Combustor and a central backdraft boiler comprising same

A burner, gas technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as increased smoke exhaust, high oxygen content, and reduced thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

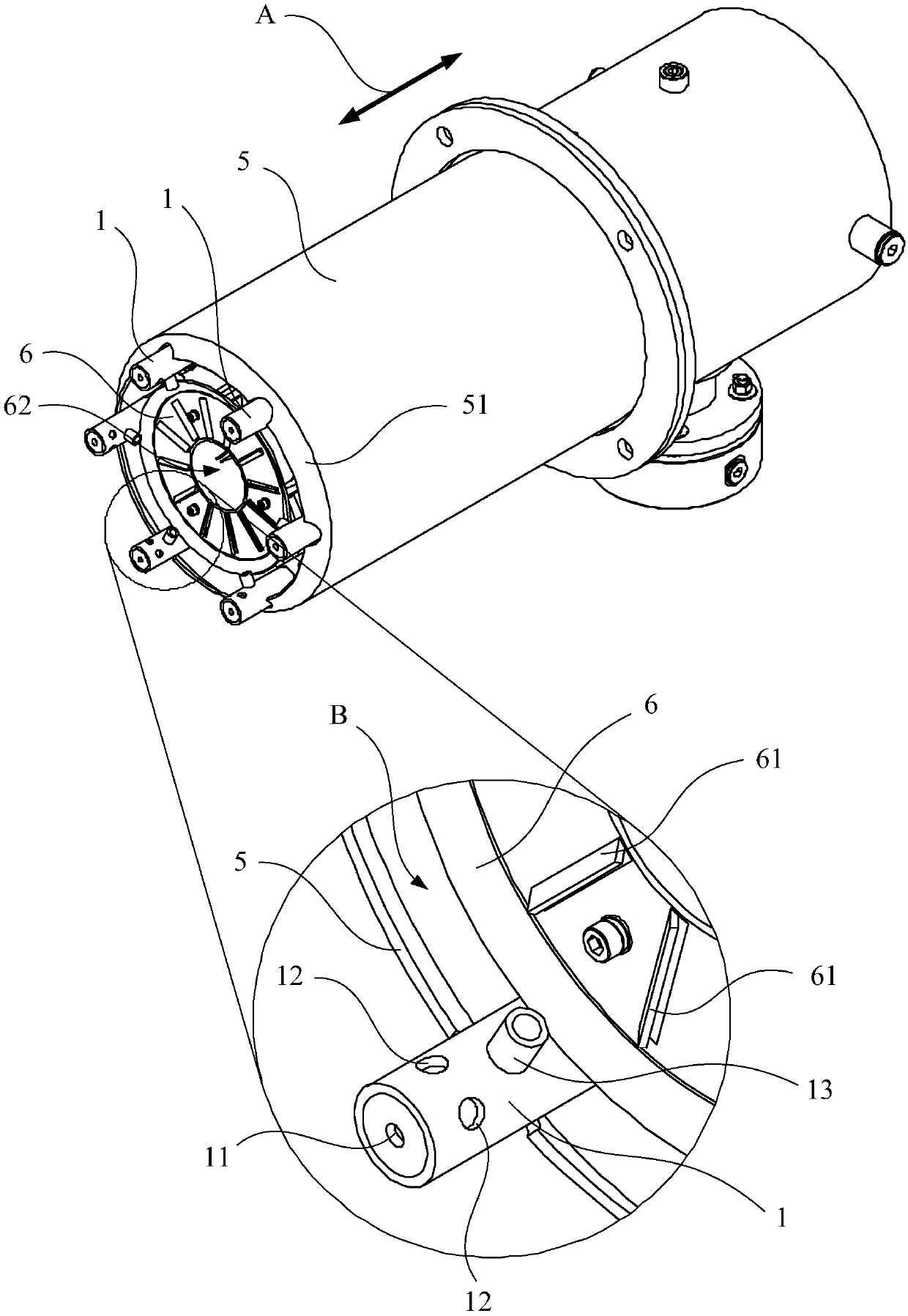

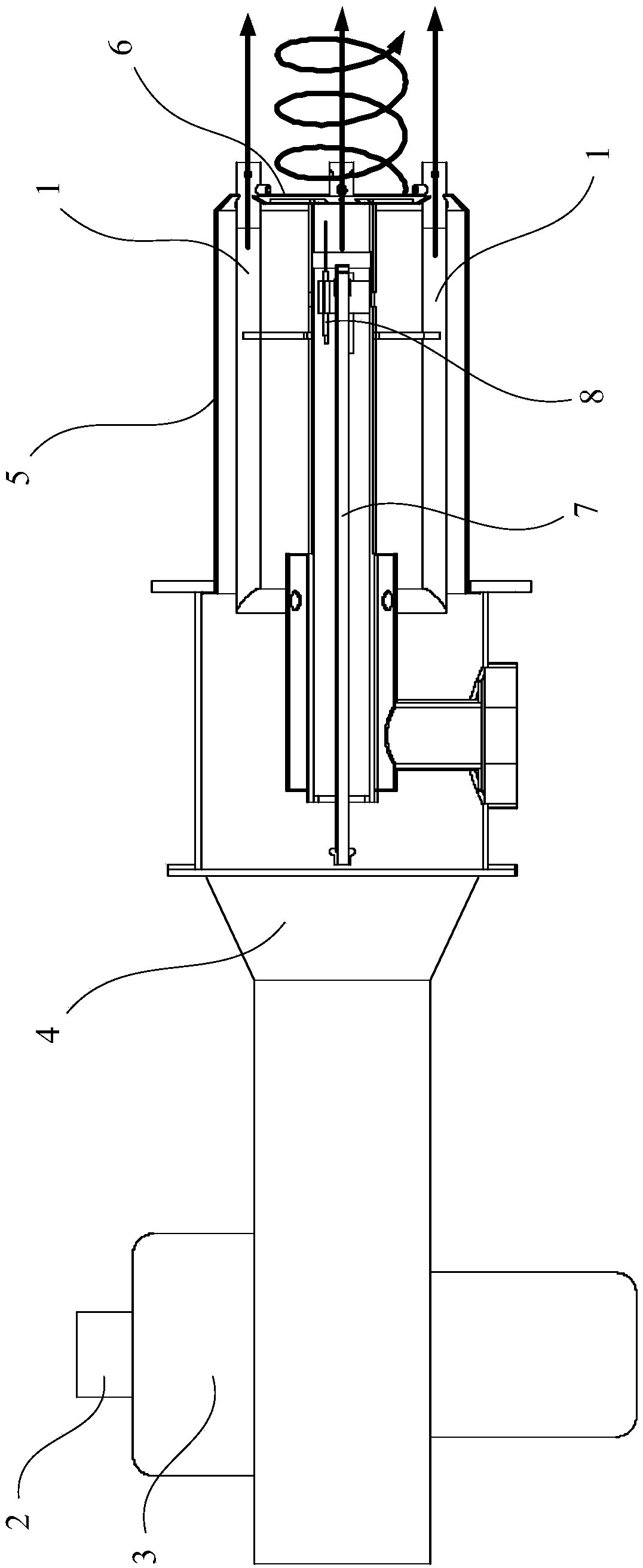

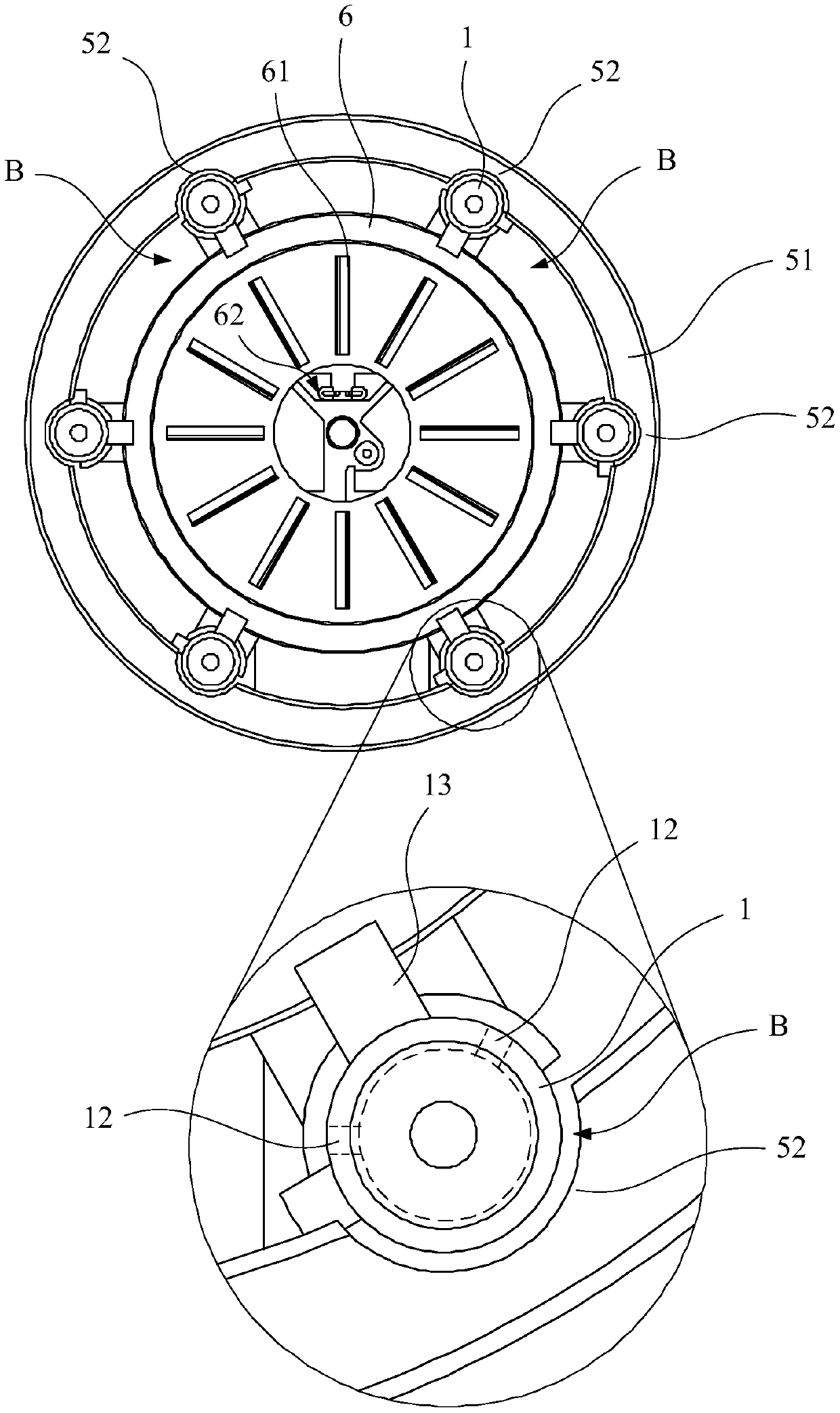

[0045] Such as figure 1 and figure 2 As shown, the present invention provides a burner, which includes six gas nozzles 1 , and the end of each gas nozzle 1 has a first injection port 11 and a second injection port 12 . Among them, the first injection port 11 is arranged along the length direction A of the gas nozzle 1 for directly injecting gas to the front of the burner, while the second injection port 12 is arranged along the length direction perpendicular to the gas nozzle 1 A is provided, and an air outlet B that provides air to the second injection port 12 is also provided at the position where the burner is located around the gas nozzle 1 . The second injection port 12 is also arranged towards the direction of the air outlet B, so that the gas injected perpendicular to the length direction A of the gas nozzle 1 is mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com