Chemical waste gas treatment device and treatment technology

A waste gas treatment device and chemical technology, applied in the direction of incinerators, chemical instruments and methods, combustion methods, etc., can solve the problems of hidden safety hazards in chemical production areas, difficult disassembly and replacement of devices, and high safety requirements, so as to improve the effect of waste gas treatment, Prevents backburning flames and improves treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

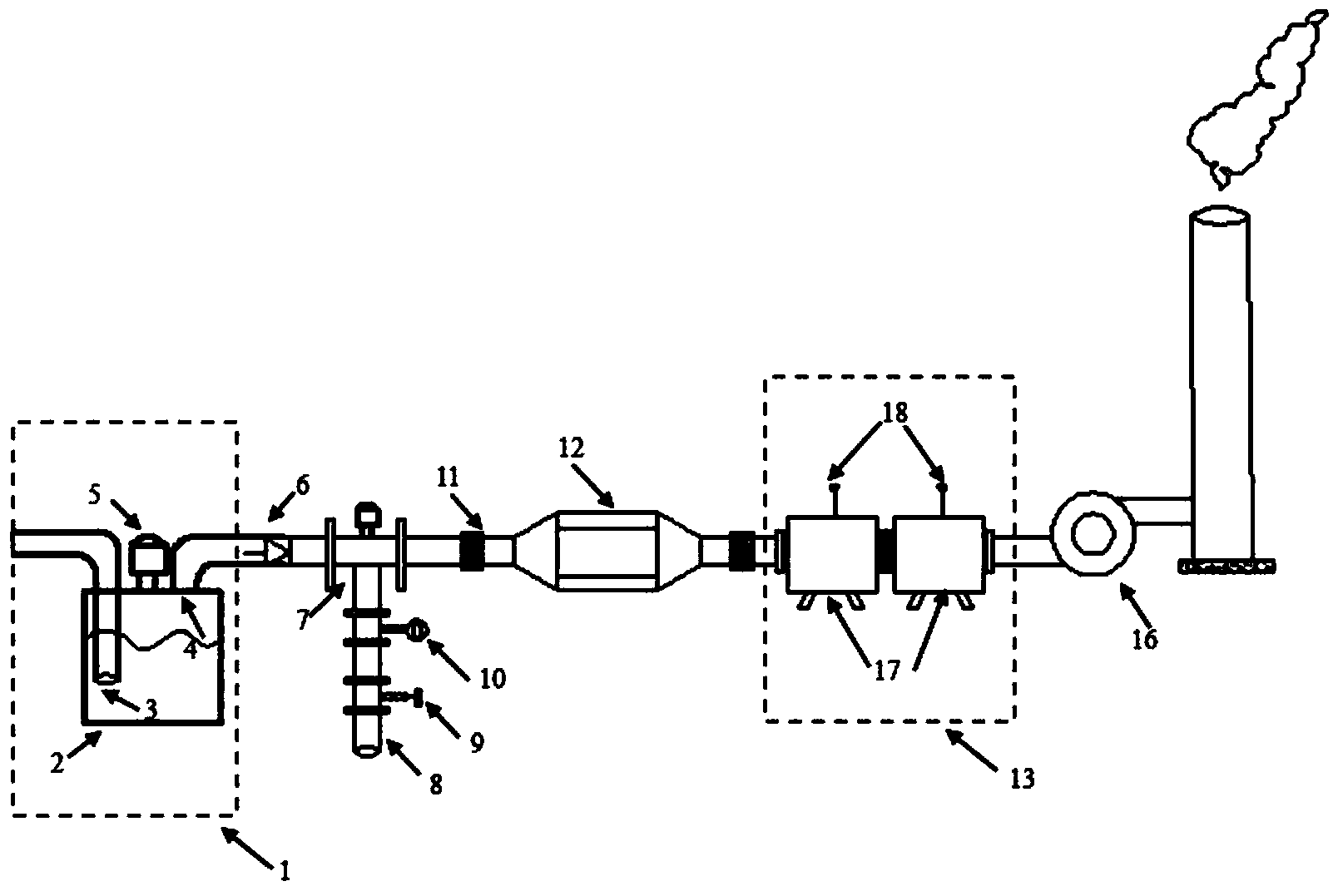

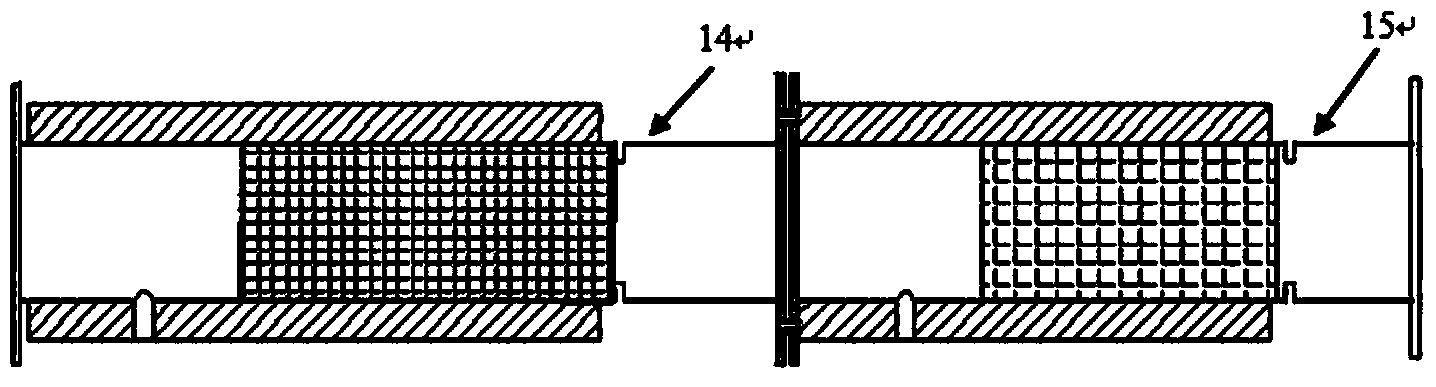

[0034] Such as figure 1As shown, a chemical waste gas treatment device includes an explosion-proof container 1 , a gas mixer 7 , a plasma reactor 12 and a catalytic combustion reactor 13 connected in sequence. The explosion-proof container 1 comprises a water-holding container 2, an air inlet pipe 3 extending into the liquid surface of the container and an air outlet pipe 4 arranged at the top of the container. The distance between the mouth of the air inlet pipe 3 and the water surface must not be less than 100 mm, and the height of the mouth of the air outlet pipe 4 above the water surface must be greater than 50 mm. The air inlet pipe 3 of the explosion-proof container 1 extends into the water surface of the container to dissolve part of the water-soluble organic pollutants in the waste gas into the water. The explosion-proof container 1 is placed at the forefront of the whole device, that is, the upstream of the gas mixer 7, which can isolate the fire source and ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com