Anti-cracking refractory material

A technology of refractory materials and refractory fibers, which is applied in the field of refractory materials, can solve problems such as cracks, achieve fast drying speed, high energy saving rate, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

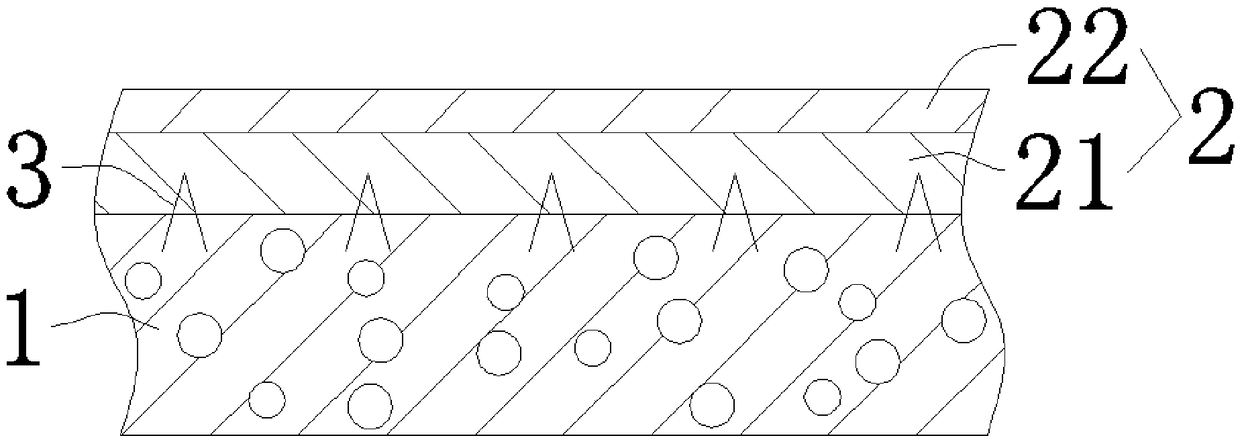

[0024] Embodiment 1: A kind of anti-crack refractory material, such as figure 1 As shown, it includes a fire prevention layer 1, a V-shaped hook 3 and a composite fire prevention layer 2. The backfired layer 1 is the non-high temperature working surface of the alumina refractory material, and the backfired layer 1 includes matrix and aggregate. Matrix includes corundum and Al 2 o 3 Micropowder, aggregates include aluminum oxide hollow spheres, chromium oxide particles and refractory fiber paste, refractory fiber paste is used as an organic binder. The composite fire-facing layer 2 is a high-temperature working surface of alumina refractory material, and the composite fire-facing layer 2 includes expanded vermiculite-refractory fiber paste-graphite mixed emulsion 21 and far-infrared radiation coating 22 .

[0025] Its preparation method is as follows:

[0026] (1) Corundum and Al 2 o 3 The micropowder is mixed according to the weight ratio of 1:1, stirred evenly by stirri...

Embodiment 2

[0034] Embodiment 2: A kind of anti-crack refractory material, such as figure 1 As shown, the difference from Example 1 is that the matrix accounts for 25% of the total weight of the alumina refractory. Aggregate accounts for 55% of the total weight of the alumina refractory material, alumina hollow balls account for 35% of the total mass of the aggregate, and refractory fiber paste used as an aggregate component accounts for 45% of the total mass of the aggregate.

[0035] The thickness of the expanded vermiculite-refractory fiber paste-graphite mixed emulsion 21 is 12cm. The far-infrared radiation coating 22 has a thickness of 4 cm.

[0036] The alumina refractory material obtained in this example has a high refractoriness, which can reach 1700°C±30°C, is suitable for a working environment with a temperature of ≤1600°C, has relatively moderate cost, and is not prone to cracks during long-term use.

Embodiment 3

[0037] Embodiment 3: A kind of anti-crack refractory material, such as figure 1 As shown, the difference from Example 1 is that the matrix accounts for 20% of the total weight of the alumina refractory. Aggregate accounts for 50% of the total weight of the alumina refractory material, alumina hollow balls account for 30% of the total mass of the aggregate, and refractory fiber paste used as an aggregate component accounts for 40% of the total mass of the aggregate.

[0038] The thickness of expanded vermiculite-refractory fiber paste-graphite mixed emulsion 21 is 10cm. The far-infrared radiation coating 22 has a thickness of 2 cm.

[0039] The alumina refractory material obtained in this example has a high refractoriness, which can reach 1650°C±20°C, is suitable for working environments with a temperature of ≤1550°C, has low cost, and is not prone to cracks during long-term use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com