the inorganic inert nanopowder, the amino-terminated benzenesulfonamide surfactant and the matrix material in a polar solvent to form a coating layer solution, coating the surface of the porous film with the coating layer solution, and removing the polar solvent to form the heatproof coating layer on the surface of the porous film. Theporous film containing the heatproof coating layer of the present invention has an excellent heat shrinkage resistance and a small thickness, and can be used as a micro-porous separator for a lithiumion battery to improve the heating safety and the specific capacitance of the lithium ion battery.

Owner:上海钱丰纺织品有限公司

Welding rod containing waste propellant and preparation method thereof

InactiveCN102528313AStrong combustion safetyStrong combustion stabilityWelding/cutting media/materialsSoldering mediaCombustionSlag

The invention relates to a welding rod containing waste propellants and a preparation method thereof. The welding rod is made from waste propellants, a thermit chemical agent, a slag-forming agent and a stabilizer by the following steps of: grinding, gelating, extrusion-molding and completely dissolving. The invention reduces the pressure of disposing the waste propellants, avoids waste of resources and provides a novel welding material which can be effectively applied to battlefield equipment emergency repair and civil facility rescue. The welding rod is convenient to carry, easy to operate and safe to use and has strong combustion controllability, the preparation process is simple, raw materials are easily obtained, and the welding rod is favorable for industrial production.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

A gas appliance with automatic safety ignition function

ActiveCN104101001BNo deflagrationImprove yieldDomestic stoves or rangesLighting and heating apparatusCombustorCatheter

The invention discloses a gas appliance with automatic safety ignition function, which comprises a burner, a gas nozzle, a gas delivery pipe and an ignition device, one end of the gas delivery pipe is connected to the burner through a gas nozzle, and the ignition device includes a hot surface igniter And the expansion valve, the hot side igniter is close to the burner, the expansion valve includes a temperature sensing package, a valve body and an expansion power conduit, the temperature sensing package is arranged on the hot side igniter, and the temperature sensing package is connected to the valve body through the expansion power conduit, The temperature sensing bulb and the expansion power conduit are filled with expansion liquid, the valve body has a gas inlet and a gas outlet, and the gas outlet of the valve body is connected with the other end of the gas delivery pipe. The invention can completely cut off the gas delivered to the gas delivery pipe, without the possibility of accidental extinguishment, and can automatically reset the ignition without manual reset, high yield, durable, low cost of use, and the ignition device completely heats the gas and electricity Isolation is separated, there is no possibility of deflagration, and the safety is high.

Owner:DONGGUAN HYXION METAL TECH CO LTD

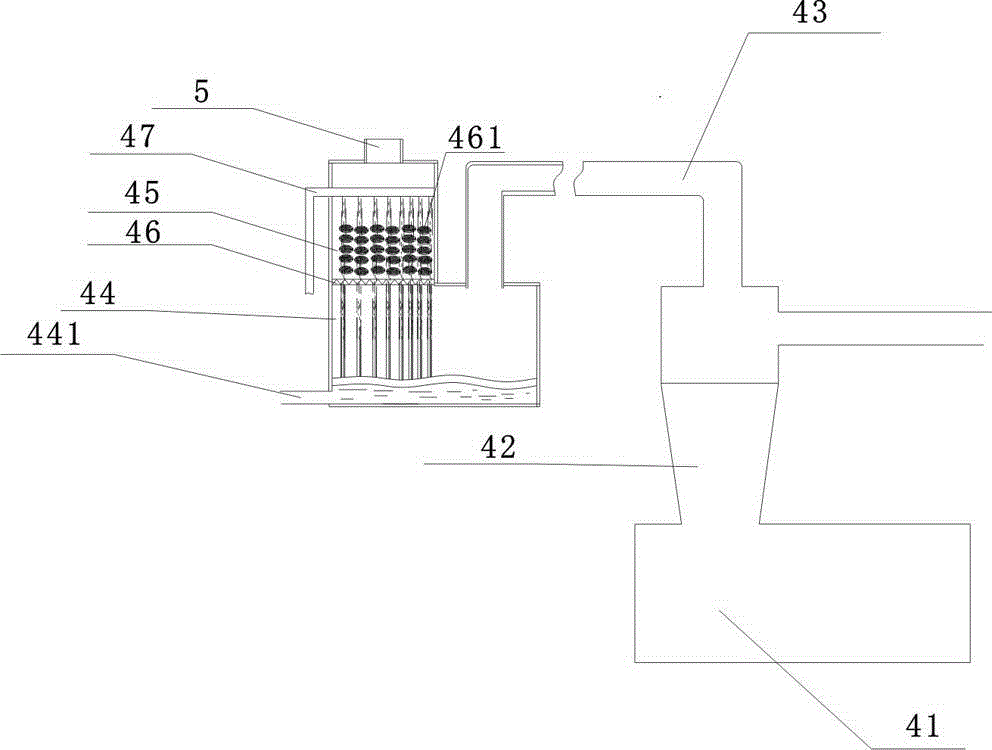

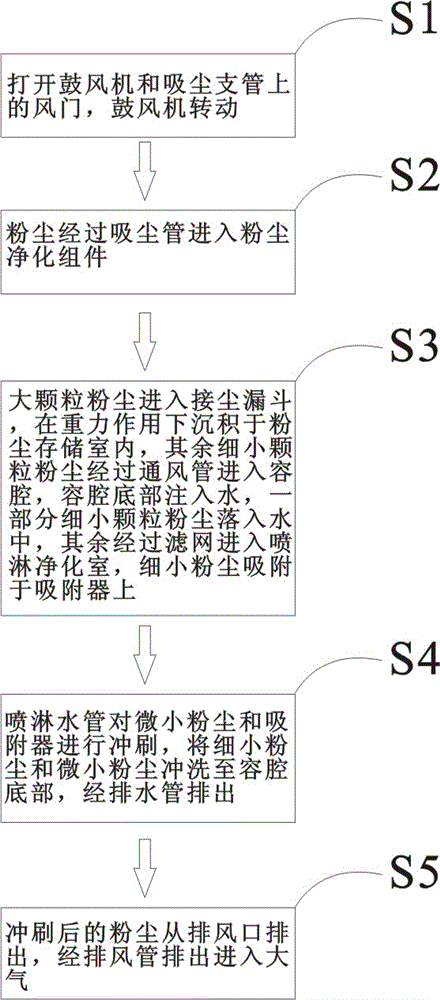

Dust purification device and method

InactiveCN104353318AThe purification process is simpleSimple purification equipmentCombination devicesWater pipeProduct gas

The invention discloses a dust purification device and method. The device comprises a dust collection pipe, a dust collection component, a power cabinet and a dust purification component, wherein one end of the dust collection pipe is connected with the dust collection component, and the other end is connected with the dust purification component; the dust collecting pipe is provided with a plurality of dust collection branch pipes and a blower, and the blower is provided with a variable frequency motor; the power cabinet is connected with the variable frequency motor, the dust purification component comprises a dust storage chamber and a dust receiving funnel, the dust receiving funnel extends into the top of the dust storage chamber and is connected with a vent pipe, the air outlet port of the vent pipe is connected with a containing cavity, the top of the containing cavity is provided with a spraying purification chamber, and the top of the spraying purification chamber is provided with an air outlet. The method comprises the following steps: opening an air door of the blower to rotate the blower; feeding dust into the dust purification component; depositing the large particle dust in the dust storage chamber, and feeding the fine particle dust in the containing cavity to enter the spraying purification chamber, washing by using a spraying pipe and flushing the dust to the bottom of the containing cavity, and discharging the flushed gas to the atmosphere from an air outlet.

Owner:ZHEJIANG JIUCHUAN BAMBOO & WOOD

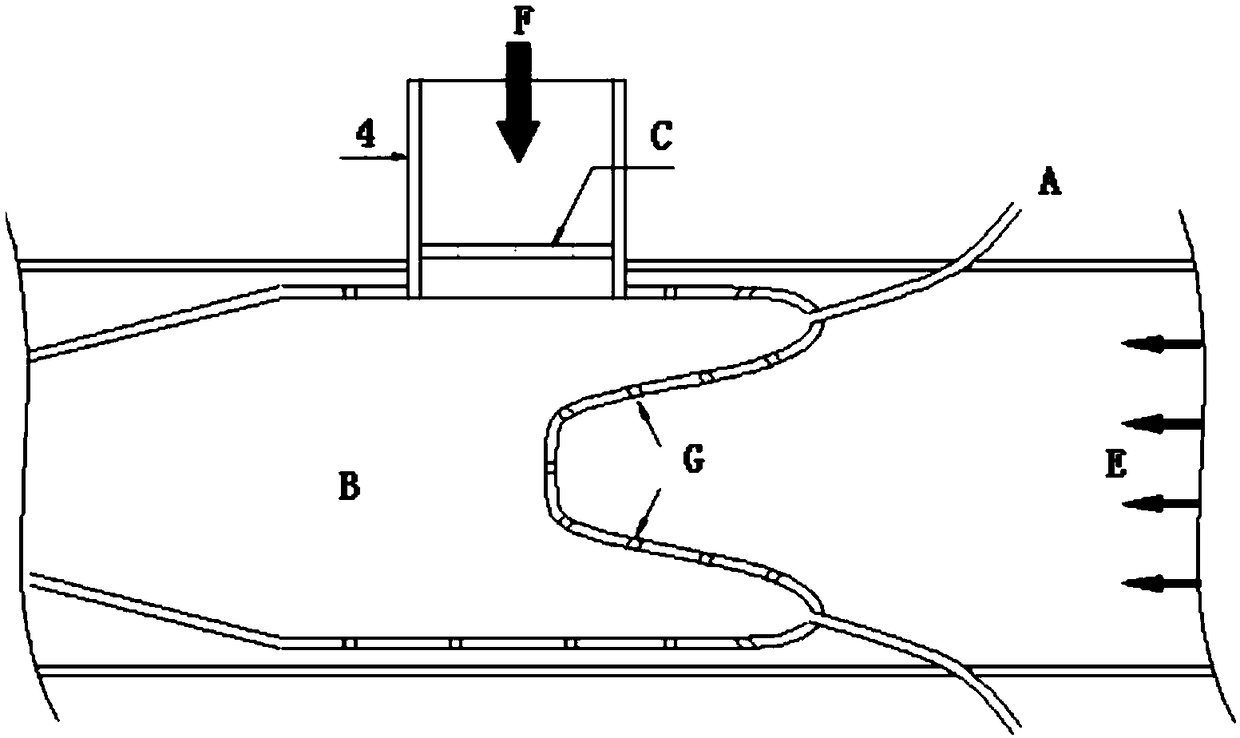

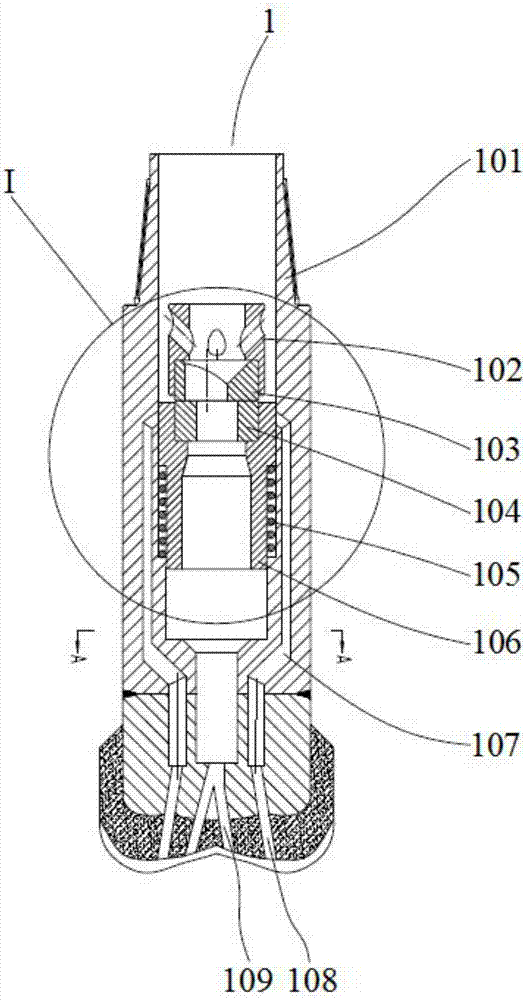

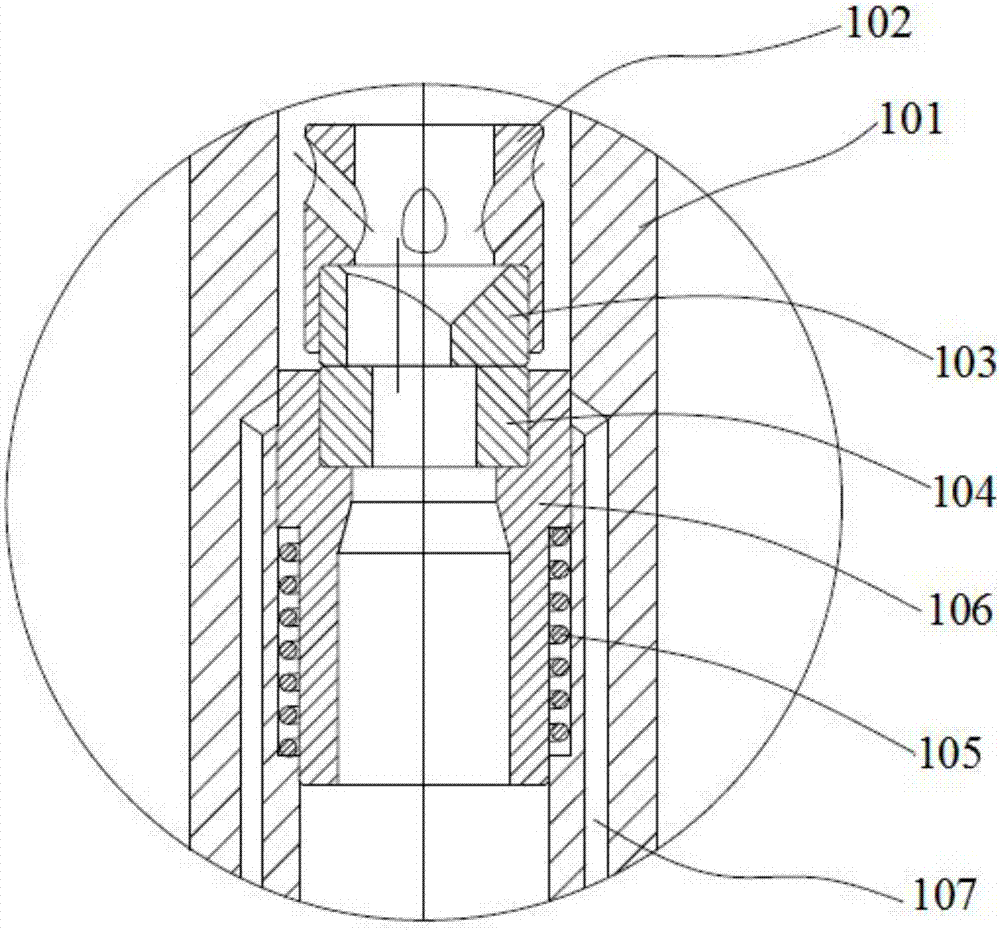

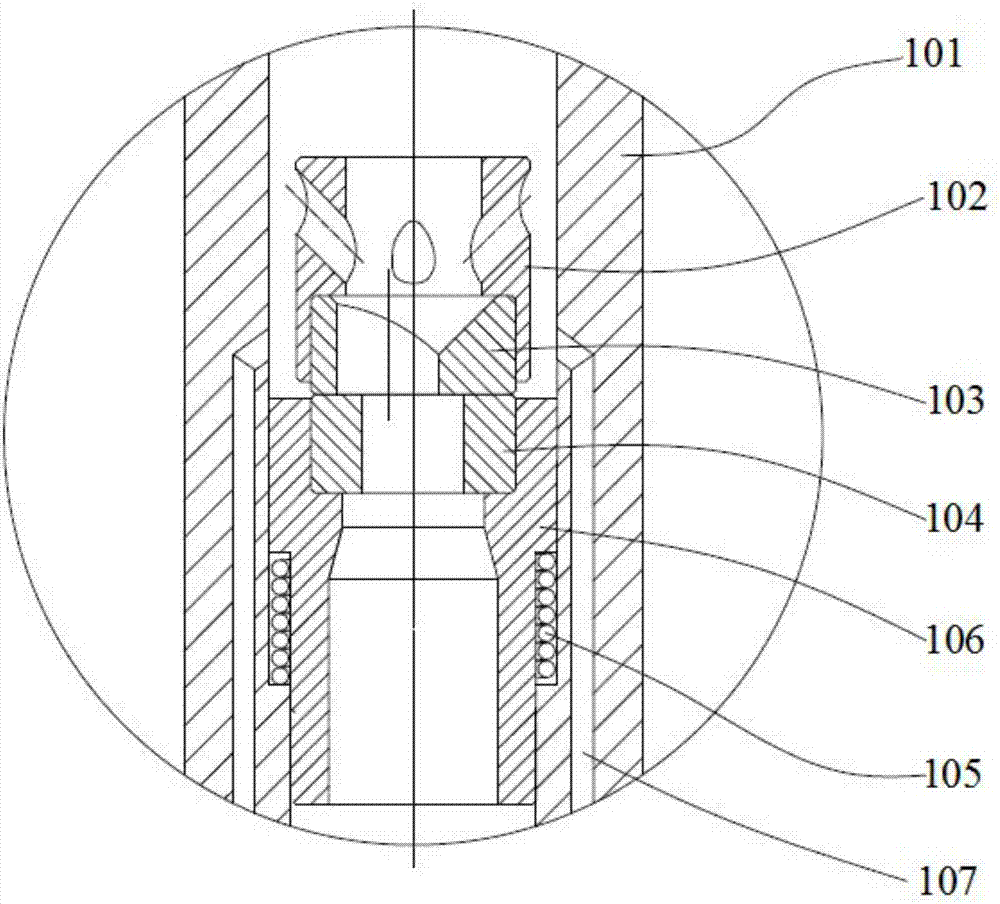

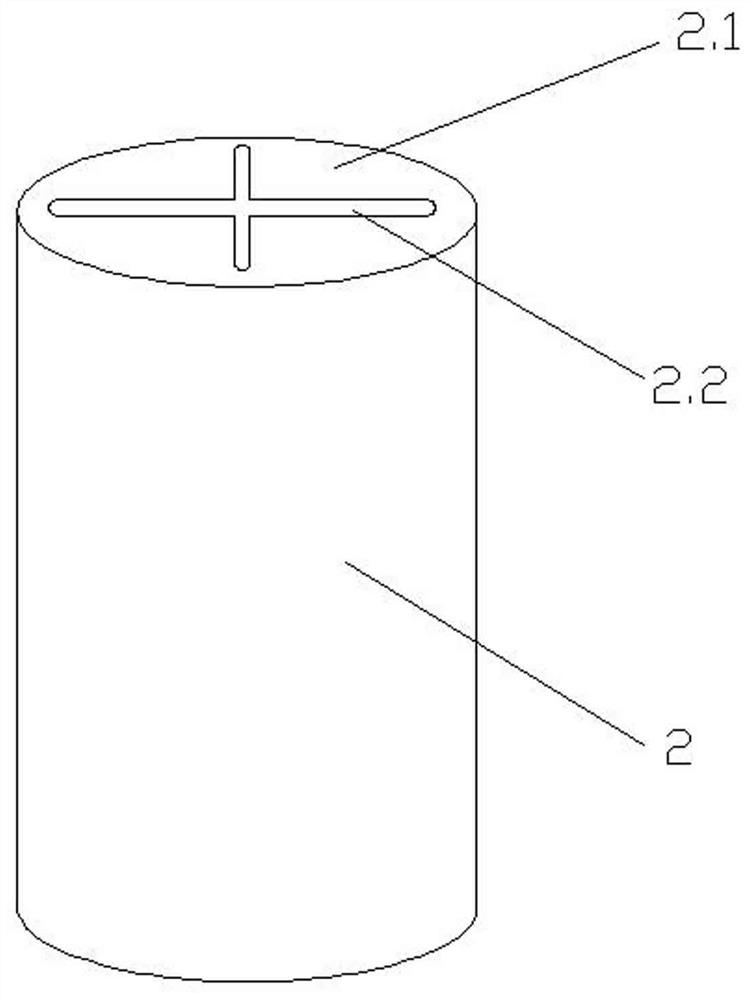

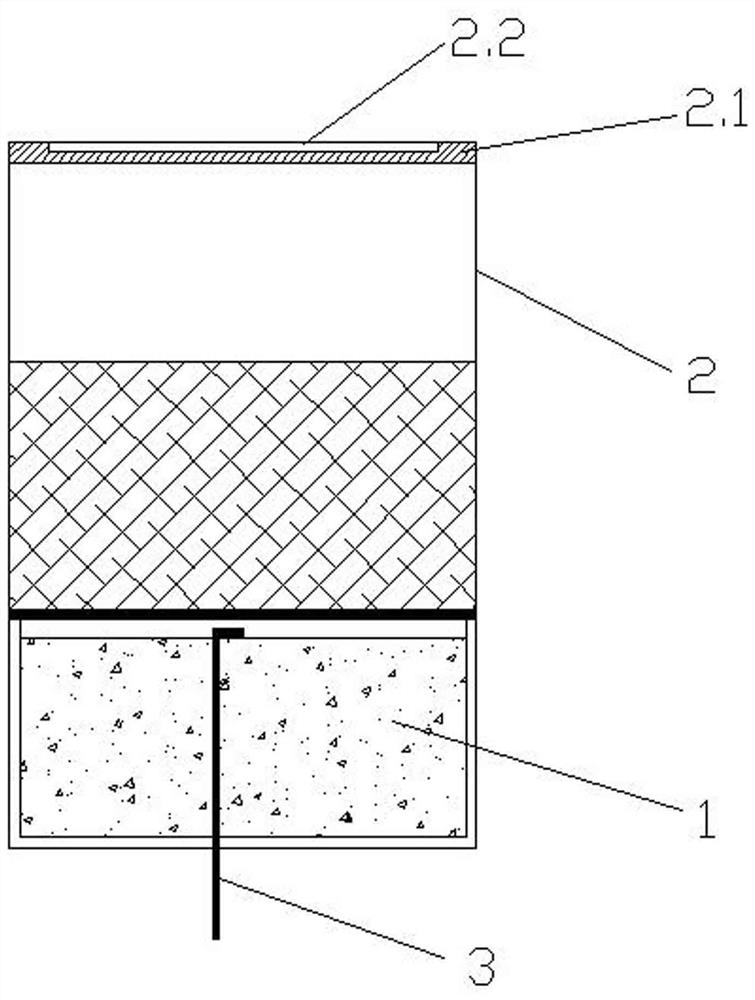

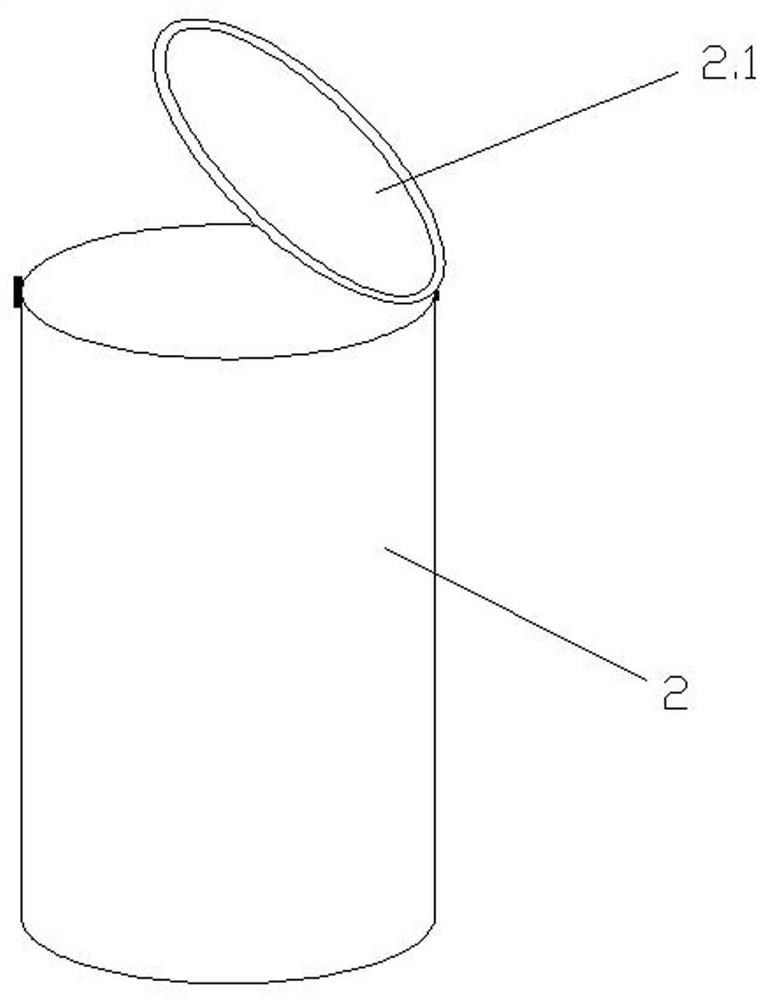

Drill bit, drilling tool and local underbalanced drilling method

ActiveCN105952383BReduce trafficReduce the risk of loss of controlConstructionsFlushingWell drillingEngineering

The invention relates to a drill bit, a drilling tool provided with the drill bit and a drilling method for realizing partial underbalance drilling by adopting the drilling tool. Annular high-speed jet flow is formed by periodically spraying high-pressure drilling liquid through a high-pressure nozzle arranged at the bottom of the drill bit; and a water hole nozzle is used for spraying drilling liquid which is at a relative negative pressure state, and a negative-pressure region is formed in high-pressure annular jet flow, so that a partial underbalance state is periodically formed at the shaft bottom and rock burst is induced. Based on an underbalance drilling principle, the partial underbalance drilling is formed at the shaft bottom and well pressure above a partial underbalance region is greater than formation pressure; and a mechanical drilling speed is increased, the limitation of an underbalance drilling technology can be overcome, the safety of a drilling process and the smoothness of the drilling work are guaranteed, and the drilling efficiency and the production benefits are effectively improved.

Owner:HISPEED WUHAN PETROLEUM TECH CO LTD

A pressure-suppressing pulse type fire extinguishing method and its fire extinguishing device

ActiveCN111013071BSpraying speed is fastImprove fire extinguishing efficiencyFire rescueFire - disastersStructural engineering

The invention discloses a pressure-holding pulse type fire-extinguishing method and a fire-extinguishing device. The method comprises the following steps: step 1): placing a fire extinguishing agent in a closed container; step 2): igniting the fire extinguishing agent when a fire occurs; step 3) : The fire-extinguishing substance produced after the fire extinguishing agent is ignited fills the entire airtight container, and the pressure in the airtight container gradually increases; Step 4): The discharge end of the airtight container is opened because the pressure reaches the critical value, and the fire-extinguishing substance is ejected to carry out the fire-extinguishing process; The present invention also provides a corresponding fire extinguishing device; the present invention greatly speeds up the spraying speed of the fire extinguishing material and improves the fire extinguishing efficiency.

Owner:YICHANG JI AN DUN FIRE FIGHTING TECH CO LTD

Method for removing carbon deposits in internal combustion engines

ActiveCN106567781BWon't hurtImprove combustion characteristicsInternal combustion piston enginesEngine componentsHydronium ionDetonation

A carbon deposits removal method for internal combustion engine suitable for removing carbon deposits in an internal combustion engine includes the following steps: A. providing hydronium ions gas containing hydronium ions and hydrogen; B. continuing the idle operation of internal combustion engine to continuously introduce the hydronium ions gas and hydrogen into the internal combustion engine for reaction of the hydronium ions gas and hydrogen with the carbon deposits; and, C. waiting for the discharge of substance after reaction. By the present invention, there is no need to disassemble the engine and the hydronium ions gas may soften the carbon deposits and react with the carbon deposits to generate water gas to be burned with hydrogen to consume the carbon deposits. The hydronium ions gas can prevent the occurrence of detonation phenomenon without the concern of engine damage. Furthermore, the substance after reaction of the hydronium ions gas and hydrogen used by the present invention with the carbon deposits is non-toxic and environmental friendly.

Owner:唐暐轩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com