Multielement recirculation furnace with function of waste gas backdraft incineration

A technology of hot air circulation and exhaust gas, which is applied in the direction of incinerators, combustion types, combustion methods, etc., can solve problems such as unfavorable energy saving, and achieve the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

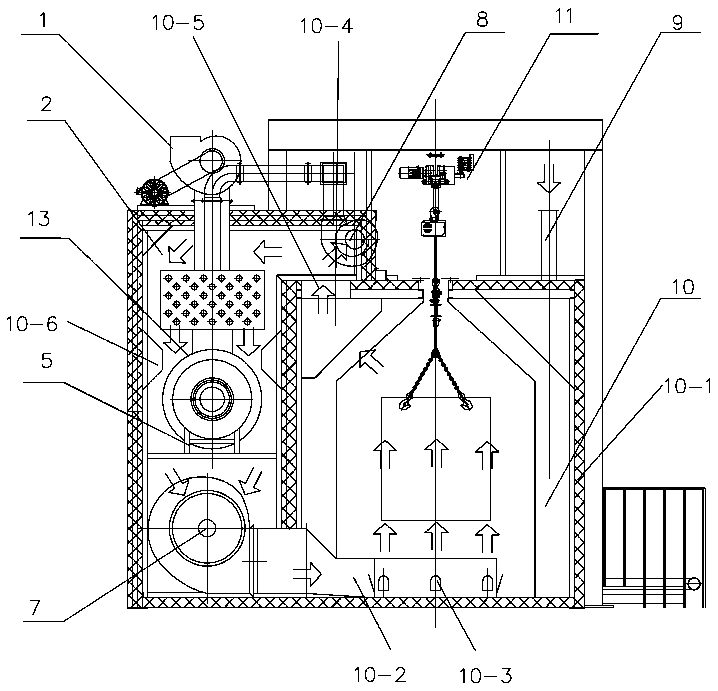

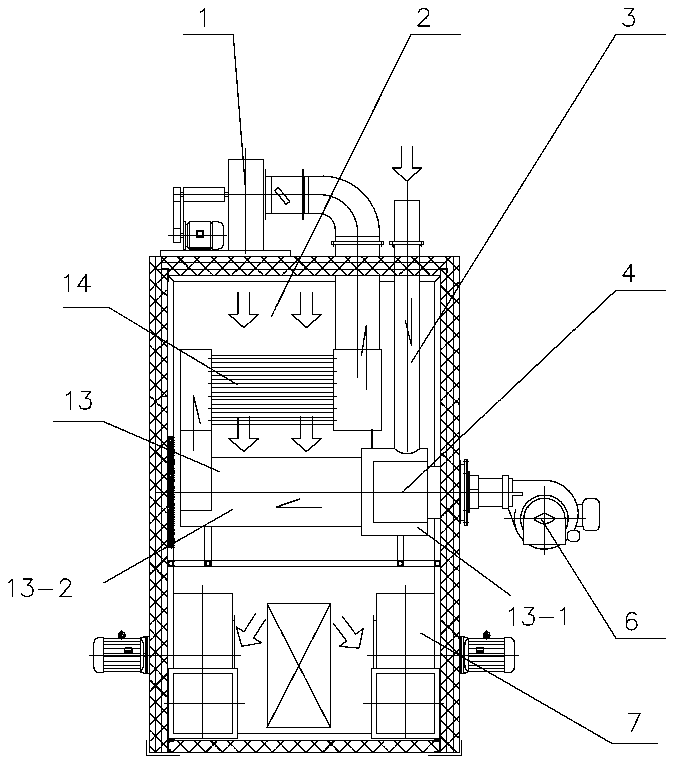

[0019] The basic structure of the multi-body waste gas backburning incineration hot air circulation furnace in this embodiment is as follows: figure 1 and figure 2 As shown, the furnace body 10 with a rectangular cross-section is surrounded by an insulated furnace wall 10-1. One side of the furnace body 10 is provided with a one-piece heating head 2 with an insulated wall. The top chamber 11 is equipped with an exhaust blower 8 for back-burning. The roof chamber 11 is equipped with a vent pipe 9 from the leveling room. On both sides of the bottom of the heating head 2, circulating fans 7 opposite to each other with air inlets are respectively arranged, and the air outlets of the two circulating fans 7 are respectively facing the furnace body 10 and are provided with an air outlet pipe 10- 2 connected. The upper part of the furnace body 10 adjacent to the side of the heating head is provided with a return air pipe 10-4 with a triangular cross-section. Since the top of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com