Domestic waste gasification device and process

A technology for domestic waste and gasification device, which is applied in the gasification of granular/powdered fuel, petroleum industry, and the manufacture of combustible gas, etc. The effect of saving treatment costs, simplifying the overall process, and eliminating exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

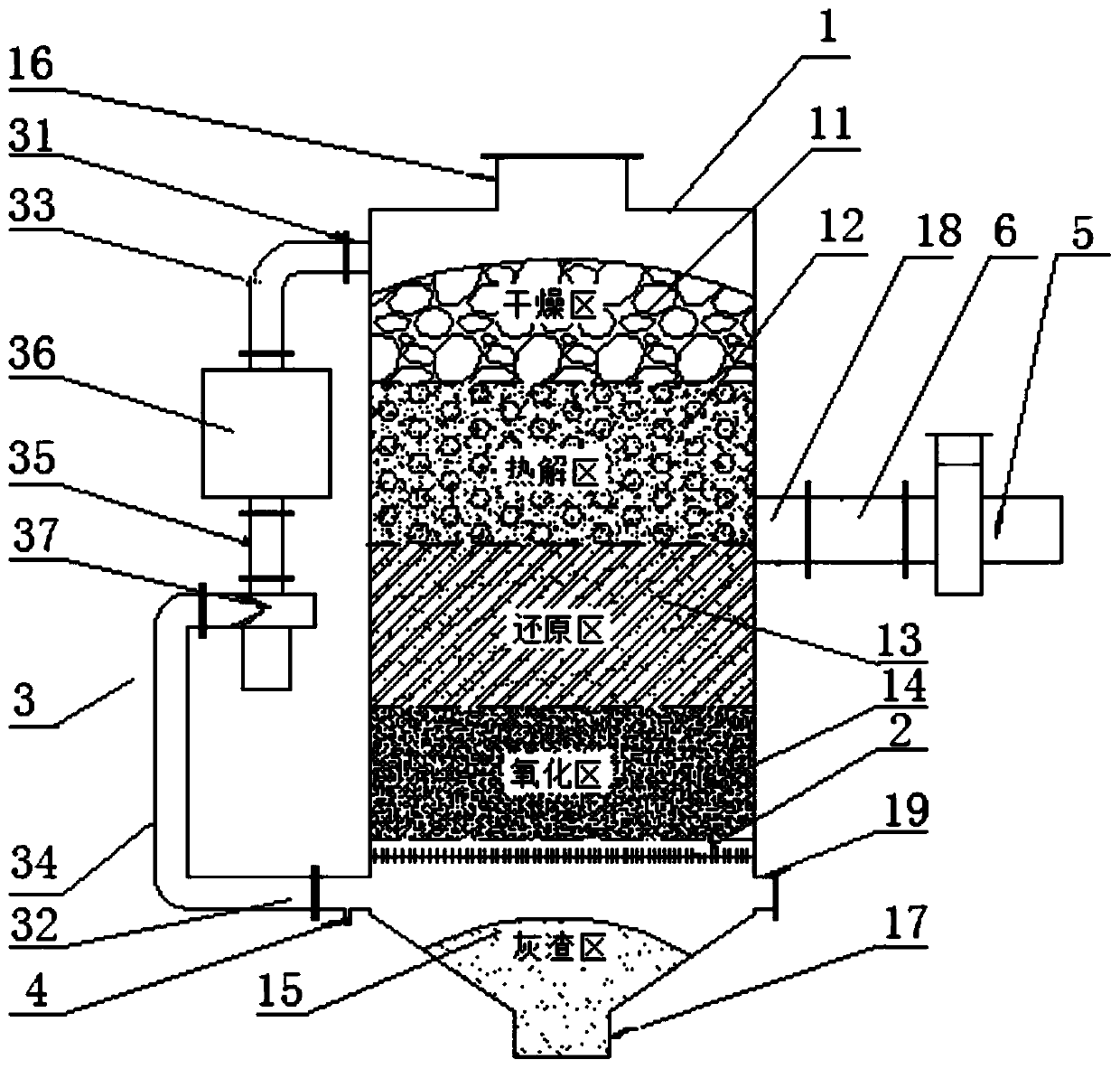

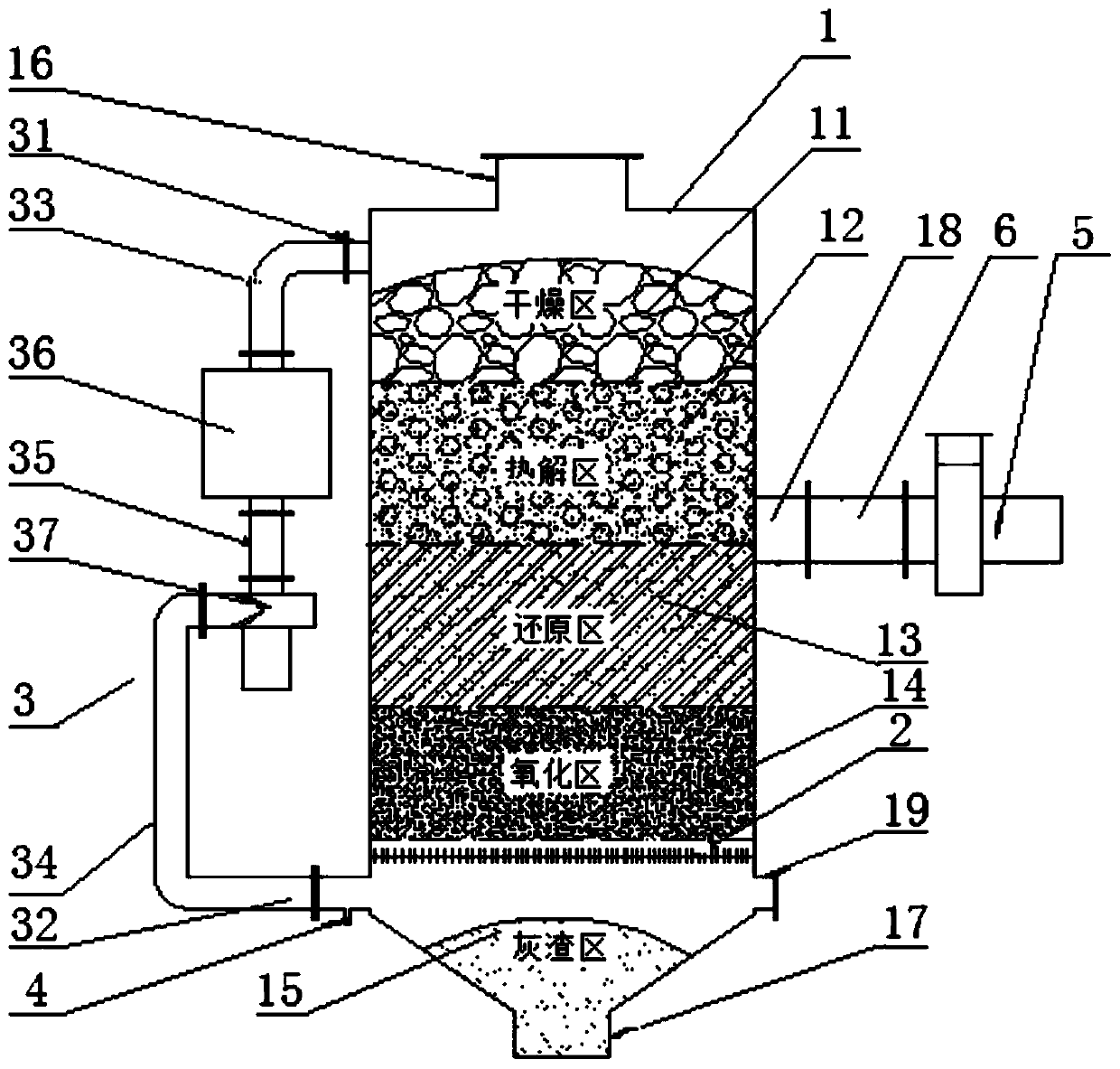

[0030] Such as figure 1 Shown is an embodiment of a domestic waste gasification device, including a gasifier 1 with a drying zone 11, a pyrolysis zone 12, a reduction zone 13, an oxidation zone 14, and an ash zone 15 from top to bottom; The top is provided with a feed port 16 for domestic garbage to enter, the bottom of the gasifier 1 is provided with an ash outlet 17, and the side wall of the gasifier 1 is provided with a gasification gas outlet 18, and the domestic garbage enters the drying zone 11 and the pyrolysis zone in turn. 12. The ash obtained after treatment in the reduction zone 13 and the oxidation zone 14 is discharged through the ash zone 15 through the ash outlet 17 and the obtained gasification gas is discharged from the gasification gas outlet 18; the junction of the oxidation zone 14 and the ash zone 15 A fire grate 2 is provided at the center, and a flashback device 3 that can dry and filter the gas is connected between the drying area 11 and the ash area 15...

Embodiment 2

[0035] This embodiment is an embodiment of the domestic waste gasification process, comprising the following steps:

[0036] S10. Domestic garbage enters the gasifier 1 through the feed port 16, and the moisture in the domestic garbage evaporates into water vapor in the drying zone 11;

[0037] S20. The domestic waste dried and processed in step S10 enters the pyrolysis zone 12 and the reduction zone 13 for pyrolysis and gasification reactions to produce combustible gas;

[0038] S30. The domestic garbage after the pyrolysis and gasification reaction in step S20 sinks into the oxidation zone 14, burns in the oxidation zone 14, and the heat generated by the combustion rises to supply the heat required for the reduction zone 13, the pyrolysis zone 12 and the drying zone 11, The ash produced by combustion enters the ash zone 15;

[0039] S40. The ash in the ash area 15 in step S30 is discharged through the ash outlet 17.

[0040] The domestic waste pyrolysis gasification reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com