Patents

Literature

51 results about "Backdraft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A backdraft is a rapid or explosive burning of superheated gasses in a fire, caused when oxygen rapidly enters an oxygen-depleted environment; for example, when a window or door to an enclosed space is opened or broken. Backdrafts present a serious threat to firefighters. There is some debate concerning whether backdrafts should be considered a type of flashover (see below).

Limited space fire blast simulation and explosion pressure relief and explosion suppression experiment platform and method

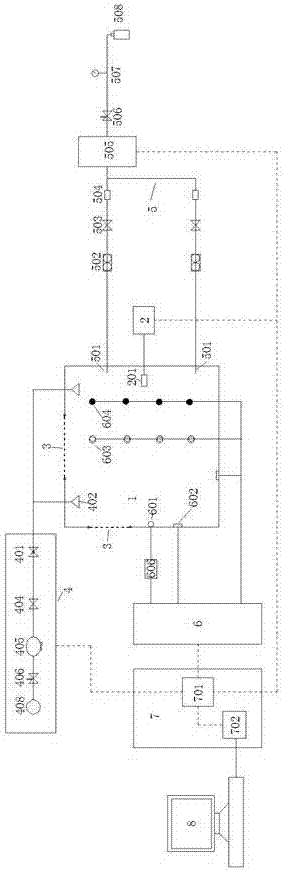

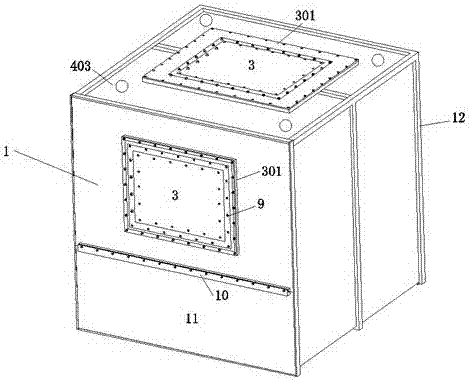

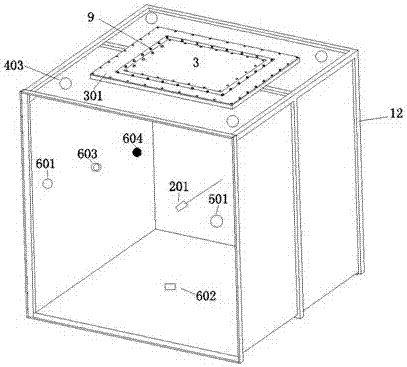

PendingCN107219258AImprove simultaneityImplement security inertnessMaterial exposibilityControl systemData acquisition

The invention discloses a limited space fire blast simulation and explosion pressure relief and explosion suppression experiment platform and a method. The platform comprises an experiment cabin, an ignition system, a suppressing system, a gas distribution system, a data acquisition system, a control system, and a computer, the experiment cabin, which is a three-dimensional cabin, is provided with inhibitor nozzles reserved on the top surface and window type explosion vents, a plurality of pressure relief membrane frames with different sizes which are of square boss structures are nested through high-strength bolts to form the window type explosion vent, and in a fire blast experiment, the window type explosion vents are arranged on the sidewalls of the experiment cabin; in a flashover and backdraft experiment, the sidewalls of the experiment cabin are arranged as door type explosion venting panels, and the door width can be adjusted by a high-strength bolt nesting method. The platform and the method can be adopted to carry out fire blast and explosion suppression experiments in the limited space of a building with real dimensions under different concentration distributions, different explosion venting conditions, different ignition positions and different explosion suppression conditions, providing related experimental parameters for the creation of explosion venting parameter prediction model in limited spaces of buildings and the proposal of a highly effectively explosion suppression technique.

Owner:TIANJIN FIRE RES INST

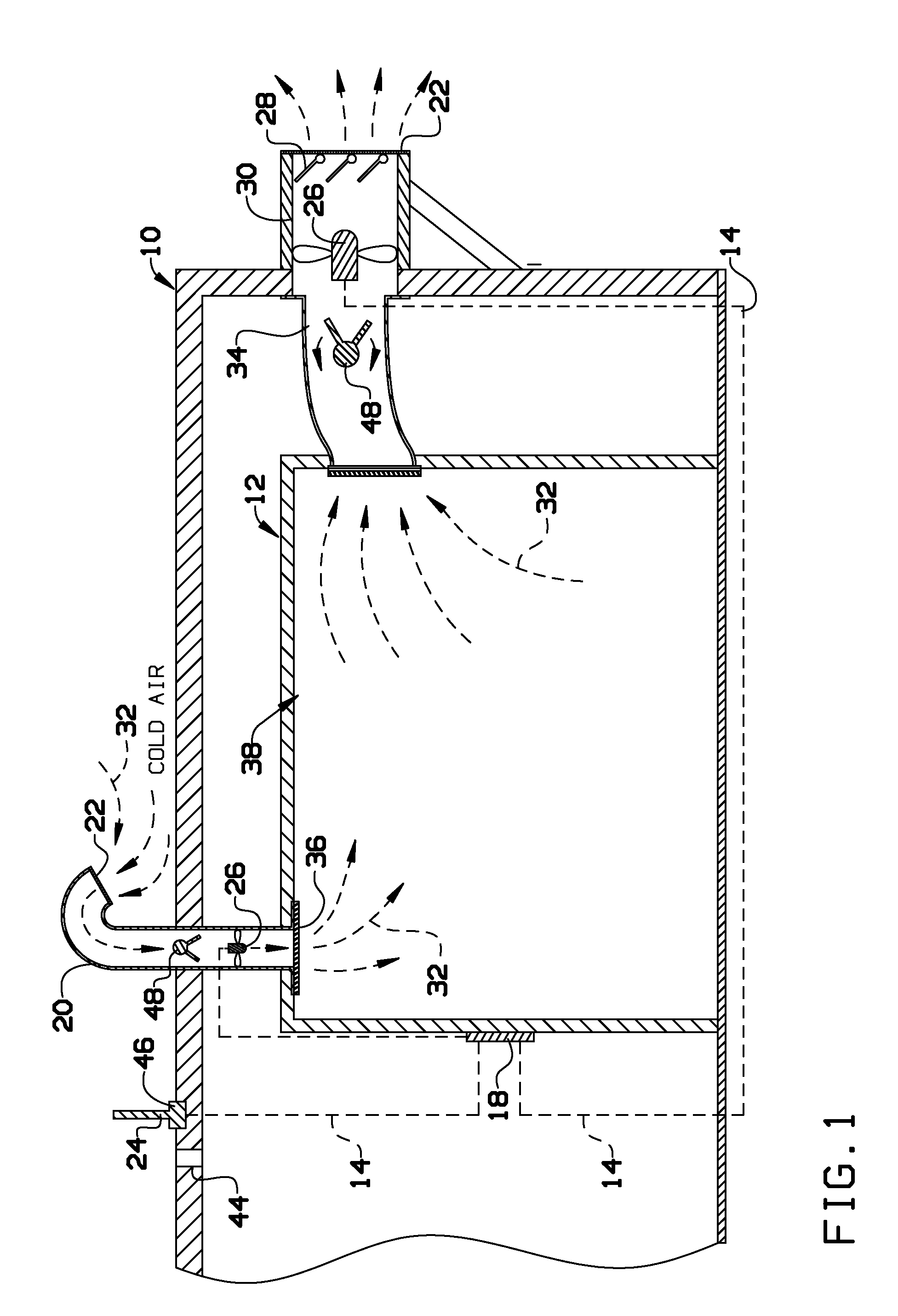

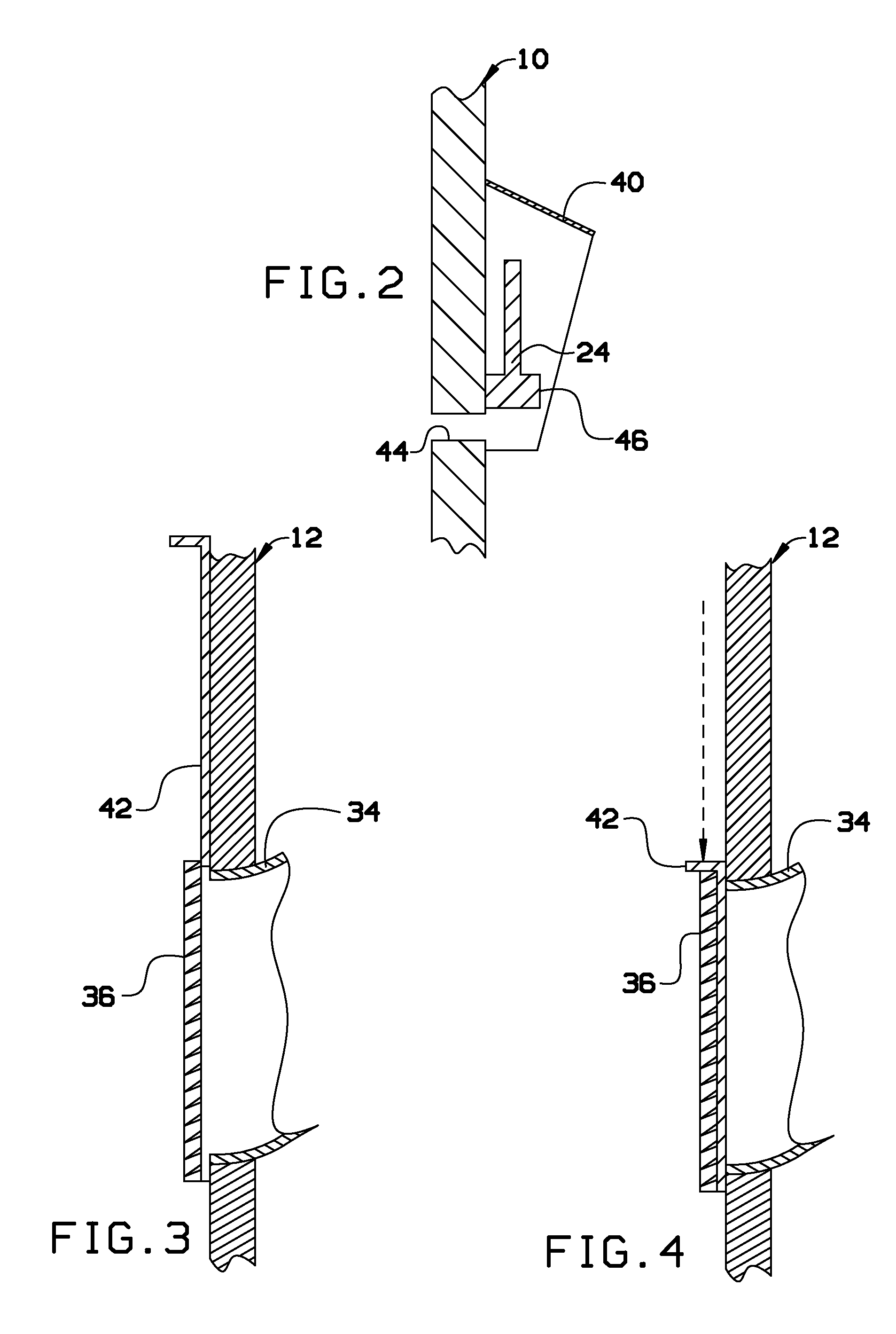

System using outdoor ambient air to cool walk in coolers and other areas

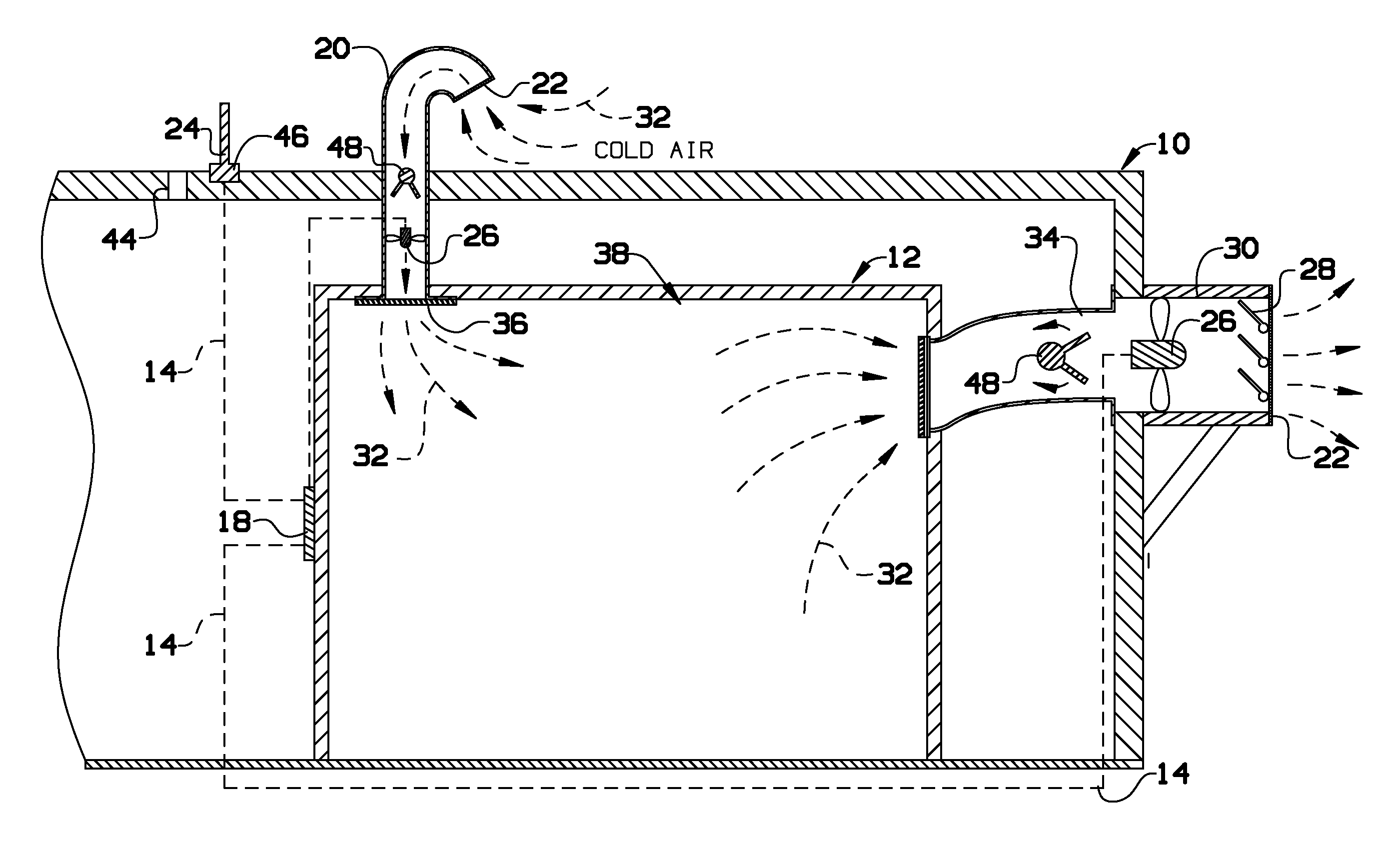

InactiveUS20130045671A1Mechanical apparatusSpace heating and ventilation safety systemsCold airBackdraft

A system cools a desired region, such as a walk-in cooler, by taking cool ambient outdoor air and delivering that air into the desired region. The system uses an outdoor temperature sensor so that any time the outdoor temperature falls below a desired degree, the thermostat can turn on fans and open backdraft dampers to bring in cold air. This process by-passes existing coolers, compressors and the like of an existing system, saving the user the high cost associated with conventional walk-in coolers.

Owner:APPLE TERRY JAY +1

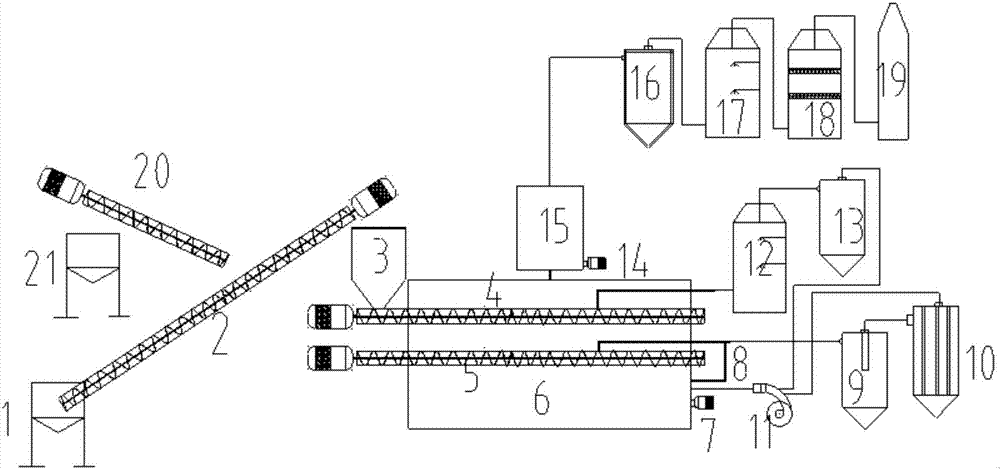

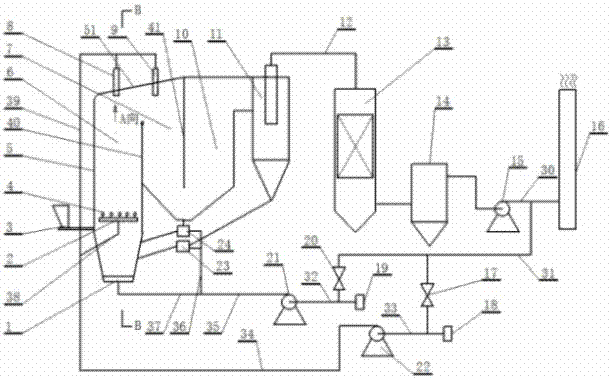

Movable integrated device and method for oil sludge pyrolysis resource treatment

PendingCN107382007AWith dry pyrolysis functionIncrease flexibilitySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustion chamberWater vapor

The invention discloses a movable integrated device for oil sludge pyrolysis resource treatment. The movable integrated device comprises a closed bin, wherein the closed bin supplies materials to a drying chamber through a sealing feeding device by passing through a sealing transition bin; the water vapor and the waste gas generated by the drying in the drying chamber are supplied as air supply to a combustion chamber through a washing tower, a waste gas demisting and separation device and an induced draft fan; the oil sludge dried in the drying chamber is supplied to a pyrolysis chamber for pyrolysis; the pyrolysis gas generated by the pyrolysis in the pyrolysis chamber is supplied as a fuel to the combustion chamber through a backdraft device or enters to a separation and condensation system to recycle light oil content; the residue generated by the pyrolysis in the pyrolysis chamber is fed into a residue storage box through a discharge device; the smoke generated in the combustion chamber is supplied to a heat exchanger with a dust removal function; the hot water generated in the heat exchanger is supplied to a feed system to heat the feeding materials or supply the materials outside; the smoke reaches the standard through a purifying system and is discharged outside. The invention also provides a corresponding treatment method which can realize reducing, harmless and clean treatment as well as resource economic recycling of the oil sludge, and is of great significance to the treatment of disperse sludge.

Owner:王凯军 +2

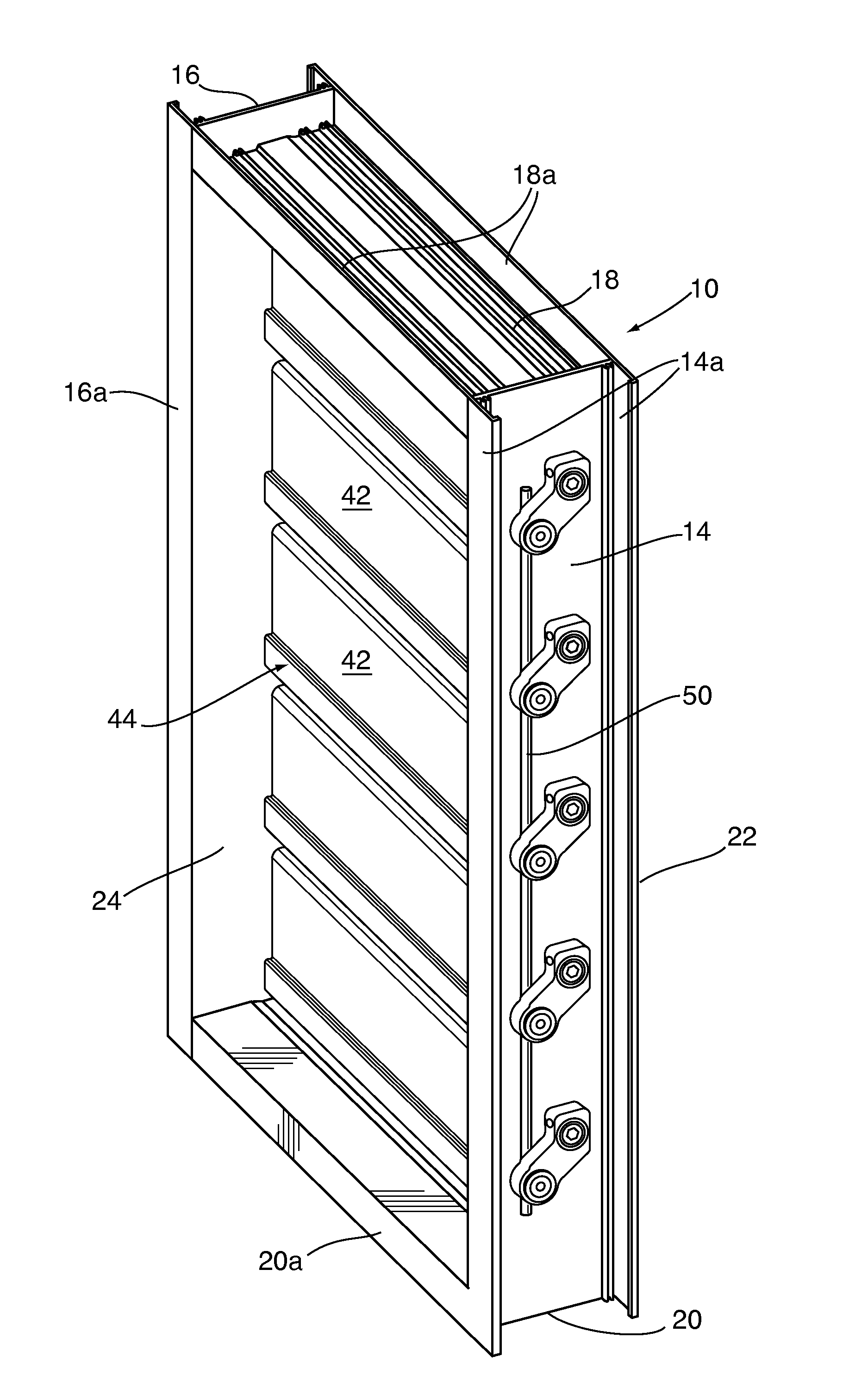

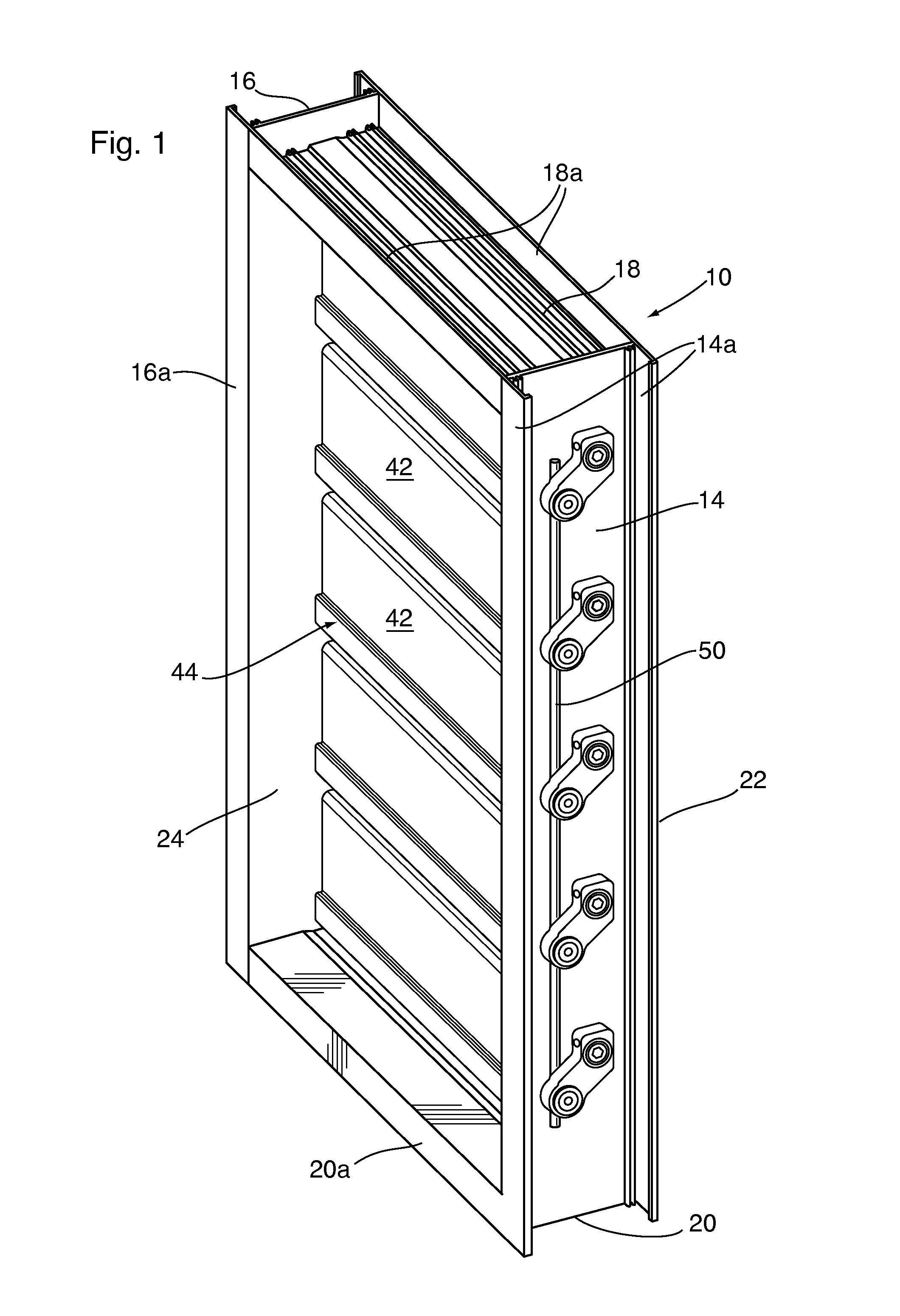

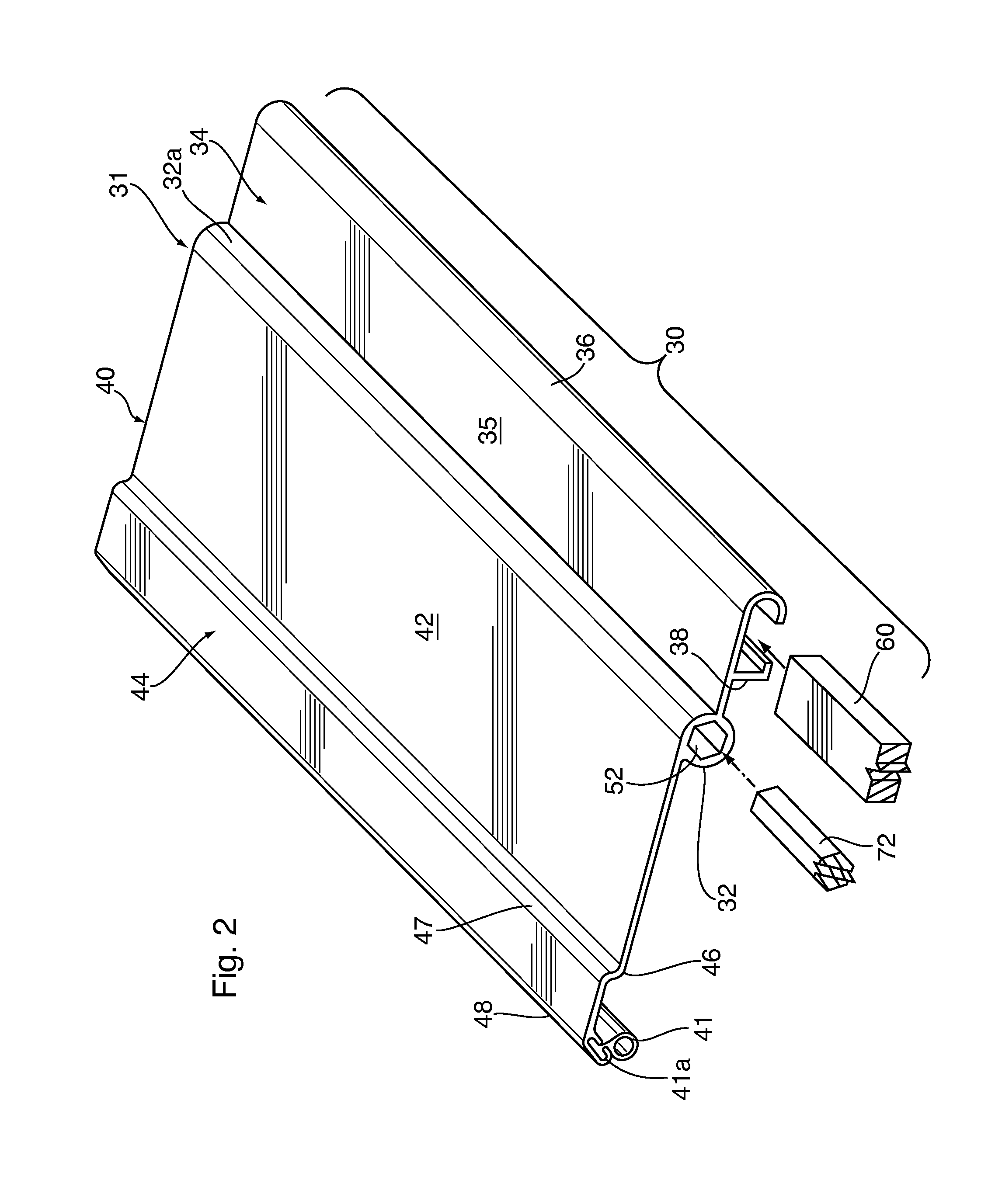

Counterweighted backdraft damper blade with improved airflow profile

ActiveUS20160265806A1Even airflowMaximize the transverse openingLighting and heating apparatusAir-flow control membersEngineeringBackdraft

A backdraft damper for permitting a flow of air in an outflow direction and preventing the flow of air in a backdraft direction has a frame provided with a transverse opening allowing the passage of air through the frame. One or more blades extend across the frame and are mounted to the frame about a central portion by pivot members, for rotation between open and closed positions. Each blade comprises a blade body having a leading portion upstream of the central portion, the leading portion of the blade body comprising a channel, a trailing portion downstream of the central portion, the trailing portion of the blade having a larger surface area than the leading portion and comprising a seal disposed adjacent to a distal edge of the trailing portion, for sealing against either the leading portion of an adjacent blade or a blade stop projecting from the frame, and a counterweight disposed in the channel, whereby the counterweight balances the blade such that the blade is biased to the closed position by gravity and movable to the open position by the force of air flowing through the frame in the outflow direction.

Owner:T A MORRISON & CO INC

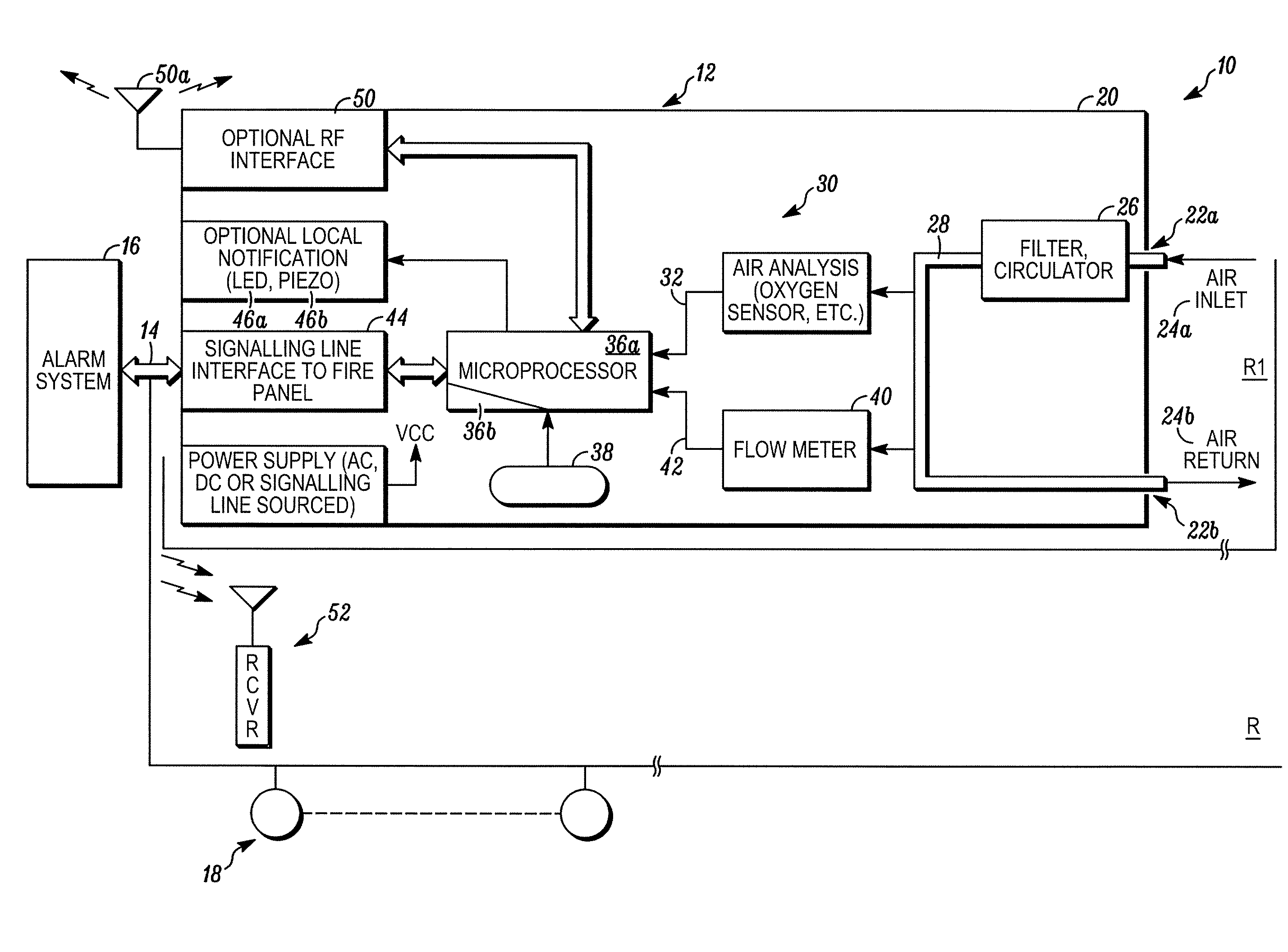

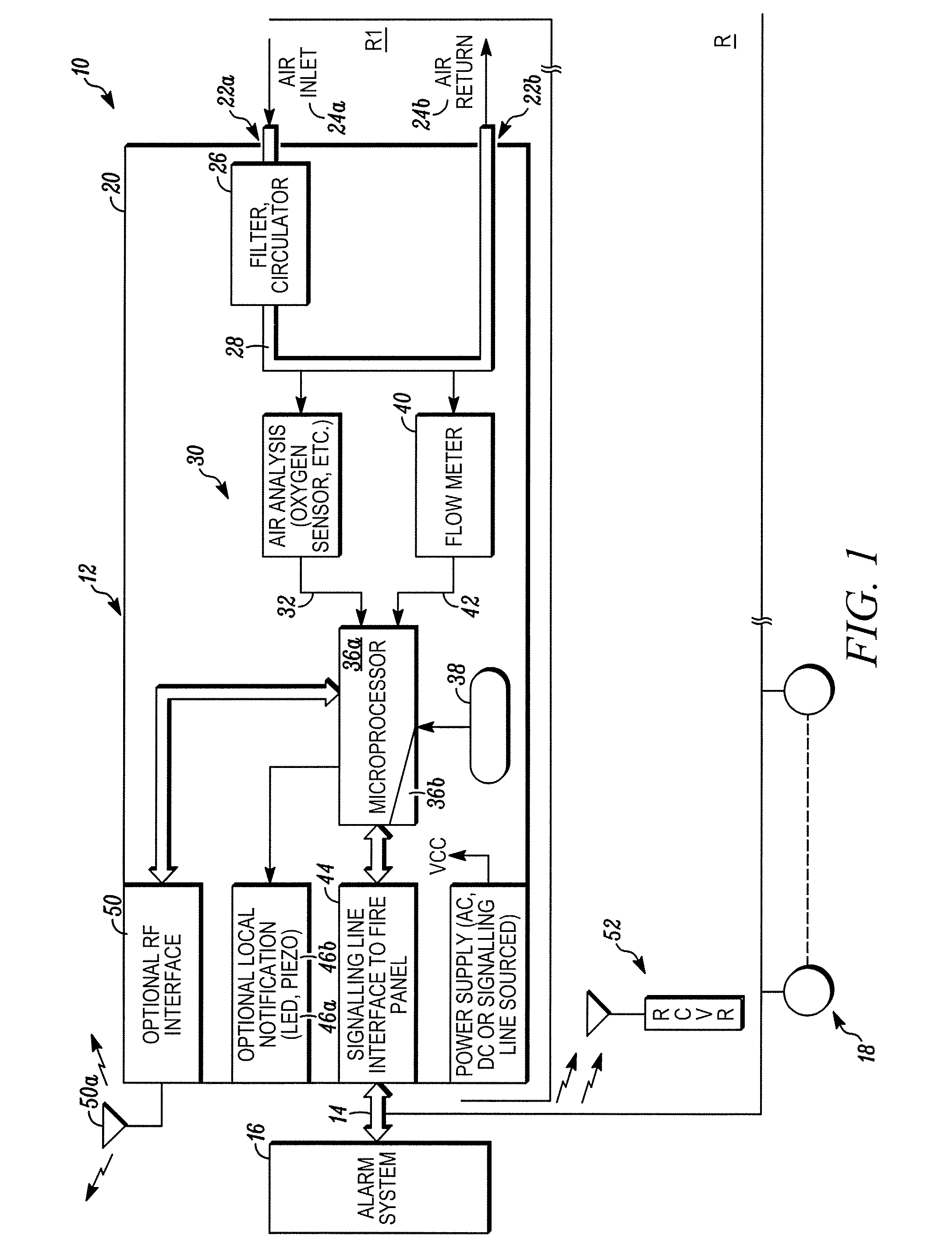

Backdraft Detector

InactiveUS20080048853A1Reduce riskMinimize particulate interferenceFire alarm smoke/gas actuationOxygen sensorBackdraft

Owner:HONEYWELL INT INC

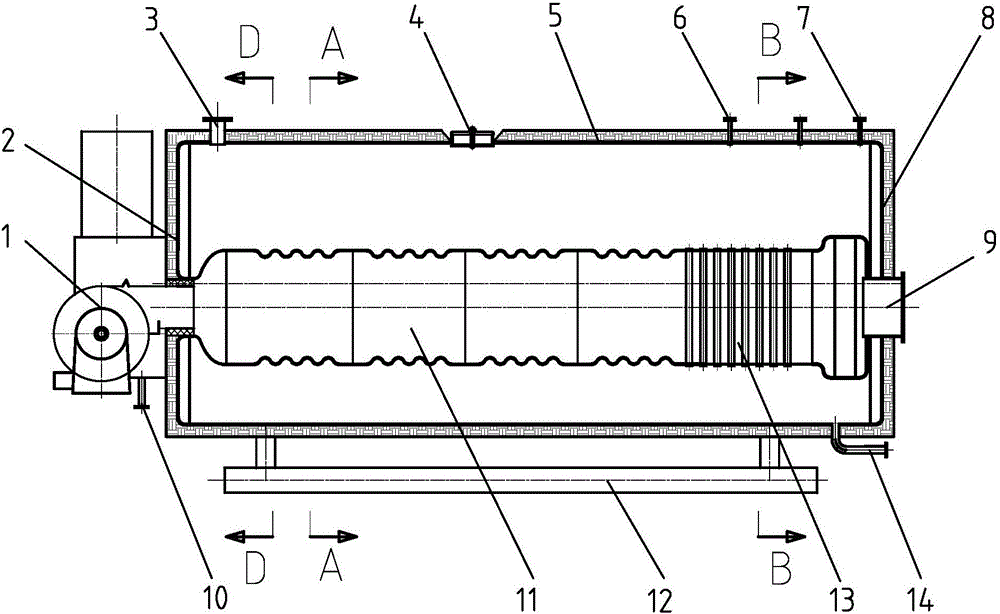

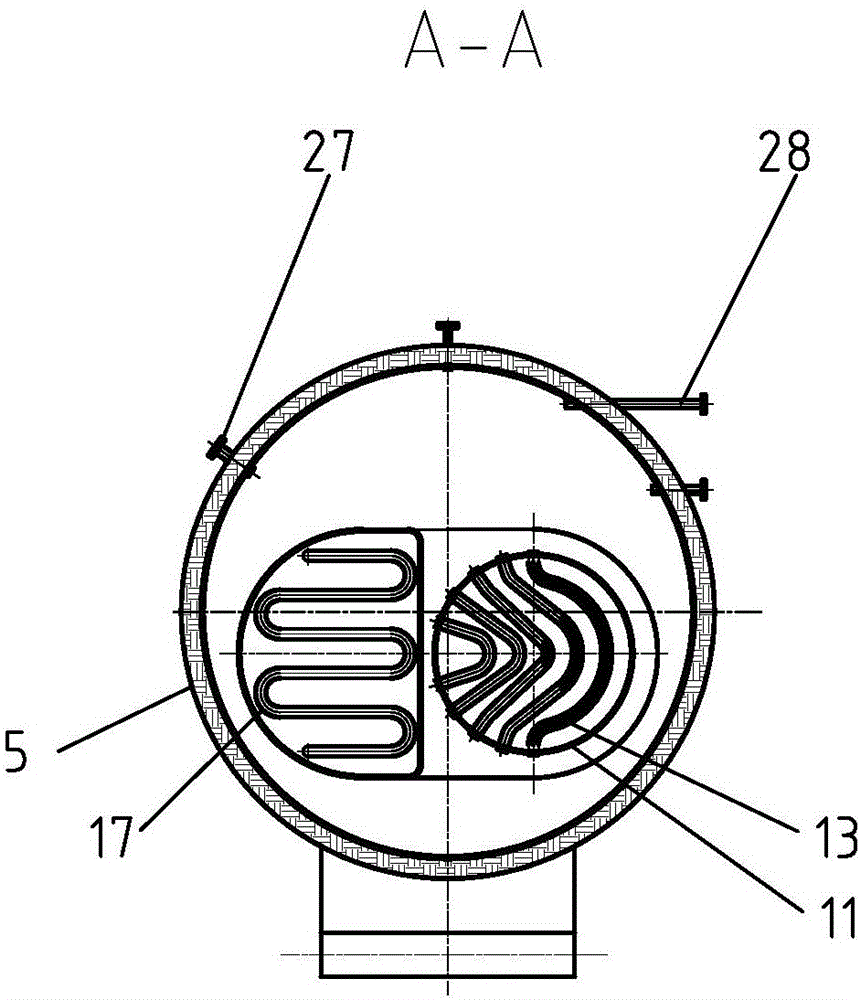

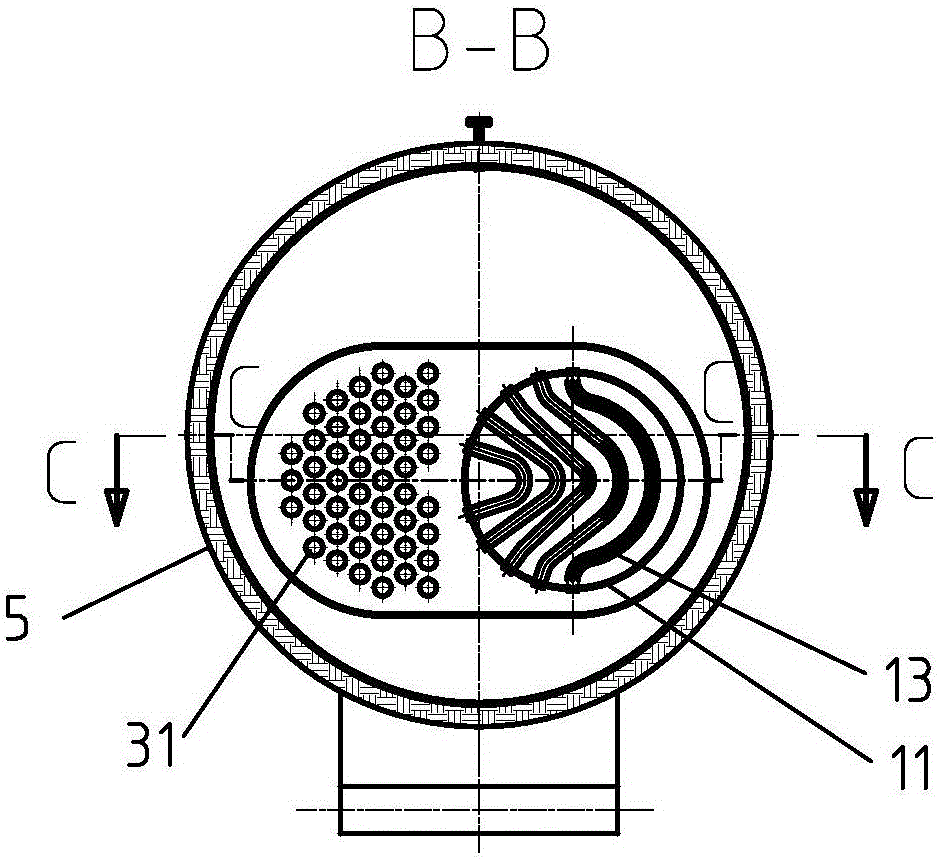

Multi-return-stroke gas-steam boiler

ActiveCN105042557AImprove efficiencySimple processIndirect carbon-dioxide mitigationFire-tube steam boilersCombustorHearth

The invention discloses a multi-return-stroke gas-steam boiler. The multi-return-stroke gas-steam boiler comprises a hearth. The front end of the hearth is connected with a burner. A steam outlet is formed in the top of the hearth. The upper portion of a backdraft chamber at the tail end of the hearth is communicated with a second-return-stroke smoke pipe. The other end of the second-return-stroke smoke pipe is communicated with a front smoke box. The front smoke box is communicated with a rear smoke box through a third-return-stroke smoke pipe. The front smoke box is divided into an upper front smoke box and a lower front smoke box. The third-return-stroke smoke pipe is communicated with the lower front smoke box. The rear smoke box and the upper front smoke box are communicated through a fourth-return-stroke smoke pipe. An annular air box is arranged on the periphery of the front smoke box and communicated with an inlet of the hearth through a hot air pipe. The steam outlet is communicated with the inlet of the hearth through a steam pipe. The fourth-return-stroke smoke pipe and the annular air box are additionally arranged, a proper amount of high-temperature steam is injected, so that burning in the hearth is improved, the maximal flame temperature is reduced, and therefore high-temperature oxynitride is reduced, the efficiency of the boiler is greatly improved, and meanwhile emission of harmful gas is reduced.

Owner:ZHEJIANG SHANGNENG BOILER

Chemical waste gas treatment device and treatment technology

ActiveCN104138705AAvoid enteringEasy to handleUsing liquid separation agentIncinerator apparatusTreatment effectPorous medium

The invention discloses a chemical waste gas treatment device. The device comprises an anti-explosion container, a gas mixer, a plasma reactor and a catalytic combustion reactor which are all connected in sequence. The anti-explosion container comprises a water containing body, a gas inlet pipe stretching into liquid of the containing body and a gas outlet pipe arranged on the top of the containing body. The catalytic combustion reactor is composed of a front segment filled with the CO catalyst and a rear segment filled with a porous medium. The invention further discloses a technology for treating chemical waste gas through the device. The mode that the plasma reactor and the catalytic combustion reactor are combined is adopted for the device, so that the waste gas treatment effect of the whole device is improved; the anti-explosion container is further arranged on the upstream of the gas mixer, air is prevented from flowing back, backdraft flames generated in reaction in the plasma reactor or the catalytic combustion reactor are prevented, and the safety of the device is improved; water-soluble organic pollutants in waste gas are dissolved in water in the anti-explosion container, and thus the waste gas treatment effect of the device can be improved easily.

Owner:ZHEJIANG UNIV +1

Flow actuated flap valve

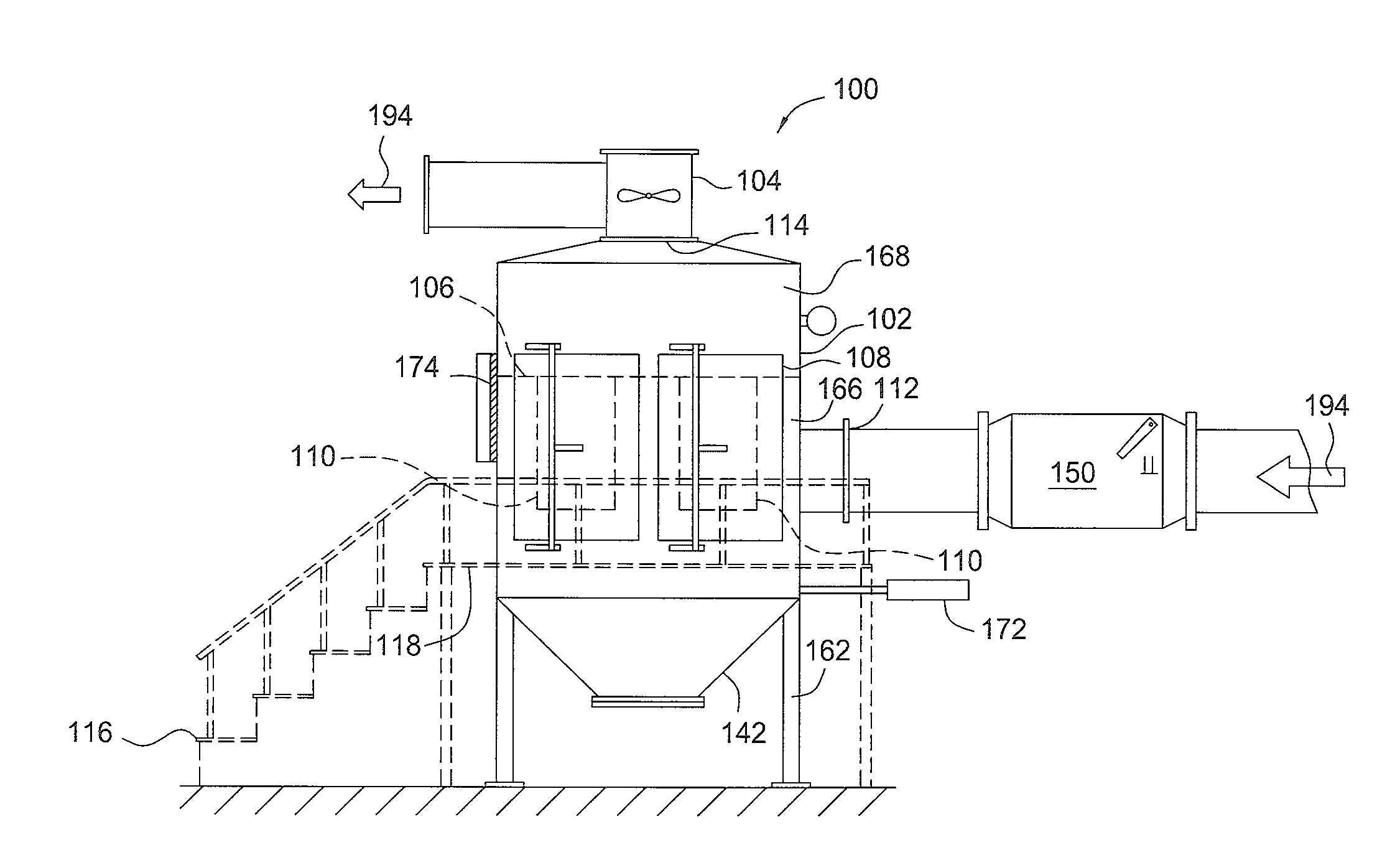

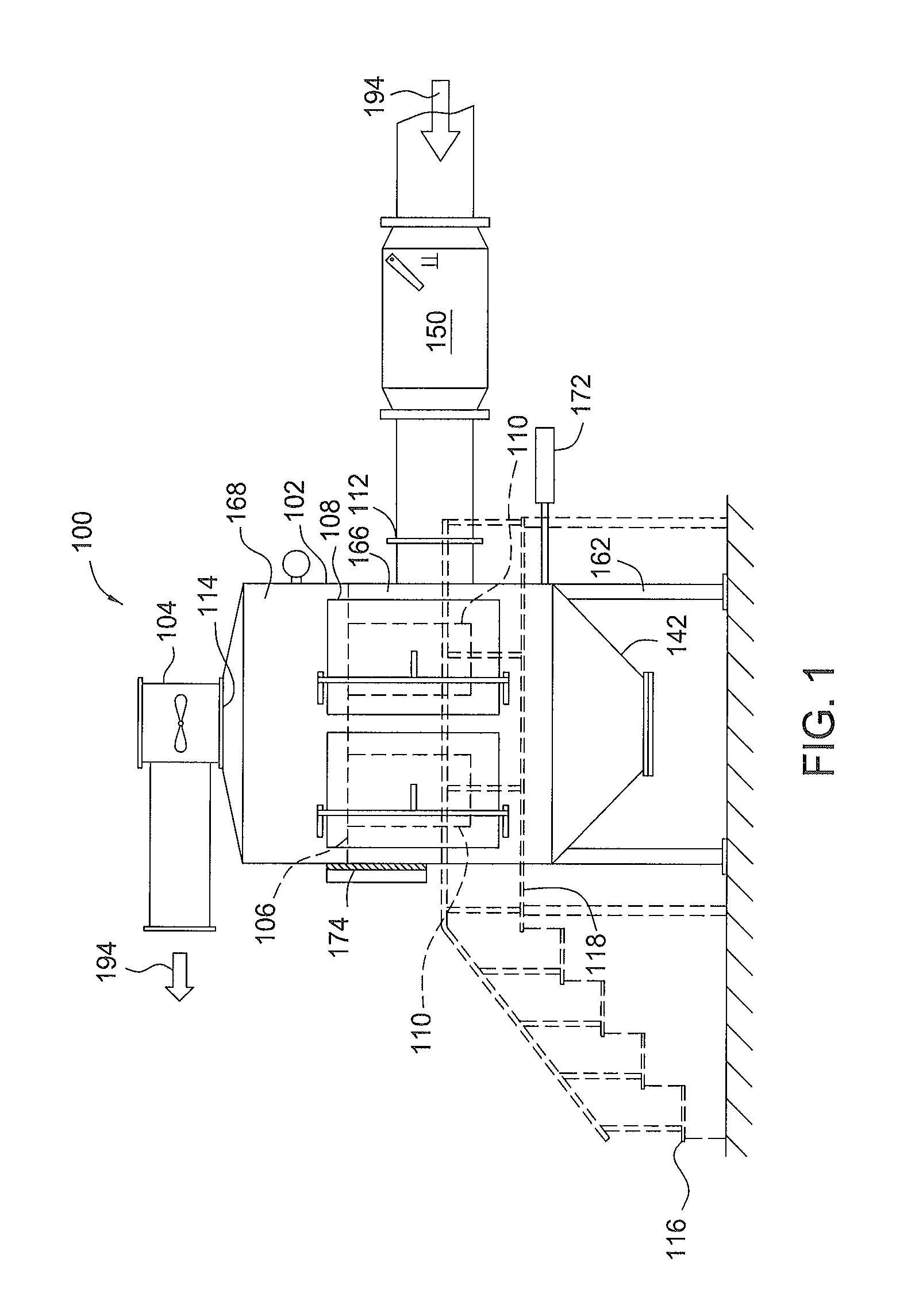

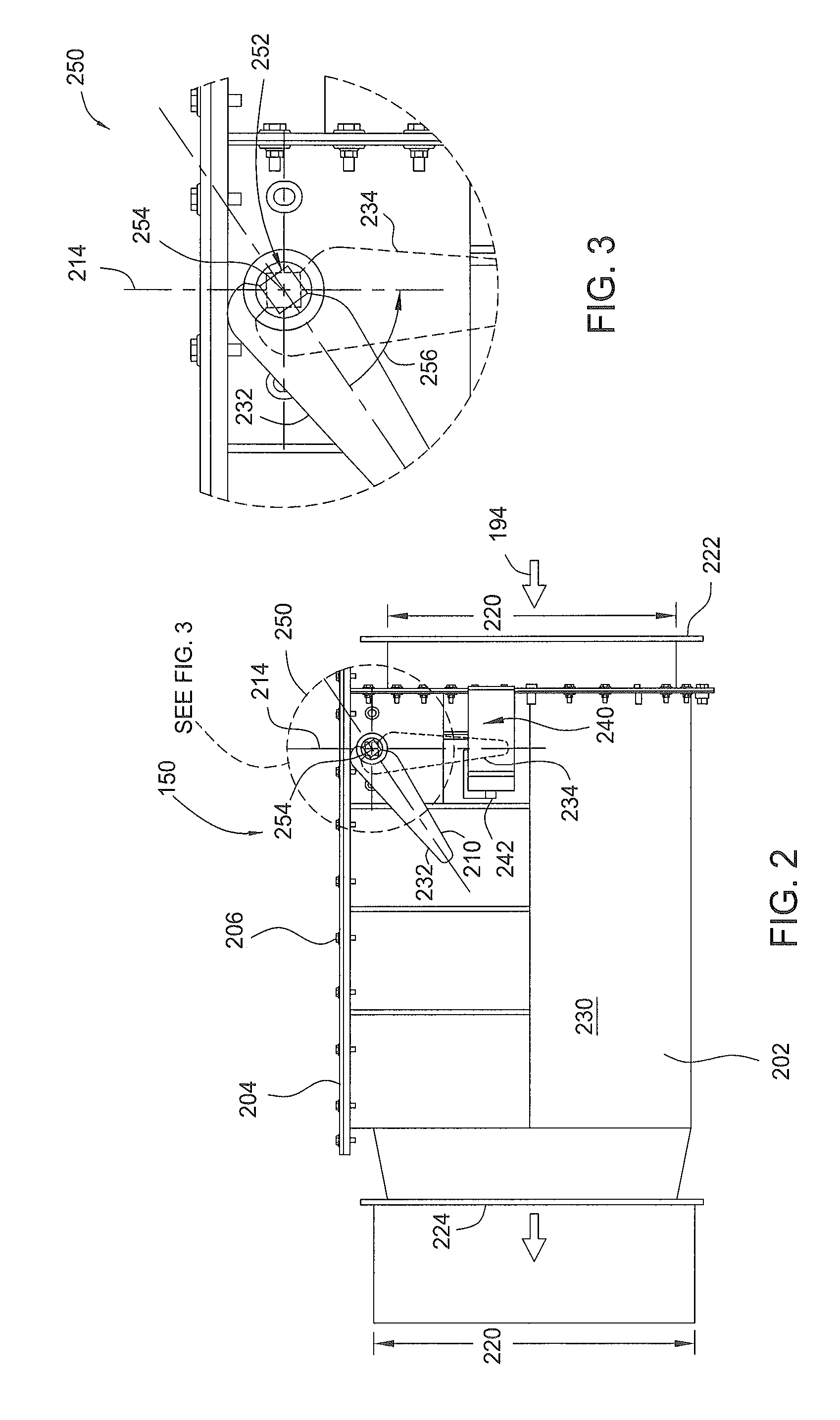

InactiveUS20150276245A1Preventing pressure wavePrevent pressureCombination devicesMechanical apparatusEngineeringBackdraft

The present invention generally relates to a backdraft damper having a flap valve, a dust collector having a backdraft damper and a method for preventing a pressure wave from propagating upstream of a dust collector. In one embodiment, a backdraft damper is provided that includes a body having a flap valve disposed therein. The flap valve includes a valve seat disposed in an interior volume of the body. The flap valve includes a blade movable between an open position and a closed position which prevents fluid flow between an inlet and an outlet of the body. The blade of the flap valve includes a core material sandwiched between a first plate and a second plate.

Owner:CAMFIL USA

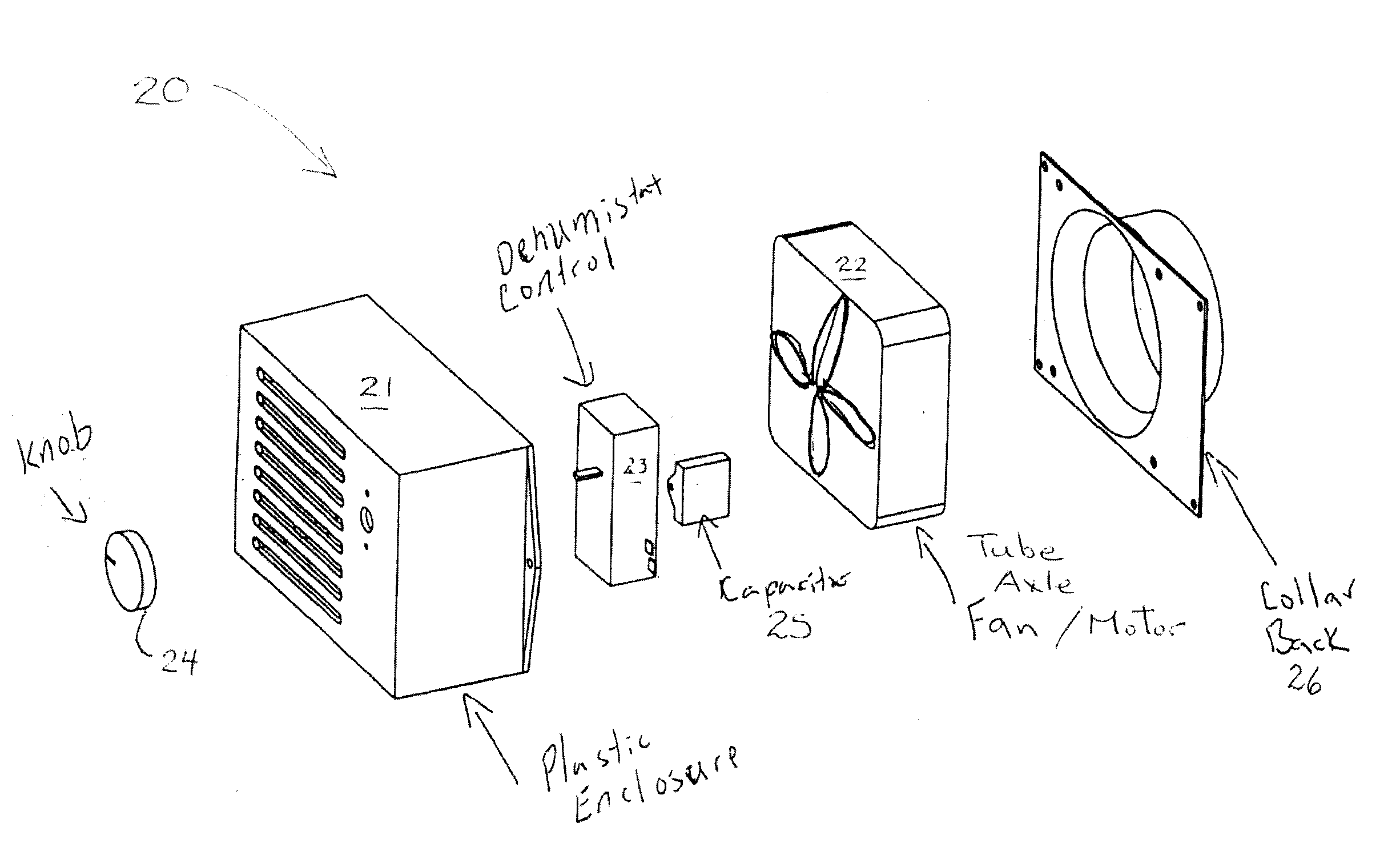

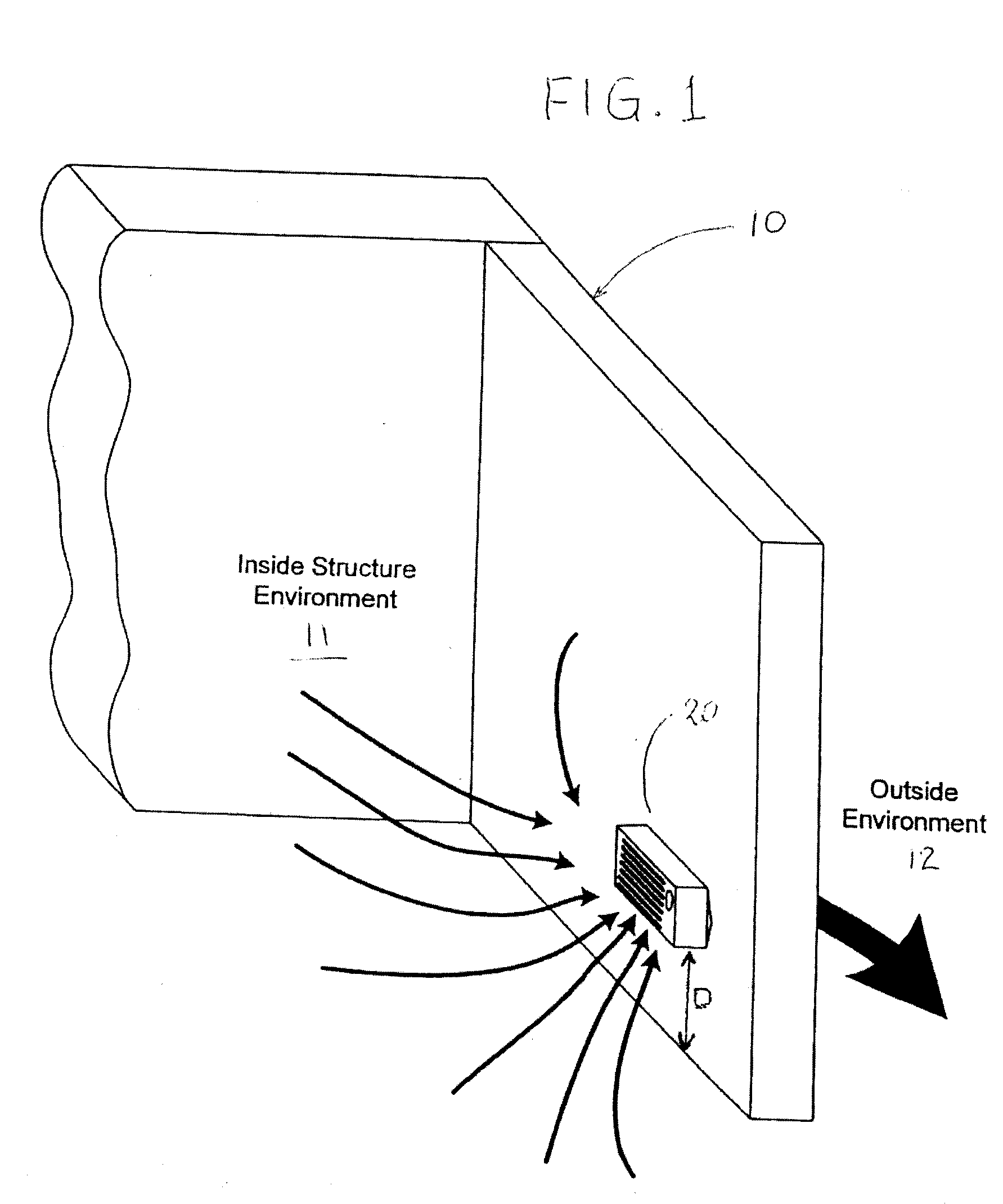

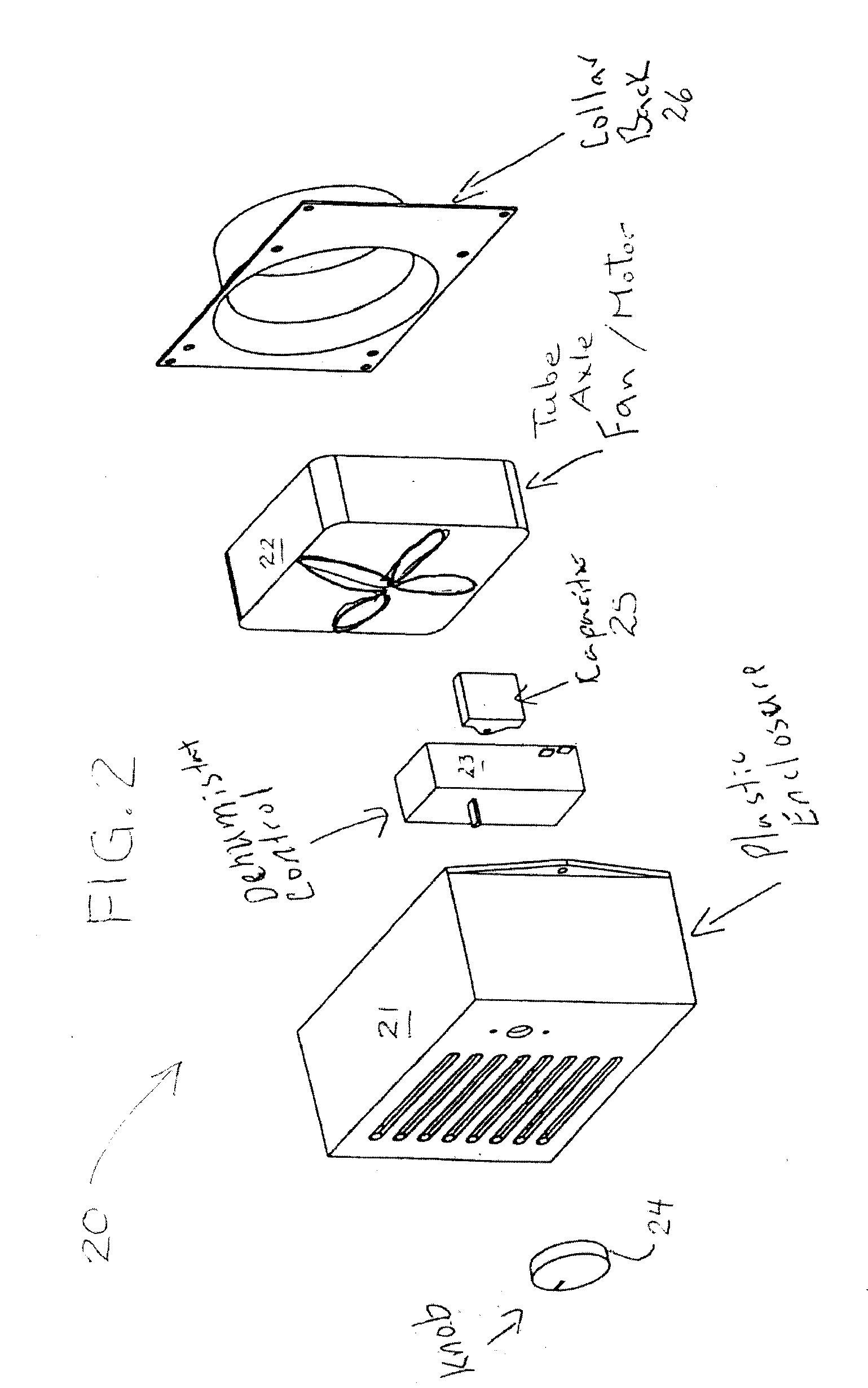

Ventilator Device For Dehumidification

InactiveUS20070158443A1Reduce humidityReduce condensationMechanical apparatusSpace heating and ventilation safety systemsMaximum ventilationGreenhouse

A ventilation device and the method of use thereof for dehumidification of residential attached or detached garages, sheds, greenhouses, RVs, motorhomes and other similar structures. This device and method uses an extraction ventilator to dry out the structure's environment, and reduce the interior humidity using a motorized fan to expel moisture latent air out of the structure. The fan continuously runs at minimal speeds to continuously exhaust interior air and ventilate the structure, thereby controlling the garage environment, while eliminating backdrafts, and preventing animals, snow and rain from entering the structure. The device uses a dehumidistat control to activate the fan to maximum ventilation capacity when the humidity reaches the set point, exhausting ambient air and extracting excess humidity from the structure. Once the humidity drops below the set point, the dehumidistat deactivates and returns the ventilator to minimum speed operator.

Owner:AIR TECH EQUIP

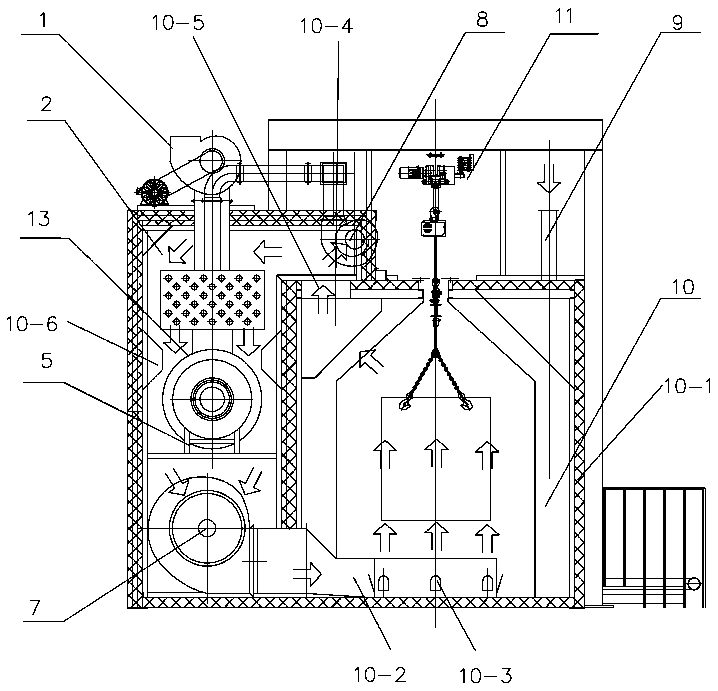

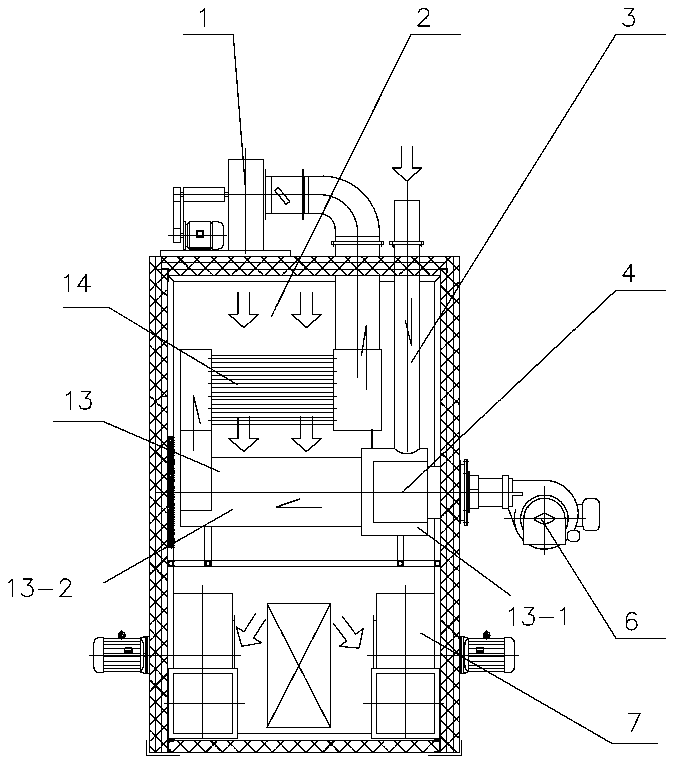

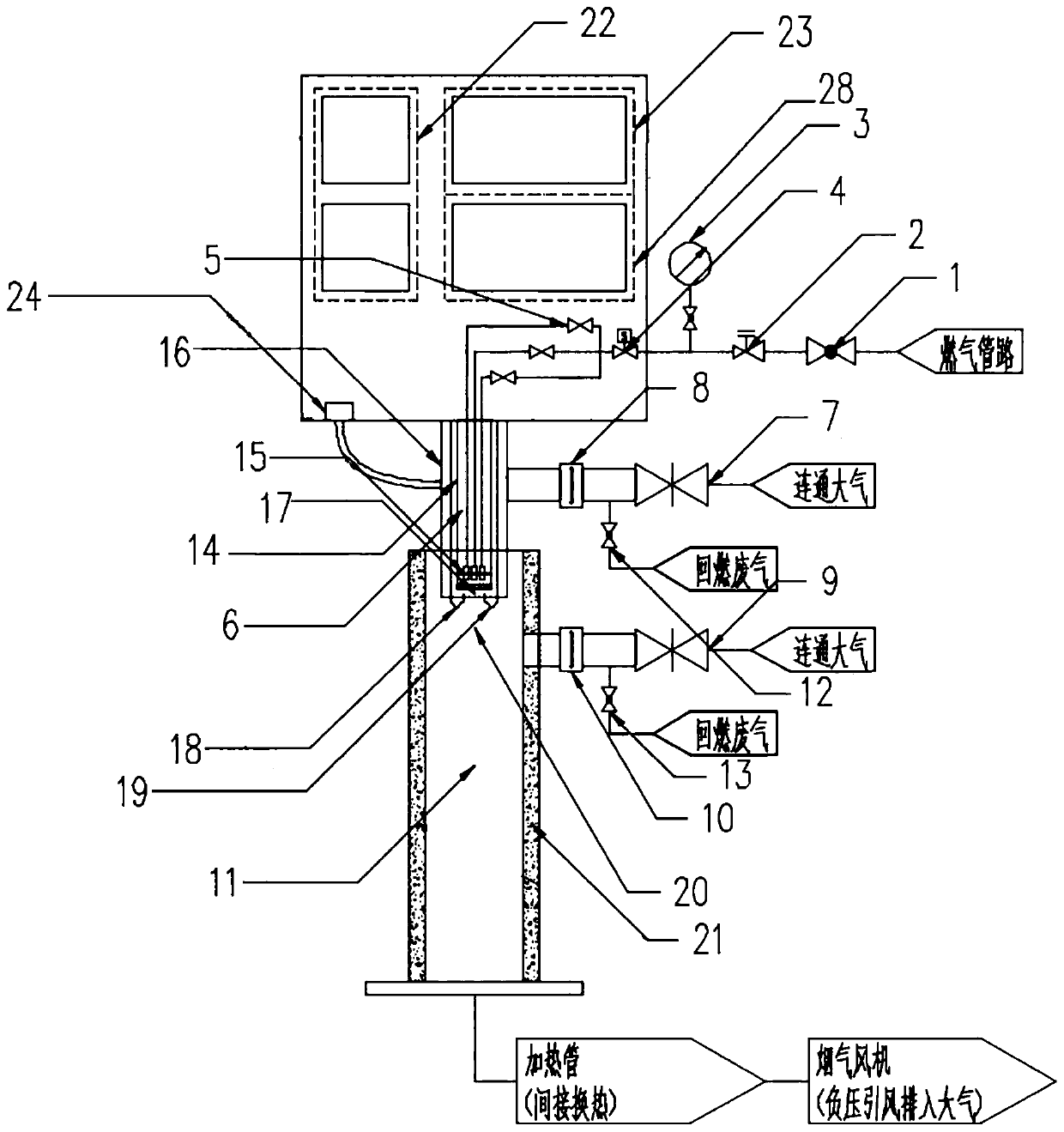

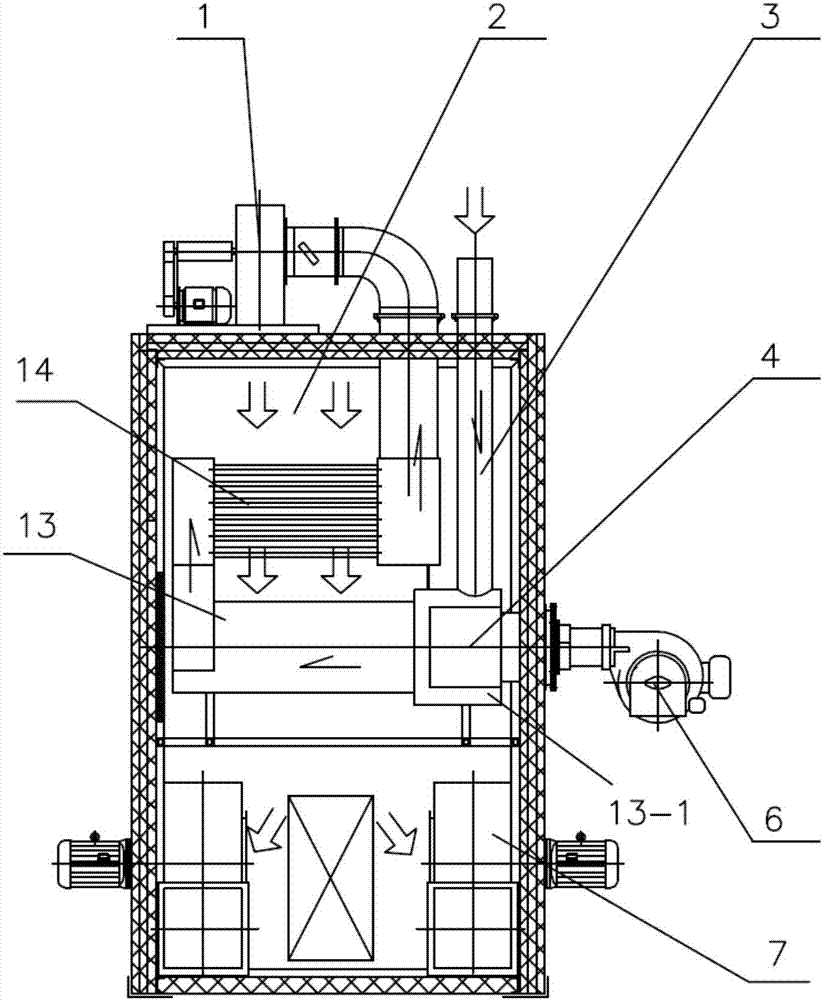

Multielement recirculation furnace with function of waste gas backdraft incineration

ActiveCN105509457AEfficient use ofMeet environmental protection requirementsDrying gas arrangementsDrying solid materialsCombustion chamberExhaust fumes

The invention belongs to the technical field of environment-friendly coating facilities and relates to a multielement recirculation furnace with a function of waste gas backdraft incineration. A heating head is arranged on one side of a recirculation furnace body, and a furnace top chamber and a waste gas backdraft blower are arranged above the furnace body. Circulating fans are mounted on two sides of the bottom of the heating head respectively, and an air return pipe is arranged on the upper portion of the furnace body and communicated with the upper portion of the heating head. A heat exchange cylinder externally sleeves a combustion chamber which is arranged on one side of the middle portion of the heating head, the heat exchange cylinder is communicated with one end of a horizontal tubular heat exchanger on the upper portion of the heating head, and the other end of the horizontal tubular heat exchanger is communicated with an inlet of a waste gas exhaust fan. An inlet of the waste gas backdraft blower is communicated with the furnace top chamber, and an outlet of the waste gas backdraft blower is connected to a position, corresponding to the combustion chamber, of the heat exchange cylinder through a connection pipe. The multielement recirculation furnace with the function of waste gas backdraft incineration has the advantages that the waste gas is preheated and incinerated completely prior to emission, so that the requirement on environment friendliness can be met; heat generated in incineration can be used for heat exchange of hot air circulation, combustible components in the waste gas are used effectively, and energy-saving effects are achieved.

Owner:明泉历升涂装工程(南京)有限公司

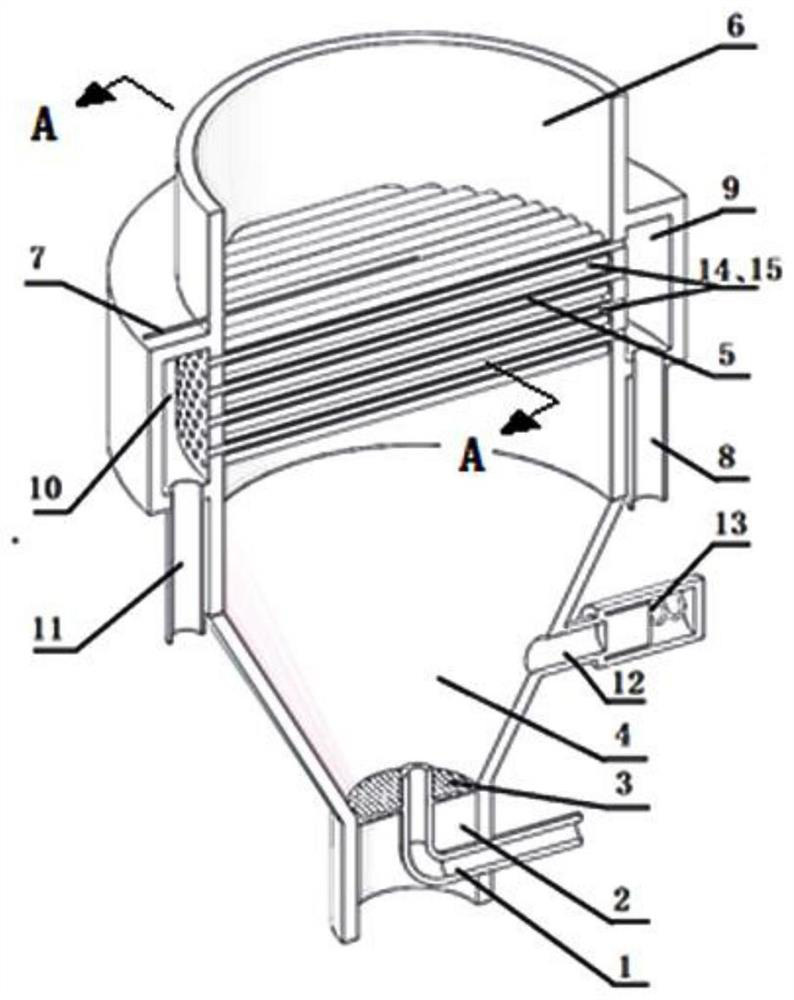

Water-fire tube gas-steam boiler with built-in condenser

InactiveCN106500318ASmall diameterCompact structureAir heatersSustainable buildingsBoiler furnaceCombustor

The invention provides a water-fire tube gas-steam boiler with a built-in condenser, and relates to a gas-steam boiler. An existing smoke-fire tube steam boiler has the problems that the structure occupies large floor area, potential safety hazards exist in the operation process, and steel consumption is high in the using process. The water-fire tube gas-steam boiler comprises a combustor, a steam tube base, a shell, a boiler furnace, a smoke tube assembly, a backdraft chamber, a condensation chamber and a smoke box; the boiler furnace, the smoke tube assembly, the backdraft chamber and the condensation chamber are all arranged in the shell, the combustor is arranged outside the shell and communicates with an inlet of the boiler furnace, an outlet of the boiler furnace communicates with an inlet of the backdraft chamber, an outlet of the backdraft chamber communicates with an inlet of the smoke tube assembly, an outlet of the smoke tube assembly communicates with an inlet of the condensation chamber, the smoke box is arranged outside the shell and communicates with an outlet of the condensation chamber, a smoke outlet is formed in the smoke box, multiple convection banks are arranged in the boiler furnace, condensation tube bundles are arranged in the condensation chamber, and the shell communicates with the steam pipe tube base. The water-fire tube gas-steam boiler is used for generating steam.

Owner:HARBIN INST OF TECH

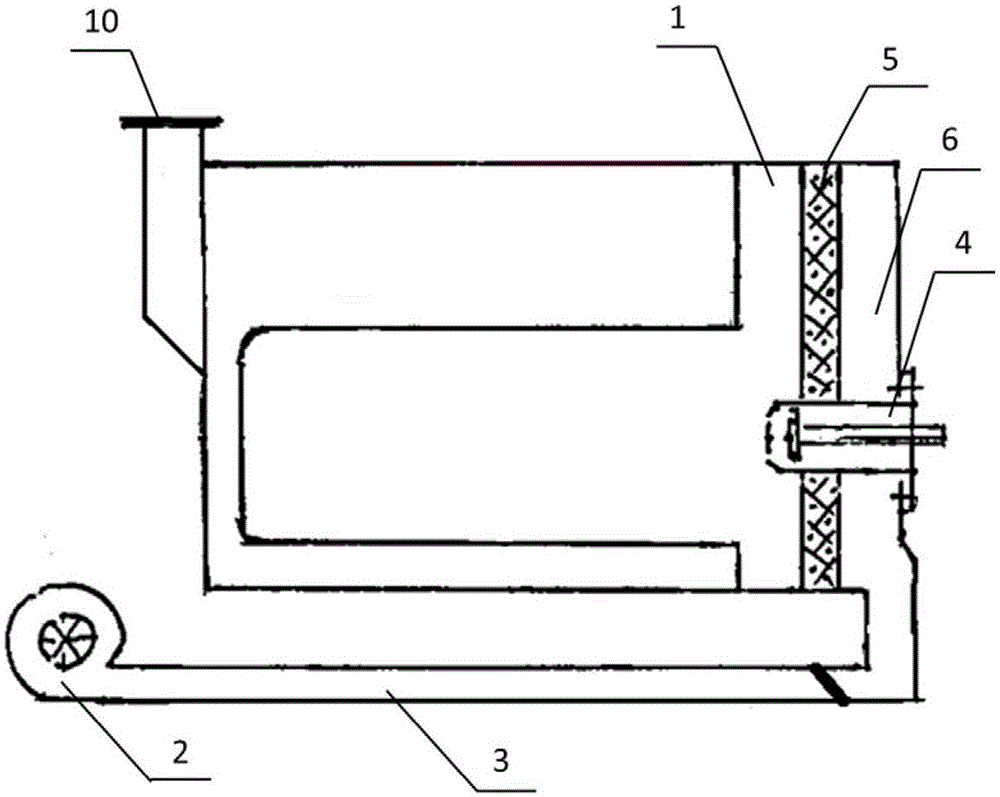

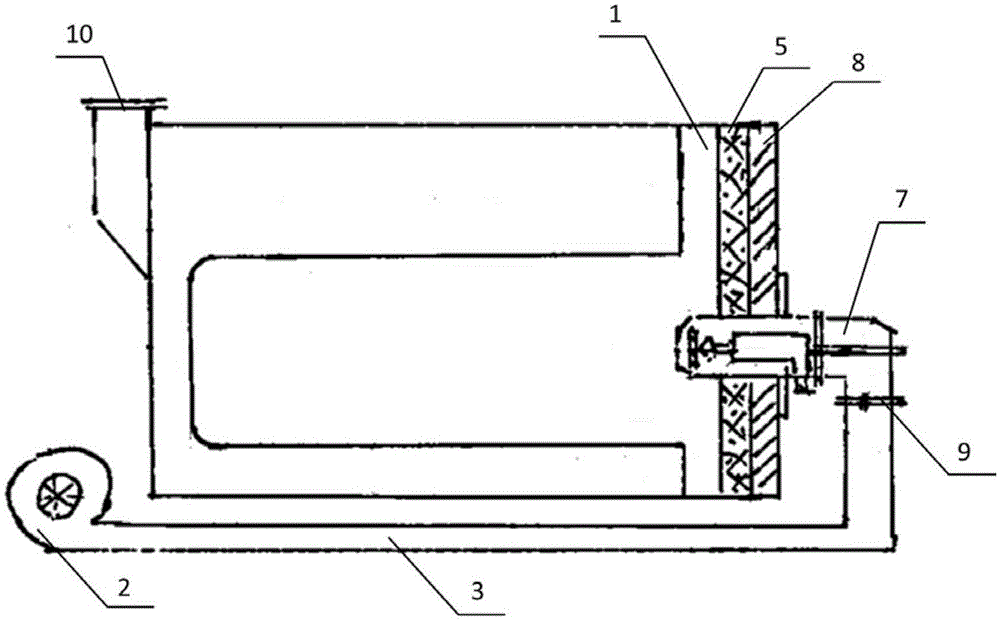

Smoke backdraft multi-flow low-NOx horizontal circulating fluidized bed boiler

ActiveCN107084387ALower the altitudeLow costFluidized bed combustionStaged combustionCombustion chamberBackdraft

A smoke backdraft multi-flow low-NOx horizontal circulating fluidized bed boiler comprises a primary air chamber, a main combustion chamber, an auxiliary combustion chamber and the like. The lower portion of a side wall of the main combustion chamber is provided with lower secondary air nozzles, and the bottoms of the lower secondary air nozzles are provided with a lower secondary air bellow. A ceiling is provided with an overhead central secondary air spray pipe and an overhead curtain secondary air spray pipe which are located at the top of the main combustion chamber and the top of the auxiliary combustion chamber correspondingly. A lower secondary air pipe is connected with the lower secondary air bellow. An upper secondary air pipe is connected with the overhead central secondary air spray pipe and the overhead curtain secondary air spray pipe. An induced draft fan outlet smoke main pipe is provided with a recycling backdraft smoke main pipe, and the backdraft smoke main pipe is connected with a primary air fan inlet air pipe and a secondary air fan inlet air pipe. A primary air backdraft smoke valve is arranged between the backdraft smoke main pipe and the primary air fan inlet air pipe. A secondary air backdraft smoke valve is arranged between the backdraft smoke main pipe and the secondary air fan inlet air pipe. The smoke backdraft multi-flow low-NOx horizontal circulating fluidized bed boiler has the advantages of being high in combustion efficiency, low in NOx generation amount, reliable in operation and the like.

Owner:TSINGHUA UNIV +1

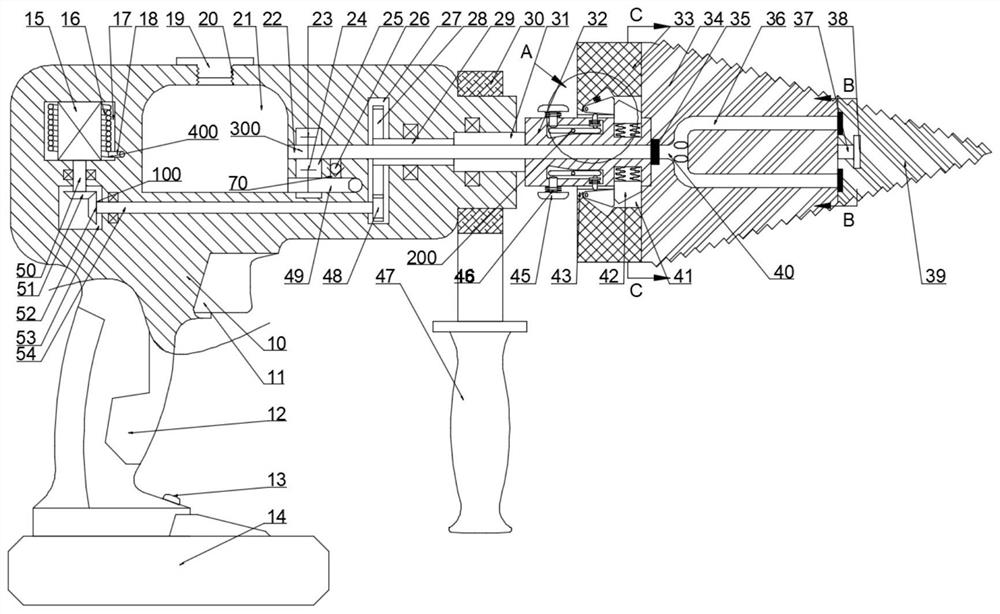

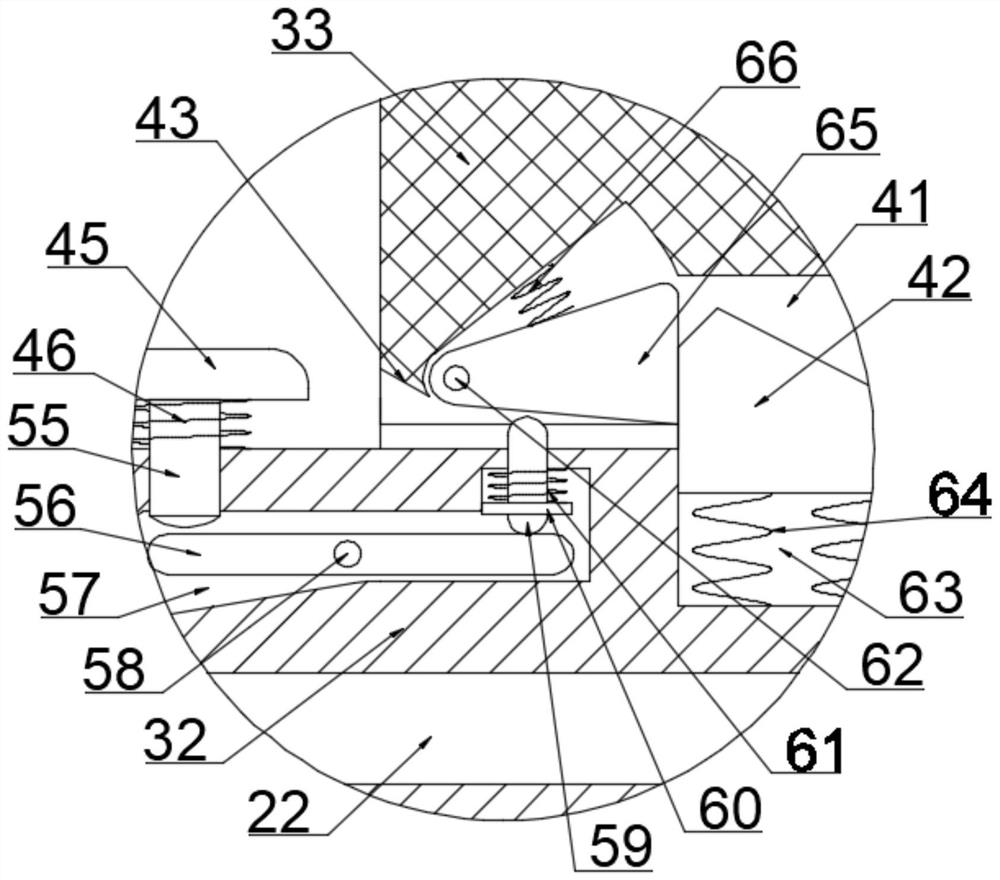

Self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill

InactiveCN113084226AAvoid contactSuitable for short-term efficient workDomestic cooling apparatusLighting and heating apparatusElectrical batteryBackdraft

The invention relates to the technical field of electric drills, in particular to a self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill. The self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill comprises a machine body, a handle is fixedly arranged at the lower end of the machine body, a storage battery is fixedly arranged at the lower end of the handle in a buckled mode, and the handle is provided with a battery dismounting button for controlling the dismounting of the storage battery. According to the self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill provided by the invention, the battery is adopted for supplying power, so that the self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill is suitable for efficient operation in a short time, and the self-cooling fire-fighting liquid nitrogen fire extinguishing electric drill is light in weight and easy to carry; the self-cooling fire-fighting liquid nitrogen fire-extinguishing electric drill is suitable for being carried by firefighters and can be suitable for most fire scenes; and therefore, the self-cooling fire-fighting liquid nitrogen fire-extinguishing electric drill can also be used at home, and is convenient and safe. The liquid nitrogen element is added, cooling treatment can be carried out while fire extinguishing is carried out, the temperature is reduced to be below an ignition point while open fire is extinguished, and fire is prevented from being ignited again; and the novel drill bit is adopted and is different from an existing drill bit in the market, the disengagement type drill bit is adopted, internal combustible substances can be effectively prevented from making contact with external oxygen, and the backdraft prevention effect is achieved.

Owner:广州翔运科技有限公司

Pipe cooling type fuel gas premixing ultra-low nitrogen combustor and premixing method

A pipe cooling type fuel gas premixing ultra-low nitrogen combustor comprises a combustor body, wherein a fuel gas inlet and a combustor-supporting gas inlet are formed in the combustor body, an inner cavity is formed in the combustor body, and the inner cavity is sequentially divided into a premixing cavity, a pipe cooling mixing chamber and a combustion chamber in the airflow direction; the fuel gas inlet and the combustion-supporting gas inlet respectively communicate with the premixing cavity, and a flow equalizing plate is arranged in the combustion-supporting gas inlet; a cooling pipe bundle is arranged in the pipe cooling mixing chamber and comprises a plurality of cooling pipes, a gap is formed between every two adjacent cooling pipes and forms a premixed gas channel, and the premixed gas channels communicate with the premixing cavity and the combustion chamber. The invention further provides a premixing method of the pipe cooling type fuel gas premixing ultra-low nitrogen combustor. Two low-nitrogen premixing combustor key elements including gas backdraft control and complete mixing of gas and combustion-supporting gas are integrated, gas and combustion-supporting gas are mixed in two stages, media in pipes are cooled, the mixing characteristic is good, the environment temperature is low, the airflow velocity is high, safety is achieved, backfire is avoided, combustion is sufficient, and ultra-low nitrogen emission is achieved.

Owner:ZHEJIANG UNIV

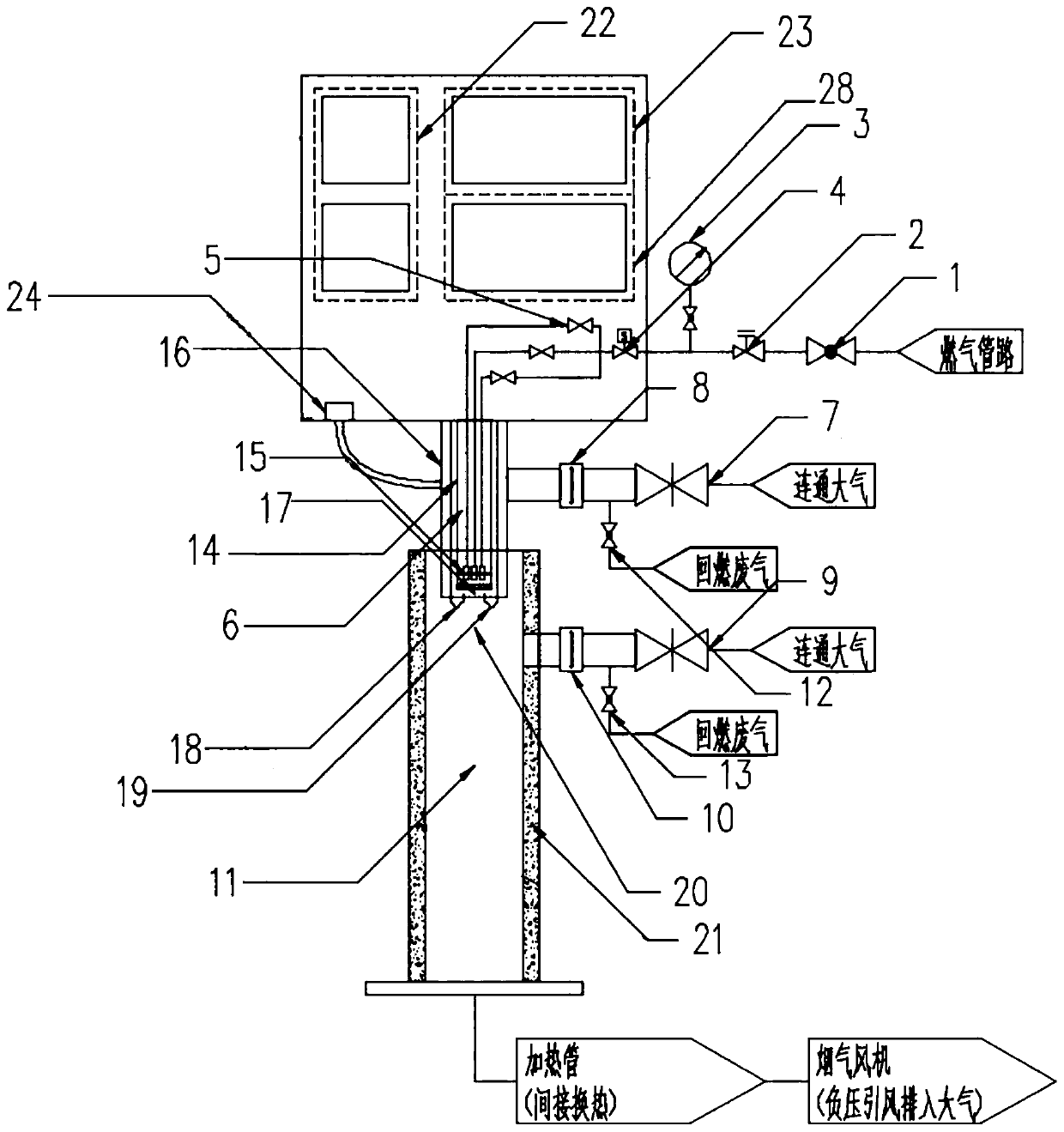

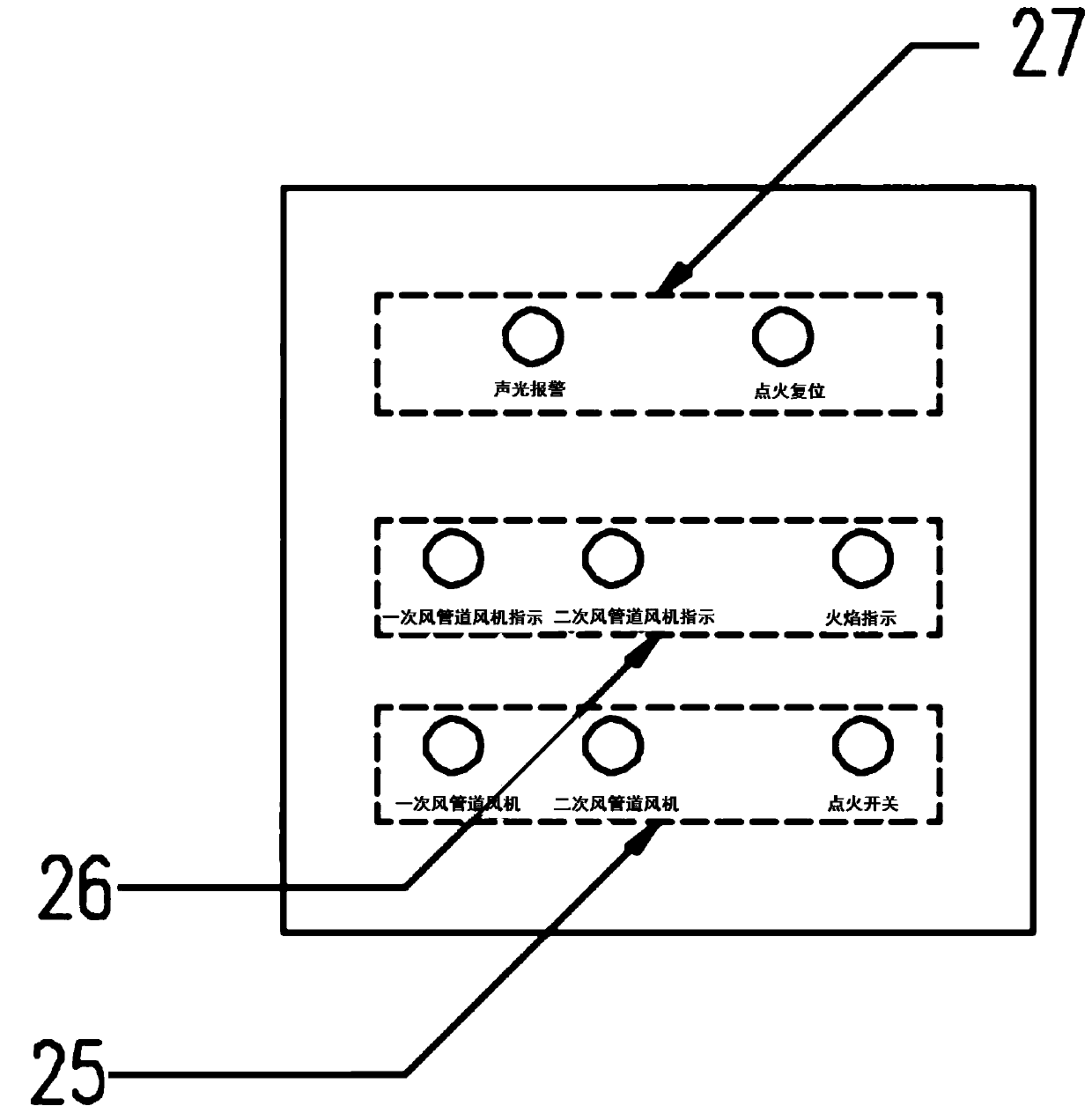

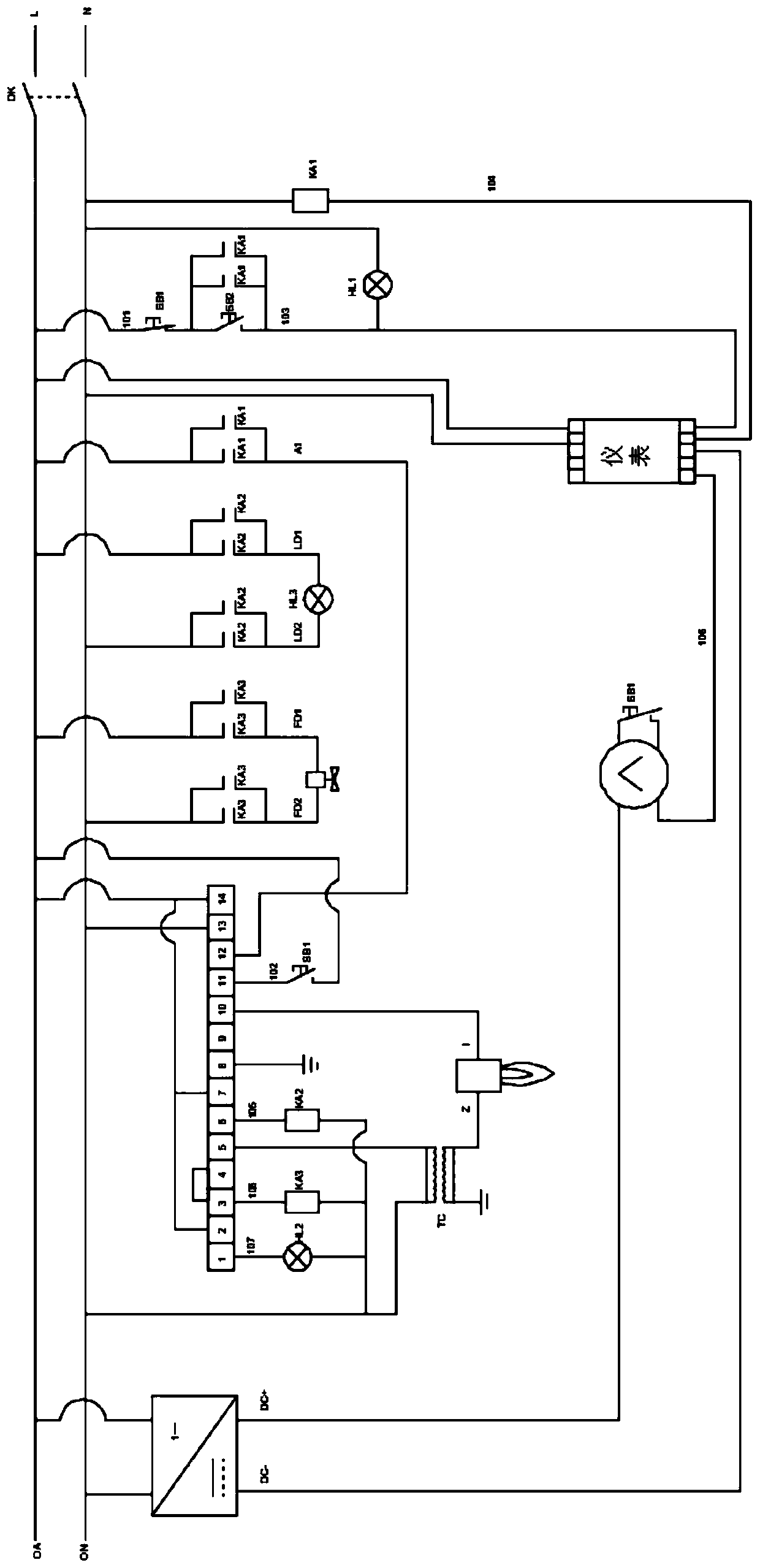

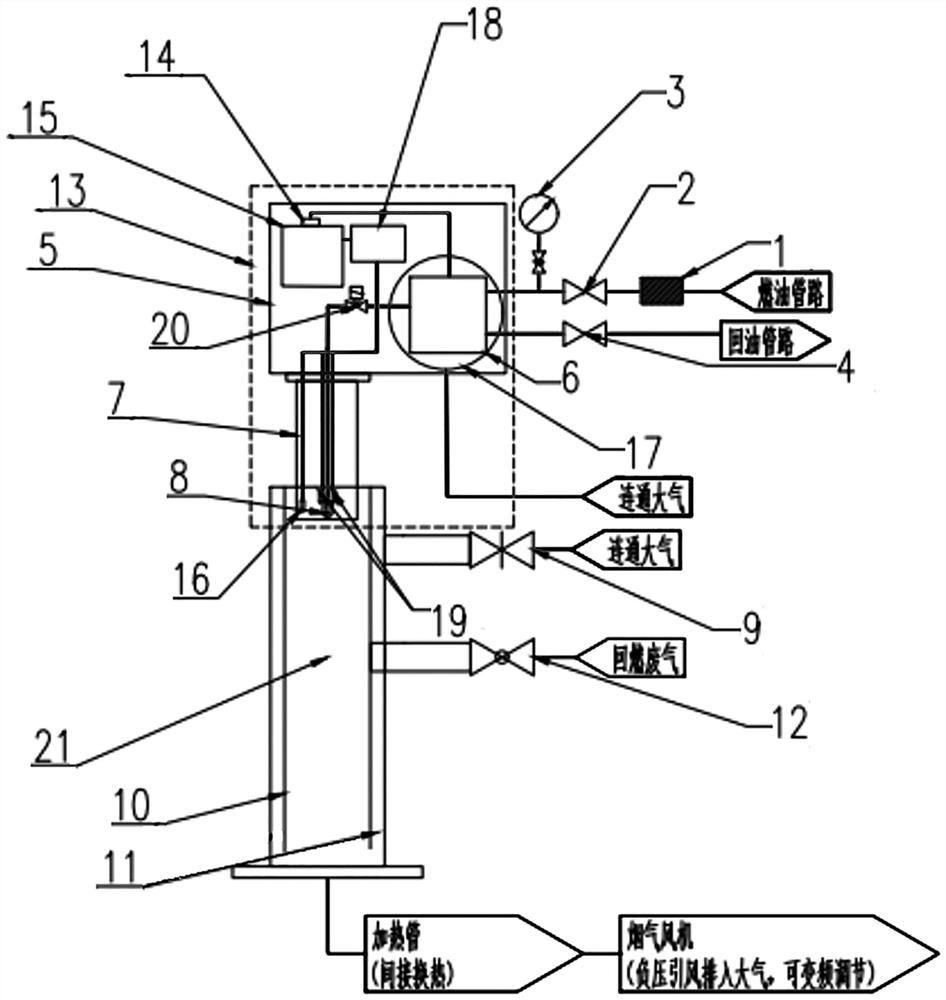

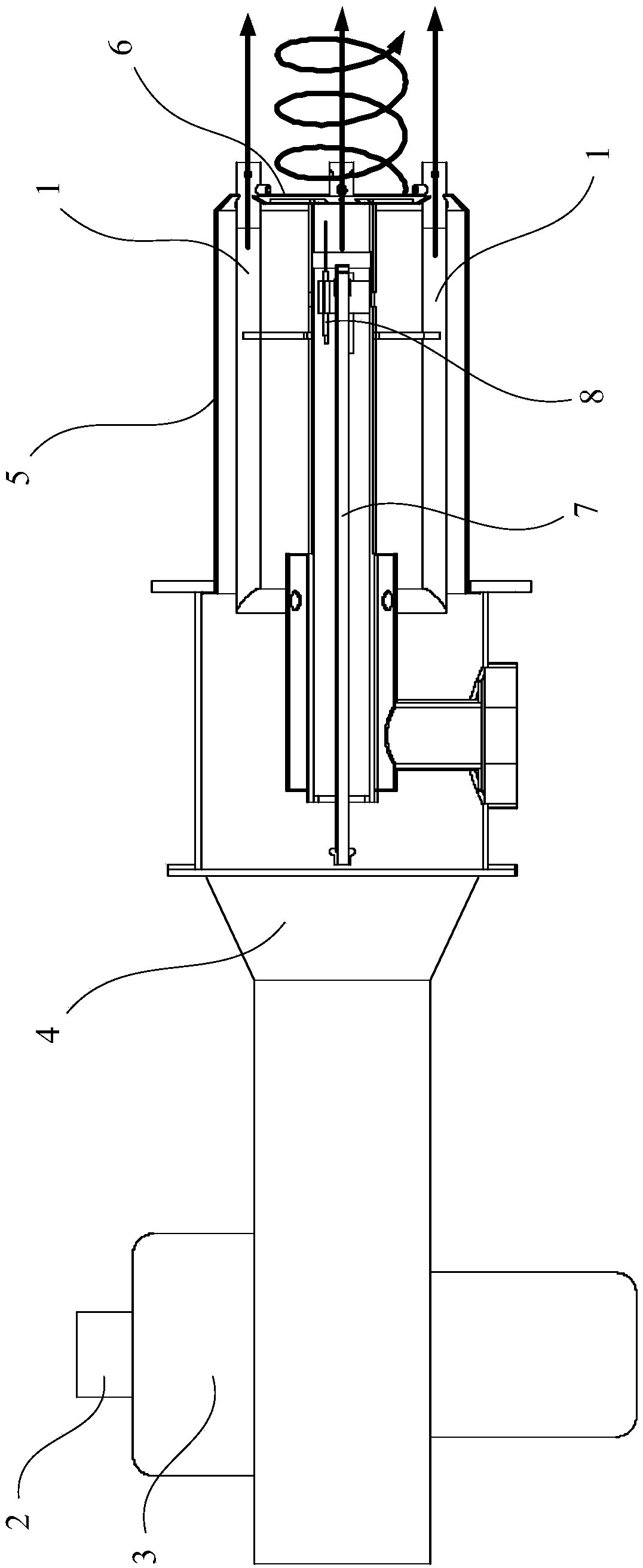

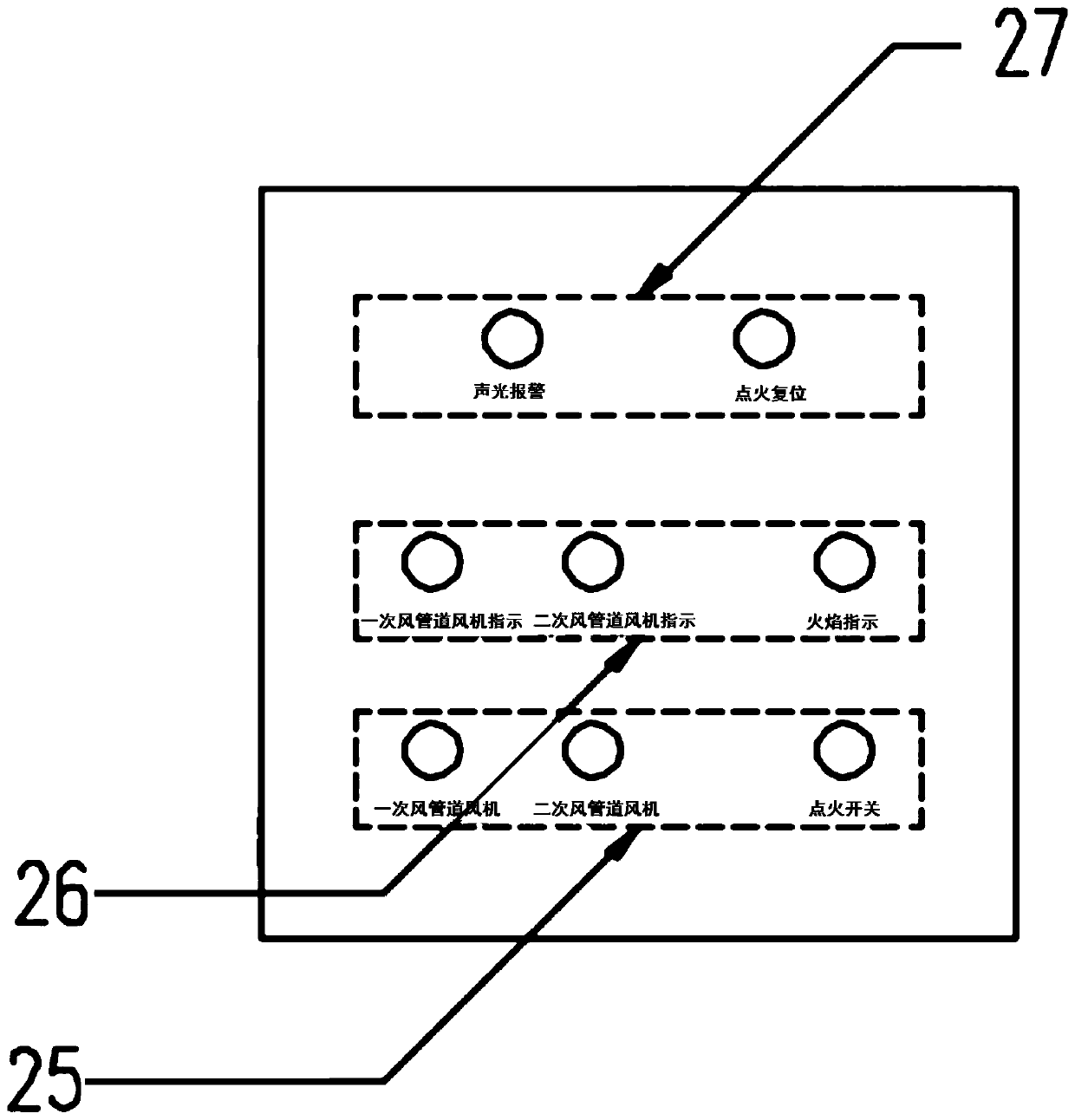

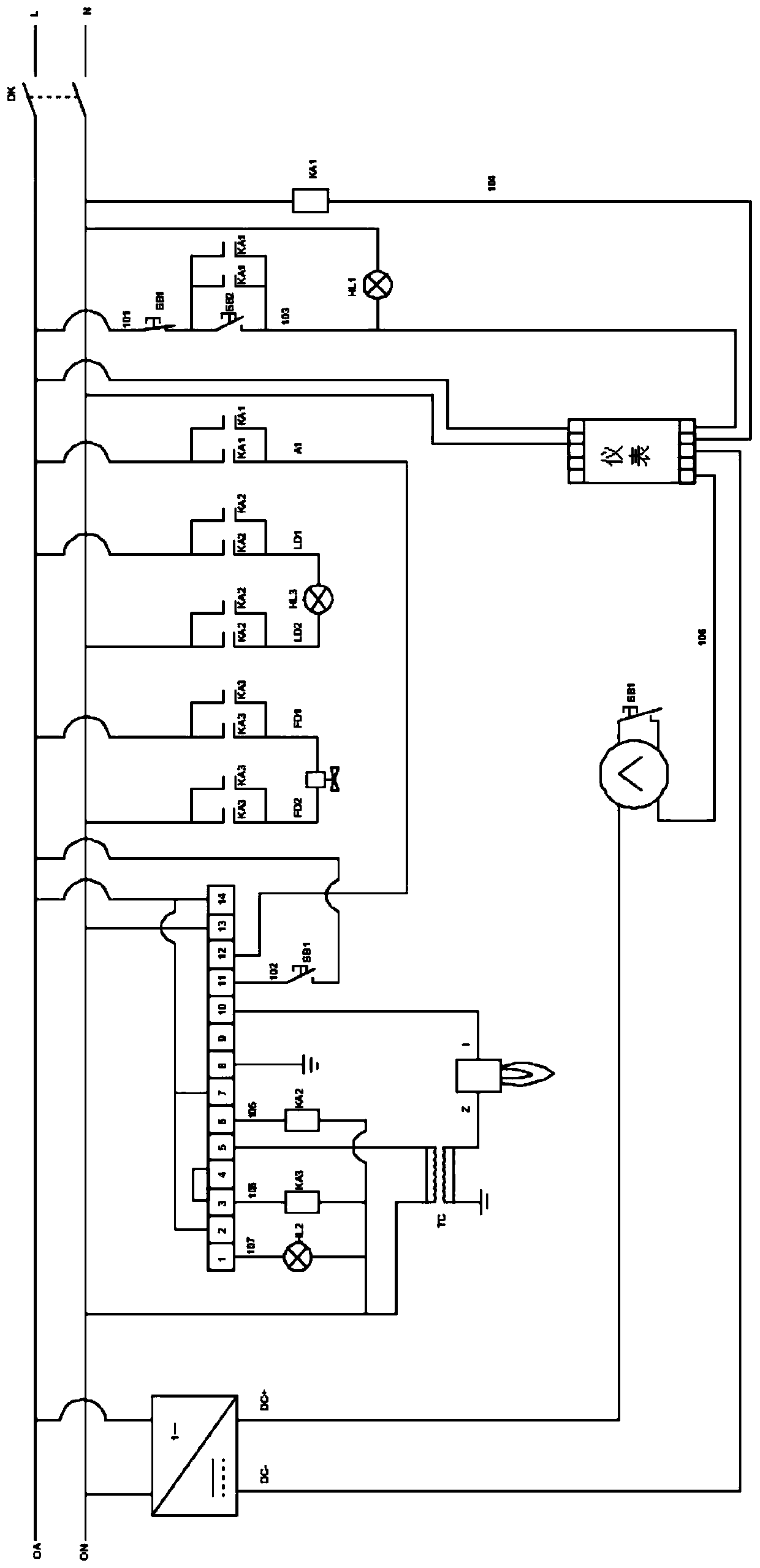

Intelligent combustion treatment integrated machine used for thermal desorption remediation of contaminated site

PendingCN110340127AReduce usageIncrease temperatureContaminated soil reclamationHigh concentrationCombustion chamber

The invention discloses an intelligent combustion treatment integrated machine used for thermal desorption remediation of a contaminated site. The integrated machine comprises a fuel gas supply unit,a combustion air supply unit, a backdraft waste-gas introduction unit, a burner, a combustion chamber, and a control cabinet. In the integrated machine, fuel gas and combustion air are contacted by the burner, ignition is performed by using an igniter, continuous stable combustion is performed in the combustion chamber, and high-temperature flue gas generated in the combustion chamber is sent to athermal desorption remediation system for indirect conduction heat exchange; and the desorbed organic waste gas generated by the thermal desorption remediation system can be sent to the combustion chamber through the backdraft waste-gas introduction unit of the intelligent combustion treatment integrated machine for thermal combustion treatment. The integrated machine provided by the invention can use the conventional gas fuel as an energy source, has high utilization efficiency of energy sources and simple, safe, stable and reliable system equipment, has the functions of combustion heat generation and waste-gas thermal combustion treatment, and can provide a stable high-temperature combustion flue gas heat source and good high-concentration desorption organic waste-gas heat treatment solution for the thermal desorption remediation technology.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

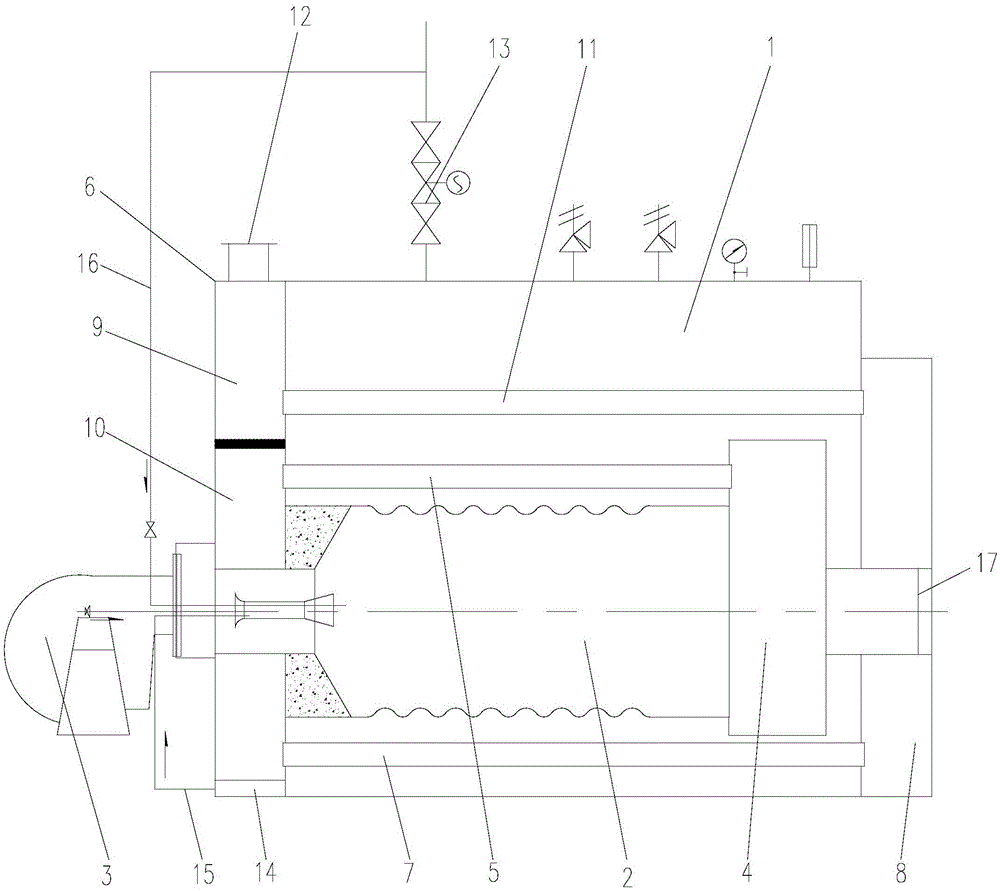

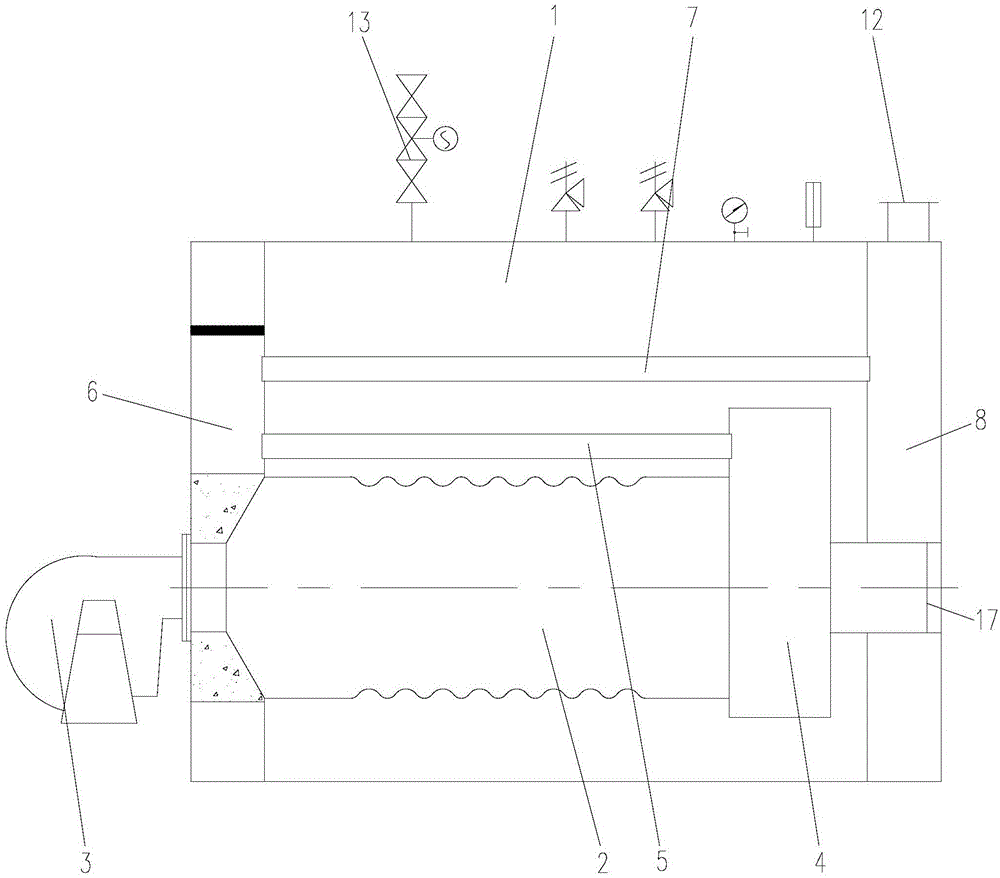

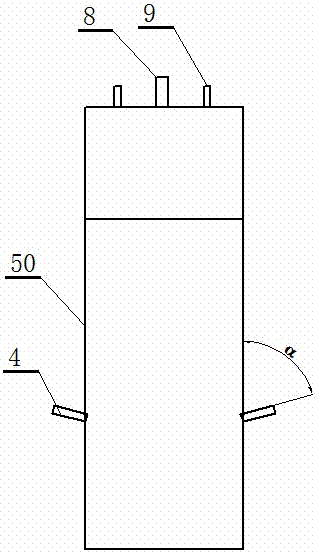

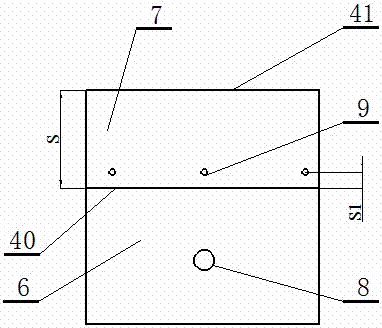

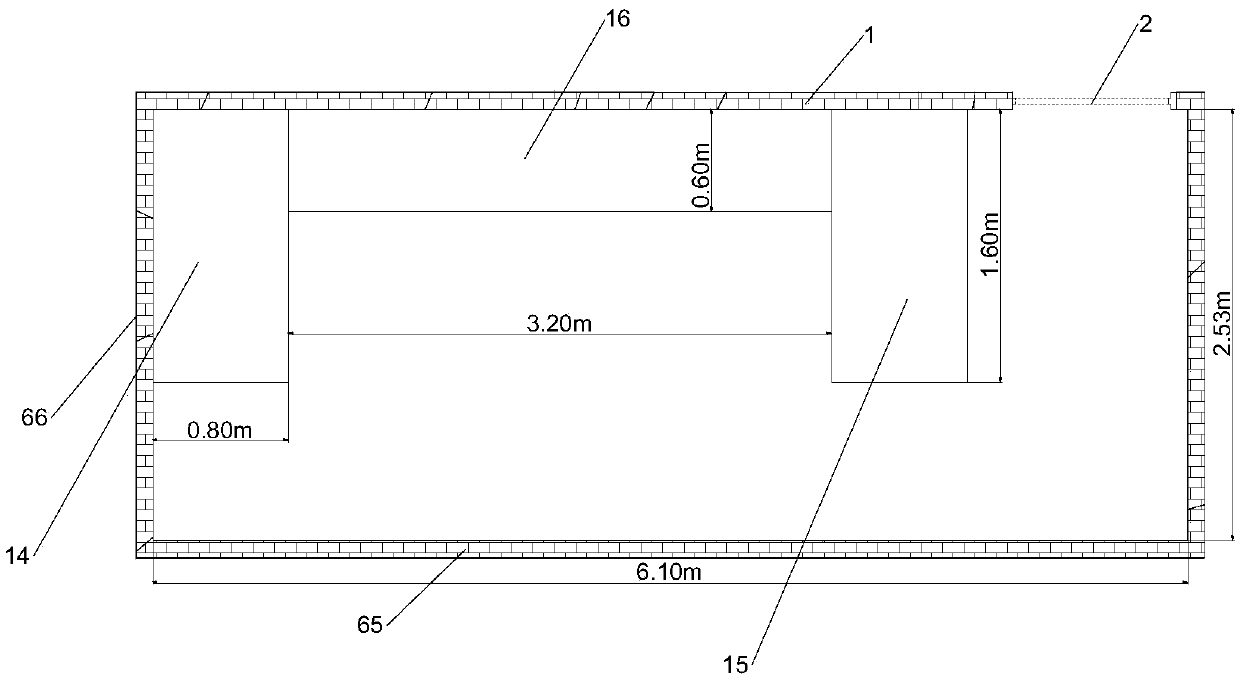

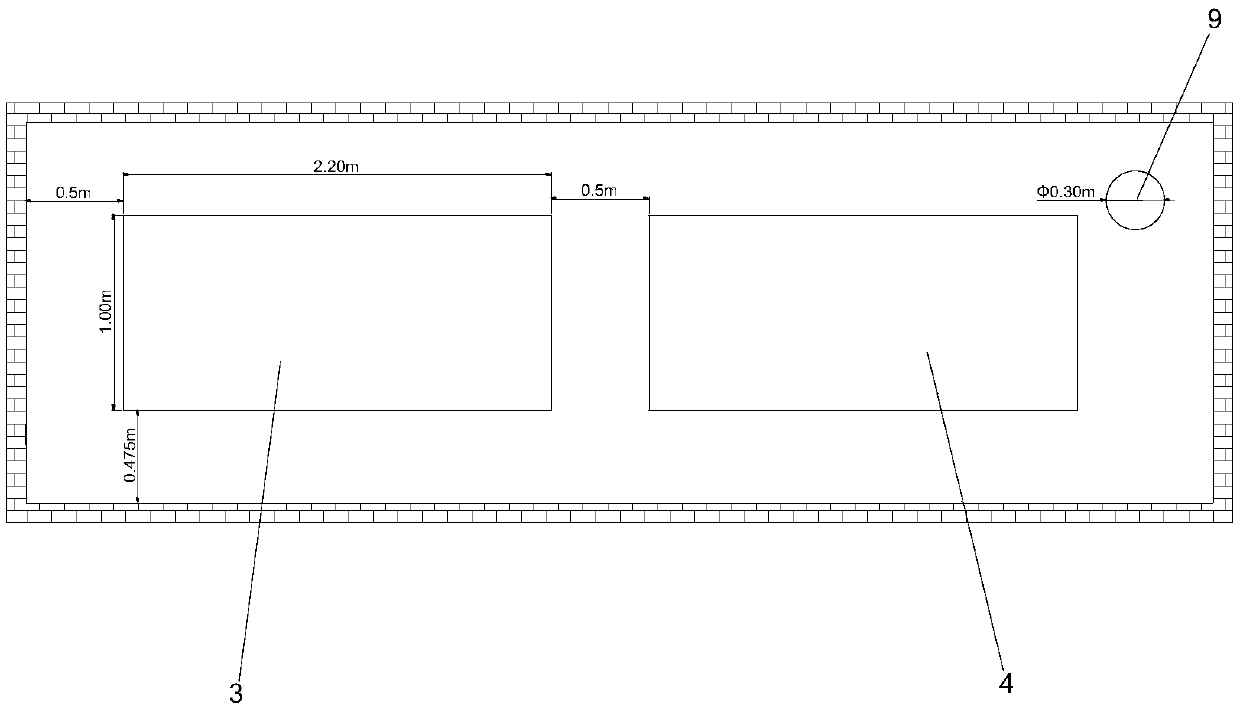

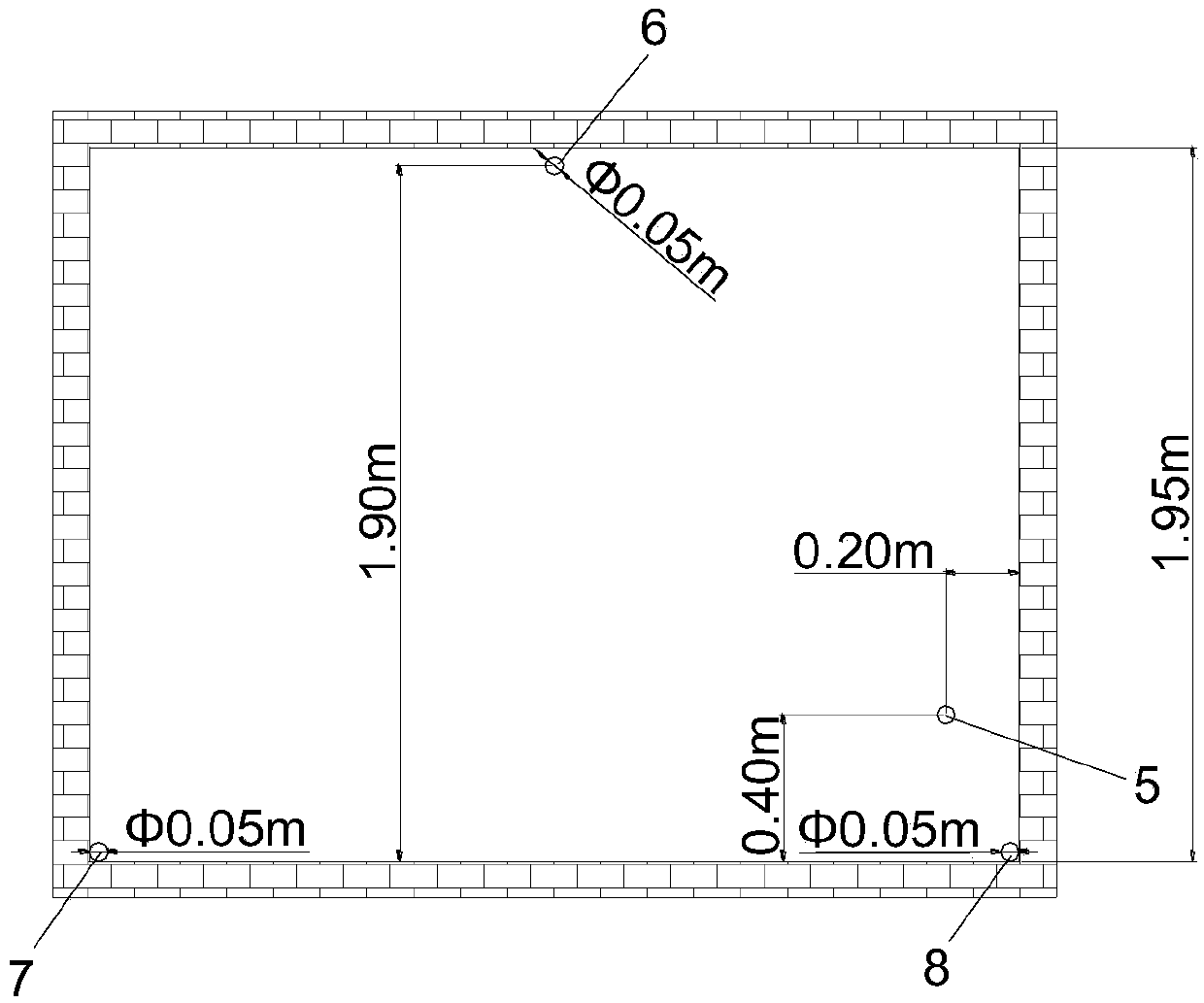

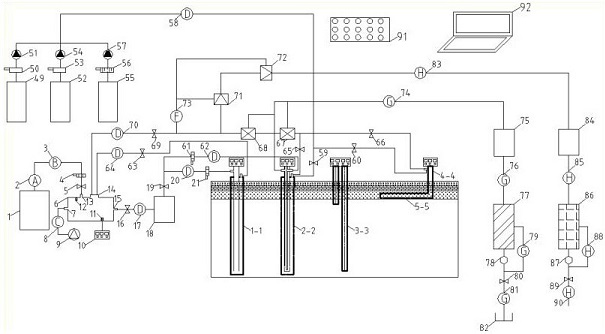

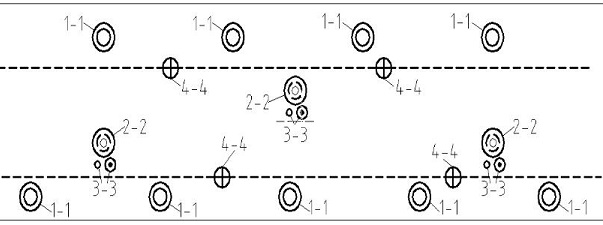

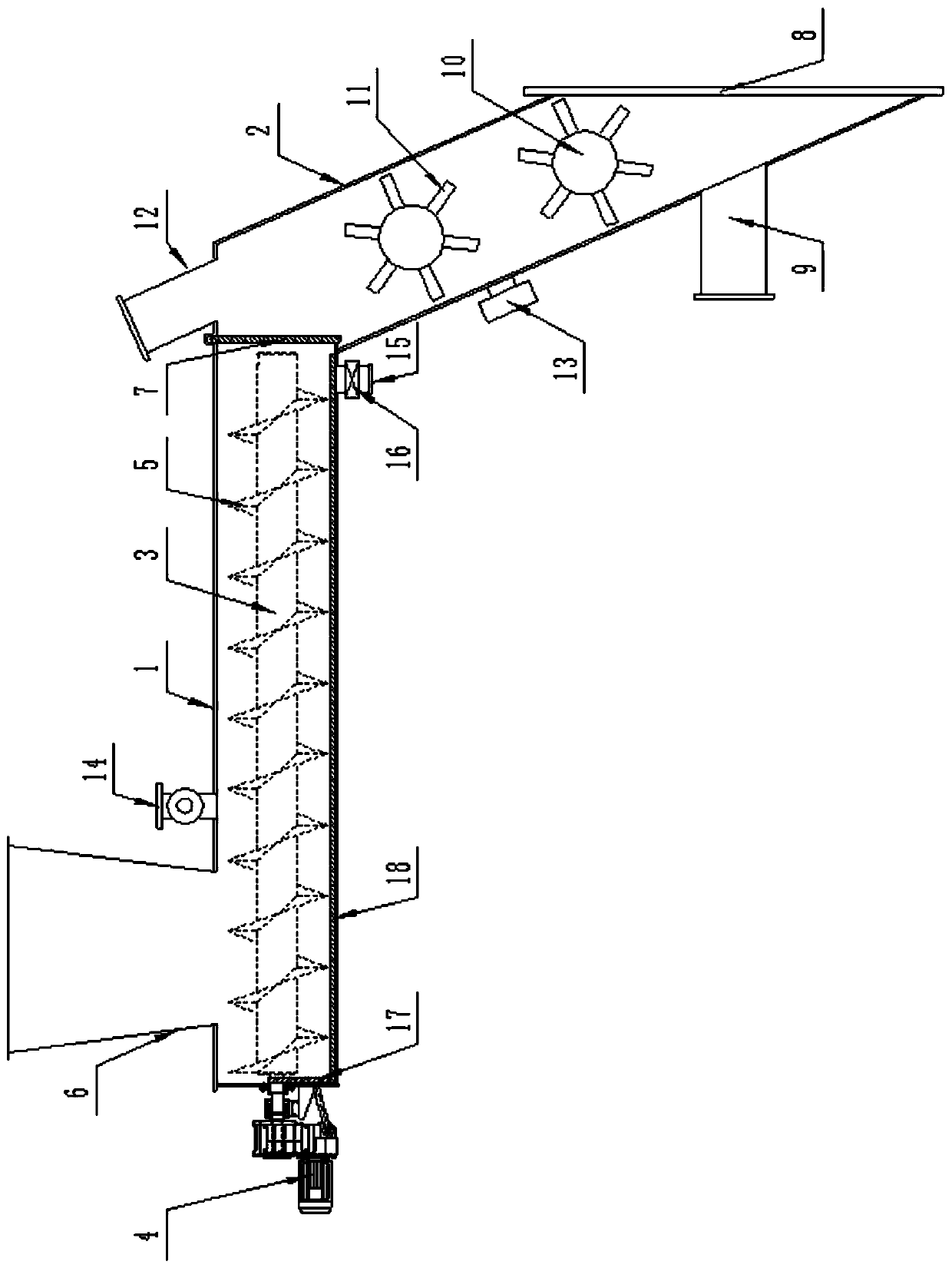

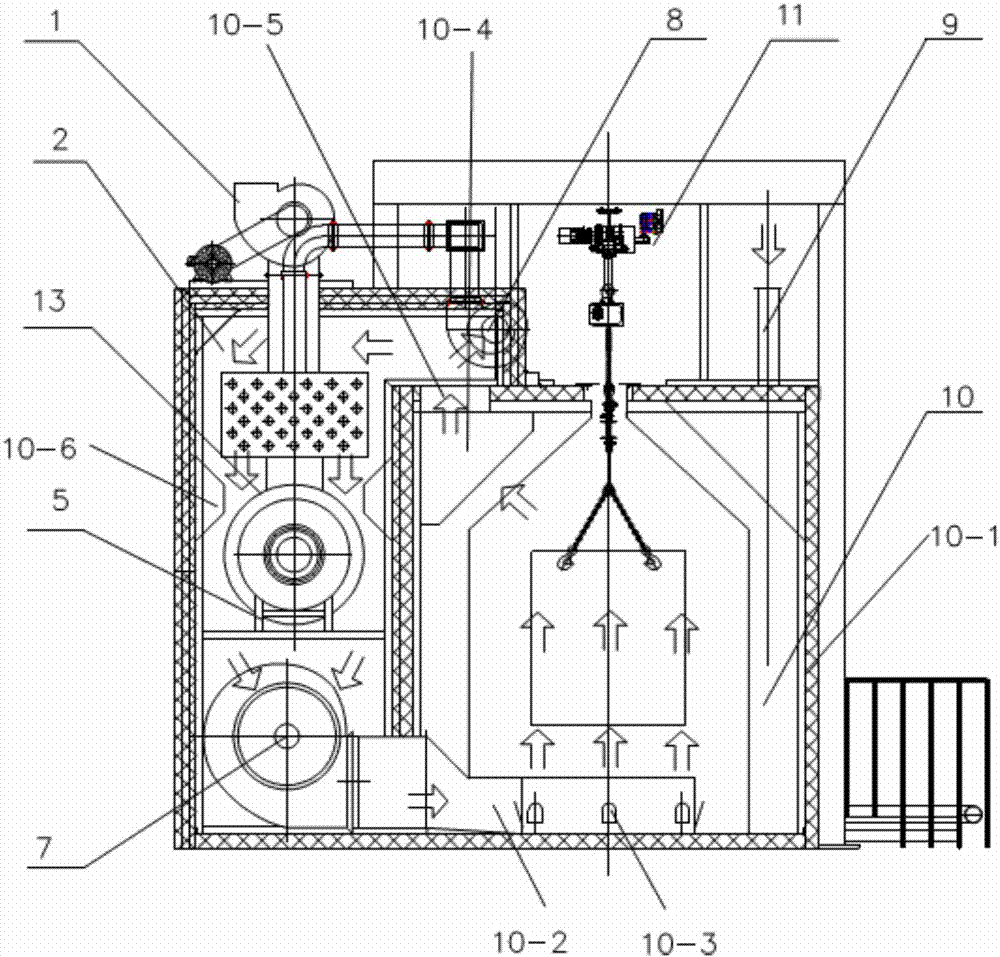

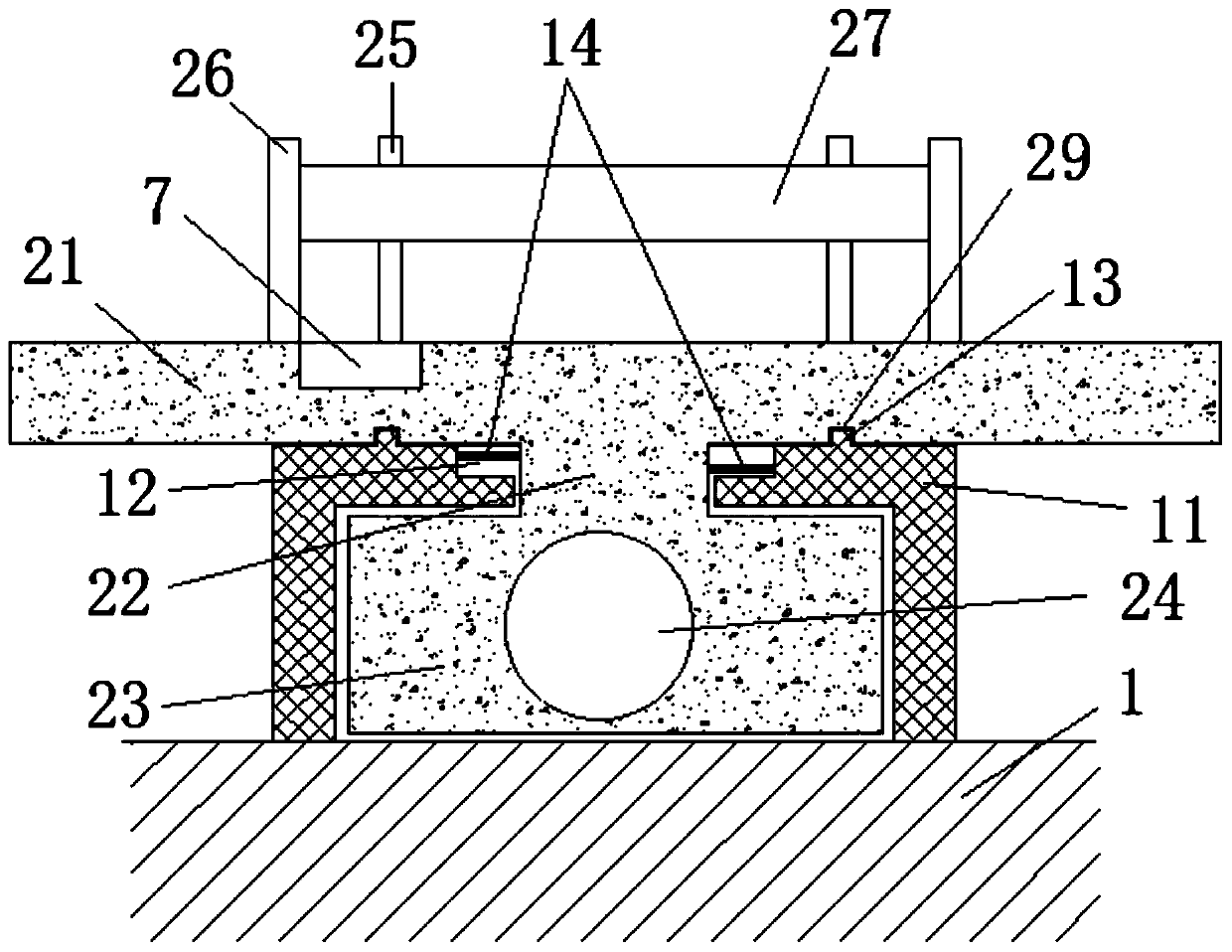

Full-size cabin backdraft simulation experiment device and method

The invention provides a full-size cabin backdraft simulation experiment device which comprises a model body, a matched simulation generation device, a measuring and control system and a smoke exhaustdevice; the model body is a simulation cabin formed by an entity steel structure on the basis of the ratio being 1:1; three model storage cabinets are arranged inside the simulation cabin for simulating a storage room conventional cabinet body; the matched simulation generation system comprises a natural gas supply system and an ignition system connected with the natural gas supply system, the natural gas supply system conveys natural gas to gas burners at three model storage cabinets through a natural gas pipeline inside the cabin, and the ignition system comprises ignitors corresponding tothe burners one to one; the measuring and control system comprises a measuring device located at the cabin ceiling for measuring the flue gas temperature; the smoke exhaust system is used for exhausting fire smoke through exhaust holes in the rear wall of the cabin. Teaching demonstrative experiments and fire control fight practical training can be performed, and the device is used for daily firecontrol technology training for firefighting officers, part-time firefighters and related employed persons.

Owner:NAVAL UNIV OF ENG PLA +1

Contaminated soil fuel gas in-situ thermal desorption repairing equipment

ActiveCN114733895ASimple structureReduce risk of leakageContaminated soil reclamationAir quality improvementBackdraftHeat conservation

The invention relates to the technical field of soil remediation, in particular to gas in-situ thermal desorption remediation equipment for contaminated soil. Comprising a combustion heating module, a plurality of heating well modules, a plurality of vertical extraction well modules, a plurality of horizontal extraction well modules, a heat preservation module, a soil conditioning module, a waste heat recovery and tail gas backdraft module, a tail water purification treatment module and a tail gas purification treatment module. The combustion heating module is respectively connected with each heating well module and each vertical extraction well module; the soil conditioning module is respectively connected with each vertical extraction well module and each horizontal extraction well module, and is used for providing chemicals to decompose organic pollutants; one end of the waste heat recovery and tail gas backdraft module is connected with the heating well modules, the vertical extraction well modules and the horizontal extraction well modules, and the other end of the waste heat recovery and tail gas backdraft module is connected with the combustion heating module, the tail water purification treatment module and the tail gas purification treatment module. The equipment is economical, efficient, convenient to operate, reasonable in structure, high in adaptability and capable of being applied to engineering large-scale application.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Biomass energy-saving and environment-friendly stove

InactiveCN104848257AImprove combustion efficiencyImprove thermal efficiencyLighting and heating apparatusStove/ranges for heating waterPush and pullCombustion chamber

An embodiment of the invention discloses a biomass energy-saving and environment-friendly stove. By the biomass energy-saving and environment-friendly stove, biomass is combusted to supply heat. The biomass energy-saving and environment-friendly stove comprises a stove body, an upper cover, secondary air distributing devices, a secondary air inlet and a grate bar rocking rod, wherein the stove body is provided with a feeding bin, a main combustion chamber and a backdraft chamber; the upper cover is arranged at the upper end of the stove body; a fire banking cover is arranged on an upper opening of the main combustion chamber; two angle-adjustable grate bars are arranged on the lower portion of the main combustion chamber; the grate bar rocking rod is in linkage with the grate bars; a switching push-and-pull plate is arranged at an end of a partition between the main combustion chamber and the backdraft chamber; a plurality of water boxes are transversely arranged on a side wall of the backdraft chamber; the secondary air inlet is formed in a side of the backdraft chamber and is communicated with the main combustion chamber; and the secondary air distributing devices are distributed on the side walls of the feeding bins and the side walls of the backdraft chamber. By the biomass energy-saving and environment-friendly stove, the combustion ratio of biomass fuels is improved. The biomass energy-saving and environment-friendly stove is simple in structure, convenient to produce and repair and low in cost.

Owner:HEBEI QUNXIANG HEATING EQUIP

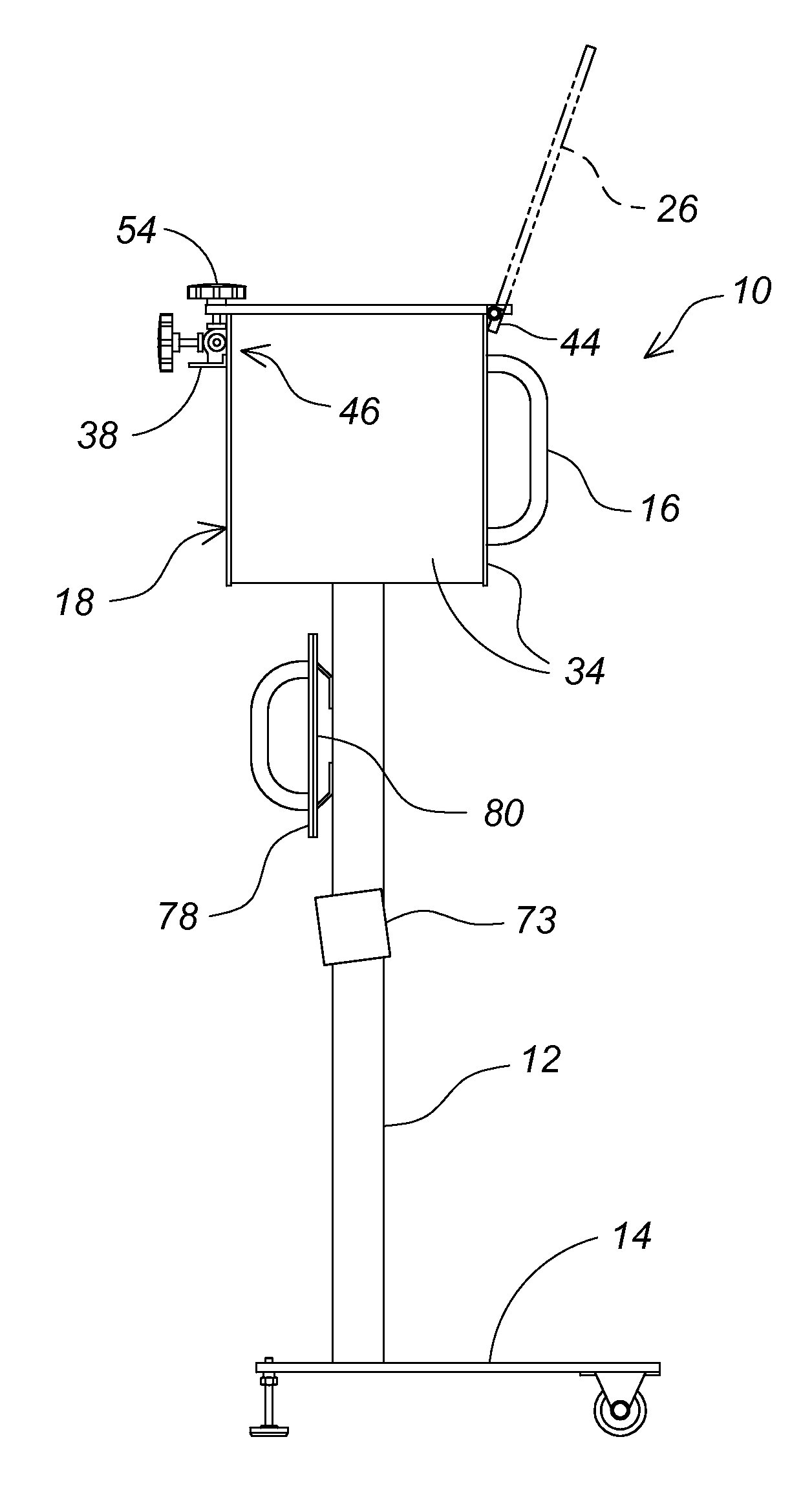

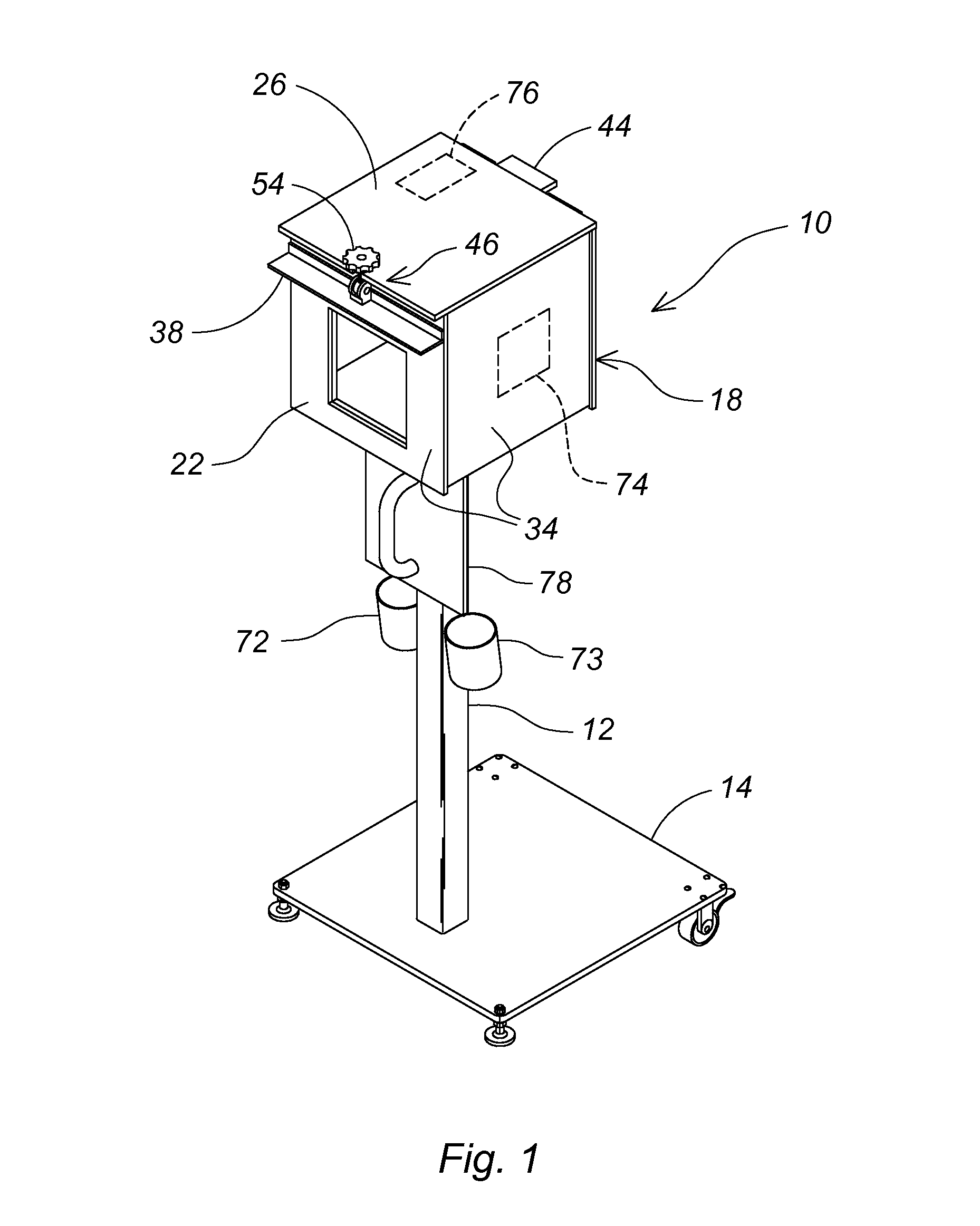

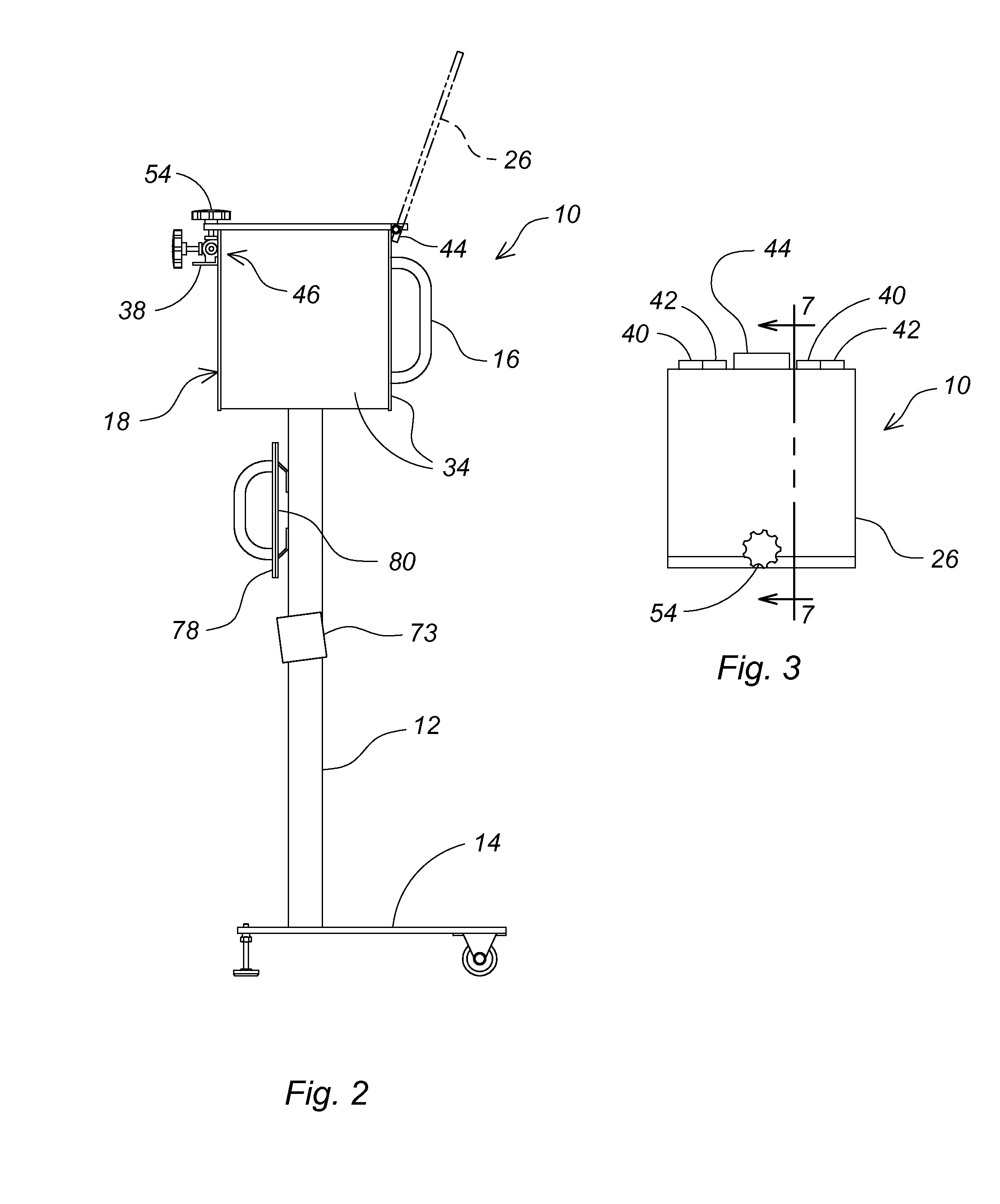

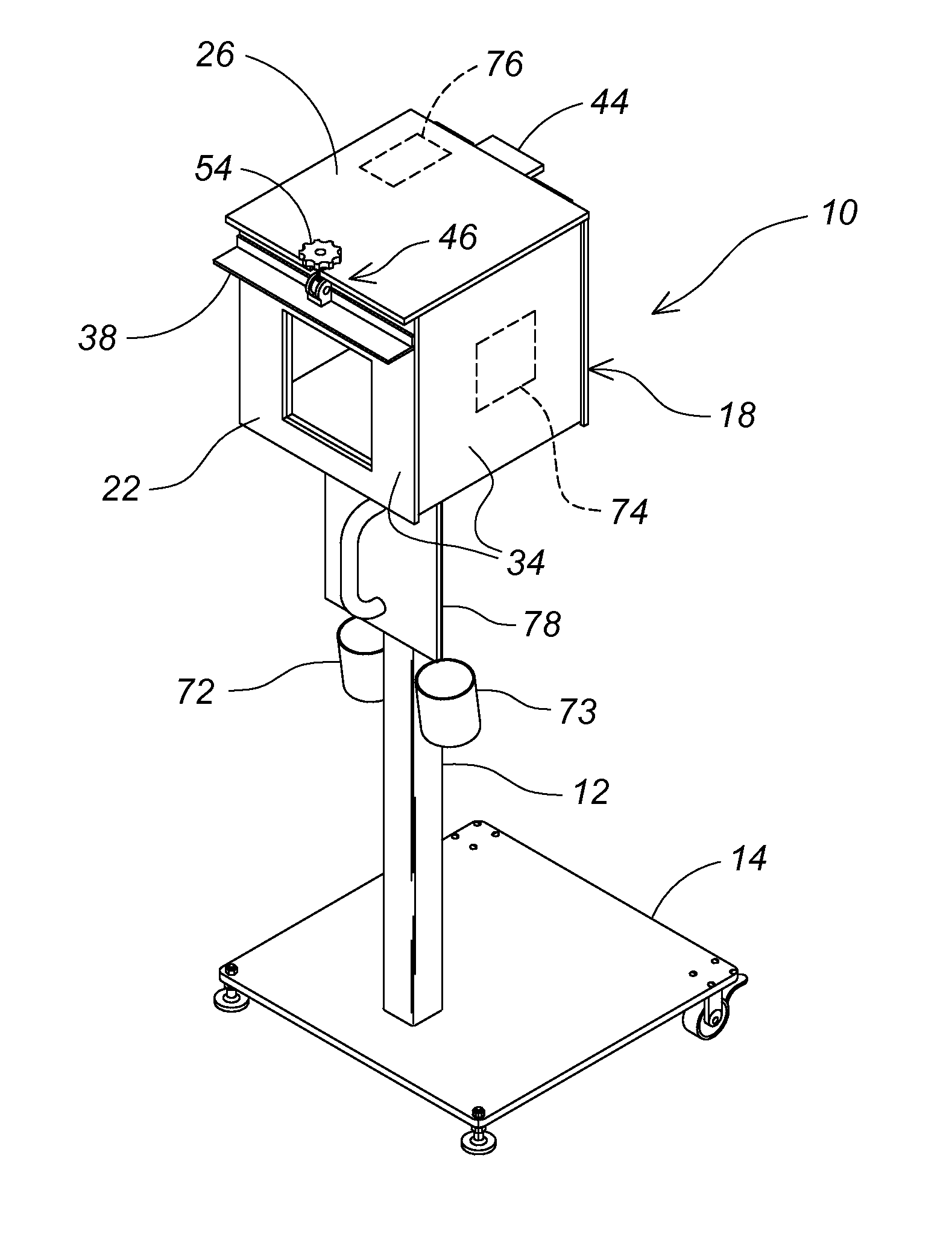

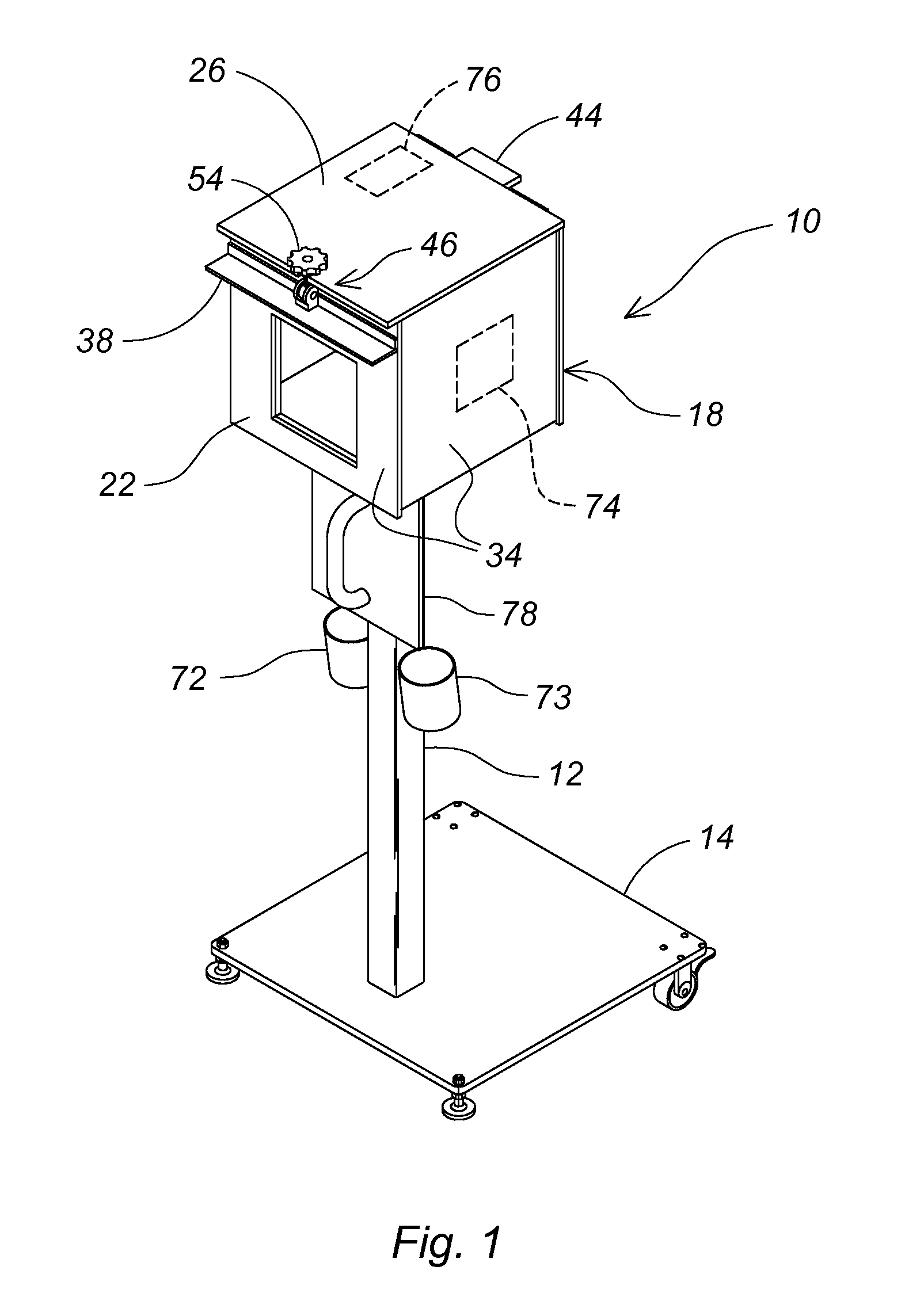

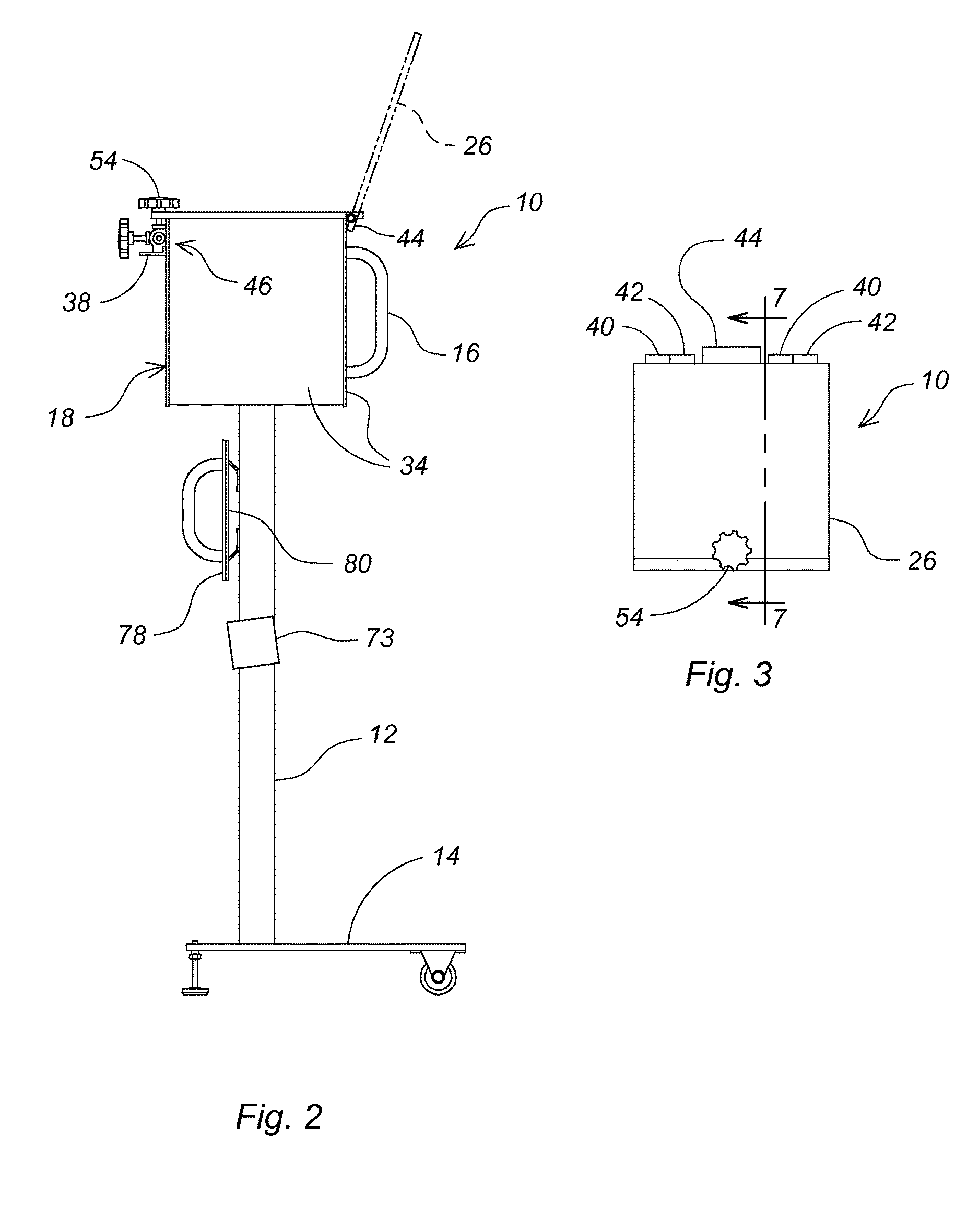

Firefighting Training Unit

A metal container with a combustible liner for use as a portable firefighting training unit. The combustible liner is formed of particle board sections loosely assembled inside the metal container with an opening in the liner in registry with an access opening in the metal container. The unit may be used to demonstrate various phenomena associated with a developing fire including the flammability of unburned products of combustion, hose stream techniques with a spray bottle filled with water, flashover and backdraft.

Owner:MAX FIRE TRAINING

Fuel oil combustion treatment method for thermal desorption remediation of polluted soil

InactiveCN112958611AReduce usageImprove utilization efficiencyContaminated soil reclamationIncinerator apparatusCombustion chamberLiquid fuel

The invention discloses a fuel oil combustion treatment method for thermal desorption remediation of polluted soil, which comprises the following steps: atomizing fuel oil in a fuel oil burner, then making hte atomized fuel oil contact and mixed with combustion air, conducting igniting by an ignition electrode for continuous and stable combusting in a combustion chamber, feeding generated high-temperature flue gas into a thermal desorption remediation system for conduction heat exchange, and enabling desorbed organic waste gas generated by the thermal desorption repair system to be fed into the combustion chamber through a backdraft waste gas guide-in unit for thermal combustion treatment. The method is carried out through a fuel oil combustion treatment all-in-one machine, and the all-in-one machine comprises a fuel oil supply unit, a fuel oil combustor, a combustion chamber, a secondary air supply unit and a backdraft waste gas guide-in unit. According to the combustion treatment method, conventional liquid fuel such as light diesel oil can serve as an energy source, the energy utilization efficiency is high, secondary pollution is controllable, system equipment is simple, safe, stable and reliable, and the combustion treatment method has the functions of combustion heat production and waste gas thermal combustion treatment.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

Firefighting training unit

A metal container with a combustible liner for use as a portable firefighting training unit. The combustible liner is formed of particle board sections loosely assembled inside the metal container with an opening in the liner in registry with an access opening in the metal container. The unit may be used to demonstrate various phenomena associated with a developing fire including the flammability of unburned products of combustion, hose stream techniques with a spray bottle filled with water, flashover and backdraft.

Owner:MAX FIRE TRAINING

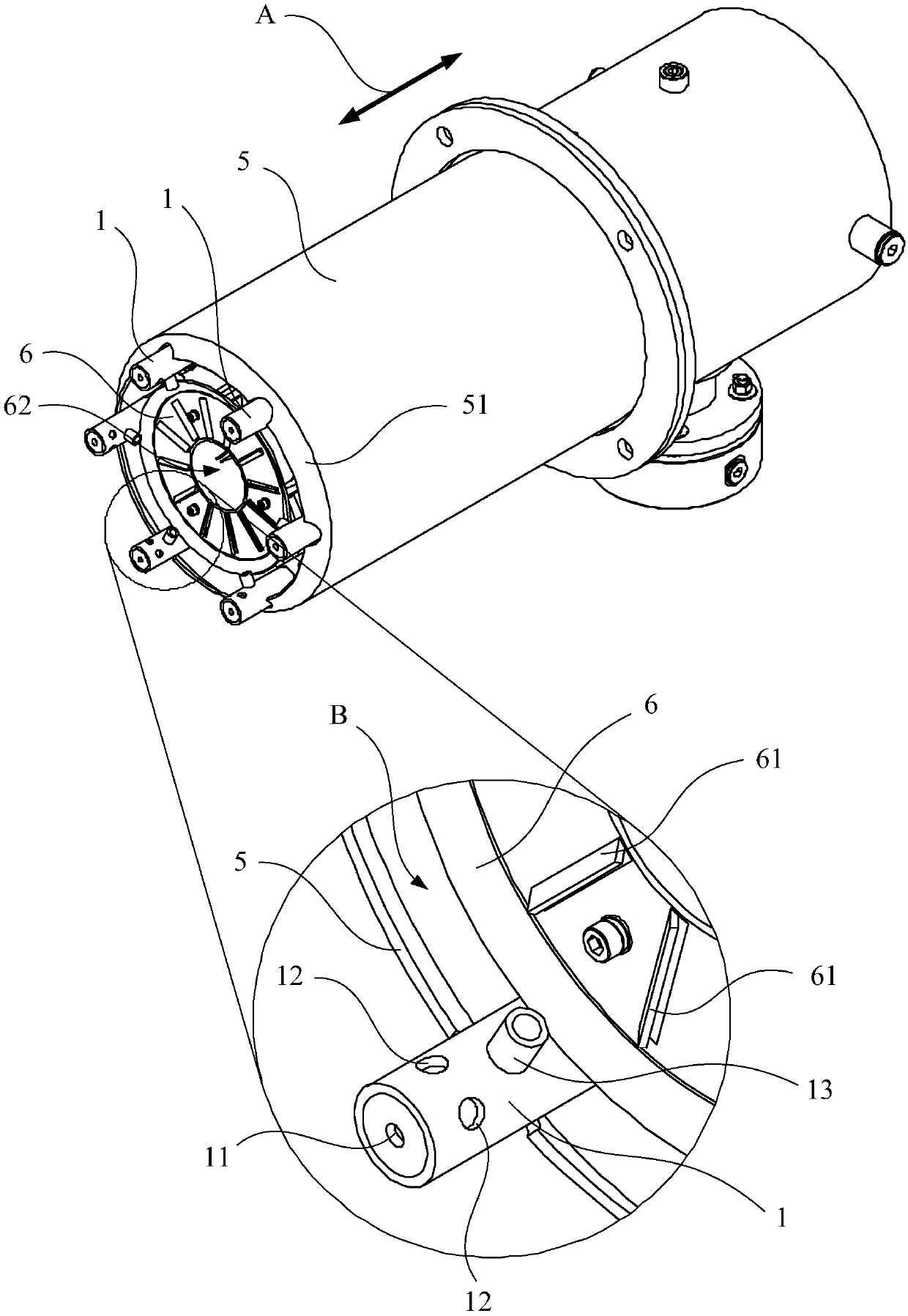

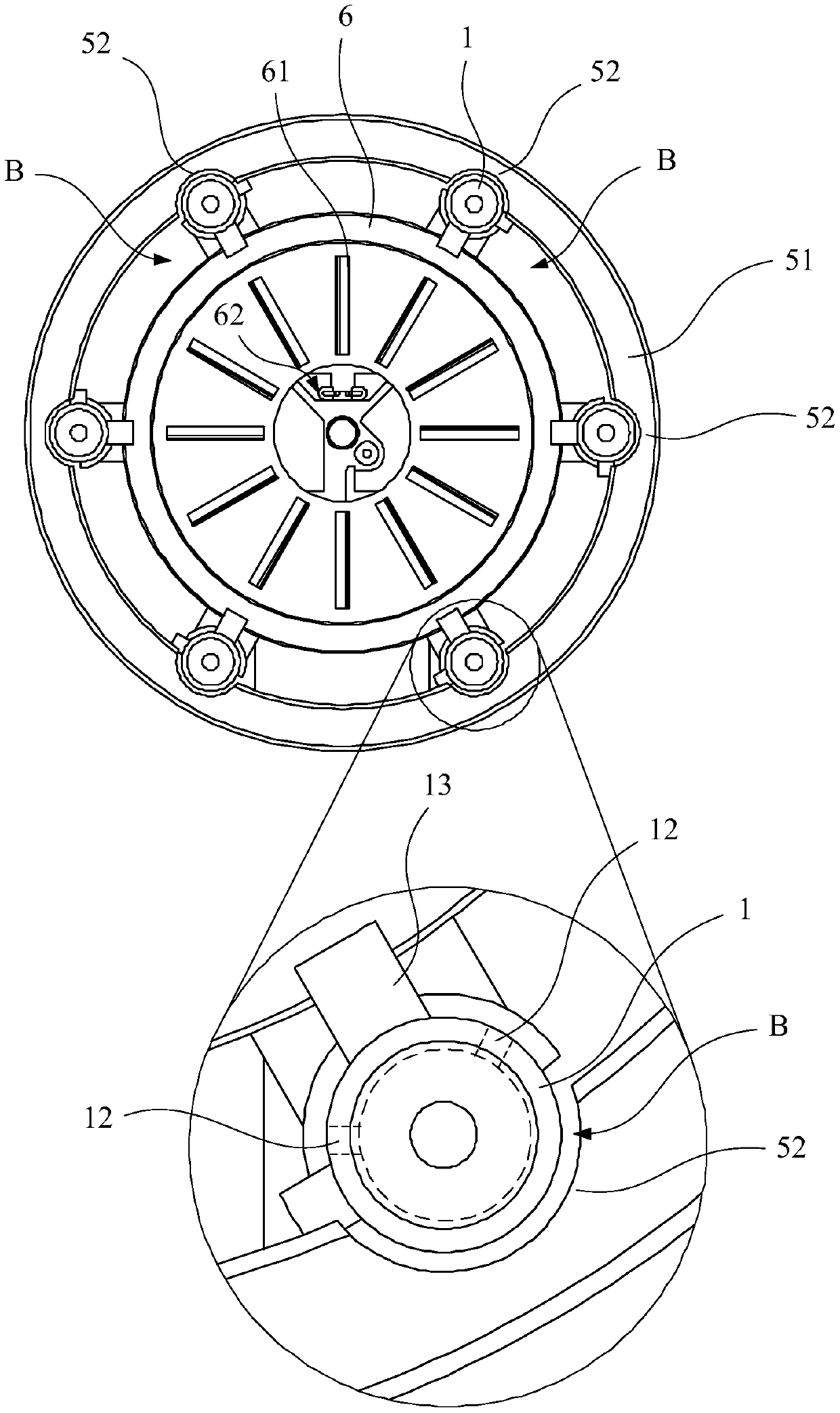

Feeding device having backdraft cutoff function and used for biomass fuel boiler

PendingCN110793054ACause oxygen deficiencyBurn fullyFuel feeding arrangementsLump/pulverulent fuel feeder/distributionElectric machineProcess engineering

The invention provides a feeding device having a backdraft cutoff function and used for a biomass fuel boiler. The feeding device comprises a screw conveyor barrel; one end of the screw conveyor barrel is closed, and the other end of the screw conveyor barrel is open; the open end of the screw conveyor barrel is connected with an oblique feeding barrel, and a conveyor shaft is arranged in the screw conveyor barrel; the conveyor shaft is connected with a conveyor motor, and conveying propeller blades are arranged on the conveyor shaft; the top of the screw conveyor barrel is provided with a feeding port, and the inner wall top of the open end of the screw conveyor barrel is provided with a flame retardant self-closing plate through a rotating shaft; the bottom of the oblique feeding barrelis provided with a vertical discharging port connected with the biomass fuel boiler, and dispersed gas ports are formed in the position, directly facing the discharging port, on the side wall of the oblique feeding barrel; a plurality of material distributing devices are arranged in the oblique feeding barrel, and each material distributing device comprises a material distributing shaft; a plurality of material distributing plates are distributed on the periphery of each material distributing shaft uniformly, and each material distributing shaft is connected with a material distributing motor;and the top of the oblique feeding barrel is provided with an oblique directional purging gas port. According to the feeding device, backdraft of hot gas in the boiler can be avoided, and the combustion of biomass fuel is more thorough; and the utilization rate is higher.

Owner:TIANJIN HUAZHILONG BIOMASS ENERGY TECH CO LTD

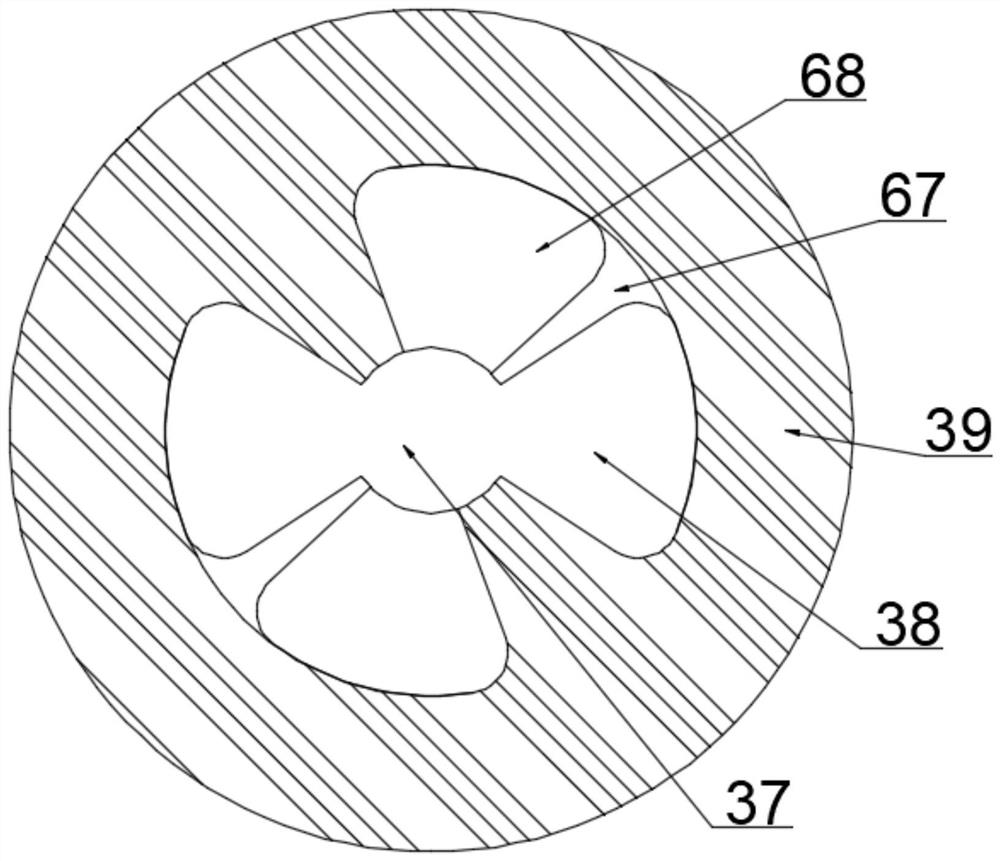

Combustor and a central backdraft boiler comprising same

PendingCN109668149AWell mixedReduce generationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorBackdraft

The invention discloses a combustor and a central backdraft boiler comprising the same. The combustor comprises a fuel gas spray tube, wherein a first jet orifice is formed in the tail end of the fuelgas spray tube and is formed in the length direction of the fuel gas spray tube; a second jet orifice is further formed in the tail end of the fuel gas spray tube; the combustor is provided with an air outlet formed in the periphery of the fuel gas spray tube and capable of providing the air for the second jet orifice; and the second jet orifice is formed in the direction perpendicular to the length direction of the fuel gas spray tube and is towards the air outlet, so that the fuel gas sprayed out of the direction perpendicular to the length direction of the fuel gas spray tube is mixed withthe air in the air outlet and burns. The combustor adopts layered and segmented fuel arrangement and supply manner at the jet orifices to avoid the situation that local fuel is excessive; in addition, a uniform fuel and air mixture is formed before reaching the ignition point, so that the combustor can have graded combustion and local oxygen-enriched combustion to reduce the flame temperature, reduce generation of heating power type NOX, and the overall thermal efficiency is high.

Owner:上海迎韦热能设备有限公司

Heating and waste-gas burning method for thermal desorption restoration of contaminated site

ActiveCN110355195AReduce usageIncrease temperatureContaminated soil reclamationIncinerator apparatusHigh concentrationCombustion chamber

The invention discloses a heating and waste-gas burning method for thermal desorption restoration of a contaminated site. According to the method, combustion gas is allowed to contact with combustionair through a burner, and the burner is ignited to allow the combustion gas to burn continuously and stably in a combustion chamber; then generated high-temperature flue gas is sent to a thermal desorption restoration system for indirect conduction and heat transfer; and desorbed organic waste gas generated by the thermal desorption restoration system is sent to the combustion chamber for thermalcombustion. The method is carried out by an intelligent integrated burning treatment machine which includes a combustion gas supply unit, a combustion air supply unit, a backdraft waste gas introduction unit, the burner, the combustion chamber and a control cabinet. The heating and waste-gas burning method of the invention can use a conventional gas fuel as an energy source, and has high energy utilization efficiency; and the used machine is simple, safe, stable and reliable, has both the functions of heat generation through combustion and thermal combustion treatment of waste gas, and can provide a stable high-temperature combustion flue gas heat source and a good high-concentration desorbed organic gas heat treatment solution for thermal desorption restoration technology.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

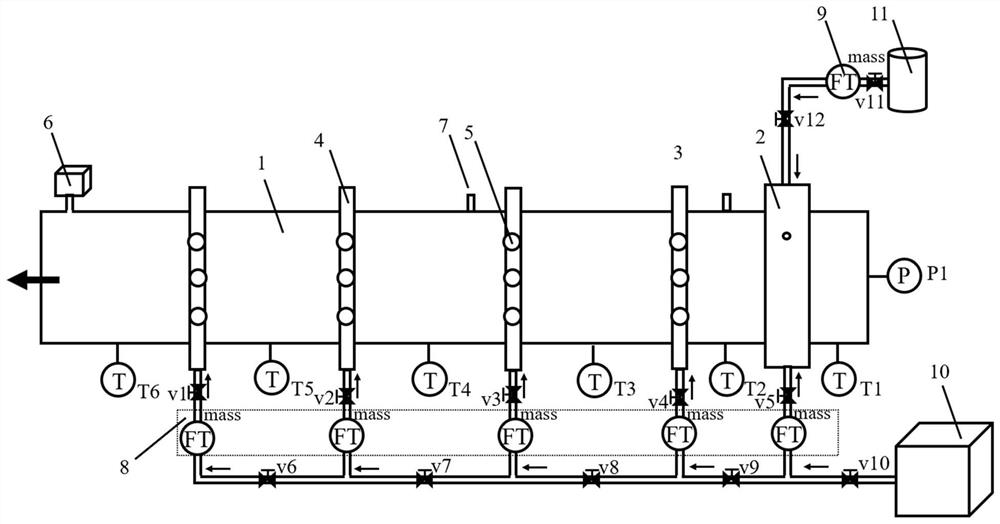

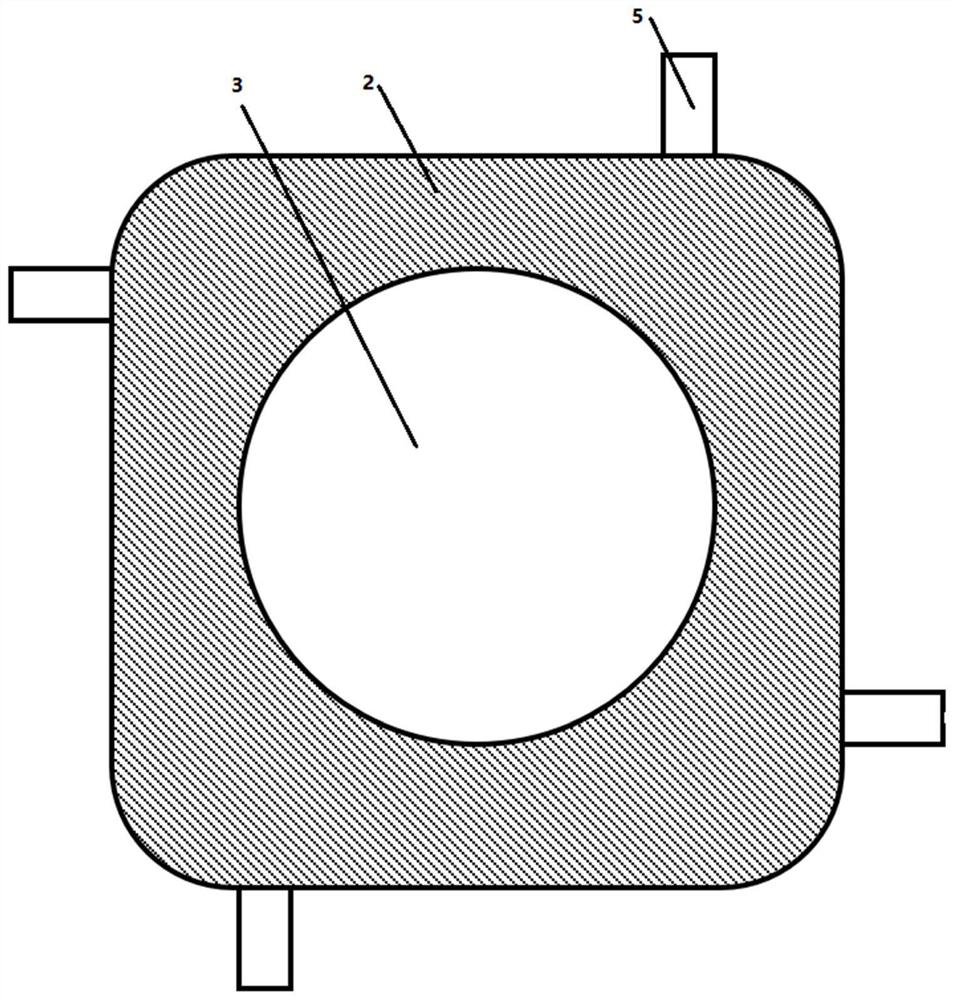

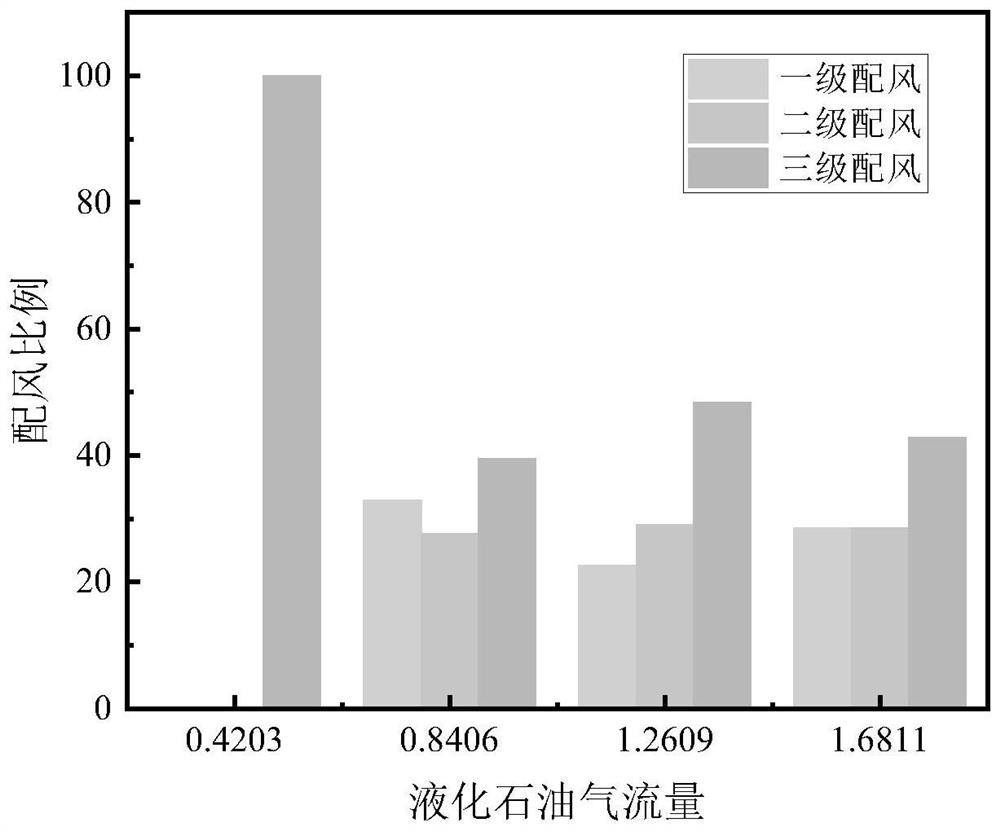

Staged combustion method and system for gaseous fuel

PendingCN114278936ACombustion multi-stageReduce the temperatureGaseous fuel burnerCombustorNitrogen oxides

The staged combustion method comprises the steps that S1, a hearth is divided into first-stage to n-stage combustion areas, all the stages of combustion areas communicate with one another, and the first-stage combustion area is controlled to be in a negative pressure state; s2, gaseous fuel and primary air are continuously fed into the first-stage combustion area, one-way spiral flames are formed in the first-stage combustion area, the one-way spiral flames flow from the first-stage combustion area to the n-stage combustion area, and the flow of the gaseous fuel and the flow of the primary air are controlled through a mass flow meter; s3, the secondary air to the nth air are sent into the secondary combustion area to the nth combustion area in sequence in a one-to-one correspondence mode, and the flow of the secondary air to the nth air is controlled through a mass flow meter; insufficient combustion is carried out in the first-stage combustion area, so that the temperature of the combustor area can be effectively reduced, and generation of thermal nitrogen oxides is controlled from the source; and through multi-stage combustion, flue gas backdraft is performed in more combustion areas, so that the pollutant emission of exhaust gas can be effectively reduced.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Transformation method for boiler

ActiveCN105090937ANot low efficiencyThe modification method is simpleCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBackdraftFuel oil

The invention discloses a transformation method for a boiler, and by means of the transformation method, a built-in fuel oil burner is transformed into an external oil gas double-fuel burner. The original boiler with the built-in fuel oil burner comprises a front backdraft chamber, the built-in fuel oil burner, an air blower, an air flue, an interlayer air chamber and a smoke outlet. A fireproof wall is arranged between the front backdraft chamber and the interlayer air chamber. The air blower is communicated with the interlayer air chamber through the air flue. The built-in fuel oil burner is arranged in the interlayer air chamber and penetrates the fireproof wall to be communicated with the front backdraft chamber. The transformation method for the boiler includes the steps that the built-in fuel oil burner is detached, and the external oil gas double-fuel burner is arranged; the connection position of the air flue and the original interlay air chamber is sealed, and the air flue is communicated with the external oil gas double-fuel burner; and the original interlay air chamber is filled with insulating materials. The transformation method is simple and easy to operate, and resources are saved.

Owner:上海申能能源服务有限公司

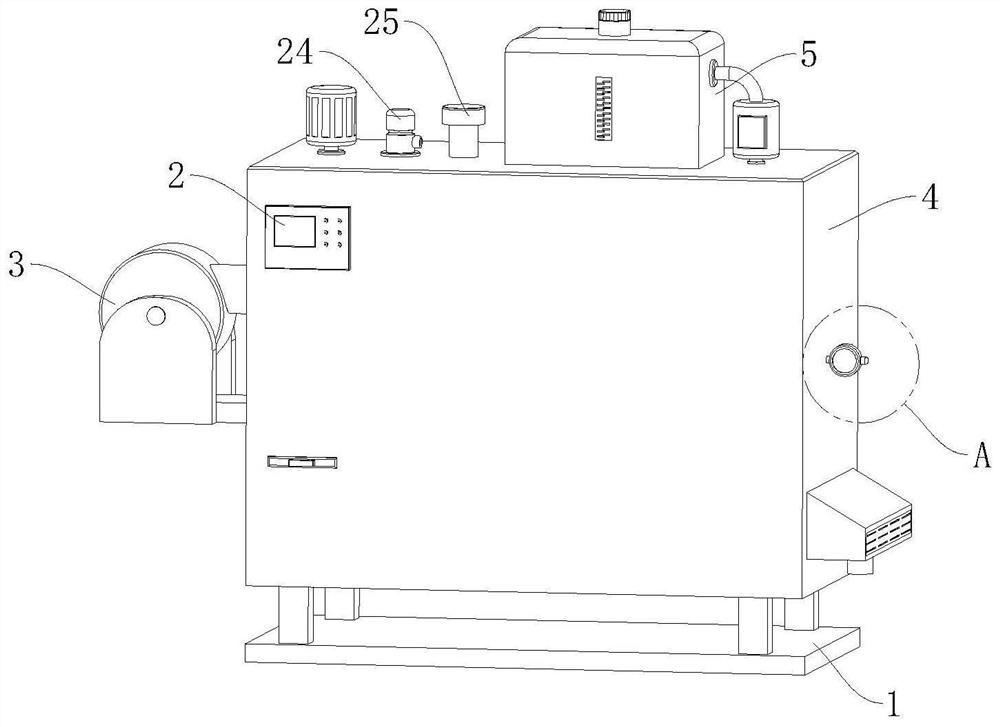

Integrated center backdraft condensation vacuum hot water boiler

PendingCN113531903AImprove heat transfer efficiencyImprove efficiencyAir heatersCombustion technology mitigationBackdraftProcess engineering

The invention relates to the technical field of oil and gas boilers, in particular to an integrated center backdraft condensation vacuum hot water boiler which comprises a base and further comprises a controller, a burner, a vacuum furnace and a backdraft mechanism, wherein the vacuum furnace is of a rectangular shell structure, the burner is fixedly arranged on one side wall of the vacuum furnace, the backdraft mechanism is arranged in the vacuum furnace and used for improving the heat exchange efficiency, the backdraft mechanism comprises a furnace pipe, a smoke guide chamber, a box type heat exchanger, a water supply assembly and a guide assembly, and the burner, the water supply assembly and the guide assembly are all electrically connected with the controller. The integrated center backdraft condensation vacuum hot water boiler can replace longitudinal scouring smoke pipe heat exchange surfaces, so that the surface heat exchange coefficient is increased, and meanwhile, high-temperature smoke can be conveniently and rapidly conveyed to the heat exchanger from the smoke guide chamber, so that the heat exchange speed is increased; latent heat resources carried in the high-temperature smoke are fully utilized, so that resource waste is effectively avoided.

Owner:浙江大工新能源有限公司

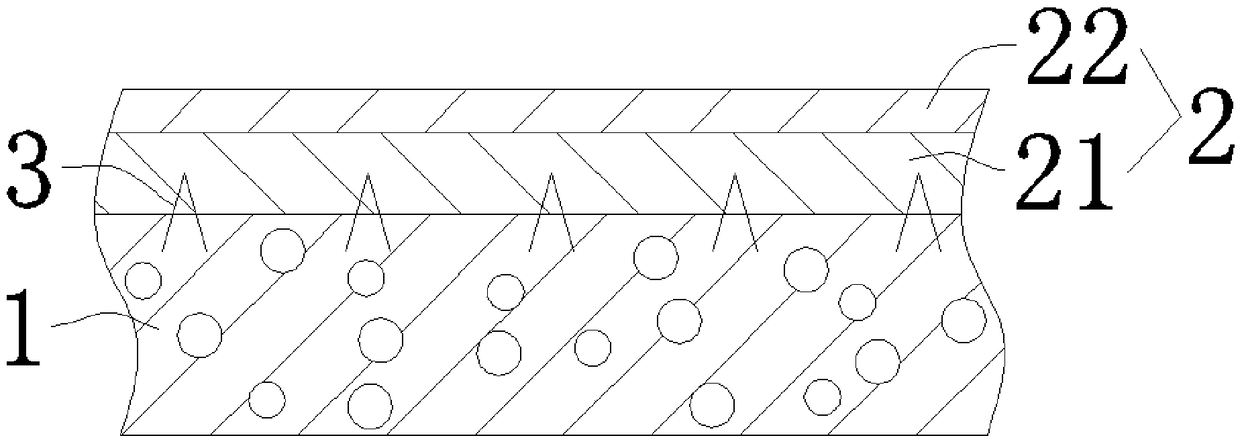

Anti-cracking refractory material

The invention discloses an anti-cracking refractory material, and belongs to the technical field of refractory materials. The aluminum oxide refractory material comprises a backdraft layer, a V-shapedhook and a composite fire facing layer, wherein the backdraft layer comprises a matrix and aggregates; the matrix comprises emery and Al2O3 micro-powder; the aggregates comprise aluminum oxide hollowspheres, chromium oxide particles and refractory fiber paste; the composite fire facing layer is a high-temperature working surface of the aluminum oxide refractory material; and the composite fire facing layer comprises expanded vermiculite-refractory fiber paste-graphite mixed emulsion and a far infrared radiation coating. The preparation method comprises the following steps: preparing the matrix; preparing the aggregates; preparing the backdraft layer; preparing the expanded vermiculite-refractory fiber paste-graphite mixed emulsion; and coating the surface of the expanded vermiculite-refractory fiber paste-graphite mixed emulsion with the far infrared radiation coating. The problem that a traditional aluminum oxide refractory material has cracks easily due to working in a high-temperature environment for a long time is solved.

Owner:湖南嘉顺华新材料有限公司

A multi-body waste gas back-combustion incineration hot air circulation furnace

ActiveCN105509457BEfficient use ofMeet environmental protection requirementsDrying gas arrangementsDrying solid materialsCombustion chamberExhaust fumes

The invention belongs to the technical field of environment-friendly coating facilities and relates to a multielement recirculation furnace with a function of waste gas backdraft incineration. A heating head is arranged on one side of a recirculation furnace body, and a furnace top chamber and a waste gas backdraft blower are arranged above the furnace body. Circulating fans are mounted on two sides of the bottom of the heating head respectively, and an air return pipe is arranged on the upper portion of the furnace body and communicated with the upper portion of the heating head. A heat exchange cylinder externally sleeves a combustion chamber which is arranged on one side of the middle portion of the heating head, the heat exchange cylinder is communicated with one end of a horizontal tubular heat exchanger on the upper portion of the heating head, and the other end of the horizontal tubular heat exchanger is communicated with an inlet of a waste gas exhaust fan. An inlet of the waste gas backdraft blower is communicated with the furnace top chamber, and an outlet of the waste gas backdraft blower is connected to a position, corresponding to the combustion chamber, of the heat exchange cylinder through a connection pipe. The multielement recirculation furnace with the function of waste gas backdraft incineration has the advantages that the waste gas is preheated and incinerated completely prior to emission, so that the requirement on environment friendliness can be met; heat generated in incineration can be used for heat exchange of hot air circulation, combustible components in the waste gas are used effectively, and energy-saving effects are achieved.

Owner:明泉历升涂装工程(南京)有限公司

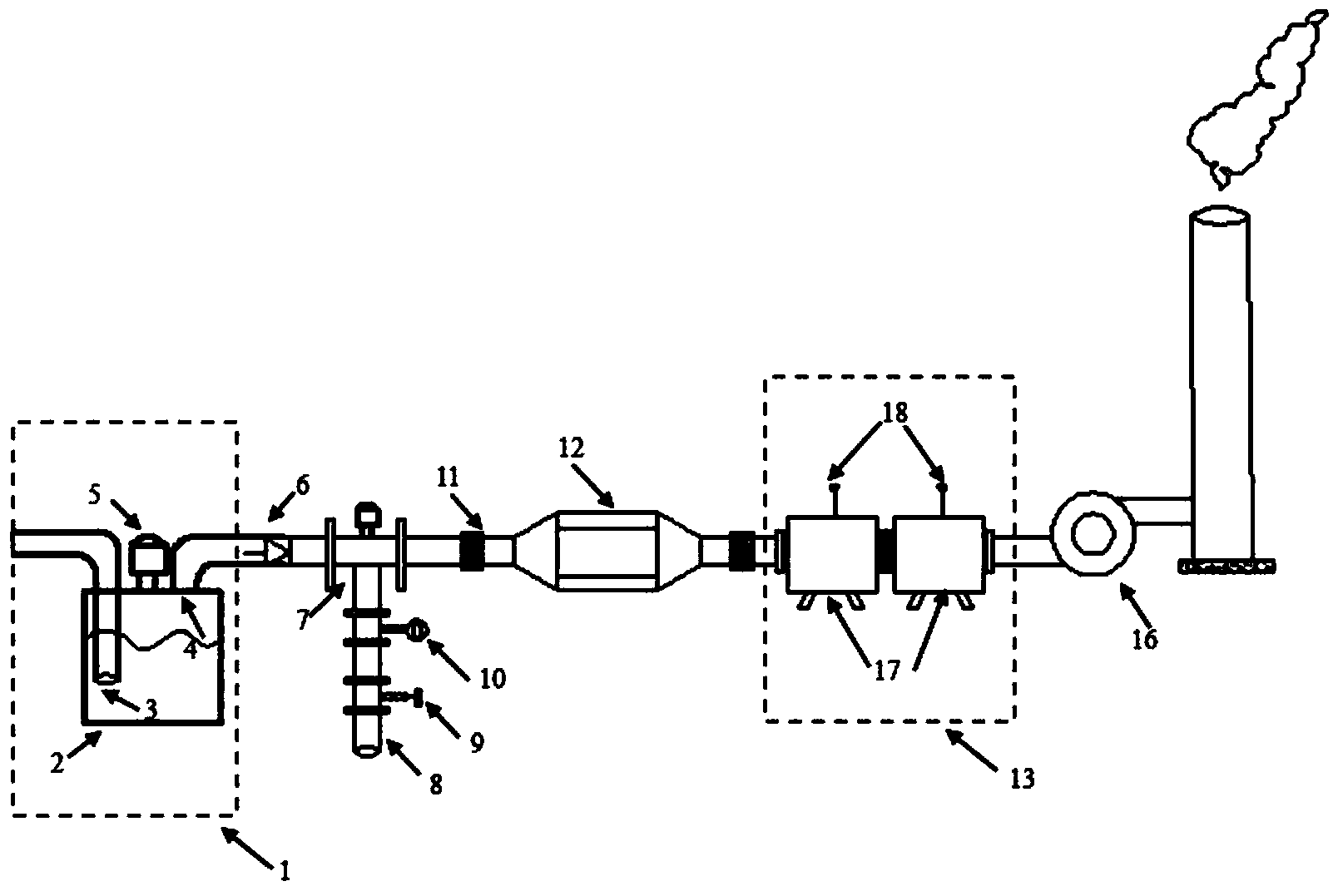

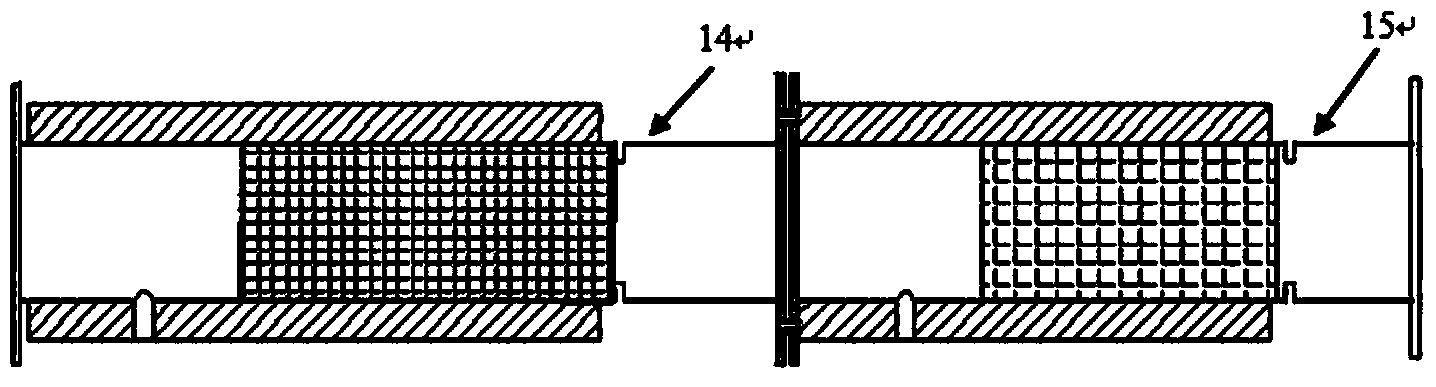

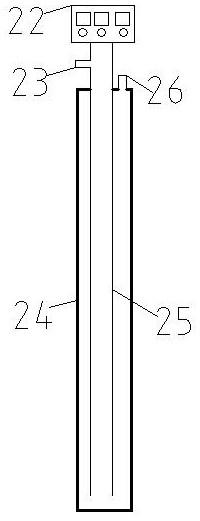

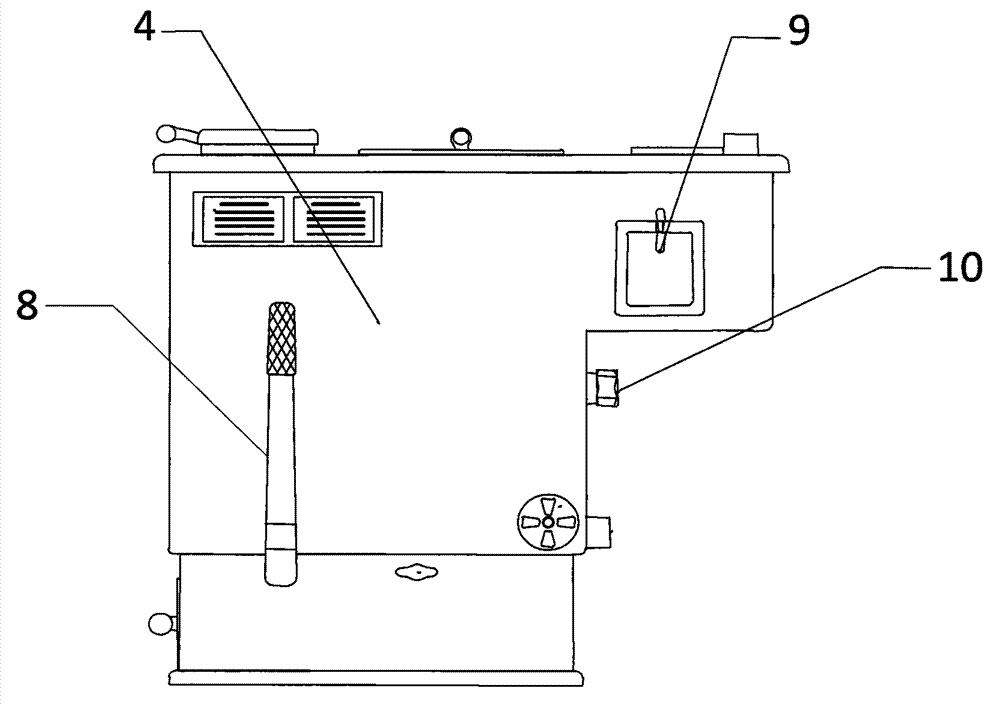

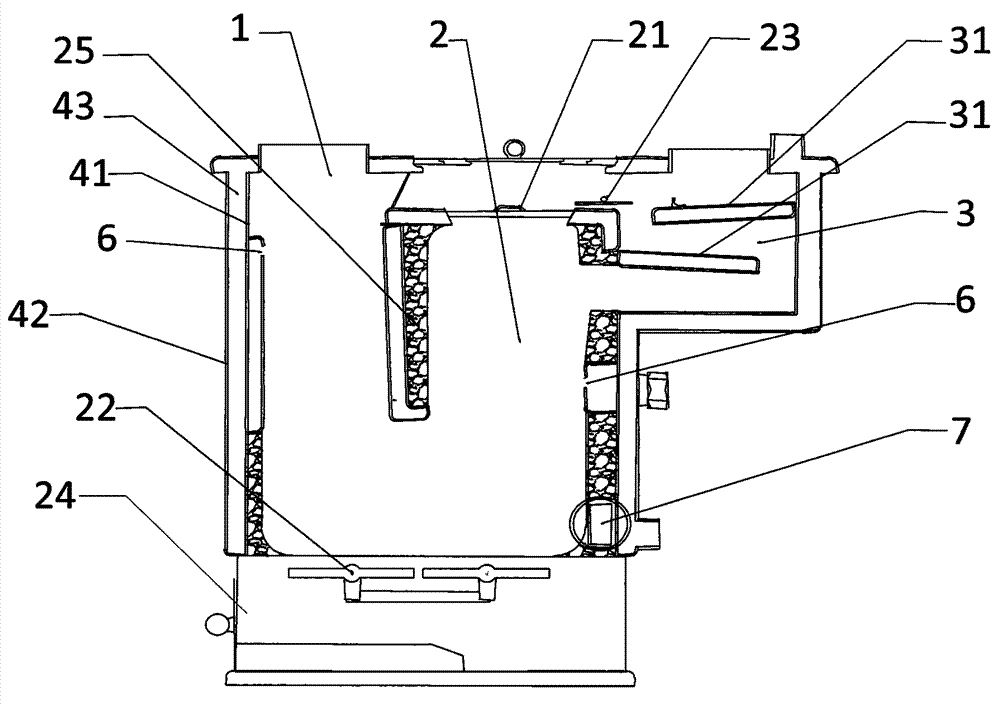

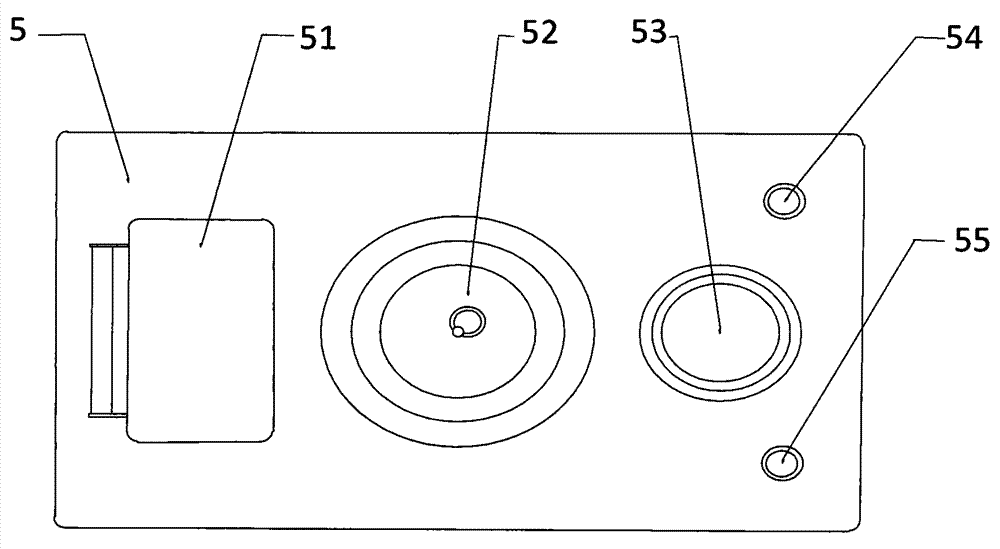

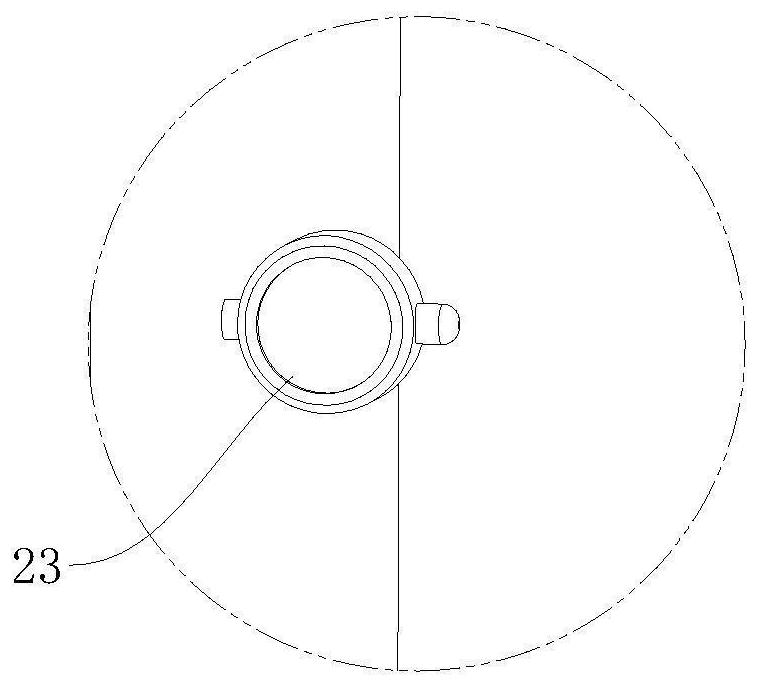

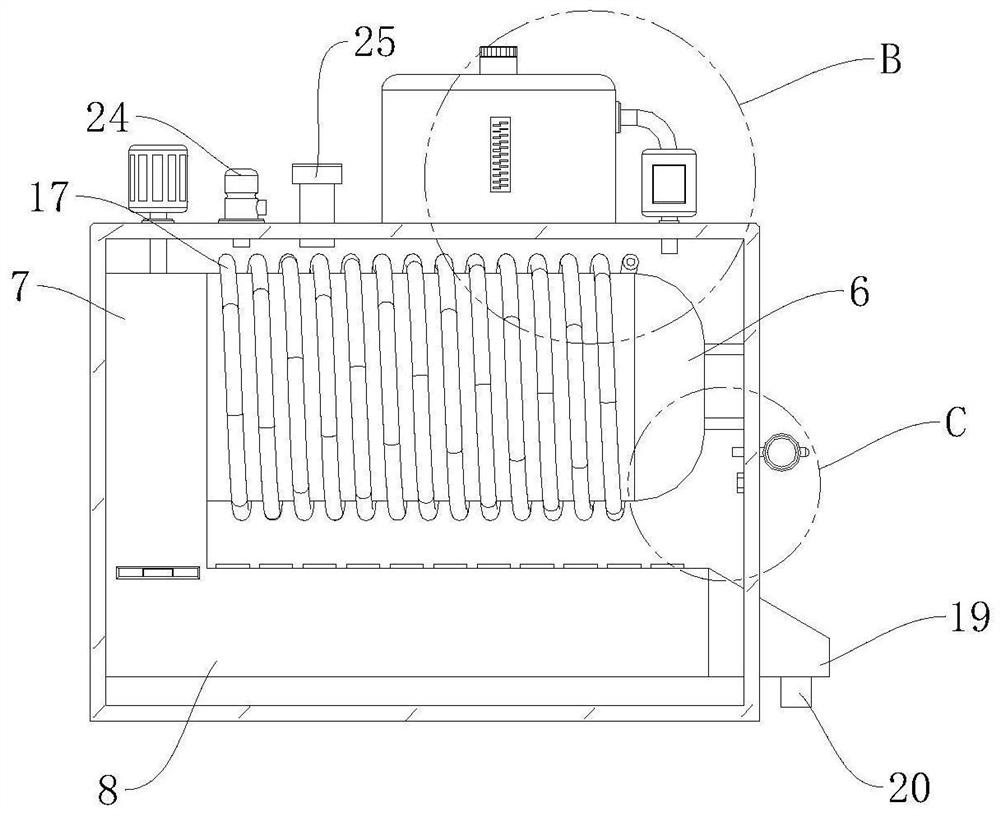

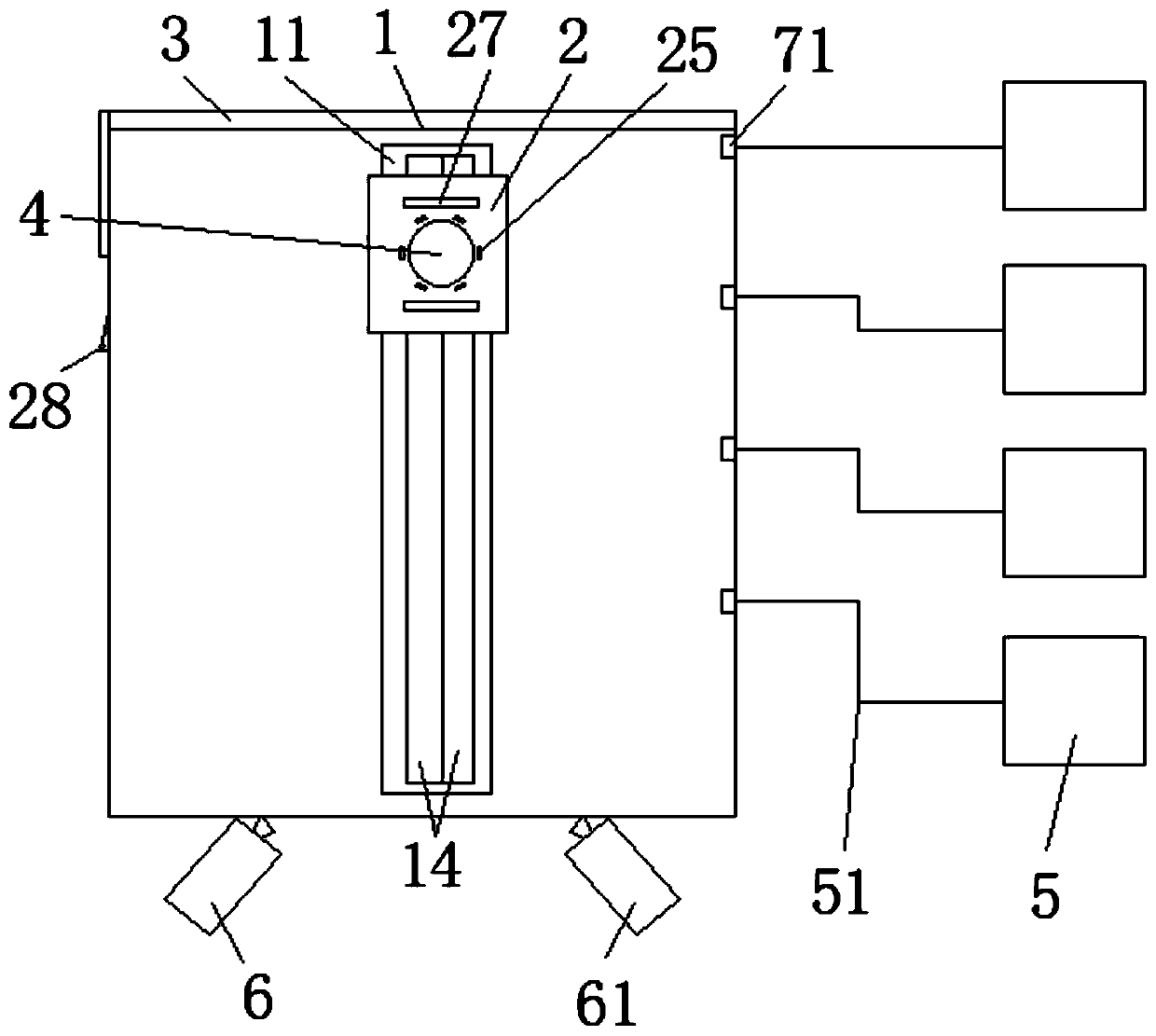

Backdraft experimental device and method for testing backdraft critical conditions and parameters based on backdraft experimental device

PendingCN109856179ASimple structureReasonable designChemical analysis using combustionMaterial thermal analysisCritical conditionEngineering

The invention discloses a backdraft experimental device and a method for testing backdraft critical conditions and parameters based on the backdraft experimental device. The device comprises a box body, a controller, a touch screen display, a remote monitoring terminal, a combustion table, a component analysis unit, a real-time monitoring unit and a temperature detecting unit box; one side of thebox body is provided with a door; the other side of the box body is provided with a transparent board; the combustion table is provided with a combustible material and an ignition assembly; the component analysis unit is communicated with the box body; the real-time monitoring unit is disposed in the box body and is connected with the controller; and the temperature detecting unit is disposed in the box body and is connected with the controller. The device has the advantages of simple structure, reasonable design and easiness in control. A control variable method is used to measure the backdraft critical conditions and parameters of combustible materials, and therefore, optimal disaster relief paths can be provided for firefighters, and the personal safety of the firefighters can be fullyensured.

Owner:应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com